Brother DX-1600 Service manual

MECHANICS & ELECTRONICS

SERVICE MANUAL

LASER PRINTER

No part this publication may be reproduced in any form or by any means without permission in writing

from the publisher.

Trademarks:

• BR-Script, and DX-1600 are registered trademarks of Brother Industries, Ltd.

• Centronics is a registered trademark of Genicom Corporation.

• PostScrip is a registered trademark of Adobe Systems Incorporated.

• IBM Proprinter XL is a registered trademark of International Business Machines Corporation.

• EPSON FX-850 is a registered trademark of Seiko Epson Corporation.

• HP-GL and HP Laser Jet 5 are registered trademarks of Hewlett Packard Company.

PREFACE

This service manual contains basic information required for after-sales service of the laser printer (hereinafter

referred to as ”this machine” or ” the printer”). This information is vital to the service technician in maintaining

the high printing quality and performance of the printer.

This manual consists of the following chapters:

Chapter I : General

Features, specifications, etc.

Chapter II : Theory of Operation

Basic operation of the mechanical system and the electrical system, and their timing.

Chapter III : Electrical System

Theory of the electronics circuit

Chapter IV : Mechanical System

Requirements for a suitable location, disassembling and reassembling procedure of

mechanical system.

Chapter V : Maintenance and Servicing

Parts replacement schedule, list of tools, lubricants and cleaners.

Chapter VI : Troubleshooting

Reference values and adjustment, troubleshooting for image defects, troubleshooting

for malfunctions, etc.

Appendices : Engine Block Diagram, PCB Circuitry Diagrams, etc.

Information in this manual is subject to change due to improvement or re-design of the product. All relevant

information in such cases will be supplied in service information bulletins (Technical Information).

A thorough understanding of this printer, based on information in this service manual and service

information bulletins, is required for maintaining its quality performance and for fostering the practical ability

to find the cause of troubles.

CONTENTS

CHAPTER I GENERAL

1. FEATURES ..........................................................................................................................I-1

2. SPECIFICATIONS ...............................................................................................................I-1

3 . SAFETY INFORMATION .....................................................................................................I-6

3.1 Laser Safety (110 - 120V Model only) ........................................................................ I -6

3.2 CDRH Regulations (110 - 120V Model only) ...............................................................I-7

3.3 Additional Information ................................................................................................I-7

4 . PAR TS OF THE PRINTER................................................................................................... I -8

4.1 External Views........................................................................................................... I -8

4.2 Cross Sectional View .................................................................................................I-9

5. S TORAGE AND HANDLING OF EP-ED CARTRIDGES..................................................... I-10

5.1 Storage of Sealed EP-ED Cartridges .......................................................................I-10

5.2 Storage of Unsealed EP-ED Cartridges ................................................................... I-10

CHAPTER II THEORY OF OPERATION

1 . BASIC OPERATIONS........................................................................................................ II -1

1.1 Mechanical Configuration ......................................................................................... II -1

1.2 Main Drive ............................................................................................................... II -2

1.3 Basic Sequence of Operations ................................................................................ II-3

2 . LASER/SCANNER SYSTEM............................................................................................. II-4

3 . IMAGE FORMA TION SYSTEM ......................................................................................... II-5

3.1 Outline ..................................................................................................................... II-5

3.2 Printing Process ...................................................................................................... II-5

3.2.1 Electrostatic latent image formation stage................................................. II-6

3.2.2 Developing stage....................................................................................... II-8

3.2.3 Transfer stage............................................................................................ II-9

3.2.4 Fixing stage..............................................................................................II-10

3.2.5 Drum cleaning stage.................................................................................II -10

3.3 Operation ................................................................................................................II-11

4 . PAPER PICK-UP/FEED SYSTEM....................................................................................II-12

4.1 Outline ....................................................................................................................II-12

4.2 Cassette Feed ........................................................................................................ II-13

4.3 MP Tray Feed .........................................................................................................II-14

4.4 Paper Jam Detection ..............................................................................................II-15

i

CHAPTER III ELECTRICAL SYSTEM

1 . MAIN PCB ........................................................................................................................ III-1

1.1 Outline .................................................................................................................... III-1

1.2 Video Controller Circuit ........................................................................................... III-2

1.3 Engine Controller Circuit ......................................................................................... III-7

2 . PAPER FEED DRIVE CIRCUIT ........................................................................................ III-9

3 . DISPLA Y CIRCUIT ..........................................................................................................III-11

3.1 Outline ...................................................................................................................III -11

3.2 Operation ...............................................................................................................III-11

4 . LOW-VOL T AGE POWER SUPPL Y ASSY.........................................................................III -12

4.1 Outline ...................................................................................................................III -12

4.2 Protection Functions..............................................................................................III-12

5 . HIGH-VOL T AGE POWER SUPPL Y ASSY .......................................................................III-14

5.1 Outline ...................................................................................................................III -14

5.2 Operation of the Components of the High-V oltage Power Supply Assy ..................III -14

CHAPTER IV MECHANICAL SYSTEM

PRINTER DISASSEMBLING PROCEDURE

PRINTER BODY

1.1 Configuration........................................................................................................... IV-3

1.2 T oner Cartridge Lid.................................................................................................. IV-3

1.3 Side Cover L........................................................................................................... IV-3

1.4 Font Cover Assy..................................................................................................... IV-4

1.5 Upper Cover Assy, Rear Cover Assy ...................................................................... IV-4

1.5.1 Upper cover assy, rear cover assy ........................................................... IV-4

1.5.2 Changeover guide, jam remove cover....................................................... IV-5

1.6 Side Cover R .......................................................................................................... IV-5

1.7 DC Fan Motor ......................................................................................................... IV-6

1.8 Main PCB ............................................................................................................... IV-6

1.9 Control Panel Unit ................................................................................................... IV-8

1.10 Scanner Unit........................................................................................................... IV-9

1.11 Cartridge Stopper Assy .......................................................................................... IV-9

1.12 Paper Feed Chassis Unit .......................................................................................IV-10

1.13 Separation Pad Assy .............................................................................................IV-11

