Brother LK3-B433E Owner's Manual

Z-8550A

INSTRUCTION MANUAL

Z-8560A

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

ELECTRONIC DIRECT DRIVE ZIGZAG LOCK STITCHER

ELECTRONIC DIRECT DRIVE ZIGZAG LOCK STITCHER

WITH THREAD TRIMMER

Thank you very much for buying a BROTHER sewing machine. Before using your new machine, please read the safety

instructions below and the explanations given in the instruction manual.

With industrial sewing machines, it is normal to carry out work while positioned directly in front of moving parts such as the

needle and thread take-up, and consequently there is always a danger of injury that can be caused by these parts. Follow

the instructions from training personnel and instructors regarding safe and correct operation before operating the machine so

that you will know how to use it correctly.

SAFETY INSTRUCTIONS

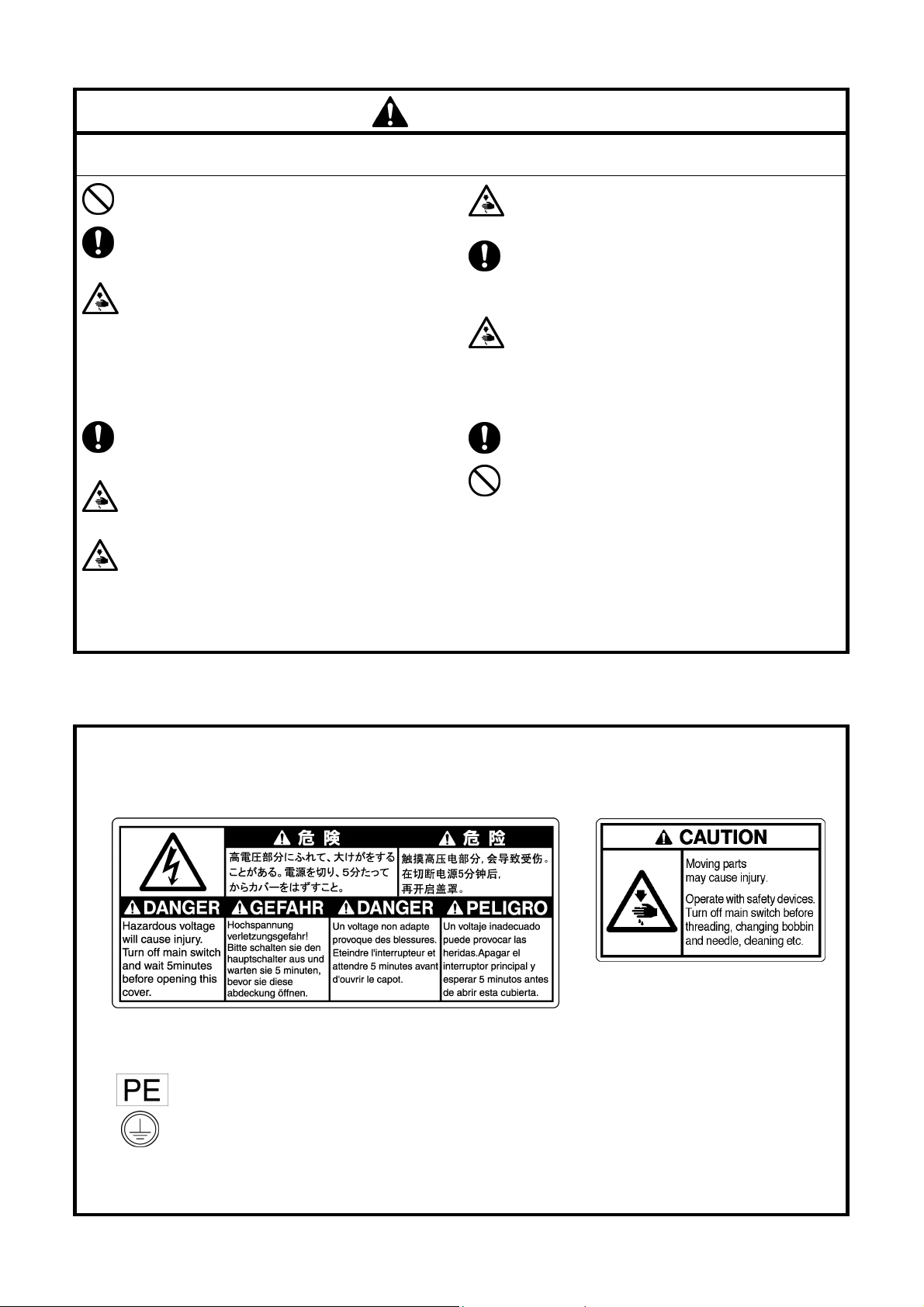

[1] Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are provided in order to ensure

safe operation of this machine and to prevent accidents and injury to yourself or other people.

Indications

DANGER

CAUTION

Symbols

· · · · ·

· · · · ·

· · · · ·

The instructions which follow this term indicate situations where failure to follow the

instructions will almost certainly result in death or severe injury.

The instructions which follow this term indicate situations where failure to follow the

instructions could cause injury when using the machine or physical damage to

equipment and surroundings.

This symbol ( ) indicates something that you should be careful of. The picture inside the triangle

indicates the nature of the caution that must be taken.

(For example, the symbol at left means “beware of injury”.)

This symbol ( ) indicates something that you must not do.

This symbol ( ) indicates something that you must do. The picture inside the circle indicates the

nature of the thing that must be done.

(For example, the symbol at left means “you must make the ground connection”.)

Z-8550A, 8560A

i

[2] Notes on safety

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet

before opening the face plate of the control box. Touching areas where high voltages are present can result in

severe injury.

DANGER

CAUTION

Environmental requirements

Use the sewing machine in an area which is free

from sources of strong electrical noise such as

high-frequency welders.

Sources of strong electrical noise may cause

problems with correct operation.

Any fluctuations in the power supply voltage

should be within ±10% of the rated voltage for the

machine.

Voltage fluctuations which are greater than this

may cause problems with correct operation.

The power supply capacity should be greater than

the requirements for the sewing machine's

electrical consumption.

Insufficient power supply capacity may cause

problems with correct operation.

Machine installation should only be carried out by

a qualified technician.

Contact your Brother dealer or a qualified

electrician for any electrical work that may need to

be done.

The sewing machine weighs more than 49 kg. The

installation should be carried out by two or more

people.

Do not connent the power cord until installation is

complete. The machine may operate if the treadle

is depressed by mistake, which could result in

injury.

Turn off the power switch before inserting or

removing the plug, otherwise damage to the

control box could result.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk of

receiving a serious electric shock, and problems

with correct operation may also occur.

The ambient temperature should be within the

range of 5°C to 35°C during use.

Temperatures which are lower or higher than this

may cause problems with correct operation.

The relative humidity should be within the range of

45% to 85% during use, and no dew formation

should occur in any devices.

Excessively dry or humid environments and dew

formation may cause problems with correct

operation.

In the event of an electrical storm, turn off the power

and disconnect the power cord from the wall outlet.

Lightning may cause problems with correct

operation.

Installation

When securing the cords, do not bend the cords

excessively or fasten them too hard with staples,

otherwise there is the danger that fire or electric

shocks could occur.

If using a work table which has casters, the casters

should be secured in such a way so that they

cannot move.

Use both hands to hold the machine head when

tilting it back or returning it to its original position. If

only one hand is used, the weight of the machine

head may cause your hand to slip, and your hand

may get caught.

Be sure to wear protective goggles and gloves

when handling the lubricating oil and grease, so that

they do not get into your eyes or onto your skin,

otherwise inflammation can result.

Furthermore, do not drink the oil or eat the grease

under any circumstances, as they can cause

vomiting and diarrhea.

Keep the oil out of the reach of children.

ii

Z-8550A, 8560A

CAUTION

Sewing

This sewing machine should only be used by

operators who have received the necessary training

in safe use beforehand.

The sewing machine should not be used for any

applications other than sewing.

Be sure to wear protective goggles when using the

machine.

If goggles are not worn, there is the danger that if a

needle breaks, parts of the broken needle may

enter your eyes and injury may result.

Turn off the power switch at the following times.

The machine may operate if the treadle is

depressed by mistake, which could result in injury.

When threading the needle

When replacing the bobbin and needle

When not using the machine and when leaving the

machine unattended

If the actuator is pressed by mistake when using the

correction sewing function, the needle will move in a

zigzag motion while the machine is operating, and

injury may result.

If using a work table which has casters, the casters

should be secured in such a way so that they

cannot move.

Attach all safety devices before using the sewing

machine. If the machine is used without these

devices attached, injury may result.

Never touch the knife on the face plate when

opening the thread takeup guard cover at times

such as when taking up slack in the thread,

otherwise injury may result.

Do not touch any of the moving parts or press any

objects against the machine while sewing, as this

may result in personal injury or damage to the

machine.

Use both hands to hold the machine head when

tilting it back or returning it to its original position. If

only one hand is used, the weight of the machine

head may cause your hand to slip, and your hand

may get caught.

If an error occurs in machine, or if abnormal noises

or smells are noticed, immediately turn off the

power switch. Then contact your nearest Brother

dealer or a qualified technician.

If the machine develops a problem, contact your

nearest Brother dealer or a qualified technician.

Turn off the power switch before carrying out

cleaning. The machine may operate if the treadle is

depressed by mistake, which could result in injury.

Do not directly touch sharp objects such as the tip

of the rotary hook when cleaning the rotary hook,

otherwise injury may result.

When removing the needle plate, auxiliary needle

plate and knife unit, use a screwdriver that matches

the size of the screw heads.

If a screwdriver with a size that does not match is

used, it may damage the screw heads and cause

personal injury or damage to the sewing articles.

Cleaning

Be sure to wear protective goggles and gloves

when handling the lubricating oil and grease, so that

they do not get into your eyes or onto your skin,

otherwise inflammation can result.

Furthermore, do not drink the oil or eat the grease

under any circumstances, as they can cause

vomiting and diarrhea.

Keep the oil out of the reach of children.

Use both hands to hold the machine head when

tilting it back or returning it to its original position. If

only one hand is used, the weight of the machine

head may cause your hand to slip, and your hand

may get caught.

Use only the proper replacement parts as specified

by Brother.

Z-8550A, 8560A

iii

Maintenance and inspection

Maintenance and inspection of the sewing machine

should only be carried out by a qualified technician.

Ask your Brother dealer or a qualified electrician to

carry out any maintenance and inspection of the

electrical system.

Turn off the power switch and disconnect the power

cord from the wall outlet at the following times,

otherwise the machine may operate if the treadle is

depressed by mistake, which could result in injury.

When carrying out inspection, adjustment and

maintenance

When replacing consumable parts such as the

rotary hook

Turn off the power switch before inserting or

removing the plug, otherwise damage to the control

box could result.

If the power switch needs to be left on when

carrying out some adjustment, be extremely careful

to observe all safety precautions.

Use both hands to hold the machine head when

tilting it back or returning it to its original position. If

only one hand is used, the weight of the machine

head may cause your hand to slip, and your hand

may get caught.

CAUTION

Never touch the knife on the face plate when

opening the thread takeup guard cover, otherwise

injury may result.

If any safety devices have been removed, be

absolutely sure to re-install them to their original

positions and check that they operate correctly

before using the machine.

When removing the needle plate, auxiliary needle

plate and knife unit, use a screwdriver that matches

the size of the screw heads.

If a screwdriver with a size that does not match is

used, it may damage the screw heads and cause

personal injury or damage to the sewing articles.

Use only the proper replacement parts as specified

by Brother.

Any problems in machine operation which result

from unauthorized modifications to the machine will

not be covered by the warranty.

