Page 1

LASER PRINTER

SERVICE MANUAL

DX-2000

MECHANICS & ELECTRONICS

Page 2

CONTENTS

CHAPTER I GENERAL....................................................................I-1

1. SPECIFICATIONS...........................................................................................I-1

CHAPTER II MECHANICAL SYSTEM............................................II-1

1. BLOCK DIAGRAM..........................................................................................II-1

2. PAPER FEED MECHANISM..........................................................................II-1

3. PAPER FEED SEQUENCE............................................................................II-2

4. PAPER PRESSER MECHANISM...................................................................II-3

CHAPTER III ELECTRICAL SYSTEM...........................................III-1

1. COMPOSITION .............................................................................................III-1

2. MAIN PCB FUNCTION..................................................................................III-1

2.1 I/F Circuit .......................................................................................................................III-1

2.2 Regulator.......................................................................................................................III-1

2.3 Fan Drive Circuit............................................................................................................III-1

2.4 Motor Drive Circuit.........................................................................................................III-1

2.5 Solenoid Actuator ..........................................................................................................III-1

2.6 Sensor Input ..................................................................................................................III-1

3. I/F PCB..........................................................................................................III-2

4. COMMUNICATION WITH THE PRINTER.....................................................III-2

CHAPTER IV DISASSEMBLY......................................................IV-1

1. EXTERNAL COVERS................................................................................... IV-1

1.1 Composition.................................................................................................................. IV-1

1.2 Side Cover R ................................................................................................................IV-1

1.3 Side Cover L.................................................................................................................IV-3

1.4 Bottom Cover................................................................................................................ IV-4

1.5 Top Cover..................................................................................................................... IV-5

2. OUTSIDE FRAME UNIT............................................................................... IV-7

2.1 Composition.................................................................................................................. IV-7

2.2.1 Removing the outside frame unit from the Duplex unit................................................. IV-7

2.2.2 Mounting the outside frame unit in the Duplex unit....................................................... IV-9

2.3 Duplex I/F PCB...........................................................................................................IV-10

2.4 Outside Frame R Assy, L Assy................................................................................... IV-11

2.5 Paper Pressing Gear 1, 2........................................................................................... IV-12

i

Page 3

2.6 Paper Presser Motor................................................................................................... IV-13

2.7 T Belt B40S2M396...................................................................................................... IV-14

2.8 Photo Interrupter 1240................................................................................................ IV-14

3. INSIDE FRAME UNIT................................................................................. IV-15

3.1 Reversible Frame ....................................................................................................... IV-15

3.2 Photo interrupter 1240................................................................................................IV-15

3.3 Solenoid...................................................................................................................... IV-16

3.4 Carriage Guide 2 Assy................................................................................................ IV-16

3.5 Carriage Guide 1 ........................................................................................................IV-17

3.6 Duplex PCB Assy ....................................................................................................... IV-17

3.7 DC Fan Motor............................................................................................................. IV-18

3.8 Reversible Motor Assy................................................................................................ IV-19

4. DU TRAY CARRYING WAY UNIT.............................................................. IV-20

CHAPTER V TROUBLESHOOTING..............................................V-1

APPENDICES

1. CONNECTION DIAGRAM............................................................................. A-1

2. MOTOR DRIVE CIRCUIT.............................................................................. A-2

3. MAIN PCB CIRCUIT...................................................................................... A-3

ii

Page 4

CHAPTER I GENERAL

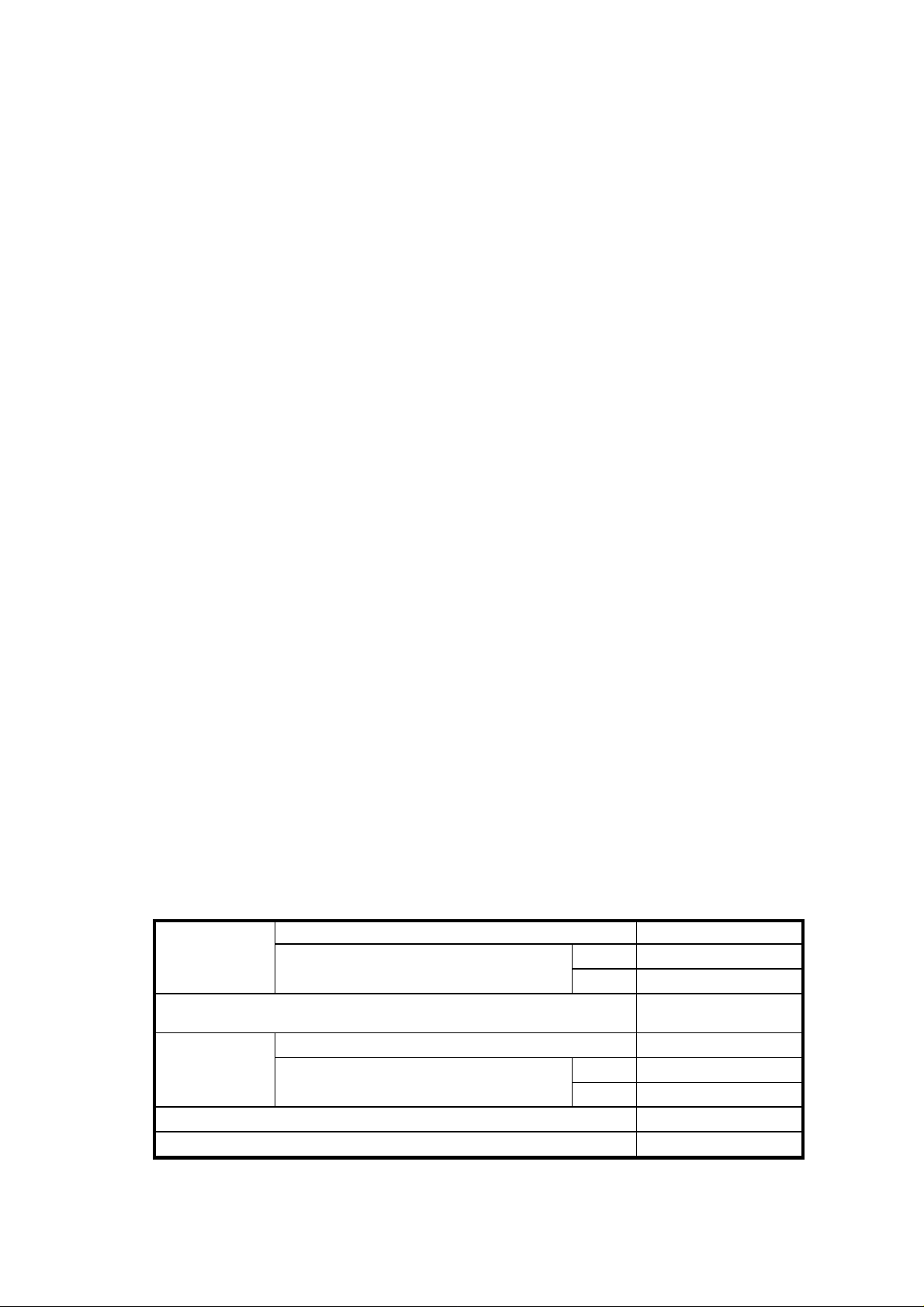

1. SPECIFICATIONS

(1) Paper type Cut sheet

Feedable paper weight : 60 ~ 105 g/ m

(2) Paper size Max. : 216.0 x 356.0 mm

Min. : 182.0 x 257.0 mm

A4, Letter, Legal, Executive, ISO B5 (not available for

the optional lower paper cassette)

(3) Input power supply 24V DC ± 10%, max. 0.7 A (supplied from the printer)

(4) Feeding system Type :Reversal type

Paper feeding system :Alternate paper feeding system

(5) Paper feed Paper feeding rate : 117.6 mm/sec. (20 ppm)

94.1 mm/sec. (16 ppm)

70.6 mm/sec. (12 ppm)

Feedable paper size :A4 210.0 x 297.0 mm

Letter 215.9 x 279.4 mm

Legal 215.9 x 355.6 mm

Executive 184.2 x 266.7 mm

B5 182.0 x 257.0 mm

(6) Dimensions 323.0 (W) x 105.0 (D) x 286.0 (H) mm

(7) Weight 5.4 kg

2

(8) Environmental conditions

1) Operating Temperature : 10°C ~ 32.5°C

Humidity : 20% RH ~ 80% RH (No dew

condensation allowed)

2) Idling Temperature : 0°C ~ 35°C

Humidity : 10% RH ~ 80% RH (No dew

condensation allowed)

3) Storage

Store the unit under the following conditions to ensure reliable performance.

Normal (90% of entire storage period)

Temperature Severe (10% of entire storage period) High

Low

Temperature variation (within 3 minutes)

Normal (90% of entire storage period) 35%RH ~ 85%RH

Humidity* Severe (10% of entire storage period) High 85%RH ~ 95%RH

Low 10%RH ~ 35%RH

Air pressure 613 ~ 1013hPa

Storage life 0.5 years

0°C ~ 35°C

35°C ~ 60°C

-20°C ~ 0°C

60°C →15°C

-20°C→25°C

*No dew condensation allowed

I-1

Page 5

4) Transportation conditions

Environment :

5) Vibration

During operation

At standby

When packed

6) Inclination The feeder must operate properly even at an

7) Mechanical noise During printing : 55 dB (A) or below

(9) Interface

1) Connector signal table (8 pin modular jack)

Temperature

-20°C ~ 60°C

Humidity 95%RH or below

Vibration

acceleration

Vibration

frequency

Measuring method

0.2 G 5 ~ 100 Hz Refer to the evaluation test standard.

0.2 G 5 ~ 100 Hz Same as above.

1.5 G 10 ~ 100 Hz Same as above.

inclination angle of 2.

