Page 1

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Title

TC-32B - NC

TC-22B - NC

TC-S2C - NC

TC-31B - NC

TC-32BN- NC

TC-S2Cz- NC

TC-S2D - NC

TC-R2B - NC

PROGRAMMING

MANUAL

Please read this manual carefully before starting operation.

2009/08/27 1 eTCOM2NCPRT.doc1

Page 2

Title TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

This manual describes the NC-Programming of the TC-32B, 22B, S2C, 31B, 32BN, S2Cz, S2D

and R2B.

The tapping centre is able to perform drilling, tapping, and facing.

We shall not bear any responsibility for accidents caused by user's special handling or handling

deviating from the generally recognized safe operation.

The relation between the manuals is as follows.

- OPERATION MANUAL

This manual describes the operations of the machine.

- INSTALLATION MANUAL

This manual describes the installation of the machine.

- PROGRAMMING MANUAL

This manual describes the programming of the machine.

Keep this manual for future reference.

Please include this manual when reselling this product.

When this manual or labels are lost or damaged, please replace them (charged) from your nearest

agency.

2009/08/27 2 eTCOM2NCPRT.doc

Page 3

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Title

INTRODUCTION

Congratulations on your purchase of the Brother CNC tapping center. Correct usag e

of the machine is of most importance to assure the expected machine capabilities and

functions as well as operator's safety. Read this Manual thoroughly before starting

operation.

* All rights reserved: No part of this manual may be reproduced, stored in a retrieval system,

or transmitted in any form without prior permission of the manufacturer.

* The contents of this Manual are subject to change without notice.

* This manual are complied with utmost care. If you encounter any question or doubt,

please contact your local dealer.

2009/08/27 3 eTCOM2NCPRT.doc1

Page 4

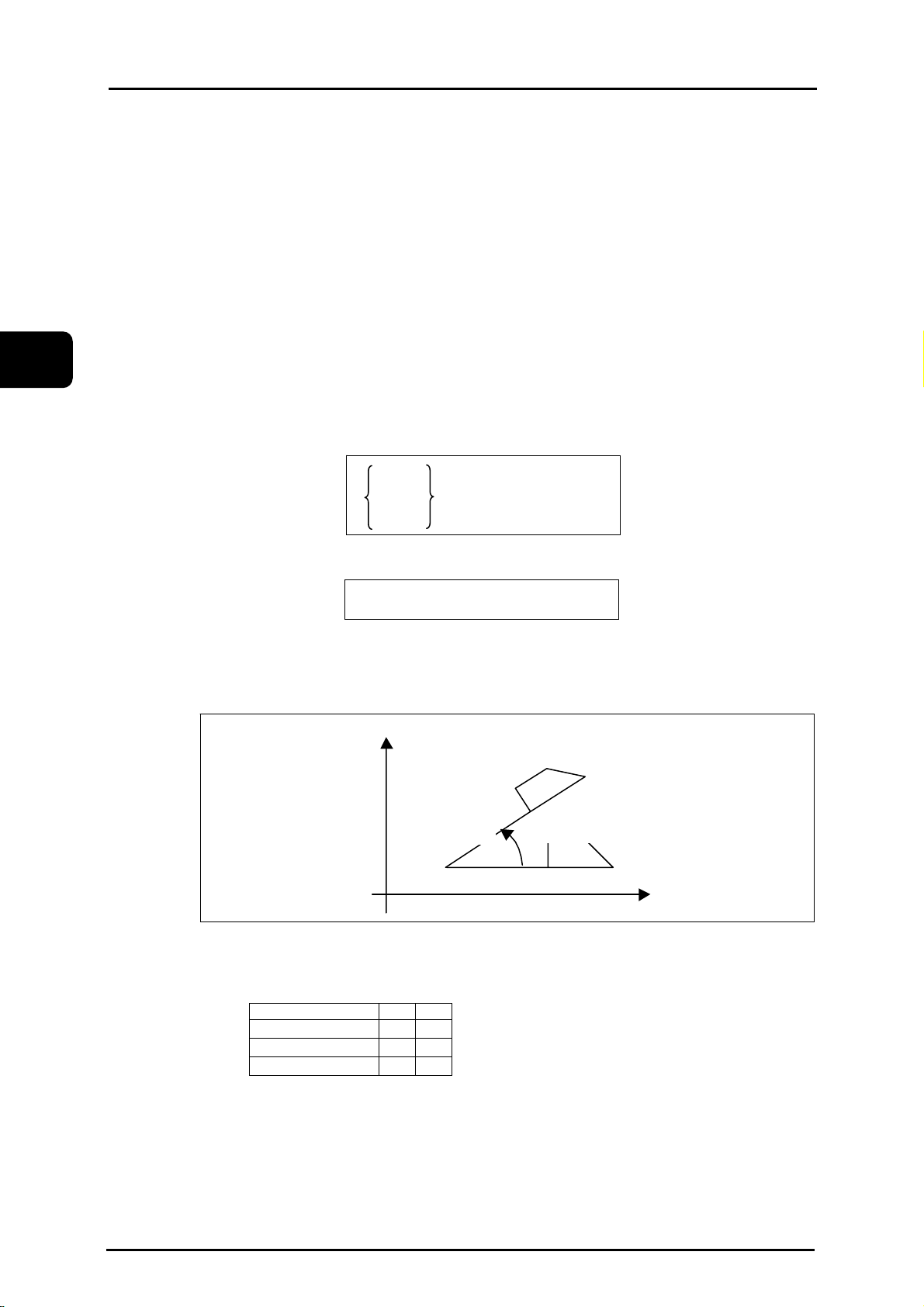

y

Title TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

HOW TO USE THE MANUAL

This Instruction Manual consists of the following elements:

(1) General description Is an outline of the description given in the section.

(2) Alarm Is a alert given against a danger which may cause serious

damage or death to human being or may damage the machine.

The hazards are explained in this order:

degree of danger,

subject of danger,

expected damage,

preventive measure,

(3) Operation procedure Is a procedure of activating a function.

(4) Screen Is given to describe important points of a procedure given.

NOTE: This screen is only a representation of the information

displayed on the actual screen and therefore differs somewhat

from the actual screen layout and screen fonts.

(5) Illustration Is a sketch, figure, view, etc. indicating dimensions, position or zone, given

in the points where it is necessary to provide complementary information to the text

description.

(2) Alarm

(3) Operation procedure

Dropping a heavy object onto

your foot may fracture your foot

bones.

When lifting heavy objects,

wear safet

WARNING

shoes.

(1) General description

1.3.1Before starting operation

Before starting operation careful to read bellow.

(1)Turn off the main power breaker handle on

the control box door. Never touch the primary side

power source or the terminal of the main power

breaker, as these have high voltage applied.

(2)Put up a signboard which says' Under Maintenance

(3)Never allow people to approach the machine,

particularly moving areas.

(4)Do not place any unnecessary object around the

machine.

(5)Wear a helmet and safety shoes.