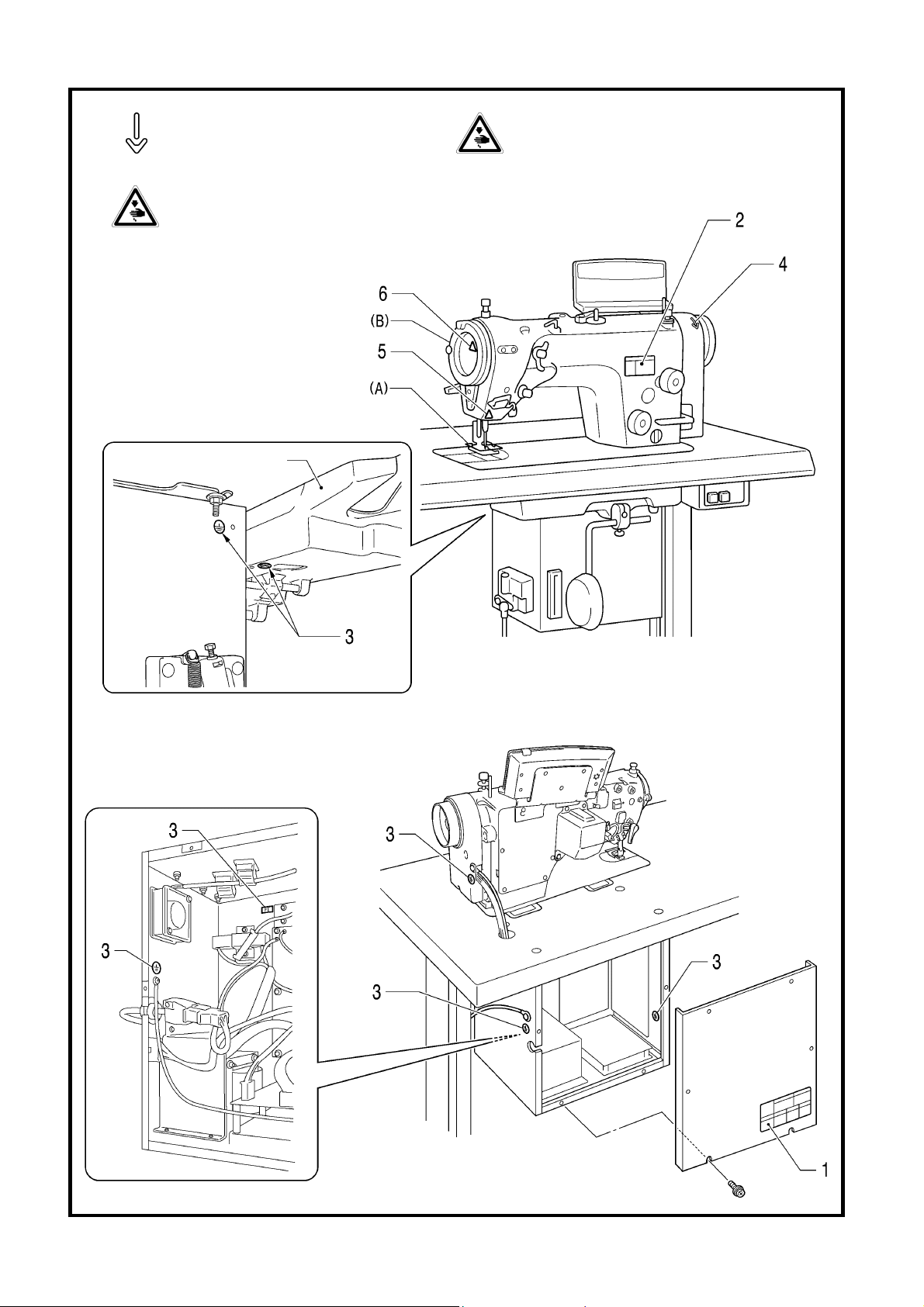

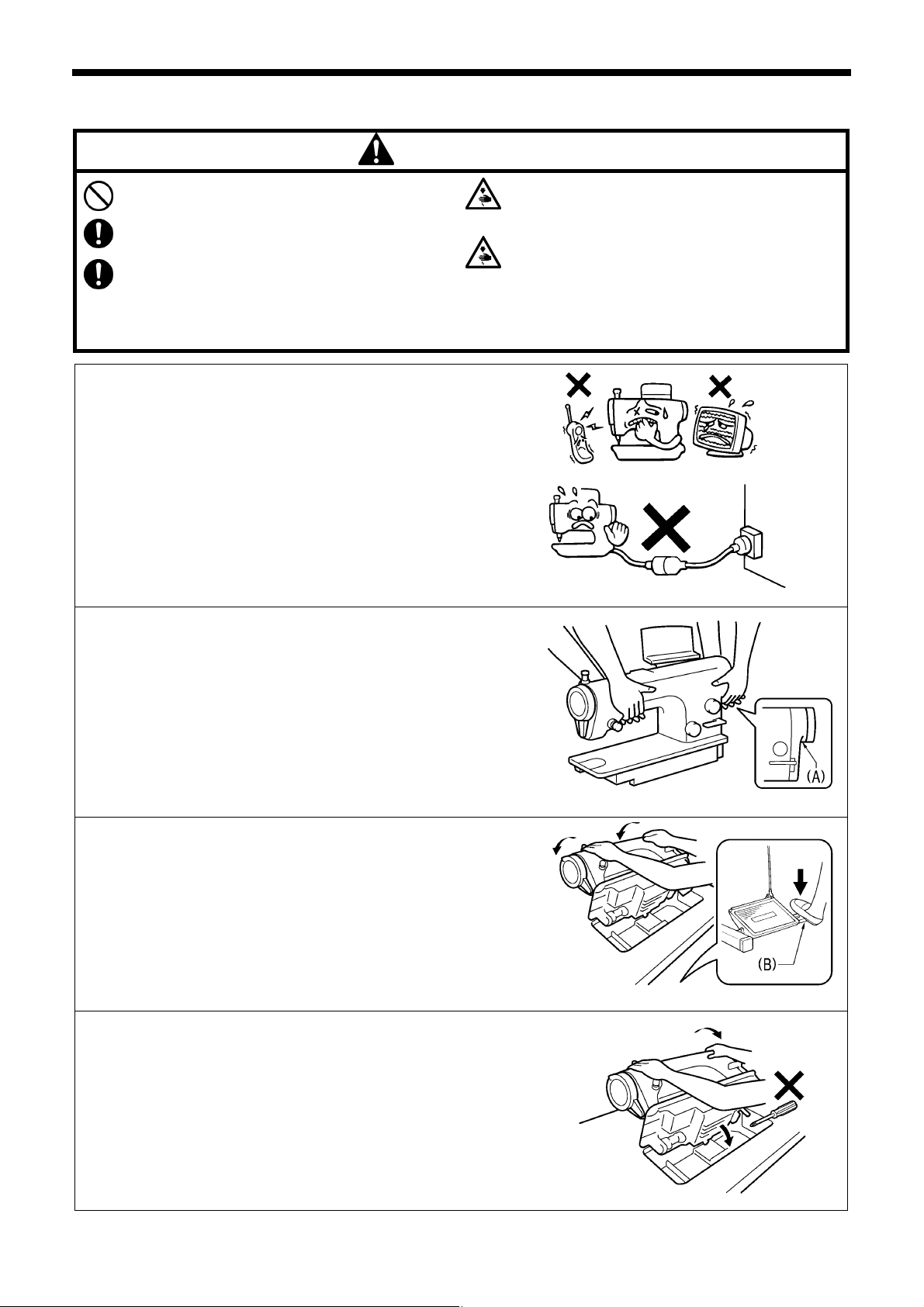

[3] Warning labels

The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels have been removed or are

difficult to read, please contact your nearest Brother dealer.

1

3

Be sure to connect the ground.

If the ground connection is not secure, you run a high

risk of receiving a serious electric shock, and

problems with correct operation may also occur.

2

Safety devices:

(A) Finger guard

(B) Thread take-up guard cover

iv

Z-8550A, 8560A

4

6

Direction of operation

Do not touch the thread take-up or the

knife, otherwise injury may result.

5

If the actuator is pressed by mistake when using

the correction sewing function, the needle will

move in a zigzag motion while the machine is

operating, and injury may result.

Oil pan

(For Europe)

3316M

Z-8550A, 8560A

3317M

v

CONTENTS

1. NAMES OF MAJOR PARTS................ 1

2. MACHINE SPECIFICATIONS.............. 2

3. SEWING PATTERN TABLE ................ 3

4. INSTALLATION.................................... 4

4-1. Table processing diagram................................ 5

4-2. Installation ........................................................ 6

4-3. Lubrication........................................................ 9

4-4. Connecting the cords ....................................... 10

4-4-1. Opening the control box cover .............. 10

4-4-2. Connecting the cords ............................ 10

4-5. Test operation (Operating the treadle) ............. 13

4-5-1. Turning on the power ............................ 13

4-5-2. Operating the treadle............................. 14

5. PREPARATION BEFORE SEWING.... 15

5-1. Installing the needle ......................................... 15

5-2. Removing the bobbin case............................... 15

5-3. Winding the lower thread ................................. 16

5-4. Installing the bobbin case................................. 16

5-5. Threading the upper thread.............................. 17

5-6. Adjusting the stitch length ................................ 18

5-7. Backtacking...................................................... 19

5-8. Using the knee lifter ......................................... 20

5-9. Using the thread wiper (8560A only) ................ 20

6. USING THE OPERATION PANEL

(BASIC OPERATIONS).......................

6-1. Names and functions ....................................... 21

6-2. Pattern setting method ..................................... 25

6-2-1. Sewing pattern table.............................. 25

6-2-2. Setting the sewing pattern..................... 26

6-2-3. Setting the zigzag width ........................ 31

6-2-4. Setting the zigzag base line position ..... 32

6-2-5. Setting the zigzag stop position............. 33

6-2-6. Setting start backtacking

(8560A, 8550A-A31 only) ...................... 34

21

6-2-7. Setting end backtacking

(8560A, 855A-A31 only) ........................35

6-2-8. Setting continuous backtacking

(8560A and 8550A-A31 only) ................36

6-2-9. Setting fixed stitches/name label

sewing (8560A, 8550A-A31 only) ..........37

6-3. Using the lower thread counter.........................39

7. USING THE OPERATION PANEL

(ADVANCED OPERATIONS).............. 40

7-1. Names and functions ........................................40

7-2. Adjusting the needle up stop position ...............41

7-3. LOCK key .........................................................42

7-4. Resetting all settings to their defaults ...............42

7-5. Using user programs ........................................43

7-5-1. Recording sewing data ..........................43

7-5-2. Retrieving recorded sewing data ...........44

7-6. Setting the maximum sewing speed .................45

8. SEWING ............................................... 46

9. THREAD TENSION .............................. 47

9-1. Adjusting the thread tension .............................47

9-2. Adjusting the presser foot pressure ..................48

10. CLEANING ......................................... 49

10-1. Daily cleaning procedures ..............................49

10-2. Applying grease

(When “GREASEUP” appears…) ..................52

11. REPLACING PARTS.......................... 55

11-1. Fixed knife and movable knife (8560A only)...55

11-2. Gauge parts

(presser foot, needle plate and feed dog)......56

11-2-1. Replacing the stopper.........................56

11-2-2. Changing the feed amount to long stitch

specifications (from 2.0mm to 5.0mm) ... 57

11-2-3. Changing the maximum feed amount ... 57

Z-8550A, 8560A

12. STANDARD ADJUSTMENTS............ 59

12-1. Actuator position ............................................ 59

12-2. Adjusting the safety switch position................ 60

12-3. Adjusting the thread tension spring ................ 61

12-4. Adjusting the presser foot height.................... 62

12-5. Adjusting the feed dog height......................... 62

12-6. Adjusting the feed dog angle.......................... 63

12-7. Adjusting the forward/back position of

the feed dog ................................................... 63

12-8. Adjusting the needle bar height...................... 64

12-9. Needle and rotary hook timing .......................64

12-10. Bobbin case holder position bracket

position......................................................... 65

12-11. Adjusting the rotary hook lubrication

amount ......................................................... 66

12-12. Adjusting the presser foot floating amount

(minute lifting amount).................................. 67

12-13. Adjusting the treadle .................................... 67

12-14. Adjusting the position of the thread trimming

cam (8560A only)..........................................68

12-15. Adjusting the tension of the lower thread

presser spring (8560A only)..........................69

12-16. Adjusting the thread trailing length after

thread trimming (8560A only) .......................69

12-17. Adjusting the thread wiper (8560A only).......70

13. OPTIONAL PARTS ............................ 71

13-1. Presser bar U and presser bar tip...................71

14. WHEN USING A NON-STANDARD

FEED DOG (8560A only) .................. 73

15. TROUBLESHOOTING ....................... 74

15-1. Sewing............................................................74

15-2. Error code displays .........................................79

Z-8550A, 8560A

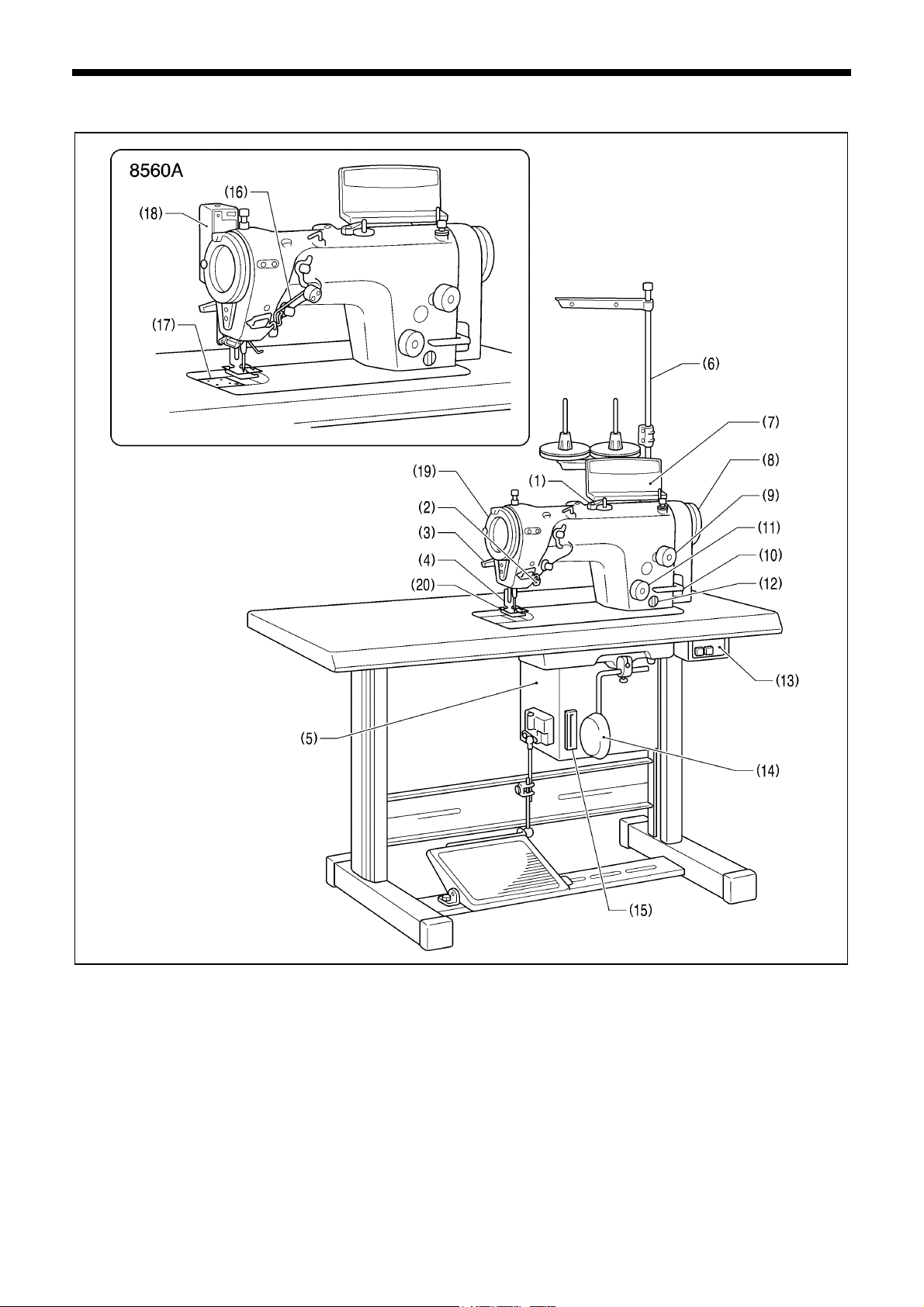

1. NAMES OF MAJOR PARTS

1. NAMES OF MAJOR PARTS

(1) Bobbin winder (2) Actuator

(3) Lifting lever (4) Presser foot

(5) Control box (6) Cotton stand

(7) Operation panel (8) Machine pulley

(9) Stitch length dial (10) Reverse lever

(11) Condense dial (12) Oil gauge window

(13) Power switch (14) Knee lifter assembly

(15) CF slot (16) Upper thread feeding device (8560A)

(17) Knife unit (8560A) (18) Thread wiper (8560A)

Safety devices

(19) Thread take-up guard cover (20) Finger guard

* CFTM is a trademark of SanDisk Corporation.

