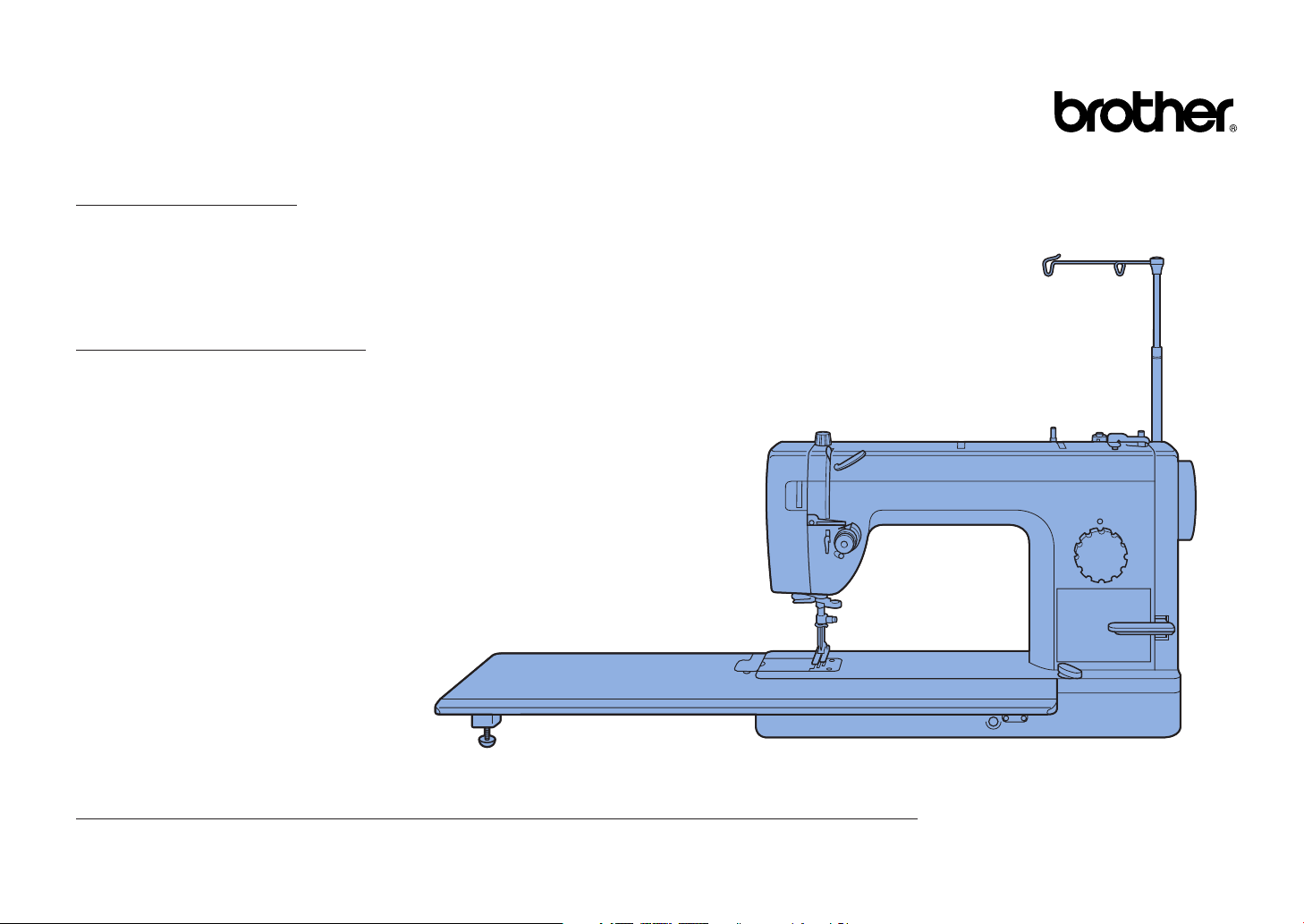

Page 1

Operation Manual

Sewing machine

Product Code: 884-639

Manuel d’instructions

Machine à coudre

Référence du produit: 884-639

Be sure to read this document before using the machine.

We recommend that you keep this document nearby for future reference.

Veillez à lire ce document avant d'utiliser la machine.

Nous vous conseillons de conserver ce document à portée de la main pour vous y référer ultérieurement.

Page 2

Page 3

IMPORTANT SAFETY INSTRUCTIONS

Read all instructions before using.

When using a sewing machine, basic safety precautions should always be taken,

including the following:

DANGER – To reduce the risk of electric shock:

The sewing machine should never be left unattended while plugged in. Always unplug the sewing machine from the electrical outlet immediately after using and before ●

cleaning.

Always unplug before changing the light bulb. Replace bulb with same type rated 120V 15 watts for 120V model or rated 240V 15 watts for 220-240V model. ●

WARNING – To reduce the risk of burns, fire, electric shock, or injury:

Do not allow this sewing machine to be used as a toy. Close attention is necessary when the sewing machine is used by or near children. ●

Use this sewing machine only for its intended use as described in this manual. Use only accessories recommended by the manufacturer as contained in this manual. ●

Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or dropped into water. Return the ●

sewing machine to the nearest authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the sewing machine and foot control free from the accumulation of lint, ●

dust, and loose cloth.

Never drop or insert any object into any opening. ●

Do not use outdoors. ●

Do not operate where aerosol (spray) products are being used or where oxygen is being administered. ●

To disconnect, turn the main switch to the symbol “O” position which represents off, then remove plug from outlet. ●

Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord. ●

Keep fingers away from all moving parts. Special care is required around the sewing machine needle. ●

Always use the proper needle plate. The wrong plate can cause the needle to break. ●

Do not use bent needles. ●

Do not pull or push fabric while stitching. It may deflect the needle causing it to break. ●

Turn off power to the machine by flipping the ON/OFF switch to the symbol “O” before making any adjustments in the needle area, such as threading the needle, ●

changing the needle, threading the bobbin or changing the presser foot etc.

Always unplug the sewing machine from the electrical outlet when removing covers, lubricating, or when making any other user servicing adjustments mentioned in ●

the instruction manual.

This sewing machine is not intended for use by young children or infirm persons without supervision. ●

Young children should be supervised to ensure that they do not play with this sewing machine. ●

CAUTION

For U.S.A. only

This appliance has a polarized plug (one blade wider than the other) to reduce the risk of electric shock, this plug is intended to fit in a polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician to install the proper outlet. Do not modify the plug in any way.

1

Page 4

2

SAVE THESE INSTRUCTIONS

This sewing machine is intended for household use.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety. Children should be supervised to

ensure that they do not play with the appliance.

FOR USERS IN THE UK, EIRE, MALTA

AND CYPRUS ONLY

IMPORTANT

In the event of replacing the plug fuse, use a fuse approved by ASTA to BS 1362, i.e. carrying the ● mark, rating as marked on plug.

Always replace the fuse cover. Never use plugs with the fuse cover omitted. ●

If the available electrical outlet is not suitable for the plug supplied with this equipment, you should contact your authorized dealer to obtain the correct lead. ●

Page 5

3

CONGRATULATIONS ON CHOOSING

A BROTHER SEWING MACHINE

Your machine is one of the finest sewing machines available for home use.

To fully enjoy all the features incorporated into it, we suggest that you study this booklet.

PLEASE READ BEFORE USING YOUR SEWING MACHINE

For safe operation

Be sure to watch the placement of your hands in relation to the needle while sewing. Do not touch moving parts such as the balance wheel, thread take-up or needle ●

while the machine is operating.

Remember to turn off the power switch and unplug the cord when: ●

Operation is completed ●

Replacing or removing the needle or any other parts ●

A power failure occurs during use ●

Maintaining the machine ●

Leaving the machine unattended ●

Do not place anything on the foot controller. ●

Plug the machine directly into the wall outlet. Do not use extension cords. ●

For a longer service life

When storing your sewing machine, avoid direct sunlight and high humidity locations. Do not store the sewing machine beside a space heater, iron, or other hot ●

objects.

Use only neutral soaps or detergents to clean the case. Benzene, thinner, and scouring powders can damage the case and machine, and should never be used. ●

Do not drop or hit the machine. ●

Always consult the operation manual when replacing any accessories, including: the presser feet, needle or other parts to assure correct installation. ●

For repair or adjustment

In the event that a malfunction occurs or adjustment is required, first follow the troubleshooting table in the back of the operation manual to inspect and adjust the

machine yourself. If the problem persists, please consult your nearest authorized Brother service center.

To find out the name and phone number for your authorized Brother service center visit www.brother.com and use our convenient dealer locator.

Page 6

CONTENTS

Accessories ................................................................................. 5

Machine Features ........................................................................ 6

Before You Begin (1) .................................................................... 7

Power Cord and Foot Controller ................................7

Power Switch .............................................................7

Thread Tension Dial ...................................................7

Hand Wheel ............................................................... 7

Stitch Length Regulator .............................................7

Reverse Stitch Lever .................................................7

Presser Foot Lift Lever ..............................................8

Knee Lift ....................................................................8

Presser Foot Pressure Adjustment Dial ....................8

Fabric Extension Table ..............................................8

Before You Begin (2) .................................................................... 9

Thread Cutter Button .................................................9

Needle Stop Position Button......................................9

Light Switch ...............................................................9

Feed Dog Adjustment Knob ......................................9

Changing Needles and Light Bulb ........................................... 10

Changing the Needle ............................................... 10

Changing the Feed Pin ............................................ 10

Changing Light Bulbs ..............................................10

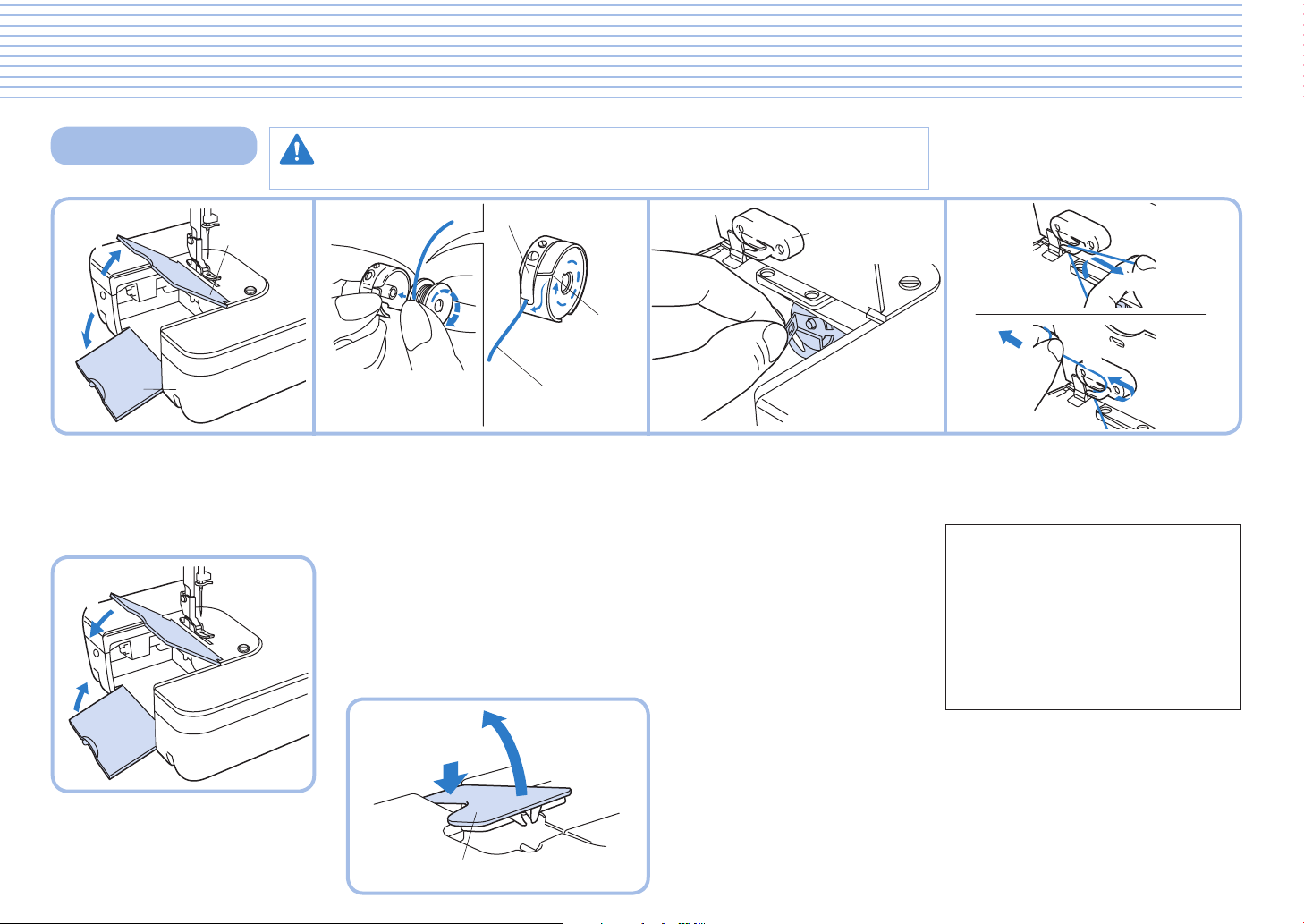

Threading (1) .............................................................................. 11