At standby : 40 dB (A) or below

Pin Signal name

1 24V

2 SIDATA

3 24V

4 SICLK

5 GND

6 /ATTN

7 /RESET

8 GND

2) Interface circuit

5V

5V

Connector

0V

74LS07 or equivalent

I-2

Page 6

CHAPTER II MECHANICAL SYSTEM

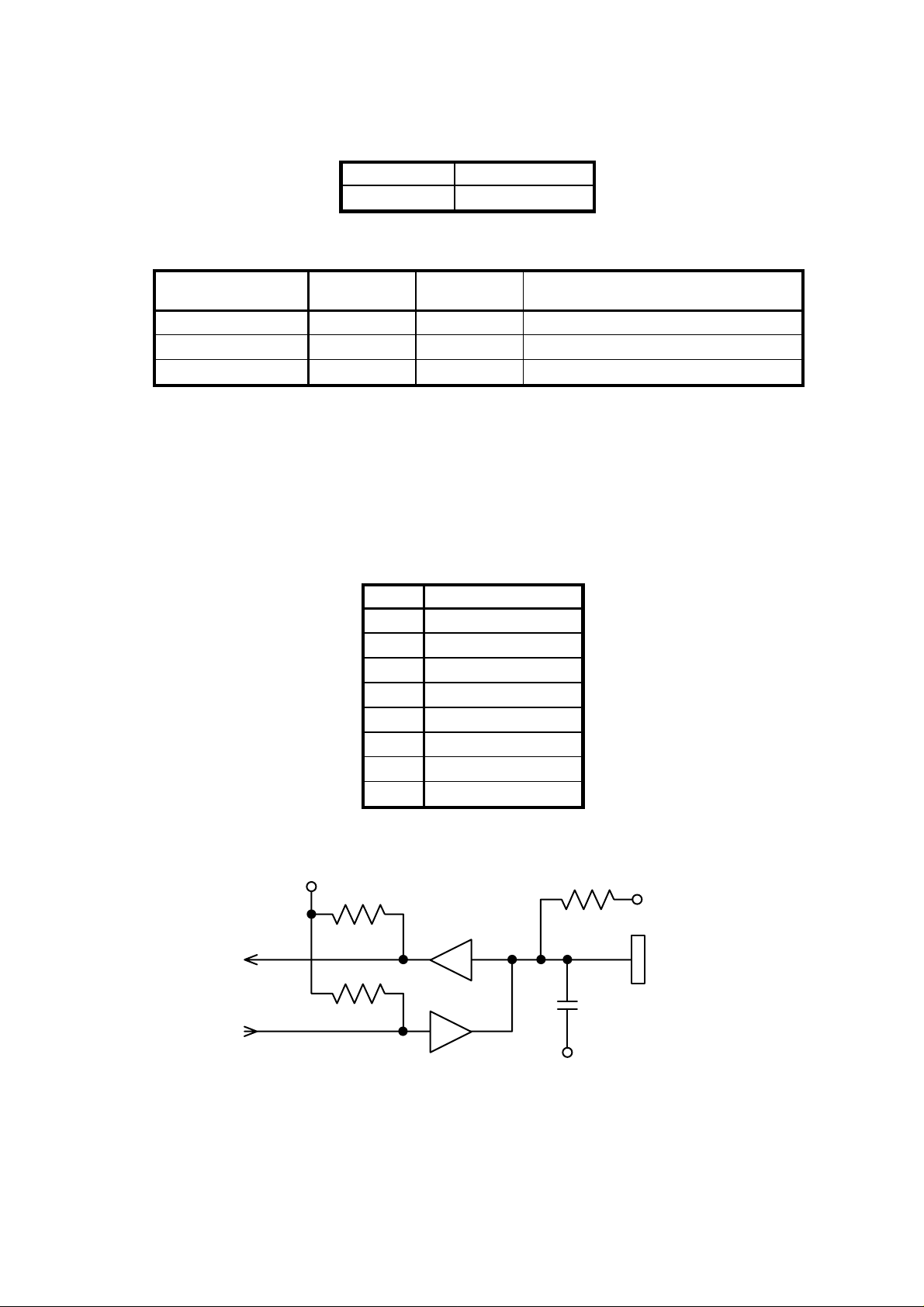

1. BLOCK DIAGRAM

The Duplex unit is composed of an outside frame, an inside frame and a Duplex tray, and

operates according to signals sent from the printer in serial communication.

Inside frame Outside frame

Printer

Serial

communication

Open cover sensor

I/F PCB

Paper pressure motor

Cassette sensor

Duplex tray

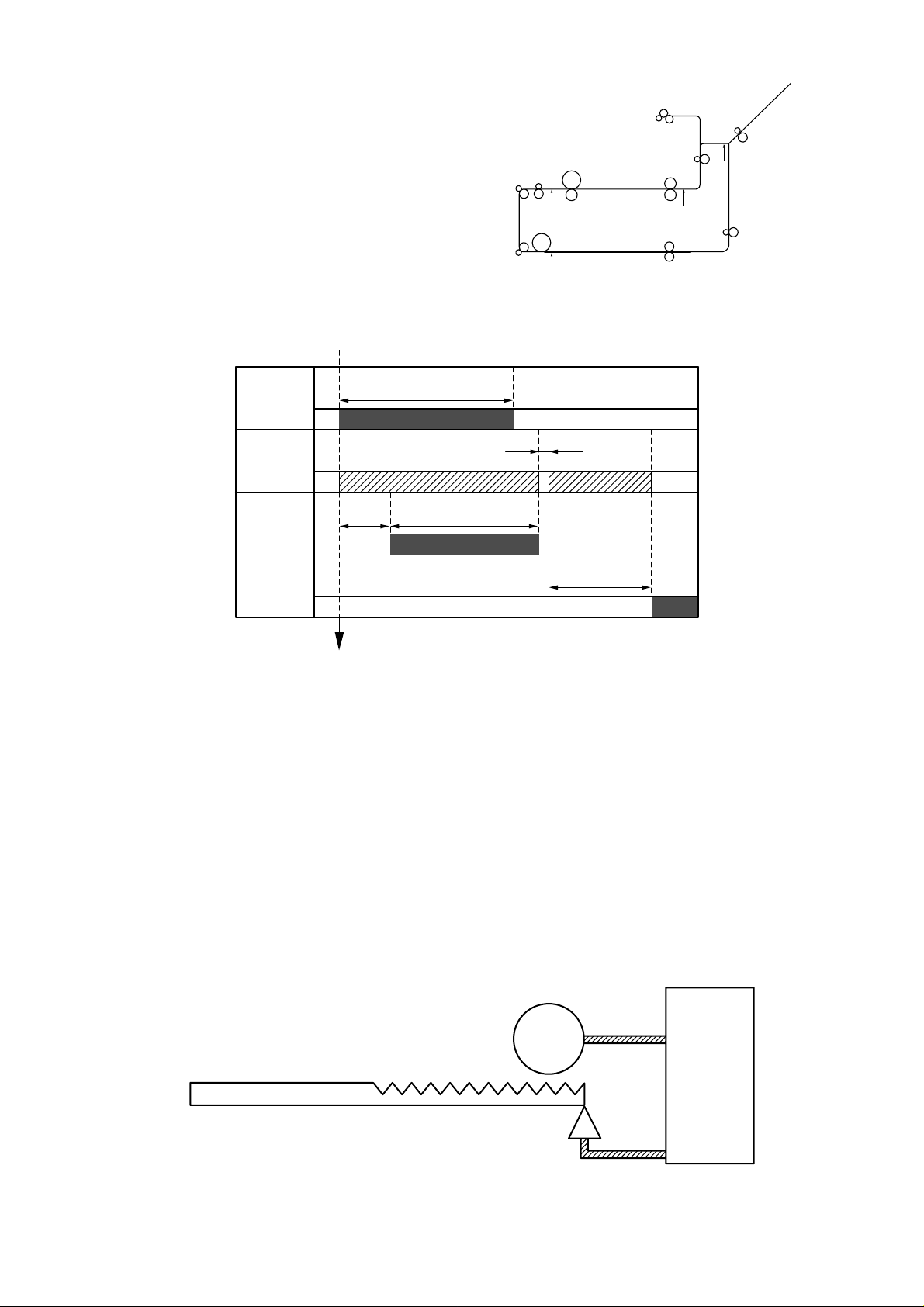

2. PAPER FEED MECHANISM

As soon as the printer requests for drive, a signal from the main PCB turns on the

solenoid to run the reversible motor clockwise (when viewed from the motor output shaft).

The Duplex unit will draw paper from the printer by turning on the solenoid.

The supplied paper is further transferred by the reversible motor driven reversible gears.

Figure 2.1

Main PCB

Fan motor

Reversible motor

Reverse sensor

Solenoid

When the reverse sensor detects the rear end of the paper, the reversible motor comes

to a momentary stop, and begins running counterclockwise.

Then the reversible motor enables the carriage rollers to feed the paper into the Duplex

tray installed within the Duplex unit. With the printer’s Duplex sensor on, the Duplex unit

stops the reversible motor by a request from the printer.

One cycle of paper feeding operation is completed in this way.

Duplex unitPrinter

Photosensitive drum

Pick up roller

Duplex sensor

Positioner

Du carriage roller

Reverse

sensor

Solenoid

Reversible gear

Reversible

motor

Main PCB

Figure 2.2

II-1

Page 7

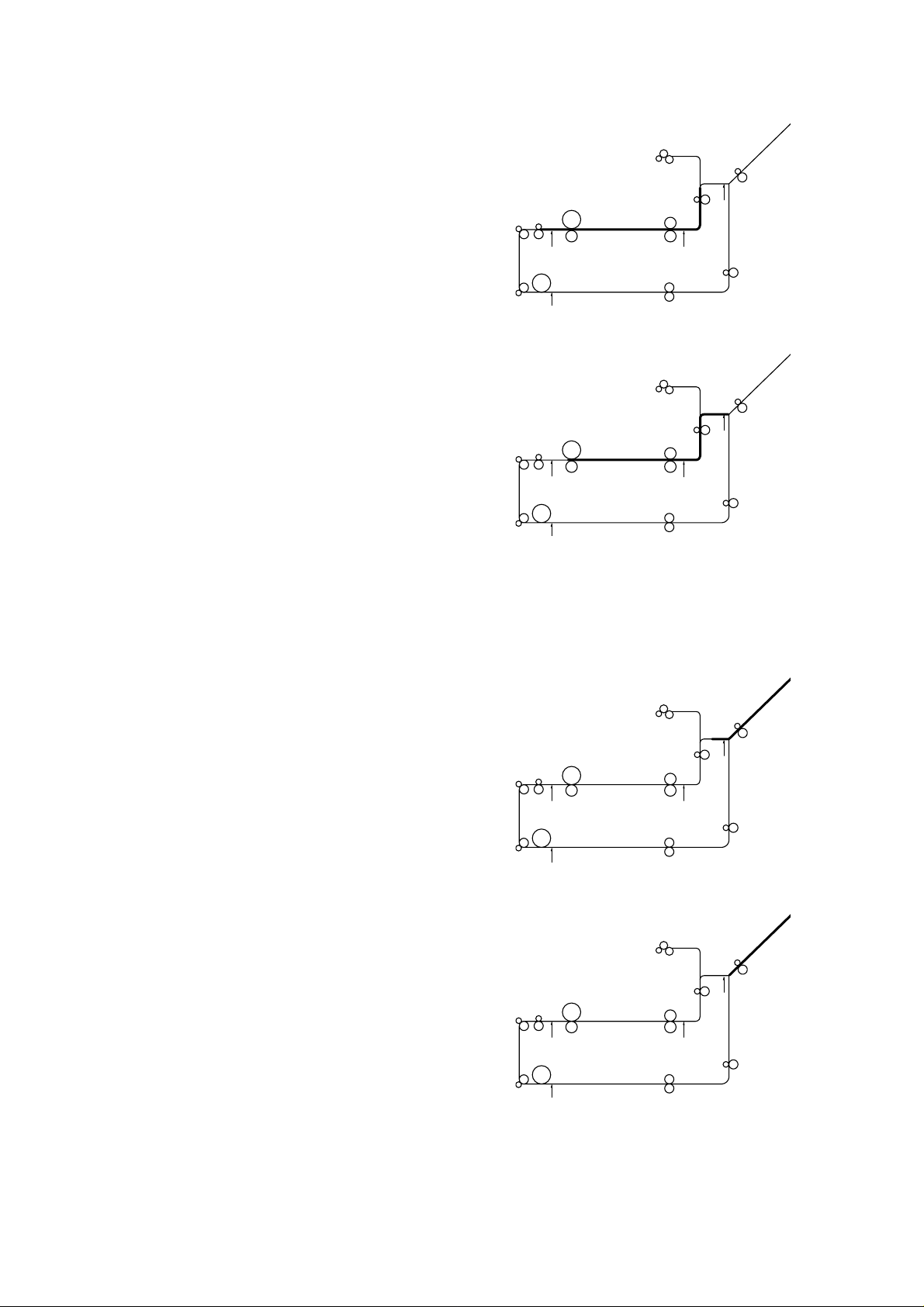

3. PAPER FEED SEQUENCE

(1) As soon as the printer requests for Duplex drive,

the solenoid is turned on, the flapper is switched,

and the motor runs forward.