3319M

1

Z-8550A, 8560A

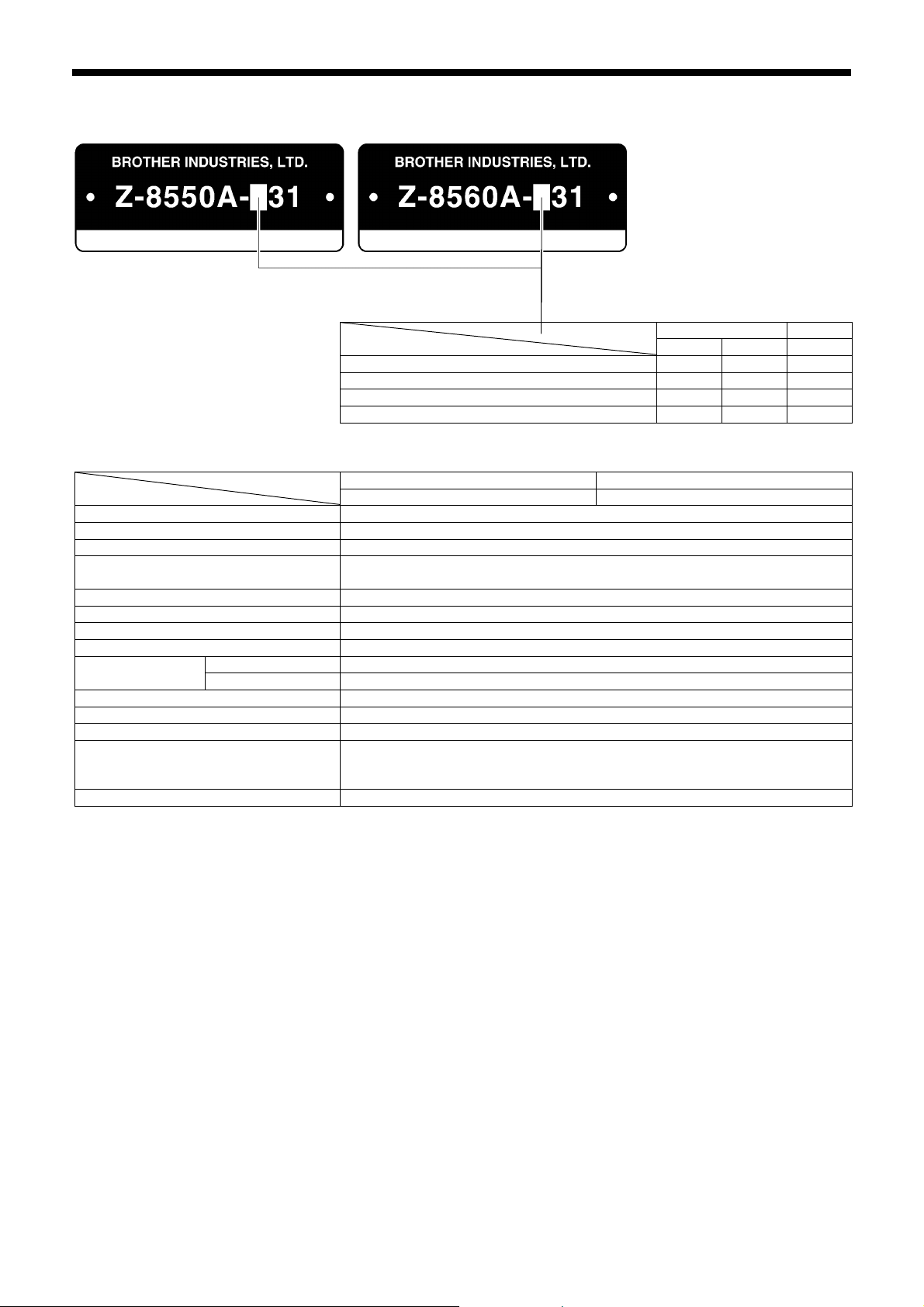

2. MACHINE SPECIFICATIONS

2. MACHINE SPECIFICATIONS

Thread trimmer - Upper thread feeding device - Back tack/condense device *1 Thread wiper - -

Use For light-weight materials-For medium- weight materials

Max. stitch length 2.0 mm *2

Max. sewing speed 5,000 rpm *3

Sewing pattern

Max. zigzag width 10 mm (Factory default 8 mm)

Thread take-up lever Rotary thread take-up

Needle bar stroke 33.3 mm

Feed dog height 1 mm

Lifting lever 6 mm Presser foot

height

Presser foot pressure 10-30 N

Needle Schmets 134SUK Nm70/10

Motor AC servo motor (4-pole, 450 W)

Power supply

Control circuit Microprocessor

*1… Used for sewing condensed stitches and backtack stitches.

*2… If replacing gauge parts and then changing the maximum feed amount setting, the maximum setting is 5 mm.

(Refer to pp. 18-19 and p. 57.)

*3… At the time of shipment from the factory, the maximum sewing speed is set to 4,000 rpm.

If using a sewing speed higher than this, use the memory switches to change the setting. (Ask the place of purchase for

details.)

Furthermore, the maximum sewing speed may be limited by the type of sewing pattern and the zigzag width. (Refer to

page 31.)

*4… The maximum number of custom-made patterns that can be stored is 99 patterns with a total of 49,500 stitches, at 500

stitches or less per pattern.

(Custom patterns can be created using the PS-300B (option device) and are saved into the control box using

commercially-available CF cards. Ask the place of purchase for details.)

Knee lifter 10 mm

(Up to 99 different types of custom-made patterns can be added *4)

8550A 8560A

-031, -A31 -431

14 patterns of eight types built-in

Single-phase: 110 V, 220 V, 230 V

3-phase: 220 V, 380 V, 400 V, 415 V

Maximum electric power consumption: 400 VA

8550A 8560A

0 A 4

c

c

c c

c

Z-8550A, 8560A

2

r

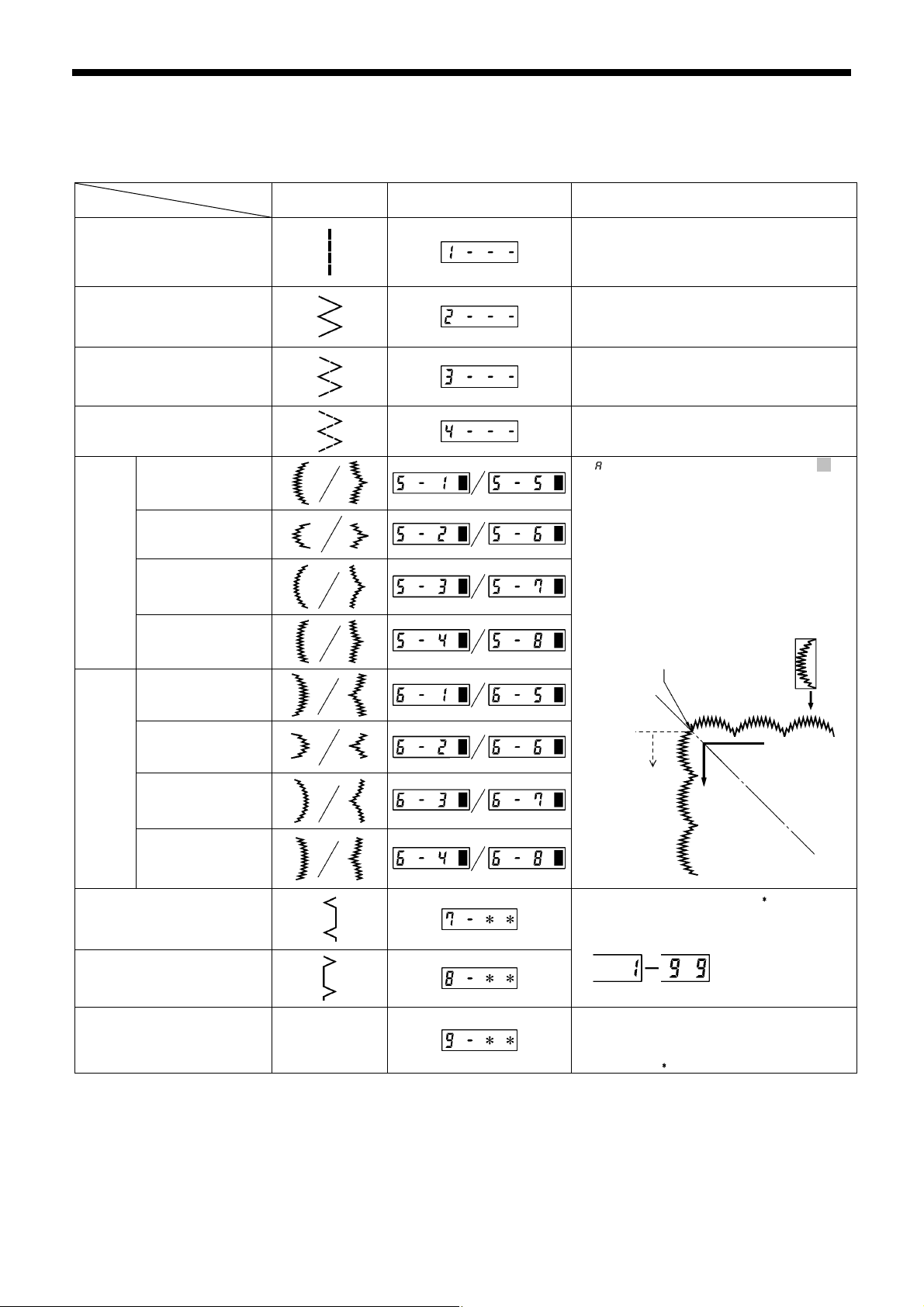

3. SEWING PATTERN TABLE

3. SEWING PATTERN TABLE

• This sewing machine is equipped with the following built-in sewing patterns. Select the pattern number from the operation

panel to use a pattern. (Refer to page 26.)

• Different zigzag widths and zigzag lengths can be set for each sewing pattern. (Refer to page 18 and 31.)

Straight stitch

Plain zigzag

2-step zigzag

3-step zigzag

Crescent scallop

(24sts.)

Even scallop

Scallop

(12sts.)

(left)

Standard scallop

(24sts.)

Even scallop

(24sts.)

Crescent scallop

(24sts.)

Sewing pattern

Pattern no.

(Main display)

Notes

If is set in the column marked with , a

reflection pattern can be sewn by stopping

the sewing machine and then pressing the

actuator.

(Refer to page 29.)

<Reflection pattern>

Sewing pattern

Press the actuato

Even scallop

Scallop

(12sts.)

(right)

Standard scallop

(24sts.)

Even scallop

(24sts.)

Blind stitch (left)

Blind stitch (right)

Custom made pattern

3320M—3333M

3334M—3348M

(Peflection

pattern)

Sewing direction

In the columns marked with

of stitches sewn in a straight line can be set

within the range of 1 to 99 stitches.

(No. of stitches)

, the number

1276M

1430M

Sewing patterns created using the

−

PS-300B (optional device) can be sewn.

(The pattern number is set in the columns

marked with

.)

3

Z-8550A, 8560A

4. INSTALLATION

CAUTION

Machine installation should only be carried out by a

qualified technician.

Contact your Brother dealer or a qualified electrician

for any electrical work that may need to be done.

The sewing machine weighs approximately 49 kg.

The installation should be carried out by two or more

people.

About the machine set-up location

• Do not set up this sewing machine near other equipment

such as televisions, radios or cordless telephones, otherwise

such equipment may be affected by electronic interference

from the sewing machine.

• The sewing machine should be plugged directly into an AC

wall outlet. Operation problems may result if extension cords

are used.

4. INSTALLATION

Do not connect the power cord until installation is

complete. The machine may operate if the treadle is

depressed by mistake, which could result in injury.

Use both hands to hold the machine head when

tilting it back or returning it to its original position. If

only one hand is used, the weight of the machine

head may cause your hand to slip, and your hand

may get caught.

3349M

Carrying the machine

• The machine should be carried by the arm by two people as

shown in the illustration.

* Hold the motor cover (A) by hand also so that the pulley

does not rotate.

Tilting back the machine head

• Hold section (B) with your foot so that the table does not

move, and then push the arm with both hands to tilt back the

machine head.

Returning the machine head to the upright position

1. Clear away any tools, etc. which may be near the table

holes.

2. While holding the arm with both hands, gently return the

machine head to the upright position.

