Page 1

Installation Instructions

OUTDOOR HEATING AND COOLING UNIT / bPliant

The Bryant Model 4dO-379H is a heating unit designed

for outdoor installation; either rooftop or at ground

level. It is available with either of two factory-in

stalled direct expansion coils (Model 180R- or 240R-

379) or with no expansion coil as Model 450-379H.

Model 180R units are equipped for use with R22

refrigerant and provide 180,000-Btuh cooling when

connected with a Bryant Model 180-566 Condensing

Unit. Model 240R units are equipped for use with

R500 refrigerant and provide 240,000-Btuh cooling

when connected with a Bryant Model 240-566 Con

densing Unit. All tluree models have a heating input of

450.000 Btuh (approximately) for both natural and

propane gas. They are equipped with a two-stage

firing arrangement for operation at a reduced input of

225.000 Btuh.

.! ,Fi L

DO NOT!

IREMOVE

I

379H

Size 450

180R & 240R

Series D

39379D35

1/3/72

Important-Read Before Installing

Be sure the available gas supply is the same as that

shown on the American Gas Association (A.G.A.)

rating plate. Check the electrical supply to be sure

that voltage, frequency, and phase correspond to that

specified on the unit rating plate.

Check all national, state, and local building codes af

fecting the installation of this unit. Check all local or

dinances that could affect the installation of this type

equipment.

WARNING: All access panels must be in place at all

times when unit is in operation.

GENERAL

The design of the unit is certified by the American

Gas Association (A.G.A.) for use with iiatural or pro

pane gas with the appropriate controls and orifices.

The units are designed specifically for outdoor in

stallation, either at rooftop or ground level.

Installation of the unit consists of the following:

I. Locating the Unit

II. Gas Piping

III. Duct Connection

IV. Venting

V. Coil Connection (Models 180R- and

240R-379H)

VI. Electrical Connections

VII. Start-up and Adjustments

VIII. Maintenance

Figure 1

SECTION I. LOCATING THE UNIT

Extreme caution should be observed to prevent dam

age when moving the unit. Maintain the unit in an up

right position at all times during rigging and moving

operations. To facilitate lifting and moving opera

tions, place the unit in an adequate rope or ca

ble sling.

CAUTION: Protect the top and sides of the unit from

possible damage from rigging sling.

Rooftop Installation

Level the unit on a base situated a minimum of 6 in

ches above the roof to insure proper drainage. Consult

local and state building codes for installation require

ments. Be assured the roof construction will support

the weight of the equipment.

Ground Level Installation

The unit should be placed on a level concrete slab (4inch minimum thickness); level the unit on the slab

with 1-inch clearance to insure proper drainage.

Combustible Clearances

Minimum clearances are: 6 inches from rear or duct

side, 24 inches on all other sides, and 0 inch on the

bottom. These clearances permit the use of combus

tible materials for supports. The top of the unit must

be kept clear at all times.

