Page 1

R

WORD PROCESSOR

SERVICE MANUAL

MODEL:DP-525CJ/DP-530CJ/DP-540CJ/DP-550CJ

LW-800ic/LW-810ic/LW-810icBL/LW-840ic

REVISED EDITION

Page 2

SERVICE MANUAL

CONTENTS

PART I THEORY OF OPERATION

CHAPTER 1 MECHANICAL THEORY....................................................................... 1-1

1. Ink Jet Printer........................................................................................................... 1-1

1.1. Ink Jet Printer System Configuration .......................................................................... 1-2

1.2. Ink Jet Operation........................................................................................................1-4

1.2.1. Paper Feed Mechanism ................................................................................ 1-4

1.2.2. Carriage Assembly ....................................................................................... 1-7

1.2.3. Carriage Motion Control.............................................................................. 1-10

1.2.4. Maintenance Station Operation................................................................... 1-11

1.2.4.1. Spitting ................................................................................................. 1-12

1.2.4.2. Wiping.................................................................................................. 1-13

1.2.4.3. Capping................................................................................................ 1-14

1.2.4.4. Purging................................................................................................. 1-14

1.2.5. Sensors...................................................................................................... 1-15

1.2.5.1. Carriage Home Position Sensor............................................................ 1-15

1.2.5.2. PE Sensor ............................................................................................ 1-16

1.3. INK CHG (Ink Change) Functions.............................................................................1-17

1.3.1. Ink Cartridge Installation/Replacement ....................................................... 1-17

1.3.2. Automatic Print head Cleaning (Purging).................................................... 1-17

2. Keyboard ................................................................................................................ 1-18

CHAPTER 2 ELECTRICAL THEORY........................................................................ 2-1

1. System Configuration...............................................................................................2-1

1.1. Main PCB (Printed Circuit Board)............................................................................... 2-1

1.2. Switch PCB (Printed Circuit Board)............................................................................. 2-1

1.3. Keyboard FPC (Flexible Printed Circuit)..................................................................... 2-1

1.4. FDD (Floppy Disk Drive) Module................................................................................ 2-1

1.5. CRT Display............................................................................................................... 2-1

2. Ink Jet Printer Configuration.....................................................................................2-3

2.1. Ink Cartridge............................................................................................................... 2-3

2.2. Carriage Motor ........................................................................................................... 2-3

2.3. Line Feed Motor......................................................................................................... 2-3

2.4. Carriage Home Position Sensor.................................................................................. 2-3

2.5. PE (Paper End) Sensor ..............................................................................................2-3

i

Page 3

SERVICE MANUAL

3. Power Supply Circuit................................................................................................ 2-4

3.1. Configuration.............................................................................................................. 2-4

3.2. +24V Generator.......................................................................................................... 2-5

3.3. +5V Generator............................................................................................................ 2-5

4. Reset Circuit.............................................................................................................2-6

4.1. Configuration.............................................................................................................. 2-6

5. CBIC and Peripherals............................................................................................... 2-7

5.1. CBIC #9 ..................................................................................................................... 2-7

5.2. Main ROM (#12, #13)................................................................................................. 2-7

5.3. Main RAM (#10, #11) ................................................................................................. 2-7

5.4. Video RAM (#7) .......................................................................................................... 2-7

5.5. Printer Driver Circuits (#2, #3, Q1 to Q4, and Q14 to Q17)......................................... 2-7

5.6. FDC (Floppy Disk Controller)...................................................................................... 2-7

5.7. Clock Circuit............................................................................................................... 2-8

5.8. Buzzer Drive Circuit ................................................................................................... 2-8

5.9. Country Specification Change-over ............................................................................2-9

5.10. RS-232C I/F Circuit.................................................................................................. 2-10

6. Printer Control........................................................................................................ 2-11

6.1. Ink Jet Head Control ................................................................................................. 2-11

6.2. Carriage Motor Control............................................................................................. 2-12

6.3. Line Feed Motor Control........................................................................................... 2-13

6.4. Carriage Home Position Sensor................................................................................ 2-14

6.5. PE Sensor................................................................................................................ 2-14

7. Switch PCB ............................................................................................................2-15

7.1. Configuration............................................................................................................ 2-15

8. Keyboard System................................................................................................... 2-16

8.1. FPC Operation ......................................................................................................... 2-16

8.2. Keyboard Scan......................................................................................................... 2-17

8.3. Keyboard Control Circuit........................................................................................... 2-18

9. CRT Control ........................................................................................................... 2-20

9.1. Configuration............................................................................................................ 2-20

9.2. SRAM and Display Screen Relationship................................................................... 2-21

9.2.1. SRAM (#7) Access ..................................................................................... 2-22

9.2.2. CRT Display Timing Chart.......................................................................... 2-23

10. FDD (Floppy Disk Drive) Control ............................................................................2-24

10.1. FDD Configuration.................................................................................................... 2-24

10.2. FDD Operation......................................................................................................... 2-25

10.2.1. Basic Operation.......................................................................................... 2-25

10.2.2. Interface between CBIC (#8) and FDC (#5)................................................. 2-25

10.3. FDD Module............................................................................................................. 2-26

ii

Page 4

SERVICE MANUAL

10.3.1. Read/Write Circuit...................................................................................... 2-26

10.3.2. Motor Drive Circuit...................................................................................... 2-26

10.3.3. Sensor Circuits........................................................................................... 2-26

PART II REPAIR

CHAPTER 3 TROUBLESHOOTING..........................................................................3-1

1. Introduction .............................................................................................................. 3-1

2. Precautions..............................................................................................................3-1

2.1. Personal Safety.......................................................................................................... 3-1

2.2. Handling ESD-Sensitive Parts.................................................................................... 3-1

3. Checks Before Repair.............................................................................................. 3-2

4. Checks After Repair................................................................................................. 3-3

5. Troubleshooting Flow Charts....................................................................................3-4

6. Failure Analysis........................................................................................................3-6

7. SELF-TESTS..........................................................................................................3-13

7.1. SERIAL NUMBER Input Display............................................................................... 3-13

7.2. Self Print Mode......................................................................................................... 3-14

7.3. Self-Test Mode......................................................................................................... 3-17

7.3.1. Display (CRT) Test..................................................................................... 3-19

7.3.1.1. Cross Hatch Pattern Test...................................................................... 3-20

7.3.1.2. Full Dot Screen Test............................................................................. 3-21

7.3.1.3. Blank Screen Test ................................................................................ 3-22

7.3.1.4. H Pattern Test ...................................................................................... 3-23

7.3.1.5. mw Pattern Test.................................................................................... 3-24

7.3.1.6. Dot Pattern Test.................................................................................... 3-25

7.3.2. Print Checks............................................................................................... 3-26

7.3.2.1. Print Test Pattern 1............................................................................... 3-26

7.3.2.2. Print Test Pattern 2............................................................................... 3-29

7.3.2.3. Dot Patterns.......................................................................................... 3-31

7.3.3. Keyboard Tests........................................................................................... 3-33

7.3.4. FDD Tests.................................................................................................. 3-36

7.3.4.1. FDD Test.............................................................................................. 3-36

7.3.4.2. Special FDD Test.................................................................................. 3-37

7.3.4.3. FDD SW Test ....................................................................................... 3-41

7.3.4.4. FDD Write Error Rate Check ................................................................ 3-42

7.3.4.5. FDD Read Error Rate Check................................................................. 3-44

7.3.5. PE (Paper-End) Sensor Test....................................................................... 3-46

7.3.6. CR (Carriage Reset) Test ........................................................................... 3-47

iii

Page 5

SERVICE MANUAL

7.3.7. DISK TYPE ................................................................................................ 3-48

7.3.8. RS-232C Test ("Echo Back") ...................................................................... 3-49

CHAPTER 4 COMPONENT DISASSEMBLY............................................................. 4-1

1. Covers...................................................................................................................... 4-1

1.1. Upper Cover ............................................................................................................... 4-2

1.1.1. Removing the Upper Cover.......................................................................... 4-2

1.1.2. Removing the Front Cover ........................................................................... 4-6

1.1.3. Installing the Upper Cover ............................................................................4-7

2. Keyboard Assembly ................................................................................................. 4-8

2.1. Removing the Keyboard............................................................................................. 4-8

2.2. Installing the Keyboard............................................................................................... 4-9

3. Ink Jet Printer Assembly.........................................................................................4-10

3.1. Removing the Printer Assembly ............................................................................... 4-11

3.2. Installing the Printer Assembly.................................................................................. 4-11

3.3. Disassembling the Printer Assembly ......................................................................... 4-12

3.3.1. Removing the CA Unit................................................................................ 4-13

3.3.2. Installing the CA Unit.................................................................................. 4-13

3.3.3. Disassembling the PF Unit.......................................................................... 4-14

3.3.3.1. Removing the Form.............................................................................. 4-15

3.3.3.2. Removing the Release Lever and Release Shaft.................................. 4-16

3.3.3.3. Removing the ACF Shaft Assembly...................................................... 4-17

3.3.3.4. Removing the Pressure Rollers and Roller Holders............................... 4-18

3.3.3.5. Removing the Holder Plate................................................................... 4-19

3.3.3.6. Removing the Hopper Assembly........................................................... 4-20

3.3.3.7. Disassembling the Paper Feed Assembly ............................................. 4-22

3.3.3.8. Removing the Eject Roller Assembly and the PF Roller Assembly........ 4-23

3.3.3.9. Removing the Motor Frame Assembly.................................................. 4-24

3.3.3.10. Removing the PF Stopper..................................................................... 4-25

3.3.3.11. Removing the PE Sensor...................................................................... 4-26

3.3.4. Disassembling the CA Unit ......................................................................... 4-27

3.3.4.1. Removing the Carriage......................................................................... 4-28

3.3.4.2. Removing the Carriage Drive................................................................ 4-30

3.3.4.3. Removing the Star Wheel Holder Assembly ......................................... 4-31

3.3.4.4. Removing the MS Holder Assembly...................................................... 4-32

3.3.4.5. Removing the Leaf Switch (Home Position Sensor).............................. 4-33

3.3.4.6. Removing and Mounting the KB Switch Assy........................................ 4-34

3.4. Adjusting the CA Unit ............................................................................................... 4-35

3.4.1. Adjusting the Carriage Home Position......................................................... 4-35

3.4.2. Adjusting Belt Tension................................................................................ 4-36

iv

Page 6

SERVICE MANUAL

4. Removing the FDD Assembly ................................................................................ 4-39

5. Switch PCB ............................................................................................................4-40

5.1. Removing the Switch PCB ....................................................................................... 4-41

5.2. Installing the Switch PCB.......................................................................................... 4-41

6. Removing the Main PCB........................................................................................ 4-42

7. Removing the Shield Plate (ESD) .......................................................................... 4-43

CHAPTER 5 MONITOR REPAIR AND ADJUSTMENT (MODEL CT-1450).............. 5-1

1. Safety Precautions...................................................................................................5-1

2. Theory of Operation.................................................................................................5-3

2.1. Video Process ............................................................................................................5-3

2.2. Video Amplifier ........................................................................................................... 5-3

2.3. Vertical Circuitry......................................................................................................... 5-4

2.4. Horizontal Sync and Drive.......................................................................................... 5-4

2.5. Horizontal Output Transistor....................................................................................... 5-5

2.6. High Voltage and Focus ............................................................................................. 5-5

3. Adjustment and Servicing......................................................................................... 5-6

3.1. Test Pattern................................................................................................................ 5-6

3.2. Measurement Conditions............................................................................................ 5-7

3.2.1. Display Dimension Measurement.................................................................. 5-7

3.2.2. Raster Centering & Tilt Adjustment (see Fig. 5.3) .........................................5-7

3.3. Adjustments ............................................................................................................... 5-8

3.3.1. B+ Voltage Adjustments: None required. ..................................................... 5-8

3.3.2. Horizontal Adjustments................................................................................. 5-8

3.3.3. Vertical Adjustments (see Fig. 5.5) ...............................................................5-9

3.3.4. Brightness & Contrast................................................................................... 5-9

3.3.5. Focus Adjustment......................................................................................... 5-9

3.3.6. Raster Geometry Adjustments.................................................................... 5-10

3.3.6.1. Pin Cushion/Barrel Correction (top, bottom and sides) Adjustment........ 5-10

3.3.6.2. Trapezoidal Correction (corners) Adjustment ........................................ 5-12

4. Troubleshooting ..................................................................................................... 5-13

5. Control Parts Location............................................................................................5-14

6. Monitor Block Diagram...........................................................................................5-15

CHAPTER 6 MAINTENANCE .................................................................................... 6-1

1. Lubrication................................................................................................................ 6-1

1.1. Lubricants................................................................................................................... 6-1

1.2. Precautions ................................................................................................................6-1

1.3. Lubrication Points....................................................................................................... 6-1

v

Page 7

SERVICE MANUAL

2. Replacing the Ink Cartridge...................................................................................... 6-5

3. Cleaning the Print Head........................................................................................... 6-9

3.1. Cleaning the Print Head Automatically........................................................................ 6-9

3.2. Cleaning the Ink Jet Nozzles and Contacts................................................................. 6-9

3.3. Cleaning the Bracket Contacts (Carriage)................................................................. 6-10

APPENDIX A SPECIFICATIONS...........................................................................APP-1

1. Electrical System.................................................................................................APP-1

2. Printing................................................................................................................APP-2

3. Keyboard .............................................................................................................APP-4

4. Monitor (CT-1450)...............................................................................................APP-4

5. Environmental Tolerance ....................................................................................APP-5

6. Dimensions & Weight..........................................................................................APP-6

vi

Page 8

SERVICE MANUAL

FIGURES

Figure Title Page

Fig. 1.1 Ink Jet Printer Assembly....................................................................................... 1-1

Fig. 1.2 General View of Printing Mechanism .................................................................... 1-3

Fig. 1.3A Paper Feed Mechanism ................................................................ ........................ 1-4

Fig. 1.3B Paper Feed Mechanism ................................................................ ........................ 1-5

Fig. 1.4 Paper Eject System.............................................................................................. 1-5

Fig. 1.5 Paper Setting System........................................................................................... 1-6

Fig. 1.6 Printer Flat Cable to Main PCB............................................................................. 1-7

Fig. 1.7 Printer Flat Cable to Cartridge Alignment.............................................................. 1-8

Fig. 1.8 Ink Jet Cartridge to Flat Cable Alignment.............................................................. 1-9

Fig. 1.9 Carriage Motion Control ................................................................ ...................... 1-10

Fig. 1.10 Print Maintenance Operation - Spitting................................................................ 1-12

Fig. 1.11 Print Maintenance Operation - Wiping................................................................. 1-13

Fig. 1.12 Print Maintenance Operation - Capping .............................................................. 1-14