(2) The reverse sensor is monitored to measure the

time from when the solenoid is turned on to when

the sensor is turned on.

If the sensor has not turned on after a specified

time passed, it is deemed that paper jam has

occurred.

(3) The solenoid is turned off in response to

instructions from the printer, and the flapper is

returned as it was before.

After the reverse sensor is turned on, the time up

to when the paper has passed through the reverse

sensor is monitored.

If the sensor has not turned off within a specified

time, it is deemed that paper jam has occurred.

(4) Immediately after the reverse sensor is turned off,

the motor begins through-down, stops for a

specified time, and runs backward.

II-2

Page 8

(5) As soon as the printer requests for stop, the motor

stops and goes into a standby state.

•• Paper Feed Timing Chart

(when only one piece of A4 paper is reversed and printing speed is 12 ppm)

Solenoid

Reversible

motor

Reverse

sensor

Duplex

sensor

Duplex drive request from the printer

1.3 sec* 4.21 sec*

4.84 sec*

C.W C.C.W

Figure 2.3

* The paper feed timing varys in the printing speed.

For 16 ppm, 12/16 times the above values.

For 20 ppm, 12/20 times the above values.

4. PAPER PRESSURE MECHANISM

Upon a request from the printer, the paper pressure unit built in the Duplex tray is moved

up or down by the paper pressure motor connected to the I/F PCB.

0.1 sec

3.2 sec*

The paper pressure unit is moved up only when the first tray is selected on the printer to

supply paper, or down when paper is fed from another tray.

The cassette sensor detects the position of the paper pressure unit, and whether the

Duplex tray is loaded into the Duplex unit.

Paper pressure motor

I/F PCB

Paper pressure unit

Cassette sensor

Figure 2.4

II-3

Page 9

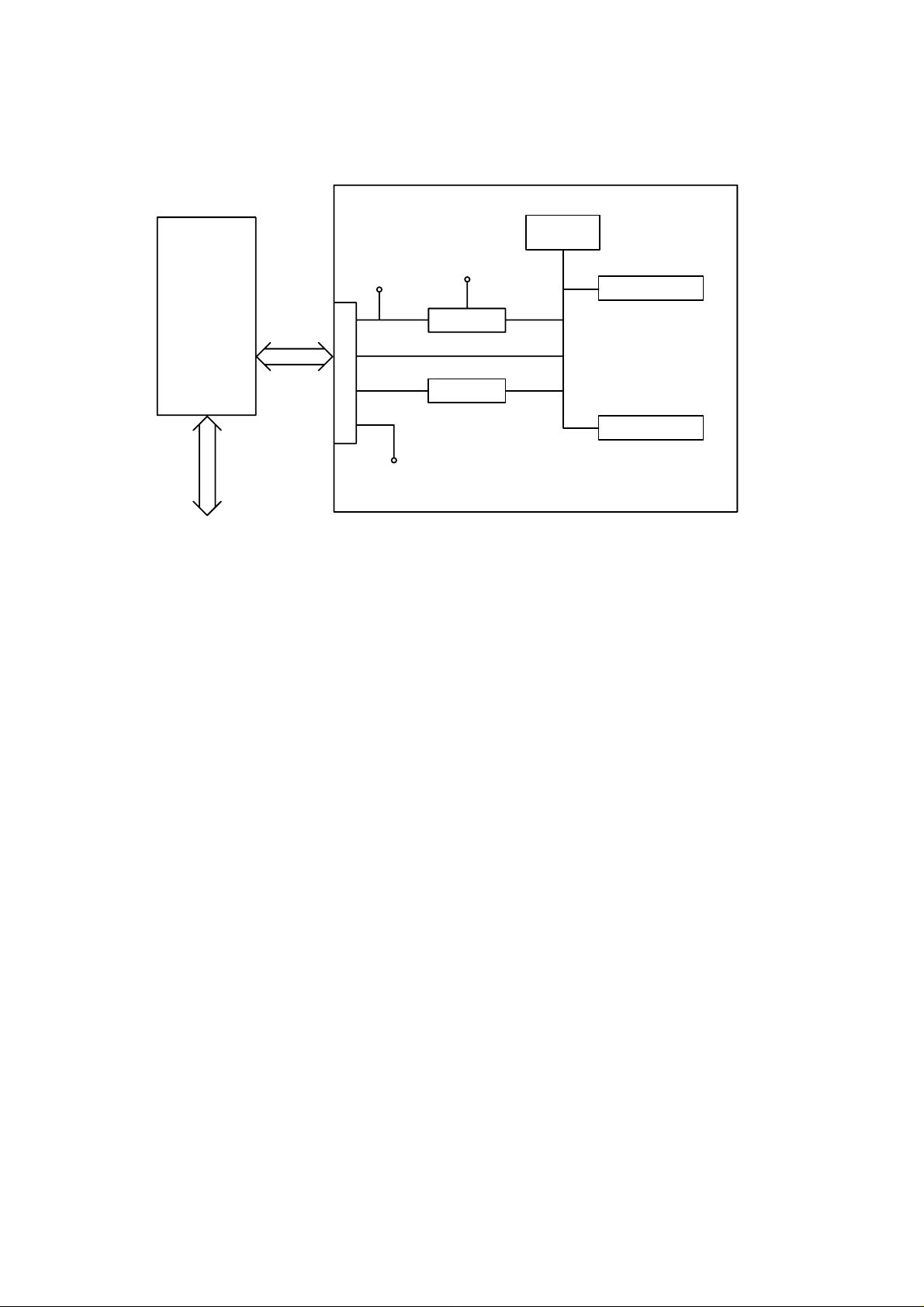

CHAPTER III ELECTRICAL SYSTEM

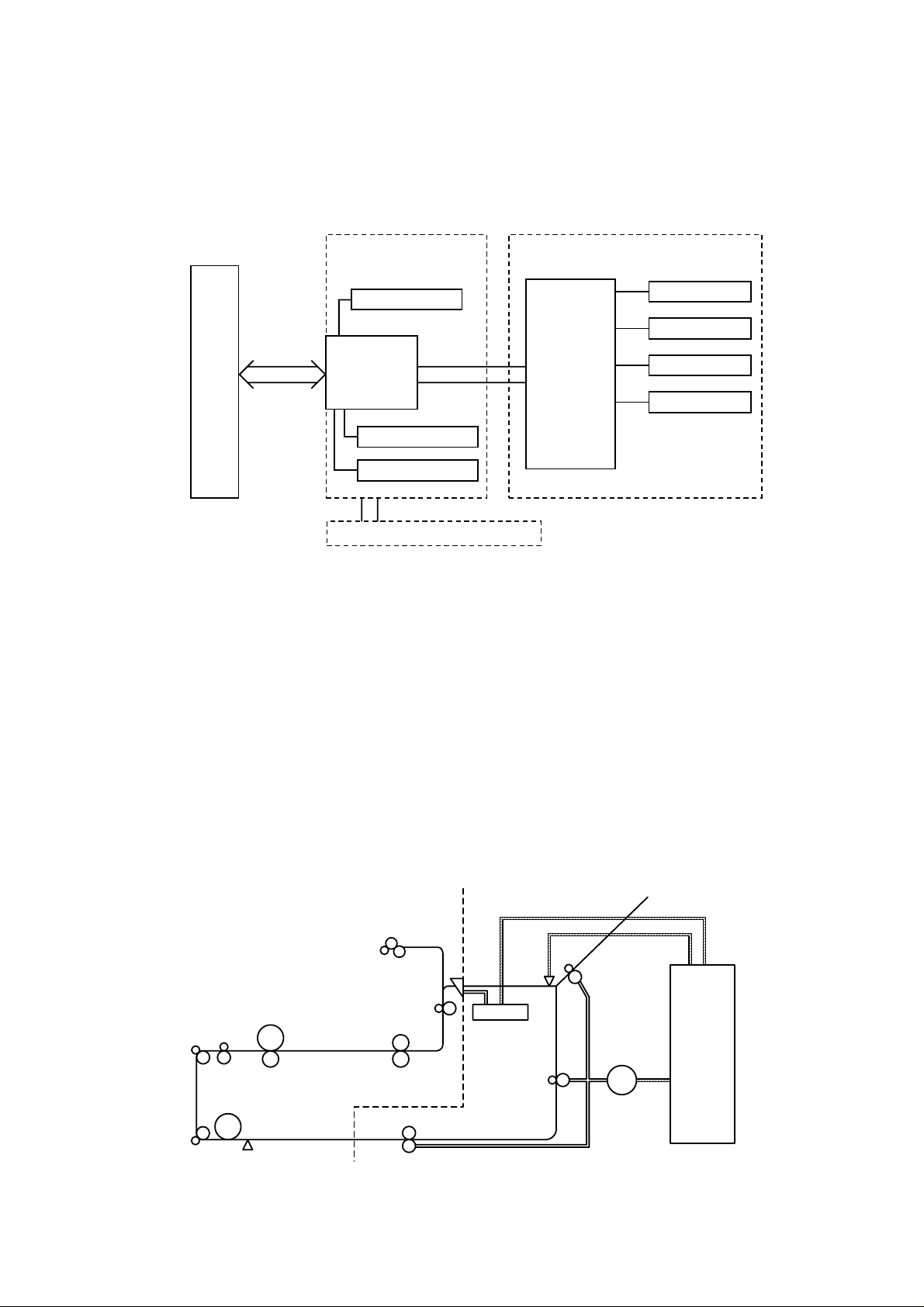

1. COMPOSITION

I/F PCB

Printer

2. MAIN PCB FUNCTION

2.1 I/F Circuit

+24V

Main PCB

CPU

M50927

+5V

Motor drive circuit

Regurator

I/F circuit

Fan drive circuit

GND

Figure 3.1

This interface circuit is used to transmit and receive data with the printer. Since the

Duplex unit responds only to commands from the printer, the Duplex unit transmits its

status upon request from the printer.

