Brother T-8752C, TL-847A, TN-842A, TN-845B Owner's Manual

INSTRUCTION MANUAL

BAS-364E,366E

BAS-370E,375E

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

PROGRAMMABLE ELECTRONIC PATTERN SEWER

Thank you very much for buying a BROTHER sewing machine. Before using your new machine, please read

the safety instructions below and the explanations given in the instruction manual.

With industrial sewing machines, it is normal to carry out work while positioned directly in front of moving parts

such as the needle and thread take-up lever, and consequently there is always a danger of injury that can be

caused by these parts. Follow the instructions from training personnel and instructors regarding safe and correct

operation before operating the machine so that you will know how to use the machine correctly.

SAFETY INSTRUCTIONS

z

Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are provided in

order to ensure safe operation of this machine and to prevent accidents and injury to yourself or other people.

The meanings of these indications and symbols are given below.

Indications

DANGER

CAUTION

Symbols

............. This symbol ( ) indicates something that you should be careful of. The picture inside

the triangle indicates the nature of the caution that must be taken.

(For example, the symbol at left means “beware of injury”.)

............. This symbol ( ) indicates something that you

............. This symbol ( ) indicates something that you

indicates the nature of the thing that must be done.

(For example, the symbol at left means “you must make the ground connection”.)

The instructions which follow this term indicate situations where failure to follow the

instructions will almost certainly result in death or severe injury.

The instructions which follow this term indicate situations where failure to follow the

instructions could cause injury when using the machine or physical damage to

equipment and surroundings.

must not do.

must do. The picture inside the circle

BAS-364E, 366E, 370E, 375E

i

x Notes on safety

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet before

opening the face plate of the control box Leg cover. Touching areas where high voltages are present can result in

severe injury.

DANGER

CAUTION

Environmental requirements

Use the sewing machine in an area which is free from

sources of strong electrical noise such as high-

frequency welders.

Sources of strong electrical noise may cause problems

with correct operation.

Any fluctuations in the power supply voltage should

be within ±10% of the rated voltage for the machine.

Voltage fluctuations which are greater than this may

cause problems with correct operation.

The power supply capacity should be greater than the

requirements for the sewing machine’s electrical

consumption.

Insufficient power supply capacity may cause problems

with correct operation.

The air supply should have a capacity greater than the

machine air consumption. If air is not supplied

sufficiently, a machine malfunction may occur.

Installation

Machine installation should only be carried out by a

qualified technician.

Contact your Brother dealer or a qualified electrician

for any electrical work that may need to be done.

The sewing machine weighs more than BAS-364E,

366E are 400 kg, BAS-370E, 375E are 600 kg. The

installation should be carried out by two or more people.

Do not connect the power cord until installation is

complete, otherwise the machine may operate if the

foot switch is pressed by mistake, which could result

in injury.

Be sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a

serious electric shock, and problems with correct

operation may also occur.

The ambient temperature should be within the range

of 5°C to 35°C during use.

Temperatures which are lower or higher than this may

cause problems with correct operation.

The relative humidity should be within the range of 45% to

85% during use, and no dew formation should occur in any

devices.

Excessively dry or humid environments and dew formation

may cause problems with correct operation.

Avoid exposure to direct sunlight during use.

Exposure to direct sunlight may cause problems with

correct operation.

In the event of an electrical storm, turn off the power

and disconnect the power cord from the wall outlet.

Lightning may cause problems with correct operation.

All cords tube should be secured at least 25 mm away

from any moving parts. Furthermore, do not excessively bend the cords or secure them too firmly with

staples.

Use the arm motor cover with the leg cover

installed.

If using a work table which has casters, the casters

should be secured in such a way so that they cannot

move.

Be sure to wear protective goggles and gloves when

handling the lubricating oil and grease, so that they do

not get into your eyes or onto your skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the grease under any circumstances, as they can cause vomiting

and diarrhoea.

Keep the oil out of the reach of children.

ii

BAS-364E, 366E, 370E, 375E

CAUTION

Sewing

This sewing machine should only be used by operators who have received the necessary training in safe

use beforehand.

The sewing machine should not be used for any

applications other than sewing.

Be sure to wear protective goggles when using the

machine.

If goggles are not worn, there is the danger that if a

needle breaks, parts of the broken needle may enter

your eyes and injury may result.

Set the needle to the needle up stop position before

turning on the power.

Turn off the power switch at the following times,

otherwise the machine may operate if the foot switch

is pressed by mistake, which could result in injury.

• When replacing the needle

• When not using the machine and when leaving the

machine unattended

Cleaning

Set the needle to the needle up stop position before

turning on the power.

If this is not done, the wiper may strike the needle,

which might cause the needle to break.

Turn off the power switch before carrying out cleaning,

otherwise the machine may operate if the foot switch

is pressed by mistake, which could result in injury.

Secure the legs of the table on a level surface so that

the sewing machine does not move.

Attach all safety devices before using the sewing

machine. If the machine is used without these devices

attached, injury may result.

Do not touch any of the moving parts or press any

objects against the machine while sewing, as this may

result in personal injury or damage to the machine.

If an error occurs in machine, or if abnormal noises or

smells are noticed, immediately turn off the power

switch. Then contact your nearest Brother dealer or a

qualified technician.

If the machine develops a problem, contact your

nearest Brother dealer or a qualified technician.

Be sure to wear protective goggles and gloves when

handling the lubricating oil and grease, so that they do

not get into your eyes or onto your skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the grease under any circumstances, as they can cause vomiting

and diarrhoea.

Keep the oil out of the reach of children.

Maintenance and inspection

Maintenance and inspection of the sewing machine

should only be carried out by a qualified technician.

Ask your Brother dealer or a qualified electrician to

carry out any maintenance and inspection of the

electrical system.

Set the needle to the needle up stop position before

turning on the power.

Turn off the power switch and disconnect the power

cord from the wall outlet at the following times,

otherwise the machine may operate if the foot switch

is pressed by mistake, which could result in injury.

• When carrying out inspection, adjustment and maintenance

• When replacing consumable parts such as the rotary hook

If the power switch needs to be left on when carrying

out some adjustment, be extremely careful to observe

all safety precautions.

Disconnect the air hoses from the air supply and wait

for the needle on the pressure gauge to drop to “0”

before carrying out inspection, adjustment andrepair

of any parts which use the pneumatic equipment.

Use only the proper replacement parts as specified by

Brother.

If any safety devices have been removed, be absolutely sure to re-install them to their original positions

and check that they operate correctly before using the

machine.

Any problems in machine operation which result from

unauthorized modifications to the machine will not be

covered by the warranty.

BAS-364E, 366E, 370E, 375E

iii

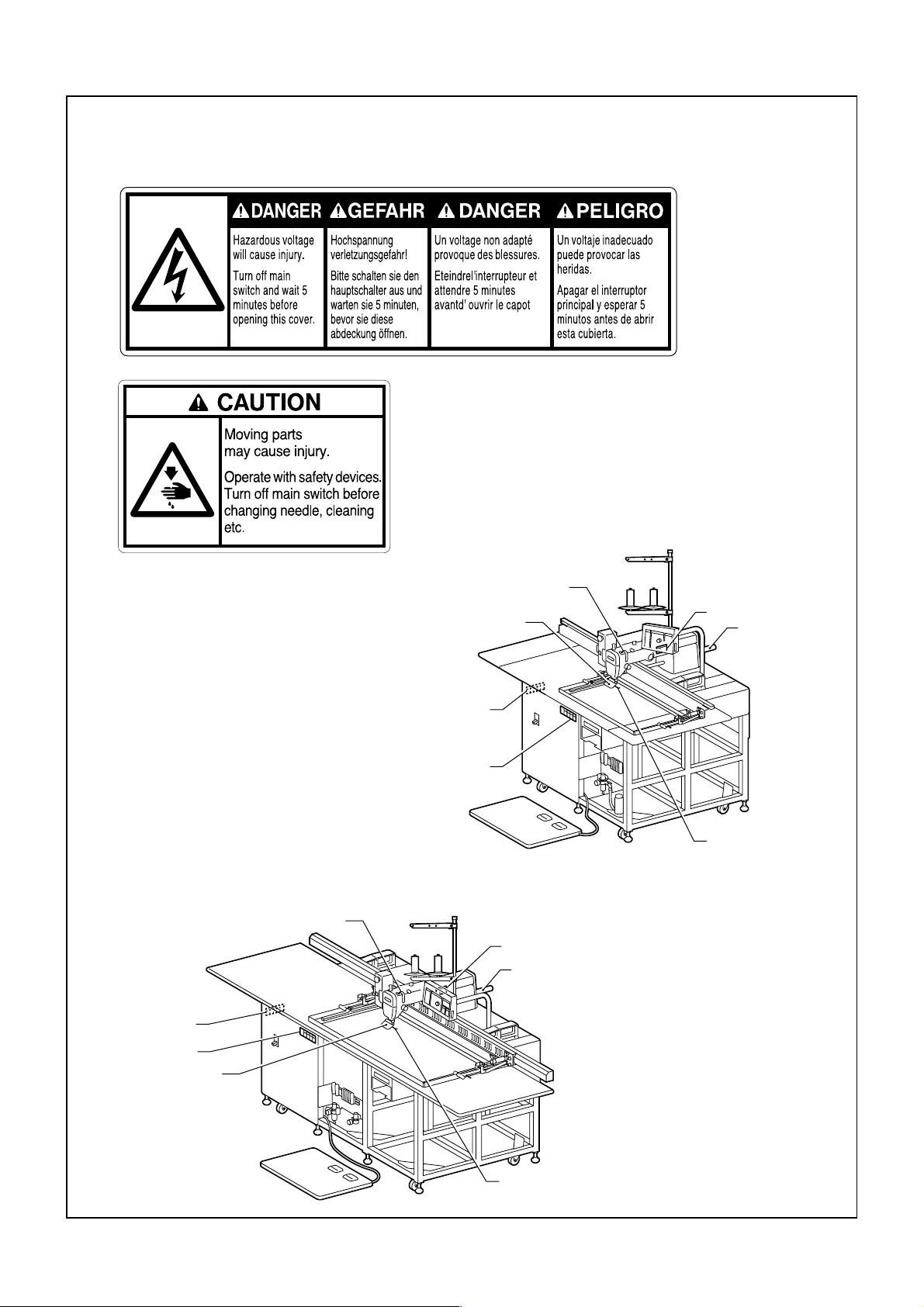

c Warning labels

★ The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels have been

removed or are difficult to read, please contact your nearest Brother dealer.

