Page 1

Step 3

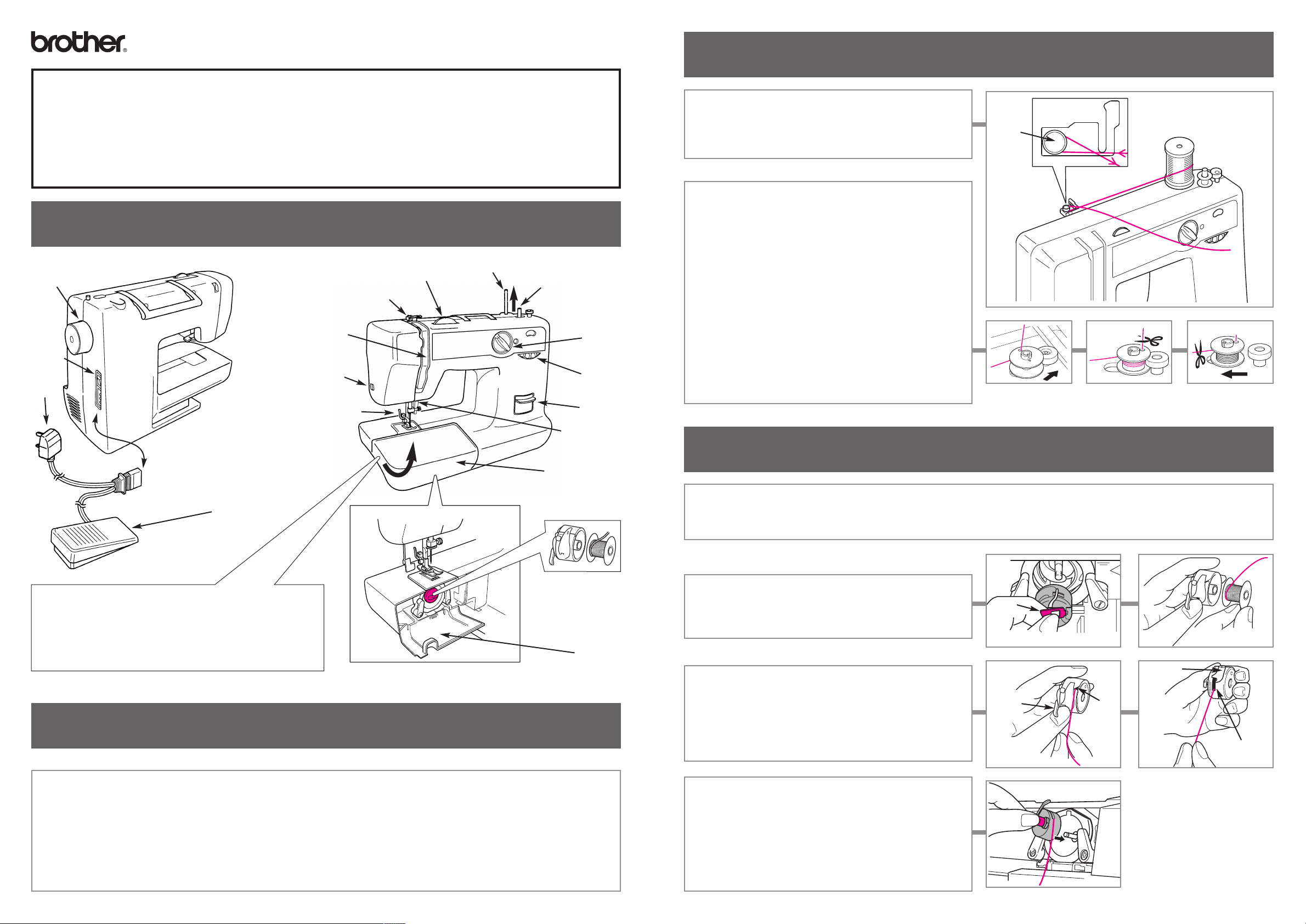

Winding the bobbin. (Your machine may be supplied with a fully wound

bobbin, but you may want to fill another bobbin with your own thread.)

