Page 1

Home Sewing Machine

SERVICE MANUAL

MODEL :

J14/LS14/LX-1400/X14/L14/STAR1400

JS1400/JS1410/J17/LS17/LX-1700

X17/L17/JS1700/AS1430S/JSL15/JSL18/LS200

LS300/artwork19/artwork22/SL10/HQ18/X7/JX1410

JX1710/JX2517/AS1450/RS100/RS200/JX1400

JS1420/LS2225/LS2325/SL100/VitrageM71

VitrageM73/ArtCity140/JS1750/NB1400/NB1700

KD144/K14/F14/K17/F17/KE14/ArtCity170

CONFIDENTIAL

c

2012 Brother Industries, Ltd.

All rights reserved.

Published :

Revised :

Aug.,2012

May,2015

Page 2

Page 3

LIST of UPDATE RECORD

Date Added Models Contents

Dec.,2012 JS1700

Feb.,2013 AS1430S

Mar.,2013 X7/artwork19/JSL15/LS200

Mar.,2013 SL10/HQ18/artwork22/JSL18/LS300

Apr.,2013 JX1710/JX2517

May,2013 JX1410

Jul.,2013 AS1450

Sep.,2013 RS100/RS200

Mar.,2014 JX1400

Apr.,2014 JS1420

Jun.,2014

LS2225/LS2325

-

-

-

-

-

-

-

-

-

-

-

Aug.,2014

Feb.,2015

Mar.,2015

Apr.,2015

Apr.,2015

May,2015

SL100

VitrageM71/VitrageM73

ArtCity140

JS1750/NB1400/NB1700

KD144/K14/F14/K17/F17/KE14

ArtCity170

-

-

-

-

-

-

Page 4

1. Outline of Mechanism ........................................................................1 - 1

Main mechanisms ..............................................................................................1 - 2

Driveline .............................................................................................................1 - 3

Positions of electronic components ...................................................................1 - 5

Control system block diagram ...........................................................................1 - 6

2. Basic of Disassembly/Assembly .......................................................2 - 1

Disassembly

Preparation ........................................................................................................2 - 2

Disconnecting cables & Removing accessories .................................................................................2 - 2

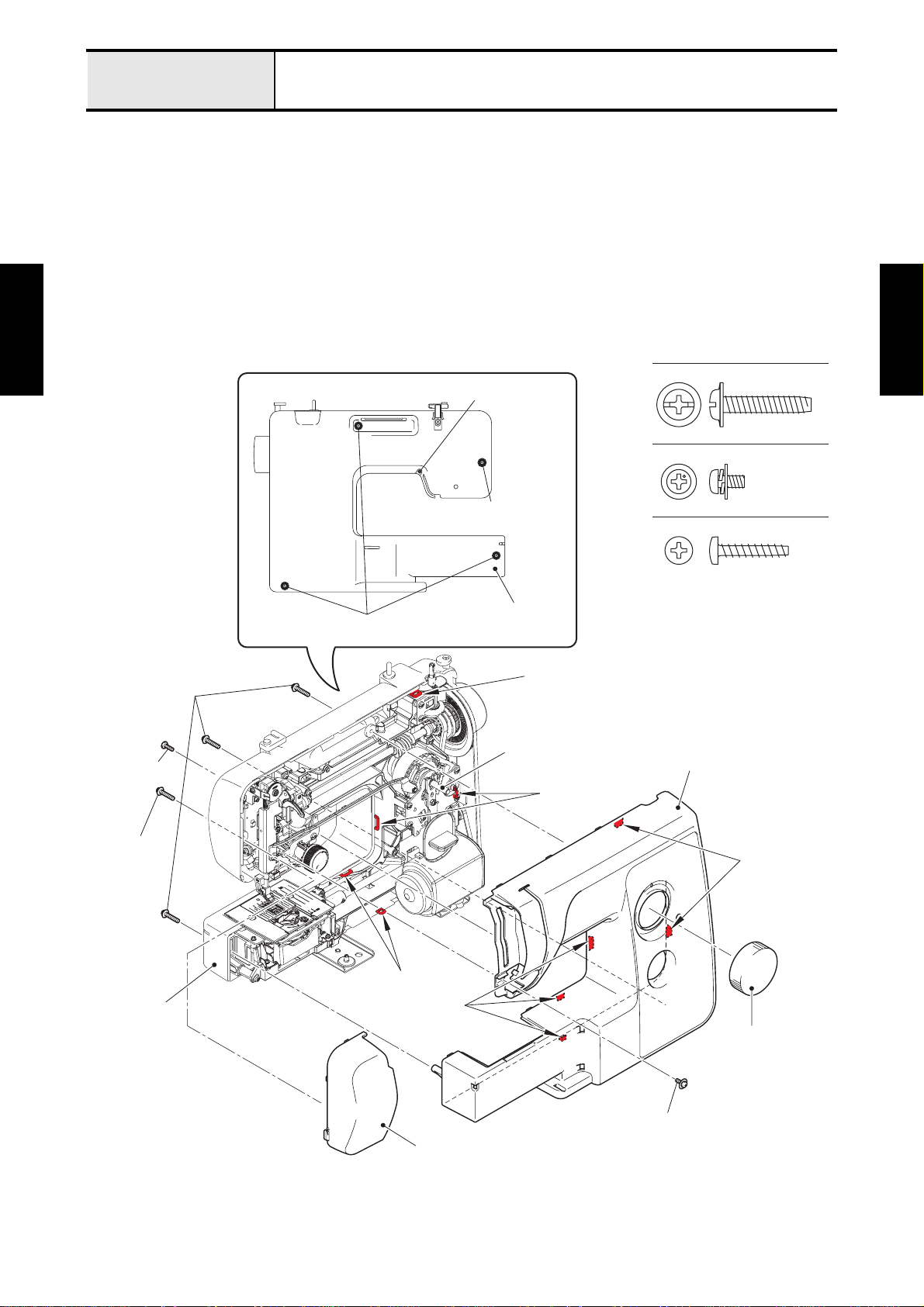

Main frame and Covers .....................................................................................2 - 3

Removal of Face plate assy and Front cover assy .............................................................................2 - 4

Removal of Rear cover assy and Base plate L/R ...............................................................................2 - 5

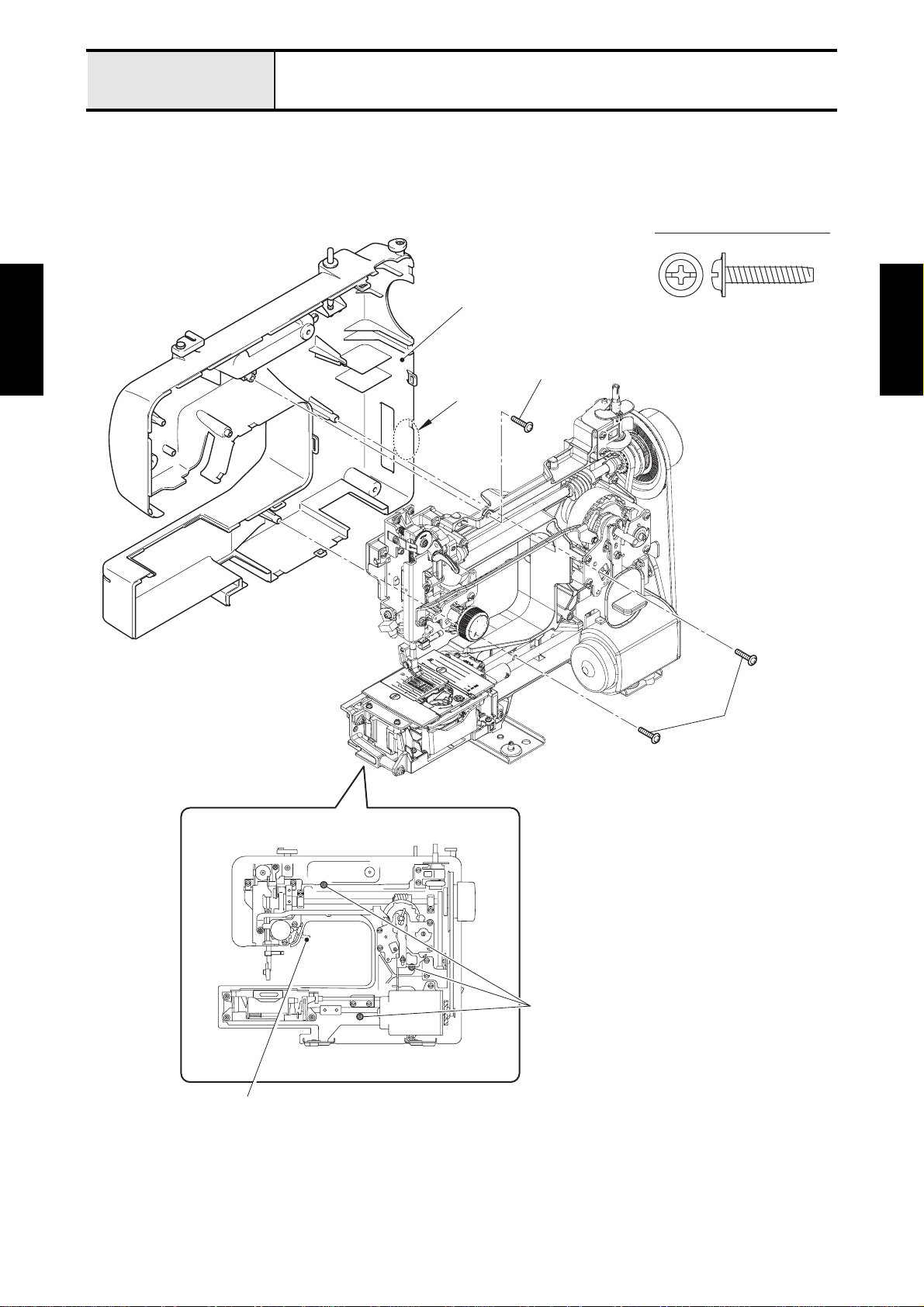

Main motor unit ..................................................................................................2 - 7

Removal of LED lamp assy ...............................................................................................................2 - 8

Removal of Motor 3P supply assy .....................................................................................................2 - 9

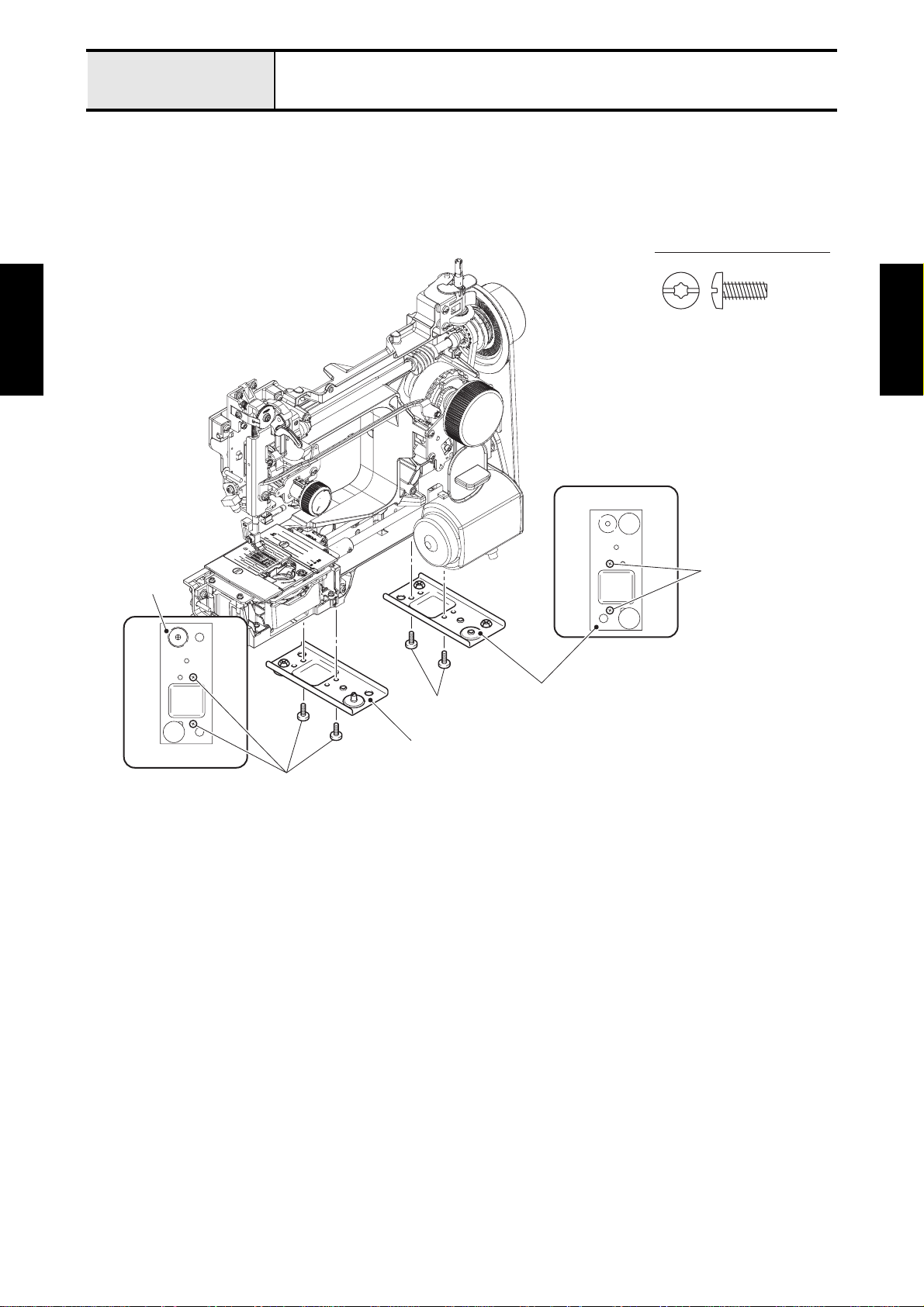

Feed unit / Feed control ...................................................................................2 - 10

Removal of Tension pulley assy and Lower shaft B assy ...............................................................2 - 11

Removal of Feed module .................................................................................................................2 - 12

Removal of Feed connecting lever assy ..........................................................................................2 - 13

Needle threading mechanism ..........................................................................2 - 14

Removal of Thread tension dial assembly .......................................................................................2 - 15

Pattern selecting mechanism ...........................................................................2 - 16

Removal of Pattern selecting unit assy ............................................................................................2 - 17

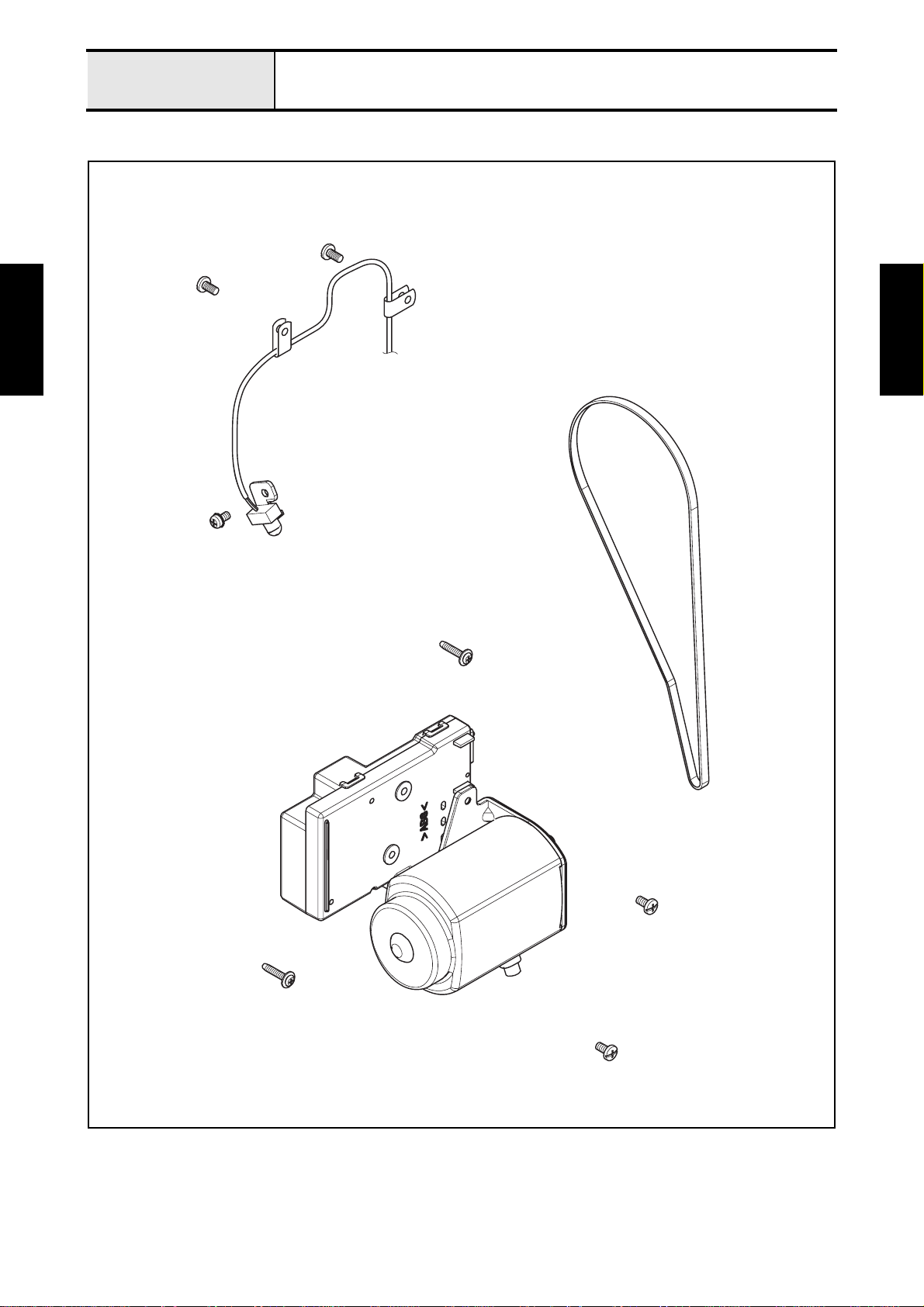

Bobbin winder, Upper shaft, Needle-presser module ......................................2 - 18

Removal of Bobbin winder assy ......................................................................................................2 - 19

Removal of Upper shaft assy ...........................................................................................................2 - 20

Removal of Needle-presser module .................................................................................................2 - 21

Assembly

Bobbin winder, Upper shaft, Needle-presser module ......................................2 - 23

Attachment of Needle-presser module ............................................................................................2 - 24