1

2

* BAS-364E, 366E

Safety devices: Thread take-up cover,

Belt cover, Eye guard,

Finger guard,

Arm motor cover, etc.

* BAS-370E, 375E

thread take-up cover

1

1

Eye guard

thread take-up cover

Eye guard

1

1

2

Arm moter

cover

2

Arm moter cover

Finger guard

Finger guard

iv

BAS-364E, 366E, 370E, 375E

Contents

Chapter 1

NAME OF MAJOR PARTS

.... 1

Chapter 2 SPECIFICATIONS................ 2

Chapter 3 INSTALLATION ........................ 3

1. Connecting the ground wire ........................ 3

2. Positioning ........................................................ 3

3. Installing the needle plates .......................... 4

4. Installing the work clamp hinge .................. 5

5. Installing the arm motor cover .................... 5

6. Installing the foot switch ............................... 6

7. Installing the programmer box .................... 6

8. Installing the programmer ............................ 6

9. Installing the spool stand.............................. 7

10. Preparation of cassette .............................. 7

11. Lubrication ..................................................... 8

12. Draining oil ..................................................... 9

13. Applying grease............................................ 10

14. Adjusting the air pressure.......................... 11

Chapter 4 CORRECT OPERATION ... 12

1. Turning the pulley by hand .......................... 12

2. Installing the needle....................................... 12

3. Threading the upper thread......................... 13

4. Winding the lower thread ............................. 14

5. Installing the bobbin case ................................. 15

6. Thread tension ................................................ 16

7. Work clamp ...................................................... 17

8.

Selecting Intermittent feed or continuous feed

Chapter 5

1.

Part names and functions of the operation panel

2. Using the floppy disk ..................................... 21

3.

Using the program R/W (Read/Write) switch

4. Using the emergency stop switch.............. 24

5. Adjusting the sewing speed control........... 25

6.

Changing the X-scale and Y-scale settings

7. Using the TEST switch

(Checking the sewing pattern)

8. Using the STEP BACK switch .................... 27

9. Using single split mode................................. 28

10. Using the bobbin thread counter ............. 29

11. Using production counter .......................... 30

12. Shifting a stitch pattern............................... 31

OPERATING PROCEDURE

...................... 26

...... 18

... 19

.. 19

........ 23

..... 25

Chapter 6 Sewing ........................................ 32

1. Before starting sewing.................................. 32

2. Sewing operation ............................................ 33

Chapter 7

1. Needle and rotary hook timing ................... 34

2. Adjusting the needle bar height ................. 35

3. Adjusting the needle clearance .................. 35

4. Adjusting the presser foot ............................ 36

5. Changing the presser foot lift amount ...... 37

6.

Replacing the fixed knife and movable knife

7. Adjusting the inner rotary hook

bobbin case holder position ........................ 39

8. Checking the input voltage .......................... 40

9. Clearing all memory settings ....................... 40

STANDARD ADJUSTMENTS

.... 34

..... 38

Chapter 8 DEVICES ................................... 41

1. Needle thread presser .................................. 41

2. Beam sensor-type needle thread

breakage detecor .......................................... 41

3. Two-stage thread tension mechanism ..... 42

4. Stepping foot control mechanism .............. 42

5. Needle cooler .................................................. 43

6. Installing the bottom plunger ....................... 43

7. Jig pattern sensor ........................................... 44

8. Sub clamp (BAS-370E, 375E only) ........... 45

Chapter 9

1. Rotary hook ...................................................... 47

2. Eye guard ......................................................... 47

3. Checking the needle ...................................... 48

CLEANING

AND INSPECTION

... 47

Chapter 10 DIP SWITCH ......................... 49

1. Panel DIP switch functions .......................... 49

2. DIP switches inside the control box .......... 50

Chapter 11

CHANGING SPECIAL FUNCTIONS

AND THE MEMORY SWITCHES

USING

..... 52

Chapter 12 ERROR CODE..................... 57

Chapter 13 TROUBLESHOOTING ... 59

OPERATION FLOW CHART ................. 61

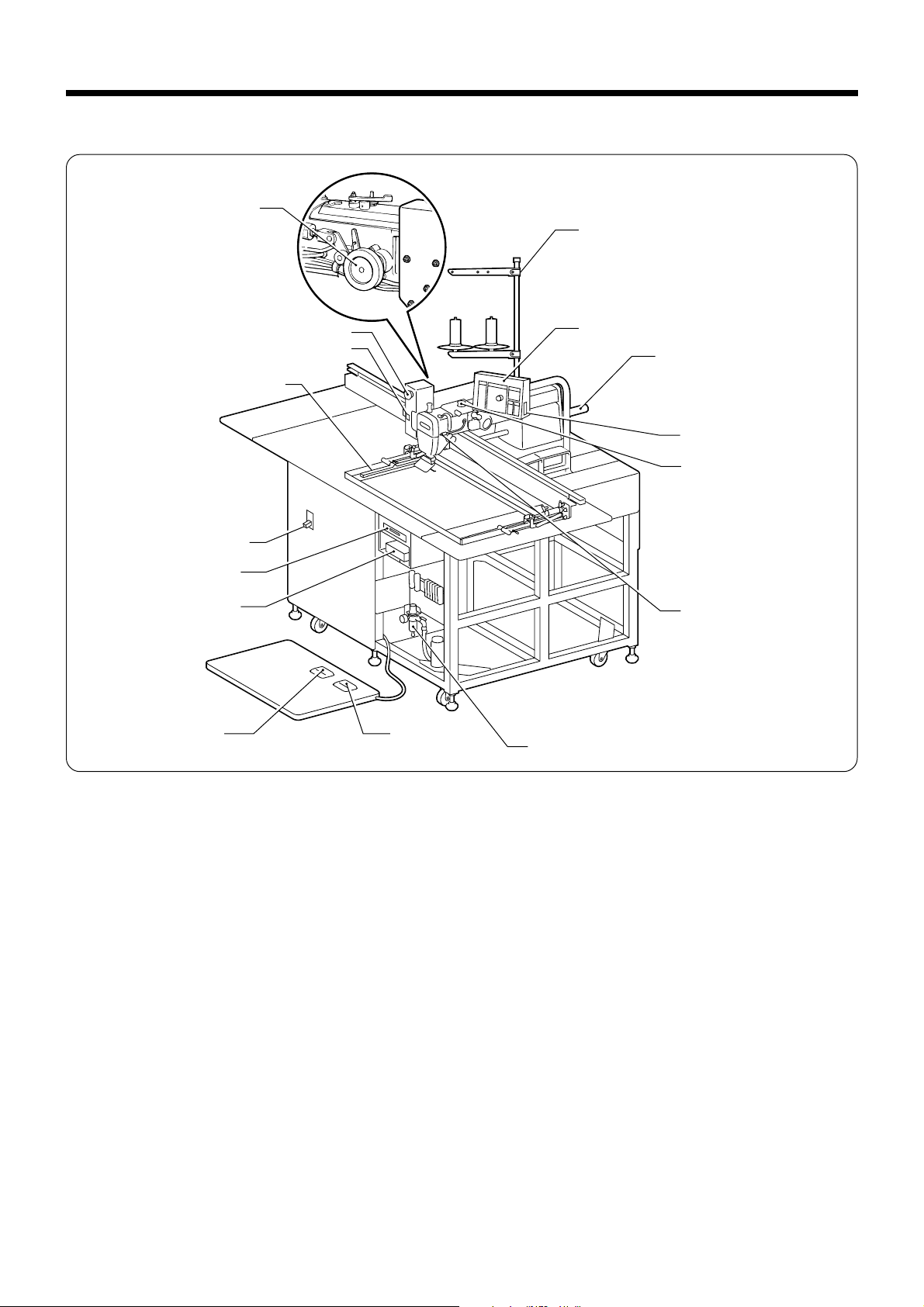

Chapter 1 NAME OF MAJOR PARTS

Chapter 1 NAME OF MAJOR PARTS

Hand Pully

Spool stand

Emergency stop switch

Reset switch

Work clamp

Power switch

Floppy disk drive

Programmer

Work clamp lift switch Start switch

Operation panel

Arm motor cover

Dip sw

Bobbin winder

Beam sensor-type

needle thread breakage

detector

Integrater

1

BAS-364E, 366E, 370E, 375E

Chapter 2 SPECIFICATIONS

Chapter 2 SPECIFICATIONS

Stitch type

Sewing machine

Rotary hook

Needle

Stitch length

Max. sewing

speed

Max. pattern size

Max. number of stitches

Work clamp lift stroke

Intermittent lift stroke

Test function

intermittent feed mode

continuous feed mode

(X - Y)