Bobbin Winding .......................................................11

Bobbin Insertion ......................................................13

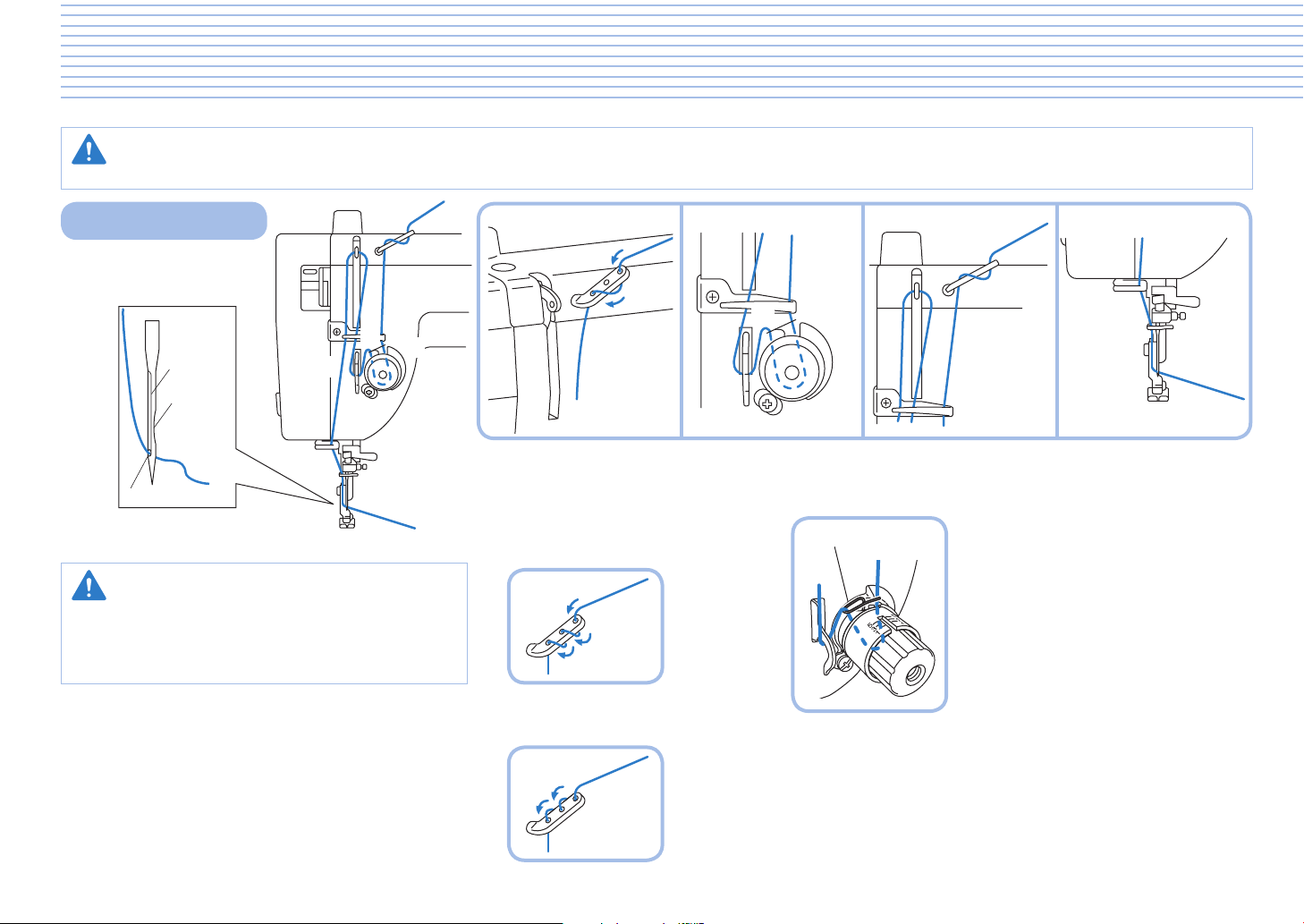

Threading (2) .............................................................................. 14

Upper Threading......................................................14

Using the Automatic Needle Threader ....................15

Using the Spool Net ................................................15

Stitch Samples and Needle Chart ............................................ 16

Stitch Samples ........................................................16

Thread Tension ........................................................16

Changing Presser Feet ............................................................. 17

Changing Presser Feet (Zipper Foot) ...................... 17

Presser Feet ............................................................17

Basic Sewing (1) ........................................................................ 18

Basic Sewing ...........................................................18

Pin Feeding (for hard-to-handle fabrics) ..................18

Pin Feeding Mechanism ..........................................18

Basic Sewing (2) ........................................................................ 19

Rolled Hem Foot .....................................................19

Basic Sewing (3) ........................................................................ 20

Zipper Foot ..............................................................20

Invisible Zipper Foot ................................................21

1/4” Foot ..................................................................21

Quilting Foot ............................................................22

Walking Foot ............................................................22

Fabric Separator (for joining lining to fabric) ..........23

Seam Guide ............................................................23

Caring for Your Machine ............................................................ 24

Cleaning the Machine .............................................. 24

Lubrication Points ....................................................24

Trouble Shooting ....................................................................... 25

Page 7

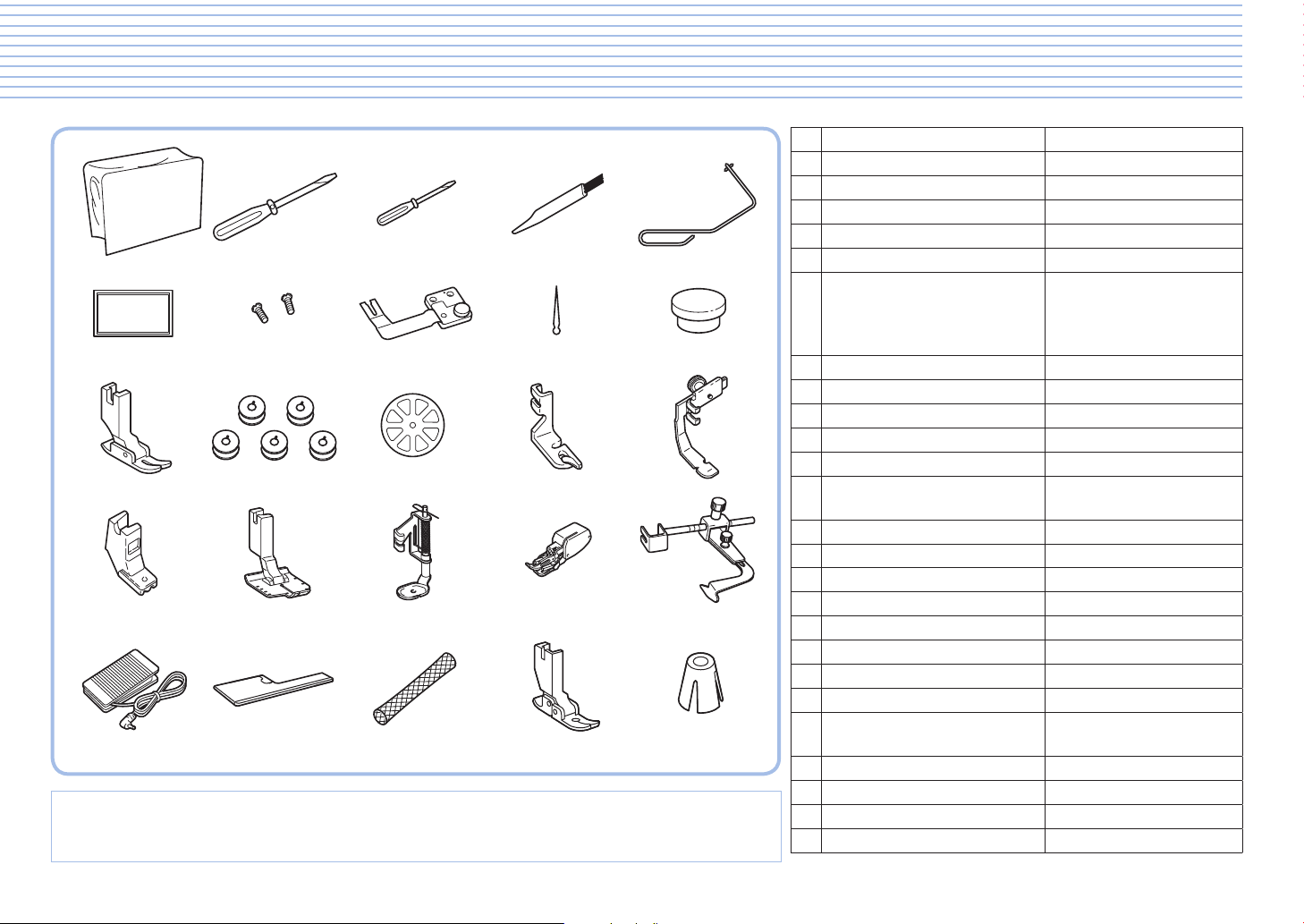

Accessories

1 2 3 4 5

6 7 8 9 10

11 12 13 14 15

16 17 18 19 20

21 22 23 24 25

Note (For U.S.A. only)

Foot controller: Model T

This foot controller is used for sewing machine model DZ1500F.

No. Part Name Part Code

1 Cover XA0917-054

2 Medium Screwdriver XC9541-051

3 Small Screwdriver X55468-051

4 Cleaning Brush X59476-051

5 Knee Lift XA0830-051

6 Needles and Case

(ORGAN HLX5)

1 Size 9, 2 Size 11, 1 Size 14,

1 Size 16, 1 Ballpoint Needle

7 Lining Plate Screw (2) 062670-817

8 Fabric Separator 184720-001

9 Feed Pin 138483-051

10 Feed Pin Changer XC1407-051

11 General Purpose Foot XA1425-001

12 Bobbin (5) SA159 (Americas)

13 Spool Cap XA2111-050

14 Rolled Hem Foot X57138-101

15 Zipper Foot 112797-001

16 Invisible Zipper Foot XC0093-001

17 1/4” Foot XA7258-001

18 Quilting Foot XA7255-301

19 Walking Foot XA7253-001

20 Seam Guide XA7256-001

21 Foot Controller XD0501-151 (EU area)

22 Fabric Extension Table XC3117-051

23 Spool Net XA5523-050

24 Pin Feed Foot (on machine) 136021-001

25 Spool Cushion (on machine) XF2071-001

X80805-151

MBN: XA8284-202(Others)

XC8816-051 (Other areas)

5

Page 8

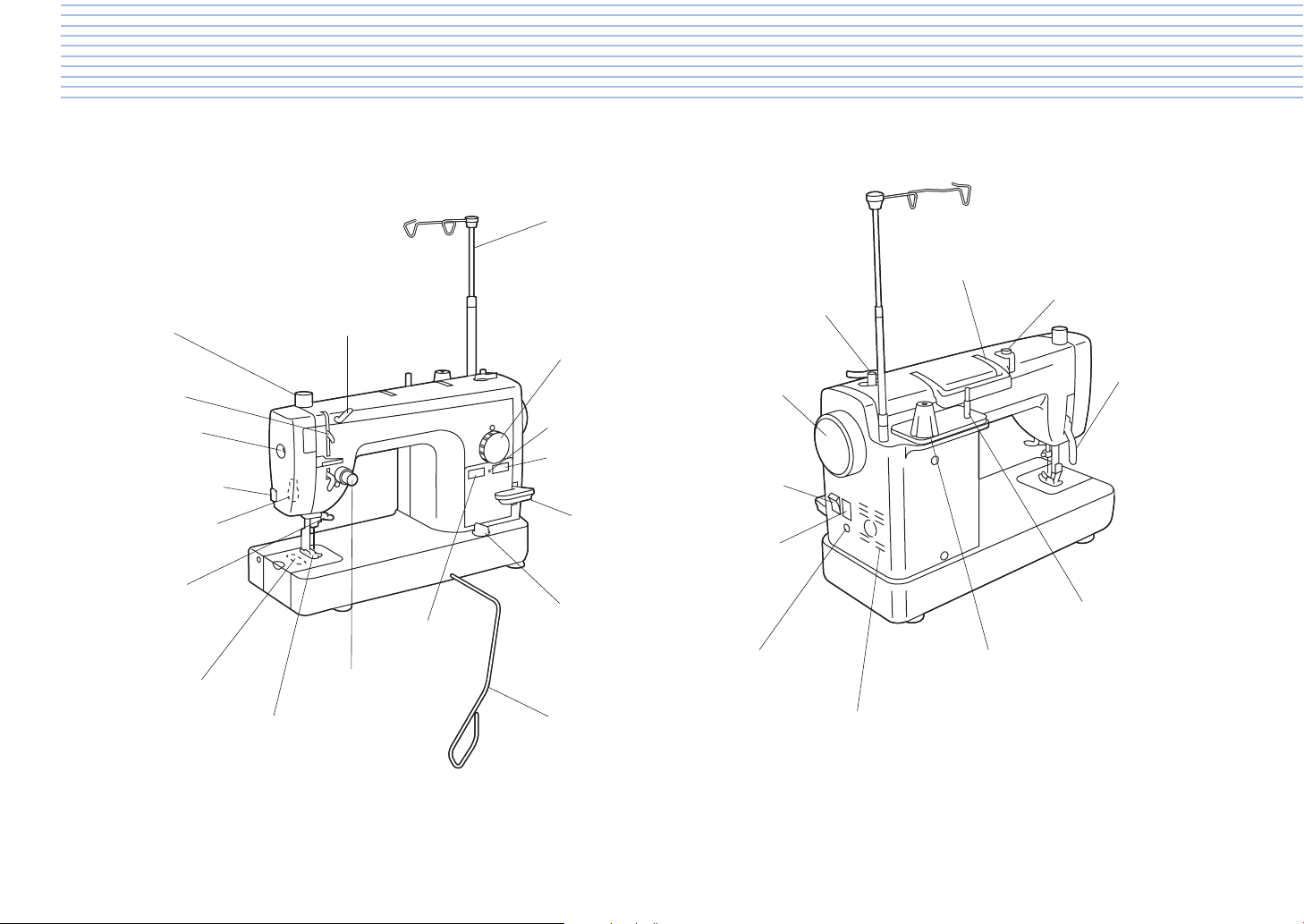

6

Machine Features

Presser Foot Pressure

Adjustment Dial (Page 8)

