Brother Sewing Machine User Manual

GETTING READY

SEWING BASICS

UTILITY STITCHES

APPENDIX

Operation Manual

Computerized Sewing Machine

Important Safety Instructions

Please read these safety instructions before attempting to use the machine.

This machine is intended for household use.

DANGER - To reduce the risk of electric shock:

1Always unplug the machine from the electrical outlet immediately after using, when cleaning,

when making any user servicing adjustments mentioned in this manual, or if you are leaving the

machine unattended.

WARNING - To reduce the risk of burns, fire, electric shock, or injury to persons.

2Always unplug the machine from the electrical outlet when removing covers, lubricating, or

when making any adjustments mentioned in the instruction manual:

• To unplug the machine, switch the machine to the symbol “O” position to turn it off, then grasp

the plug and pull it out of the electrical outlet. Do not pull on the cord.

• Plug the machine directly into the electrical outlet. Do not use an extension cord.

• Always unplug your machine if the power is cut.

3 Never operate this machine if it has a damaged cord or plug, if it is not working properly, if it has

been dropped or damaged, or water is spilled on the unit. Return the machine to the nearest

authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

While the machine is stored or in use if you notice anything unusual, such as an odor, heat,

discoloration or deformation, stop using the machine immediately and unplug the power cord.

When transporting the sewing machine, be sure to carry it by its handle. Lifting the sewing

machine by any other part may damage the machine or result in the machine falling, which could

cause injuries.

When lifting the sewing machine, be careful not to make any sudden or careless movements,

otherwise you may injure your back or knees.

1

4 Always keep your work area clear:

• Never operate the machine with any air openings blocked. Keep ventilation openings of the

sewing machine and foot control free from the build up of lint, dust, and loose cloth.

• Do not store objects on the foot controller.

• Do not use extension cords. Plug the machine directly into the electrical outlet.

• Never drop or insert any object into any opening.

• Do not operate where aerosol (spray) products are being used or where oxygen is being

administered.

• Do not use the machine near a heat source, such as a stove or iron; otherwise, the machine,

power cord or garment being sewn may ignite, resulting in fire or an electric shock.

• Do not place this sewing machine on an unstable surface, such as an unsteady or slanted table,

otherwise the sewing machine may fall, resulting in injuries.

5 Special care is required when sewing:

• Always pay close attention to the needle. Do not use bent or damaged needles.

• Keep fingers away from all moving parts. Special care is required around the machine needle.

• Switch the sewing machine to the symbol “O” position to turn it off when making any adjustments

in the needle area.

• Do not use a damaged or incorrect needle plate, as it could cause the needle to break.

• Do not push or pull the fabric when sewing, and follow careful instruction when freehand stitching

so that you do not deflect the needle and cause it to break.

6 This machine is not a toy:

• Your close attention is necessary when the machine is used by or near children.

• The plastic bag that this sewing machine was supplied in should be kept out of the reach of

children or disposed of. Never allow children to play with the bag due to the danger of

suffocation.

• Do not use outdoors.

7 For a longer service life:

• When storing this machine, avoid direct sunlight and high humidity locations. Do not use or store

the machine near a space heater, iron, halogen lamp, or other hot objects.

• Use only neutral soaps or detergents to clean the case. Benzene, thinner, and scouring powders

can damage the case and machine, and should never be used.

• Always consult the operation manual when replacing or installing any assemblies, the presser feet,

needle, or other parts to assure correct installation.

2

8 For repair or adjustment:

• If the Light unit (light-emitting diode) is damaged, it must be replaced by authorized dealer.

• In the event a malfunction occurs or adjustment is required, first follow the troubleshooting table

in the back of the operation manual to inspect and adjust the machine yourself. If the problem

persists, please consult your local authorized Brother dealer.

Use this machine only for its intended use as described in this manual.

Use accessories recommended by the manufacturer as contained in this manual.

Save these instructions.

The contents of this manual and specifications of this product are subject to change without notice.

For additional product information, visit our web site at www.brother.com

3

FOR USERS IN THE UK, EIRE, MALTA AND CYPRUS ONLY

IMPORTANT

• In the event of replacing the plug fuse, use a fuse approved by ASTA to BS 1362, i.e. carrying the

mark, rating as marked on plug.

• Always replace the fuse cover. Never use plugs with the fuse cover omitted.

• If the available electrical outlet is not suitable for the plug supplied with this equipment, you

should contact your authorized dealer to obtain the correct lead.

FOR USERS IN AUSTRALIA AND NEW ZEALAND

This sewing machine is not intended to be used by young children, and assistance may be required if

used by a person with a disability.

4

5

—————————————————————————————————————————————————————————

—

Contents

Important Safety Instructions .............................................................................................. 1

Contents .............................................................................................................................. 6

Introduction ........................................................................................................................ 8

Names of Machine Parts and Their Functions ..................................................................... 8

Machine ............................................................................................................................................................ 8

Needle and presser foot section ......................................................................................................................9

Operation buttons ........................................................................................................................................... 10

Operation panel ..............................................................................................................................................10

Flat bed attachment ....................................................................................................................................... 10

Accessories ........................................................................................................................ 11

Included accessories ...................................................................................................................................... 11

Optional accessories ...................................................................................................................................... 12

1. GETTING READY ..........................................................................................13

Turning the Machine On/Off ............................................................................................. 13

Power supply precautions .............................................................................................................................. 13

Turning on the machine ................................................................................................................................. 14

Turning off the machine ................................................................................................................................. 14

Preparing for Upper and Lower Threading ........................................................................ 15

Winding the bobbin ........................................................................................................................................ 15

Installing the bobbin ....................................................................................................................................... 18

Threading the upper thread ............................................................................................................................ 20

Threading the needle ..................................................................................................................................... 23

Threading the needle manually (without using the needle threader) .............................................................26

Using the twin needle ..................................................................................................................................... 26

Replacing the Needle ........................................................................................................29

Needle precautions ........................................................................................................................................ 29

Needle types and their uses ........................................................................................................................... 30

Checking the needle ...................................................................................................................................... 31

Replacing the needle ..................................................................................................................................... 31

Replacing the Presser Foot ................................................................................................ 33

Presser foot precautions ................................................................................................................................ 33

Replacing the presser foot ............................................................................................................................. 33

Removing the presser foot holder .................................................................................................................. 34

Using the optional walking foot ...................................................................................................................... 35

Useful Functions ................................................................................................................ 37

Changing the needle stop position ................................................................................................................. 37

Changing the initial needle position ...............................................................................................................38

Sewing Cylindrical or Large Pieces .................................................................................... 39

Stitching cylindrical pieces ............................................................................................................................. 39

Sewing large pieces of fabric ......................................................................................................................... 39

2. SEWING BASICS ...........................................................................................41

Starting to Sew .................................................................................................................. 41

Sewing procedure .......................................................................................................................................... 41

Selecting a stitch ............................................................................................................................................ 42

Adjusting the stitch length and width ..............................................................................................................42

Positioning the fabric ......................................................................................................................................43

Starting to sew ...............................................................................................................................................44

Securing the stitching ..................................................................................................................................... 46

Cutting the thread ...........................................................................................................................................48

Automatically sewing reverse/reinforcement stitches .................................................................................... 48

6

Adjusting the thread tension ........................................................................................................................... 49

Useful Sewing Tips ............................................................................................................ 50

Trial sewing .................................................................................................................................................... 50

Changing the sewing direction ....................................................................................................................... 50

Sewing curves ................................................................................................................................................ 50

Sewing thick fabrics ....................................................................................................................................... 50

Sewing thin fabrics ......................................................................................................................................... 51

Sewing stretch fabrics .................................................................................................................................... 51

Pulling up the bobbin thread .......................................................................................................................... 52

3. UTILITY STITCHES ........................................................................................53

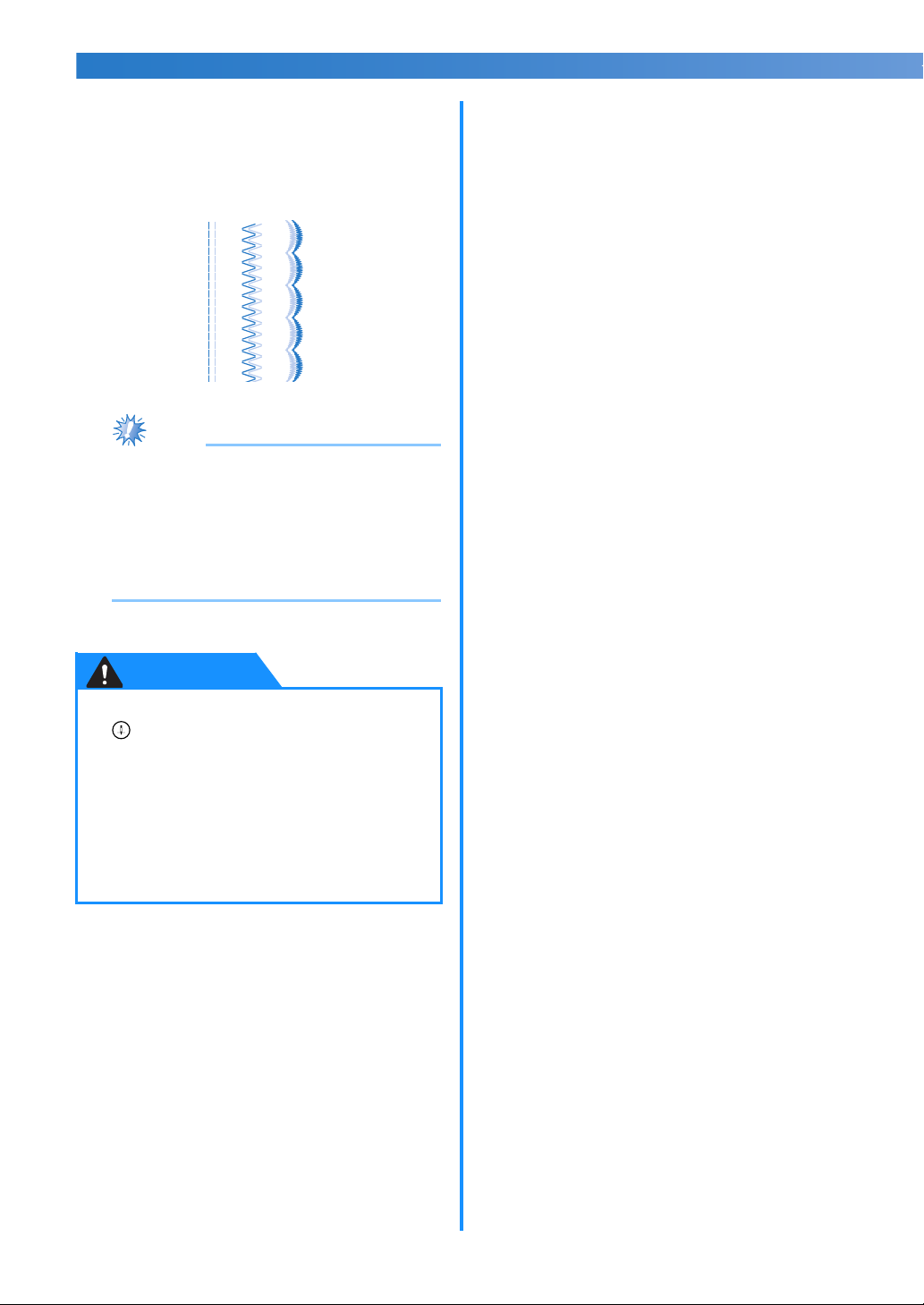

Overcasting ....................................................................................................................... 53

Sewing overcasting stitches using zigzag foot “J” .......................................................................................... 54

Sewing overcasting stitches using overcasting foot “G” ................................................................................. 54

Basic Stitching ...................................................................................................................55

Blind Hem Stitching ..........................................................................................................56

Buttonhole Stitching ..........................................................................................................58

Button sewing ................................................................................................................................................. 63

Zipper Insertion .................................................................................................................65

Inserting a centered zipper ............................................................................................................................. 65

Inserting a side zipper .................................................................................................................................... 66

Sewing Stretch Fabrics and Elastic Tape ............................................................................ 69

Stretch stitching .............................................................................................................................................. 69

Elastic attaching ............................................................................................................................................. 69

Appliqué, Patchwork and Quilt Stitching .......................................................................... 71

Appliqué stitching ........................................................................................................................................... 72

Patchwork (crazy quilt) stitching ..................................................................................................................... 73

Piecing ........................................................................................................................................................... 73

Quilting ........................................................................................................................................................... 74

Free-motion quilting ....................................................................................................................................... 75

Reinforcement Stitching .................................................................................................... 77

Triple stretch stitching ....................................................................................................................................77

Bar tack stitching ............................................................................................................................................78

Decorative stitching .......................................................................................................... 80

Fagoting ......................................................................................................................................................... 81

Scallop stitching ............................................................................................................................................. 82

Smocking ....................................................................................................................................................... 82

Shell tuck stitching ......................................................................................................................................... 83

Joining ............................................................................................................................................................ 83

Heirloom stitching ........................................................................................................................................... 84

Using the side cutter (optional) ...................................................................................................................... 86

4. APPENDIX .....................................................................................................89

Stitch Settings .................................................................................................................... 89

Utility stitches ................................................................................................................................................. 89

Maintenance ...................................................................................................................... 95

Cleaning the machine surface ........................................................................................................................ 95

Cleaning the race ........................................................................................................................................... 95

Removing the needle plate ............................................................................................................................ 96

Troubleshooting ................................................................................................................97

Error Messages ................................................................................................................ 101

Operation Beep ............................................................................................................... 102

Canceling the operation beep ...................................................................................................................... 102

Index ............................................................................................................................... 103

7

Introduction

Thank you for choosing this product.

Before using this sewing machine, carefully read “Important Safety Instructions”, and then study this manual for

the correct operation of the various functions.

In addition, after you have finished reading this manual, store it where it can quickly be accessed for future

reference.

