Page 1

A U G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 1

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

and operating

DGWNFLQW/HGRIZONTAL;

G1ÜFIBED FURNACE. : ■

364AAN

Index - ,

SAFETY CO^rsiDERATIONS

Minimum Clearanct t,p Combustibles

INTRQDXJipXiOii ..........................................................

LocAjio>f.x;„:„„;;.:..2.„„

Air for Combustion anji Vcntilatioi^,......--- -

Ductwork Recomniendatipns

ve^in,c2instruc.tiqn&‘,.„,1

Pre“InstaJl8ition;VentOSystem Inspection

Masonry Chimney

Factpiy.-PuiJt Chimnpys..,:...

Horizontal :Venting,„.

OIL BURKERi.

OIL CONNECTIONS

BAROMETRIC DRAFT CONTROL;;..-,...

ELECTRICAL',........

FILTERS

Keeping Filters Clean.

REVERS.lNQ-INSTitUGTIONS FOR REAR FLUE,

OPTrQfe,:i-.„;:/;v..i...v..;;.;it..;

ASSEMBLYTNSMCTIONS

OPERATIONAL CHECKOUT

St^-Up

Recommended Installation Practipcs and

. Combustion Check,.,.,,.......................................................S-9

Fan;Adju5ihne)^^

Limit^CqntTol Check...,,

For Year Rouiid ,^r Conditioning,.,,:,,.,.....,

Heating..........,.^

Cooling

'Gpnstant^jBjoiwer Switch

MAINTENANCE

Oil Burner.-.,,ft

Heat Exchanger and, Flue Pipe..,.

Blower Removal

Airflow

Dimensional Drawing-.

E arometne. Damper'Locati ons..... ..

Wiring Diagram...............................

USER^sllNFORMATION

Here's Hbw Your Heating System Works

Preparing Your Furnace For Operation ,',,■.-15

Lighting Your Furnace

Turning Off Your Furnace

'i' 'V '>■ ■

.................................................................

.........................

..................

................

..........................

................................................

........................

..........................................

............J.....................

.........................................

..........................................

......................................

..........

................................:.....

..............................................................,..9,,

.......

,,,

..................

.......

.

.............

...............

...........................................

.-

;

........

.....................

,................

................

............

......li-.i..--,..,..

...............

...............

...........

......

.............

...............

.........

.............................

......

..................

„■.fj.'l:

Page

....

1^2

.......

.

.

.........

-A-X2^

.....

2-3

......

3-4

.......

.

....

.i-;..

:

......

.

......

.........

.......

........

.......4

........

........

.......;5

......,...,5

:5-6

„.7.78

.......

...........

„,,9

,,...,,..,....,1,9

,-.'-;9

d5

....

.......

15

.4

4

-4

4

Cancels: 'New

SAFETY considerations

2

2

FOR YOUR SAFETY

II â64A-7d7Î

DO NOT STORE .OR. USE GASOLINE OR

OTHER fLAMîVïABÜE YARORS A^ LIQ

UIDS IN XHE-YlCtNITYLOFATHIS OR.ANY

OTHER APPLIANCE, _

.

....

- ,, ■AAil

.

DO NOT ATTEMPT TO START THE BURNER

WHEN EXCESS OIL HAS ACGUMtlLATED,

4

4

4

5

WHEN THE FURNACE IS FULL GF_ VAPOR, OR WHEN THE COMBUSTION CHAMBER IS^

VERY HOT.

■ ■ ...... .....

WARNING: For use with grade-2 Fuel Oil liiaximum.

ж

Do not use Gasoline, Crankcase Oil, or any Oil contain-^

ing Gasoline!

CÀüf IpW:' burn/garbi^e^ or 'papér in 'the hc^tihg"

A

system and never leave rags or paper around .fhennit;.

CAUTION,' These .^instfuctio'ns'hre,intended to be',^used

by qualified personnel who have been trained in installing

A

this type of furnace. Installation of this furnace by an

unqualified person damage an,d/pi:.

a hazardous condition which-'may icad to bodily harm-

AJ] local and national code requirements governing installation of

oil burning equipment^ wiring, and flue ¿onnecdons'^nitist bë

followed. Some of thé codes (issued by thé Canadian Standards

Association) the Niiiqnhl ‘Fire Protection Agencÿ; ahd/oPthc

American National StandardsThstitute) th'atiihaÿ bë’ appiioiijie 'aje",

CSAB1^9 ' ‘mSTALLA^ON CODEfbR'''

‘^ ANSiONFPA 31 ‘ INSTALLATION OF OIL BURNIN<5

‘ ANSÏ/NFPA90B WARM AiR HEATING AND

^ AN5I/NFFA211

....

.....

- - -

. ,S:I .

,oiL,Büiüjiï^ckû0ffMEi^

-EQUIPMENT ' '

conditioning’SYSTEMS

CHIMNEYS, FIREPLACES, VENTS,

AND 'SOLID FUEL BURNING

APPLIANCES ' '

.......

...

.." 1Ч;

U

-1-

.,ANSI/NFPA 70

eSA C22.1

NATIONAL ELECTRICAL CODE

CANADIAN ELECTRIOAL CODE ’

Page 2

A U G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 1

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

f the latest issued Of above codes ^hoiild be used, ;and 'are

a't/ail^blc frOin cither The National Fire jprptecfion-^en^y

tcrymarch Par]?, Quincy, MA 02269 qr;'l^e Gapadian Standards.

Association, 178 fe.exdalc PJvd,', Reifdale, 'Oiiiadci ;>

Recognize safety infonnaiion. This is the safety-aleirt symbol A

When you sec this symbol On fhe furnace and in instryctions or

manuals, be jslcrt to the potential for personal injuryi ‘ / '

Understand the signal wprds pANGEBit, i^^ARNlNG, and .CAU-'

TIQN/TTiese words are used with the safety-alert symbol, DAN

GER: identifies the most serious hazards which wUI result in severe

personal injury Or death. WARNING signifies a hazard which

could result in personal injury or death, CAUTION is used to

identify unsafe practices which wotild result in minor personal

injury or product and property damage.

TABLE ,1—MINIMUM CLEARANCES TO COMBUSTIBLE

UNIT AF^FLICATION

Furnace

Sides Supply Plenum and ^ '

. .Warm-:Air DuCt Within ,6 ft

: -;Of.FurnaCO ' :■ '■

POWNFLOW HORIZONTAL

1

Back

Furnace Casing or

Planum

Top"'^"

i......,Hortïorita! WarmÁif'Duct.

Within 6 ft of Furnaca ; : ■

Bottom ;

Horizontally or Below Pipe

Flue

Pipȓ

Vertically Above Pipe'

Front

* AqoBssory dDwnflOW Subbase. rsquirsd whsn installing on DOmbLtStible floor.

If instalicd on'downflow subbase, 4-In: supply plenum claarance may ba

reduced to 2 in,..; - - . . ■

t Floor.may be e'ombustible,....

NOTES:

1. Adequate service clearance should be provided over and above these

dimensions, as required.

2. In downflow position, may be installed in closet or alcove,. ,

3- In horizontal position, may oe Installed in alcove or attic.

16

■hy- iût ■ ,.c..

jV^'^TROpUpTpN.,,..

The model 364AAN Furnaces are available in sizes 70,000

througjb ,155,000 Btuh.input capacities. ^ ^

This ; ^mace, is ;-a position unii,-jthat,viiiay;bP ^

dpwhHow, horizontal left,: or horizontal right positions;

Since it is shipped without bpimcr Mild coritrpl^ rapiinted, there |s

no additipnai effoii required, to, charige ^oih 1 airfloty configuration to anpther. The irist^ier''merely: places burp^r/^ in

proper position fp.t“ m?tallation. Ip addition, it is shipped *hs a'front

flue unit (flue connection on same side of furnace as burpw), but

maj',be changed, to .reai;flue ^t timo p:l;iiistallal^pn.'.(^,c(; 'Reversing

Instructions for Rear Flue Gptidn;.s6ctiQn,)

The furnace .is, ,shipped.in.,.2 packages,. 1 with ,b^sic.fumacc and 1

with dirbunier iand epniroi box. .The burner is frliy wired, so the

only assembly required'is mounting' of control box (4 screws),

mounting of burlier Til'nuts),'inpuntiiig of limit cover (Z,scr,ews),

and conii;ection;^pf motor and limit wires (ajl quick-connect

terminals). It requires a line voltage (115 vac) connection to

control box, thermostat connections as shown on wiring diagram,

oil line'¿onnediibh{i)i adequate ductwork, and connection to a

properly sized vent.

The air handling capacity of this furnace is designed for cooling

airflow. Refer to Table 4 for expected airflows at various external

duct static pressures.

WA

24

LOCATION

WARNit^G: This furnace is .not water tight and is not

designed for ;outdo6r;installation- This furnace shall be

installed in such a tnanper -as to protect- electrical cotn-

A

pbhents from water. Outdoor installation would lead to a'

hazardous electf|caj condition and to premature funjacc

failure;:'"'^''"-'''.A

CAUTION; For an attic installation, it is important to

keep insulation 12 in. or more away from any fiimace

A

openings. Some types of insulating materials may be

combustible.