Step 4

Lower threading. (Your machine may be supplied with a threaded bobbin,

but you may want to use another bobbin with your own thread.)

• Set the power switch to on (I).

Place a spool of thread on the spool pin (

figure 3a).

Unwind some thread and pass the thread around the

tension disk.

• Take one of the bobbins from the accessory pack.

• Pass the thread through the hole in the bobbin from

the inside.

Clip the bobbin onto the bobbin winding shaft.

Push the bobbin winding shaft firmly to the right until

it clicks into place against the stop (

figure 3b).

• Hold the end of the thread and press the foot controller

to wind the thread around the bobbin a few times.

Trim the excess thread (

figure 3c), and continue

winding until the winding shaft stops automatically.

• Push the bobbin winding shaft back to the left, cut the

thread, and remove the bobbin from the shaft (

figure 3d).

Unwind the thread from the tension disk.

• Set the power switch to off (O).

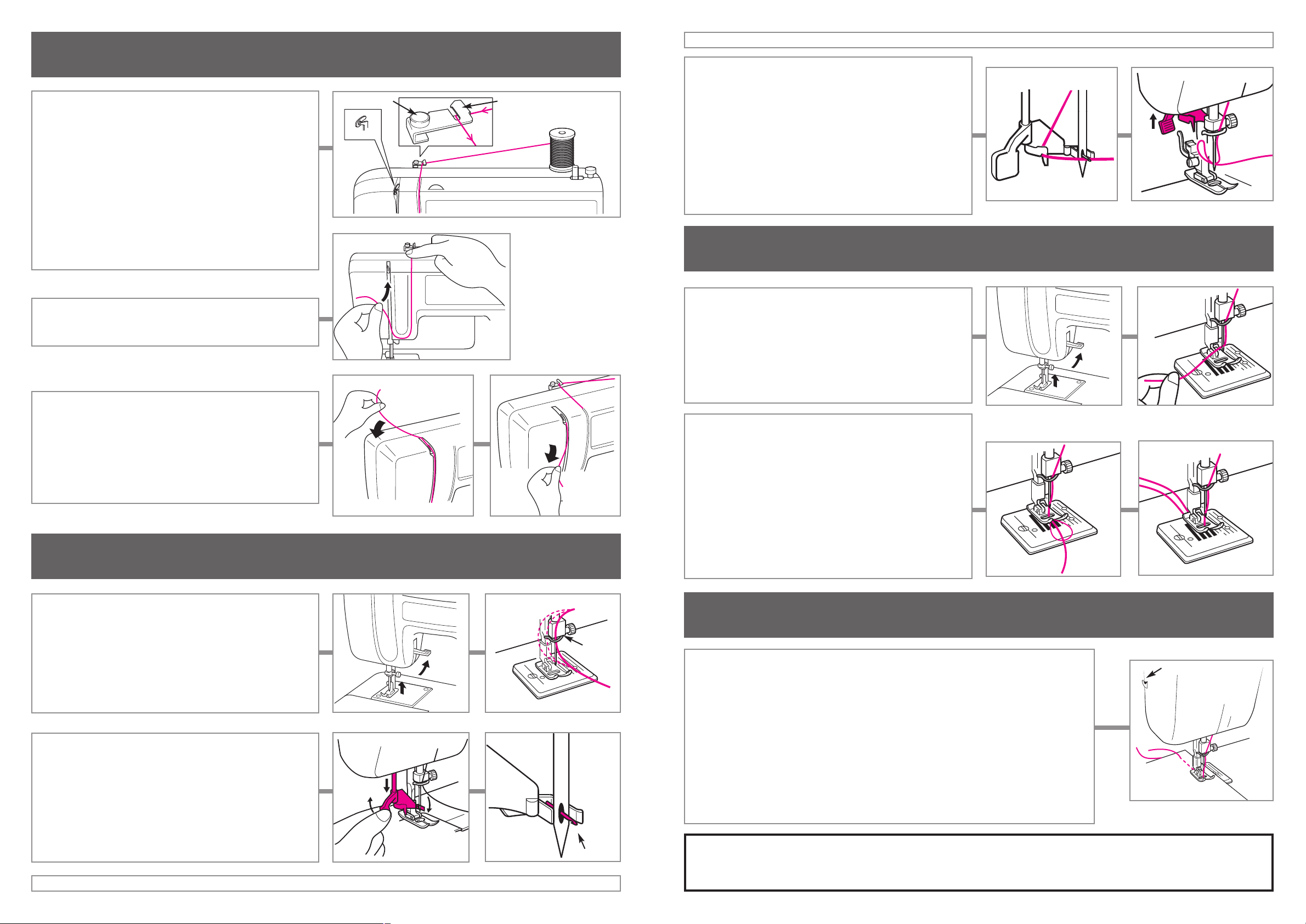

Raise the needle to its highest position by turning the balance wheel towards you (counter-clockwise).

Open the shuttle cover behind the extension table.

• Hold the bobbin case in your left hand with the

bobbin case finger pointing towards you (

figure 4c).

With your right hand, pull the trailing thread into the

slot in the bobbin case (

figure 4c).

• Draw the thread down under the spring into the

delivery eye (

figure 4d).

• Hold the bobbin case by the latch, with the finger

pointing upwards (figure 4e).

Insert the bobbin back into the shuttle, release the

latch, and push the bobbin in until it clicks.

Make sure the bobbin case goes in all the way, or the

latch will not hold the bobbin properly.

Leave the shuttle cover open.

delivery

eye

bobbin

case

finger

spring

tension

disk

slot

latch

• Remove the bobbin case from the shuttle, by pulling