1.14 MP PE Sub Actuator .............................................................................................IV-12

1.15 P Feed /Size-SW PCB Assy .................................................................................IV-12

1.16 Side-Switch Spring ................................................................................................IV-12

1.17 Regist Sensor Actuator..........................................................................................IV-13

1.18 MP Paper Detection Actuator.................................................................................IV-13

1.19 PE Sensor Actuator MP ........................................................................................IV-13

1.20 Tray Sensor Holder ................................................................................................IV-14

1.21 Roller Holder ..........................................................................................................IV-14

1.22 Paper Pick-up Roller Assy, Bearing........................................................................IV-15

1.23 Paper Pick-up Solenoid..........................................................................................IV-16

1.24 Paper Feed Motor Assy .........................................................................................IV-16

1.25 MP Tray Cover .......................................................................................................IV-17

1.26 MP Tray Assy ........................................................................................................IV-17

1.27 Paper Path Separation Plate, Paper Path Separation Film ......................................IV-18

1.28 Latch .....................................................................................................................IV-19

1.29 Fixing Unit (for both 120V and 230V , the only difference is the halogen heater) ....IV-19

1.30 Transfer Unit ..........................................................................................................IV-22

ii

1.31 DC Gear Holder Assy ............................................................................................IV-23

1.32 PS Switch Wire, Remote Switch ............................................................................IV-23

1.33 High-Voltage Power Supply PCB Assy...................................................................IV-24

1.34 Low-Voltage Power Supply PCB Assy ...................................................................IV-24

1.35 Toner Cartridge (EP-ED Cartridge) .........................................................................IV-25

1.36 Paper Tray..............................................................................................................IV-25

CHAPTER V MAINTENANCE AND SERVICING

1 . PERIODICAL REPLACEMENT P ARTS ............................................................................. V-1

2 . CONSUMABLE PARTS ST ANDARD ENDURANCE T ABLE ............................................... V -1

3 . LIST OF ST ANDARD TOOLS............................................................................................. V-2

4 . LIST OF LUBRICANTS AND CLEANERS ......................................................................... V -3

CHAPTER VI TROUBLESHOOTING

1. INTRODUCTION ............................................................................................................... VI-1

1.1 Initial Check............................................................................................................ VI-1

1.2 Basic Procedure ..................................................................................................... VI-2

2. TEST PRINTING AND MECHANICAL CHECK................................................................. VI-2

2.1 T est Printing............................................................................................................ VI-2

3 . IMAGE DEFECTS ............................................................................................................ VI-3

3.1 Image Defect Examples ......................................................................................... VI-3

3.2 Troubleshooting Image Defects ............................................................................... VI-4

4 . TROUBLESHOOTING OF MALFUNCTIONS .................................................................. VI-11

5. TROUBLESHOOTING P APER TRANSPORT PROBLEMS............................................. VI-19

5.1 Paper Jams .......................................................................................................... VI-19

5.2 Incomplete Paper Feed ......................................................................................... VI-22

6. OPERA TION ................................................................................................................... VI-23

6.1 Line Inspection Mode Procedure........................................................................... VI-23

6.2 DRAM T est ........................................................................................................... VI-25

7. STATUS MESSAGE LIST............................................................................................... VI-26

APPENDICES

1. Engine Block Diagram ....................................................................................................... A-1

2. Paper Feed/Size-SW PCB Circuitry Diagram (1/1) ............................................................. A- 2

3. Main PCB Circuitry Diagram (1/7) ...................................................................................... A-3

4. Main PCB Circuitry Diagram (2/7) ...................................................................................... A-4

5. Main PCB Circuitry Diagram (3/7) ...................................................................................... A-5

6. Main PCB Circuitry Diagram (4/7) ...................................................................................... A-6

7. Main PCB Circuitry Diagram (5/7) ...................................................................................... A-7

8. Main PCB Circuitry Diagram (6/7) ...................................................................................... A-8

9. Main PCB Circuitry Diagram (7/7) ...................................................................................... A-9

10. Control Panel PCB Circuitry Diagram (1/1) ....................................................................... A-10

11. Scanner LD PCB Circuitry Diagram (1/1).......................................................................... A-11

iii

CHAPTER I GENERAL

1. FEATURES

A. This high-speed, non-impact (low-noise) printer is based on electrophotography, electronics

and laser technology.

B. The printer is compact and easy to carry. The internally-storable, front-loading paper

cassette enables you to save an occupation space for the machine; the printer can now

be installed in a smaller place.

C. The charging roller, developing cylinder, photosensitive drum and cleaner of the printer

are combined into a single assembly called an ”EP-ED cartridge”. The cartridge can be

replaced by the user when necessary without a need of service call. High printing quality

is maintained by a simple cleaning procedure.

D. Laser beam safety is designed into the printer. The printer is approved by the US Center

for Devices and Radiological Health (CDRH).

E. Paper can be fed in two ways, by the multi-purpose paper feed tray and paper cassette.

F. Maintenance is easy with print component units which are directly detachable, and they

require no adjustment after reassembly.

2. SPECIFICATIONS

(1) Type Desktop page printer

(2) Printing method Electrophotography (single-component dry toner)

(3) Printing speed

Cassette feed 12 pages/minute (A4/Letter size by cassette feed)

10.2 pages/minute (Legal size)

(4) First print time Approx. 20 seconds

(A4 size by face-down print delivery from the paper cassette)

(5) Warm-up (WAIT) time Max. 1 minute at 20°C (68°F)

(6) Optical system

Laser Semiconductor laser

Output power : 5mW max.