This frrnace is approved for reduced clearances to combustible

construction, therefore, it may be installed in a closet, alcove,‘'or'

similar enclosure. It is also approved for attic installation. As this

unit may be installed as a downflow or'horizontarfurhace,' it >may

be located in a basement, on the same level as area to be Eeated,suspended, or in a crawlspace. In any case,-.unit should always^be

installed level.

....... .r;-

When installed in horizontal position, furnace'may be suspended

by using an -angle-iron frame, as -long ,as ntotar :wcight of froth

furnace,,and.frame.are,.allowed ior..in .support calculations. (Gfhbr

metho.ds of,suspending-urp.acceptable.). : "2

When .installed in downflowvposirion, this fr'riiacé ïiÆÜST NÔT be

installed, on combustible flooring unless approved subbastis used.

The'required minimum clearances-for this fumaoc in ail iposirions

8

arc spcdñcd in Tabic..1,

The furnace should be IScâted ás close as'possible or

........................

2

vent in Order to keep vent-connections ¿short, andi' direct. The

furnace should also be locaied.,as near ás'^pbssibie to center-,of air

distribution system.

I. AIR FOR COMBUSTION AND VENTILATION t;

.......

..................'r '

This furnace should be inStailcd in a location in whichTacilities'for

ventilation pennit satisfactory combustion pf oil, proper-venting,

and maintenance of ambient :temperatufe at safe limits ¿under

norinal conditions of-use. The ¿location bhould not interfere with

proper-circulation of air -withm ihe confined space,' ; :

In addition' to -aif-¿needed for ¿combustion, jprooess air ¿shall "be

provided as ¿required iorv' ^oling of equipment , of m

contrblhng dew point, beating! Hfying/frxidation or dildtion, safetÿ

6xhaust2.and for Odor cqiitÉok . --¿-72''^V2:. 22 .2:.2-''2- 2 .^

In addition to air needed .for combustión, air sháll he' supplied for

ventilatiom jncluding all . air required for comfortv and proper

working .conditions''forRexsonneL-'' . ^

...

......

..-i -c: --■

The: barometric dfaft .regulator, (included with furnace) shall fre

installed ih-sám.eTÓotn or .enclosure as fumacein such”aimannerias

to prevent any difference in pressure becweeh ¿regulator aijd

combustion air Supply.

..........

........

Air requirements for operation of exhaust fans, MtChén yentilatiüA

systems, clothes dryers,, and fireplaçéç sljaill. be ■:considered,dn

determining the adequacy,of a..TSpitcc. to prA^ii* combustion air

requirements.

.....

In unconfíned spaces ijj.buildlnga of conventional frame, brick,-.or

Stone construction, infíltration MAY be adequate to provide air for

combustion, ventilation, and dilution of flue gases. This determination must be made on an individual jnstallaUon basis and must

take into consideration the overall volume of unconfined space, the

number of doors to the outside, internal doors which can close off

unconfined space, and overall tightness of building construction.

Many new buildings and homes (and older ones that have been

weatheiized) MUST BE considered as being tight construction,

therefore, infiltration will not be èuffjcient to supply necessary air

for combustion and ventilation.

-2"

Page 3

AUG/26/2008/TÏÏE 10:01

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

0 0 3 / 0 1 6

A building can be considered as being of tight construction when:

1. Walls and ceilings exposed to outside atmosphere have a

continuous water vapor retarder with a rating of 1 perm or

less with openings gasketed or sealed and/or

2. Wcatherstripping has been added on operable windows and

doors, and/or

5. Caulking or sealants are applied to areas such as joints

around window door. frames; between sole plates and

floors; between wall-ceiling joints; between wall panels; at

penetrations for pluptbing, electrical, and fuel lines; and at

other openings.

If combustion and ventilation air must be supplied to an unconfined space from Outside, an opening with ii JExREE AREA of not

less than 1 sq in. per 1ÚÜO Stub of total input of all appliances

within unconfined space (but.nqt.less than .;(Op sq-in.) must be

provided. This opening must be ]pcatcd..such,.that,it.pan pot,be

blocked at any time. ■ ' '

When furnace is installed in a closet or enclosure, 2 ventilatior}

openings, with OPEN AREA as dimensioned in example below

are required for combustion air. The openings ¿houlcí be located

about 6 in. from tOp and bottom of enclosure at front of furnace.

For Esfample:

UNIT

SIZE

036070

036090

048125

046155

LENGTH

16

:;ie

20

20,..

HEIGHT

1. (IN.)

10

10

WARNING: Do not block combustion air openings in

the burner. Any blockage will result in iiqproper com

A

bustion ventilation which m^y result in a .fire hazard

and/or cause bodily harm, „ ' '

il. DUCTWORK RECOMMENDATIONS

The proper sizing of warm air ducts is necessary to ensure

satisfactory ^mace operation. Ductwork should be in accordance

with the latest editions of NFPA-90A (Installation pf Air Condi

tioning and Ventilating ^yst^ms) and NFPA-90E (Warm Air

Heating and Air Conditioning Systems) or Canadian equivalent

The supply ductwork should be attached to flanged -opening

provided at discharge end of furnace. See Fig. 14 for dimensions

of’this opening'.'

The return air ductwork should be connected to opening on inlet

end pf furnace. AN E?(TERNALLY .MpUNTED AIR FILTER

MUST BE USED WITH THIS FURNACE! The filter .should .be

mounted in return air ductwork in ,a position that j,5., readily

accessible to homeowner. Besure that filter is large enough that,air

velocity through filter (iqps not exceed rating of'filter (typically

300 ft per minute velocity rating). An external filter 'ffaine kit is

available to mount directly to outside of furnace. Contiipt your

dealer for details. ■ ■ ' ■ ‘

The following recommendations should be followed when install

ing ductwork:

1. Install locking type dampers in all branches of individual

ducts,to .balance put system. Dampers should.b.e adjusted to

Impose proper static a'i outlet of furnace. ^

For a confined space, where air . is taken from an interior .space, 2

permanent openings of equal-area-are required. One opening must

be within 12 in, of ceiling and the other within 12 in. of floor. Each

opening must have a free area of at lea^t 1 sq in. per IODO Btuh of

total input rating but no less-'than 1ÖÖ sq fri.

If outside;aír is supplied.to.a confined sp^cc, th6n>th'e .2, openings

must be^e^ual and located a? above. The free Mea of each must be:

1. One sq in. per 4000 Btuh of total rating When air is directly

commupicatEd'-fimm outdoors,if :/-; ... ‘3 "'Xv '

2. One.,i5q jn¿/^^PQQ Btuh of tot^l^ipputräting whqp air is

brought in through .veitical ducts,..

3. Onc^sqihrper 2000'Btuh ortothTiiiptil rating when air is

■■ transferred through horizontal-;ducis',"- /-[-,: 7¡"^~

When ducts are used to siipply airi they must be of the säinc cross

sectional área a$^eb area Of openihgS'ib'which'they com

^ -.'i" V' i-lr. .V.V.'

The minimum dimension of rectangular air ducts must not be less

than 3 in, ^ .

In calculating irfce area,'¿onsideratjon shill be gív'eríTb blocking

effect of loiiverá, grilles, of screen^ protecting opening^.' Screens

used shall not be smaller than 1/4-m. m6sh''ahd 'áíiaí]’be‘readily

accessible for cleaning. If free area through a design of louver or

grille is known, it shall .be used in calculating isjae design and free

area specified.. If design and free area js not known, it may be

assumed that wood louvers havq 20 percpnt free ar,ea, and pietal

louvers and grilles have 60 percent free area. Louvers shall be

fixed in open position or interlocked with furnace so they open

automatically at furnace start-up and remain open during furnace

operalion-

2. A flexible duct cppuector -of,,,noncombustible material

should be installed at unit on both supply-and . retum^air

systems. In applications where extremely quiet operation is

necessary, the first 10 fr (if possible) of supply and return

ducts should be internally'lined with'acoustical material.

3. In cases where return air grille is located dose to fan inlet,

there should 'be at least ope 90^ '¿if turn between _fan inlet

and grille. Further reduction'in sound le^l can be accom

plished by installing acoustical air taming vanes dr lining

duct as described in item 2 above. >

4. When a single air grille is used, duct between grille and

furnace mustfre the same siie'as return Opening in furnace.

CAUTION; Return, air grilles and .-warm ait, registers

A

must not be obstructed. ..r

WARNING: When, supply ducts .cany air circulated by

furnace to areas outside spaces containing furnace^ rptpni

air shall also be handled by a duct sealed to furnace

A

casing and terminating outside space containing frirnace.

Incorrect ductwork termination .and sealing will create a

hazardous condition which could lead to bodily harm-'

When installing furnace with cooling equipment for year round

operation, the following recommendations must be follovyted for

series or parallel airflow;

1, In series airflow applications, coil is mounted after frirnace

in an enclosure in supply-ajr stream. The furnace blower is

used for both heating and cooling airflow.