1 - 2

(5) Illustration

2009/08/27 4 eTCOM2NCPRT.doc

1 - 3

(4) Screen

Page 5

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Contents

Chapter 1 Program Composition----------------------1-1

1.1 Types and composition of program ----------------------------------- 1-2

1.2 Composition of block ------------------------------------------------------1-2

1.3 Composition of word -------------------------------------------------------1-3

1.4 Numerical values ---------------------------------------------------------1-3

1.5 Sequence number--------------------------------------------------------------1-4

1.6 Optional block skip ------------------------------------------------------------1-4

1.7 Control out/in function--------------------------------------------------------1-4

Chapter 2 Coordinate Command----------------------2-1

2.1 Coordinate system and coordinate value ------------------------------2-2

2.2 Machine zero point and machine coordinate system --------------2-3

2.3 Working coordinate system -------------------------------------------------2-3

Chapter 3 Preparation Function-----------------------3-1

3.1 Outline of G code---------------------------------------------------------------3-3

3.2 Positioning (G00)---------------------------------------------------------------3-7

3.3 Linear interpolation (G01) ---------------------------------------------------3-8

3.3.1 Chamfering to desired angle and cornering C---------------------------------------------3-9

3.4 Circular/helical interpolation (G02, G03)--------------------------------3-12

3.4.1 Circular interpolation-------------------------------------------------------------------------3-12

3.4.1.1 Circular interpolation--------------------------------------------------------------------3-12

3.4.1.2 XZ Circular interpolation---------------------------------------------------------------3-13

3.4.1.3 YZ Circular interpolation---------------------------------------------------------------3-14

3.4.2 Helical thread cutting interpolation---------------------------------------------------------3-18

3.4.3 Spiral interpolation (G02, G03)-------------------------------------------------------------3-19

3.4.4 Conical interpolation (G02, G03)-----------------------------------------------------------3-21

3.4.5 Tool dia offset procedure for spiral interpolation and conical interpolation

(G02, G03)-------------------------------------------------------------------------------------3-24

3.5 Circle Cutting (G12, G13) ----------------------------------------------------3-25

3.6 Plane Selection (G17, G18, G19)-------------------------------------------3-26

3.7 Dwell (G04) -----------------------------------------------------------------------3-26

3.8 Exact stop check (G09, G61, G64) ----------------------------------------3-27

3.9 Programmable data input (G10) -------------------------------------------3-28

3.10 Soft limit---------------------------------------------------------------------------3-30

3.10.1 Stroke -----------------------------------------------------------------------------------------3-30

3.10.2 Stroke limit-----------------------------------------------------------------------------------3-30

3.10.3 Programmable stroke limit (G22) ---------------------------------------------------------3-31

3.11 Return to the reference point (G28)--------------------------------------3-31

3.12 Return from the reference point (G29) ----------------------------------3-32

3.13 Return to the 2nd to 6th reference point (G30) -----------------------3-32

3.14 Selection of machine coordinate system (G53) ----------------------3-33

3.15 Selection of working coordinate system (G54~G59) ---------------3-33

3.16 Additional working coordinate system selection (G54.1)---------3-33

3.17 Scaling (G50, G51) -------------------------------------------------------------3-34

2009/08/27 1 eTCOM2NCPRC.doc

Page 6

Contents TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

3.18 Programmable Mirror Image (G50.1, G51.1)---------------------------3-38

3.19 Rotational transformation function (G68, G69)-----------------------3-40

3.20 Coordinate rotation using measured results (G168) ---------------3-42

3.21 Absolute command and incremental command (G90, G91) -----3-42

3.22 Change of workpiece coordinate system (G92)----------------------3-44

3.23 Skip function (G31, G131, G132) ------------------------------------------3-46

3.24 Continuous skip function (G31) -------------------------------------------3-46

3.25 Change of tap twisting direction (G133,G134)------------------------3-47

3.26 High speed peck drilling cycle (G173))----------------------------------3-47

3.27 Peck drilling cycle (G183) ---------------------------------------------------3-49

3.28 Local coordinate system function (G52)--------------------------------3-51

3.29 Single direction positioning function (G60) ---------------------------3-51

3.30 G code priority ------------------------------------------------------------------3-52

Chapter 4 Preparation Function (tool offset function)---4-1

4.1 Tool Dia Offset (G40,G41,G42)---------------------------------------------4-2

4.1.1 Tool dia offset function ----------------------------------------------------------------------4-2

4.1.1.1 Wear offset of tool diameter------------------------------------------------------------4-2

4.1.2 Cancel Mode ---------------------------------------------------------------------------------4-3

4.1.3 Start -up ----------------------------------------------------------------------------------------4-4

4.1.3.1 Inside cutting ----------------------------------------------------------------------------4-4

4.1.3.2 Outside cutting ---------------------------------------------------------------------------4-5

4.1.3.3 Outside cutting (θ < 90°)----------------------------------------------------------------4-6

4.1.4 Offset Mode----------------------------------------------------------------------------------4-7

4.1.4.1 Inside cutting -----------------------------------------------------------------------------4-7

4.1.4.2 Outside cutting (90° ≤ θ < 180°)-------------------------------------------------------4-9

4.1.4.3 Outside cutting (θ < 90°)----------------------------------------------------------------4-10

4.1.4.4 Exceptional case -------------------------------------------------------------------------4-11

4.1.5 Offset Cancel ----------------------------------------------------------------------------------4-12

4.1.5.1 Inside cutting (180° ≤ θ) ----------------------------------------------------------------4-12

4.1.5.2 Outside cutting (90° ≤ θ < 180°)-------------------------------------------------------4-13

4.1.5.3 Outside cutting (θ < 90°)----------------------------------------------------------------4-14

4.1.6 G40 single command-------------------------------------------------------------------------4-15

4.1.7 Change of offset direction in offset mode -------------------------------------------------4-16

4.1.8 Change of offset direction in offset mode ------------------------------------------------4-17

4.1.8.1 When there is a cross point ------------------------------------------------------------4-17

4.1.8.2 When there is no cross point ----------------------------------------------------------4-18

4.1.8.3 When offset path becomes more than a circle----------------------------------------4-19

4.1.9 G code command for tool dia offset in offset mode--------------------------------------4-20

4.1.10 Notes on tool dia offset-----------------------------------------------------------------------4-21

4.1.11 Override function related to tool dia offset------------------------------------------------4-27

4.1.11.1 Automatic corner override ------------------------------------------------------------4-27

4.1.11.2 Override of the inside circular cutting-----------------------------------------------4-28

4.2 Tool length offset (G43, G44, G49)---------------------------------4-29

4.2.1 Wear offset of tool length--------------------------------------------------------------------4-29

2009/08/27 2 eTCOM2NCPRC.doc

Page 7

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Contents

Chapter 5 Preparation Function (canned cycle)------------ 5-1

5.1 List of canned cycle function ---------------------------------------------5-2

5.2 Basic motions in canned cycle --------------------------------------------5-3

5.3 General description of canned cycle -----------------------------------5-4

5.3.1 Command related to canned cycle motions ----------------------------------------------5-4

5.3.2 Setting of data in absolute / incremental command-------------------------------------5-4

5.3.3 Types of return point (G98, G99) ---------------------------------------------------------5-5

5.3.4 Canned cycle motion conditions-----------------------------------------------------------5-5

5.3.5 Machining data of canned cycle-----------------------------------------------------------5-6

5.3.6 Repeat number of canned cycle------------------------------------------------------------5-7

5.4 Details of Canned Cycle------------------------------------------------------5-8

5.4.1 High-speed peck drilling cycle (G73)-----------------------------------------------------5-8

5.4.2 Reverse tapping cycle (G74)---------------------------------------------------------------5-9

5.4.3 Fine boring cycle (G76) --------------------------------------------------------------------5-10

5.4.4 Tapping cycle (G77) ------------------------------------------------------------------------5-11

5.4.5 Reverse tapping cycle (Synchro mode) (G78)-------------------------------------------5-12

5.4.6 Drilling cycle (G81 G82)-------------------------------------------------------------------5-13

5.4.7 Peck drilling cycle (G83)-------------------------------------------------------------------5-15

5.4.8 Tapping cycle (G84) ------------------------------------------------------------------------5-16

5.4.9 Boring cycle (G85, G89) -------------------------------------------------------------------5-17

5.4.10 Boring cycle (G86)--------------------------------------------------------------------------5-18

5.4.11 Back boring cycle (G87)--------------------------------------------------------------------5-19

5.4.12 End mill tap cycle (G177)------------------------------------------------------------------5-20

5.4.13 End mill tap cycle (G178)------------------------------------------------------------------5-21

5.4.14 Double drilling cycle (G181, G182) ------------------------------------------------------5-22

5.4.15 Double boring cycle (G185, G189) -------------------------------------------------------5-23

5.4.16 Double boring cycle (G186) ---------------------------------------------------------------5-24

5.4.17 Canned cycle of reducing step-------------------------------------------------------------5-25

5.4.18 Canned cycle cancel (G80)-----------------------------------------------------------------5-29

5.4.19 Notes on canned cycle ---------------------------------------------------------------------5-30

5.5 Canned cycle for tool change (non-stop ATC)(G100) --------------5-31

Chapter 6 Preparation Function (coordinate calculation)6-1

6.1 List of coordinate calculation function----------------------------------6-2

6.2 Coordinate calculation parameter ----------------------------------------6-2

6.3 Details of coordinate calculation function -----------------------------6-3

6.3.1 Bolt hole circle-------------------------------------------------------------------------------6-3

6.3.2 Linear (Angle) -------------------------------------------------------------------------------6-3

6.3.3 Linear (X, Y)---------------------------------------------------------------------------------6-4

6.3.4 Grid -----------------------------------------------------------------------------------------6-5

6.4 Usage of coordinate calculation function------------------------------6-5

2009/08/27 3 eTCOM2NCPRC.doc

Page 8

Contents TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

Chapter 7 Macro------------------------------------------------------- 7-1

7.1 What is a Macro? ---------------------------------------------------------------7-2

7.2 Variable Function---------------------------------------------------------------7-3

7.2.1 Outline of variable function----------------------------------------------------------------7-3

7.2.2 Expression of variable ----------------------------------------------------------------------7-3

7.2.3 Undefined variable --------------------------------------------------------------------------7-4

7.2.4 Types of variables ---------------------------------------------------------------------------7-5

7.2.5 Variable display and setting----------------------------------------------------------------7-6

7.2.6 System variable ------------------------------------------------------------------------------7-6

7.3 Calculation Function--------------------------------------------------------7-12

7.3.1 Calculation type -----------------------------------------------------------------------------7-12

7.3.2 Calculation order ----------------------------------------------------------------------------7-12

7.3.3 Precautions for calculation-----------------------------------------------------------------7-13

7.4 Control Function--------------------------------------------------------------7-14

7.4.1 GOTO statement (unconditional branch) ------------------------------------------------7-14

7.4.2 IF statement (conditional branch)---------------------------------------------------------7-14

7.4.3 WHILE statement (repetition)-------------------------------------------------------------7-15

7.4.4 Precautions for control function-----------------------------------------------------------7-16

7.5 Call Function-------------------------------------------------------------------7-18

7.5.1 Simple call function ------------------------------------------------------------------------7-18

7.5.2 Modal call function-------------------------------------------------------------------------7-19

7.5.3 Macro call argument------------------------------------------------------------------------7-20

7.5.4 Difference between G65 and M98--------------------------------------------------------7-22

7.5.5 Multiple nesting call------------------------------------------------------------------------7-22

7.6 External Output Function----------------------------------------------------7-23

7.6.1 POPEN ---------------------------------------------------------------------------------------7-23

7.6.2 BPRNT---------------------------------------------------------------------------------------7-23

7.6.3 DPRNT---------------------------------------------------------------------------------------7-24

7.6.4 PCLOS ---------------------------------------------------------------------------------------7-25

7.6.5 Precautions on external output command------------------------------------------------7-26

Chapter 8 Automatic work measurement--------------------- 8-1

8.1 Before automatic work measurement -----------------------------------8-4

8.2 Setting of data on automatic work measurement--------------------8-4

8.3 Operation of automatic work measurement---------------------------8-8

8.3.1 Corner-----------------------------------------------------------------------------------------8-8

8.3.2 Parallel----------------------------------------------------------------------------------------8-12

8.3.3 Circle------------------------------------------------------------------------------------------8-14

8.3.4 Z level-----------------------------------------------------------------------------------------8-18

8.3.5 Positioning to the measurement position -------------------------------------------------8-18

8.4 Handling of measured results----------------------------------------------8-19

8.4.1 Display of the measured results------------------------------------------------------------8-19

8.4.2 Reflection of measured results on the workpiece coordinate system-----------------8-20

8.5 Lock key operations-----------------------------------------------------------8-21

2009/08/27 4 eTCOM2NCPRC.doc

Page 9

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Contents

Chapter 9 High Accuracy Mode A -------------------------------- 9-1

9.1 Outline -----------------------------------------------------------------------------9-2

9.2 Usage-------------------------------------------------------------------------------9-3

9.2.1 User parameter setting ---------------------------------------------------------------------9-3

9.2.2 User parameter description-----------------------------------------------------------------9-4

9.2.3 Usage in a program--------------------------------------------------------------------------9-5

9.2.4 Conditions available-------------------------------------------------------------------------9-6

9.2.5 Conditions where high accuracy mode A is released -----------------------------------9-6

9.3 Restrictions ----------------------------------------------------------------------9-7

9.3.1 Functions available ------------------------------------------------------------------------9-7

9.3.2 Additional axis travel command-----------------------------------------------------------9-7

9.4 Effective Functions ------------------------------------------------------------9-8

9.4.1 Automatic corner deceleration function --------------------------------------------------9-8

9.4.2 Automatic arc deceleration function -----------------------------------------------------9-9

9.4.3 Automatic curve approximation deceleration ------------------------------------------9-10

Chapter 10 Subprogram function--------------------------------- 10-1

10.1 Making subprogram -----------------------------------------------------------10-2

10.2 Simple call ---------------------------------------------------------------------10-3

10.3 Return No. designation from sub program ----------------------------10-4

10.4 Call with Sequence Number ------------------------------------------------10-5

Chapter 11 Feed function-------------------------------------------- 11-1

Chapter 12 S,T,M function------------------------------------------- 12-1

12.1 S function -------------------------------------------------------------------------12-2

12.2 T function -------------------------------------------------------------------------12-2

12.2.1 Commanded by tool No.--------------------------------------------------------------------12-2

12.2.2 Commanding by pot No. (magazine No.) ------------------------------------------------12-2

12.2.3 Commanded by group No. -----------------------------------------------------------------12-2

12.3 M function ------------------------------------------------------------------------12-3

12.3.1 Program stop (M00)-------------------------------------------------------------------------12-7

12.3.2 Optional stop (M01)-------------------------------------------------------------------------12-7

12.3.3 End of program (M02, M30)---------------------------------------------------------------12-7

12.3.4 Commands on the spindle (M03, M04, M05, M19, M111)----------------------------12-7

12.3.4.1 Spindle orientation to desired angle (M19) --------------------------------------12-7

12.3.5 M signal level output (M400~M409) -----------------------------------------------------12-7

12.3.6 Tool change (M06)--------------------------------------------------------------------------12-8

12.3.7 Workpiece counter specification (M211~M214)----------------------------------------12-8

12.3.8 Workpiece counter cancel (M221~M224) -----------------------------------------------12-8

12.3.8.1 Tool life counter---------------------------------------------------------------------12-8

12.3.9 Tool breakage detection (M120 and M121)----------------------------------------------12-8

12.3.10 Tool breakage detection (M200 and M201)----------------------------------------------12-8

12.3.11 Tap time constant selection (M241 to 250) ----------------------------------------------12-9

2009/08/27 5 eTCOM2NCPRC.doc

Page 10

Contents TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

12.3.12 Pallet related M codes (M410, M411, M430, and M431)------------------------------12-9

12.3.13 Unclamping and clamping C axis (M430 and M431) ----------------------------------12-10

12.3.14 Unclamping and clamping B axis (M440 and M441) ----------------------------------12-10

12.3.15 Unclamping and clamping A axis (M442 and M443) ----------------------------------12-10

12.3.16 One-shot output (M450, M451, M455, and M456)-------------------------------------12-10

12.3.17 Waiting until response is given (M460 to M469) ---------------------------------------12-11

12.3.18 Magazine rotate speed (M435 to M437)--------------------------------------------------12-11

12.3.19 Magazine rotate to tool setting position (M501 to M599)------------------------------12-11

12.3.20 Positioning finished check distance (M270 to M279)----------------------------------12-11

12.3.21 M codes related to shutter/cover (M434, M438, M439, M448, M449) --------------12-12

12.3.22 Arm rotation speed change (low speed) (M432) ----------------------------------------12-12

12.3.23 Tool replacement Z axis lower speed change (M290~M293) -------------------------12-12

12.3.24 Tool replacement tool washing off (M497)----------------------------------------------12-12

12.3.25 Tool wash filter check (M294) ----------------------------------------------------------12-13

12.3.26 Tool wash level sensor failure diagnosis (M295) ---------------------------------------12-13

Chapter 13 Option------------------------------------------------------ 13-1

13.1 Programming precautions when using rotation axis---------------13-2

2009/08/27 6 eTCOM2NCPRC.doc

Page 11

TC-32BQT/31BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Quick index

Chpt. 1 PROGRAM COMPOSITION

Chpt. 2 COORDINATE COMMAND

Chpt. 3 PREPARATION FUNCTION

PREPARATION FUNCTION

Chpt. 4

(TOOL OFFSET FUNCTION)

Chpt. 5 PREPARATION FUNCTION (CANNED CYCLE)

PREPARATION FUNCTION

Chpt. 6

(COORDINATE CALCULATION))

Chpt. 7 MACRO

Chpt. 8 AUTOMATIC WORK MEASUREMENT

1

2

3

4

5

6

7

8

8

Chpt. 9 HIGH ACCURACY MODE A

Chpt.10 SUBPROGRAM FUNCTION

Chpt.11 FEED FUNCTION

Chpt.12 S, T, M FUNCTION

Chpt.13 OPTION

9

10

11

12

13

2009/08/27 1 eTCOM2PRIN.doc

Page 12

Quick index TC-32BQT/31BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

(This page is blank.)

2009/08/27 2 eTCOM2PRIIN

Page 13

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 1 Program Composition

CHAPTER 1

PROGRAM COMPOSITION

1.1 Types and composition of program

1.2 Composition of block

1.3 Composition of word

1.4 Numerical values

1.5 Sequence number

1.6 Optional block skip

1.7 Control out/in function

1

2009/08/27 1 - 1 eTCOM2NCPR1.doc

Page 14

1

Chapter 1 Program Composition TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

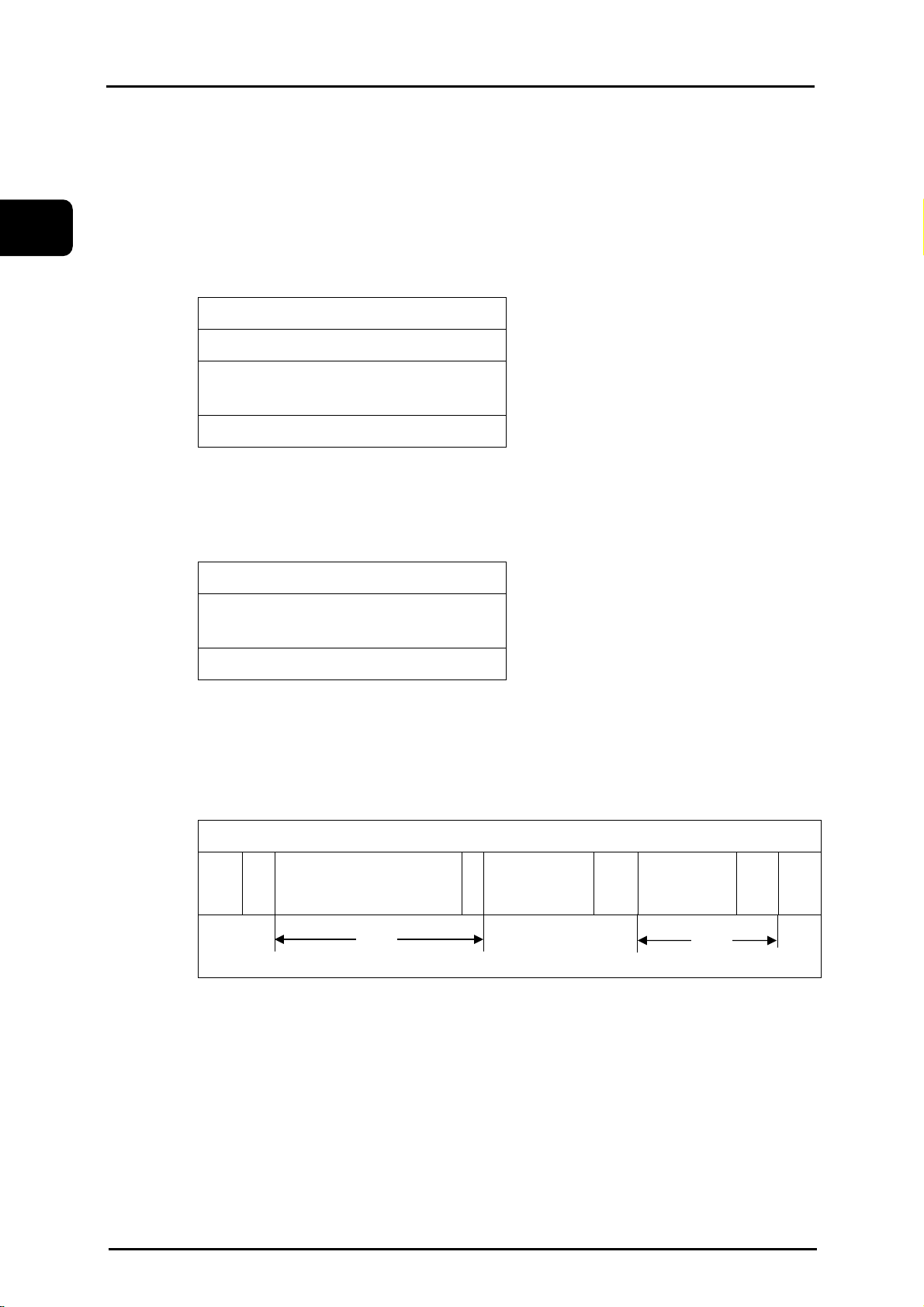

1.1 Types and Composition of Program

The program is divided into the main program and the subprogram.

(1) Main program

The main program is for machining one workpiece. While the main program is in use, a

subprogram can be called to use the program more efficiently.

Command M02 (or M30) to finish the main program.

Main program

N0001 G92X100;

N0002 G00Z30

:

:

:

M02;

(2) Subprogram

A subprogram is used by calling it from the main program or other subprograms.

Command M99 to finish the subprogram.

Subprogram

N0100 G91X10;

:

:

:

M99;

1.2 Composition of Block

The program is composed of several commands. One command is called a block. A block is

composed of one or more words. One block is discriminated from another block by an end of

block code (EOB).

This manual expresses the end of block code by the symbol ";".

