Page 1

Brother Inkjet DCP/MFC

SERVICE MANUAL

MODELS: DCP-J572DW/J772DW/J774DW/

DCP-J1100DW/T310/T510W/T710W

MFC-J491DW/J497DW/J690DW/

MFC-J805DW/J815DW/J890DW/J895DW/

MFC-J995DW/J1300DW/T810W/T910DW

August 2017

SM-FAX185

8CH4*(7)

Read this manual thoroughly before maintenance work.

Keep this manual in a convenient place for quick and easy reference at all times.

Confidential

Page 2

Copyright © 2017 BROTHER INDUSTRIES, LTD.

All right reserved.

Copyright for this Service Manual belongs to Brother Industries, Ltd. Reproduction or reprinting of any

part of or all of this manual is prohibited.

The contents of this manual may change without notice according to future specification improvements,

etc.

Trademarks

BROTHER is either a registered trademark or trademark of Brother Industries, Ltd.

Microsoft, Windows, Windows Vista and Windows Server are either registered trademarks or

trademarks of Microsoft Corporation in the United States, Japan, and/or other countries.

Macintosh, Mac OS, OS X, and AirPrint are trademarks of Apple Inc., registered in the United States

and other countries.

®

Wi-Fi

, Wi-Fi Direct®, WPATM, WPA2TM, and Wi-Fi Protected SetupTM (WPS) are registered

trademarks or trademarks of Wi-Fi Alliance

Google Cloud Print is a trademark of Google Inc. Usage of this trademark is subject to Google

Permissions.

SDHC Logo is a trademark of SD-3C, LLC.

AOSS is a trademark of Buffalo Inc.

Trade names and product names of other companies appearing in this manual are registered

trademarks or trademarks of those respective companies.

The contents of this manual and specifications of this machine may change without notice.

®

.

Confidential

Page 3

Preface

This Service Manual is intended for use by service personnel and details the specifications,

construction, and maintenance for the Brother machines noted on the front cover. It includes

information required for troubleshooting and service--disassembly, reassembly, and

lubrication--so that service personnel will be able to understand equipment function, repair the

equipment in a timely manner and order spare parts as necessary.

To perform appropriate maintenance so that the machine is always in the best possible condition

for the customer, service personnel must adequately understand and apply this manual.

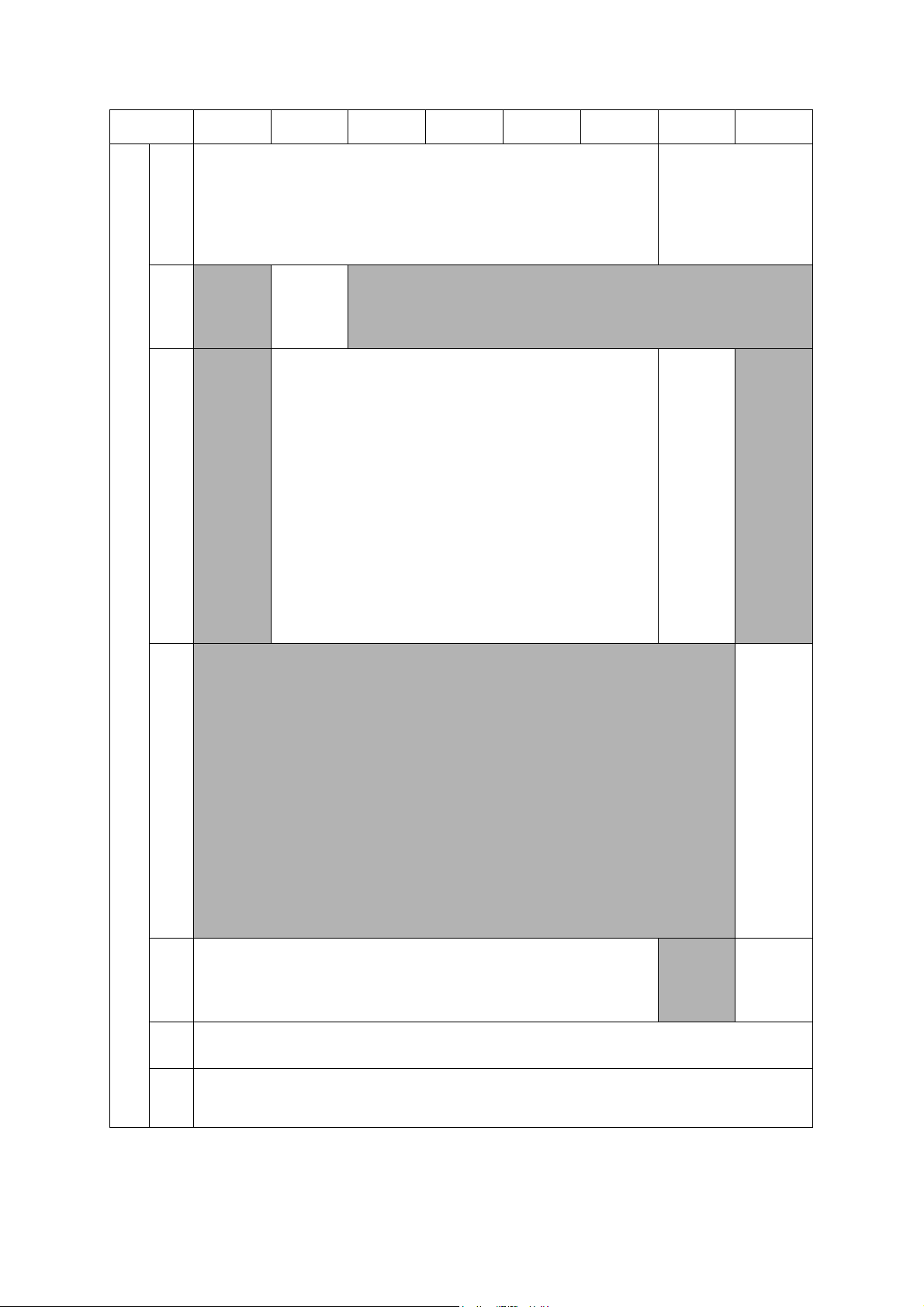

The table below shows the functional comparison between the models covered by this

manual.

DCP-J572DW DCP-J772DW

Print Head Low Step Step Low Low Step

Wired LAN --- --- --- --- --- ---

Wireless LAN ---

NFC --- --- --- --- --- ---

Photo Capture Center --- --- ---

ADF --- --- Ready-ADF --- --- Ready-ADF

LCD 1.8 inch 2.7 inch 2.7 inch 1-Line 1-Line 1-Line

Touch Panel --- --- --- ---

Photo Tray --- --- --- ---

Manual Feed Slot

MP Tray --- --- --- --- --- ---

Auto Duplex Print --- --- ---

Ink Cartridge Regular Regular Simple --- --- ---

Ink Tank --- --- ---

MFC-J491DW

MFC-J497DW

Print Head Low Step Low Step Step Step Step Step

Wired LAN --- --- ---

Wireless LAN

NFC --- --- --- --- ---

Photo Capture Center --- --- ---

ADF Flat-ADF Flat-ADF Ready-ADF Flat-ADF Ready-ADF Ready-ADF Ready-ADF Ready-ADF

LCD 1.8 inch 2.7 inch 1.8 inch 2.7 inch 2.7 inch 2.7 inch 1-Line 1.8 inch

Touch Panel --- --- --- ---

Photo Tray --- --- --- --- --- --- ---

Manual Feed Slot --- ---

MP Tray --- --- --- --- --- --- ---

Auto Duplex Print ---

Ink Cartridge Regular Regular Simple Regular Simple Simple --- ---

Ink Tank --- --- --- --- --- ---

DCP-J774DW

MFC-J690DW MFC-J805DW

MFC-J815DW

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

MFC-J890DW

MFC-J895DW

MFC-J995DW

MFC-J1300DW

MFC-T810W

MFC-T910DW

Confidential

Page 4

TABLE OF CONTENTS

SAFETY INFORMATION........................................................................................................ ix

CHAPTER 1 SPECIFICATIONS ......................................................................................... 1-1

1 GENERAL ......................................................................................................................1-1

1.1 General.................................................................................................................. 1-1

1.2 Media Specification ...............................................................................................1-2

1.3 Paper Handling...................................................................................................... 1-5

1.4 LCD Panel.............................................................................................................1-5

1.5 Memory.................................................................................................................. 1-6

1.6 Interface................................................................................................................. 1-7

1.7 Others.................................................................................................................... 1-9

2 FAX...............................................................................................................................1-10

3 PRINTER ......................................................................................................................1-11

4 COPY............................................................................................................................1-12

5 SCANNER ....................................................................................................................1-13

6 SOFTWARE .................................................................................................................1-13

7 NETWORK ...................................................................................................................1-14

7.1 Network ............................................................................................................... 1-14

7.2 Wired ...................................................................................................................1-14

7.3 Wireless............................................................................................................... 1-15

8 SUPPLIES/OPTIONS...................................................................................................1-16

9 SERVICE INFORMATION............................................................................................1-17

10 PAPER .........................................................................................................................1-18

10.1 Paper...................................................................................................................1-18

10.2 Printable Area...................................................................................................... 1-21

CHAPTER 2 TROUBLESHOOTING...................................................................................2-1

1 INTRODUCTION ............................................................................................................2-1

1.1 Precautions............................................................................................................ 2-1

1.2 Initial Check...........................................................................................................2-2

2 OVERVIEW .................................................................................................................... 2-3

2.1 Cross-section Drawings.........................................................................................2-3

2.1.1 Document scanning ...................................................................................... 2-3

i

Confidential

Page 5

2.1.2 Printer part ....................................................................................................2-3

2.2 Document Feeding/Recording Paper Feeding path ..............................................2-5

2.2.1 Document feeding path .................................................................................2-5

2.2.2 Recording paper feeding path.......................................................................2-5

2.3 Function of Each Sensor/Roller.............................................................................2-7

2.4 Block Diagram .......................................................................................................2-9

2.5 Components ........................................................................................................2-10

3 ERROR INDICATION...................................................................................................2-11

3.1 Error Code...........................................................................................................2-11

3.2 Error Messages .................................................................................................. 2-17

3.3 Communications Error......................................................................................... 2-20

4 TROUBLESHOOTING .................................................................................................2-24

4.1 Error Cause and Solutions ..................................................................................2-24

4.2 Recording Paper Feeding Problems ...................................................................2-52

4.2.1 Paper is not fed from paper tray.................................................................. 2-52

4.2.2 Paper is not fed from manual feed slot .......................................................2-53

4.2.3 Paper is not fed from MP tray ..................................................................... 2-54

4.2.4 Two or more sheets of paper are fed from the paper tray........................... 2-55

4.2.5 Two or more sheets of paper are fed from the MP tray. .............................2-55

4.2.6 Paper feeding at an angle ...........................................................................2-55

4.2.7 Recording paper jam...................................................................................2-56

4.2.8 Prints only single side of the paper when duplex-printing ...........................2-60

4.3 Print-image Problems.......................................................................................... 2-61

4.3.1 Defective images.........................................................................................2-61

4.3.2 Print-image problems ..................................................................................2-62

4.4 Software-related Problems..................................................................................2-74

4.4.1 Cannot print data.........................................................................................2-74

4.5 Network Problems ............................................................................................... 2-74

