Page 1

Operation Manual

Be sure to read this manual before using the machine.

We recommend that you keep this document nearby for future reference.

Sewing

Embroidery and Sewing Machine

Product Code: 882-W30

Be sure to read this manual before using the machine.

Be sure to read this manual before using the machine.

We recommend that you keep this document nearby for future reference.

We recommend that you keep this document nearby for future reference.

Page 2

Page 3

INTRODUCTION

INTRODUCTION

Thank you for purchasing this machine.

Before using this machine or attempting any maintenance, carefully read the “IMPORTANT SAFETY

INSTRUCTIONS” on this page, and then study the Operation Manual for the correct operation of the

various functions. In addition, after you have finished reading this product safety manual, store it where it

can quickly be accessed for future reference. Failure to follow these instructions may result in an

increased risk of personal injury or damage to property, including through fire, electrical shock, burns or

suffocation.

IMPORTANT SAFETY INSTRUCTIONS

Please read these safety instructions before attempting to use the machine.

DANGER - To reduce the risk of electric shock

1Always unplug the machine from the electrical outlet immediately after using, when cleaning, when making any

user servicing adjustments mentioned in this manual, or if you are leaving the machine unattended.

WARNING - To reduce the risk of burns, fire, electric shock, or injury to

persons.

2Always unplug the machine from the electrical outlet when removing covers, or when making any adjustments

mentioned in the instruction manual.

• To unplug the machine, switch the machine to the symbol “O” position to turn it off, then grasp the plug and pull

it out of the electrical outlet. Do not pull on the cord.

• Plug the machine directly into the electrical outlet. Do not use an extension cord.

• Always unplug your machine if the power is cut.

3Electrical Hazards:

• This machine should be connected to an AC power source within the range indicated on the rating label. Do not

connect it to a DC power source or inverter. If you are not sure what kind of power source you have, contact a

qualified electrician.

• This machine is approved for use in the country of purchase only.

4Never operate this machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped

or damaged, or water is spilled on the unit. Return the machine to the nearest authorized Brother dealer for

examination, repair, electrical or mechanical adjustment.

• While the machine is stored or in use if you notice anything unusual, such as an odor, heat, discoloration or

deformation, stop using the machine immediately and unplug the power cord.

• When transporting the sewing machine, be sure to carry it by its handle. Lifting the sewing machine by any other

part may damage the machine or result in the machine falling, which could cause injuries.

• When lifting the sewing machine, be careful not to make any sudden or careless movements, otherwise you may

injure your back or knees.

1

Page 4

IMPORTANT SAFETY INSTRUCTIONS

5Always keep your work area clear:

• Never operate the machine with any air openings blocked. Keep ventilation openings of the sewing machine and

foot control free from the build up of lint, dust, and loose cloth.

• Do not store objects on the foot controller.

• Do not use extension cords. Plug the machine directly into the electrical outlet.

• Never drop or insert any object into any opening.

• Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

• Do not use the machine near a heat source, such as a stove or iron; otherwise, the machine, power cord or

garment being sewn may ignite, resulting in fire or an electric shock.

• Do not place this sewing machine on an unstable surface, such as an unsteady or slanted table, otherwise the

sewing machine may fall, resulting in injuries.

6Special care is required when sewing:

• Always pay close attention to the needle. Do not use bent or damaged needles.

• Keep fingers away from all moving parts. Special care is required around the machine needle.

• Switch the sewing machine to the symbol “O” position to turn it off when making any adjustments in the needle

area.

• Do not use a damaged or incorrect needle plate, as it could cause the needle to break.

• Do not push or pull the fabric when sewing, and follow careful instruction when free motion stitching so that

you do not deflect the needle and cause it to break.

7This machine is not a toy:

• Your close attention is necessary when the machine is used by or near children.

• The plastic bag that this sewing machine was supplied in should be kept out of the reach of children or disposed

of. Never allow children to play with the bag due to the danger of suffocation.

• Do not use outdoors.

8For a longer service life:

• When storing this machine, avoid direct sunlight and high humidity locations. Do not use or store the machine

near a space heater, iron, halogen lamp, or other hot objects.

• Use only neutral soaps or detergents to clean the case. Benzene, thinner, and scouring powders can damage the

case and machine, and should never be used.

• Always consult the operation manual when replacing or installing any assemblies, the presser feet, needle, or

other parts to assure correct installation.

9For repair or adjustment:

• If the light unit is damaged, it must be replaced by an authorized Brother dealer.

• In the event a malfunction occurs or adjustment is required, first follow the troubleshooting table in the back of

the operation manual to inspect and adjust the machine yourself. If the problem persists, please consult your

local authorized Brother dealer.

2

Page 5

IMPORTANT SAFETY INSTRUCTIONS

Use this machine only for its intended use as described in the manual.

Use accessories recommended by the manufacturer as contained in this manual.

Use only the mouse designed specifically for this machine.

The contents of this manual and specifications of this product are subject to change without notice.

For additional product information and updates, visit our website at www.brother.com

SAVE THESE INSTRUCTIONS

This machine is intended for household use.

FOR USERS IN COUNTRIES EXCEPT CENELEC COUNTRIES

This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction concerning use of the

appliance by a person responsible for their safety. Children should be supervised

to ensure that they do not play with the appliance.

FOR USERS IN CENELEC COUNTRIES

This appliance can be used by children aged from 8 years and above and persons

with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved. Children shall not

play with the appliance. Cleaning and user maintenance shall not be made by

children without supervision.

FOR USERS IN THE UK, EIRE, MALTA AND CYPRUS

ONLY

IMPORTANT

• In the event of replacing the plug fuse, use a fuse approved by ASTA to BS 1362, i.e. carrying the mark,

rating as marked on plug.

• Always replace the fuse cover. Never use plugs with the fuse cover omitted.

• If the available electrical outlet is not suitable for the plug supplied with this equipment, you should contact your

authorized Brother dealer to obtain the correct lead.

3

Page 6

IMPORTANT SAFETY INSTRUCTIONS

Federal Communications Commission (FCC) Declaration

of Conformity (For U.S.A. Only)

Responsible Party: Brother International Corporation

200 Crossing Boulevard

P.O. Box 6911

Bridgewater, NJ 08807-0911 USA

TEL : (908) 704-1700

declares that the product

Product Name:

Model Number:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one or more of the following measures:

Brother Sewing Machine

XP1

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the authorized Brother dealer or an experienced radio/TV technician for help.

• This transmitter must not be co-located or operated in conjunction with any other antenna or transmitter.

Important

Changes or modifications not expressly approved by Brother Industries, Ltd. could void the user's authority to

operate the equipment.

This equipment complies with FCC/IC radiation exposure limits set forth for an uncontrolled environment and meets

the FCC radio frequency (RF) Exposure Guidelines and RSS-102 of the IC radio frequency (RF) Exposure rules. This

equipment has very low levels of RF energy that it deemed to comply without maximum permissive exposure

evaluation (MPE).

4

Page 7

IMPORTANT SAFETY INSTRUCTIONS

For users in Canada

This equipment complies with FCC/IC radiation exposure limits set forth for an uncontrolled environment and meets the FCC

radio frequency (RF) Exposure Guidelines and RSS-102 of the IC radio frequency (RF) Exposure rules. This equipment has very

low levels of RF energy that it deemed to comply without maximum permissive exposure evaluation (MPE).

For users in Mexico

The operation of this equipment is subject to the following two conditions:

(1) it is possible that this equipment or device may not cause harmful interference, and

(2) this equipment or device must accept any interference, including interference that may cause undesired operation.

La operación de este equipo está sujeta a las siguientes dos condiciones:

(1) es posible que este equipo o dispositivo no cause interferencia perjudicial y

(2) este equipo o dispositivo debe aceptar cualquier interferencia, incluyendo la que pueda causar su operación no deseada.

Declaration of Conformity (Europe and Turkey only)

We, Brother Industries, Ltd.

15-1 Naeshiro-cho, Mizuho-ku, Nagoya 467-8561 Japan

declare that this product is in conformity with the essential requirements of all relevant directives and regulations applied within

the European Community.

The Declaration of Conformity (DoC) can be downloaded from Brother Solutions Center.

Visit support.brother.com

click “Manuals”

select your model

click “Declaration of Conformity”

click “Download”

Your Declaration will be downloaded as a PDF file.

and:

Declaration of Conformity for RE Directive 2014/53/EU

(CENELEC and Turkey only)

(Applicable to models with radio interfaces)

We, Brother Industries, Ltd.

15-1 Naeshiro-cho, Mizuho-ku, Nagoya 467-8561 Japan

declare that these products are in conformity with the provisions of the RE Directive 2014/53/EU. A copy of the Declaration of

Conformity can be downloaded by following the instructions in the Declaration of Conformity (CENELEC and Turkey only)

section.

Wireless LAN (Models with Wireless LAN function only)

This machine supports wireless interface.

Frequency band(s): 2400-2483.5 MHz

Maximum radio-frequency power transmitted in the frequency band(s): Less than 20 dBm(e.i.r.p)

For users in Norway

* This subsection does not apply for the geographical area within a radius of 20 km from the centre of Ny-Alesund on Svalbard.

* Dette underavsnittet gjelder ikke for det geografiske området innenfor en radius av 20 km fra sentrum av Ny-Ålesund på

Svalbard.

For users in Thailand

This telecommunication equipment conforms to NTC technical requirement.

5

Page 8

Trademarks

Trademarks

Secure Digital (SD) Card is a registered trademark or a trademark of SD-3C, LLC.

CompactFlash is a registered trademark or a trademark of Sandisk Corporation.

Memory Stick is a registered trademark or a trademark of Sony Corporation.

SmartMedia is a registered trademark or a trademark of Toshiba Corporation.

MultiMediaCard (MMC) is a registered trademark or a trademark of Infineon Technologies AG.

xD-Picture Card is a registered trademark or a trademark of Fuji Photo Film Co. Ltd.

IBM is a registered trademark or a trademark of International Business Machines Corporation.

“Adobe” and “Adobe Reader” are either registered trademarks or trademarks of Adobe Systems Incorporated in the United States and/or other

countries.

Artifex, the Artifex logo, MuPDF, Ghostscript, the SmartOffice logo, and the Ghostscript logo are registered trademarks of Artifex Software, Inc.

Portions Copyright © 1998/2016 Artifex Software Inc.

This software is based in part on the work of the Independent JPEG Group.

Portions Copyright © 1998 Soft Horizons.

Portions Copyright © 2005 LuraTech Imaging GmbH. All Rights Reserved.

Each company whose software title is mentioned in this manual has a Software License Agreement specific to its proprietary programs.

Any trade names and product names of companies appearing on Brother products, related documents and any other materials are all trademarks

or registered trademarks of those respective companies.

Open Source Licensing Remarks

This product includes open-source software.

To see the open source licensing remarks, please go to the manual download section on your model's

home page of Brother Solutions Center at “ http://s.brother/cpdab/

”.

6

Page 9

HOW TO USE THIS MANUAL

The Operation Manuals for this machine consist of the Operation Manual (Sewing) and the Operation

Manual (Embroidery). Refer to the appropriate Operation Manual according to your needs. For basic

information about, for example, the included accessories or the settings screen, refer to chapter 1 of the

Operation Manual (Sewing).