2.2 Regulator

The regulator produces +5V logic power supply from the +24V supplied by the printer.

2.3 Fan Drive Circuit

This circuit drives the cooling DC fan.

The fan rotation speed is switched between two different levels according to the signal

from the CPU. It operates at high speed when the Duplex unit feeds paper, or it runs at

low speed while the unit is not in operation.

When the DC fan functions properly, it sends a /FLOCK signal to the CPU to confirm that

it is normal.

2.4 Motor Drive Circuit

According to the signal from the CPU, this circuit drives both the reversible motor and the

paper pressure motor.

2.5 Solenoid Actuator

According to the signal from the CPU, this actuator turns the solenoid on or off.

2.6 Sensor Input

Signals to each of the reverse sensor, cassette sensor and open cover sensor are

imported to the CPU port.

III-1

Page 10

3. I/F PCB

The I/F PCB consists of two connectors (8-pin modular jack connectors) for connection of

the printer to other optional devices, a paper pressure motor, a cassette sensor, an open

cover sensor connector, and a connector for connection of the harness from the main

PCB.

This board only relays signals among the paper pressure motor, cassette sensor, open

cover sensor and printer and the main PCB.

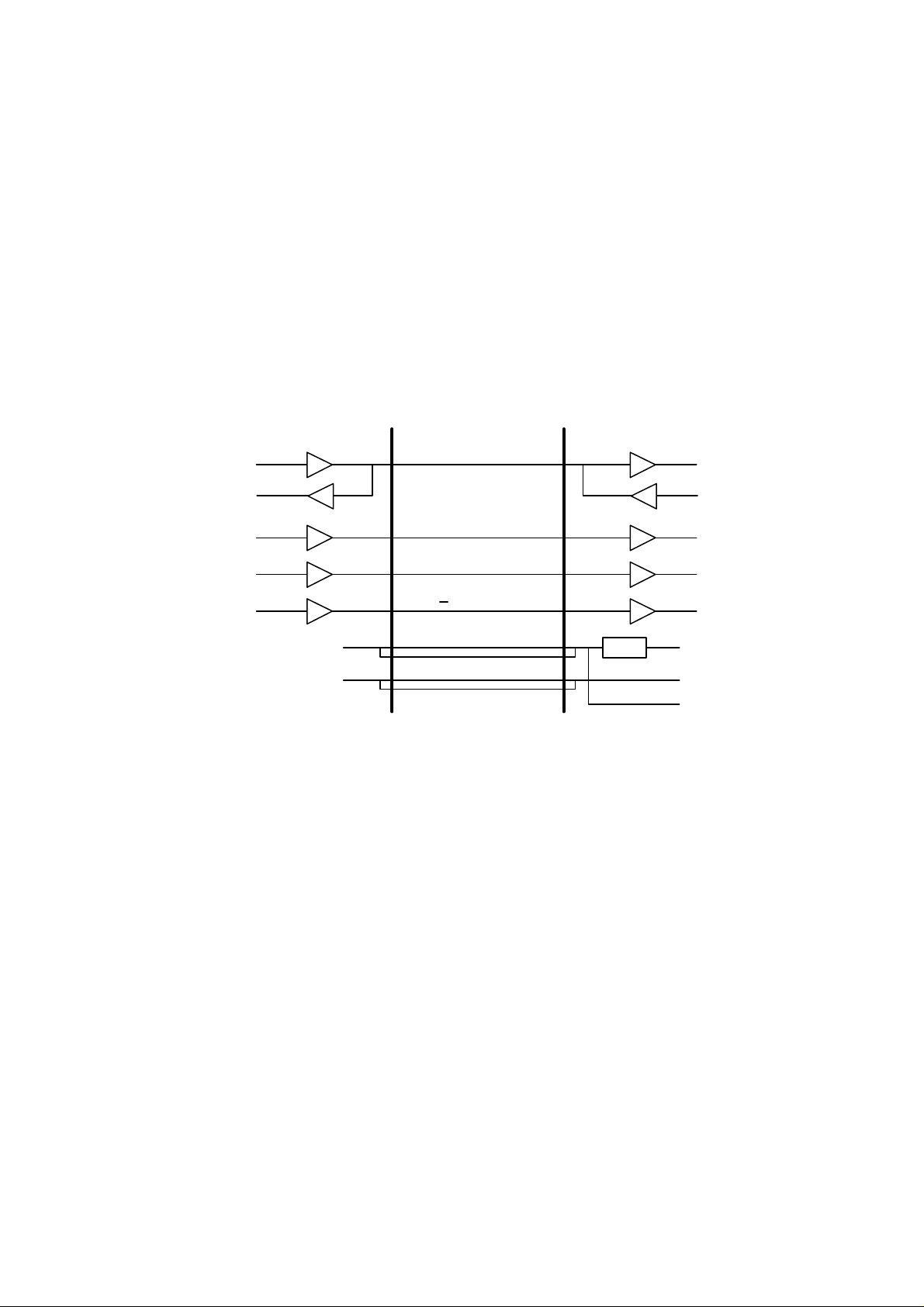

4. COMMUNICATION WITH THE PRINTER

A 3-line clock synchronous serial interface is used for communication between the

Duplex unit and the printer.

The following describe the timing of communication way.

Printer Duplex unit

DATAOUT

DATAIN

CLKOUT

/ATNOUT

/OPRST

+24V

GND

SIDATA

SICLK

/ATTN

/OP RESET

+24V

GND

Figure 3.2

REG.