4.5.1 Cannot make a print through network connection....................................... 2-74

4.6 Control Panel Problems.......................................................................................2-75

4.6.1 No display on LCD/Incorrect display on LCD..............................................2-75

4.6.2 LED does not light up..................................................................................2-75

4.6.3 The control panel does not work .................................................................2-75

4.6.4 Touch panel inoperative..............................................................................2-76

4.6.5 LCD display is in recovery mode................................................................. 2-76

4.7 Document Feeding Problems.............................................................................. 2-77

4.7.1 Document can not be fed ............................................................................2-77

ii

Confidential

Page 6

4.7.2 Document double feeding ...........................................................................2-77

4.7.3 Document jam .............................................................................................2-78

4.7.4 Wrinkles on documents...............................................................................2-80

4.7.5 Document size not correctly detected ......................................................... 2-80

4.8 Scanned-image Problems ................................................................................... 2-81

4.8.1 Defective images.........................................................................................2-81

4.8.2 Troubleshooting from image defect............................................................. 2-81

4.9 Fax Problems ......................................................................................................2-86

4.9.1 No faxes can be sent .................................................................................. 2-86

4.9.2 No faxes can be received............................................................................ 2-86

4.9.3 A communications error occurs................................................................... 2-86

4.10 Other Problems ...................................................................................................2-87

4.10.1 The machine cannot be powered ON .........................................................2-87

4.10.2 External memory does not function or functions despite not being

inserted. ......................................................................................................2-87

4.10.3 Data of external memory does not read......................................................2-87

4.10.4 Internal memory errors................................................................................ 2-88

4.10.5 Security Function Lock related problems ....................................................2-88

4.10.6 Ink cartridge related problems..................................................................... 2-88

4.10.7 Noise comes from machine......................................................................... 2-89

4.10.8 “Unusable Device” is displayed................................................................... 2-89

CHAPTER 3 DISASSEMBLY AND ASSEMBLY ............................................................... 3-1

1 PRECAUTIONS BEFORE PROCEEDING .................................................................... 3-1

2 PACKING .......................................................................................................................3-1

3 SCREW CATALOGUE...................................................................................................3-2

4 SCREW TORQUE LIST .................................................................................................3-3

5 LUBRICATION ............................................................................................................... 3-4

6 OVERVIEW OF GEARS...............................................................................................3-11

7 ROUTING OF HARNESSES, FLAT CABLE AND INK SUPPLY TUBES................... 3-12

8 DISASSEMBLY FLOW ................................................................................................3-23

9 DISASSEMBLY PROCEDURE.................................................................................... 3-24

9.1 Preparation..........................................................................................................3-24

9.2 MP Tray ASSY/ MP Paper Detection Sensor PCB .............................................3-27

9.3 Scanner Cover Damper/Scanner Cover Support ................................................ 3-30

iii

Confidential

Page 7

9.4 Head/carriage Unit/CR Timing Belt .....................................................................3-31

9.5 Document Scanner Unit/ADF Unit (Models with ADF)/Document Cover ASSY

(Models without ADF)..........................................................................................3-41

9.6 CIS Unit/CIS Flat Cable.......................................................................................3-47

9.7 ADF Document Support ......................................................................................3-52

9.8 ADF Cover ASSY ................................................................................................ 3-54

9.9 ADF Separation Pad Holder ASSY .....................................................................3-55

9.10 Document Scanning Position Sensor PCB ASSY............................................... 3-56

9.11 Document Detection Sensor PCB ASSY.............................................................3-57

9.12 Document Separate Roller ASSY........................................................................ 3-58

9.13 Ink Cartridge Cover .............................................................................................3-60

9.14 Control Panel ASSY/Panel Flat Cable/NFC PCB/Panel PCB ASSY/LCD/

Panel Key PCB/Rubber Key................................................................................ 3-61

9.15 Front Cover.......................................................................................................... 3-70

9.16 Manual Feed Slot ASSY......................................................................................3-71

9.17 Wireless LAN PCB ASSY....................................................................................3-71

9.18 Jam Clear Cover..................................................................................................3-72

9.19 Upper Cover ........................................................................................................3-73

9.20 Carriage PCB ASSY............................................................................................ 3-75

9.21 Ink Absorber Box.................................................................................................3-76

9.22 Tank Case ASSY (Ink tank model only) ..............................................................3-78

9.23 Ink Refill ASSY ....................................................................................................3-80

9.24 Ink Absorber Felt (For Ink Refill ASSY) (Regular Ink cartridge model only)........ 3-81

9.25 Ink Cartridge Cover Sensor ASSY ......................................................................3-81

9.26 Main PCB ............................................................................................................3-83

9.27 Power Supply PCB ASSY ................................................................................... 3-87

9.28 Modem PCB ASSY..............................................................................................3-90

9.29 CR Encoder Strip.................................................................................................3-91

9.30 Carriage Motor..................................................................................................... 3-92

9.31 Flushing Base...................................................................................................... 3-93

9.32 Flushing Foam..................................................................................................... 3-93

9.33 PF Encoder Disk..................................................................................................3-94

9.34 Registration Sensor PCB ASSY.......................................................................... 3-94

9.35 Paper Feed Roller ...............................................................................................3-96

9.36 Paper Feed Motor................................................................................................3-98

9.37 PF Encoder Sensor PCB ASSY .......................................................................... 3-98

9.38 Maintenance Unit.................................................................................................3-99

9.39 Ink Absorber Felt (For Maintenance Unit)

(Regular Ink cartridge model only) .................................................................... 3-100

iv

Confidential

Page 8

9.40 Ink Absorber Felt (Ink tank model/ Simple Ink cartridge model only) ................3-100

9.41 Platen ASSY/Paper ejection roller..................................................................... 3-101

9.42 Switchback Roller ASSY ................................................................................... 3-104

9.43 Paper Pull-in Roller............................................................................................3-105

9.44 Bank ASSY........................................................................................................ 3-106

9.45 Base Pad/Base Pad W......................................................................................3-107

CHAPTER 4 ADJUSTMENTS AND UPDATING OF SETTINGS, REQUIRED AFTER

PARTS REPLACEMENT...............................................................................4-1

1 IF YOU REPLACE THE MAIN PCB ASSY....................................................................4-1

1.1 Customize destinations (Maintenance mode 74) .................................................. 4-3

1.2 Set the CIS type (Maintenance mode 59) .............................................................4-3

1.3 Install the firmware (Maintenance mode 28) .........................................................4-3

1.4 Set the serial number (Maintenance mode 80) .....................................................4-6

1.5 Set the initial administrator password (Maintenance mode 51)............................. 4-7

1.6 Initialize the EEPROM parameters (Maintenance mode 01)................................. 4-7

1.7 Restore the head Calibration data (Maintenance mode 68).................................. 4-7

1.8 Update the head property information (Maintenance mode 68)............................4-7

1.9 Restore machine information (Maintenance mode 46)..........................................4-8

1.10 Adjust the touch panel (Maintenance mode 78).................................................... 4-8

1.11 Acquire white/black level data (Maintenance mode 55) ........................................4-8

1.12 Adjustment of software correction for inclination/corrugation/ruled lines

(Maintenance mode 65/ User menu).....................................................................4-8

1.13 Update the paper feeding correction values

(Maintenance mode 58/ User menu).................................................................... 4-8

1.14 Adjust margins in borderless printing (Maintenance mode 66) ............................. 4-9

1.15 Reset purge and flushing counts...........................................................................4-9

1.16 Write head calibration data (Maintenance mode 02)........................................... 4-10

1.17 Check scanning and printing ............................................................................... 4-10

2 IF YOU REPLACE THE HEAD/CARRIAGE UNIT....................................................... 4-11

2.1 Update the head property information (Maintenance mode 68)..........................4-12

2.2 Perform ink supply purge (Maintenance mode 76)..............................................4-13

2.3 Check head nozzles (Maintenance mode 09) .....................................................4-13

2.4 Adjust head inclination......................................................................................... 4-14

2.5 Adjustment of software correction for inclination/corrugation/ruled lines

(Maintenance mode 65/ User menu)...................................................................4-18

2.6 Update the paper feeding correction values

(Maintenance mode 58/ User menu)...................................................................4-18

2.7 Adjust margins in borderless printing (Maintenance mode 66) ........................... 4-18

v

Confidential

Page 9

2.8 Write head calibration data (Maintenance mode 02)........................................... 4-18

2.9 Check printing...................................................................................................... 4-18

2.10 Obtain machine information at the user site (Instruction to the end user)........... 4-19

3 IF YOU REPLACE THE DOCUMENT SCANNER UNIT, ADF UNIT OR CIS UNIT .... 4-20

3.1 Set the CIS type (Maintenance mode 59) (Not required after replacement of the

ADF unit) .............................................................................................................4-20

3.2 Acquire white/black level data (Maintenance mode 55) (Not required after

replacement of the ADF unit)............................................................................... 4-20

3.3 Check scanning...................................................................................................4-20

4 IF YOU REPLACE THE CONTROL PANEL ASSY, LCD, PANEL PCB ASSY,

PANEL KEY PCB OR RUBBER KEY .........................................................................4-21

4.1 Adjust the touch panel (Maintenance mode 78).................................................. 4-21

4.2 Check LCD operation (Maintenance mode 12) ................................................... 4-21

4.3 Check the operation of the control panel keys (Maintenance mode 13) ............. 4-21

5 IF YOU REPLACE THE INK ABSORBER BOX OR FLUSHING FOAM .................... 4-21

5.1 Reset purge or flushing counts............................................................................ 4-21

6 IF YOU REPLACE THE RECORDING PAPER FEEDING PARTS, HEAD/

CARRIAGE PARTS OR MAINTENANCE UNIT ..........................................................4-22

6.1 Check head nozzles (Maintenance mode 09) .....................................................4-23

6.2 Adjustment of software correction for inclination/corrugation/ruled lines

(Maintenance mode 65/ User menu)...................................................................4-23

6.3 Update paper feeding correction values

(Maintenance mode 58/ User menu)...................................................................4-23

6.4 Adjust margins in borderless printing (Maintenance mode 66) ........................... 4-23

6.5 Check printing...................................................................................................... 4-23

CHAPTER 5 SERVICE FUNCTIONS ................................................................................. 5-1

1 MAINTENANCE MODE .................................................................................................5-1

1.1 Entry to the Maintenance Mode.............................................................................5-1

1.1.1 How to Enter the Maintenance Mode for Service Personnel ........................5-1

1.1.2 How to Enter the End User-accessible Maintenance Mode.......................... 5-3

1.2 Operations of the Keys in the Maintenance Mode.................................................5-4

1.2.1 Entering ten keys and the other keys in the maintenance mode with models

without these keys.........................................................................................5-4

1.3 List of Maintenance-mode Functions.....................................................................5-5

1.4 Detailed Description of Maintenance-mode Functions.......................................... 5-6

1.4.1 EEPROM Parameter Initialization (Maintenance mode 01, 91) ....................5-6

1.4.2 Creating of Head Calibration Data and Writing it into Flash ROM

(Maintenance mode 02) ................................................................................ 5-7

vi

Confidential

Page 10

1.4.3 ADF Performance Test (Maintenance mode 08) ........................................ 5-10

1.4.4 Printout of Test Pattern (Maintenance mode 09) ........................................5-11

1.4.5 Worker Switch Setting and Printout (Maintenance modes 10 and 11)........ 5-12

1.4.6 Operational Check of LCD (Maintenance mode 12) ................................... 5-14

1.4.7 Operational Check of Keys on Control Panel (Maintenance mode 13)....... 5-16

1.4.8 Updating of Firmware Using an External memory

(Maintenance mode 28) .............................................................................. 5-18

1.4.9 Sensor Operational Check (Maintenance mode 32) ................................... 5-19

1.4.10 Printout of Dial Log (Maintenance mode 37)............................................... 5-20

1.4.11 Backup of Machine Information (Maintenance mode 46)............................ 5-21

1.4.12 Initial Setting for Administrator Password (Maintenance mode 51) ............ 5-23

1.4.13 Transfer of Received FAX Data and/or Equipment's Log

(Maintenance mode 53) .............................................................................. 5-24