In the screens appearing in the step-by-step instructions, the parts referred to in the operations are marked

with . Compare the screen in the directions with the actual screen, and carry out the operation.

If, while using the machine, you experience something you do not understand, or there is a function you

would like to know more about, refer to the index at the back of the Operation Manual in conjunction

with the table of contents to find the section of the manual you should refer to.

7

Page 10

CONTENTS

CONTENTS

INTRODUCTION ................................................. 1

IMPORTANT SAFETY INSTRUCTIONS ................ 1

Trademarks........................................................... 6

Open Source Licensing Remarks........................... 6

HOW TO USE THIS MANUAL ............................. 7

Chapter 1 Getting Ready 11

NAMES OF MACHINE PARTS AND THEIR

FUNCTIONS....................................................... 12

Machine............................................................................... 12

Needle and Presser Foot Section .......................................... 14

Embroidery Unit................................................................... 15

Operation Buttons................................................................ 15

Using the Flat Bed Attachment............................................. 16

Using the Accessory Case..................................................... 16

Storing Bobbin Clips............................................................. 17

Included Accessories............................................................ 18

Options................................................................................ 21

Using the Multi-purpose Screwdriver ................................... 24

Using the Spool Stand .......................................................... 24

Assembling the Spool Stand ................................................. 25

TURNING THE MACHINE ON/OFF................... 26

Setting Your Machine for the First Time................................ 27

LCD SCREEN ...................................................... 28

Using the Machine Setting Mode Key................................... 29

Sewing Settings .................................................................... 29

General Settings................................................................... 30

Embroidery Settings.............................................................. 32

Wireless LAN settings........................................................... 33

Setting Functions.................................................................. 33

Using the Machine Help Key................................................ 39

Using the Operation Guide Function.................................... 40

Using the Sewing Guide Function ........................................ 41

Playing a Tutorial Video....................................................... 42

Playing MPEG-4 (MP4) Videos............................................. 43

Using the Stitch Pattern Explanation Function ...................... 44

Viewing the Operation Manual (PDF File) on the Machine... 45

WIRELESS NETWORK CONNECTION FUNCTIONS

Specifying Wireless Network Connection Settings ................ 46

Using the Wizard to Set Up the Wireless Network Connection

... 46

... 47

CONNECTING THE ACCESSORY TO THE

MACHINE........................................................... 49

Using USB Media/SD card (Sold Separately)......................... 49

Using a USB Mouse (Sold Separately)................................... 49

Chapter 2 Sewing Basics 51

LOWER THREADING ......................................... 52

Winding the Bobbin ............................................................. 52

Setting the Bobbin ................................................................ 58

Pulling Up the Bobbin Thread .............................................. 59

UPPER THREADING........................................... 61

Upper Threading.................................................................. 61

Using the Twin Needle Mode............................................... 64

Using the Spool Stand .......................................................... 66

Using Threads that Unwind Quickly .................................... 68

CHANGING THE NEEDLE.................................. 69

Fabric/Thread/Needle Combinations.................................... 71

CHANGING THE PRESSER FOOT ...................... 72

Removing the Presser Foot ................................................... 72

Attaching the Presser Foot .................................................... 72

Attaching the Presser Foot with the Included Adapter........... 73

Using the Dual Feed Foot..................................................... 74

SEWING ............................................................. 77

Sewing a Stitch..................................................................... 77

Sewing Reinforcement Stitches............................................. 79

Automatic Reinforcement Stitching ...................................... 79

Automatic Presser Foot Lowering Function and Thread Cutting

Function .............................................................................. 81

Sewing Curves..................................................................... 81

Changing Sewing Direction ................................................. 81

Sewing Heavyweight Fabrics ............................................... 82

Sewing Hook-and-Loop Fastener Tape................................. 83

Sewing Lightweight Fabrics.................................................. 84

Sewing Stretch Fabrics......................................................... 84

STITCH SETTINGS ............................................. 85

Setting the Stitch Width ....................................................... 85

Setting the Stitch Length....................................................... 86

Setting the “L/R Shift”........................................................... 86

Setting the Thread Tension................................................... 87

USEFUL FUNCTIONS ........................................ 88

Automatic Thread Cutting.................................................... 88

Pivoting ............................................................................... 89

Using the Knee Lifter ........................................................... 90

Automatic Fabric Sensor System (Automatic Presser Foot

Pressure).............................................................................. 91

Needle Position - Stitch Placement ...................................... 92

Checking the Needle Location in the Screen........................ 92

USING THE PROJECTOR ................................... 94

Convenient Sewing Features by Using the Projector ............ 94

About the Dual Purpose Stylus............................................. 94

Installing a Battery in the Dual Purpose Stylus ..................... 94

Operating the Projector with the Dual Purpose Stylus.......... 95

Using the Dual Purpose Stylus Holder ................................. 95

PROJECTOR FUNCTIONS (UTILITY STITCHES

AND CHARACTER/DECORATIVE STITCHES).... 96

Projection Area of Projector................................................. 96

Projecting the Stitch Pattern with the Projector .................... 96

Selecting a Stitch Pattern with the Dual Purpose Stylus........ 97

Editing a Stitch Pattern Selected with the Dual Purpose Stylus

Projecting the Guidelines with the Projector........................ 98

... 97

Chapter 3 Utility Stitches 101

SELECTING UTILITY STITCHES ....................... 102

Selecting a Stitch ............................................................... 105

Saving Your Stitch Settings................................................. 107

SEWING THE STITCHES .................................. 108

Straight Stitches ................................................................. 108

Dart Seam.......................................................................... 112

Gathering .......................................................................... 113

Flat Fell Seam.................................................................... 113

Pintuck .............................................................................. 114

Zigzag Stitches................................................................... 116

Elastic Zigzag Stitches........................................................ 117

Overcasting ....................................................................... 118

Quilting............................................................................. 121

Blind Hem Stitches............................................................ 131

Appliqué............................................................................ 133

Shelltuck Stitches............................................................... 134

Scallop Stitches.................................................................. 135

Crazy Quilting................................................................... 135

Smocking Stitches.............................................................. 136

Fagoting............................................................................. 137

Tape or Elastic Attaching ................................................... 137

Heirloom........................................................................... 138

Basting............................................................................... 140

One-step Buttonholes ........................................................ 141

Four-step Buttonholes........................................................ 145

Bar Tacks........................................................................... 148

Button Sewing ................................................................... 149

Eyelet................................................................................. 150

Multi-directional Sewing (Straight Stitch and Zigzag Stitch)

Zipper Insertion................................................................. 152

... 151

8

Page 11

CONTENTS

Chapter 4

SELECTING STITCH PATTERNS ....................... 158

Selecting Decorative Stitch Patterns ................................... 160

Selecting Character Stitch Patterns ..................................... 160

SEWING STITCH PATTERNS ............................ 163

Sewing Attractive Finishes.................................................. 163

Basic Sewing...................................................................... 163

Making Adjustments .......................................................... 164

EDITING STITCH PATTERNS ........................... 166

Changing the Size.............................................................. 169

Changing the Length (for 7mm Satin Stitch Patterns Only)

Creating a Vertical Mirror Image........................................ 169

Creating a Horizontal Mirror Image ................................... 169

Sewing a Stitch Pattern Continuously ................................. 169

Changing Thread Density (for Large Satin Only)................. 170

Returning to the Beginning of the Stitch Pattern ................. 170

Checking the Image ........................................................... 171

COMBINING STITCH PATTERNS .................... 172

Before Combining.............................................................. 172

Combining Various Stitch Patterns ..................................... 172

Combining Large and Small Stitch Patterns ........................ 173

Combining Horizontal Mirror Image Stitch Patterns ........... 174

Combining Stitch Patterns of Different Length.................... 175

Making Step Stitch Patterns................................................ 175

USING THE MEMORY FUNCTION.................. 178

Stitch Data Precautions ...................................................... 178

Saving Stitch Patterns in the Machine’s Memory ................ 179

Saving Stitch Patterns to USB Media .................................. 179

Retrieving Stitch Patterns from the Machine’s Memory....... 180

Recalling from USB Media................................................. 181

Managing Saved File .......................................................... 182

Transferring Stitch Patterns to the Machine (PE-DESIGN to this

machine)............................................................................ 183

Character/Decorative Stitches

157

1

... 169

2

3

4

5

Chapter 5 MY CUSTOM STITCH 185

DESIGNING A STITCH .................................... 186

ENTERING STITCH DATA................................ 188

Editing Stitch Stored in the Machine................................... 192

USING STORED CUSTOM STITCHES .............. 194

Storing Custom Stitches in Your List................................... 194

Retrieving Stored Stitches................................................... 195

Chapter 6 Appendix 197

CARE AND MAINTENANCE............................. 198

Restrictions on oiling ......................................................... 198

Precautions on storing the machine ................................... 198

Cleaning the LCD Screen................................................... 198

Cleaning the Machine Casing ............................................ 198

Cleaning the Race.............................................................. 198

Cleaning the Cutter in the Bobbin Case Area ..................... 200

About the Maintenance Message ....................................... 200

TROUBLESHOOTING ...................................... 201

Frequent Troubleshooting Topics ....................................... 201

Upper Thread is Too Tight ................................................. 201

Tangled Thread on Wrong Side of Fabric ........................... 202

Incorrect Thread Tension ................................................... 204

Fabric is Caught in the Machine and Cannot be Removed

List of Symptoms................................................................ 208

ERROR MESSAGES ........................................... 213

SPECIFICATIONS ............................................. 216

UPGRADING YOUR MACHINE’S SOFTWARE

Upgrade Procedure Using USB Media ............................... 217

STITCH SETTING CHART................................. 218

INDEX .............................................................. 227

... 205

... 217

6

9

Page 12

CONTENTS

10

Page 13

Chapter 1

Getting Ready

Page 14

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

CAUTION

a

b

c

d

ef

g

h

o

p

i

j

l

m

n

k

q

*

CAUTION

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

The names of the various parts of the machine and their functions are described below. Before using the

machine, carefully read these descriptions to learn the names of the machine parts.

Machine

■ Front View

a Top cover

Open the top cover when threading the machine or winding the

bobbin.

• Do not place any object weighing 1 kg or more

on the top cover, otherwise the cover may be

damaged.

b Pretension disk

Pass the thread around the pretension disk when winding the

bobbin thread. (page 52)

c Thread guide for bobbin winding

Pass the thread through this thread guide when winding the

bobbin thread. (page 52)

d Spool pin

Place a spool of thread on the spool pin. (page 61)

e Spool cap

Use the spool cap to hold the spool of thread in place.

(page 61)

f Supplemental spool pin

Use this spool pin to wind the bobbin thread, or to sew with the

twin needle. (page 52, 64)

g Bobbin winder

Use the bobbin winder when winding the bobbin. (page 52)

h Bobbin winding slider

Adjust the amount of thread wound onto the bobbin. (page 54)

i LCD (liquid crystal display)

Settings for the selected stitch and error messages appear in

the LCD. (page 28)

j Speaker

k Knee lifter

Use the knee lifter to raise and lower the presser foot. (page 90)

l Knee lifter slot

Insert the knee lifter into the slot. (page 90)

m Operation buttons (7 buttons) and sewing speed

controller

Use these buttons and the slide to operate the machine.

(page 15)

n Needle plate lever

Slide the lever toward you to remove the needle plate.

