Page 1

Installation Instructions

379A

Models

48W- & 60W-379A

Series C

OUTDOOR HE ATI N G UNIT

Bryant Models 48W-379A and 60W-379A are outdoor

heating units designed for installation on a rooftop or

at ground level. Both models have a chilled water coil

factory installed. Model 48W-379A is equipped with a

48.000 Btuh coil while Model 60W-379A is equipped

with a 60,000 Btuh coil.

These units were designed for use in split systems with

matching Bryant gas-fired water chillers. Both models

have 150,000 Btuh heating input rating and a 112,500

Btuh heating output rating. Model 48W-379A has a

48.000 Btuh cooling rating when connected to a

Bryant Model 48-453 Gas-Fired Water Chiller. Model

60W-379A has 60,000 Btuh cooling rating when con

nected to a matching Bryant Model 60-452 Gas-Fired

Water Chiller.

Important—Read before Installing

1. Check all local or other applicable codes for in

formation concerning proximity to property lines,

height above roof, obstructions, etc.

2. Be sure the power supply available (voltage,

frequency, and phase) corresponds to that specified

on the unit rating plate.

3. Check the electrical service provided by the utility

for the building to be sure that the service capacity is

sufficient to handle the load imposed by this unit.

4. Refer to the regulations of the serving gas supplier

and the local building, heating, plumbing, or other

codes in effect in the area in which installation is to

be made.

