Page 1

378

Installation Instructions

ALL WEATHER HEATING & COOL!!^iG

GENERAL

The Model 378 is approved by the American &

Association for:

1. Use with natural, mixed, and propane gases.

2. Outdoor installation

a. On a roof

b. At ground level

3. Indoor installation (when equipped with Bryant

draft hood assembly. Part No, 36154C8 and special

front door in place of door furnished.)

a. Attic

b. Basement, utility room, etc.

4. Use with 36W, 54W, 90W, and 108W water coils.

5. Use with 48R, 60R, 90R, and 120R direct expan

sion coils.

Series B

bpi|ont

39378 D9

5/10/65

INSPECTION

Be sure available gas supply is the same as shown

on American Gas Association rating plate.

Check electric supply - voltage, phase, and fre

quency - to be sure that it is the same as required

on the rating plate. Check to be sure that adequate

power is available to handle the increased electri

cal load when the unit is used for cooling.

Installation of the all-weather heating and cooling

unit consists of the following:

1. Locating the Unit

2. Gas Piping

3. Venting

4. Electric Connections

5. Start-up and Adjustment

6. Connection with Electric Air Conditioner (when

used)

7. Connection with Gas Air Conditioner (when

used)

LOCATING THE UNIT

When installing in conjunction with a cooling sys

tem refer to the applicable section of this instruc

tion for additional information.

Before locating the unit, refer to local codes.

OUTDOOR INSTALLATION

Mounting

The unit design permits use of four corner posts,

rails, or any other method of support sufficiently

strong to accommodate the weight; however, consult

local codes - particularly for roof installation.

Units must be level.

Clearances

1. Provide a minimum 1 inch clearance on bottom

for water drainage (rain, sleet, and snow).

Page 2

m

3;