Attachment of Upper shaft assy .......................................................................................................2 - 26

Attachment of Bobbin winder assy ..................................................................................................2 - 27

Pattern selecting mechanism ...........................................................................2 - 28

Lubrication .......................................................................................................................................2 - 29

Attachment of Pattern selecting unit assy ........................................................................................2 - 30

Needle threading mechanism ..........................................................................2 - 32

Attachment of Thread tension dial assembly ...................................................................................2 - 33

Feed unit / Feed control ...................................................................................2 - 34

Lubrication .......................................................................................................................................2 - 35

Attachment of Feed connecting lever assy ......................................................................................2 - 36

Attachment of Feed module .............................................................................................................2 - 37

Attachment of Lower shaft B assy and Tension pulley assy ........................................................... 2 - 38

Phase matching of Upper shaft and Lower shaft .............................................................................2 - 39

i

Page 5

Main motor unit ................................................................................................2 - 40

Attachment of Motor 3P supply assy ...............................................................................................2 - 41

Attachment of LED lamp assy .........................................................................................................2 - 42

Main frame and Covers ...................................................................................2 - 43

Attachment of Rear cover assy and Base plate L/R .........................................................................2 - 4 4

Attachment of Face plate assy and Front cover assy .......................................................................2 - 46

3. Application of Disassembly/Assembly .............................................3 - 1

Disassembly

Main frame and Covers .....................................................................................3 - 2

Disassembly of Face plate assy .........................................................................................................3 - 3

Disassembly of Rear cover assy ................................. .......................................................................3 - 4

Disassembly of Base plate L/R ..........................................................................................................3 - 5

Main motor unit ..................................................................................................3 - 6

Disassembly of Motor 3P supply assy ...............................................................................................3 - 7

Feed unit ............................................................................................................3 - 8

Disassembly of Tension pulley assy ..................................................................................................3 - 9

Disassembly of Lower shaft B assy .................................................................................................3 - 10

Disassembly of Feed module ...........................................................................................................3 - 11

Needle threading mechanism ..........................................................................3 - 19

Disassembly of Thread tension dial assembly .................................................................................3 - 20

Pattern selecting mechanism ...........................................................................3 - 21

Disassembly of Pattern selecting unit assy ...................................................................................... 3 - 22

Bobbin winder, Upper shaft, Needle-Presser module ......................................3 - 23

Disassembly of Bobbin winder assy ................................ ................................................................3 - 24

Disassembly of Upper shaft assy ........................................... .......................................................... 3 - 25

Disassembly of Needle-presser module ...........................................................................................3 - 26

Assembly

Bobbin winder, Upper shaft, Needle-Presser module ......................................3 - 30

Lubrication .......................................................................................................................................3 - 31

Assembly of Needle-presser module ...............................................................................................3 - 32

Assembly of Upper shaft assy .........................................................................................................3 - 36

Assembly of Bobbin winder assy ............................ ........................................................................3 - 37

Pattern selecting mechanism ...........................................................................3 - 38

Lubrication .......................................................................................................................................3 - 39

Assembly of Pattern selecting unit assy ..........................................................................................3 - 40

Needle threading mechanism ..........................................................................3 - 41

Assembly of Thread tension dial assembly .....................................................................................3 - 42

Feed unit ..........................................................................................................3 - 43

Lubrication .......................................................................................................................................3 - 44

Assembly of Feed module ...............................................................................................................3 - 45

Assembly of Lower shaft B assy .....................................................................................................3 - 53

Assembly of Tension pulley assy ....................................................................................................3 - 54

Main motor unit ................................................................................................3 - 55

Assembly of Motor 3P supply assy .................................................................................................3 - 56

ii

Page 6

Main frame and Covers ...................................................................................3 - 57

Assembly of Base plate L/R ............................................................................................................3 - 58

Assembly of Rear cover assy ....................... ....................................................................................3 - 59

Assembly of Face plate assy ............................................................................................................3 - 60

4. Adjustment ..........................................................................................4 - 1

Removal of covers .............................................................................................4 - 2

Needle point damage .........................................................................................4 - 4

Timing belt tension .............................................................................................4 - 5

Motor belt tension ..............................................................................................4 - 6

Needle plate holder assy position ......................................................................4 - 7

Presser foot hole / Needle plate hole position (front/back) ................................4 - 8

Needle swing timing ...........................................................................................4 - 9

Three point needle drop ...................................................................................4 - 10

Needle interference left/right ............................................................................4 - 11

Needle bar rising ..............................................................................................4 - 12

Needle bar height ............................................................................................4 - 14

Needle clearance .............................................................................................4 - 15

Left straight stitch needle drop and

zigzag stitch maximum left needle drop position .............................................4 - 16

Feed dog position (front/back and left/right) ....................................................4 - 18

Feed dog height ...............................................................................................4 - 19

Upper thread tension .......................................................................................4 - 20

Left and right stitch of buttonhole stitch length ................................................4 - 22

Bobbin winder ..................................................................................................4 - 25

Lower thread tension .......................................................................................4 - 26

5. Failure Investigation for Electronic Parts .........................................5 - 1

Sewing lamp does not light ................................................................................5 - 2

Main motor does not turn or Rotation speed is slow ..........................................5 - 3

6. Special Instructions of Wiring ...........................................................6 - 1

Motor 3P supply assy ........................................................................................6 - 2

LED lead wire ....................................................................................................6 - 3

iii

Page 7

1

Outline of Mechanism

Main mechanisms..................................................... 1 - 2

Driveline.................................................................... 1 - 3

Positions of electronic components........................... 1 - 5

Control system block diagram................................... 1 - 6

1 - 1

Page 8

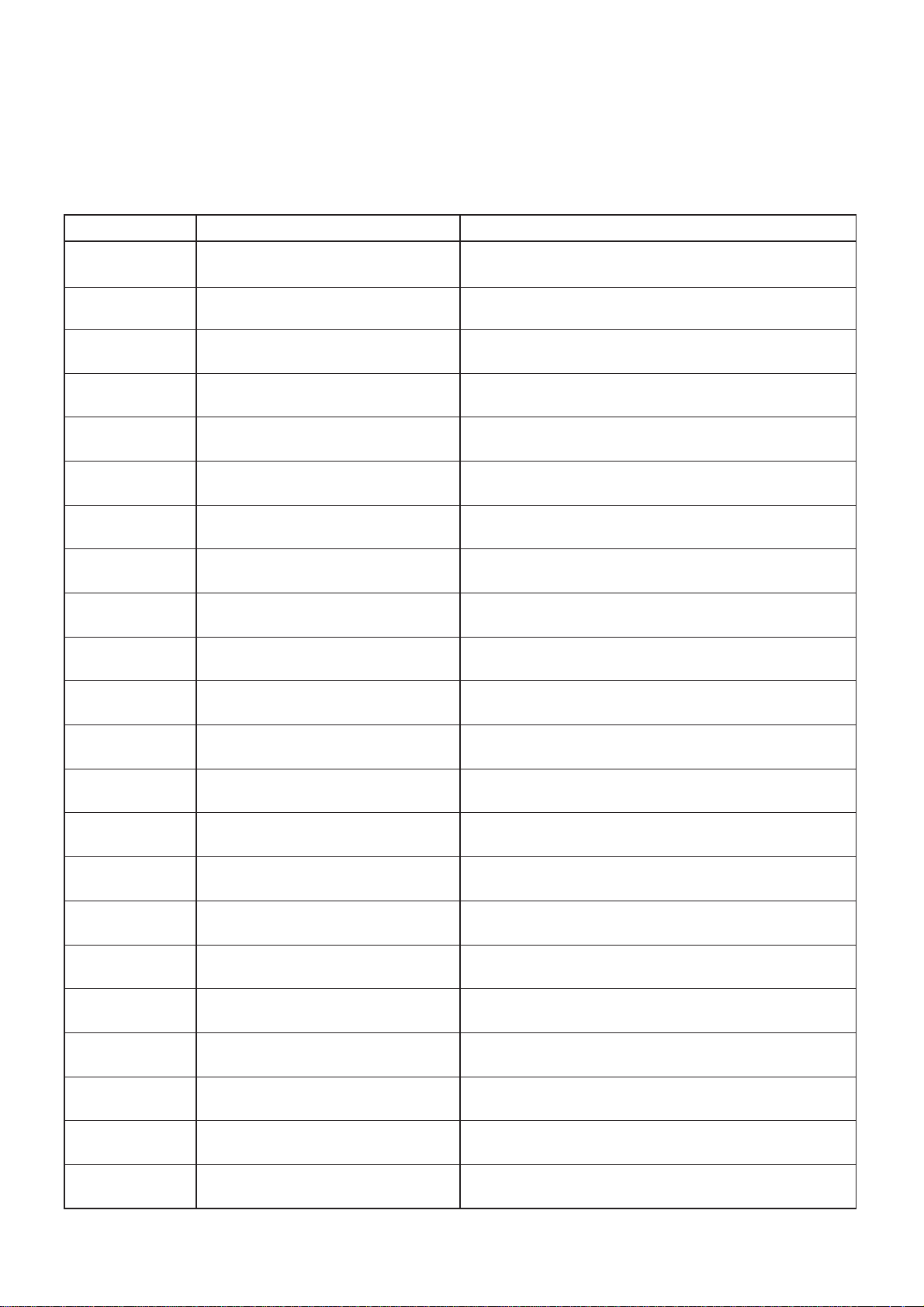

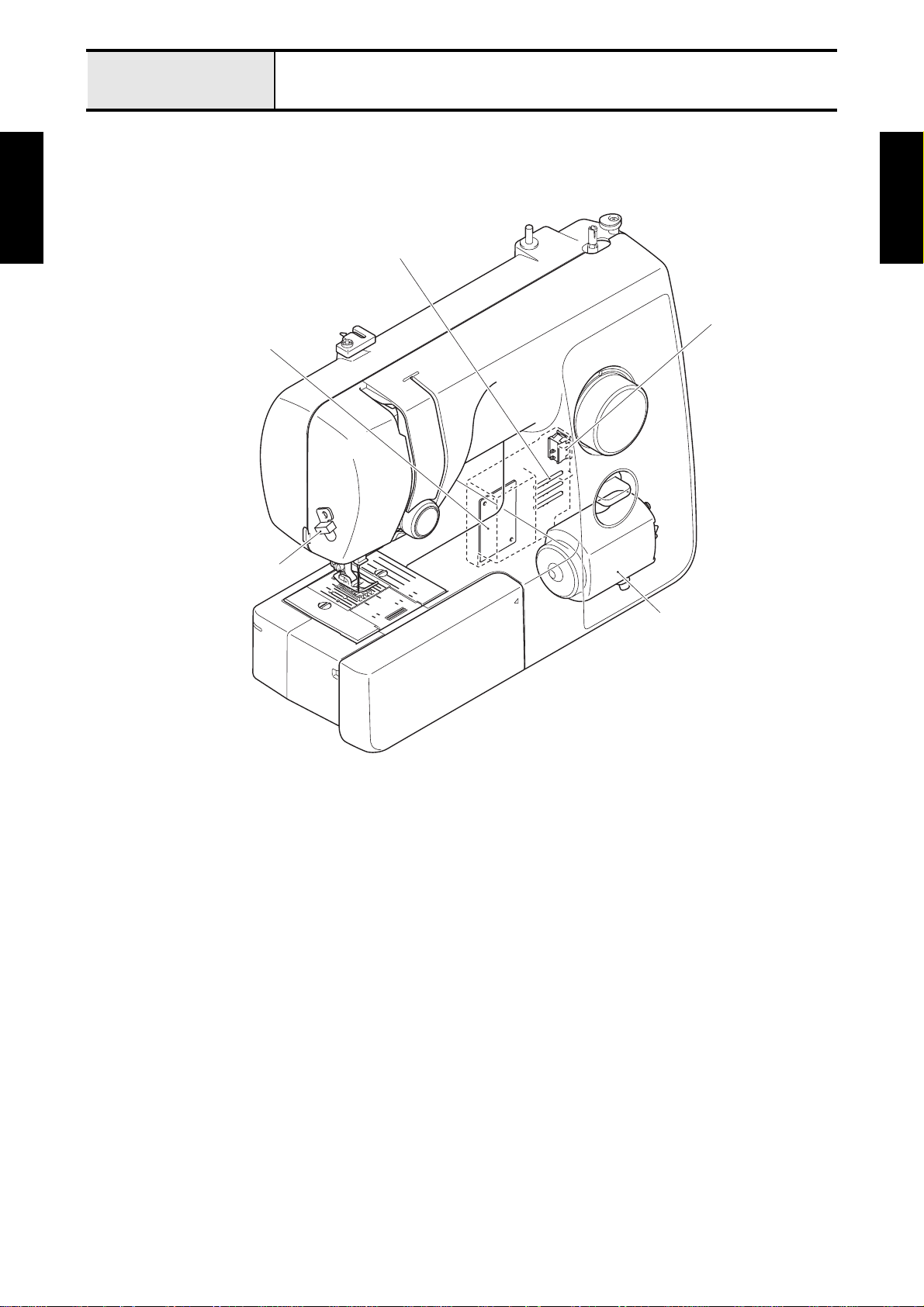

Outline of Mechanism

Main mechanisms

Bobbin winder Mechanism

Outline of

Mechanism

Needle bar / Presser foot

Mechanism

Front Side View

Zigzag Mechanism

Lower shaft Mechanism

Thread guide Mechanism

Horizontal feed Mechanism

Feed / Rotary hook Mechanism

Upper shaft Mechanism

Pattern selecting

Mechanism

Outline of

Mechanism

1 - 2

Back Side View

Page 9

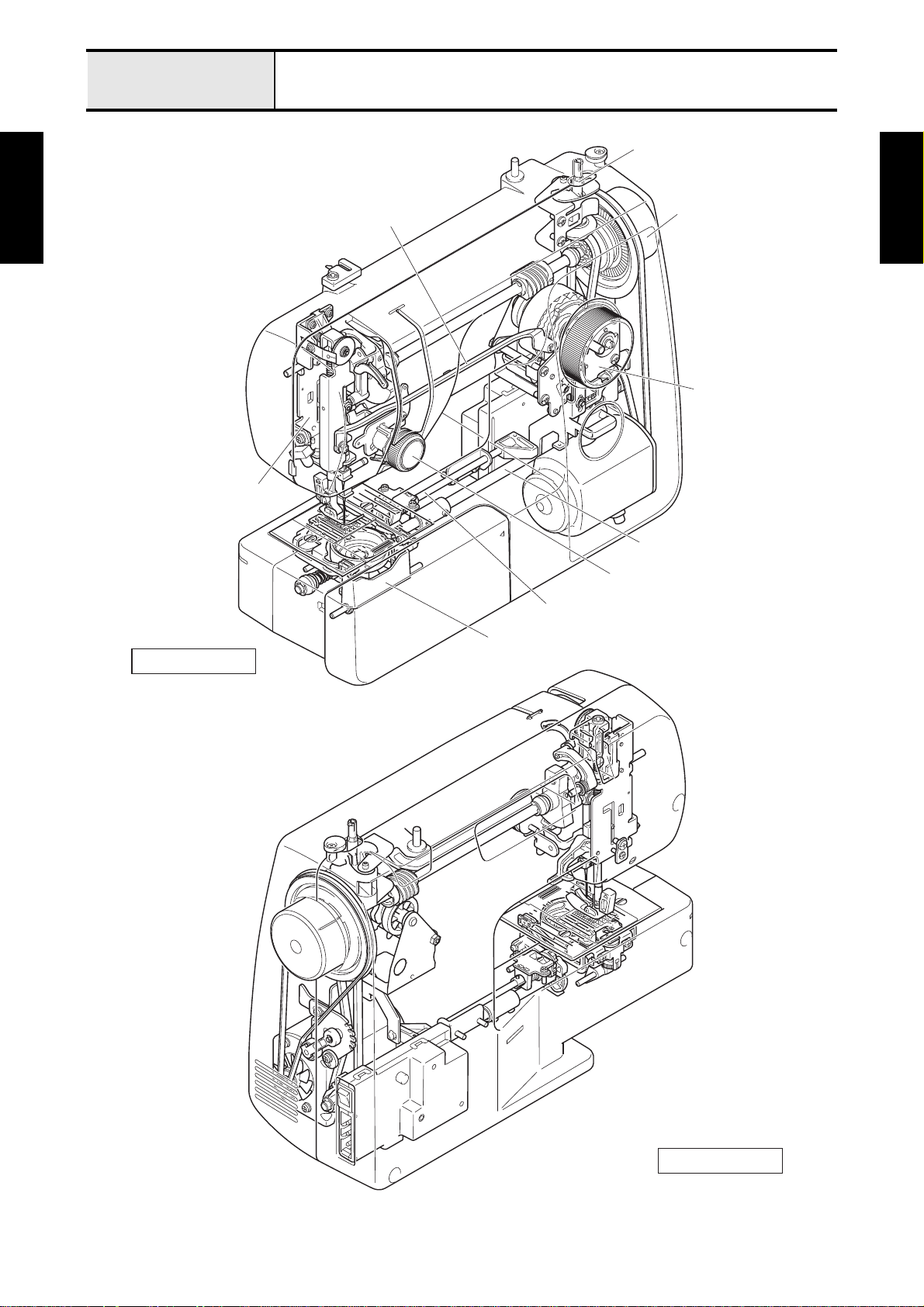

Outline of Mechanism

Driveline

(A) Up and down movement of needle bar, movement of thread take-up lever and

zigzag movement of needle bar mechanism

Main motor

Outline of

Mechanism

Needle bar crank

Needle bar

crank rod

Needle bar

block shaft

Needle bar block

Needle bar

Needle

Z finger frame

Thread take-up

counter weight

Needle bar

supporter

Pattern cam

Worm gear

Motor belt

Timing pulley

Upper shaft Pulley

Worm gear

Pattern cam

Z finger frame

Zigzag

connecting rod

Timing pulley

Selecting cam

Pulley

Outline of

Mechanism

A

Thread take-up counter weight

Needle bar crank rod

Needle bar block

Needle bar

supporter

Needle

Upper shaft

Needle bar crank

Needle bar block shaft

Zigzag connecting rod

Needle bar

1 - 3

Selecting cam

A

Motor belt

Main motor

Page 10

Outline of Mechanism

Driveline

(B) Movement of feed dog and rotary hook

Main motor

Motor belt

Outline of

Mechanism

Lower shaft gear

Outer rotary

hook assy

Vertical lever

Vertical adjuster screw

Feed stand spring cap

Feed cam

Feed arm B

Feed arm A

Feed stand

Feed dog

Timing pulley DLower shaft

Feed adjuster

Timing belt

Feed connecting

lever

Upper shaft pulley

Upper shaft

pulley

Feed regulator plate

A / B

Timing pulley

Timing pulley

Upper shaft

Selecting cam

Pulley

Pattern selecting dial

Pulley

Outline of

Mechanism

Feed stand spring cap

Vertical lever

Feed dog

Feed stand

Lower shaft gear

Upper shaft

Feed cam

Feed connecting lever

Vertical adjuster screw

Feed adjuster

Feed arm A

Outer rotary hook assy

Selecting cam

Pattern selecting dial

Feed regulator plate A / B

Feed arm B

V feed attachment

Timing belt

Motor belt

Timing pulley D

Main motor

Lower shaft

1 - 4

Page 11

Outline of Mechanism

Positions of electronic components

Outline of

Mechanism

Power supply PCB

Sewing lamp (LED)