⋅⋅⋅

(Note 1) The end of block code

ISO code : [LF] 0A(hexadecimal)

EIA code : [CR] 80(hexadecimal)

(Note 2) One block has maximum 128 characters.

;

N0001 G92X100

Block

;

⋅⋅⋅

;

M02

Block

;

2009/08/27 1 - 2 eTCOM2NCPR1.doc

Page 15

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 1 Program Composition

1.3 Compositiom of Word

A word is composed of an address and some digit of figures as shown below.

(Algebraic sign + or - may added before a numerical value.)

(Note 1) The address uses one of the alphabetical letters.

(Note 2) The address "O" can not be used except for comments.

X

Address numerical value

-1000

1.4 Numerical Values

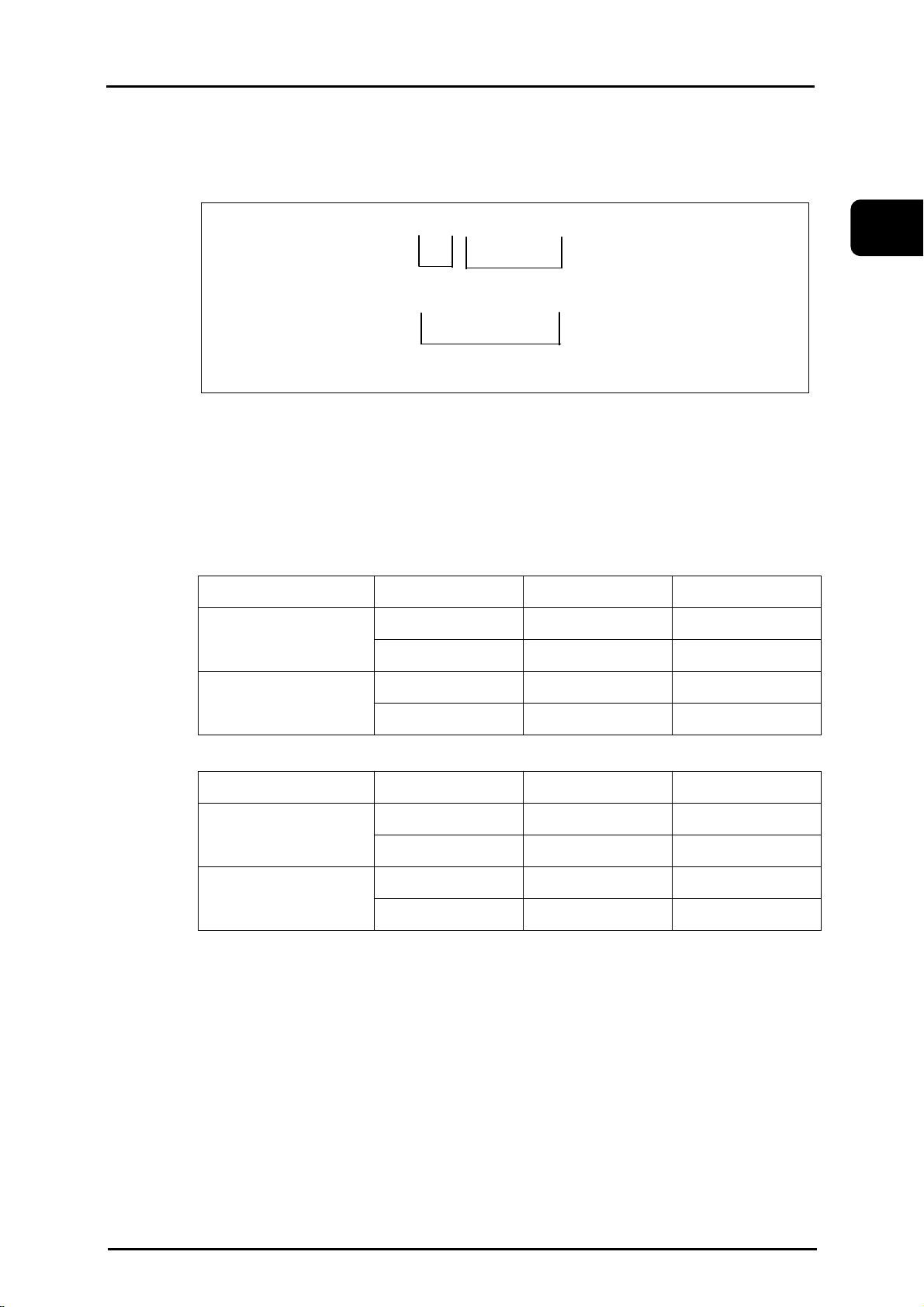

(1) Decimal point programming

Numerical values can be input in the following two ways and set by the user parameter1 (Switch

1).

Command type 1 (Standard)

Programmed command Commanded axis Actual amount (mm) Actual amount (inch)

1

Feed axis 1mm 1 inch

1

Rotation axis 1 deg 1 deg

1.

Command type 2 (Minimum)

Programmed command Commanded axis Actual amount (mm) Actual amount (inch)

1

1.

(Note) User parameter : Refer to Instruction manual.

Rotation axis 1 mm 1 inch

Rotation axis 1 deg 1 deg

Feed axis 0.001 mm 0.0001 inch

Rotation axis 0.001 deg 0.001 deg

Rotation axis 1 mm 1 inch

Rotation axis 1 deg 1 deg

(2) Programmable range of address

The programmable range deffers depending on the address.

The digits less than the minimum range are ignored.

2009/08/27 1 - 3 eTCOM2NCPR1.doc

Page 16

1

Chapter 1 Program Composition TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

1.5 Sequence Number

A sequence number (1~99999) can be used following the address N for each block.

Command format N *****;

i) A sequence number is used following the address N.

ii) A sequence number can be specified with up to 5-digit number.

(Note 1) The sequence number "N0" should not be used.

(Note 2) It is used at the head of a block.

Ex.) N0100 G90X100;

When a block has a slash (/) code at the head of block (the optional block skip is

commanded), a sequence number can be used either before or after it.

Ex.) N0100/ G90X100; or /N0100 G90X100;

(Note 3)

The order of sequence numbers is arbitary and need not be consecutive.

(Note 4)

The sequence number is recognized as numerical values. Therefore such

numerical values as 0001, 001, 01 and 1 are regarded as the same number.

1.6 Optional Block Skip

When a block has a slash (/) code at the start and [BLOCK SKIP] key on the operation panel is

turned ON, all information in the block with the slash code is ignored during the automatic

operation.

If the [BLOCK SKIP] key is OFF, information in the block with the slash code is effective.

That is, the block with a slash code can selectively be skipped.

..... ; / N0100 G00X100 ..... ; N0101 .....

Ignore these words

(Note 1)

A slash (/) code must be put at the start of a block. If it is placed elsewhere in the

block, an alarm is generated.

This code can be also put right after a sequence number.

(Note 2)

In the single block mode during automatic operation, when the [BLOCK SKIP] key

is ON the operation does not stop at a block with a slash code, but stops at the

next block.

1.7 Control Out/In Function

For a easier look at the program, comments can be inserted in the program.

The comment is discriminated from operation by "(" and ")" at the start and the end.

( ............. )

(Ex.) N1000 G00X200 (PRO-1);

(Note)

A comment including the control out and in codes should not be longer than one

block.

2009/08/27 1 - 4 eTCOM2NCPR1.doc

Page 17

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 2 Coordinate Command

CHAPTER 2

COORDINATE COMMAND

2.1 Coordinate system and coordinate value

2.2 Machine zero point and machine coordinate system

2.3 Working coordinate system

2

2009/08/27 2 - 1 eTCOM2NCPR2.doc

Page 18

2

Chapter 2 Coordinate Command TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

2.1 Coordinate system and coordinate value

Coordinate values should be set in one coordinate system to specify a tool movement.

There are two types of coordinate systems.

(i) Machine coordinate system

(ii) Working coordinate system

The coordinate values are expressed by each component of the program axes (X, Y and Z for this

unit).

Z

Y

Tool targetposition:

Commanded X20.Y10.Z15.;

15

10

X

0

20

eNCPR2.01.ai

2009/08/27 2 - 2 eTCOM2NCPR2.doc

Page 19

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 2 Coordinate Command

2.2 Machine Zero Point and Machine Coordinate System

(1) Machine zero point

The machine zero point is the reference point on the machine.

(2) Machine coordinate system

The coordinate systen with the machine zero point as its reference point is called the machine

coordinate system. Each machine has its own coordinate system.

-X

Y axis

stroke

X axis stroke

Table

Machine zero point

(0,0,0)

-Y

eNCPR2.02.ai

2

2.3 Working Coordinate System

The working coordinate system is used to specify a tool motion for each workpiece.

A coordinate system previously set in the "Data Bank" is once selected, programming afterward

can be easily done by specifying that coordinate system.

Each coordinate system is set by using an offset amount from the machine zero point to the

working zero position.

(Note) Data Bank : Refer to Operation manual for the data.

2009/08/27 2 - 3 eTCOM2NCPR2.doc

Page 20

2

Chapter 2 Coordinate Command TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

( This page is blank.)

2009/08/27 2 - 4 eTCOM2NCPR2.doc

Page 21

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

CHAPTER 3

3

PREPARATION FUNCTION

3.1 Outline of G code

3.2 Positioning (G00)

3.3 Linear interpolation (G01)

3.4 Circular/helical thread cutting interpolation (G02,

G03)

3.5 Circle cutting (G12, G13)

3.6 Plane selection (G17, G18, G19)

3.7 Dwell (G04)

3.8 Exact stop check (G09, G61, G64)

3.9 Programmable data input (G10)

3.10 Soft limit

3.11 Return to the reference point (G28)

3.12 Return from the reference point (G29)

3.13 Return to the 2nd/3rd/4th reference point (G30)

3.14 Selection of machine coordinate system (G53)

3.15 Selection of working coordinate system (G54~G59)

3.16 Additional working coordinate system selection

(G54.1)

3.17 Scaling (G50, G51)

3.18 Programmable mirror image (G50.1, G51.1)

3.19 Coordinate rotation function (G68, G69)

3.20 Coordinate rotation using measured results (G168)

3.21 Absolute command and incremental command

(G90, G91)

3.22 Change of working coordinate system (G92)

3.23 Skip function (G31, G131, G132)

3.24 Continuous skip function (G31)

2009/08/27 3 - 1 eTCOM2NCPR3.doc

Page 22

3

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

3.25 Change of tap twisting direction (G133, G134)

3.26 High speed peck drilling cycle (G173)

3.27 Peck drilling cycle (G183)

3.28 Local coordinate system function (G52)

3.29 Single direction positioning function (G60)

3.30 G code priority

2009/08/27 3 - 2 eTCOM2NCPR3.doc

Page 23

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

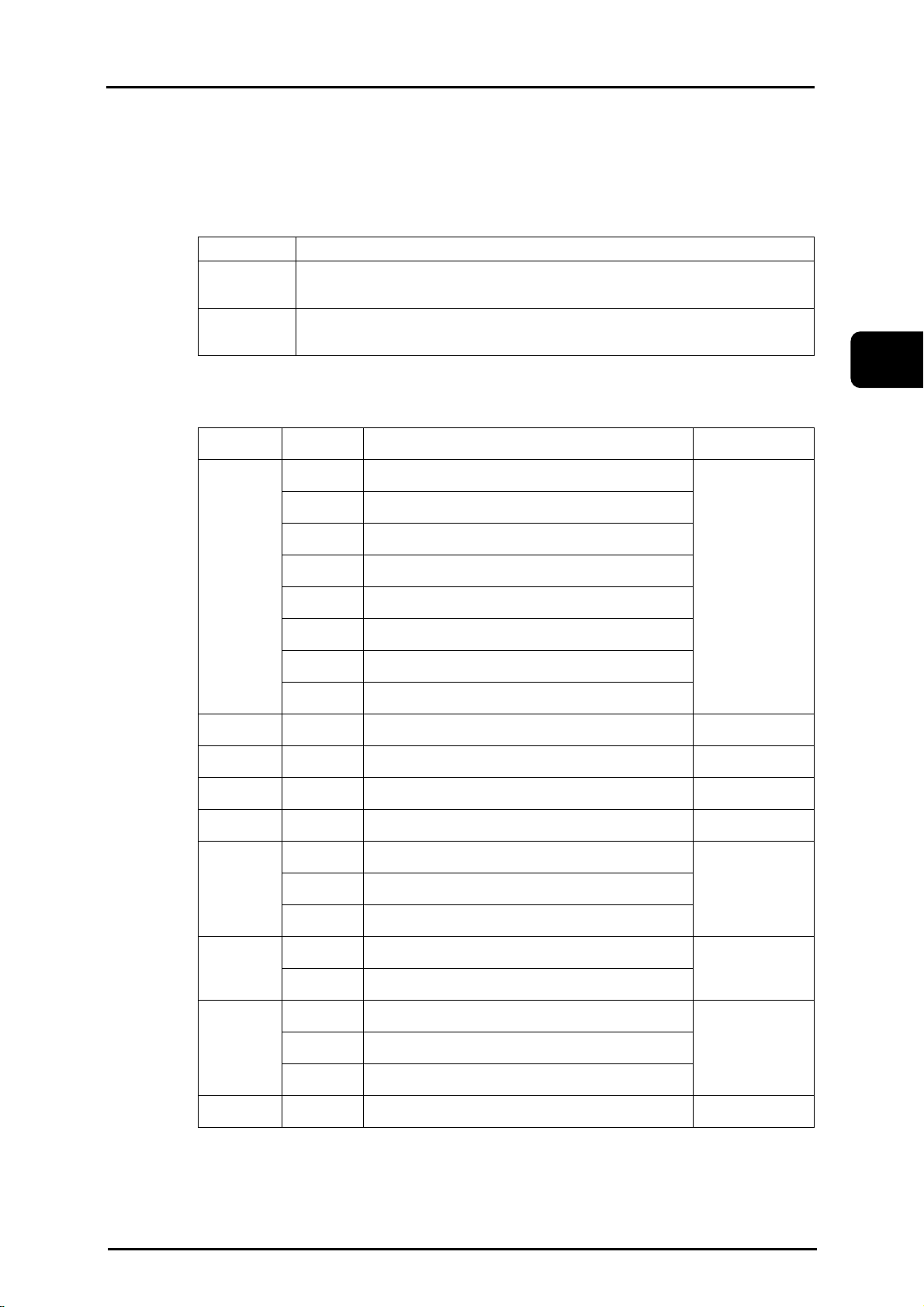

3.1 Outline of G code

Within 3-digit number following the address G determines the meaning of the command of the

block concerned.

The G codes are divided into the following two types.

Type Meaning

Modal The G code is effective until another G code in the same group is commanded.

One-shot The G code is effective only at the block in which it is specified.

The G codes with * mark indicates the modal status when the power is turned ON.

(Note1) Details of coordinate calculation functions are described in " Chapter 6 ".

(Note2) Details of tool dia offset are described in " Chapter 4 ".