Three Holed

Thread Guide (Page 14)

Light Switch

(Page 9)

Thread Trimmer

Sewing Area

Light (Page 10)

Feed Dogs

(Page 9 and 18)

Thread Guide Bar

(Page 11)

Stitch Length

Regulator (Page 7)

Needle Stop Position

Button (Page 9)

Reverse Stitch

Lever (Page 7)

Feed Dog Adjustment

Knob (Page 9)

Knee Lift

(Page 8)

Bobbin Winder

(Page 11)

Hand Wheel

(Page 7)

Power Switch

(Page 7)

Foot Controller Jack

(Page 7)

Power Socket

(Page 7)

Spool Cushion

(Page 11)

Spool Pin

(Page 11)

Presser Foot

Lift Lever (Page 8)

Thread Guide for

Bobbin Winding (Page 11)

Handle

Air Vents

Thread Cutter

Button (Page 9)

Thread Tension Dial

(Page 7 and 16)

Indicator Lamp

Automatic Needle

Threader (Page 15)

Quick Bobbin

Thread Device (Page 13)

Thread Take-up Lever

(Page 14)

Page 9

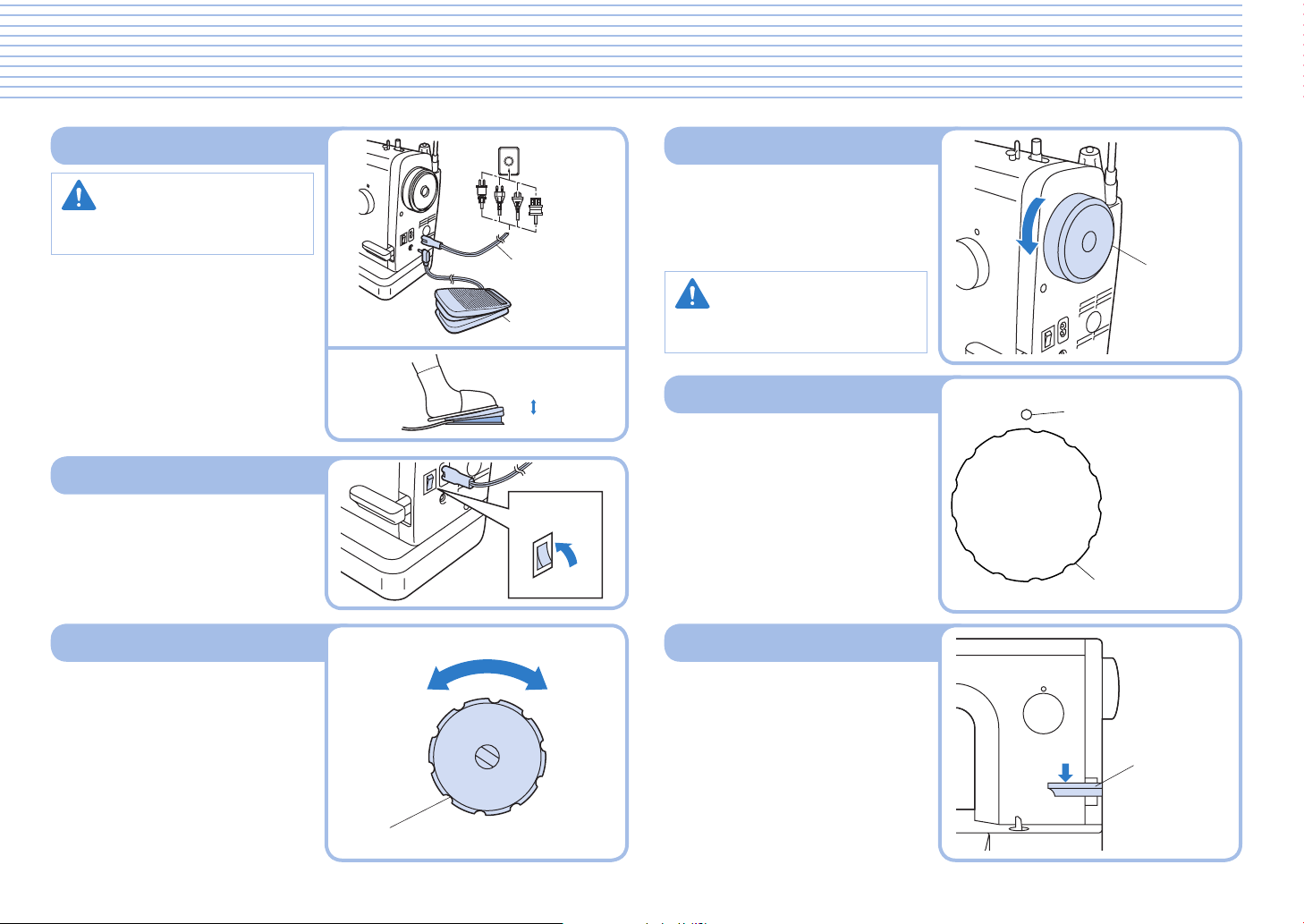

7

Before You Begin (1)

Power Cord

Foot Controller

Power Switch

I

O

Hand Wheel

1

2

3

4

5

6

7

Stitch Length Regulator

Reference Mark

Lower number

= shorter stitches

Higher number

= longer stitches

Stitch Length

Reverse Stitch

Lever

Upper Thread Tension

Loosen Tighten

Tension Block

Slower

Faster

Power Cord and Foot Controller

WARNING

Please use common household

current.

Plug in cord. ●

Plug foot controller into machine. ●

When you press the foot controller

●

down lightly, the machine will run

at a low speed. When you press

harder, the machine’s speed will

increase. When you take your foot

off the foot controller, the machine

will stop.

Power Switch

Flip power switch to “I” position ●

to turn on.

To switch power off, flip switch to ●

“O” position.

Thread Tension Dial

Hand Wheel

Position needle using hand ●

wheel.

Always turn hand wheel towards ✽

you.

CAUTION

Be sure to keep the area under

and around the needle clear.

Stitch Length Regulator

Adjust desired stitch length ●

using stitch regulator dial.

Reverse Stitch Lever

When tighter thread tension is ●

desired, turn the tension dial

to the right. Upper and bobbin

threads will meet on right side of

the fabric.

When looser thread tension is

●

desired, turn tension dial to the

left. Upper and lower threads

will then meet on wrong side of

fabric.

Sewing in reverse is possible ●

when the reverse stitch lever is

in the lowered position.

Make sure to continuously press ✽

the lever to its lowest position

when reverse sewing is desired.

When the feed adjustment dial is

✽

set between 5-7 mm, the reverse

stitch length is always 5 mm.

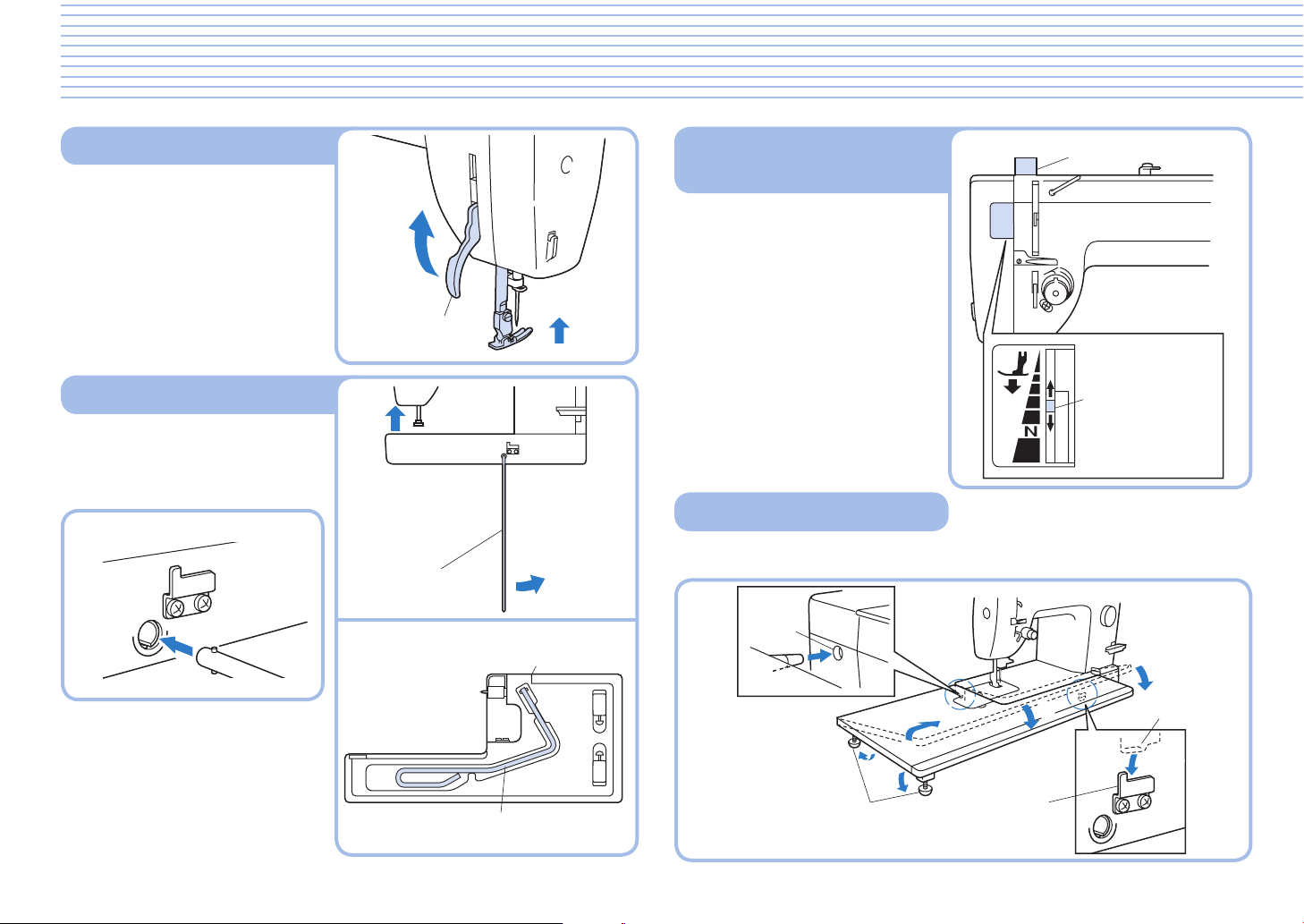

Page 10

8

Presser Foot Lift Lever

Presser Foot

Lift Lever

Knee Lift

Setting up the knee lift.

Presser Foot Pressure Adjustment Dial

Pressure Indicator

Needle

Fabric Extension Table

Knee Lift

Table legs

1

3

2

Stopper

Hook

3

Guide pin

Hole

2

Lowering the presser foot ●

lift lever lowers the sewing

foot down onto the fabric and

engages the thread tension

function.

When working with heavy ✽

fabrics or other fabrics that don’t

slide easily under the foot, raise

the presser foot lever to position

the fabric.

Knee Lift

Using the convenient knee lift ●

to lift and lower the presser foot

easily, leaving both your hands

free.

Presser Foot Pressure

Adjustment Dial

Turning the pressure adjustment ●

dial raises and lowers the

pressure indicator needle as

the amount of pressure on the

presser foot changes.

See also: “Feed Dog Adjustment

Knob” on page 9.

See “Thread Tension” on page ✽

16.

Fabric Extension Table

Lower the adjustable table feet and slide the fabric extension table on to the

●

machine.

Push the knee lift bar all the ✽

way into the socket.

When knee lift is not in use, ✽

it can be stored beneath the

fabric extension table.