(page 198)

o Flat bed attachment with accessory compartment

Store presser feet and bobbins in the accessory compartment

of the flat bed attachment. When sewing cylindrical pieces,

remove the flat bed attachment. (page 16)

p Thread cutter

Pass the threads through the thread cutter to cut them.

(page 63)

q Thread guide plate

Pass the thread around the thread guide plate when threading

upper thread. (page 61)

* Camera and projector (built-in)

• Do not touch the camera or projector.

Otherwise, it will not display properly.

■ Right-side/Rear View

l

k

j

i

h

g

a Connector for the presser foot

Connect the dual feed foot or embroidery foot with LED pointer

(sold separately). (page 74)

b Handle

Carry the machine by its handle when transporting the

machine.

c Presser foot lever

Raise and lower the presser foot lever to raise and lower the

presser foot. (page 72)

d Air vent

The air vent allows the air surrounding the motor to circulate.

Do not cover the air vent while the machine is being used.

e Main power switch

Use the main power switch to turn the machine ON and OFF.

(page 26)

f Foot controller

Use the foot controller to operate the machine.

g Power cord receptacle

Insert the power cord into the machine receptacle. (page 26)

h Dual purpose stylus holder connector

Connect the included dual purpose stylus holder. (page 95)

i Foot controller jack

Insert the foot controller plug into its jack on the machine.

(page 78)

f

d

e

a

b

c

12

Page 15

j USB port

In order to send stitch patterns and embroidery patterns from/

to USB media, plug the USB media directly into the USB port.

k SD card slot

Insert an SD card into the SD card slot in order to import/export

stitch patterns and embroidery patterns.

l Handwheel

Rotate the handwheel toward you (counterclockwise) to raise

and lower the needle. The wheel should be turned toward the

front of the machine.

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

1

Getting Ready

13

Page 16

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

a

b

c

d

g

h

e

f

a

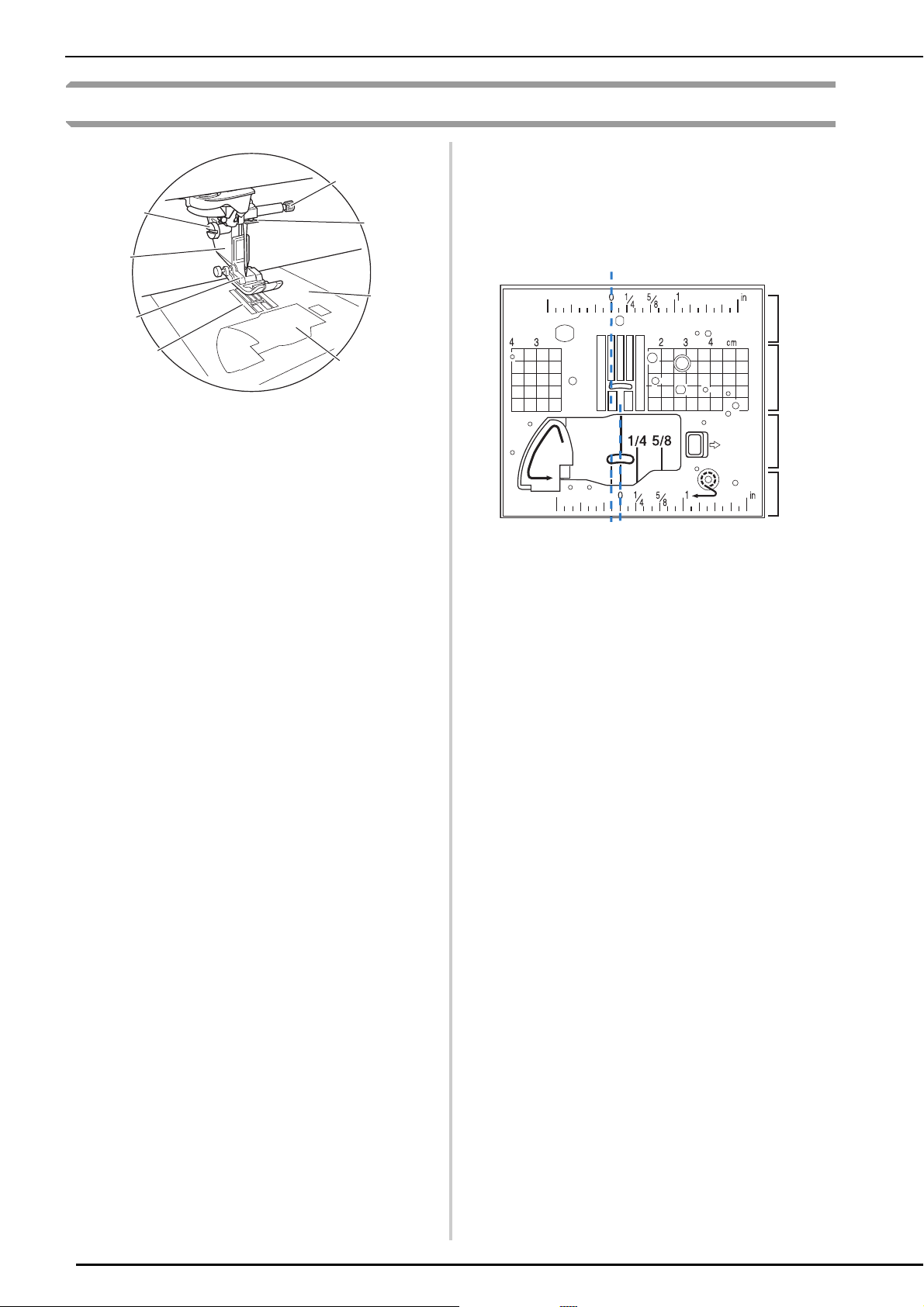

Needle and Presser Foot Section

a Presser foot holder screw

Use the presser foot holder screw to hold the presser foot in

place. (page 73)

b Presser foot holder

The presser foot is attached to the presser foot holder.

(page 72)

c Presser foot

The presser foot consistently applies pressure to the fabric as

sewing takes place. Attach the appropriate presser foot for the

selected stitch. (page 72)

d Feed dogs

The feed dogs feed the fabric in the sewing direction.

e Bobbin cover

Open the bobbin cover to set the bobbin. (page 58, 117)

f Needle plate

The needle plate is marked with guides to help sew straight

seams. (page 110)

Remove the needle plate to clean the race. (page 111, 198)

g Needle bar thread guide

Pass the upper thread through the needle bar thread guide.

(page 61)

h Needle clamp screw

Use the needle clamp screw to hold the needle in place.

(page 73)

Measurements on the needle plate and the bobbin

cover (with mark)

The measurements on the bobbin cover and

needle plate are references for stitch patterns with

a left or middle (center) needle position.

b

c

d

e

f

b

a For stitches with a middle (center) needle position

b For stitches with a left needle position

c Left needle position on the needle plate <inch>

d Left needle position on the needle plate <cm>

e Middle (center) needle position on the bobbin cover

(with mark) <inch>

f Middle (center) needle position on the needle plate

<inch>

14

Page 17

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

CAUTION

a

b

c

d

e

CAUTION

abc

d

e

fg

h

Embroidery Unit

a Carriage

The carriage moves the embroidery frame automatically when

embroidering.

b Release lever (located under the embroidery unit)

Press the release lever to remove the embroidery unit.

c Embroidery frame holder

Insert the embroidery frame into the embroidery frame holder

to hold the frame in place.

d Frame-securing lever

Press the frame-securing lever down to secure the embroidery

frame.

e Embroidery unit connection

Insert the embroidery unit connection into the connection port

when attaching the embroidery unit.

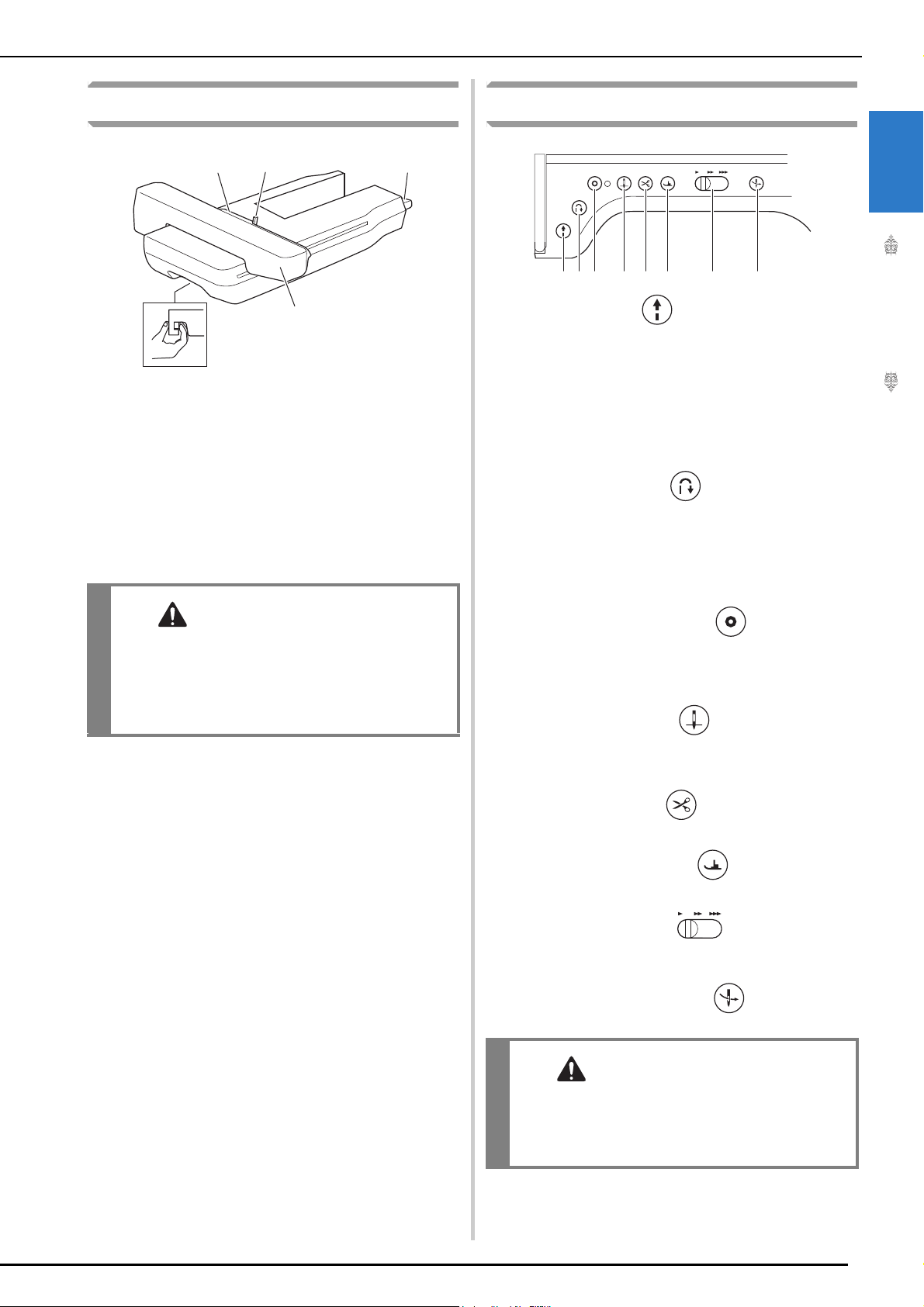

Operation Buttons

a “Start/Stop” button

Press this button and the machine will sew a few stitches at a

slow speed and then begin sewing at the speed set by the

sewing speed controller. Press the button again to stop the

machine. Hold the button in to sew at the machine’s slowest

speed. The button changes color according to the machine’s

operation mode.