Page 4

A U G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 2

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

WARNINGI pe ;con; MUCT pn air dis-:

chflirge side of :^rnacP. Under“ no circumstances should

aiffloiy tic 5uch that: cobied^ conditioned air can pass over

furjiacc he^t exchanger. This will cavse condensation in

heat cxP^ariger and possible, failure of heat., exchanger

A

which could lead to a fire hazard and/or a hazardous

condition which may lend to bodily harm. Heat exchanger

failure due tp improper installation may not be covered by

warranty. : ■' -y-i'-''

5. Tnparallel airflow ihstallation/dampcrs musfbe prdvided to

direct air over fiimace heat exchanger when heat is desired

' ~ ^tid over cooing ’cbil when cbbJing ÜS desired, ■

IMPORTANT: The dampers shoüid be adequate to present

pooled .-air from entering furnace, If manually "Operated, dampers

ipust -;b6:.cquipped with paeans- prevent -operation of »either

cooling unit or furnace ,Unless ,'damper is in fujf cppl. p;r ,hegt

position

.... ...................'1,'..'.,..

VENTING ÍÑSTRÜCTIÓÑS ^

f^enting of furnace should be' tb 'the outside 'and in' acfcortíánc'e with

ibcBl'codes'loE'requirements'bf local Utility:’■

OtepiRED'.APP^^ ICOi^CTiD TÓ

ÎFi:UES..;HAyiNG SU^ICmNT At AJCJL TIMES TO

^N5U^. Sj^V^PTRQPER operation OÍf j^PPLlANŒFor'- additional venting information, refer to ANSÍ/NEPA 211

Chimney,j;FirepIacfts, :Vcnts, and Solid Fuel Burning Appliances

and/of GSA B139Installatioir Code. - ,

This funlaçe'is certified for use with Type "L" vent (maximum flue

gas';tèn]peratür&';5.75fF)-':ii

10. Check local codesTOr any variance.

III. FXcf ORY-BUlLt fcHIliilMEYS

Listed factory-built chimneys may be used. Refer to chimney

manufacturbr'sin^tructions for proper “installatibn.

IV. HORIZONTAL YElilTIN 7:

This 'fimiace may be vented horizontally through an outside wall

when installed with 1 of the following auxiliary inducer blowers:

Tjemlund Products, Inc. Model SSlC

available from; Tjemiund Products, Inc.

...........

or ' ■ ■■ ■■ 'yy-

Fields Controls Model SWGII-5 (with a CK-6Í timer). . :í!?í

available fromj^ The Fiejds 99n^ojis 'C™ »

ir ¥RÉ“ÍN¿TÁLtAT^^^^

Before fiimace is installe4 it is highly recommended that any

existing vent system’he^complettfly inspected.

For anÿ chimney Or veny this Sboüld include thc'follówiñg:

. Ij,, Inspection., for. any deterioration .in..chimney, or vent. If

,,.deterioration is;di^cüveced,^iChimuey,¡m^^^^ .repaired or

vent must be replaced,

2, Inspection to'ascertain! that vent system'is clear and free of

'' 7 ' obsîfiictions: 'blPcK^ge. 5mAt be^,cleared^ .'Astall-

....

^''jj^g.fuimacsA,-.,' ............................7, '^,27' ..-27-722," .22722:2.27

3, 'Cleaning Chimney or' vent if pfevidusly ;usbd Torwepting a

solid fuel buming appliance pt Ereplace,

..

unu'sed Chinine^.or..:venL;co|t^^ are

■''7__.2,pAp?f^y ...2.....77_.277..7. 7.2 :.72m,71;.2:72.2.77,A72---

■ I :5., :V:erification that 'chimney is propéfly .lined an^ pAlíA

I applicable codes. (Refer' tp list';óí'codes A-Shfety 'CdAtA

cratibiis sectio'm) '" """" "

II. .MA3QNRY CHIMNEY

This fúfnáce-can be'Yèhtéd'ihiô'an.éxistïiig masbinry'-chihiney-^This

fu^mabe 'inüst»h,dt be vented, into á.chífflhé'y‘seiVi¿íué''2t!sóÍid fuel

bum'iug ^'.appliance; :B¿fb're ' ^veh'tirig" :fii Aác'í'.'. iijib' '.a ■ -chim'iifcy,/f]ije

chimnfcy ^MUST be chebkcql 'fo'f détéfitífátibn h'hd: repaired if

necessary. The chimney 'iUüst''bc’'proA’tly -lihéd l'a'n'd'sîzëd.per local

or, natibïial ,bodé^ 'ly f;,^ .

If fiirjiace is vented into a common chimney, the chimney must be

of suffldent area to accommodate the total flue products of all

àpplia‘nceè'!ventea'''inlO chimh'ty,"''■ r,' 'i ",, ■ r-

The'''ïoïÎow]rtg' 'rèqùtrem6hls'''''àre 'pfovide'd''fóf a 'safe'“^ieuting

system: ' ' ^ ‘

''I:'.‘Be'sure-that chimney:'»flUe is ■ dear of ahy 'dirt or debris,

' ’2. Be sûre that chimnby 'ïfi hbl-séfvicing an open fireplace.

................

.

-4-

A

This,furnace :is supplied with a.;highT»pressure ;atGipizing retention

hcad)'t'yA'tiymA, (fAhse',,'vvifh'n'ot''liea\^ier.:tAn

Thef’air.iiibe length, rppunting pUic to extrcmelface of

end.cppe,,shopld be'a^.,shpwn,dn,.Table.'2. .^,r^

LübricáteXpmer mOtpr,Atb SA^;Íp piÍx-|6nA PPJ4.ti^'

teaspoons of oil slowly into each oil 'cup.

Complete instructions for installation of'ftiek-ojl piping ,yvill be

found ip. pfl w,kh A^^nace.

An oil .fAsf tshpuId'ibe .P^bd. with should be

installed as..|clpse.itq;burner,'.as:pM ', , , . ....

The barpAetfic draft'control shibpp^ With'fuifiabe'MUST'be us'*'^'

with'^i'hace t'q'Asure prbper■;Aeration!'(Some'’s^ units '2'

hav^''bdroWetrid''cPntfdl :p'a'A*d'in'buther'cartd'ri:) Instnictibiis for"""

infitaiiing 'control ¿re'''|jacked' 'with'' -¿oiitrOl. 'Refei-'’''tci'’'Fig.' 15 ’ icf

suggested iocatiP'nsr■ ■■'''■'■■■ ■"‘ i-‘- '

3- Never reduce pipe siic below Size of furnace flue pipe.

4, AH pipe should be supported using proper clamps and/or

straps. These supports should be at least every 4 ft.

5, All horizontal mhs of pipe should have at least 1/4-in per ft

of upward slope.'

6. All Tuns'of pipe should be as short as possible with as few

turns as possible.

7. Seams should he tightly joined and checked for leak;s.

s. The flue pipe must not extend into chimn&y but bo flush

with Inside wall, : ;

9. The chimney must extend 3 ft above highest^point Where it

passes though the roof of a building and at least'2 ft higher

than any {portion of :a.'building .within a horizontal distance

r of 3,0 ft. Jt shall .also be extended at least:-5 .it above highest

' connected equipment flue collar.

J;601'Ninth Street;.:'. ,, ''' '"

‘ 7 Lake, jfe‘55110-6795 -27 r

'itíj-'í'..'

23Ô8 AJiport Road i ■ ; ;

Kinston, NC iSO’STT '

CAUTION: USE . METALLIC. yENT TIPE ONLY!

PLASTIC VENTING, MATERIALS ARE PROHIB-

îTEÜr-',' .. . ■'

------

-------

■ '■' '———; "—■' -

BURNER .

TABLE 2—OIL BURNER AIR TUBE LENGTH

iUNiT.sizE

036Ó70 , ,.5'T . ,|r ' . '.

036090. 5

yy-,048125 ■ ' "‘'A

04815S ■■

OIL CONNECTIONS

■■ , ...

..............

LENGTH (IN.) . "

........................

Page 5

A U G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 2

The appliaflce must be installed in accordance with current

ANSI/NFPA 70 National Electrical Code* CSA C22.1 Canadian

Electrical Code Part 1, and/or local codes.

О

The control system depends on correct polarity of power supply.

Connect HOT wire (H) and NEUTRAL wire (N) as shown in Fig.

16.

A separate line voltage supply should be used with a fused

disconnect switch or circuit breaker between main power panel

and unit. (See Fig. 16-).

WARNING: The unit cabinet must have an uninter

rupted or unbroken ground to minimiie personal injury if

A

an electrical fault should occur. A green ground screw is

provided in control box for this connection.

Use only copper wire for 115-y supply service to unit.

When replacing any original furnace wiring* use only:^iip5“C No.

16 AWG copper wire,. ■ '

Instructions for wiring thermostat .(field supplie'd) are packed in

thermostat box. Make thermostat connections as sjiown in Fig. 16

at 24-v terminál board 0,n control box4 ;- ■ . ■ ,

When installing optional accessories to this /Appliance, follow

manufacturer’s Installation Instructions included with accessory.

Other than wiring for thermostat, wire with a minimum of lype "T"

insulation (63'’F rise) must be used for accessories- % á

A FILTER MUST BE USEÓ Wlni THIS FURNACE! ,

An external filter rack is available as optional equipment:.with this

furnace..