Page 2

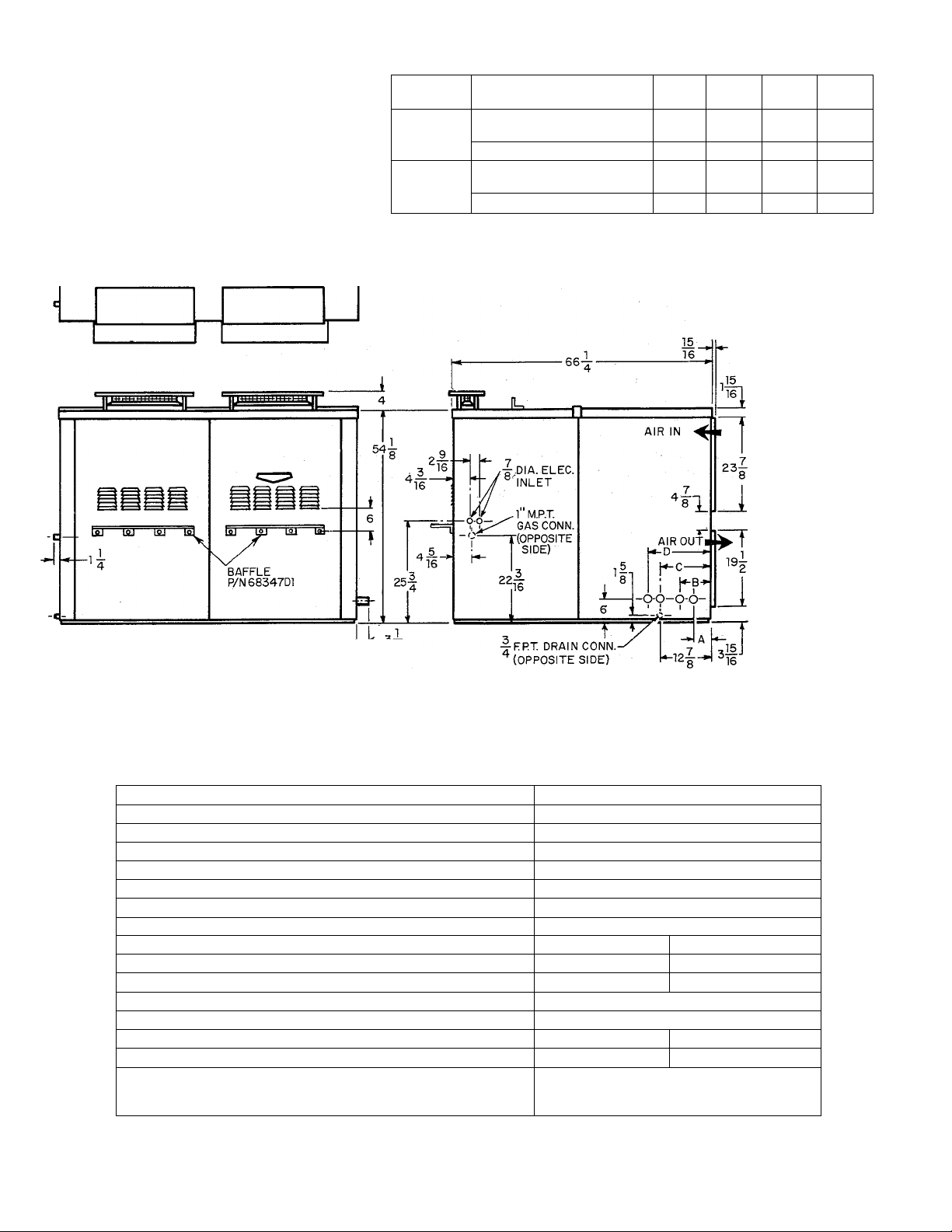

-ssl-

-76f-

UNIT

SIZE

180R-379H

240R-379H

*Refer to condensing unit for compressor suction and liquid line sizes

CONNECTION

SIZE (COIL)

7/8 OD

(Suction)*

5/8 OD (Liquid)*

1-3/8 OD

(Suction)

5/8 OD (Liquid)

A B c

2 ea 6-3/16 14-13/16

2 ea

2 ea 7-3/16

2 ea

10-3/16

10-3/16

D

18-13/16

12-5/8

18-1/2

Approximate

Shipping Weights

450-379H—1425 lbs

180R-379H—1460 lbs

240R-379H—1565 lbs

^4

Figure 2-Dimensional Drawing

TABLE I- Ratings and Capacities

• Model 450-, 180R-, & 240R-379H

Heating Input, 1st Stage

Heating Output, 1st Stage

Heating Input, 1st & 2nd Stages Btuh

Heating Output, 1st & 2nd Stages Btuh

Approved Temp Rise

CFM 0.5 inch wc S.P.

Blower Motor

Power Supply

Full Load Current

Locked Rotor Current

Speed

Frame Size 56

Branch Circuit Wire Size Min*

Branch Circuit Fuse Size Max

Filters Size

Btuh 225,000

Btuh 168,000

°F 20-75

HP

208-60-3 230-60-3

Amps 8.4 8.4

Amps

RPM

AWG No. 14 14

Amps 25 25

58.2 53.0

(450-379H) (6) 16x25x1

(180R & 240R) (3) 16x25x1

A69420

450,000

337,000

6,000

3

3450

(3) 20x25x1

*If alumimun conductors are to be used, the connections must be made in accordance with the National Electric Code. The

wire size selected must have a current capacity not less than that of the copper wire specified and must not create a voltage

drop between the service panel and the unit in excess of 2% of the unit rated voltage.