3pin socket

Power SW

Main motor

Outline of

Mechanism

1 - 5

Page 12

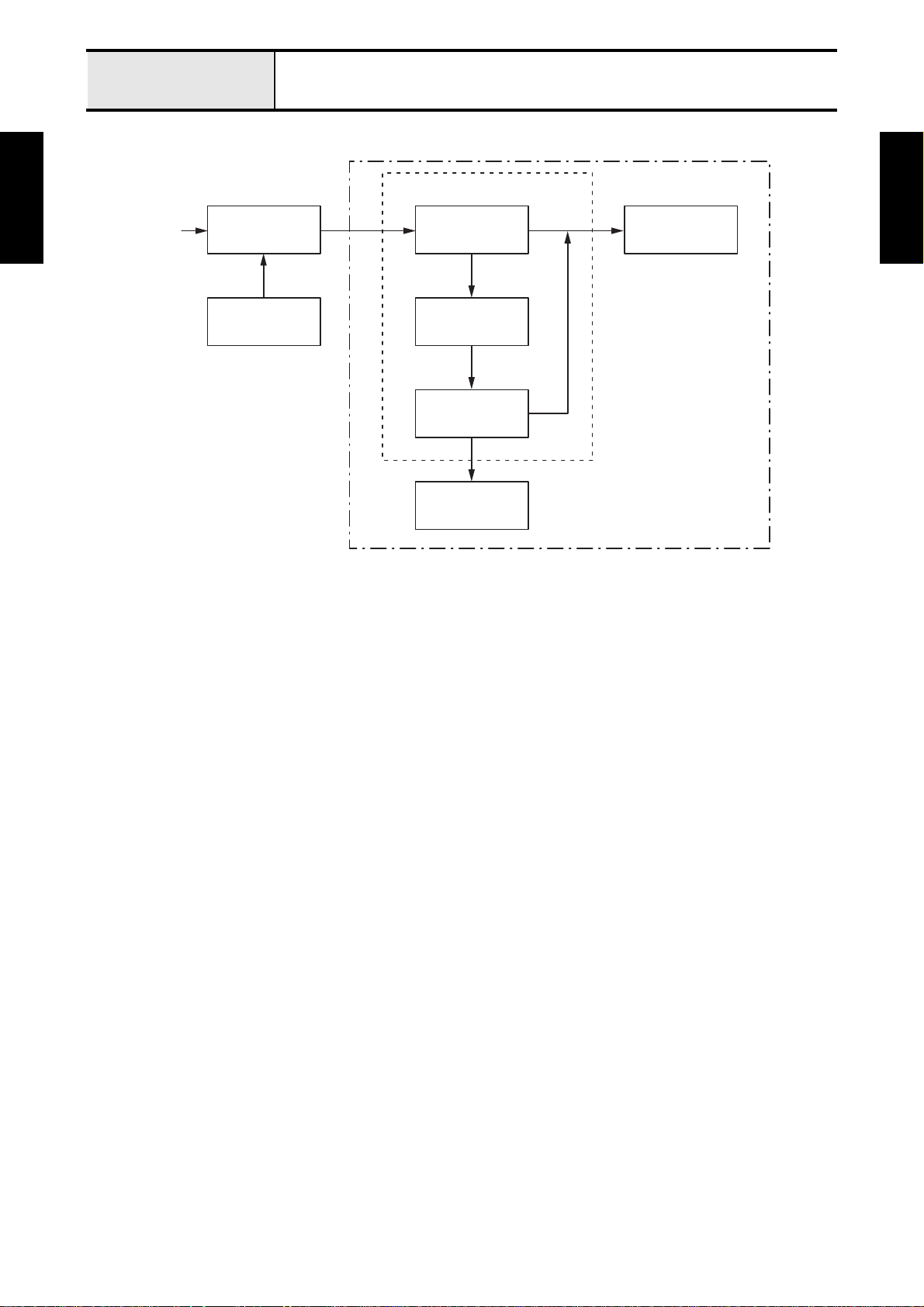

Outline of Mechanism

Control system block diagram

In the 3pin socket

Outline of

Mechanism

AC

Foot controller plug

(3pin)

Foot controller

3pin socket

Power SW

Power supply PCB

Sewing lamp

(LED)

Main motor

SEWING MACHINE

Outline of

Mechanism

1 - 6

Page 13

Basic of

2

Disassembly/Assembly

When repair and replace the part of the unit, refer to

“CHAPTER 3: Application of Disassembly/Assembly”.

Disassembly Preparation...................................... 2 - 2

Main frame and Covers................... 2 - 3

Main motor unit................................ 2 - 7

Feed unit / Feed control................. 2 - 10

Needle threading mechanism........ 2 - 14

Pattern selecting mechanism ........ 2 - 16

Bobbin winder, Upper shaft,

Needle-presser module................. 2 - 18

Assembly Bobbin winder, Upper shaft,

Needle-presser module................. 2 - 23

Pattern selecting mechanism ........ 2 - 28

Needle threading mechanism........ 2 - 32

Feed unit / Feed control................. 2 - 34

Main motor unit.............................. 2 - 40

Main frame and Covers................. 2 - 43

2 - 1

Page 14

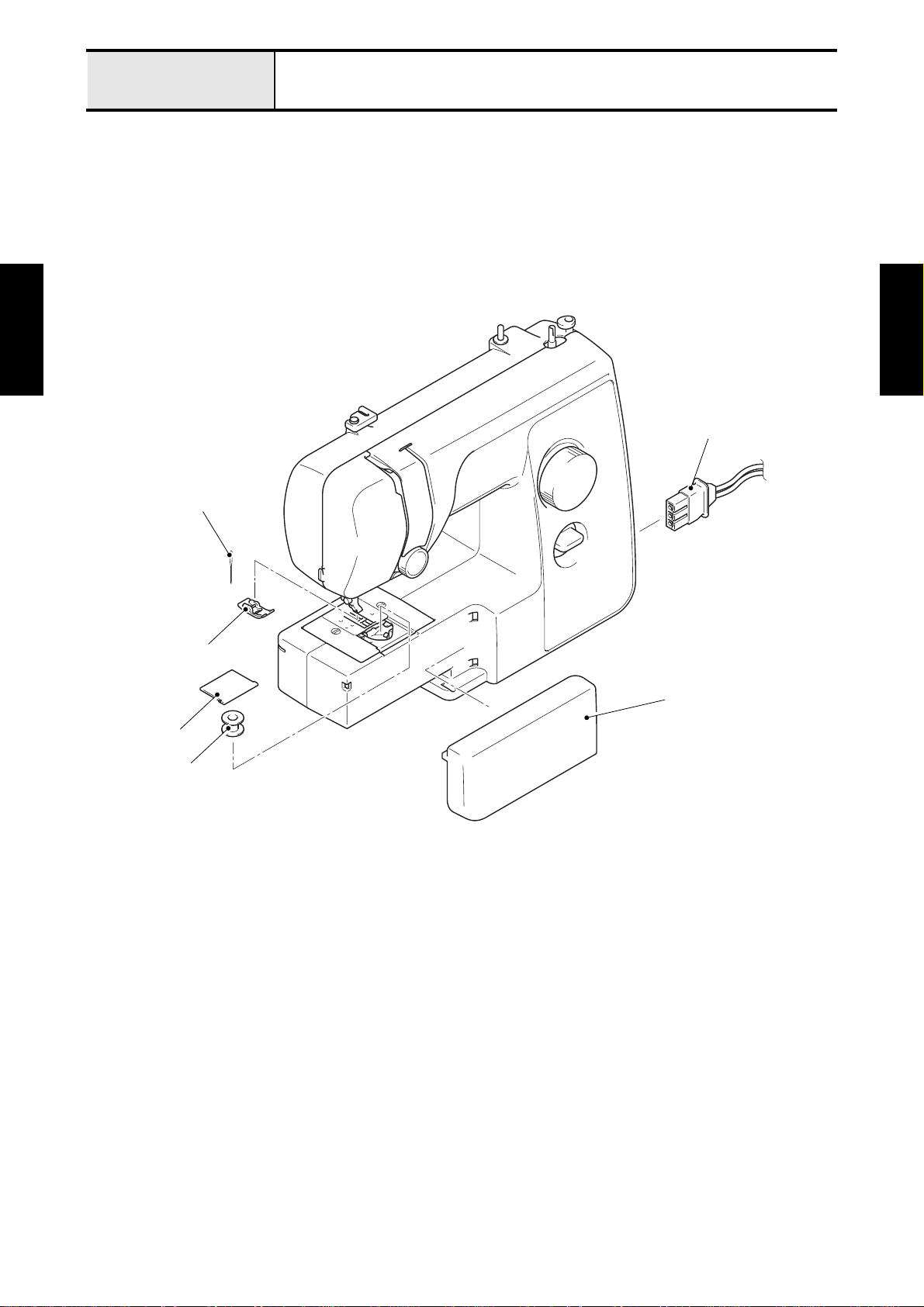

Basic of Disassembly

Preparation

1 Disconnecting cables & Removing accessories

• Foot controller socket

• Needle

• Presser foot

• Accessory table

• Slide plate

• Bobbin

Basic of

Disassembly

Basic of

Disassembly

Foot controller socket

Needle

Presser foot

Accessory table

Slide plate

Bobbin

2 - 2

Page 15

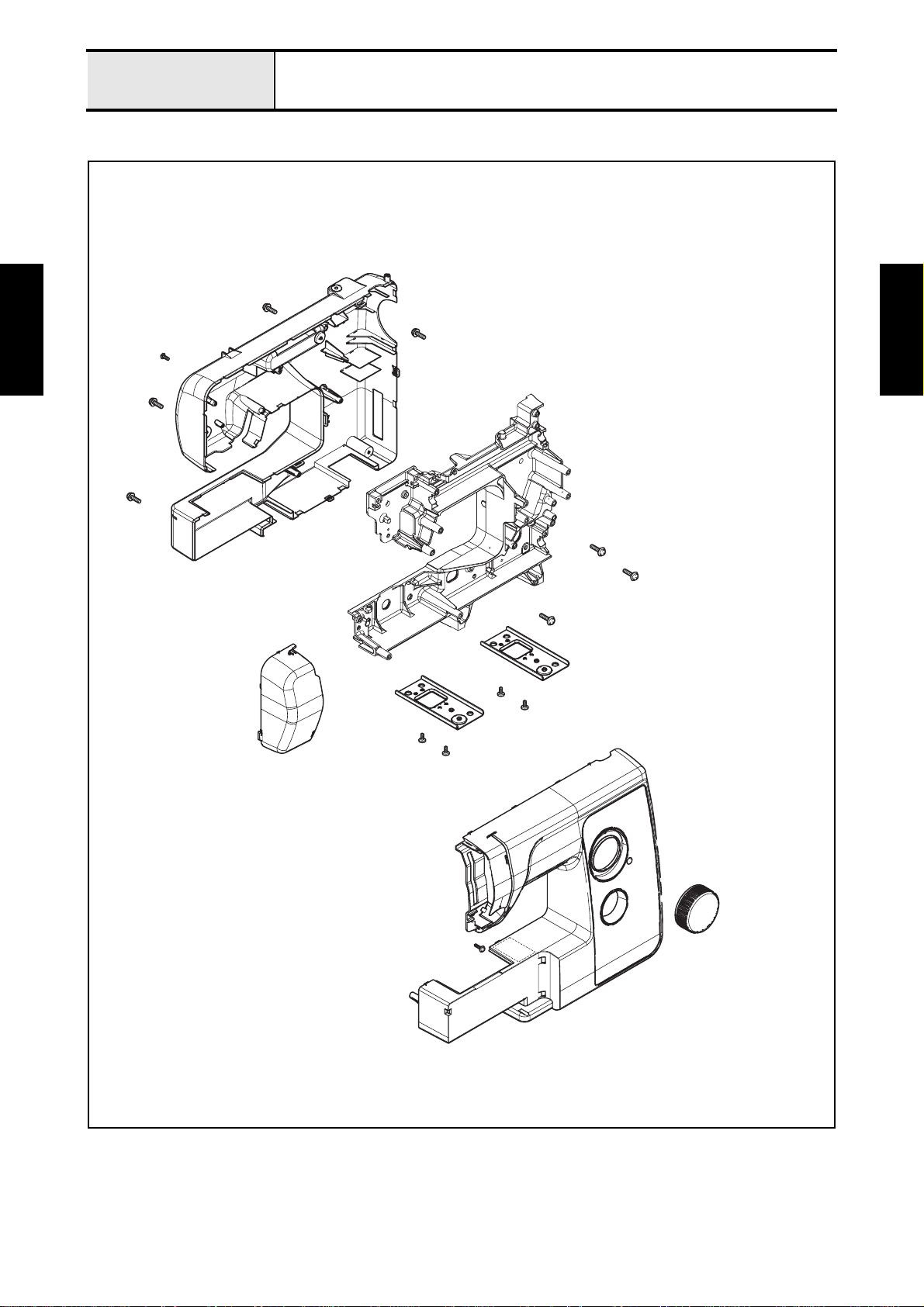

Basic of Disassembly

Main frame and Covers

Main frame and Covers location diagram

Basic of

Disassembly

Basic of

Disassembly

2 - 3

Page 16

Basic of Disassembly

Main frame and Covers

1 Removal of Face plate assy and Front cover assy

1. Remove the screw (taptite, cup P M4X20) from the rear cover side, and then open the bottom side of

face plate assy to remove the face plate assy from the rear cover assy.

→Refer to 3 - 3 Disassembly of Face plate assy.

2. Remove the pattern selecting dial from the shaft of pattern selecting unit assy.

3. Remove the screw (screw, pan (S/P washer) M3X6) from the front cover side. And remove the three

screws (taptite, cup P M4X20) and screw (taptite, bind P M3X16) from the rear cover side.

4. Release the five hooks of front cover assy from the five hook trays of rear cover assy, and then open

the bottom side of front cover assy to remove the front cover assy from the rear cover assy.

→Refer to 3 - 4 Disassembly of Rear cover assy.

Basic of

Disassembly

Taptite, cup P

M4X20

Taptite, bind P

M3X16

Taptite, cup P M4X20

Taptite, bind P M3X16

Taptite, cup P M4X20

(Face plate assy)

Rear cover assy

Hook tray

Shaft of pattern

selecting unit assy

Hook trays

Taptite, Cup P M4X20

Screw, Pan (S/P washer) M3X6

Taptite, Bind P M3X16

Front cover assy

Basic of

Disassembly

Taptite, cup P

M4X20

Rear cover

assy

Hooks

Hook trays

Hooks

Pattern

selecting dial

Screw, pan (S/P washer) M3X6

Face plate assy

2 - 4

Page 17

Basic of Disassembly

Main frame and Covers

2 Removal of Rear cover assy and Base plate L/R

1. Pull down the presser foot lifter.

2. Remove the three screws (taptite, cup P M4X20), and then remove the rear cover assy fro m the arm

bed while the "A" of rear cover assy is bending.

Taptite, Cup P M4X20

Rear cover assy

Basic of

Disassembly

Taptite, cup P M4X20

"A"

Basic of

Disassembly

Taptite, cup P

M4X20

Presser foot lifter

Taptite, cup P M4X20

2 - 5

Page 18

Basic of Disassembly

3. Remove the two screws (taptite, bind S M4X10) to remove the base plate L from the bottom side of arm

bed.

4. Remove the two screws (taptite, bind S M4X10) to remove the base plate R from the bottom side of

arm bed.

Main frame and Covers

→Refer to 3 - 5 Disassembly of Base plate L/R.