1.4.14 Fine Adjustment of Scanning Position (Maintenance mode 54) .................5-26

1.4.15 Acquisition of White/Black Level Data (Maintenance mode 55)..................5-27

1.4.16 Periodic Purge Time Setting (Maintenance mode 56) ................................5-27

1.4.17 Cartridge IC Communication Check (Maintenance mode 57)..................... 5-28

1.4.18 Updating of Paper Feeding Correction Values (Maintenance mode 58)..... 5-29

1.4.19 Checking of CIS Travel and Specifying of CIS Type

(Maintenance mode 59) .............................................................................. 5-33

1.4.20 Printout of PRN/JPEG Files in External Memory

(Maintenance mode 61) .............................................................................. 5-34

1.4.21 Move of the Head/Carriage Unit to the Adjustment Position

(Maintenance mode 63) .............................................................................. 5-35

1.4.22 Adjustment of Software Correction for Inclination/Corrugation/Ruled Lines

(Maintenance mode 65) .............................................................................. 5-36

1.4.23 Margin Adjustment in Borderless Printing (Maintenance mode 66) ............5-38

1.4.24 Updating of Head Property Information and Backup/Restoration of Head

Calibration Data (Maintenance mode 68) ...................................................5-41

1.4.25 Traveling Speed Check of Head/Carriage Unit (Maintenance mode 69).... 5-43

1.4.26 Customizing Destinations (Maintenance mode 74)..................................... 5-43

1.4.27 Move of the Head/Carriage Unit to the Center of its Travel

(Maintenance mode 75) .............................................................................. 5-49

1.4.28 Purge Operation (Maintenance mode 76)................................................... 5-50

1.4.29 Print of the Maintenance Information (Maintenance mode 77) ................... 5-59

1.4.30 Adjustment of Touch Panel (Maintenance mode 78) ..................................5-64

1.4.31 Display of the Equipment's Log (Maintenance mode 80)............................5-65

1.4.32 Equipment Error Code Indication (Maintenance mode 82) .........................5-79

1.4.33 Output of Transmission Log to the Telephone Line

(Maintenance mode 87) .............................................................................. 5-79

vii

Confidential

Page 11

1.4.34 Assurance Mode Switch Setting (Maintenance mode 88) ..........................5-80

1.4.35 Printout of Block Pattern (Ink tank model only)

(Maintenance mode 89) .............................................................................. 5-88

2 OTHER SERVICE FUNCTIONS .................................................................................. 5-89

2.1 Displaying the Firmware Version......................................................................... 5-89

2.2 Moving the Head/Carriage Unit ........................................................................... 5-89

2.3 Special purge (SPP) < Ink tank model only >......................................................5-90

CHAPTER 6 CIRCUIT DIAGRAMS AND WIRING DIAGRAMS ........................................6-1

CHAPTER 7 PERIODICAL MAINTENANCE .....................................................................7-1

1 PERIODICAL REPLACEMENT PARTS ........................................................................ 7-1

APPENDIX 1. SERIAL NUMBERING SYSTEM ........................................................ App. 1-1

APPENDIX 2. DELETION OF USER SETTING INFORMATION .............................. App. 2-1

APPENDIX 3. INSTALLING THE MAINTENANCE PRINTER DRIVER.................... App. 3-1

viii

Confidential

Page 12

SAFETY INFORMATION

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injures.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injuries.

IMPORTANT

IMPORTANT indicates a potentially hazardous situation which, if not avoided, may result in

damage to property or loss of machine functionality.

NOTE

NOTE specifies the operating environment, conditions for installation, or special conditions of

use.

Prohibition icons indicate actions that must not be performed.

This icon indicates that flammable sprays must not be used.

This icon indicates that organic solvents such as alcohol and liquids must not be used.

Electrical Hazard icons alert you to possible electrical shocks.

Fire Hazard icons alert you to the possibility of fire.

Italics

Italicized typeface emphasizes an important point or refers you to a related topic.

Follow all warnings and instructions marked on the machine.

NOTE

The illustrations in this section show the MFC-J895DW.

ix

Confidential

Page 13

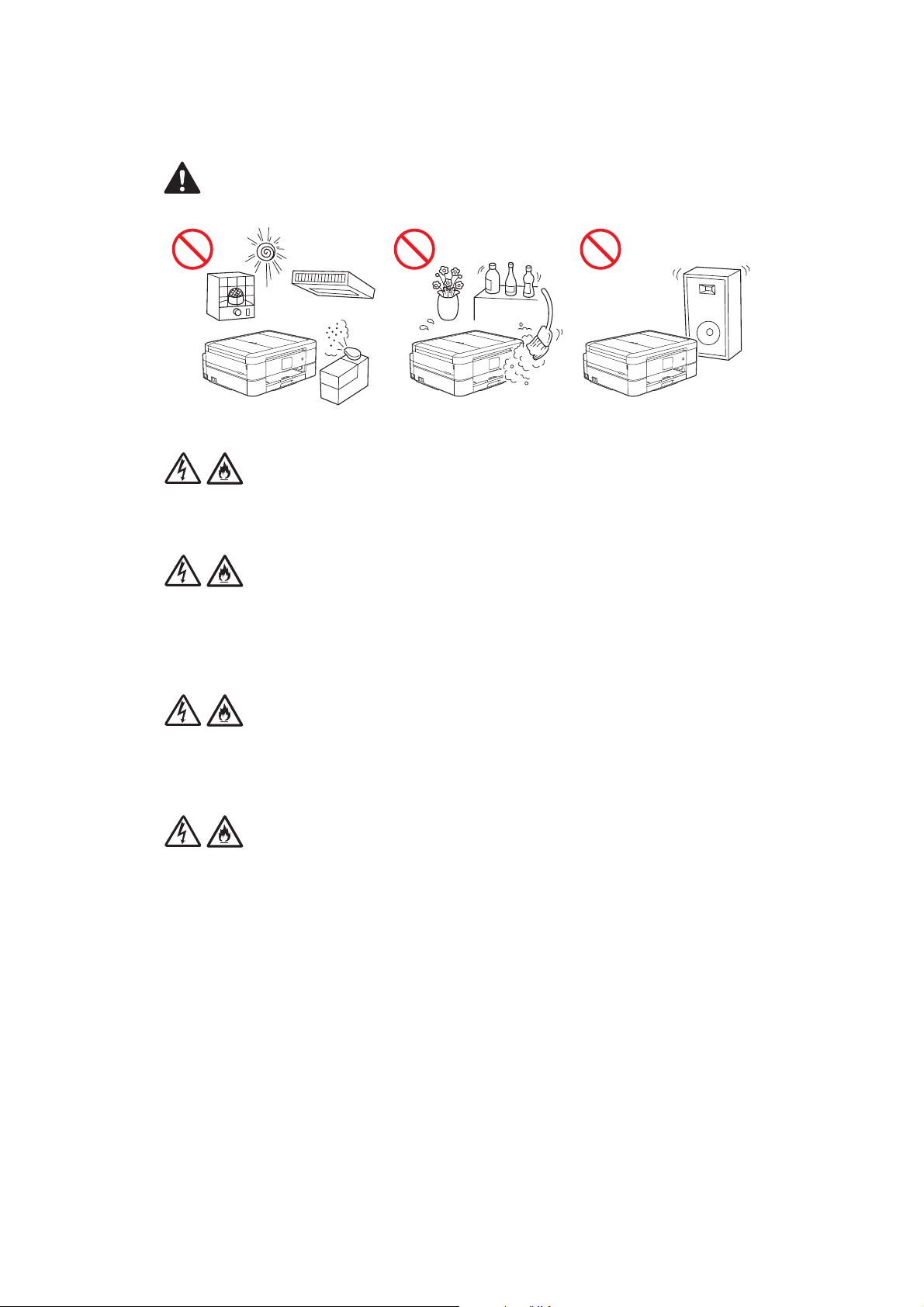

Choose a Safe Location for the Machine

WARNING

Choose a location where the temperature remains between 10°C and 35°C, the humidity is

between 20% and 80%, and where there is no condensation.

DO NOT place the machine near heaters, air conditioners, electrical fans, refrigerators, or

water. Doing so may create the risk of an electrical shock, short circuit, or fire, as water may

come into contact with the machine (including condensation caused by heating/air conditioning/

ventilation equipment).

DO NOT expose the machine to direct sunlight, excessive heat, open flames, corrosive gasses,

moisture, or dust. Doing so may create a risk of an electrical shock, short circuit, or fire, causing

damage to the machine and/or rendering it inoperable.

DO NOT place the machine near chemicals or in a place where chemicals could be spilled on it.

Should chemicals come into contact with the machine, there may be a risk of fire or electrical

shock. In particular, organic solvents or liquids such as benzene, paint thinner, polish remover,

or deodoriser may melt or dissolve the plastic cover and/or cables, resulting in a risk of fire or

electrical shock. These or other chemicals may cause the machine to malfunction or become

discoloured.

x

Confidential

Page 14

CAUTION

DO NOT place the machine on an unstable cart, stand, or table, particularly if children are

expected to be near the machine. The machine is heavy and may fall, causing injury to you or

others and serious damage to the machine. For the machines with scanning functionality, there

is an added risk of injury if the scanner glass should break.

Avoid placing the machine in a busy area. If you must place it in a busy area, ensure that the

machine is in a safe location where it cannot be accidentally knocked over, which could cause

injury to you or others and serious damage to the machine.

Ensure that cables and cords leading to the machine are secured so as not to pose a tripping

hazard.

DO NOT place heavy objects on the machine.

DO NOT place any objects around the machine. Such objects block the access to the electrical

socket in case of emergency. It is important that the machine can be unplugged whenever

needed.

IMPORTANT

• DO NOT place the machine next to devices that contain magnets or generate magnetic fields.

Doing so may interfere with the operation of the machine, causing print quality problems.

• DO NOT place the machine on any tilted/slanted surface. DO NOT tip the machine after ink

cartridges are installed or ink tank is filled. Doing so may cause ink spillage and internal

damage to the machine.

• DO NOT place the machine next to sources of interference, such as speakers or the base

units of non-Brother cordless telephones. Doing so may interfere with the operation of the

machine's electronic components.

• DO NOT place anything in front of the machine that will block printed pages or received faxes

(MFC models only). DO NOT place anything in the path of printed pages or received faxes

(MFC models only).

xi

Confidential

Page 15

Connect the Machine Safely

WARNING

ELECTRICAL HAZARDS

Failure to follow the warnings in this section may create the risk of an electrical shock. In

addition, you could create an electrical short, which may create the risk of a fire.

There are high-voltage electrodes inside the machine. Before you access the inside of the

machine, including for routine maintenance such as cleaning, make sure you have unplugged

the telephone line cord first (MFC models only) and then the power cord from the electrical

socket, as well as any telephone/RJ-11 (MFC models only) or Ethernet/RJ-45 cables (Network

models only) from the machine.

DO NOT push objects of any kind into this machine through slots or openings in the machine,

as they may touch dangerous voltage points or short-out parts.

DO NOT handle the plug with wet hands. Doing this might cause an electrical shock.

Always make sure the plug is fully inserted. DO NOT use the machine or handle the cord if the

cord has become worn or frayed.

Unplug the power plug regularly to clean it. Use a dry cloth to clean the root of the plug blades

and between the blades. If the power plug is plugged into the socket over a long period, dust

accumulates around the plug blades, which may cause a short circuit, resulting in a fire.

xii

Confidential

Page 16

DO NOT drop any metallic hardware or any type of liquid on the power plug of the machine. It

may cause an electrical shock or a fire.

If water, other liquids, or metal objects get inside the machine, immediately unplug the machine

from the electrical socket.