Page 11

9

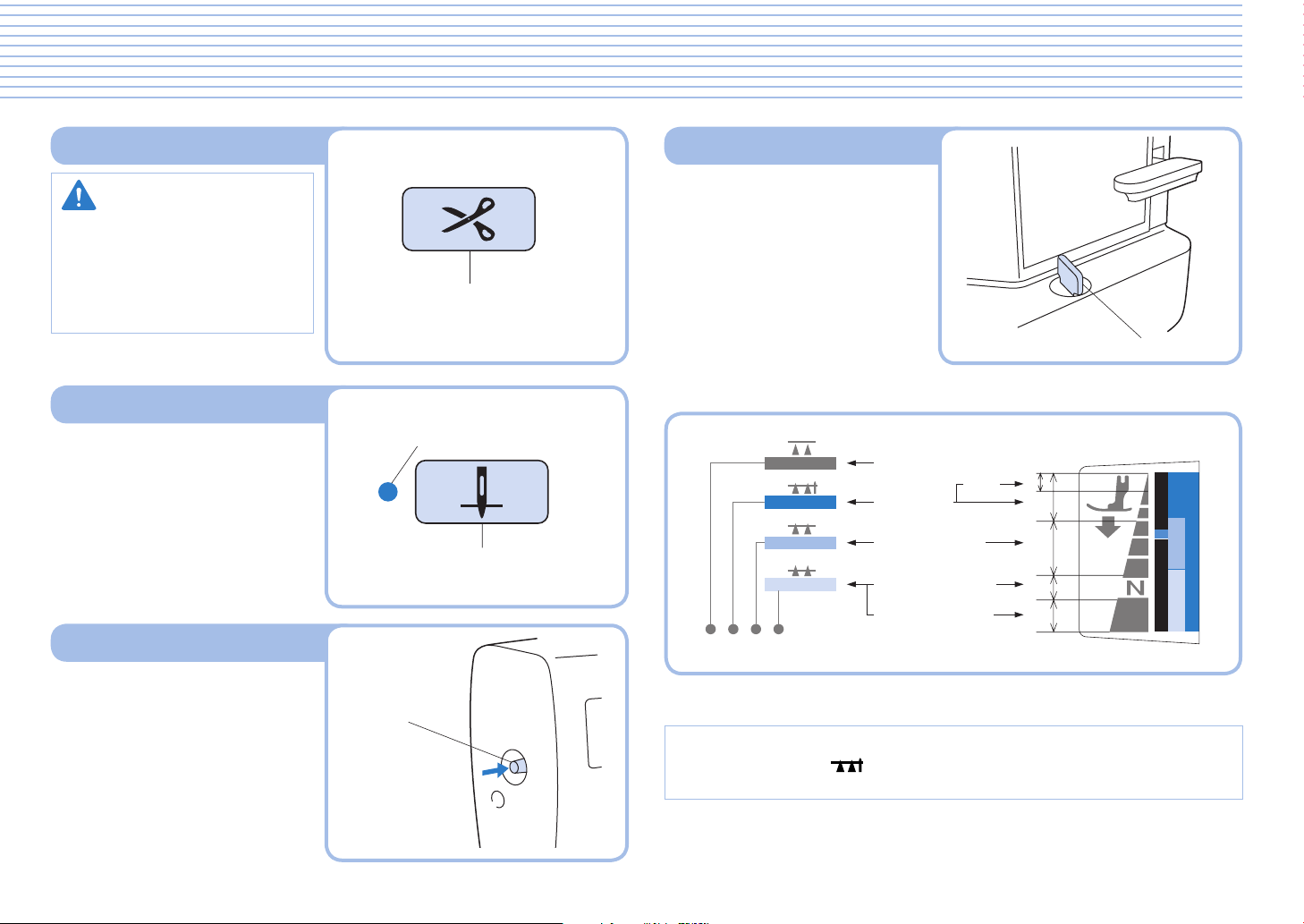

Before You Begin (2)

Thread Cutter Button

Indicator Lamp

Needle Stop Position Button

Light Switch

Feed Dog Adjustment Knob

(Feed Dogs Down)

(Pin Feeding)

Velvet

Lightweight Fabrics

Middleweight Fabrics

Heavyweight Fabrics

Thread Cutter Button

CAUTION

When the machine stops due to

jammed threads and so forth, do

not step on the foot controller,

turn the power off, and moving

the needle with the hand wheel,

check the situation.

The thread cutter trims upper and

●

bobbin threads at the end of seams.

Needle Stop Position Button

When indicator lamp is lit up, the

●

machine will stop sewing with the

needle lowered through the fabric.

When indicator lamp is off, the ●

needle position when sewing

stops, will be random.

If the safety mechanism is activated,

●

for example if the thread becomes

tangled, the red lamp flashes.

Light Switch

Feed Dog Adjustment Knob

Height of feed dogs can be ●

adjusted to coincide with fabric

weights.

Press with the presser lever down. ✽

Foot Pressure and Feed Dog Position

Push light switch to turn the light ●

over the sewing area on and off.

Select one of four feed dog positions according to your needs.

Note

If a setting other than is selected, the pin feed mechanism will not

operate.

Page 12

10

Changing Needles and Light Bulb

Screwdriver

Flat surface

Lay needle on

a flat surface

(such as the needle

plate or a plate

of glass).

The needle should lay

parallel to a surface.

Screwdriver

120V

Light

Bulb

Light

Bulb

230V

Please make sure the power to the machine is turned

off before carrying out the following operations. There

is a chance of injury if the machine accidentally starts

running during this operation.

Changing the Needle

Turn the sewing machine

1

off. Raise needle to highest

position using hand wheel,

and lower presser foot.

Loosen screw with 2

screwdriver, and

remove needle.

Hold the needle with the flat

3

side to the right, and insert

the needle as far as it will go.

Make sure needle is securely

set in the needle chamber by

screwing in tightly.

If the needle is not ✽

adequately inserted or

the screw is loose, this

may break the needle

or cause a breakdown

and the needle

threader will not work.

Check needles on a ✽

flat surface to make

sure they are not bent.

Note

HLX5 needles should be used; however, Schmetz

130/705H may also be used under normal circumstances.

CAUTION

Changing the Feed Pin

Set the feed dogs to “velvet”

1

position. (See page 9.)

Remove needle, presser

2

foot and needle plate.

Lower presser foot and turn

3

hand wheel until feed pin is

in its highest position.

Insert small screwdriver

4

(included) as shown in diagram.

While holding spring 5

with fingertip, lower the

feed pin changer onto

the needle to pick it up.

Attach new feed pin

6

to feed pin changer,

lower and attach while

holding spring with

fingertip.

Remove screwdriver.7

Re-attach needle plate, 8

needle and presser

foot.

CAUTION

Please make sure the power to the machine

is turned off before carrying out the following

operations. The glass plate over the light bulb will be

hot immediately after using the machine, therefore

it is advisable to wait until the light bulb has had a

chance to cool down before changing bulbs.

Changing Light Bulbs

Turn off power.1

Remove screw from 2

head.

Remove bulb housing.3

Unscrew bulb and 4

remove.

Screw in new bulb. 5

Sewing Light:

See page 24.

Re-attach bulb housing 6

and tighten screw.

Page 13

11

b

c

d

a

c

a

b

Spool of Thread

�2

Spool Cushion

Spool Cap

�1

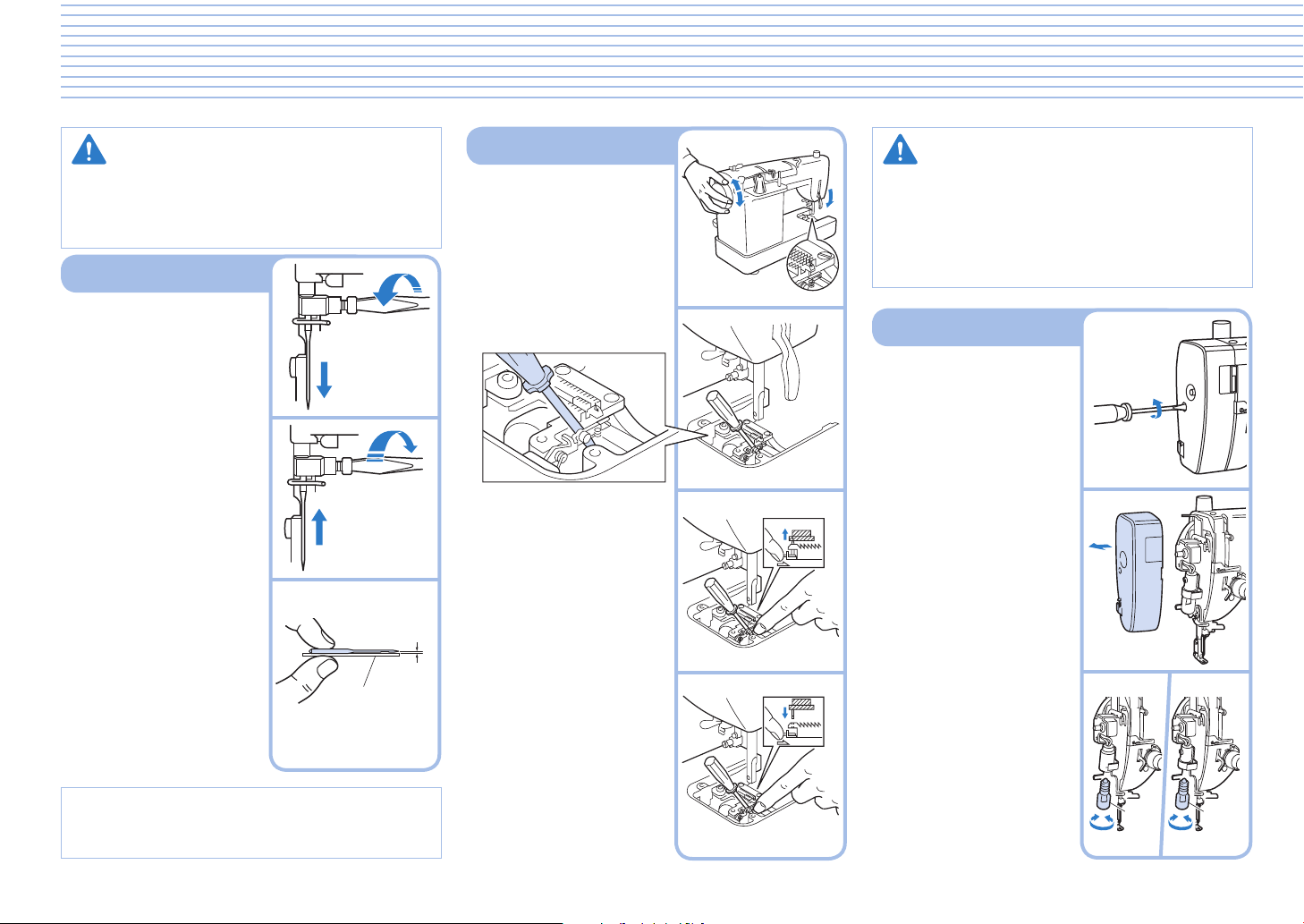

Threading (1)

Bobbin

Bobbin Winder

Shaft

Guide Pin

Thread Notch 1

Thread Notch 2

Bobbin Winding Clutch

Bobbin Winding

CAUTION

Do not move bobbin winding clutch while

machine is running.

Raise the thread guide bar all the way.1

Mount a spool of thread on the spool pin.2

✽1 Use spool cap when using parallel-wound thread.

✽2 Use spool cushion when using cross-wound thread.

5 - 0: See the following illustrations.

Pass the thread through the 3

triangular hole.

Pass thread through bobbin winding 4

thread guide as shown in drawing.

Run thread through top 5

thread notch 1, and turning

the bobbin align bottom

thread notch 2 of the bobbin

with guide pin on bobbin

winder shaft.

Press bobbin winding clutch up against 6

empty bobbin. If the bobbin stop does not

slide easily between the top and bottom of

the bobbin, check that the bobbin is seated

properly with the guide pin (5) inserted into

the lower notch.

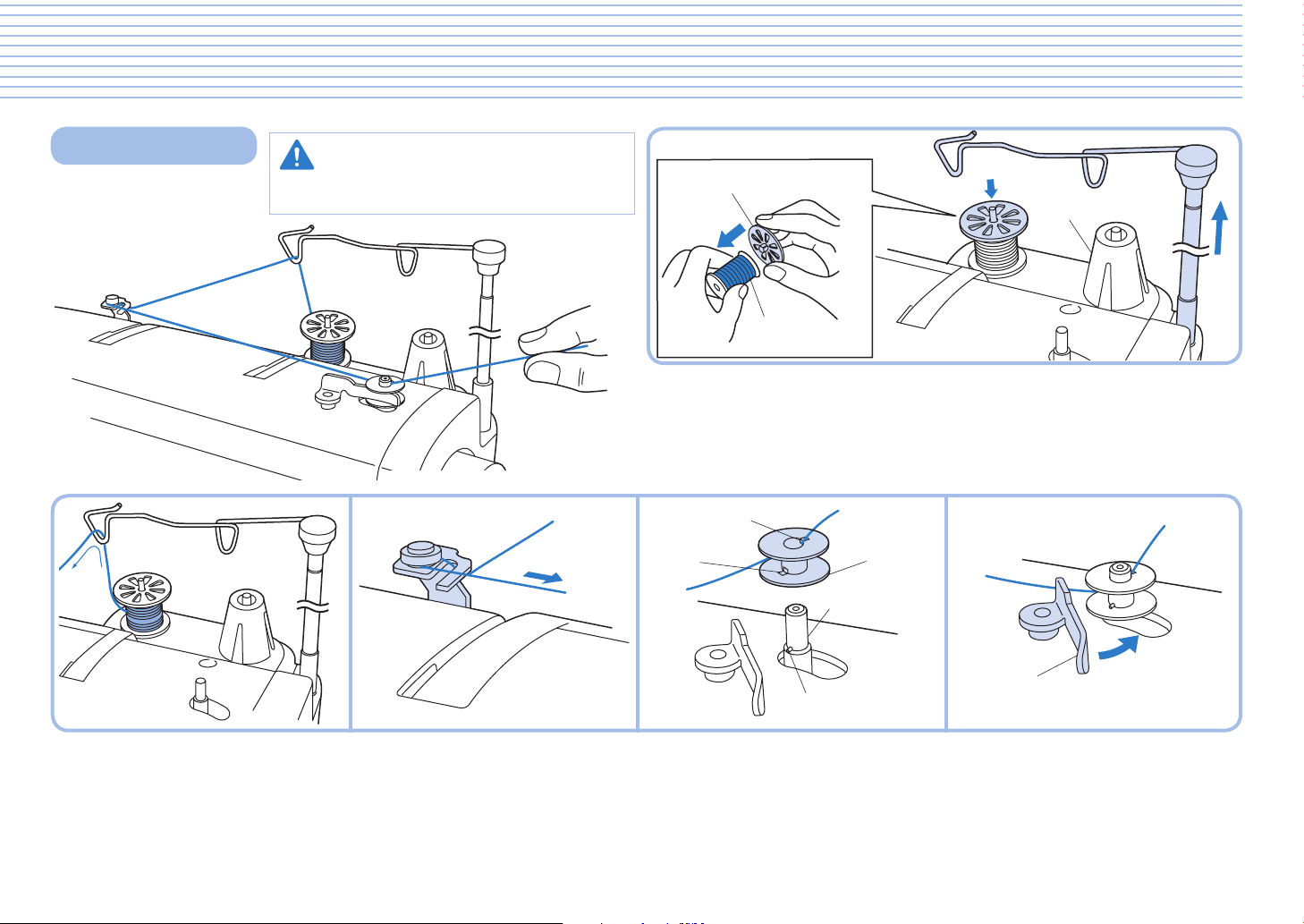

Page 14

12

While holding the end of the thread, 7

�

Place the thread end so that it does

not protrude from the bobbin.