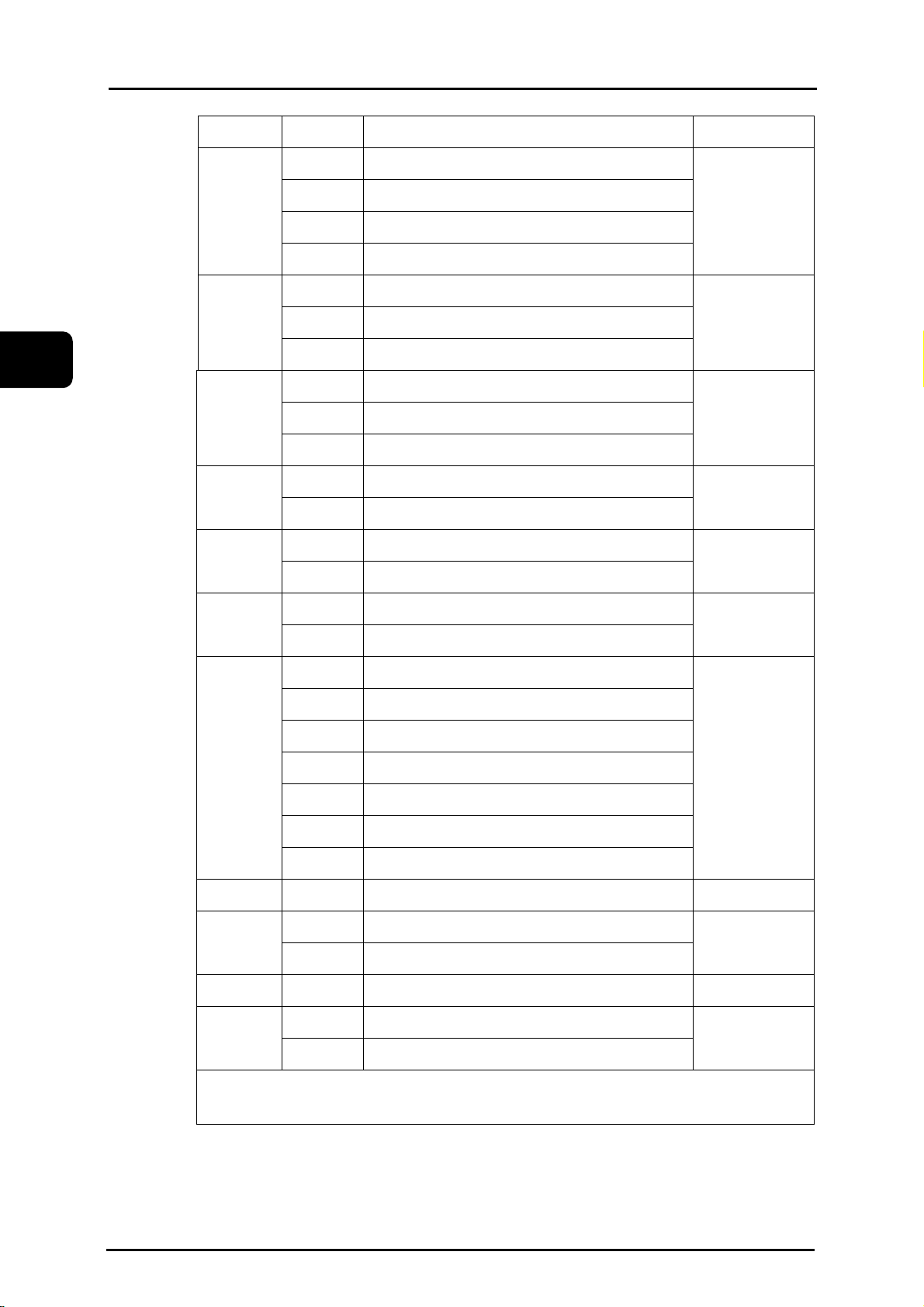

Group G cord Contents Modal

G00* Positioning

G01 Linear interpolation

G02 Circular/ helical interpolation (CW)

G03 Circular / helical interpolation (CCW)

G102 XZ Circular interpolation (CW)

G103 XZ Circular interpolation (CCW)

G202 YZ Circular interpolation (CW)

G203 YZ Circular interpolation (CCW)

G04 Dwell One-shot

G09 Exact stop check One-shot

G10 Programmable data input One-shot

Modal

3

G13 Circular cutting CCW One-shot

G17* XY plane selection

G31 Skip function One-shot

2009/08/27 3 - 3 eTCOM2NCPR3.doc

G18 ZX plane selection

G19 YZ plane selection

G22* Programmable stroke limit on

G23 Programmable stroke limit cancel

G28 Return to the reference point

G29 Return from the reference point

nd

G30 Return to the 2

/3rd/4th reference point

Modal

Modal

One-shot

Page 24

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

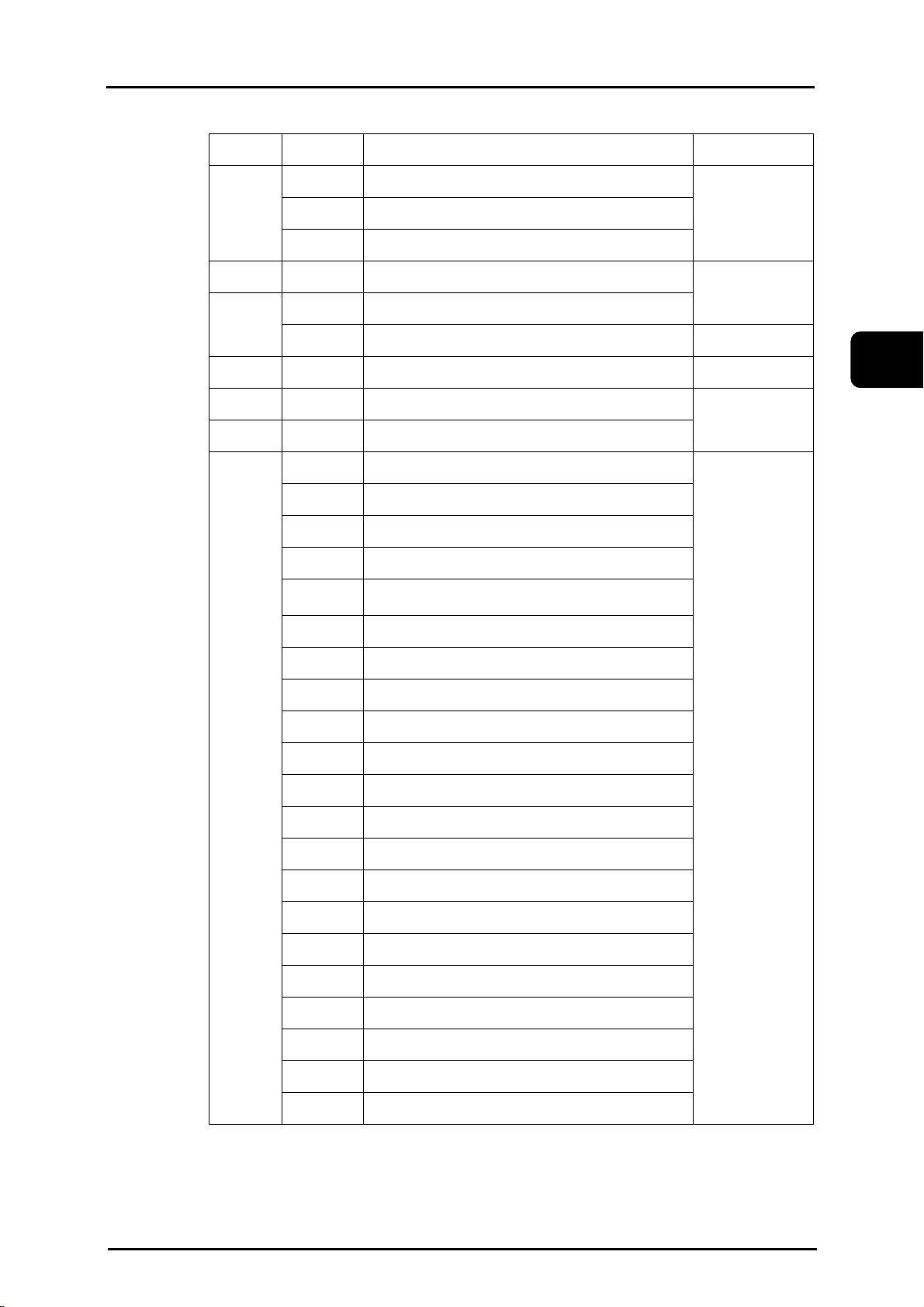

Group G cord Contents Modal

G36 Coordinate calculation function (Bolt hole circle)

G37 Coordinate calculation function (Line-angle)

G38 Coordinate calculation function (Line-angle)

G39 Coordinate calculation function (Grid)

G40* Tool dia offset cancel

One-shot

3

G41 Tool dia offset left

G42 Tool dia offset right

G43 Tool length offset +

G44 Tool length offset -

G49* Tool length offset cancel

G50* Scaling cancel

G51 Scaling

G50.1 Mirror image cancel

G51.1 Mirror image

G52 Local coordinate system

G53 Machine coordinate system selection

G54* Working coordinate system selection 1

G55 Working coordinate system selection 2

G56 Working coordinate system selection 3

G57 Working coordinate system selection 4

Modal

Modal

Modal

Modal

One-shot

Modal

G58 Working coordinate system selection 5

G59 Working coordinate system selection 6

G54.1 Extended working coordinate system selection

G60 Single direction positioning One-shot

G61 Exact stop mode

G64* Cutting mode

G65 Macro call One-shot

G66 Macro modal call

G67* Cancel macro modal call

The G codes with * mark indicates the modal status when the power is turned ON.

(Note1) Details of coordinate calculation functions are described in " Chapter 6 ".

(Note2) Details of tool dia offset are described in " Chapter 4 ".

Modal

Modal

2009/08/27 3 - 4 eTCOM2NCPR3.doc

Page 25

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

Group G cord Contents Modal

G68 Coordinate rotation function

G69* Coordinate rotation function cancel

G168 Coordinate rotation using measured results

G90* Absolute command

G91 Incremental command

G92 Working coordinate system setting One-shot

G94 Feed rate per minute

G98* Return to the initial point level

G99 Return to the R point level

G73 Canned cycle (High-speed peck drilling cycle)

G74 Canned cycle (Reverse tapping cycle)

G76 Canned cycle (Fine boring cycle)

G77 Canned cycle (Tapping cycle, synchro mode)

G78

G80* Canned cycle cancel

Canned cycle (Reverse tapping cycle, synchro

mode)

Modal

Modal

3

Modal

G81 Canned cycle (Drill, spot drilling cycle)

G82 Canned cycle (Drill, spot drilling cycle)

G83 Canned cycle (Peck drilling cycle)

G84 Canned cycle (Tapping cycle)

The G codes with * mark indicates the modal status when the power is turned ON.

G85 Canned cycle (Boring cycle)

G86 Canned cycle (Boring cycle)

G87 Canned cycle (Back boring cycle)

G89 Canned cycle (Boring cycle)

G177 Canned cycle (End mill tap cycle)

G178 Canned cycle (End mill tap cycle)

G181 Canned cycle (Double drilling cycle)

G182 Canned cycle (Double drilling cycle)

G185 Canned cycle (Double boring cycle)

G186 Canned cycle (Double boring cycle)

G189 Canned cycle (Double drilling cycle)

Modal

2009/08/27 3 - 5 eTCOM2NCPR3.doc

Page 26

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

Group G cord Contents Modal

G173 Canned cycle (High-speed peck drilling cycle) One-shot

G183 Canned cycle cancel (Peck drilling cycle) One-shot

G100 Non-stop automatic tool change One-shot

The G codes with * mark indicates the modal status when the power is turned ON.

Note1) Details of canned cycle function are described in " Chapter 5 ".

Group G cord Contents Modal

3

G120 Positioning to the measuring point One-shot

G121 Automatic measurement Corner (Boss)

G122 Automatic measurement Parallel (Groove)

G123 Automatic measurement Parallel (Boss)

G124 Automatic measurement Circle center (Hole, 3 points)

The G codes with * mark indicates the modal status when the power is turned ON.

(Note)

Commands G120 to G129 are described in detail in " Option, Automatic

Measurement " in the instruction manual.

G125 Automatic measurement Circle center (Boss, 3 points)

G126 Automatic measurement Circle center (Hole, 4 points)

G127 Automatic measurement Circle center (Boss, 4 points)

G128 Automatic measurement Z-axis height

G129 Automatic measurement Corner (Groove)

G131 Measurement feed

G132 Measurement feed

G133 Changeover of tap twisting direction (CW)

G134 Changeover of tap twisting direction (CCW)