Fig. 1.13 Carriage Home Position Sensor ................................ .......................................... 1-15

Fig. 1.14 PE Sensor Mechanism....................................................................................... 1-16

Fig. 1.15 Keyboard Assembly............................................................................................ 1-18

Fig. 1.16 Key Top/Key Stem Assembly ............................................................................. 1-19

Fig. 1.17 LCD Unit Installation in the Upper Cover ................................ ............................. 1-21

Fig. 1.18 LCD of DP-525CJ/LW-800ic............................................................................... 1-22

Fig. 1.19 LCD of DP-530CJ/LW-810ic and LW-810icBL .................................................... 1-23

Fig. 1.20 LCD of DP-540CJ, DP-550CJ/LW-840ic............................................................. 1-24

Fig. 2.1 Major Electronic Component Parts........................................................................ 2-2

Fig. 2.2 Power Supply Circuit ............................................................................................ 2-4

Fig. 2.3 Timing Chart of +24V Generation Circuit............................................................... 2-5

Fig. 2.4 Timing Chart of +5V Generation Circuit ................................................................ 2-5

Fig. 2.5 Reset Circuit......................................................................................................... 2-6

Fig. 2.6 Buzzer Drive Circuit.............................................................................................. 2-8

Fig. 2.7 Country & Model Specification Change-over Circuit.............................................. 2-9

Fig. 2.8 RS-232C I/F Circuit ............................................................................................ 2-10

Fig. 2.9 Ink Jet Head Drive Circuit................................................................................... 2-11

i

Page 9

SERVICE MANUAL

Figure Title Page

Fig. 2.10 Carriage Motor Drive Circuit................................................................................ 2-12

Fig. 2.11 Line Feed Motor Drive Circuit ............................................................................. 2-13

Fig. 2.12 Carriage Home Position Sensor Circuit............................................................... 2-14

Fig. 2.13 PE Sensor Detection Circuit ............................................................................... 2-14

Fig. 2.14 External View of the Switch PCB........................................................................ 2-15

Fig. 2.15 Switch PCB Circuit ............................................................................................. 2-15

Fig. 2.16 Key/FPC Operation ............................................................................................ 2-16

Fig. 2.17 Electrode Wiring................................................................................................. 2-17

Fig. 2.18 Keyboard Control Circuit ................................................................ ..................... 2-18

Fig. 2.19 Keyboard Matrix ................................................................................................. 2-19

Fig. 2.20 Keyboard Symbols (Corresponding to Keyboard Matrix in Fig. 2.19)................... 2-19

Fig. 2.21 LCD Display Operation Block Diagram................................................................ 2-20

Fig. 2.22 Example of Control Signal Timing Chart.............................................................. 2-21

Fig. 2.23 LCD Drive Voltage Generation Circuit (Minus Voltage VEE)................................ 2-22

Fig. 2.24 LCD Drive Voltage Generation Circuit (Plus Voltage VEE).................................. 2-22

Fig. 2.25 CFL Backlight Circuit.......................................................................................... 2-23

Fig. 2.26 FDD Block Diagram............................................................................................ 2-25

Fig. 3.1 Troubleshooting Flowchart.................................................................................... 3-4

Fig. 3.2 Troubleshooting Flowchart (continued) ................................................................. 3-5

Fig. 3.3 Serial Number Entry Display............................................................................... 3-14

Fig. 3.4 Self-Print Pattern................................................................................................ 3-15

Fig. 3.5 Results of Self-Print Test.................................................................................... 3-17

Fig. 3.6 Self-Test Menu................................................................................................... 3-18

Fig. 3.7 LCD Test Menu.................................................................................................. 3-20

Fig. 3.8 CHECK Test Display (magnified)........................................................................ 3-21

Fig. 3.9 CROSS Test Display (magnified)........................................................................ 3-22

Fig. 3.10 BLACK Test Display........................................................................................... 3-23

Fig. 3.11 DISP Q Test Display (magnified)........................................................................ 3-24

Fig. 3.12 Slant Line Test Display (magnified)..................................................................... 3-25

Fig. 3.13 Printer Check #1 (in progress) Display................................................................ 3-26

Fig. 3.14 Diagram of Print Test Pattern 1 .......................................................................... 3-27

Fig. 3.15 Sample Print Test Pattern 1................................................................................ 3-28

ii

Page 10

SERVICE MANUAL

Figure Title Page

Fig. 3.16 Printer Check #2 (in progress) Display................................................................ 3-29

Fig. 3.17 Sample Test Pattern 2........................................................................................ 3-30

Fig. 3.18 Dot Patterns for Print Test #2 (Patterns 1 to 4)................................................... 3-31

Fig. 3.19 Dot Patterns for Print Test #2 (Patterns 5 and 6) ................................................ 3-32

Fig. 3.20 Keyboard Test #1 Display ................................................................ ................... 3-33

Fig. 3.21 Keyboard Test Key Locations............................................................................. 3-33

Fig. 3.22 FDD Test (in progress) Display ................................ ........................................... 3-36

Fig. 3.23 Special FDD Test Display 1................................................................................ 3-37

Fig. 3.24 Special FDD Test Display 2................................................................................ 3-38

Fig. 3.25 Special FDD Test (in progress) Display .............................................................. 3-38

Fig. 3.26 Special FDD Test Display 1................................................................................ 3-41

Fig. 3.27 FDD Write Error Rate Check Display.................................................................. 3-42

Fig. 3.28 FDD Read Error Rate Check Display.................................................................. 3-44

Fig. 3.29 PE Sensor Test Start Display 1 .......................................................................... 3-46

Fig. 3.30 PE Sensor Test Start Display 2 .......................................................................... 3-46

Fig. 3.31 CR Test Start Display 1...................................................................................... 3-47

Fig. 3.32 Self-Test Menu (DISK TYPE Setting) ................................................................. 3-48

Fig. 3.33 RS232C Echo-Back Test Start Display............................................................... 3-49

Fig. 4.1 Cover Assemblies................................................................................................. 4-1

Fig. 4.2 Removing the Sub Paper Support and Paper Support .......................................... 4-3

Fig. 4.3 Removing the Top Cover...................................................................................... 4-4

Fig. 4.4 Removing the Upper Cover................................................................................... 4-5

Fig. 4.5 Removing the Core............................................................................................... 4-8

Fig. 4.6 Removing the LCD Unit........................................................................................ 4-9

Fig. 4.7 Removing the LCD Lower Cover......................................................................... 4-10

Fig. 4.8 Removing the LCD PCB (1)................................................................................ 4-12

Fig. 4.9 Removing the LCD PCB (2)................................................................................ 4-13

Fig. 4.10 Removing the LCD PCB (3)................................................................................ 4-14

Fig. 4.11 Removing the LCD PCB (4)................................................................................ 4-15

Fig. 4.12 Removing the LCD PCB (5)................................................................................ 4-16

Fig. 4.13 Removing LCD Latch and LCD Plate.................................................................. 4-17

Fig. 4.14 Installing LCD Latch............................................................................................ 4-19

iii

Page 11

SERVICE MANUAL

Figure Title Page

Fig. 4.15 Fitting LCD Volume Guide to LCD Volume Knob................................................. 4-21

Fig. 4.16 Installing the LCD Lower Cover........................................................................... 4-22

Fig. 4.17 Fitting the Core ................................................................ .................................. 4-23

Fig. 4.18 Installing the Hinge Assy..................................................................................... 4-24

Fig. 4.19 Removing the Keyboard Assembly ..................................................................... 4-25

Fig. 4.20 Installing the Keyboard ....................................................................................... 4-26

Fig. 4.21 Removing the Carrying Handle........................................................................... 4-27

Fig. 4.22 Ink Jet Printer Assembly..................................................................................... 4-28

Fig. 4.23 Disassembling the Printer Assembly................................................................... 4-30

Fig. 4.24 Construction of the PF Unit................................................................................. 4-32

Fig. 4.25 Removing the Form............................................................................................ 4-33

Fig. 4.26 Removing the Release Lever and Release Shaft from the PF Base Assembly.... 4-34

Fig. 4.27 Removing the ACF Shaft Assembly.................................................................... 4-35

Fig. 4.28 Removing the Pressure Rollers and Roller Holders............................................. 4-36

Fig. 4.29 Removing the Holder Plate................................................................................. 4-37

Fig. 4.30 Removing the Hopper Assembly ................................ ......................................... 4-39

Fig. 4.31 Disassembling the Paper Feed Assembly........................................................... 4-40

Fig. 4.32 Removing the Eject Roller Assembly and the PF Roller Assembly...................... 4-41

Fig. 4.33 Removing the Motor Frame Assembly................................................................ 4-42

Fig. 4.34 Removing the PF Stopper................................................................................... 4-43

Fig. 4.35 Removing the PE Sensor.................................................................................... 4-44

Fig. 4.36 Construction of the CA Unit ................................................................................ 4-45

Fig. 4.37 Printer Mechanism.............................................................................................. 4-46

Fig. 4.38 Removing the Carriage....................................................................................... 4-47

Fig. 4.39 Removing the Carriage Drive.............................................................................. 4-48

Fig. 4.40 Removing the Star Wheel Holder Assembly........................................................ 4-49

Fig. 4.41 Removing the MS Holder Assembly.................................................................... 4-50

Fig. 4.42 Removing the Leaf Switch (Home Position Sensor) ............................................ 4-51

Fig. 4.43 Removing and Mounting the KB Switch Assy...................................................... 4-52

Fig. 4.44 Adjusting the Belt Tension.................................................................................. 4-55

Fig. 4.45 Measuring Friction during Carriage Movement.................................................... 4-56

Fig. 4.46 Removing the FDD Assembly............................................................................. 4-57

iv

Page 12

SERVICE MANUAL

Figure Title Page

Fig. 4.47 Switch PCB........................................................................................................ 4-58

Fig. 4.48 Switch PCB........................................................................................................ 4-59

Fig. 4.49 Removing the Main PCB..................................................................................... 4-60

Fig. 4.50 Removing the Shield Plate (ESD)....................................................................... 4-61

Fig. 5.1 Carriage Assembly Lubrication Points................................................................... 5-2

Fig. 5.2 Paper Feed Assembly Lubrication Points ................................ .............................. 5-3

Fig. 5.3 Eject Roller Assembly and PF Roller Assembly Lubrication Points........................ 5-4

Fig. 5.4 Open the Paper Support and Top Cover and

Tilting the LCD to the Uprige Position ................................................................... 5-6

Fig. 5.5 Removing the Ink Jet Cartridge............................................................................. 5-7

Fig. 5.6 Removing the Protection Tape.............................................................................. 5-7

Fig. 5.7 Placing the Cartridge in the Carriage .................................................................... 5-8

Fig. 5.8 Fitting the Cartridge in the Carriage ...................................................................... 5-8

Fig. 5.9 Cleaning the Bracket Contacts............................................................................ 5-11

TABLES

Table 1.1 Summary of Maintenance Operations................................................................. 1-11

Table 2.1 Clock Circuit ......................................................................................................... 2-8

Table 2.2 Table of LCD Modules........................................................................................ 2-21

Table 2.3 FDC(#5) and FDD Module Links (Interface Signals)............................................ 2-24

Table 3.1 Failure Analysis .................................................................................................... 3-6

Table 3.2 FDD Special Test Error Stage Codes ................................................................. 3-39

Table 3.3 FDD Special Test Error Codes............................................................................ 3-40

Table 5.1 Recommended Lubricants .................................................................................... 5-1