Wave length : 780 nm

Scanning system Rotating six-faced polygon mirror

(7) Resolution

Horizontal 600 dots/inch and high resolution control (HRC)

Vertical 600 raster lines/inch

I - 1

(8) Printing system

Photosensitive drum OPC

Charging Charging Roller

Exposure Laser scanning system

Development Toner projection development system

Paper feed Cassette or manual feed

Image transfer Roller method

Separation Natural(utilizing a small drum radius), Static charge eliminator

Fixing Heated fixing roller

Toner supply Included in the replaceable EP-ED cartridge

Life expectancy 6000 pages/cartridge

(9) Paper

Cassette feed Plain paper for Letter, Legal, A4, ISO B5, A5, ISO B6, A6,

Multi-purpose Tray Plain paper of 90 x 148 mm 216 x 356 mm (recommended:

(10) Cassette (Tray 1)

Executive (A4 or letter size paper with the print density set at

level 8 with 4% coverage, recommended: 60 g/m 105 g/m )

2

and Envelope (com10, monarch, C5, DL, ISO B5)

2

60g/m 135 g/m , overhead projector (OHP) film, postcards,

2

label stock and envelopes (specified sizes)

2

Universal cassette A4, Letter, Legal, ISO B5, Executive, A5, ISO B6, and A6

Maximum load height 55 mm (500 sheets of 80 g/m paper)

Feedable paper type 60 105 g/m

2

Envelopes 40 envelopes

(11) Print delivery Face-down or (face-up)

(12) Print delivery tray capacity

Face-down 250 sheets (80 g/m )

2

Face-up Discharge only

2

I - 2

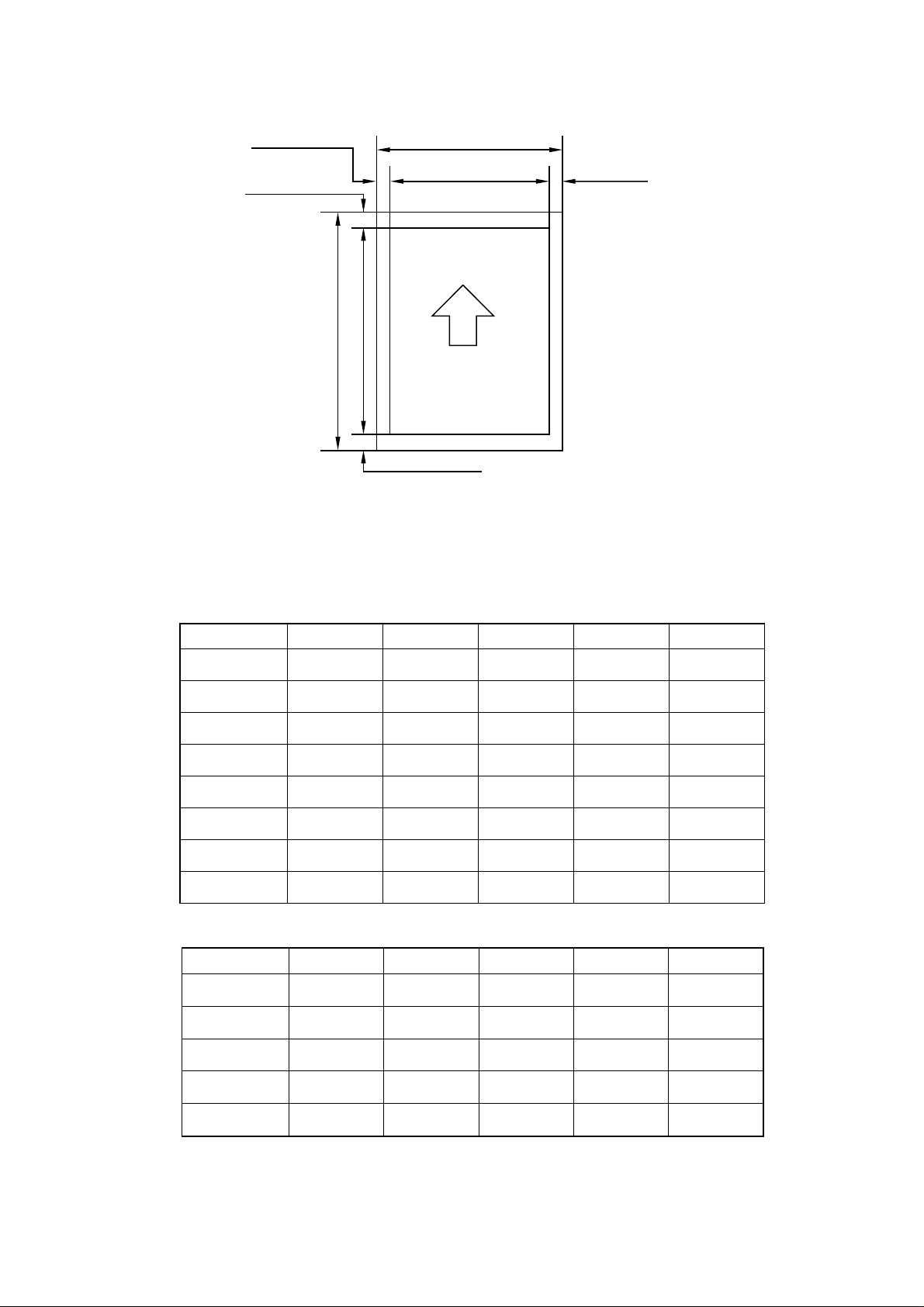

(13) Effective printing area

E

E

A

C

E

Printable area

D

B

E

Figure 1.1 Printable Area

Effective printable area is referred to as a area within which is guaranteed the printing of all

interface signal data on a hard copy without any omission.

The tables below shows the effective printable area for each paper size.

Table 1.1 Plain Paper

SIZE A (mm) B (mm) C (mm) D (mm)

A 4

Letter

Legal

B 5 (ISO)

Executive

A 5

B 6 (ISO)

A 6

210.0 297.0 203.2

215.9 279.4 207.4 270.9

215.9 355.6 207.4 347.1

176.0 250.0 167.5 241.5

184.2 266.7 175.7 258.2

148.0 210.0 139.5 201.5

125.0 176.0 116.5 167.5

105.0 148.0 96.5 139.5

Table 1.2 Envelope

SIZE A (mm) B (mm) C (mm) D (mm)

COM-10

MONARCH

DL

104.8 241.3 96.3

98.4 190.5 89.9 182.0

110.1 221.0 101.6 212.5

288.5

232.8

E (mm)

3.39 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

E (mm)

4.23 ± 1.0

4.23 ± 1.0

4.23 ± 1.0

C5

B5 (ISO)

162.2 228.6 154.1 220.1

176.0 250.0 167.5 241.5

(The sizes above are nominal sizes according to ISO.)