Single needle, lock stitch

Lock stitch, double rotary hook, long arm machine

Double rotary hook

DP✕17, MR

0.05 - 12.7 mm

2,000 rpm (Max. stitch length 3 mm)

3,200 rpm (Max. stitch length 3 mm)

420 ✕ 400 mm ........... (BAS-364E)

650 ✕ 400 mm ........... (BAS-366E)

800 ✕ 400 mm ........... (BAS-370E)

1,200 ✕ 400 mm ........ (BAS-375E)

20,000 stitches per pattern

Max. 50 mm

16 mm

Operation test function provided for use with low speed drive

Safety devices

Machine dimensions

Data storage method

Power supply

Motor

Air pressure

Weights

Automatic stop function for activation in the event of misoperation realized

with intermediate stop function and safety circuits

W. 1,624 mm D. 1,100mm H. 1,868mm ...... (BAS-364E)

1,624mm 1,557mm 1,868mm ...... (BAS-366E)

1,625mm 1,820mm 1,868mm ...... (BAS-370E)

1,625mm 2,620mm 1,868mm ...... (BAS-375E)

3.5 - floppy disc 2HD/ 1.44 MB, 2DD

Three phase 220V, 380V, 400V 1KVA

AC Servo motor 750W

0.5 MPa 1.8 l/ min

BAS-364E

400kg

BAS-366E BAS-375E

BAS-370E

600kg

BAS-364E, 366E, 370E, 375E

2

Chapter 3 INSTALLATION

Chapter 3 INSTALLATION

CAUTION

Machine installation should only be carried out

by a qualified technician.

Contact your Brother dealer or a qualified

electrician for any electrical work that may need

to be done.

The sewing machine head weighs more than

65 kg. The installation should be carried out by

two or more people.

Do not connect the power cord until installation

is complete, otherwise the machine may operate

if the foot switch is depressed by mistake, which

could result in injury.

Be sure to connect the ground. If the ground

connection is not secure, you run the risk of

receiving a serious electric shock.

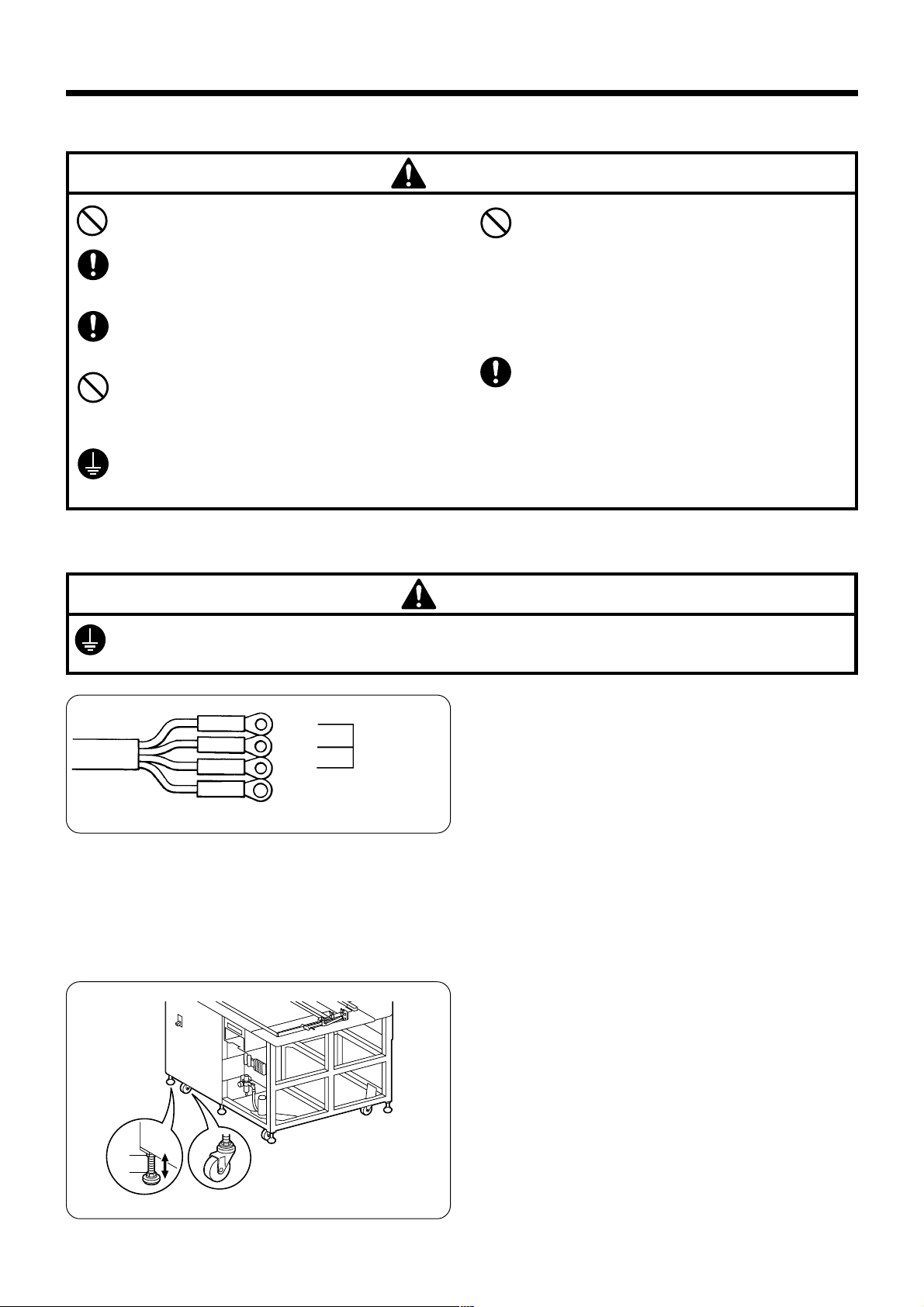

1. Connecting the ground wire

DANGER

Be sure to connect the gound. If the ground connection is not secure, you run the risk of receiving a serious

electric shock.

Be sure to wear protective goggles and gloves

when handling the lubricating oil and grease,

so that they do not get into your eyes or onto

your skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the

grease under any circumstances, as they can

cause vomiting and diarrhoea.

Keep the oil out of the reach of children.

Avoid setting up the sewing machine near

sources of strong electrical noise such as

highfrequency welding equipment.

If this precaution is not taken, incorrect machine

operation may result.

Connection method for 3-phase power supply

Red

White

Black

Green/Yellow

....... Connect to ground

3-phase

power supply

2. Positioning

Note

●

Disconnect the power supply from the special socket afrer install has been completed.

●

Be sure to connect the ground. If it is not connected, damage to the machine, incorrect operation and electric

shocks may result.

Decide the position for the sewing machine. Loosen nuts

of six level adjusters q. Lower the level adjusters and

secure them with nuts w. Turning the level adjuster

counterclockwise will raise its height and turning it

clockwise will lower it.

Note

If the level adjusters are not secured properly, the

w

q

machine may move during operation, which could

result in injury or damage.