co

00

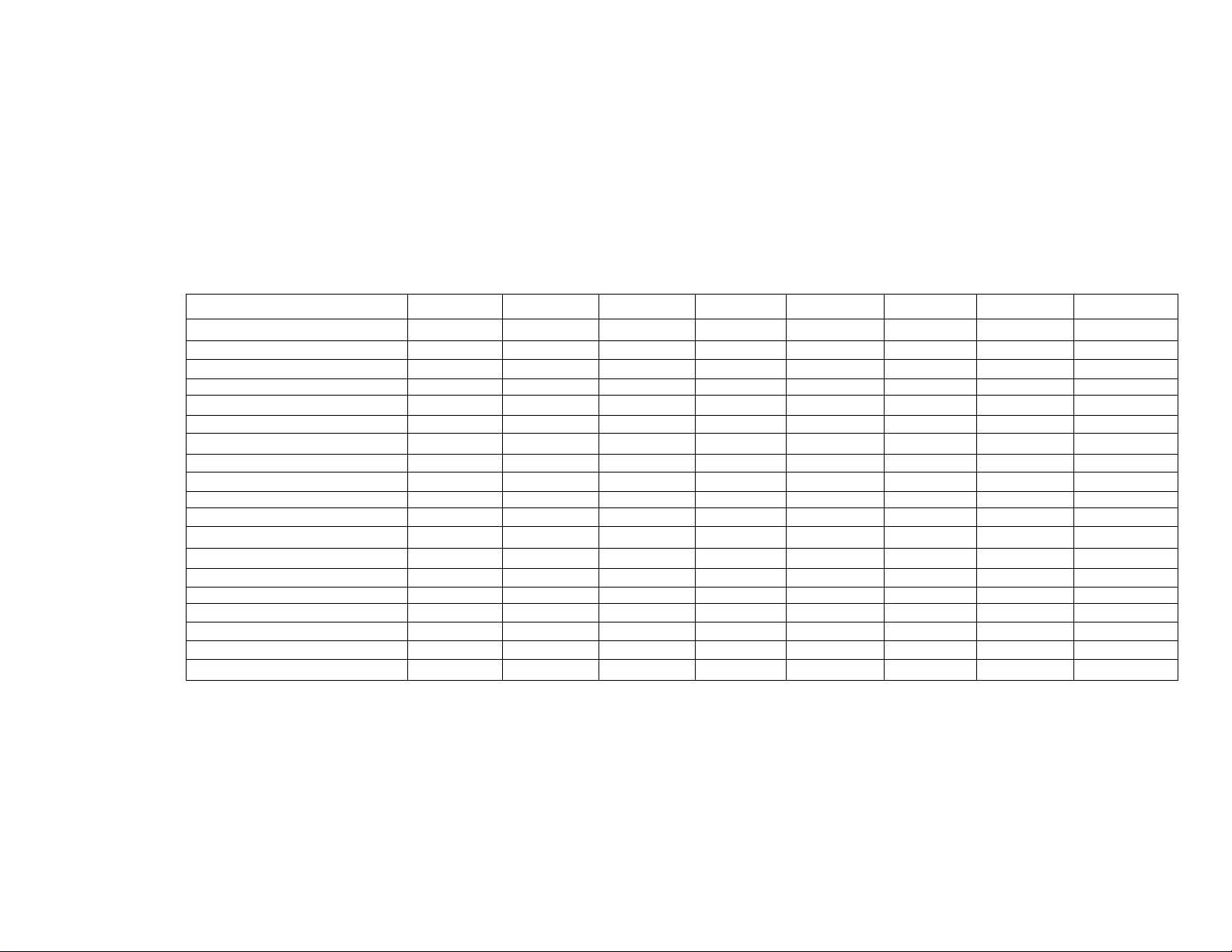

378 ALL WEATHER INDOOR/OUTDOOR UNIT

48R-378 60R-378

Heating input Btuh 150-100,000

Bonnet capacity

Btuh 112-75,000

DX Coil rating Btuh 48,000

Water Coil rating

Btuh

— —

Air flow CFM 1600

External static

Blower motor

In. water 0.20

H.P.

Volts

Phase

150-100,000

112-75,000 112-75,000

60,000

2000

0.20 0.15

1/2 3/4

230 230

1 1 1

Cycle 60

FLA

4

Suction line In. o.d. 1-1/8 7/8

Liquid line

Inlet water line

Outlet water line NPT

Condensate drain In. o.d. 7/8

Refrigerant R 500

Filters (disposable) In.

Approx, shipping wt. Lbs.

In. o.d.

NPT

1/2

3/8

- -

- 7/8

500

(2)25x20x1 (2)25x20x1

580

600

36W-378 54W-378

150-100,000

- -

36,000

1200 1800 3000 ' 4000

1/2

230

60

60

5 4

- - 1-1/8

1-1/4

JTTpri

7/8

- -

(2) 25x20x1

595 605 975 985

90R-378 120R-378 90W-378

150-100,000

300-200,000

300-200,000

112-75,000 225-150,000 225-150,000

54,000

0.20

90,000

—

0.25 0.30 0.25

110,000

■ — 90,000

3/4 1 Ir 1/2

230 230 230

1 1 1

60

60

5 7

1-3/8

1-1/4

1-1/4 ■■

7/8

5/8 5/8

-

—

7/8

-

7/8

22 500

(2) 25x20x1

(4) 25x20x1

(4)25x20x1 (4) 25x20x1

■ 300-200,000

225-150,000 225-150,000

: 3000

1 1- 1/2

: ; (230

1

60 60

9 7

- - - —

1-1/4

1-1/4

7/8

—

710

108W-378

300-200,000

__

108.000

3600

0.30

230

1

60

9

' -

1-1/4

1-1/4

7/8

(4)25x20x1

995

Page 3

Outdoor Installation - Clearances (cont’d)

2. Provide adequate clearance for outlet and return

duct connections.

3. Clearance from combustibles:

From casing, all sides and top 6"

* From base ...............................

0”

When the furnace is installed in a building of un

usually tight construction, air for combustion and

ventilation should be obtained from outdoors or from

spaces freely communicating with the outdoors. Two

openings should be provided, each having a free

area of one square inch for each 2000 Btu per hour one located above the draft diverter relief opening

and the other near the floor.

*This permits use of combustible material as sup

port.

Caution: When using rails, etc. as support, do not

enclose unit so as to interfere with drainage.