An A4 sheet accepts 80 PICA-pitch characters (203.2mm).

I - 3

4.23 ± 1.0

4.23 ± 1.0

(14) Standard interfaces Automatic interface selection

• Centronics, Bi-directional parallel

• RS-232C serial

Baud rate : 150, 300,1200, 2400, 4800, 9600

19200, 38400, 57600 bps

Stop bit : 1 bit

Start bit : 1 bit or 2 bits

Data length : 7 bits or 8 bits

Parity : Odd, Even, or None

Protocol : Xon/Xoff or DTR

(15) Emulation Automatic emulation selection

• HP Laser Jet 5 (PCL Level 6)

• EPSON FX-850

• IBM Proprinter XL

• BR-Script level 2 (PostScript language emulation interpreter)

• HP- GL

(16) CPU MB86832

(17) Resident fonts 75 scalable fonts and 12 bitmapped fonts

HP Laser Jet 5, EPSON FX-850, IBM Proprinter XL

Scalable Fonts:

Intellifont Compatible Fonts:

• Albertville, Extrabold

• Antique Oakland, Oblique, Bold

• Brougham, Oblique, Bold,

Bold Oblique

• Cleveland Condensed

• Connecticut

• Guatemala Antique, Italic, Bold,

Bold Italic

• Letter Gothic, Oblique, Bold

• Maryland

• Oklahoma, Oblique, Bold,

Bold Oblique

• PC Brussels Light, Light Italic, Demi,

Demi Italic

• PC Tennessee Roman, Italic, Bold,

Bold Italic

• Utah, Oblique, Bold, Bold Oblique

• Utah Condensed, Oblique, Bold,

Bold Oblique

Windows 3.1 Compatible Fonts:

• Tennessee Roman, Italic, Bold,

Bold Italic

• Helsinki, Oblique, Bold, Bold Oblique

• BR Symbol

• W Dingbats

BR-Script Fonts:

• Atlanta Book, Book Oblique, Demi,

Demi Oblique

• Copenhagen Roman, Italic, Bold,

Bold Italic

• Portugal Roman, Italic, Bold, Bold Italic

• Calgary Medium Italic

Brother Original Fonts:

• Bermuda Script

• Germany

• San Diego

• US Roman

Bitmapped Fonts (Portrait and Landscape):

• Letter Gothic 16.66 Medium, Italic, Bold, Bold Italic

• OCR-A

• OCR-B

I - 4

BR-Script Level 2 Mode

Scalable Fonts:

• Atlanta Book, Book Oblique, Demi,

Demi Oblique

• Brussels Light, Light Italic, Demi,

Demi Italic

• Brougham, Oblique, Bold, Bold Oblique

• Helsinki, Oblique, Bold, Bold Oblique

• Helsinki Narrow, Oblique, Bold,

Bold Oblique

• Copenhagen Roman, Italic, Bold,

Bold Italic

• Portugal Roman, Italic, Bold, Bold Italic

• Tennessee Roman, Italic, Bold, Bold Italic

• Calgary Medium Italic

• BR Symbol

• BR Dingbats

(18) RAM 8M bytes (expandable to 72M bytes)

(19) Font cartridge/card slots Two slots

One font cartridge slot and one font card slot

• Albertville, Extrabold

• Antique Oakland, Oblique, Bold

• Cleveland Condensed

• Conecticut

• Guatemala Antique, Italic, Bold, Bold Italic

• Letter Gothic, Oblique, Bold

• Maryland

• Oklahoma, Oblique, Bold, Bold Oblique

• Utah, Oblique, Bold, Bold Oblique

• Utah Condensed, Oblique, Bold,

Bold Oblique

• Bermuda Script

• Germany

• San Diego

• US Roman

(20) Power souse USA and Canada : AC 110 to 120 V, 60 HZ

Europe and Australia : AC 220 to 240 V, 50 HZ

(21) Power consumption Printing : 500 WH or less

Stand-by : 80 WH or less

Sleep : 20 WH

(22) No i s e Printing : 49 dB A or less

Stand-by : 40 dB A or less

(23) Dimensions (W x H x D) 371.6 x 326.5 x 393 mm (14.6 x12.9 x 15.5 inches)

(24) Weight Approx. 15 kg (32.6 Ibs)

(25) Environmental conditions

Operating Temperature10 ~ 32.5°C

environment Relative humidity 20 ~ 80%RH

(No condensation allowed)

Air pressure 613 ~ 1013 hPa

(0 ~ 2,500 m above sea level)

Non-operating Temperature0 ~ 35°C

environment Relative humidity 10 ~ 80%RH

(No condensation allowed)

Storage conditions

• Printer Temperature

Normal (total storage time x 9/10)

0 ~ 35°C

Severe (total storage time x 1/10)

High Low

35°C ~ 60°C -20°C ~ 0°C

Temperature change (within 3 minutes)

High Low

60°C 15°C -20°C 25°C

I - 5

Relative humidity

Normal (total storage time x 9/10)

35 ~ 85%RH

Severe (total storage time x 1/10)

High Low

85 ~ 95%RH 10 ~ 35%RH

Air pressure 613 ~ 1013 hPa

Total storage time 0.5 years

• EP-ED cartridge Temperature

Normal (2.45 years max.)

0 ~ 35°C

Severe (0.05 years max.)

High Low

35°C ~ 40°C -20°C ~ 0°C

Temperature change (within 3 minutes)

High Low

40°C 15°C -20°C 25°C

Relative humidity

Normal (2.45 years max.)

35 ~ 85%RH

Severe (0.05 years max.)

High Low

85 ~ 95%RH 10 ~ 35%RH

Air pressure 613 ~ 1013 hPa

Maximum total storage time: 2.5 years including used time

3. SAFETY INFORMATION

3.1 Laser Safety (110 ~ 120V Model only)

This printer is certified as a Class 1 laser product under the US Department of Health and

Human Services (DHHS) Radiation Performance Standard according to the Radiation

Control for Health and Safety Act of 1968. This means that the printer does not produce

hazardous laser radiation,

Since radiation emitted inside the printer is completely confined within the protective

housings and external covers, the laser beam cannot escape from the machine during any

phase of user operation.