v

Page 13

SERVICE MANUAL

PART I THEORY OF OPERATION

CHAPTER 1 MECHANICAL THEORY

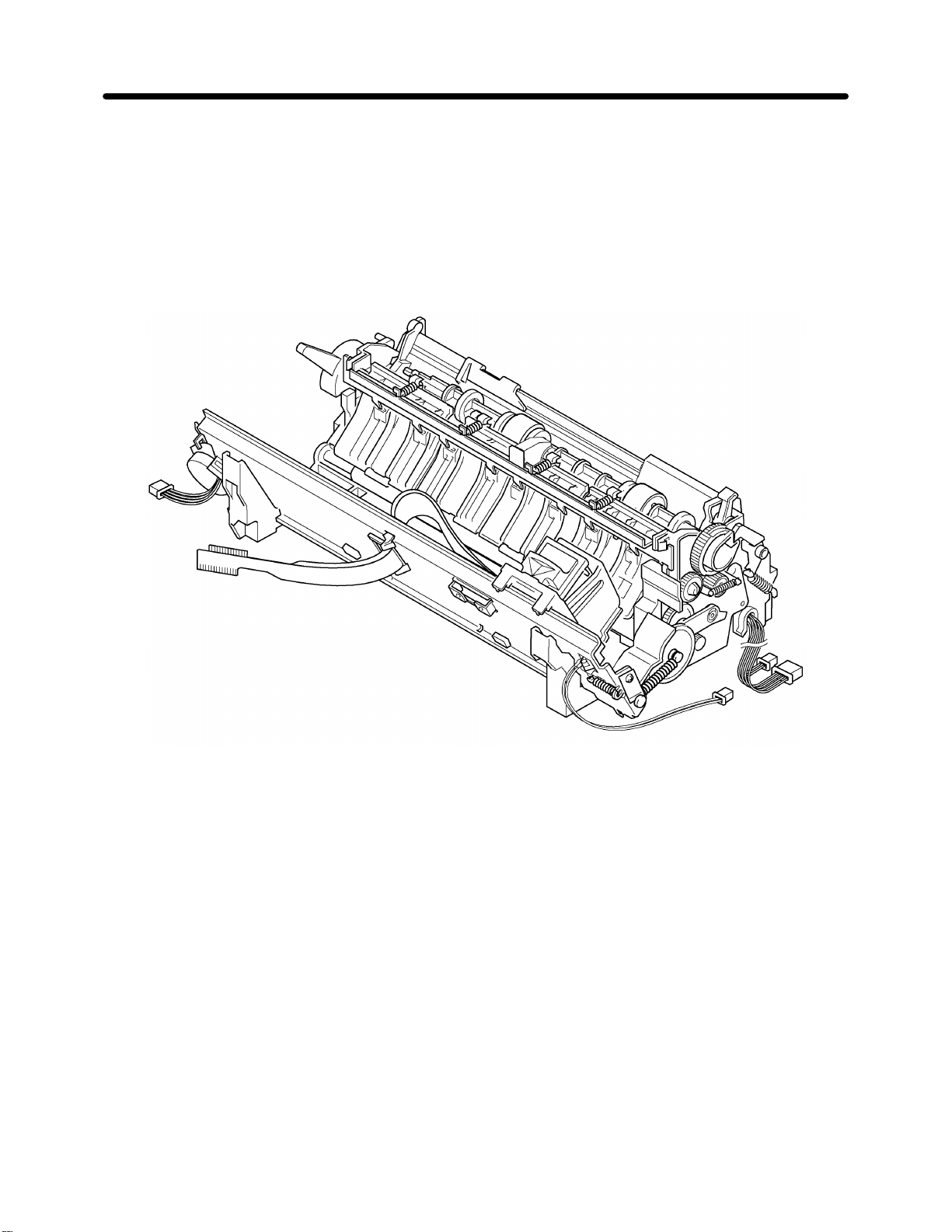

1. Ink Jet Printer

THEORY

Mechanical

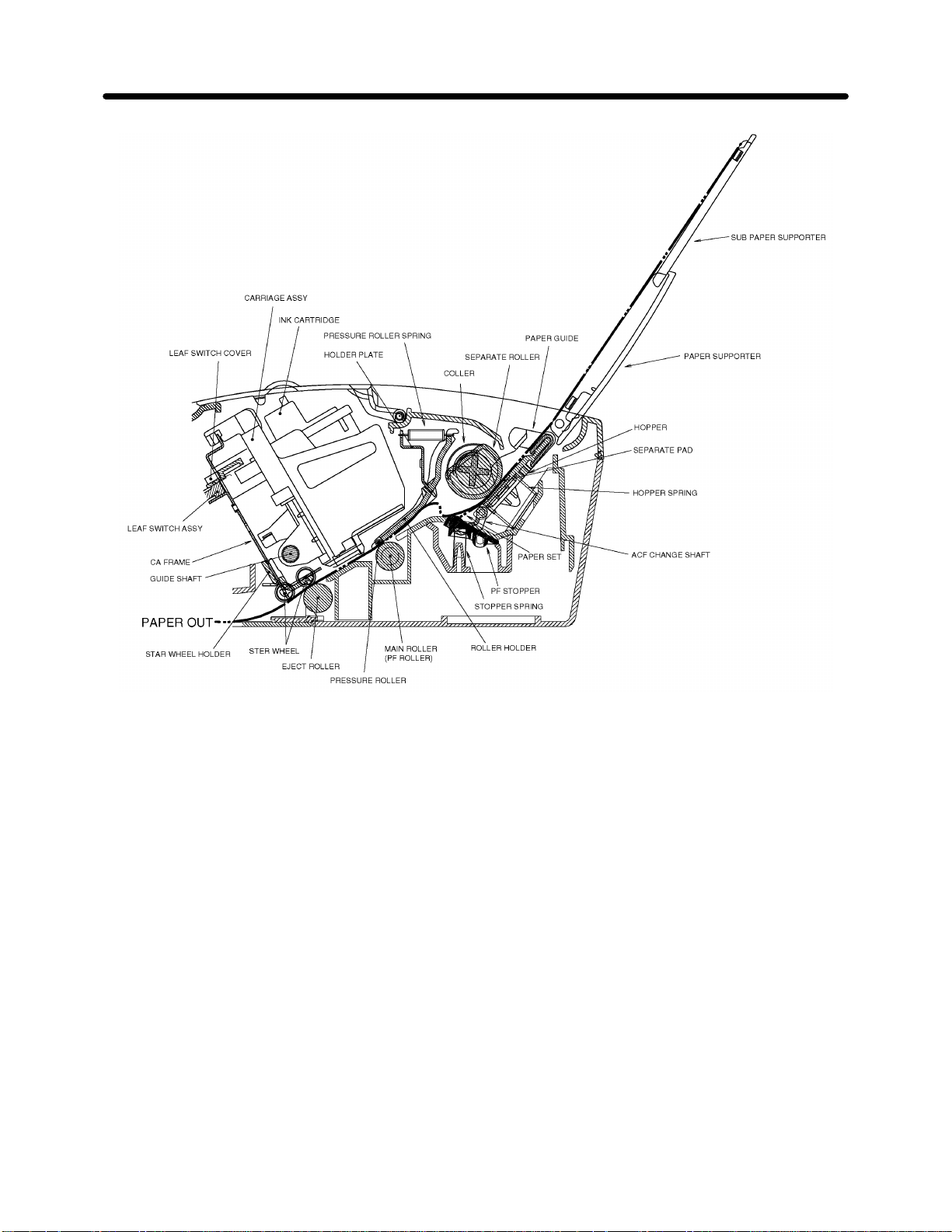

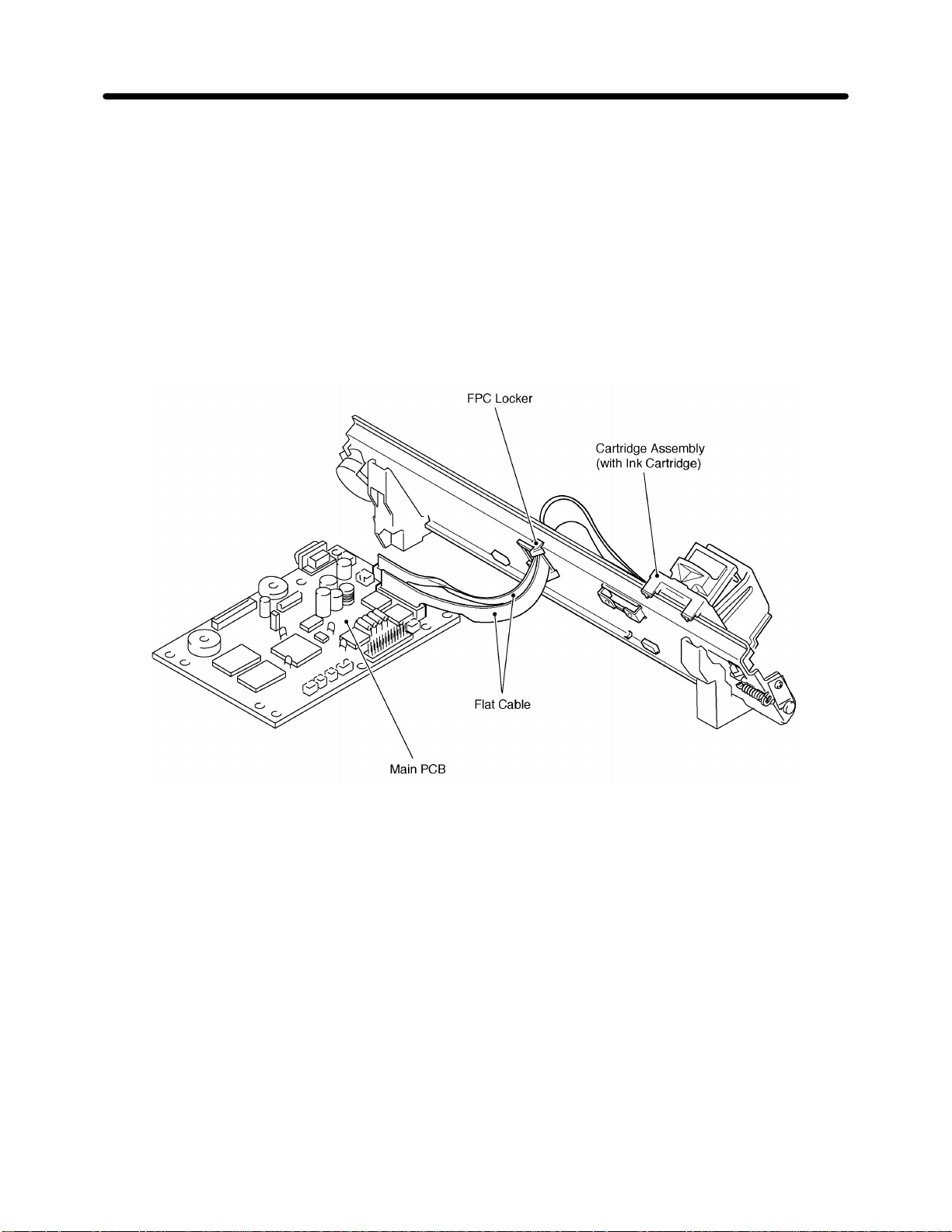

Fig. 1.1 Ink Jet Printer Assembly

1-1

Page 14

THEORY

Mechanical

1.1. Ink Jet Printer System Configuration

The ink jet printer contains the following components:

Carriage assembly

•

Carriage motion control system

•

Paper feed mechanism

•

Maintenance station

•

Sensors

•

The outline of these components are described below.

1. Carriage Assembly

The carriage assembly consists of the carriage and ink cartridge (the cartridge

contains the ink jet nozzles). The carriage consists of the head locker and locker

spring, the rubber pad, and the flat cable.

SERVICE MANUAL

2. Carriage Motion Control System

The carriage motion control system consists of the carriage motor, motor pulley,

timing belt, idle pulley, and the idle pulley holder and holder spring.

3. Paper Feed Mechanism

The paper feed mechanism consists of the paper feed system, paper eject system,

and the paper setting system.

4. Maintenance Station

The maintenance station consists of the MS holder, the MS carriage assembly

(carriage, rubber cap, plunger, compression spring, and extension spring), the wiper,

and the felt form ink absorbers (in spitting trough and under carriage assembly ).

5. Sensors

There are two sensors in the printer assembly: the carriage home position sensor

(attached to the top right end of the CA frame) and the paper end sensor (attached to

the bottom of the PF base at the right rear).

1-2

Page 15

SERVICE MANUAL

THEORY

Mechanical

Fig. 1.2 General View of Printing Mechanism

1-3

Page 16

THEORY

Mechanical

1.2. Ink Jet Operation

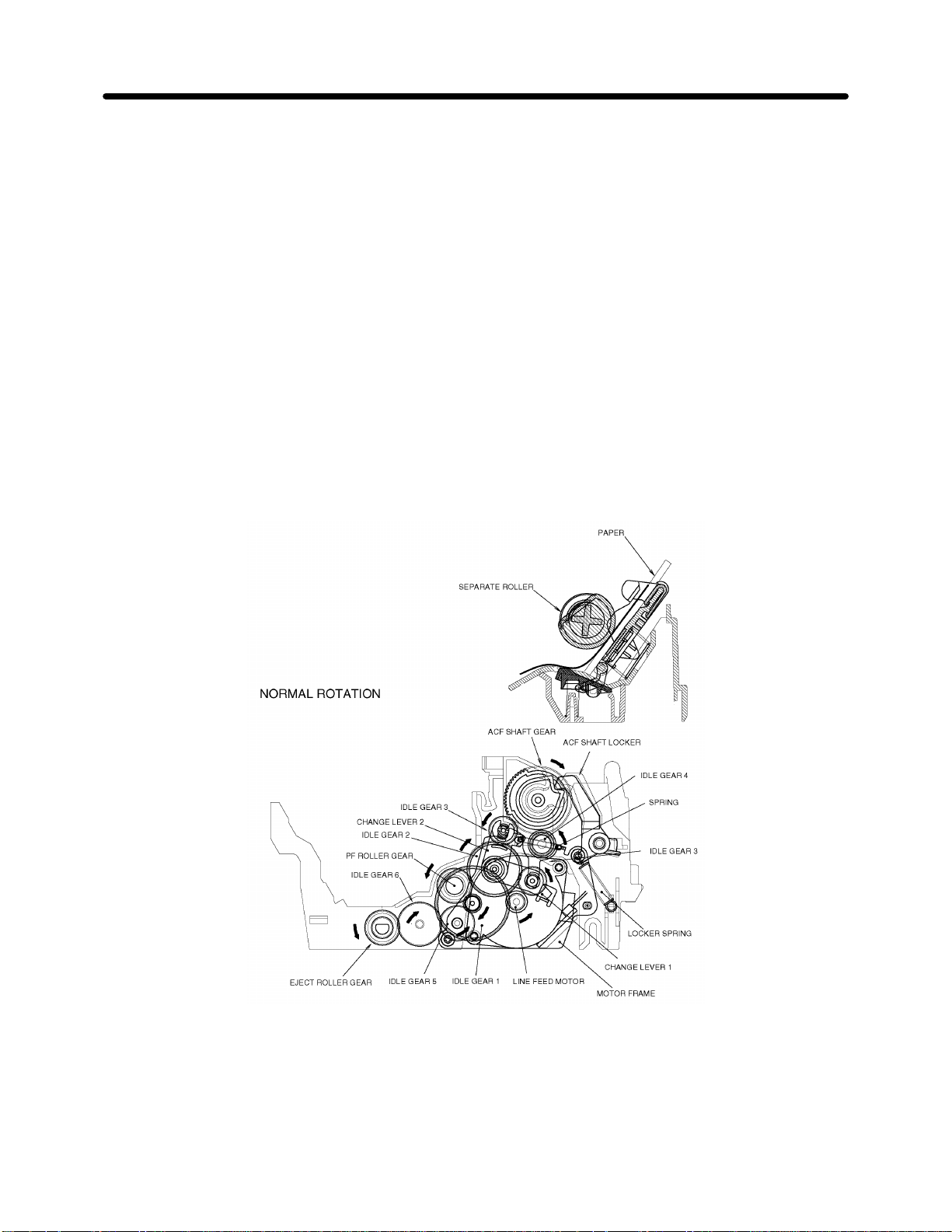

1.2.1. Paper Feed Mechanism

The paper feed mechanism consist of the paper feed system, paper eject system, and

the paper setting system.

(1) The paper feed system consists of the ACF shaft gear, separate roller, ACF shaft

locker, locker spring, idle gears 1, 2, 3, and 4, PF roller gear, changer lever 1 and 2,

spring, and the line feed motor.

Paper feed system ACF(Auto cut-sheet feeder)

When the paper feed motor is driven in the opposite direction (reverse rotation) of the

paper feeding, the change lever 1 moves to engage the ACF shaft gear via the idle

gear. The separate roller rotates in the paper separation direction (normal rotation)

and separates a sheet of paper. The separate roller rotates with paper feeding

operation and returns to the initial position. Separated paper is fed to contact PF

roller and the pressure roller by the separate roller where the top of the paper is

registered.