the latch (marked in red on

figure 4a).

• Leaving about 10 cm (4 in) of thread trailing, insert

the bobbin into the bobbin case (

figure 4b).

figure 3a

figure 3b

figure 4a

figure 4b

figure 4c

figure 4d

figure 4e

figure 3c

figure 3d

GETTING STARTED:

XL series Sewing Machines

XL5050NTC XL5060NTC XL5070NTC

To help you get started, please follow these simple instructions in the order shown below.

However, before you do so, read the safety instructions in the Instruction Manual.

Step 1

Unpack the sewing machine, and familiarise yourself with all the parts

and controls that are mentioned in these instructions.

Step 2

Prepare the sewing machine for use.

Foot

Controller

Mains

Plug

Power

Switch

Balance

Wheel

Foot

Controller

Connection

Bobbin Winding

Shaft

Stitch

Length

Dial

Pattern

Dial

Reverse

Lever

Take-up

Lever

Guide

Thread

Cutter

Presser Foot and

Needle Assembly

Presser Foot

Lever

Extension Table

(accessories and

bobbins inside)

Shuttle

Cover

Spool Pin

Tension

Dial

Tension Disk and

Thread Guide

Figure 1a Figure 1b

Bobbin and

Bobbin Case

• Plug in the foot controller connector at the right hand side of the machine, as shown in figure 1a. Connect the

mains plug into a wall socket, and place the controller on the floor.

Grip the top of the spool pin, and pull it upwards as shown in

figure 1b until it clicks into place at a height of

about 50 mm (2 in). Be careful not to pull the pin off the machine.

Set the tension dial to 5.

Set the pattern dial to straight stitch.

Set the stitch length dial to between 2 and 3.

• Using the fingerhold on the left-hand side, pull firmly

upwards and forwards to remove the extension table.

• Inside the extension table is the storage compartment.

Open the storage compartment with a sharp tug, to

find various accessories and a number of bobbins.