I - 6

3.2 CDRH Regulations (110 ~ 120V Model only)

The center for Devices and Radiological Health (CDRH) of the US Food and Drug

Administration implemented regulations for laser products on August 2, 1976. These

regulations apply to laser products manufactured from August 1, 1976. Compliance is

mandatory for products marketed in the United States. The label shown below indicates

compliance with the CDRH regulations and must be attached to laser products marketed in

the United States.

MANUFACTURED :

BROTHER INDUSTRIES, LTD.

15-1, Naeshiro-cho, Mizuho-ku Nagoya 467, Japan.

This product complies with FDA radiation

performance standards , 21 CFR chapter 1

subchapter J.

Figure 1.2

Caution: Use of controls, adjustments or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

3.3 Additional Information

When servicing or adjusting the optical system of the printer, be careful not to place

screwdrivers or other reflective objects in the path of the laser beam. Be sure to take off any

personal accessories such as watches and rings before working on the printer. A reflected

beam, though invisible, can permanently damage the eyes.

Since the beam is invisible, the following label is attached to the inside of covers where

danger of exposure to laser radiation exist.

Figure 1.3

I - 7

4. PARTS OF THE PRINTER

4.1 External Views

1 Upper cover

2 Control panel

3 MP tray

4 Tray 1

5 Tray 2 (Option)

6 Font card slot

7 Font cartridge slot

8 Power switch

11

9 AC inlet

10 Face-up print delivery port

11 Fan outlet port

12 Rating label

13 Optional I/O slot

14 RS-232C interface connector

15 Centronics interface connector

16 Optional interface connector

1

2

10

15

13

3

8

5

4

6

7

Figure 1.4

9

12

14

16

I - 8

4.2 Cross Sectional View

12

11

13

14

1

2

3

4

5

6

7

8

1 Registration rollers

2 EP-ED cartridge

3 Photosensitive drum

4 Laser scanner unit

5 Transfer unit

6 Face-down tray

7 Print-delivery path

8 Fixing unit

10

Figure 1.5

9

9 Low-voltage power supply assy

10 High-voltage power supply assy

11 Paper cassette (Tray 1)

12 Pick-up rollers

13 MP tray

14 Control panel

I - 9

5. STORAGE AND HANDLING OF EP-ED CARTRIDGES

An EP-ED cartridge is influenced by the storage conditions even if it is sealed in its package,

so its life depends on the way in which it is used or stored. EP-ED cartridges should be

handled carefully.

5.1 Storage of Sealed EP-ED Cartridges

When storing sealed EP-ED cartridges in a warehouse or workshop, the storage conditions

shown in (25) Environmental conditions on Page 1-5 must be met. Follow the instructions

below:

1) Avoid direct sunlight.

2) Do not store cartridges on a surface that is subject to vibration.

3) Do not hit or drop the packages containing cartridges.

4) The cartridges should be stored horizontal when they are removed from the body (with

their label side upside).

5) Avoid putting the cartridges near a CRT screen, a disk or a floppy disk (to keep their data

from being destroyed).

5.2 Storage of Unsealed EP-ED Cartridges

Each EP-ED cartridge contains a photosensitive drum that has an organic photoconductor

(OPC) which deteriorates when exposed to strong light. It also contains toner. The user,

therefore, should be fully informed about the correct storage and handling of EP-ED

cartridges.

(1) Storage requirements

1) Avoid places exposed to direct sunlight or near a window. Do not leave an EP-ED

cartridge in a car in warm or hot weather even if it is in its storage box.

2) Avoid places with a too-high or too-cool temperature and/or humidity. Also avoid

places exposed to sudden temperature or humidity changes (such as near an air

conditioner outlet).

3) Avoid dusty places or places exposed to ammonia fumes or other harmful fumes.

4) Do not store an EP-ED cartridge in a temperature above 40°C.

(2) EP-ED cartridge life

The effective life of an EP-ED cartridge is 2.5 years from the date of manufacture

(printed on the cartridge.) The expiry year and month (date of manufacture plus 2.5

years) is shown on the EP-ED cartridge box. An EP-ED cartridge used after the expiry

may produce low-quality printing, so a cartridge should be used within the stated

period.

I - 10

CHAPTER II THEORY OF OPERATION

This chapter describes the printer functions, the relationship between the electrical systems and

mechanical systems, and the timing of operations. Striped conduits ( ) indicate mechanical

linkages; solid thin arrows ( ) appearing with a signal name indicate the transmission of

single control signals and outlined thick arrows ( ) indicate the transmission of groups of

signals.

1. BASIC OPERATIONS

1.1 Mechanical Configuration

The printer functions can be divided into four blocks: the laser/scanner system, the image

formation system, the paper pick-up/feed system and the control system.

Expansion memory

(SIMM)

Control panel

Font cartridge/card

Main PCB

IMAGE FORMATION SYSTEM

Photosensitive drum

Cleaning unit

Optional I/O

(MIO)

External Device

CONTROL SYSTEM

Laser/scanner

unit

Developing

unit

Delivery rollers

PAPER PICK-UP/FEED SYSTEM

Fixing unit

Feeder

LASER/SCANNER

SYSTEM

Transfer

separation

unit

MP tray

Tray 1

Tray 2

(Option)

Figure 2.1

II - 1

1.2 Main Drive

The power necessary for driving the printer is supplied by the main motor, the paper feed motor

and the scanner motor.

The main motor is controlled by the main motor drive signal (MDRIVE) output from the main

PCB, and the paper feed motor is controlled by the paper feed motor drive signal output from

the main PCB, and the scanner motor is controlled by the scanner motor drive signal (SDRIVE)

output from the main PCB.