This machine should be connected to an AC power source within the range indicated on the

rating label (You can find the rating label on the machine). DO NOT connect it to a DC power

source or inverter.

Use the Machine Safely

WARNING

ELECTRICAL HAZARDS

Failure to follow the warnings in this section may create the risk of an electrical shock. In

addition, you could cause an electrical short, which may lead to a fire.

If the machine has been dropped or the casing has been damaged, there may be the possibility

of an electrical shock. Unplug the machine from the electrical socket.

DO NOT use the machine during a thunderstorm. There may be a remote risk of an electrical

shock from lightning.

FIRE HAZARDS

Failure to follow the warnings in this section may create the risk of a fire.

DO NOT use flammable substances, any type of spray, or an organic solvent/liquid containing

alcohol or ammonia to clean the inside or outside of the machine. Doing so could cause a fire.

Instead, use only a dry, lint-free cloth.

xiii

Confidential

Page 17

(Models with Wireless LAN function only)

DO NOT use the machine near any medical electrical equipment. The radio waves emitted from

the machine may affect medical electrical equipment and cause a malfunction, which may result

in accident or injury.

For users with pacemakers:

This machine generates a weak magnetic field. If you feel anything wrong with the operation of

your pacemaker when near the machine, move away from the machine and consult a doctor

immediately.

DO NOT place the following objects on the machine.

If these objects contact the electrical parts inside the machine, it may cause a fire or electrical

shock.

• Metal objects such as a clip or a staple

• Precious metals such as a necklace or a ring

• Containers holding water or liquid such as a glass, a flower vase, or a flower pot

If the machine becomes unusually hot, releases smoke, generates any strong smells, or if you

accidentally spill any liquid on it, immediately unplug the machine from the electrical socket.

Plastic bags are used in the packing of this machine. Plastic bags are not toys. To avoid the

danger of suffocation, keep these bags away from babies and children, and dispose of them

properly.

(MFC models only)

Use caution when installing or modifying telephone lines. Never touch telephone wires or

terminals that are not insulated unless the telephone line has been unplugged from the wall

socket.

Never install telephone wiring during a thunderstorm. Never install a telephone wall socket in a

location that is wet or may become wet, for example, near a refrigerator or other appliance that

produces condensation.

xiv

Confidential

Page 18

Power Cord Safety:

• The machine is equipped with an earthed plug. This plug will only fit into an earthed electrical

socket. This is a safety feature. DO NOT attempt to defeat the purpose of the earthed plug.

• DO NOT allow anything to rest on the power cord.

• DO NOT place the machine where people might step on the cord.

• DO NOT place the machine in a position where the cord is stretched or strained, as it may

become worn or frayed.

• DO NOT use the machine or handle the cord if the cord has become worn or frayed. If

unplugging the machine, DO NOT touch the damaged/frayed part.

• DO NOT pull on the middle of the AC power cord; pulling on the middle may cause the cord to

separate from the plug. Doing this might cause an electrical shock.

• DO NOT use any undesignated cables (or optional devices). Doing so may cause a fire or

injuries. Installation must be performed properly.

• It is strongly recommended that you DO NOT use any type of extension cord.

• The machine should be positioned so that nothing pinches or constricts the power cord.

• DO NOT use any cable that does not meet the applicable cable specifications. Doing so may

cause a fire or injuries. If the power cord is provided with the machine, use ONLY the provided

cord. Installation must be performed properly.

CAUTION

Wait until pages have exited the machine before picking them up. Failure to do this may cause

injury to your fingers by trapping them in a roller.

DO NOT put your hand or any foreign objects into the ink insertion slot. Doing this may cause

injury.

xv

Confidential

Page 19

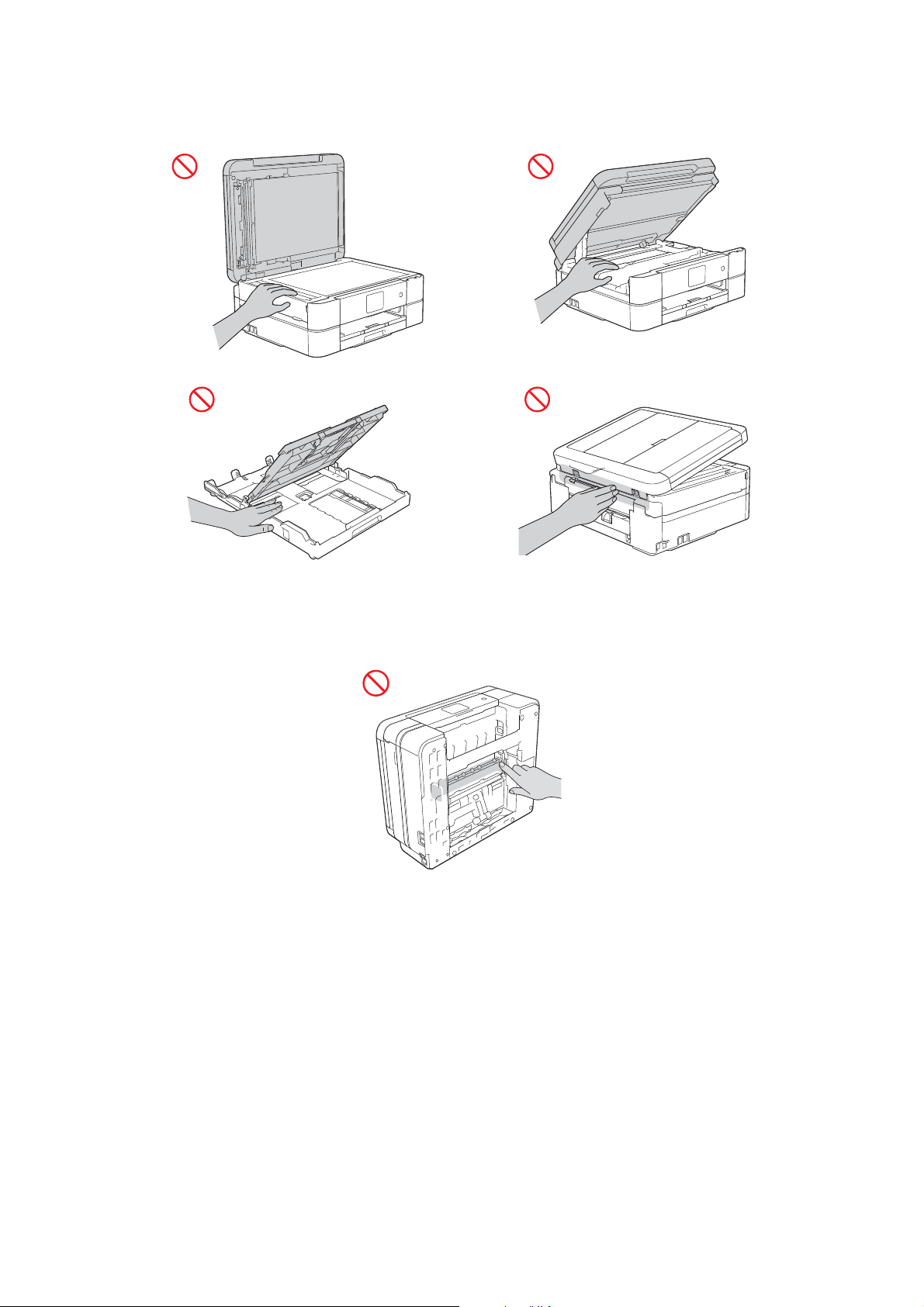

To prevent injuries, be careful not to put your fingers in the areas shown in the illustrations.

DO NOT touch the edges of the metal parts behind the rollers in the grey shaded area shown in

the illustration. These parts have sharp edges and touching the metal parts behind the rollers

may cut your fingers or otherwise injure them.

xvi

Confidential

Page 20

(MFC-J491DW/J497DW/J690DW/J890DW/J895DW)

DO NOT apply pressure with your hand or elbow in the grey shaded area shown in the

illustration below. Doing so may cause the ADF document support (1) to inadvertently open.

1

DO NOT carry the machine by holding the scanner cover, the Jam Clear Cover, the manual

feed slot cover (some models only), or the control panel. Doing this may cause the machine to

slip out of your hands and may result in injury.

Only carry the machine by placing your hands under the entire machine.

Some machines and/or their cartons contain a silica gel pack. DO NOT eat the silica gel pack;

throw it away. If you ingest it, seek medical attention immediately.

xvii

Confidential

Page 21

If the ink contacts your skin or gets into your eye or mouth, follow these steps immediately:

• If your skin comes into contact with the ink, wash your skin with water and soap immediately.

• If the ink gets into your eye, rinse it with water immediately. If left as is, it may cause redness

or mild inflammation of the eye. In case of any abnormality, consult with your doctor.

• If the ink gets into your mouth, spit it out, rinse your mouth, and consult your doctor

immediately.

DO NOT run your hand over the edge of the paper. The thin and sharp edges of the paper may

cause an injury.

• Be careful not to get the ink in your eye when replacing ink cartridges or refilling ink.

• Keep ink cartridges or ink bottles out of the reach of children.

• Avoid swallowing ink.

IMPORTANT

• DO NOT connect the machine to an electrical socket controlled by wall switches or automatic

timers, or to the same circuit as a large appliance or other equipment that requires a

significant amount of electricity. It could disrupt the power supply. Disruption of the power

supply may also delete information from the machine's memory, and repeated cycling of the

power supply can damage the machine.

• We recommend that you use our genuine ink cartridges to replace cartridges that come with

the device. Non-genuine ink cartridges may cause damage to the print head. They may also

result in differences in the colours or storage stability. (Not all non-genuine ink cartridges

cause these issues.)

• DO NOT put objects on top of the machine. Doing so may cause the machine to malfunction.

• If the machine does not operate normally when the operating instructions are followed, adjust

only those controls that are covered by the operating instructions. Incorrect adjustment of

other controls may result in damage.