SERVICE MANUAL

Fig. 1.3A Paper Feed Mechanism

1-4

Page 17

SERVICE MANUAL

THEORY

Mechanical

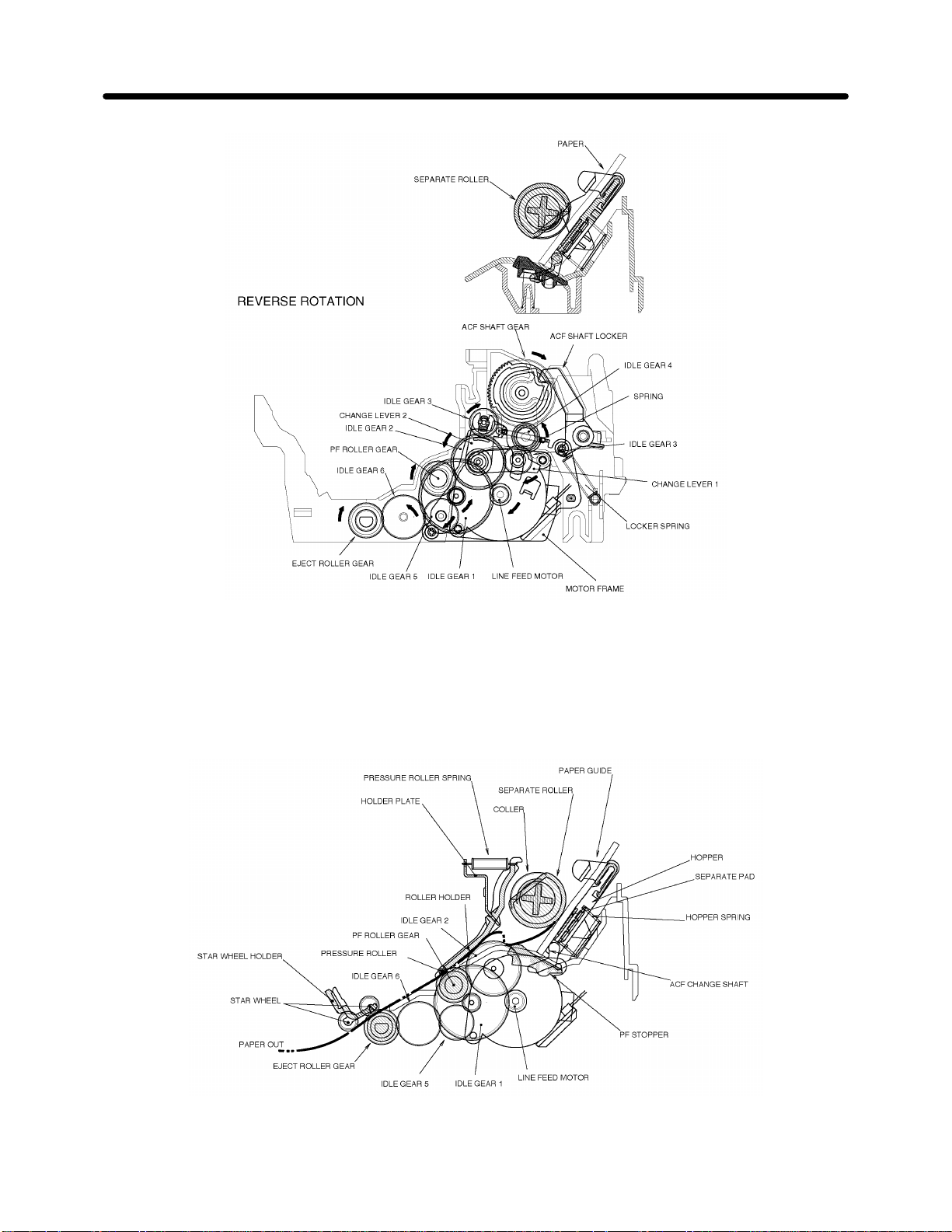

Fig. 1.3B Paper Feed Mechanism

(2) The paper eject system consists of the line feed motor, collar, idle gears 1, 5, and 6,

PF roller gear, eject roller gear, pressure roller, roller holder, holder plate, pressure

roller spring, star wheel holder, and the star wheel.

After paper is registered, the paper feed motor is driven in the paper feeding direction

(normal rotation) and paper is fed by the PF roller and the pressure roller. After

printing paper is ejected by the eject roller and star wheel.

Fig. 1.4 Paper Eject System

1-5

Page 18

THEORY

Mechanical

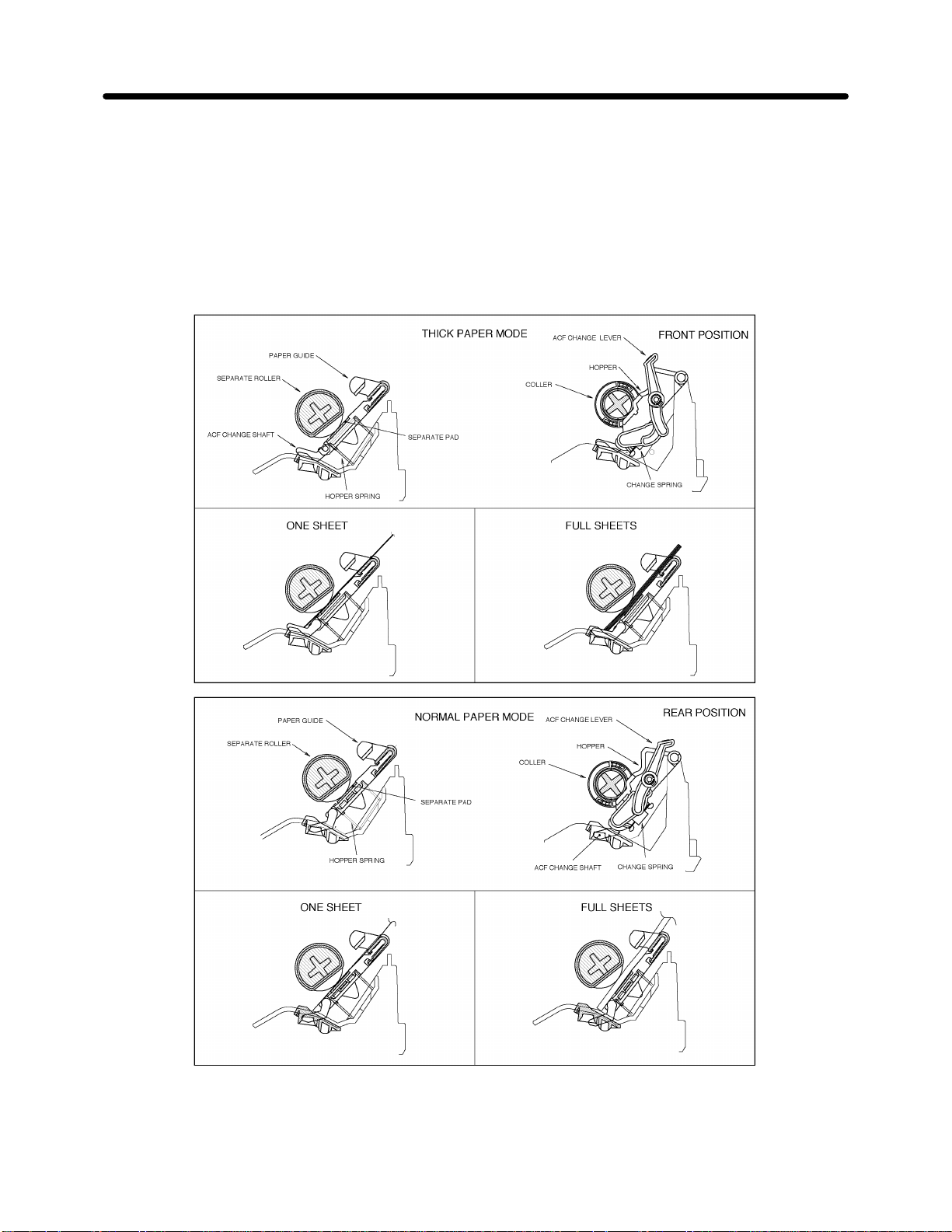

(3) The paper setting system consists of the hopper, hopper spring, separate pad, collar,

SERVICE MANUAL

paper guide, ACF change lever, change spring, and the ACF change shaft.

When inserting a thick paper, the ACF change lever should place at the front

position.

24lb Thick Paper

Envelope

Label

Transparency etc.

Fig. 1.5 Paper Setting System

1-6

Page 19

SERVICE MANUAL

1.2.2. Carriage Assembly

The carriage assembly consists of the carriage and ink cartridge (the cartridge contains

the ink jet nozzles). The carriage consists of the head locker and locker spring, the

rubber pad, and the flat cable. The flat cable connects to the main PCB. See Fig. 1.6.

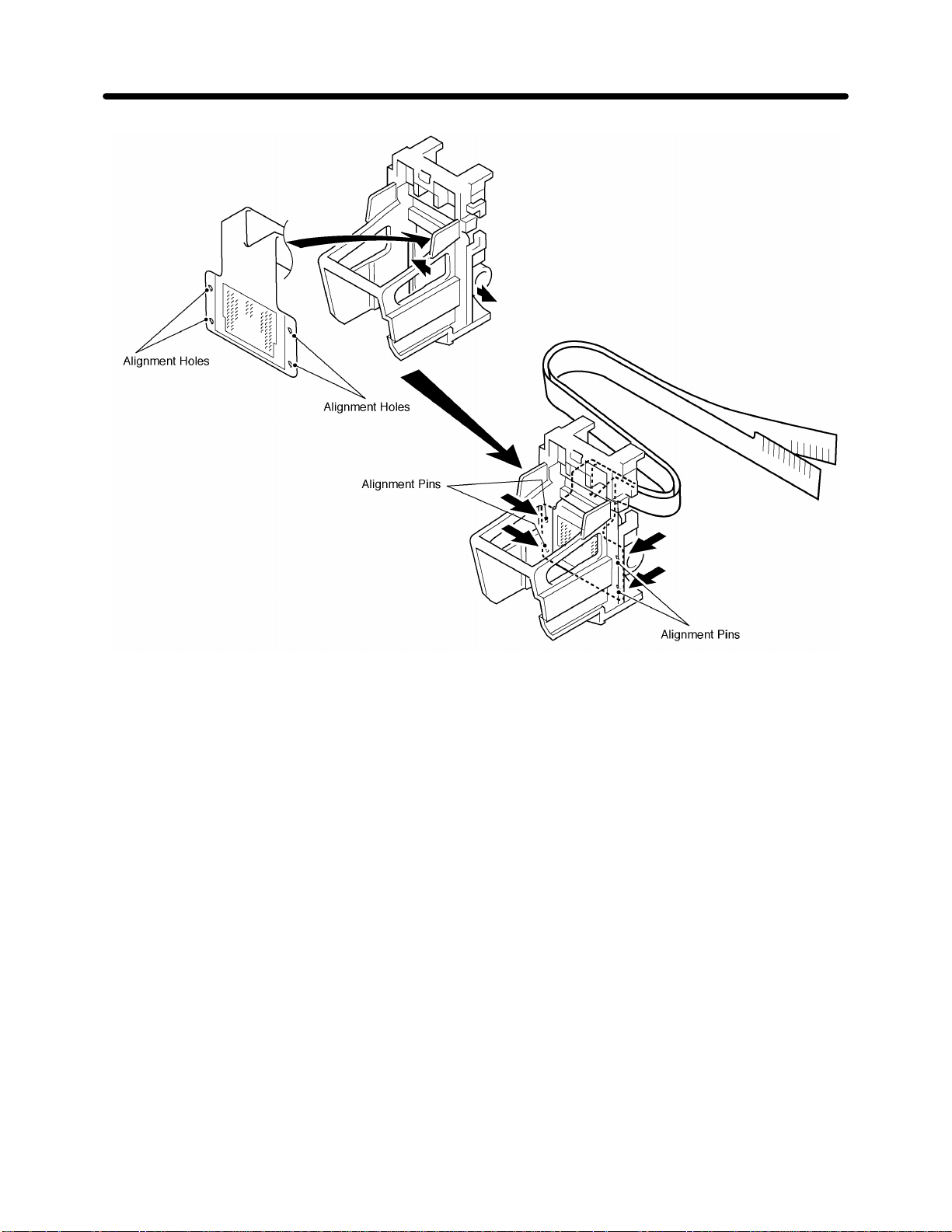

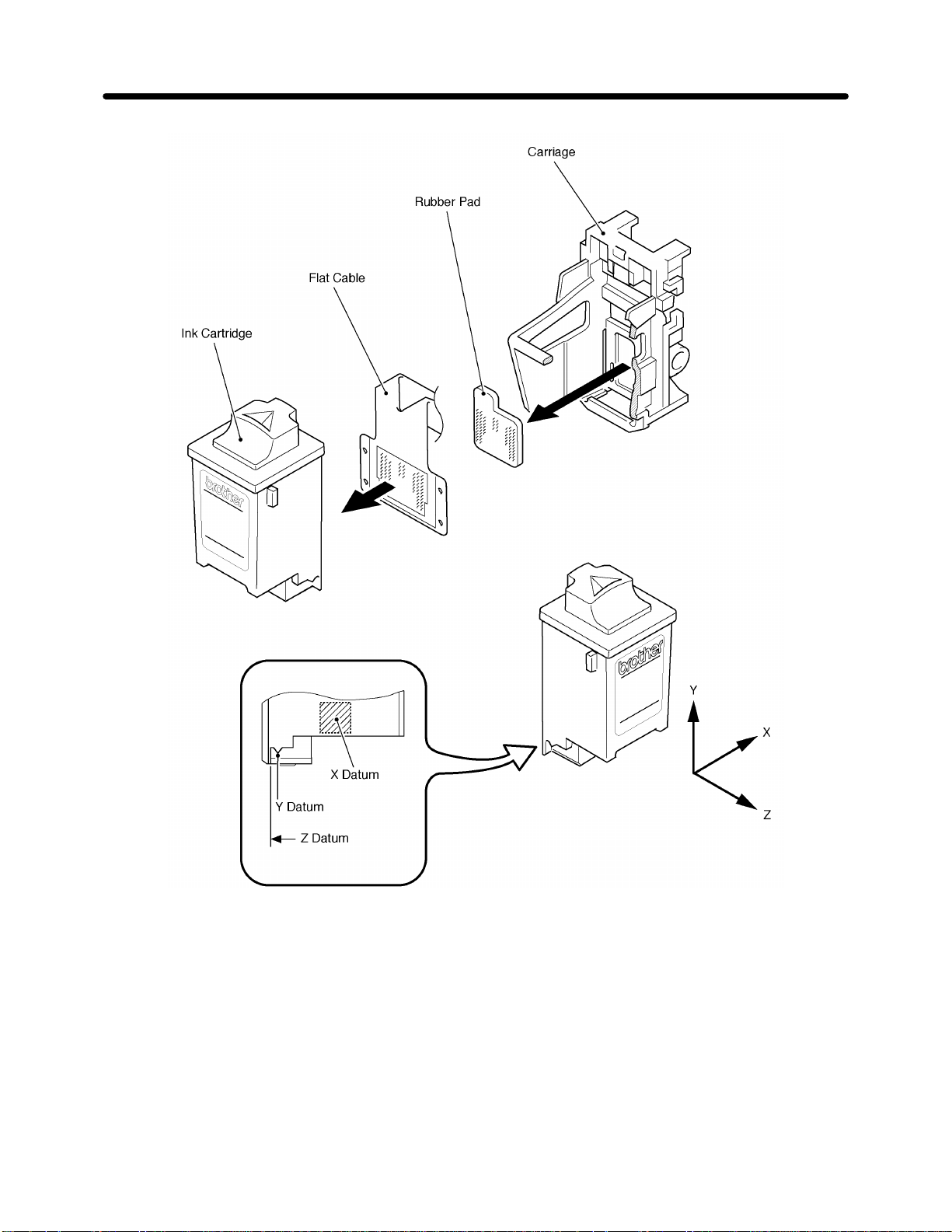

The printer flat cable must be firmly in contact with the ink jet cartridge for printing to be

enabled. The flat cable is located in the carriage by four alignment pins; proper

alignment of the cartridge to the cable is established in three datums (reference

planes/points): X, Y, and Z. When the cartridge is installed in the carriage, the flat cable

contacts are compressed against the cartridge contacts by the rubber pad. See Figs.