-2-

Page 3

SECTION II. GAS PIPING

A separate gas supply line should be installed to run

directly from the meter to the heating section. Check

your local utility for recommendations concerning

existing lines. Choose a supply pipe large enough to

keep the pressure loss as low as practical. Never use

pipe smaller than the gas connection to the heating

section. Observe local codes for all gas pipe in

stallations.

The following are pertinent recommendations:

1. Avoid low spots in long runs of pipe. It is best to

grade all pipe 1/4 inch in every 15 feet to prevent

traps. All horizontal runs should grade downward to

risers. Risers should be used to connect to heating

section and to meter.

2. Install drip leg in riser leading to heating section.

Drip leg will function as trap for dirt and condensate.

Drip legs should be installed where condensate will

not freeze.

3. Install manual shutoff valve in gas supply pipe

near heating section, where it can be easily reached.

4. Install ground joint union close to furnace between

gas controls manifold and manual shutoff valve.

5. Support all piping with appropriate hangers, etc.

Use a minimum of one hanger every 10 feet.

SECTION IV. VENTING

The vent cap assemblies, including three sheet metal

angles, are packaged in the gas control compartment.

Installation of these assemblies is as follows:

1. Remove the discard cover on each of vents on roof

of unit.

2. Remove top plate from each vent cap assembly by

removing four retaining screws.

3. Use screws supplied with assemblies to fasten base

section of vent cap assembly to vent-section top cover

plate: unit top is drilled to receive these screws.

4. Reattach top cover plate removed in Step 2 above.

5. Remove three self-tapping retaining screws (located

approximately 7 inches behind each vent cap) from

unit cover. Fasten sheet metal angle from each vent

cap (use retaining screws previously removed).

SECTION V. COIL CONNECTION

(180R- & 240R-379)

1. Refer to condenser installation sheet for coil con

nections of R Models. NOTE: Coil connections are

sealed and seals should not be broken until just im

mediately before making connections to condenser

unit.

6. Use joint compound (pipe dope) that is resistant to

action of propane gas.

7. After all connections are made, use soap-and-water

solution to check for leaks (or method specified by

local utility regulations).

WARNING: Never use a match or other open flame.

SECTION III. DUCT CONNECTIONS

Before ductwork can be attached to the unit, remove

the panels located over the outlet and the return air

opening. The ductwork may be screwed or bolted to

the unit flange with suitable gaskets to insure a

weathertight seal. Be sure that the sheet metal over

laps the flange on the unit.

NOTE: When using Bryant plenum package, the up

per skirt of the plenum should be placed up and under

top cover of the unit, then sealed properly. All duct

work external of the structure must be properly insu

lated and waterproofed. All openings in the structure

must be properly flashed in accordance with local

codes and good building practices. The supply and re

turn ductwork should be provided with an approved

vibration eliminator.

NOTE: The vibration eliminator must be located

within the structure.

SECTION VI. ELECTRICAL CONNECTIONS

IMPORTANT: Before proceeding with the electrical

connections, check the power supply to be sure that

the voltage, frequency, and phase correspond to that

specified on the unit rating plate.

All electrical connections must be made in accordance

with the National Electrical Code and local codes

governing such wiring. The field connections must be

made in accordance with the wiring diagrams in

cluded in this instruction (see Figures 3 and 4). A

separate electrical line should be run for this installa

tion and it should contain a fused disconnect switch

placed in a convenient location. For maximum fuse

and minimum wire sizes, refer to Ratings and Capaci

ties Table. Field wiring connections are made in the

control box located in the gas control compartment of

the unit. Wiring entrances are made to the control box

through knock-outs provided in the casing. All wiring

entrances to the unit must be weatherproof and

watertight. The thermostat heating anticipator should

be set at 0.8 amperes for the first stage and 0.4 am

peres for the second stage. Use thermostat assembly

Bryant Part No. 34427D57 (782F) and sub-base

assembly Bryant Part No. 34427D59 (Q672B).