3

BAS-364E, 366E, 370E, 375E

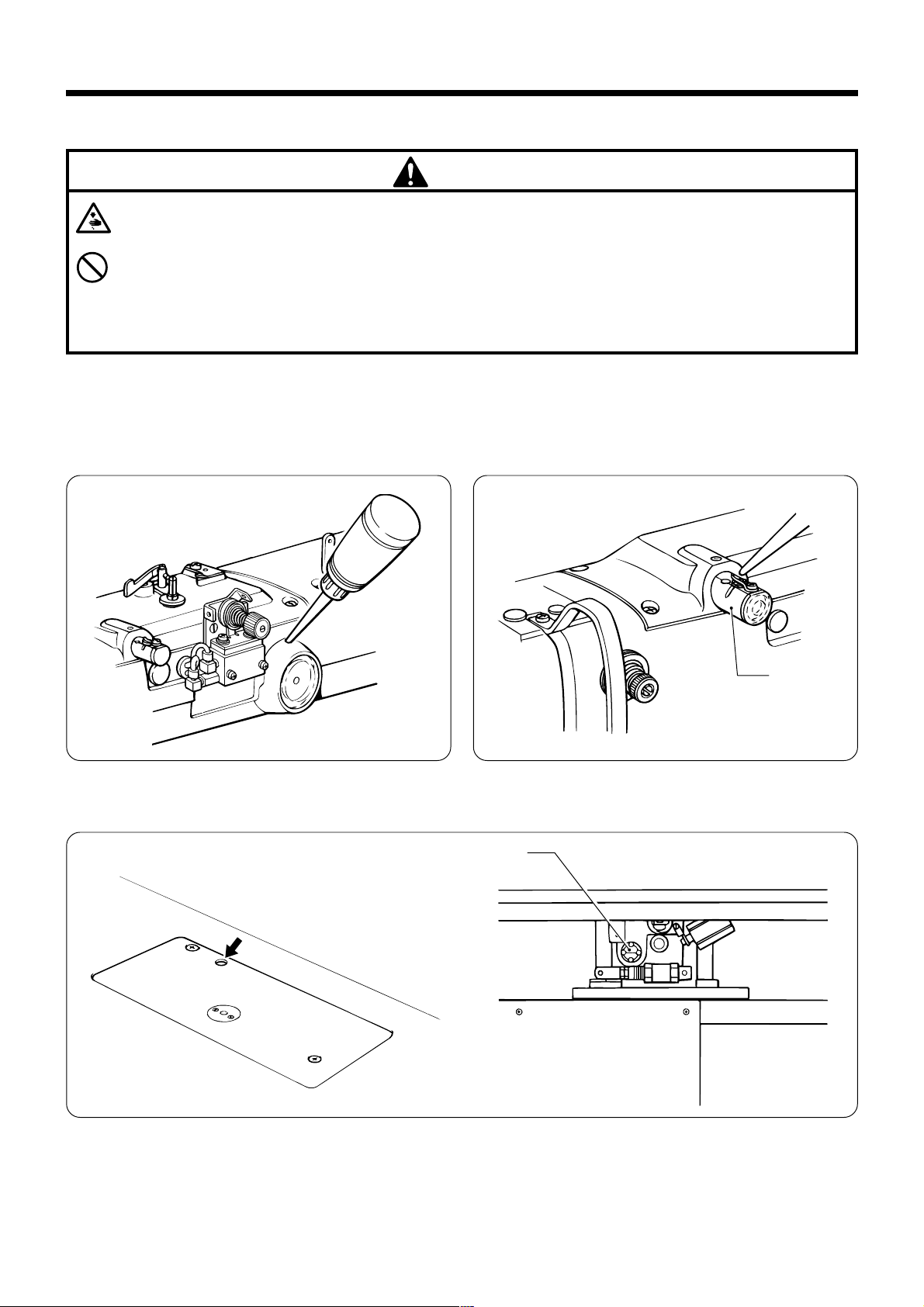

3. Installing the needle plates

* For BAS-370E, 375E

r

u

r

i

t

w

Chapter 3 INSTALLATION

!0oi

r

y

q

e

* For BAS-364E, 366E

!1

q

w

1. Loosen the bolts q, and then pull the needle plate support bases w to the outside.

2. Secure the needle plate support bases w by tightening the bolts q and the bolts e.

3. Install the needle plate support brackets r to the needle plate support bases w by tightening the bolts t from

below.

* For the BAS-366E and BAS-375E, install the needle plate support brackets y to the needle plate support brackets

r with the bolts u.

4. Place the screw holes in the left needle plate i, center needle plate o and right needle plate !0 on top of the

needle plate support hases w so that the screw holes are aligned, and then secure them by tightening the screws.

* For the BAS-364E, install the center needle plate !1 only.

e

BAS-364E, 366E, 370E, 375E

4

Chapter 3 INSTALLATION

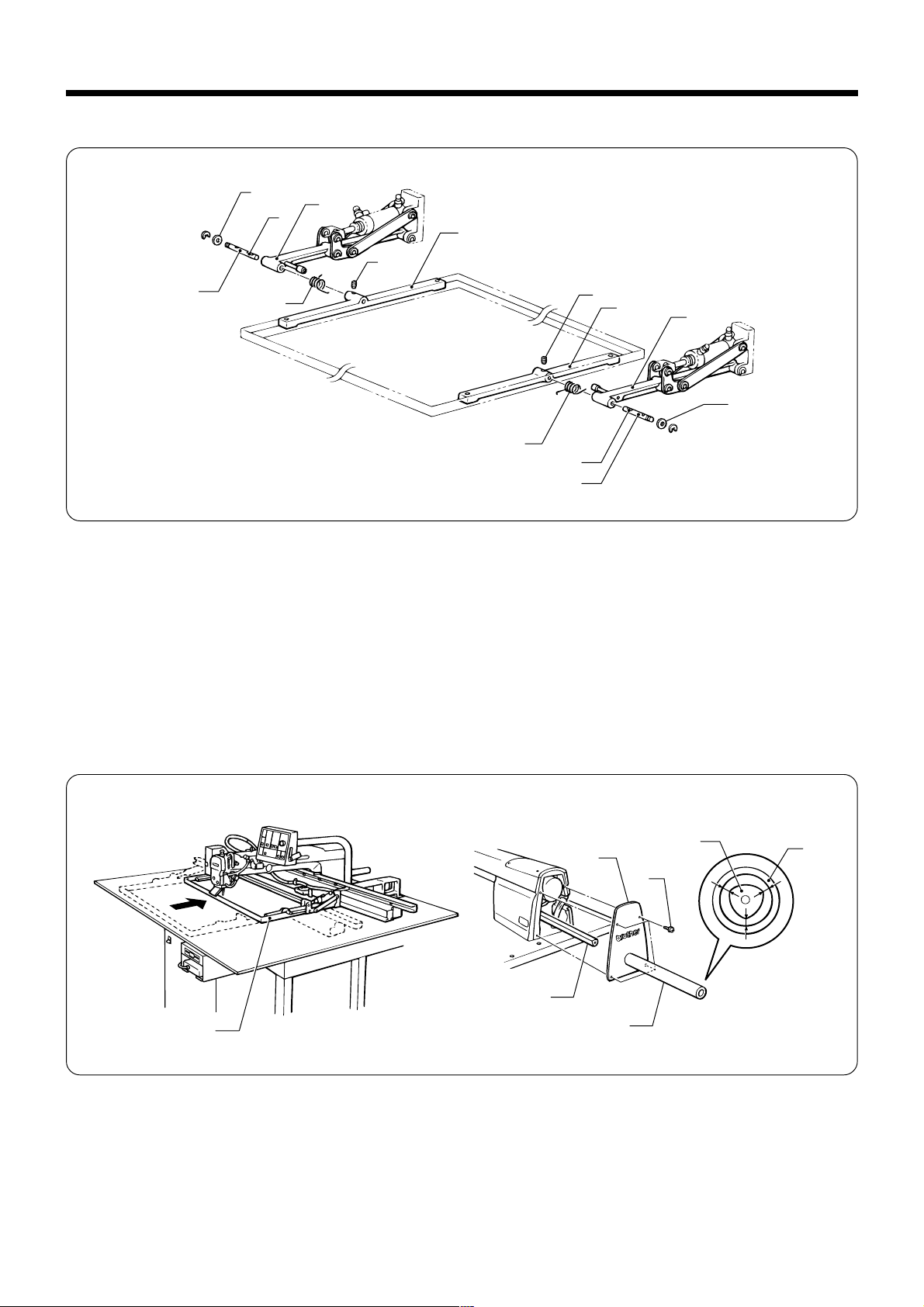

4. Installing the work clamp hinge

y

t

1. Clamp hinge spring (R) e and hinge spring (L) r with the work clamp arm q and work clamp hinge w.

2. After placing the thrust washer y onto Y pulley shaft (A) t, insert Y pulley shaft (A) t into the work clamp arm q

and work clamp hinge w.

Note

Insert Y pulley shaft (A) t into the hole of the work clamp hinge w so that the screw stop u is facing upward.

3. Secure the work clamp hinge w and Y pulley shaft (A) t with the set screw i.

Note

Make sure that the set screw i goes into the screw stop u of Y pulley shaft (A) t.

u

r

q

i

w

e

u

t

i

w

q

y

5. Installing the arm motor cover

e

t

w

q

1. Move the feed mechanism q manually until it is as far into the machine as it will go.

(The ball spline w should be extended fully toward the front when looking from behind the arm.)

2. Aligh the arm motor cover e with the rear of the arm so that there is even clearance between the tube section r

and the ball spline w, and then secure with the accessory screws t.

Note

If noise is heard from the tubular section r of the arm motor cover e while the machine is operating, adjust the

installation position of the arm motor cover e according to the procedure in step 2. above.