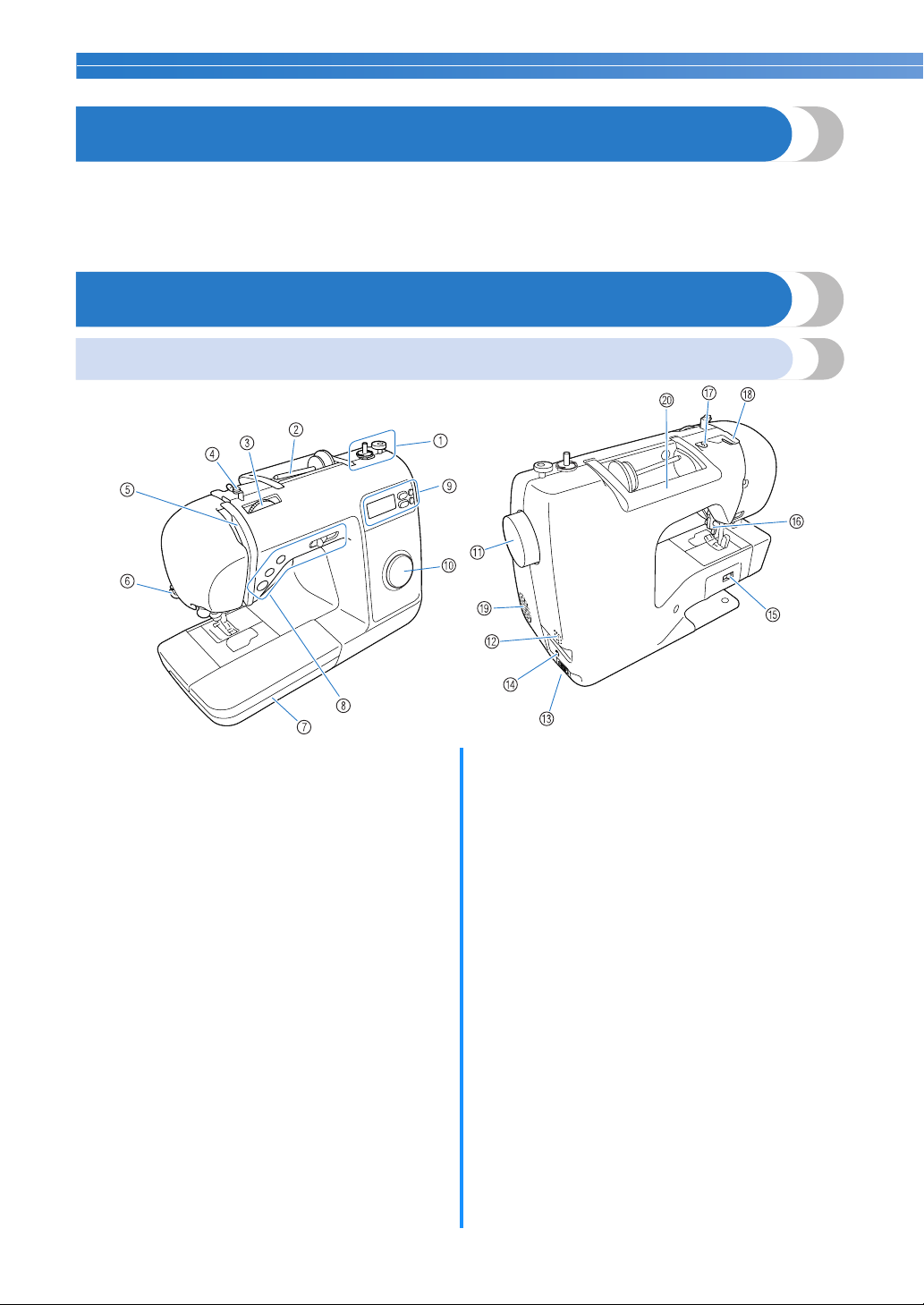

Names of Machine Parts and Their Functions

Machine

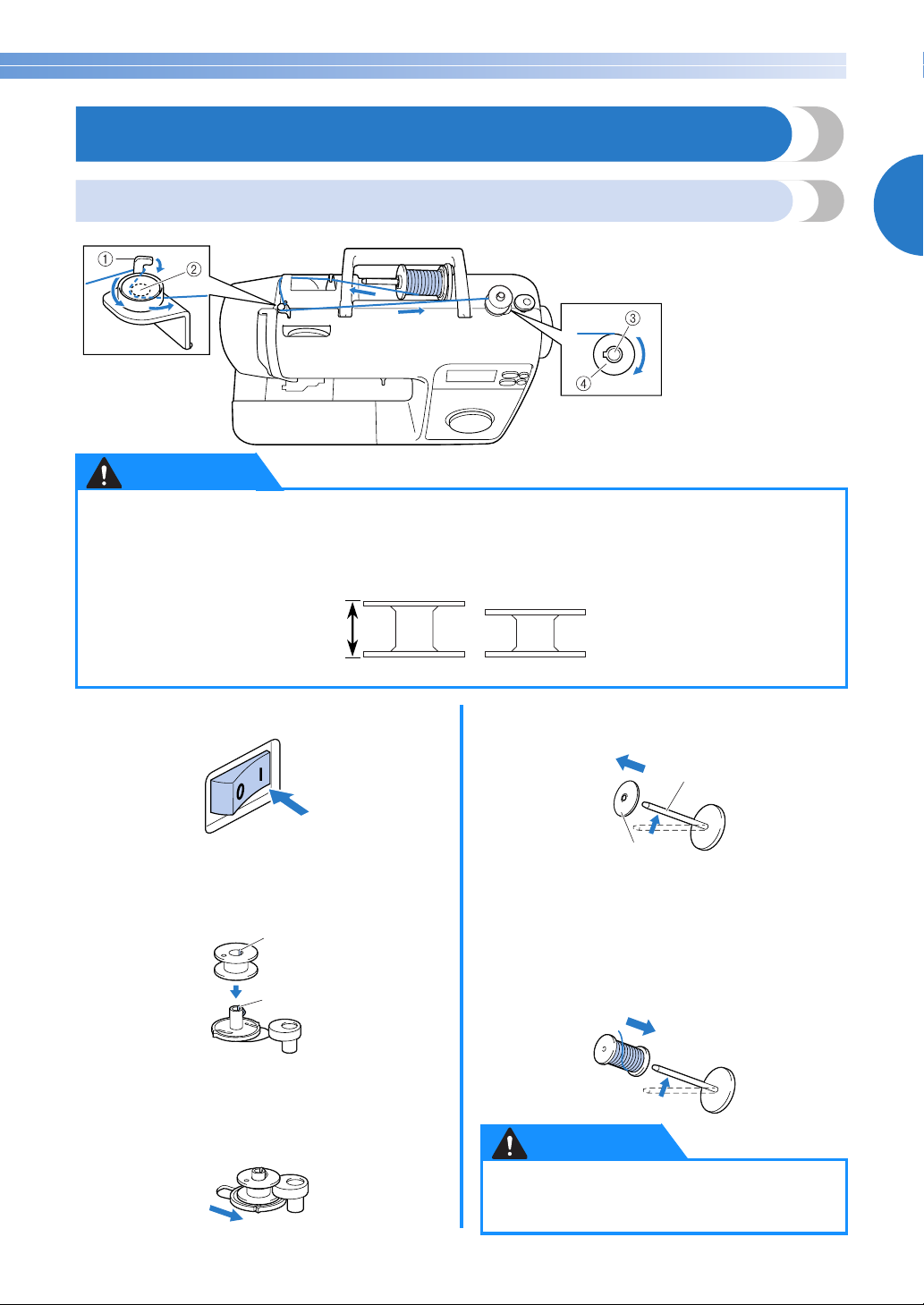

a Bobbin winder (page 15)

Use the bobbin winder when winding the bobbin.

b Spool pin (page 15, 20)

Place a spool of thread on the spool pin.

c Thread tension dial (page 49)

Use the thread tension dial to adjust the tension of the

upper thread.

d Bobbin-winding thread guide and pretension disc

(page 15)

Pass the thread under this thread guide and around the

pretension disc when winding the bobbin thread.

e Thread take-up lever (page 23)

Slide the thread into the thread take-up lever from the

right side of slot to the left side of slot.

f Thread cutter (page 48)

Pass the threads through the thread cutter to cut them.

g Flat bed attachment (page 10, 11, 39)

Store presser feet and bobbins in the flat bed

attachment. Remove the flat bed attachment when

sewing cylindrical pieces such as sleeve cuffs.

h Operation buttons and sewing speed controller

(page 10)

Use these buttons and the slide to operate the sewing

machine.

i Operation panel (page 10)

Use to select stitches and various other stitch settings.

j Pattern selection dial (page 42)

Use to select the pattern to sew.

8

k Handwheel

Turn the handwheel toward you to sew one stitch or to

raise or lower the needle.

l Main power switch (page 14)

Use this switch to turn the sewing machine on and off.

m Power supply jack (page 14)

Insert the plug on the power cord into the power supply

jack.

n Foot controller jack (page 45)

Insert the plug on the end of the foot controller cable

into the foot controller jack.

o Feed dog position switch (page 75)

Use this switch to lower the feed dogs.

p Presser foot lever (page 20)

Raise and lower this lever to raise and lower the presser

foot.

q Thread guide (page 16)

Pass the thread under this thread guide when winding

the bobbin thread and threading the machine.

r Thread guide cover (page 16)

Pass the thread under this thread guide when winding

the bobbin thread and threading the machine.

s Air vent

This vent allows the air surrounding the motor to

circulate.

t Handle

Carry the sewing machine by its handle when

transporting the machine.

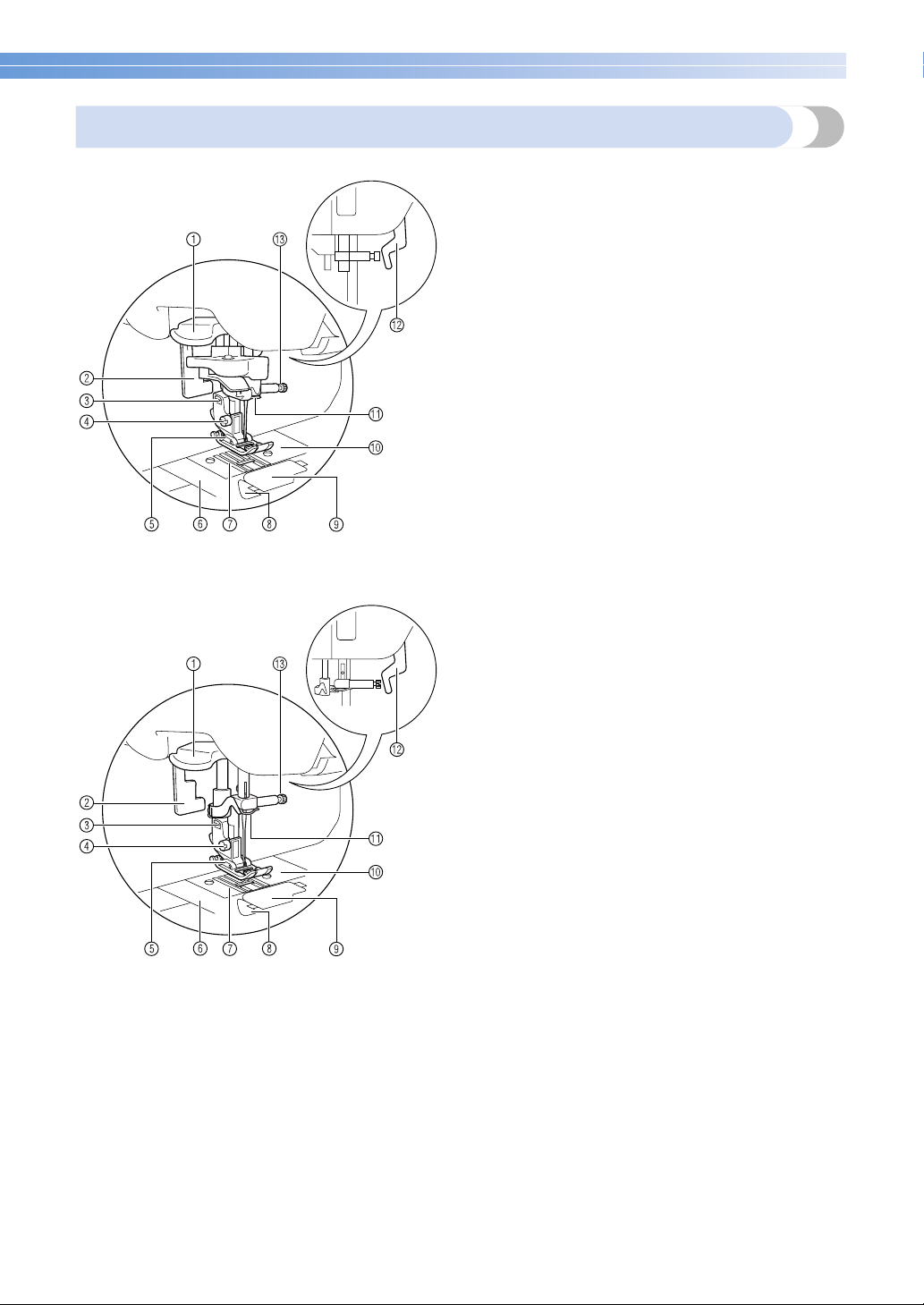

Needle and presser foot section

a Needle threader lever

Use the needle threader to thread the needle.

b Buttonhole lever

Lower the buttonhole lever when sewing buttonholes

and bar tacks.

c Presser foot holder

The presser foot is attached to the presser foot holder.

d Presser foot holder screw

Use the presser foot holder screw to hold the presser

foot holder in place.

e Presser foot

The presser foot applies pressure to the fabric during

sewing. Attach the appropriate presser foot for the

selected stitch.

f Needle plate cover

Remove the needle plate cover to clean the bobbin case

and race.

g Feed dogs

The feed dogs feed the fabric.

h Quick-set bobbin

Begin sewing without pulling up the bobbin thread.

i Bobbin cover

Remove the bobbin cover and then insert the bobbin

into the bobbin case.

j Needle plate

The needle plate is marked with guides to help sew

straight seams.

k Needle bar thread guide

Pass the upper thread through the needle bar thread

guide.

l Presser foot lever

Raise and lower this lever to raise and lower the presser

foot.

m Needle clamp screw

Use the needle clamp screw to hold the needle in place.