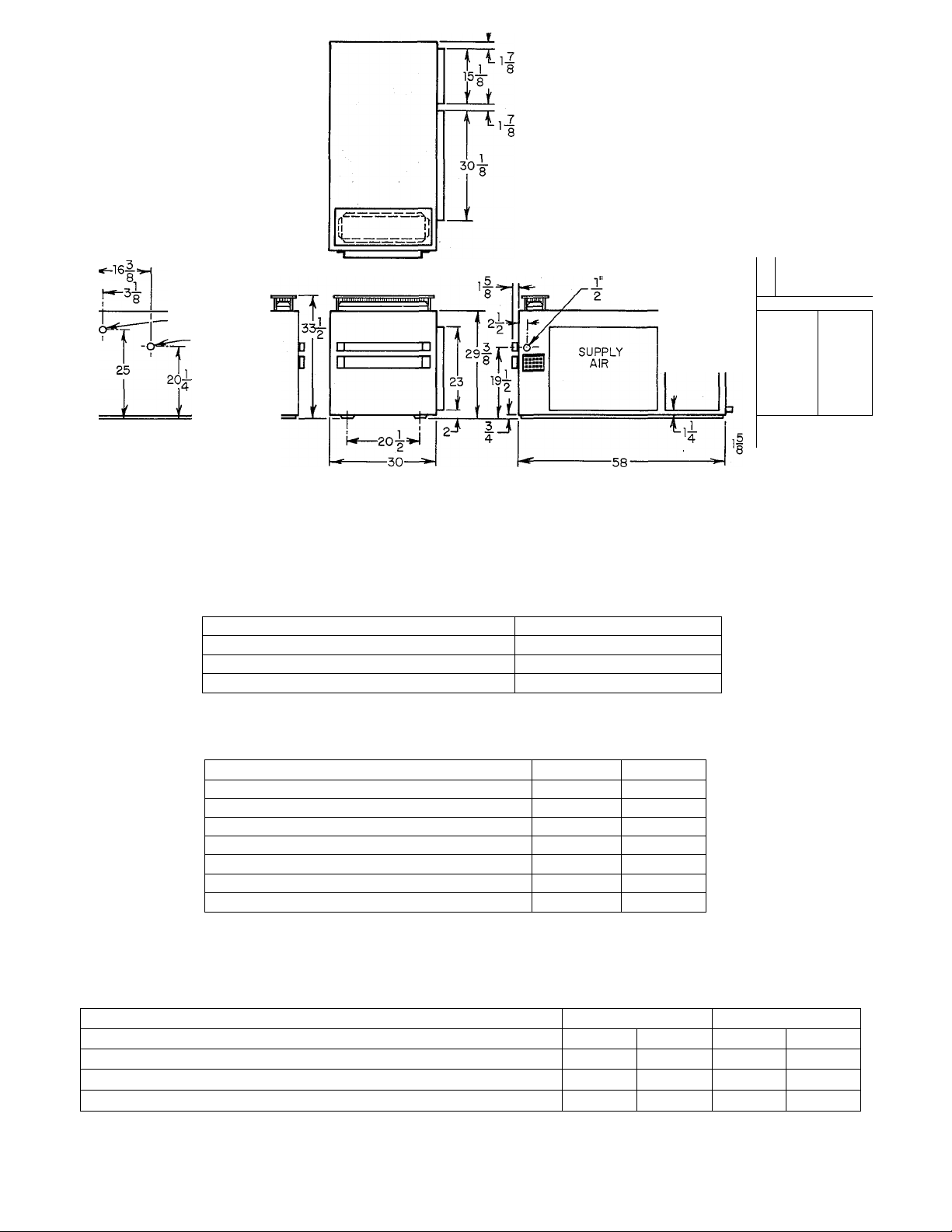

5. Refer to the dimensional drawing on page 2 for

location of electrical, gas, and chilled water con

nections prior to setting the unit in place.

GENERAL

The design of this unit is certified by A.G.A. for use

with natural or propane gases with appropriate con

trols and orifices. This unit is designed for outdoor in

stallation only.

Installation of the unit consists of the following:

I. Locating the Unit

II. Gas Piping

III. Duct Connections

IV. Venting

V. Coil Connections

VI. Electrical Connections

VII. Start-up and Adjustments

fariiant

39379D36

4/15/72

I

I i

L<-:

I.DO

’REMOVc- '

Figure 1—Model 48W-379A

In addition, the following section should be reviewed

by the equipment owner.

VIII. Maintenance

I. LOCATING THE UNIT

Extreme caution should be used when rigging and

moving the unit to prevent damage. The unit should

be kept upright during all rigging and moving

operations. To facilitate lifting and moving, place the

unit in an adequate sling made of rope or cable.

CAUTION: Be sure to protect the top and sides of the

unit from cable damage when rigging the unit to be

lifted.

Rooftop Installation

Level the unit on a base that is at least 6 inches above

the roof to provide drainage from beneath the unit.

Consult local codes for installation requirements. Be

sure that the roof will support the additional weight.

Ground Level Installation

If the unit is to be installed on the ground, it should

be placed on a level concrete slab with a minimum

thickness of 4 inches.

Page 2

LINE VOLTAGE

LOW VOLTAGE

LEFT SIDE

1 FP.T. WATER

CONNECTIONS-

GAS CONNECTION

FRONT RIGHT SIDE

Figure 2—Dimensional Drawing

RETURN

AIR

43

1

4 IH*'....................M

rIN

2

=16

23|

'

■H i

|0.D.

CONDENSATE DRAIN

REAR

A69163

TABLE 1 - HEATING

Model

Heating Input Btuh

Heating Output

Approved Temp Rise °F

Buth

CAPACITY

48W-379A & 60W-379A

150,000

112,500

45 - 75

TABLE II • «RATINGS AND PERFORMANCE

Model 48W-379A

Cooling Capacity

Airflow

External Static Pressure

Entering Air Temp

Entering Water Temp °F 45

Water Flow GPM

Water Pressure Drop Ft w.c. 18.1

Btuh 48,000

CFM

In. w.c. 0.43 0.52

°F 80DB/67WB 80DB/67WB

1600 2000

10

*Ratings given in Table II are for Model 48W-379A connected to a Model 48-453

Chiller and Model 60W-379A connected to a Model 60-452 Chiller.

60W-379A

60,000

TABLE III—ELECTRICAL CONNECTIONS

Model 48W-379A

Nameplate Voltage-Hertz-Phase

Unit Ampacity for Electrical Conductor Sizing

Min Branch Circuit Wire Size (75°C copper*) AWG

Max Branch Circuit Fuse Size Amps

Amps

208-60-1

6.2

14 14

15

45

12.5

9.8

230-60-1

4.9

15

60W-379A

208-60-1 230-60-1

8.6 6.9

14 14

15 15

*If other than 75°C copper is used, determine size from unit ampacity and the National Electric Code. Voltage drop of wire

selected must be less than 2% of unit rated voltage. Connections of aluminum wire must be in accordance with the National

Electric Code.