r

w

r

5

BAS-364E, 366E, 370E, 375E

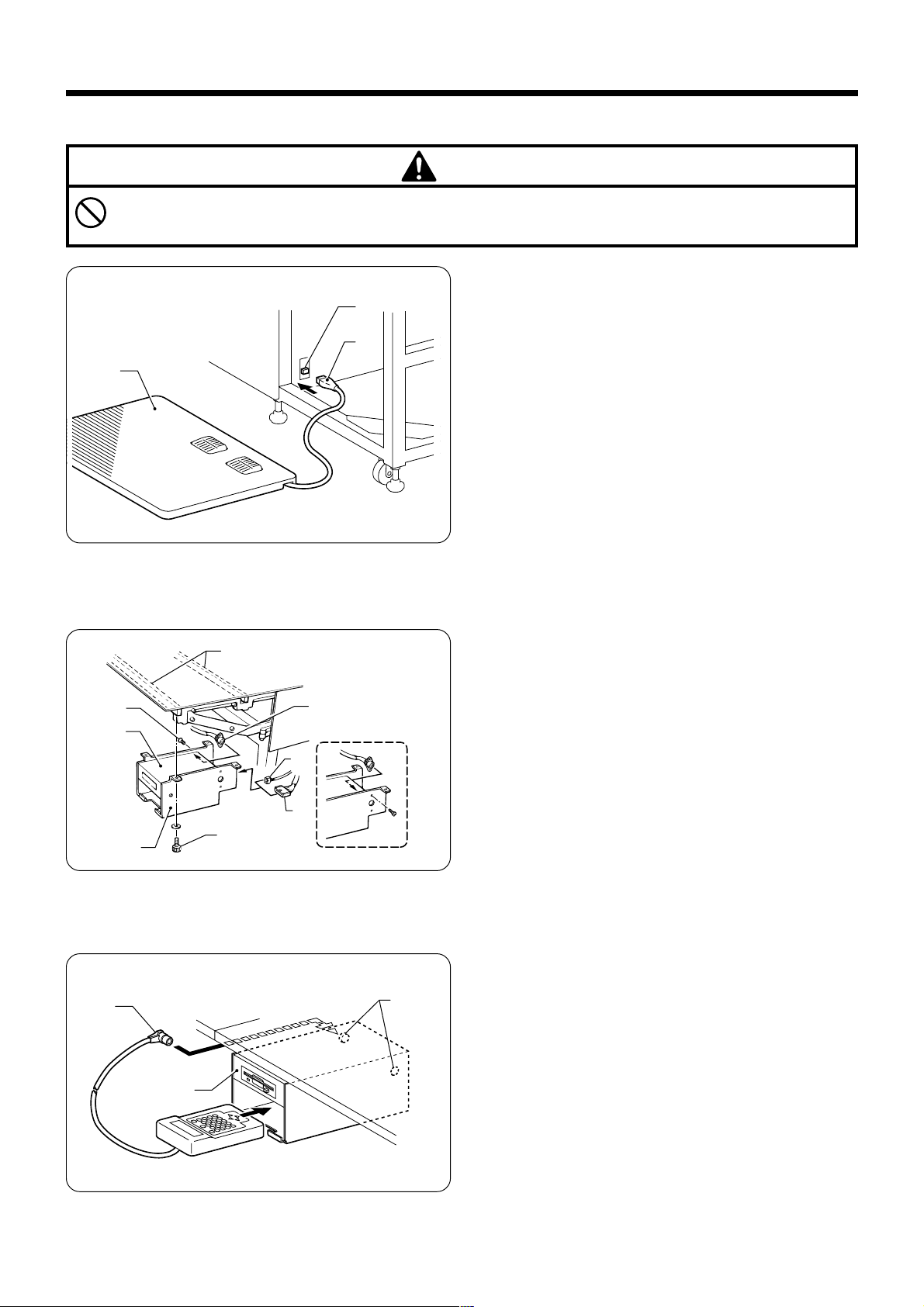

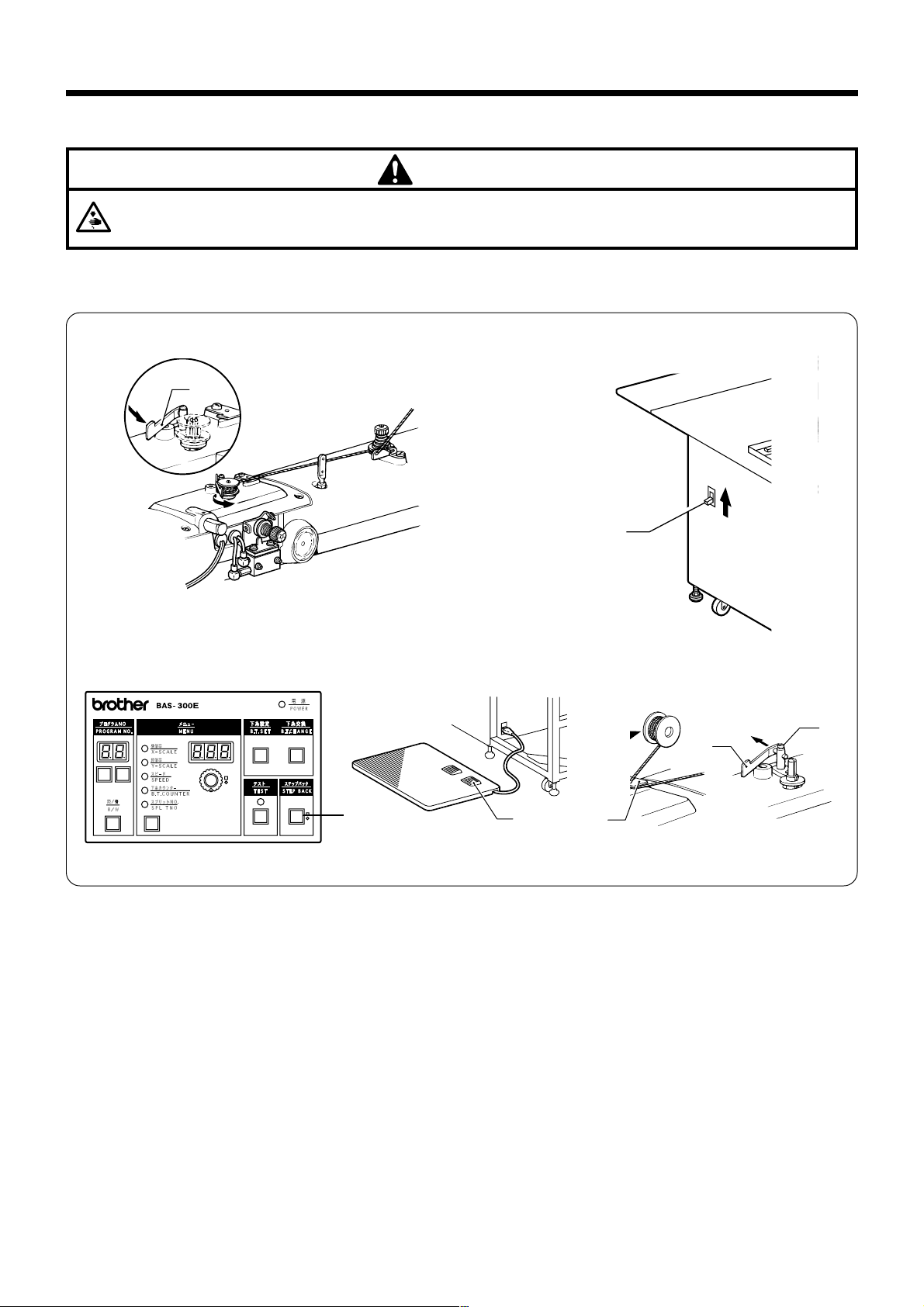

6. Installing the foot switch

CAUTION

Do not connect the power cord until installation si compleate, otherwise the machine may operate if the foot

switch is depressed by mistake, which could result in injury.

q

e

w

Chapter 3 INSTALLATION

Be sure to attach the connector e of the foot switch w to

the connector q whose cord comes from the center of

the front cover at the bottom of the machine.

7. Installing the programmer box

1. Attach the programmer box q to the needle plate

support w using the screws.

2. Be sure to attach the two connectors r and t to the

respective receptacles on the rear of the floppy disk

drive y.

3. Attach the connector u to the side of the programmer

box q using the two screws i.

i

y

w

u

r

t

e

q

8. Installing the programmer

1. Insert the cord q of the programmer into the connector

w below the needle plate.