WARNING: Never operate,.unit without a filter or with

filter access door removed. Failure to adhere to this

Л

warning could lead to a haaardous condition which could

lead to equipment damage and bodily harm.

UTC TECH PUB

E^CTRICAL

' FILTERS

F A X N o , 3 1 7 2 4 0 5 6 6 2

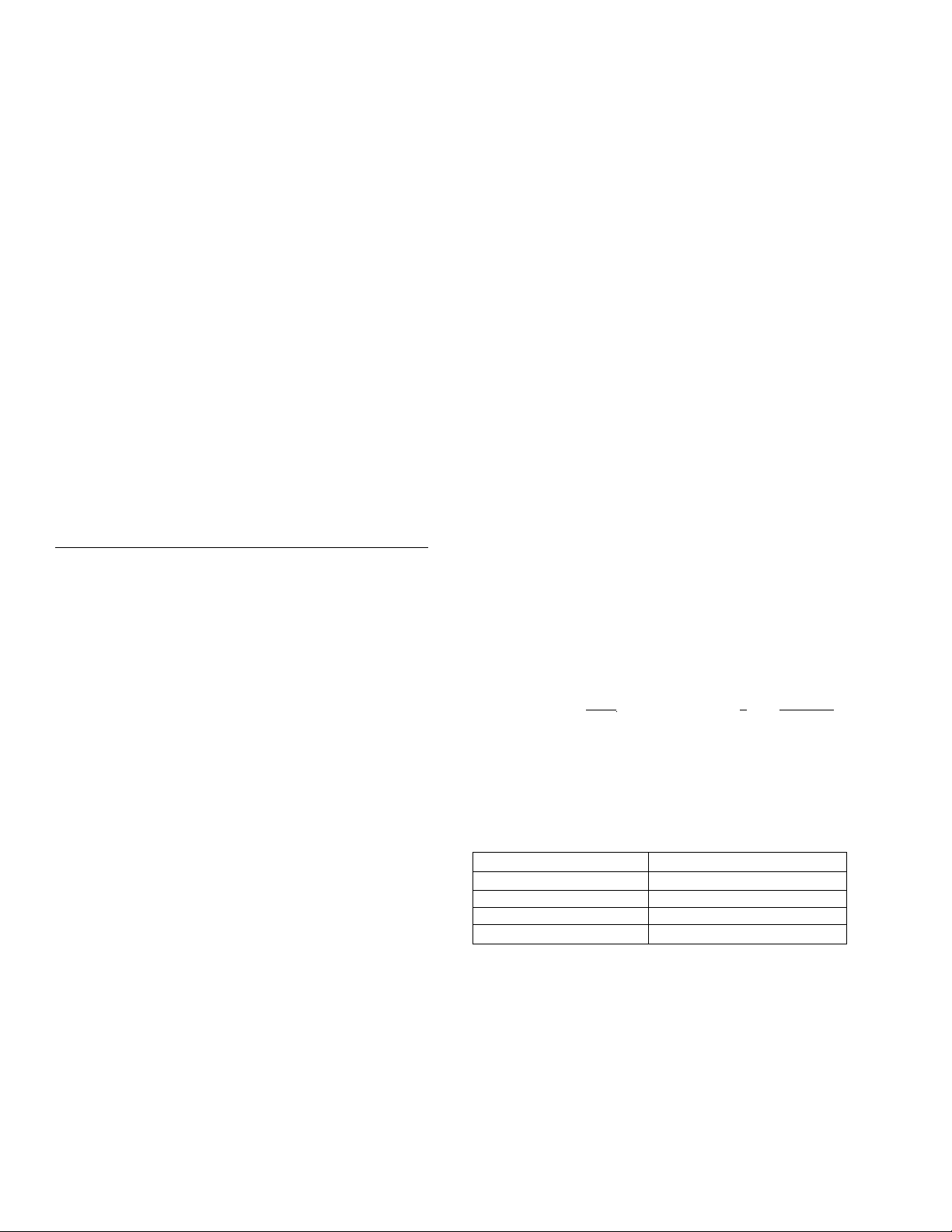

Fig. 1"™Component Lopation..

3. Remove rosette from around fluc;oonncctof, ' . „

4. Remove front panel and flue panel from Unit,

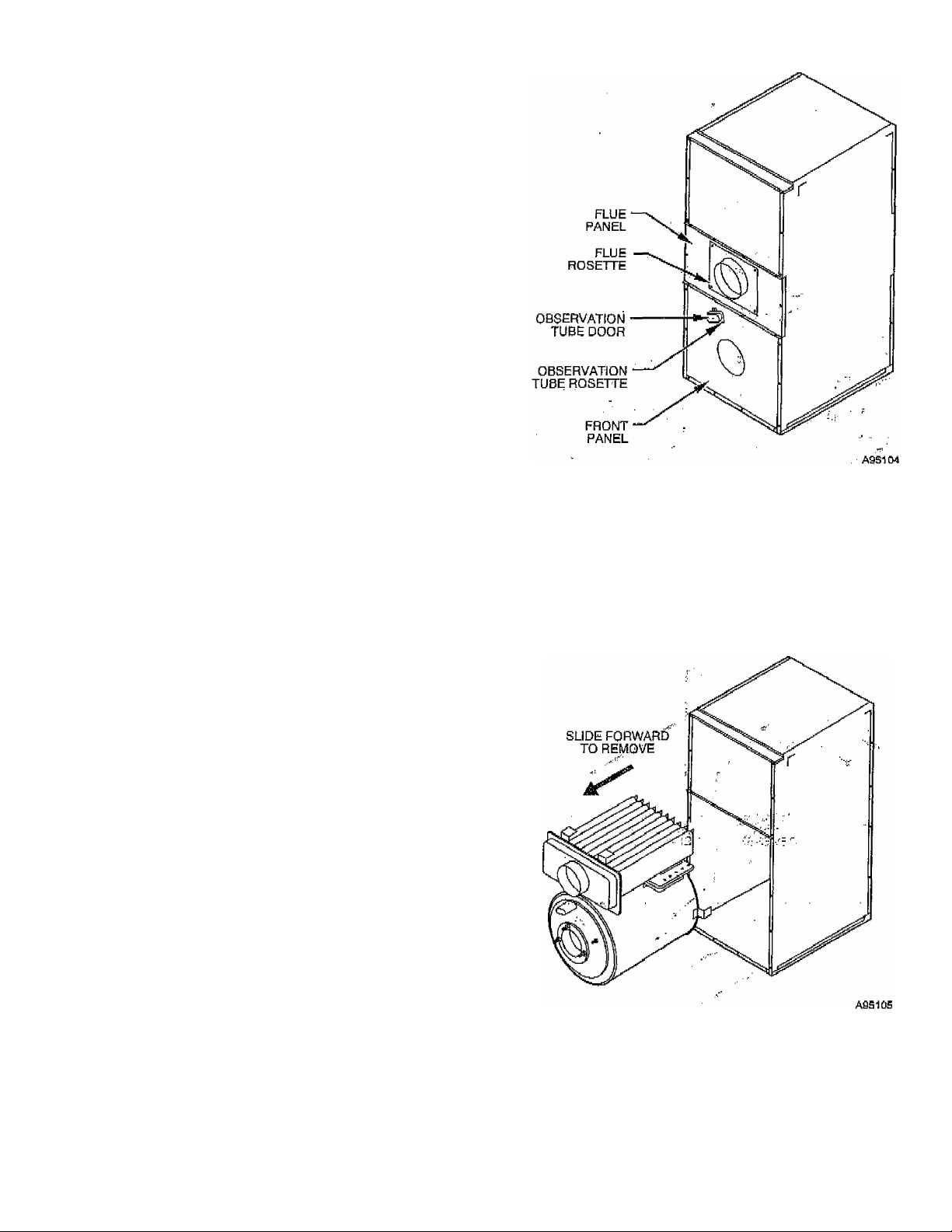

IMPORTANT: The heat exchanger is only secured in place by

heat exchanger ..support legs ,hopked into, brackets on blower

partition at this time. Care should be taken to adequately support

heat exchanger and prevent if from falling. Be careful not to

damage limit control.

5. Supporting heat exchanger so that it does not fail, remove

heat exchanger from cabinet by pulling it straight forward,

(See Fig. 2.)

0 0 5 / 0 1 6

I. KEEPING FILTERS CLEAN

As a homcownerj this is your mbit important respo'jiisibility. A

dirty .filter. LteduCes ¿f^ficiency. df 'your ,System, causes erratic

perforipance of controls, and could result,in damage to^motor or

heating equipment. . г.

1- Inspect filters at regular intervals depending upon dirt

conditions.'pof ■'hew homes, ehcplci'fiUcrs every weeliTor 4

consecutive weeks, iln all cases, inspect filters at least every

3 to 4 weeks when sysfem is inPoiistant operation. Replace

or clean filter at least at beginning of each season (heatirig

and cooling) and thereafter as ■needed.