Taptite, Bind S M4X10

Basic of

Disassembly

Base plate L

<bottom side>

Basic of

Disassembly

<bottom side>

Taptite, bind S M4X10

Base plate R

Taptite, bind S M4X10

Base plate L

Taptite, bind S M4X10

2 - 6

Page 19

Basic of Disassembly

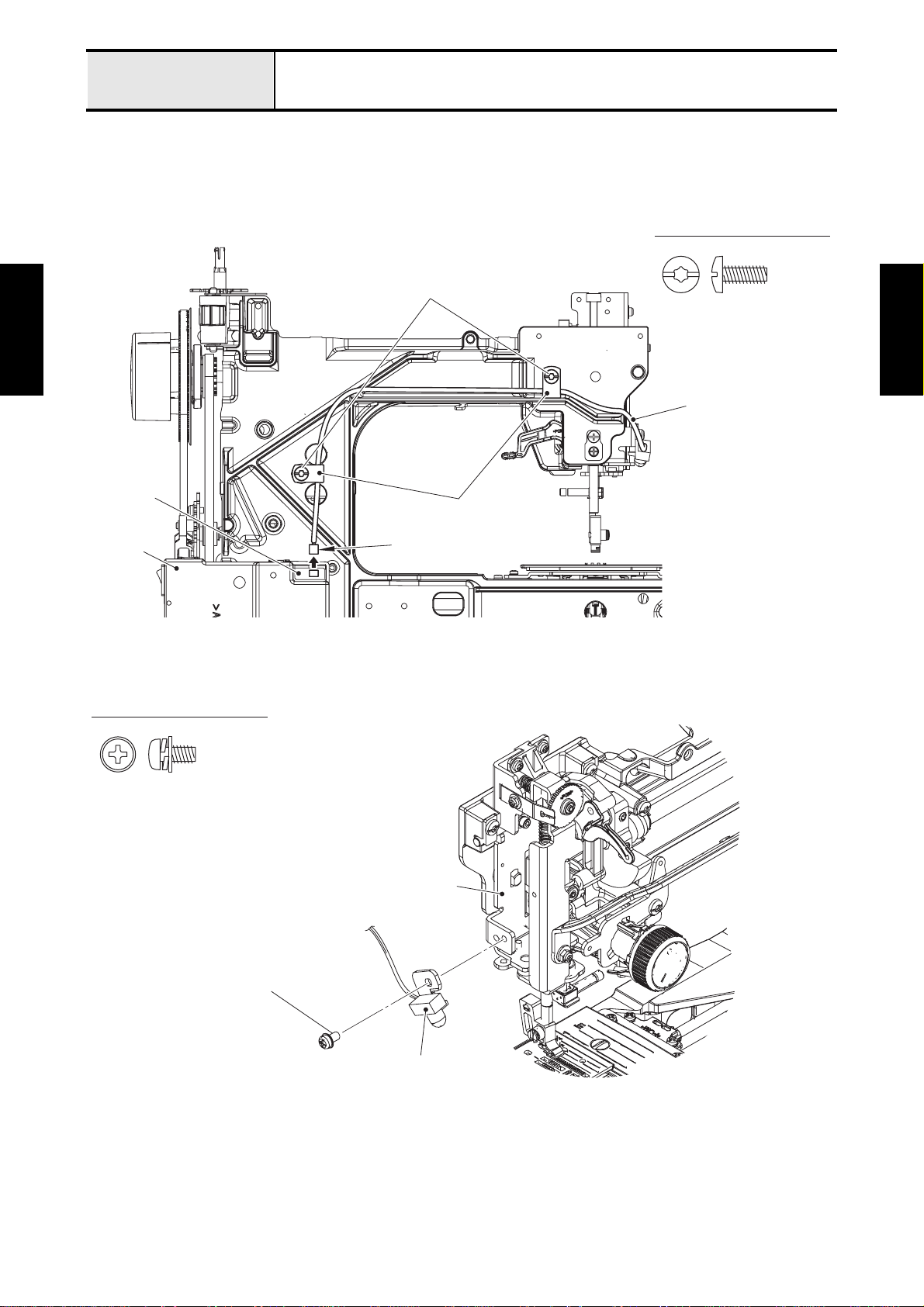

Main motor unit

Main motor unit location diagram

Basic of

Disassembly

Basic of

Disassembly

2 - 7

Page 20

Basic of Disassembly

Main motor unit

1 Removal of LED lamp assy

1. Remove the two screws (taptite, bind S M4X10) to remove the two cord clamps from the arm bed, and

then remove the two cord clamps from the lead wire of LED lamp assy.

2. Disconnect the connector of LED lamp assy from the PCB of motor 3P supply assy.

Taptite, Bind S M4X10

Taptite, bind S M4X10

Basic of

Disassembly

Lead wire of LED

lamp assy

PCB

Cord clamps

Motor 3P

supply assy

3. Remove the screw (screw, pan (S/P washer) M4X8) to remove the LED lamp assy from the b ase holder

assy.

Screw, Pan (S/P washer) M4X8

Connector of LED

lamp assy

Basic of

Disassembly

Screw, pan (S/P washer) M4X8

Base holder assy

LED lamp assy

2 - 8

Page 21

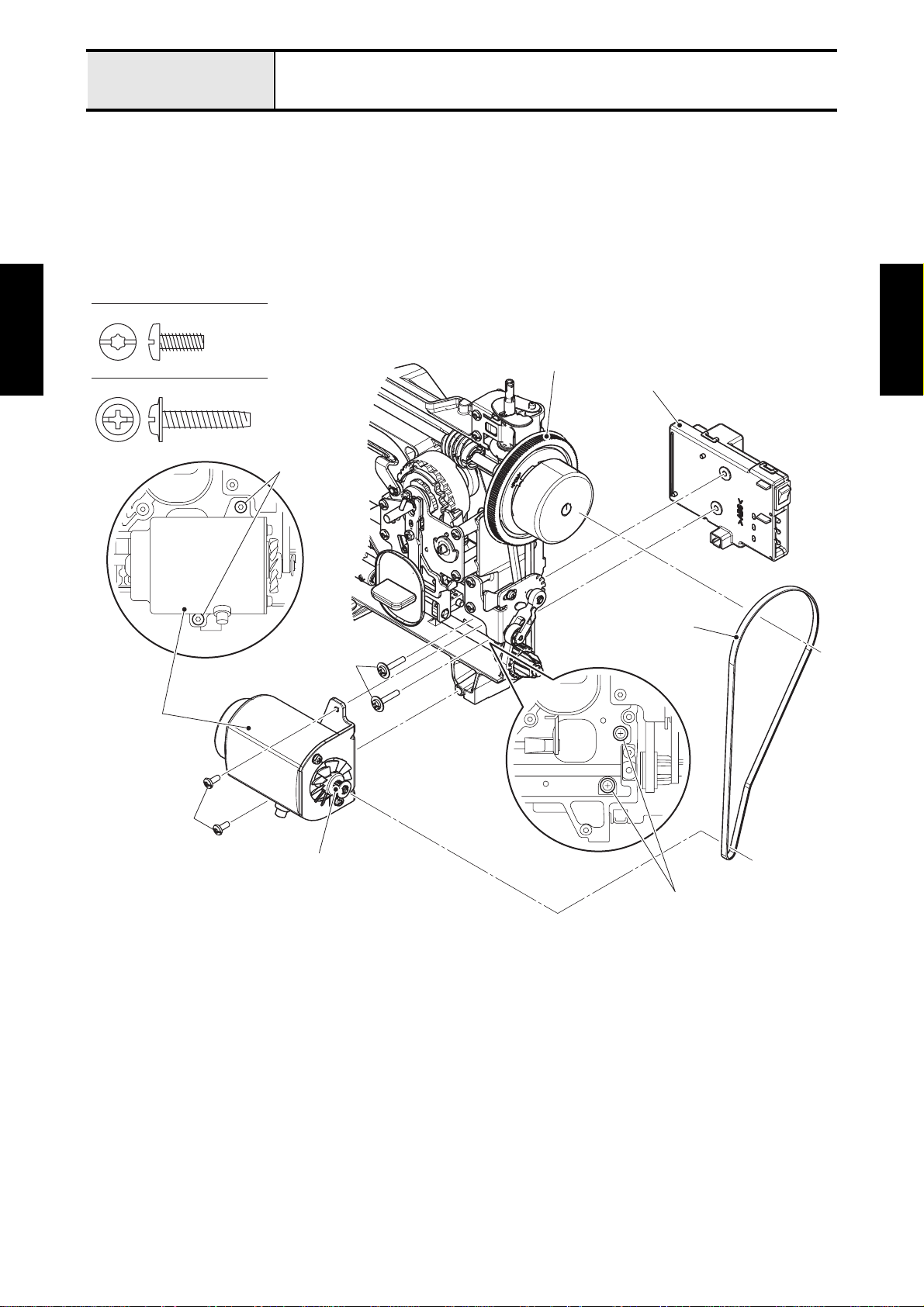

Basic of Disassembly

Main motor unit

2 Removal of Motor 3P supply assy

1. Remove the timing belt from the T pulley and motor T-pulley.

2. Remove the two screws (taptite, bind S M4X10) to remove the motor assy of motor 3P supply assy

from the arm bed.

3. Remove the two screws (taptite, cup P M4X20) to remove the 3P socket unit of motor 3P supply assy

from the arm bed.

→Refer to 3 - 7 Disassembly of Motor 3P supply assy.

Taptite, Bind S M4X10

Basic of

Disassembly

Taptite, Cup P M4X20

Motor assy

Taptite, bind S

M4X10

Taptite, cup P

M4X20

T pulley

3P socket unit

Timing belt

Basic of

Disassembly

Taptite, bind S

M4X10

Motor T-pulley

Taptite, cup P M4X20

2 - 9

Page 22

Basic of Disassembly

Feed unit / Feed control

Feed unit / Feed control location diagram

Basic of

Disassembly

Basic of

Disassembly

2 - 10

Page 23

Basic of Disassembly

Feed unit / Feed control

1 Removal of Tension pulley assy and Lower shaft B assy

1. Remove the two screws (taptite, bind S M4X10) to remove the tension pulley assy from th e arm bed.

→Refer to 3 - 9 Disassembly of Tension pulley assy.

Taptite, Bind S M4X10

Basic of

Disassembly

Basic of

Disassembly

Tension pulley assy

Taptite, bind S M4X10

2. Remove the timing belt from the timing pulley D of lower shaft B assy.

3. Remove the screw (taptite, bind S M4X10) to remove the bushing presser from the arm bed.

4. Remove the two screws (set screw, socket (CP) M5X5) from the fixed joint. And pull out the lower shaft

B assy from the fixed joint of feed module while lifting up the lower shaft bushing of lower shaft B assy.

→Refer to 3 - 10 Disassembly of Lower shaft B assy.

Feed module

Fixed joint

Taptite, Bind S M4X10

Set Screw, Socket (CP) M5X5

Hex wrench 2.5 mm

Set screw, socket

(CP) M5X5

Lower shaft B assy

Taptite, bind S M4X10

Timing belt

Bushing presser

Lower shaft bushing

Timing pulley D

2 - 11

Page 24

Basic of

Disassembly

Basic of Disassembly

Feed unit / Feed control

2 Removal of Feed module

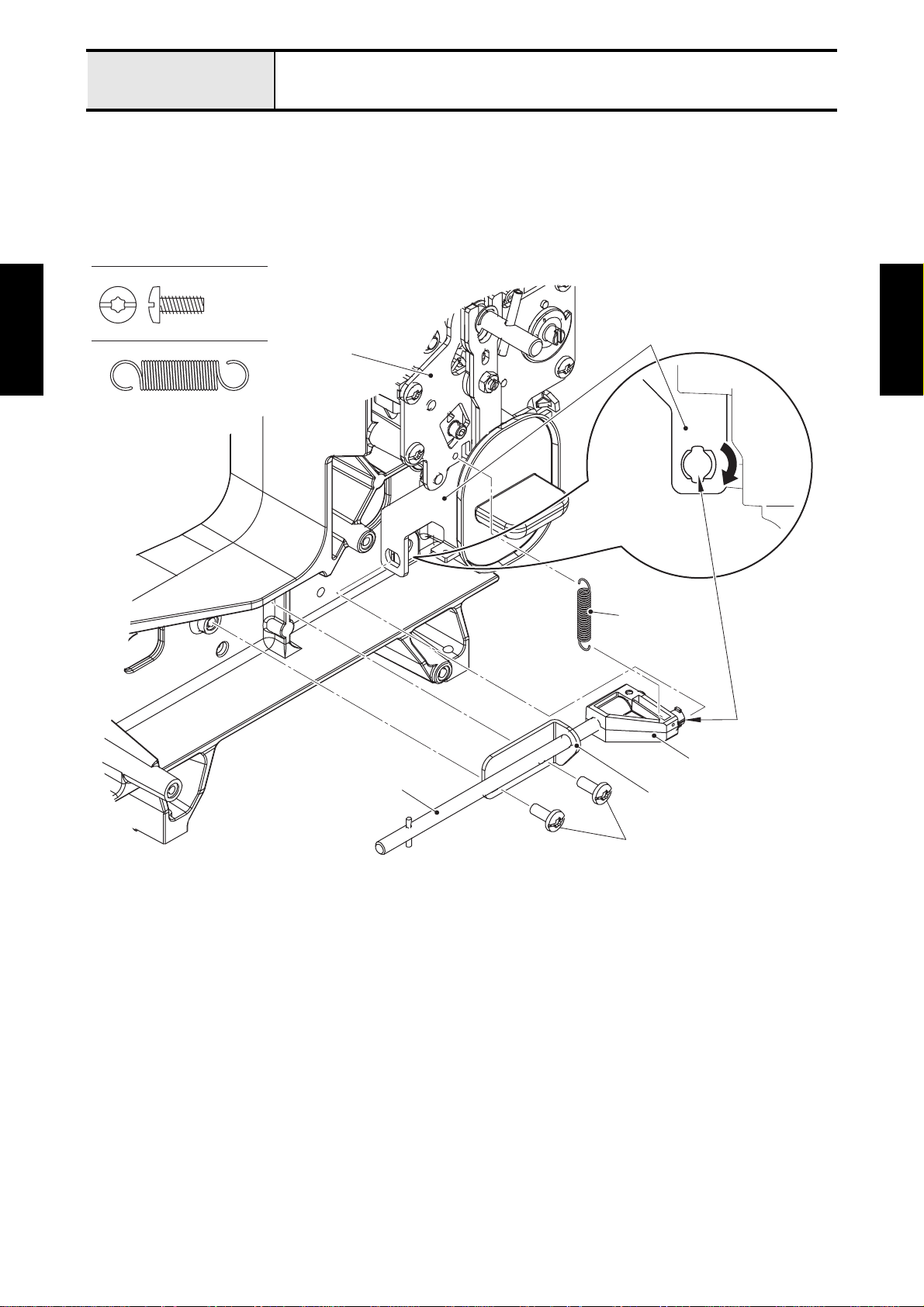

1. Remove the spring (XF5134) from the feed adjusting shaft of feed connecting lever assy and the arm

bed.

2. Remove the three screws (screw, pan (S/P washer) M4X10) from the feed module. And lift up the feed

module to remove it from the two bosses on arm bed, and slide it in the direction of the arrow to remove

the feed adjuster of feed module from the feed adjusting shaft of feed connecting lever assy.

→Refer to 3 - 11 Disassembly of Feed module.

Spring (XF5134)

Pin

Feed adjusting

shaft

Bosses

Spring

(XF5134)

Basic of

Disassembly

Feed module

Screw, Pan (S/P washer) M4X10

Screw, pan

(S/P washer) M4X10

2 - 12

Page 25

Basic of Disassembly

Feed unit / Feed control

3 Removal of Feed connecting lever assy

1. Remove the spring extension C (XE9262) from the fee d connecting lever of feed connecting lever assy

and the pattern selecting unit assy.

2. Remove the two screws (taptite, bind S M4X10) to remove the feed adjusting shaft holder of feed

connecting lever assy from the arm bed. And turn the feed connecting lever of feed connecting lever

assy 90 degrees to remove it from the feed regulator plate B of pattern selecting unit assy.

Taptite, Bind S M4X10

Basic of

Disassembly

Spring extension C (XE9262)

Pattern selecting

unit assy

Feed connecting lever assy

Feed regulator plate B

Basic of

Disassembly

90°

Spring

extension C

(XE9262)

Boss

Feed connecting lever

Feed adjusting shaft holder

2 - 13

Taptite, bind S M4X10

Page 26

Basic of Disassembly

Needle threading mechanism

Needle threading mechanism location diagram

Basic of

Disassembly

Basic of

Disassembly

2 - 14

Page 27

Basic of Disassembly

Needle threading mechanism

1 Removal of Thread tension dial assembly

1. Remove the spring (XF3522) from the tension control holder assy of thread ten sion dial assem bly and

the zigzag connecting rod.

2. Remove the two screws (taptite, bind S M4X10) to remove the thread tension dial assembly from the

arm bed.

→Refer to 3 - 20 Disassembly of Thread tension dial assembly.

Taptite, Bind S M4X10

Basic of

Disassembly

Spring (XF3522)

Thread tension dial assembly

Taptite, bind S M4X10

Basic of

Disassembly

Tension control holder assy

Zigzag connecting rod

Spring (XF3522)

2 - 15

Page 28

Basic of Disassembly

Pattern selecting mechanism

Pattern selecting mechanism location diagram

Basic of

Disassembly

Basic of

Disassembly

2 - 16

Page 29

Basic of Disassembly

Pattern selecting mechanism

1 Removal of Pattern selecting unit assy

1. Remove the screw (screw, pan M3X10) to remove the zigzag adjusting nut from the base holder assy

of needle unit supply assy. And remove the retaining ring E4 to remove the zigzag connecting rod from

the shaft of pattern selecting unit assy.

Screw, Pan M3X10

Needle unit supply assy

Basic of

Disassembly

Shaft

Pattern selecting

unit assy

Retaining ring E4

Zigzag connecting rod

Zigzag adjusting nut

Screw, pan M3X10

2. Remove the four screws (taptite, bind S M4X10) to remove the pattern selecting unit assy from the arm

bed.

→Refer to 3 - 22 Disassembly of Pattern selecting unit assy.