4. Service clearance:

Front - 24"

Side - Provide adequate side clearance for fil

ter removal. Clearance on left side for blower

service; side clearance for coil service.

Provide adequate clearance when air conditioner is

located adjacent to unit.

INDOOR INSTALLATION

Mounting

Unit may be set flush with floor or mounted on sup

ports. There is no need to provide clearance under

the base. Shim as required to make unit level.

Clearances

1. From combustible materials:

a. 0 " clearance on bottom.

b. 6" clearance from casing surface; line con

tact allowed.

c. 6" vent and draft hood.

2. Service access: Same as for outdoor installa

tion.

COMBUSTION AND VENTILATION AIR

When the furnace is installed in a confined space,

but in a building otherwise having adequate infiltra

tion from the outside, air for combustion and venti

lation may be taken from the building. Two openings

should be provided, each having a free area of one

square inch for each 1000 Btu per hour- one located

above the draft diverter relief opening and the other

near the floor.

For further information on this subject, refer to

ASA Z21.30-1959, or later editions of this standard,

“Installation of Gas Appliances and Gas Piping.”

GAS PIPING

The gas supply line should be a separate line direct

from the meter to the furnace.

Check local utility for recommendations concerning

existing lines. Choose a supply pipe size large

enough to keep the pressure loss as low as practi

cal.

Never use pipe smaller than the gas connection to

the furnace. Observe local codes for all gas pipe

installation.

The following are pertinent recommendations:

1. Avoid low spots in long runs of pipe, it is best

to grade all pipe 1/4 inch in 15 feet to prevent

traps. All horizontal runs should grade to risers.

Risers should be used to connect to the furnace and

to the meter.

2. Install a drip leg in the riser leading to the

furnace. This drip leg will serve as a trap for dirt

and condensate.

The drip leg can be installed by connecting a tee to

the riser leading to the furnace so that the straightthrough section of the tee is vertical. Then, connect

a capped nipple to the tee. The capped nipple

should extend below the level of the gas controls

a minimum of 6 inches.

3. A manual shut-off valve should be installed in

the gas line within sight of and convenient to the

furnace. This shut-off valve is furnished.

4. Support all piping with appropriate hangers, etc.

Properly support gas piping at furnace to prevent

damage to weather tight seal.

5. After all connections are made, check for leak

age using soap and water solution, or in accordance

with local utility regulations. Never use a match or

other open flame.

- 3

EH 378

Page 4

VENTING

INDOOR INSTALLATION

Consult local codes. Unless the local codes direct

otherwise, the unit may be vented to a permanent

chimney, or to a listed Type B or Type C gas vent.

The Model 378 furnace is approved for indoor instal

lation only when used with draft hood, Bryant Part

No. 36154C8.

To install indoor draft hood:

a. Remove upper front access panel to gain en

trance to flue collector.

8. If more than oiie appliance is vented into the

same chimney, the cross-sectional area of the chim

ney must be as large as the largest flue pipe being

connected, plus 50 per cent of the cross-sectional

areas of the additional flue pipes being connected.

9. If more than one appliance is manifolded into the

same flue connecting pipe, the cross-sectional area

of this manifold pipe must be as large as the sum of

the cross-sectional areas of the pipes connecting

into it.

10. Flue pipe must be at least 6 inches from any

combustible materials.

b. Insert draft hood inside furnace casing collar

and push it down over the flue collector collar to

form snug connection.

c. Fasten draft hood to flue collector collar with

sheet metal screws.

The following recommendations are made:

1. Select flue connection material that is satis

factory for the installation and that meets the

requirements of the local codes.

2. The flue connection pipe must be the same size

as the outlet collar on the furnace. No reduction in

this size is permissible in the pipe run.

3. Run pipe as directly as possible with a minimum

number of turns.

4. Maintain a minimum of 1/4 inch per linear foot

upward slope on all horizontal runs.

5. Rigidly support the flue pipe with hangers and

straps to insure that there will be no movement after

installation.

6. Extend the flue connection pipe through the

chimney wall, flush with the inner face of the chim

ney liner. Never connect into a chimney serving an

open fireplace unless the fireplace opening is

sealed off.