39379D36

-2

Page 3

NOTE: It is important that the unit be installed in a

level position.

Clearances

The rm'nimmn clearance is 6 inches from the duct

side, 24 inches on all other sides, and 0 inches on the

bottom. This permits the use of combustible materials

for supports.

CAUTION: When using rails, etc., as support, make

allowances for surface water drainage under the unit.

II. GAS PIPING

2. A separate gas supply line should be installed to

run directly from the meter to the furnace. Check your

local utility for recommendations concerning existing

lines. Choose a supply pipe sized large enough to keep

the pressure loss as low as practical.

CAUTION: Never use pipe smaller than the gas con

nection to the furnace. Observe local codes for all gas

pipe installations.

The following are pertinent recommendations:

1. Avoid low spots in long runs of pipe. It is best to

grade all pipe 1/4 inch in every 15 feet to prevent

traps. All horizontal runs should grade downward to

risers. Risers should be used to coimect to the furnace

and to the meter.

2. Install a drip leg in the riser leading to the furnace.

This drip leg will serve as a trap for dirt and con

densate. Drip legs should be installed where con

densate will not freeze. (See Figure 3 for drip leg

location.)

3. A manual shutoff valve should be installed in the

gas supply pipe near the furnace where it can be

easily reached.

4. Place a ground joint union close to the unit be

tween the gas controls manifold and the manual

shutoff valve.

5. Support all piping with appropriate hangers, etc.

The maximum distance between hangers should be 10

feet.

6. Joint compound (pipe dope) must be resistant to

the action of propane gas.

WARNING: Never use a match or other open flame

to check for gas leakage.

7. After all connections are made, check for leakage

by using soap-and-water solution (or in accordance

with local utility regulations).

III. DUCT CONNECTIONS

Before ductwork can be attached to the unit, remove

and discard the cover panel that is located over the

outlet and return air openings. The ductwork may be

screwed or bolted to the unit flange with suitable

gaskets to insure weathertight seal. Be sure that the

sheet metal overlaps the flange on the unit.

All ductwork external of the structure must be

properly insulated and waterproofed. All openings in

the structure must be properly flashed and vibrationisolated in accordance with local codes and good

building practices. The supply and return ductwork

should be provided with an approved vibration

eliminator.

NOTE: The vibration eliminator must be located

within the structure.

NOTE: An external filter must be supplied and in

stalled where easily accessible for service. For the

minimum filter area, see the: unit rating plate.

IV. VENTING

A vent cap assembly and a sheet metal angle (air

deflector) are packaged and shipped with the unit.

The package is located in the blower compartment.

DRIP LEG

WITHIN STRUCTURE

Figure 3—Drip Leg Location

— 3 —

A70676

39379D36

Page 4

Figure 4—Mounting Air Shroud on Propane Unit

An air shroud is also shipped with propane units only.

Install these items as follows:

1. Remove the cover from the vent opening on the

unit.

2. Remove the top plate from the vent cap assembly

(held by 4 sheet metal screws).

3. Use the screws supplied with the assembly to fasten

the base section of the vent cap assembly to the top

cover of the unit (the unit top is predrilled to receive

the screws).

4. Reattach top plate removed in step 2.

5. Remove the 3 self-tapping screws located ap

proximately 7 inches behind the vent cap. Use these

screws to attach the sheet metal angle to the unit top

cover at this location.

6. Use the screws enclosed in the air shroud package

to mount the air shroud as shown in Figure 4

(propane units only).

V. COIL CONNECTIONS

Figure 5 is a rear view photo of a partially disassem

bled Model 48W-379A unit.

The coil location and chilled water connections for

both the 48W- and 60W-379A are the same for both

units. These two models differ only in the size of the

factory installed chilled water coil.

Two 2-3/8-inch diameter holes are provided in the

right rear corner panel for the chilled water piping en

trance to the unit.

NOTE: Two packaged vinyl grommets are shipped

loose in the blower compartment. Insert one grommet

in each of the 2-3/8-inch corner panel holes.

Route the chilled water piping through the two grom

mets and connect to the two 1-inch F.P.T. connectors

on the coil header. Refer to Figure 5 for chilled water

inlet and outlet connections.