NOTE: Both thermostat and sub-base assemblies are

for heating only. For field wiring diagram, refer to

Figure 3.

■ 3-

39379D35

Page 4

NOTE; If aluminum conductors are used, the connec

tions must be made in accordance with the National

Electric Code. Aluminum wire connections must be

made with special connectors. In preparing the wire

just before installing the connector, all aluminum

wire must be “brush-scratched” and the wire coated

with a corrosion inhibitor, such as “Pentrox A.” When

I

it is suspected that the connection will be exposed to

moisture, it is very important to cover the entire con

nection completely to prevent an electro-chemical ac

tion that will cause the connection to fail very quickly.

Reducing the effective size of the wire, such as cutting

off strands so that the wire will fit a connector, is very

poor practice. Proper size connectors should be used.

2. To check this operation, turn pilot gas valve off

manually. The pilots should re-ignite automatically

when pilot gas valve is turned on.

NOTE; There will be a time interval or delay before

the pilot coils will ignite the pilot again.

Limit Control

1. Bryant Model 379 is equipped with lower and up

per limit controls.

2. If lower limit opens, first stage of automatic gas

valve is de-energized, shutting off gas.

SECTION VII. START-UP AND ADJUSTMENTS

Before starting the unit, make sure that the gas pipe is

purged and free from air. Do not purge into the com

bustion chambers. All gas piping connections should

be leak-tested.

WARNING; Do not use an open flame to leak-test.

Use a soap-and-water solution.

Start-Up

COOLING

Refer to appropriate Bryant Model 566 installation

instructions for cooling section starting procedure.

HEATING

Follow the lighting instructions attached to the unit.

The sequence of control operation is as follows;

1. Turn on electrical power and gas supply to unit.

2. When pilot gas cock is opened, gas flows to pilot

and to pilot pressure switch. Pilot pressure switch

then closes to complete 24-Volt circuit. Pilot then

lights automatically. The circuit is then completed

through switching of first pilot to second-pilot igniter

coil automatically lighting second pilot. After the

pilots have been automatically lighted, electrical po

tential is available to first stage gas valve. When

thermostat calls for heating, a circuit is completed be

tween Wl and 4. This allows current to flow through

first-stage gas valve and fan switch. If room tempera

ture continues to drop, second stage of thermostat will

complete a circuit between 4 and W2, energizing

second-stage gas valve, bringing unit to full power. On

setting room thermostat below room temperature,

both stages of firing will shut off.

Safety Pilot Test

1. If any one pilot should be extinguished, switch ac

tion of pilot will interrupt electrical circuit of firststage gas valve consequently, unit will shut off.

3. If upper limit opens, first stage of the automatic gas

valve is de-energized, and the SPDT switching action

of upper limit bypasses gas valves circuit and ener

gizes fan delay relay and blower motor starts.

4. Upper limit control has a dual function; its primary

action is to shut off the gas valve, but it also energizes

the blower motor if the furnace becomes overheated.

The recommended method of checking the limit con

trols is to gradually block off the return air after the

furnace has been operating for a period of at least 5

minutes. As soon as the limit is proved safe, the return

air opening should be unblocked to permit normal air

circulation. By using this method to check the limit, it

can be established that (providing the limit is func

tioning properly) it will fail-safe if there is motor

failure or overheating of the heating section of the

unit.

Fan Relay

The unit utilizes a fan delay relay located in the con

trol box. Upward movement of the adjustment lever

causes a lengthening in the “off’ cycle, this results

automatically in shortening the “on” cycle. Down

ward movement of the adjustment lever has the oppo

site effect, the “off” cycle is shortened, the “on” cycle

is lengthened.

Adjusting Gas Input (Natural Gas Unit)

The gas input should agree with that shown on the

unit rating plate (450,000 Btuh). The burners are

equipped with fixed orifices. The burners on the

natural gas units are equipped with No. 38 drill size

orifices.

The following method may be used to adjust the input

on natural gas units.

