Brother DB2-8773, DB2-8774, DB2-87740 Service Manual

SERVICE

FOR

082-8773

082-8774

082-87740

MANUAL

SINGLE NEEDLE

BOTTOM FEED

ADJUSTABLE

LOCK

STITCH

TOP AND

MACHINE

I

NAMES

I

SPECIFICATIONS

I

MECHANICAL

OF

MAIN

rn

Upper shaft and needle bar mechanism 0 0 0

[2}

Lower shaft and rotary

IJJ

Upper feed mechanism . 0 0

1!1

~

Feed

Feed

mechanism

adjusting mechanism and quick reverse mechanism 0 0 0 0 0 0 0 0 0 8

[§]Upper feed mechanism and shirring mechanism (subclass -006) 0 0 0 0 9

[l]Threadtrimmer

liD

Tension release

~Thread

1m

Automatic

lllJ

Lubrication

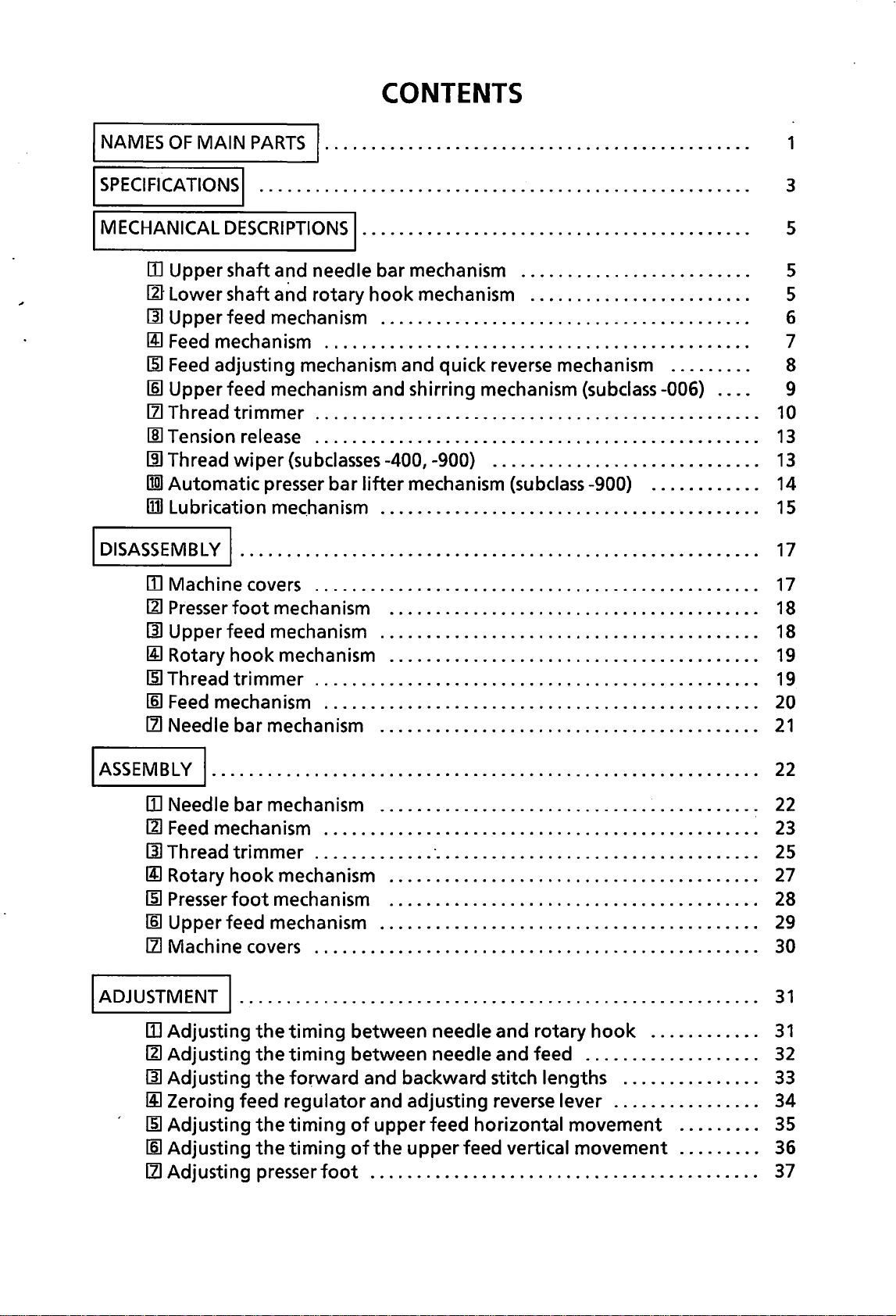

CONTENTS

PARTS

I·

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

DESCRIPTIONS

wiper

(subclasses

presser bar

me~han

I·.........................................

0.

0 0 0 0

0.

0 0 0 0 0 0 0 0 0 0 0 0 0 0 5

..

00000

...

0

••

0

••

ism

hook

oooooooooooo

lifter

mechanism . o o

0. 0 0.

0 0

•• 0 0. 0 0. 0. 0.

0 • 0 0 0 • 0 0 • 0 0

0 • 0 • 0 • 0 0

••

0 0 • 0 0 • 0 • 0 • 0 0 • 0 0 0 0 0 0 • 0 0 • 0 0 0 0 0 7

••• o •• o .o.o.o.ooooooooooooooooo

••

0 0 0 • 0 0 0 0 0 0 • 0 • 0 0 • 0 • 0 0 0 0 0 0 0 0 0 0 0 0 0 0

-400, -900) 0 0 • 0 0 0

••

0 0 o o 0 0 0 0 0 • 0 0 • 0 o

0 0 0 0 0

0. 0 0.

0.

0 0

0.

0 0 0 0 0 0 0 • 0 0 0 0 0

mechanism (subclass -900) 0

. 0 0 0 0 0 0 0 0 0 0 0 • 0 0 0 0 0 0 • 0 • 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

••

0 0 5

0 0 0 0 0

0.

0 6

0.

0 0

0.

