Page 1

mzm~e,ij~

INSTRUCTION MANUAL

DH4-B980, 8981

'·"

',

~

c:OJmaBJUI~~A,

c:

OJmaB.iji§l~,

c1J'5,

®~~ c ~

~~~L:fi@Jf.I"'Fc~\o

ll:

9 ~ ll:Jm

b W

tt

~i.IPJT

ll:,

fi~

lJ

-r:

< tt.c

~\a

--:>------1

~------------------~

5.)(

AON~mJO)~J!

[C::~i\]

8981

l:i:O)flfjg1Jt3ij ~ 8:"ttl\lo

1-1

g;g~l±1lra,<

1.

;1.

A

J±~~ffl

iTo

2.

~m-1JrQ1':~-?

3.

-:::>ih-8~r'f~To

1-2

~~1±1lf§;<

1.

::I-;~7f)~Mt:iTo

matr:

..

2.

-:>

i

h.

iK'JJvO)!lSKb't«l:t

3.

-:::>

i h-tl

4.

-:>

~

h-8

s.

::1

·:~ 7 f)~

iK'JJvl~~b'.A~

6.

-:>

i

h.f)~~~t1JrQ1~:illl

7.

-:::>ich&~r,fi-to

_.:

.....

-.

g-~~a

v

~

.:z.

v-

9 Q(J)-:> i

/j.f)~

.

<

~

illi

L0.3Mpa~:~b1ti

g-~~a

iili\,\Eilm~0)8:8:~9o

tl

t:O

~

~En1JrQ1

..

mtttJ'""FtJ'~*t"

t:O~f$i)

~~I~

...I:Jf,

1m~

iTo

..

m!t1Jt..t1J'~8:9o

':

~

~

i)

i-to

o

i-to

JX~~t1JitiH:

L0.3Mpa':~:b-tti

illi

LiTo

~I~

..t'f

To

To

·/

Page 2

3.

:;;~."At:.

I

\:.r~-C1)1J'dJ.8btt~m

IN0$"1-LJJJ

· -?i)j.tlt:O:a-$ocVJ,

IN

b i'il:t15

.

I\/?-

:a-~

/9~:~

J&l'J{;j£tiTo

/\/?-8~~'?~Li"to

L*

-c'

"'? i

)j.;b

t:O:a-frffci)

-c

J\::.r~-~l:timl~~:i~?~c~"-1'':/

1.

/\

/7-

:a-3lEJf'J:J}J ~ -tt

2 .

.1-

AfiJFiJ~Js.J-~:1t

< i

_1.

A

UdF

-c:-1\

/7-(J){~.IE,

i'IJ

-cas<

~1ttt

iT

c.>C;(JJ)1J'Ji'f->9<~o

0

iJ~)j.-g..t.J-tt~~~t~

•

~iEicti~

•

1\':/'l-lctJib

4.1

·f/7

3fhzzzzzzJ

Ll\/?-:a-,~1A

2.

4.2

0 X X X

l.J\/?-:a-J~1A

2.

1.

~iJn.A

2.

1-'~f'J:;

3.

12345678

~~~~~~~~

OFF

71

~9 o

'?

Ji

Li-to

{IJli';( 'J)

lSmmOJFclic!li:~:Q~c{!JiEc~~-g

.>(:AifB1J'=m~tel~tmt.t991~::>t,

*111

EI

(/)~""A

.>(

:Afgj1J'~

*IH

Et

(!)~""\'A

,i

-c:wu

"*'

·;~

'?

1

·;t

Jv

7°A

7 .-f

<

1

..

;-

-r

~w

t

fffl

1

·;~

'Y

"7~1

~cJSflt,

(7J1J)

1

J

-c:

.~-A fYFtJ~t~

::>l,

\tel\

(7J1J)

IJ

-c:

7-

o

'?

i

t t i To

7-(J)2ilttW

'Y

7 No.2 J

OFF

ON

\(teet,

t:'i~h.,

::J~-o.>~IE

t:'i~h.,

A

IMFtJ~:tS.J--ei~"

;-

o

'?~xi

\o

o

\tel

\::J~-o.>~IE

191Ji:LiTo

x

.o

1

-r:wu

'? 1 ;-

o

191Ji:LiTo

\

-t

t:~xt:

~

To

\/~-b't!b''J

25ms

50ms

"t'l.