Bobbin Winding Clutch

Controller

Pedal

Press down

�

Pressing down on the controller

harder increases the winding speed.

step on the foot controller for a few

seconds. Once enough thread has

wound itself around the bobbin

to hold itself in place, release the

foot controller and trim the excess

thread.

Start winding the bobbin again by 8

pressing down on the foot controller.

Stop winding process when 9

bobbin is full. Take the foot off foot

controller.

Manually move bobbin winding 0

clutch back to original position.

Cut thread and remove bobbin.A

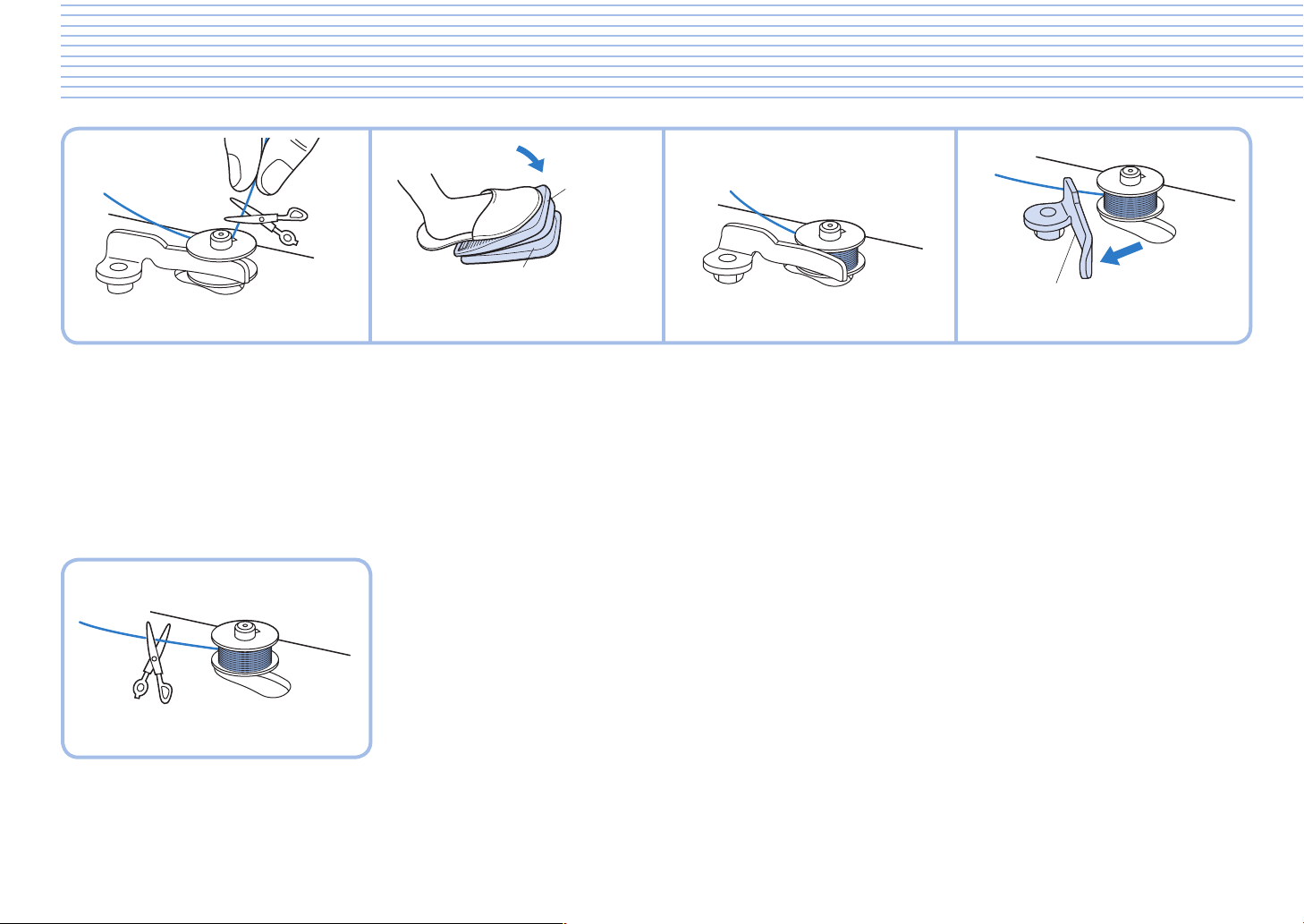

Page 15

13

Quick Bobbin

Thread Device

Bobbin Insertion

� Bobbin should be

positioned so it

winds to the left.

Latch Spring

Thread Notch

10 cm (4 inches)

2

1

2

1

Bobbin Door

Needle Plate

1

2

3

Bobbin Thread Setting Cover

CAUTION – Moving parts –

To reduce risk of injury, turn the power to the machine off before servicing. Open covers.

Lift needle plate and open 1

bobbin door.

Lower slide plate and close 5

bobbin door, following numbers

1 2 above in order.

Put bobbin into the bobbin case.2

Run thread through thread notch and ✽

under latch spring, so that a length of

thread is exposed.

Always use the bobbin case that was ✽

supplied with this machine. A secondary

bobbin case can be ordered from your

dealer.

When the fabric extension table is set in place ●

Pull the latch lever of the bobbin 3

case out and push the bobbin case

into the shuttle race and release the

latch lever.

If the latch lever is not set securely on

✽

the hook, it may fly off during sewing

and cause lower thread breakage.

Rotate the hand wheel one full

rotation towards you to check that the

bobbin case is set securely.

Open the bobbin thread setting cover

beforehand, then following the above

directions set the bobbin thread in

place. (You can set the bobbin thread

in place without removing the fabric

extension table.)

Pass the thread through the quick 4

bobbin thread device in the order 1

2, pull in the direction of the arrow

3, then cut the thread.

★

Quick Bobbin Thread Device

This device cuts the bobbin thread end

to an appropriate length after the bobbin

has been replaced and holds it at that

length. Following this process eliminates

the need to manually pull the bobbin

thread through the hole in the needle

plate. Simply close the bobbin case and

continue the upper threading process.

Page 16

14

Threading (2)

1

2

6

7

8

9

0

A

3

4

5

Long

Groove

Scarf

(depression on

needle shaft)

Thread

Needle Hole

1

7

2

3

5

6

4

7

8

9

0

A

Thread take-up spring

CAUTION

Please turn off the power to the machine before using the automatic needle threader. Accidentally stepping on the foot controller during this operation could cause bodily injury or damage to the machine.

Upper Threading

Make sure thread take-up lever

●

(7) is in highest position and

presser foot is up.

When using polyester thread or thread that

✽

tangles or breaks, run the thread through

all three holes of the thread guide.

Thread tension may not be adjusted ✽

adequately unless the thread runs

correctly through the take-up spring.

CAUTION

Turn off the power to the machine before using the

automatic needle threader. Otherwise, it may cause

injuries when you unintentionally press down on the

foot controller.

If the thread is still tangles or breaks,

✽

run the thread through the holes

backwards as shown in diagram.

Page 17

15

Using the Automatic Needle Threader

Pin

Thread

1

2

Hook

Automatic

Needle

Threader

a

b

c

d

Pull the thread to

✽

the left and check

that it is caught

on the hook.

Rotate hand wheel towards you 1

until needle is in the highest

position, and lower presser foot.

Take thread in your left hand, and 2

gently pull it forward.

Before sewing, pull the thread loop to the

6

right and then pull the thread tail towards

the back of the machine following the

opening in the presser foot.

Lower automatic needle threader.3

Pull thread along the right side of the pin.

✽

Do not force the needle threader lower

✽

than the eye of the needle. Be sure that

the needle is in the highest position.

Needle (HLX5) Thread

#9 #20 #30 #50 #60

#11 #20 #30

#14 #20 #30

#16 #20

The automatic needle-threader cannot be

●

used with the thread-needle combinations

illustrated in the chart shown above.

Transparent nylon thread can be used

regardless of the chart, providing the

needle used is a #14 or #16.

Turn the needle threader lever all the

4

way in the direction of 1 and when

the hook extends from the needle

hole, pull the thread in the direction

of 2 to catch it on the hook.

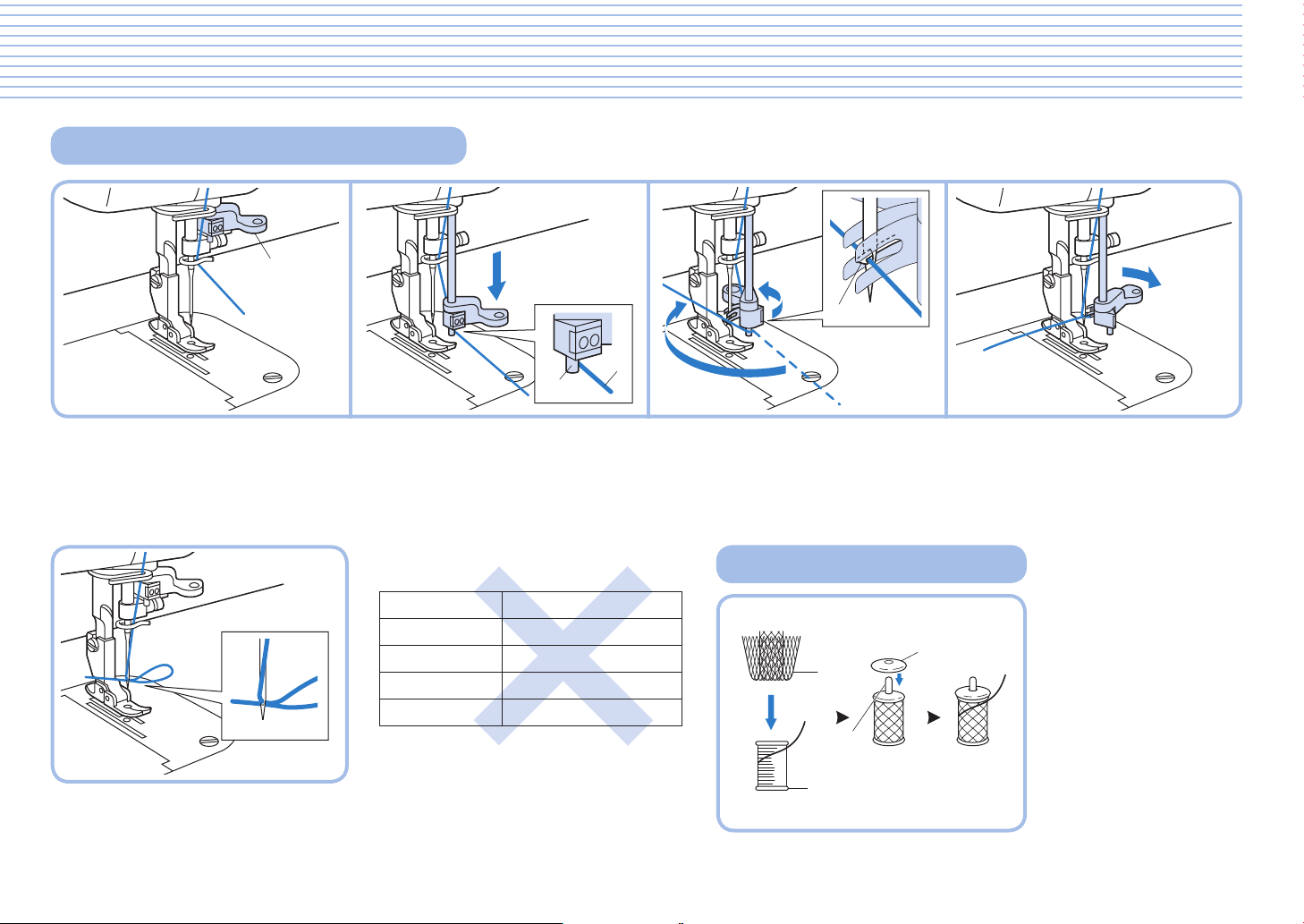

Using the Spool Net

While holding the thread gently, return

5

the needle threader lever to the right. As

you do this the hook that has caught the

thread will move as well, pulling a loop

of thread through the eye of the needle.

If using transparent nylon

thread, metallic thread, or

other strong thread, place

the included spool net over

the spool before using.

If the spool net is too long,

fold it once to match it to the

spool size before placing it

over the spool.

Spool net1

Thread spool2

Spool pin3

Spool cap4

Page 18

16

Stitch Samples and Needle Chart

to increase

bobbin

tension

to reduce

needle

thread

tension

to increase

needle

thread

tension

Fabric

Upper

Thread

Lower

Thread

to reduce

bobbin

tension

Correct thread tension

Incorrect thread tension can lead

to such undesirable results as

messy stitches, puckered seams

and thread breakage.

Upper

Thread

Lower

Thread

Right side of Fabric

Upper

Thread

Lower

Thread

Right side of Fabric

Wrong side of fabric

Bobbin tension . . .

Proper

When it is week

Bobbin tension . . .

Proper

When it is strong

Wrong side of fabric

Adjust the upper thread to match the bobbin thread.

Stitch Samples

Set stitch length regulator to 1

desired stitch length.

Make sure approximately 15 cm 2

of upper thread is pulled out and

laying behind presser foot. While

needle is in raised position,

insert a test strip from the

garment fabric under the foot.