Main motor

Main motor drive signal (MDRIVE)

Main PCB

Paper feed motor

Drum gear

Fixing unit

Paper feed motor drive signal

MP tray pick-up roller solenoid drive signal (MPSOL)

MP tray pick-up

roller solenoid

Tray1 pick-up roller solenoid drive signal (PUCL1)

Tray1 pick-up

roller solenoid

Photosensitive

drum

Paper delivery

rollers

MP tray

pick-up roller

Tray1

pick-up roller

Scanner motor

Scanner unit

Scanner motor drive signal (SDRIVE)

Note: There are cases, in the following pages, that

Scanning mirror

Figure 2.2

II - 2

a main motor is referred to as a DC motor, but

they are identical.

1.3 Basic Sequence of Operations

Power on Print

WAIT STBY PRINT

Ready lamp

Fixing heater

Main motor

170 C control 190 C

STBY

control

170 C

control

Scanner motor

Paper feed

motor

Pick-up roller

solenoid

Laser diode

Registration

sensor

0.15 sec

0.15 sec

1.88 sec

1.73 sec

3.18 sec

Timing for two consecutive prints on A4 paper.

Figure 2.3

II - 3

2. LASER/SCANNER SYSTEM

To external device

SBD DATA VOFF

Collimator lens

Main PCB

Scanner driver

Cylindrical lens

Scanning mirror

Optical sensor

Figure 2.4

In response to the print signal transmitted from the external device, the main PCB generates the

drive signals (DATA,VOFF) for the laser diode and sends the signals to the scanner unit.

The laser diode in the scanner unit generates a laser beam modulated by DATA.

The modulated laser beam is aligned into a parallel beam by a collimator lens and a cylindrical

lens and then brought to the scanning mirror which is rotating at a constant speed.

The laser beam reflected by the scanning mirror focuses on the photosensitive drum via the

focusing lenses arranged in front of the scanning mirror.

The path of the beam coming through the focusing lenses is reflected by the reflective mirror.

Scanner motor

Focusing lenses

Beam detect mirror

As the scanning mirror rotates at a constant speed, the laser beam scans the photosensitive

drum at a constant speed.

As the photosensitive drum rotates at a constant speed and the laser beam scans the drum, an

images is formed on the drum.

II - 4

3. IMAGE FORMATION SYSTEM

3.1 Outline

The image formation system is the main part of the printer. The print information, after input from

the video controller circuit into the engine controller circuit as a TVDO signal, forms a toner image

on the photosensitive drum.

Then the toner image is transferred onto the paper by the transfer charging roller. The image

formation system is composed of the photosensitive drum the charging unit, the developing unit

and the cleaning unit.

3.2 Printing Process

The major part of the image formation system is contained in the cartridge, as shown in Figure

2.5.

Laser beam

Cartridge

Primary charging roller

Cleaning blade

Photosensitive drum

Static charge eliminator

Blade

Developing cylinder

Paper

Transfer charging roller

Figure 2.5

The cartridge used by the printer has a seamless photosensitive drum with the structure shown

in Figure 2.6. The outer layer of the drum consists of an organic photoconductor (OPC); the base

is aluminum.

The printing process can be divided into five major stages:

Photoconductive layer

Figure 2.6

1. Electrostatic latent image formation stage

Step 1 Primary charge (-)

Step 2 Scanning exposure

2. Developing stage

Step 3 Development

II - 5

Base

3. Transfer stage

Step 4 Transfer (+)

Step 5 Separation

4. Fixing stage

Step 6 Fixing

5. Drum cleaning stage

Step 7 Drum cleaning

Electrostatic latent image

formation stage

2. Scanning exposure

1. Primary charge

6. Fixing

7. Drum cleaning

5. Separa tion

4. Transfer

Drum cleaning stage

Fixing stage

Print delivery

Transfer stage

Figure 2.7

3.2.1 Electrostatic latent image formation stage

This stage has two steps, which together produce a pattern of electrical charges on the

photosensitive drum.

At the end of the stage, negative charges remain in the unexposed ”dark” area. Charges are

absent from the ”light” areas, where the laser beam struck (exposed) the drum surface.

Since this image of negative charges on the drum is invisible to the eye, it is called an

”electrostatic latent image”.

3. Develop

ment

Cassette feed

Developing stage

Registration

Paper path

Direction of drum rotation

Multi-purpose tray feed

0

-100

-500

Primary

Surface potential (V)

charge

(step 1)

Exposed

area

Scanning

exposure

(step 2)

Figure 2.8

II - 6

Time (t)

Unexposed

area

Transfer

(step 4)

Primary

charge

(step 1)

Step 1 Primary charge

,,

,

,

,,

,,

,

,

,

,,

,,

,,

,

,

,,

As preparation for latent image formation, a uniform negative potential is applied to the

photosensitive drum surface. The printer uses the charging method that directly charges the

drum for the primary charge.

The primary charging roller consists of conductive rubber. In addition to DC bias, AC bias is

applied to the primary charging roller to keep the potential on the drum surface uniform. This DC

bias is changed with the developing DC bias.

This charging method has advantages such as lower applied voltage, less ozone generation,

etc., compared with the corona charge system.

Primary charging roller

AC bias

Photosensitive drum

DC bias

Figure 2.9

Step 2 Scanning exposure

Unexposed area

When the laser beam scans the drum surface, it causes the charge to be neutralized in the areas

struck by the beam. Areas on the drum with no charge form the electrostatic latent image.

Laser beam

___

+++

Exposed area

Figure 2.10

II - 7

3.2.2 Developing stage

Development places particles of toner onto the areas of the drum that have been cleared of

charge by the laser beam. This makes a visible image. This printer uses the toner projection

development method with a single-component toner.

Step 3 Development

Blade

Photo-

sensitive

drum

AC bias

DC bias

Developing cylinder

Cylinder

Magnet

Stirrer

Figure 2.11

Note: The charges on the light areas on the photosensitive drum are shown as positive in this

figure. Actually they are negative, but they are more positive than the developing

cylinder and explanation is simplified by regarding them as positive.

As shown in Figure 2.11, the developing unit consists of a developing cylinder and rubber blade.