DATAIN

DATAOUT

CLKIN

/ATNIN

/RESET

+5V

GND

+24V

III-2

Page 11

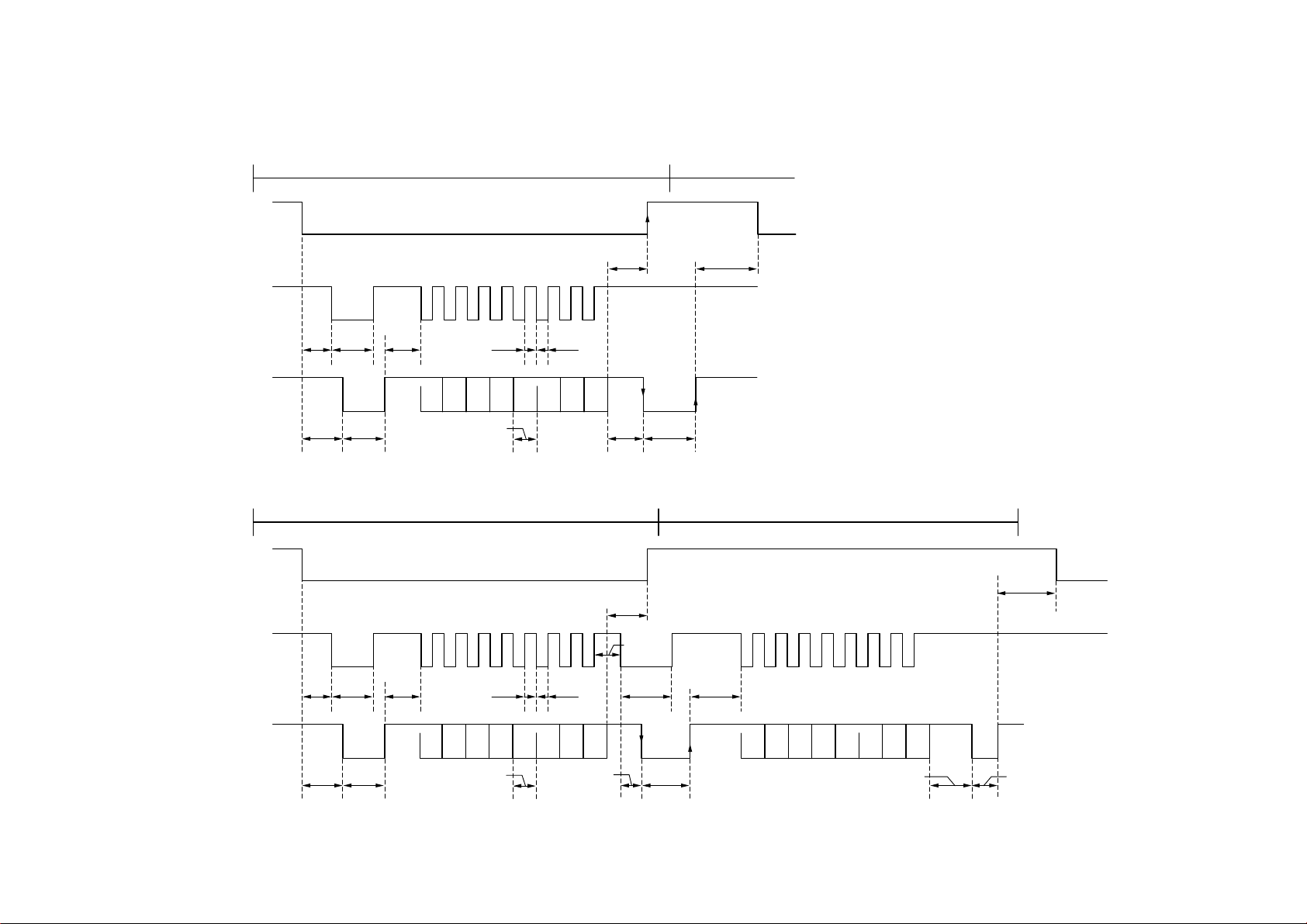

• Without a STATUS request

COMMAND transmission/receipt sequence

/ATTN

SICLK

500 min200 µs

III-3

400 min4µs

SIDATA

500 max

350 max

50 µs 12.8 µs

• Within a STATUS request

COMMAND transmission/receipt sequence

/ATTN

SICLK

400 min4µs

SIDATA

500 max

350 max

50 µs 350 max

6.4 min6.4 min

D0 D1 D2 D3 D4 D5 D6 D7

6.4 min

D0 D1 D2 D3 D4 D5 D6 D7

6.4 min

350 max

200 µs

350 max

200 µs

150 min

150 µs12.8 µs

STATUS transmission/receipt sequence

500 min

350 max

D0 D1 D2 D3 D4 D5 D6 D7

70 µs/1000 max 350 min

Page 12

CHAPTER IV DISASSEMBLY

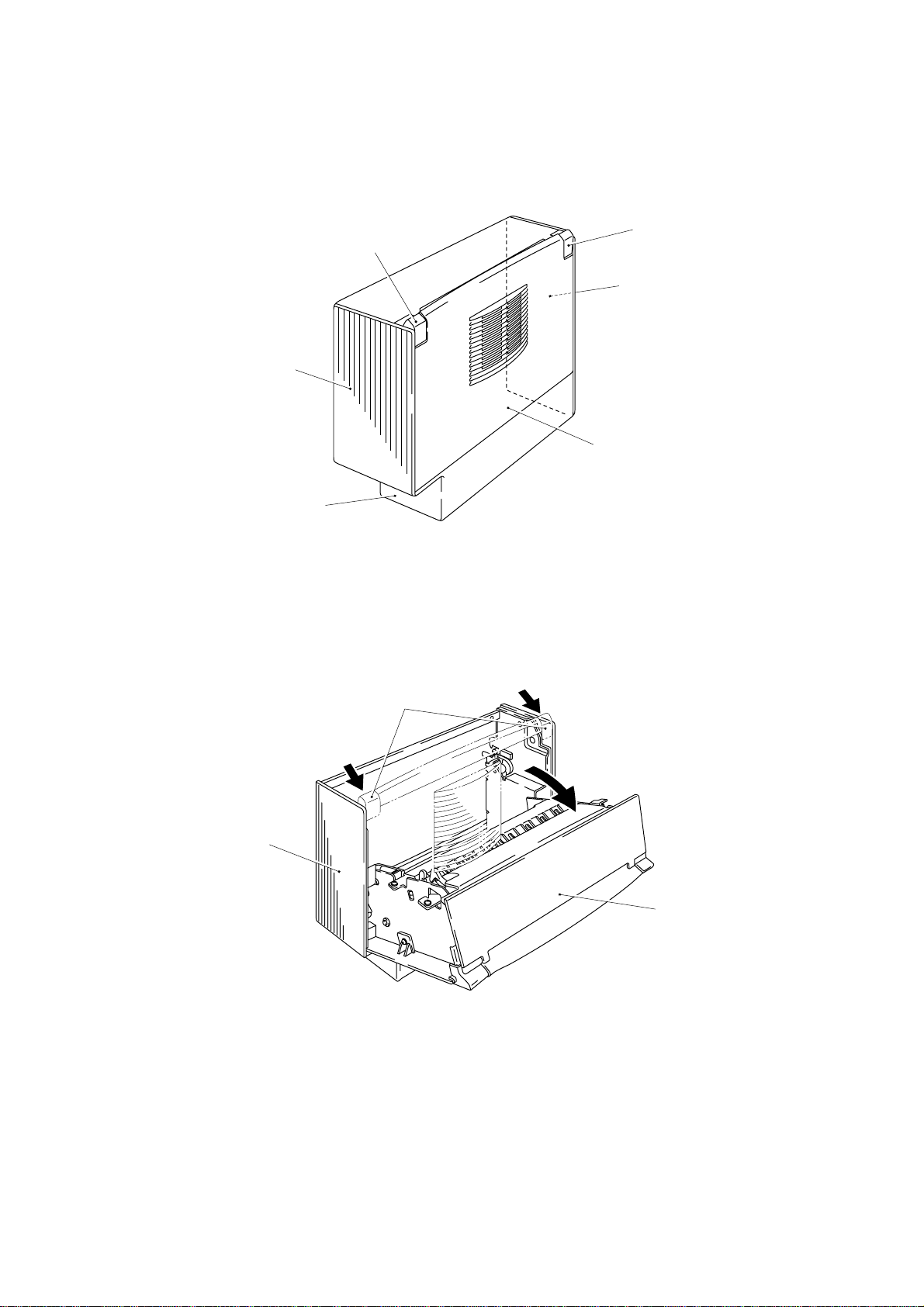

1. EXTERNAL COVERS

1.1 Composition

Side cover R

Bottom cover

1.2 Side Cover R

(1) Push the lock lever cover, turn and open the inside frame unit.

Lock lever cover

Lock lever cover

Side cover L

Top cover

Figure 4.1

Outside frame unit

Lock lever cover

Inside frame unit

Figure 4.2

IV-1

Page 13

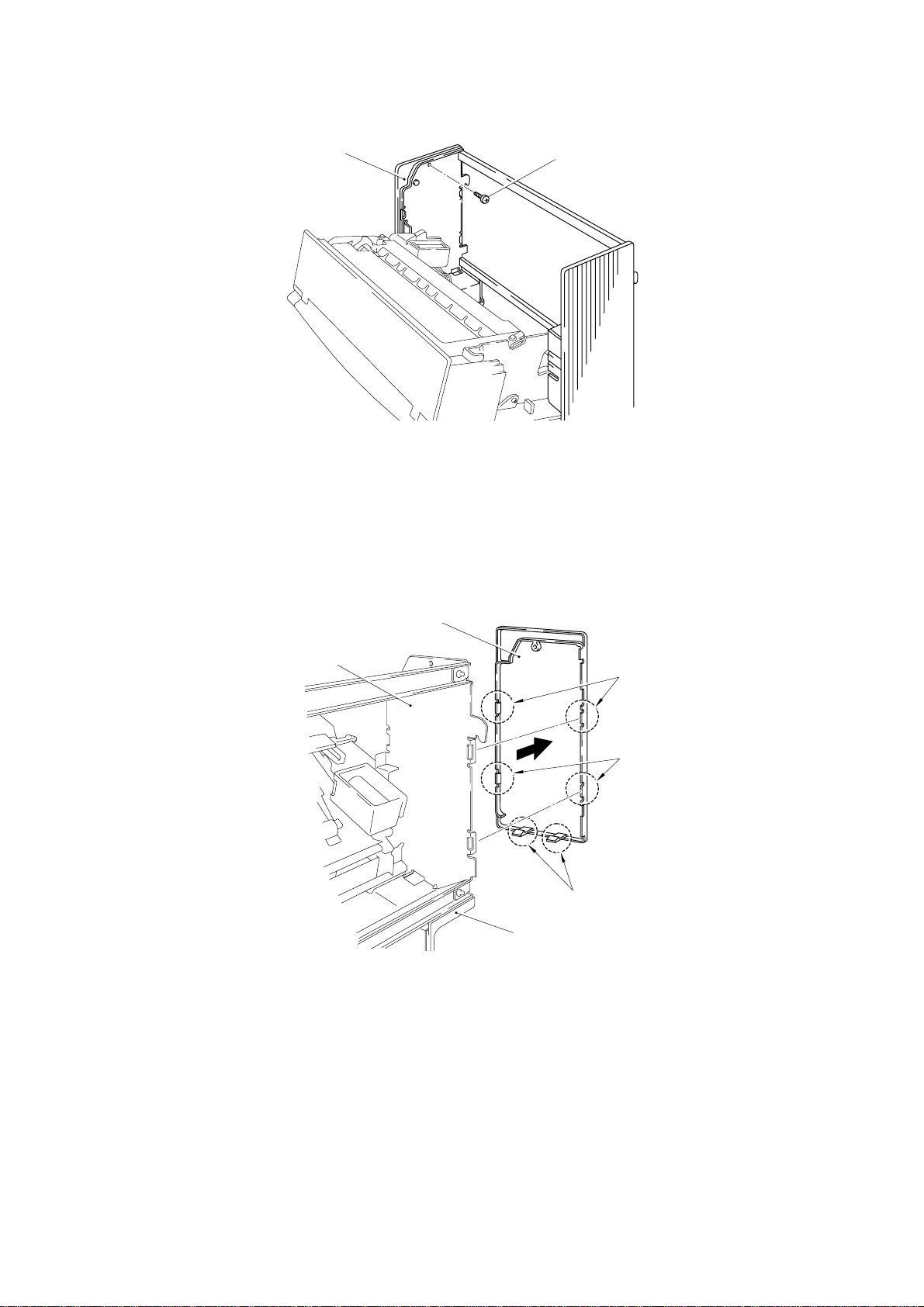

(2) Loosen the screw fastening the side cover R.

Side cover R

Taptite, bind B M3 x 6

Figure 4.3

(3) Using a small minus screwdriver, disengage the six hooks to remove the side

cover R from the outside frame R and the bottom cover.

(4) Separate the side cover R from the Duplex unit.

Outside frame R

Side cover R

Hooks

Hooks

Hooks

Bottom cover

Figure 4.4

IV-2

Page 14

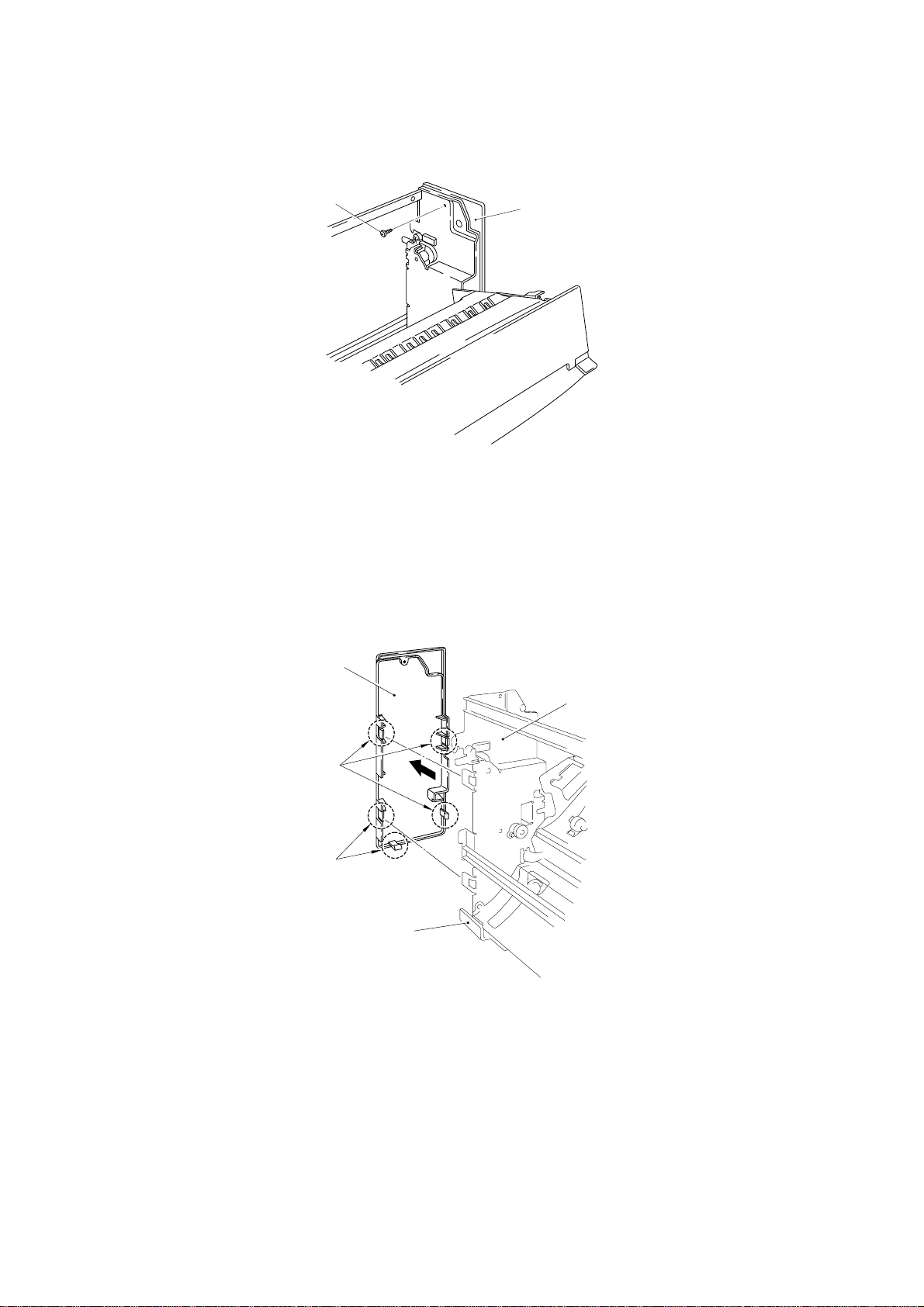

1.3 Side Cover L

(1) Unfasten the screw fastening the side cover L.