0 0 0 0 0 0 0 0 0 14

5

10

13

13

15

I

DISASSEMBLY

[I]Machinecovers

lZJ

Presser

[ID

Upper feed mechanism . 0 • 0 0 0 0 0 0 0 0 0 0 0 0 0 0 • 0 • 0 • 0 0 • 0 0

1!1

Rotary

f.SlThreadtrimmer

[§]

Feed

mechanism 0 • 0 0 0 0 0 0 0 0 0 0 • 0 0

[1]

Needle bar mechanism .

I

ASSEMBLY

[]

lZJ

[ID

1!1

~

rnJ

[1]

I.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Needle bar mechanism 0 • 0 0 0 • 0 0 0 0 0 0 0 0 0 0 0 0

Feed

mechanism 0 0 0 0 • 0 0 • 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Thread

Rotary

Presser

Upper feed mechanism 0 0

Machine covers 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

'ADJUSTMENT ,

,.

. . . . . . . . . . . . . . . . . . . . . . . .

·o···ooooooooo··o•oooooo•o•o•ooo·ooooooooooooooo

foot

mechanism 0 • 0 • 0 0 • 0 0 • 0 • 0

hook

trimmer

hook

foot

mechanism 0 • 0 0 0 0 0 0 0 • 0 • 0 0 • 0 0 0 • 0 • 0 0 • 0 0 • 0 0 0 • 0 0 0 0 0 0 0 0 0

...

ooooooooooooooooooooooooooooo•ooooooooooooooo

0.

0 0 0 0 0 0 0 0

. 0 0 0 0 • 0 0 • 0 0 0 0

mechanism . 0 0 0 0 • 0 0 0 0 0 0 • 0 0 • 0 0 0 • 0 0 • 0 0 • 0 0 0 0 0 0 0 0 0 • 0 0 0 •

mechanism 0 0 • 0 0 • 0 0

0.

0 0 0 0

..

. . . . . . . . . . . . . . .

••

0 • 0 • 0 • 0 0 • 0 0 • 0 0 0 0 0 0 • 0 0 0 • 0 0

••••

0 0 • 0 0 0 • 0

0. 0 0.

·0

0 0 0 0 0 0 • 0 0 • 0 • 0 • 0 • 0 0 0 0 0 0 0 0 0 0 0 0 0 0 • 0 0 0

••

0 0 • 0 0 • 0 0 0 • 0 0 • 0 0 • 0 0 0 0 0 0 • 0 0

0.

0.

••

0.

0. 0 0.

0 0

0 0 • 0 • 0 0 • 0 0 • 0 0

........................................................

..

. .

.. . ..

••

0 0 0 0 0 0 0 0 0 0 0 0

••••

0 0 0 0 0 0 0 0 0 0 0 0 0 0 • 0

0. 0 •• 0 •••••

••

0 0 • 0 • 0 0 0 0 0 0 0 0 0 0 0 0 0 0 • •

0. 0 0.

0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0 0 0

0.

••

0 • 0 0

0.

0 0 0 0 0 0 0

••

0 • 0 • 0 0 0 0

. . . . . 17

17

18

18

19

19

20

21

22

22

~

23

25

27

••

0 0 0

28

29

30

31

[I] Adjusting

[l]

Adjusting

[ID

Adjusting

1!1

Zeroing feed regulator and adjusting reverse lever

~Adjusting

rnJ

Adjusting

I1J

Adjusting presser

the

the

the

the

the

timing

timing

fofward

timing

timing

foot

between needle and rotary

between needle and feed

and backward stitch lengths 0 0 0 0 0 0

of

upper

of

the

0 0 0 • 0 0 • 0 0 0 0 • 0 0 0 0 0 0 0 • 0 0 0 0 0 • 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 37

feed horizontal movement 0 0 0

upper

feed vertical movement 0 0 0 0 0 0 0 0 0 36

hook

0. 0 0.

0.

0 0 0 o o 0 o o o o o 0

0 0 0 0 0

0. 0 0.

0. 0 0.

0. 0 0.

0 0 0

0 0 0 0

0 0

0.

0.

0 0 0 0 34

0.

0 0 0 0

31

32

33

35

liD

Adjusting

liD

Adjusting tension release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IDl

Adjusting

lll1

Adjusting synchronizer {082-8774) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1121

Adjusting

1131

Adjusting

1m

Checking feed mechanism

ll51

Adjusting sensor position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Ill

Adjusting

sensor (877

I

REPLACEMENTS

li1

Replacing Solenoids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

l1l

Replacing tension release

~

Replacing

~Replacing

[SJ

Replacing Synchronizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

thread

thread

thread

potentio-meter

the

40) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

I.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

bobbin

photo-cell and

trimmer

tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

wiper

indication

tension spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

(87740) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

weight

of

the

wire

reflector

(87740) . . . . . . . . . . . . . . . . . . . . . . . .

distance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

between

{87740) . . . . . . . . . . . . . . . . . . . . . . .

needle

hole

and

39

41

44

50

50

51

53

I OPTIONAL

li1

l2l

EQUIPMENT!................................................