Green: The machine is ready to sew or is sewing.

Red: The machine cannot sew.

b “Reverse Stitch” button

For straight, zigzag, and elastic zigzag stitch patterns that take

reverse stitches, the machine will sew reverse stitches at low

speed only while holding down the “Reverse Stitch” button.

The stitches are sewn in the opposite position.

For other stitches, use this button to sew reinforcement

stitches at the beginning and end of sewing. Press and hold

this button, and the machine sews 3 stitches in the same spot

and stops automatically. (page 79)

1

Getting Ready

• Before inserting or removing the embroidery

unit, turn the main power to off.

• After the embroidery frame is set in the frame

holder, be sure the frame-securing lever is

correctly lowered.

c “Reinforcement Stitch” button

Use this button to sew a single stitch repeatedly and tie-off.

For character/decorative stitches, press this button to end with

a full stitch instead of at a mid-point. The LED light beside this

button lights up while the machine is sewing a full motif, and

automatically turns off when the sewing is stopped. (page 79)

d “Needle Position” button

Use this button when changing sewing direction or for detailed

sewing in small areas. Press this button to raise or lower the

needle position. With this button, you can lower and raise the

needle to sew a single stitch.

e “Thread Cutter” button

Press this button after sewing to automatically trim the excess

thread.

f “Presser Foot Lifter” button

Press this button to lower the presser foot and apply pressure

to the fabric. Press this button again to raise the presser foot.

g Sewing Speed controller

Use this controller to adjust the sewing speed. Move the slide

to the left to sew at slower speeds. Move the slide to the right

to sew at higher speeds.

h “Automatic Threading” button

Use this button to automatically thread the needle.

• Do not press the thread cutter button after the

threads have been cut. The needle may break

and threads may become tangled, or damage

to the machine may occur.

15

Page 18

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

a

b

Using the Flat Bed Attachment

Pull the top of the flat bed attachment to open the

accessory compartment.

Using the Accessory Case

■ Opening the Accessory Case

Slide the latches on the front of the accessory case

outward to open it.

■ Using the Accessory Trays

Three presser foot storage trays are stored in the

included accessory case.

For your convenience, a presser foot storage tray

can be stored in the accessory compartment of the

flat bed attachment.

a Latches

a

a Presser foot storage space of the flat bed

attachment

b Presser foot storage trays

16

Page 19

Storing Bobbin Clips

Memo

Bobbin clips can be stored inside of the accessory

case cover.

• Placing bobbin clips on bobbins helps

prevent the thread from unwinding from the

bobbin. In addition, snapping bobbin clips

together allows the bobbins to be

conveniently stored and prevents them from

rolling around if they are dropped.

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

1

Getting Ready

17

Page 20

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

J

N

G

I

R

M

O

O

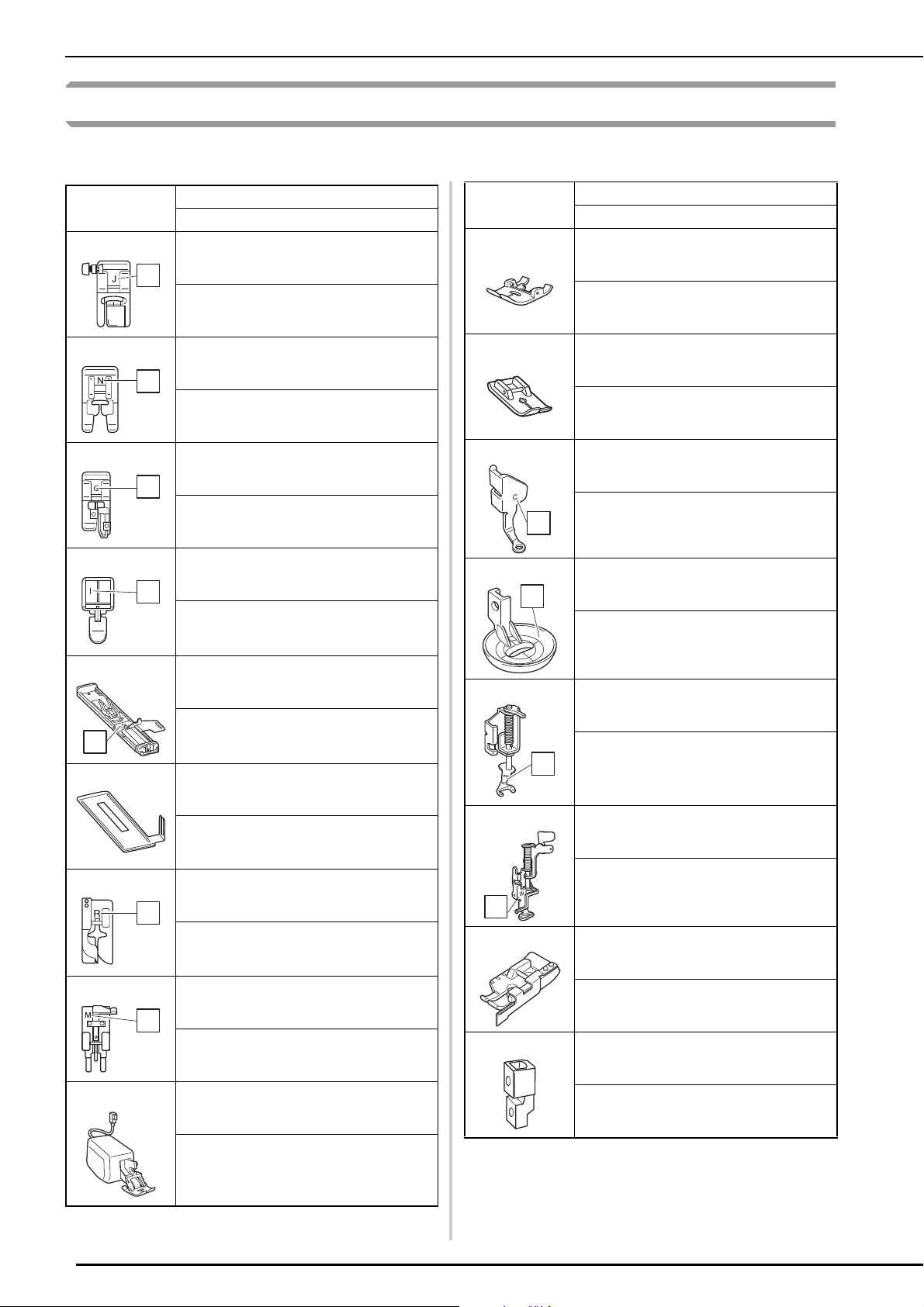

Included Accessories

After opening the box, check that the following accessories are included. If any item is missing or

damaged, contact your authorized Brother dealer.

Part Name

Part Code

1.

Zigzag foot “J” (on machine)

10.

Regular dual feed foot

Part Name

Part Code

XF3022-001

2.

Monogramming foot “N”

X53840-351

3.

Overcasting foot “G”

XC3098-051

4.

Zipper foot “I”

11.

12.

13.

XF4419-001

Straight stitch foot

SA167 (Americas)

F042: XC1973-052 (other area)

Free motion quilting foot “C”

XF4737-001

C

Free motion echo quilting foot “E”

E

X59370-051

5.

Buttonhole foot “A+”

A+

6.

XH2665-001

Buttonhole foot stabilizer

XH1726-001

14.

15.

E

XE0766-001

Free motion open toe quilting foot “O”

XF4873-001

Embroidery foot “W”

18

7.

Blind stitch foot “R”

XF4012-001

W

X56409-051

8.

Button fitting foot “M”

130489-001

9.

Dual feed foot

SA196 (Americas)

DF1: XF4166-001 (Europe)

DF1AP: XF6843-001 (other area)

16.

1/4 quilting foot with guide

SA185 (Americas)

F057: XC7416-252 / 115C05E0005 (Europe)

F057: 115C05E7005 (other area)

17.

Adapter

SA131 (Americas)

F010N: XF3613001 / 115Z05E0004 (Europe)

F010AP: 115Z05E7004 (other area)

Page 21

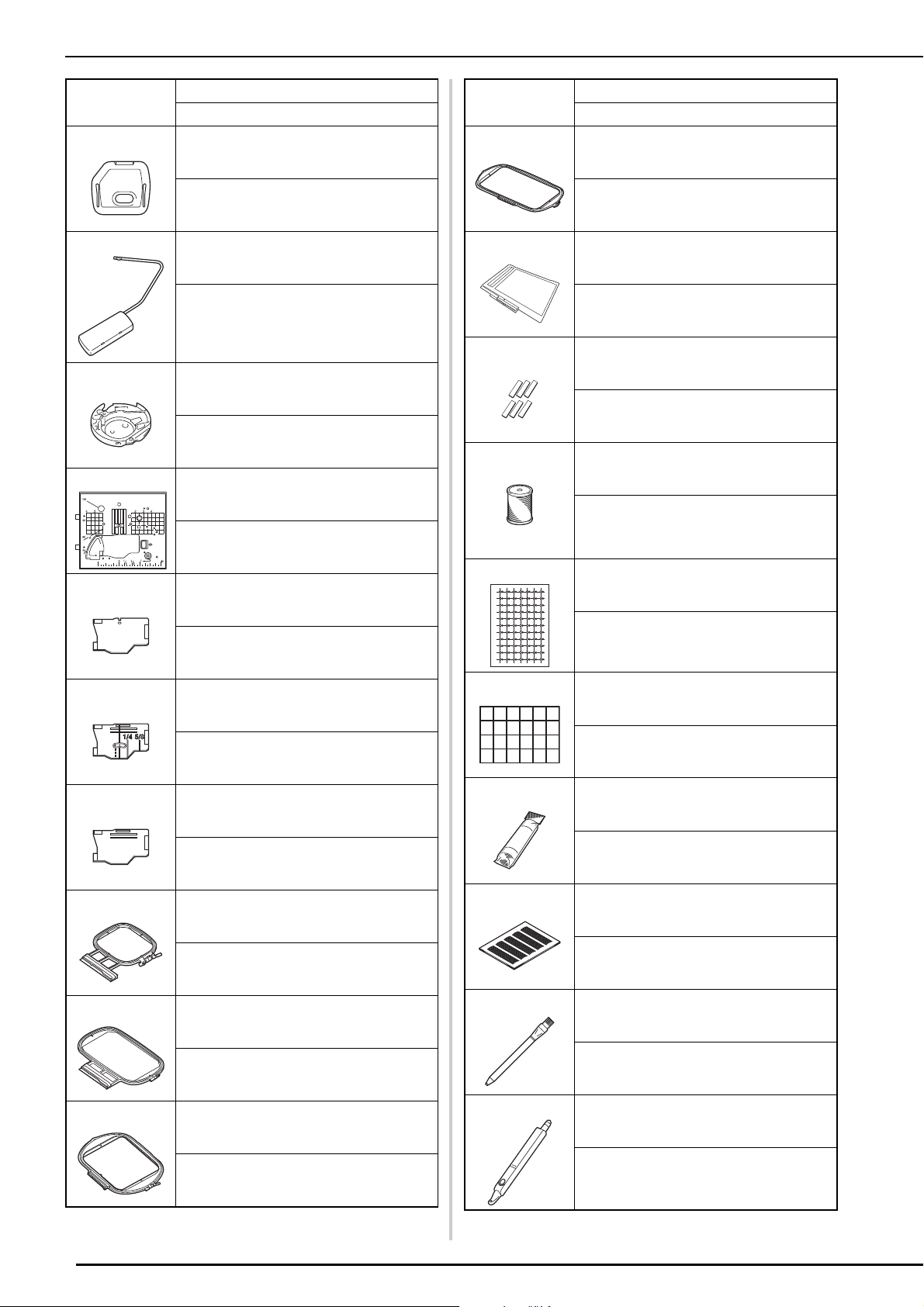

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

Part Name

Part Code

18.