Taptite, bind B M3 x 6

Side cover L

Figure 4.5

(2) Using a small minus screwdriver, disengage the five hooks to remove the side

cover L from the outside frame L and the bottom cover.

(3) Separate the side cover L from the Duplex unit.

Side cover L

Hooks

Hooks

Outside frame L

Bottom cover

Figure 4.6

IV-3

Page 15

1.4 Bottom Cover

(1) Turn and close the inside frame unit.

(2) Lay down the Duplex unit on the side to face up the bottom cover.

(3) Loosen the two screws.

Bottom cover

Taptites, cup S M3 x 6

PR99079

Figure 4.7

(4) Disengage the engaging locks of the bottom cover from the outside frame L, and

separate the cover from the Duplex unit.

Bottom cover

Engaging locks

Figure 4.8

IV-4

Page 16

1.5 Top Cover

(1) Place the Duplex unit with the bottom down.

(2) Pushing the lock lever cover, turn and open the inside frame slightly. (approx.

30°)

Lock lever cover

Outside frame unit

Lock lever cover

Approx. 30°

Inside frame unit

Figure 4.9

(3) Disengage the hook of the lock lever cover by using a minus screwdriver, and pull

out the cover slantingly.

Lock lever cover

Top cover

Hook

Figure 4.10

IV-5

Page 17

(4) Loosen the four screws (two on each side).

g

Top cover

Taptites,

cup S M3 x 6

(5) Slide up the top cover to disengage the five engaging locks from the inside frame

unit, and separate the top cover from the Duplex unit.

Push the bosses in these holes,

and remove the

ear cover.

Top cover

Taptites,

cup S M3 x 6

Top cover

Figure 4.11

Gear cover

Engaging locks

Inside frame unit

Engaging locks

Figure 4.12

IV-6

Page 18

2. OUTSIDE FRAME UNIT

2.1 Composition

Outside frame R assy

Carriage guide 3

Paper pressure motor

Tower bars

Outside frame L assy

Figure 4.13

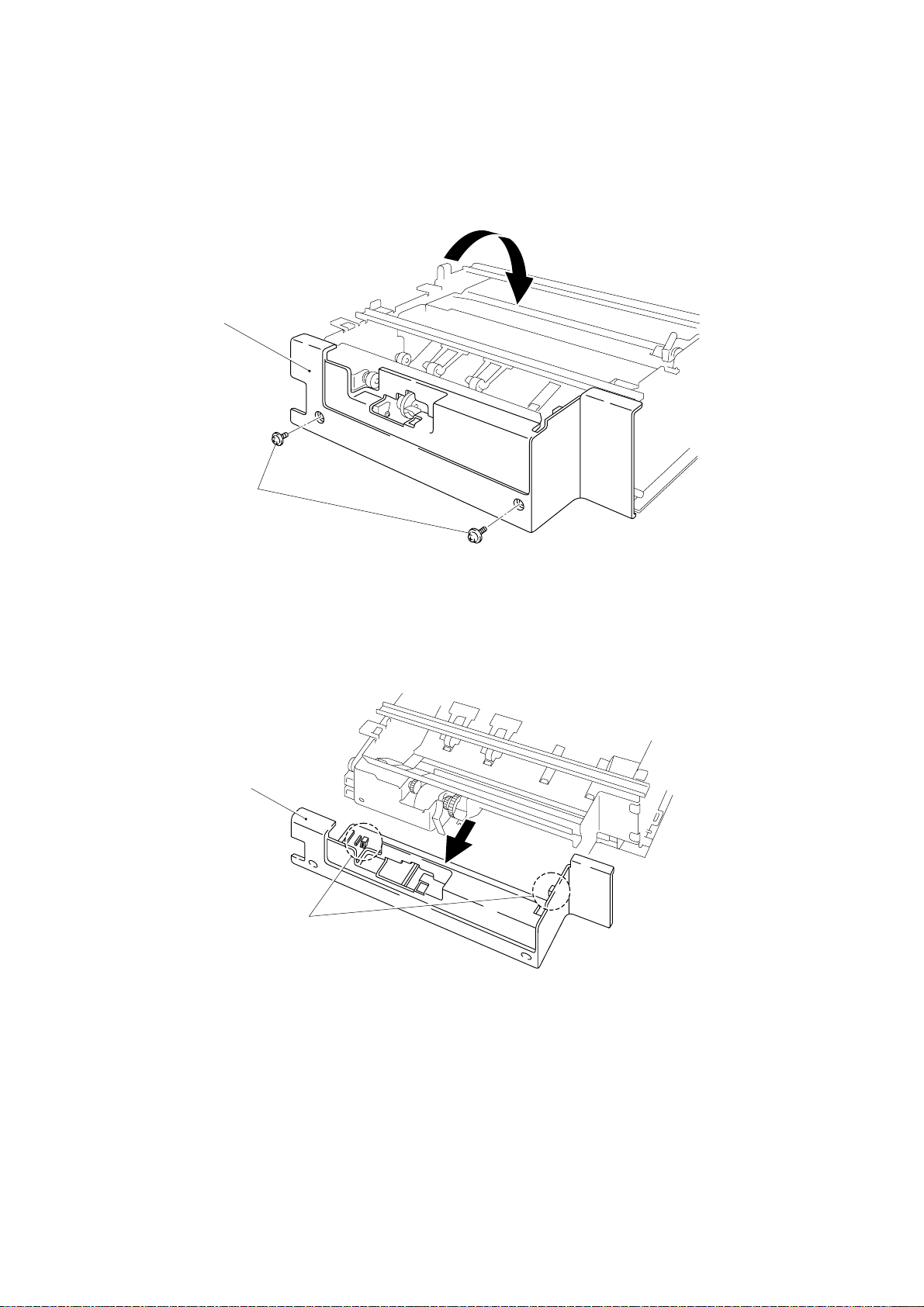

2.2.1 Removing the outside frame unit from the Duplex unit

(1) Turn and close the inside frame unit.

(2) Disconnect the relay harness assy from the Duplex I/F PCB assy and the edge

saddle.

(3) Pull out the fulcrum shaft R by using pliers.

(4) Remove the fulcrum spring.

Retaining ring E4

Retaining ring E6

Outside frame unit

Inside frame unit

Fulcrum shaft L

Fulcrum shaft R

Bearing collar

Fulcrum spring

Figure 4.14

IV-7

Page 19

Edge saddle

Relay harness assy

Duplex I/F PCB assy

Figure 4.15

(5) Slide the R side of inside frame unit toward you to remove it from the fulcrum

shaft L and the outside frame unit.

Inside frame unit

R side

Outside frame unit

Fulcrum shaft L

Figure 4.16

IV-8

Page 20

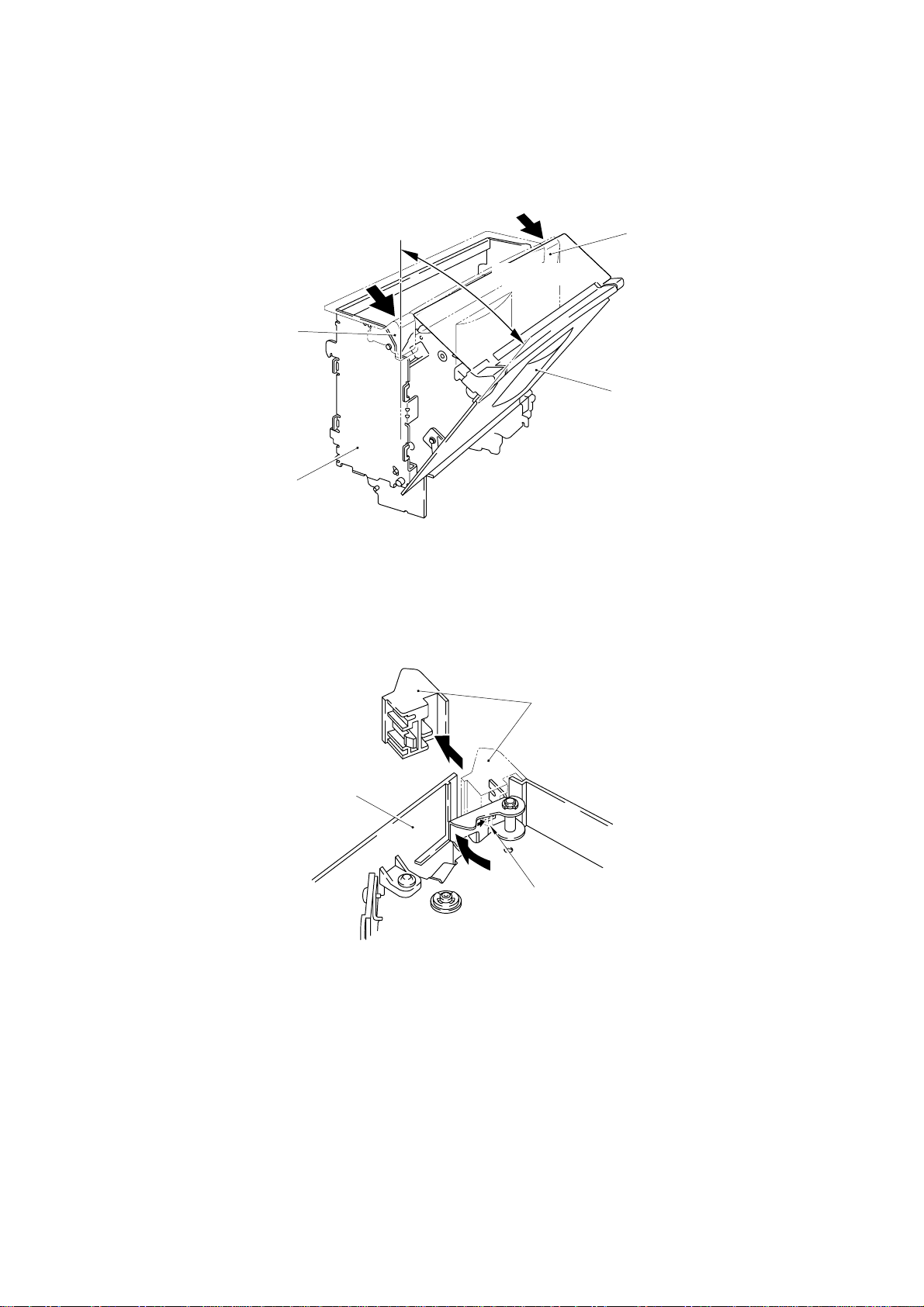

2.2.2 Mounting the outside frame unit in the Duplex unit

(1) Keeping the inside frame unit slantwise, mate the hole for the fulcrum shaft L of

the inside frame unit with the fulcrum shaft L.