2. If a permanent filter is used, it^can be cleaned witl); cold

water,and soap. ;; . , ,

Be Sure that filter is thoroughly dry before installing bacic' into

furnace. - ‘

reversing INSTRUCTIONS FOR REAR FLUE^OPTION ,

NOTE: These steps are only for installations where it is nfecessaiy

to have flue ccumection on Opposite side of furnace from biimef

and controls, Jf rear flue is not required, skip to Assembly

Instructions section.

Unit should be reversed prior to installing cabinet iri position. See

Fig, 1 for cdhiponent location, '' '

1. Remove observation tube door from front panel* taking care

not to let door spring ’’snap" hinge and pinch your fingers,

2, Remove flat rosette and gasket fram around observation

tube,-

Fig. 2—Removing Combustion Chamber and

Neat Exchanger

6. Remove cover plate/combugtion chamber assembly from

heat'exchanger drum by removing 12 parkerized screws

securing it to drum front. CAREFULLY slide combustion

chamber out of drum, taking care not to damage relatively

fragile chamber material- (See Fig, 3.)

7- Remove "blank" cover plate on rear of drum by removing

12 parkerized screws on dnim rear. Install this "blank" plate

on front (flue connector side) of drum. Ensure that gasket is

intact and all screws are secure.

-5^

Page 6

A Ï Ï G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 2

UTC TECH PUB

) . 3 1 7 2 4 0 5 6 6 2

11. Turn heat exchanger so that flue connector is toward rear of

unit and reinstall in cabinet. The heat exchanger support

legs will now engage in hangers at rear of blower partition

instead of hangers at front. The fine connector should

, protrude through opening in flue panel on rear of unit with

burner mounting flange still at front of unit. (See Fig. 6.)

P ,

Fig, 3—Removing Combustion Chamber

8. Install cover platc/combustion chamber assembly (removed

in item 6) into rear opening of drum, taking care not to

dnm&ge chamber, cin^unng gasket is Jn-place, and verifying

that screws are ialEseeurely tightened. (See Fig. 4.)

- 'Ags'fci?

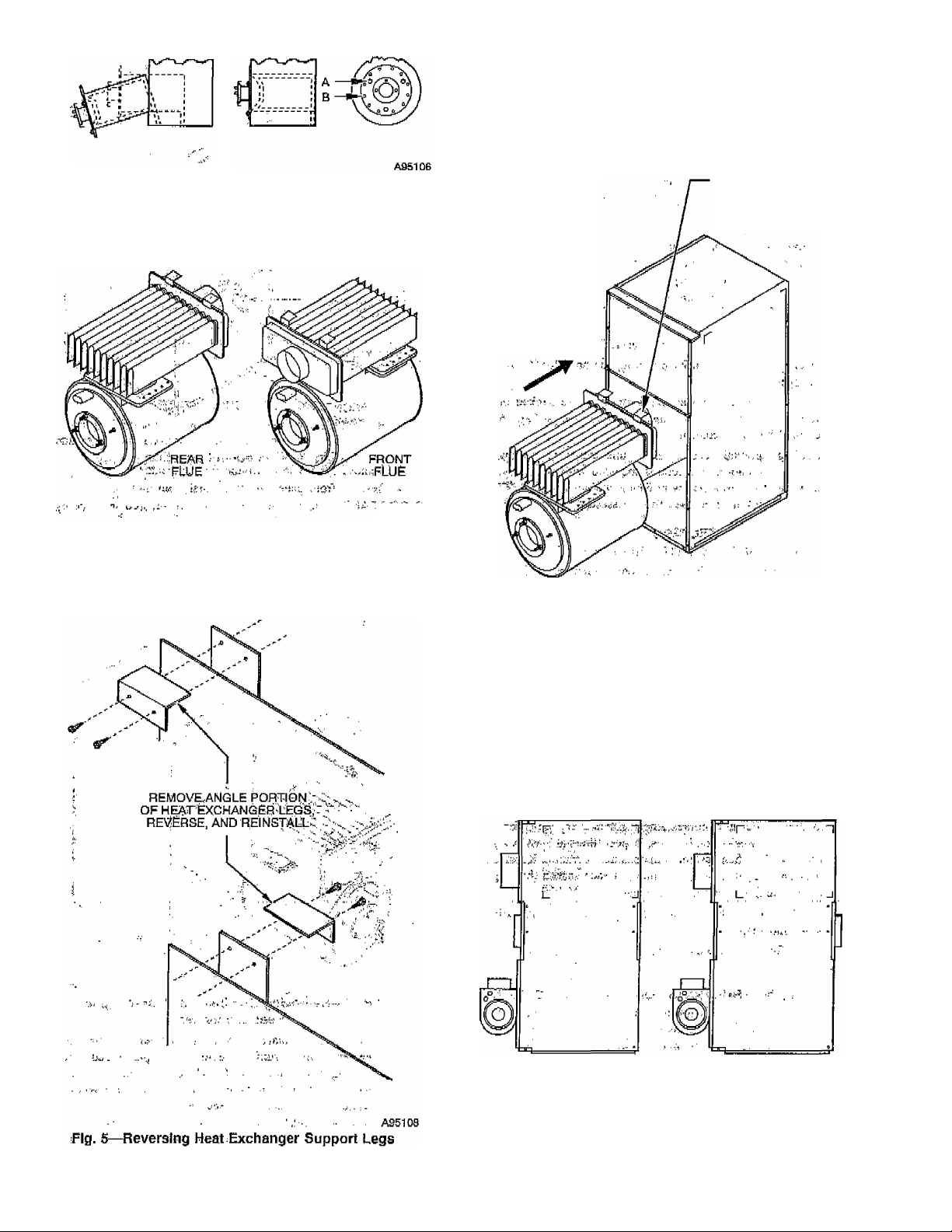

Fig. "4—Front/R^r Flue Üflehtatibhs

9. Remove 2 screws that attach angle portion of heat eX“

changer legs to straight portion, rotate angle portion so that

they point thti opposite direction, and reattach to straight

.portion,>using.priginal screws. (See Fig. 5.)

HOOK SUPPORT u

LEGS UNDER,

CLIPS ON REAR

OF BLOWER PANEL

INSTALL BY

SLIDING BACK

Fig. 6™ReinstalMng Combustion Chamber and

' ■ i' Héât Exchanger "

A951Û9

12. Reinstall frOni pà^erîfemdv^^ 4) and install rear

ccoterT?ancl,(rcmQyc.d îh.ithiii..liQ whdrfeZfliic panel origi

nally was. BE CAREFUL NOT TO DAMAGE LIMIT

CONTROL.

13. Replacp. rosette op ^i^.C!C|nncctpr (now at rear of furnace),

observaMon tube^ rosette M door. ■

14. ;;Froceed with'lnstàllîng futhaçeicabinetTand. mounting oil

bumer.:and controls. .■

FRONT FLUE

(AS SHIPPED)

. REAR FLUE

(AFTER REVERSAL)

10. RentOve rear center panel from cabinet and replace it with

flue panel removed in item 4.

A95110

Fig, 7—Component Location Before and After

Flue l^eversal

^6-

Page 7

A U G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 3

It is easier to install furnace if cabinet assembly (shipped in carton

■ 1 of 2) is placed into positionj ductwork connected, and THEN

control box/burn,er assembly (shipped in carton 2 of 2) is mounted

to cabinet. Electrical^ thermostat^ and oil line connections can then

be made to completed unit.

To attach control box/burner assembly to cabinet:

1. Carefully unpack carton 2 containing prewired control

box/burncr assemb.ly .and hardware bag.

2. Remove 3 burner mounting nuts securing shipping plate on

front of furnace cabinet at burner mounting flange. Remove

and discard shipping plate. When furnace is in installed

position^ burner mounting studs should be in the 12, 3, and

9 o’clock positions, leaving bottom hole empty.

a. If furnace is being installed in downflow position, studs

are in correct .position wjie^ ,shipped from factory, ‘

. b. ff furnaceJs beingJnstallcd in horizontal position, it is

necessary to remove stud that ris mow in .6 .o^dlock

posirioti and reposition it so thaFstuds are in l2, 3', and

9 o’clock positions. It may be necessary to use Z of the

burner mpunting'iiuts as ''jsrrr"> puts pn. stud in order to

provide a means of using a‘wrench to remove,a tight

stud. 1.'

3. If furnace is installed in horizontal left airflow positíoii, it is

necessary to relocate burner wiring conduit from'ii^t side

of burner to left side as follows: (See Eig. S.) ^ > i-.-.,

a. Release clip(s) securing ignition control ^on top of burner

and swing control open to gain access to wiring com

partment inside burner.

b. Disconnect wire nuts on .black, white, and orange, wires

inside burner.

c. Remove conduit nut securing conduit to right side of

burner and detach conduit and .wires from .burner/housing. .

d. Reipovc hole plug from left side of burner housing and

install it in hole on right side (where :;Condujt was

removed). ... ^ ,

e. Feed conduifand ¡wires through-(eft^side hofe and secure

with conduifnufremoved imlteirij c'.^ ■/;

f. Reconnect blacki white, and orange wires inside burner

using'wire nuts removed in item 'b.

Close anB secure ignition control.

f'f-V., ' 'i.H| 1'.'