1.7 and 1.8.

THEORY

Mechanical

Fig. 1.6 Printer Flat Cable to Main PCB

1-7

Page 20

THEORY

Mechanical

SERVICE MANUAL

Fig. 1.7 Printer Flat Cable to Cartridge Alignment

1-8

Page 21

SERVICE MANUAL

THEORY

Mechanical

Fig. 1.8 Ink Jet Cartridge to Flat Cable Alignment

1-9

Page 22

THEORY

Mechanical

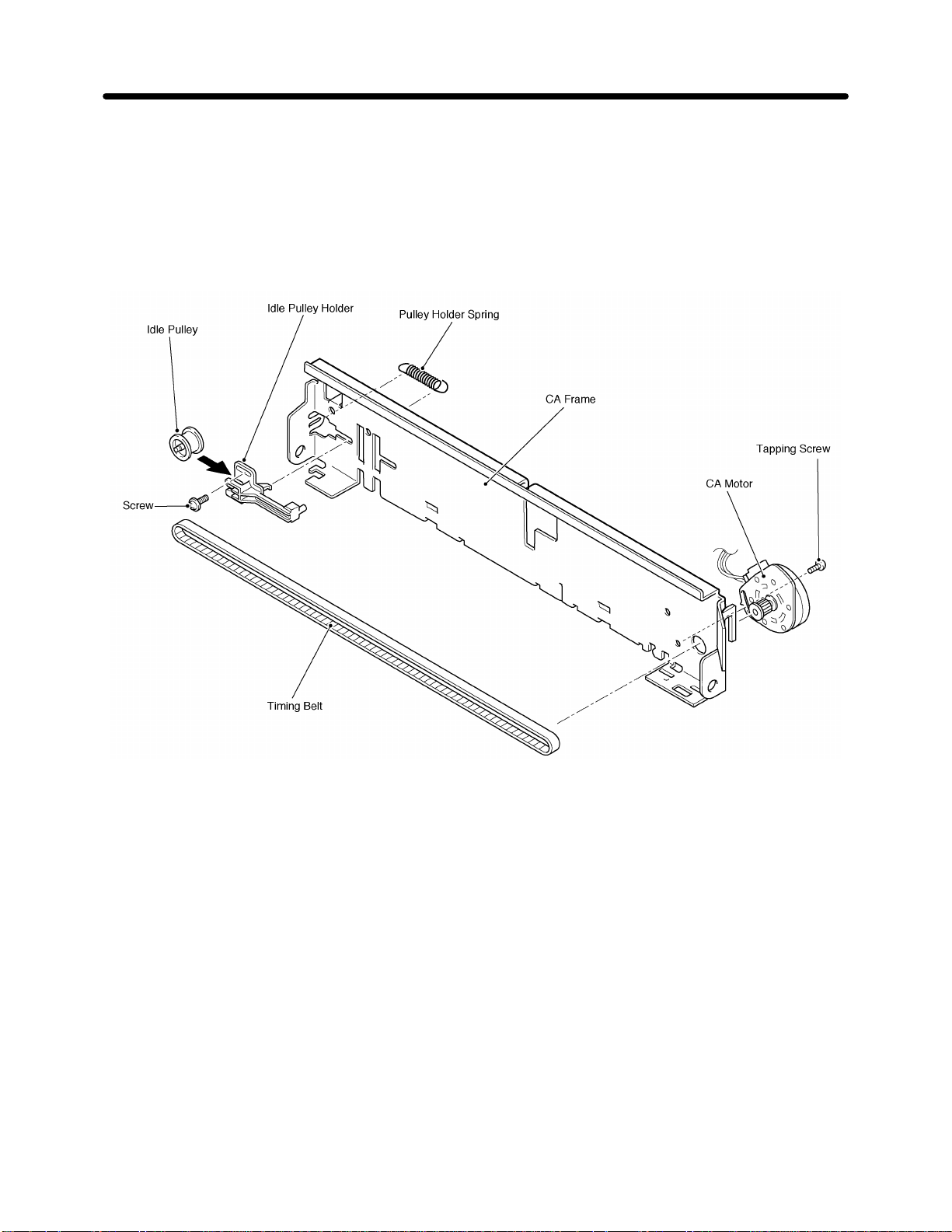

1.2.3. Carriage Motion Control

All operations related to carriage movement are driven by the CA motor. The CA motor

assembly consists of a motor, a timing belt, an idle pulley, and an idle pulley holder and

pulley holder spring: the motor and the idle pulley holder are mounted to the CA frame;

the belt runs between the motor and the pulley. The pulley holder spring between the

idle pulley holder and the CA frame sets belt tension. See Fig. 1.9.

SERVICE MANUAL

Fig. 1.9 Carriage Motion Control

1-10

Page 23

SERVICE MANUAL

1.2.4. Maintenance Station Operation

The maintenance station operation consists of spitting, wiping, capping, and purging.

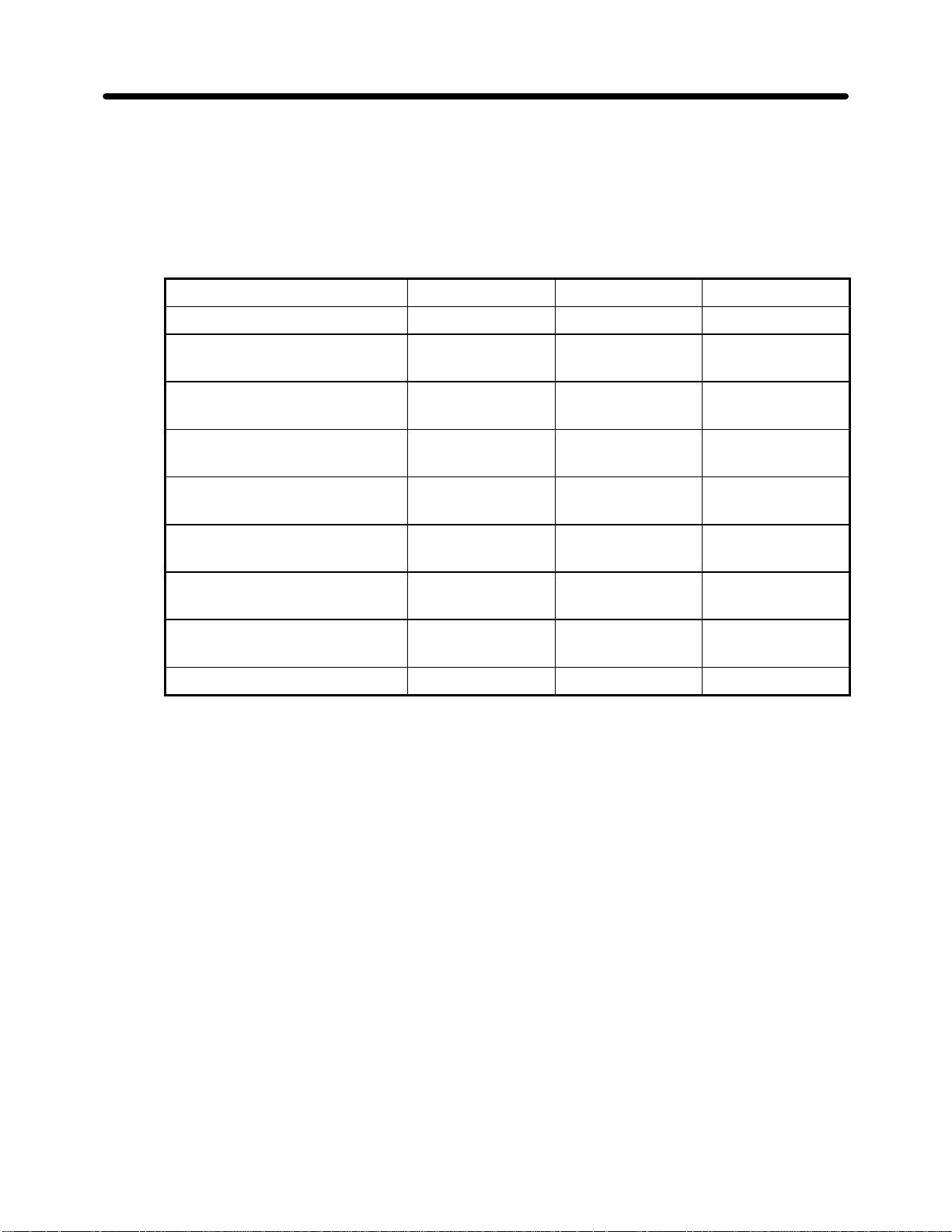

Table 1.1 shows a summary of maintenance operation for various printer states.

Printer State Spitting Wiping Capping

Power-on 204 2 1

Table 1.1 Summary of Maintenance Operations

THEORY

Mechanical

Beginning of print job 204

(after wiping)

Between pages of continuous

printing

After 6 pages of continuous

printing

After 50 seconds of printing

on the same page

Purging 6,000

Ink cartridge change 204

If no cartridge motion for

more than 30 seconds

Power-off 0 0 0

12 1 0

204

(after wiping)

12

(after wiping)

(after wiping)

(after wiping)

011

10

10

10

11

11

1-11

Page 24

THEORY

Mechanical

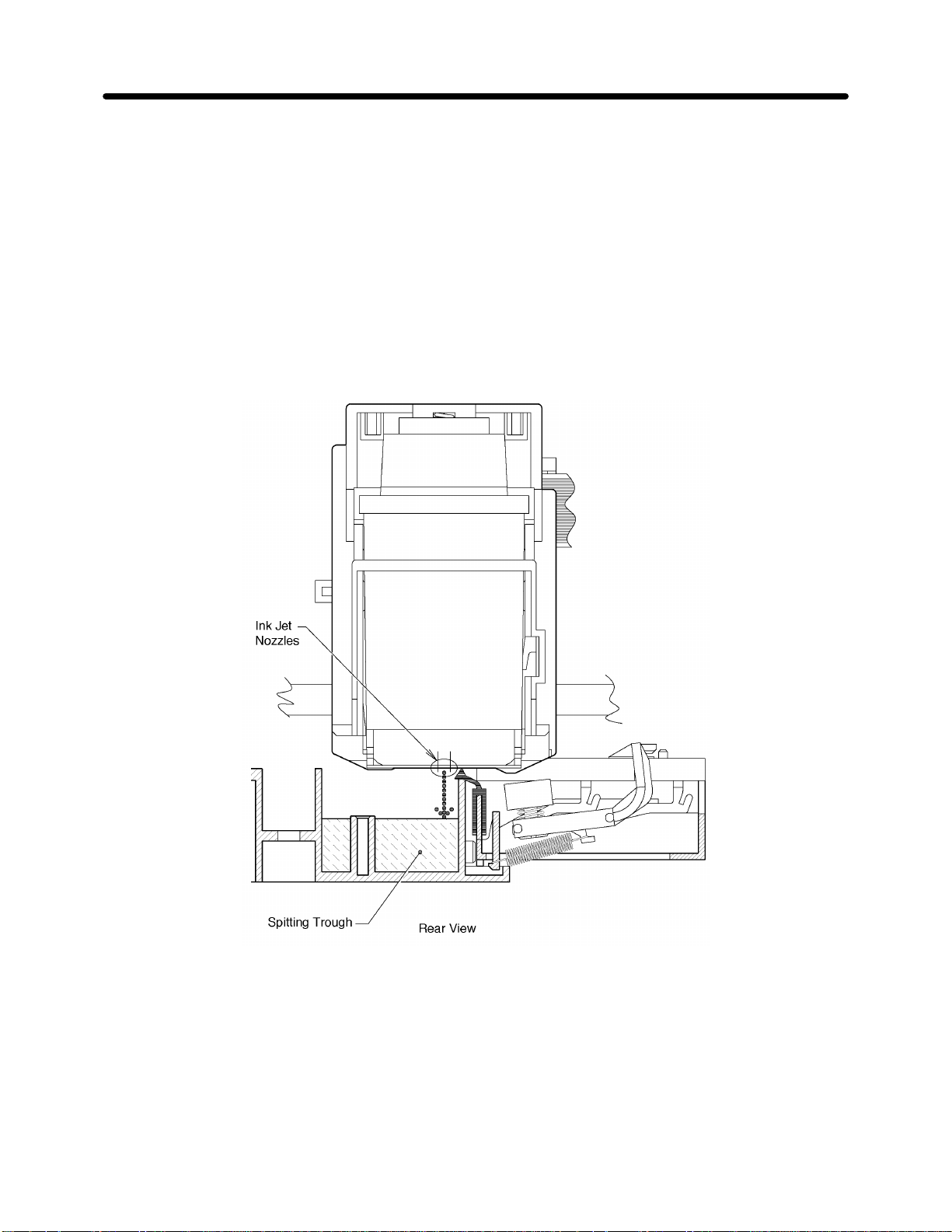

1.2.4.1. Spitting

Spitting is performed at machine power-on, after uncapping from the maintenance

station to clear dormant nozzles, and during the printing process to ensure that

infrequently used nozzles are available when required to print. There must also be

spitting after a wipe cycle, except when the printhead is going to the cap position;

otherwise wiping causes distorted printing if the wiper has experienced any wear.

The trough below he print line is intended to capture the ink during a spit cycle when no

paper is present in the print area. The cup around the wiper is used when spitting is

required and paper is present in the print area. Spitting with paper in print area occurs

when a single page requires longer than 50 seconds to print. All spitting occurs in

trough. At power on, any paper in the print area is ejected.