xviii

Confidential

Page 22

xix

Confidential

Page 23

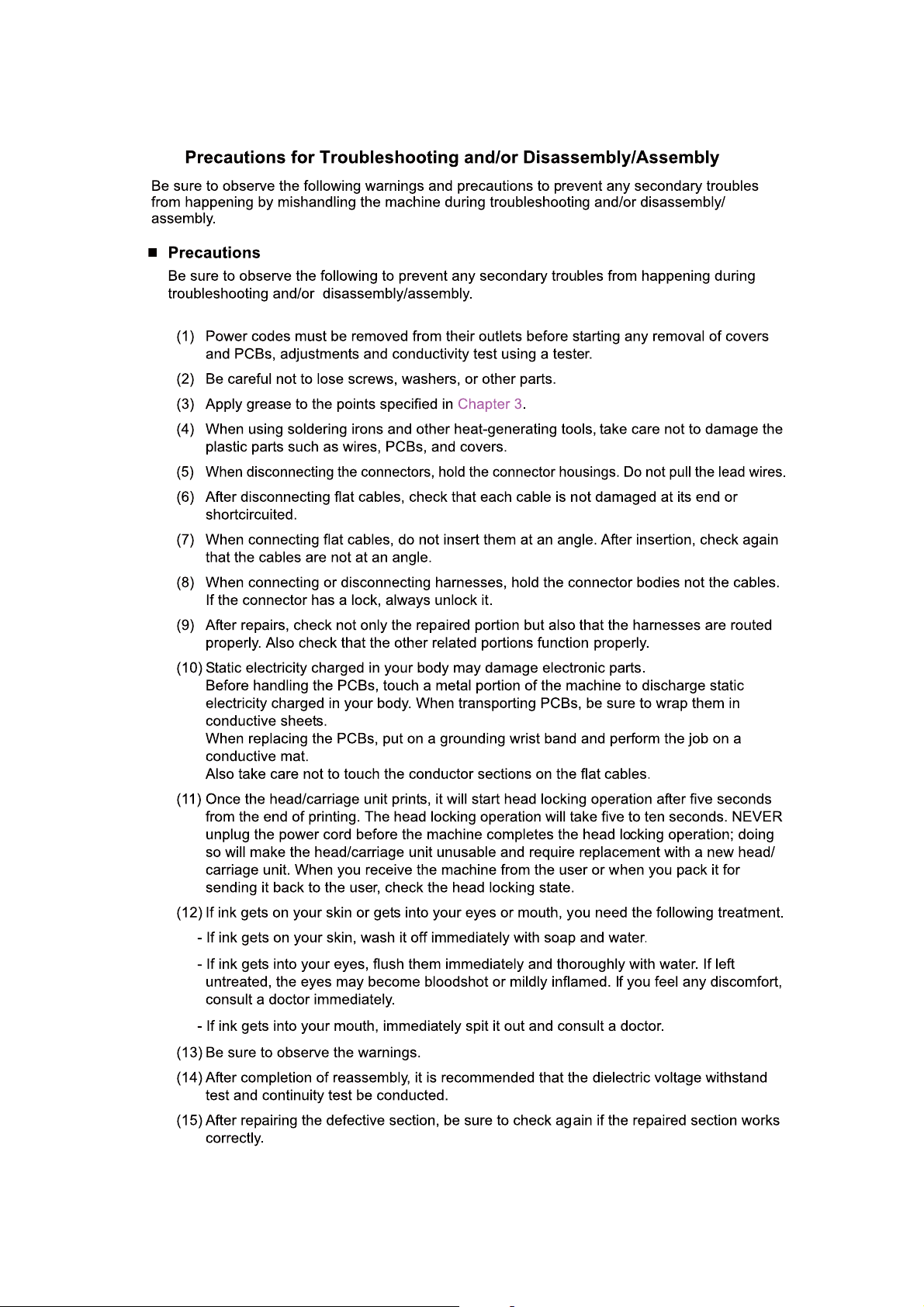

(16) Before packing the machine for sending it back to the user after repairs, be sure to clean

Flushing guide

Cleaner stick

the flushing guide with a cleaner stick as shown below to prevent ink splashing during

transportation.

xx

Confidential

Page 24

CHAPTER 1 SPECIFICATIONS

For details on product specifications, refer to the user's guide.

If there is a difference between the product specifications and the user's guide, the user's

guide should take precedence over the product specifications.

The product specifications may change without prior notice.

1GENERAL

1.1 General

Model DCP-J572DW

Print Head

Minimum

Droplet Size

Scanning

Method

CPU Speed 576 MHz

Backup Clock

Model

Print Head

Minimum

Droplet Size

Scanning

Method

CPU Speed 576 MHz

Backup Clock

BK/C/M/Y: 210/70/

70/70 nozzle

MFC-J491DW

MFC-J497DW

BK/C/M/Y:

210/70/70/70

nozzle

DCP-J772DW

DCP-J774DW

BK/C/M/Y: 210/210/210/210 nozzle BK/C/M/Y: 210/70/70/70 nozzle

Yes

(Up to 1 hour)

MFC-J690DW

BK/C/M/Y:

210/210/210/

210 nozzle

MFC-J805DW

MFC-J815DW

BK/C/M/Y:

210/70/70/70

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

BK: 3 pl CMY: 1.5 pl

CIS

nozzle

MFC-J890DW

MFC-J895DW

BK: 3 pl CMY: 1.5 pl

MFC-J995DW

CIS

Yes

(Up to 1 hour)

N/A

MFC-J1300DW

BK/C/M/Y: 210/210/210/210 nozzle

MFC-T810W MFC-T910DW

BK/C/M/Y: 210/210/

210/210 nozzle

1-1

Confidential

Page 25

1.2 Media Specification

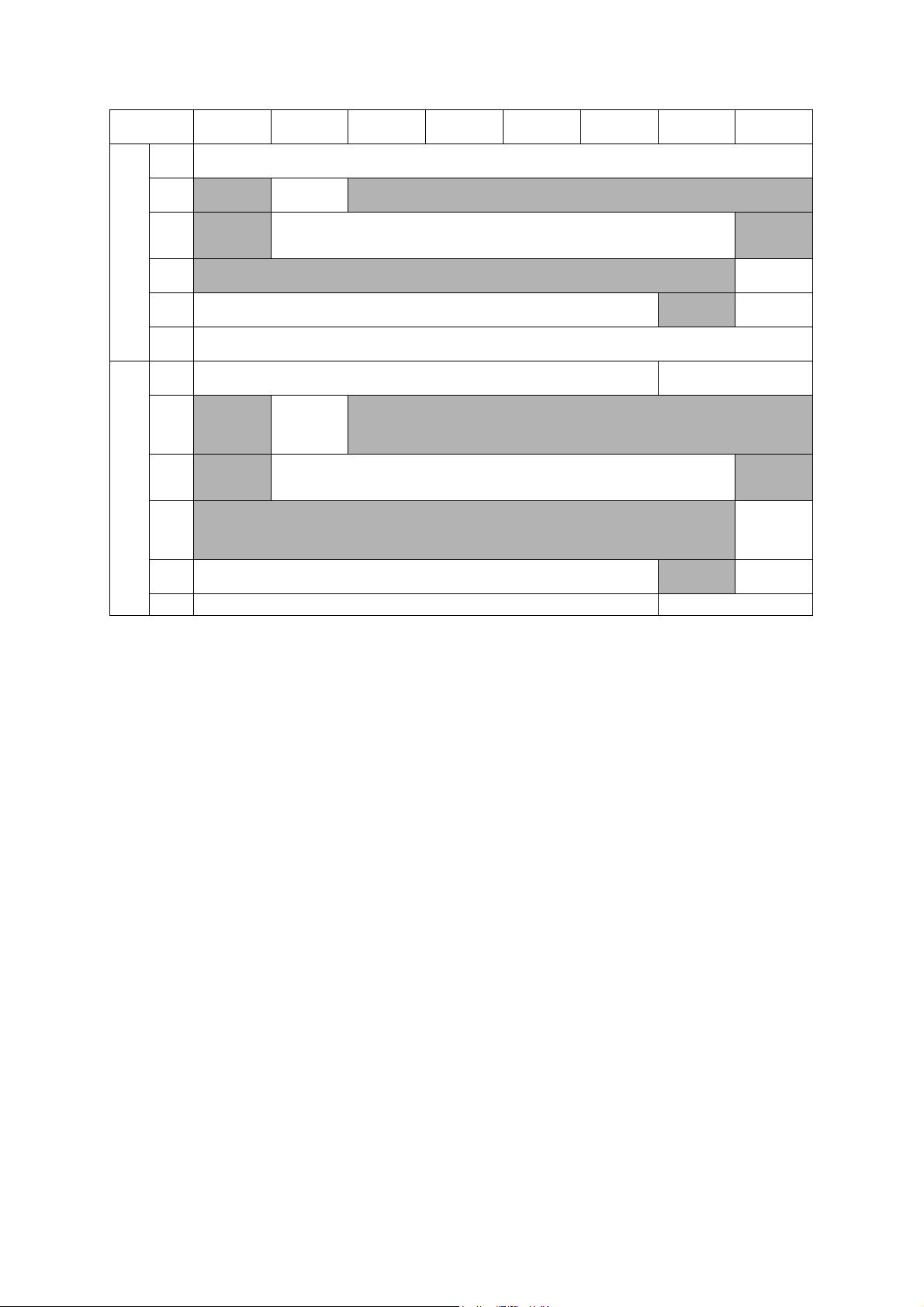

Model DCP-J572DW

A4, LTR, LGL

Standard

Tray

Photo Tray

Photo (102x152 mm/4x6"), Indexcard (127x203 mm/5x8"),

Photo-2L (127x178 mm/5x7"), C5 Envelope, Com-10,

Photo (102x152 mm/4x6"),

Photo-L (89x127 mm/3.5x5")

A4, LTR, LGL

Manual Feed

Slot

Photo (102x152 mm/4x6"), Indexcard (127x203 mm/5x8"),

Photo-2L (127x178 mm/5x7"), C5 Envelope, Com-10,

DCP-J772DW

DCP-J774DW

*1

, EXE, A5, A6, B5 (JIS)*3, B6 (JIS)*3,

16K (195x270 mm)

DL Envelope, Monarch

*1

, EXE, A5, A6, B5 (JIS)*3, B6 (JIS)*3,

16K (195x270 mm)

DL Envelope, Monarch,

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

*2

*2

A4, LTR, LGL

Photo (102x152 mm/4x6"), Indexcard (127x203 mm/5x8"),

Photo-2L (127x178 mm/5x7"), C5 Envelope, Com-10,

DL Envelope, Monarch, Mexico Legal

A4, LTR, LGL

Photo (102x152 mm/4x6"), Photo-L (89x127 mm/3.5x5"),

Photo-2L (127x178 mm/5x7"), C5 Envelope, Com-10,

Photo-L (89x127 mm/3.5x5")

Media

MP tray N/A

Sizes

Duplex Print

ADF (width/

length)

<PC Print> A4, LTR, EXE, A5, B5 (JIS)

<Copy> LTR, A4, A5, EXE

N/A

*3

*3

,16K

*6

148/148 mm to

215.9/355.6 mm

(5.8/5.8" to 8.5/

14.0")

*Documents that

are longer than

297 mm (11.7")

must be fed one

page at a time.

Media

Weights

Media

Types

Scanner Glass

(width/length)

Standard

Tray

Photo Tray

Manual Feed

Slot

MP tray

Duplex Print

ADF

Standard

Tray

Photo Tray

Manual Feed

Slot

MP tray

64-220 g/m

2

(17-58 lb.)

64-105 g/m

(17-28 lb.)

N/A

Plain, Inkjet, Glossy (cast/resin), Recycled Plain, Inkjet, Glossy (cast/resin)

Plain, Inkjet, Glossy (cast/resin),

Recycled

up to 215.9/297 mm (up to 8.5/11.7")

64-220 g/m

(17-58 lb.)

64-300 g/m

(17-79 lb.)

2

2

N/A

2

(17-24lb.)

2

64-90 g/m

Plain, Inkjet, Glossy (cast/resin), Recycled

N/A

Duplex Print Plain, Recycled

ADF

*1

Only for US area, SIN, GULF and IDN

*2

Only for CHN, HK, KOR and TWN

*3

Only for CHN, HK and TWN

*4

Only for China

*5

Only for US area, PHL, IDN, India, Gulf/Turkey and some countries in Europe

*6

Only for US area

*7

Only for US area and CHN

N/A Plain, Recycled N/A Plain

*5

, Folio*5, EXE, A5, A6, B5

*2

(JIS), B6

*5

, India Legal*5, 16K

N/A

*5

, Folio*5, EXE, A5, A6, B5

*2

(JIS), B6

Indexcard (127x203 mm/5x8"),

DL Envelope, Monarch,

Mexico Legal*5, India Legal*5, 16K

N/A

148/148 mm to

215.9/355.6 mm

(5.8/5.8" to 8.5/

N/A

*Documents that

are longer than

297 mm (11.7")

must be fed one

page at a time.

N/A

N/A

N/A

N/A

N/A

*2

*2

*4

14.0")

64-90 g/m

(17-24lb.)