Screw (small)

XA4813-051

19. Needle set

20.

21. Ball point needle set

22.

75/11 2 needles

90/14 2 needles

90/14 2 needles: Ball point needle (gold

colored)

XE4962-001

Twin needle

2.0/11 needle

XE4963-001

75/11 2 needles:

Ball point needle for embroidery

HAX130EBBR

XD0705-151

Bobbin × 10 (One is on machine.)

28.

29.

30.

31.

32.

Part Name

Part Code

Screwdriver (large)

XC4237-021

Multi-purpose screwdriver

SAMDRIVER1 (U.S.A) / SAMDRIVER1C

(Canada)

MDRIVER1: XG1298-001 / 115Z05E0003

(Europe)

MDRIVER1AP: 115Z05E7003 (other area)

Spool cap (small)

130013-154

Spool cap (medium) × 2 (One is on machine.)

X55260-153

Spool cap (large)

1

Getting Ready

23.

24.

25.

26.

27.

SA156 (Americas)

SFB: XA5539-151 / 115J05E0001 (Europe)

SFB: 115J05E7001 (other area)

Seam ripper

XF4967-001

Scissors

XF2052-001

Cleaning brush

X59476-051

Eyelet punch

XZ5051-001

Screwdriver (small)

130012-054

33.

Thread spool insert (mini king thread spool)

XA5752-121

34.

Spool stand

XH1606-001

Refer to “Using the Spool Stand” on page 24.

35.

Bobbin clip × 10

XE3060-001

36.

Spool felt (on machine)

X57045-051

37.

Spool net × 2

X55468-051

XA5523-050

19

Page 22

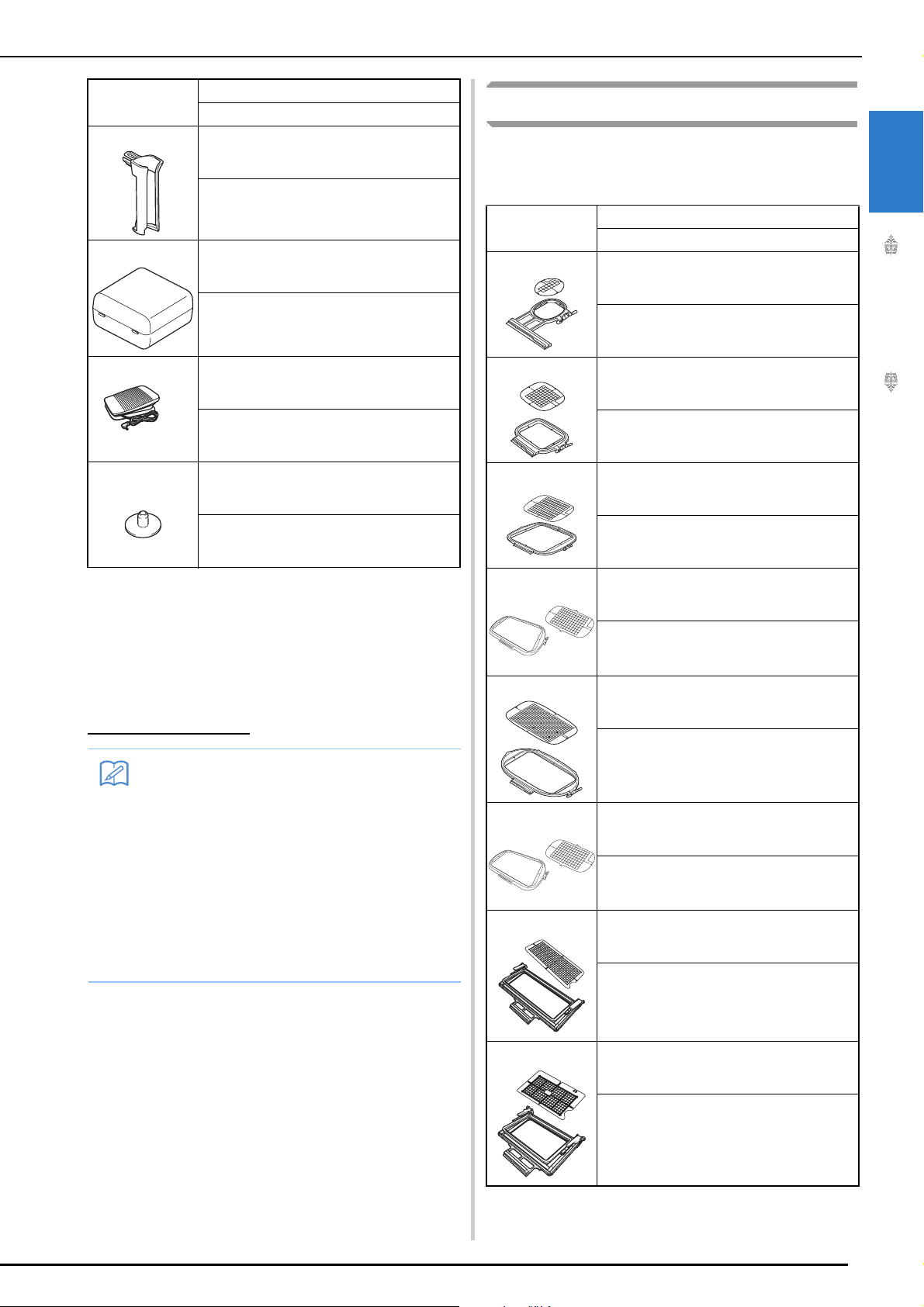

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

38.

39.

40.

41.

42.

Part Name

Part Code

Embroidery needle plate cover

XE4708-001

Knee lifter

SA599 (Americas)

KL1: XG6723-001 /115Z05E000C (Europe)

KL1: XE5902-001 / 115Z05E700C (other area)

Alternate bobbin case (no color on the screw)

XC8167-651

Straight stitch needle plate

XH1569-001

Cord guide bobbin cover (with single hole)

48.

49.

50.

51.

52.

Part Name

Part Code

Embroidery frame (LL) H 408 mm × W 272 mm

(H 16 inches × W 10-5/8 inches)

XH1466-001

Scanning frame

XF9321-001

Magnet × 6

XF9325-001

Embroidery bobbin thread

SA-EBT (Americas)

EBT-CEN: X81164-001 / 115G05E0001

(Europe)

EBT-CEN: 115G05E7001 (other area)

Embroidery positioning sticker sheets × 2

43.

44.

45.

46.

47.

XE0085-101

Bobbin cover (with mark)

XH3126-001

Bobbin cover (on machine)

XF9666-101

Embroidery frame (medium) H 100 mm × W

100 mm (H 4 inches × W 4 inches)

SA438 (Americas)

EF74: XC8480-152 / 115D05E0005 (Europe)

EF74: 115D05E7005 (other area)

Embroidery frame (large) H 180 mm × W 130

mm (H 7 inches × W 5 inches)

SA439 (Americas)

EF75: XC8481-152 / 115D05E0001 (Europe)

EF75: 115D05E7001 (other area)

Embroidery frame (quilt) H 240 mm × W 240

mm (H 9-1/2 inches × W 9-1/2 inches)

SAEPS2 (U.S.A.) / SAEPS2C (Canada)

EPS2: XG6749-001 / 115Z05E000E (Europe)

EPS2: 115Z05E700E (other area)

53.

White calibration stickers (solid)

XE7916-001

54.

Stabilizer material

SA519 (Americas)

BM3: XG6683-001 / 115Z05E0007 (Europe)

BM3: 115Z05E7007 (other area)

55.

Grid sheet set

SA507 (Americas)

GS3: X81277-151 (other area)

56.

Chalk pencil

XE8568-001

57.

Dual purpose stylus

20

XG5558-001

XH1791-001

XH1807-001 (Europe)

Page 23

58.

Memo

59.

Part Name

Part Code

Dual purpose stylus holder

XH1805-001

Accessory case

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

Options

The following are available as optional accessories

to be purchased separately from your authorized

Brother dealer.

Part Name

Part Code

1.

Embroidery frame set (small) H 20 mm × W 60

mm (H 1 inch × W 2-1/2 inches)

1

Getting Ready

XH1836-001

60.

Foot controller

XC8816-051

61.

Bobbin center pin and instruction sheet

XF5048-001

Following documents can be downloaded at

Brother Solutions Center:

• Operation Manual (Sewing)

• Operation Manual (Embroidery)

• Embroidery Design Guide

• DISNEY DESIGN GUIDE

http://s.brother/cpdab/

• (For U.S.A. only)

Foot controller: Model T

This foot controller can be used on the

machine with product code 882-W30. The

product code is mentioned on the machine

rating plate.

• Always use accessories recommended for

this machine.

• The screw for the presser foot holder is

available through your authorized Brother

dealer (Part code XA4813-051).

SA437 (Americas)

EF73: XG6663-001 (Europe)

EF73: XC8479-152 (other area)

2.

3.

4.

5.

6.

7.

8.