Do not use dampers or other adjustable restrictions

in flue.

Any part of the vent which is outdoors must be ade

quately insulated to assure proper chimney action

and prevent condensation.

OUTDOOR INSTALLATION

The Model 378 all-weather unit is shipped with out

door vent as standard equipment and must be instal

led in accordance with the following instructions

and without alterations.

Installing Outdoor Vent

1. Remove upper front access panel to gain en

trance to flue collector.

2. Insert cap and pipe assembly through furnace

casing.

Important: Be sure the outer wall of the double

walled pipe extends over the furnace casing con

nector collar to assure weather tight connection and

that the inner wall connects to the flue collector

collar.

3. Fasten the flue pipe assembly to the flue col

lector collar with sheet metal screws. Note: Addi

tional venting is not required on outdoor units.

7. The chimney or gas vent should extend high

enough above the roof or neighboring obstruction

so that wind from any direction will not create a

positive pressure in the vicinity of the outlet of the

chimney or gas vent. The installer is referred to

Part V of American Standard “Installation of Gas

Appliances and Gas Piping”, ASA Z21.30, 1959 for

detailed information on chimney and gas vent use.

In general, the chimney or gas vent should extend

3 feet higher than the point of emergence through

the roof, and at least 2 feet higher than any object

within a radius of 15 feet.

EH 378

ELECTRIC CONNECTIONS

1. All electrical connections are to be made in

accordance with National Electrical Codes and

local codes governing such wiring.

Field connections are to be made in accordance

with wiring label attached to unit. See Figures 1 and

2.

2. Weather tight connections must be made at elec

trical entrance to the unit on all outdoor installa

tions.

4 -

Page 5

3. Thermostat connections for heating only are to

be made at terminals 4 and W. See Figure 3 for low

voltage connections when cooling equipment is

used.

unit. The limit will shut off the main gas if the

temperature goes too high. The limit may be checked

by removing the fan belt and firing the unit. The

burners should shut in a few minutes.

4. A separate, fused, electrical line should be run

for this installation.

START-UP AND ADJUSTMENT

1. Before Starting the Unit:

a. Check to see that electric and piping con

nections have been made.

b. Make sure gas piping is purged and free of

air; do not purge into the combustion chamber

of the furnace. All gas piping connections

should be leak tested. Do not use an open

flame. Use a soap and water solution.

2. Start-Up:

'Follow lighting instructions attached to the unit.

Sequence of control operation is as follows:

a. When pilot gas cock is opened, gas flows to

the pilot and to the pilot pressure switch.

b. Pilot pressure switch then closes to com

plete the 24 volt circuit. The pilot then

lights automatically.

3. Adjust Gas Input:

Air Shutter Adjustment - To adjust the air shutter,

pull the shutter closed until there is a slight yellow

tip at the top of each flame. Then open the shutter

until the yellow tip disappears.

Gas input should agree with that shown on the rating

plate of the unit. The burners are equipped with

orifices sized to give the correct input with a mani

fold pressure of 3 inches w.c. ± 0.3 for natural and

mixed gases, and II inches w.c. for propane gas.

The furnaces are approved for minimum firing rates

(shown on rating plate) as follows:

Size 150 - May be fired at 100,000 BTUH input.

Size 300 - May be fired at 200,000 BTUH input

Note: The size 150 furnace (natural gas only) is

also approved for modulated input down to 50,000

BTUH when equipped with an approved modulating

valve. The size 300 furnace (natural gas only) is

approved for modulated input down to 100,000 BTUH.

c. Subsequent switch action completes circuit

through Y and W to energize the electric gas

valve.

When the thermostat calls for heat, circuit is closed

between W and 4. This allows current to flow through

combustion air fan relay which energizes the com

bustion air blower and builds up pressure in the

combustion air switch. When combustion air pres

sure switch is closed, low voltage is completed.

The conditioning air blower is not actuated by a fan

switch, but by a delay fan relay.

If the lower limit opens, the automatic gas valve is

de-energized.