9

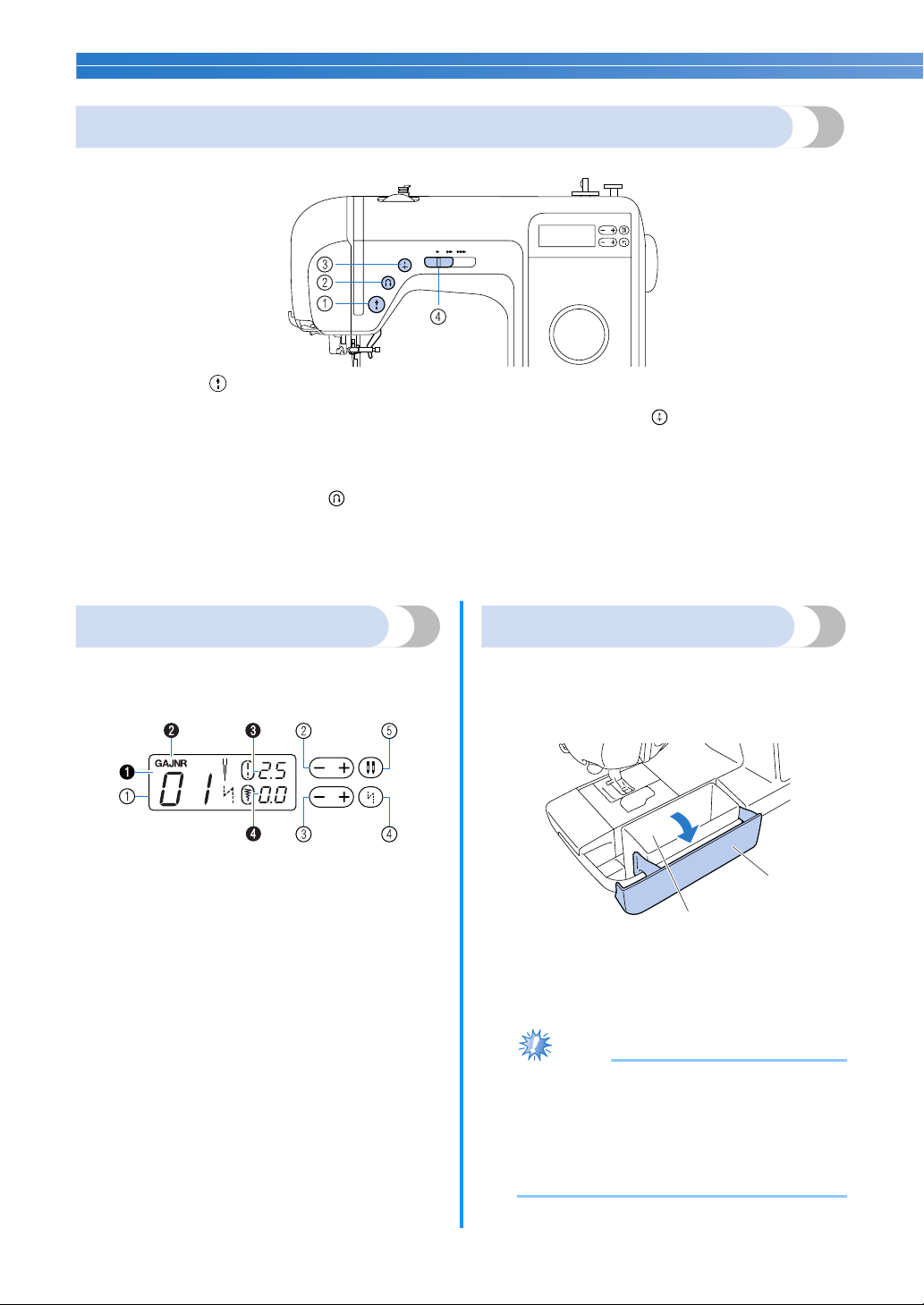

Operation buttons

The operation buttons help you to easily perform various basic sewing machine operations.

a Start/stop button

Press the start/stop button to start or stop sewing. The

machine sews at a low speed at the beginning of sewing

while the button is continuously pressed. When sewing

is stopped, the needle is lowered into the fabric. For

details, refer to “Starting to sew” (page 44).

b Reverse/reinforcement stitch button

Press the reverse/reinforcement stitch button to sew

reverse stitches or reinforcement stitches. Reverse

stitches are sewn by keeping the button pressed down to

sew in the opposite direction. Reinforcement stitches

Operation panel

The operation panel, located on the front of the

sewing machine, allows you to select a stitch and

specify how the stitch will be sewn.

a LCD (liquid crystal display)

The number of the selected stitch (

to be used (

stitch width (mm) (

b Stitch length key (page 42)

Use to adjust the length of the stitch. (Press the “–” side

for a shorter stitch length, or press the “+” side for a

longer stitch length.)

c Stitch width key (page 43)

Use to adjust the width of the stitch. (Press the “–” side

for a more narrow stitch width, or press the “+” side for

a wider stitch width.)

d Automatic reverse/reinforcement stitch key (page 48)

The sewing machine can be set to automatically sew

reverse or reinforcement stitches at the beginning and

end of the stitching.

e Needle mode selection key (single/twin) (page 26)

Press this key to select the twin needle sewing setting.

Each time this key is pressed, the setting switches

between that for single needle sewing and for twin

needle sewing.

2), the stitch length (mm) (3), and the

4) are displayed here.

1), the presser foot

are sewn by sewing 3 to 5 stitches on top of each other.

For details, refer to“Securing the stitching” (page 46).

c Needle position button

Press the needle position button to raise or lower the

needle. Pressing the button twice sews one stitch.

d Sewing speed controller

Slide the sewing speed controller to the left or right to

adjust the sewing speed.

Slide the sewing speed controller to the left to reduce

the sewing speed, or slide the speed controller to the

right to increase the sewing speed.

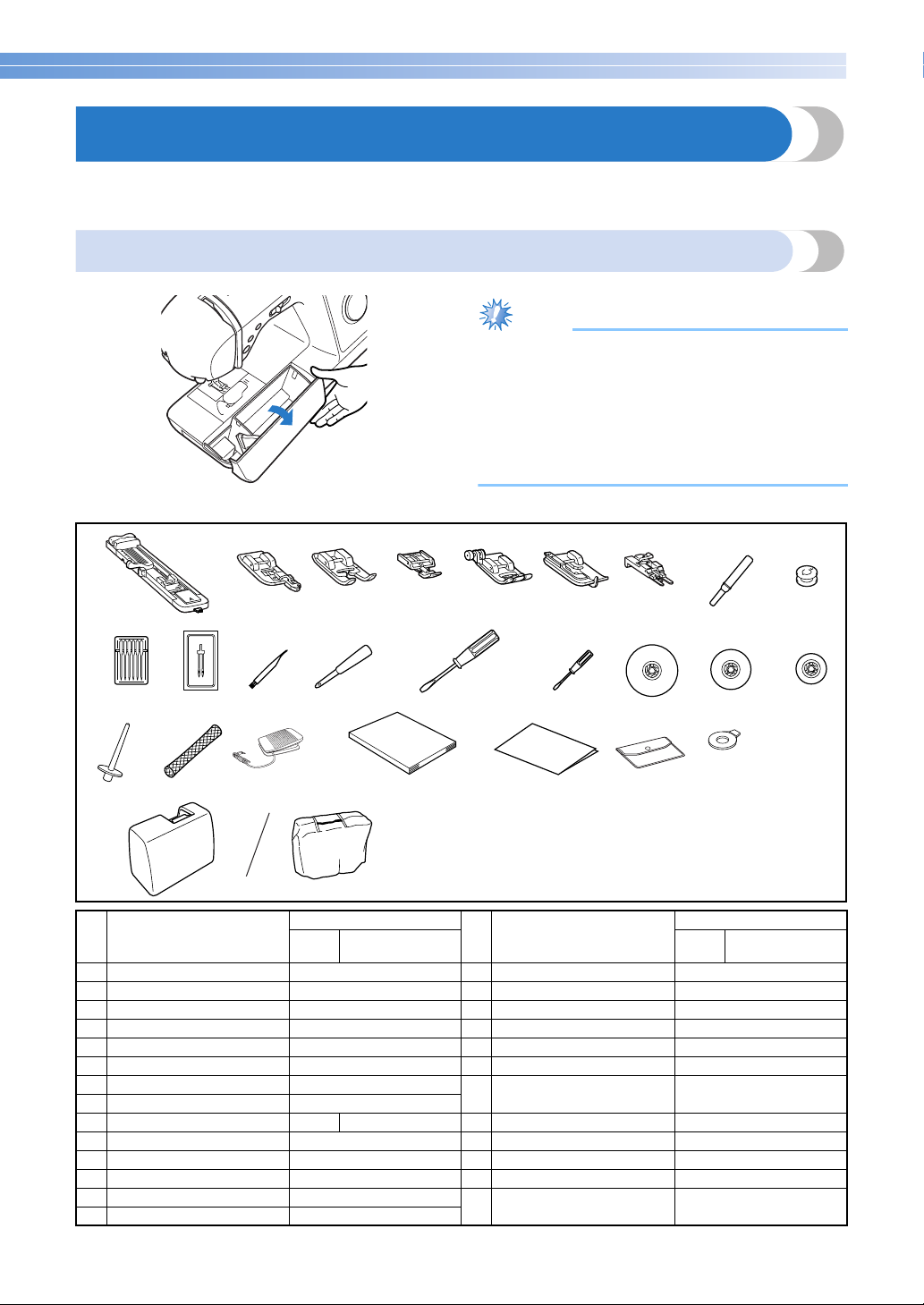

Flat bed attachment

The accessories are stored in the storage space in the

flat bed attachment.

Swing the lid of the flat bed attachment

a

toward you to open the storage space.

a

b

a Flat bed attachment

b Accessory compartment

X The bag of accessories is in the storage

space.

Note

● Place the accessories in the bag before

storing them in the flat bed attachment. If the

accessories are not placed in the accessory

bag when stored in the flat bed attachment,

accessories may fall out and be lost or

damaged.

10

Accessories

After opening the box, check that the following accessories are included. If any item is missing or damaged,

contact your dealer.

Included accessories

The following items should also be included in the box.

Note

(For U.S.A. only)

● Foot controller: Model T

This foot controller can be used on this machine

model NS40.

● The screw for the presser foot holder is available

through your authorized dealer.

(Part code: XA4813-051)

1. 2. 3. 4. 5. 6. 7. 8. 9.

10.* 11. 12. 13. 14. 15. 16. 17. 18.

19. 20. 21. 22. 23. 24. 25.

26.**

No. Part Name

1 Buttonhole foot “A” XC2691-033 15 Screwdriver (small) X55648-051

2 Overcasting foot “G” XC3098-031 16 Spool cap (large) 130012-054

3 Monogramming foot “N” XD0810-031 17 Spool cap (medium) XE1372-001

4 Zipper foot “I” X59370-021 18 Spool cap (small) 130013-154

5 Zigzag foot “J” (on machine) XC3021-051 19 Extra spool pin XE2241-001

6 Blind stitch foot “R” X56409-051 20 Spool net XA5523-020

7 Button fitting foot “M” 130489-001

8 Seam ripper X54243-051 XC8816-021 (other areas)

9 Bobbin (4) SA156 SFB (XA5539-151) 22 Operation manual XE2417-001

10 Needle set X58358-021 23 Quick reference guide XE2425-001

11 Twin needle X59296-121 24 Accessory bag XC4487-021

12 Cleaning brush X59476-021 25 Disc-shaped screwdriver XC1074-051

13 Eyelet punch 135793-001

14 Screwdriver (large) XC8349-051

U.S.A./

Canada

* 75/11 2 needles

90/14 2 needles

90/14 2 needles: Ball point needle

(gold colored)

Part Code

Others

No. Part Name

21 Foot controller

Hard case

26

Soft cover

** The type of case that is included

depends on the machine model.

Part Code

U.S.A./

Canada

XD0501-021 (EU area)

Others

XE2446-001

XC1103-022

11

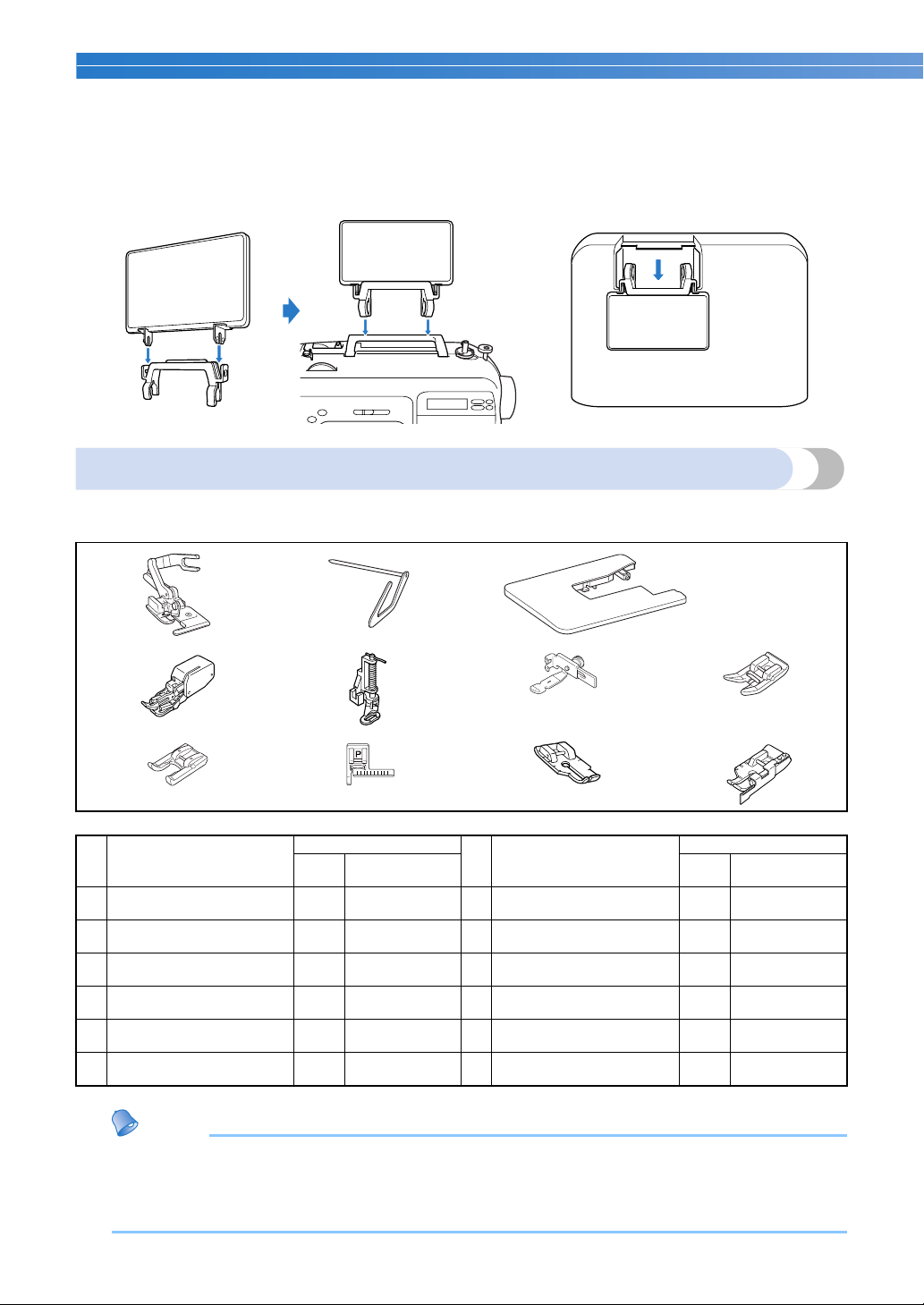

■ Attaching the stitch pattern plate (for models equipped with the stitch pattern plate)

The stitch pattern plate shows the stitches and the stitch numbers. A letter (A, G, J, N or R) indicating the

presser foot that should be used appears below the stitch number. Attach the stitch pattern plate to the stitch

pattern plate holder, and then attach the holder to the handle of the sewing machine as shown in the

illustration below.