3350M

3351M

3352M

Z-8550A, 8560A

4

4. INSTALLATION

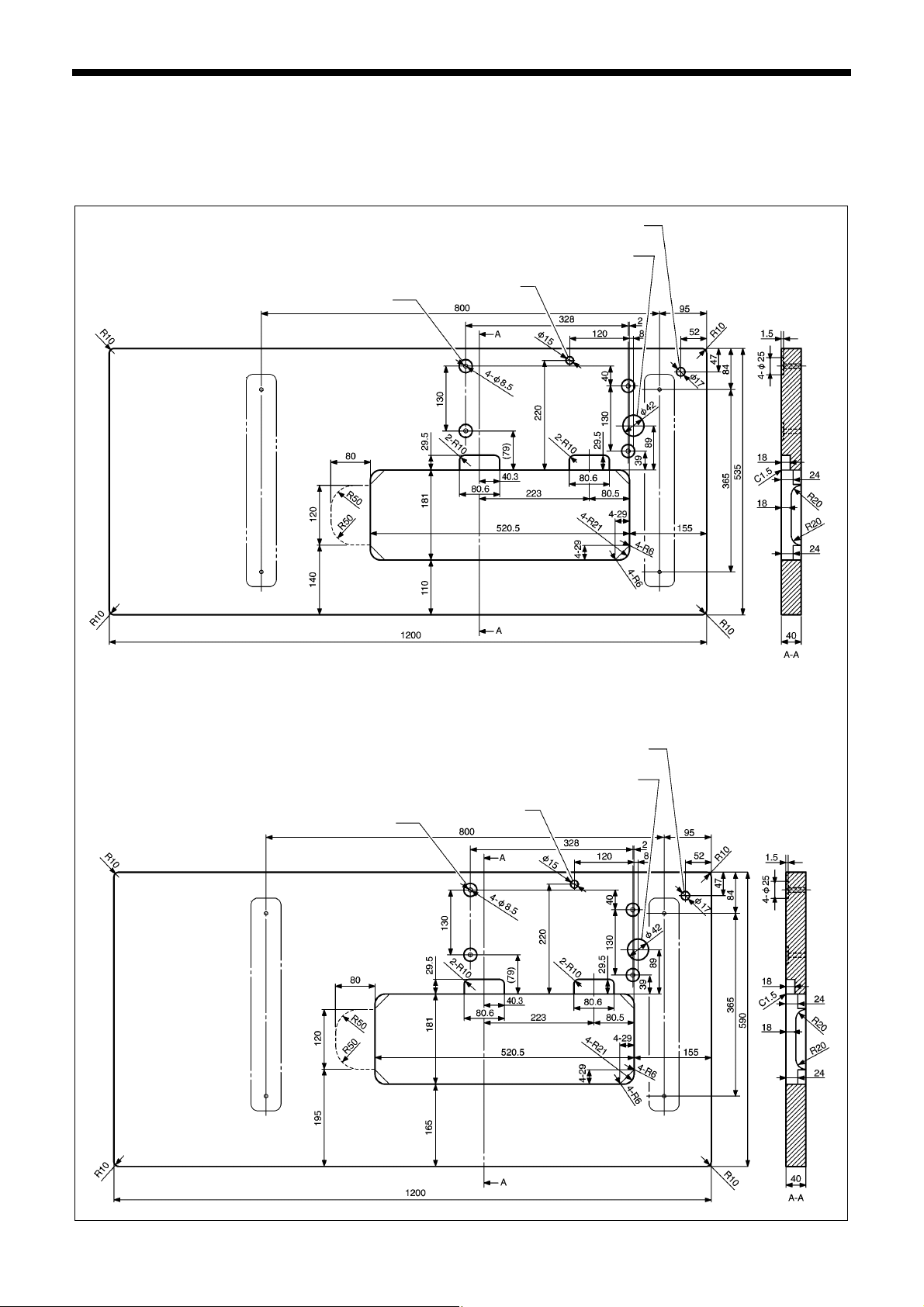

4-1. Table processing diagram

• The top of the table should be 40 mm in thickness and should be strong enough to hold the weight and with-stand the

vibration of the sewing machine.

• Drill holes as indicated in the illustration below.

• Select a method that is easy to carry out for the type of table used.

<Standard type>

Control box mounting hole

Head rest hole

<Wide type>

This type has a wider front/back dimensions at the front of the sewing machine.

Control box mounting hole

Head rest hole

Cotton stand hole

Cord hole

3353M

Cotton stand hole

Cord hole

3354M

5

Z-8550A, 8560A

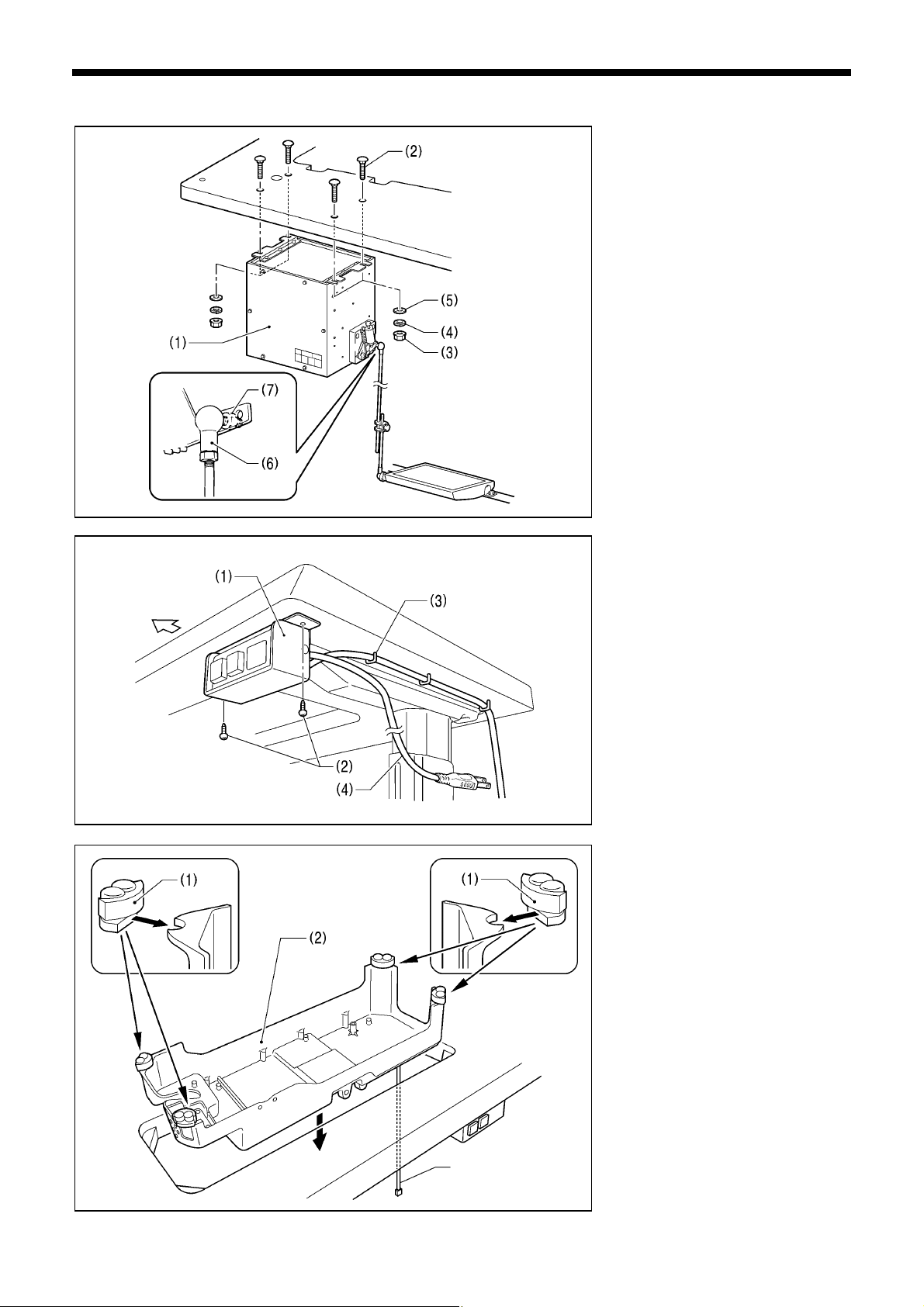

4-2. Installation

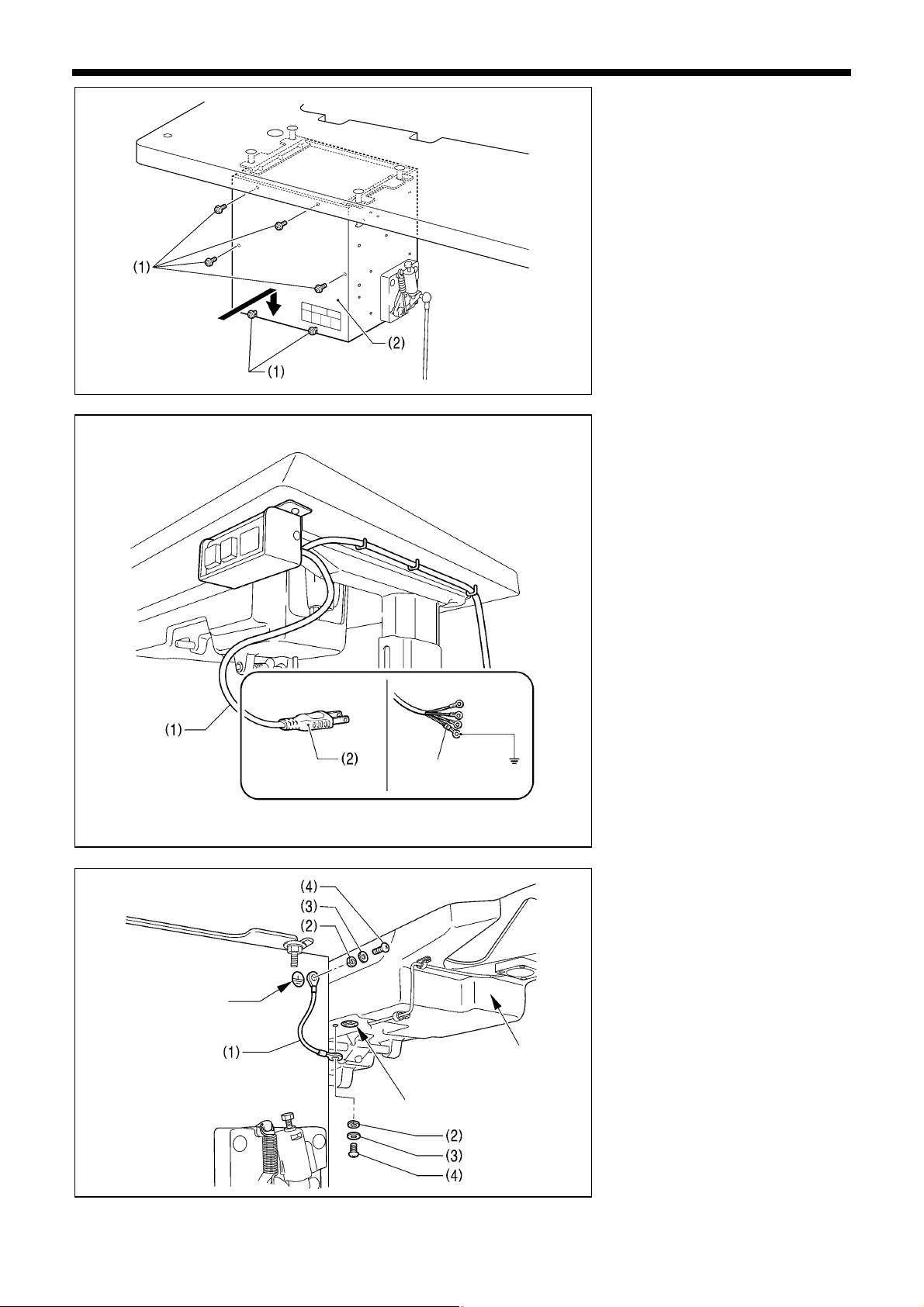

3355M

4. INSTALLATION

1. Control box

(1) Control box

(2) Bolts [4 pcs]

(3) Nuts [4 pcs]

(4) Spring washers [4 pcs]

(5) Washers [4 pcs]

2. Connecting rod

(6) Connecting rod

(7) Nut

Operator

3356M

3. Power switch

(1) Power switch

(2) Screws [2 pcs]

(3) Staples [5 pcs]

Secure the power cord (4) in a suitable

place depending in the position of the

wall outlet.

4. Oil pan

(1) Head cushions [4 pcs]

(2) Oil pan

Cord

Z-8550A, 8560A

3357M

6

4. INSTALLATION

3358M

3359M

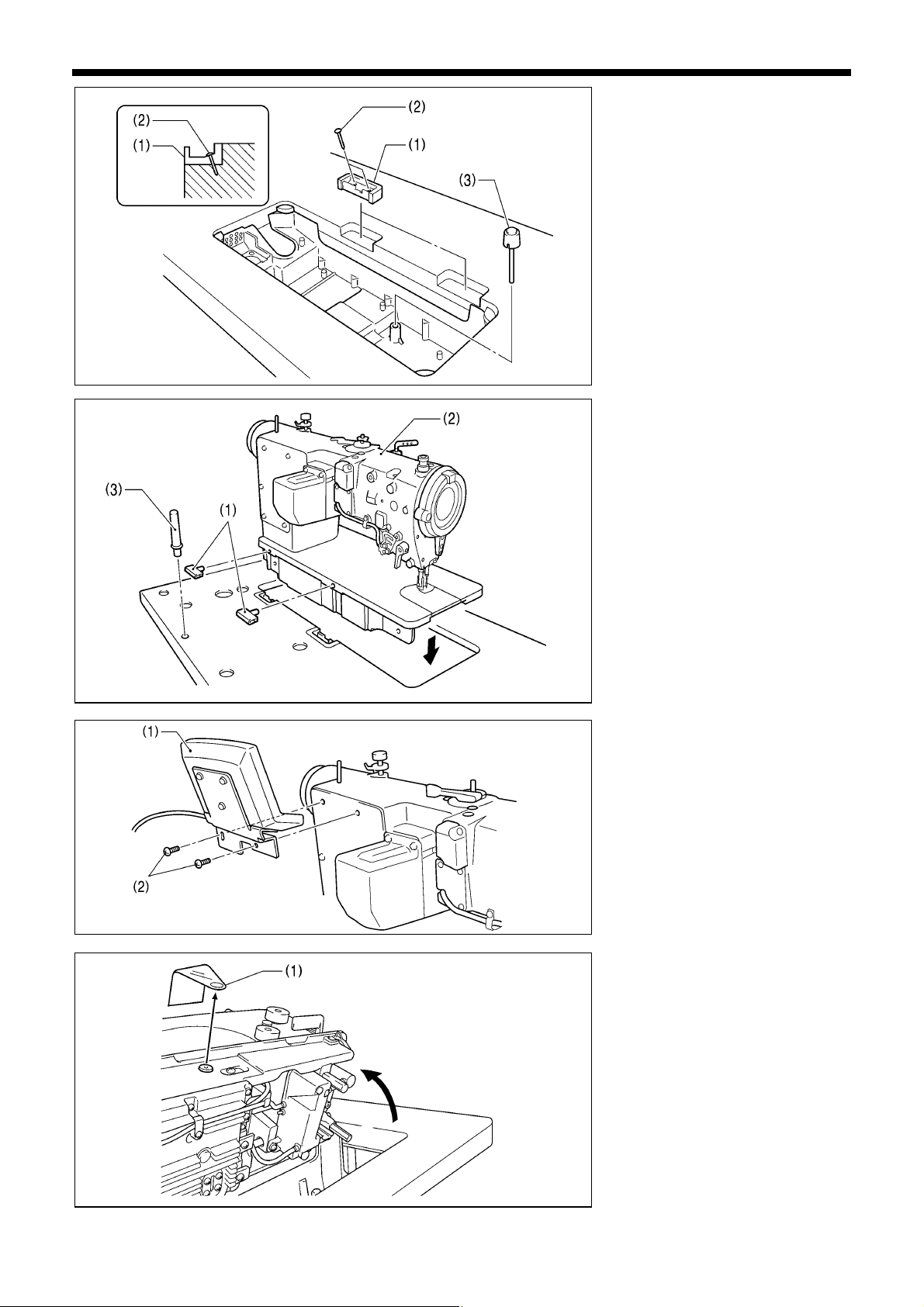

5. Rubber cushions

(1) Rubber cushions [2 pcs]

(2) Nails [4 pcs]

6. Knee lifter complying bar

(3) Knee lifter complying bar

7. Machine head

(1) Hinges [2 pcs]

(2) Machine head

(3) Head rest

NOTE:

• Tap the head rest (3) securely into

the table hole.