Note1 : Do not get the relay harness assy caught between the inside

frame unit and the outside frame unit.

Note2 : If the solenoid assy harness is slack, stretch it.

(2) Turn the inside frame unit on the fulcrum shaft L to set it in the outside frame unit.

Solenoid assy harness

Solenoid

Outside frame unit

Inside frame unit

Hole for the fulcrum shaft L

Fulcrum shaft L

Figure 4.17

(3) Insert one end of the fulcrum spring in the hole in the outside frame unit.

Outside frame unit

Hole in the outside frame unit

Fulcrum spring

Relay harness assy

Inside frame unit

Figure 4.18

IV-9

Page 21

(4) Pass the fulcrum shaft R through the outside frame unit, the fulcrum spring and

the inside frame unit.

(5) Using nippers, set the other end of the fulcrum spring (inside frame unit side) in

the inside frame unit.

Outside frame unit

Retaining ring E6

2.3 Duplex I/F PCB

(1) Disconnect the paper pressure motor harness, the cover sensor harness assy

and the cassette sensor assy from the Duplex I/F PCB assy.

(2) Unfasten the screw.

(3) Remove the Duplex I/F PCB from the outside frame L.

Retaining ring E4

Fulcrum shaft R

Fulcrum spring

Figure 4.19

Inside frame unit

Bearing collar

Outside frame L

Taptite, cup S M3 x 5

Duplex I/F PCB

Cassette sensor assy

Cover sensor harness assy

Paper pressure motor harness

Figure 4.20

IV-10

Page 22

2.4 Outside Frame R Assy, L Assy

(1) Unfasten the four screws.

(2) Remove the two tower bars from the outside frame unit.

Taptites, cup S M3 x 5

(3) Unfasten the two screws.

(4) Remove the outside frame R assy from the carriage guide 3.

Tower bars

Taptite, cup S M3 x 5

Outside frame unit

Taptite, cup S M3 x 5

Figure 4.21

Outside frame R assy

Taptites, cup S M3 x 5

Carriage guide 3

Figure 4.22

IV-11

Page 23

(5) Unfasten the four screws.

(6) Remove the outside frame L assy and the paper pressure frame assy from the

carriage guide 3.

Taptites, cup S M3 x 5

Outside frame L assy

Carriage guide 3

Paper pressure frame assy

Taptites, cup S M3 x 5

Figure 4.23

2.5 Paper Pressing Gear 1, 2

(1) Remove the gear release spring from the paper pressure frame assy and the gear

release lever.

(2) Draw the paper pressure frame assy from the gear release lever in the direction

of the arrow.

(3) Remove the paper pressing gear 2.

Paper pressing gear 2

Gear release spring

Paper pressure frame assy

Gear release lever

Figure 4.24

IV-12

Page 24

(4) Remove the two retaining rings E3.

(5) Pull out the two paper pressing gear shafts.

(6) Remove the paper pressing gears 1 and 2.

Paper pressing gear 2

Gear release lever

Paper pressing gear shafts

2.6 Paper Pressure Motor

(1) Unfasten the screw A.

(2) Remove the cassette sensor lever and the leaf switch from the outside frame L

assy.

(3) Unfasten the two screws B.

Paper pressing gear 1

Retaining rings E3

Figure 4.25

(4) Remove the paper pressure motor from the outside frame L assy.

Paper pressure motor

Outside frame L assy

Leaf switch

Screw B (Taptite, bind S M3 x 5)

Cassette sensor lever

Screw A (Taptite, cup S M3 x 5)

Figure 4.26

Screw B (Taptite, bind S M3 x 5)

IV-13

Page 25

2.7 T Belt B40S2M396

(1) Remove the belt tension spring.

(2) Unfasten the screw.

(3) Remove the T belt B40S2M396.

Outside frame L assy

Taptite, cup S M3 x 5

T Belt B40S2M396

Belt tension spring

2.8 Photo Interrupter 1240

(1) Flexing the hook inward, turn the photo interrupter 1240 in the direction of the

arrow and remove it.

Photo interrupter 1240

Figure 4.27

Outside frame L assy

Hooks

Figure 4.28

IV-14

Page 26

3. INSIDE FRAME UNIT

3.1 Reversible Frame

(1) Unfasten the six screws.

(2) Remove the reversible frame.

Screws, pan

(S/P washer) M3 x 8

Switching guide

Reversible frame

Taptites, cup S M3 x 6

Inside frame unit

3.2 Photo interrupter 1240

(1) Disconnect the reverse sensor harness assy from the photo interrupter 1240.

(2) Flex the hooks of the photo interrupter 1240 to the inside to remove it.

Figure 4.29

Reverse sensor harness assy

Photo interrupter 1240

Hooks

Figure 4.30

IV-15

Page 27

3.3 Solenoid

y

(1) Remove the solenoid spring.

(2) Unfasten the two screws.

(3) Remove the solenoid.

(4) Detach the retaining ring E3.

(5) Remove the switch arm and the solenoid link.

Note1 : Since the solenoid assy harness is connected to the conductor,

handle it with care.

Note2 : Mount the solenoid without leaving the harness exposed

excessively.

Inside frame unit

Retaining ring E3

Switch arm

Solenoid link assy

Solenoid spring

Solenoid

3.4 Carriage Guide 2 Assy

(1) Unfasten the screw A and the screw B.

(2) Slide the carriage guide 2 assy slightly in the direction of the arrow, and

disengage the hooks.

(3) Remove the carriage guide 2 assy.

Note1 : When removing the carriage guide 2 assy, take care not to

damage the solenoid assy harness.

Hook

Screws, cup M3 x 5

Solenoid assy harness

Figure 4.31

Carriage guide 2 assy

Hook

(Taptite,

Screw A

cup S M3 x 5)

Figure 4.32

Solenoid ass

Washer

Screw B (Shoulder screw M3-4 x 4.4)

harness

IV-16

Page 28

3.5 Carriage Guide 1

(1) Slid the carriage guide 1 slightly in the direction of the arrow.

(2) Disengage the carriage guide 1 from the engaging locks of the inside frame assy.

(3) Slide up and remove the carriage guide 1.

Carriage guide 1

Engaging lock

Engaging lock

Inside frame unit

Figure 4.33

3.6 Duplex PCB Assy

(1) Disconnect the connectors of the solenoid, DC fan motor, reversible motor assy

and reverse sensor harness assy from the Duplex PCB assy.

(2) Detach the two retaining rings E3.

(3) Remove the two PF bearings 05.

(4) Remove the carriage roller assy.

Reversible motor assy

Retaining rings E3

PF bearing 05

DC fan motor

Duplex PCB assy

PF bearing 05

Retaining ring E3

Reverse sensor

harness assy

Solenoid

Carriage roller assy

Figure 4.34

IV-17

Page 29

(5) Unfasten the four screws.

(6) Remove the Duplex PCB assy.

Taptites, cup S M3 x 5

Duplex PCB assy

Taptites, cup S M3 x 5

Figure 4.35

3.7 DC Fan Motor

(1) Use a minus screwdriver to disengage the hook of the reversible gear 15-30, and

detach the gear.

(2) Detach the retaining ring E3.

(3) Remove the PF bearing 05.

(4) Remove the reversible gear assy.

Reversible gear 15-30

DC fan motor

PF bearing 05

Retaining ring E3

Reversible gear 15-30Hook

Reversible gear assy

Figure 4.36

IV-18

Page 30

(5) Unfasten the three screws.

,

y

(6) Remove the DC fan motor.

Note1 : The DC fan motor should be so mounted that the label will not be

Screws, pan (washer)

M3 x 29.5

exposed.

Screw, pan (washer)

M3 x 29.5

DC fan motor

3.8 Reversible Motor Assy

(1) Unfasten the two screws.

(2) Remove the reversible motor assy.

Figure 4.37

Figure 4.38

Reversible motor ass

Screws

cup M4 x 6

IV-19

Page 31

4. DU TRAY CARRYING WAY UNIT

(1) Unfasten the screw on the back of unit.

Taptite, bind B M3 x 6

DU tray carrying way

Roller

Figure 4.39

(2) Turn the unit to the face and remove the pressure roller.

DU tray carrying way

Pressure roller

Figure 4.40

IV-20

Page 32

(3) Unfasten the three screws.

Taptite, bind B M3 x 6

Carriage guide 4

Figure 4.41

(4) Remove the four hooks on the back of unit and carriage guide 4.

Hook

Hook

Hook

Carriage guide 4

Hook

DU tray carrying way

Figure 4.42

Figure 4.43

IV-21

Page 33

Front ground spring

(5) Remove the tray pulley gear shaft from the clamp.

Note1 : Take care not to come off the rear ground spring.

When reassembling the rear ground spring, put it in the locating boss.

Rear ground spring

Locating boss

Figure 4.44

Paper pressure plate

DU tray carrying way

T Belt B40S2M396

Tray pulley gear

Clamp

Figure 4.45

IV-22

Page 34

(6) Remove the paper pressure fulcrum shaft from the two clamps.

Paper pressure 1

Paper pressure 2 assy

Paper pressure fulcrum shaft

DU tray carrying way

Clamps

Figure 4.46

(7) Remove the roller assy from the clamp.

Clamp

Figure 4.47

Roller assy

IV-23

Page 35

(8) Remove the discharge brush.

Discharge brush

Front ground spring

Clamps

Figure 4.48

IV-24

Page 36

Troubleshooting (1)

Problem Cause Check Result Remedy

CHAPTER V TROUBLESHOOTING

V-1

be set on the panel.

message appears.

appears.