Optional accessories

The following are available as optional accessories.

1. 2. 3.

4. 5. 6.

8. 9.

No. Part Name

1 Side cutter SA177

2 Quilting guide SA132

3 Wide table SA552

4 Walking foot SA140

5 Quilting foot SA129

6 Adjustable zipper/piping foot SA161

U.S.A./

Canada

Part Code

Others

F054

(XC3879-002)

F016N

(XC2215-002)

WT8

(XE2472-001)

F033N

(XC2214-002)

F005N

(XC1948-002)

F036N

(XC1970-002)

10.

No. Part Name

7 Non stick foot SA114

8 Open toe foot SA147

9 Stitch guide foot “P” SA160

10 1/4 inch quilting foot SA125

1/4 inch quilting foot with

11

guide

7.

11.

U.S.A./

Canada

SA185

Memo

● To obtain optional accessories or parts, contact the nearest authorized dealership.

● All specifications are correct at the time of printing. The part codes are subject to change without

notice.

● Visit your Brother dealer for a complete listing of optional accessories available for your machine.

Part Code

Others

F007N

(XC1949-002)

F027N

(XC1964-002)

F035N

(XC1969-002)

F001N

(XC1944-052)

F057

(XC7416-252)

12

1 GETTING READY

Turning the Machine On/Off

This section explains how to turn the sewing machine on and off.

Power supply precautions

Be sure to observe the following precautions concerning the power supply.

WARNING

● Use only regular household electricity for the power source. Using other power sources may

result in fire, electric shock, or damage to the machine.

● Make sure that the plugs on the power cord are firmly inserted into the electrical outlet and

the power supply jack on the machine.

● Do not insert the plug on the power cord into an electrical outlet that is in poor condition.

● Turn off the main power and remove the plug in the following circumstances:

• When you are away from the machine

• After using the machine

• When the power fails during use

• When the machine does not operate correctly due to a bad connection or a disconnection

• During electrical storms

1

CAUTION

● Use only the power cord included with this machine.

● Do not use extension cords or multi-plug adapters with many other appliances plugged in to

them. Fire or electric shock may result.

● Do not touch the plug with wet hands. Electric shock may result.

● When unplugging the machine, always turn off the main power first. Always grasp the plug to

remove it from the outlet. Pulling on the cord may damage the cord, or lead to fire or electric

shock.

● Do not allow the power cord to be cut, damaged, modified, forcefully bent, pulled, twisted,

or bundled. Do not place heavy objects on the cord. Do not subject the cord to heat. These

things may damage the cord and cause fire or electric shock. If the cord or plug is damaged,

take the machine to your authorized dealer for repairs before continuing use.

● Unplug the power cord if the machine is not to be used for a long period of time. Otherwise a fire may

result.

13

GETTING READY —————————————————————————————————————————————————————————————————————————————————————————————————————

——

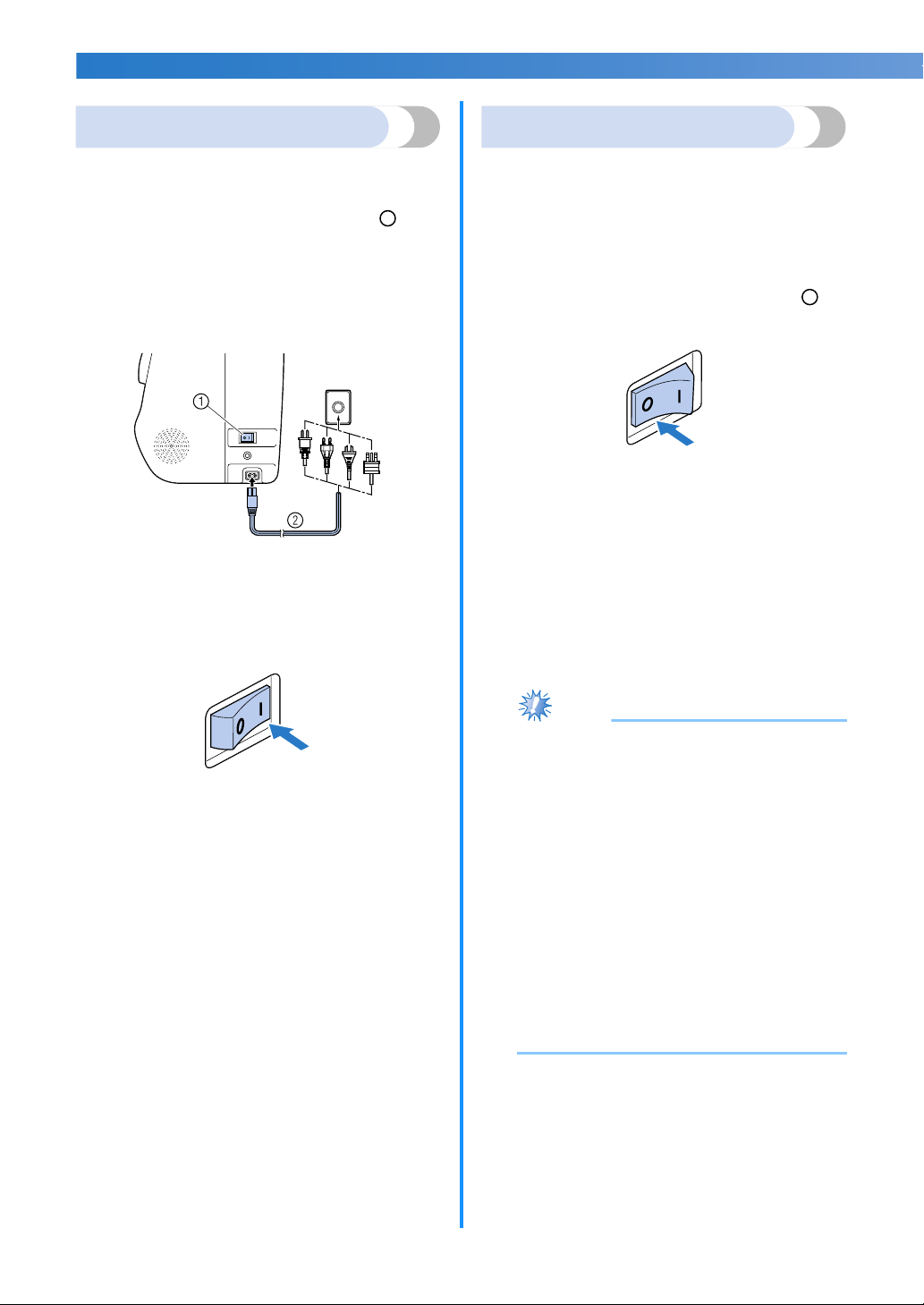

Turning on the machine

Prepare the included power cord.

Make sure that the sewing machine is turned

a

off (the main power switch is set to “ ”),

and then plug the power cord into the power

supply jack on the right side of the machine.

Insert the plug of the power cord into a

b

household electrical outlet.

a Main power switch

b Power cord

Press the right side of the main power switch

c

on the right side of the machine (set it to “|”).

Turning off the machine

When you are finished using the sewing machine,

turn it off. In addition, before transporting the sewing

machine to another location, be sure to turn it off.

Make sure that the machine is not sewing.

a

Press the left side of the main power switch on

b

the right side of the machine (set it to “ ”).

X The sewing lamp and the LCD go off

when the machine is turned off.

Unplug the power cord from the electrical

c

outlet.

Grasp the plug when unplugging the power

cord.

Unplug the power cord from the power

d

supply jack.

X The sewing lamp and the LCD come on

when the machine is turned on.

Note

● If a power outage occurs while the sewing

machine is being operated, turn off the

sewing machine and unplug the power

cord. When restarting the sewing machine,

follow the necessary procedure to correctly

operate the machine.

(For U.S.A. only)

● This appliance has a polarized plug (one

blade wider than the other). To reduce the

risk of electrical shock, this plug is intended

to fit in a polarized outlet only one way. If

the plug does not fit fully in the outlet,

reverse the plug. If it still does not fit,

contact a qualified electrician to install the

proper outlet. Do not modify the plug in any

way.