CHILLED WATER

CONNECTIONS

1 /

IN OUT

CONDENSATE

DRAIN CONNECTION

BLOWER MOTOR TRANSFORMER

BELT TENSION

ADJUSTING SCREW ■

POWER

CONNECTIONS

TAG

OILING

LABEL

Figure 5—Rear View of Partially

Disassembled 48W -379A

Refer to the chiller installation instructions for per

tinent information concerning type and size of piping,,

length of pipe permissible, type of freeze protection,

and chilled water additive required.

VI. ELECTRICAL CONNECTIONS

CAUTION: Before proceeding with the electrical con

nections, check the power supply to be sure that the

voltage, frequency, and phase correspond to that

specified on the unit rating plate.

All electrical connections are to be made in ac

cordance with the National Electrical Code and the

39379D36

-4-

Page 5

local code governing such wiring. Field low voltage

connections are to be made in accordance with the

wiring diagram shown in Figure 8.

A separate electrical line should be run for this in

stallation and should contain a fused switch in a con

venient location. Refer to Electrical Connections

(Table III) on page 2 for maximum fuse size and

minimum wire size. Field wiring connections are

made in the control box located in the blower com

partment. See Figure 5.

NOTE: If aluminum conductors are used, the con

nections must be made in accordance with the

National Electric Code. Aluminum wire connections

must be made with special connectors. In preparing

the wire just before installing the connector, all

aluminum wire must be “brush-scratched” and the

wire coated with a corrosion inhibitor, such as “Pentrox A.” When it is suspected that the connection will

be exposed to moisture, it is very important to cover

the entire connection completely to prevent an electro

chemical action that will cause the connection to fail

very quickly. Reducing the effective size of the wire,

such as cutting off strands so that the wire will fit a

connector, is very poor practice. Proper size con

nectors should be used.

Wiring entrances are provided in the left side of the

unit. Wiring entrances to the unit are shown in the

dimensional drawing on page 2.

NOTE: The wiring entrances to the unit must be

weathertight.

Use thermostat and subbase assembly P/N

34427D031. Set thermostat heat anticipator at 0.8

amps.

tacts to close. This action breaks the ignition circuit

and makes the control circuit to the gas valve.

When the thermostat calls for heating, terminal 4 is

connected to terminal W through the thermostat. This

completes the circuit to the gas valve (5B) and to the

heating blower relay (2G). The energized gas valve

opens and supplies gas to the burners. The contacts of

the energized heating blower relay close and make the

line voltage circuit to the blower motor (3A) and,

starts the blower fan.

Pilot Safety Test

If the pilot should go “out”, the pilot assembly’s nor

mally open contacts (which were closed by pilot

ignition) will reopen and break the circuit to the gas

valve. The de-energized gas valve will close and

shutoff the gas supply to the burners.

This safety feature can be checked by closing the pilot

gas cock. The -burners should shutoff within 90

seconds.

NOTE: The pilot will reignite automatically by

means of glow coil ignition when the pilot gas cock is

opened again. There will be a short time delay before

pilot reignition occurs.

Limit Control

The function of the hi-temp limit control (7K) is to

shutoff the gas supply to the burners and maintain an

electrical circuit to the blower motor if the furnace

becomes overheated. The limit control can be checked

by gradually blocking off the return air after the fur

nace has been operating for at least five minutes. As

soon as the limit has functioned to shutoff the gas

valve, unblock the return air opening to permit nor

mal air circulation.

VII. STARTUP AND ADJUSTMENTS

Before starting the unit, make sure the gas pipe is

purged and free from air. Do not purge into the com

bustion chamber. All gas piping should be leak tested.

CAUTION: Remove shipping bolt from blower as

described on label attached to blower access panel.

WARNING: Never use a match or other open flame

to check for gas leakage.

Refer to chiller installation instructions for a circuit

description of the cooling section.

The sequence of control operation for the furnace is as

follows:

1. Turn on electrical power and gas supply to unit.

2. Refer to Figure 7. Note that the 24V control circuit

voltage is applied across unit terminals 4 and X when

power is turned on to the furnace.