(JIS),

(JIS),

2

*4

1-2

Confidential

Page 26

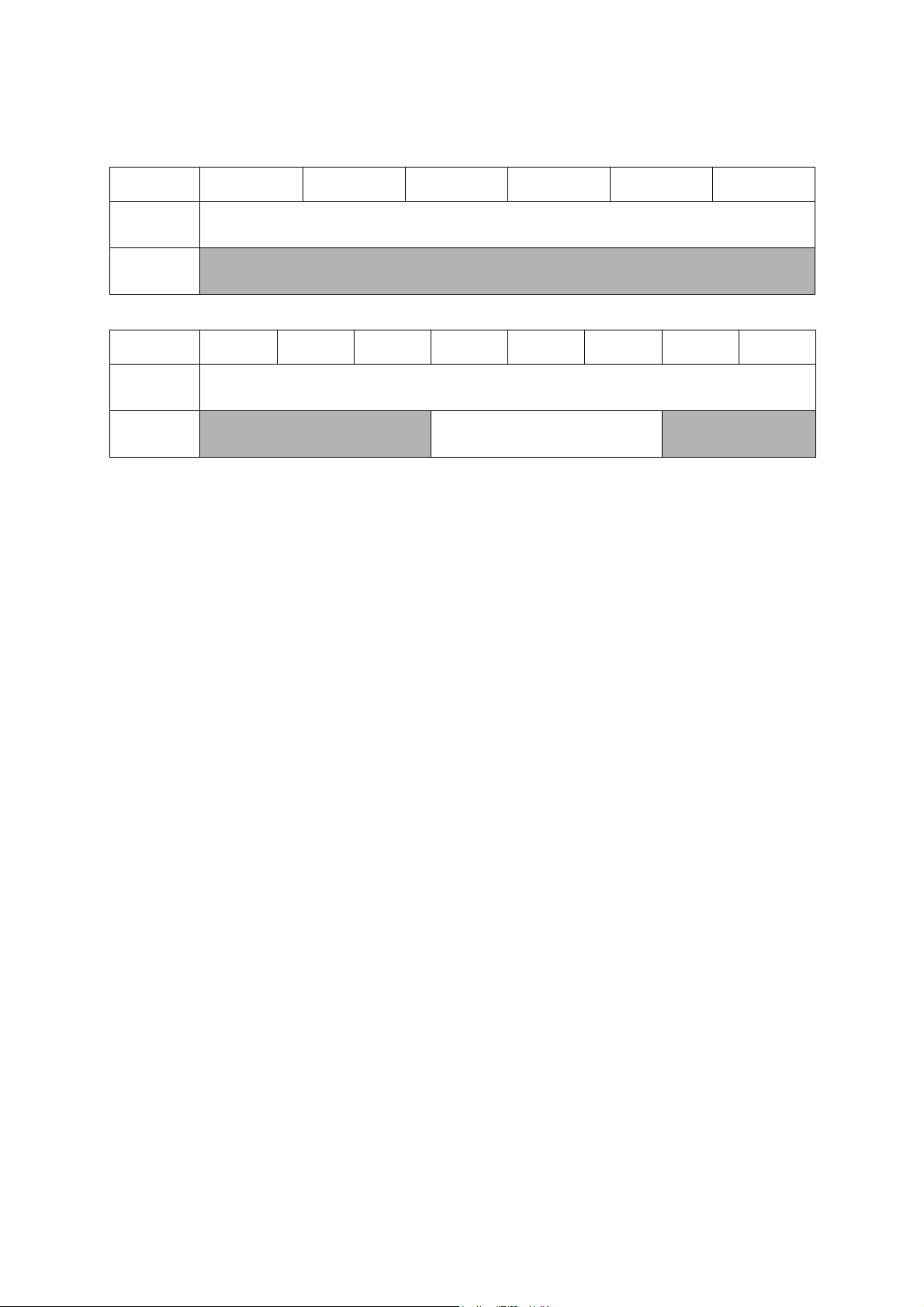

Media

Sizes

Model

Standard

Tray

Photo

Tray

Manual

Feed

Slot

MP tray

Duplex

Print

ADF

(width/

length)

Scanner

Glass

(width/

length)

MFC-J491DW

MFC-J497DW

A4, LTR, LGL*1, EXE, A5, A6, B5 (JIS)*3, B6 (JIS)*3, 16K (195x270 mm)

N/A

N/A

MFC-J690DW

MFC-J805DW

MFC-J815DW

MFC-J890DW

MFC-J895DW

MFC-J995DW

MFC-J1300DW

*2

Photo (102x152 mm/4x6"), Indexcard (127x203 mm/5x8"),

Photo-2L (127x178 mm/5x7"), C5 Envelope, Com-10,

Photo

(102x152 mm/

4x6"),

Photo-L

(89x127 mm/

3.5x5")

DL Envelope, Monarch

N/A

*1

A4, LTR, LGL

Photo (102x152 mm/4x6"), Indexcard (127x203 mm/5x8"),

Photo-2L (127x178 mm/5x7"), C5 Envelope, Com-10,

, EXE, A5, A6, B5 (JIS)*3, B6 (JIS)*3,

16K (195x270 mm)

DL Envelope, Monarch,

Photo-L (89x127 mm/3.5x5")

*2

N/A

<PC Print> A4, LTR, EXE, A5, B5 (JIS)*3, 16K

<Copy> LTR, A4, A5, EXE

*6

*3

148/148 mm to 215.9/355.6 mm

*Documents that are longer than 297 mm (11.7") must be fed one page at a time.

(5.8/5.8" to 8.5/14.0")

up to 215.9/297 mm

(up to 8.5/11.7")

MFC-T810W MFC-T910DW

A4, LTR, LGL

A5, A6, B5

Photo (102x152 mm/4x6"),

Indexcard (127x203 mm/5x8"),

Photo-2L (127x178 mm/5x7"),

C5 Envelope, Com-10,

DL Envelope, Monarch,

A4, LTR,

*5

LGL

EXE, A5, A6,

B5

B6

Photo

(102x152 mm/

4x6"), Photo-L

(89x127 mm/

3.5x5"),

Indexcard

(127x203 mm/

5x8"),

Photo-2L

(127x178 mm/

5x7"),

C5 Envelope,

Com-10,

DL Envelope,

Monarch,

Mexico

Legal

Legal

*2

Mexico Legal

India Legal

, Folio*5,

*2

(JIS),

*2

(JIS),

*5

, India

*5

*4

, 16K

*5

, Folio*5, EXE,

*2

(JIS), B6

*5

,

*5

*4

,16K

N/A

A4, LTR,

*5

, Folio*5,

LGL

EXE, A5, A6,

*2

(JIS),

B5

*2

(JIS),

B6

Photo

(102x152 mm/

4x6"), Photo-L

(89x127 mm/

3.5x5"),

Indexcard

(127x203 mm/

5x8"),

Photo-2L

(127x178 mm/

5x7"),

C5 Envelope,

Com-10,

DL Envelope,

Monarch,

Mexico

*5

Legal

*5

, 16K

Legal

(JIS),

, India

<PC Print>

N/A

A4, LTR, EXE,

A5, B5 (JIS)

<Copy> LTR,

A4, A5, EXE

16K

*4

*4

*4

,

*7

1-3

Confidential

Page 27

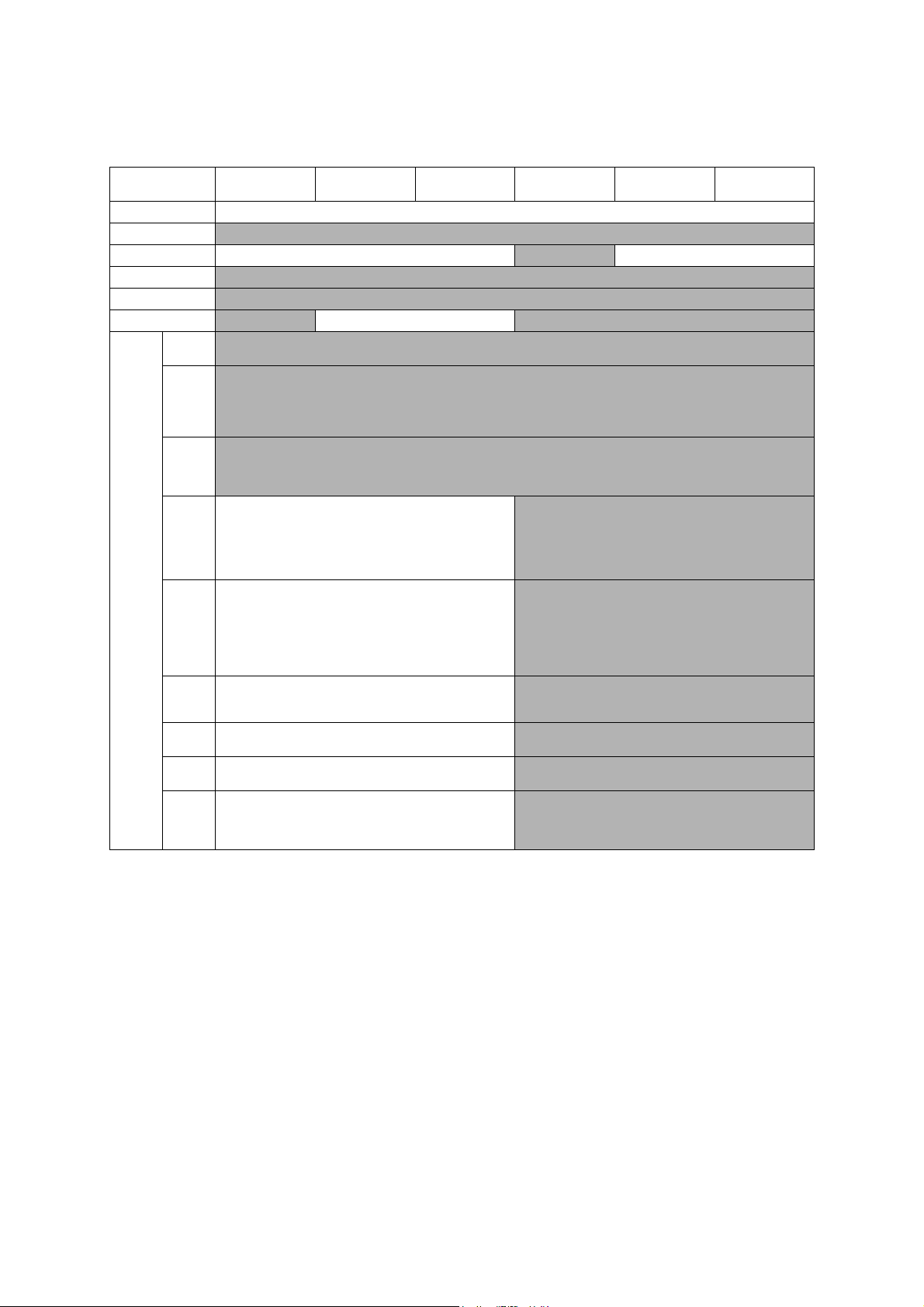

Model

Media

Weights

Media

Types

*1

Only for US area, SIN, GULF and IDN

*2

Only for CHN, HK, KOR and TWN

*3

Only for CHN, HK and TWN

*4

Only for China

*5

Only for US area, PHL, IDN, India, Gulf/Turkey and some countries in Europe

*6

Only for US area

*7

Only for US area and CHN

MFC-J491DW

MFC-J497DW

Standard

Tray

Photo

Tray

Manual

Feed

Slot

MP tray

Duplex

Print

ADF

Standard

Tray

Photo

Tray

Manual

Feed

Slot

MP tray

Duplex

Print

ADF Plain, Recycled Plain

N/A

N/A

N/A

N/A Plain, Inkjet, Glossy (cast/resin), Recycled N/A

MFC-J690DW

64-220 g/m

(17-58 lb.)

Plain, Inkjet,

Glossy (cast/

resin),

Recycled

MFC-J805DW

MFC-J815DW

2

Plain, Inkjet, Glossy (cast/resin), Recycled

MFC-J890DW

MFC-J895DW

64-105 g/m

(17-28 lb.)