\:QIIijfm

.o

·

.>C;(~~m9:Qc~fctJ\':/~-I;:Mt,\1t.>C;(!li1J'~t:lJ;t:Q~c

tgg

0

Sic

lJ

-c

< n:c!t,

•

,c;(~fN09f.9ouli:.>C;(0

~l,

\C::

C

~fil~

lJ

-c

1.

~N'Jtl

2.

*'fLv\7-A:a-.J..A.A

t:8:a-

~

Ji:LiTo

3.

3.;(

A c

I\/?-

\o

c.>CAA

( n:c!l,

.0

\o

cVJ

7-

At

~

·;~;'\8t:~L~-c~N'Jtlt:-r:·~

(!)7}\h.ilb-tt~~:a-

1&

~'~

J(fJOJmJr;:-g~rdJn'

'?

9~

LiTo

LiT

0

Page 3

DH4-B980, 8981

Please read this manual before making any adjustments.

Please keep this manual within easy reach for quick reference.

•When replacing the cutting

to

3.

block. (Refer

and 4.)

block

with a new one, be sure

to

adjust the contact between the knife and the cutting

Poor buttonhole cutting correction flowchart

Turn off the power.

1. Adjusting the cutting pressure

No the knife pressure adjustment regulator is set to

~-....:....:~

-=>.....;....;..;;-t

No the knife incision breaks

-====---~~~~~~~!!!!.r__~::::::=---:l

~::::::---=N~o=----~4.2

------=.::...:.::.:.:::::..:.:..:==::.:.:.:::;;:.:;..:.-

Note: The knife should be able to cut sufficiently if the air pressure for

Note: If the cutting pressure is increased to more than 0.3 Mpa, it will

cause the cutting block to become worn

damaged.

·12.

Removing and installing the cutting block I

Replacing the cutting block

(Refer to 2.)

4.1

Filing the cutting surface of the cutting block on which

Note: If the knife incision breaks off on the cutting block

or

is shifted, poor buttonhole cutting in the material

will be the result.

Filing the cutting surface

knife incision

If the knife incision in the cutting block is deep, it

Note:

'

--....

will damage the knife.

is

deep

3.