One-shot

One-shot

One-shot

2009/08/27 3 - 6 eTCOM2NCPR3.doc

Page 27

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

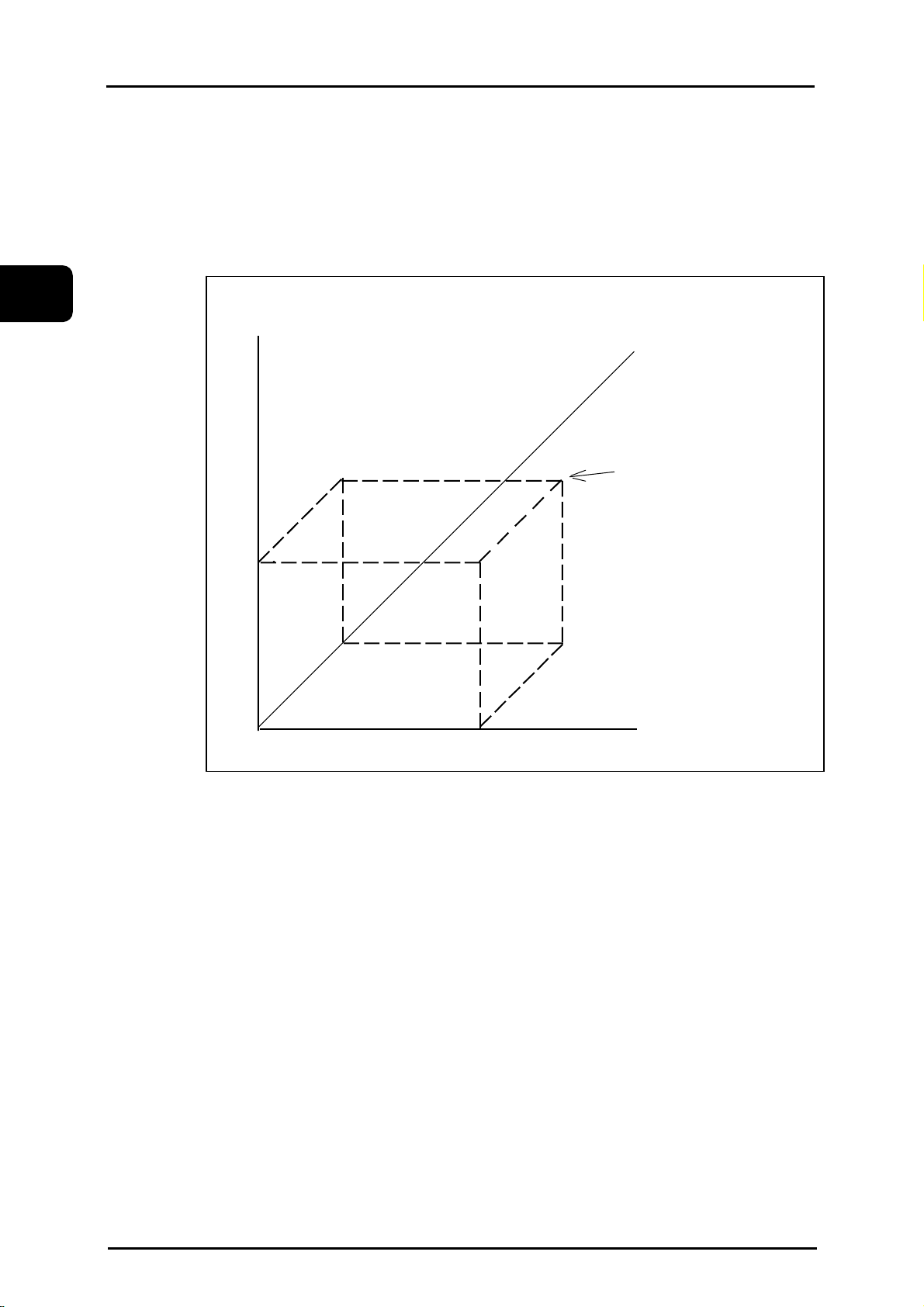

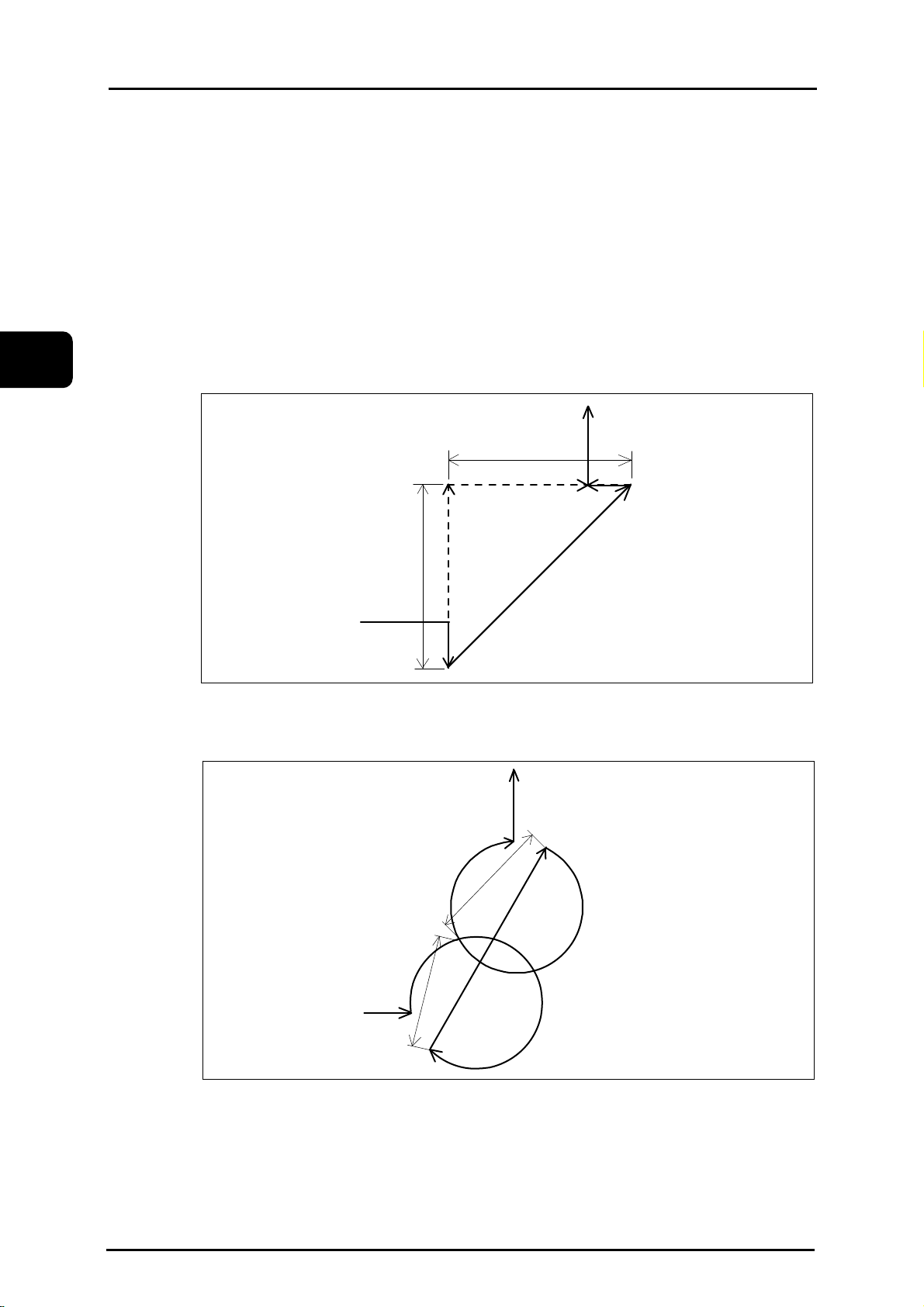

3.2 Positioning (G00)

A tool moves from its current position to the end point at the rapid traverse rate in

each axis direction independently. Therefore, a tool path is not always a linear line.

Command format G00 X_Y_Z_A_B_C_ ;

When the additional axis is commanded and the optional additional axis is not installed, an alarm

will occur.

In the positioning mode actuated by the G00 code, the execution proceeds to the next block after

confirming the in-position check. (Note 1)

(Note 1)

In-position check is to confirm that the machine detecting position is within the

specified range around the target (end) point.

(This range is set by the machine parameter for each axis.)

(Note 2)

The rapid traverse rate is set by the machine parameter for each axis.

Accordingly, rapid traverse rate cannot be specified by the F command.

eNCPR3.01.ai

3

2009/08/27 3 - 7 eTCOM2NCPR3.doc

Page 28

3

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

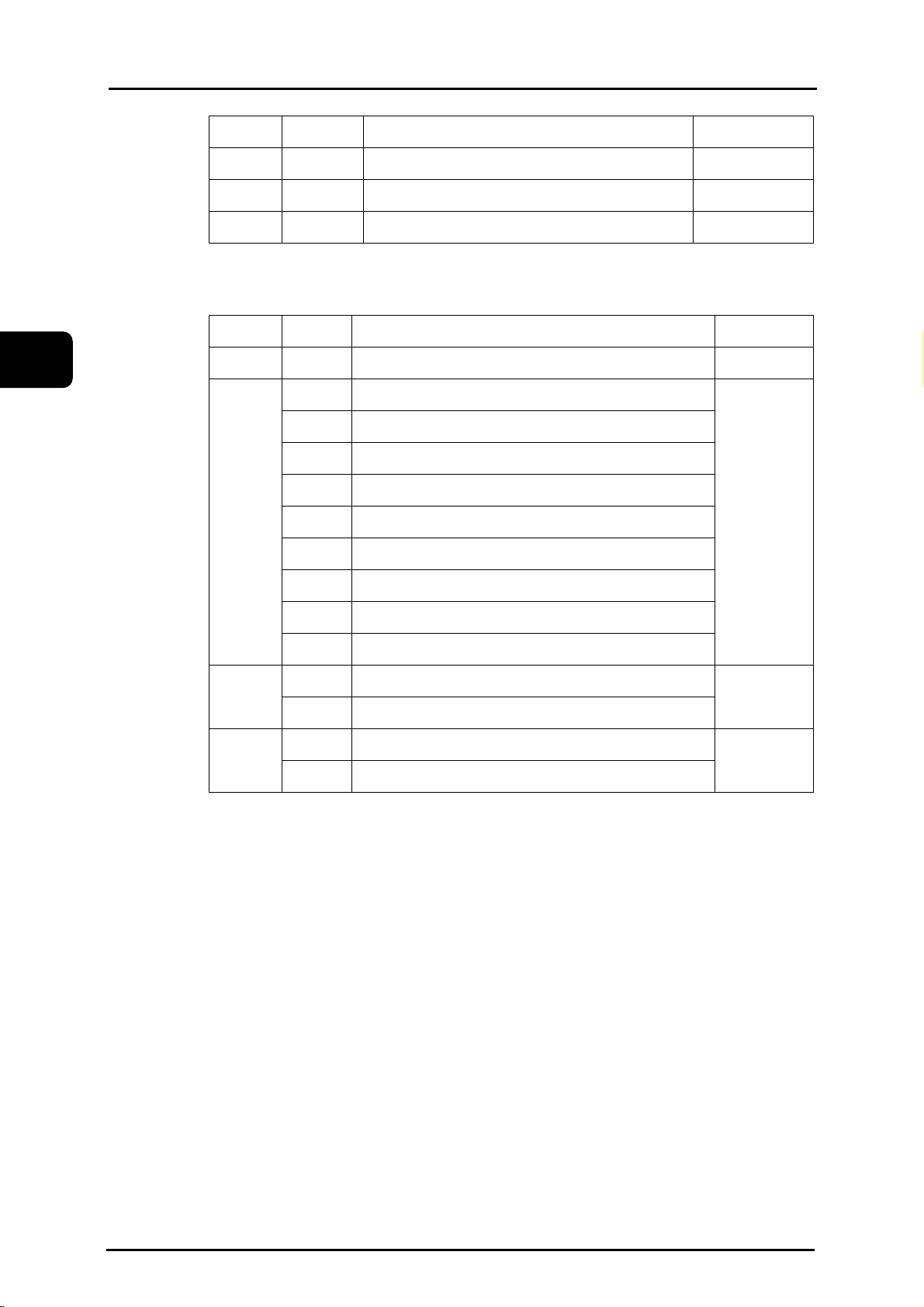

3.3 Linear interpolation (G01)

Linear interpolation moves a tool linearly from the current position to the target position at the

specified feed rate.

Command format G01 X_Y_(Z_A_B_) F_ ;

Up to three linear axes and one additional axis can be controlled simultaneously.

When the additional axis is commanded and the optional additional axis is not installed, an alarm

will occur.

The feed rate is commanded by the address F. Once the feed rate is commanded, it is effective

until another value is specified.

When the X, Y, and Z axes are commanded, the feed rate is determined by the value entered to

mm / min.

When the additional axis is commanded, the feed rate is determined by the value entered to -/min.

(Note 1) Feed rate along each axis is as follows:

When " G01 G91 Xα Yβ Zγ Ff;" is programmed:

Feed rate along X axis Fx = ─── · f

Feed rate along Y axis: Fy = ─── · f

Feed rate along Z axis: Fz = ─── · f

2

( L = α

+ β2 + γ

Start

point

2

α

L

β

L

γ

L

)

End

point

eNCPR3.2.ai

2009/08/27 3 - 8 eTCOM2NCPR3.doc

Page 29

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

(Note2)

The example below shows linear interpolation of linear axis

When " G01 G91 Xα Yβ Zγ Bδ Ff;" is programmed:

Time taken for B-axis movement:1 Tb = ───

Feed rate along B axis: Fb = ────

Feed rate along X axis Fx = ─── · f

Feed rate along Y axis: Fy = ─── · f

Feed rate along Z axis: Fz = ─── · f

( L = α

2

+ β2 + γ2 + δ2 )

L

δ

Tb

α

L

β

L

γ

L

f

and rotation axis.

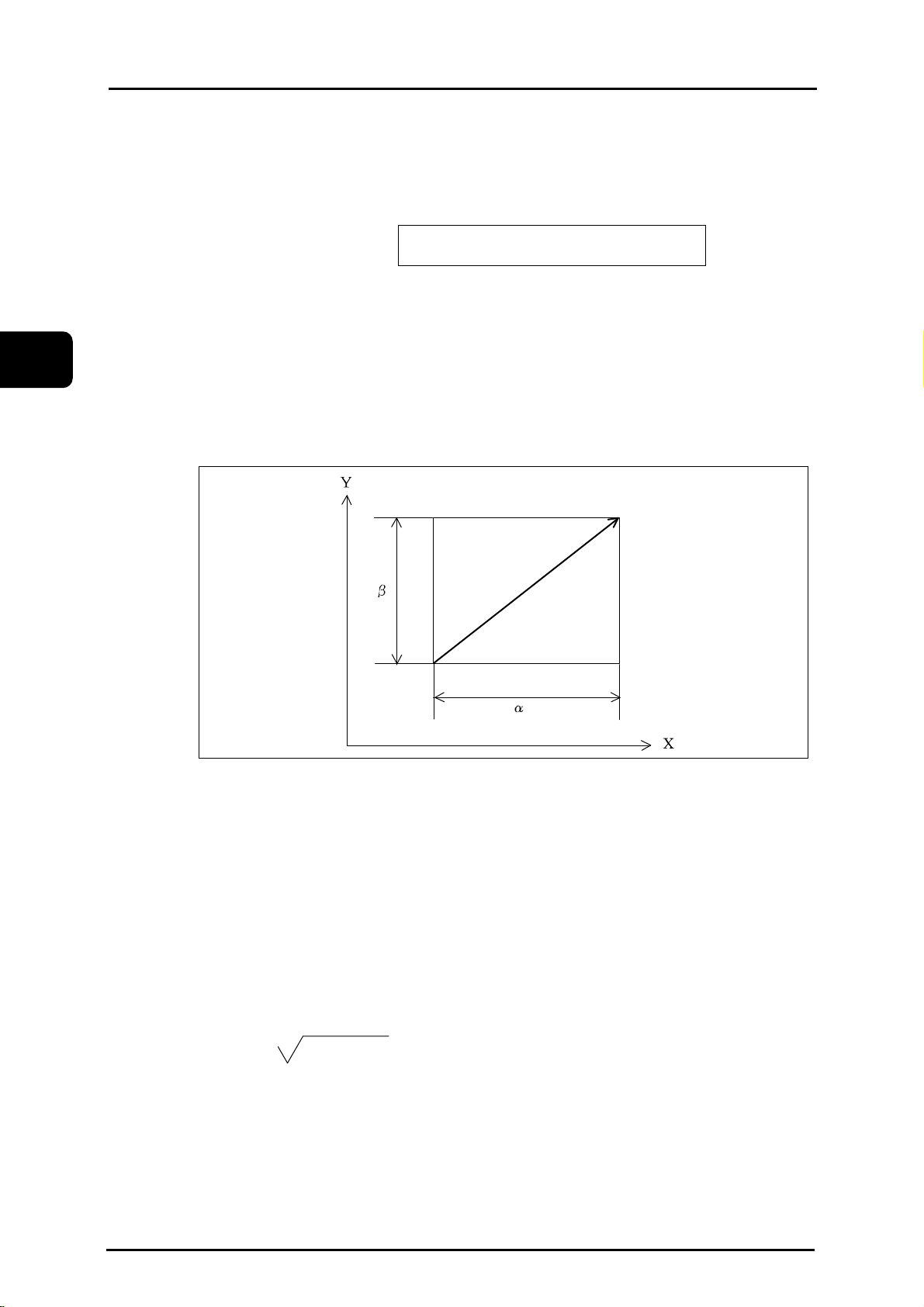

3.3.1 Chamfering to desired angle and cornering C

Chamfering to the desired angle or rounding can be performed between interpolation commands.