Taptite, Bind S M4X10

Basic of

Disassembly

Pattern selecting unit assy

2 - 17

Taptite, bind S M4X10

Page 30

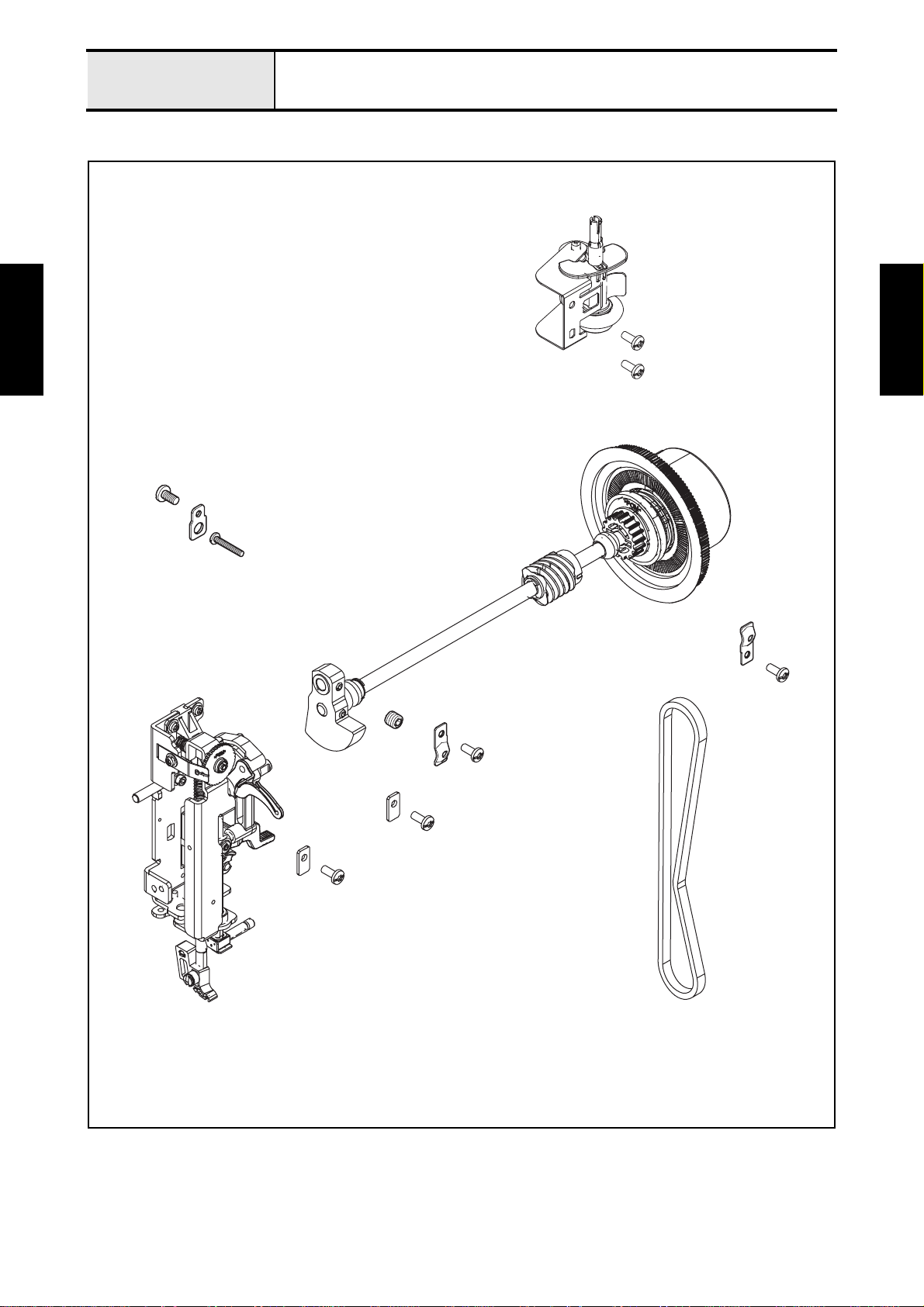

Basic of Disassembly

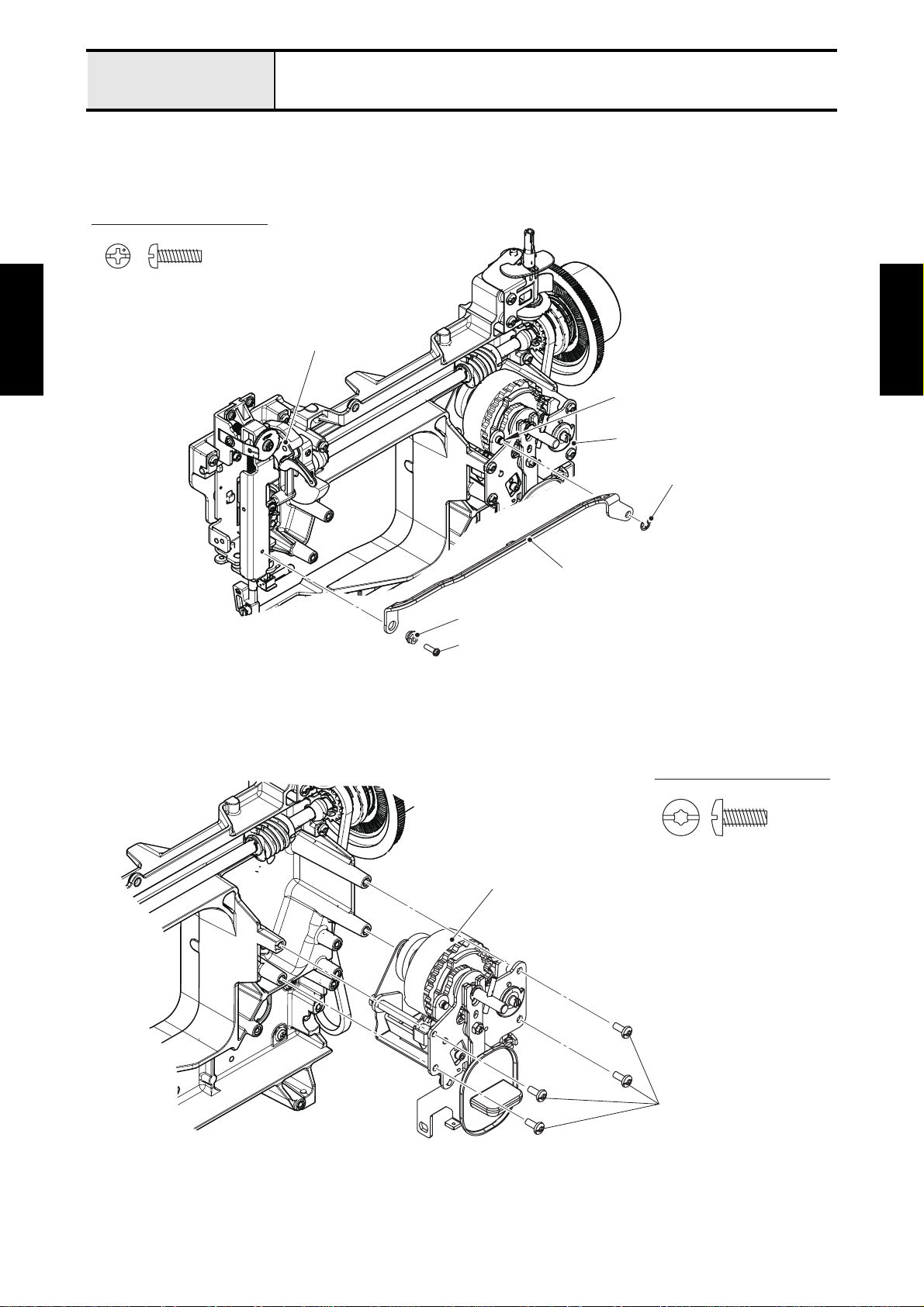

Bobbin winder, Upper shaft, Needle-presser module

Bobbin winder, Upper shaft, Needle-presser module location diagram

Basic of

Disassembly

Basic of

Disassembly

2 - 18

Page 31

Basic of Disassembly

Bobbin winder, Upper shaft, Needle-presser module

1 Removal of Bobbin winder assy

1. Remove the two screws (taptite, bind S M4X10) to remove the bobbin winder assy from the arm bed.

→Refer to 3 - 24 Disassembly of Bobbin winder assy.

Taptite, Bind S M4X10

Basic of

Disassembly

Basic of

Disassembly

Taptite, bind S M4X10

Bobbin winder assy

2 - 19

Page 32

Basic of Disassembly

Bobbin winder, Upper shaft, Needle-presser module

2 Removal of Upper shaft assy

1. Remove the timing belt from the upper shaft assy.

2. Remove the screw (set screw, socket (FT) M5X5) from the thread take- up counter weight of upp er shaft

assy.

3. Remove the two screws (taptite, bind S M4X10) to remove the two bushing pressers from the arm bed.

And remove the two lower shaft bushings of upper shaft assy from the arm bed, and then slide the

upper shaft assy in the direction of the arrow to remove the thread take-up counter weight of upper

shaft assy from the shaft of thread take-up lever.

→Refer to 3 - 25 Disassembly of Upper shaft assy.

Basic of

Disassembly

Mounting positions

Shaft of thread take-up lever

Thread take-up

counter weight

Upper shaft assy

Lower shaft bushing

Bushing pressers

Taptite, bind S M4X10

Lower shaft bushing

Set screw, socket (FT) M5X5

Timing belt

Set Screw, Socket (FT) M5X5

Hex wrench 2.5 mm

Taptite, Bind S M4X10

Basic of

Disassembly

2 - 20

Page 33

Basic of Disassembly

Bobbin winder, Upper shaft, Needle-presser module

3 Removal of Needle-presser module

1. Remove the screw (screw, bind M4X8) to remove the stopper plate from the back side of arm bed.

2. Remove the screw (cup screw M3X20) from the back side of arm bed.

Screw, Bind M4X8

Cup screw M3X20

Basic of

Disassembly

Basic of

Disassembly

Stopper plate

Screw, bind M4X8

Cup screw M3X20

2 - 21

Page 34

Basic of Disassembly

3. Remove the two screws (screw, bind M4X10) to remove the two presser plates from the arm bed. And

remove the needle-presser module from the arm bed.

→Refer to 3 - 26 Disassembly of Needle-presser module.

Bobbin winder, Upper shaft, Needle-presser module

Screw, Bind M4X10

Basic of

Disassembly

Basic of

Disassembly

Presser plates

Needle-presser module

Screw, bind M4X10

2 - 22

Page 35

Basic of Assembly

Bobbin winder, Upper shaft, Needle-presser module

Bobbin winder, Upper shaft, Needle-presser module location diagram

Basic of

Assembly

Basic of

Assembly

2 - 23

Page 36

Basic of Assembly

Bobbin winder, Upper shaft, Needle-presser module

1 Attachment of Needle-presser module

1. Set the shaft of needle-presser module to the two mounting positions on arm bed, and insert the tab of

arm bed into the positioning hole of needle-presser module.

2. Attach the presser plate to the arm bed with th e scr ew (screw, bind M4X10). (2 locations)

Screw, Bind M4X10

Mounting positions

Basic of

Assembly

Tab

Shaft

Positioning hole

Needle-presser module

Presser plates

Screw, bind M4X10

Basic of

Assembly

2 - 24

Page 37

Basic of Assembly

3. Tighten the screw (cup screw M3X20) temporarily to the back side of arm bed.

4. Attach the stopper plate to the back side of arm bed with the screw (screw, bind M4X8).

Bobbin winder, Upper shaft, Needle-presser module

→Refer to 3 - 32 Assembly of Needle-presser module.

Cup screw M3X20

Screw, Bind M4X8

Basic of

Assembly

Stopper plate

Screw, bind M4X8

Cup screw M3X20

Basic of

Assembly

2 - 25

Page 38

Basic of Assembly

Bobbin winder, Upper shaft, Needle-presser module

2 Attachment of Upper shaft assy

1. Insert the thread take-up counter weight of the upper shaft assy into the shaft of needle bar crank rod

assy, and set the two lower shaft bush ings of upper shaft assy to the two moun ting positions on arm

bed. And attach the two bushing pressers to the arm bed with the two screws (taptite, bind S M4X10).

2. Align the D cut surface of needle bar crank rod assy with the screw hole on thread take-up counter

weight, and secure it with the screw (set screw, socket (FT) M5X5).

3. Pass the timing belt to the upper shaft assy.

→Refer to 3 - 36 Assembly of Upper shaft assy.

Basic of

Assembly

Shaft of thread take-up lever

Needle bar

crank rod assy

Mounting positions

D cut surface

Thread take-up

counter weight

Thread take-up counter weight

Screw hole

Upper shaft assy

Upper shaft assy

Lower shaft bushing

Bushing pressers

Lower shaft bushing

Set screw, socket (FT) M5X5

Timing belt

Taptite, bind S M4X10

Taptite, Bind S M4X10

Set Screw, Socket (FT) M5X5

Hex wrench 2.5 mm

Basic of

Assembly

2 - 26

Page 39

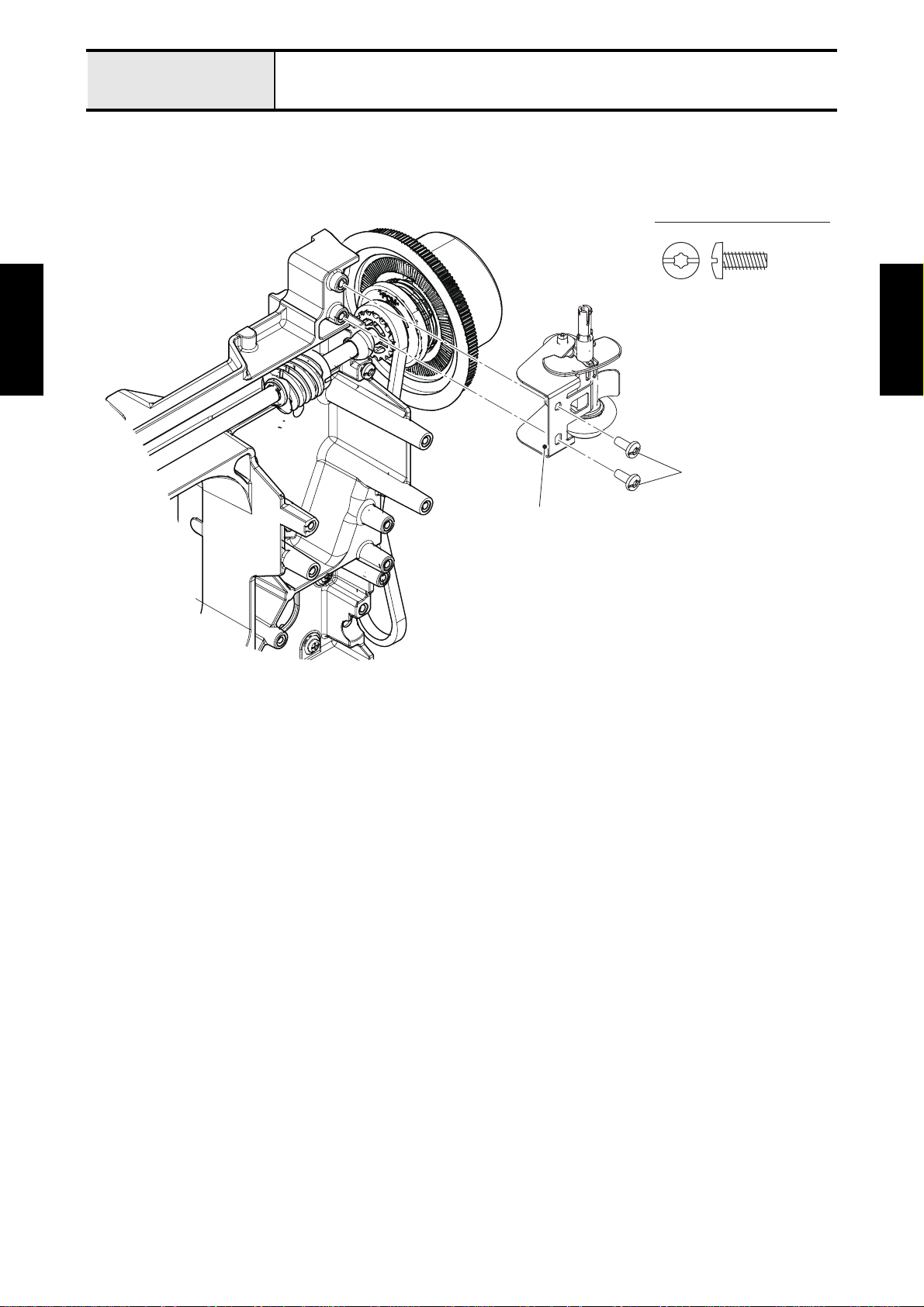

Basic of Assembly

Bobbin winder, Upper shaft, Needle-presser module

3 Attachment of Bobbin winder assy

1. Attach the bobbin winder assy to the arm bed with the two screws (taptite, bind S M4X10).

→Refer to 3 - 37 Assembly of Bobbin winder assy.

Taptite, Bind S M4X10

Basic of

Assembly

Bobbin winder assy

Taptite, bind S M4X10

Basic of

Assembly

2 - 27

Page 40

Basic of Assembly

Pattern selecting mechanism

Pattern selecting mechanism location diagram

Basic of

Assembly

Basic of

Assembly

2 - 28

Page 41

Basic of Assembly

Pattern selecting mechanism

1 Lubrication

Lubrication point Lubricating oil type Quantity of lubrication

1 Z finger frame assy 1 place EPNOC AP (N) 0 Rice-grain size

2 Zigzag adjusting nut 1 place EPNOC AP (N) 0 Rice-grain size

Basic of

Assembly

Z finger frame assy

Basic of

Assembly

1

2

Zigzag adjusting nut

2 - 29

Page 42

Basic of Assembly

Pattern selecting mechanism

2 Attachment of Pattern selecting unit assy

1. Match the mark on worm gear of upper shaft assy with the mark on gear of pattern selecting unit assy,

and attach the pattern selecting unit assy to the arm bed with the four screws (taptite, bind S M4X10).

Basic of

Assembly

Upper shaft assy

Worm gear

Pattern selecting

unit assy

Marks

Gear

Taptite, Bind S M4X10

Taptite, bind S M4X10

Basic of

Assembly

2 - 30

Page 43

Basic of Assembly

Pattern selecting mechanism

2. Set the zigzag connecting rod to the shaft of pattern selecting un it assy, and secure it with the retaining

ring E4. And set the zigzag adjusting nut to the zigzag connecting rod, and set them to the base holder

assy of needle unit supply assy, and tighten the screw (screw, pan M3X10) temporarily.

*Key point

• Confirm that place the zigzag adjusting nut with the larger en d facing the top side.

• Fully tighten the screw after performing “4 - 10 Three point needle drop”.

→Refer to 3 - 40 Assembly of Pattern selecting unit assy.

Screw, Pan M3X10

Basic of

Assembly

Zigzag adjusting nut

Screw, pan M3X10

Base holder assy

Needle unit supply assy

Zigzag connecting rod

Zigzag adjusting nut

Screw, pan M3X10

Shaft

Pattern selecting

unit assy

Retaining ring E4

Basic of

Assembly

2 - 31

Page 44

Basic of Assembly

Needle threading mechanism

Needle threading mechanism location diagram

Basic of

Assembly

Basic of

Assembly

2 - 32

Page 45

Basic of Assembly

Needle threading mechanism

1 Attachment of Thread tension dial assembly

1. Attach the thread tension dial assembly to the arm bed with the two screws (taptite, bind S M4X10).

*Key point

• Confirm that there is "A" of upper tension control releaser on the upper side of presser foot lifter as shown in

the illustration below.

2. Hang the spring (XF3522) to the tension control holder assy and the zigzag connecting rod.

→Refer to 3 - 42 Assembly of Thread tension dial assembly.