Plain, Recycled

2

64-220 g/m

64-300 g/m

N/A

64-90 g/m

N/A

MFC-J995DW

(17-58 lb.)

(17-79 lb.)

(17-24lb.)

MFC-J1300DW

2

N/A

2

2

N/A

MFC-T810W MFC-T910DW

N/A

64-220 g/m

(17-58 lb.)

N/A

Plain, Inkjet, Glossy (cast/

N/A

64-105 g/m

(17-28 lb.)

resin)

Plain, Inkjet,

Glossy (cast/

Recycled

Recycled

resin),

Plain,

2

2

1-4

Confidential

Page 28

1.3 Paper Handling

Model DCP-J572DW

Standard

Tray

Photo

Tray

Paper

Manual

Input

(sheets)

Feed

Slot

MP Tray

ADF

Output Paper

Capacity (sheets)

Model

Standard

Tray

Photo

Tray

Paper

Manual

Input

Feed

(sheets)

Slot

MP Tray

ADF 20 (80 g/m

Output Paper

Capacity (sheets)

*

For details, refer to Section 10.1 Paper.

MFC-J491DW

MFC-J497DW

100 (80 g/m

20 (thickness: 0.25 mm)

100 (80 g/m

N/A

N/A 1 N/A

DCP-J772DW

DCP-J774DW

2

) 150 (80 g/m2)

N/A 20 (80 g/m2) N/A 20 (80 g/m2)

MFC-J690DW

2

) 150 (80 g/m2)

20 (thickness:

0.25 mm)

MFC-J805DW

MFC-J815DW

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

N/A

1

N/A

50 (80 g/m

MFC-J890DW

MFC-J895DW

N/A 80 (80 g/m2)

50 (80 g/m

2

)

MFC-J995DW

2

)

2

)

MFC-J1300DW

N/A

MFC-T810W MFC-T910DW

1.4 LCD Panel

LCD

LCD

Model

Type &

Size

To uc hPanel

Model

Type &

Size

To uc hPanel

DCP-J572DW

1.8 inch TFT 2.7 inch TFT

N/A Yes

MFC-J491DW

MFC-J497DW

1.8 inch TFT 2.7 inch TFT 1.8 inch TFT

N/A Yes N/A

DCP-J772DW

DCP-J774DW

MFC-J690DW

MFC-J805DW

MFC-J815DW

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

1-Line

N/A

MFC-J890DW

MFC-J895DW

MFC-J995DW

2.7 inch TFT 1-Line

Yes

MFC-J1300DW

MFC-T810W MFC-T910DW

1.8 inch TFT

N/A

1-5

Confidential

Page 29

1.5 Memory

Model DCP-J572DW

Memory Capacity

(physical:

Mbytes)

Memory Backup

(with Flash

memory)

Model

Memory Capacity

(physical:

Mbytes)

Memory Backup

(with Flash

memory)

MFC-J491DW

MFC-J497DW

DCP-J772DW

DCP-J774DW

MFC-J690DW

N/A

MFC-J805DW

MFC-J815DW

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

128 MB

N/A

MFC-J890DW

MFC-J895DW

128 MB

MFC-J995DW

Yes

MFC-J1300DW

MFC-T810W MFC-T910DW

N/A

1-6

Confidential

Page 30

1.6 Interface

Model DCP-J572DW

Host Interface Hi-Speed USB 2.0

LAN

Wireless LAN Yes

NFC

PictBridge

USB Memory

Acceptable

Media

(Type &

Size)

Memory

Stic k Duo

Memory

Stic k

Extended

High

Capacity

Memory

Stic k Pro/

Pro Duo/

Micro

SD Memory

Card

(miniSD,

microSD

with

adapter)

SDHC

Memory

Card

(miniSDHC,

microSDHC

with

adapter)

SDXC

Memory

Card

MultiMedia

Card

MultiMedia

Card plus

MultiMedia

Card mobile

(with

adapter)

N/A Yes N/A

DCP-J772DW

DCP-J774DW

16 MB-2 GB N/A

4 GB-32 GB N/A

48 GB-256 GB N/A

32 MB-2 GB N/A

128 MB-4 GB N/A

64 MB-1 GB N/A

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

N/A

N/A

N/A

N/A

N/A

N/A

N/A Yes

1-7

Confidential

Page 31

Model

Host Interface Hi-Speed USB 2.0

LAN

Wireless LAN Yes

NFC

PictBridge

USB Memory

Memory

Stic k Duo

Memory

Stic k

Extended

High

Capacity

Memory

Stic k Pro/

Pro Duo/

Micro

SD Memory

Card

(miniSD,

microSD

with

Acceptable

Media

(Type &

Size)

adapter)

SDHC

Memory

Card

(miniSDHC,

microSDHC

with

adapter)

SDXC

Memory

Card

MultiMedia

Card

MultiMedia

Card plus

MultiMedia

Card mobile

(with

adapter)

MFC-J491DW

MFC-J497DW

N/A Yes N/A

N/A 16 MB-2 GB N/A 16 MB-2 GB N/A

N/A 4 GB-32 GB N/A 4 GB-32 GB N/A

N/A

N/A 32 MB-2 GB N/A 32 MB-2 GB N/A

N/A 128 MB-4 GB N/A 128 MB-4 GB N/A

N/A 64 MB-1 GB N/A 64 MB-1 GB N/A

MFC-J690DW

N/A Yes

N/A Yes N/A

48 GB-256

GB

MFC-J805DW

MFC-J815DW

N/A 48 GB-256 GB N/A

MFC-J890DW

MFC-J895DW

MFC-J995DW

N/A

Yes

N/A

N/A

N/A

MFC-J1300DW

MFC-T810W

N/A Yes

MFC-T910DW

1-8

Confidential

Page 32

1.7 Others

Model DCP-J572DW

Operating

Environment

Temperature

(Best Print Quality)

Operating

Environment

Humidity

(Best Print Quality)

US

*1

Model

area

Europe

Asia/

Oceania

China

US

*1

area

Europe

Asia/

Oceania

China

16/3/0.7/0.2 W 17/3/0.8/0.2 W 20/3.5/0.9/0.2 W 14/2.5/0.7/0.2 W 14/3/0.7/0.2 W

16/3/0.7/0.2 W 17/3/0.8/0.2 W 20/3.5/0.9/0.2 W 14/2.5/0.7/0.2 W 14/3/0.7/0.2 W

*2

W400 x D341 x H151 mm

MFC-J491DW

MFC-J497DW

17/3.5/1/0.2 W18/3.5/1.2/0.2 W17/3.5/1/0.2 W18/3.5/1.2/0.2 W20/3.5/1.2/0.2

16/3.5/1/0.2

W

16/3.5/1/0.2 W17/3.5/1.2/0.2

*2

W400 x D341 x H172 mm

US area: 8.2/18.1 (kg/lbs)

Except for US area: 8.3/18.3

(kg/lbs)

Power

Consumption

(Operating/

Standby/

Sleep mode/

Off)

Machine Noise

(Operating)

Machine

Dimensions

Machine Weight 7.2/15.9 (kg/lbs) 8.8/19.4 (kg/lbs) 7.4/16.3 (kg/lbs) 8.6/19.0 (kg/lbs)

Operating

Environment

Temperature

(Best Print Quality)

Operating

Environment

Humidity

(Best Print Quality)

Power

Consumption

(Operating/

Standby/

Sleep mode/

Off)

Machine Noise

(Operating)

Machine

Dimensions

Machine Weight

*1

As for Argentina and Chile, refer to Asia/Oceania.

*2

As for India, refer to China. As for Taiwan, refer to US area

DCP-J772DW

DCP-J774DW

MFC-J690DW

W

N/A 14/2.5/0.8/0.2 W 17/3/0.8/0.2 W

N/A 15/3/1/0.4 W

MFC-J805DW

MFC-J815DW

N/A

W435 x D341

x H195 mm

MFC-J805DW:

MFC-J805DW

XL/J815DW

XL: 9.2/20.3

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

10-35 (20-33) degrees centigrade

50-95 (68-91.4) degree fahrenheit

20-80 (20-80) %

50 dB (A)

N/A

9.0/19.8

(kg/lbs)

(kg/lbs)

W435 x D341 x

H195 mm

MFC-J890DW

MFC-J895DW

10-35 (20-33) degrees centigrade

50-95 (68-91.4) degree fahrenheit

20-80 (20-80) %

17/3.5/1.2/0.2

W

17/3.5/1.2/0.2

W

N/A 16/3.5/1.4/0.4 W

50 dB (A)

W400 x D341

x H172 mm

US area: 8.2/

18.1 (kg/lbs)

Except for US

area: 8.3/18.3

(kg/lbs)

W435 x D380 x H159 mm

W

MFC-J1300DW

N/A

20/4/1.3/0.2

20/4/1.3/0.2 W16/3.5/1.1/0.2 W16/3.5/1.2/0.2

8.8/19.4

(kg/lbs)

MFC-J995DW

N/A

N/A

W435 x D341 x H195 mm

MFC-J995DW:

8.7/19.2

(kg/lbs)

MFC-J995DW

XL: 8.8/19.4

(kg/lbs)

MFC-T810W

15/3/1.1/0.2 W16/3.5/1.2/0.2

W

N/A

W435 x D380

x H195 mm

8.7/19.2

(kg/lbs)

W435 x D380 x

H195 mm

MFC-T910DW

W

16/3.5/1.2/0.2

W

W

W435 x D439

x H195 mm

9.8/21.6

(kg/lbs)

1-9

Confidential

Page 33

2FAX

Model DCP-J572DW

Modem Speed (bps)

Transmission Speed

ITU-T Group

Document

(Send/

Receive)

COLOR

FAX

Memory

(Send/

Receive)

Model

Modem Speed (bps) 14,400 (FAX)

Transmission Speed

ITU-T Group

Document

(Send/

Receive)

COLOR

FAX

Memory

(Send/

Receive)

MFC-J491DW

MFC-J497DW

DCP-J772DW

DCP-J774DW

MFC-J690DW

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

N/A

N/A

N/A

N/A

N/A

MFC-J805DW

MFC-J815DW

Yes /Ye s (I TU -T c ol or FA X)

MFC-J890DW

MFC-J895DW

Approx.7 sec (ITU-T Test Chart #1, MMR)

G3

N/A

MFC-J995DW

MFC-J1300DW

MFC-T810W

MFC-T910DW

N/A

1-10

Confidential

Page 34

3 PRINTER

Model DCP-J572DW

Print Speed ESAT

(mono/color)

(based on ISO/IEC

24734)

Draft Print Speed

(mono/color)

*Paper feeding time

is included.

Resolution

(horizontal x vertical)

Auto Duplex Print Yes (up to A4/LTR)

Model

Print Speed ESAT

(mono/color)

(based on ISO/IEC

24734)

Draft Print Speed

(mono/color)

*Paper feeding time

is included.

Resolution

(horizontal x vertical)

Auto Duplex Print Yes (up to A4/LTR)

12/6 ipm 12/10 ipm 12/6 ipm 12/10 ipm

27/10 ppm 27/23 ppm 27/10 ppm 27/23 ppm

Windows: up to

1,200 x 6,000 dpi

Macintosh: up to

1,200 x 3,600 dpi

MFC-J491DW

MFC-J497DW

12/6 ipm 12/10 ipm 12/6 ipm 12/10 ipm

27/10 ppm 27/23 ppm 27/10 ppm 27/23 ppm

Windows: up

to 1,200 x

6,000 dpi

Macintosh: up

to 1,200 x

3,600 dpi

DCP-J772DW

DCP-J774DW

MFC-J690DW

up to 1,200 x

6,000 dpi

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

up to 1,200 x 6,000 dpi

MFC-J805DW

MFC-J815DW

Windows: up

to 1,200 x

6,000 dpi

Macintosh: up

to 1,200 x

3,600 dpi

MFC-J890DW

MFC-J895DW

Windows: up to 1,200 x 6,000 dpi

Macintosh: up to 1,200 x 3,600 dpi

N/A

MFC-J995DW

MFC-J1300DW

up to 1,200 x 6,000 dpi

up to 1,200 x 6,000

MFC-T810W

N/A

dpi

MFC-T910DW

Yes (up to A4/

LTR)

1-11

Confidential

Page 35

4COPY

Model DCP-J572DW

Copy Speed ESAT

(based on ISO/IEC

24735) (mono/color)

*This spec is for

ADF model only.