14

Preparing for Upper and Lower Threading

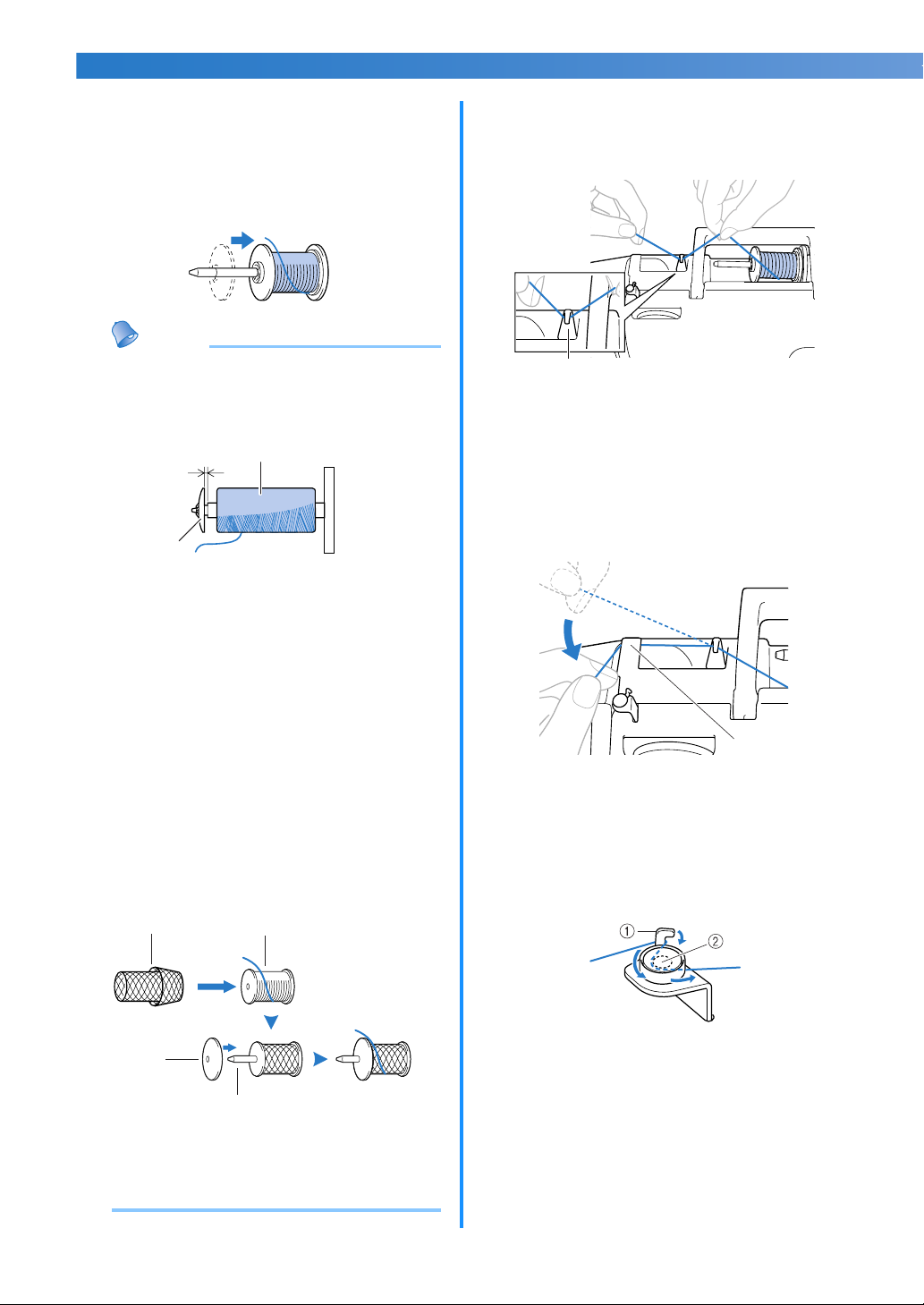

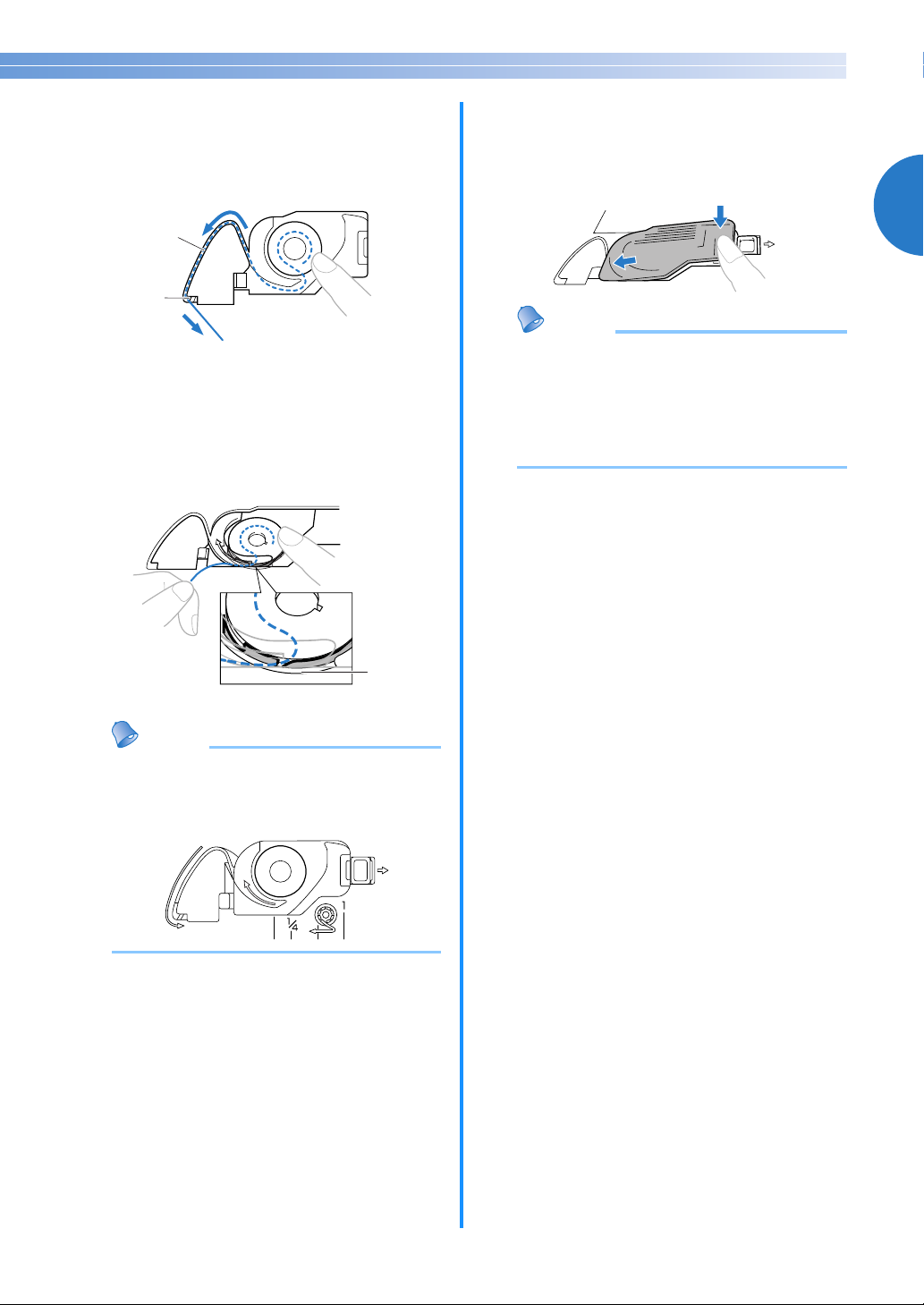

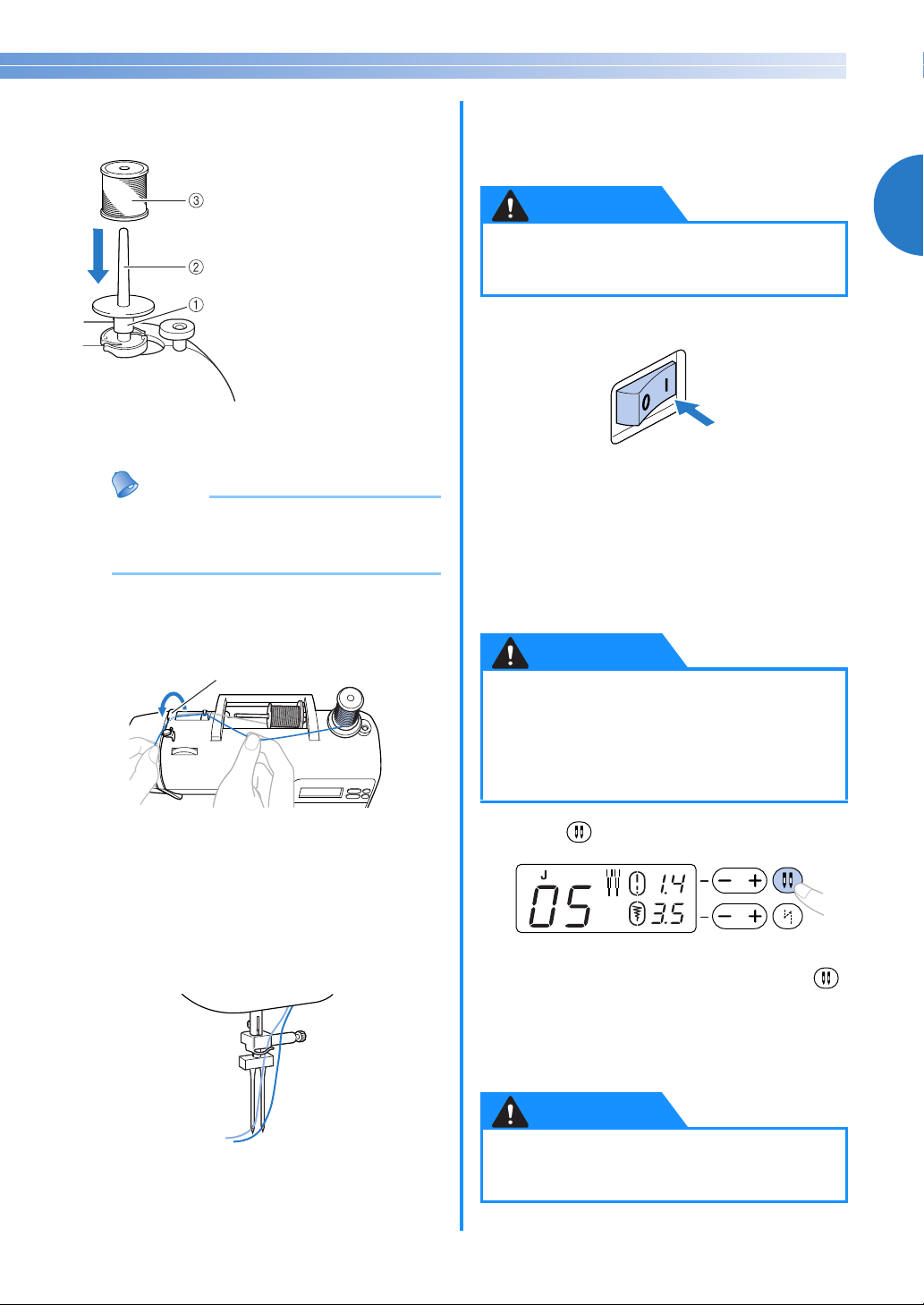

Winding the bobbin

Wind the thread onto the bobbin.

a Hook of the

bobbin-winding

thread guide

b Pretention disk

c Bobbin winder

shaft

d Bobbin

CAUTION

● Only use the bobbin (part code: SA156, SFB(XA5539-151)) designed specifically for this sewing

machine. Use of any other bobbin may result in injuries or damage to the machine.

● The included bobbin was designed specifically for this sewing machine. If bobbins from other models

are used, the machine will not operate correctly. Use only the included bobbin or bobbins of the same

type (part code: SA156, SFB(XA5539-151)).

a This model

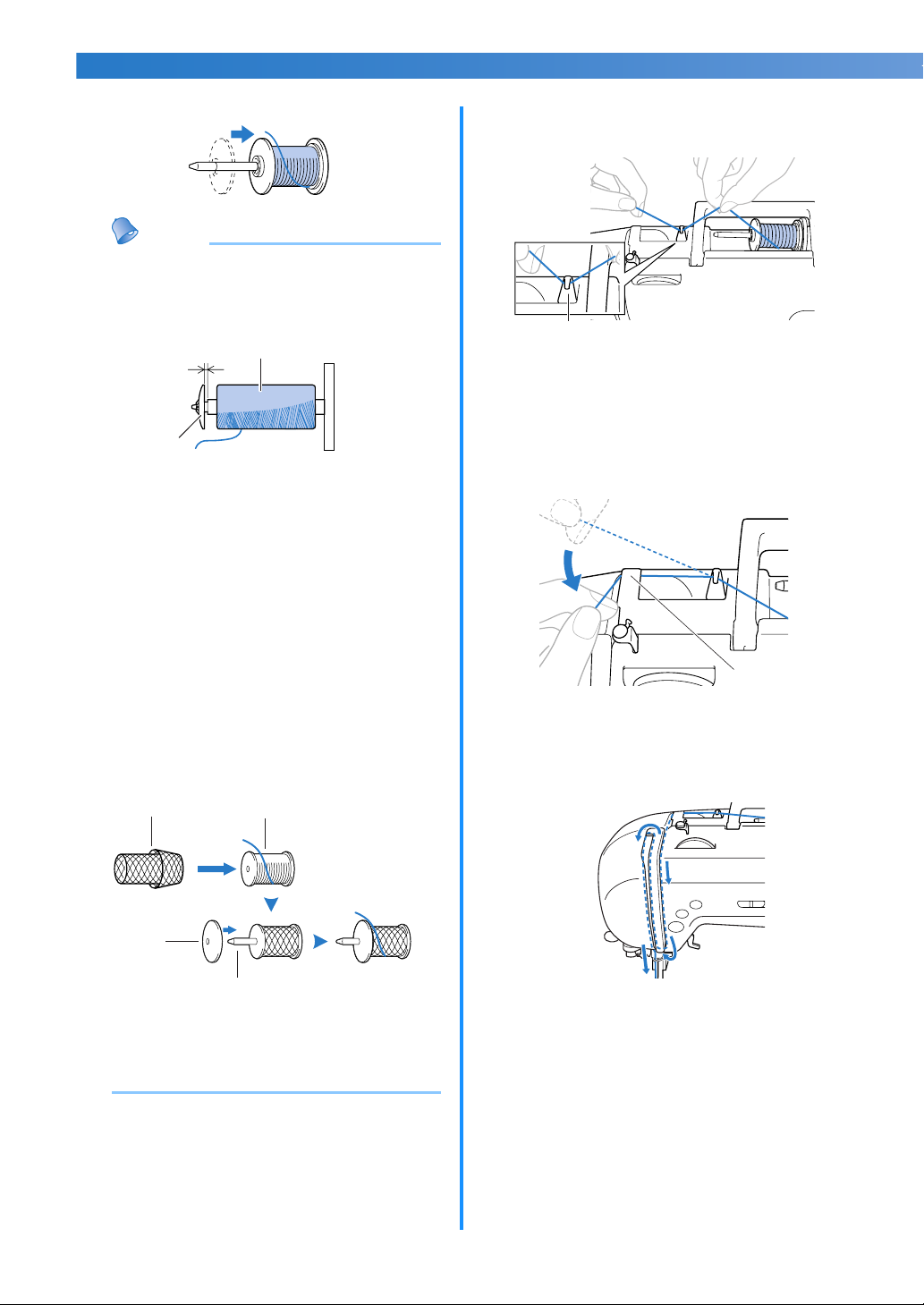

Turn on the sewing machine.

a

c

ab

Swing up the spool pin, and then remove the

d

spool cap.

b Other model

c 11.5 mm (7/16 inch)

(actual size)

1

Place the bobbin on the bobbin winder shaft

b

so that the spring on the shaft fits into the

notch in the bobbin.

a

b

a Notch

b Bobbin winder shaft spring

Slide the bobbin winder shaft to the right until

c

it snaps into place.

a

b

a Spool pin

b Spool cap

Fully insert the spool of thread for the bobbin

e

onto the spool pin.

Slide the spool onto the pin so that the spool is

horizontal and the thread unwinds to the front

at the bottom.

CAUTION

● If the spool is not positioned so that the thread

unwinds correctly, the thread may become

tangled around the spool pin.

15

GETTING READY —————————————————————————————————————————————————————————————————————————————————————————————————————

——

1

Slide the spool cap onto the spool pin.

f

With the slightly rounded side of the spool cap

positioned toward the left, slide the spool cap

onto the spool pin as far as possible to the right

so that the spool is moved to the right end of

the spool pin.

Memo

● When sewing with fine, cross-wound

thread, use the small spool cap, and leave a

small space between the cap and the spool.

c

a

a Spool cap (small)

b Spool (cross-wound thread)

c Space

b

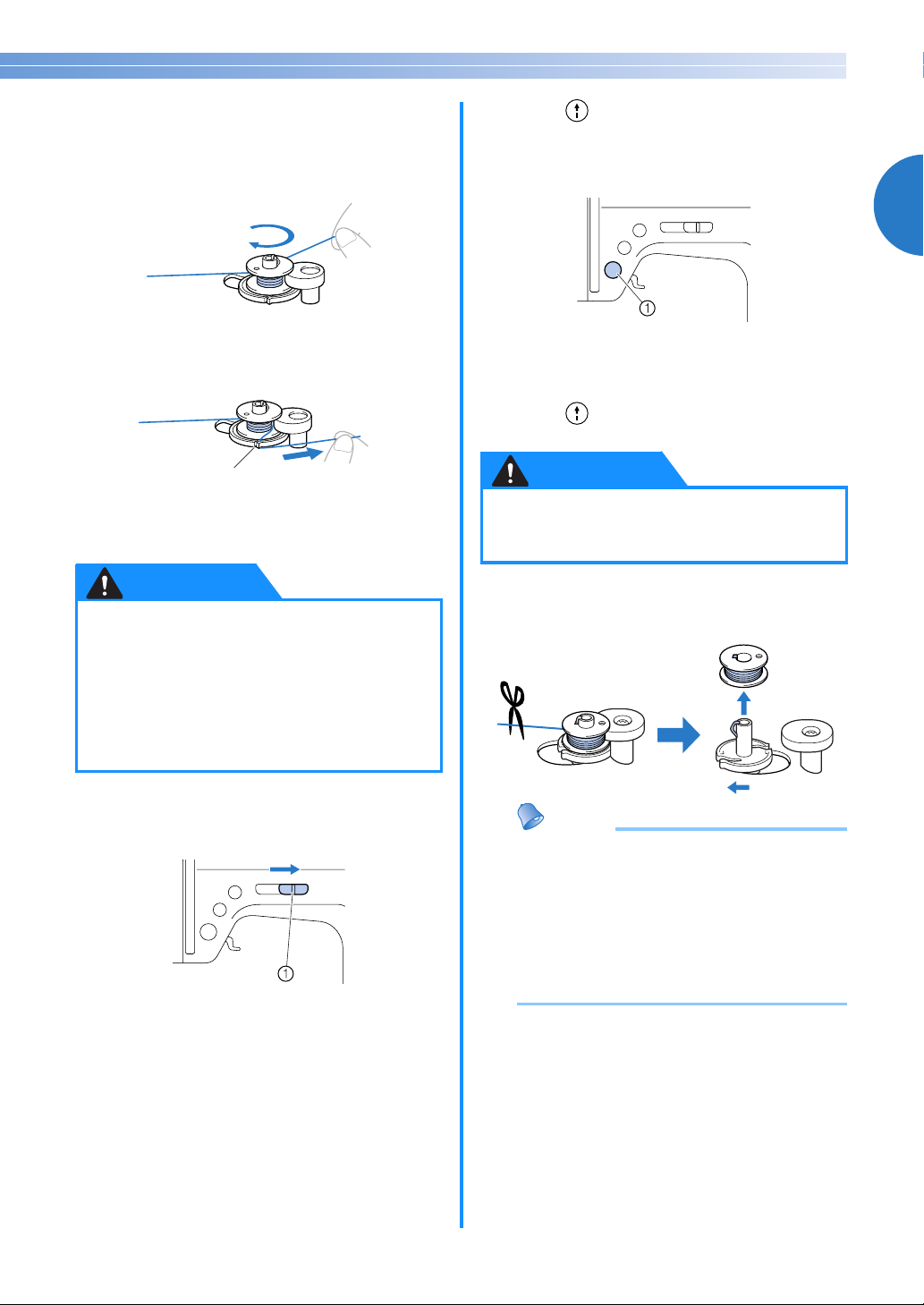

While holding the spool with your right hand,

g

pull the thread with your left hand, and then

pass the thread under the thread guide.