4. Carefully'install burner onto burner mounting,studs, ¡ensur

ing that mounting flange ¡gasket is jpositioned between

. flange on .burner .and fronf pf furnace.. Secure, .burner ¡in

position with 3 burner mounting.y^ashers,and.iiuts removed

in item 2. .if;.

IMPORTANT: The burner must álwayS’bfe^jnstdlled in upright

position with ignition control on top, (Sec Fig. 9i)^

5'- Attacft bontfol bok to bloyi'CT'abéMsS

sTieet 'métál'''Screws ‘froin ''hárdw'ain:'''t7'¿g''in' carton '2. The

vyirés exteh'diug .frOm'biower access párífcT.muk be routed

through large ho)c)n back of control bóxj taklng ¿aré not to

gcrapt o'rjpiiich insulation on wires.'The wires''¿hotild be

connected to1:he 2-pin harness conhéctor ánd aflfíropriate

terminals on fan control board. (See Fig. 10 arid Í6-)

o

6. Attach the 2 limit switch , wires to terminals of limit switch

located on lower portion of front panel. After attaching

wires, secure limit cover to front panel using 2 No. B sheet

.metal screws from hardware bag in carton 2, (See Fig. 11.)

UTC TECH PUB

ASSEMBLY INSTRUCTIONS

......

F A X N o , 3 1 7 2 4 0 5 6 6 2

iiimiiiiiiiinm

llllllllllllllllllj

CONDUIT LOCATION

FOR HORIZONTAL-RIGHT

{AFTER RELOCATING)

Fig. 8—Burner Wiring Conduit Location for

Horizontal Applications

(Downflow Orientation Shown)

0 0 7 / 0 1 6

CONDUIT LOCATION

FOR DOWNFLOW

AND HORIZONTAL-L^FT

(AS SHIPPED)

ASSÍ11

-7-

Page 8

A U G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 3

UTC TECH PUB

F A X N o . 3 1 7 2 4 0 5 6 6 2

P .

(5>

CONSTANT BLOWER

ROCKER SWITCH

2 - FOR STHE..155.MODEL OR

3-FOR THE 125 MODEL

R = RED BK = BLACK \N = WHITE

Fig. lo-T-Blowor Control Board

АЙЙИЙ

^s~

WARNING: Do not u$c this furnace as a construction

heater. Use of this furnace as a construction heater

exposes furnace to abnormal conditions* contaminated

combustion air* and lack of air filters. Failure to follow

A

this warning can lead to premature furnace failure and/or

vent failure which could result in a fire hazard and/or

bodily harm, ■

WARNING: Installation of this furnace in an area where

it, will .receive .contaminated combustiq^, air .¡nust be

avoidetl. Such contamination would include the follow

ing: ammonia, chlorine, hydrogen sulfide, halQgenated

hydrocarbons, carbon tetrachloride* cleaning solvents,

A

hydrochloric acid, water softening chemicals, and similar

chemicals, failure to follow this warning will lead to

premature rusting of heat exchanger and possible furnace

failure: .iand/or. Vent failure- which could result in fire

hazard and/or bodily .rharm. :

^ OPERATIÜNAL^GHECK^

DO -NOT''START^BURMER :UNLESS BLOWER ACCESS

PANEL IS SECURED IN PLACE.

Installatigm of-furnace is novv .f;oinplete and operational ^checkout

may b&;:parforffled., ,_V, 2 ■■

I. START^UP : V,

1. Check wiring against wiring'diagram shown in Fig. 16.

2. -Open valve on oil siipply line. '

3. Reset primary control.

4. Set thermostat above room temperature.

5. Set main ebctrical switch to ON position. Вигам should

start. ■ '

DO NOT TAMPERS WITH UNIT OR CONTROLS - CALL

YOUR SERVICE. TECHNICIAN.

II. RECOMMENDED INSTALLATION PRACTICES AND

COMBUSTION CHECK -

In order to obtain optimum performance from oil burner, the

following^setupiprocedurés must be followed: ' i- ,

1. A test kit (Bachafach No, 5022; kif^f equivalent to’measure

smoke, stack dfaft, over:^fire draft, COj, and:stacfc témjperatures MUST be used in order/to’.ohtaiti pfopur mr band

setting. Although all. of the^aboyc measurements a^s re

quired for optimum setup and' efficiency data, the most

important:readings that.mustbe taken are smoke numbers,

■■; ■ ,ov.er-Ere (draft,- :and stackrdra^t:.

2. The'proper-smolid number' has,.b?en established by etigi-

- ■' ■ n'eeririg' ÍeSts tii b¿ -between 0 arid 'I'.' This degree of sm oke

emissions is commonly referred to as a "Trace" of smoke. It

is recommended to use a^Bacharnch^true spot smoke test set

or equivalents - - ' ;í^■ tci'/v or-

3. In order to ensure proper dr^t,thqugh..furnace, g b^roroctric

draft regulator .(supplied, with furn4po|), must .hjs in^talícd as

close to outlet of furWee a's "poss^bl^^^^ to

function .properly, barometric ОаГОрёт'щцд!. be'mounted

with^hinge pins horizontal an^ faceipf datiíp^ veríical, (See

iristníctions included with .^эщреН) 'Lhe dr aft.,Regulator

should be adjusted after ifuniace has been firing at least

5 minutes, and stack draft should be measured and set

between-'-0:025 ¡and -ОЮЗЗ'in. wc. The draft should be

checked with, a Bacharach MZF draft gage or equivalent.

4. The dver-firf: drilft* Which is taken th/o'ugh hole provided in

observation door, is a measurement necessary to determine

if there is a blockage between oil burner and Sue outlet.

О

Page 9

A U G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 3

UTC TECH PUB

F A X N o . 3 1 7 2 4 0 5 6 6 2

There showJd b? e prtsspte irop of between 0.005 and 0,020

in. wc through furnace. This would set the range of the

over-fire draft between -0.01 and ~0.03 in. wc. A reading

above -0.01 in. wc (for example +0.1 in. wc) would indicate

that furnace is in an extremely high-pressure condition in

primary section- This condition may be caused by excessive

combustion air due to air baud being too wide open or.a:]ack

of flue draft (chimney effect) or some other blockage, such

as soot, in secondary section of heat exchanger.

5. The COj and stack temperature instruments ciiable you to

obtain data required to determine thermal efficiency of

furnace.

6. An oil filter should be installed as close to burner as

possible with ALL oil burners and is essential On lower

firing rate burners. We recommend the Use of a low

pressure drop oil filter such as the General Filter, lup, model

#lA‘í25A Of equivalent. It is .critical that oil capacity be

equivalent or greater than fuel pump gear capacity. For a

2-pipc system, this is 25 gph.

7. The oil pressure regulator is factory set to give uo^ile oil

pressures of 100 psig. The firing rate noted on nameplate

may be obtained with "standard" nozzles by adjusting pump

pressure as noted in Table 3 or on label iop fumacç,

TABLE 3—BURNER, NOZZLE, ANÒ PUMP PRESSURE

CHART

UNIT

SIZE

036070

036090

040125

046155

FIRING

RATE

GAUHR (US)

0.50

0,65

0.9Q

1.12

PUMP

PRESSURE

(PSIG)

100

100

100

104

&ECKETT OIL BURNER

Model

AFG

^ AFG

AFG

AFG

Nozzle

0,50 gph

80“ Solid

0-65 gph

70“ Hollow

0.90 gph

70“ HOMw-

1.10 gph

70° Hollow

On a new installation, air entrapped in oil line leading from

tank to nOizIe must be thoroughly purged in order to

prevent excessive after drip. The oil pump is provided with

a Special fittihg enabling'^bu to purge any air between tank

and oil pump. The proper .procedure for performiuS this

operation is as follows;

a. Place a piq^pc of dear plasticT/4-in. diameter tubing over

purge fitting on oil pump. . '

b. Start oil burner, then open purge fitting and aillow burner

to run until purge tube is completely free of air bubbles.

’ c. Tighten purge fitting .which will allow oil'to fun to

nosizle and fire burner.

d. If purging takes longer than „3,0 seo and no flame has

been, established, burner stops- i^ush reset button on top

of primary contro] to restart burneri

e. For detailed information On Operation of primary control,

refer to instructions included with furnace,

S. After all setup procedures mentioned above have been

completed, burner should be allowed to operate. Use an

■ inspection mirror to observe flame pattern. Any irtegularities such as burning to 1 side or pulsating flame patterns

should be corrected by changing nozzle.

III. FAN ADJUSTMENT CHECK

This furnace is equipped with ft 3-5pccd direct drive motor to

deliver a temperature rise within range specified on rating plate,

between return and supply plenums, at external duct static pressure

noted on rating plate.