Thread

Presser

wiper

foot

I TROUBLESHOOTING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

lifting

GUIDE

solenoid set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

54

55

59

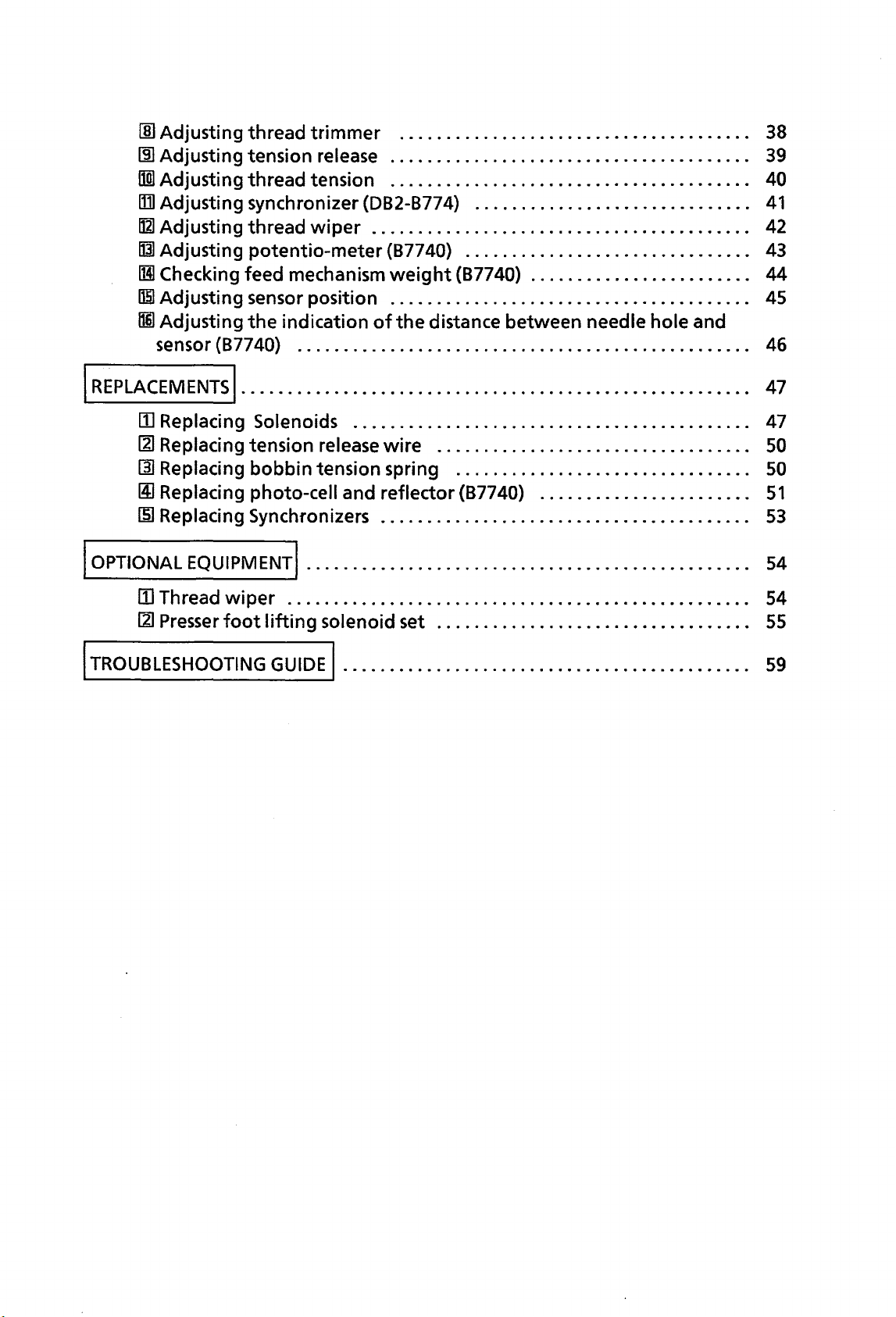

INAMESOF

MAI

N PARTS I

[082-8773

0 Needle

@ Presser

-003]

bar

regulating

[082-8774]

@ Thread retainer

screw 0 Tension

nut

[082-8773-006]

@Machine

@ Reverse lever

[082-87740]

pulley

0 Needle bar @ Pre-tension

Co

ntr

ol panel {87740)

brother

@Presser

~

EXE~A·

regulating

~-m

r 3

~

1om

o@

screw 0

~nrg

o~ ul!l)il~

Tens

ion nu t

~~

oooo

~

Fo4l

fo

4 0 l

~~ ~·lruM

W"~l"'

-1-

SPICII>=

1 H +

+0.5

I

H -

@Machine

@ Reverse lever

A

B

c 0

IDDDD

r3Jrill§~

'r\~:

tc

~

~~~

pulley

COftRECTlON

I +

I:::

~

STTTQtES

I

+!-!..

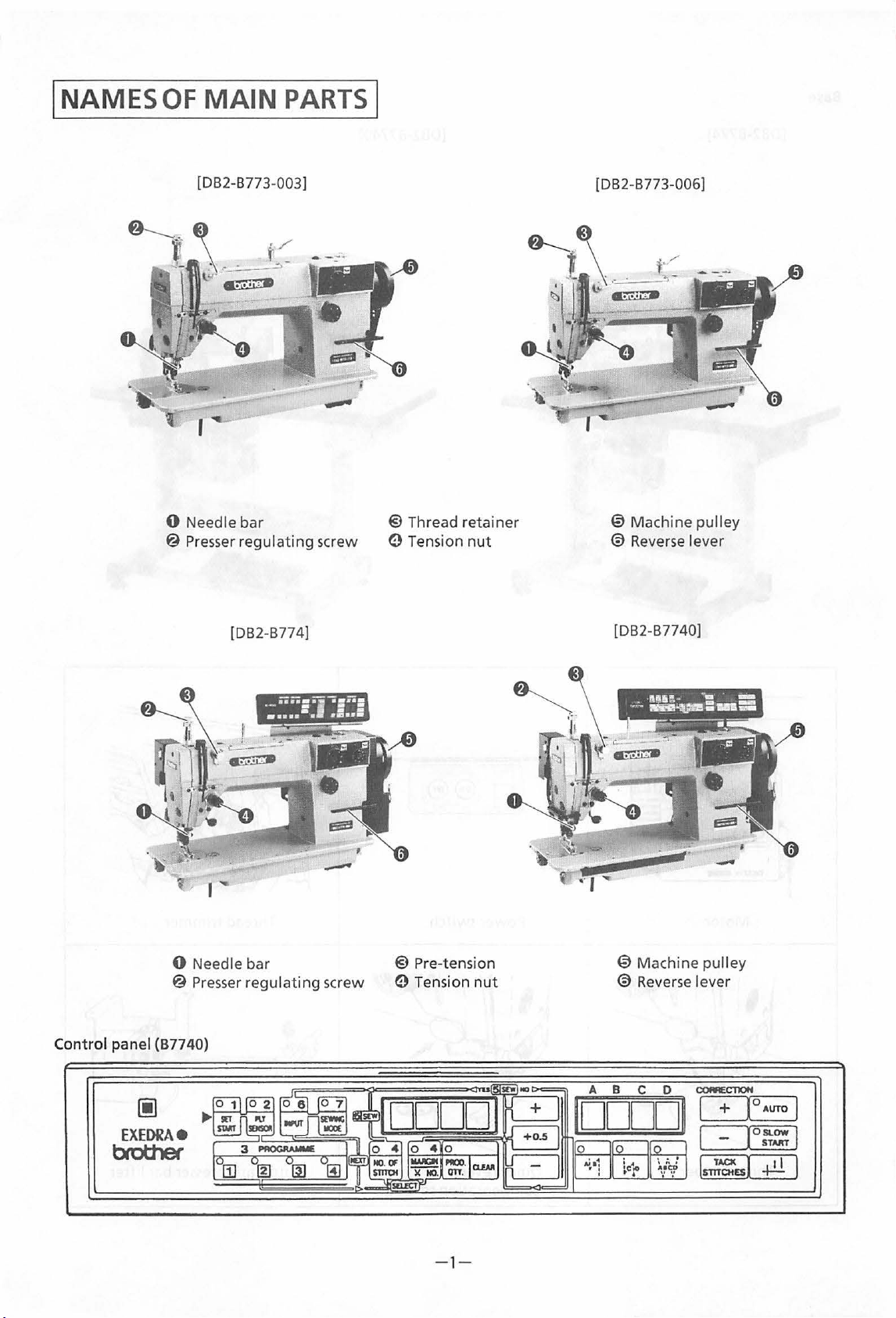

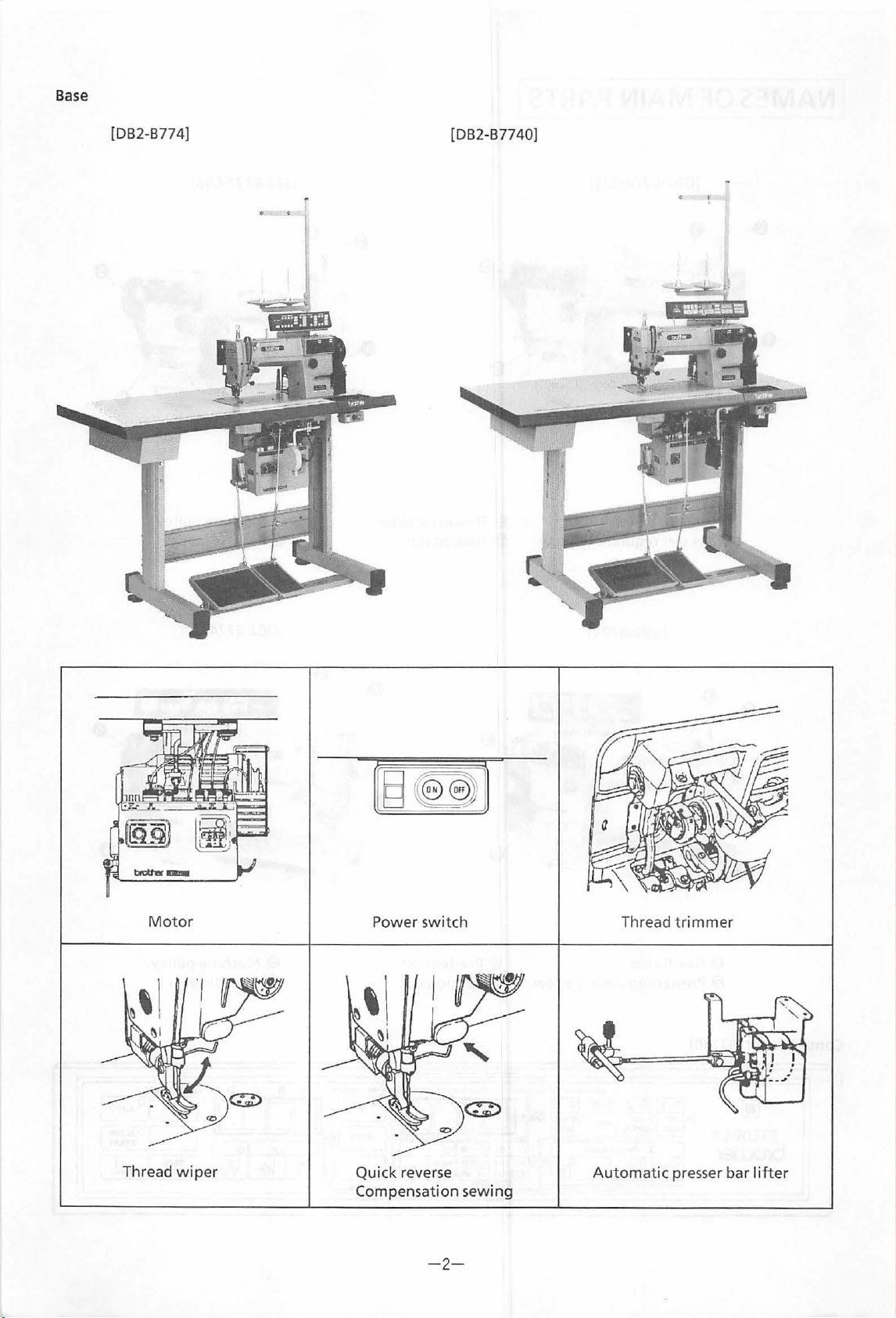

Base

[DB2-B774]

[DB2-B7740]

Motor

Thread w iper

Power swi

Quick rever

Compensation

tch

se

-

2-

se

w

.

1ng

Thread t

Automatic

rimmer

presser bar I i

fter

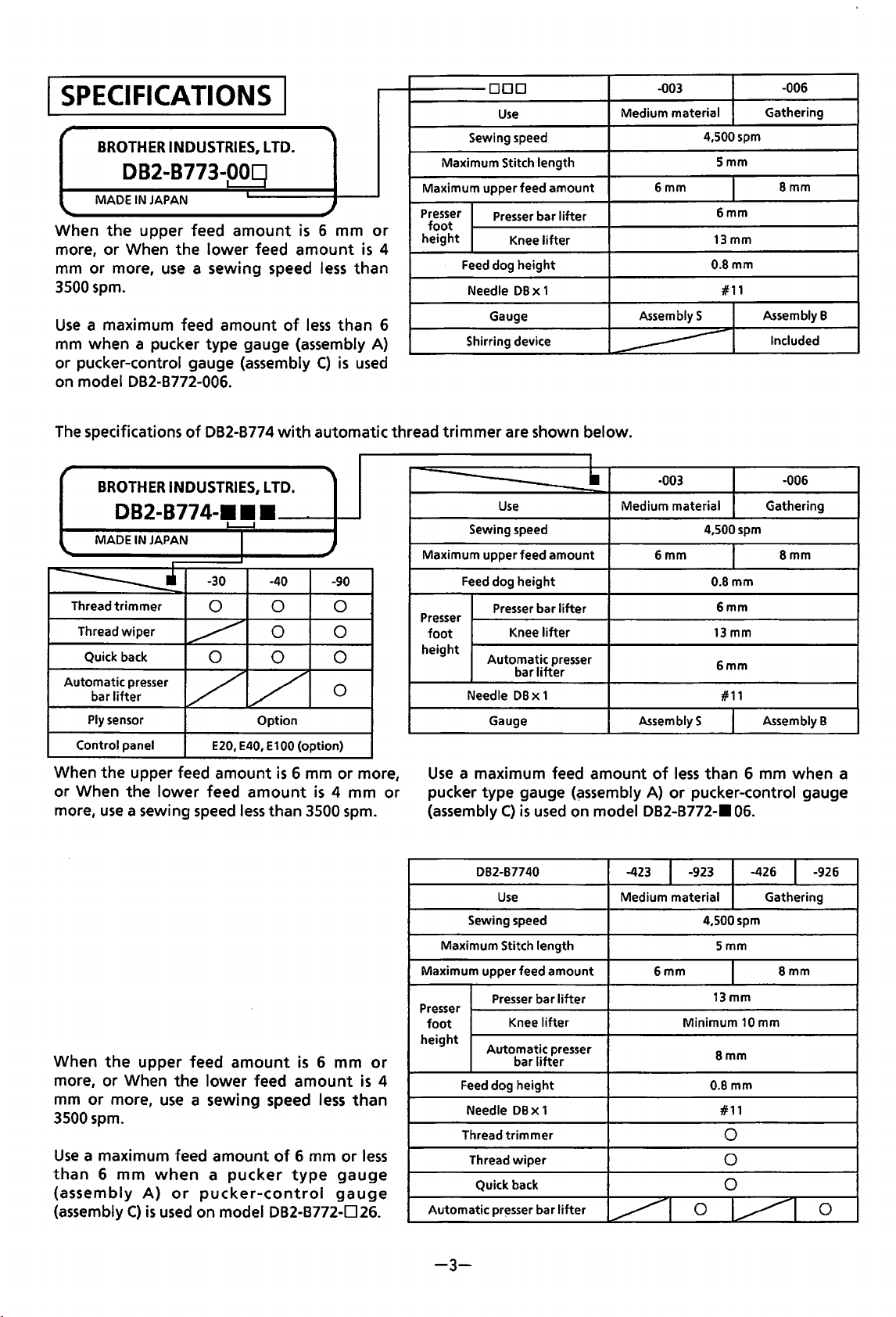

SPECIFICATIONS

I

..,

BROTHER

INDUSTRIES,

LTD.

082-8773-poq

MADE

IN

JAPAN

""

w hen

more,

mm

3

Use

m m when a pucker type gauge (assembly A)

or pucker-control gauge (assembly

on model 082-8772-006.

The

the

upper feed

or

500

or

spm.

When

more,

the

lower

use

a sewing speed

a maximum feed amount

specifications

BROTHER

of

082-8774

INDUSTRIES,

082-8774-···

MADE

IN

JAPAN

==------.!

Thread

trimmer

Thread

wiper

Quick back

Automatic

Control

presser

bar

lifter

Ply sensor

panel

-30 -40

0 0 0

~

0

/ /

E20, E40,

amount

feed

with

LTD.

L--..J

I

0

0 0

Option

E100

.J

is

6 mm

amount

less

of

less

C)

is

than

than

1s

used

or

automatic thread trimmer are shown below.

.J

-90

0

0

(option)

ODD

Medium material

AssemblyS

Maximum Stitch length

Maximum upper feed

Presser

foot

height

4

6

Use

Sewing speed