Lower presser foot.3

Turn the hand wheel forward to 4

lower the needle through the

fabric, then step gently on the

foot controller to begin.

Turn the hand wheel towards you

5

to raise the needle and thread

take-up lever to their highest

positions.

Lift presser foot, remove fabric 6

and then manually cut the

thread with the cutter on the left

side of the head of the machine

or with a pair of scissors.

When using thread cutter: ✽

5

Press the thread cutter button

while the presser foot lever in the

down position

6

Lift foot and remove fabric.

.

Thread Tension

Selecting the proper needle for use with the fabric and thread you are working with

●

The following chart applies to many different fabric, thread and needle combinations.

✽

Specialty

fabrics

Light

weight

fabrics

Middle

weight

fabrics

Heavy

weight

fabrics

HLX5 needles are recommended; however, Schmetz 130/705H needles may ✽

also be used under normal sewing conditions.

Adjust the pressure adjustment dial and the feed dog adjustment knob ✽

according to the chart on the sewing machine.

When sewing on knit fabrics such as jersey or tricot, use a ballpoint needle ✽

or a needle designed for use with knit fabrics.

Velvet Silk, Polyester #30 – #50 #11 – #14

Quilt Polyester #20 – #50 #11 – #16

Synthetic Suede Polyester #20 – #50

Knit Polyester #20 – #50

Coating Polyester #50 #11 – #14

Lawn Cotton #80 #9

Tricot Polyester #60

Silk Georgette Silk #50

Wool Georgette Silk, Polyester #50 #11

Gingham Cotton #60 – #80 #11 – #14

Lightweight Jersey Polyester #60 #11

Gabardine, Flannel Silk #50

Denim Cotton #20 – #50 #14 – #18

Jersey Polyester #20 – #50 #11 – #16

Tweed Silk #20 – #50

Bobbin thread should feed smoothly. Adjust bobbin

✽

thread to match that of upper thread. (If bobbin

thread is too tight it may cause fabric to bunch up.)

Cloth Thread Needle (HLX5)

Fabric - Thread - Needles

Schmetz

HLX5

130/705H

#9 #65

#11 #75

#14 #90

#16 #100

#18 #110

Page 19

17

Changing Presser Feet

CAUTION

Make sure the power to the machine is off before changing presser feet.

Changing Presser Feet

(Zipper Foot)

Raise presser foot, and raise 1

needle to highest position.

Loosen and remove screw using 2

screwdriver.

Attach zipper foot and tighten 3

screw.

Use the same method to attach ✽

the other feet that come with

your machine.

See page 22 for directions on ✽

attaching the “Walking Foot”.

Use the position knob on back of ✽

the zipper foot to adjust position

of foot in relation to needle.

Only the zipper foot has a ✽

position knob. You can begin

sewing with all other presser feet

immediately after attaching.

Presser Feet

Pin Feed Foot ●

For perfect

stitching on

otherwise difficult

fabrics like velvet,

leather and suede.

Rolled Hem Foot ●

Use on the edge

of fabric, such as

on hems of dress

shirts, to fold the

edge of the fabric

in three while

sewing.

Walking Foot ●

For sewing or

quilting on fabrics

which stick or tend

to slip Useful for

sewing multiple

layers as in quilting.

Quilting Foot ●

Spring action

foot for darning,

quilting or

free-motion

embroidery.

Use only feet supplied with your machine. Each foot is

✽

specially designed for this machine and has clearance

for the pin at the rear of each foot. Use of other presser

feet may damage or break the pin feed mechanism.

General purpose Foot

●

This foot is used for

most sewing. (Can

also be used for

sewing thick fabrics or

seams.)

When sewing thick

✽

seams, lightly guide

the fabric with your

hand on the downward

side of the seam.

Can also be used with

✽

pin feeding.

Invisible Zipper Foot

●

Use to attach

concealed fasteners.

Zipper Foot ●

Use to attach fasteners

other than concealed

fasteners. The zipper

foot can also be used

to secure piping in

place as you sew. Use

the side of the foot

closest to the needle to

rest against the edge of

the piping as you sew.

1/4” Foot ●

For quilt and

patchwork piecing

with 1/4” or 1/8”

seam allowance.

Page 20

18

Basic Sewing (1)

Before

sewing.

Begin

sewing.

Finish

sewing.

�

When changing sewing directions.

Backstitches

1 cm

1 cm

Feed Pin

Feed Pin

Fabric

Feed Dog

Indicator Needle

Basic Sewing

Lift foot, pull about 15 cm 1

of upper and bobbin thread

under and behind foot, and

position fabric under foot.

Pin Feeding (for hard-to-handle fabrics)

Fabric:

Velvet

Quilt

Synthetic

Suede

Knit

Coating

Others

The fabrics shown

✽

above can be joined

evenly by activating the

pin feed mechanism.

CAUTION

While the presser foot lever is lowered, the feed pin appears up through the feed dog. Keep your fingers away from the feed pin.

1

Lower presser foot lever to 2

lower foot.

Turn the hand wheel toward 3

you to lower the needle

through the fabric, then step

gently on the foot controller

to begin.

Move feed

adjustment knob to

pin feeding position.

Adjust pressure adjustment

2

dial until indicator needle is

in the right position in the

matching color coded area.

At the beginning and end ✽

of a seam, press down the

reverse stitch lever and

backstitch about 1 cm.

Gently pull thread until 3

feed pin catches fabric

and sew.

Raise needle to highest position.

4

Lift foot, remove fabric and cut thread.

5

When using thread trimmer: ✽

4

Push thread trimmer button (this will

cause the upper and bobbin threads

to be cut automatically and the

needle to stop in a raised position).

5

Lift presser foot and remove fabric.

Make sure needle is pierced 1

all the way through fabric.

Lift presser foot, and turn 2

fabric using needle as an

axis.

Lower presser foot and 3

continue sewing.

Pin Feeding Mechanism

The feed pin passes up through all layers of fabric moving with the feed dog’s

motion to feed all layers of the fabric evenly.

For safety, the feed pin is automatically lowered when presser foot is raised. ✽

Page 21

19

Basic Sewing (2)

0.5 cm

0.5 cm

Thread end

Rolled Hem

Thread

CAUTION

Make sure the power to the machine is off before changing presser feet.

Rolled Hem Foot

Attach rolled hem foot.1

Refer to page 17 for instructions ✽

on changing sewing feet.

Position the fabric (reverse side 2

facing up) under the presser

foot. Insert needle approximately

0.5 cm from the edge of the

fabric and sew 2 stitches.

Turn the hand wheel towards 3

you to raise the needle, raise the

presser foot, then pull the fabric

forward.

Be sure not to unthread the ✽

fabric while pulling it forward.

Hold the 4 threads in your left 4

hand.

With your right hand, put the 5

edge of the rolled hem under

the presser foot, from the spot

where the threads come out.

Insert the edge so that it lies

directly under the needle. Lower

the presser foot.

Pull gently on threads in left 6

hand while sewing the first 3-4

stitches to hold them in place.

Fold hem over about 0.5 cm and 7

continue feeding folded hem

under foot while sewing towards

the curved guide on the foot.

Page 22

20

Basic Sewing (3)

A

0.5 cm

Slide

Base of

Opening

Stop

0.2 cm

B

CAUTION

Make sure the power to the machine is off before changing feet.•

When attaching zippers to stretch fabrics, use the pin feed method and •

adjust foot pressure accordingly.

The zipper foot can also be used as a guide when attaching piping to •

fabric.

Zipper Foot

Attach zipper foot.1

See “Changing Presser Feet ✽

(Zipper Foot)” on page 17.

Turn the hand wheel towards you

2

to lower the needle and adjust

the position of the foot relative to

the needle using the adjustment

screw to slide the foot from left

to right.

Line up zipper to the section of 3

fabric it will be attached to, and

mark the base of the opening

on the fabric. It should be set

approximately 0.5 cm below zip

stop. Sew from below the base

of the opening.

Secure the zipper with basting 5

and sew along the mark.

CAUTION

Make sure the needle does not

strike the metal part of the zipper

when sewing. The needle may

break and cause injury.

Line up the folded hem on the 6

opposite side with the stitches.

Change position of zipper foot.7

Turn the hand wheel to lower the 8

needle and position the presser

foot.

Divide the seam margin. Fold 4

the seam margin with the

overlap of the zipper position

facing down 0.2 cm on the

outside of the mark.

With the fabric right side up,

9

baste the zipper onto the fabric,

then sew the edge of the basting.

Reinforce base of opening by

✽

sewing over it twice.

If the zipper slide gets in the

✽

way, lower the needle all the way

through the fabric, lift the foot, and

move the slider out of the way.

Page 23

21

Invisible Zipper Foot

Baste

2 cm

Base of

Opening

Slide

Teeth

Basting

Basting

Seam allowance

(1/4”, 6.4 mm)

End of

stitching

Align this

mark with

edge of

fabric

Align this

mark with

edge of

fabric

Beginning

of

stitching

Top of fabric

Seam

(1/8”, 3.2 mm)

1/4” Foot

Attach invisible zipper foot.1

Align zipper with fabric. Mark 2

the base of the opening

approximately 2 cm above the

end of the zipper.

Baste the zipper position.3

Separate the seam allowance.4

With the zipper mounted, baste 5

just the seam margin on one

side of the zipper.

Close the zipper and baste the 6

other side of the zipper.

Remove the basting at the 7

zipper position.

Fit the zipper teeth into the 8

presser foot groove, guide them

to prevent them from falling

over, and sew to the base of the

opening.

Sewing machine settings: ●

Stitch length = 2 - 2.5 mm

Sew a consistent seam •

allowance (1/4”, 6.4 mm) when

piecing together a quilt.

Use guides (mark) to begin, •

end, or pivot 1/4” from edge of

fabric.

Accurately top stitch 1/8” from •

seam.

When sewing with the teeth to ✽

the right, the left side of the foot

should line up with the left teeth

of the zipper.

Page 24

22

Quilting Foot

Forked part

of operation

lever

Secure the

capscrew

with a

screwdriver.

1

2

Walking Foot

Reduce the foot pressure and turn

the dial on the machine lowering the

feed dogs for free motion quilting.

Note

If the foot is frequently used, be

sure to apply a small amount of

oil about once a month to the

area indicated by the arrows. (If

too much oil is applied, wipe off

the excess with a cloth.)

Note

Do not press the foot controller •

all the way down.

Try to keep the sewing speed

low (500 r.p.m. or less).

The fabric may not feed if you •

sew at high speeds.

The feed dog for feeding the •

cloth may not move if the foot

pressure on the fabric is too

strong. Use the presser foot

pressure adjustment dial to

achieve the desired results.

It is not advisable or necessary •

to use the Pin Feed mode with

the walking foot.

Insert the forked part of the 1

operation lever while raised

in an upright position onto the

screw on the right side of the

needle bar, as shown and then

insert the capscrew.

Tighten the screw securely 2

with a screwdriver. Tightening

adequately is important as the

screw might loosen due to the

foot and forked operation lever

vibration.

Page 25

23

a

Fabric Separator (for

Fabric

Separator

Needle

Separator

Needle

Separator

Lining

Velvets

joining lining to fabric)

Use this technique for sewing ✽

velvet and lining together.

Raise needle and foot.1

Move separator so it sits under 2

presser foot.

Make sure it is lined up so that 3

the needle passes through the

slot of the separator without

hitting the plate itself.

Secure liner plate in place with 4

lining plate screws.

Set pressure of sewing feet 5

and feed position to pin feeding

position.

Pull thread until lower needle 6

catches fabric.

Sew 2-3 reinforcement stitches. ✽

Seam Guide

Tighten the screw securely 1

with a screwdriver since it

might otherwise loosen due to

vibration.

Installation

Turn adjustment screws as arrows

images suggest to set the position of

the Seam Guide foot.

When not using separator, it 7

can be swung off to the side as

illustrated in drawing.

Note

• Lightenthepresserfootpressureslightlywhenusingthefabricseparator.

• Usetheseparatortoneatlysew2layersofhardtomanagefabricstogetherbykeepingthem

from interacting with one and other before the needle sews them together in a perfect seam.

Adjustment

Page 26

24

Caring for Your Machine

Hook

Cleaning the Machine

CAUTION

Make sure the power to the

machine is off before cleaning

sewing machine.

Turn machine off.1

Remove foot.2

Remove needle plate.3

Clean out dust and thread 4

scraps.

Thread scraps can be swept out ✽

through the bobbin door.

When the area under the needle 5

plate is cleaned out, oil hook

of bobbin case with sewing

machine oil.

Use a cloth to clean the machine ✽

of any excess oil.

Attach needle plate and foot.6

Lubrication Points

When using the sewing machine ●

every day, apply a few drops of

oil to each location indicated

twice a month.

Use a cloth to wipe the machine ✽

clean of any oil spilled near the

lubrication points.

Keep Your Sewing Machine Clean ■

Please use a soft, dry cloth to wipe off light dirt and

dust. If sewing machine is very dirty, wipe with a cloth

soaked in warm water, or in warm water containing a

neutral detergent. Then wipe off any detergent residue,

and wipe off water with a dry cloth.

Precautions ■

Please keep sewing machine away from heat sources

such as irons and space heaters. Do not use chemicals

like benzine or thinner to clean your machine. When

machine is not in use, please keep machine out of

direct sunlight.

Item Specification

Sewing Speed

(maximum)

Stitch Length

(pitch)

Stroke of

Needle

Stroke of

Thread TakeUp Lever

Foot Height

1,500 stitches per minute

Foot Lift One 6 mm

Knee control Over 10 mm

0 – 7 mm

34.1 mm

64.7 mm

Tw o 9 mm

Item Specification

Height of feed dog

Height of

lower needle

Needles that

may be used

Bed dimensions

Total weight 11 kg (24 1/4 lbs.)