When the pilot gas cock is opened, the pilot pressure

switch closes and completes the circuit to the glow coil

of pilot assembly (6B) which ignites the pilot Ap

proximately one minute after the pilot is ignited, heat

from the pilot causes the pilot assembly’s normally

closed contacts to open and the normally open con

Blower Fan Relay (Heating)

The heating blower fan relay (2G) is located in the

control box and is adjustable to permit lengthening or

shorting the “OFF” cycle. The “ON” cycle is

automatically adjusted as the “OFF” cycle is changed.

The fan control adjusting lever is factory-set at the

center position and should give optimum performance

in most installations. However, on unusual in

stallations or where the line voltage is considerably

above or below the rated output, it may be necessary

to increase or decrease the length of time the blower

remains on. For longer blower operation, move the

adjusting lever toward the “MAX OFF” position. In

this position the control line switch makes contact

sooner and takes the maximum time to break contact.

For shorter blower operation, move the lever in the

opposite direction.

Blower Fan Relay (Codling)

The unit is also equipped with a cooling blower fan

relay (2A). When a chiller is used in conjunction with

the furnace to form a combination heating and

cooling system, this relay is energized by the chiller

transformer when there is a demand for cooling.

— 5 39379D36

Page 6

Adjusting Gas Input

The gas input must be checked and adjusted, if

necessary, to agree with that shown on the unit rating

plate (150,000 Btuh). The burners are equipped with

fixed orifices. The burners on natural gas units use

No. 41 drill size orifices while the burners on the

propane units are equipped with No. 54 drill size

orifices.

The natural gas unit is equipped with an A639 gas

valve and a combination regulator/shutoff valve. The

propane gas unit uses an A639 gas valve but is not

equipped with a regulator. The regulator for propane

units is located at the supply tank.

CAUTION: The unit may be run for short periods

with the panels removed. Prolonged operation with

the panels removed should not be attempted.

One of the two following methods may be used to ad

just the gas input on a natural gas unit.

A. Measuring Gas Flow at Meter

All other gas appliances must be turned off when

measuring the gas flow at meter to adjust the gas in

put. Proceed as follows when using this method.

1. Determine the number of seconds required for the

gas meter test dial to complete one revolution.

2. Divide 3600 by the number of seconds in Step 1.

3. Multiply the result in Step 2 by the number of cubic

feet of gas flow per hour.

4. Multiply the result of Step 3 by the Btu heating

value of the gas (consult local utility for value). This

is the total measured Btu/hr input.

Compare this value with the one shown on the rating

plate.

Example: Suppose the size of the test dial is 2 cubic

feet; it takes 50 seconds for the dial to complete one

revolution; heating value of the gas is 1050 Btu per

cubic foot. Proceed as follows:

(a) 50 seconds to complete one revolution.

(b) 3600 divided by 50 equals 72.

(c) 72x2 = 144 cubic feet per hour of gas flow.

(d) 144x1050 = 151,200 Btuh input.

Only minor changes should have to be made at the

pressure regulator to bring it within the rated input of

the unit.

B. Using Water Manometer

When using a water manometer to measure the gas

manifold pressure, proceed as follows to adjust the

gas input.

1. Turn off gas to unit.

2. Remove the 1/8-inch pipe plug on the furnace

manifold and connect manometer here. See Figure 6.

3. Turn on gas to unit. With the burners fired, adjust

the pressure regulator to obtain the correct manifold

pressure as shown in Table IV. Check with local gas

utility for Btu value and specific gravity of gas in the

area.

PILOT

GAS COCK

COMBINATION

REGULATORSHUTOFF

VALVE

' GAS VALVE

PILOT BURNERS

A72154

Figure 6—Front View of Partially Disassembled

48W-379A

4. Remove manometer from manifold and replace the

1/8-inch pipe plug removed in Step 2 above.

Example: Heating value of gas is 1050 Btu and

specific gravity of gas is 0.63.

(a) From Table IV, the manifold pressure required

for 150,000 Btuh input is 2.8 inches water column.

(b) Set manifold pressure to 2.8 inches w.c. by ad

justing gas pressure regulator adjusting screw.

If required manifold pressure exceeds 3.3 inches w.c.

or is less than 2.7 inches w.c., the burner orifices

should be sized according to unit requirements. Con

sult your Bryant Distributor.