Copy Speed sESAT

(based on ISO/IEC

29183) (mono/color)

*This spec is for

non-ADF model

only.

Copy Speed FCOT

(based on ISO/IEC

24735 Anex D)

(mono/color)

Mono

Resolution

(horizontal x

vertical)

Color

Auto Duplex Copy

Model

Copy Speed ESAT

(based on ISO/IEC

24735) (mono/color)

*This spec is for

ADF model only.

Copy Speed sESAT

(based on ISO/IEC

29183) (mono/color)

*This spec is for

non-ADF model

only.

Copy Speed FCOT

(based on ISO/IEC

24735 Anex D)

(mono/color)

Mono

Resolution

(horizontal x

vertical)

Color

Auto Duplex Copy

DCP-J772DW

DCP-J774DW

N/A 6/6 ipm N/A

5.6/2.7 ipm 5.6/5.6 ipm

24/33 sec 24/24 sec 13/14 sec 24/33 sec 24/24 sec

Print: Max. 1,200 x

1,200 dpi

Scan: Max. 1,200 x

1,200 dpi

Print: Max. 1,200 x

1,200 dpi

Scan: Max. 1,200 x

600 dpi

MFC-J491DW

MFC-J497DW

6/3 ipm

24/33 sec 24/24 sec 24/33 sec

Print: Max.

1,200 x 1,200

dpi

Scan: Max.

1,200 x 1,200

dpi

Print: Max.

1,200 x 1,200

dpi

Scan: Max.

1,200 x 600

dpi

MFC-J690DW

1,200 x 2,400

1,200 x 1,200

1,200 x 2,400

1,200 x 600

Print: Max. 1,200 x 2,400 dpi

Scan: Max. 1,200 x 1,200 dpi

Print: Max. 1,200 x 2,400 dpi

Scan: Max. 1,200 x 600 dpi

MFC-J805DW

MFC-J815DW

6/6 ipm

Print: Max.

dpi

Scan: Max.

dpi

Print: Max.

dpi

Scan: Max.

dpi

Print: Max.

1,200 x 1,200

Scan: Max.

1,200 x 1,200

Print: Max.

1,200 x 1,200

Scan: Max.

1,200 x 600

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

N/A 5.6/2.7 ipm

Print: Max. 1,200 x 1,200 dpi

Scan: Max. 1,200 x 1,200 dpi

Print: Max. 1,200 x 1,200 dpi

Scan: Max. 1,200 x 600 dpi

N/A

MFC-J890DW

MFC-J895DW

6/3 ipm 6/6 ipm

24/24 sec

dpi

dpi

dpi

dpi

MFC-J995DW

N/A

N/A

MFC-J1300DW

13/14 sec 24/24 sec

Print: Max. 1,200 x 2,400 dpi

Scan: Max. 1,200 x 1,200 dpi

Print: Max. 1,200 x 2,400 dpi

Scan: Max. 1,200 x 600 dpi

MFC-T810W

1,200 x 2,400 dpi

1,200 x 1,200 dpi

1,200 x 2,400 dpi

1,200 x 600 dpi

6/6 ipm

N/A

Print: Max.

Scan: Max.

Print: Max.

Scan: Max.

MFC-T910DW

1-12

Confidential

Page 36

5 SCANNER

Model DCP-J572DW

Scan speed

(Mono/Color) *@100

dpi

FB: 1,200 x 2,400 dpi

MFC-J491DW

MFC-J497DW

Model

Optical

Interp

olated

Optical

Interp

olated

Resolution

(horizontal x

vertical)

Scan speed

(Mono/Color) *@100

dpi

Resolution

(horizontal x

vertical)

6 SOFTWARE

DCP-J772DW

DCP-J774DW

ADF: N/A

MFC-J690DW

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

A4: 3.35 sec/4.38 sec

LTR: 3.15 sec/4.12 sec

FB: 1,200 x 2,400

dpi

ADF: 1,200 x 600

dpi

For Windows 7/ 8/ 10, up to 19,200 x 19,200 dpi with Scanner Utility

MFC-J805DW

MFC-J815DW

For Windows 7/ 8/ 10, up to 19,200 x 19,200 dpi with Scanner Utility

MFC-J890DW

MFC-J895DW

A4: 3.35 sec/4.38 sec

LTR: 3.15 sec/4.12 sec

FB: 1,200 x 2,400 dpi

ADF: 1,200 x 600 dpi

FB: 1,200 x 2,400 dpi

MFC-J995DW

ADF: N/A

MFC-J1300DW

MFC-T810W

FB: 1,200 x 2,400

dpi

ADF: 1,200 x 600

dpi

MFC-T910DW

Model DCP-J572DW

Driver

Support

OS

Vers ion

Driver

Support

OS

Vers ion

Windows

Macintosh

Model

Windows

Macintosh

DCP-J772DW

DCP-J774DW

Windows Server 2008/2008 R2/2012/2012 R2/2016

OS X v10.11.6,

macOS v10.12.x/

10.13.x

MFC-J491DW

MFC-J497DW

OS X

v10.11.6,

macOS

v10.12.x/

10.13.x

Windows 7/8/8.1/10

OS X v10.10.5/

10.11.x, macOS

v10.12.x

MFC-J690DW

OS X

v10.11.6,

macOS

v10.12.x/

10.13.x

(for US area)

OS X

v10.10.5/

10.11.x,

macOS

v10.12.x

(except for

US area)

MFC-J805DW

MFC-J815DW

v10.12.6/

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

Windows Server 2008/2008 R2/2012/2012 R2/2016

macOS

10.13.x/

10.14.x

MFC-J890DW

MFC-J895DW

Windows 7/8/8.1/10

OS X

v10.11.6,

macOS

v10.12.x/

10.13.x

(for US area)

OS X

v10.10.5/

10.11.x,

macOS

v10.12.x

(except for

US area)

Windows

7/8/8.1/10

OS X v10.11.6, macOS v10.12.x/10.13.x

MFC-J995DW

MFC-J1300DW

OS X v10.11.6, macOS v10.12.x/10.13.x

Windows 7/8/8.1/10

Windows Server 2008/2008 R2/2012/

2012 R2/2016

MFC-T810W

MFC-T910DW

1-13

Confidential

Page 37

7NETWORK

7.1 Network

Model All models

Internet FAX

(Firmware)(versionT

37)

7.2 Wired

N/A

Model DCP-J572DW

Model Name

(Ethernet)

Network Connection

(Ethernet)

Model

Model Name

(Ethernet)

Network Connection

(Ethernet)

MFC-J491DW

MFC-J497DW

DCP-J772DW

DCP-J774DW

MFC-J690DW

N/A

N/A

MFC-J805DW

MFC-J815DW

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

N/A

N/A

MFC-J890DW

MFC-J895DW

Embedded

(NC-400h)

MFC-J995DW

Ethernet 10/100BASE-TX Auto Negotiation

MFC-J1300DW

Embedded

(NC-420h)

MFC-T810W

Embedded

(NC-400h)

MFC-T910DW

1-14

Confidential

Page 38

7.3 Wireless

Model DCP-J572DW

Model Name

(Wireless)

Network Connection

(Wireless)

Wireless Security

AOSS

Setup

Support

Utility

Model Name

(Wireless)

Network Connection

(Wireless)

Wireless Security

Setup

Support

Utility

WPS

(Wi-Fi

Protected

Setup)

Model

AOSS

WPS

(Wi-Fi

Protected

Setup)

DCP-J772DW

DCP-J774DW

Embedded (NC-410w)

IEEE 802.11 b/g/n (Infrastructure)

IEEE 802.11 g/n (Wi-Fi Direct)

SSID (32 chr), WEP 64/128bit,

WPA-PSK (TKIP/AES),

WPA2-PSK (TKIP/AES)

**NO LEAP**"

Yes

MFC-J491DW

MFC-J497DW

MFC-J690DW

Embedded (NC-410w) Embedded (NC-430w) Embedded (NC-410w)

SSID (32 chr), WEP 64/128bit,

WPA-PSK (TKIP/AES), WPA2-PSK (TKIP/AES)

MFC-J805DW

MFC-J815DW

**NO LEAP**"

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

Embedded

(NC-430w)

SSID (32 chr),

WEP 64/128bit,

WPA-PSK

(TKIP/AES),

WPA2-PSK

(TKIP/AES)

N/A

MFC-J890DW

MFC-J895DW

IEEE 802.11 b/g/n (Infrastructure)

IEEE 802.11 g/n (Wi-Fi Direct)

N/A

Yes

N/A

N/A

N/A

N/A Yes

MFC-J995DW

SSID (32 chr), WEP 64/

128bit, WPA-PSK (TKIP/

WPA2-PSK (TKIP/AES)

IEEE 802.11 b/g/n (Infrastructure)

MFC-J1300DW

AES),

Embedded

(NC-410w)

IEEE 802.11 g/n (Wi-Fi Direct)

SSID (32 chr), WEP 64/128bit,

WPA-PSK (TKIP/AES),

WPA2-PSK (TKIP/AES)

**NO LEAP**"

MFC-T810W

SSID (32 chr), WEP 64/

128bit, WPA-PSK (TKIP/

WPA2-PSK (TKIP/AES)

MFC-T910DW

AES),

**NO LEAP**"

1-15

Confidential

Page 39

8 SUPPLIES/OPTIONS

Model DCP-J572DW

Bundled

Cartridge

(BK/CL)

Supply

Standard

Ink

Cartridge

Yield @

ISO

pattern

(Pages)

Ink Bottle

Yield @

ISO

pattern

(Pages)

Storage Condition of

Ink Cartridge

Cartridge

(BK/CL)

Supply

High Yield

Cartridge

(BK/CL)

Supply

Super

High Yield

Cartridge

(BK/CL)

Bundled

Bottle

(BK/CL)

Supply

High

Yield

Bottle

(BK/CL)

DCP-J772DW

DCP-J774DW

200/200

200/200

400/400 3,000/1,500

N/A

N/A 6,175/4,500

N/A

* Storage condition at the temperature of 40 to 50°C and the humidity of 80 to 95%: Up to 5 days

* Storage condition at the temperature of 40 to 60°C and the humidity of Non control condition: Up to 5 days

DCP-J1100DW DCP-T310 DCP-T510W DCP-T710W

Europe: 5,400/

4,000

Asia: 2,250/1,125

N/A

Europe: 6,000/

5,000

Asia: N/A

(Temperature) Normal condition: -20 to 40°C

(Humidity) Normal condition: 20 to 80%

N/A

N/A

N/A

6,500/5,000

Model

Bundled

Cartridge

(BK/CL)

Ink

Cartridge

Yield @

ISO

pattern

(Pages)

Ink Bottle

Yield @

ISO

pattern

(Pages)

Storage Condition of

Ink Cartridge

Supply

Standard

Cartridge

(BK/CL)

Supply

High Yield

Cartridge

(BK/CL)

Supply

Super

High Yield

Cartridge

(BK/CL)

Bundled

Bottle

(BK/CL)

Supply

High