Adjusting

the knife and the cutting block

off

or

is

shifted

of

the cutting block in which

0.2 Mpa.

or

the knife to become

the

contact

between

Replace the knife

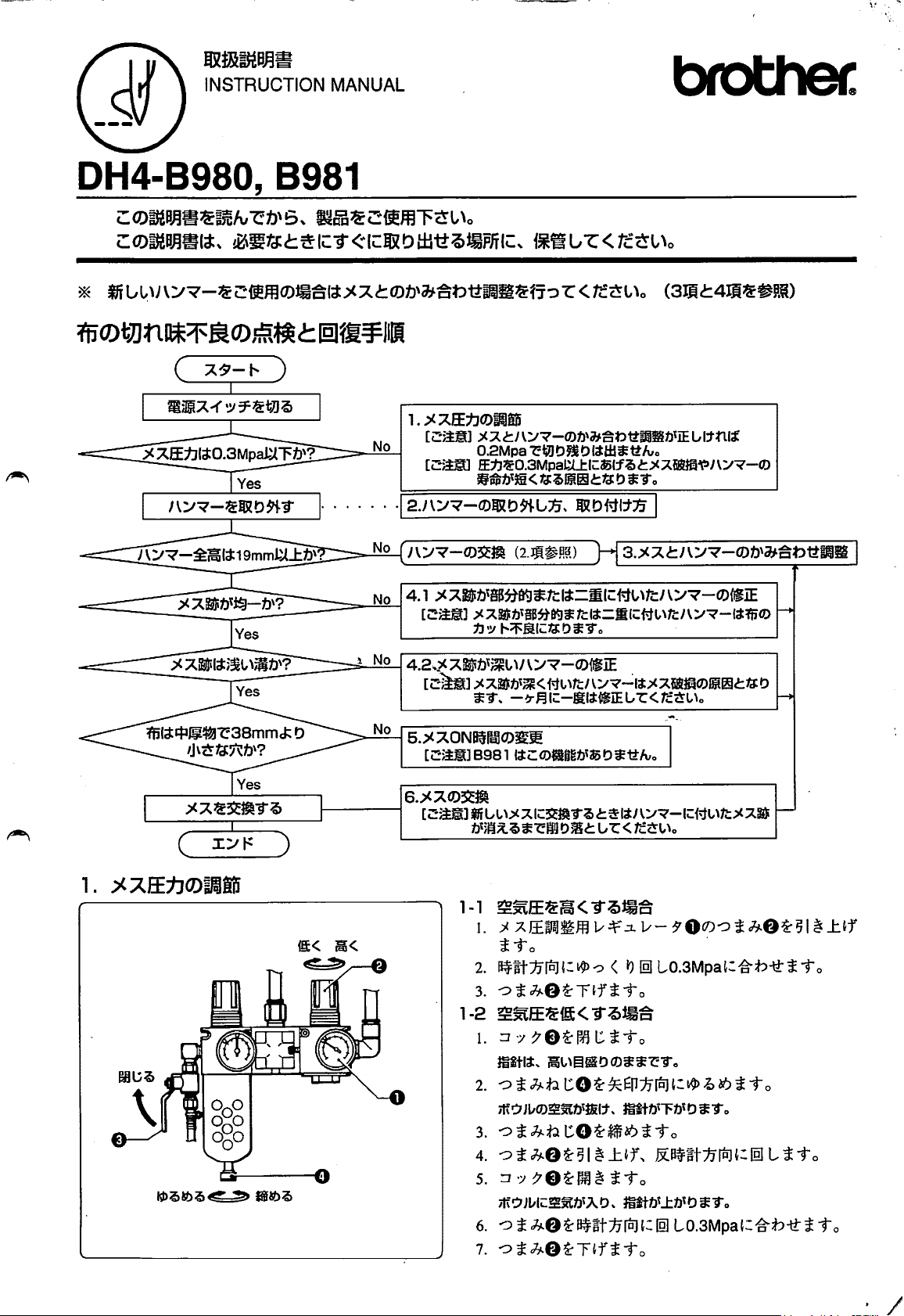

1. Adjusting the air pressure

To decrease To increase regulator

To loosen

~To

tighten

5.

Changing the knife operation time

~---;

for

the knife pressure

Note: The 8981 does not have this function.

6.

Replacing the knife

Note: When replacing the knife with a new one, file the

surface of the cutting block smooth and until the

knife does not leave a mark

1-1. To increase the air pressure

1-2. To decrease the air pressure

on

the cutting block.

1. Lift the knob

f)

of the knife pressure adjustment

0.

2.

Gently turn the knob

0.3Mpa.

3. Push down the knob

1. Close the cock E).

The needle will remain at the high-pressure position.

2. Turn the knob screw 0 in the direction of the arrow in

the

illustration to loosen it.

The air

will

escape from the reservoir and the needle

3.

Tighten the knob screw

4. Lift the knob 8 and turn it counterclockwise.

5.

Open the cock

Air

will enter the reservoir and the needle

6.

Gently turn the knob

0.3Mpa.

7.

Push down the knob

8.

f)

and set the air pressure to

f).

0.

will

move.

f)

and set the air pressure to

f).

will

drop.

.

I

Page 4

2.Removing and installing the cutting block

Removing the cutting block

Loosen the screw

0,

and then remove the cutting block

8.

Installing the cutting block

Press the cutting block against the pin

thescrewO.

3.

Adjusting the contact between the knife and the cutting block

To see the knife incision more easily, color the cutting surface

1.

Operate the cutting block three times with the knife making a mark on it each time.

2.

Adjust the position of the cutting block or contact between the knife and the cutting block until the knife consistently

makes a mark

4.