1

a Thread guide

Pass the thread under the thread guide cover

h

from the back to the front.

Hold the thread with your right hand so that

there is no slack in the thread that is pulled out,

and then pass the thread under the thread

guide cover with your left hand.

● When using thread that winds off quickly,

such as transparent nylon thread or metallic

thread, place the spool net over the spool

before placing the spool of thread onto the

spool pin.

If the spool net is too long, fold it to fit the

size of the spool.

When the spool net is used, the tension of

the upper thread will slightly increase. Be

sure to check the thread tension. For details,

refer to “Adjusting the thread tension”

(page 49).

2

3

4

a Spool net

b Spool

c Spool cap

d Spool pin

a

a Thread guide cover

Pull the thread to the right, pass it under the

i

hook of the bobbin-winding thread guide, and

then wind the thread counterclockwise

between the discs, pulling it in as far as

possible.

a Hook of the bobbin-winding thread guide

b Pretension disk

16

While using your left hand to hold the thread

j

that was passed through the bobbin-winding

thread guide, use your right hand to wind the

end of the thread clockwise around the

bobbin five or six times.

Press (start/stop button) once.

m

X The bobbin starts spinning and the

thread is wound around the bobbin.

1

Pass the end of the thread through the slit in

k

the bobbin winder seat, and then pull the

thread to the right to cut it.

a

a Slit in bobbin winder seat (with built-in

cutter)

X The thread is cut to a suitable length.

CAUTION

● Be sure to cut the thread as described. If the

bobbin is wound without cutting the thread

using the cutter built into the slit in the

bobbin winder seat, the bobbin may not be

wound correctly. In addition, the thread may

become tangled in the bobbin or the needle

may bend or break when the bobbin thread

starts to run out.

Slide the sewing speed controller to the right

l

to increase the bobbin winding speed and

slide to left to decrease.

a Sewing speed controller

a Start/stop button

When the bobbin winding becomes slow,

n

press (start/stop button) once to stop the

machine.

CAUTION

● When the bobbin winding becomes slow, stop

the machine, otherwise the sewing machine

may be damaged.

Cut the thread, slide the bobbin winder shaft

o

to the left, and then remove the bobbin from

the shaft.

Memo

● When the sewing machine is started or the

handwheel is turned after winding the

thread around the bobbin, the machine will

make a clicking sound; this is not a

malfunction.

● The needle cannot move (sewing is not

possible) while the bobbin winder shaft is

moved to the right.

17

GETTING READY —————————————————————————————————————————————————————————————————————————————————————————————————————

——

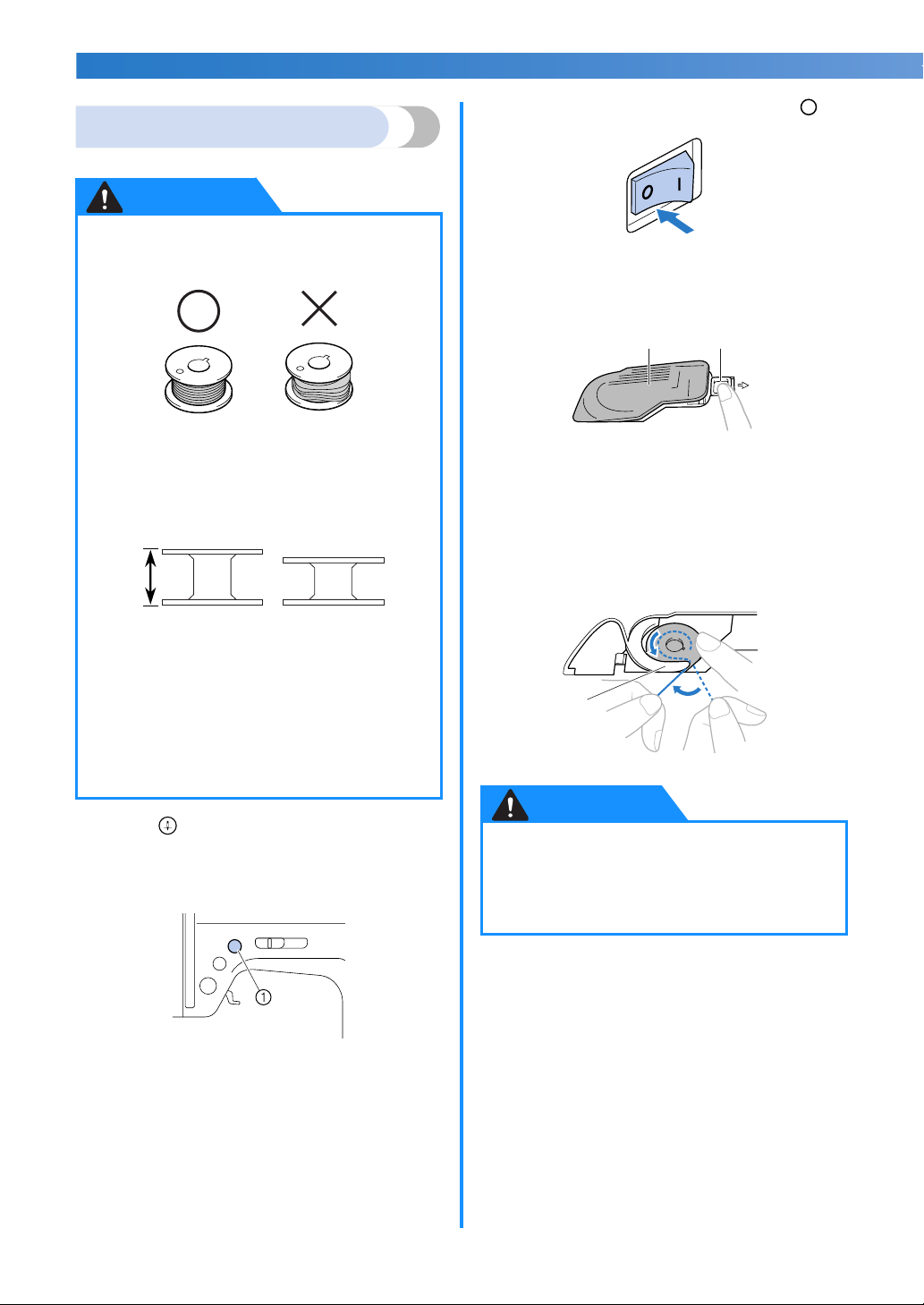

Turn off the sewing machine (set it to “ ”).

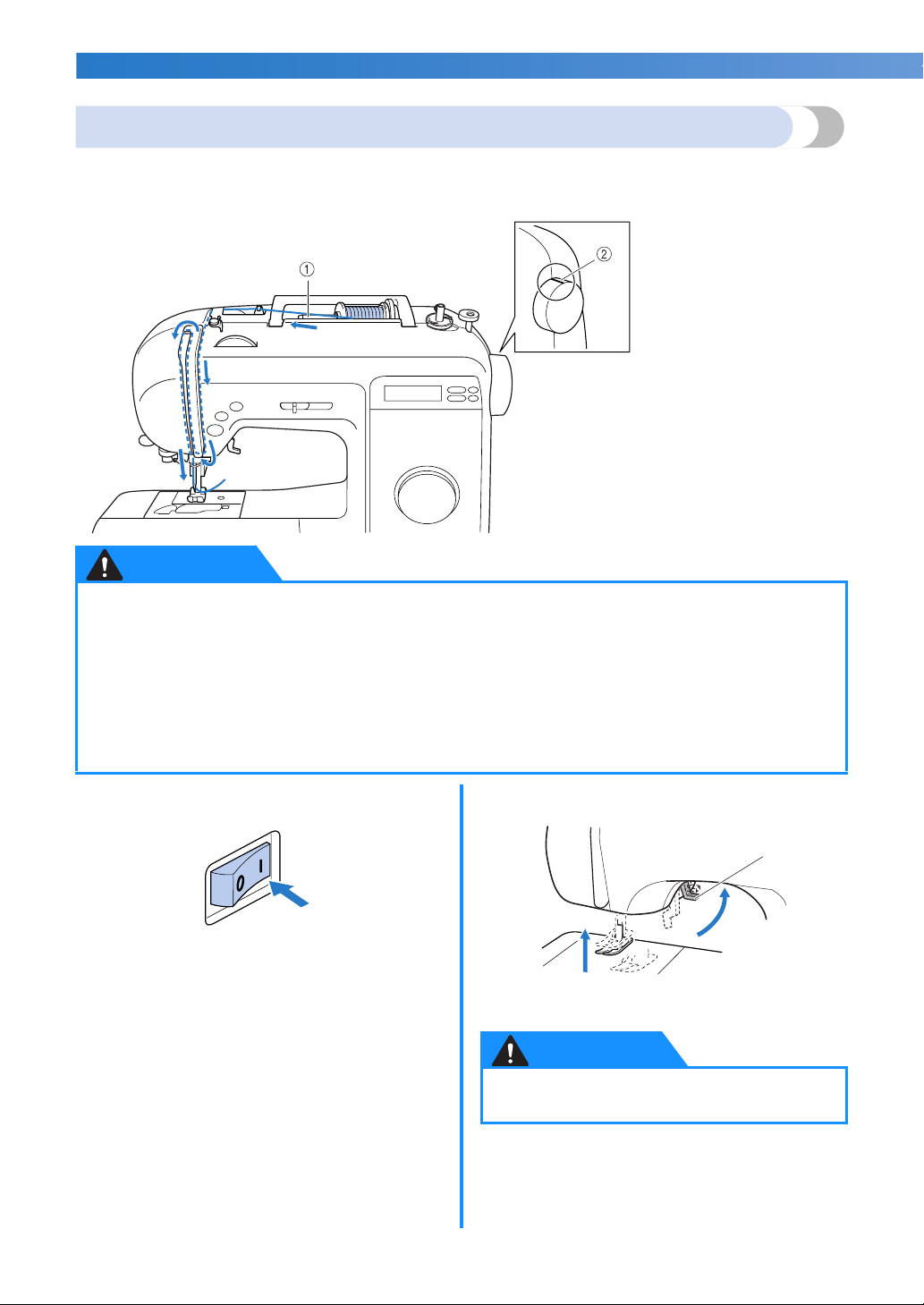

Installing the bobbin

Install the bobbin wound with thread.

b

CAUTION

● Use a bobbin that has been correctly wound,

otherwise the needle may break or the thread

tension will be incorrect.

● The bobbin was designed specifically for this

sewing machine. If bobbins from other

models are used, the machine will not operate

correctly. Use only the included bobbin or

bobbins of the same type (part code: SA156,

SFB(XA5539-151)).

c

Slide the latch on the right side of the bobbin

c

cover to the right, and then remove the

bobbin cover.

ab

a Bobbin cover

b Latch

Insert the bobbin with your right hand so that

d

the thread unwinds to the left side, and then

pull the thread firmly under the tab with your

left hand.

ab

a This model

b Other model

c 11.5 mm (7/16 inch) (actual size)

● Before installing the bobbin or replacing the

needle, be sure to turn off the sewing

machine, otherwise injuries may occur if the

start/stop button is accidentally pressed and

the machine starts sewing.

Press (needle position button) once or

a

twice to raise the needle, and then raise the

presser foot lever.

a Needle position button

a

a Tab

CAUTION

● Be sure to hold down the bobbin with your

finger and install the bobbin so that the thread

unwinds in the correct direction, otherwise

the needle may break or the thread tension

will be incorrect.

18

Lightly hold down the bobbin with your right

e

hand, and guide the thread through the slot,

and then pull it toward you to cut it with the

cutter.

Reattach the bobbin cover.

f

Insert the tab in the lower-left corner of the

bobbin cover (A), and then press down on the

right side (B).

a

b

a Slot

b Cutter

X The cutter cuts the thread.

• Make sure that the thread is correctly passed

through the flat spring of the bobbin case. If

it is not inserted correctly, reinstall the

bobbin.

a

a Flat spring

B

1

AA

Memo

● You can begin sewing without pulling up

the bobbin thread. If you wish to pull up the

bobbin thread before starting to sew, finish

threading the machine, and then pull up the

thread according to the procedure in

“Pulling up the bobbin thread” (page 52).

Memo

●

The direction for feeding the bobbin thread is

indicated by marks around the needle plate

cover. Be sure to thread the machine as

indicated.