The developing cylinder rotates around a fixed internal magnet. The single-component toner

consists of magnetite and a resin binder, and is held to the cylinder by magnetic attraction. The

toner is an insulator, and acquires a negative charge by friction due to the rotation of the cylinder.

The areas on the drum that were exposed to the laser beam have a higher potential (are less

negative) than the negatively charged toner particles on the developing cylinder. When these

areas approach the cylinder, the potential difference projects the toner particles onto them. This

is called toner projection, and the latent image on the drum becomes visible.

Developing cylinder

surface potential

+V

0

-V

Voltage (V)

Time t

Drum surface

potential

(exposed area)

DC bias

Drum surface

potential

(unexposed area)

Figure 2.12

An AC bias is applied to the developing cylinder to help project the toner particles to the drum

surface and improve the contrast of the printed image. The center voltage of the AC bias (1600

Vp-p) varies with the DC bias voltage.

The IMAGE DENSITY ADJUSTMENT signal (sent from the Engine CPU to the high-voltage

power supply) changes the DC bias, and thus the potential difference between the cylinder and

drum. This changes the density of the print.

This printer has a stirring mechanism to supply toner in the cartridge smoothly to the cylinder.

II - 8

3.2.3 Transfer stage

ging

In the transfer stage, the toner image is transferred from the drum surface to the paper.

Step 4 Transfer

A positive charge applied to the back of the paper attracts the negatively charged toner particles

to the paper. The printer accomplishes transfer by using the charging roller method. Advantages

compared with the corona transfer method are as follows:

Photo-

sensitive

drum

Transfer charging roller

Figure 2.13

Paper

• Low transfer voltage that is less than half that for corona transfer.

• Less ozone generation.

• The paper is supported by the transfer charging roller and photosensitive drum, so feed is

more stable.

Reference:

If the image on the photosensitive drum is not completely transferred to the paper due to

jamming, etc., the toner may adhere to the transfer charging roller. The printer removes the toner

from the transfer charging roller by switching the transfer voltage between positive and negative

in sequence. During wait, initial rotation, and last rotation, the printer sets the primary DC voltage

to zero, and sets the charge on the drum to zero. In this case, the transfer voltage is made

negative to remove the negatively-charged toner on the transfer charging roller to the drum. The

transfer charging roller is thus cleaned.

Step 5 Separation

Photo-

sensitive

drum

Paper

Static charge

eliminator

Transfer char

roller

Figure 2.14

The stiffness of the paper causes it to separate from the drum. (Curvature separation)

To stabilize the paper feed and prevent small white circles from appearing in the printed image

at low temperature and humidity, the charge on the back of the paper is reduced by the static

charge eliminator after transfer.

II - 9

3.2.4 Fixing stage

The toner image transferred to the paper in the transfer stage is held only by electrostatic

attraction and slight physical adhesion, so even a light touch will smear the image.

In the fixing stage, the toner image is fixed by heating the paper and applying pressure. This

fuses the toner particles to the paper to make a permanent image.

Step 6 Fixing

The upper roller surface is PFA-coated. The upper and lower roller surfaces are grounded via

a diode to prevent the negative potential of the upper roller becoming higher than that of the

lower roller, resulting in the toner being drawn to the lower roller, and adhering to the lower roller

surface.

3.2.5 Drum cleaning stage

Halogen heater

Upper fixing roller

Toner

Paper

Lower fixing roller

Figure 2.15

In the transfer stage, not all the toner is transferred to the paper. Some remains on the

photosensitive drum. This residual toner is cleaned off in the drum cleaning stage so that the

next print image will be clear.

Step 7 Drum cleaning

Prior to the next printing, the residual toner on the drum surface is scraped away by the cleaning

blade to clean the drum surface. The removed toner is collected in the cleaner container.

Cleaning blade

Cleaner container

Photo-

sensitive

drum

Sweeper strip

Figure 2.16

II - 10

3.3 Operation

When the engine controller circuit receives a print signal (PRINT) or a pre-feed signal (PRFD)

from the video controller circuit, the engine controller circuit drives the main motor to rotate the

photosensitive drum.

After the drum surface is charged negatively by the primary charge roller, the laser beam

modulated by a DATA signal scans the drum surface to from a latent image on the drum.

The latent image formed on the drum surface is converted into a visible image by the toner on

the developing cylinder and then image is transferred onto the paper by the transfer roller unit.

Then the residual toner is removed from the drum surface with the cleaner blade.

The cartridge also has a toner sensor. When the output from this sensor falls below a certain

level, it warns that the EP-ED cartridge will be out of toner with an alarm.

Scanner unit

Reflection mirror

Laser beam

Laser diode drive signal (DATA)

Scanner motor drive signal (SDRIVE)

Primary charge (AC) drive (HV1AC)

Main

PCB

Primary charge (DC) drive (HV1DC)

Developing bias (AC) drive (DBAC)

Developing bias (DC) drive (DBDC)

Transfer charger 1 drive (HVT1)

Transfer charger 2 drive (HVT2)

Transfer charger 3 drive (HVT3)

Transfer charger 4 drive (HVT4)

EP-ED cartridge

Transfer

roller

High-voltage

power supply

PCB

Toner sensor signal 1 (TONER 1)

Toner sensor signal 2 (TONER 2)

Figure 2.17

II - 11

4. PAPER PICK-UP/FEED SYSTEM

4.1 Outline

If a tray1 paper pick-up roller solenoid drive signal (PUCL1) is input to the circuit while the paper

feed motor is rotating, the paper pick-up solenoid comes on and the paper pick-up roller solenoid

is engaged. As a result, the paper pick-up roller rotates to feed paper down to the photosensitive

drum.

The paper position is controlled by the registration sensor so that the leading edge of the paper

is aligned with the leading edge of the image on the photosensitive drum. After this operation,

the paper is deliveried to the face down tray via the fixing unit. Paper ejection is detected by the

paper ejection sensor; if printed paper has not reached or not cleared the paper ejection sensor

in a specified time, the printer judges that a paper jam has occurred. In this case a paper jam

is noticed to the external devise by a status signal.