Presser

Knee

Feed

dog

height

Needle

Shirring device

DBx

Gauge

amount

bar

lifter

lifter

1

-----------

I

---------·

Maximum upper feed

Presser

foot

height

Use

Sewing speed 4,500spm

amount

Feed

dog

height

Presser

bar

lifter

Knee

lifter

Automatic

Needle DBX 1

Gauge Assembly$ Assembly B

bar

presser

lifter

Medium material Gathering

-003

6mm

-003

6mm

4,500

Smm

6mm

13mm

O.Bmm

#11

O.Bmm

6mm

13mm

6mm

#11

-006

Gathering

spm

Bmm

Assembly B

Included

-006

Bmm

When the upper feed amount

or

When

more,

When

more, or When

mm

use

or

the

a sewing

the

upper feed

more,

lower

feed

speed

amount

the

lower feed

use

a sewing speed

amount

Jess

3500spm.

Use

a maximum feed amount

than 6 mm

(assembly

(assembly

when a pucker

A)

or

pucker-control

C)

is

used

on model 082-8772-D

is

6 mm or more,

is

4 mm

than

3500

is

6 mm

amount

less

of

6 mm or

type

gauge

gauge

spm.

is

than

less

26.

or

4

Use

a maximum feed amount

or

pucker type gauge

(assembly

Sewing speed

Maximum Stitch length Smm

Maximum upper feed

Presser

foot

height

Feed

Needle

Thread

Thread

Automatic

C)

is

DB2-B7740

Use

Presser

Knee

Automatic

bar

dog

height

DBx

trimmer