Embroidery frame set (square) H 150 mm × W

150 mm (H 6 inches × W 6 inches)

SA448 (U.S.A.) SA448C (Canada)

SEF150: XG6761-001 (Europe)

SEF150: 115D05E000E (other area)

Embroidery frame set (quilt) H 200 mm × W

200 mm (H 8 inches × W 8 inches)

SA446 (U.S.A.) SA446C (Canada)

EF91: XG6715-001 (Europe)

EF91: XE5068-101 (other area)

Embroidery frame set (extra large) H 300 mm ×

W 200 mm (H 12 inches × W 8 inches)

SA447 (Americas)

EF92: XG6717-001 (Europe)

EF92: XE5071-001 (other area)

Embroidery frame set (extra large) H 260 mm ×

W 160 mm (H 10-1/4 inches × W 6-1/4 inches)

SA441 (Americas)

EF81: XG6673-001 (Europe)

EF81: XC9763-152 (other area)

Embroidery frame set (super large) H 360 mm

× W 240 mm (H 14 inches × W 9-1/2 inches)

XF9309-001

Border embroidery frame H 300 mm × W 100

mm (H 12 inches × W 4 inches)

SABF6200D1 (U.S.A.) SABF6200D1C

(Canada)

BF3: XG6763-001 (Europe)

BF3: XF4170-001/115D05E000N (other area)

Border embroidery frame set H 180 mm × W

100 mm (H 7 inches × W 4 inches)

SABF6000D (U.S.A.) SABF6000DC (Canada)

BF2: XG6079-001 (Europe)

BF2: XE5059-001 (other area)

21

Page 24

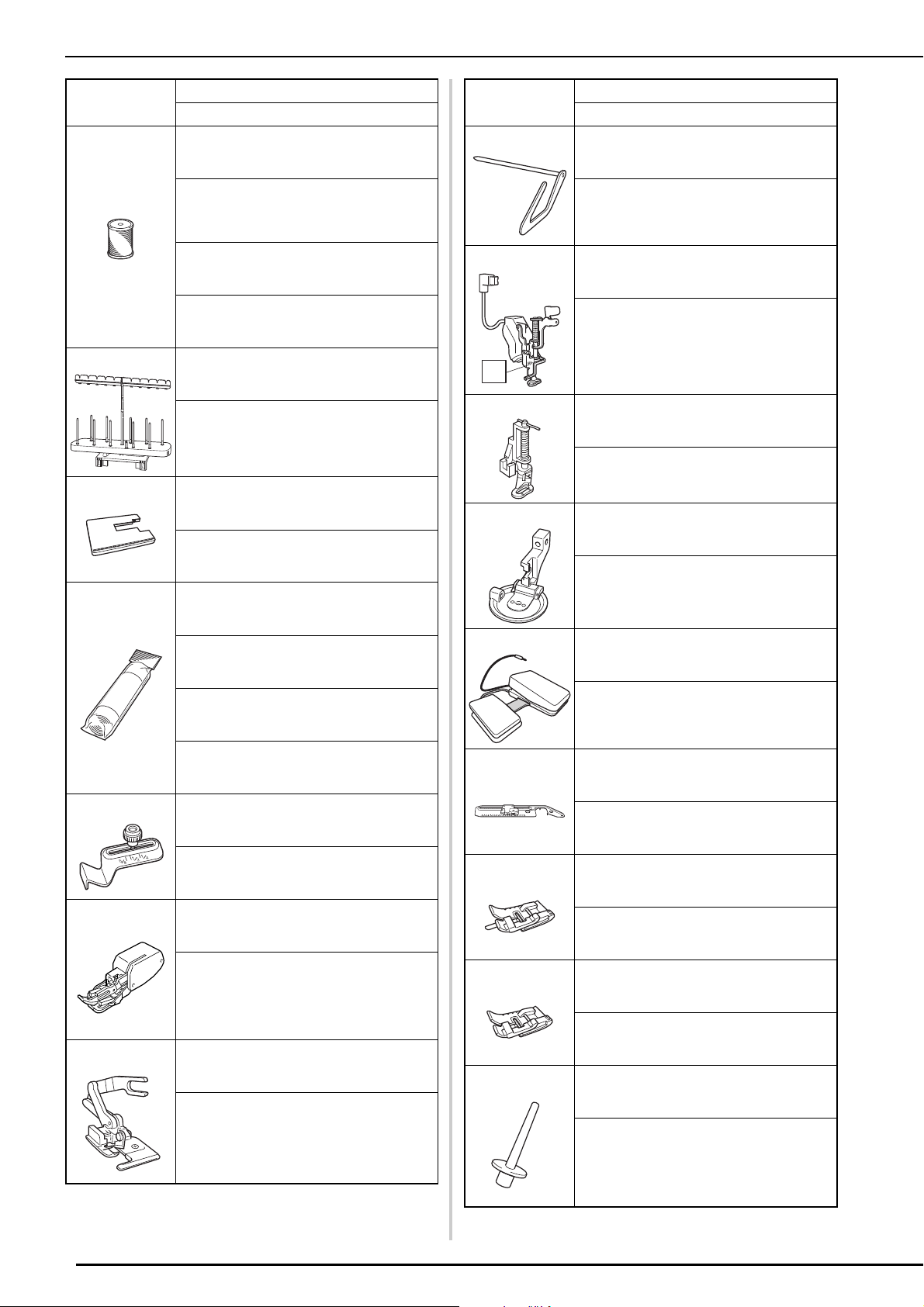

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

9.

10.

11.

12.

Part Name

Part Code

Embroidery bobbin thread (white)

SA-EBT (Americas)

EBT-CEN: X81164-001 / 115G05E0001

(Europe)

EBT-CEN: 115G05E7001 (other area)

Embroidery bobbin thread (black)

SA-EBT999 (Americas)

EBT-CEBN: XG6643-001 (Europe)

EBT-CEBN: XC5520-001 (other area)

10 spool stand

SA561 (U.S.A.) SA561C (Canada)

TS5: XG6765-001 (Europe)

TS5: XF4175-001 (other area)

Wide table

SAWTXP1 (U.S.A.)

SAWTXP1C (Canada)

WT16AP: 115K05E700J (other area)

Stabilizer material

Part Name

Part Code

16.

Quilting guide

SA132 (Americas)

F016N: XC2215-052 (Europe)

F016N: 115Z05E7001 (other area)

17.

Embroidery foot “W+” with LED pointer

SA197 (U.S.A.) SA197C (Canada)

FLED1: XF4168-001 (Europe)

FLED1AP: 115C05E700W (other area)

W+

18.

Free-motion quilting foot

SA129 (Americas)

F005N: XC1948-052 (Europe)

F005N: 115C05E7002 (other area)

19.

Couching foot

SA199V (U.S.A.) SA199VC (Canada)

F073: XF8185-001 (Europe)

F073AP: XF8188-001 (other area)

13.

14.

15.

SA519 (Americas)

BM3: XG6683-001 / 115Z05E0007 (Europe)

BM3: 115Z05E7007 (other area)

Water soluble stabilizer

SA520 (Americas)

BM5: XG6681-001 (Europe)

BM5: XE0615-001 (other area)

Seam guide

SA538 (Americas)

SG1: XC8483-052 (Europe)

SG1: 115Z05E7002 (other area)

Walking foot

SA140 (Americas)

F033N: XG6623-001 (Europe)

F033N: 115C05E7015 (other area)

Side cutter foot

20.

Multi-Function Foot controller

SAMFFC (U.S.A.) SAMFFCC (Canada)

MFFC1: XG6777-001 (Europe)

MFFC1OC: XF4471-001 (Australia)

21.

Circular attachment

SACIRC1 (Americas) SACIRC1C (Canada)

CCIRC1: XG6705-001 (Europe)

CIRC1: 115Y05E7003 (other area)

22.

Stitch in the ditch foot

SA191 (Americas)

F065: XF2339-001 (Europe)

F065: 115C05E700C (other area)

23.

Edge joining foot

SA184 (Americas)

F056: XC6441-352 (Europe)

F056: 115C05E700K (other area)

24.

Vertical spool pin

22

SA177 (Americas)

F054: XC3879-152 (Europe)

F054: 115C05E7008 (other area)

XC8619-052

Page 25

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

I+

Memo

Note

25.

26.

27.

28.

29.

Part Name

Part Code

Embroidery positioning sticker sheets × 8

SAEPS2 (U.S.A.) / SAEPS2C (Canada)

EPS2: XG6749-001 / 115Z05E000E (Europe)

EPS2: 115Z05E700E (other area)

Free motion guide grip

SAFMGRIP (Americas)

FMG2: XF6266-001 (Europe)

FMG2AP: XF6267-001 (other area)

USB mouse

XE5334-101

Vertical stitch alignment foot “V”

V

SA189 (Americas)

F063: XG6721-001 (Europe)

F063: XE5224-001 (other area)

Open toe for dual feed foot

35.

36.

37.

38.

39.

Part Name

Part Code

Bi-level Foot (Right)

SA103 (U.S.A.) SA103C (Canada)

F081: 115C05E002F (Europe)

F081AP: 115C05E702F (other area)

Bi-level Foot (Left)

SA104 (U.S.A.) SA104C (Canada)

F082: 115C05E002G (Europe)

F082AP: 115C05E702G (other area)

Concealed Zipper Foot “K”

K

SA102 (U.S.A.) SA102C (Canada)

F080: 115C05E002E (Europe)

F080AP: 115C05E702E (other area)

Embroidery frame sheet (medium) H 100 mm ×

W 100 mm (H 4 inches × W 4 inches)

XC8357-051

Embroidery frame sheet (large) H 180 mm × W

130 mm (H 7 inches × W 5 inches)

1

Getting Ready

30.

31.

32.

33.

34.

SA195 (Americas)

F070: XG6773-001 (Europe)

F070: XF6096-001 (other area)

Stitch in the Ditch Dual Feed Foot

SA204 (U.S.A.) SA204C (Canada)

F075: XG3155-001 (Europe)

F075AP: 115C05E700Y (other area)

1/4 inch Guide Dual Feed Foot

SA205 (U.S.A.) SA205C (Canada)

F076: XG4868-001 (Europe)

F076AP: 115C05E701D (other area)

Dual Feed Quilting Guide

SA206 (U.S.A.) SA206C (Canada)

F077: XG4879-001 (Europe)

F077AP: 115Z05E7008 (other area)

Ruffler foot

SA143 (Americas)

F051: XA9093-052 (Europe)

F051: 115C05E700L (other area)

Narrow Zipper Foot “I+”

SA208 (U.S.A.) SA208C (Canada)

F079: 115C05E002D (Europe)

F079AP: 115C05E702D (other area)

XC8359-051

40.

41.

42.

Embroidery frame sheet (quilt) H 240 mm × W

240 mm (H 9-1/2 inches × W 9-1/2 inches)

XG5566-001

Embroidery frame sheet (LL) H 408 mm × W

272 mm (H 16 inches × W 10-5/8 inches)

XH1825-001

Bobbin Work Kit

SABWRK1 (U.S.A.) SABWRK1C (Canada)

BWRK1: XG6745-001 (Europe)

BWRK1: XE9099-001 (other area)

• All specifications are correct at the time of

printing. Please be aware that some

specifications may change without notice.

• Visit your nearest authorized Brother dealer

for a complete listing of optional

accessories for your machine.

23

Page 26

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

Note

CAUTION

Using the Multi-purpose

Screwdriver

Since the screwdriver can be changed to three

different positions, it can be extremely useful for

the various machine preparations. With this

machine, position “1” and position “3” are used.

■ Position “1”

You can install/remove the presser foot holder,

needle clamp screw.

Using the Spool Stand

The included spool stand is useful when using

thread spools with a large diameter (cross-wound

thread). The spool stand can hold two spools of

thread.

123

456

No. Part Name Part Code

1 Spool stand XH1606-001

2 Spool cap (XL) × 2 XE0779-001

3 Spool holder × 2 XA0679-050

4 Spool cap base × 2 XE0780-001

5 Spool felt × 2 XC7134-051

6 Ring × 4 026030-136

* No.2 to No.6 are included in a plastic bag.

■ Position “3”

The multi-purpose screwdriver can be positioned

over the screw on the embroidery frame to tighten

the screw after hooping the fabric or when removing

the fabric.

• When rotating the multi-purpose

screwdriver, do not forcefully rotate it in the

direction that it does not rotate; otherwise, it

may break.

• Do not lift the handle of the machine while the

spool stand is installed.

• Do not push or pull the telescopic thread

guide or spool pins with extreme force,

otherwise damage may result.

• Do not place any object other than spools of

thread on the spool support.

• Do not try to wind thread on the bobbin while

sewing using the spool stand.

■ Warning label

This product contains magnets.

a Be careful not to pinch your fingers or any objects

between the spool stand and the upper cover of

the machine.

b Be sure to keep the magnets away from precision

electronics, computer disks, credit cards with a

magnetic stripe, etc.

c Do not use the spool stand if you have a

pacemaker.