If the upper limit opens, the automatic gas valve is

de-energized, and the combustion air pressure switch

is by-passed so that the conditioning air blower will

continue to run.

The automatic pilot turns the main gas off, should

pilot flame be put out. This can be checked by turn

ing the main burners and pilot oh, then shutting the

pilot gas off. The main burners should shut off.

See next page for

Gas Input Measurement

The limit controls the temperature reached in the

5 -

EH 378

Page 6

Determine gas input as follows:

a. Determine the number of seconds required for

the gas meter test dial to complete one revo

lution.

b. Divide 3600 by the nuniber of seconds in

Item (a) above.

c. Multiply result of Item (b) by the number of

cubic feet shown for one revolution of the

test dial. This gives you cubic feet per hour

of gas flow.

d. Multiply result of Item (c) by the heating

value of the gas in BTU (consult local util

ity for value). This gives you the total meas

ured input in BTUH. Compare this value with

that on your rating plate.

TABLE

Model No.

36W, 54W, 48R,

60R,&l50-378

90W, 108W, 90R

120R, 8s300-378

Input Btu

per hr.

150,000 45 ° F to 75 ° F

100,000

300,000 45 ° F to 75 ° F

200,000

Temperature Rise Air

through Furnace

20 ° F to 75 ° F

20 ° F to 75 ° F

The pulley setting has been made at the factory to

give an air flow compatible with the intended use of

the equipment; i. e., the setting varies with the

type of cooling coil to be used. Table II gives the

pulley setting as the furnace leaves the factory,

and shows also how the pulley can be adjusted to

give the desired air flow if the duct resistance is

higher than normal.

Example: Suppose that the size of the test dial is

1/2 (.5) cu. ft.; it takes 20 seconds for the dial to

complete one revolution; heating value of gas is

1050 BTU/cu. ft. Proceed as follows:

a. 20 seconds to complete one revolution.

b. 3600 divided by 20 equals 180.

c. 180 X 0.5 equals 90 cu. ft. per hour of gas

flow.

d. 90 X 1050 equals 94,500 BTUH input.

Only minor changes should have to be made at the

pressure regulator. If the manifold pressure must be

changed more than ±.3 w.c. to obtain rated input,

the orifices should be changed accordingly.

4. Air Flow and Temperature Rise

The furnace is approved for operation under the

temperature rise conditions shown in Table I.

Model Normal Static (ARI)

No.

Static

in. w.c. Pulley Turns Open in. w.c.

Factory Setting of

36W - 378 0.15 31/2

54W - 378 0.20 4

48R - 378 0.20

60R - 378 0.20

150 - 378 0.20

The static pressure against which the furnace is

operating is the difference in pressures in the

return air duct and the discharge duct hear the

furnace. If this differential pressure, determined

when the filters are clean and the pulley is opened

the number of turns shown for normal static, is more

than shown for normal static in Table II, the blower

speed should be increased by changing the pulley

setting to that shown in the column for higher than

normal static pressures.

The temperature rise is the difference between the

temperature of the air in the return duct and in the

discharge duct near the furnace. This temperature

rise, measured after equilibrium has been attained,

should be within the range shown in Table I. The

pulley setting shown in Table II should give an air

rise within the approved range.

TABLE II

High

er Static *

Static Pulley Setting

Turns Open

IV2

3V2

21/2

0.50

0.50

0.40

0.50

0.50

1V2

2

0

IV2

V2

90W - 378

108W - 378

0.25

0.30

90R - 378 0.25

120R - 378

0.30 1

300 - 378 0.25

* The furnaces are approved for operation up to 0.50 in. w.c.

EH 378 . 6 -

11/2

21/2

ya

V2

0.45 0

0.50

0.35 0

0.40 0

0.35 0

1

Page 7

CONNECTING CONDENSING UNIT

TO R TYPE MODEL 378

The evaporator coil is supplied as an integral part

of the “R” Type 378 unit.

The condensing unit may be installed remotely or

adjacent to the “R” Type 378 unit.

Consult Condensing Unit Installation Instructions

for minimum clearances and connection of refrigerant

tubing.