q

w

2. The programmer can be placed inside the box e.

e

BAS-364E, 366E, 370E, 375E

6

Chapter 3 INSTALLATION

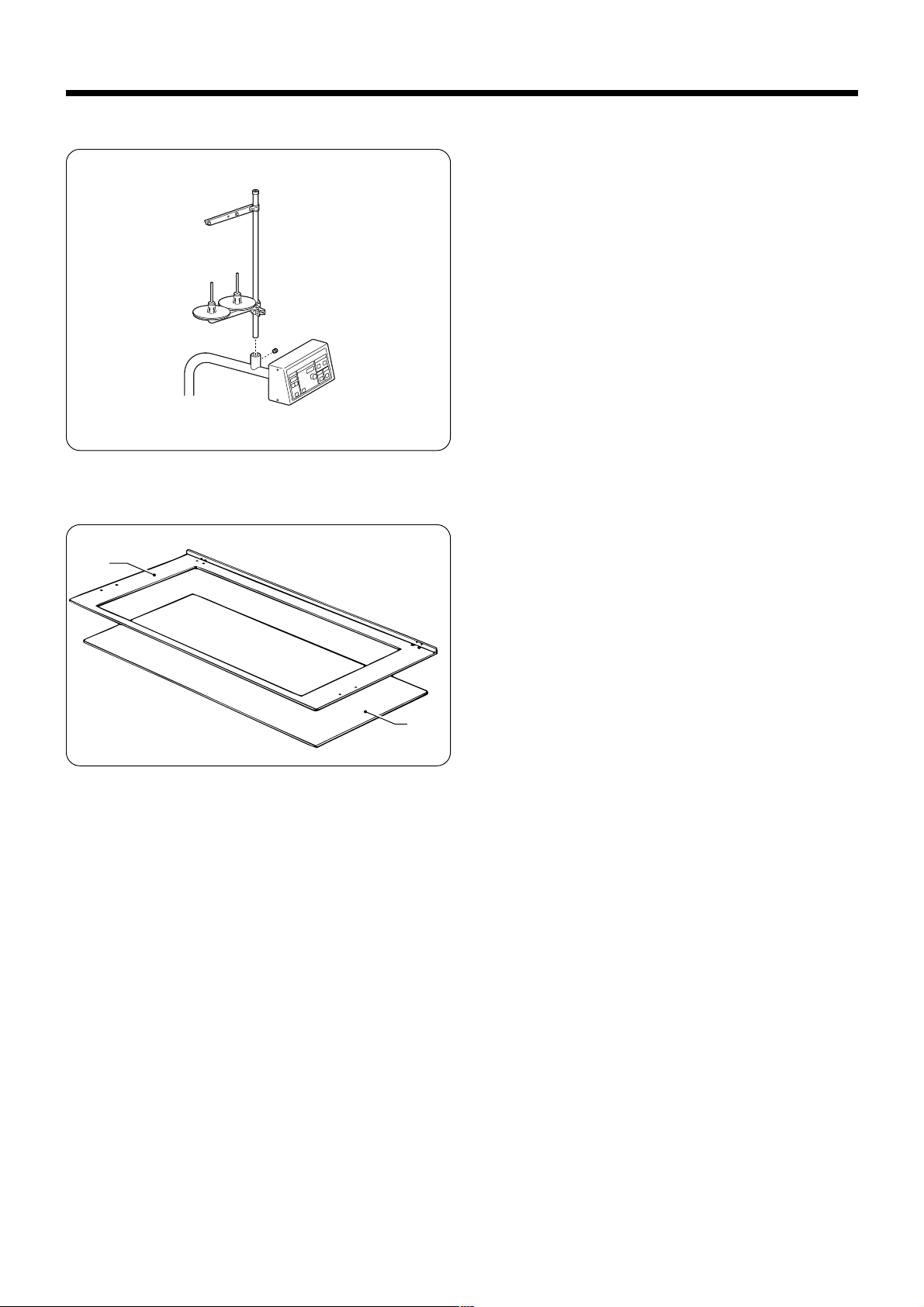

9. Installing the spool stand

10. Preparation of cassette

Install the spool stand to the support of the panel.

w

When not using the presser plate lower q, put the teflon

tape on the rear of the cassette w.

Note

If tape is not attached to the rear of the cassette, the

top of the needle plate will become dirty, which could

cause the material to become dirty.

q

7

BAS-364E, 366E, 370E, 375E

Chapter 3 INSTALLATION

11. Lubrication

CAUTION

Turn off the power switch before starting any cleaning work, otherwise the machine may operated if the foot

switch is depressed by mistake, which could result in injury.

Be sure to wear protective goggles and gloves when handling the lubricating oil and grease, so that they do

not get into your eyes or onto your skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the grease under any circumstances, as they can cause vomiting

and diarrhoea.

Keep the oil out of the reach of children.

Note

●

Fill the machine with oil when the oil level is down to about one-third full in the oil sight glass. If oil is not added

and the oil drops below this level, there is the danger that the machine may seize during operation.

●

Be sure to let the machine operate for a while after adding the oil.

●

Be sure to use Brother-specified machine oil (Nisseki Sewing Lub. 10).

1. Fill the oil tank with sewing machine oil.

A

q

2. Fill the cooling tank q with silicon oil.

B

3. Once or twice a week, fill the rotary hook lubrication tank B with machine oil from lubrication oil hole A until the tank

is approximately two-thirds full. If more oil than this is added, oil may leak from the rotary hook.

BAS-364E, 366E, 370E, 375E

8

Chapter 3 INSTALLATION

12. Draining oil

q

Remove and empty the waste oil tank q whenever it is

full.

The waste oil tank q is underneath the front right leg.

9

BAS-364E, 366E, 370E, 375E

Chapter 3 INSTALLATION

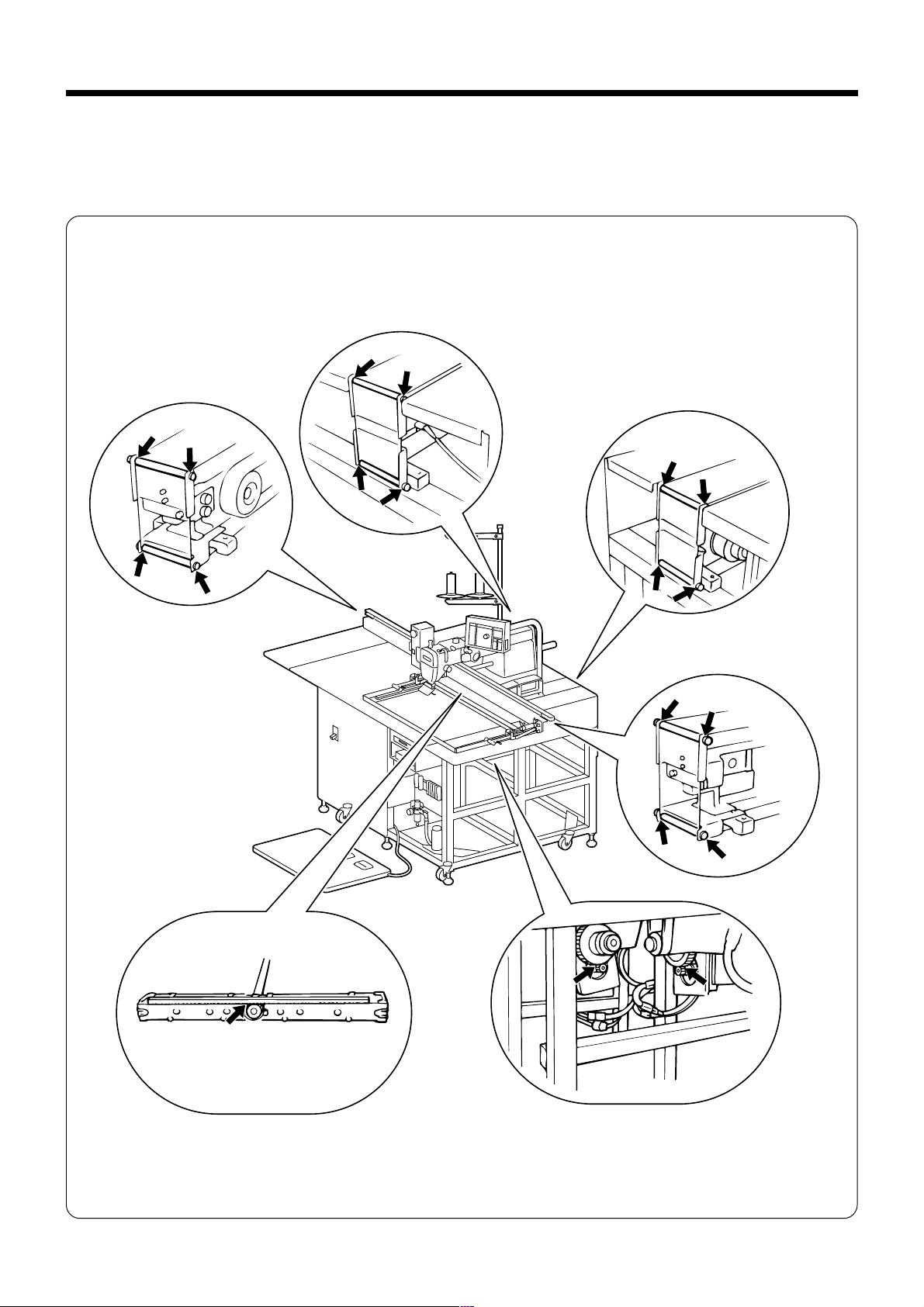

13. Applying grease

If the grease has run out, apply more grease in the places indicated by the arrows below.

Note

If you continue to operate the machine without any grease, it will cause abnormal noise and malfunctions to occur.