Page 2

Starting to sew.

• With your right hand, turn the balance wheel towards

you (counter-clockwise), so that the needle moves

down and back up again to its highest position.

Pull the upper thread towards you, and the lower thread

will come up from the bobbin in a small loop (

figure 7c).

Pull the free end of the loop all the way out.

• Pull out both threads to about 15 cm (6 in), pass them

between the toes of the foot, and out to the back of the

machine, straight behind the foot (

figure 7d).

Close the shuttle cover and refit the extension table.

• Set the power switch to on (I).

Make sure the presser foot is up, and raise the needle to its highest position

using the balance wheel.

Place the fabric under the foot with the needle about 1 cm (3/8 in) from the rear

edge of the fabric, and lower the presser foot onto the fabric.

• To start sewing, press down on the foot controller.

To stop, release the foot controller.

To reverse sew, hold the reverse lever all the way down whilst sewing.

• When you have finished sewing, raise the presser foot and the needle.

Gently pull the fabric out, and cut the thread using the thread cutter (

figure 8).

Step 6 continued

To learn how to use the more advanced features of the XL series sewing machine, you should read the Instruction Manual.

For further assistance, phone: 0870 830 4020, email: support@brother-support.co.uk

or visit our website: www.brother-support.co.uk

Thank you for choosing a Brother product.

thread cutter

Step 7

Drawing up the thread from the bobbin.

• Make sure the power switch is set to off (O).

Raise the needle to its highest position by turning the

balance wheel towards you (counter-clockwise).

Raise the presser foot by pushing the presser foot

lever upwards (

figure 7a).

• With your left hand, hold the end of the upper thread

(

figure 7b).

• Hook the thread around the needle threader and

across the front of the needle, just below the hook

(

figure 6e).

• Holding the thread loosely with your right hand, rotate

the needle threader, so that the hook comes back out

of the eye and the threader springs back upwards.

The hook should pull a loop of thread through the

needle (

figure 6f). If it does not, then try again.

• Pull the free end of the loop to draw the thread all the

way out through the back of the needle.

figure 6e

figure 7a figure 7b

figure 7c figure 7d

figure 8

figure 6f

Step 5

Upper threading.

• Make sure the power switch is set to off (O).

Important: Raise the presser foot by pushing the

presser foot lever upwards.

(see

figure 6a in step 6 below)

Raise the take-up lever (just visible through the slot)

to its highest position by turning the balance wheel

towards you (counter-clockwise).

Place a spool of thread on the spool pin (

figure 5a).

Unwind some thread and hook the thread around the

back of the thread guide, making sure that the thread

is not wound round the tension disk.

• Holding the thread at the top of the take-up lever guide,

pass the thread down to the right of the guide, then

under the guide and back up the left side (figure 5b).

• Pull the thread up the left of the take-up lever guide,

and all the way to the back of the slot (figure 5c).

• Pull the thread over to the left, then back downwards

again (

figure 5d).

This should hook the thread around the take-up lever,

which is just visible inside the slot. If it does not, then

try again.

needle

guide

take-up

lever

tension disk

thread

guide

Step 6 continued over the page

Step 6

Threading the needle.

• Make sure the power switch is set to off (O).

Raise the needle to its highest position by turning the

balance wheel towards you (counter-clockwise).

Raise the presser foot by pushing the presser foot

lever upwards (

figure 6a).

• Pass the thead behind the needle guide, leaving about

10cm (4in) of thread trailing (

figure 6b).

• If your machine doesn’t have a needle threader, then

thread the needle by hand (from front to back), and go

straight to Step 7.

Needle threader:

• Pull the needle threader down and rotate it (

figure 6c)

so that the hook passes right through the eye of the

needle from the back (

figure 6d).

hook

figure 5a

figure 5b

figure 5c

figure 5d

figure 6a

figure 6b

figure 6c figure 6d

XC8334021

Loading...

Loading...