Adjust fan speed so that temperature rise is within rise range

specified on rating: ¿plate. Consult wiring diagram for speed

changes on direct-drive motor. - „

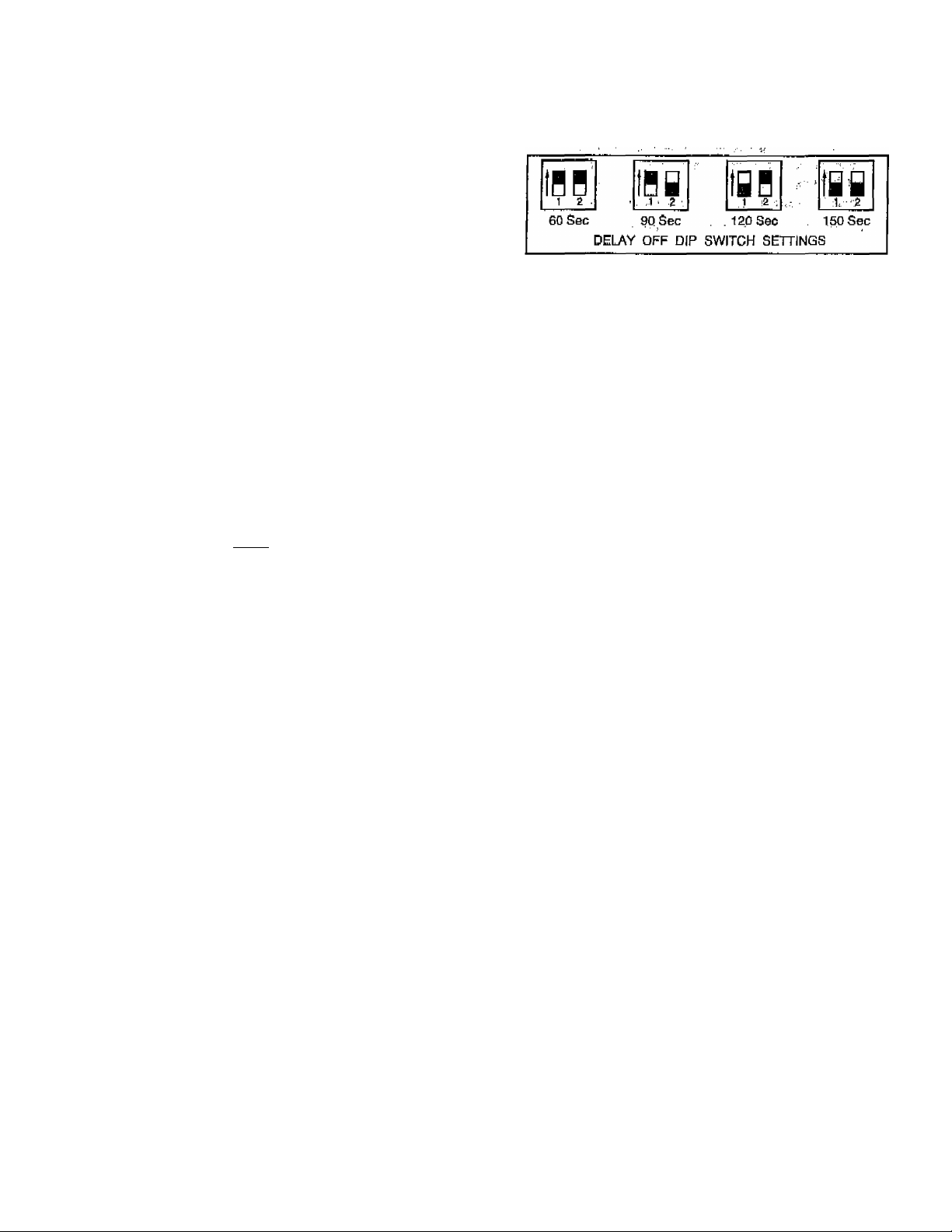

To adjust fan off time, get DIP switches on control board to obtain

desired timingV(See Fig, 12,)

■ Vf.

AS5116

Fig. 12^Fan Off Time DIP Switch Settings

IV.

LIMIT CONTROL CHECK

After furnace has been in operation for at least 15 minutes, restrict

rctum-air supply by blocking filters or closing return registers and

allow furnace to shut down on high limit, Th<: burner should shut

off, and main blower should continue to run.

Remove restriction, and burner should come back On iij a few

minutes, V'

V. FOR YEAR ROUND-air CONDmONING

This furnace is designed for use in crinjunction-with cooling

equipment to provide year rgund air conditioning. The.blower has

been sized for both heating and cooling, however, fan motor speed

may heed to be changed to obtain ncccsshry codling airflow'.

VI. HEATING

The blower speed is factory set to deliver required-airflow at

normal duct static pressure.

VII. COOLING

The blower spqcd may be adjusted in the field to ¡deliver required

airflow,for cooling application^CScc Eig, 16.)

VIII. CONSTANT BLOWER SWITCH

Thib furnace is equipped with a constant low-speed blower option.

Whenever room thermostat is not calling for heating or'cooling,

blower runs on low speed in order ;to provide air. circulation. If

constant blower option is not desired, the rocker switch-on side of

control-box .may-bc-uscdfo-turn-off-constant-speed.- .

This furnace should .never be operated, vvithout air ,filt6r(s)..Filters

' MAiNtENArjce: '7 T7 -

should be cleaned at least twice a year.

To avoid personal injury, make sure electrical supply power is off

before servicirig. ^ .

ALWAYS KEEP MAIN ' OIL VALVIE/TURhnED./PFF IF

BURNER IS SHUT- DOWN FOR AN EXTENi?Et? PERIOD OF

_

, ^ L>v * _. *.■ . I ' T ,

TIME,

WARNING; Before performing any service functions,

unless Operations specifically require power to be on,

A

make sure all utilities are turned off upstream oL appli

ance. Failure to-comply with this warning wili cause a fire

hazard and/or bodily harm. <.

I. OIL BURNER

Per jodio oiling of blower motor may be necessary. Check for

instructions on inside of blower access panel.

To maintain proper performance, ’ oil burner nozzle must be

replaced once a year. Contact your dealer service technician if you

arc unsure of this procedure.

The procedure for nozzle installation and/or replacement is out

lined in oil burner instruction manual which came wi№ furnace.

For ease of maintenance, the oiling procodure for burner motor, as

Outlined in burner manual, should be performed at this time.

-9-

Page 10

A U G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 4

UTC TECH PUB

F A X N o , 3 1 7 2 4 0 5 6 6 2

After rcpiacxment of nozzle, burner should be adjusted in accor

dance with Combustion Chccjt.. section of the mstnicUon,

II. HEAT EXCHANGER AND FLUE PIPE

Ordinarily, it is not necessary to clean heat e^pçl^anger or flue pipe

every year but it is necessary tp have your oil burner service

technician" check uhit bcfôrc caçh ‘heating season to determine

whether ^leaning or replacement of parts/is repujreti.

If cleaning is necessaiy, the following^Steps should be performed:

; i."Turn off all utilities upstream of fiimace.

. 2..Disconnect flue pipe,.

3, Remove collar on flue connection.

4. Rempye:flue'.panél,'.¡"i":

5. Remove flue collector b6x¥fûih-sé'côhdafÿ:ihea"ïièxchangér

., , tube flange. This ^exposes inside surfaces.pfisecqn^ary tpbes

of .heatÆXchàngerVi^ rA,A'i A

6, clean secondary iubtis and flüc pipé with a stiff^briish ^nd

vacuum cleaner!'■■■■'v. - ■ n^r i,;;:

'7. if only "secondary "tubes' nCd^cicà'heH^'no;'further

disassembly is required. Proceed to item IS for reassembly.

If primâr^ÿ "heat ^exchariger' ^seCtion ^'iS"'àlSo -to'^'be'''cleaned

■pr.ocecd..;tpinçxt.item:;,.

g : 'Disccinnect'‘Tim ft cbntrdl ■ wireè. ' ' ^ ; 1.1.

'l. i.y''/;....., . ! '.iir rt}'' . ..--i.,.

9. Disconnçqt oil lme..and renioye oilJiurner fr.om fernaeç,

10- Remove observation door. .'îÆj ' ,,

; 11,'Remoye„collar'iOn;0b5crv,^tionfubc. ■ .ij . . '

12. Remove front panel. Care must-be takeji('-not tb'bbnd Or

damage 'limit control. ' 'i

■ 13. Looscri''to-'hand tightness "the'3 nütsdabeled' f'A" in Fig;'i3,

Remove screws labeled ""B" in Fig, 3, Slide combustion

chamber forward put.of heat exchangeri,Be*careful not .to

bqmp, .combustion chamber as it become^ brittle^ ^^Çer

A ' having been fired.

■ 14. Use.-a.stiff brush and vacuum iC)eaner/tO 'dean-,inside^'bf

primary^drum:,. -.r,. ..^ ■■ ■. :ivt.v. ■■■i.-. ' ..

CAUTION: Never-use incendiary type cleaners (smoke

A

sticks) for cleaniiigT‘ A

i .