19

GETTING READY —————————————————————————————————————————————————————————————————————————————————————————————————————

——

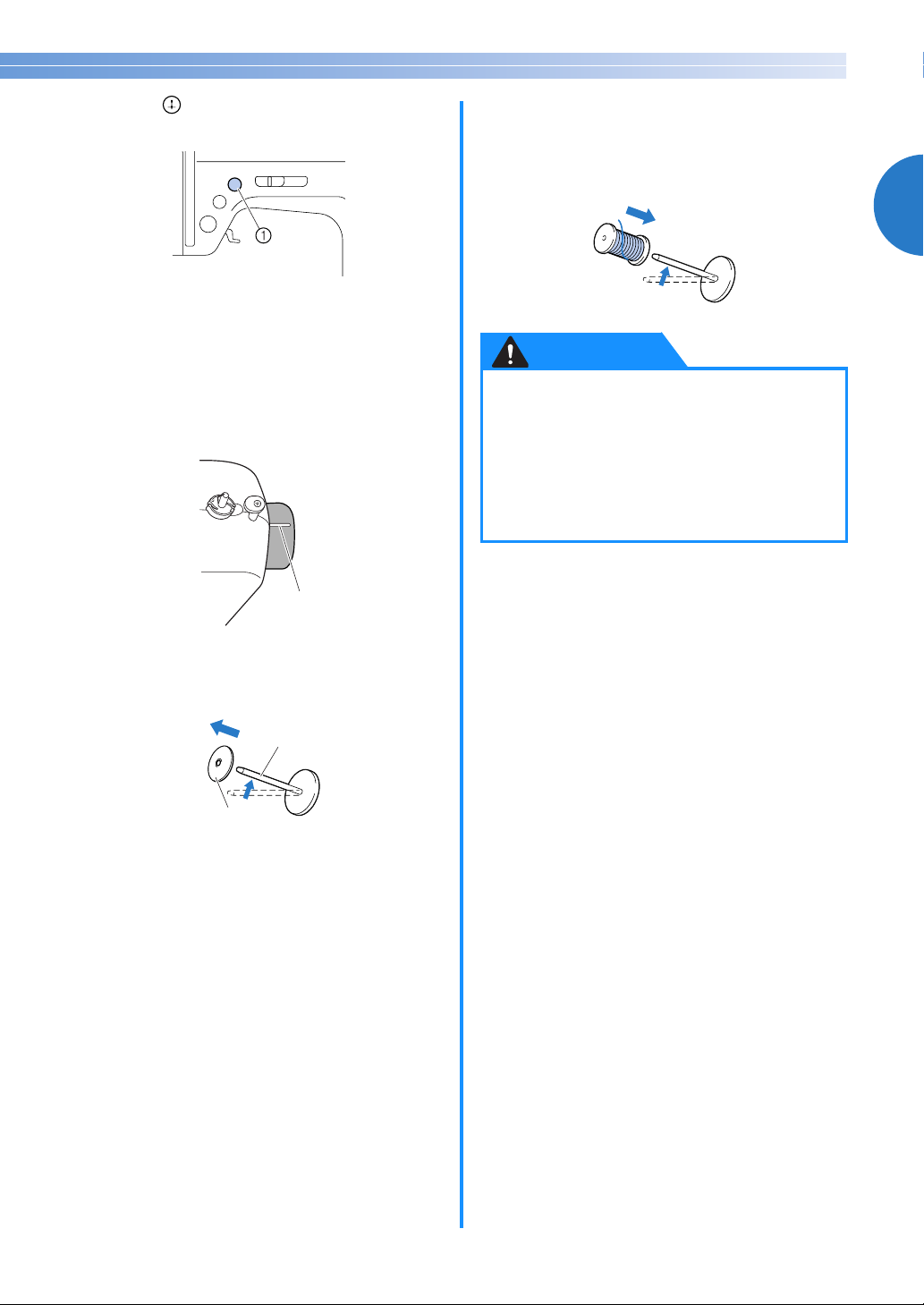

Threading the upper thread

In this section, the procedures for installing the spool for the upper thread and threading the needle are

described.

a Spool pin

b Mark on handwheel

CAUTION

● When threading the machine, carefully follow the instructions. If the upper threading is not performed

correctly, the thread may become tangled and the needle may bend or break.

● The needle threader can be used with sewing machine needles 75/11 through 100/16.

● Use appropriate thread and needle combinations. For details on appropriate needle and thread

combinations, refer to “Needle types and their uses” (page 30).

● Thread with a thickness of 130/20 or thicker cannot be used with the needle threader.

● The needle threader cannot be used with the wing needle or the twin needle.

● If the needle threader cannot be used, refer to “Threading the needle manually (without using the

needle threader)” (page 26).

Turn on the sewing machine.

a

Raise the presser foot lever.

b

a

a Presser foot lever

CAUTION

● If the presser foot is not raised, the sewing

machine cannot be threaded correctly.

20

Press (needle position button) once or

c

twice to raise the needle.

a Needle position button

• If the needle is not correctly raised, the

sewing machine cannot be threaded. Check

that the mark on the handwheel points up as

shown in the illustration below. If the

handwheel is not in this position, be sure to

press the needle position button to raise the

needle before continuing the procedure.

a

Fully insert the spool for the upper thread

e

onto the spool pin

Slide the spool onto the pin so that the spool is

horizontal and the thread unwinds to the front

at the bottom.

CAUTION

● If the spool is not positioned so that the

thread unwinds correctly, the thread may

become tangled around the spool pin and the

thread or needle may break.

● If the spool cap that is used is smaller than the

spool, the thread may catch, for example, on

the notch in the spool, or the needle may

break.

1

a Mark on handwheel

Swing up the spool pin, and then remove the

d

spool cap.

a

b

a Spool pin

b Spool cap

21

GETTING READY —————————————————————————————————————————————————————————————————————————————————————————————————————

——

Slide the spool cap onto the spool pin.

f

Memo

● When sewing with fine, cross-wound

thread, use the small spool cap, and leave a

small space between the cap and the spool.

c

a

a Spool cap (small)

b Spool (cross-wound thread)

c Space

● When using thread that winds off quickly,

such as transparent nylon thread or metallic

thread, place the spool net over the spool

before placing the spool of thread onto the

spool pin.

If the spool net is too long, fold it to fit the

size of the spool.

When the spool net is used, the tension of

the upper thread will slightly increase. Be

sure to check the thread tension. For details,

refer to “Adjusting the thread tension”

(page 49).

1

b

2

While holding the spool with your right hand,

g

pull the thread with your left hand, and then

pass the thread under the thread guide.

1

a Thread guide

Pass the thread under the thread guide cover

h

from the back to the front.

Hold the thread with your right hand so that

there is no slack in the thread that is pulled

out, and then pass the thread under the thread

guide cover with your left hand.

a

a Thread guide cover

Thread the machine by guiding the thread

i

along the path indicated by the number on the

machine.

22

3

4

a Spool net

b Spool

c Spool cap

d Spool pin

Slide the thread into the thread take-up lever

j

from the right to the left.

a

a Thread take-up lever

Memo

● If the needle is not raised, the thread takeup lever cannot be threaded. Be sure to

press the needle position button to raise the

needle before threading the thread take-up

lever.

Pass the thread behind the needle bar thread

k

guide.

The thread can easily be passed behind the

needle bar thread guide by holding the thread

in your left hand, and pulling the thread into

the guide from right to left.

Threading the needle

This section describes how to thread the needle.

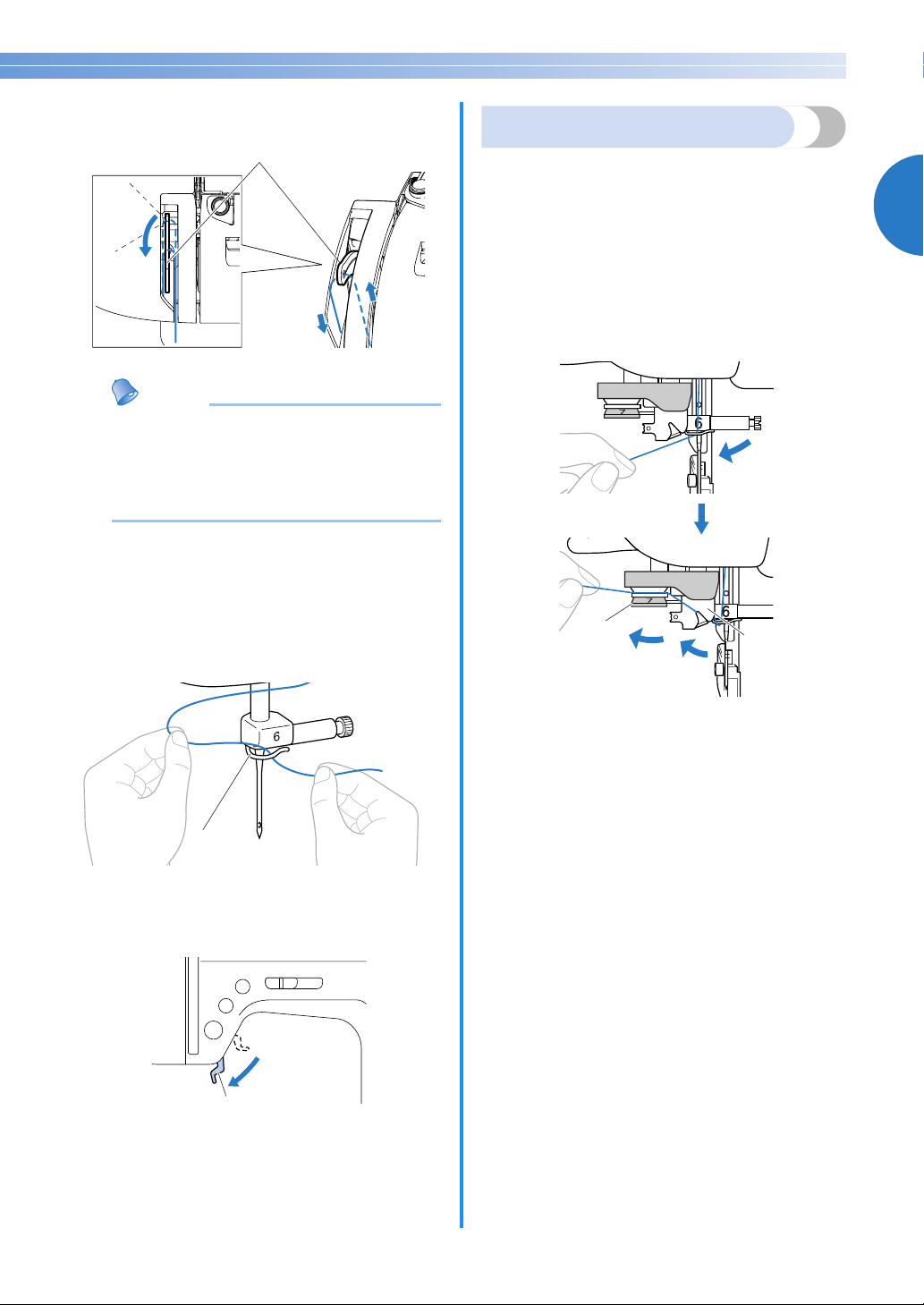

■ For models equipped with the thread guide

disk

Pull the end of the thread, which has been

a

passed through the needle bar thread guide,

to the left (A), and then firmly pull it from the

front (B) through the slit in the thread guide

disk.

a

B

A

b

1

a

a Needle bar thread guide

Lower the presser foot lever.

l

a Presser foot lever

a Thread guide disk

b Thread guide

a

23

GETTING READY —————————————————————————————————————————————————————————————————————————————————————————————————————

——

Cut the thread with the thread cutter on the

b

left side of the machine.

a

a Thread cutter

Note

● When using thread that quickly winds off

the spool, such as metallic thread, it may be

difficult to thread the needle if the thread is

cut.

Therefore, instead of using the thread cutter,

pull out about 80 mm (approx. 3 inches) of

thread after passing it through the thread

guide disks (marked “7”).

Lower the needle threader lever on the left

c

side of the machine, and then slowly return

the lever to its original position.

a

a Needle threader lever

X The thread is passed through the eye of

the needle.

Note

● If the needle was not completely threaded,

but a loop in the thread was formed in the

eye of the needle, carefully pull the loop

through the eye of the needle to pull out the

end of the thread.

1

a 80 mm (3 inches) or more

CAUTION

● When pulling out the thread, do not pull it

with extreme force, otherwise the needle may

break or bend.

24

Raise the presser foot lever, pass the end of

d

the thread through the presser foot, and then

pull out about 5 cm (2 inches) of thread

toward the rear of the machine.

Catch the thread on the hook as shown below.

b

a

a 5 cm (2 inches)

X The upper threading is finished.

Now that the upper threading and the

lower threading are finished, you are

ready to begin sewing.

Note

● If the needle is not raised, the needle

threader cannot thread the needle. Be sure

to press (needle position button) to raise

the needle before using the needle threader.

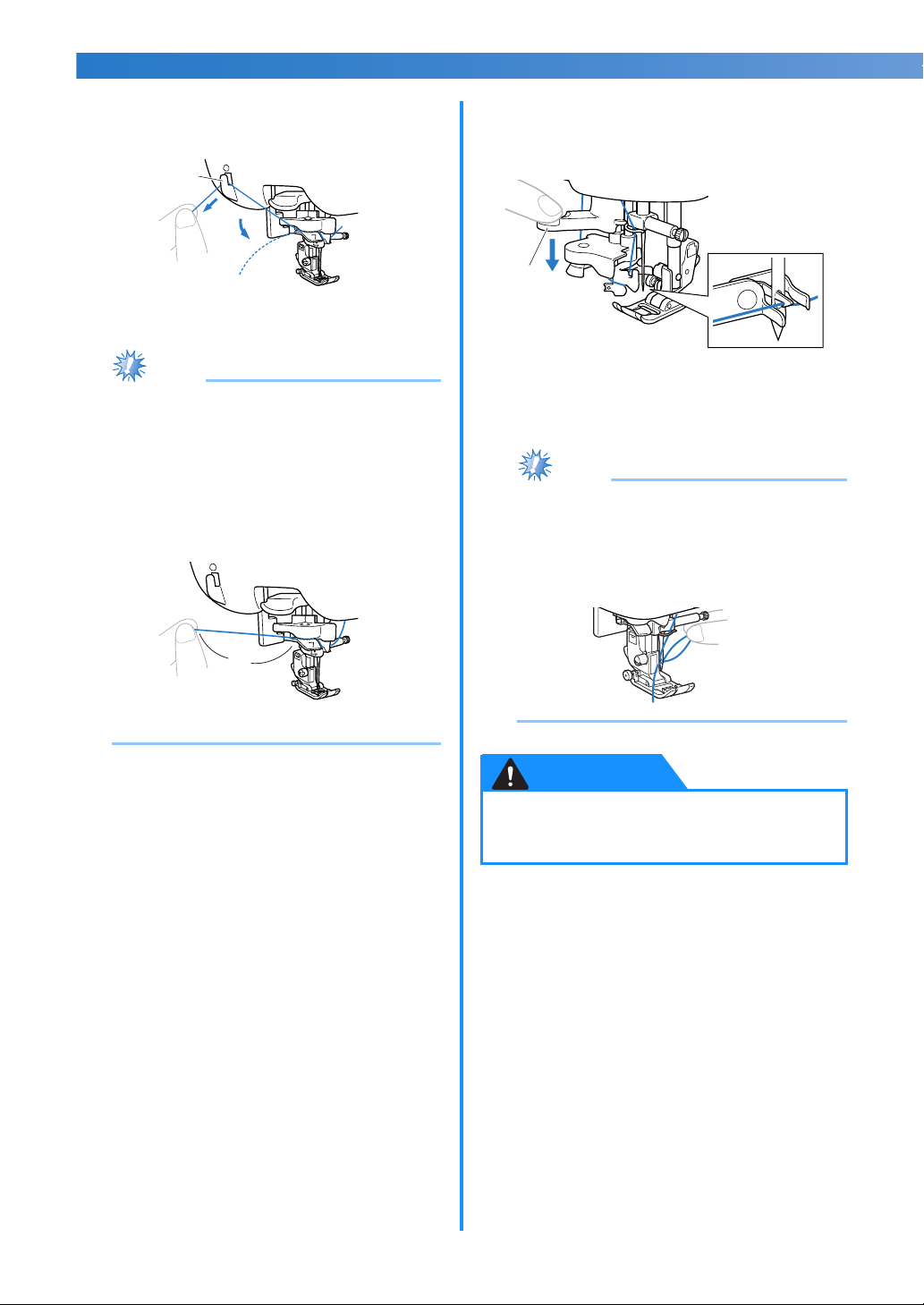

■ For models without the thread guide disk

While lowering the needle threader lever,

a

hook the thread onto the guide.

a

a Needle threader lever

Raise the needle threader lever, and then pull

c

the end of the thread which passed through

the eye of the needle.