All openings in refrigerant lines from evaporator

coil and condensing unit are plugged or capped to

keep moisture out of the system. These plugs or

caps should not be removed until each connection

is made. Each connection should be made in the

shortest time possible to avoid contamination from

surrounding air.

Note: The 90R and 120R 378 units have a factory

installed expansion valve. Items 1 through 5 will,

therefore, not apply for these sizes in the following

instructions. The expansion valves for the 48R and

60R 378 units are supplied as a loose part with the

condensing unit.

5. Uncoil capillary line of Expansion valve and

attach sensing bulb to top of horizontal suction

line inside of unit casing. Wrap bulb with prestite

tape (shipped with unit as a loose part).

6. Connect coil to condensing unit per instructions

packaged with the condensing unit.

7. Follow procedures outlined in Condensing Unit

Installation Instruction for leak testing and evacua

tion.

8. Replace panels on unit and connect condensate

(located on opposite side of unit) to a suitable

drain site.

9. All electrical connections should be made in

accordance with National Electric Code and any

local codes that might apply. Make electrical con

nections as shown in wiring diagram in condensing

unit instruction and the low voltage diagram in this

instruction.

To install the expansion valve, proceed as follows:

1. Remove panels from right-hand side of the 378

unit.

2. Remove plug from flare nut connector on dis

tributor and insert expansion valve.

3. Remove plug from external equalizer line flare

fitting and connect equalizer to expansion valve.

4. Shipped as loose parts on 48 & 60 sizes are

2 large metal seals, a neoprene gasket, and nuts and

nuts and bolts to seal the liquid line opening. In

stall air seals as shown.

CONNECTING GAS AIR CONDITIONER

TO W TYPE 378

AH Weather Indoor—Outdoor Unit

Water Coil Connections

For installation of chilled water lines from the gas

air conditioner to the water coil in the Model 378,

refer to installation instructions furnished with the

gas air conditioner.

For piping and wiring recommendations on multiple

gas air conditioner installations as required for the

Models 90W 378 and 108W, contact your Bryant

distributor.

Winter Shut-Down Protection

It will be necessary to add anti-freeze to the chilled

water system for winter protection whether the

Model 378 is installed indoors or outdoors. The ad

dition of the anti-freeze will furnish freeze protec

tion for the coil and piping. It will also provide for

expansion of water in the coil if the coil is located

in the heated air stream.

- 7 -

EH 378

Page 8

Winter Shut-Down Protection (continued)

MAINTENANCE

Winter shut-down protection can be provided as

follows:

1. With the pump circulating water with additive

(borax), add one gallon of methanol (uninhibited

methyl alcohol) for each 20 gallons of water or

fraction thereof, and circulate for ten minutes.

2. It is not necessary to drain the system,

3. Tag the unit to show methanol has been added.

4. Determine the correct amount of methanol re

quired as follows:

a. Estimate the system water capacity in gal

lons from table below. Multiply the length of

pipe in feet by the gallons in one foot; then

add the gallons of water in chiller, or chil

lers, and coil.

b. Water Capacity Table:

Water Capacity Gallons

36-450 Chiller

54-450 Chiller .....

36W-378 or 54W-378 Coil

90W-378 or 108W-378 Coü

1 ft. of 3/4 inch pipe

1 ft. of 1 inch pipe . . .

1 ft. of 1 -1/4 inch pipe.

1 ft. of 1 -1/2 inch pipe.

c. With the pump operating, adjust the water

.....................

______

5

8

1.5

3.0

.03

.05

.08

.12

operating level in the chiller.

Summer Operation

In general, it is recommended that the methanol be

flushed from the chilled water system for summer

operation. The presence of methanol in the chilled

water will reduce the capacity with a corresponding

increase in operating cost. However, the reduction

in capacity resulting from the 5% solution of meth

anol is small (less than 1%) and the methanol may be

left in the system.

If the system is drained, flushed, and refilled with

water, be sure to add one box of chilled water ad

ditive (borax) for each 20 gallons of water or frac

tion thereof in the system.

Note: The above explanation covers only the normal

winter shut-down protection. If, for any reason, the

gas air conditioner must operate when the outdoor

temperatures are below freezing, it will be neces

sary to prepare the chilled water system for the

minimum temperature. Consult your Bryant distri

butor for special procedures to follow.