BAS-364E, 366E, 370E, 375E

10

Chapter 3 INSTALLATION

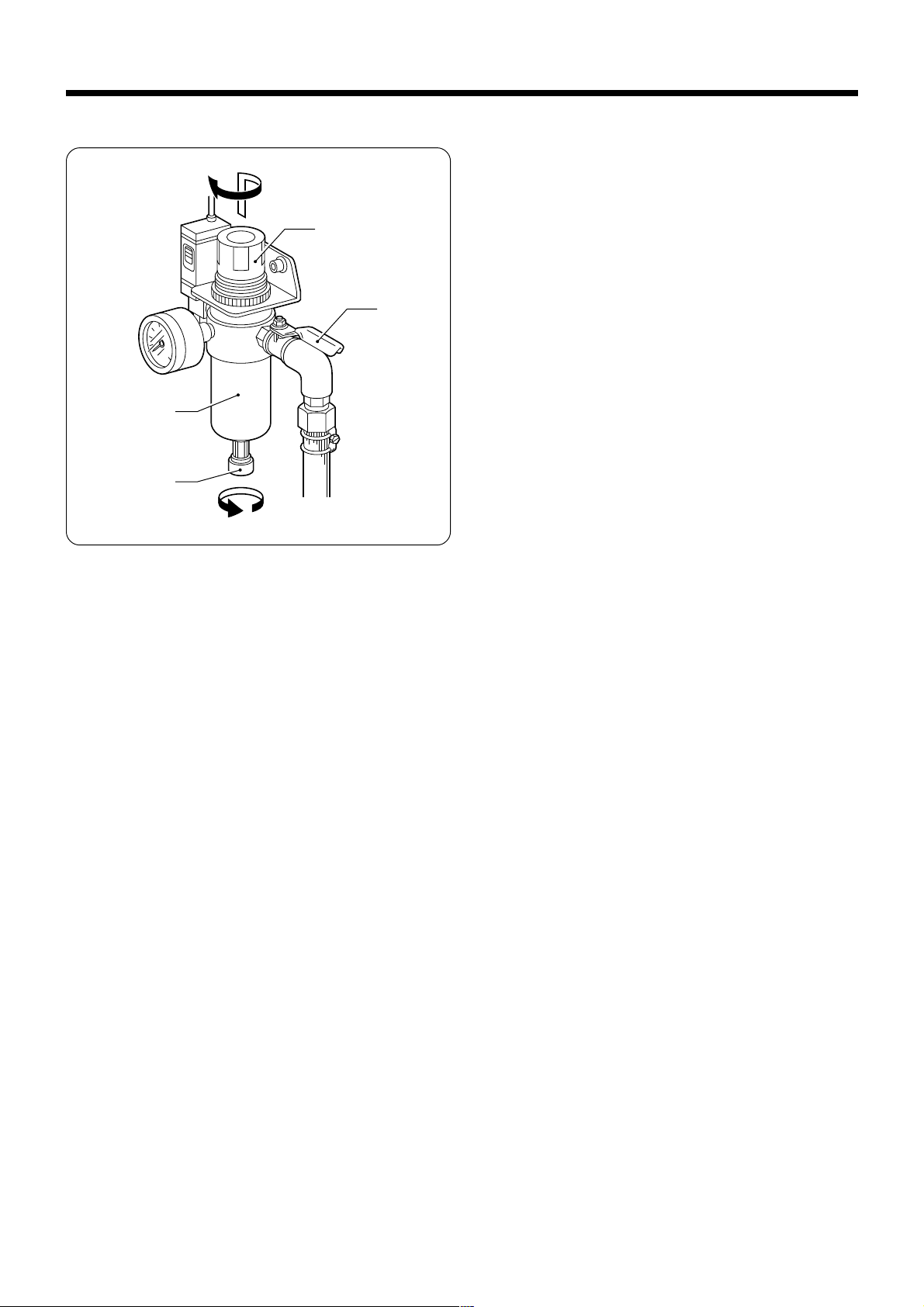

14. Adjusting the air pressure

1. Air pressure should be 0.5 MPa.

w

2. If water stands in the bottle of the integrator q, turn

r

q

e

Note

The air pressure can be adjusted by pulling up and

turning the control knob w on the integrator q.

After adjustment is complete, push the control knob w

downward to lock it.

the drain cock e in the direction indicated by an arrow

to drain the water.

Open the air cock r slowly.

11

BAS-364E, 366E, 370E, 375E

Chapter 4 CORRECT OPERATION

Chapter 4 CORRECT OPERATION

1. Turning the pulley by hand

CAUTION

If the power switch and air need to be left on when carrying out some adjustment, be extremely careful to

observe all safety precautions.

After pressing the hand pulley q in, it can then be turned

by hand. To return the hand pulley q, pull the lever w

w

r

e

q

toward you.

* Furthermore, the hand pulley q will automatically return

to its original position at the sewing start and when the

work clamp is raised and lowered.

Note

Do not touch the hand pulley q, lever w, work clamp

lifter arm e or cylinder r while the machine is

operating and when the work clamp is being raised

and lowered, otherwise injury may result.

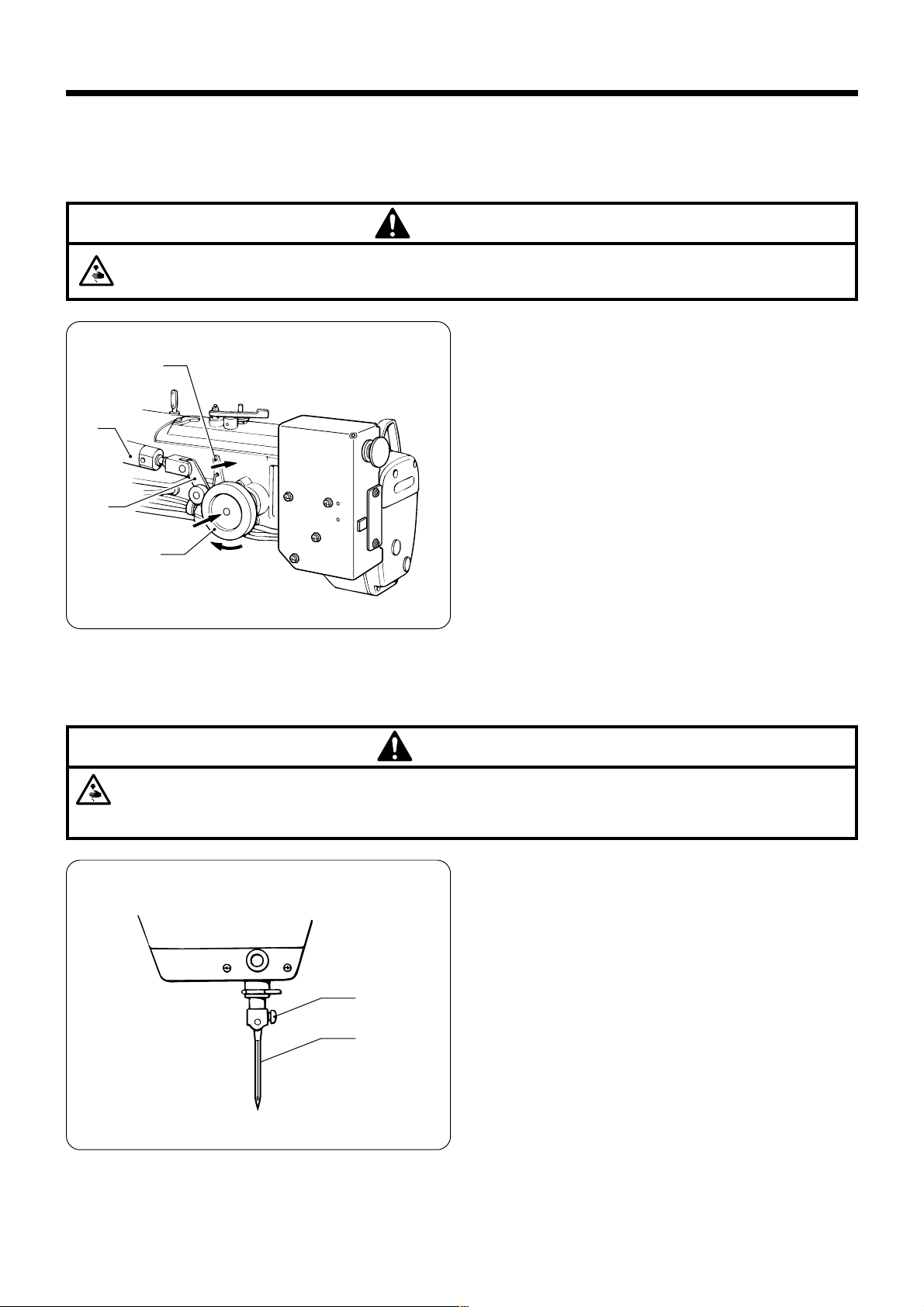

2. Installing the needle

Turn off the power switch at the following times, otherwise the machine may operate if the start switch is

pressed by mistake, which could result in injury.

●

When replacing the needle

q

w

CAUTION

Loosen set screw q. Fully insert the needle w with the

groove facing the front, and then retighten set screw q.

Note

●

Always make sure that the needle w is fully inserted

facing the front.

●

If the needle is installed incorrectly, problems such

as needle breakage may occur.

BAS-364E, 366E, 370E, 375E

12

Chapter 4 CORRECT OPERATION

3. Threading the upper thread

CAUTION

If the power switch needs to be left on when carrying out threading, be extremely careful to observe all

safety precautions.

The machine may operate if the foot switch is depressed by mistake, which could result in injury.

(ex. Continuing sewing from a stopping point)

Thread the upper thread as shown in the diagrams below.