24

Page 27

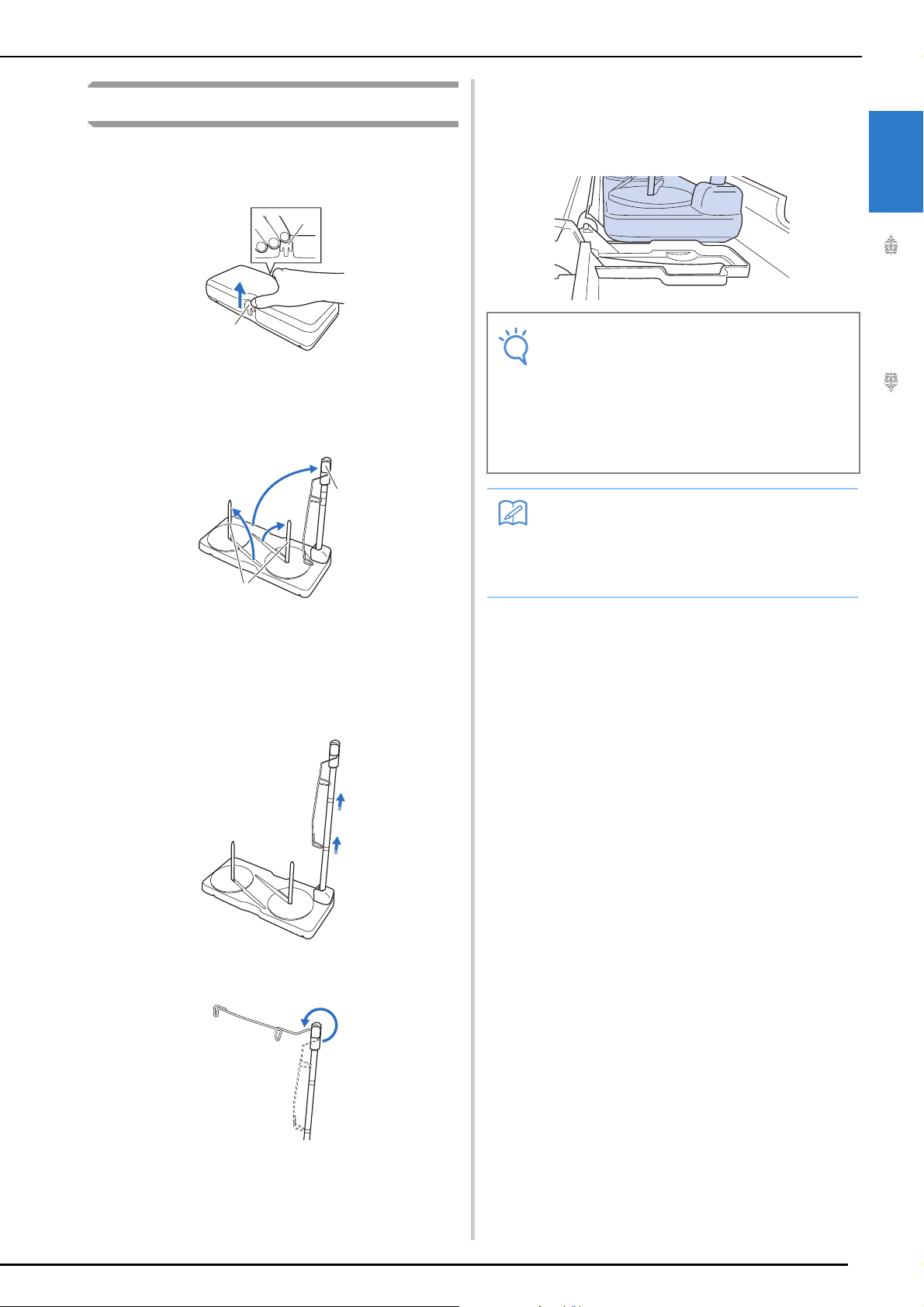

Assembling the Spool Stand

a

a

b

a

Note

Memo

Hold in the tabs on the spool stand and

a

remove the lid.

a Tabs

Raise the telescopic thread guide shaft and

b

the two spool pins.

NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

Open the upper cover of the machine, and

e

then place the spool stand on the upper

cover with the notches in the spool stand

aligned with the tabs on the upper cover.

• Make sure that the spool stand is firmly

secured. Otherwise, the spool stand may

fall during sewing.

• Do not place any object weighing 1 kg or

more on the top cover. The weight of the

spool stand with its lid removed is about

280 g.

1

Getting Ready

a Spool pins

b Telescopic thread guide shaft

Fully extend the telescopic thread guide

c

shaft until the two internal stoppers snap

into place.

Turn the thread guide counterclockwise.

d

• For details on winding the bobbin using the

spool stand, refer to page 56.

• For details on upper threading using the

spool stand, refer to page 66.

25

Page 28

TURNING THE MACHINE ON/OFF

WARNING

CAUTION

TURNING THE MACHINE ON/OFF

• Use only regular household electricity for the power source. Using other power sources may result in fire,

electric shock, or damage to the machine.

• Make sure that the plugs on the power cord are firmly inserted into the electrical outlet and the power

cord receptacle on the machine. Otherwise, a fire or electric shock may result.

• Do not insert the plug on the power cord into an electrical outlet that is in poor condition.

• Turn the main power to OFF and remove the plug in the following circumstances:

When you are away from the machine

After using the machine

When the power fails during use

When the machine does not operate correctly due to a bad connection or a disconnection

During electrical storms

• Use only the power cord included with this machine.

• Do not use extension cords or multi-plug adapters with many other appliances plugged in to them. Fire or

electric shock may result.

• Do not touch the plug with wet hands. Electric shock may result.

• When unplugging the machine, always turn the main power to OFF first. Always grasp the plug to remove

it from the outlet. Pulling on the cord may damage the cord, or lead to fire or electric shock.

• Do not allow the power cord to be cut, damaged, modified, forcefully bent, pulled, twisted, or bundled.

Do not place heavy objects on the cord. Do not subject the cord to heat. These things may damage the

cord, or cause fire or electric shock. If the cord or plug is damaged, take the machine to your authorized

Brother dealer for repairs before continuing use.

• Unplug the power cord if the machine is not to be used for a long period of time. Otherwise, a fire may

result.

• When leaving the machine unattended, either the main switch of the machine should be turned to OFF or

the plug must be removed from the socket-outlet.

• When servicing the machine or when removing covers, the machine must be unplugged.

•For U.S.A only

This appliance has a polarized plug (one blade wider than the other). To reduce the risk of electrical

shock, this plug is intended to fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified

electrician to install the proper outlet. Do not modify the plug in any way.

26

Page 29

TURNING THE MACHINE ON/OFF

Memo

Memo

Note

b

a

c

d

Insert the power supply cord into the power

a

cord receptacle, then insert the plug into a

wall outlet.

a

b

a Main power switch

b Power supply cord

Turn the main power switch to “I” to turn

b

on the machine.

Press and to set your local language.

a

Press .

b

The message screen, confirming if you want

c

to set time/date, appears. To set the time/

date, press ; to cancel the setting,

press .

The screen to set time/date appears.

Press or to set time date.

d

1

Getting Ready

a OFF

b ON

• When the machine is turned on, the needle

and the feed dogs will make sound when

they move; this is not a malfunction.

Turn the main power switch to “O” to turn

c

off the machine.

• If the machine is turned off in the middle of

sewing in the “Sewing” function, the

operation will not be continued after turning

the power on again.

Setting Your Machine for the First

Time

When you first turn on the machine, set the

language and time/date to your language and local

time/date. Follow the procedure below when the

settings screen appears automatically.

a Press to display the time on the screen.

b Set the year (YYYY), month (MM) and date (DD).

c Select whether 24h or 12h setting to display.

d Set the current time.

Press to start using your machine.

e

The clock starts from 0 second of the time you set.

• The time/date you set may be cleared, if

you don't turn on the machine for an

extended period of time.

• Time setting is also available by pressing

clock button/time on the LCD screen.

27

Page 30

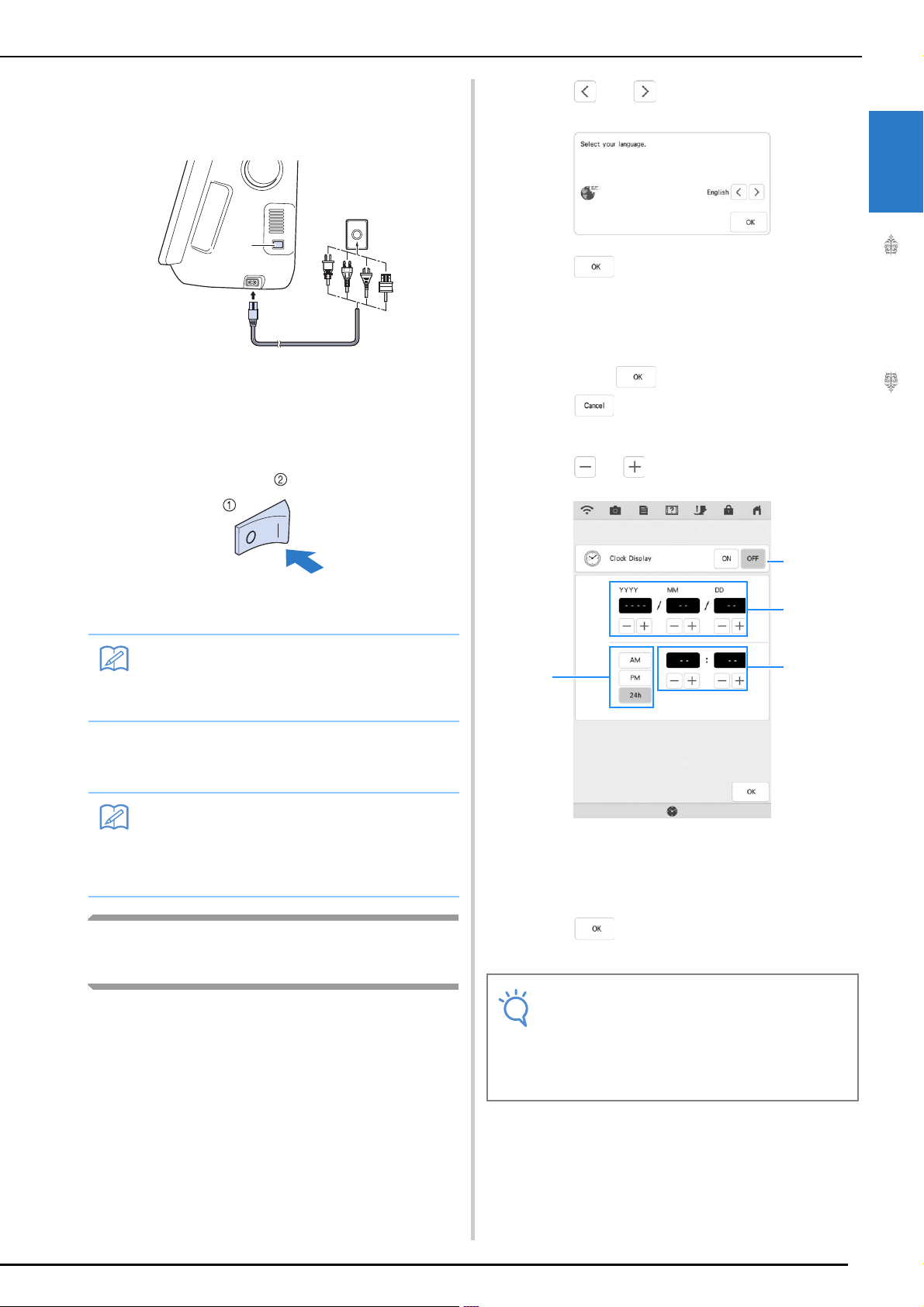

LCD SCREEN

Note

Memo

b

c

a

l

e f g h i jdk

LCD SCREEN

When the machine is turned on, the opening

movie is played. Touch anywhere on the screen

for the home page screen to be displayed. Touch

the LCD screen or a key with your finger or the

included dual purpose stylus to select a machine

function.