SERVICE MANUAL

Fig. 1.10 Print Maintenance Operation - Spitting

1-12

Page 25

SERVICE MANUAL

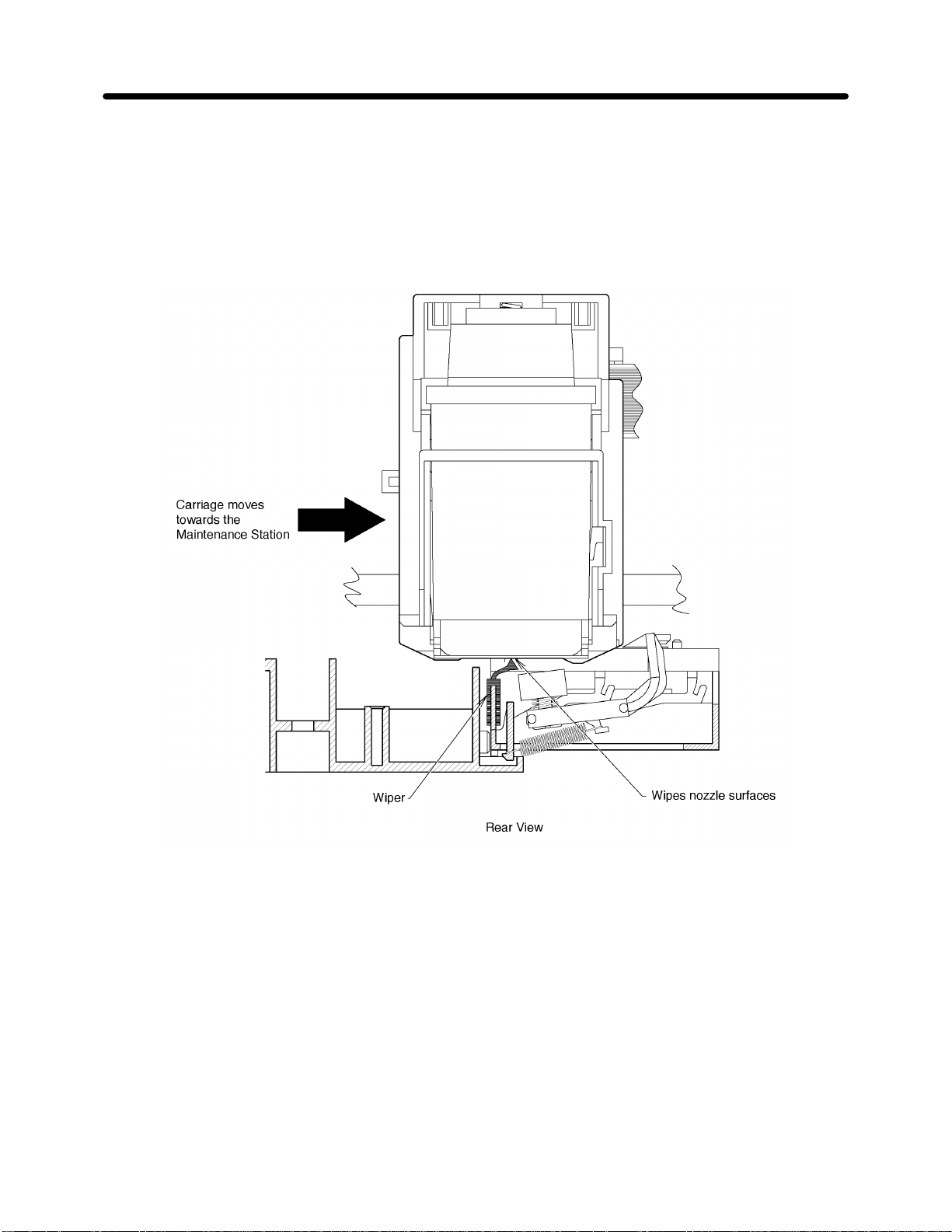

1.2.4.2. Wiping

Wiping of the print head occurs when the cartridge moves across the wiper (in either

direction). The printhead is wiped (twice) when power is turned on, when beginning a

print job (after the print head has been capped for more than four minutes), after six

pages of continuous printing, after 50 seconds of printing on the same page, and after

purging or changing the ink cartridge.

THEORY

Mechanical

Fig. 1.11 Print Maintenance Operation - Wiping

1-13

Page 26

THEORY

Mechanical

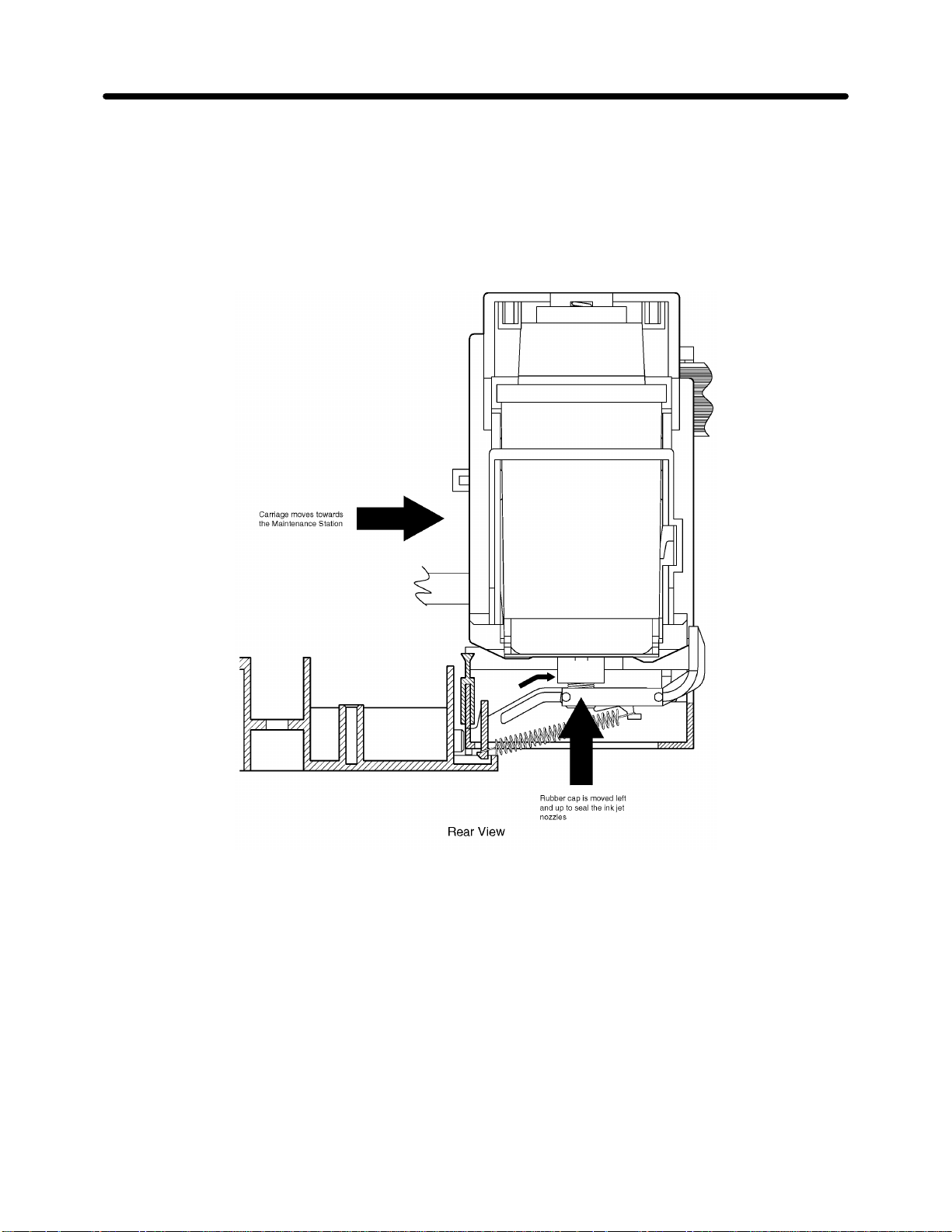

1.2.4.3. Capping

Capping occurs by the movement of the carriage assembly to the maintenance station,

which moves the MS carriage up to the ramp to align the rubber cap with the ink jet

nozzles. The rubber cap prevents the ink from drying and causing the printhead to clog.

The printer will automatically cap the printhead when the system is powered on, when

no data is received for 30 seconds, and after purging or ink cartridge change.

SERVICE MANUAL

1.2.4.4. Purging

The purging function of the maintenance station is a combination of the wipe, cap, and

spit operations. This initiates a sequence of 6,000 spits of each nozzle, in order to clear

clogged ink from the nozzles. The ink is captured in the trough located below the print

line. Purging is user-activated by pressing

keyboard. See 3. "Cleaning the Print head" in Chapter 5, MAINTENANCE, for

instructions.

Fig. 1.12 Print Maintenance Operation - Capping

CODE + SHIFT + INK CHG

1-14

from the

Page 27

SERVICE MANUAL

1.2.5. Sensors

There are two sensors in the printer assembly: the carriage home position sensor (leaf

switch assembly, attached to the right end of the CA frame) and the paper end sensor

(attached to the bottom of the PF base at the right rear).

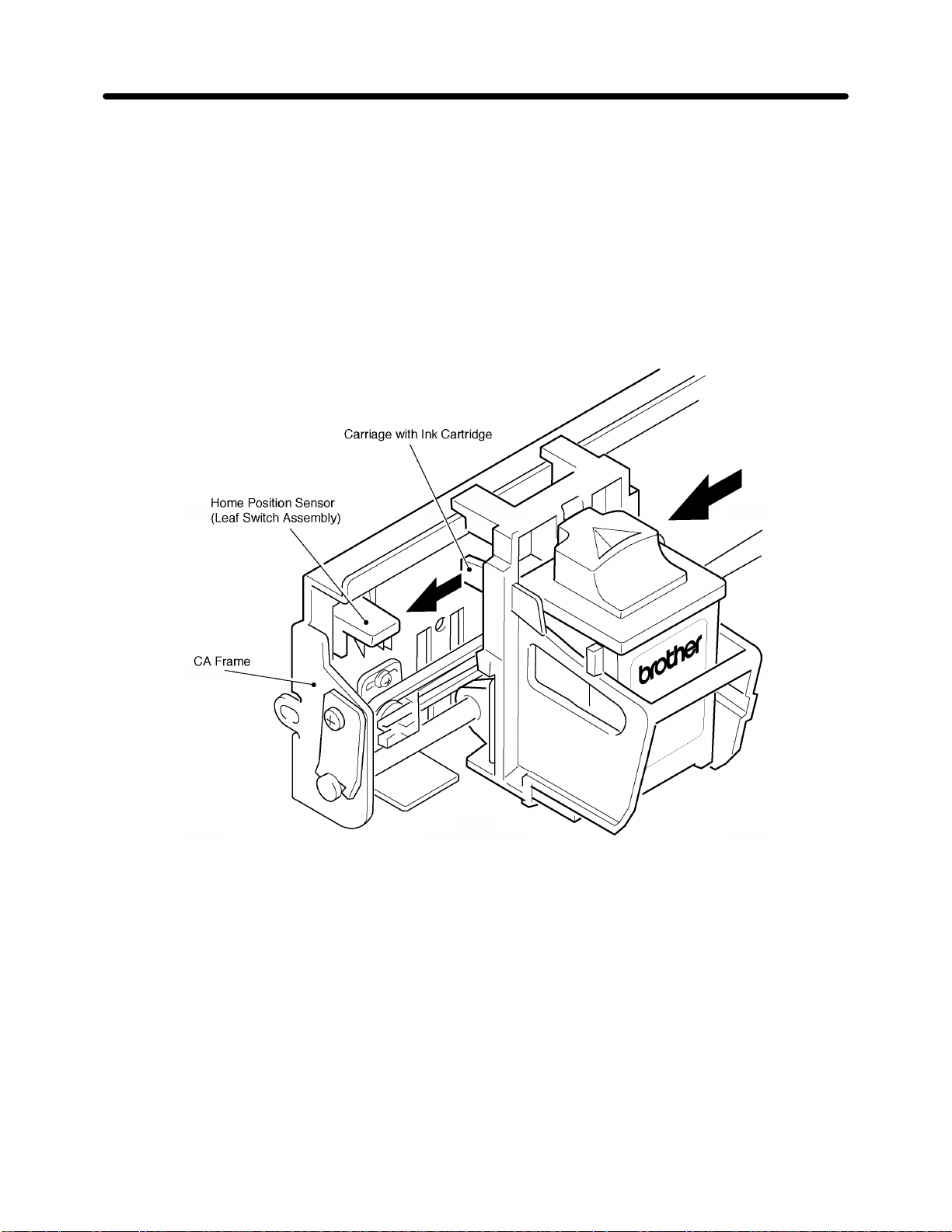

1.2.5.1. Carriage Home Position Sensor

Upon power-up of the system or when the carriage is reset, the carriage moves to the

right end of the printer assembly and activates the home position sensor (leaf switch

assembly). See Fig. 1.13.

THEORY

Mechanical

Fig. 1.13 Carriage Home Position Sensor

1-15

Page 28

THEORY

Mechanical

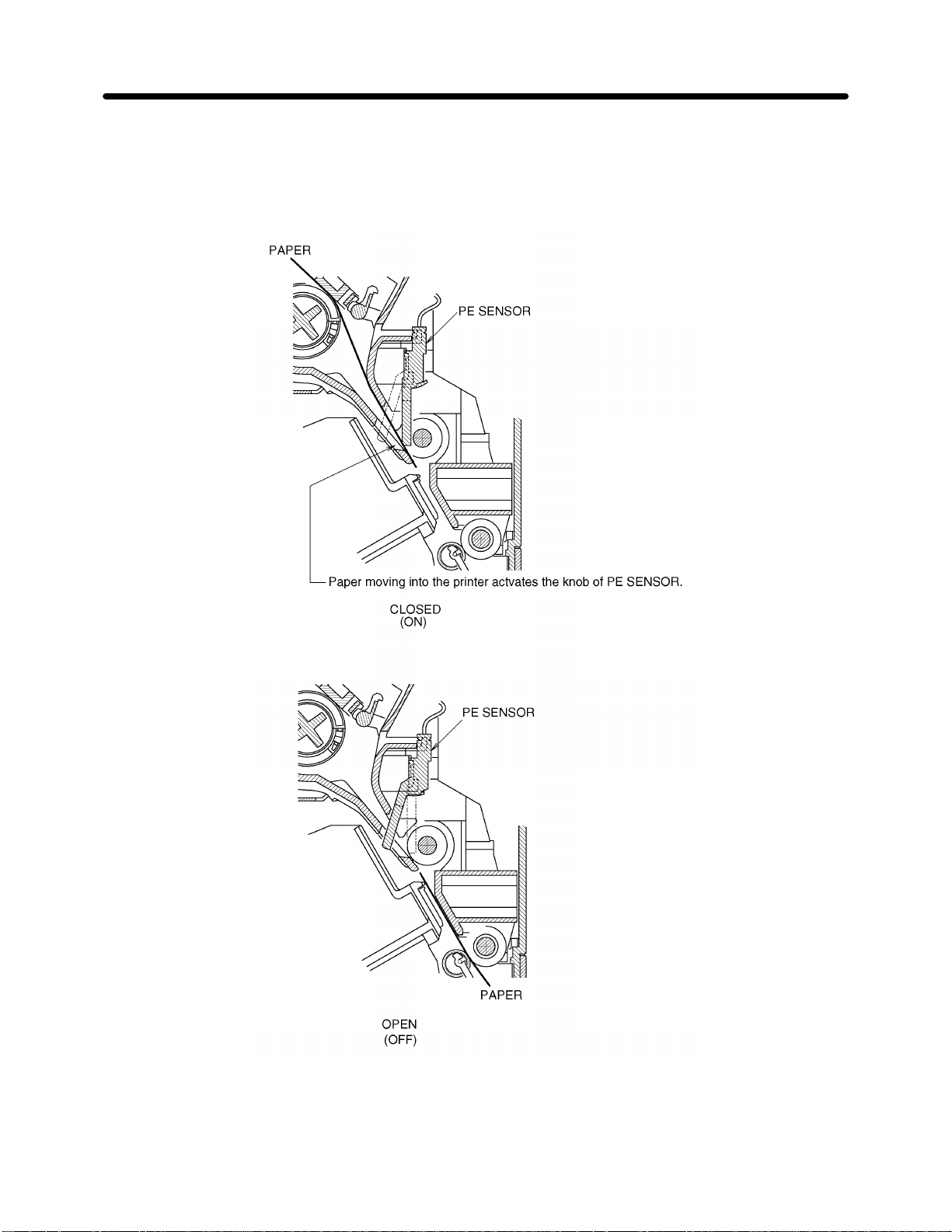

1.2.5.2. PE Sensor

PE sensor detects when the trailing edge of the paper passes the knob of PE sensor.