• If the head rest (3) is not pushed in

as far as it will go, the machine

head will not be sufficiently stable

when it is tilted back.

3360M

8. Operation panel

(1) Operation panel

(2) Screws [2 pcs]

(Use for tightening rear cover)

9. Sticker (Remove)

(1) Sticker

3361M

7

Z-8550A, 8560A

4. INSTALLATION

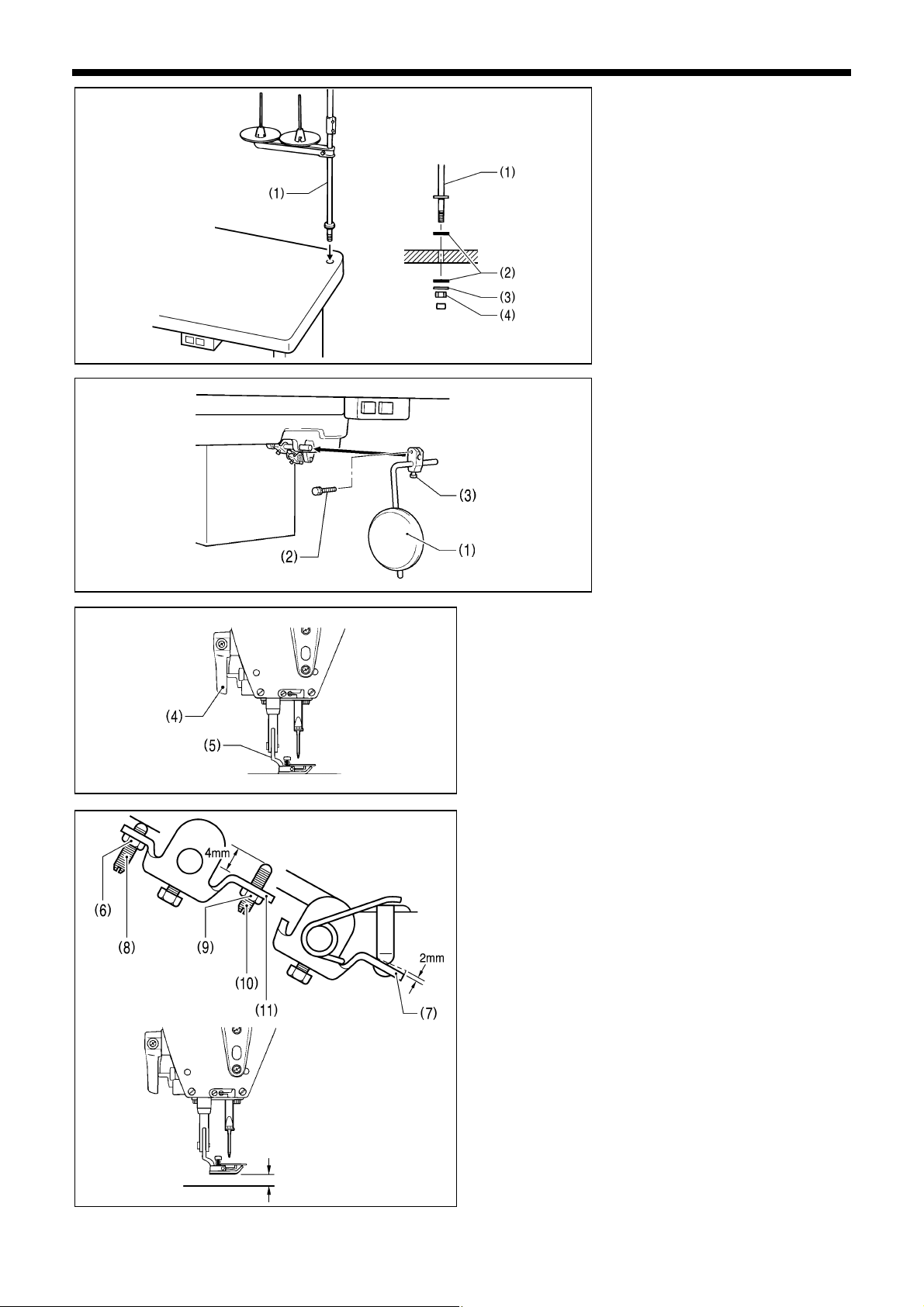

10. Cotton stand

(1) Cotton stand

NOTE:

Securely tighten the nut (4) so that

the two rubber cushions (2) and the

washer (3) are securely clamped and

so that the cotton stand (1) does not

move.

2098M

11. Knee lifter plate

(1) Knee lifter plate

(2) Bolt

* Loosen the bolt (3) and move the

knee lifter plate (1) to a position

where it is easy to use.

3362M

<Knee lifter adjustment>

1. Turn the machine pulley so that the feed dog is below the

top of the needle plate.

2. Lower the presser foot (5) by using the lifting lever (4).

3363M

2101M

3. Loosen the nut (6).

4. Turn the screw (8) to adjust so that the amount of play in

the knee lifter (7) is approximately 2 mm when the knee

lifter plate (1) is gently pressed.

5. Securely tighten the nut (6).

6. Loosen the nut (9).

7. Turn the screw (10) until the distance between the end of

the screw (10) and the knee lifter (11) is approximately 4

mm.

8. Turn the adjusting screw (10) to adjust so that the

presser foot (5) is at the desired position within a

distance of 10 mm of the needle plate when the knee liter

plate (1) is fully pressed.

9. After adjustment is completed, securely tighten the nut

(9).

Within 10 mm

3364M

Z-8550A, 8560A

8

4. INSTALLATION

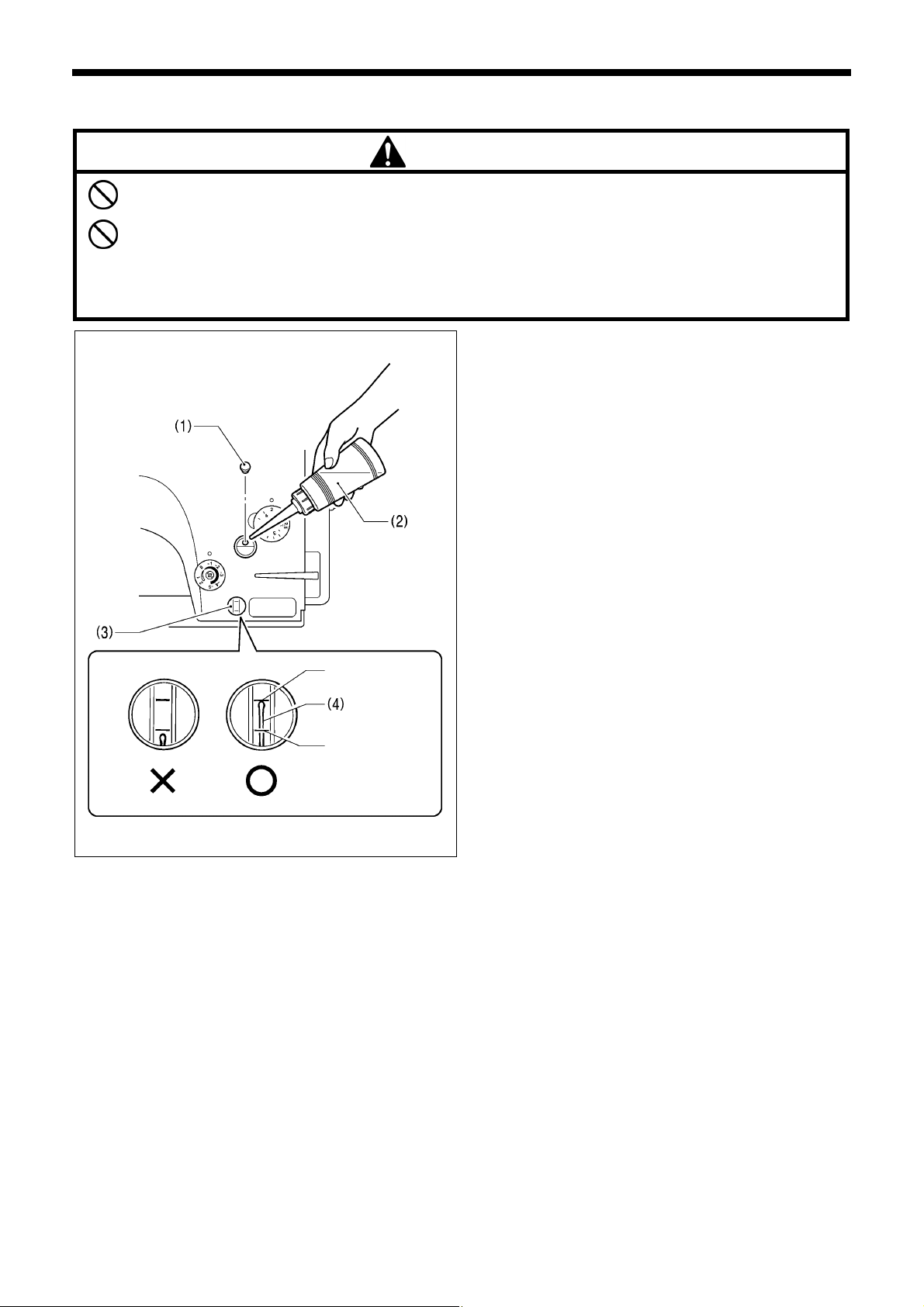

4-3. Lubrication

Do not connect the power cord until lubrication has been completed, otherwise the machine may operate if the

treadle is depressed by mistake, which could result in injury.

Be sure to wear protective goggles and gloves when handling the lubricating oil and grease, so that they do not get

into your eyes or onto your skin, otherwise inflammation can result.

Furthermore, do not drink the oil or eat the grease under any circumstances, as they can cause vomiting and

diarrhea.

Keep the oil out of the reach of children.

CAUTION

• The sewing machine should always be lubricated and the

oil supply replenished before it is used for the first time,

and also after long periods of non-use.

• Use only the lubricating oil (Nisseki Mitsubishi Sewing

Lube 10N; VG10) specified by Brother.

* If this type of lubricating oil is difficult to obtain, the

recommended oil to use is <Exxon Mobil Essotex SM10;

VG10>.

1. Remove the rubber cap (1).

2. Use the accessory oiler (2) to add lubricating oil until

the oil gauge (4) comes to the top reference line of the oil

gauge window (3).

NOTE:

• Pour in the lubricating oil slowly while checking the

position of the oil gauge (4).

• Do not let the oil gauge (4) go higher than the top

reference line when adding the oil.

3. Replace the rubber cap (1).

Upper reference

Lower reference

line

3365M

* Be sure to add more oil if the oil gauge (4) is below the

lower reference line.

9

Z-8550A, 8560A

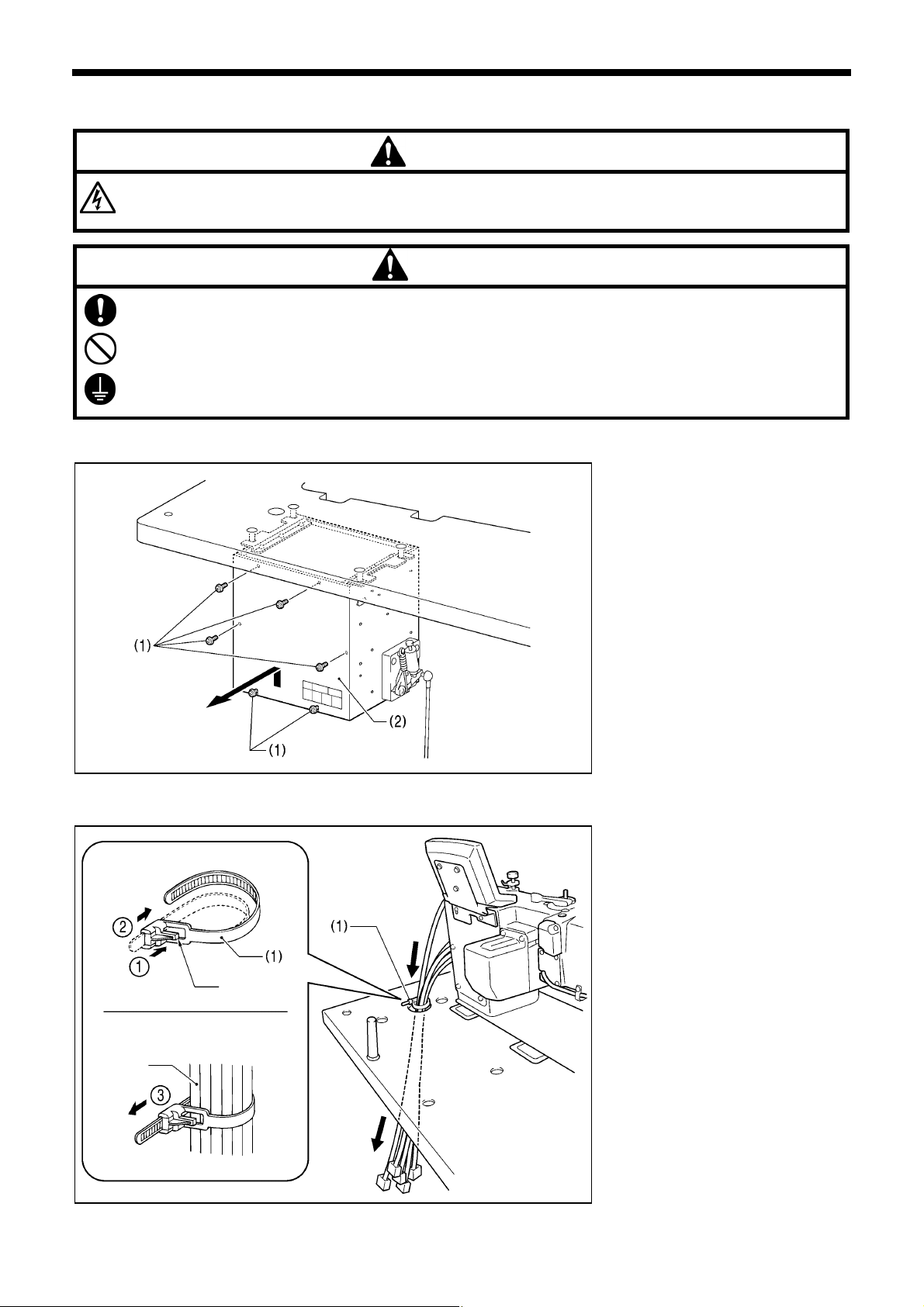

4-4. Connecting the cords

DANGER

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from the wall outlet

before opening the face plate of the control box. Touching areas where high voltages are present can result in

severe injury.