CAUTION: Do not redrill orificesunder any cir

cumstances.

TABLE IV — MANIFOLD PRESSURES

(Inches w.c.)

BTU

Value

900 3.6 3.7 3.8 3.9

950 3.2

1000 2.9

1025 2.8 2.9 3.0

1050 2.6 2.7 2.8

1100

0.59

2.4

Specific Gravity

0.61

3.3 3.4

3.0 3.1 3.2 3.3

2.5

0.63

2.6 2.7 2.8

0.65 0.67

3.5

3.1 3.2

2.9 3.0

3.6

Adjusting Pressure Regulator

If measured and rated input are not approximately

the same, the gas pressure regulator may be adjusted

as follows:

To increase input. Remove regulator sealing cap

and turn gas pressure regulator adjusting screw

clockwise.

To decrease input. Remove regulator sealing cap

39379D36

6 —

Page 7

and turn gas pressure adjusting screw counter

clockwise.

Checking Propane Gas input

The burner orifices are sized for rated input with a

manifold pressure of 11.0” w.c. for propane gas. Con

nect a manometer to the 1/8" pressure tap on the gas

manifold. With the burners fired, adjust regulator at

the supply tank to provide a pressure of 11.0" w.c.

Air Shutter Ad|ystmerit

To adjust the primary air to each burner, partially

close tire air shutter until there is a slight yellow tip

on the top of the ñame, then open the air shutter until

the yellow tip just disappears. This should be done af

ter the burners have been operating at full input for 5

or 10 minutes (approximately).

Airflow and Temperature Rise

The furnace is designed for operation within a tem

perature rise of 45 °F to 75 °F, all against an external

static pressure up to 0.5 inch water column.

The external static pressure against which the blower

is operating is the difference in pressures in the return

air duct and discharge air duct near the furnace.

An adjustable flange on the blower motor pulley is

used to adjust the blower speed. Proceed as described

below to adjust blower motor speed.

WARNING: Turn off power at disconnect switch

before removing blower belt.

1. Refer to Figure 5. Loosen the belt tensioning ad

justing screw until there is slack in belt. Remove belt

from pulleys.

2. Loosen setscrew in movable flange of blower motor

pulley. Screw movable flange toward fixed flange to

increase blower speed, and away from fixed flange to

reduce blower speed. Tighten set screw on one of the

two flat surfaces on the pulley hub.

GAUTION: Increasing the blower speed will impose

a greater load on the blower motor. Do not exceed

the rated current draw of the motor.

3. Replace belt and adjust for proper tension. The belt

should have approximately a 3/4-inch sag under nor

mal finger pressure midway between pulleys.

4. Check motor pulley and blower pulley for proper

alignment.

VIII. MAINTENANCE

Blower Motor Lubrication

Lubricate the blower motor per oiling label located in

blower compartment. See Figure 5.

Cleaning the Heating Section

1. Turn off power at main disconnect switch.

WARNING: Tag switch with suitable warning label.

2. Remove front access panel.

3. Turn off manual gas valve and pilot gas cock.

4. Disconnect pilot and escapement tubing.

5. Remove burners.

6. Remove flue baffle retainer and vent section shelf.

7. Remove flue baffle.

8. Clean passages with suitable brush.

9. Reassemble furnace by reversing above procedure.

Filters

Every two months throughout the heating season,

remove and inspect air filters for clogging due to dirt.

When necessary, replace disposable filters or clean

permanent type filters using clear water. Be sure to

coat permanent filters with a water-soluble oil after

cleaning if instructions require it.

11A - Resistor

Figure 7—Models 48W- and 60W-379A Wiring Diagram

— 7 —

LEGEND

IB - Transformer

2A - Blower Fan Relay (Cooling)

2G - Blower Fan Relay (Heating)

3A - Blower Motor

5B - Magnetic Gas Valve

6B - Reignition Piiot

7K - Hi-Temp Limit

7P - Pilot Pressure Switch

39379D36

Page 8

CONTROL BOX

CONTROL BOX

Figure 8—Connecting Modei 48W-379A to Modei

48-453 Chiiier or Connecting Model 60W-379A to

Model 60-452 Chiller.

A72163

39379D36

-8

Loading...

Loading...