PE sensor is 1C-1P Switch (normal open.) See Fig. 1.14.

SERVICE MANUAL

Fig. 1.14 PE Sensor Mechanism

1-16

Page 29

SERVICE MANUAL

1.3. INK CHG (Ink Change) Functions

There are two operator-initiated printer maintenance functions available from the

keyboard: ink cartridge replacement and automatic printhead cleaning (purging).

1.3.1. Ink Cartridge Installation/Replacement

There is an ink cartridge installation/replacement function available from the keyboard.

Pressing the key combination

maintenance station to the right end of the printer assembly. Pressing RETURN after

installing or replacing the ink cartridge initializes the system: the cartridge activates the

home position sensor switch and moves the printhead back to the maintenance station.

See Chapter 5, MAINTENANCE, for ink cartridge replacement instructions.

1.3.2. Automatic Print head Cleaning (Purging)

CODE + INK CHG

THEORY

Mechanical

moves the printhead from the

With the ink cartridge installed, pressing the key combination

initiates print head purging. See Chapter 5, MAINTENANCE, for the instructions

CHG

to manually clean the print head.

CODE + SHIFT + INK

1-17

Page 30

THEORY

Mechanical

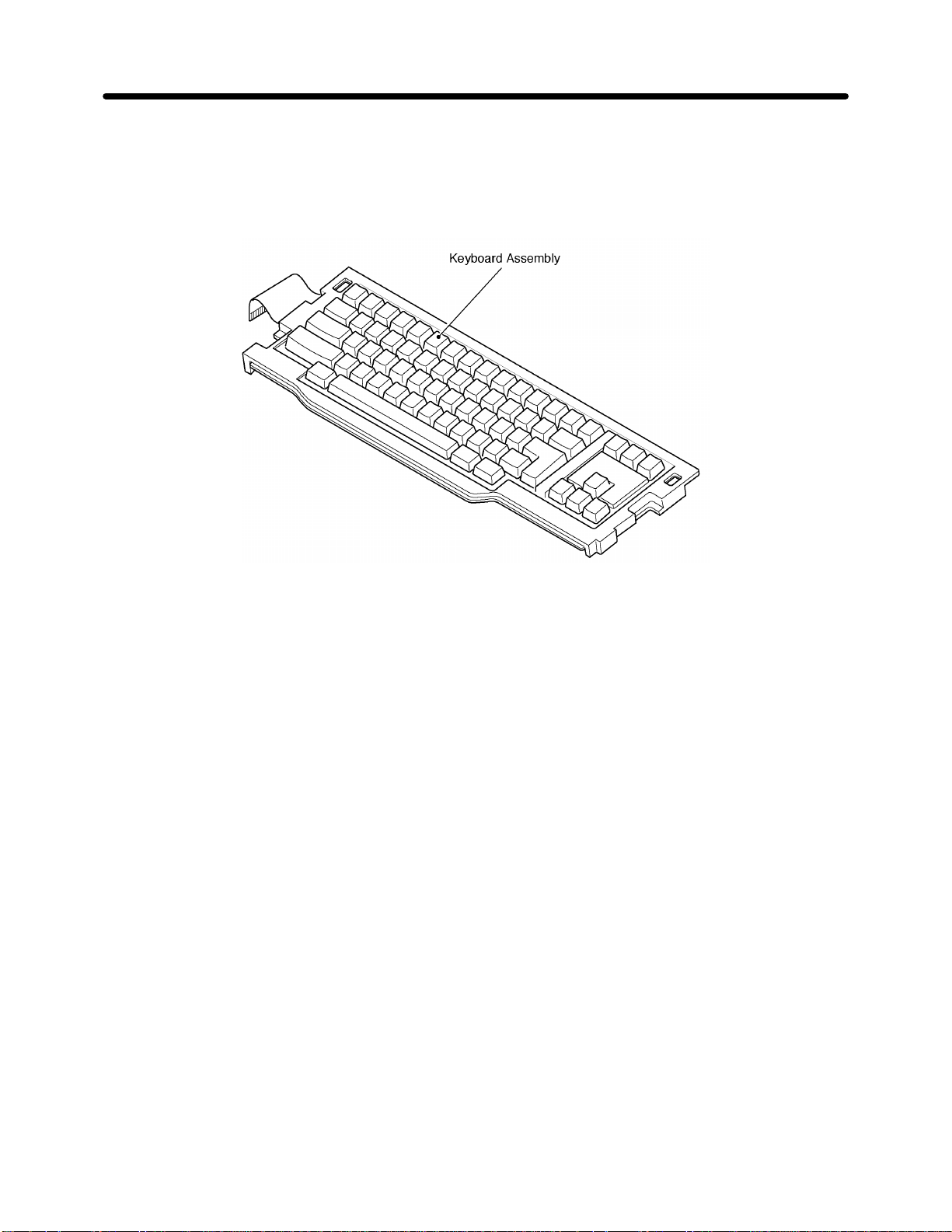

2. Keyboard

The keyboard assembly consists of the keyboard panel and keys, the FPC (flexible

printed circuit) board, and the keyboard base plate.

SERVICE MANUAL

Fig. 1.15 Keyboard Assembly

1-18

Page 31

SERVICE MANUAL

The key tops and key stems are assembled in the keyboard panel. The FPC (flexible

printed circuit) board with rubber contacts is fitted to the base plate. See Fig. 1.16.

The FPC board is a single sheet of film (FPC) on which an electrode pattern is printed in

layers. When the key top is pressed, the key actuator presses the rubber contact; the

conductive part of the contact connects both of the electrodes to output the

predetermined signal for the key.

THEORY

Mechanical

Fig. 1.16 Key Top/Key Stem Assembly

1-19

Page 32

THEORY

Mechanical

3. LCD

The LCD (Liquid Crystal Display) module is secured inside the upper cover by the LCD

bearing at one end and the hinge assembly at the other end so that it can rotate up and

down.

From the closed position, the LCD can be tilted up as much as approximately 132°. The

hinge assembly is the friction type holder that holds the LCD at whatever angle the user

sets within a range approximately 31° from the upright position.

Contrast adjustment varies depending on the model, as indicated below.

<DP-525CJ/LW-800ic, DP-530CJ/LW-810ic, LW-810icBL>

The slide type LCD volume knob located on the right side of the LCD upper cover is

used to adjust the contrast.

<DP-540CJ, DP-550CJ/LW-840ic>

SERVICE MANUAL

The LCD volume located on the left side of the bottom cover is used to adjust the

contrast.

1-20

Page 33

SERVICE MANUAL

THEORY

Mechanical

Fig. 1.17 LCD Unit Installation in the Upper Cover

1-21

Page 34

THEORY

Mechanical

<DP-525CJ/LW-800ic>

SERVICE MANUAL

Fig. 1.18 LCD of DP-525CJ/LW-800ic

1-22

Page 35

SERVICE MANUAL

<DP-530CJ/LW-810ic, LW-810icBL>

THEORY

Mechanical

Fig. 1.19 LCD of DP-530CJ/LW-810ic and LW-810icBL

1-23

Page 36

THEORY

Mechanical

<DP-540CJ, DP-550CJ/LW-840ic>

SERVICE MANUAL

Fig. 1.20 LCD of DP-540CJ, DP-550CJ/LW-840ic

1-24

Page 37

SERVICE MANUAL

CHAPTER 2 ELECTRICAL THEORY

1. System Configuration

The major electronic component parts of the machine are shown in Fig. 2.1.

1.1. Main PCB (Printed Circuit Board)

The main PCB controls the entire system including the LCD, ink cartridge, and the

motors in the printer.

The motors and the ink cartridge are driven by +24 VDC, and the CPU and other

devices are driven by +5 VDC.

1.2. Switch PCB (Printed Circuit Board)

Receiving power from the AC adaptor, the switch PCB supplies voltage to the main

PCB, through the power switch and the fuse.

THEORY

Electrical

1.3. Keyboard FPC (Flexible Printed Circuit)

The keyboard FPC has electrodes arranged in a matrix circuit pattern. The keyboard

status is sent from the FPC to the main PCB.

1.4. FDD (Floppy Disk Drive) Module

The FDD can read and write information supplied to the main PCB. The FDD is driven

by +5 VDC.

1.5. LCD (Liquid Crystal Display) Module

The LCD PCB contains the driver for the dot matrix of the LCD on which various

information is displayed. The CFL backlight (Models: DP-550, LW-810icBL, and LW840ic) is driven by +5 VDC from the main PCB.

2-1

Page 38

THEORY

Electrical

SERVICE MANUAL

Fig. 2.1 Major Electronic Component Parts

2-2

Page 39

SERVICE MANUAL

2. Ink Jet Printer Configuration

The following describes the operation of the ink cartridge, motors and other

components.

2.1. Ink Cartridge

An ink cartridge contains both ink and the print head which has 56 nozzles and prints at

a resolution of 300 dpi.

2.2. Carriage Motor

The carriage step motor drives the carriage right and left with precision motion control.

2.3. Line Feed Motor

The line feed motor feeds the paper forward and in reverse.

THEORY

Electrical

2.4. Carriage Home Position Sensor

The carriage home position sensor is mounted on the right of the CA frame. It detects

the carriage home position to synchronize the carriage position and motor phase.

2.5. PE (Paper End) Sensor

The PE sensor detects whether or not paper is in the printer. The PE sensor is located

at the right rear of the bottom of the PF base.

2-3

Page 40

THEORY

Electrical

3. Power Supply Circuit

3.1. Configuration

Fig. 2.2 shows the power supply circuit.

The power supply section converts the unstable input (PWR) supplied from the switch

PCB into stable +24 VDC (for motors and print head) and +5 VDC (for logic).

A 2-channel switching regulator IC (#4) converts unstable input into stable output.

SERVICE MANUAL

Fig. 2.2 Power Supply Circuit

2-4

Page 41

SERVICE MANUAL

3.2. +24V Generator

The timing chart of the +24V generation circuit during idling is shown in Fig. 2.3.

Switching Q6 by #4 at 100 kHz boosts the input to a stable +24V.

Energy is accumulated in L1 while Q6 is ON and the power is transmitted to the output

side by the back electromotive force generated from the moment Q6 is turned OFF.

Stabilization to +24V is achieved by changing the ON-OFF duty ratio of Q6.

THEORY

Electrical

3.3. +5V Generator

The timing chart of the +5V generation circuit during idling is shown in Fig. 2.4.

Switching Q12 by #4 at 100 kHz reduces the input voltage to a stable +5V.

While Q12 is ON, energy is supplied to L3, C31, and load. The energy accumulated in

L3 is supplied to load through D2. Stabilization to +5V is achieved by changing the ONOFF duty ratio of Q6.

Fig. 2.3 Timing Chart of +24V Generation Circuit

Fig. 2.4 Timing Chart of +5V Generation Circuit

2-5

Page 42

THEORY

Electrical

4. Reset Circuit

4.1. Configuration

The reset circuit is shown in Fig. 2.5. The reset signal (MRST) used to initialize the

system is generated using the leading and trailing edges of the +5V voltage.

The reset signal is input to the following devices.

SERVICE MANUAL

Device Pin

CBIC (#8) 17

Printer drivers (#2, #3) 5

Fig. 2.5 Reset Circuit

2-6

Page 43

SERVICE MANUAL

5. CBIC and Peripherals

5.1. CBIC #8

CBIC (#8) is a Cell-based IC in which logic circuits for controlling peripherals are

integrated with the CPU core. With the functions incorporated in it, CBIC (#8) controls

all the functions of the system including printer control and control of the LCD display.

5.2. Main ROM (#11, #12)

Installation of a maximum of 8 Mbytes (32 Mbits x 2 pcs.) of ROM is possible. The

capacity of ROM installed in the machine is determined by whether or not the chip

resistor R71 is installed.

R71 installed: 32 Mbit ROM

R71 not installed: 16 Mbit ROM

THEORY

Electrical

5.3. Main RAM (#9, #10)

The following RAM can be installed at #9 and #10.

#9: 16 Mbit DRAM

#10: 4 Mbit DRAM

Note that simultaneous installation of RAM at #9 and #10 is not allowed.

5.4. Video RAM (#6)

The capacity of the video RAM used to retain the data to be displayed on the LCD is

256 Kbit. It secures the display area for different sizes of LCDs, from 480 x 64 dots to

640 x 400 dots.

The RAM area not necessary for the LCD display can be used as the work area.

5.5. Printer Driver Circuits (#2, #3, Q1 to Q4, and Q23 to Q26)

The printer driver circuits convert the motor phase driver signals output from CBIC (#8)

to +24V drive signals, which are output to the motors and ink cartridge.

5.6. FDC (Floppy Disk Controller)

The FDC controls floppy disk drive access through the FDD drive circuit.

2-7

Page 44

THEORY

Electrical

5.7. Clock Circuit

Four different clock circuits shown in Table 2.1 are incorporated in the main PCB.