Sewing Light

Sewing area

0.7 mm, 1.1 mm

3 mm – 3.5 mm

HLX5#9 – #18

SCHMETZ 130/705H #65 – #110

439 mm × 178 mm (17 1/4 × 7 inches)

120V model: 120V/15W

220-240V model:

(23 3/8 × 11 1/4 inches)

Parts code: X53061-050

240V/15W

Parts code: 205336-050

595 mm × 285 mm

Page 27

25

Trouble Shooting

13-15.24

Thread

Breakage

Upper threading is not

threaded correctly.

Re-thread machine

properly.

Thread is getting tangled.

Rethread machine.

Clean bobbin case and under

needle plate. Oil the machine.

Upper thread tension is

too high.

Reduce tension.

Improper fabric/needle/

thread combination.

See chart on p.16 for the right

needle to use with your

fabric and thread.

Bobbin case is scratched.

Remove needle plate and

check bobbin case.

Bobbin Thread

Breakage

Skipped

Stitches

Fabric

Puckers

Fabric Won’t Feed

Properly or Irregular

Stitches

Loop in

Seam

Needle

Breakage

Sewing Machine

Doesn’t Run

Machine is

Noisy

Automatic Needle

Threader Doesn’t

Work

Thread Cutter

Doesn’t Work

Bobbin thread is not passing

correctly from bobbin case.

Needle is not inserted

correctly.

Wrong needle.

See chart on p.16 to choose the

needle that best fits your

fabric-thread combination.

Threading is incorrect.

Wrong needle for the fabric

and thread you are using.

See chart on p.16 to choose the

needle that best fits your

fabric-thread combination.

Stitch length is too short.

Pressure of sewing foot is

too weak.

Increase foot pressure.

Upper threading is

incorrect.

Thread is not passing through

bobbin case correctly.

Reset bobbin case.

Needle is not attached

correctly.

Wrong needle.

Change needles.

The power isn’t on.

Machine’s not plugged in.

Check to make sure the

machine’s plugged in.

The area under the needle

plate needs to be cleaned.

Needle is not in the

highest position.

Needle is not properly

inserted.

Reinsert bobbin

properly.

Bobbin tension is too high.

Reduce tension.

Bobbin case is scratched.

Remove needle plate and

check bobbin case.

Reinsert.

Machine is not threaded

properly.

Rethread machine.

Rethread machine.

Needle is bent, or tip is

dulled.

Change needles.

Clean feed dog and bobbin

case. Oil the machine.

Area under needle

plate needs to be cleaned.

Upper thread tension is

too high.

Reduce tension.

Reduce tension.

Bobbin tension is too high.

You’re sewing a lightweight fabric with

feed dogs in heavyweight position.

Adjust feed dogs.

Sewing heavyweight fabric with

feed dogs in lightweight fabric

position.

Adjust feed dogs.

Rethread machine. Clean needle

plate and bobbin case.

Thread is getting tangled.

Adjust stitch length.

Re-thread machine

properly.

Improper fabric/needle/

thread combination.

See chart on p.16 for the right

needle to use with your

fabric and thread.

You’re pulling the fabric

too hard.

Pull the fabric more gently.

Improper fabric/needle/

thread combination.

See chart on p.16 for the right

needle to use with your

fabric and thread.

Reattach.

Turn the power on.

The foot controller has

come unplugged.

Reattach foot controller.

Clean feed dog and

bobbin case.

Turn hand wheel to

raise needle.

Wrong needle for the

thread you’re using.

See chart on p.16.

Hook of needle threader doesn’t

pass through eye of needle.

Check to make sure the hook isn’t

bent. Needle may need to raised

to the highest position.

Using the automatic needle

threader incorrectly.

Check the use of the automatic needle threader.

Reinsert. Set needle to highest

position in chamber.

Wrong needle.

See chart on p.16 to choose the

needle that best fits your

fabric-thread combination.

Needle is bent, or tip is

dulled.

Change needles.

Area under needle plate

needs to be cleaned.

Clean feed dog and

bobbin case.

Upper threading is

incorrect.

Re-thread machine.

If you still cannot find the problem, please take your sewing machine into the

shop where you purchased it, or your nearest authorized Brother dealer for repair.

Thread is getting tangled.

Rethread machine.

Clean bobbin case and

under needle plate.

14

13

10

7

14

10

7

24

Machine is out of oil.

Oil the machine.

24

7

10

13-15

16

16

8

13

10

7

16

16

16

16

10

16

9

16

16

7

Machine is out of oil.

Clean and oil the

machine.

24

The automatic safety

device has operated.

10

16

24

16

24

15

14

9

13-15

13-15.24

13-15.24

Upper thread does not run

through the take-up spring.

Pass thread through the

take-up spring correctly.

14

Before taking your sewing machine in for service, check the following chart. You can solve most problems by yourself. If you need additional help, the Brother ✽

Solutions Center offers the latest FAQs and troubleshooting tips. Visit us at “ http://solutions.brother.com ”.

Page 28

13-15.24

Hand Wheel

Doesn’t Rotate

Needle is not attached

correctly.

Reattach.

Thread is getting tangled.

Rethread machine.

Clean bobbin case and under

needle plate. Oil the machine.

Needle is bent, or tip is

dulled.

Change needles.

Thread Gets

Tangled on Wrong

Side of Fabric

Upper threading is not

threaded correctly.

Re-thread machine

properly.

Bobbin case is scratched.

Remove needle plate and

check bobbin case.

If you still cannot find the problem, please take your sewing machine into the

shop where you purchased it, or your nearest authorized Brother dealer for repair.

Upper thread tension is

too low.

Increase tension.

10

14

10

16

If you find it difficult to turn the hand wheel, you may also see “Sewing Machine Doesn’t Run” in “Trouble Shooting”. ✽

26

Page 29

INSTRUCTIONS DE SÉCURITÉ IMPORTANTES

Lisez toutes les instructions avant d'utiliser la machine.

Lorsque vous utilisez cette machine, vous devez toujours respecter les précautions de sécurité de base, à savoir :

DANGER – Pour réduire le risque de choc électrique :

Ne laissez jamais la machine sans surveillance pendant qu'elle est branchée. Débranchez toujours la machine de la prise de courant dès que vous avez fini de ●

l'utiliser et avant de la nettoyer.

Débranchez toujours la machine avant de changer l'ampoule. Remplacez-la par une ampoule de même type, d’une puissance de 120 V (15 watts) pour le modèle 120 ●

V ou d’une puissance de 240 V (15 watts) pour le modèle 220-240 V.

AVERTISSEMENT – Pour réduire le risque de brûlure, d'incendie, de choc électrique ou de blessure :

Cette machine n'est pas un jouet. Vous devez être très attentif lorsqu'elle est utilisée par des enfants ou à proximité d'enfants. ●

N'utilisez pas cette machine à d'autres fins que celles pour lesquelles elle a été conçue, telles que décrites dans ce manuel. N'utilisez que les accessoires ●

recommandés par le fabricant, tels que repris dans ce manuel.

N'utilisez jamais cette machine si sa fiche ou son cordon d'alimentation sont endommagés, si elle ne fonctionne pas correctement, si on l'a fait tomber, si elle a été ●

endommagée ou si elle est tombée dans l'eau. Renvoyez-la au revendeur agréé ou au centre de dépannage le plus proche pour qu'elle soit examinée et réparée ou

pour qu'elle fasse l'objet de réglages électriques ou mécaniques.

N'utilisez jamais cette machine lorsque les ouvertures de ventilation sont bouchées. Ne laissez pas les peluches, la poussière et les tissus s'accumuler car ils ●

pourraient boucher les ouvertures de ventilation de la machine et de la pédale du rhéostat.

N'insérez jamais et ne laissez jamais tomber aucun objet dans ces ouvertures. ●

N'utilisez pas la machine à l'extérieur. ●

Ne faites pas fonctionner la machine en cas d'utilisation de produits aérosols (vaporisateurs) ou d'administration d'oxygène. ●

Pour débrancher la machine, placez l'interrupteur principal en position « O » (arrêt), puis retirez la fiche de la prise de courant. ●

Ne débranchez pas la machine en tirant sur le cordon d'alimentation. Pour débrancher la machine, saisissez la fiche et non pas le cordon. ●

Ne touchez pas les pièces mobiles. Vous devez faire preuve d'une grande prudence avec l'aiguille de la machine. ●

Utilisez toujours la plaque à aiguille appropriée. L'utilisation d'une plaque incorrecte pourrait entraîner la cassure de l'aiguille. ●

N'utilisez pas d'aiguilles tordues. ●

Ne tirez et ne poussez pas le tissu pendant que vous cousez. Cela pourrait faire dévier l'aiguille et la casser. ●

Placez l'interrupteur de la machine en position « O » pour la mettre hors tension lorsque vous effectuez des réglages à proximité de l'aiguille, comme l'enfilage de ●

l'aiguille, le changement d'aiguille, la mise en place de la canette ou le changement de pied-de-biche, etc.

Débranchez toujours la machine de la prise de courant lorsque vous retirez les couvercles, que vous ajoutez du lubrifiant ou que vous effectuez d'autres opérations ●

d'entretien mentionnées dans ce manuel d'utilisation.

Cette machine à coudre n'est pas conçue pour être utilisée sans surveillance par de jeunes enfants ou des personnes handicapées. ●

Les enfants doivent être surveillés pour s'assurer qu'ils ne jouent pas avec cette machine. ●

27

Page 30

28

CONSERVEZ CES INSTRUCTIONS

Cette machine est conçue pour une utilisation domestique.

Cet appareil n’est pas conçu pour une utilisation par des personnes (adultes ou enfants) souffrant d’incapacités physiques, sensorielles ou mentales, ou ne disposant

pas de l’expérience ou des connaissances nécessaires, à moins qu’elles ne soient aidées par une personne veillant à leur sécurité. Il faut surveiller les enfants pour

s’assurer qu’ils ne jouent pas avec cet appareil.

POUR LES UTILISATEURS AU ROYAUME-UNI,

EN IRLANDE, À MALTE ET À CHYPRE UNIQUEMENT

IMPORTANT

En cas de remplacement du fusible de la fiche, utilisez un fusible certifié ASTA à BS 1362, c’est-à-dire portant la marque ● , d’une capacité correspondant à celle

indiquée sur la fiche.

Remettez toujours le couvercle du fusible. Ne branchez jamais la machine lorsque le couvercle du fusible est ouvert. ●

Si la prise électrique disponible ne correspond pas à la fiche fournie avec cet équipement, vous devez contacter votre revendeur agréé pour obtenir le cordon correct. ●

Page 31

29

NOUS VOUS REMERCIONS D’AVOIR CHOISI LA

MACHINE A COUDRE ELECTRONIQUE BROTHER.

Cette machine à coudre est une des meilleures disponibles actuellement pour l’usage domestique.

Cependant, nous vous conseillons la lecture de ce fascicule afin de profiter pleinement de toutes les fonctions intégrées.

RECOMMENDATIONS AVANT D’UTILISER VOTRE MACHINE A COUDRE BROTHER

Précautions d’utilisation

Toujours bien vérifier la position de vos mains par rapport à l’aiguille pendant la couture. Ne pas toucher le volant, le releveur de fil, l’aiguille ou les autres parties en ●

mouvement.

Se rappeler qu’il faut éteindre la machine et débrancher le cordon secteur quand: ●

l’utilisation est terminée ●

vous remplacez ou échangez l’aiguille ou toutes autres pièces ●

une panne de courant se produit en cours d’utilisation ●

vous faites l’entretien et la lubrification de la machine ●

vous laissez la machine sans surveillance ●

Ne rien poser sur la pédale de commande. ●

Brancher la machine directement dans une prise secteur. Ne pas utiliser de rallonge électrique. ●

Pour une vie prolongée de votre machine

Ne pas ranger votre machine dans des endroits exposés au soleil et très humides. Ne pas ranger votre machine à coudre à proximité d’un appareil de chauffage, d’un ●

fer à repasser, ou de tout autre appareil dégageant de la chaleur.

Utiliser seulement des savons ou des détergents neutres pour nettoyer le coffret de la machine. Ne jamais utiliser de benzine, de diluants, de décapants, car ces ●

produits risquent d'endommager le coffret et la machine.

Ne pas laisser tomber ou ne heurter pas la machine. ●

Toujours consulter le manuel d’instructions lors de la mise en place du pied-de-biche, de l’aiguille ou d’autres éléments accessoires pour s’assurer de les installer ●

correctement.

Pour la réparation et le réglage

Dans le cas d’une anomalie ou lorsqu’un réglage est nécessaire, se rapporter au chapitre « Résolution des problèmes » afin d’inspecter et de régler vous-même la

machine. Si le problème persiste, consultez votre revendeur Brother.

Pour obtenir le nom et le numéro de téléphone du centre technique agréé de Brother le plus proche, visiter le site www.brother.com et utiliser notre localisateur

fonctionnel de revendeurs.