Chamfering

Command format G01 X_Y_, C_ ;

C: Distance from virtual corner to the chamfer start point and send point.

This can be commanded only for the selected plane surface.

Y

Chamfer start point

Virtual

corner

intersection

c

Chamfer end point

c

X

eNCPR3.03.ai

3

2009/08/27 3 - 9 eTCOM2NCPR3.doc

Page 30

3

7

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

(1) The corner chamfering command block and subsequent block must contain the

interpolation command (G01-G03).

When the subsequent block does not contain an interpolation or movement command, an

alarm will occur.

(2) The inserted block belongs to the corner chamfering command block. Thus, if the feed rate

differs from the corner chamfering command block and the subsequent block , the inserted

block moves at the feed rate of the corner

chamfering command block. Further, the program does not stop before the inserted block

occurs even during single block operation. (It stops after the inserted block occurs.)

(3) Tool diameter offset applies to the configuration after corner chamfering is performed.

(4) When the chamfering amount is longer than the chamfering command block and feeding

quantity of the subsequent block, set extended point from each blocks as "chamfer start

point" and "chamfer end point".

Example.1: Liner cutting

When set the programmed path to (1.2.3.4.) and the block C as (2), operate to 1-5-6-7-4.

Example.2: Circular cutting

When set the programmed path to (1.2.3.4.) and the block C as (2), operate to 1-5-6-7-4.

(1)

(2)

(1)

(2)

C

(5)

(3)

(6)

C

C

(3)

(6)

(4)

C

(5)

(4)

(7)

eNCPR3.04.ai

(

eNCPR3.05.ai

2009/08/27 3 - 10 eTCOM2NCPR3.doc

Page 31

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

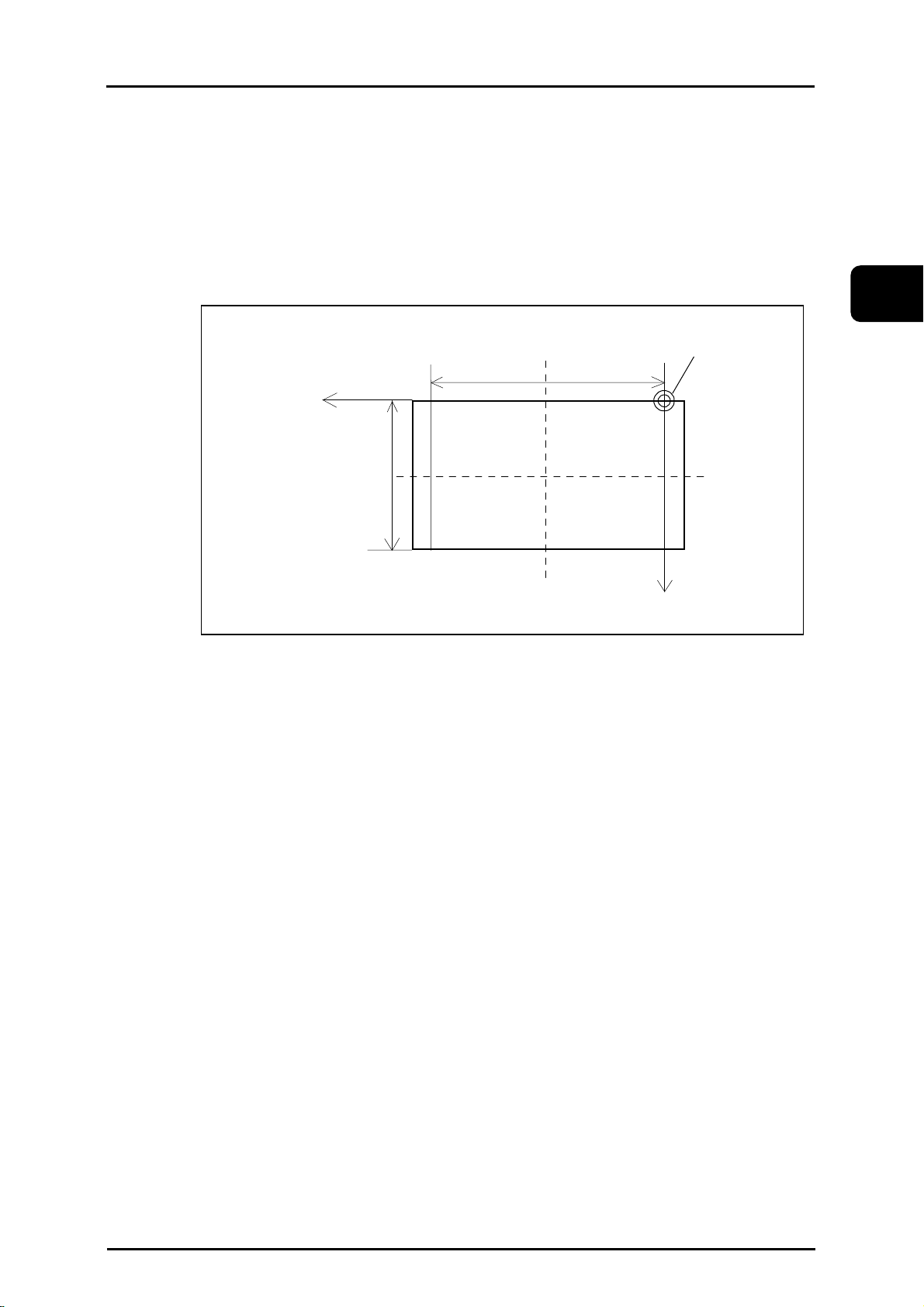

Cornering

Command format G01 X_Y_, R_ ;

R : Radius of cornering

This can be commanded only for the selected plane surface.

(1) The cornering command block and the subsequent block must contain the interpolation

(2) The inserted block belongs to the cornering command block. Thus, if the feed rate differs

(3) Tool diameter offset applies to the configuration after cornering is performed.

(4) When the radius is longer than the corner R command block and the subsequent command

Example.1: Liner cutting

When set the programmed path to (1.2.3.4.) and the block R as (2), operate to 1-5-6-7-4.

Y

Corner-R end point

R

Virtual corner

Corner-R start point

command (G01-G03).

When the subsequent block does not contain an interpolation or movement command, an

alarm will occur.

from the cornering command block and the subsequent block , the inserted block moves at

the feed rate of the cornering command block. Further, the program does not stop before

the inserted block occurs even during single block operation. (It stops after the inserted

block occurs.)

block, set extended point from each blocks as "chamfer start point" and "chamfer end

point".

R

(6)

(5)

(2)

(1)

intersection

X

(7)

(4)

(3)

eNCPR3.07.ai

3

2009/08/27 3 - 11 eTCOM2NCPR3.doc

Page 32

3

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

3.4 Circular/Helical Interpolation (G02, G03)

3.4.1 Circular interpolation

Circular interpolation moves a tool along a circular arc from the current position to the end point at

the specified feed rate.

3.4.1.1 Circular interpolation

G17G02 X_ Y_ I_ J_ F_;

Command format R_

G18G02 Z_ X_ K_ I_ F_;

G19G02 Y_ Z_ J_ K_ F_;

R_

The commands are gives in the following format:

Rotation direction

X-Y plane

G17G03 X_ Y_ I_ J_ F_;

R_

Z-X plane

R_

G18G03 Z_ X_ K_ I_ F_;

R_

Y-Z plane

G19G03 Y_ Z_ J_ K_ F_;

R_

G 02 Clockwise (CW).

G 03 Counterclockwise (CCW).

G90 mode X,Y,Z End point in the working coordinate system.

Distance from the start point to the end point

X

End

point

Distance between start point and arc

Clockwise and counterclockwise are the rotation direction viewed from the positive direction to

the negative direction on the Z axis of the plus direction.

G91 mode

center

Arc radius R Arc radius

Feedrate F

in the X direction.

Distance from the start point to the end point

Y

in the Y direction.

Distance from the start point to the end point

Z

in the Z direction.

Distance from the start point to the center of

I

arc in the X direction.

Distance from the start point to the center of

J

arc in the Y direction.

Distance from the start point to the center of

K

arc in the Z direction.

Feedrate in the tangential direction of circular

arc.

2009/08/27 3 - 12 eTCOM2NCPR3.doc

Page 33

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

3.4.1.2 XZ Circular interpolation

G102 X_ Y_ I_ J F_;

Command format

G103 R_

The commands are given in the following format:

G 102 Clockwise (CW).

Rotation direction

G103 Counterclockwise (CCW).

G90 mode X,Y End point in the working coordinate system.

End

point

Distance between start point and arc

Clockwise and counterclockwise are the rotation direction viewed from the positive direction to

the negative direction on the Y axis of the X-Z plane.

(Note 1)

In contrast to the XY arc case, an error occurs when the diameter offset command

(G41, G42) or coordinate rotation command (G68, G168) is used, and the machine

stops operation.

G91 mode

center

Arc radius R Arc radius

Feedrate F Feedrate in the tangential direction of circular arc.

Distance from the start point to the end point in

X

the X direction.

Distance from the start point to the end point in

Y

the Y direction.

Distance from the start point to the center of arc in

I

the X direction.

Distance from the start point to the center of arc in

J

the Y direction.

3

2009/08/27 3 - 13 eTCOM2NCPR3.doc

Page 34

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

3.4.1.3 XZ Circular interpolation

G202 X_ Y_ I_ J F_;

Command format

G203 R_

The commands are given in the following format:

G202 Clockwise (CW).

Rotation direction

G203 Counterclockwise (CCW).

3

G90 mode X,Y End point in the working coordinate system.

End

point

Distance between start point and arc

Clockwise and counterclockwise are the rotation direction viewed from the positive

direction to the negative direction on the X axis of the Y-Z plane.

(Note 1)

In contrast to the XY arc case, an error occurs when the diameter offset command

(G41, G42) or coordinate rotation command (G68, G168) is used, and the machine

stops operation.

G91 mode

center

Arc radius R Arc radius

Feedrate F Feedrate in the tangential direction of circular arc.

Distance from the start point to the end point in

X

the X direction.

Distance from the start point to the end point in

Y

the Y direction.

Distance from the start point to the center of arc

I

in the X direction.

Distance from the start point to the center of arc in

J

the Y direction.

2009/08/27 3 - 14 eTCOM2NCPR3.doc

Page 35

n

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

The end point of the circular arc takes either the absolute value or the incremental

value according to G90 or G91. The incremental value commands the distance from the circular

arc start point to the end point.

The circular arc center is commanded by both I,J and K according to X,Y and Z axes. I,J and K

form a vector component when viewed from the circular arc start point to the center.

It is commanded by the incremental value regardless of G90 or G91.

Instead of commanding I, J and K to specify the center of arc, the radius of arc can be used.

There are two types of circular arcs (one is less than 180° and the other is more than 180°).

When commanding a circular arc of more than 180°, put the algebraic mark "-" before the value

for the radius.

Absolute command;

G90G03XxYyIiJjFf;

Incremental comma

G91G03XxYyIiJjFf;

eNCPR3.08.ai

(1)G02XxYyFf

(2)G02XxYyFf

eNCPR3.09.ai

3

2009/08/27 3 - 15 eTCOM2NCPR3.doc

Page 36

3

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

Absolute command;

G03X-60. Y-10. I-50. J-20. F1000 ;

Incremental command;

G03X-30. Y30. I-50. J-20. F1000 ;

eNCPR3.10.ai

(1) G02X-70. Y-50. R25. F1000 ;

(2) G02X-70. Y-50. R-25. F1000 ;

(Note 1) When either I, J or K is omitted, it is regarded zero.

(Note 2) The circular arc, when its radius is zero, cannot be commanded.

(Note 3) When both X,Y and Z are omitted, the end point and the start point are

regarded identical, and:

i) 360°arc (full circle) is assumed to be commanded when the arc center

is programmed using the address I,J and K.

ii) When the address R is used, an alarm occurred.

(Note 4) The address R and "I, J and K" cannot be commanded simultaneously.

(Note 5) When the end point is not on the arc specified by start point and arc

radius, the tool moves as shown below.

2009/08/27 3 - 16 eTCOM2NCPR3.doc

eNCPR3.11.ai

Page 37

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

Transition of radius

eNCPR3.15.ai

eNCPR3.14.ai

(Note 6) If the ending radius is extremely larger than that of the starting radius,

an alarm will occur.

(Note 7) The G36~G39 codes cannot be commanded in the circular arc mode.

(Note 8) If the tool radius compensation is applied to small circular

interpolation, the positional relation between start point and end point

of an arc may be reversed depending on the offset value or adjacent

commands, causing an arc to be a full circle. Check the tool path

beforehand in the dry run mode or using the drawing function.

3

2009/08/27 3 - 17 eTCOM2NCPR3.doc

Page 38

3

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

3.4.2 Helical thread cutting interpolation

Putting the other than selected plane axis command in the circular arc block permits a helical

thread cutting.

Command format

X-Y plane:

G17G02 X_Y_Z_ I_ J_ (A_B_)F_;

R_

G17G03 X_Y_Z_ I_ J_ (A_B_)F_;

R_

Z-Y plane:

G18G02 Z_X_Y_ K_I_ (A_B_)F_;

R_

G18G03 Z_X_Y_ K_I_ (A_B_)F_;

R_

Y-Z plane:

G19G02 Y_Z_X_ J_K_ (A_B_)F_;

R_

G19G03 Y_Z_X_ J_K_ (A_B_)F_;

R_

Up to one linear axis and one additional axis can be controlled simultaneously when commanded

for the surface other than selected plane.

The F code commands the feedrate in the circular interpolation axis..

If the value of F is larger than the MAXIMUM CUTTING SPEED or the FEEDRATE SPEED set

by the machine parameter, an alarm is generated.

The feedrate in the other than selected plane axis is determined by the values of "feedrate" in the

circular interpolation axis, "end point X", "end point Y" and "end point Z". It can be calculated as

follows:

180

F

= × F

Z

F: Command speed (X, Y axes)

R: Radius

θ: Angle

Fz: Other than selected plane of feedrate speed.

L: Other than selected plane of feed distance.

Ex.)

Setting following values:

F=500 (mm/min), R=10 (mm), θ=360 (°), L=2 (mm)

Fz = (180×2×500)/(

If the other than selected plane axis feedrate is larger than the MAXIMUM CUTTING SPEED or

FEEDRATE SPEED set by the machine parameter , an alarm is generated.

When tool dia offset command is given, an offset is applied to the selected plane.

(Note) For TC-32B, TC-22B and TC-31B, the optional helical thread cutting

function is required. When the optional helical thread cutting function is

not installed, an alarm will occur.

× L

π × R × θ

.

π×10×360) 15.9 (mm/min)

.