1^. Befbre reáSsemtíiyríisaTexcEánger^

ber sJjOuIi^.be m^pCcted to deterinine ,if;iqp^

required .;!“^er ^lea'mng,,piace^'dp'n;l(bus

'■ ' ^ into'primary drum'and secure witli''''B"'SCrews';'Bnsuriprth^^

cover plate gasket is in place.before tightening screws:' Cái¿

'"■■ ■ müít be taken"'nüt'td'’aaroagéi:dfflbii';^fjdh":c’j^iiji[íbí^^

i.f: ■■ ,.r, yi .-I..' ■

16. Tighten'"A"-nuts to!30 lb-ip. of torque,(firm^,butj]ipt Overly

.. flghO-.i,.--. •••■> ■ .■ :n;.' (;■ ■mi ciiif ■ ■

17. Replace front panel, bbservatiOri^tube collar^ óbseryation

door, Um.U .wiring, and oilbiirner. ■ ■ - .

IS. Replace collector box on secondary tube flange, ensuring

proper placement of gasket. IF GASKÍETt IS^DAMACED

IN ANY WAY, IT SHOULD BE REPLACE,D! Tighten

screws'fü'30-lb-in. Of torque.’'

19. Replace flue panel and flue COUaL^ ■

20. Reconnect flue pipe, and :oil,pipéis) if removed;; Í ■

21. Readjust burner for proper operátíbií. Check limit operation

as outlined in this manual,

lU. pLÓWEíi RfeMpVAL

To remove (blower from furnace;-

■■ . ■ -'j. ■ f.;-' 'I' .■ '.

..............

NOTE: All directions are given as though fiimacc were installed

in downflow position. For either horizontal position, "left" and

"right" become "up" and "down" depending on position in which

furnace is installed. /

1, Turn off all utilities upstream of furnace.

2, Remove control box cover and disconnect black, red, blue,

and White blower wires from blower control board and

constant blower rocker switch. (See. -Fig. 10.) Disconnect

2-pin harness connector for auxiliary limit wires.

3. Remove screws securing blower access panel and rotate

panel (with control box attached) down and out of way of

blower compartment. B,e careful pot to scrape or pinch

blower anid auxiliary limit wires ps they pull through wiring

hole in panel. 7j ,,

4. Remove blower retaining screw located at front of left

blower leg. (See Fig. 13.) '■

Aa$iie

f

Fig. 13-^Blower Rfitalnlng Screw

5- Slide Blower frirward bn fSii^'^&nd but, Of unit: Cafe must be

taken not to.scrape or pinch motof br 'liihit wires.

CAUTION: Be sure blower ?Js : adequately supported

when sliding opt pf mq,unring rails,iespccially ioihorizon-

A

tal posiflon,..jn ofdcr tp .pre^^^ dropping blower and

injuring yourself or damaging blower!

t::-

■6, Reverse items 1 thrblighiS to r^ihStdR blOwCr..Refer to Fig.

10 and. wiring diagram ^(Figi ‘16) -of this instruction, or

diagram located on inside- of blower ¡access panel to

properly rewir^.unit-

-10-

Page 11

AUG/26/2008/TUE 10; 04

UNIT

SKE

036070

036090

04S125

046155

NOTES: 1. Airflow VBluea in cubic ft par minute toundcd to nearest S CFM.

s. Data taken without filters in place.

BLOWER

SPEED

High

Medium

Low

High

Medium

Low

High

Medium

Low

High

i*

Medium

Low

UTC TECH PUB

TABLE 4—AIBELOW DATA (CFM)

0.1

ises

1250

905

158S 1530

'1250

905

1065 1795

1725

1505

i960

1790

1460

0.2 0,3

1530

1220

670

1220

870

1676

1475

1900

1740

1430

1470

1185

S45

1470

1185

845

1720

1610

1430

1840

1685

1380

FAI No. 317 240 5662

EXTERNAL STATIC PRESSURE IN. WC

0,4

1405 (1350

1130

795

1405 1350

1130

795

1650

1545

1375

1776 1700

1605

1340

0.5

1080

765 ^ 730

1080

765 .

1610

149P

1325

1545 1475 1280

O.B

42S0

1050

1280

1050 1000

730

1520

'1420

1270

1625 1550

1220

0.7' 0,8

1215

1000

690

1215 .

690

1455

1350 ^

1200

1415 ^

1145

P.

0.9

1140

‘ 925 /855

650 600

1140

925 855

650

1380

1270 1200

1145 1065

1465

1330 1250

1080

1075

1075

600

1295

1380 1285

1015

1.0

985

785

565

985

705

565

1215

1110

970

1160

925

^ 1 1

—

Page 12

A U G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 4

RETURN AIR

OPENING

UTC TECH PUB

ELECTRICAL

ni

N o , 3 1 7 2 4 0 5 6 6 2

7 0 1 2 .

r

1

UNIT

SIZE

□3S070

036090

048125

048155

UNIT DIMENSIONS

Depth

20^/4

20-'3/4

25'3/4

25^3/4

Width Height

A

20

2b

22

22

‘^4"

A9437S

DIMENSIONS (IN.)

DUCT SUPPLY OPENING

B

C

46'

■■ -J-g'"'' -■■■■

46

48

D

2Ó

Fig. —Dimensional Drawing

E

, 17

22

22

DUCT RETURN OPENING

D

18

16

20

20

E

17

17

22

22

FLUE

LOCATION

F

10

10

11

n

FLUE

DIAMETER

G

6

6

e

s

Page 13

AUG/26/2008/TUE 10:04 AM

UTC TECH PUB

BAROMETRIC DAMPER LOCATIONS

FIG. D

1,31 7 240 5662

P, 013/016

GOOD LOCATIONS

-I- •

BAD LOCATIONS

Fig. 15—Barometric Damper Locations

POOR

A95117

Page 14

>=c=l

!:r:i

t-O

t-O

CZJ

oo

>=-

—3

O

—3

O

-C

od

c

Fig. 16—Wiring Diagram

'I

Asstia

-3171

>=-

>=i

on

t-o

Page 15

A U G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 5

UTC TECH PUB

F A X N o . 3 1 7 2 4 0 5 6 6 2

0 1 5 / 0 1 6

USER’S INFORMATION

I. HERE’S HOW YOUR HEATING SYSTEM WORKS

The furnace operates autpipaMcaJly, It is controlled by a thermostat

which you set at temperature most comfortable to you. When the

inside temperature drops below this setting, your thermostat will

turn on heating system.

When thermostat call for heat, power from transfotmer energizes

fan control board* The fan control energizes ignition control. The

ignition control lights burner automatically.

The electronic fan control automatically turns On blower after 30

sec. Fan on control Js not adjustable. The air moved over heat

exchanger by the blower is warmed and passes through ducts to

room registers.

When thermostat is satisfied, the circuit is de-energized and

primary control shuts off burner. The blower continues to run until

selectable fan off time period has expired.

The heat sensing switch performs as furnace high-temperature

limit switch. If furnace overheats for any reason, the limit sviijtch

opens, breajiing circuit to burner. The blower motor is energized,

and as unit cools, the limit switch closes. This will relight burner,

but unless overheating condition is corrected, furnace will cycle on

limit.

This unit is equipped with an interrupted ignition electronic

control. If main burner does not ignite within 15 sec from cal) for

heat, the control goes into lockout. The red button On top of control

must be depressed for 3 sec in order to reset control. The control

CANNOT be reset from room thermostat.

II. PREPARING YOUR FURNACE FOR OPERATION

Before attempting to put your furnace into operation for the

heating season, you should perform the following procedures:

WARNING; If you do not follow these instructions

A

exactly, a fire or explosion may result causing property

damage, personal injury, or loss of life.

1, Open all warm-air registers and make sure all retum-air

grilles arc unobstructed.

2. If a humidifier is installed with your system, open water

supply valve.

3. Set thennostat to lowest setting.

4. Turn On electric power to furnace.

5. Open oil supply valve.

6. Check all connections to ensure there are no leaks.

Ill, LIGHTING YOUR FURNACE

CAUTION; This furnace is equipped with an interrupted

type electronic ignition system. DO NOT ATTEMPT TO

A

nOHT WITH A MATCH.

HIGH VOLTAGE AT IGNITOR.

1. This appliance is equipped with an ignition device which

automatically lights burner. Do NOT try to light burner by

hand.

2. After preparing furnace for heating operation (see previous

section) and checking for oil, proceed as follows,

3. For heating/cooling system, set thermostat to HEAT and fan

to AUTO. Set thermostat to desired room temperature and

turn on electrical power to furnace.

4. The burner should light and system should be controlled by

thermostat.

IV. TURNING OFF YOUR FURNACE

Follow these simple procedures to put your furnace into "retire

ment" for the summer.

1. Set thermostat to lowest setting.

2. Turn off all electrical power to appliance.

3. Turn Off Oil supply.

4. If applicable, turn off water supply to humidifier.

5. If furnace blower will be necessary for cooling system,

remember to turn electrical power back on when needed for

air conditioning.

NAME:

ADDRESS;

TELEPHONE:

FOR SERVICE CALL

Page 16

A U G / 2 6 / 2 0 0 8 / T U E 1 0 : 0 5

UTC TECH PUB

■A' i

3 1 7 2 4 0 5 6 6 2

n

■■ ¿' '

, Tri- ì

ri*-'

e 1993 BOP Cd. ■ P.O. Bùie 70 ■ IndlanapoJIS, IN 45206 Printed in U.3.A, — 16 —

CJ

364fl701 CùtalDg No. BDP‘9996-400

Loading...

Loading...