Taptite, Bind S M4X10

Basic of

Assembly

Spring (XF3522)

Presser foot lifter

Thread tension dial assembly

Taptite, bind S M4X10

"A"

Upper tension control releaser

Tension control holder assy

Zigzag connecting rod

Basic of

Assembly

Spring (XF3522)

2 - 33

Page 46

Basic of Assembly

Feed unit / Feed control

Feed unit / Feed control location diagram

Basic of

Assembly

Basic of

Assembly

2 - 34

Page 47

Basic of Assembly

Feed unit / Feed control

1 Lubrication

Lubrication point Lubricating oil type Quantity of lubrication

1 Feed adjusting shaft holder 1 place EPNOC AP (N) 0 Rice-grain size

2 Feed connecting lever 1 place EPNOC AP (N) 0 Rice-grain size

Basic of

Assembly

Feed adjusting shaft holder

Basic of

Assembly

Feed connecting lever

1

2

2 - 35

Page 48

Basic of Assembly

Feed unit / Feed control

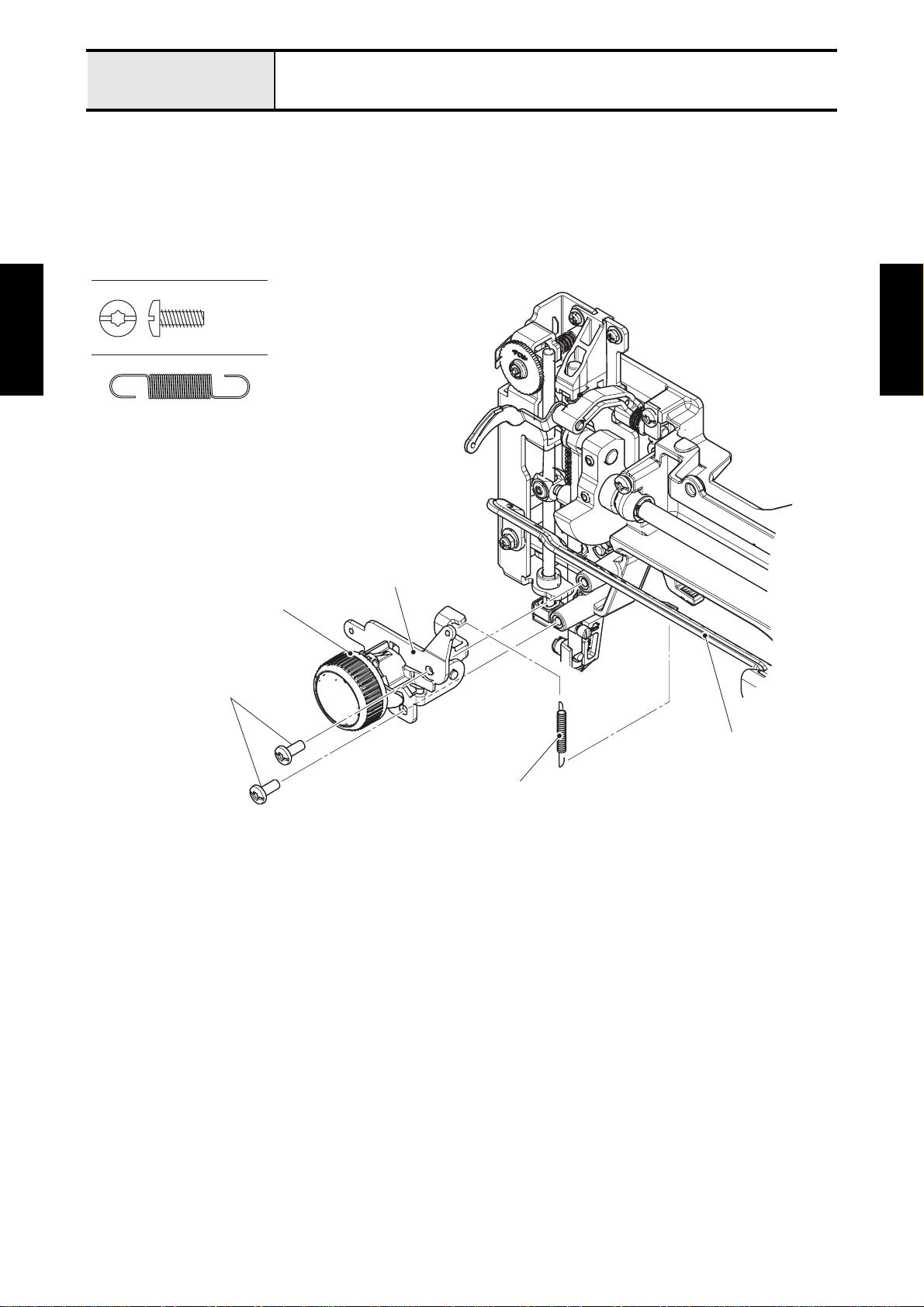

2 Attachment of Feed connecting lever assy

1. Insert the boss of feed connecting lever into the positioning hole of feed regu lator plate B, and turn it 90

degrees. And attach the feed adjusting shaft holder of feed connecting lever assy to the arm bed with

the two screws (taptite, bind S M4X10).

2. Attach the spring extension C (XE9262) to the feed connecting lever and the pattern selecting unit

assy.

Taptite, Bind S M4X10

Basic of

Assembly

Spring extension C (XE9262)

Pattern selecting unit assy

Feed connecting lever assy

Feed regulator plate B

Spring

extension C

(XE9262)

Feed adjusting shaft holder

Positioning hole

Boss

Feed connecting lever

Basic of

Assembly

2 - 36

Taptite, bind S M4X10

Page 49

Basic of

Assembly

Basic of Assembly

Feed unit / Feed control

3 Attachment of Feed module

1. Insert the feed adjuster into the feed adjusting shaft of feed connecting lever assy, a nd set the pin of the

feed adjusting shaft to the two slits of feed adjuster. And insert th e two positioning holes of back side of

feed module into the two tabs of arm bed, and set the feed module to the arm bed, and secure it with

the three screws (screw, pan (S/P washer) M4X10).

2. Attach the spring (XF5134) to the feed adjusting shaft of feed connecting lever assy and the arm bed as

shown in the illustration below.

→Refer to 3 - 45 Assembly of Feed module.

Spring (XF5134)

Pin

Feed adjusting

shaft

Tabs

Pin

Spring

(XF5134)

Feed adjusting

shaft

Basic of

Assembly

Feed module

Screw, Pan (S/P washer) M4X10

Feed adjuster

Screw, pan

(S/P washer) M4X10

2 - 37

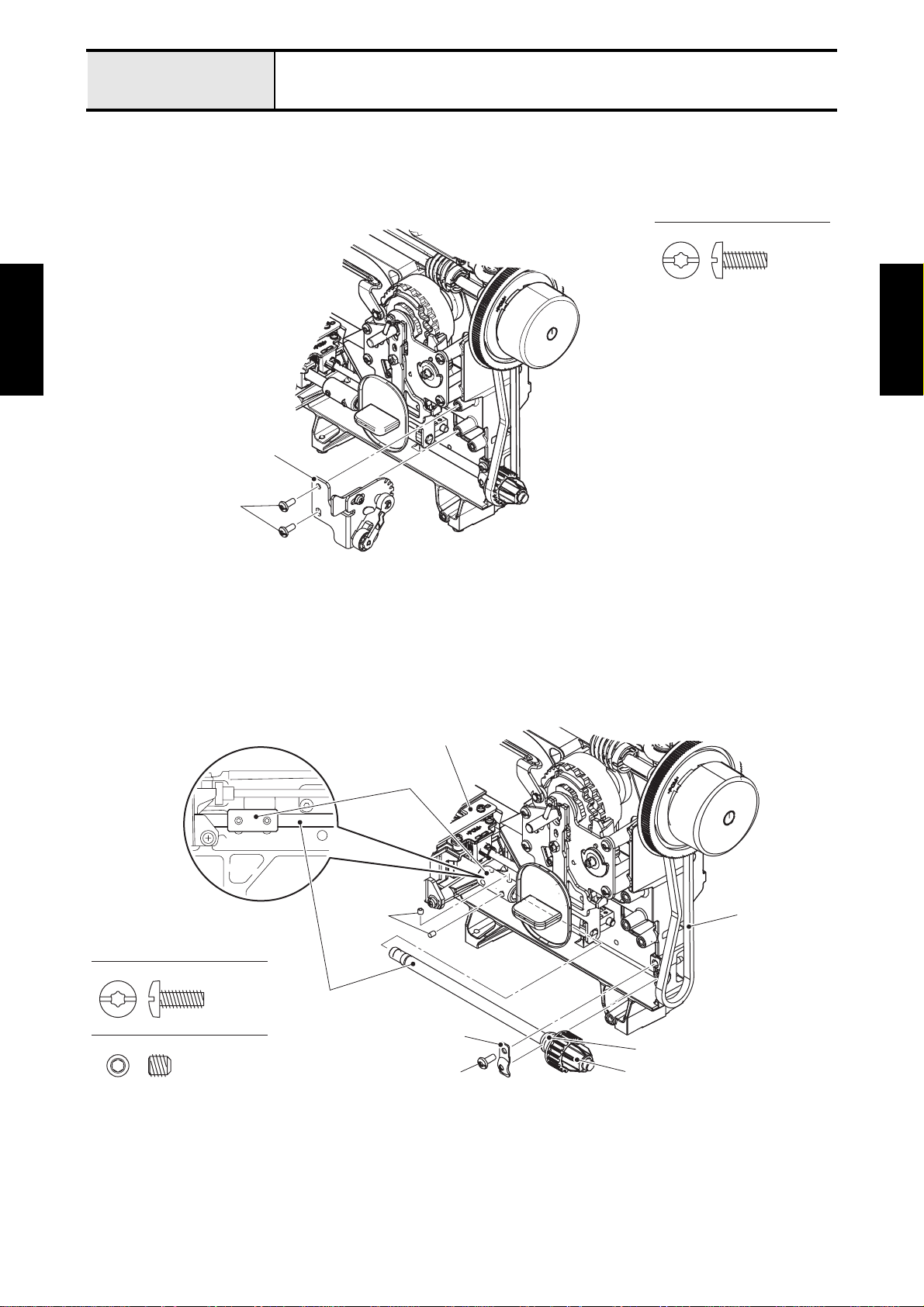

Page 50

Basic of

Assembly

Basic of Assembly

Feed unit / Feed control

4 Attachment of Lower shaft B assy and Tension pulley assy

1. Insert the lower shaft B assy into the fixed joint, and set the lower shaft bushing of the lower shaft B

assy to the mounting position of arm bed. And attach the bushing presser to the arm bed with the screw

(taptite, bind S M4X10). And tighten the two screws (set screw, socket (CP) M5X5) temporarily to the

fixed joint.

*Key point

• Fully tighten the two screws after performing “4 - 12 Needle bar rising”.

2. Hang the timing belt to the timing pulley D of lower shaft B assy.

→Refer to 3 - 53 Assembly of Lower shaft B assy.

Feed module

Fixed joint

Set screw,

socket (CP)

M5X5

Timing belt

Basic of

Assembly

Taptite, Bind S M4X10

Lower shaft B assy

Set Screw, Socket (CP) M5X5

Hex wrench 2.5 mm

Bushing presser

Taptite, bind S M4X10

Lower shaft bushing

Timing pulley D

3. Attach the tension pulley assy to the arm bed with the two screws (taptite, bind S M4X10).

→Refer to 3 - 54 Assembly of Tension pulley assy.

Taptite, Bind S M4X10

Tension pulley assy

Mounting position

Taptite, bind S M4X10

2 - 38

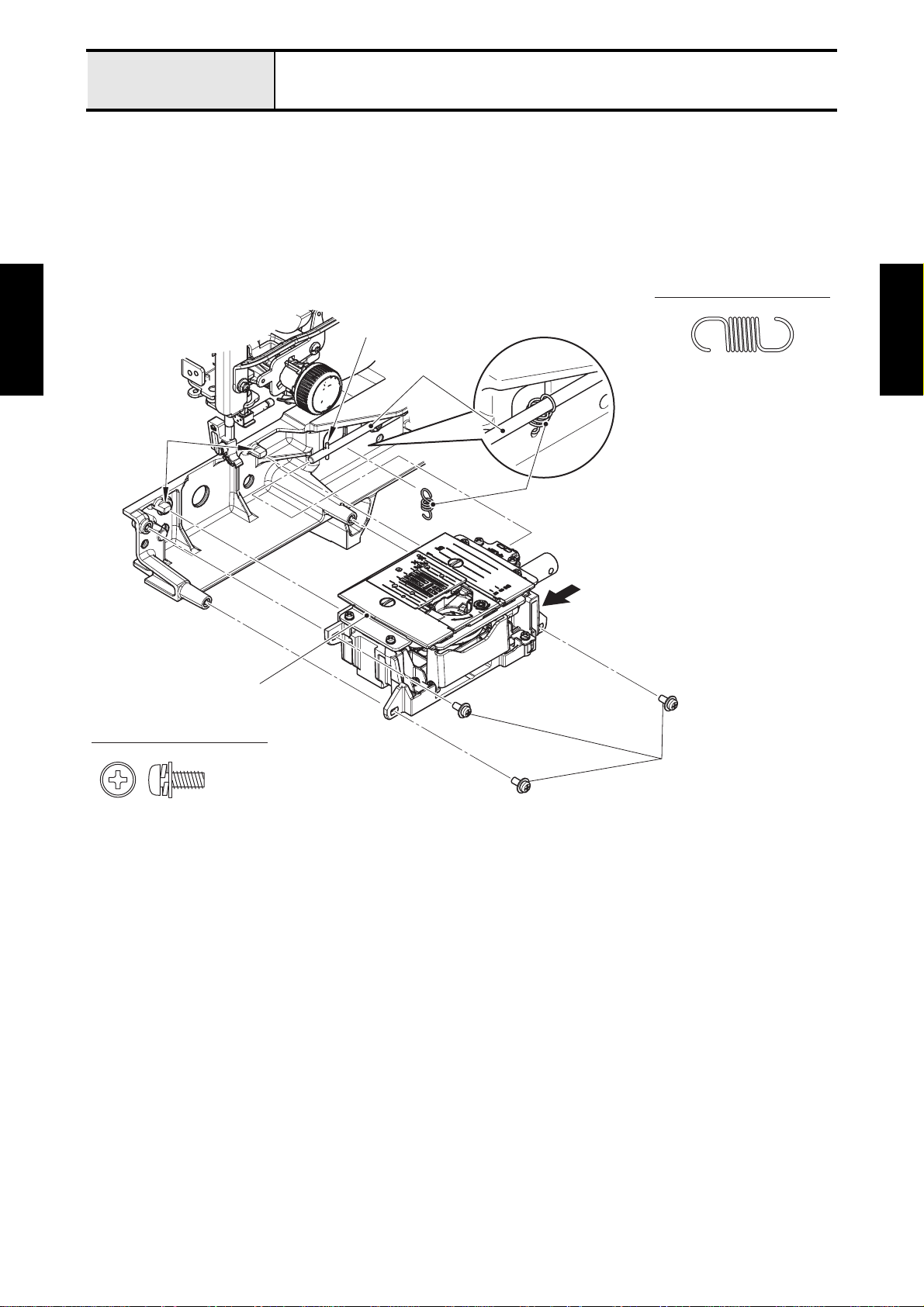

Page 51

Basic of Assembly

Feed unit / Feed control

5 Phase matching of Upper shaft and Lower shaft

1. When set the groove of upper shaft pulley frontward by rotating the pulley of upper shaft, and set the

mark of outer rotary hook assy frontward by rotating the lower shaft A assy, and set the feed cam with

larger end facing backward, and tighten the two screws (set screw, socket (CP) M5X5) of fixed joint.

Set Screw, Socket (CP) M5X5

Basic of

Assembly

Hex wrench 2.5 mm

Feed cam

Outer rotary

hook assy

Upper shaft pulley

Groove

Lower shaft A assy

Basic of

Assembly

Mark

Fixed joint

Set screw, socket (CP) M5X5

2 - 39

Page 52

Basic of Assembly

Main motor unit

Main motor unit location diagram

Basic of

Assembly

Basic of

Assembly

2 - 40

Page 53

Basic of Assembly

Main motor unit

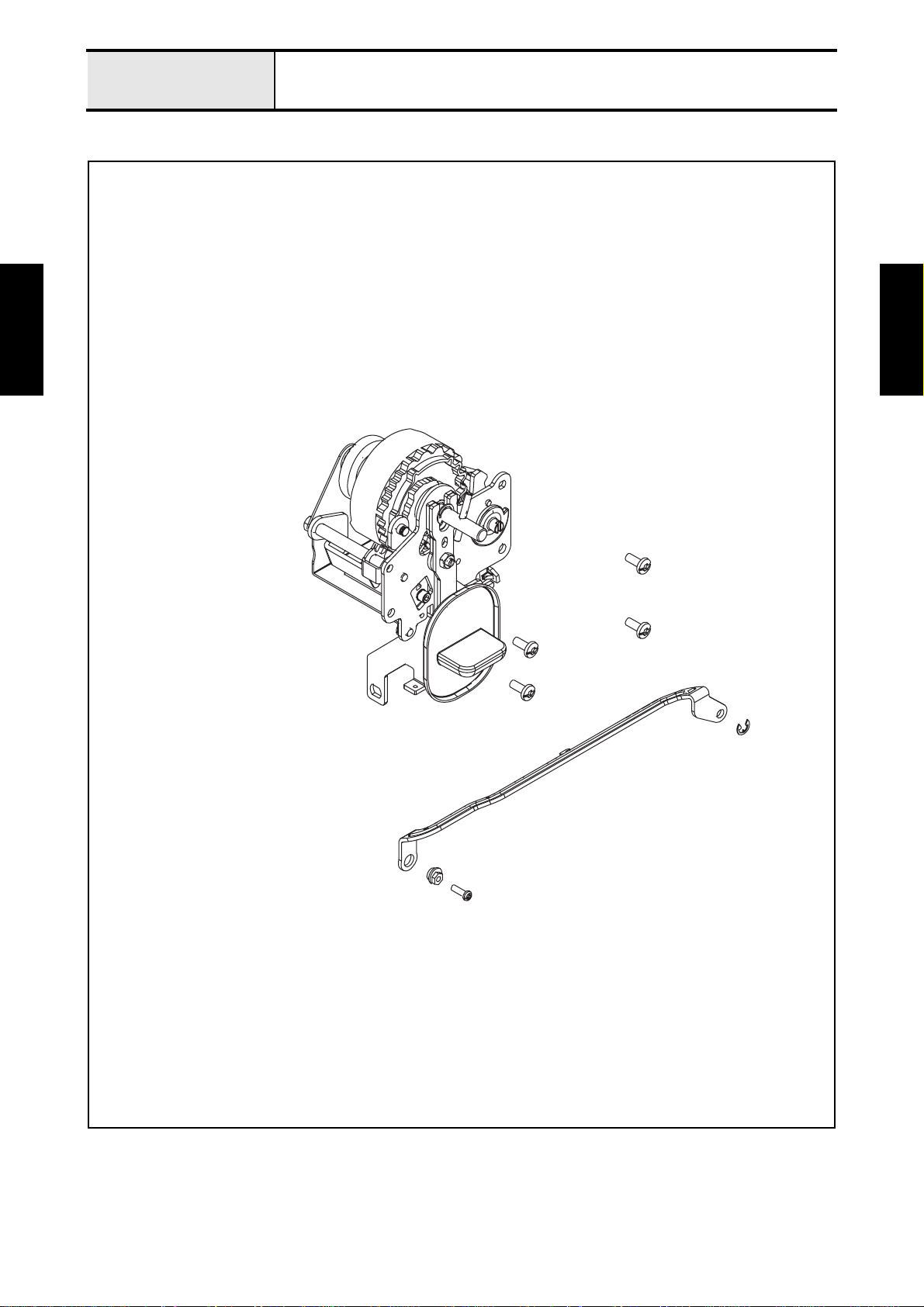

1 Attachment of Motor 3P supply assy

1. Insert the two pins of 3P sock et un it of motor 3 P su pply assy int o the tw o positio ni ng hole s of ar m be d,

and secure it to the arm bed with the two screws (taptite, cup P M4X20).