-4-

Page 5

Water Manometer

When using a water manometer to measure the mani

fold pressure, proceed as follows to adjust the gas in

put:

1. Turn off gas to unit. Connect manometer to 1/8-

inch pressure tap at outlet of gas valve.

2. Turn on gas to unit. With burners fired and both

first and second stage gas valves open, adjust the

pressure regulator to obtain the correct manifold

pressure as shown in Table II. Check with local gas

utility for Btu value and specific gravity of gas in the

area.

TABLE II

Temperature Rise

Models 450-379H, 180R-, and 240R-379 are designed

for operation within a temperature rise range of 20 °F

to 75°F against an external static pressure up to 1.0

inch water column.

NOTE: Temperature rise is the difference between

the temperature of the air in the return air duct and

the temperature of the air in the discharge duct near

the heating section.

SECTION VIII. MAINTENANCE

Lubrication: Refer to the rating plate for the blower

motor lubrication requirements.

BTU

Value 0.59 0.61

900

950

1000 3.0

1025 2.8 2.9 3.0

1050

1100

3.8 3.9

3.3

2.7 2.8 2.9

2.4

Specific Gravity

0.63 0.65

4.0

3.4

3.1 3.2 3.3

2.5

3.5

.L.C 2.7

4.1

3.6 3.7

3.1 3.2

3.0 3.1

0.67

4.2'

3.4

2.8

Example; Heating value of gas in the area is 1030

Btu; Specific gravity is 0.62.

(a) From Table II the manifold pressure required for

450,000 Btuh is 3.0 inches wc.

(b) Set manifold pressure to 3.0 inches water column

by adjusting gas pressure regulating screw.

If the required manifold pressure exceeds 3.3 inches

w.c. or is less than 2.7 inches w.c., the orifices should

be sized according to unit requirements.

CAUTION: Do not redrill orifices under any circum

stances.

Air Shutter Adjustment

To adjust the primary air to each burner, partially

close the air shutter until there is a slight yellow tip

on the top of the flame, then open the air shutter until

the yellow tip just disappears. This should be done af

ter the burners have been operating at full input for 5

or 10 minutes (approximately).

Cleaning the Heating Unit

1. Be sure that main line disconnect switch is in OFF

position.

TAG SWITCH WITH SUITABLE WARNING

LABEL.

2. Remove front access panel.

3. Turn off manual gas valve and pilot valve.

4. Disconnect pilot and escapement tubing.

5. Remove burners.

6. Remove flue baffle retainer and the flue baffles.

7. Clean flue passages with suitable brush.

8. Reassemble furnace by reversing above procedure,

making sure all seals are reinstalled properly.

9. Check belt conditions and for proper belt tension

(1/2 inch deflection).

Filter

Filters in Models 240R- and 450-379H are of the

permanent type and should be inspected and cleaned

at regular intervals. Filters used in Model 180R-379H

are of the disposable type and should be inspected

and replaced with filters of the same type and size. In

spections should be made on a regular basis; the time

interval between inspection will depend on the type

of application.

-5-

39379D35

Page 6

FACTORY WIRING

FIELD WIRING

— • •—•- MECHANCIAL CONNECTIONS

THERMOSTAT

34427 D57(872F)

Figure 3-Field Wiring Low-Voltage, Models 450H-, 180R-, 240R-379

1. Blower Motor

2. Contactor

3. Cooling Fan Relay

4. Delay Heating Relay

5. Transformer

6. Gas Pressure Switch

7. Resistor

8. 733 Automatic Pilot

9. Limit Switch

10. 1st Stage Gas Valve

11. Secondary Limit Switch

12. 2nd Stage Gas Valve

13. Motor Overloads

^^(^(g)0©©©Q

III

____________________________

ÓÓÓÓOOOOO

W1 W2 4 G Y1 Y2 R F X

ooooooooo

SUBBASE

34427 D59(Q672B)

UNIT

LOW-VOLTAGE

TERMINAL STRIP

39379D35

Figure 4-450-379H Series C, 208 or 230 Volt, 60 Hertz, 3 Phase

-6-

Loading...

Loading...