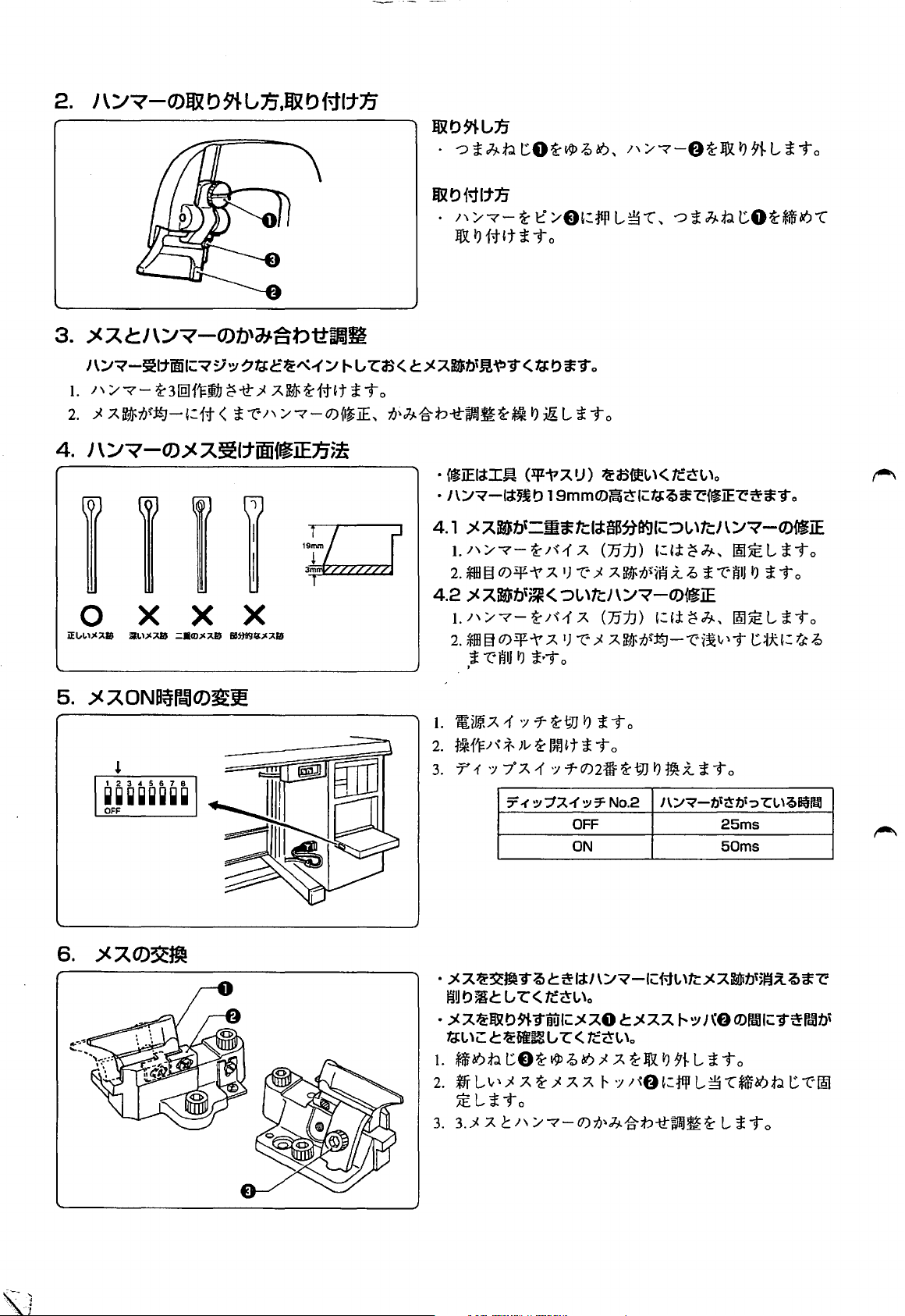

Filing the cutting surface

0

Knife Knife Two Partial

incision incision is knife knife

is correct too deep inc:isions incision

X

in

the same place.

1

X

X

of

the cutting block

1~

3~

• Use a flat file

•The

4.1

1.

2.

4.2 Filing the cutting surface of the cutting block in which

1.

2.

of

the cutting block with a marker pen.

for

filing.

cutting block can be filed until

Filing the cutting surface of the cutting block on which

the knife incision breaks off or is shifted

Grip the cutting block in a vise.

File the surface of the cutting block smoothly until the

knife incision is erased away.

incisior is deep

knife

Grip the cutting block

File the surface of the cutting block smoothly until a

_

...

:s{ngle

knife incision can still be seen faintly.

in

a vise.

its

8,

height

and tighten

is

19 mm.

5.

Changing the knife operation time

12345678

~~~~~~~~

OFF

&.Replacing the knife

1. Turn off the power switch.

Open the operation panel.

2.

3.

Set DIP switch No.2 to ON.

DIP switch No.2 Cutting block on time

OFF 25ms

ON

•When replacing the knife with a new one, file the surface

the cutting block until smooth and until the knife does

leave a mark on the cutting block.

•

Before replacing the knife, be sure

gap between the knife

1.

Loosen the screw

2.

Insert the new knife 0 into the knife stopper

then tiguten it with the screw

3.

3.

Adjusting the contact between the knife and the cutting

block.

0 and the knife stopper

8,

and then remove the knife

to

8 .

SOms

check that there

8.

8,

is

0.

of

not

no

and

brother.

BROTHER INDUSTRIES,LTD. NAGOYA,JAPAN

118-980, 981

591980-251

1997

.ll.

H

CD

Loading...

Loading...