LUBRICATION

Blower Motor - if equipped with oil cups, oil motor

bearings with SAE10-20 non-detergent oil each

heating and cooling season. Use approximately six

drops for each bearing. Some motors are equipped

with bearings of a permanently lubricated type and,

therefore, need no further oiling.

Blower Bearings -are of the permanently lubricated

type and, therefore, need no further oiling.

Combustion Air Blower Motor — (located in control

compartment). Oil motor bearings with SAE 10-20

non-detergent oil each heating season. Use approxi

mately three drops for each bearing.

Air Filter

Periodically inspect air filters. Replace when dirty

with filters of the same size (see marking on fil

ters), making sure that arrows on edge of filter

point in direction of air flow (toward blower).

Excessively dirty filters reduce furnace efficiency.

Cleaning the Unit

1. Be sure main line disconnect switch is in the

“off”^ position. Tag with suitable warning label.

2. Turn manual gas and pilot valve to “off” posi

tion.

3. Remove upper and lower front access panels.

4. Disconnect pilot and escapement tubing.

5. Remove burners.

6. Remove screws holding horizontal dividing panel

and flue collector in place,

7. Tip dividing panel and flue collector up and

back to give access to flue outlets.

8. Remove flue baffles.

9. Clean flue passages with suitable brush.

10. Re-assemble furnace by reversing the above

procedure, making sure all seals are properly re

placed.

See following pages for Wiring Diagrams.

EH 378

- 8 -

Page 9

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THIS APPLIANCE MUST BE

REPLACED, IT MUST BE REPLACED WITH SAME OR EQUIVALENT WIRE:

LOW VOLTAGE WIRES—18 A.W.G. 4/64THK. 600V. I05“C. INSULATION

LINE VOLTAGE WIRES—14 A.W.G. 5/64 THK, 600V. I05®C. INSULATION

S.P.D.T. LIMIT SWITCH WIRES--» A.W.G. 2/64 THICK 600V. I50**C. INFLATION

IF THIS APPLIANCE IS CONVERTED TO PROPANE GAS THE INSTALLATION WILL NOT

BE COMPLETE UNLESS THIS WIRING LABEL IS REPLACED WITH THE WIRING

LABEL SUPPLIED WITH CONVERSION KIT.

57389CI

Figure 1 - Wiring for City Gases

- 9 -

EH 378

Page 10

208/230 VOLTS

60 CYCLE

SINGLE PHASE

CURRENT DRAW LESS

THAN 12 AMPERES

--------

FACTORY LOW VOLTAGE

--------

FIELD LOW VOLTAGE

—— FACTORY LINE VOLTAGE

-—FIELD LINE VOLTAGE

LIMIT SWITCH

S. P. D. T.

COMBUSTION

AIR BLOWER

MOTOR

EH 378

ONE PILOT RELAY

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THIS APPLIANCE MUST BE

REPLACED, IT MUST BE REPLACED WITH SAME OR EQUIVALENT WIRE-*

LOW VOLTAGE WIRE I8A.W.6. 4/64 THICK 600V. I05»C. INSULATION.

LINE VOLTAGE WIRE

S.P. D.T. LIMIT SWITCH WIRES

THIS APPLIANCE IS CONVERTED TO PROPANE GAS THE INSTALLATION WILL NOT

BE COMPLETE UNLESS THIS WIRING LABEL REPLACES THE WIRING LABEL

SUPPLIED ON UNIT.

-------------

I4A.W.G. 5/64 THICK 600 V. 105® C. INSULATION .

----------------

18 A.W.6. 2/64 THICK 600V. 150“C. INSULATION.

TWO PILOT RELAYS

57814 CI

Figure 2 - Wiring for Propane Gas

- 10 -

Page 11

LOW VOLTAGE

TERMINAL STRIP

ON CONDENSING UNIT

LOW VOLTAGE

TERMINAL STRIP

ON 378 UNIT

Figure 3 - Low Voltage Wiring

- 11 -

EH 378

Loading...

Loading...