CAUTION

Contact your Brother dealer or a qualified electrician for any electrical work that may need to be done.

Do not connect the power cord until all cords have been connected.

The machine may operate if the treadle is depressed by mistake, which could result in injury.

sure to connect the ground. If the ground connection is not secure, you run a high risk of receiving a serious electric

shock, and problems with correct operation may also occur.

4-4-1. Opening the control box cover

Loosen

3366M

4. INSTALLATION

(1) Screw [6 pcs: With washer]

(2) Cover

4-4-2. Connecting the cords

<Removal>

Press the tab.

<Securing>

Cords

Z-8550A, 8560A

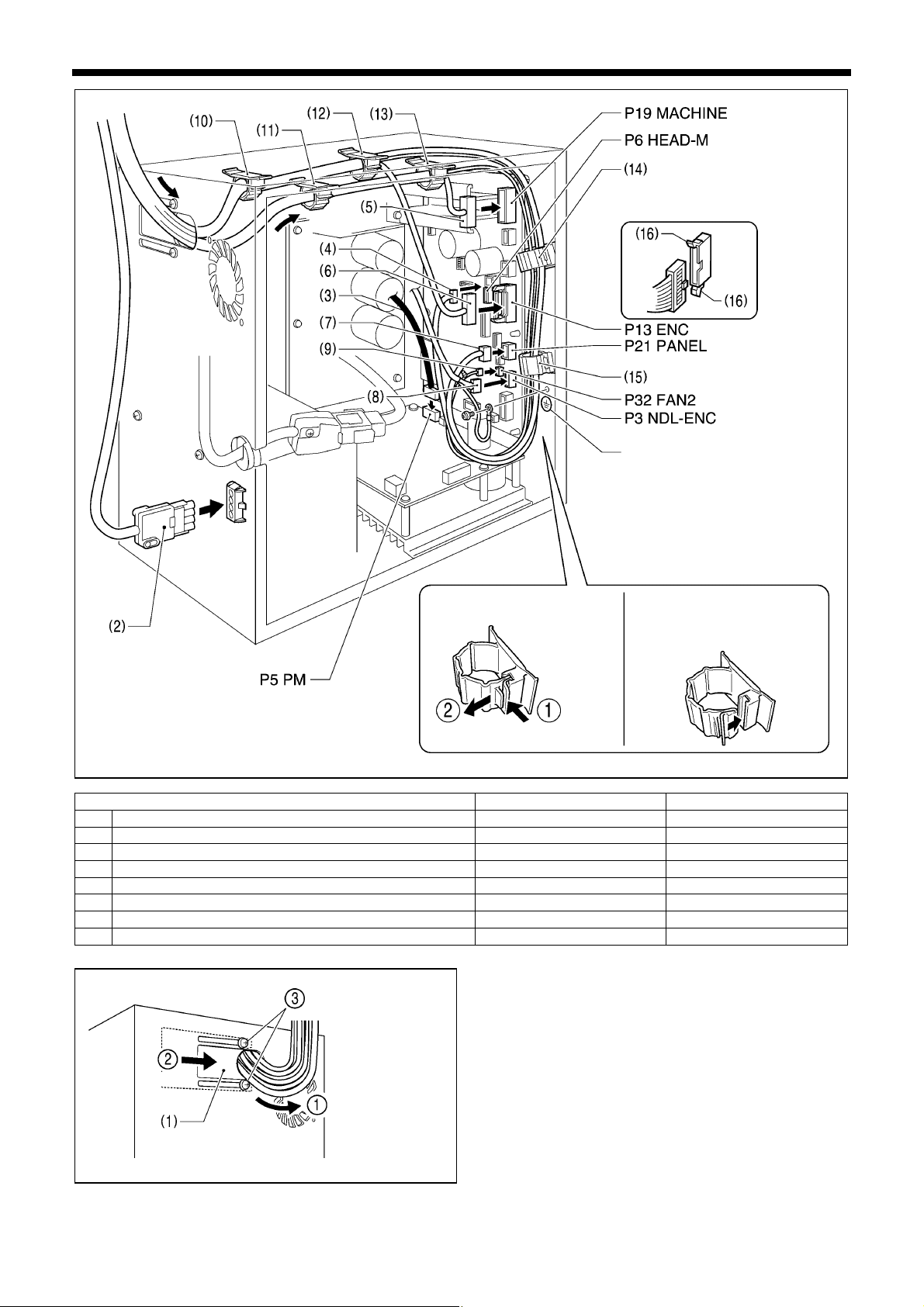

1. Sewing machine cords

(1) Repeat cable tie

3367M

10

4. INSTALLATION

Push in securely until

the tabs (16) engage.

Ground symbol

<Removal> <Securing>

Insert firmly until a click is heard.

Press the tab.

Connector P.C. board indication Cord clamp

(2) 4-pin motor connector Outside of control box

(3) 5-pin zigzag motor connector P5 PM (10)

(4) 7-pin head detector unit connector P6 HEAD-M (10) (12) (14) (15)

(5) 14-pin machine connector P19 MACHINE (11) (13)

(6) 14-pin encoder connector P13 ENC (10) (12)

(7) 8-pin operating panel connector P21 PANEL (10) (12) (14) (15)

(8) 5-pin zigzag motor encoder connector P3 NDL_ENC (10)

(9) 3-pin DC fan connector (oil pan) P32 FAN2 (11) (13) (14) (15)

2. Closing the cord presser plate

Tighten

Close

Loosen as much as

possible.

(1) Cord presser plate

NOTE:

• Loosen the cables outside the control box without

stretching them too much inside the control box.

• If the cord presser plate (1) is not closed firmly, dust

will get inside the control box and may cause

problems.

3369M

11

3368M

Z-8550A, 8560A

w

4. INSTALLATION

3. Closing the cover

(2) Screw [6 pcs: With washer]

(3) Cover

Tighten

3370M

4. Power cord

(1) Power cord

<For single-phase specifications>

Insert the power cord plug (2) into a

wall outlet.

<For three-phase specifications>

1. Attach an appropriate plug to the

power cord (1). (The green and

yellow wire is the ground wire.)

2. Insert the plug into a

properly-grounded AC power supply.

NOTE:

Do not use extension cords,

otherwise machine operation

<Single-phase> <Three-phase>

problems may result.

Green and yello

wire (ground wire)

3371M

5. Ground wire

(1) Ground wire

(2) Spring washer [2 pcs]

(3) Plain washer[2 pcs]

(4) Screw [2 pcs]

Ground symbol

Oil pan

Ground symbol

3372M

Z-8550A, 8560A

12

4. INSTALLATION

4-5. Test operation (Operating the treadle)

CAUTION

Do not touch any of the moving parts or press any objects against the machine while sewing, as this may result in

personal injury or damage to the machine.

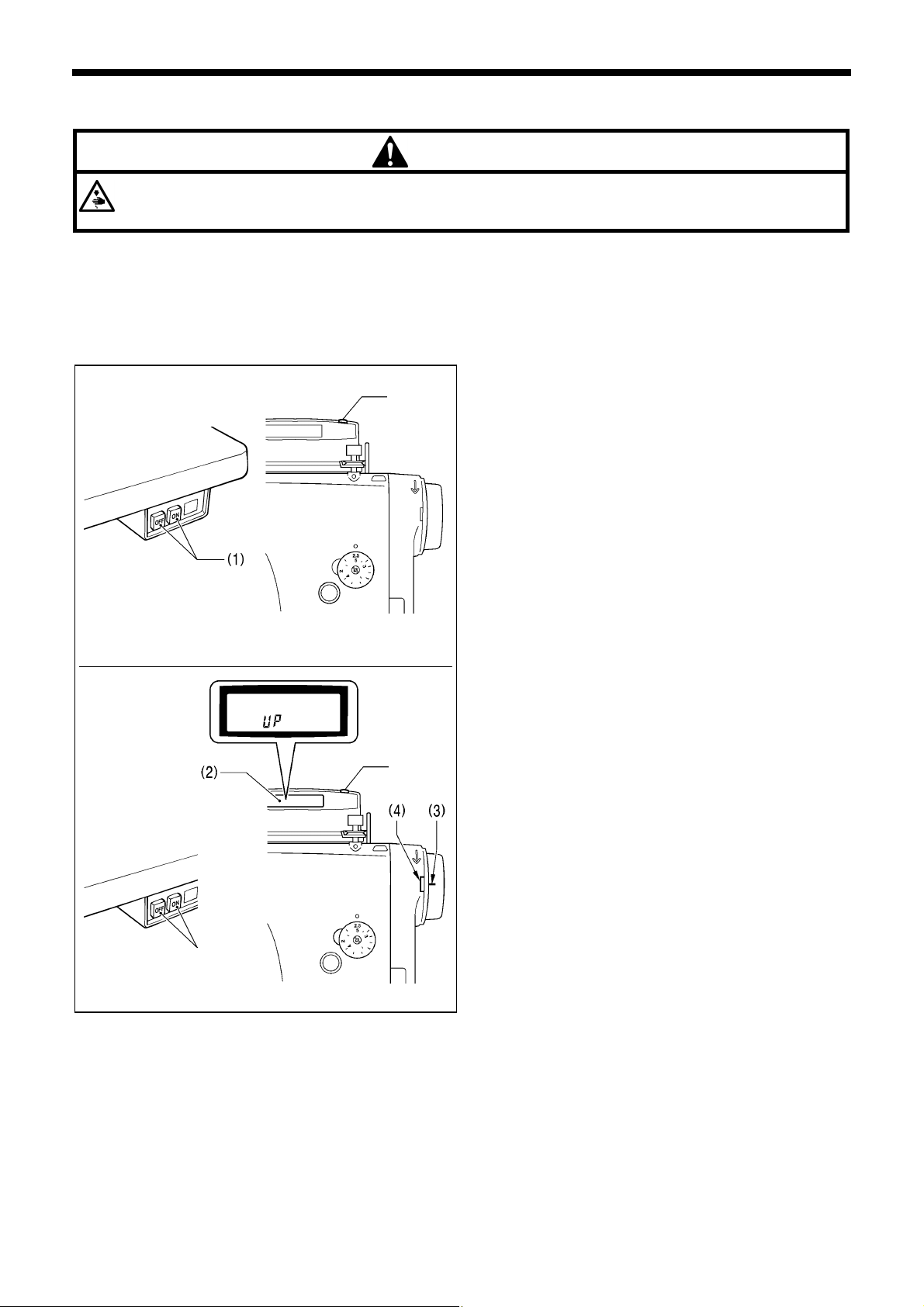

4-5-1. Turning on the power

• Release the treadle when turning on the power.

(If the treadle is depressed, “Err 95” will appear in the main display. At this time, “PoFF” will appear when you take your

foot off the treadle, so turn the power off and back on again.)

• After the power is turned on, the subsequent operation of the sewing machine will vary according to the needle bar position

at that time.

<If the needle bar is at the needle up stop position>

Turn on the POWER switch (1).

The buzzer will sound for about one second, and then the

needle bar will move horizontally to the sewing start position.

Sewing will then be possible.

2114M

Illuminate

3373M

<If the needle bar is not at the needle up stop position>

1. Turn on the POWER switch(1). The buzzer will sound for

about one second, and then “ UP ” will appear in the

main display (2).

2. Turn the machine pulley slowly to move the needle bar to

Illuminate

2114M 3374M

Panel setting status

• The panel setting status will be the same status that was active at the time the power was last turned off.

• The pattern number will appear in the main display while the buzzer is sounding, and after that the zigzag width and zigzag

base line position will appear.

the needle up stop position. (Align the reference line (3)

on the sewing machine pulley within the indent (4) in the

motor cover.)

The needle bar will then move horizontally to the sewing

start position and sewing will then be possible.