<With cotton thread>

0

4

1

3

2

Hole inclination 45˚

<With synthetic thread>

0

4

1

3

2

13

BAS-364E, 366E, 370E, 375E

Chapter 4 CORRECT OPERATION

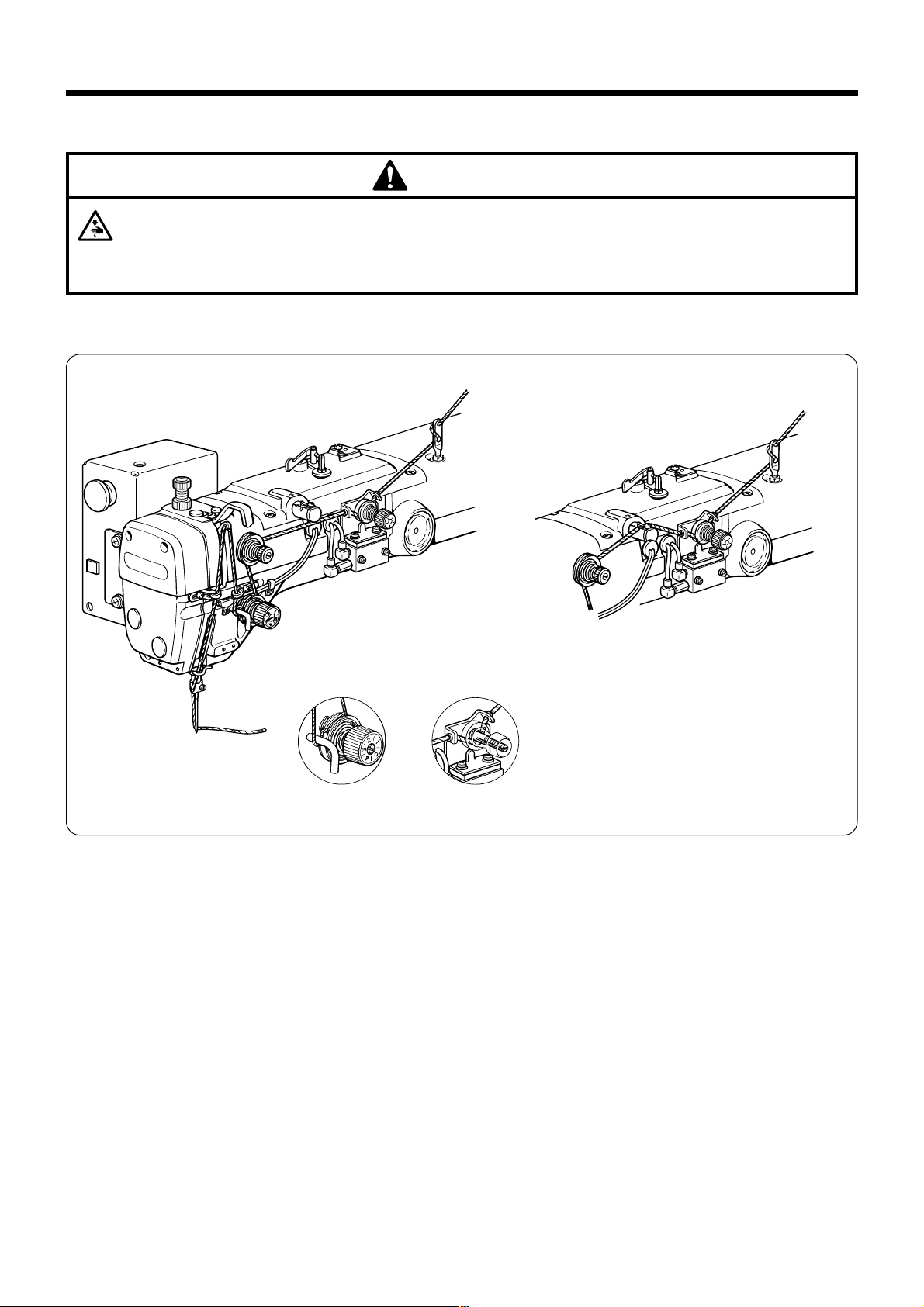

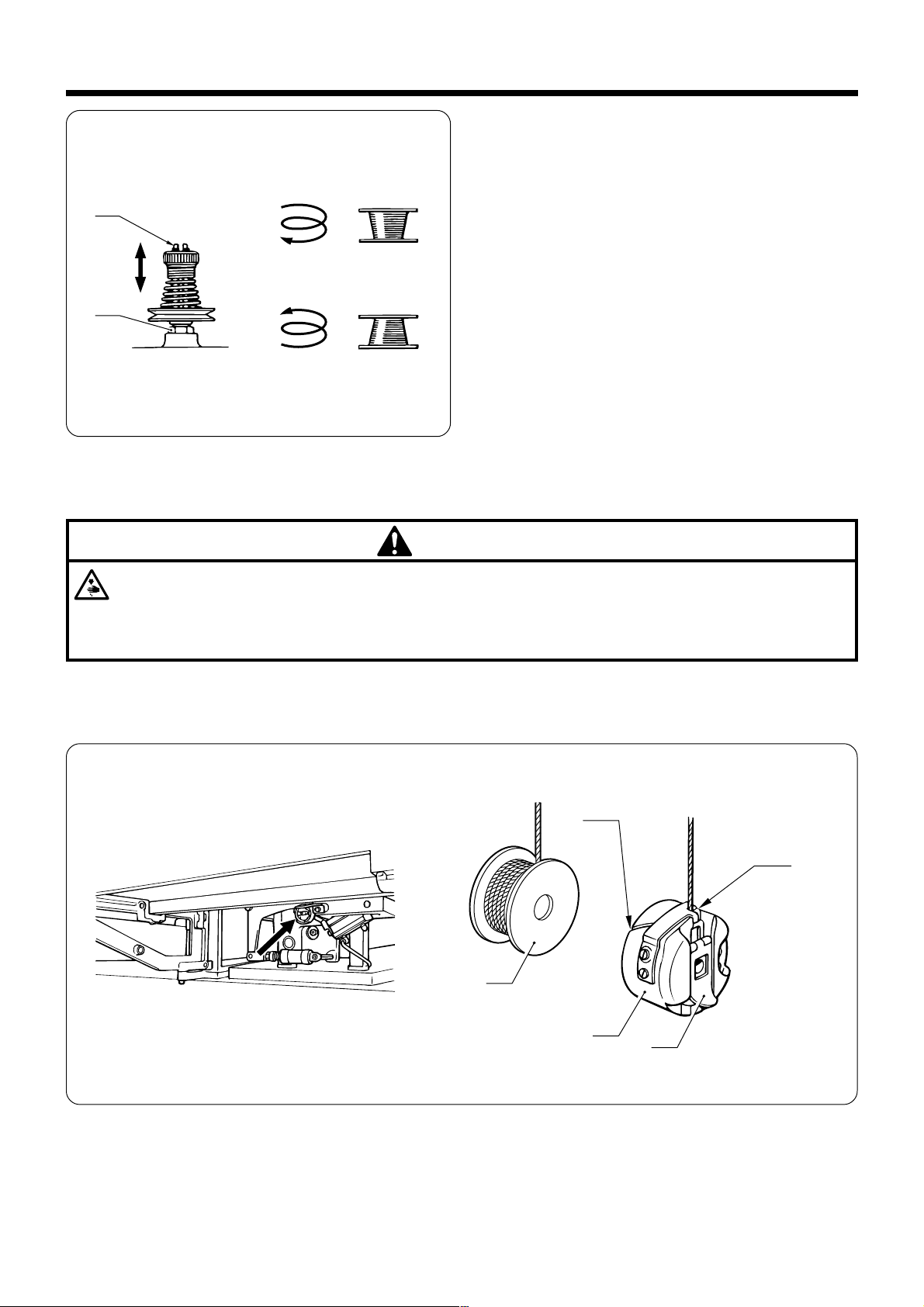

4. Winding the lower thread

CAUTION

Do not touch any of the moving parts or press any objects against the machine while the bobbin is turning,

as this may result in personal injury or damage to the machine.

Note

Do not touch the bobbin or the bobbin holder while the bobbin is turning, otherwise injury may result.

q

O

N

O

F

F

0

4

1

3

2

w

series

y

q

e

r

t

1. Slide the bobbin all the way onto the spindle.

2. Thread the thread as shown in the illustration (in the case of the BAS-364E and 366E, there is no lower thread

guide u), wind the thread around the bobbin several time in the direction shown by the arrow, and then press the

bobbin presser q.

3. Turn the power switch w on.

●

The power indicator on the operation panel will light.

4. Press and hold the STEP BACK switch e on the operation panel, and depress the start switch r to start the

sewing machine.

●

Keep the start switch depressed until the bobbin is fully wound.

●

Release the STEP BACK switch e when the sewing machine starts.

5. The bobbin holder q will automatically return when the bobbin is filled to capacity (approximately 80 - 90 % of the

bobbin diameter).

6. Release the start switch r.

7. Remove the bobbin, and pull the bobbin in the direction of the arrow to cut the thread on the thread cutter t.

8. To wind more thread onto the bobbin, loosen the set screw y and move the bobbin holder q out in the direction of

the arrow.

BAS-364E, 366E, 370E, 375E

14

Chapter 4 CORRECT OPERATION

w

A

q

B

5. Installing the bobbin case

Note

If the bobbin thread is wound unevenly onto the bobbin,

loosen nut q, and turn thread tension stud w to adjust

so that the thread is wound evenly. If the bobbin is

wound as in Fig. A, turn the stud clockwise, if Fig. B,

turn the stud counterclockwise.

CAUTION

If the power switch needs to be left on when carrying out replacing the bobbin, be extremely careful to

observe all safety precautions.

The machine may operate if the foot switch is depressed by mistake, which could result in injury.

(ex. Continuing sewing from a stopping point)

Note

● Do not replace the bobbin or put your hand close to the bobbin case while the machine is operating.

● Do not operate the machine while replacing the bobbin, otherwise injury and damage could result.

r

e

t

q

1. Raise the bobbin case latch w, and then remove the bobbin case q from inside the rotary hook at the front of the

machine head.

2. While the bobbin case latch w is still lowered, remove the bobbin e from the bobbin case q.

3. Place a new bobbin with the bobbin thread already wound on into the bobbin case q, and then pass the thread

through the slot r and pull it out from the thread hole t.

BAS-364E, 366E, 370E, 375E

15

w

Loading...

Loading...