MisoperationThe Duplex mode cannot

Modular cable

Main PCB

Misoperation“NO DX TRAY” error

Main PCB Does a voltage of 24V appear at pins 3

Paper pressure

motor

Misoperation“DX OPEN” error message

Open cover sensor

Main PCB

Is the modular cable connected properly? No Turn off the power to the printer, and connect

Does a voltage of 24V appear at pin 14 or

15 of I/F PCB’s connector P4?

Is the Duplex tray loaded properly into the

cassette according to the manual?

and 4 of I/F PCB’s connector P3, and does

the voltage vary from 0V to 24V at pins 1,

2, 5 and 6 when the paper cassette is set?

Does the paper pressure motor run when

the paper cassette is set?

Is the hook of the Duplex unit’s reversing

mechanism engaged completely with the

outside frame?

Does a voltage of 5V appear at pin 3 of I/F

PCB’s connector P1 when the cover is

closed?

the modular cable properly. Then, turn on the

power again.

Yes Replace the main PCB.

No

No Load the Duplex tray into the cassette according

No Replace the main PCB.

No Replace the paper pressure motor.

Yes Replace the cassette sensor lever and

No Close the reversing mechanism so as to engage

No Replace the open cover sensor or cover sensor

Yes Replace the main PCB.

Replace the modular cable.

to the manual.

leaf switch. Refer to Figure 4.26 (IV-9).

the hook securely with the outside frame.

harness.

message apprears.

Main PCB“DX FAN MALF” error

Fan

Main PCB

Does a voltage of more than15V appear

at pin 1 of main PCB’s connector P1?

Is the voltage 0V at pin 2 of main PCB’s

connector P1?

No Replace the main PCB.

No Replace the fan.

Yes Replace the main PCB.

Page 37

Troubleshooting (2)

Problem Cause Check Result Remedy

V-2

the Duplex unit.

"JAM DUPLEX" error

message appears though

no paper is supplied in the

Duplex unit.

The paper supplied in the

Duplex unit stops halfway.

"JAM TRAY" error

message appears.

The first or second sheet of

paper is not supplied to the

HL-1260 resist sensor.

MisoperationPaper is not supplied in

Main PCB Does the voltage vary from 24V to 0V at

Solenoid Does the solenoid function? No Replace the solenoid.

Main PCB Does the voltage vary from 24V to 0V at

Reversible motor Does the reversible motor run? No Replace the reversible motor.

Switching guide Does the switching guide move smoothly?

Main PCB

Reverse sensor

DU detection

(HL-1660/2060)

HL-1660/2060 unit

Pickup roller

(HL-1660/2060)

Duplex tray

Is the Duplex unit set properly in the

printer?

pin 2 of main PCBÕs connector P2?

pins 1, 2, 3 and 4 of main PCB's

connector P6?

Refer to Figure 4.29 (IV-11).

Does the voltage vary from 5V to 0V at pin

3 of main PCB's connector P5 while the

switching guide is moving?

Does the actuator (Parts reference list,

11-20) move smoothly?

Supply paper in Simplex mode.

Is paper correctly supplied?

No Set the Duplex unit properly according to the

manual.

No Replace the main PCB.

No Replace the main PCB.

No Reset the switching guide, or replace its parts.

No Replace the reverse sensor or reverse sensor

harness.

Yes Replace the main PCB.

No Replace the HL-1660/2060 actuator.

No Repair the HL-1260 unit.

(Pickup mistake with the first sheet of paper)

Yes Set the Duplex tray correctly.

1

2

Set the HL-1660/2060 pickup roller correctly.

(Pickup mistake with the second sheet of paper)

Page 38

Appendix 1. Connection Diagram

A-1

Page 39

Appendix 2. Motor Drive Circuit

A-2

Page 40

Appendix 3. Main PCB Circuitry Diagram

A-3

Page 41

July, ’98

54T047NE0-DX-2000

Page 42

R

DUPLEX UNIT

PARTS REFERENCE LIST

MODEL:DX-2000

Page 43

NOTE FOR USING THIS PARTS REFERENCE LIST

1. In the case of ordering parts, it needs mentioning the following items:

(1) Code

(2) Q'ty

(3) Description

(4) Symbol ( PCB No., Revision , and Parts location mounted on the PCB.)

Note : No orders without Parts Code or Tool No. can be accepted.

< Example >

(1)

REF.NO. CODE Q’TY DESCRIPTION SYMBOL REMARK

Revision No.: marked on the printed circuit board.

(2)

(3)

(4)

B48K056 - 201A

Design change indication

Specification No .

Pattern alteration No.

Circuit board No.

2. Design-changed parts :

If the parts are changed, any one of the following symbols is indicated in the REMARKS

column.

#A : compatible between old and new

#B : replaceable from old to new

#D : incompatible

# : newly established

3. The original of this list was made based on the information available in November, 1997.

4. Parts are subject to change in design without prior notice.

Page 44

CONTENTS

1. INSIDE FRAME UNIT ...........................................................................1

2. OUTSIDE FRAME UNIT .......................................................................1

3. MAIN PCB.............................................................................................3

4. COVERS...............................................................................................3

5. TRAY CARRYING UNIT .......................................................................5

6. PAPER TRAY .......................................................................................5

7. DOCUMENTS & ATTACHMENTS........................................................7

8. PACKING MATERIALS.........................................................................7

Page 45

1. INSIDE FRAME UNIT

3

4

1

2

6

5

2

8

7

MODEL DX-2000 54T-X10-510

2. OUTSIDE FRAME UNIT

2

3

7

6

5

4

8

1

-1-

MODEL DX-2000 54T-X10-550

Page 46

1. INSIDE FRAME UNIT

REF.NO. CODE Q'TY DESCRIPTION REMARK

1 UH2124001 1 DC FAN MOTOR

2 UJ3415001 2 SCREW, PAN(P WASHER) M3X29.5

3 UH3726001 1 REVERSING MOTOR 55 ASSY 2

4 UF4444001 2 SCREW, PAN(P WASHER) M4X6

5 UH1707001 1 SOLENOID ASSY

6 U50553001 2 SCREW, CUP M3X5

7 UJ4232000 1 PHOTO INTERRUPTER:1240

8 UH1732001 1 REVERSE SENSOR HARNESS ASSY

MODEL DX-2000 54T-X10-510

2. OUTSIDE FRAME UNIT

REF.NO. CODE Q'TY DESCRIPTION REMARK

1 UH1655001 1 T BELT, B40S2M396

2 Z25996001 1 MOTOR, BP484223LM31-FD

3 085320515 2 TAPTITE, BIND S M3X5

4 UH1734001 1 CASSETTE SENSOR ASSY

5 UH1751000 1 CASSETTE SENSOR LEVER

6 UJ4232000 1 PHOTO INTERRUPTER:1240

7 UH1733001 1 COVER SENSOR HARNESS ASSY

8 UH1786001 1 P PRESSURE MOTOR HARNESS ASSY

- 2 -

MODEL DX-2000 54T-X10-550

Page 47

3 . MAIN PCB

2

1

4

2

3

T/I No. PR99027

2

9

MODEL DX-2000 54T-X10-100

4 . COVERS

9

1

2

8

6

7

10

5

-3-

3

4

MODEL DX-2000 54T-X10-400

Page 48

3. MAIN PCB PR99027

REF.NO. CODE Q'TY DESCRIPTION SYMBOL REMARK

1 UK4106001 1 MAIN PCB ASSY, DX-2000 B48K264-2A CHG REV.

2 087320516 4 TAPTITE, CUP S M3X5

3 UK4108001 1 DUPLEX IF PCB ASSY, DX-2000 B48K265-1

4 087320516 1 TAPTITE, CUP S M3X5

MODEL DX-2000 54T-X10-100

4. COVERS

REF.NO. CODE Q'TY DESCRIPTION REMARK

1 UH1667001 1 TOP COVER

2 087320616 4 TAPTITE, CUP S M3X6

3 UH1668001 1 BOTTOM COVER

4 087320616 2 TAPTITE, CUP S M3X6

5 UH1669001 1 SIDE COVER L

6 085310616 1 TAPTITE, BIND B M3X6

7 UH1670001 1 SIDE COVER R

8 085310616 1 TAPTITE, BIND B M3X6

9 UH1671001 2 LOCK LEVER COVER

10 UH1770001 1 GEAR COVER

- 4 -

MODEL DX-2000 54T-X10-400

Page 49

5 . TRAY CARRYING UNIT

1

MODEL DX-2000 54T-X10-610

6 . PAPER TRAY

5

1-7

6

1

3

2

4

7

MODEL DX-2000 54T-X10-650

-5-

Page 50

5. TRAY CARRYING UNIT

REF.NO. CODE Q'TY DESCRIPTION REMARK

1 UH2035001 1 DU TRAY CARRYING WAY UNIT 2

MODEL DX-2000 54T-X10-610

6. PAPER TRAY

REF.NO. CODE Q'TY DESCRIPTION REMARK

1 - 7 UH3162001 1 PAPER TRAY S UNIT DX3 (SP)

1 UH2487001 1 SEPARATION PAD ASSY T

2 UH2841001 1 SEPARATION PAD SPRING 200

3 UH2360000 1 ROLLER

4 UH2459000 1 ROLLER HOLDER

5 UH1776001 1 PAPER FRONT GUIDE DU, BLUE6155

6 UH2472001 1 TRAY GUIDE PLATE 1

7 UH2804001 1 ADJUST KNOB STOPPER

- 6 -

MODEL DX-2000 54T-X10-650

Page 51

7 . DOCUMENTS & ATTACHMENTS

1

4

2

3

MODEL DX-2000 54T-X10-910

8 . PACKING MATERIALS

1

2

4

2

R

3

-7-

MODEL DX-2000 54T-X10-930

Page 52

7. DOCUMENTS & ATTACHMENTS

REF.NO. CODE Q'TY DESCRIPTION REMARK

1 UH3728001 1 USER'S GUIDE, DX-2000

2 UH1735001 1 MODULAR CORD 8PDX

3 UH2440001 1 PAPER FEED ROLLER ASSY DU2

4 UH2439001 1 INSERTION SHEET

MODEL DX-2000 54T-X10-910

8. PACKING MATERIALS

REF.NO. CODE Q'TY DESCRIPTION REMARK

1 UE0694001 1 CARTON, DX-2000

1 UE0695001 1 CARTON, DX-2000 BROTHER

2 UE0457000 1 STYROFOAM PAD ASSY

3 UE0454000 1 CARTON ,TRAY

4 UE1109001 1 PE BAG, 215X290H

- 8 -

MODEL DX-2000 54T-X10-930

Page 53

July, ’98

54T048NE0-DX-2000

Loading...

Loading...