Bryant 394B User Manual

Bryant

Airconditioning

Company

installation instructions

GAS-FIRED FORCED-

AIR FURNACE

39 4B &D

Series A

Sizes 050

thru 200

INTRODUCTION

Before installing the furnace, refer to “Procedure for

Gas Furnace Installation” (packaged with the equip

ment) for information concerning combustion, vent

ing, piping, and other standard installation practices.

Further reference is made to the current edition of the

American National Standard “Installation of Gas

Appliances and Gas Piping,” Z21.30.

Model 394 Gas Furnaces are shipped from the factory

completely assembled and wired ready for indoor

heating installation. They are manufactured with two

types of blowers: belt and direct drive. The four

smaller sizes, 50, 80, 100, and 125, are direct drive

only. All sizes incorporate a low-voltage terminal

strip for convenience of field wiring (except 50,000-

Btuh unit with complete shut-off gas controls.)

This publication covers installation, startup and

maintenance. For accessory installation details, refer

to applicable installation literature.

CAL’TTON: Do Tiot insrall hirnace in a coitosívp or

coiiTaminated almosphcre. Makp sure tliaV all local

ordinance's for coinbusTioii and circiilaTing air supply

are obser\ed.

Cancels: 39394D82

Figure 1—Modei 394D

39394DP85

11/1/74

A72548

The design of the 394B&D Upflow Gas-Fired Fur

naces is A.G.A. certified for installation on com

bustible flooring in alcoves, basements, closets, or

utility rooms.

CLEARANCE REQUIREMENTS

(in inches)

Sides............................................................................1

Back.............................................................................0

Top of Plenum.............................................................1

Vent Connector (single wall)

Type B (double wall)...............................................1

Front........................................................................ ..6

Provide service clearance of 30 in. at front of unit.

Bryant Automatic Gas Controi Vaive

NOTE: On units equipped with an A-643 Bryant

automatic gas control valve, there are three positions

for the manual valve knob (OFF-PILOT-ON). There

is a position stop at the PILOT position. To move the

manual valve knob from the PILOT position to either

ON or OFF position, the manual valve knob must be

depressed.

......................................

6

If not already checked when lighting the main burn

er, check the proper operation of this valve by

moving the room thermostat pointer above and below

room temperature and observing that the main burn

ers light on call for heat and go off when the pointer

is moved below the room temperature setting. All

Bryant automatic gas control valves have a delay

when opening or closing.

Fan/Limit Control Operation

At the moment the thermostat calls for heat, the time

delay mechanism of the control is energized. If, due to

pilot outage, the control bimetal element does not

sense a temperature change, the control will turn on

the blower strictly by means of the time delay feature.

If for any reason the time delay is not energized as the

thermostat calls for heat, the control bimetal element

will bring on the blower when it senses a temperature

rise of 50 degrees Fahrenheit (standard differential)

above the turn-off setting. During the blow-down

period and after the thermostat is satisfied, the con

trol will turn the blower off at the indicated setting

sensed by the control bimetal element.