Page 32

TABLE DES MATIÈRES

Accessoires ............................................................................... 31

Fonctions de la machine ........................................................... 32

Avant de commencer (1) ........................................................... 33

Cordon d’alimentation et pédale .............................. 33

Interrupteur d’alimentation.......................................33

Disque sélecteur de tension du fil ...........................33

Volant ......................................................................33

Sélecteur de longueur de point ...............................33

Levier de point arrière .............................................33

Levier du pied-de-biche ...........................................34

Levier de levage au genou ......................................34

Disque sélecteur de réglage de la pression

du pied-de-biche ...................................................... 34

Table de rallonge pour tissu ....................................34

Avant de commencer (2) ........................................................... 35

Bouton de ciseaux ...................................................35

Bouton de position d’arrêt d’aiguille ........................35

Interrupteur de la lampe ..........................................35

Bouton de réglage des griffes d’entraînement ........35

Remplacement de l’aiguille et de l’ampoule de lampe ........... 36

Remplacement de l’aiguille .....................................36

Remplacement de l’ergot d’entraînement ...............36

Remplacement de l’ampoule ...................................36

Enfilage (1) ................................................................................. 37

Remplissage de la canette ......................................37

Insertion de la canette .............................................39

Enfilage (2) ................................................................................. 40

Mise en place du fil supérieur..................................40

Utilisation de l’enfileur automatique ......................... 41

Utilisation du filet de la bobine ................................. 41

Points d’essai et tableau d’aiguilles ........................................ 42

Points d’essai ..........................................................42

Tension des fils ........................................................42

Changement du pied-de-biche ................................................. 43

Changement du pied-de-biche

(Pied pour fermeture à glissière) .............................43

Les différents pied-de-biche ....................................43

Couture de base (1) ................................................................... 44

Couture de base ......................................................44

Entraînement par ergot

(pour les tissus difficiles à manipuler) .....................44

Mécanisme d’entraînement par ergot ...................... 44

Couture de base (2) ................................................................... 45

Pied pour ourlet rouleauté .......................................45

Couture de base (3) ................................................................... 46

Pied pour fermeture à glissière ...............................46

Pied pour fermeture à glissière invisible .................47

Pied 1/4” ..................................................................47

Pied transparent pour ouatinage/matelassage ........ 48

Pied double-entrainement .......................................48

Séparateur de tissu

(pour fixer une doublure au tissu) .......................... 49

Guide de couture .....................................................49

Entretien de la machine à coudre ............................................ 50

Nettoyage de la machine ......................................... 50

Points de graissage .................................................50

Dépannage ................................................................................. 51

Page 33

Accessoires

1 2 3 4 5

6 7 8 9 10

11 12 13 14 15

16 17 18 19 20

21 22 23 24 25

No. de

pièce

1 Couvercle XA0917-054

2 Tournevis moyen XC9541-051

3 Petit tournevis X554680-51

4 Brosse de nettoyage X59476-051

5 Levier de levage au genou XA0830-051

6

7

8 Séparateur de tissu 184720-001

9 Axe d’avance 138483-051

10 Extracteur d’axe d’avance XC1407-051

11 Pied à usage général XA1425-001

12 Canette (5)

13 Capuchon de bobine XA2111-050

14 Pied pour ourlet rouleauté X57138-101

15

16 Pied pour fermeture à

17 Pied 1/4” XA7258-001

18 Pied transparent pour

19 Pied double-entrainement XA7253-001

20 Guide de couture XA7256-001

21 Pédale du rhéostat

22

23 Filet de la bobine XA5523-050

24

25 Broche porte-bobine

Désignation Code de pièce

Aiguilles et boîte (ORGAN HLX5)

1 Taille 9, 2 Taille 11,

1 Taille 14, 1 Taille 16,

1 aiguille à pointe-bille

Vis de plaque de doublure (2)

Pied pour fermeture à glissière

glissière invisible

ouatinage/matelassage

Table de rallonge pour tissu

Pied à ergot d’entraînement

(sur la machine)

conique (sur la machine)

SA159 (Continent americain)

MBN: XA8284-202 (Autres)

XD0501-151 (zone UE)

XC8816-051 (autres zones)

X80805-151

062670-817

112797-001

XC0093-001

XA7255-301

XC3117-051

136021-001

XF2071-001

31

Page 34

32

Fonctions de la machine

Disque sélecteur de réglage de la

pression du pied-de-biche

(Page 34)

Guide-fils à trois

trous (Page 40)

Interrupteur de la

lampe (Page 35)

Coupe-fil

Lampe de section de

couture (Page 36)

Griffes d’entraînement

(Pages 35 et 44)

Barre de guidage

du fil (Page 37)

Sélecteur de longueur

de point (Page 33)

Bouton de position

d’arrêt d’aiguille

(Page 35)

Levier de point

arrière (Page 33)

Bouton de réglage des

griffes d’entraînement

(Page 35)

Levier de levage

au genou (Page 34)

Dévidoir (Page 37)

Volant (Page 33)

Interrupteur

d’alimentation

(Page 33)

Prise de pédale du

rhéostat (Page 33)

Prise de courant

(Page 33)

Coussinet de

bobine (Page 37)

Porte-bobine

(Page 37)

Levier du

pied-de-biche

(Page 34)

Guide-fils du

dévidoir (Page 37)

Poignée

Orifices de ventilation

Bouton de

ciseaux (Page 35)

Disque sélecteur de tension du fil

(Pages 33 et 42)

Enfileur automatique

(Pages 41)

Voyant indicateur

Dispositif de remontée

rapide du fil de la canette

(Page 39)

Levier de relevage du fil

(Page 40)

Page 35

33

Avant de commencer (1)

Cordon

d’alimentation

Pédale de rhéostat

Vitesse réduite

Vitesse élevée

I

O

Interrupteur

d’alimentation

Tension de fil supérieur

Desserrer Serrer

Bloc de tension

Volant

1

2

3

4

5

6

7

Sélecteur de longueur de point

Repère de référence

Nombre inférieur

=

points plus courts

Nombre supérieur

=

points plus longs

Longueur de point

Levier de

point arrière

Cordon d’alimentation et pédale

AVERTISSEMENT

Utiliser un courant secteur

domestique ordinaire.

Brancher le cordon. ●

Brancher la pédale sur la ●

machine.

Lorsque vous appuyez légèrement sur la

●

pédale de rhéostat, la machine fonctionne à

vitesse réduite. Lorsque vous appuyez plus

fort, la vitesse de la machine augmente.

Lorsque vous enlevez votre pied de la

pédale de rhéostat, la machine s’arrête.

Interrupteur d’alimentation

Basculer l’interrupteur sur la position

●

« I » pour allumer la machine à coudre.

Pour éteindre la machine, basculer

●

l’interrupteur sur la position « O ».

Disque sélecteur de tension du fil

Volant

Positionner l’aiguille à l’aide du ●

volant.

Toujours tourner le volant vers ✽

soi.

ATTENTION

Veillez à dégager la zone en

dessous et autour de l’aiguille.

Sélecteur de longueur de point

Régler la longueur de point à ●

l’aide du sélecteur de longueur

de point.

Levier de point arrière

Pour augmenter la tension du fil,

●

tourner le sélecteur de tension

vers la droite. Le fil supérieur et

le fil de la canette se rejoignent

sur le bon côté du tissu.

Pour diminuer la tension du fil,

●

tourner le sélecteur de tension

vers la gauche. Le fil supérieur et

le fil de la canette se rejoignent

sur le mauvais côté du tissu.

Pour coudre en marche arrière, ●

abaisser le levier de point

arrière.

Abaissez en continu et au ✽

maximum le levier pour coudre

en marche arrière.

Lorsque le sélecteur de réglage de

✽

l’entraînement est réglé entre 5-7 mm, la

longueur du point arrière est toujours de 5 mm.

Page 36

34

Levier du pied-de-biche

Levier du

pied-de-biche

Installation du levier de levage au genou.

Levier de

levage au genou

Table de rallonge pour tissu

Levier de levage au genou

Disque sélecteur de réglage de

la pression du pied-de-biche

Aiguille de

l’indicateur de

pression

a

c

b

c

b

Pieds de table

Butée

Crochet

Tige de guidage

Trou

Abaisser le levier du pied-de- ●

biche pour abaisser le pied sur

le tissu et activer la fonction de

tension du fil.

Pour travailler dans du tissu ✽

lourd et des tissus qui ne

glissent pas facilement sous le

pied, relever le levier du pied-debiche pour placer le tissu.

Levier de levage au genou

Le levier de levage au genou ●

est pratique pour soulever et

abaisser le pied-de-biche en

gardant les mains libres.

Enfoncer la barre du levier de ✽

levage au genou à fond dans la

prise.

Lorsqu’on ne se sert pas du ✽

levier de levage au genou, on

pourra le laisser sur I’envers de

la table de rallonge pour tissu.

Disque sélecteur de réglage de

la pression du pied-de-biche

Tourner le sélecteur de pression

●

pour faire monter ou descendre

l’aiguille de l’indicateur de

pression à mesure que la pression

du pied-de-biche change.

Voir également: « Bouton de réglage

des griffes d’entraînement », page 35.

Voir « Tension des fils » à la ✽

page 42.

Table de rallonge pour tissu

Abaissez les pieds de table réglables et faites glisser la table de rallonge pour

●

tissu sur la machine.

Page 37

35

Avant de commencer (2)

Bouton de ciseaux

Voyant indicateur

Bouton de position d’arrêt d’aiguille

Interrupteur

de la lampe

Bouton de réglage des

griffes d’entraînement

(Griffes d’entraînement rentrées)

(Entraînement par tige)

Velours

Tissus légers

Tissus moyens

Tissus lourds

Bouton de ciseaux

ATTENTION

Si la machine s’arrête, notamment

en cas de bourrage de fils, ne pas

appuyer sur la pédale; vérifier la

situation après avoir mis la machine

hors tension et en déplaçant

l’aiguille avec le volant à main.

Les ciseaux coupent le fil supérieur et

●

le fil de la canette à la fin des coutures.

Bouton de position d’arrêt d’aiguille

Quand le voyant est allumé, la machine

●

arrêtera la couture lorsque l’aiguille sera

abaissée et enfoncée dans le tissu.

Si le voyant est éteint, la position de

●

l’aiguille au moment de l’arrêt de la

couture sera aléatoire.

Si le mécanisme de sécurité s’est

●

déclenché, par exemple si le fil est

emmêlé, le voyant rouge clignote.

Interrupteur de la lampe

Appuyer avec le levier du pied- ✽

debiche abaissé.

Bouton de réglage des

griffes d’entraînement

Il est possible de régler ●

la hauteur des griffes

d’entraînement en fonction du

poids du tissu.

Pression du pied-de-biche et position des griffes d’entraînement

Appuyer sur l’interrupteur pour ●

allumer et éteindre la lampe sur

la section de couture.

Sélectionner l’une des quatre positions de griffes d’entraînement, en fonction des

besoins.

Remarque

Si on sélectionne un réglage autre que , le mécanisme d’entraînement

par ergot ne fonctionnera pas.

Page 38

36

Remplacement de l’aiguille et de l’ampoule de lampe

Tournevis

Surface plane

Poser l’aiguille sur une

surface plane (par

exemple la plaque à

aiguille ou une plaque

de verre).

L’aiguille doit être parallèle par

rapport à une surface plane.

Tournevis

120V230V

Ampoule

de lampe

Ampoule

de lampe

ATTENTION

Bien éteindre la machine à coudre avant

d’effectuer les opérations suivantes. Sinon,

la machine risque de se mettre en marche

accidentellement et de provoquer des blessures.

Remplacement de l’aiguille

Eteindre la machine. 1

Relever l’aiguille sur

la position de levage

maximal à l’aide du

volant, et abaisser le

pied-de-biche.

Desserrer la vis avec

2

un tournevis et retirer

l’aiguille.

Tenir l’aiguille avec la section

3

plate sur la droite, et insérer

l’aiguille à fond. Assurez-vous de

fixer correctement l’aiguille au

boîtier à aiguille en vissant à fond.

Si l’aiguille n’est pas insérée

✽

correctement ou si la vis est

trop lâche, l’aiguille risque

de se casser ou la machine

risque de tomber en panne et

l’enfileur ne fonctionnera pas.

Vérifier les aiguilles sur une

✽

surface plane pour s’assurer

qu’elles ne sont pas tordues.

Remarque

Utiliser des aiguilles HLX5; toutefois, on pourra également utiliser des

aiguilles Schmetz 130/705H dans des circonstances normales d’utilisation.

Remplacement de l’ergot d’entraînement

Régler les griffes d’entraînement sur

1

la position « velours ». (Voir page 35.)

Retirer l’aiguille, le pied-de-

2

biche et la plaque à aiguille.

Abaisser le pied-de-biche et tourner le

3

volant jusqu’à ce que l’ergot d’entraînement

soit à la position de levage maximale.

Insérer le petit tournevis (fourni)

4

comme indiqué sur le schéme.

Tout en tenant le ressort

5

du bout des doigts,

abaisser le changeur

d’ergot d’entraînement

sur l’aiguille pour

relever la tige.

Fixer un nouvel ergot

6

d’entraînement au changeur

d’ergot d’entraînement,

abaisser et fixer tout en tenant

le ressort du bout des doigts.

Retirer le tournevis.7

Remonter la plaque à 8

aiguille et le pied-debiche.

ATTENTION

Veiller à ce que la machine à coudre soit hors tension

avant d’effectuer les opérations suivantes. La plaque

de verre qui abrite l’ampoule de la lampe est chaude

immédiatement après l’utilisation de la machine; nous

conseillons dès lors d’attendre que l’ampoule ait

refroidi avant de changer cette dernière.

Remplacement de

l’ampoule

Eteindre la machine.1

Retirer la vis de la tête.2

Retirer le logement de 3

l’ampoule.

Dévisser l’ampoule et 4

la retirer.

Visser une nouvelle 5

ampoule. Lampe de

couture : voir page 50.

Remonter le logement 6

de l’ampoule et visser

à fond.

Page 39

37

b

c

d

a

c

Enfilage (1)

a

b

Capuchon de bobine

�1

Bobine de fil

�2

Coussinet de bobine

Canette

Arbre du dévidoir

Tige de guidage

Encoche à fil 1

Encoche à fil 2

Butée de canette

Remplissage de

la canette

ATTENTION