2. Attach the motor assy of motor 3P supply assy to the arm bed with the two screws (taptite, bind S

M4X10).

3. Hang the timing belt on the T pulley and the motor T-pulley. And set the motor tension pulley on the

timing belt so that pushing it.

→Refer to 3 - 56 Assembly of Motor 3P supply assy.

Taptite, Cup P M4X20

Basic of

Assembly

Taptite, Bind S M4X10

Motor assy

Taptite, bind S

M4X10

Taptite, cup P

M4X20

Positioning holes

T pulley

Motor tension pulley

3P socket unit

Pins

Timing belt

Pin

Basic of

Assembly

Taptite, bind S

M4X10

Motor T-pulley

Pin

Taptite, cup P M4X20

2 - 41

Page 54

Basic of Assembly

Main motor unit

2 Attachment of LED lamp assy

1. Align the boss of LED lamp assy with the positioning hole of base holder assy, and attach it with the

screw (screw, pan (S/P washer) M4X8).

Screw, Pan (S/P washer) M4X8

Base holder assy

Basic of

Assembly

Positioning hole

Boss

Screw, pan (S/P washer) M4X8

LED lamp assy

2. Connect the connector of LED lamp assy to the PCB of motor 3P supply assy.

3. Set the cord clamp to the lead wire of LED lamp assy, and attach it to the arm bed with the screw

(taptite, bind S M4X10). (2 locations)

Taptite, Bind S M4X10

Taptite, bind S M4X10

Basic of

Assembly

PCB

Motor 3P supply assy

Lead wire of LED

lamp assy

Cord clamps

Connector of LED

lamp assy

2 - 42

Page 55

Basic of Assembly

Main frame and Covers

Main frame and Covers location diagram

Basic of

Assembly

Basic of

Assembly

2 - 43

Page 56

Basic of Assembly

Main frame and Covers

1 Attachment of Rear cover assy and Base plate L/R

1. Attach the base plate R to the bottom side of arm bed with the two screws (taptite, bind S M4X10).

2. Attach the base plate L to the bottom side of arm bed with the two screws (taptite, bind S M4X10).

→Refer to 3 - 58 Assembly of Base plate L/R.

Taptite, Bind S M4X10

Basic of

Assembly

Base plate L

<bottom side>

Taptite, bind S M4X10

Taptite, bind S M4X10

Base plate L

Base plate R

<bottom side>

Taptite, bind S M4X10

Basic of

Assembly

2 - 44

Page 57

Basic of

Assembly

Basic of Assembly

3. Pull down the presser foot lifter.

4. Set the rear cover assy to the arm bed, and secure it with the three screws (taptite, cup P M4X20).

Main frame and Covers

→Refer to 3 - 59 Assembly of Rear cover assy.

Taptite, Cup P M4X20

Rear cover assy

Taptite, cup P M4X20

Basic of

Assembly

Presser foot lifter

Taptite, cup P

M4X20

Taptite, cup P M4X20

2 - 45

Page 58

Basic of Assembly

Main frame and Covers

2 Attachment of Face plate assy and Front cover assy

1. Set the front cover assy to the rear cover assy, and hang the five hooks of front cover assy on the five

hook trays of rear cover assy.

2. Secure the front cover assy to the arm bed with the three screws (taptite, cup P M4X20) and the screw

(taptite, bind P M3X16) from the rear cover side. And tighten the screw (screw, pan (S/P washer)

M3X6) to the front cover side.

3. Attach the pattern selecting dial to the shaft of pattern selecting unit assy.

4. Insert the pin of face plate assy into the positioning hole of front cover assy, and set the face plate assy

to the rear cover assy, and secure it with the screw (taptite, cup P M4X20) from the rear cover side.

→Refer to 3 - 60 Assembly of Face plate assy.

Basic of

Assembly

Taptite, cup P M4X20

Taptite, bind P

M3X16

Taptite, cup P M4X20

Taptite, bind P M3X16

Taptite, cup P M4X20

(Face plate assy)

Hook tray

Shaft of pattern

selecting unit assy

Hook trays

Taptite, Cup P M4X20

Screw, Pan (S/P washer) M3X6

Taptite, Bind P M3X16

Front cover assy

Basic of

Assembly

Taptite, cup P

M4X20

Rear cover assy

Face plate assy

Hook trays

Hooks

Pin

2 - 46

Hooks

Pattern

selecting dial

Screw, pan (S/P washer) M3X6

Positioning hole

Page 59

Application of

3

Disassembly/Assembly

In this chapter, explains the disassembly and assembly of

the each module. When fix and replace the each module,

use this chapter.

Disassembly Main frame and Covers................... 3 - 2

Main motor unit................................ 3 - 6

Feed unit.......................................... 3 - 8

Needle threading mechanism........ 3 - 19

Pattern selecting mechanism ........ 3 - 21

Bobbin winder, Upper shaft,

Needle-Presser module................. 3 - 23

Assembly Bobbin winder, Upper shaft,

Needle-Presser module................. 3 - 30

Pattern selecting mechanism ........ 3 - 38

Needle threading mechanism........ 3 - 41

Feed unit........................................ 3 - 43

Main motor unit.............................. 3 - 55

Main frame and Covers................. 3 - 57

3 - 1

Page 60

Application of

f

Main frame and Covers

Disassembly

Main frame and Covers location diagram

Disassembly

Application o

Disassembly

Application of

3 - 2

Page 61

Application of

f

Main frame and Covers

Disassembly

1 Disassembly of Face plate assy

1. Remove the screw (taptite, bind B M3X1 0) to remove the face plate cutter holder and the NT lower

thread cutter from the face plate assy.

Taptite, Bind B M3X10

Face plate assy

NT lower thread cutter

Face plate cutter holder

Disassembly

Application o

Taptite, bind B M3X10

Disassembly

Application of

3 - 3

Page 62

Application of

f

Main frame and Covers

Disassembly

2 Disassembly of Rear cover assy

1. Remove the spool pin from the rear cover while pulling the spool pin spring.

2. Remove the spool pin spring from the rear cover.

3. Remove the spool pin stand from the rear cover.

4. Remove the screw (taptite, pan P (S/P W) 3X12) to remove the bobbin presser from the rear cover.

5. Remove the screw (taptite, cup P M4X20) to re mo ve the threa d gu id e ass y fro m th e re ar cover.

Spool pin

Taptite, pan P (S/P W) 3X12

Disassembly

Application o

Spool pin spring

Spool pin stand

Rear cover

Bobbin presser

Positioning groove

Spool pin spring

Thread guide assy

Taptite, cup P M4X20

Disassembly

Application of

Taptite, Pan P (S/P W) 3X12

Taptite, Cup P M4X20

3 - 4

Page 63

Application of

f

Main frame and Covers

Disassembly

3 Disassembly of Base plate L/R

1. Remove the base rubber A from the base plate L.

2. Remove the adjusting screw assy from the base plate L.

3. Remove the two base rubbers A from the base plate R.

Base plate R

Base plate L

Disassembly

Application o

Base rubber A

Base rubbers A

Adjusting screw assy

Disassembly

Application of

3 - 5

Page 64

Application of

f

Main motor unit

Disassembly

Main motor unit location diagram

Disassembly

Application o

Disassembly

Application of

3 - 6

Page 65

Application of

f

Main motor unit

Disassembly

1 Disassembly of Motor 3P supply assy

1. Remove the retaining ring E3 to remove the frange and motor T-pulley from the shaft of motor 3P

supply assy.

Disassembly

Application o

Motor 3P supply assy

Shaft

Motor T-pulley

Frange

Retaining ring E3

Disassembly

Application of

3 - 7

Page 66

Application of

f

Feed unit

Disassembly

Feed unit location diagram

Disassembly

Application o

Disassembly

Application of

3 - 8

Page 67

Application of

f

Feed unit

Disassembly

1 Disassembly of Tension pulley assy

1. Remove the retaining ring E3 to remove the motor tension pulley assy and the spring (XF3404) from

the shaft of tension pulley holder B assy.

2. Remove the screw (screw, pan (S/P washer) M4X8) to remove the M tension pulley stopper from the

tension pulley holder B assy.

3. Remove the screw (screw, pan (S/P washer) M4X8) to remove the tension pulley sub assy from the

tension pulley holder B assy.

Spring (XF3404)

Tension pulley sub assy

Shaft

Disassembly

Application o

Tension pulley holder B assy

Screw, Pan (S/P washer) M4X8

M tension pulley stopper

Screw, pan (S/P washer) M4X8

Spring (XF3404)

Motor tension pulley assy

Boss

Retaining ring E3

Disassembly

Application of

3 - 9

Page 68

Application of

f

Feed unit

Disassembly

2 Disassembly of Lower shaft B assy

1. Remove the lower shaft bushing from the lower shaft B sub assy.

2. Remove the retaining ring E6 to remove the timing pulley D from the lower shaft B sub assy.

Retaining ring E6

Disassembly

Application o

Lower shaft bushing

Lower shaft B sub assy

Timing pulley D

Disassembly

Application of

3 - 10

Page 69

Application of

f

Feed unit

Disassembly

3 Disassembly of Feed module

1. Remove the two screws (screw needle plate) to remove the needle plate B from the need le plate holder

assy.

2. Remove the two screws (screw, pan (P washer) M2.6X6) to remove the needle p late A fro m the nee dle

plate B.

3. Remove the four screws (taptite, pan P (S/P W) 3X12) to remove the needle plate holder assy from the

feed holder.

4. Remove the screw (screw, bind M3X3), and remove the spring plate and the spring assist plate from

the needle plate holder.

5. Remove the inner rotary hook assy from the outer rotary hook assy.

6. Remove the sheet from the feed adjuster holder.

Disassembly

Application o

Screw needle plate

Needle plate A

Screw, pan

(P washer)

M2.6X6

Taptite, pan P (S/P W) 3X12

Screw needle plate

Needle plate B

Spring plate

Needle plate holder

Spring assist plate

Inner rotary hook assy

Screw, bind

M3X3

Sheet

Feed

adjuster

holder

Disassembly

Application of

Screw, Pan (P washer) M2.6X6

Taptite, Pan P (S/P W) 3X12

Screw, Bind M3X3

Feed holder

Pins

Outer rotary hook assy

3 - 11

Page 70

Application of

f

Feed unit

Disassembly

7. Remove the two screws (bolt, socket M3X5) to remove the feed dog from the feed stand.

8. Release the four hooks to remove the two feed arm A pins. And remove the feed stand from the feed

arm A sub assy.

Bolt, Socket M3X5

Bolt, socket M3X5

Hex wrench 2.5 mm

Disassembly

Application o

Feed dog

Hooks

Feed arm B assy

Feed stand

Hooks

Feed arm A pin

Disassembly

Application of

Feed arm A pin

Feed arm A sub assy

3 - 12

Page 71

Application of

f

Feed unit

Disassembly

9. Remove the two screws (screw, bind M3X3) to remove the vertical feed spring plate from the feed

stand.

10.Turn the feed stand spring cap 90 degrees in the direction of th e arrow to align the tab “B” of feed stand

spring cap with the notch part of feed stand, and remove it from the feed stand.

11.Remove the feed stand spring (XF3457) from the vertical adjuster screw. And remove the vertical

adjuster screw from the feed stand.

Screw, Bind M3X3

Feed stand spring (XF3457)

Disassembly

Application o

Vertical feed spring plate

Feed stand spring

(XF3457)

Feed stand spring cap

Notch part

Tab A

Feed stand

90°

Tab B

Feed

stand

Disassembly

Application of

Screw, bind M3X3

Vertical adjuster screw

3 - 13

Page 72

Application of

f

Feed unit

Disassembly

12.Remove the two screws (taptite, pan P (S/P W) 3X12) to remove the feed adjuster holder fr om the feed

holder.

13.Pull out the feed adjuster and the feed adjuster spring (XF5127) from the feed a djuster holde r as shown

illustration below.

Taptite, Pan P (S/P W) 3X12

Disassembly

Application o

Groove

Feed adjuster spring (XF5127)

Feed adjuster

Shaft

Taptite, pan P (S/P W) 3X12

Feed adjuster holder

Groove

Feed holder

Tab

Feed adjuster

Tab

Groove

Disassembly

Application of

Feed arm B assy

Feed adjuster spring (XF5127)

3 - 14

Page 73

Application of

f

Feed unit

Disassembly

14.Remove the two screws (taptite, pan P (S/P W) 3X12) to remove the two horizontal feed shaft pressers

from the feed holder. And remove the horizontal feed shaft of feed arm A sub assy from the feed holder.

Taptite, Pan P (S/P W) 3X12

Disassembly

Application o

Taptite, pan P (S/P W) 3X12

Horizontal feed shaft presser

Feed arm A sub assy

Horizontal feed shaft presser

Horizontal feed shaft

Disassembly

Application of

Feed holder

3 - 15

Page 74

Application of

f

Feed unit

Disassembly

15.Release the two hooks to pull out the feed arm B assy from the feed arm A sub assy. And remove the

screw (taptite, cup B M4X10) to remove the feed supporting plate from the feed arm B assy.

16.Remove the retaining ring E3 from the horizontal feed shaft, and pull out the horizontal feed shaft to

remove the horizontal feed shaft washer, the horizontal feed shaft spring (XF3451), the two polyester

sliders from the feed arm A sub assy. And remove the retaining ring E3 from the horizontal feed shaft.

Taptite, Cup B M4X10

Disassembly

Application o

Hooks

Taptite, cup B M4X10

Feed arm A sub assy

Groove B

Horizontal feed shaft

Horizontal feed shaft washer

Retaining ring E3

Feed arm B assy

Feed supporting plate

Groove A

Retaining ring E3

Polyester sliders

Horizontal feed shaft spring (XF3451)

Horizontal feed shaft spring (XF3451)

Disassembly

Application of

3 - 16

Page 75

Application of

f

Feed unit

Disassembly

17.Remove the screw (set screw, socket (CP) M4X6) from the shaft supporter. And pull out the outer

rotary hook shaft to remove the washer, the magnet, the washer, the outer rotary hook assy and the

washer,thrust from the shaft supporter.

18.Remove the two screws (taptite, pan P (S/P W) 3X12) to remove the shaft supporter from the feed

holder.

Set Screw, Socket (CP) M4X6

Disassembly

Application o

Outer rotary hook shaft

Magnet

Washer

Outer rotary hook assy

Taptite, pan P (S/P W) 3X12

Shaft supporter

Washer

Wahser,thrust

Hex wrench 2.0 mm

Taptite, Pan P (S/P W) 3X12

Disassembly

Application of

Feed holder

Set screw, socket (CP) M4X6

3 - 17

Page 76

Application of

f

Disassembly

19.Remove the two screws (taptite, pan P (S/P W) 3X12) to remove the bushing presser from the feed

20.Remove the retaining ring E6 to pull out the washer,thrust, the lower shaft bushing, the lower shaft

21.Release the two h ooks to remove the ve rtical feed shaft from the feed holder. And pull out the vertical

Retaining ring E6

Disassembly

Application o

Feed unit

holder. And remove the lower shaft A sub assy from the feed holder.

washer and the lower shaft spring (XF3479) from the lower shaft A sub assy. And remove the two

screws (set screw, socket (FT) M5X5) to remov e the fixed joint from the lower shaft A sub assy.

lever from the vertical feed shaft.

Taptite, Pan P (S/P W) 3X12

Washer,thrust

Lower shaft washer

Lower shaft bushing

Lower shaft spring

(XF3479)

Taptite, pan P (S/P W) 3X12

Bushing presser

Lower shaft A sub assy

Set Screw, Socket (FT) M5X5

Hex wrench 2.5 mm

Lower shaft spring (XF3479)

Disassembly

Application of

Feed holder

Fixed joint

Vertical feed shaft

Hooks

Set screw, socket (FT) M5X5

Vertical lever

3 - 18

Page 77

Application of

f

Needle threading mechanism

Disassembly

Needle threading mechanism location diagram

Disassembly

Application o

Disassembly

Application of

3 - 19

Page 78

Application of

f

Needle threading mechanism

Disassembly

1 Disassembly of Thread tension dial assembly

1. Release the hook to turn the thread tension stand in the direction of the arrow while pulling the hook,

and then align the three tabs of thread tension stand with the three notch parts of tension control hold er

assy, and remove it from the tension control holder assy.

2. Remove the thread tension label from the tension control knob. And remove the screw (taptite, bind B

M3X10) to remove the tension control knob from the thread tension stand. And remove the tension

control stud to remove the tension control nut and the tension spring (X55630) from the thread tension

stand. And pull out the tension disc plate, the two tension discs, the th read tension d isc presser and the

spring (X55821) from the thread tension stand.

3. Remove the retaining ring E4 to remove the upper tension control releaser from the shaft on tension

control holder assy.

Tension control nut

Disassembly

Application o

Upper tension

control releaser

Lock

Notch part

Tension spring

(X55630)

Tab

Tab

Retaining ring E4

Thread tension stand

Notch part

Notch part

Thread tension stand

Tension control holder assy

Hook

Straight

line part

Hook part

Tab

Spring (X55821)

Thread tension disc presser

Notch part

Tension discs

Tension disc plate

Taptite, Bind B M3X10

Tension spring (X55630)

Spring (X55821)

Tension control stud

Taptite, bind B M3X10

Disassembly

Application of

Tension control knob

Thread tension label

3 - 20

Page 79

Application of

f

Pattern selecting mechanism

Disassembly

Pattern selecting mechanism location diagram

Disassembly

Application o

Disassembly

Application of

3 - 21

Page 80

Application of

f

Pattern selecting mechanism

Disassembly

1 Disassembly of Pattern selecting unit assy

1. Remove the reverse sewing button from the feed regulator plate B.

2. Remove the retaining ring E3 to remove the washer plain M4 from the shaft A of pattern selecting unit

assy. And remove the retaining ring E5 from the shaft B of pattern selecting unit assy to remove the

feed regulator plate B and the feed regulator plate A assy from the pattern selecting unit assy. And

remove the nut 4 from the feed adjusting screw to remove the feed adjusting screw from the feed

regulator plate B.