13

Z-8550A, 8560A

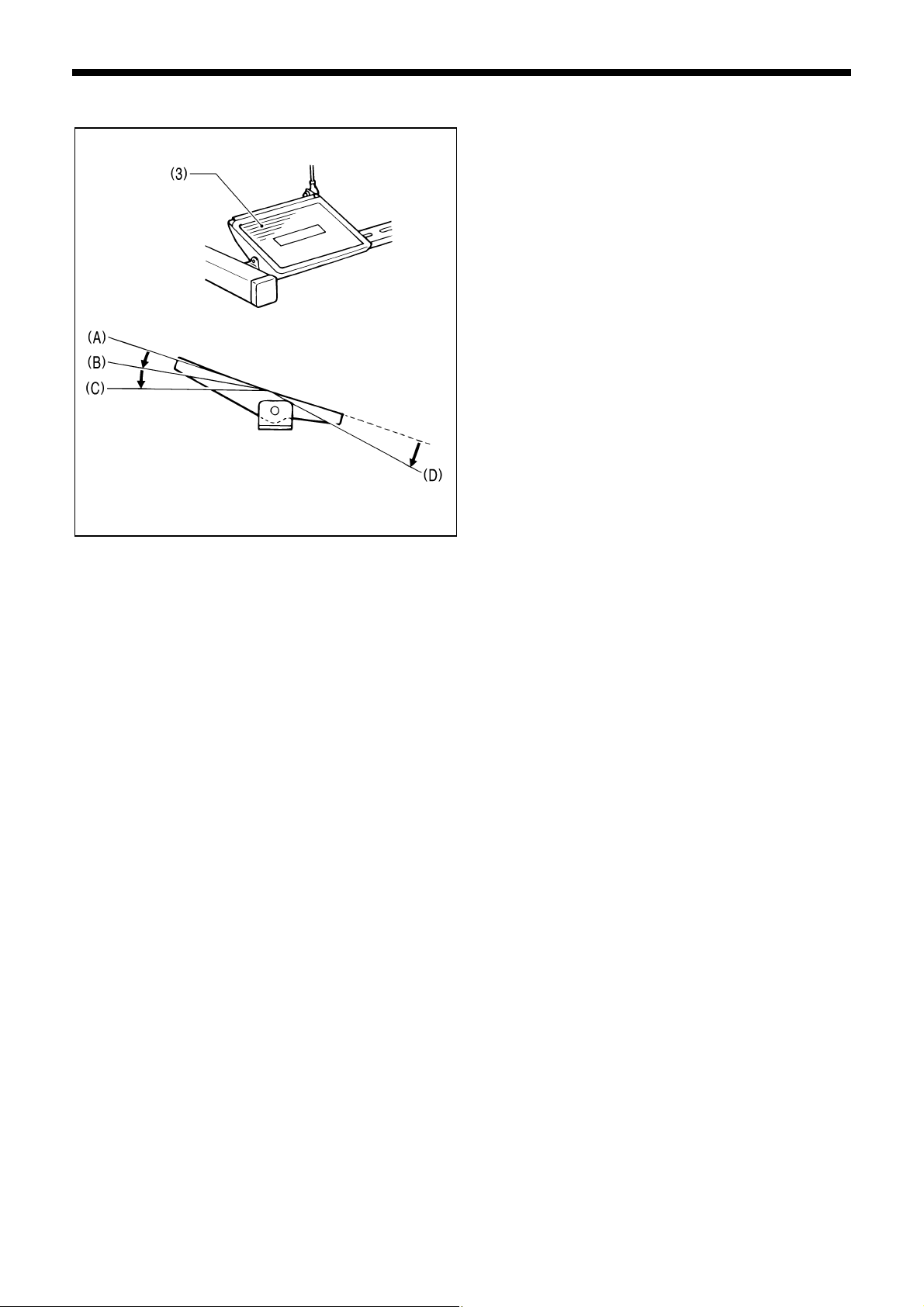

4-5-2. Operating the treadle

4. INSTALLATION

2116M

2117M

1. When the treadle (3) is gently depressed to position (B),

low-speed sewing is carried out.

2. If it is then depressed as far as (C), high-speed sewing is

carried out.

3. When the treadle (3) is pressed forward and then back to

the neutral position (A), the needle will stop below the

needle plate (when needle down stop mode has been

set).

If the needle bar has been set to stop in the needle up

position, the needle will stop at a position above the

needle plate (needle up stop position).

4. When the treadle (3) is depressed all the way to position

(D) (or if the treadle (3) is depressed to position (D) and

then returned to the neutral position (A)), the mechanism

will sew half a stitch or one stitch, and then the needle

bar will stop at the needle up stop position.

(With the 8560A, the thread will be trimmed at this point.)

Furthermore, no needle zigzagging will be carried out at

this time.

Z-8550A, 8560A

14

5. PREPARATION BEFORE SEWING

5. PREPARATION BEFORE SEWING

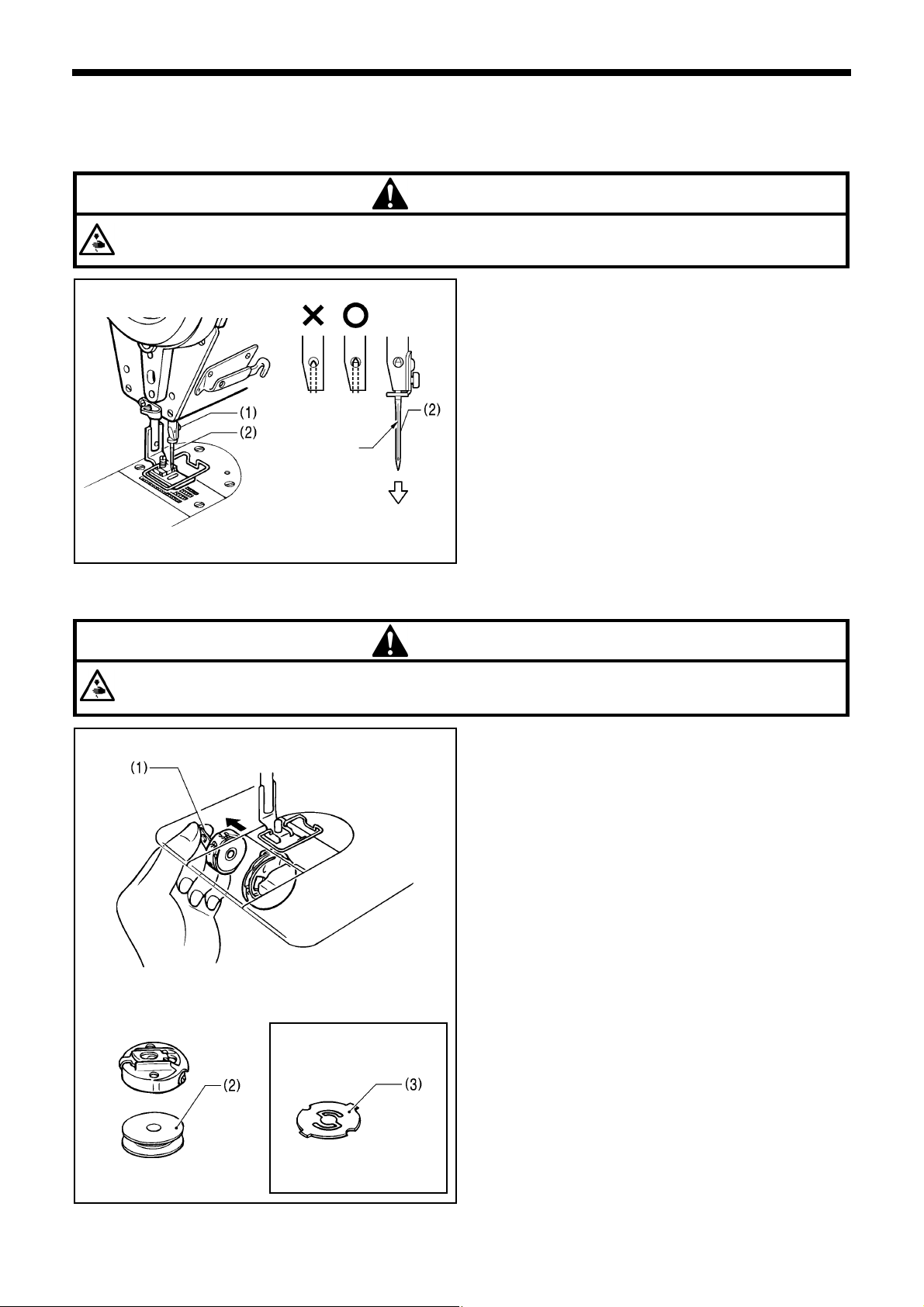

5-1. Installing the needle

CAUTION

Turn off the power switch before installing the needle.

The machine may operate if the treadle is depressed by mistake, which could result in injury.

1. Turn the machine pulley to move the needle bar to its

highest position.

2. Loosen the screw (1).

3. Insert the needle (2) in a straight line as far as it will go,

making sure that the long groove on the needle is toward

the front, and then securely tighten the screw (1).

Long groove

Front

3376M3375M

5-2. Removing the bobbin case

CAUTION

Turn off the power switch before removing the bobbin case.

The machine may operate if the treadle is depressed by mistake, which could result in injury.

<8560A>

3377M

1. Turn the machine pulley to raise the needle until it is

above the needle plate.

2. Pull the latch (1) of the bobbin case upward and then

remove the bobbin case.

3. The bobbin (2) will come out when the latch (1) is

released.

* Use bobbins (2) made of light alloy as specified by

BROTHER.

8560A

There is an anti-spin spring (3) inside the bobbin case. The

anti-spin spring (3) prevents the bobbin from racing at times

such as during thread trimming.

3378M

15

3379M

Z-8550A, 8560A

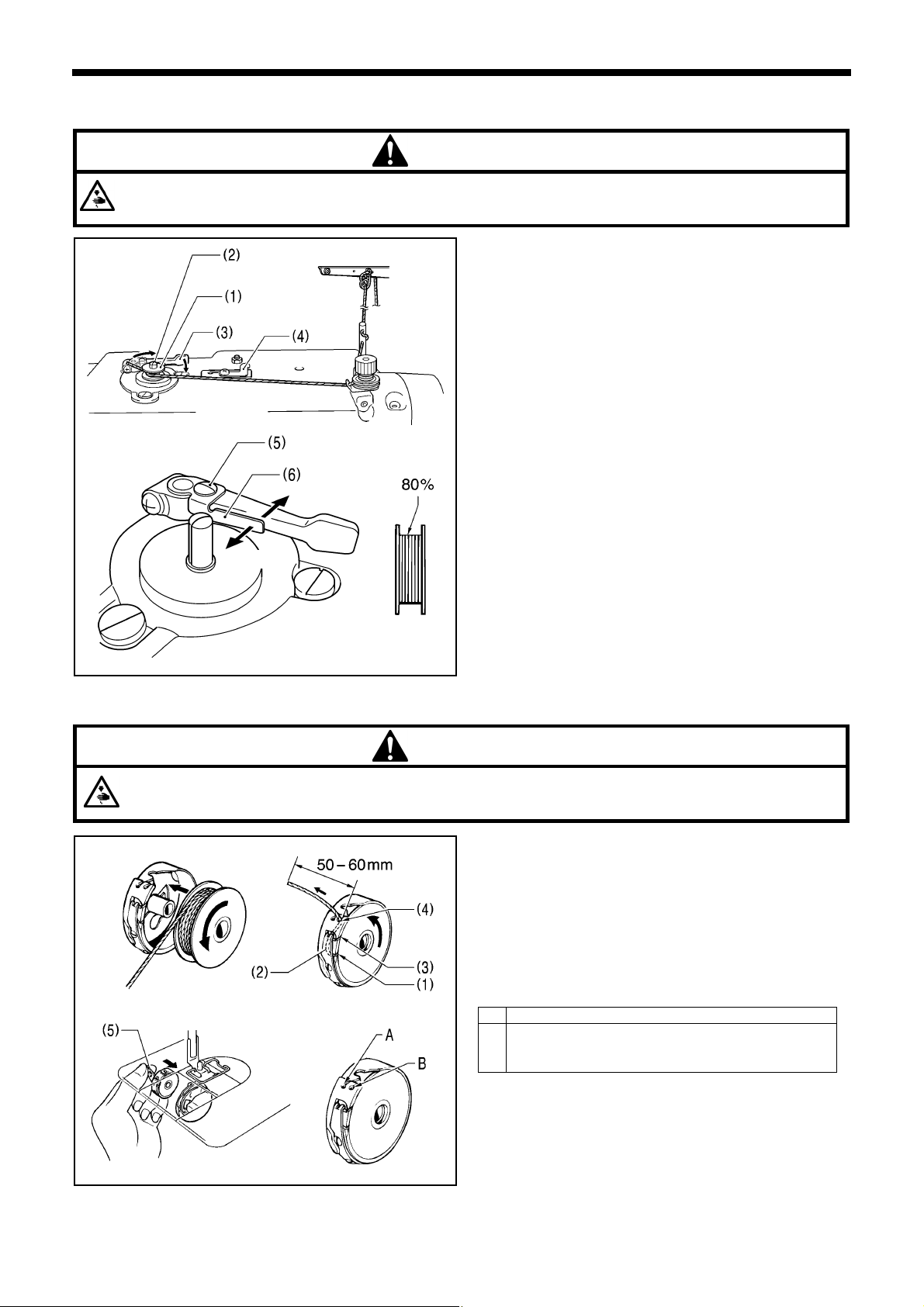

5-3. Winding the lower thread

Do not touch any of the moving parts or press any objects against the machine while winding the lower thread, as

this may result in personal injury or damage to the machine.

5. PREPARATION BEFORE SEWING

CAUTION

3380M

Less thread

More thread

2123M

1. Turn on the power switch.

2. Place the bobbin (1) onto the bobbin winder shaft (2).

3. Wind the thread several times around the bobbin (1) in

the direction indicated by the arrow.

4. Push the bobbin presser arm (3) toward the bobbin(1).

5. Raise the presser foot with the lifting lever.

6. Depress the treadle. Lower thread winding will then start.

7. Once winding of the lower thread is completed, the

bobbin presser arm (3) will return automatically.

8. After the thread has been wound on, remove the bobbin

and cut the thread with the knife (4).

* Loosen the screw (5) and move the bobbin presser (6) to

adjust the amount of thread wound onto the bobbin.

NOTE:

The amount of thread wound onto the bobbin should

be a maximum of 80 % of the bobbin capacity.

3381M

5-4. Installing the bobbin case

Turn off the power switch before installing the bobbin case.

The machine may operate if the treadle is depressed by mistake, which could result in injury.

CAUTION

1. Turn the sewing machine pulley to align the reference

line on the pulley with the indent in the motor cover.

2. Hold the bobbin so that the thread spools out

counterclockwise, and place the bobbin into the bobbin

case.

3. Pass the thread through slot (1) and hook it under the

tension spring (2).

4. Pass the thread back through the slot (3) and then pull it

out from the thread guide (4).

A and B on the thread guide (4) (guide to identification)

A Normally A should be used.

The amount of lower thread feeding-out is greater

B

than for A, so this is ideal for extremely stretchy

materials and medium-weight materials.

5. Check that the bobbin rotate counterclockwise when the

thread is pulled out.

6. While holding the latch (5) of the bobbin case, insert the

bobbin case into the rotary hook.