wiper

Quick back

pr~sser

of

less

than 6 mm when a

(~ssembly

used

on model DB2-B772-•

amount

bar

lifter

lifter

presser

lifter

1 #11

bar

lifter

A)

or

pucker-control gauge

-423

Medium material Gathering

~I

-923

I

4,500spm

6mm

Minimum 10 mm

O.Bmm

0

13mm

Bmm

06.

-426

0

0

0

~I

I

Bmm

-926

0

-3-

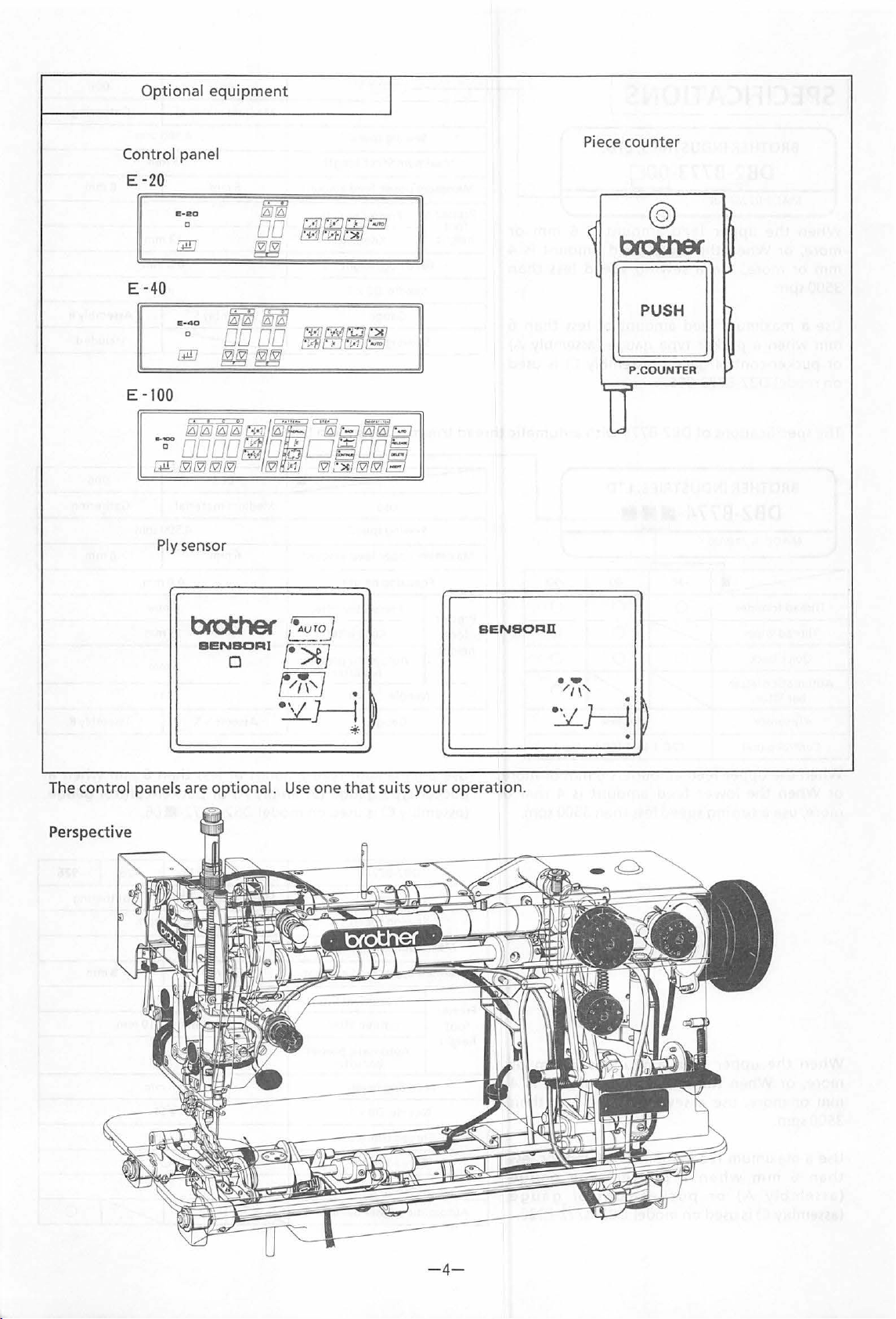

Optional

equipment

I

Con

trol panel

E -20

E -

40

E -100

Ply sensor

E-RD

11-40

Piece counter

c

@

brother

c

EJ

P.

COUNTER

u

Th

e con

trol

Perspective

panels are optional.

Use

one

that

suits y

our

operation.

SENSORfi

-4-

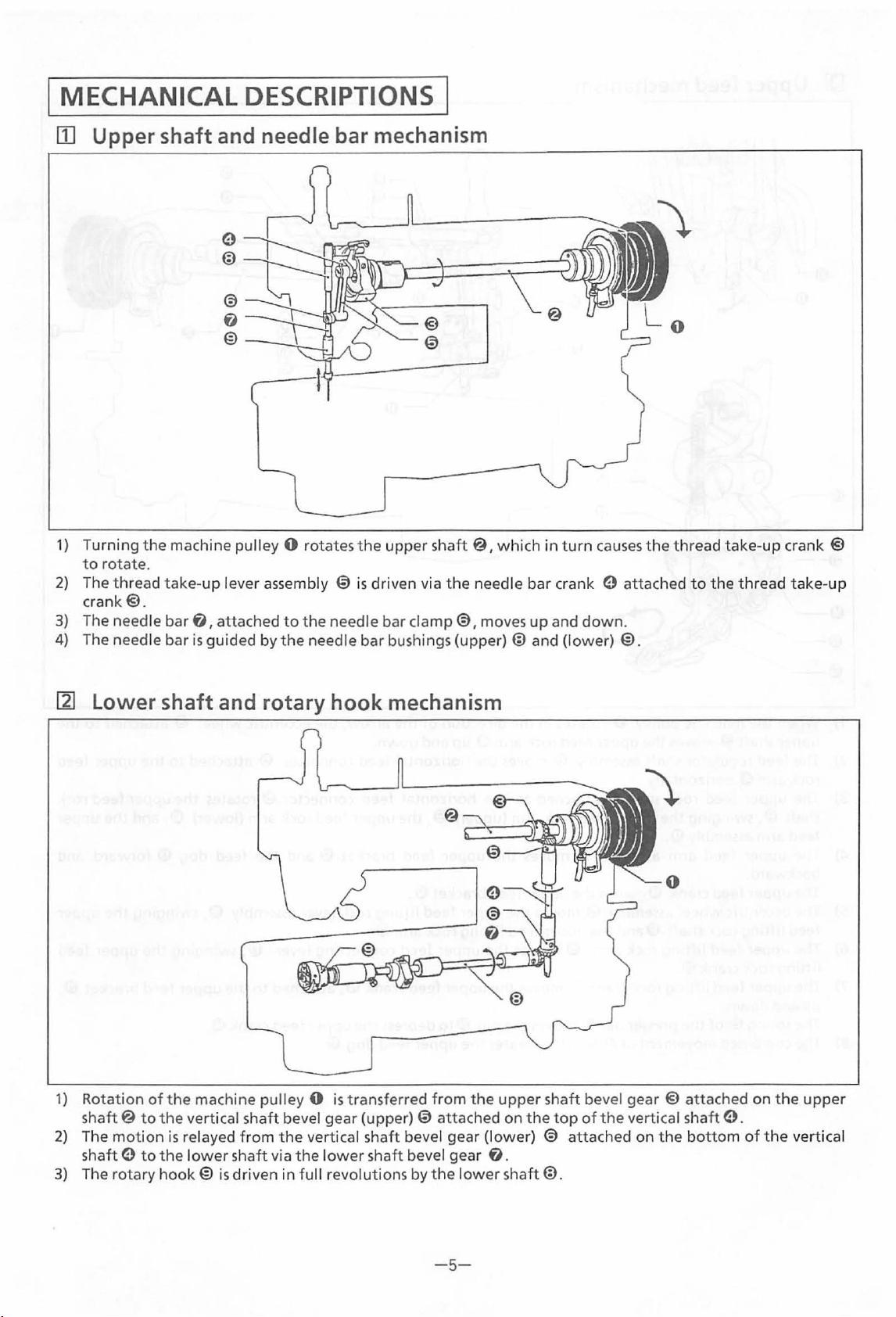

MECHANICAL DESCRIPTIONS

III Upper shaft and needle bar mechanism

1)

Turning

to

2)

The thread take-up lever assembly

crank@.

3)

The needle bar

4) The needle bar

the

rotate.

machine pulley 0 rotates the upper

€)

is

driven via

f)

I attached

is

guided by

to

the

needle bar

the

needle bar bushings

clamp@

shaft@ I which

the

needle bar crank e attached

I moves

(upper)@

in

turn

causes

up

and

down.

and (lower) @.

the

thread

to

the

take-up

thread

crank @

take-up

l1l

Lower shaft and rotary hook mechanism

1)

Rotation

shaft@

2)

The

shaft e

3)