2009/08/27 3 - 18 eTCOM2NCPR3.doc

Page 39

p

(

(

)

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

3.4.3 Spiral interpolation (G02, G03)

An increment or decrement per rotation is specified for the circular interpolation command to

perform spiral interpolation.

Command format

X-Y plane:

{G17}G02X_Y_I_J_Q_L_F_;

{G17}G03X_Y_I_J_Q_L_F_;

Z-Y plane:

{G18}G02Z_X_K_I_Q_L_F_;

{G18}G03Z_X_K_I_Q_L_F_;

Y-Z plane:

{G19}G02Y_Z_J_K_Q_L_F_;

{G19}G03Y_Z_J_K_Q_L_F_;

G02 : Clockwise cutting direction

G03 : Counterclockwise cutting direction

XYZ : Coordinates of end point

L : Number of rotations (An integer number is used to command. When the number is

with decimal point, the number is rounded off.)

Example: Set "L6" for five and 1/4 rotations (5.25 rotations).

Q : Increment or decrement in radius per rotation

Setting a positive value increases the radius for each rotation.

Setting a negative value decreases the radius for each rotation.

IJK : Vector (distance and direction) from the start point to the center (the same as

circular interpolation)

F : Cutting speed

(Note)

Either L (number of rotations) or Q (increment/decrement in radius) can be omitted.

If "L" and "Q" are used together, "Q" is used.

20

20

100

-50

-

Y

Start point (0,100)

X,Y)(0,-50.)

oint

End

Distance to the center

Increment/decrement in radius Q –20.0

No. of rotations L 3

X

1) G90G02X0.Y-50.I0J-100.Q-20.;

2) G90G02X0.Y-50.I0J-100.L3;

Incremental command

1) G91G02X0Y-150.I0J-100.Q-20.;

2) G91G02X0Y-150.I0J-100.L3;

Setting either 1) or 2) is acceptable.

I,J)(0,-100.

3

2009/08/27 3 - 19 eTCOM2NCPR3.doc

Page 40

3

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

Tool dia offset can be performed only in offset mode. An alarm will occur when this is

attempted in startup or cancel mode.

The setting for [Tool dia offset] is applied relative to the start point and end point specified in the

program during tool dia offset.

An alarm will occur when the tool path after tool dia offset intersects or contacts with the spiral

center.

An alarm will occur when the spiral end point that is determined by increment/decrement in radius

per rotation doesn’t match with the program end point and also the difference exceeds the circle

radius fudge factor limit.

An alarm will occur when corner CR is specified in the block immediately before a block that

performs spiral interpolation.

Automatic corner override is not possible for the blocks immediately before and after a block that

performs spiral interpolation.

Corner CR cannot be specified for spiral interpolation.

An alarm will occur when the radius is zero (0) or less (including negative values) as a result of

setting an increment/decrement in the radius per rotation and the number of rotations.

An alarm will occur when the radius is specified using R parameter.

An alarm will occur when the increment or decrement in radius is zero (0).

When Start point radius = End point radius, do not command Q0(zero).(Use the L command.)

When Start point = Center or End point = Center, tool dia offset even to the outside of the spiral

cannot be performed.

When Start point = Center, the travel direction of start point side is the same as that of end point

side.

When End point = Center, the travel direction of end point side is the same as that of start point

side.

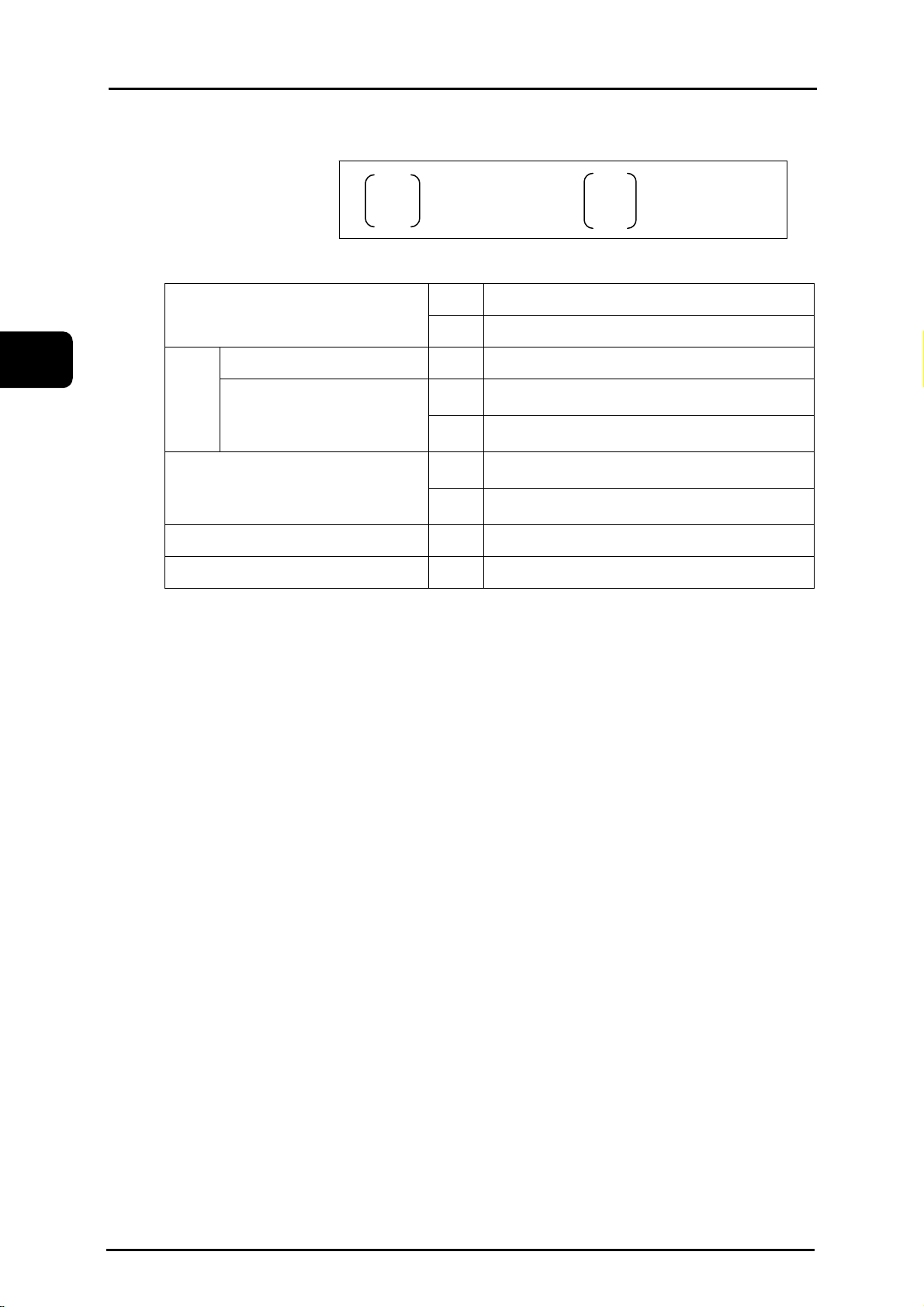

(Start point = Center) (End point = Center)

Start point

End

point

Not commanded when mirror image is effective.

Not commanded when scaling image is effective.

When a tool dia offset cancel command is included in the block immediately after a block that

performs spiral interpolation and tool dia offset, the position given by the vertical vector from the

end point of spiral interpolation on the selected plane will be the end point.

An in-position check is performed between the blocks immediately before and after a block that

performs spiral interpolation.

2009/08/27 3 - 20 eTCOM2NCPR3.doc

Start point

(Center)

Travel directions of

start point and end

point are the same.

End point

(Center)

0317.ai

Page 41

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

3.4.4 Conical interpolation (G02, G03)

The travel command of another axis in addition to the spiral interpolation command is added and

an increment and decrement is specified for that axis per spiral rotation to perform conical

interpolation.

Command format

X-Y plane:

{G17}G02X_Y_Z_I_J_K_Q_L_(A_B_)F_;

{G17}G03X_Y_Z_I_J_K_Q_L_(A_B_)F_;

Z-X plane:

{G18}G02Z_X_Y_K_I_J_Q_L_(A_B_)F_;

{G18}G03Z_X_Y_K_I_J_Q_L_(A_B_)F_;

Y-Z plane:

{G19}G02Y_Z_X_J_K_I_Q_L_(A_B_)F_;

{G19}G03Y_Z_X_J_K_I_Q_L_(A_B_)F_;

Up to one axis (linear axis or additional axis) can be controlled when commanded for the surface

other than selected plane.

G02 : Clockwise cutting direction

G03 : Counterclockwise cutting direction

XYZ : Coordinates of end point

L : Number of rotations (An integer number is used to command. When the number is

with decimal point, the number is rounded off.)

Example: Set "L6" for five and 1/4 rotations (5.25 rotations).

Q : Increment or decrement in radius per rotation

Setting a positive value increases the radius for each rotation.

Setting a negative value decreases the radius for each rotation.

IJK : Set a vector from the start point to the center for two axes and the

increment/decrement in height per spiral rotation used for conical interpolation for

the remaining axis.*

Plane to be set Vector from start point to center

G17 X-Y plane I, J K

G18 Z-X plane K, I J

G19 Y-Z plane J, K I

F : Cutting speed

*) As long as one of IJK, L, and Q (increment/decrement in height, number of rotations,

increment/decrement in radius) is set, setting the remaining two items can be omitted.

If there is a discrepancy between "L" and "Q," the latter is used.

If there is a discrepancy between "L" and the increment/decrement in height, the latter is used.

If there is a discrepancy between "Q" and the increment/decrement in height, the former is used.

Priority Higher ← "Q" > Increment/decrement in height > "L" → Lower

(Note) For TC-32B and TC-22B, the optional helical thread cutting function is

required. When the optional helical thread cutting function is not

installed, an alarm will occur.

Increment and decrement in

height per spiral rotation

3

2009/08/27 3 - 21 eTCOM2NCPR3.doc

Page 42

3

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

Example of program: The orders of the numerical values in the brackets( ) are X,Y and Z.

Start point (0.,100.,0.)

End point (0.,-37.5,12.5)

Distance to the center (0.,-100.)

Increment/decrement in radius -25.

Increment/decrement in height 5.

No. of rotations 3

Absolute command G90G02X0 Y-37. 5Z12.5I0.J -100. F300.;

Incremental command G90G02X0 Y-137. 5Z12.5I0.J -100. F300.;

(0,-37.5,12.5)

+X

+Z

-

25.0

100

25.0

5.0

5.0

+Y

100.0

K5.

Q25.

L3

K5.

Q25.

L3

2009/08/27 3 - 22 eTCOM2NCPR3.doc

Page 43

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

Tool dia offset can be performed only in offset mode. An alarm will occur when this is

attempted in startup or cancel mode.

The setting for [Tool dia offset] is applied to the start point and the end point specified in the

program and also to the selected plane during tool dia offset.

An alarm will occur when the tool path after tool dia offset intersects or contacts with the

conical center.

An alarm will occur when the circular cone end point that is determined by increment/decrement

in radius per rotation doesn’t match with the program end point and also when the difference

exceeds the circle radius fudge factor limit.

An alarm will occur when corner CR is specified in the block immediately before a block that

performs conical interpolation.

Automatic corner override is not possible for the blocks immediately before and after a block that

performs conical interpolation.

Corner CR cannot be specified for conical interpolation.

An alarm will occur when the tool dia offset direction (G41, G42) is changed between the blocks

immediately before and after a block that performs conical interpolation.

An alarm will occur when the radius is specified using R parameter.

An alarm will occur when the increment or decrement in radius is zero (0).

When Start point radius = End point radius, do not command Q0(zero).(Use the L command.)

When Start point = Center or End point = Center, tool dia offset even to the outside of the spiral

cannot be performed.

When Start point = Center, the travel direction of start point side is the same as that of end point

side.

When End point = Center, the travel direction of end point side is the same as that of start point

side.

(Start point = Center)

(End point = Center)

3

Start point

End

point

Not commanded when mirror image is effective.

Not commanded when scaling image is effective.

When a tool dia offset cancel command is included in the block immediately after a block that

performs conical interpolation and tool dia offset, the position given by the vertical vector from the

end point of conical interpolation on the selected plane will be the end point.

An in-position check is performed between the blocks immediately before and after a block that

performs conical interpolation.

2009/08/27 3 - 23 eTCOM2NCPR3.doc

Start point

(Center)

Travel directions of

start point and end

point are the same.

End point

(Center)

0317.ai

Page 44

p

(

)

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

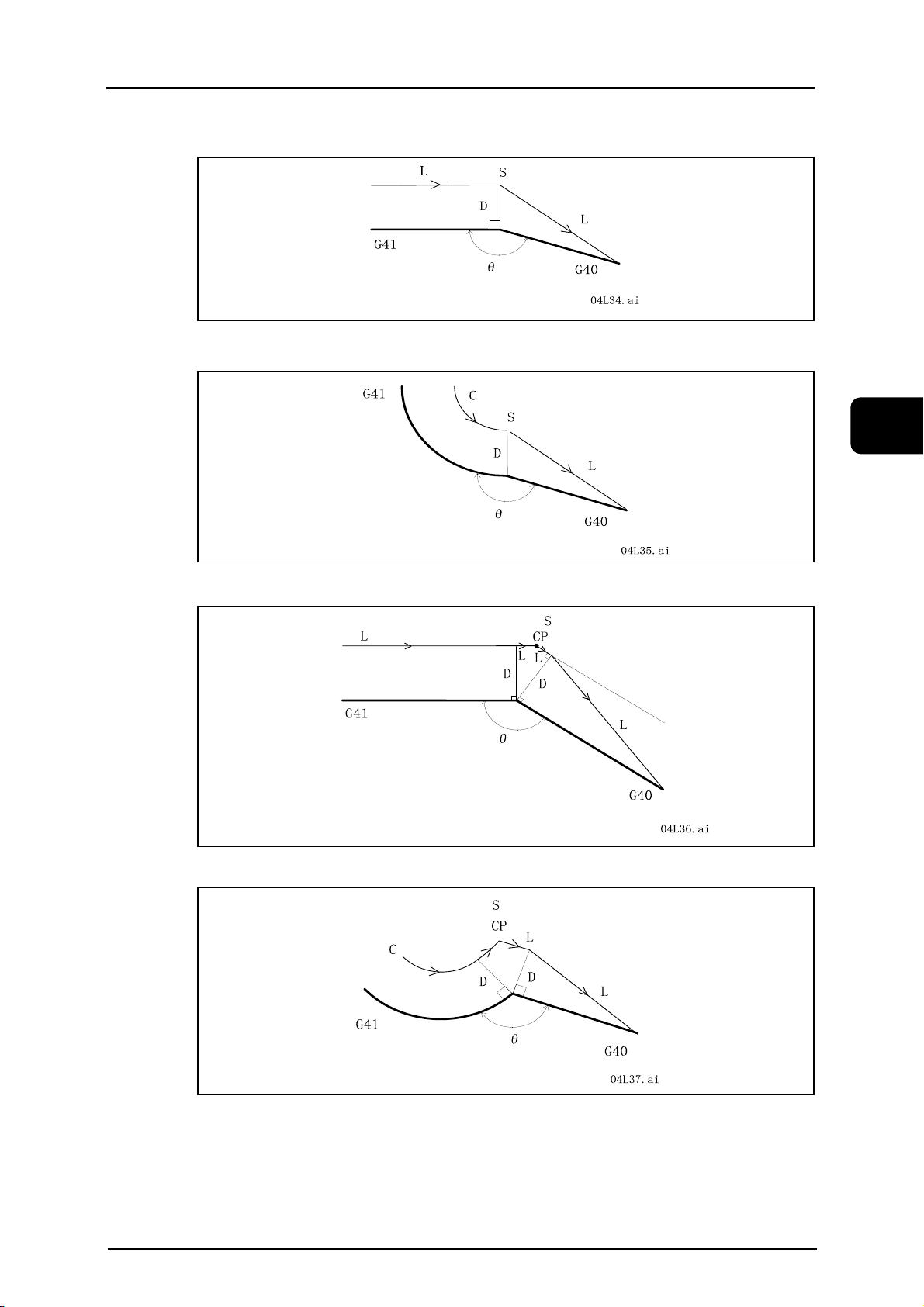

3.4.5 Tool dia offset procedure for spiral interpolation and conical interpolation (G02, G03)

Assuming a virtual circle with the center of the spiral interpolation as the center for the start point

and end point of the block, tool dia offset is performed for the virtual circle and then spiral

interpolation is performed based on the result of tool dia offset.