SERVICE MANUAL

Table 2.1 Clock Circuit

Clock Circuit Frequency Function

16MHz XT2 is the standard

clock for FDD control;

it inputs for #5 (pins

25, 26).

18MHz XT1 is the standard

clock for FDD control;

it inputs for #8 (pin

167).

5.8. Buzzer Drive Circuit

The buzzer drive circuit is shown in Fig. 2.6. A 4 kHz pulse of 50% duty is output from

port BUZ (pin 25) of CBIC (#8) when buzzer operation is needed.

The piezoelectric element in BZ1 generates sound on reception of this pulse. The

output from port BUZ is Hi-Z when the buzzer is not in operation.

20MHz XT3 is the standard

clock for printer control

and other several

timing; it inputs for #8

(pints 14, 15).

14.74MHz XT4 is the standard

clock for CPU core; it

inputs for #8 (pints 94,

95).

Fig. 2.6 Buzzer Drive Circuit

2-8

Page 45

SERVICE MANUAL

5.9. Country Specification Change-over

The country specification change-over circuit is shown in Fig. 2.7. The country

specification is recognized by the CPU by sensing solder on the solder points.

THEORY

Electrical

Fig. 2.7 Country & Model Specification Change-over Circuit

2-9

Page 46

THEORY

Electrical

5.10. RS-232C I/F Circuit

The RS-232C I/F circuit is shown in Fig. 2.8. The driver IC (#1) converts the signal level

(+5V – ±0V) on the main PCB to the RS-232C signal level in the external line and vice

versa.

SERVICE MANUAL

Fig. 2.8 RS-232C I/F Circuit

2-10

Page 47

SERVICE MANUAL

6. Printer Control

6.1. Ink Jet Head Control

The ink jet head drive circuit is shown in Fig. 2.9. The ink jet head has 50 active

nozzles (monochrome). Two addressable multiplexing printer drive circuits (#2, #3)

activate the nozzles for printing. Custom circuitry controls the timing and

synchronization of ink deposited as the cartridge moves across the paper in printing.

The same system controls ink jet head maintenance (spitting into the trough).

THEORY

Electrical

Fig. 2.9 Ink Jet Head Drive Circuit

2-11

Page 48

THEORY

Electrical

6.2. Carriage Motor Control

The carriage motor control circuit is shown in Fig. 2.10. +24 VDC is supplied to the

motor through connector CN3, pin 5. Motor phases A, B, C, and D are driven by the

CBIC (#8) through pins 150 - 153, respectively. The outputs of the CBIC turn darlington

transistors Q1 - Q4 on and off, which in turn affect the motor phases.

SERVICE MANUAL

Fig. 2.10 Carriage Motor Drive Circuit

2-12

Page 49

SERVICE MANUAL

6.3. Line Feed Motor Control

The line feed motor drive circuit is shown in Fig. 2.11. The line feed motor is powered

by +24 VDC. Each of he four phases of the motor is excited when CBIC (#8), via ports

LF-A, B, C, and D, outputs to turn on the darlington transistors Q23 - Q26.

This provides a path to ground through the transistor, which allows current to flow.

When the printer gate array outputs a LOW, the transistor remains off.

THEORY

Electrical

Fig. 2.11 Line Feed Motor Drive Circuit

2-13

Page 50

THEORY

Electrical

6.4. Carriage Home Position Sensor

The carriage home position sensor circuit is shown in Fig. 2.12. The HIGH/LOW status

of the sensor is read by pin 164 of the CBIC (#8). The signal goes LOW when the

carriage reaches the home position.

Fig. 2.12 Carriage Home Position Sensor Circuit

6.5. PE Sensor

The PE sensor detection circuit is shown in Fig. 2.13. The HIGH/LOW status of the PE

sensor is read by pin 165 of the CBIC (#8). The signal is HIGH if there is no paper at

the sensor position.

SERVICE MANUAL

Fig. 2.13 PE Sensor Detection Circuit

2-14

Page 51

SERVICE MANUAL

7. Switch PCB

7.1. Configuration

The Switch PCB is installed between the AC adaptor and the main PCB to turn the

power on and off and protect devices at the occurrence of an alarm, etc.

Fig. 2.14 shows the external view of the switch PCB and Fig. 2.15 the switch PCB

circuit.

THEORY

Electrical

Fig. 2.14 External View of the Switch PCB

Fig. 2.15 Switch PCB Circuit

2-15

Page 52

THEORY

Electrical

8. Keyboard System

8.1. FPC Operation

The keyboard is a flexible printed circuit (FPC) board on which the circuit pattern and

electrodes are printed. When a key is pressed, the key stem is forced down until the

carbon-type conductive silicone rubber makes a contact with the FPC electrode and

electricity is conducted. See Fig. 2.16.

SERVICE MANUAL

Key Actuator

Contact Rubber

Carbon Electrodes

Carbon Silicon Conductive Rubber

FPC Board

Base Plate

Fig. 2.16 Key/FPC Operation

2-16

Page 53

SERVICE MANUAL

8.2. Keyboard Scan

Fig. 2.17 shows the pattern from wiring electrodes on the board (this figure shows only

simplified wiring for ease of explanation and is slightly different from the actual wiring).

Refer to Fig. 2.17 to understand the keyboard scanning operation described. When a

key is not pressed, continuity does not exist in any combination of the matrix (e.g. X1

and Y1 or X2 and Y2). For example, if key [A] is pressed, continuity will exist only in X2

and Y3, but not between any other pairs of points which are left in the OFF status. In

other words, if continuity exists between X2 and Y3, it means that key [A] is being

pressed.

THEORY

Pattern Circuit

Pattern Circuit

Electrical

Fig. 2.17 Electrode Wiring

2-17

Page 54

THEORY

Electrical

8.3. Keyboard Control Circuit

The keyboard control circuit is shown in Fig. 2.18.

The matrix pattern on the keyboard FPC controls port 7 (0:7) of CBIC (#8) according to

data signals KO0 through KO8. The LOW level signals are output to output lines KO0

through KO8. The electrode wiring is scanned line by line. The result of scanning is

input to P70 through P77 of CBIC (#8). CBIC (#8) detects which key has been pressed.

The key matrix given in Fig. 2.19 corresponds to the key arrangement shown in Fig.

2.20.

SERVICE MANUAL

Fig. 2.18 Keyboard Control Circuit

2-18

Page 55

SERVICE MANUAL

THEORY

Fig. 2.19 Keyboard Matrix

Electrical

Fig. 2.20 Keyboard Symbols (Corresponding to Keyboard Matrix in Fig. 2.19)

2-19

Page 56

THEORY

Electrical

9. LCD Module

The block diagram of the LCD display operation is shown in Fig. 2.21. CBIC (#8) on the

main PCB outputs the LCD module control signals to the LCD module. The LCD drive

voltage (VEE) is generated by DC-DC convertor by the pulses output from CBIC (#8).

Display data, the data written to the SRAM (#6) that functions as Video RAM is always

sent to the LCD module as 4-bit parallel data.

SERVICE MANUAL

Fig. 2.21 LCD Display Operation Block Diagram

2-20

Page 57

SERVICE MANUAL

9.1. LCD Control

The CBIC (#8) controls the LCD control signals and the SRAM access.

The display data written to the SRAM (#6) is read by the CBIC (#8) in regular intervals,

converted into the 4-bit parallel data by the CBIC (#8) and then sent to the LCD module.

Black and white of the display data are inverted by connecting the R55 (#8 REV

terminal). Connect the R55 if the transmission type LCD is used.

The timing of display control signals differs according to the LCD type. The timing is set

by the status of the DMODE (3:0) terminal in the CIBC (#8) in the reset state and by the

setting in the program after the reset is canceled. An example of the control signal

timing chart is shown in Fig. 2.22.

THEORY

Electrical

Fig. 2.22 Example of Control Signal Timing Chart

9.2. LCD Module

The LCD modules used in the respective models are shown in Table 2.2. The control

signal timing and drive voltage (VEE) differ according to the LCD module.

Table 2.2 Table of LCD Modules

Specification No. of Horizontal

Model Name

DP-525CJ LW-800ic 480 64 Reflective no –17.5 to –14.5

DP-530CJ LW-810ic 480 128 Reflective no –17.5 to –14.5

LW-810icBL 480 128 Transflective yes –17.5 to –14.5

DP-540CJ 640 400 Reflective no +22 to +30

DP-550CJ LW-840ic 640 400 Transmissiveyes +26 to +37

Dots

Note: VEE voltage is the values measured at connectors CN7 and CN8.

No. of

Vertical Dots

Panel Type Backlight VEE (V)

2-21

Page 58

THEORY

Electrical

9.3. LCD Drive Voltage (VEE) Generation Circuit

The polarity of the LCD drive voltage (VEE) differs according to the LCD module.

Fig. 2.23 shows the circuit for the LCD module driven by the minus VEE voltage. The

+5 VDC source voltage is switched continuously by the 20 kHz pulses from CBIC (#8) to

energize L5. The reverse voltage generated by L5 is rectified by D6 and regulated by

ZD5. The ZD5 determines the VEE voltage (about -16 V).

The LCD module driven by the plus VEE voltage uses the circuit shown in Fig. 2.24.

The +24 VDC source voltage is switched continuously by the 90 kHz pulses from CBIC

(#8) to energize L2. The voltage generated by L2 is rectified by D5 and regulated by

ZD4 and ZD6. The ZD4 and ZD6 determine the VEE voltage.

VEE voltage is adjusted by turning VR1.

SERVICE MANUAL

Fig. 2.23 LCD Drive Voltage Generation Circuit (Minus Voltage VEE)

Fig. 2.24 LCD Drive Voltage Generation Circuit (Plus Voltage VEE)

2-22

Page 59

SERVICE MANUAL

9.4. Power Supply for CFL Backlight

The CFL backlight circuit consists of the control circuit that turns ON/OFF the CFL and

the inverter PCB.

The ON/OFF status of the CFL is controlled by the CFLON terminal of the CBIC (#8).

The inverter PCB converts +5V to AC voltage to drive the CFL tube. The type of

inverter PCB differs according to the LCD.

Fig. 2.25 shows the CFL backlight circuit.

THEORY

Electrical

Fig.2.25 CFL Backlight Circuit

2-23

Page 60

THEORY

Electrical

10. FDD (Floppy Disk Drive) Control

10.1. FDD Configuration

The FDD consists of two sections: the FDD controller and the FDD module. The FDD

controller circuit controls the contents to be received and stores the data in the FDD

module. The FDD module drives the motors, sensors, and magnetic head. The

interface signals between the FDD and the FDC are shown in Table below:

Table.2.3 FDC(#5) and FDD Module Links (Interface Signals)

Signals Pin No. Function

Read/Write

Circuits

Motor Drive

Circuit

Status Check WRITE PROTECT 28

DRIVE SELECT Ø 10 12

WRITE GATE 24

WRITE DATA 22

READ DATA 30

SIDE1 SELECT 32

DC

MOTOR

STEP

MOTOR

16

ON

STEP 20

MOTOR

DIRECTION

SELECT

18

INDEX 8

TRACKØØ 26

DISK CHANGE 34

SERVICE MANUAL

This signal is set to LOW when the FDD unit is

opening (except for the DC Motor).

When this signal is set to LOW, data can be written

by the WRITE DATA signal. When this signal is set

to HIGH, the READ and STEP operations are

enabled.

Data is written at the falling edge of this signal while

the WRITE GATE signal is LOW.

This signal indicates the polarity data read by the

head.

This signal is used to select the head:

LOW: Head 1

HIGH: Head 0

This signal becomes LOW, starting the DC motor,

when a disk is set in the drive. Setting this signal to

HIGH or removing the disk stops the DC Motor.

This signal sets the head in the direction designated

by the DIRECTION signal.

This signal designates the movement of the

read/write head:

LOW: Inward to the disk's center

HIGH: Outward from the disk's center.

When this signal is LOW, either there is no disk in

the drive or the disk in the drive is write-protected.

This signal indicates the beginning of a track by

outputting one pulse in each rotation of the disk.

When this signal is LOW, the head is located at track

00 (the outside track).

Otherwise, the signal is HIGH.

When this signal is LOW, there is no disk in the drive.

2-24

Page 61

SERVICE MANUAL

10.2. FDD Operation

10.2.1. Basic Operation

CBIC(#8) writes commands to FDC(#5), and the FDC(#5) controls the FDD in

accordance with these commands and reads/writes data.

See Fig. 2.26.

10.2.2. Interface between CBIC (#8) and FDC (#5)

If CBIC(#8) accesses an internal register other than the data resister in FDC (#5), the

normal read/write operation will be performed.

If CBIC(#8)transmits data to or receives data from FDC (#5), DMA communications will

be performed using the DMA function of CBIC(#8).

CBIC(#8) resets FDC(#5),detects the density signal which indicates whether the floppy

disk is a 2DD or 2HD, and output to FDC(#5).

THEORY

Electrical

Fig.2.26 FDD Block Diagram

2-25

Page 62

THEORY

Electrical

10.3. FDD Module

The FDD Module is composed of the motor, sensor, magnetic head, and the IC that

drives them. The FDD Module is controlled by the FDC (#5) of the MAIN PCB.

10.3.1. Read/Write Circuit

In read operation, the circuit amplifies the analog signals picked up by the magnetic

head and converts the analog signal to serial digital pulses. The serial pulses are then

transmitted to the FDC (#5) and decoded to parallel digital data.

In write operation, the circuit controls the current at the magnetic head according to the

serial digital pulses from the FDC #5.

10.3.2. Motor Drive Circuit

The motor drive circuit consists of two parts: a DC motor drive circuit and a stepping

motor drive circuit.

The DC motor drive circuit controls the DC motor, which rotates the spindle according to

the MOTOR ON signal from the FDC. The stepping motor drive circuit controls the

stepping motor, which operates the magnetic head unit according to the "STEP" and

"DIRECTION SELECT" signals from the FDC #5.

SERVICE MANUAL

10.3.3. Sensor Circuits

The following sensor circuits detect the status of the FDD:

1. Write Protect Sensor

When a write-protect notch on a disk is set to the write-protect position, the "WRITE

PROTECT" signal becomes LOW. A micro-switch is used for detection.

2. Index Sensor

The "INDEX" signal shows the beginning of a track; when the beginning of a track is

detected, the "INDEX" signal becomes LOW. A magnetic sensor is used for

detection.

3. Track00 Sensor

When the magnetic head is positioned in track 0 on a disk, the "TRACK 00" signal

becomes LOW. A photo sensor is used for detection.

2-26

Page 63

SERVICE MANUAL

4. Disk-in Sensor

When a disk is inserted in the FDD, this sensor outputs a LOW level signal (HIGH

when no disk).

The output of the sensor is connected to the controller and sent as a "DISK