The rotary

of

to

motion

to

the

machine

the

vertical shaft bevel gear (upper)@ attached on

is

relayed

the lower

hook@

pulley 0 is

from

the

shaft via

is

driven in full revolutions by

the

transferred

vertical shaft bevel gear (lower) @ attached on

lower

shaft bevel gear

from

the

the

f)

lower

upper

shaft bevel

the

.

shaft@.

top

gear@

of

the

vertical shaft e.

attached on

the

bottom

of

the

the

upper

vertica l

-5-

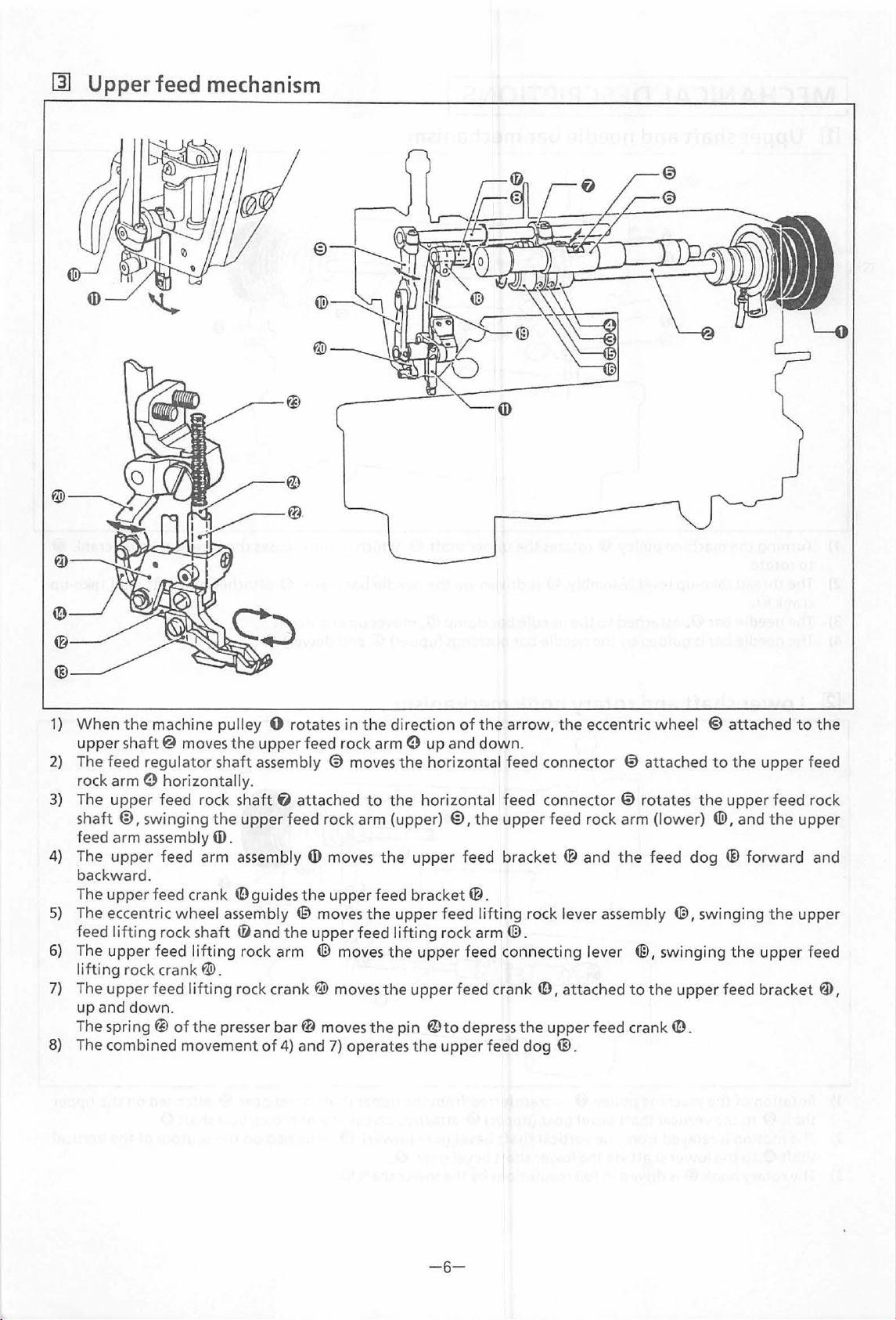

[1]

Upper feed mechanism

1)

When

the

machine pulley 0 rotates

upper

shaft@

2)

The feed regul

rock arm

3) The

shaft

feed arm assembly

4)

The

backward.

The

5)

The eccentric wheel

feed

6)

The

lift

7)

The upper feed

up and

The

8)

The

a

upper

@,swinging

upper

upper

feed crank IDgui

lifting

upper feed

ing rock cran

down.

spring ®

combined movement

moves

ato

horizontally

feed rock shaft

the

upper feed rock arm a

r shaft assembly ® moves the horizontal feed connector @ attached

.

f)

the

upper feed rock arm (upper)

m.

feed arm assembly

des

assem

bly ® moves

rock

shaft

(f) and

the

lifting

k@.

lifting

of

the

rock arm ® moves

rock

crank@

presser bar

of

4) and

in

attached

ID

moves