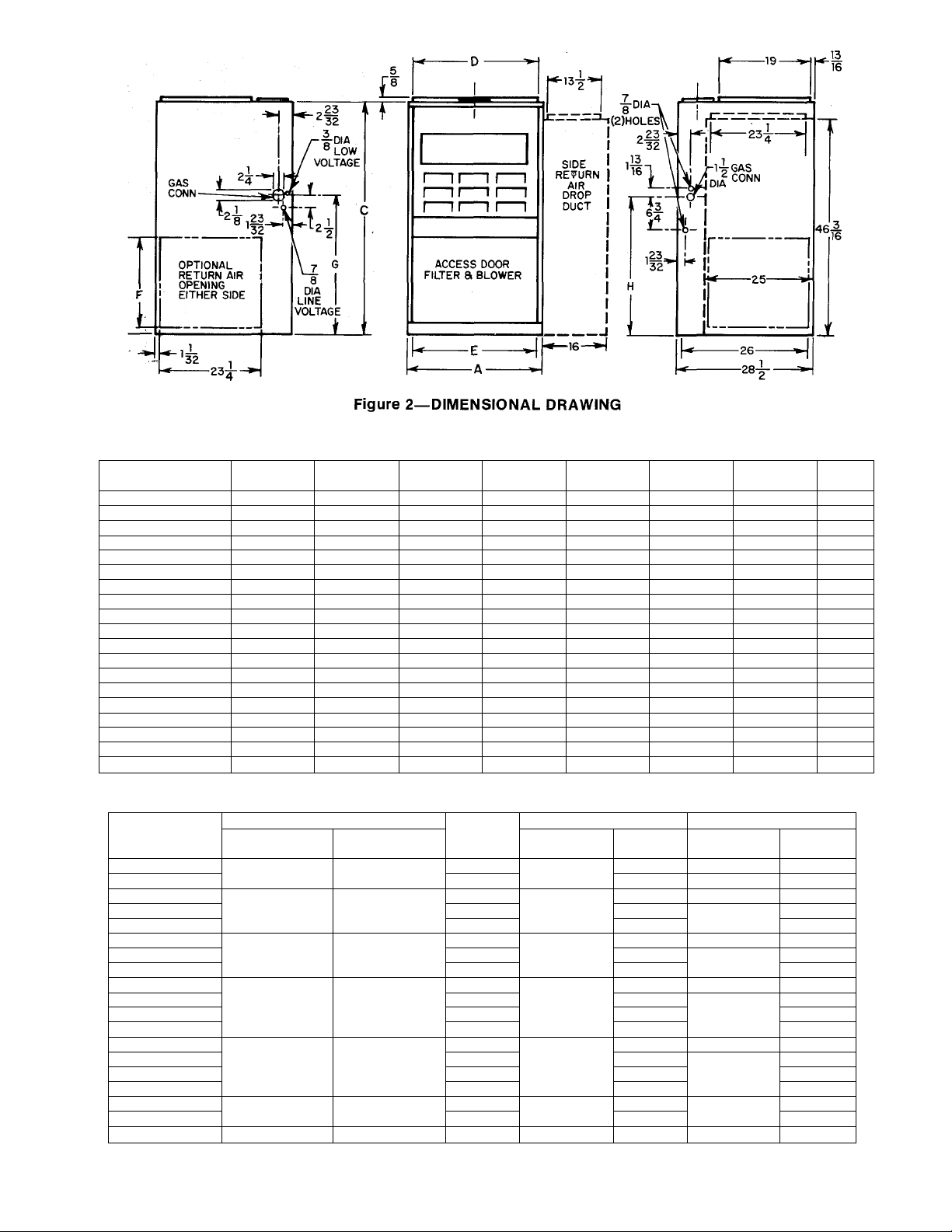

TABLE I—DIMENSIONS IN INCHES

MODEL & SIZE A

394D-000050

3940-024050

394D-000080

14-3/16 46-3/16

12

12

C

46-3/16

46-3/16 10-3/8 9-1/2 14-1/2 27-1/8

394D-024080 14-3/16 46-3/16

3940-036080 14-3/16 46-3/16 12-9/16

394D-000100

394D-036100

3940-048100

394D-000125

394D-036125

394D-048125

394D-060125

394D-000150

3940-048150

394D-060150

394B-060150

394D-060175

394B-060175

394B-060200

17-1/2 46-3/16

17-1/2

46-3/16 15-7/8 15 14-1/2 27-1/8

21 46-3/16

21

21

46-3/16

46-3/16

21 46-3/16

21

46-3/16 19-5/16 18-1/2 14-1/2 27-1/8

24-1/2 46-3/16

24-1/2 46-3/16

24-1/2

24-1/2

31-1/2

31-1/2

31-1/2

49 22-7/8 21 18 29-15/16

49 22-7/8 21 18 29-15/16

49 29-7/8 29 18 29-15/16

49 29-7/8 29 18 29-15/16

49 29-7/8 ' 29 18 29-15/16

D E F

10-3/8 9-1/2

14-1/2 27-1/8

12-9/16 11-11/16 14-1/2

12-9/16 11-11/16

11-11/16

15-7/8 15

19-5/16 18-1/2

19-5/16

19-5/16

19-5/16

18-1/2 14-1/2 27-1/8

18-1/2 14-1/2 27-1/8

18-1/2 14-1/2 27-1/8

14-1/2 27-1/8

14-1/2 27-1/8

14-1/2 27-1/8

14-1/2 27-1/8

G

27-1/8

22-7/8 21 14-1/2 27-1/8

22-7/8

21 14-1/2

27-1/8

H

32-9/16

32-9/16

32-9/16

32-9/16

32-9/16

32-9/16 5

32-9/16

32-9/16

32-9/16 5

32-9/16

32-9/16 5

32-9/16 5

32-9/16

32-9/16

35-3/8 6

35-3/8 6

35-3/8

35-3/8 7

35-3/8

TABLE II—RATINGS AND PERFORMANCE*

NATURAL and LP Temp

Rise

MODEL

394D-000050

3940-024050

394D-000080

394D-024080

3940-036080

394D-000100

394D-036100

Input Btuh

50,000

80,000

100,000

Output Btuh

40,000

64,000

80,000

Range

70-100

45-100

70-100

70-100

45-100

70-100

45-100

3940-048100 45-75

394D-000125

394D-036125

394D-048125

125,000 '

100,000

394D-060125

394D-000150

394D-048150

394D-060150

150,000

120,000

394B-060150

394D-060175

394B-060175

175,000

140,000

394B-060200 200,000 160,000

"The above ratings are certified for altitudes to 2000 ft. For elevations above 2000 ft. reduce ratings 4% for each 1000 ft. above sea

level.

70-100

70-100

45-100

45-75

70-100

45-100

45-75

45-100

45-100

45-100

70-100

Heating

Ext Static

Pressure

0.12

0.12

0.15

0.2

0.2

0.5

0.5 1634

Cooling

Ext Static

CFM

408

Pressure

—

482 0.5

654 —

772 0.5

772

818

—

965 0.5 1200

1157 1540

1020

—

1069

1206

0.5

1447

1225

— —

1454

1736

0.5

1447

1688

1688 2290

0.5

0.5 2460

A72591

Vent

Dia

4

4

4

4

4

5

5

5

6

6

7

7

CFM

—

780

—

790

1190

—

—

1210

1560

2000

1500

2080

2310

2010

—2-

Loading...

Loading...