• When the straight stitch needle plate is on

the machine, the needle will automatically

move to the middle position.

• Only touch the screen with your finger or the

included dual purpose stylus. Do not use a

sharp pencil, screwdriver, or other hard or

sharp object. It is not necessary to press

hard on the screen. Pressing too hard or

using a sharp object may damage the

screen.

■ Home Page Screen

No. Display Key Name Explanation Page

d My Design

Center key

e Wireless

LAN key

f Camera

view key

g Machine

setting

screen key

h Machine

help key

i Presser

foot/

Needle

exchange

key

j Screen

lock key

k Home

page

screen key

l Time/Date

key

Press this key to start

creating your custom

design embroidery

patterns.

Check the machine’s

signal strength. Press this

key to specify the wireless

settings.

Press this key to check the

needle location as it is

shown on the screen

through the built-in

camera.

Press this key to change

the needle stop position,

adjust the stitch patterns

and embroidery patterns

or screen, and change

other machine settings.

Press this key to see

explanations on how to

use the machine. You can

see the tutorial videos and

also the MP4 movie files

that you have.

Press this key before

changing the needle, the

presser foot, etc. This key

locks all key and button

functions to prevent

operation of the machine.

Press this key to lock the

screen. When the screen

is locked, can still sew, but

cannot change any of the

screen functions. Press

this key again to unlock

the settings.

Press this key anytime it is

displayed to return to the

home page screen and

select a different category

- “Sewing”, “Embroidery”

or “My Design Center”.

Press this key to set the

clock to your local time.

–

46

92

29

39

58, 72

158

–

27

No. Display Key Name Explanation Page

a Sewing key Press this key to sew utility

b Embroidery

key

c Disney key Press this key to sew

stitches or character/

decorative stitch patterns.

Attach the embroidery unit

and press this key to

embroider patterns.

Disney stitch patterns.

28

102, 158

–

–

Page 31

LCD SCREEN

Memo

a

b

c

d

e

f

g

h

i

j

k

Using the Machine Setting Mode Key

Press to change the default machine settings (needle stop position, embroidery speed, opening

display, etc.). To display the different settings screens, press for “Sewing settings”, for “General

settings”, for “Embroidery settings” or for “Wireless LAN settings”.

1

• Press or to display a different settings screen.

Sewing Settings

■ Page 1

a Select whether to use the sewing speed controller

to determine the zigzag width (page 125).

b Make adjustments to character or decorative

stitch patterns (page 164).

c Adjust the presser foot height. Select the height of

the presser foot when the presser foot is raised.

d Adjust the presser foot pressure. The higher the

number, the greater the pressure will be. Set the

pressure at “3” for normal sewing.

e When set to “ON”, the thickness of the fabric is

automatically detected by an internal sensor while

sewing. This enables the fabric to be fed smoothly

(pages 83 and 91).

Getting Ready

■ Page 2

f Select whether “1-01 Straight stitch (Left)” or “1-

03 Straight stitch (Middle)” is the utility stitch that

is automatically selected when the machine is

turned on.

g Change the height of the presser foot when

sewing is stopped when the pivot setting is

selected (page 89). Adjust the presser foot to one

of the four heights.

h Change the height of the presser foot when the

machine is set to free motion sewing mode

(page 126).

i Adjust the amount of fabric feeding of the dual

feed foot (page 76).

j Pressing the “Start/Stop” button or depressing the

foot controller automatically lowers the presser

foot (if it is raised) before starting sewing.

k Pressing the “Thread Cutter” button automatically

lowers the presser foot before cutting the thread.

The presser foot will be raised after the thread is

cut.

29

Page 32

LCD SCREEN

n

l

m

a

d

f

b

c

e

■ Page 3

l Select whether utility stitches ( ) or quilting

stitches ( ) are displayed first in the stitch

selection screen.

m When set to “ON”, reinforcement stitches are

sewn at the beginning and/or end of sewing for a

reinforcement stitch pattern, even when the

“Reverse Stitch” button is pressed (page 79).

n You can activate this setting after connecting the

multi-function foot controller (optional). (These

settings are not operable unless the multi-function

foot controller is attached to the machine.)

(page 34)

General Settings

■ Page 4

a Change the display language.

b Change the brightness of the needle area and

work area lights.

c If the screen is not very clear in certain

environments, you can adjust the brightness of the

screen.

d Turn both the upper and bobbin thread sensor

“ON” or “OFF”. If it is turned “OFF”, the machine

can be used without thread.

e Change the speaker volume. Increase the number

for louder volume, decrease for softer volume.

f Select the operation of the “Needle Position -

Stitch Placement” button from the following two

sequences. (page 92)

30

Page 33

LCD SCREEN

i

h

j

k

g

p

o

n

l

m

q

t

r

s

■ Page 5

g Select whether to display the opening screen

video when the machine is turned on.

h Select to save the machine power by setting the

“Eco Mode” or the “Shutoff Support Mode”

(page 35).

i Select the length of time until the screen saver

appears.

j Change the image of the screen saver (page 36).

k Change the shape of the pointer when a USB

mouse is used. The setting remains selected even

after the machine is turned off.

■ Page 7

1

Getting Ready

q Display the service count which is a reminder to

take your machine in for regular servicing.

(Contact your authorized Brother dealer for

details.)

r Display the total number of stitches sewn on this

machine.

s The “No.” is the internal machine number for the

machine.

t Display the program version.

■ Page 6

l Select the brightness of the projector.

m Select whether to show background color when

using projector function.

n Select whether to display outline of the pattern.

o Select the color of the pointer.

p The camera needle drop point can be specified.

(page 37)

31

Page 34

LCD SCREEN

a

d

e

f

b

c

j

k

g

h

l

i

m

p

q

o

n

Embroidery Settings

For details on embroidering settings, refer to the

Operation Manual (Embroidery).

■ Page 8

a Select from among 12 embroidery frame displays.

b Change the center point marker or grid lines.

c Adjust the maximum embroidery speed setting.

d Adjust the upper thread tension for embroidering.

e Select the height of the embroidery foot during

embroidering.

f Adjust the needle position for embroidering.

■ Page 9

g Change the display units (mm/inch).

h Change the thread color display on the

“Embroidery” screen; thread number, color name.

i Select the thread brand used to display a pattern

when it is opened.

j Change the color of the background for the

embroidery display area.

k Change the color of the background for the

thumbnail area.

l Press to specify the size of pattern thumbnails.

m Adjust the distance between the pattern and the

basting stitching.

■ Page 10

32

n Select the quality for displaying the fabric in the

screen.

o Erase the scanned image.

p Set to “ON” when positioning the pattern on the

thick fabric using the built-in camera.

q Adjust the position and brightness of the

embroidery foot “W+” with LED pointer (sold

separately). (These settings are not available

unless embroidery foot “W+” with LED pointer is

installed on the machine.)

Page 35

Wireless LAN settings

c

d

b

a

e

f

g

h

a

b

■ Page 11

Press .

b

The settings screen appears. Select the settings

screen page that you want to save the screen image

of.

Press .

c

The image file will be saved to the USB media.

LCD SCREEN

1

Getting Ready

a Enable/disable the wireless LAN function.

b Display the connected SSID.

c Set the machine to connect wireless LAN function.

d Display the machine name of wireless LAN

function.

e Press to change the machine name of

wireless LAN function.

f Check the wireless LAN status.

g Display other menus.

h Press to reset network operations.

Setting Functions

■ Saving a Settings Screen Image to

USB Media

An image of the settings screen can be saved as

.PNG file.

Insert the USB media into the USB port on

a

the right side of the machine.

a USB media

b USB port

33

Page 36

LCD SCREEN

Memo

Note

■ Specifying the Multi-Function Foot

Controller (Sold Separately)

With the multi-function foot controller, various

machine operations in addition to starting/

stopping sewing, such as thread cutting and

reverse stitching, can be specified to be

performed.

Functions that can be specified

Controller Functions that can be specified

a Main foot controller Start/Stop

b Heel switch Select any of the following:

c Side pedal

* If you set the “Reverse Stitch” function on the heel

switch, machine operates the same as pressing the

“Reverse Button” on the machine.

* Reinforcement stitching may be applied depending

on the selected stitch pattern. For the details, refer to

“Automatic Reinforcement Stitching” on page 79.

• Thread Cutting

• Needle Position – Up/Down

• Single Stitch

• Reverse Stitch (Reinforcement

Stitch) *

• Presser Foot Up/Down

• No Setting

Press .

a

Display page 3 of the settings screen.

b

Select the functions to be performed by the

c

multi-function foot controller.

Press .

d

• If you set “Reverse Stitch” on the side

pedal, you can create a darning stitch effect

using zigzag stitches. With both feet, keep

pressing the main foot controller, and

repeat pressing and releasing the side pedal

to sew forward and reverse in turn. Machine

will reverse at the speed you press the main

foot controller.

Specifying the functions

The functions performed by the multi-function foot

controller can be specified in the settings screen.

• Before specifying the functions, connect the

multi-function foot controller to the

machine. The settings screen is activated

the first time that the machine detects the

multi-function foot controller.

• After the multi-function foot controller is

connected to the machine and the functions

are specified, the “Start/Stop” button

cannot be used. All buttons other than the

“Start/Stop” button can continue to be

used.

34

Page 37

■ Selecting the “Eco Mode” or

Note

LCD SCREEN

“Shutoff Support Mode”

You can save the machine power by setting the eco

mode or the shutoff support mode.

If you leave the machine without using for a

specified period of time, the machine enters in one

of these modes.

“Eco Mode”;

Machine will enter a sleep mode. Touch the screen

or press the “Start/Stop” button to continue sewing.

“Shutoff Support Mode”;

Machine will enter the lower power mode after set

period of time. Turn machine off and then back on

to restart sewing.

Condition Eco Mode Shutoff Support

Available time OFF, 10 - 120

(minute)

“Start/Stop” button Green flashing Green slow flashing

Suspended function Machine light,

Screen display

After recovering The machine starts

from the previous

operation.

Mode

OFF, 1 - 12 (hour)

All functions

You need to turn off

the machine.

• If you turn off the machine while the

machine is in the “Eco Mode” or the

“Shutoff Support Mode”, wait for about 5

seconds before turning on the machine

again.

1

Getting Ready

Press the “Start/Stop” button or touch the screen

display to recover from these modes.

Press .

a

The settings screen appears.

Press .

b

The General settings screen appears.

Display page 5 of the General settings

c

screen.

Press circled area to select the time until

d

entering the mode.

35

Page 38

LCD SCREEN