MP tray

paper empty sensor

MP tray paper empty sensor signal (PEMP)

Tray paper

empty sensor

Tray1 Pick-up

roller solenoid

Transfer roller

MP tray Pick-up

roller solenoid

Tray1 pick-up roller solenoid drive signal (PUCL1)

Tray1 paper empty sensor signal (PETRAY1)

Registration

Photosensitive

MP tray pick-up roller

solenoid drive signal (MPSOL)

Paper feed motor drive signal

Paper-

feed

motor

Registration sensor signal (REGIST)

sensor

drum

Main motor drive

signal (MDRIVE)

Main motor

Main PCB

Fixing rollers

Paper ejection sensor

Figure 2.18

II - 12

Paper ejection sensor signal (EJECT)

4.2 Cassette Feed

When the fixing rollers reach the specified temperature while a cassette with paper is in the

printer, the READY lamp changes from flashing to lighting.

When the engine controller circuit receives PRNT or PRFD signal from the video controller

circuit, the paper feed motor starts rotation. About 0.2 seconds later, the printer actuates the

tray1 pick-up roller solenoid and the pick-up roller makes one rotation. This feeds paper to the

photosensitive drum.

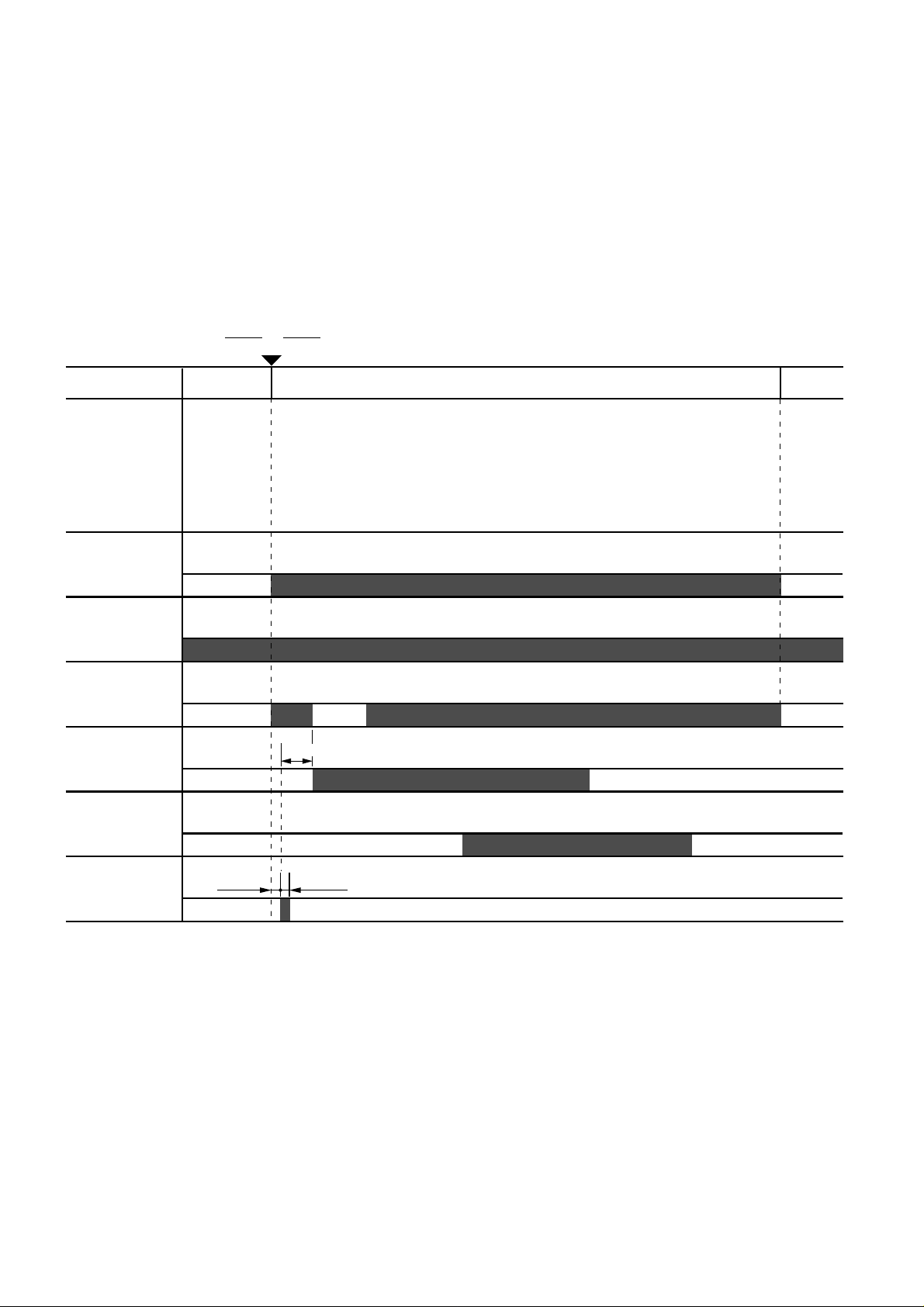

Timing chart for the pick-up one sheet

PRNT or PRFD

STBY PRINT STBY

Main motor

Paper empty

sensor

Paper feed

motor

Registration

sensor

Paper ejection

sensor

Pick-up roller

solenoid

0.15 sec

1.73 sec 3.18 sec

2.17 sec

0.15 sec

Figure 2.19

II - 13

4.3 MP Tray Feed

The timing of the MP tray feed is identical to the timing of the cassette paper feed except for

the following points:

(1) The paper empty sensors are different.

Cassette feed : Tray1 paper empty sensor

MP tray feed : MP tray paper empty sensor

(2) The pick-up roller solenoids are different.

Cassette feed : Tray1 pick-up roller solenoid

MP tray feed : MP tray pick-up roller solenoid

PRNT or PRFD

STBY PRINT STBY

Main motor

Paper empty

sensor

Paper feed

motor

Registration

sensor

Paper ejection

sensor

Pick-up roller

solenoid

0.84 sec

0.15 sec 0.15 sec

Figure 2.20

II - 14

Loading...

Loading...