3

(1)

Program path

(3)

Intersection

(start point)

(2)

Set a virtual circle for the start

(4)

oint.

Intersection

start point

Set the tool dia offset for the virtual circle.

(5)

Intersection

(end point)

Set the tool dia offset for the virtual circle.

Intersection

(start point)

Set a virtual circle for the end point.

(6)

End point

Spiral interpolation and tool dia offset with

the start/end points taken as the intersection

points.

Virtual

circle for

cutter

Start point

Virtual circle for

tool dia offset

Tool dia offset based

on program path

Tool dia offset based

on virtual circle

2009/08/27 3 - 24 eTCOM2NCPR3.doc

Page 45

(2)

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

3.5 Circle Cutting (G12, G13)

Starting from the center of the circle, the tool cuts the inner side of the circle and returns to the

center of the circle.

Command format G12I_D_F_;

G13I_D_F_;

G12 : Clockwise cutting direction

G13 : Counterclockwise cutting direction

I : Radius of circle + and - symbols are ignored, and the value is always regarded as

+ (positive).

D : Compensation.

Set the tool number for compensation.

When compensation value is a plus (+), the inner side of the radius specified by

command "I" is cut.

When compensation value is a minus (-), the outer side of the radius specified by

command "I" is cut.

F : Cutting speed

[Motion (When X, Y plane selected)]

The tool moves in a circle half the distance from the center of the circle in the X-axis direction.

The rotation direction is specified to G12 or G13.

The tool completes one rotation in the rotation direction specified by G12 or G13 from start point.

It then moves in a circle half the distance from the end point of circle cutting to the center of the

circle in the rotation direction specified by G12 or G13.

When G12 is used and the compensation is a positive value.

Radius

(2)

Y

Y

(1)

Compensation

Tool path

X

Tool path

工具経路

(3)

Compensation (-)

(3)

X

3

Radius

When G13 is used and the compensation is a negative value.

2009/08/27 3 - 25 eTCOM2NCPR3.doc

(1)

Page 46

3

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

An alarm will occur when command "D" is omitted.

An alarm will occur when the product of the radius (command "I") minus compensation is zero (0)

or a negative value.

An alarm will occur when the circle cutting command (G12, G13) is specified together with the

tool dia offset command (G40, G41, G42) (startup or cancel mode).

Corner CR cannot be set for a block that contains the circle cutting command and the block

immediately before that block.

An alarm will occur when the radius after tool dia offset is smaller than the tool diameter.

Circle cutting is performed on the plane currently selected (G17, G18, G19).

The start point and end point are the same for circle cutting.

When circle cutting (G12, G13) is executed during tool dia offset (G41, G42), tool dia offset is

valid for the path compensated by command "D."

3.6 Plane Selection (G17, G18, G19)

Select the plane surface to which circular interpolation, tool dia offset, coordinate system rotation,

corner CR, circle cutting, spiral interpolation or conical interpolation are executed.

XY Plane Selection

Command format

ZX Plane Selection

Command format

YZ Plane Selection

Command format

Tool length offset is applied to Z-axis regardless of which plane surface is selected.

The fixed cycle, the automatic workpiece measurement and the coordinate calculation are

available for G17 command only. An error will occur when G18 or G19 is selected.

The corner CR is applied only when the target block and following block are on the same selected

plane. An alarm will occur when each block is on the different plane.

An alarm will occur when a plane that differs from modal is selected during tool dia offset.

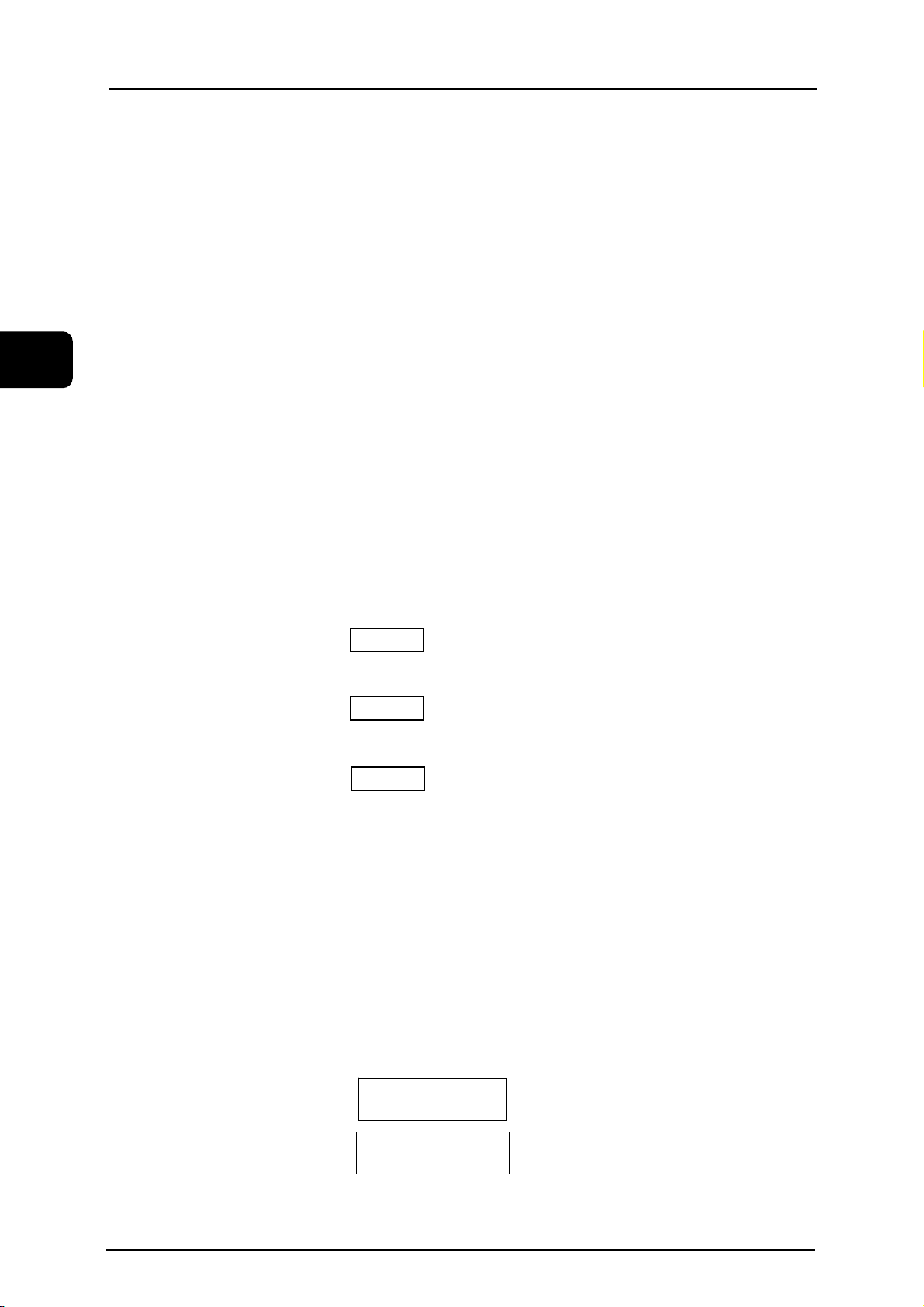

G17

G18

G19

3.7 Dwell (G04)

Upon completion of the previous block and in-position check, some time elapses before executing

the next block.

Command format G04 P_ ;

G04 X_ ;

P,X : Dwelling time (sec)

2009/08/27 3 - 26 eTCOM2NCPR3.doc

Page 47

TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B Chapter 3 Preparation Function

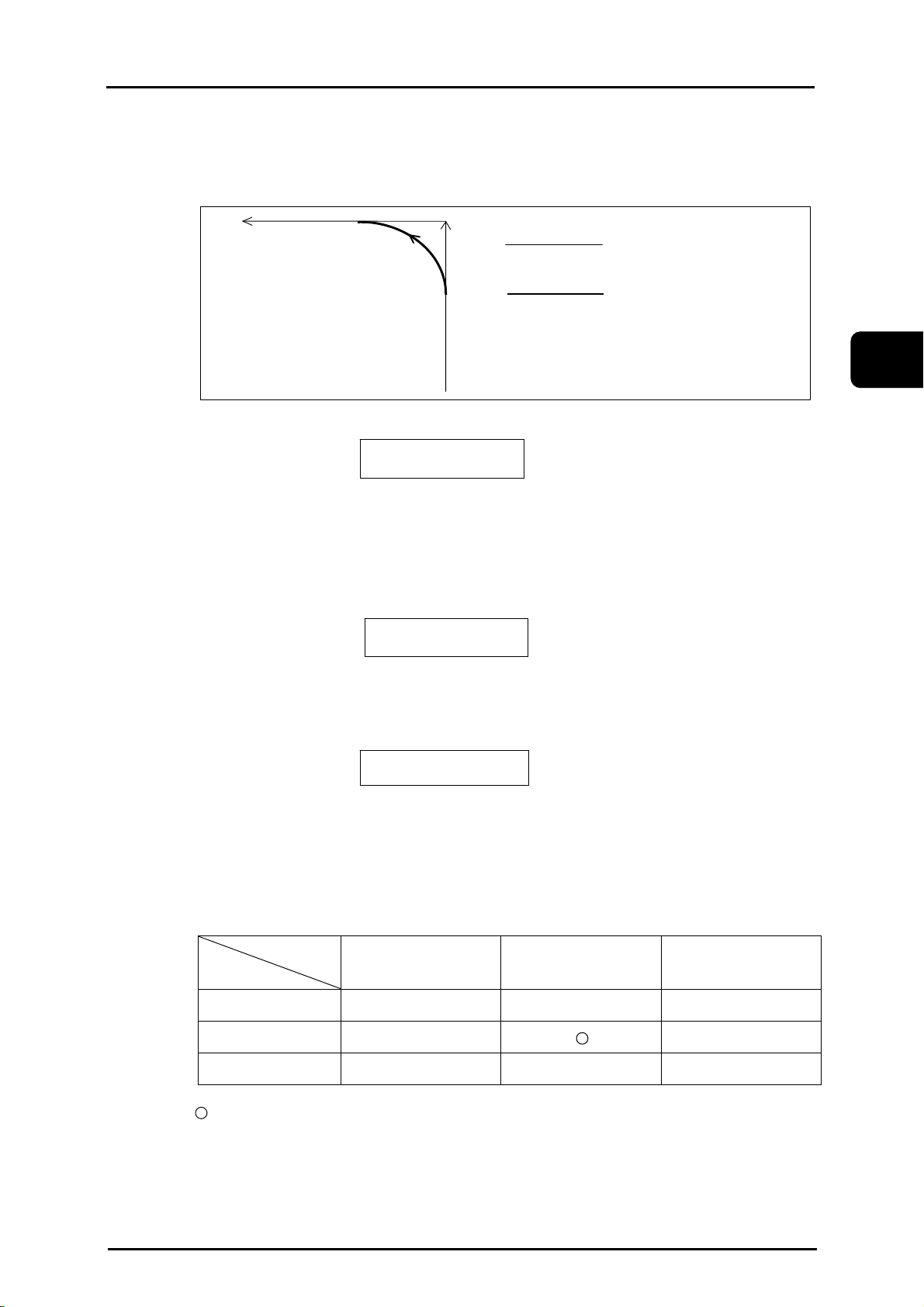

3.8 Exact Stop Check (G09, G61, G64)

Since acceleration and deceleration is applied independently to each axis, the actual tool path

comes inside the programmed path if each axis speed changes greatly between the former block

and the new block in the cutting feed. The exact stop check is used to solve this problem.

(1) Exact stop check (G09)

Command format G09 ;

This command executes an in-position check at the end of a block before proceeding to the next

block.

(Note 1) G09 is effective only in the commanded block.

(Note 2) In the positioning mode (G00) the exact stop check function is effective

regardless of this command.

(2) Exact stop check mode (G61)

Command format G61 ;

After this command is given, the exact stop check function is effective at the end of each block

until the cutting mode (G64) is commanded.

(3) Cutting mode (G64)

Command format G64 ;

When this command is given, the execution proceeds to the next block without slowing down

between the continuing two blocks. This command is effective until G61 is commanded.

(Note 1) Even during the cutting mode (G64), the exact stop check is executed in

the blocks in the positioning mode (G00) or in the exact stop check mode (G09),

or in the disconnected cutting feed block.

(Note 2)

: Programmed path

: Actual tool path

3

Positioning

Cutting feed

No traveling

Cutting mode

× × ×

×

× × ×

Cutting feed No traveling

×

× Exact stop check mode

When the old block is clamped while the additional axis is traveling, exact stop check is executed.

When the new block is unclamped while the additional axis is traveling, exact stop check is

executed.

2009/08/27 3 - 27 eTCOM2NCPR3.doc

Page 48

3

Chapter 3 Preparation Function TC-32BQT/32BFT/22B/S2C/31B/32BN/S2Cz/S2D/R2B

3.9 Programmable Data Input (G10)

(1) Input of working zero position

Command format G10L2Pn X_ Y_ Z_ A_ B_ C_ ;

n=1 : G54

n=2 : G55

n=3 : G56

n=4 : G57

n=5 : G58

n=6 : G59

When the G90 mode (absolute command) is selected, the commanded offset amount becomes

newly effective.

When the G91 mode (incremental command) is selected, the commanded offset amount is added

to the currently set offset amount to become a renewed offset amount.

When the additional axis is commanded while an optional additional axis is not installed, an alarm

will occur.

(Note) Working zero position … Refer to “Operation Manual (Data bank)”.

(2) Input of tool data

Tool length offset data G10L10 P_ R_ ;