Pattern selecting unit assy

Disassembly

Application o

Shaft A

Feed regulator plate A assy

Feed regulator plate B

Retaining ring E5

Shaft B

Feed adjusting screw

Nut 4

Washer plain M4

Retaining ring E3

Disassembly

Application of

3 - 22

Reverse sewing button

Page 81

Application of

f

Bobbin winder, Upper shaft, Needle-Presser module

Disassembly

Bobbin winder, Upper shaft, Needle-Presser module location diagram

Disassembly

Application o

Disassembly

Application of

3 - 23

Page 82

Application of

f

Bobbin winder, Upper shaft, Needle-Presser module

Disassembly

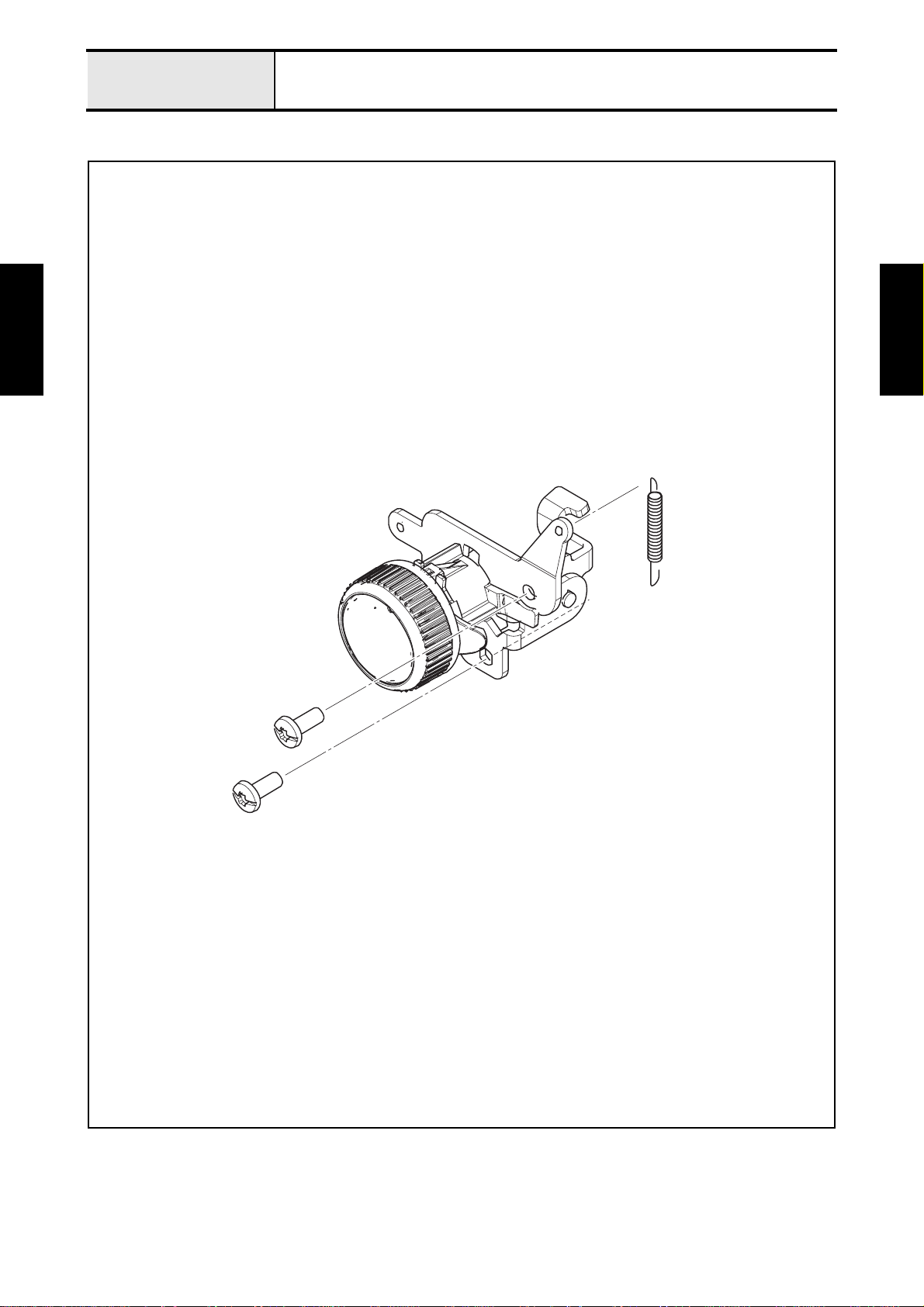

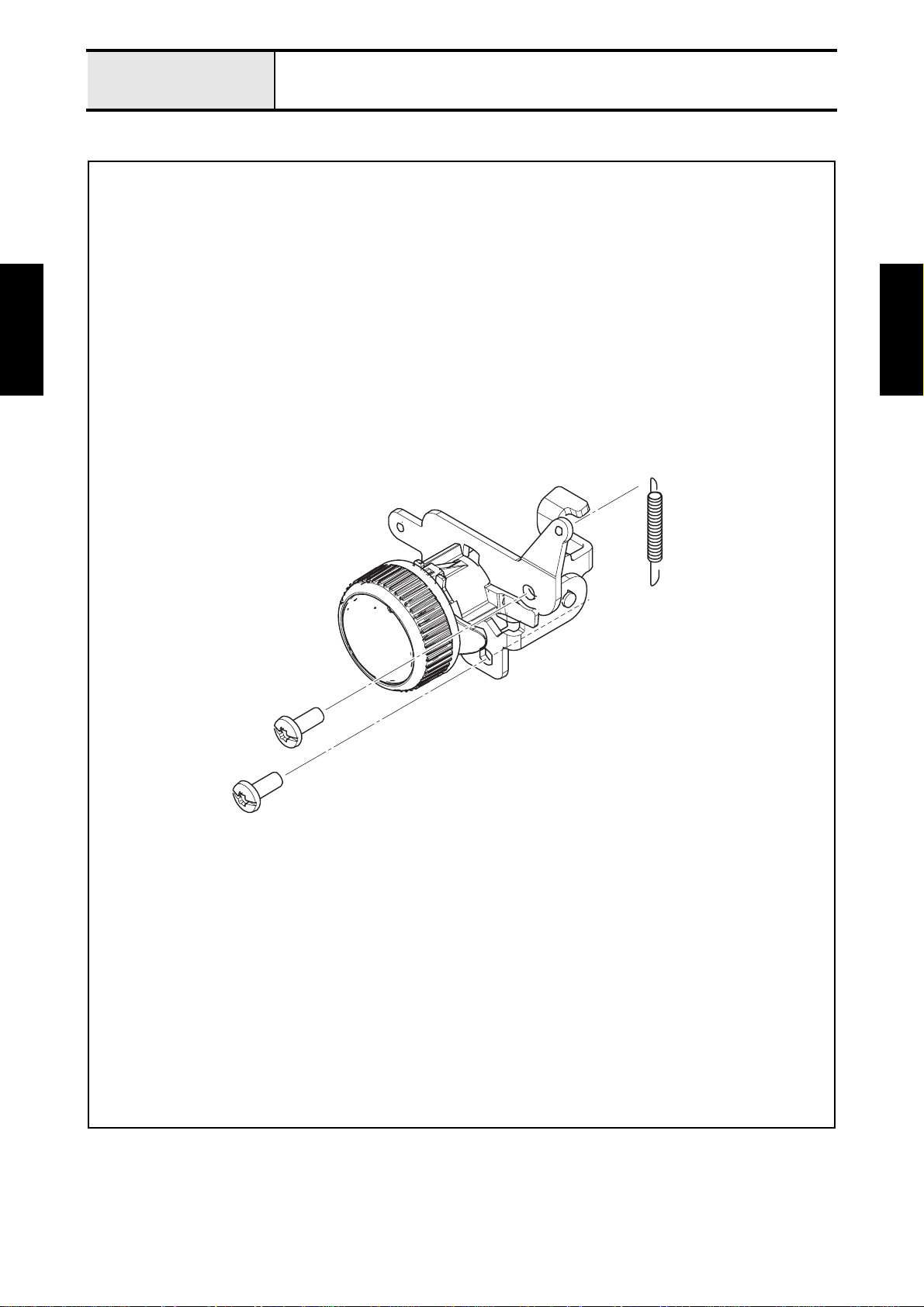

1 Disassembly of Bobbin winder assy

1. Remove the bobbin winder assy from the bobbin winder spring plate.

2. Remove the bobbin winder rubber band from the bobbin winder assy.

Bobbin winder assy

Bobbin winder spring plate

Disassembly

Application o

Bobbin winder rubber band

Disassembly

Application of

3 - 24

Page 83

Application of

f

Bobbin winder, Upper shaft, Needle-Presser module

Disassembly

2 Disassembly of Upper shaft assy

1. Remove the pulley from the upper shaft supply assy.

Pulley

Upper shaft supply assy

Disassembly

Application o

Disassembly

Application of

3 - 25

Page 84

Application of

f

Bobbin winder, Upper shaft, Needle-Presser module

Disassembly

3 Disassembly of Needle-presser module

1. Remove the screw (tightening scr ew 3.57) to rem ove the presser foot holder from the presser bar sub

assy.

2. Remove the retaining ring E4 to remove the washer, the spring (XF3413) and the thread take-up lever

link from the shaft.

3. Remove the thread take-up lever and the needle bar crank rod assy from the needle bar block shaft of

needle bar crank rod assy.

Tightening screw 3.57

Shaft

Spring (XF3413)

Retaining ring E4

Disassembly

Application o

Tightening screw 3.57

Presser foot holder

Needle bar

block shaft

Thread take-up lever

Presser bar sub assy

Needle bar

crank rod assy

Thread take-up lever li nk

Spring (XF3413)

Washer

Disassembly

Application of

3 - 26

Page 85

Application of

f

Bobbin winder, Upper shaft, Needle-Presser module

Disassembly

4. Remove the screw (screw, flat SM3.57-40X7 L) to remove the thread take-up lever from the needle bar

crank rod assy.

*Key point

• The screw is reverse threaded.

Needle bar crank rod assy

Thread take-up lever

Disassembly

Application o

5. Remove the screw (set screw, socket (FT) M4X4), and then pull out the needle bar assy N from the

6. Remove the needle clamp screw from the needle block of needle bar assy N.

Screw, flat SM3.57-40X7 L

base holder assy to remove the needle bar block of needle bar crank rod assy.

Set screw, socket (FT) M4X4

Base holder assy

Needle bar block

Needle bar assy N

Disassembly

Application of

Needle block

Set Screw, Socket (FT) M4X4

Hex wrench 2.0 mm

Needle clamp screw

3 - 27

Page 86

Application of

f

Bobbin winder, Upper shaft, Needle-Presser module

Disassembly

7. Remove the screw (screw, pan (S/P wa sher) M3X6) to remove the spring plate fr om the base holder

assy.

8. Remove the nut 2 M3 and needle bar supporter presser to remove the needle bar supporter assy from

the base holder assy.

9. Remove the needle bar supporter spring (XF3423) from the base holder assy.

10.Remove the screw (screw 3X10) to remove the needle bar supporter guide from the base holder assy.

11.Remove the screw (screw 3X10) to remove the shaft from the base holder assy.

Screw, Pan (S/P washer) M3X6

Screw 3X10

Hex wrench 2.5 mm

Disassembly

Application o

Base holder assy

Spring plate

Screw, pan (S/P washer) M3X6

Shaft

Screw 3X10

Needle bar supporter spring

(XF3423)

Needle bar supporter presser

Needle bar supporter assy

Nut 2 M3

Disassembly

Application of

Needle bar supporter guide

Screw 3X10

Needle bar supporter spring (XF3423)

3 - 28

Page 87

Application of

f

Bobbin winder, Upper shaft, Needle-Presser module

Disassembly

12.Remove the two screws (screw, pan (S/P washer) M3X6), and then pull out the presser bar guide and

the spring (XC4900) from the presser bar sub assy.

13.Slide the presser bar sub assy until the presser bar clamp pin align with the notch part, and turn it to the

direction of the arrow 90 degrees. And pull out the presser bar sub assy from the base holder assy.

14.Release the two hooks to pull out the presser foot lifter from the base holder assy.

Screw, Pan (S/P washer) M3X6

Disassembly

Application o

Spring (XC4900)

Presser bar sub assy

Spring (XC4900)

Disassembly

Application of

Screw, pan (S/P washer) M3X6

Presser bar guide

Hooks

Notch part

Presser bar clamp pin

Base holder assy

Shaft

Presser foot lifter

3 - 29

Page 88

Application of

f

Bobbin winder, Upper shaft, Needle-Presser module

Assembly

Bobbin winder, Upper shaft, Needle-Presser module location diagram

Assembly

Application o

Assembly

Application of

3 - 30

Page 89

Application of

f

Bobbin winder, Upper shaft, Needle-Presser module

Assembly

1 Lubrication

Lubrication point Lubricating oil type Quantity of lubrication

1 Base holder assy 1 place EPNOC AP (N) 0 Small amount

2 Presser foot lifter 2 places EPNOC AP (N) 0 Rice-grain size

3 Presser bar sub assy 1 place Oiler Apply liberally (tip 20mm)

4 Presser bar clamp pin 1 place EPNOC AP (N) 0 Rice-grain size

5 Needle bar supporter assy 2 places EPNOC AP (N) 0 Rice-grain size

6 Needle bar supporter presser 1 place EPNOC AP (N) 0 Rice-grain size

7 Needle bar assy N 1 place Oiler Apply liberally (tip 20mm)

8 Thread take-up lever 1 place EPNOC AP (N) 0 Rice-grain size

9

Needle bar crank 2 places

10 EPNOC AP (N) 0 Small amount

11 Needle bar block shaft 1 place MOLYKOTE M DISPERSION* 1 to 2 drops

12 Shaft 1 place EPNOC AP (N) 0 Rice-grain size

13 Lower shaft bushing 1 place FBK OIL RO 100 1 to 2 drops

* Mix the MOLYKOTE M DISPERSION in the following rations. MOLYKOTE M DISPERSION 10% : OILER 90%

EPNOC AP (N) 0 Rice-grain size

Assembly

Application o

Presser bar

clamp pin

Base holder assy

4

Shaft

3

1

2

12

8

2

Presser foot lifter

9

10

Thread take-up lever

5

Needle bar crank

Assembly

Application of

11

Needle bar block shaft

6

Needle bar

supporter

presser

7

Presser bar sub assy

5

Needle bar

13

Lower shaft bushing

of upper shaft assy

13

supporter assy

Needle bar assy N

3 - 31

Page 90

Application of

f

Bobbin winder, Upper shaft, Needle-Presser module

Assembly

2 Assembly of Needle-presser module

1. Set the presser foot lifter to the shaft of base holder assy, and secure it with the two hooks.

2. Insert the presser bar sub assy into the base holder assy, and slide it to the position where the presser

bar clamp pin matches the notch part. And turn the presser bar sub assy to th e directio n of the arrow 90

degrees, and align the pin with the groove. And slide the presser bar sub assy to the direction of the

arrow.

3. Set the spring (XC4900) to the presser bar sub assy. And set the presser bar guide to the base holder

assy and the presser bar sub assy, and secure it with the two screws (screw, pan (S/P washer) M3X6).

Spring (XC4900)

Assembly

Application o

Screw, Pan (S/P washer) M3X6

Spring (XC4900)

Assembly

Application of

Presser bar clamp

Presser bar sub assy

Groove

Screw, pan (S/P washer) M3X6

Presser bar guide

Hooks

Notch part

Presser bar clamp

Presser bar clamp pin

Base holder assy

Shaft

Presser foot lifter

3 - 32

Page 91

Application of

f

Bobbin winder, Upper shaft, Needle-Presser module

Assembly

4. Set the shaft to the base holder assy, and secure it with the screw (screw 3X10).

5. Align the boss of base holder assy with the positioning hole of needle bar supporter guide, and set the

needle bar supporter guide to the base holder assy, and tighten the screw (screw 3X10) temporarily.

*Key point

• Fully tighten the screw after performing “4 - 11 Needle interference left/right”.

6. Set the needle bar supporter spring (XF3423) to the shaft of base holder assy.

7. Set the pin of needle bar supporter assy to the positioning hole on needle bar supporter guide, and set

the needle bar supporter assy to the shaft of base holder assy. And set the nut 2 M3 to the needle bar

supporter presser, and tighten them to the shaft of base holder assy.

8. Set the spring plate to the base holder assy, and secure it with the screw (screw, pan (S/P washer)

M3X6).

Screw, Pan (S/P washer) M3X6

Screw 3X10

Assembly

Application o

Hex wrench 2.5 mm

Base holder assy

Spring plate

Screw, pan (S/P washer) M3X6

Boss

Pin

Shaft

Screw 3X10

Shaft

Needle bar supporter spring (XF3423)

Needle bar supporter presser

Nut 2 M3

Needle bar supporter assy

Assembly

Application of

Positioning hole

Needle bar supporter guide

Screw 3X10

Needle bar supporter spring (XF3423)

3 - 33

Page 92

Application of

f

Bobbin winder, Upper shaft, Needle-Presser module

Assembly

9. Tighten the needle clamp screw to the needle block of needle bar assy N.

10.Insert the needle bar assy N into the bottom side hole of base holder assy, the needle bar block of

needle bar crank rod assy and the upper side hole of base holder assy, and tighten the screw (set

screw, socket (FT) M4X4) temporarily.

*Key point

• Fully tighten the screw after performing “4 - 14 Needle bar height”.

Assembly

Application o

Set Screw, Socket (FT) M4X4

Hex wrench 2.0 mm

Base holder assy

Set screw, socket (FT) M4X4

Needle bar block

Needle bar assy N

Assembly

Application of

Needle block

Needle clamp screw

11.Set the thread take-up lever to the needle bar crank rod assy, and secure it with the screw (screw, f lat

SM3.57-40X7 L).

*Key point

• The screw is reverse threaded.

Needle bar crank rod assy

Thread take-up lever

Screw, flat SM3.57-40X7 L

3 - 34

Page 93

Application of

f

Bobbin winder, Upper shaft, Needle-Presser module

Assembly

12.Set the thread take-up lever and the needle bar crank rod assy to the needle bar block shaft of needle

bar crank rod assy.

13.Set the thread take-up lever link to the shaft and the shaft of thread take-up lever. And set the spring

(XF3413) and the washer, and attach the retaining ring E4.

14.Set the presser foot holder to the pres ser bar sub assy, and secure it with the screw (tightening screw

3.57).

Tightening screw 3.57

Shaft

Spring (XF3413)