3382M

Z-8550A, 8560A

16

5. PREPARATION BEFORE SEWING

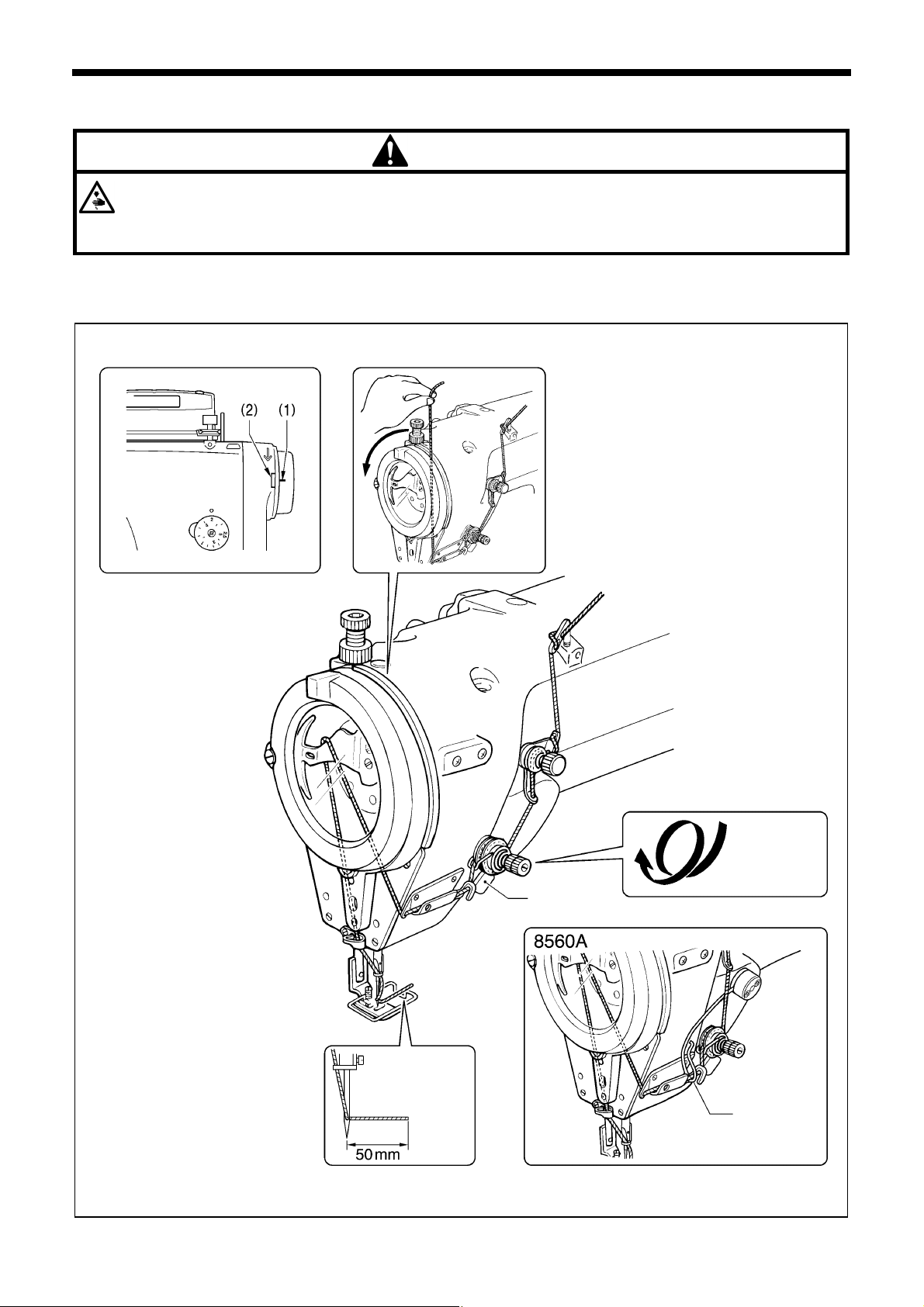

5-5. Threading the upper thread

CAUTION

Turn off the power switch before threading the upper thread.

The machine may operate if the treadle is dep ressed by mistake, which could result in injury.

If the actuator is pressed by mistake when using the correction sewing function, the needle will move in a zigzag

motion while the machine is operating, and injury may result.

Turn the sewing machine pulley to align the reference line (1) on the pulley with the indent (2) in the motor cover (needle up

stop position).

This will make threading easier and it will prevent the thread from coming out at the sewing start.

Actuator

Wind around once.

17

Leave a 50 mm

thread leader.

Upper thread

feeding device

3383M

Z-8550A, 8560A

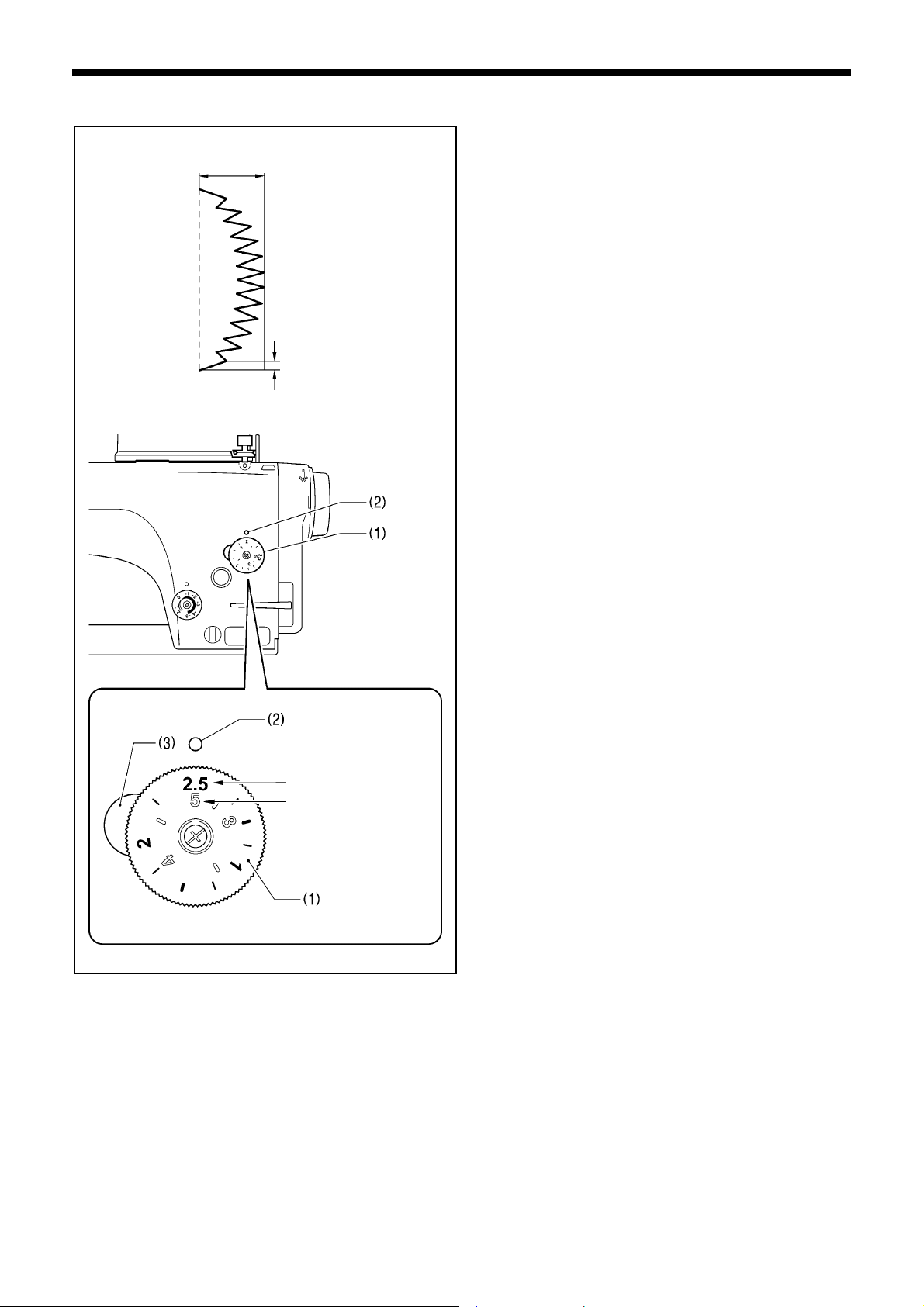

5-6. Adjusting the stitch length

5. PREPARATION BEFORE SEWING

(Zigzag width)

Stitch length

3470M

Turn the stitch length dial (1) until the desired stitch length

number is aligned with the index mark (2) above the dial.

* The larger the number, the longer the stitch length will be.

* The numbers on the dial are for use as a guide. The

length of the finished stitches may vary depending on the

type and thickness of material being sewn. Adjust while

looking at the finished stitches.

If the stitch length dial (1) is turned to a setting greater

than 2.5

* In this case, replace gauge parts such as the feed dog

with parts for using with a feed amount of more than 2.0

mm.

In addition, change the maximum feed amount setting

while referring to page 57, and then adjust the stitch

length dial (1) as described below.

1. Turn the stitch length dial (1) all the way to “2.5”.

2. After this, push the left lever (3) while turning the stitch

length dial (1) so that it can be turned a second time.

When the stitch length dial (1) is turned a second time,

the settings will be those on the inside of the scale (3−5).

* When turning the dial from a larger number to a smaller

number, it can be turned to the second time setting

without pushing the left lever (3).

Setting for 1st turn

Setting for 2nd turn

3384M

Z-8550A, 8560A

18

5. PREPARATION BEFORE SEWING

5-7. Backtacking

• Backtack stitches with short stitch lengths can be sewn

easily during sewing just by pressing the reverse lever (1).

This is useful for preventing fraying of the seam at the

sewing end.

• Before sewing, turn the condense dial (2) to the left or

right to set the stitch length for these shorter backtack

stitches.

If using the 8560A, 8550A-A31

The actuator (3) can be used instead of the reverse lever

(1).

3385M

(Sewing

direction)

When reverse

lever is pressed

When reverse

lever is pressed

3386M

3387M

When the condense dial (2) is set to a number from -2 to -5

In this case, replace gauge parts such as the feed dog with parts for using with a feed amount of more than 2.0 mm.

In addition, change the maximum feed amount setting while referring to page 57, and then adjust the condense dial (2) to a

number from –2 to –5.

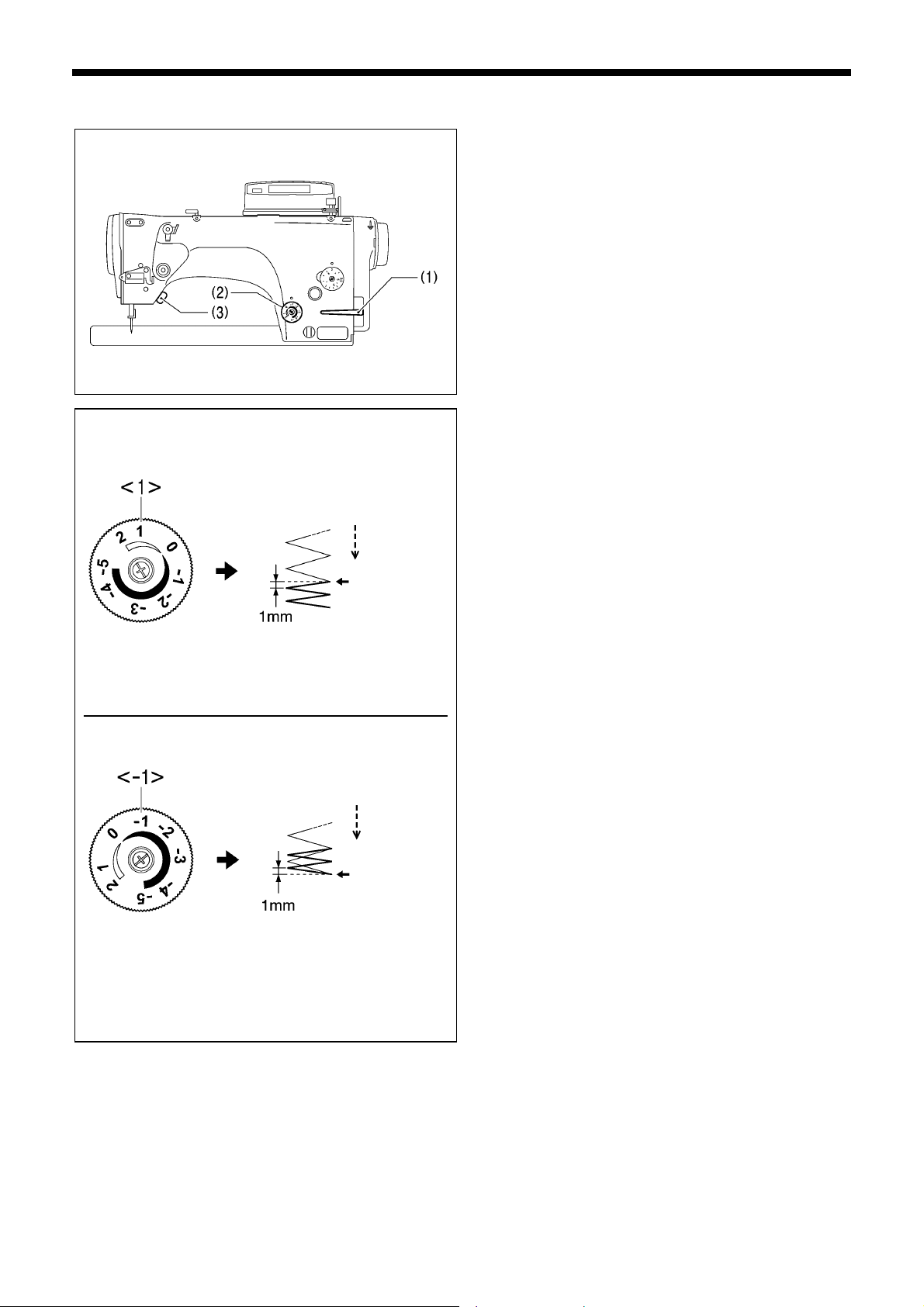

< Sewing condensed stitches >

• When the condense dial (2) is set to a positive number,

backtack stitches with a stitch length that matches the

dial setting will be sewn in the normal sewing direction

while the reverse lever is pressed.

• If the condense dial (2) is set to “0”, backtack stitches will

be sewn without the material being fed while the reverse

lever is pressed.

< Backtacking >

When the condense dial (2) is set to a negative number,

backtack stitches with a stitch length that matches the dial

setting will be sewn in the reverse sewing direction while the

reverse lever (1) is pressed.

* The numbers on the dial are for use as a guide. The

length of the finished stitches may vary depending on the

type and thickness of material being sewn. Adjust while

looking at the finished stitches.

19

Z-8550A, 8560A

Loading...

Loading...