CAUTION

● Be careful not to pull on the thread with force

or it may bend the needle.

1

a Needle threader

b Thread

c Guide

Raise the presser foot lever, pass the end of

d

the thread through the presser foot, and then

pull out about 5 cm (2 inches) of thread

toward the rear of the machine.

a

a 5 cm (2 inches)

X The upper threading is finished.

25

GETTING READY —————————————————————————————————————————————————————————————————————————————————————————————————————

——

Threading the needle manually

(without using the needle

threader)

When using special thread, thread with a thickness

of 130/20 or thicker, the wing needle or the twin

needle which cannot be used with the needle

threader, thread the needle as described below.

Thread the machine to the needle bar thread

a

guide.

• For details, refer to “Threading the upper

thread” (page 20).

Lower the presser foot lever.

b

a

a Pressor foot lever

Pass the thread through the eye of the needle

c

from front to back.

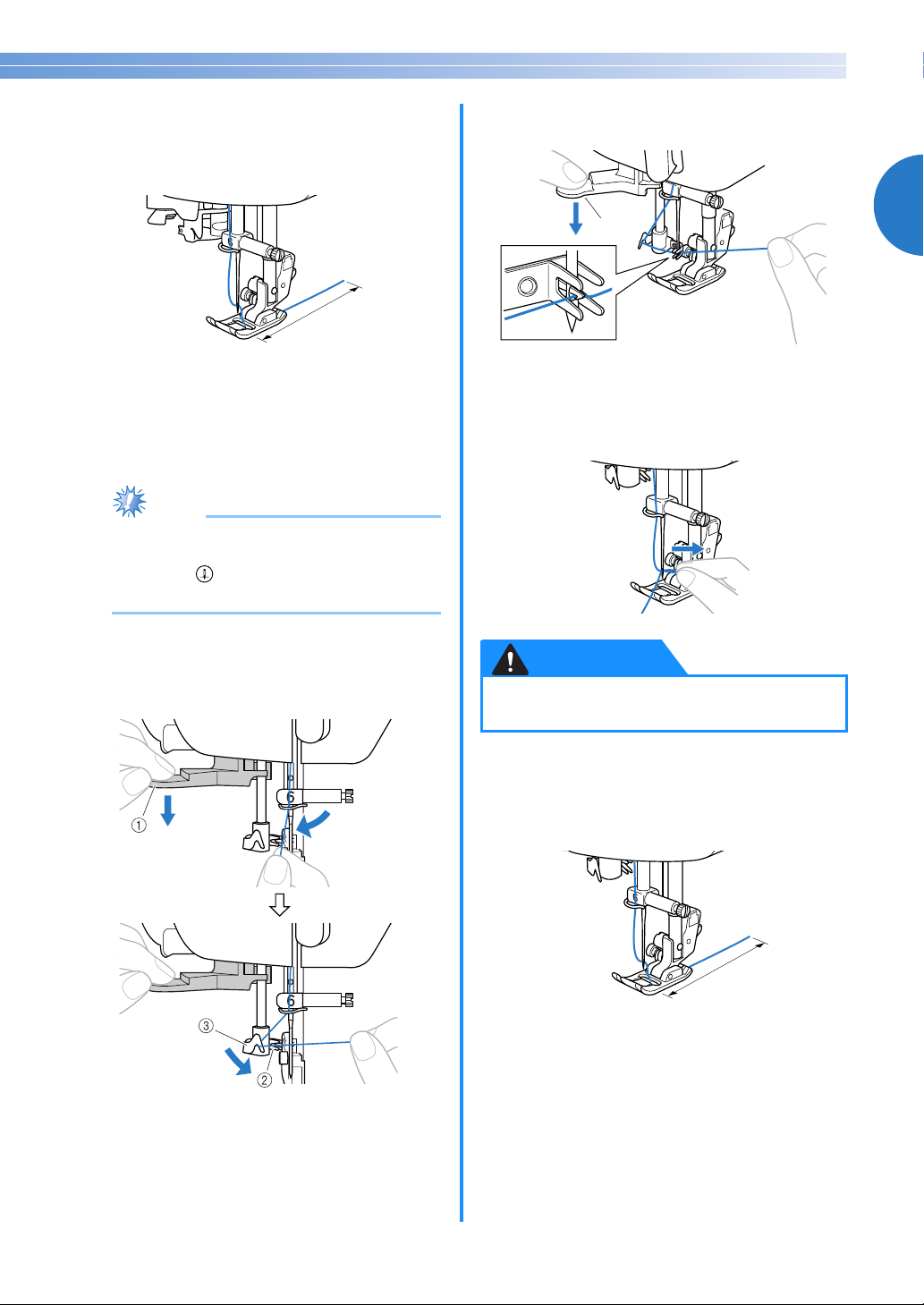

Using the twin needle

With the twin needle, you can sew two parallel lines

of the same stitch with two different threads. Both

upper threads should have the same thickness and

quality. Be sure to use the twin needle and the extra

spool pin.

For details on the stitches that can be sewn with the

twin needle, refer to “Stitch Settings” (page 89).

ab

a Twin needle

b Extra spool pin

CAUTION

● Only use the twin needle (part code: X59296-

121). Use of any other needle may bend the

needle or damage the machine.

● Never use bent needles. Bent needles can

easily break, possibly resulting in injuries.

● The needle threader cannot be used with the

twin needle. If the needle threader is used

with the twin needle, the sewing machine

may be damaged.

Raise the presser foot lever, pass the end of

d

the thread through the presser foot, and then

pull out about 5 cm (2 inches) of thread

toward the rear of the machine.

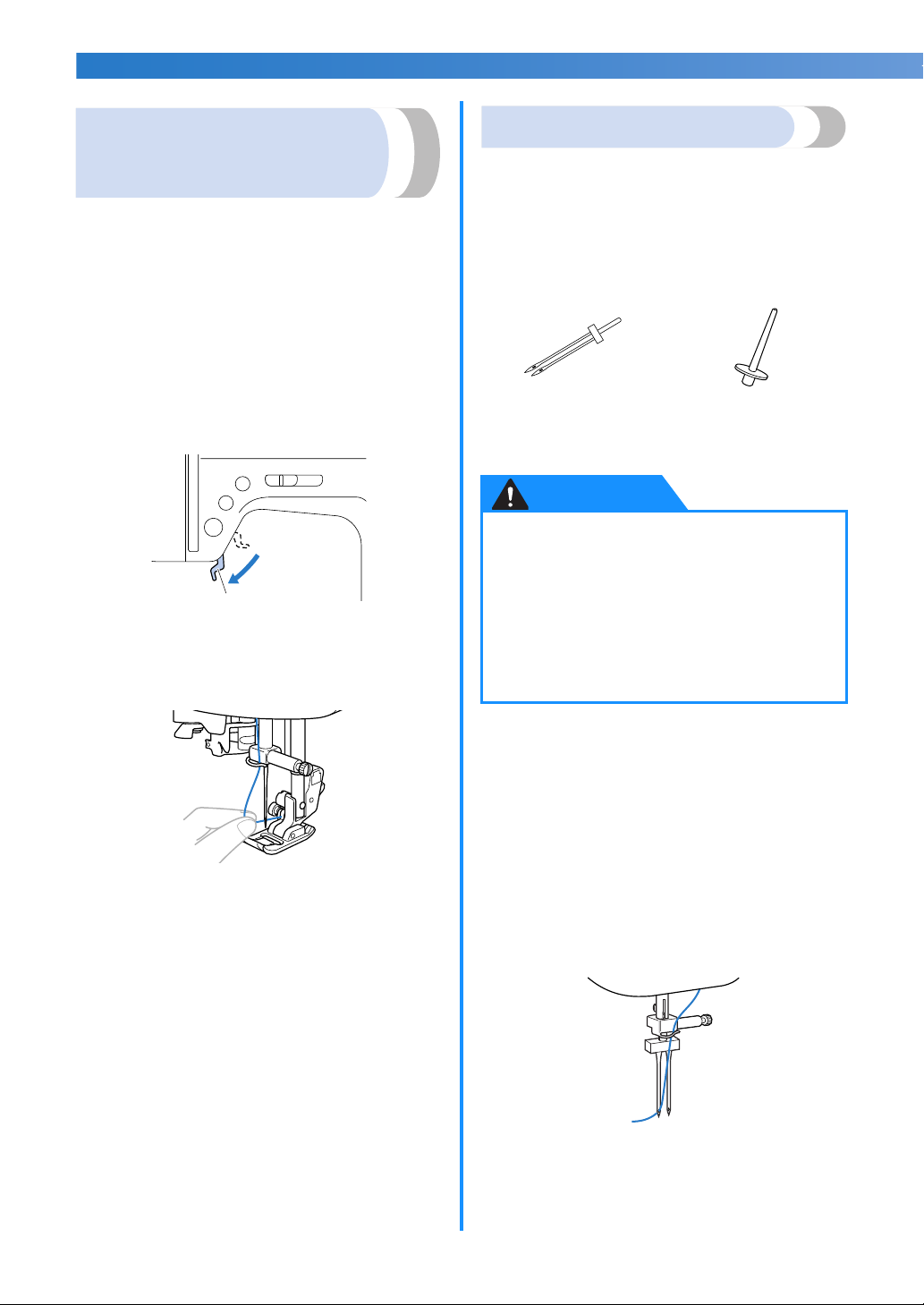

Install the twin needle.

a

• For details on installing a needle, refer to

“Replacing the needle” (page 31).

Thread the upper thread for the left needle.

b

• For details, refer to steps

“Threading the upper thread” (page 20).

Manually thread the left needle with the

c

upper thread.

Pass the thread through the eye of the needle

from the front to the back.

a through j of

26

Insert the extra spool pin onto the end of the

d

bobbin winder shaft.

a Bobbin winder shaft

b Extra spool pin

c Thread spool

Install the thread spool and thread the upper

e

thread.

Memo

● When setting the thread spool, set it so that

the thread winds off from the front of the

spool.

Thread the upper thread for the right side in

f

the same way that the upper thread for the

left side was threaded.

1

Attach zigzag foot “J”.

h

• For details on changing the presser foot, refer

to “Replacing the presser foot” (page 33).

CAUTION

● When using the twin needle, be sure to attach

zigzag foot “J”, otherwise the needle may

break or the machine may be damaged.

Turn on the sewing machine.

i

X The LCD comes on.

Select a stitch.

j

• For details on selecting a stitch, refer to

“Selecting a stitch” (page 42).

• For details on the stitches that can be sewn

with the twin needle, refer to “Stitch

Settings” (page 89).

CAUTION

● After adjusting the stitch width, slowly turn

the handwheel toward you

(counterclockwise) and check that the needle

does not touch the presser foot. If the needle

hits the presser foot, the needle may bend or

break.

1

a Thread guide cover

• For details, refer to step a through j of

“Threading the upper thread” (page 20).

Without passing the thread through the

g

needle bar thread guide, manually thread the

right needle.

Pass the thread through the eye of the needle

from the front to the back.

Press (Needle mode selection key).

k

X The twin needle can now be used.

• To return to single needle sewing, press

(Needle mode selection key).

• Even after the sewing machine is turned off,

the twin needle setting is not cancelled.

CAUTION

● When using the twin needle, be sure to select

the twin needle setting, otherwise the needle

may break or the machine may be damaged.

27

GETTING READY —————————————————————————————————————————————————————————————————————————————————————————————————————

——

Start sewing.

l

• For details on starting to sew, refer to

“Starting to sew” (page 44).

X Two lines of stitching are sewn parallel

to each other.

Note

● When using the twin needle, the stitches

may become bunched together, depending

on the types of thread and fabric that are

used. If this occurs, increase the stitch

length. For details on adjusting the stitch

length, refer to “Adjusting the stitch length

and width” (page 42).

CAUTION

● When changing the sewing direction, press

(needle position button) to raise the

needle from the fabric, and then raise the

presser foot lever and turn the fabric.

Otherwise the needle may break or the

machine may be damaged.

● Do not try turning the fabric with the twin

needle left down in the fabric, otherwise the

needle may break or the machine may be

damaged.

28

Replacing the Needle

This section provides information on sewing machine needles.

Needle precautions

Be sure to observe the following precautions concerning the handling of the needle. Failure to observe these

precautions is extremely dangerous, for example, if the needle breaks and fragments are dispersed. Be sure to

read and carefully follow the instructions below.

CAUTION

● Only use home sewing machine needles. Use of any other needle may bend the needle or damage the

machine.

● Never use bent needles. Bent needles can easily break, possibly resulting in injuries.

1

29

Loading...

Loading...