the

upper

upper feed

moves

til

mo

ves

7)

operates

the

direction

to

the horizontal feed connec

the

upper

feed

bracket®.

the

upper feed

lifting

the

the

upper

the

pin

the

up

and down.

@,the

rock

upper

fnto

upper

of

the

arrow,

upper

feed brac

lifting

arm®.

feed connecting lever ®, swinging the upper feed

feed crank

depress

the

feed dog

the

eccentric wheel

tor

@ rotates

feed rock arm (lower)

ket

® and the feed dog ®

rock lever assembly

(9,

attached

upper feed crank

to

the

®.

@attached

to

the

the

upp

@,and

forward

@,swinging

upper feed

(9.

to

upper

er

feed rock

the

the

bracket

the

feed

upper

and

upper

@,

- 6-

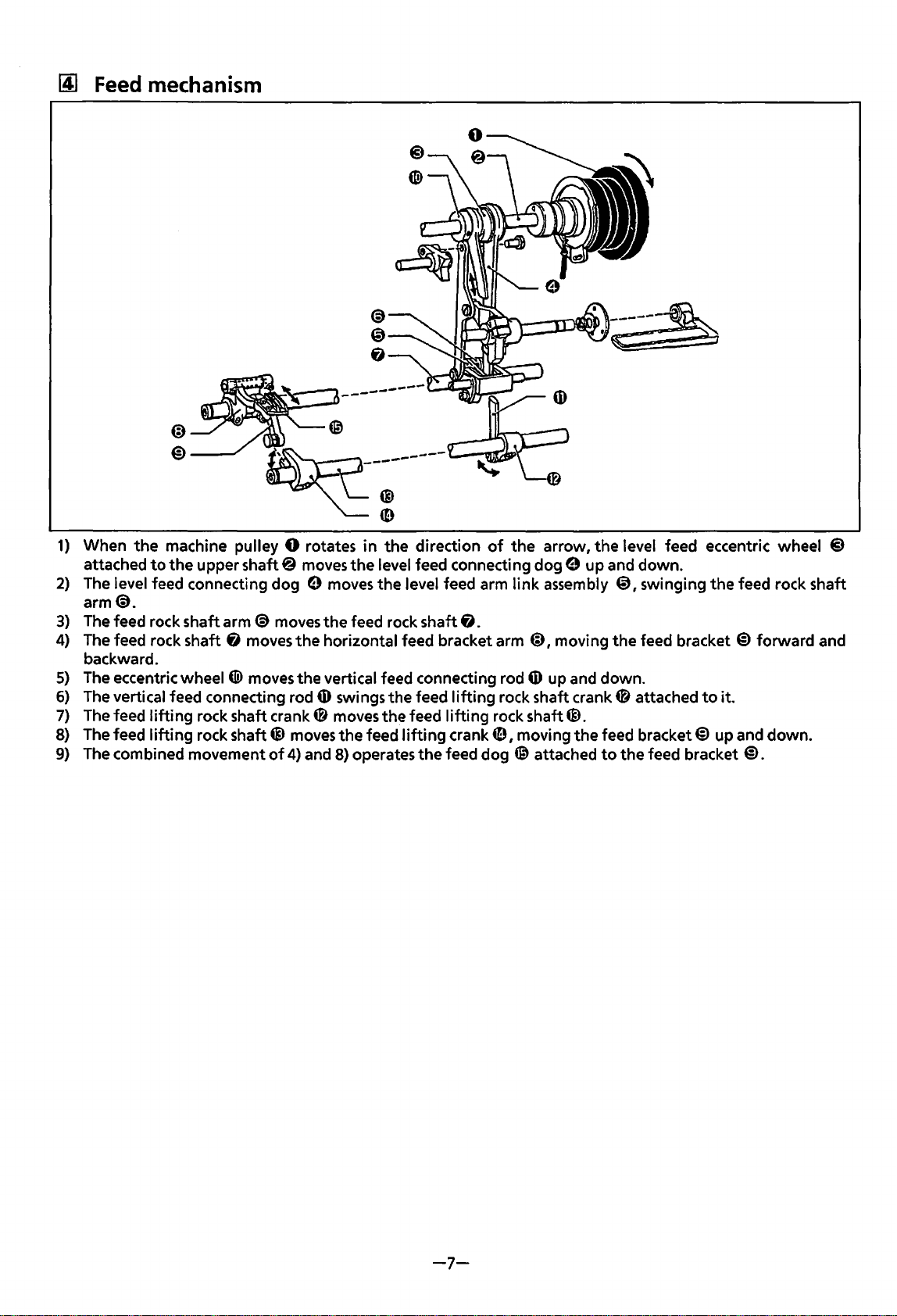

lAJ

Feed

mechanism

@

@---

----

---------

@

~

1)

When the machine pulley 0 rotates in the direction

attached

2)

The

arm

3)

The

4)

The

backward.

5)

The

6)

The

7)

The

8)

The

9)

The

to

the

upper shaft@

level feed connecting dog 0 moves the level feed arm link assembly @,swinging the feed rock shaft

moves

the

level feed connecting dog 0 up and down.

<9.

feed rock shaft arm @

feed rock shaft & moves

eccentric wheel

vertical feed connecting rod

feed

lifting

feed

lifting

combined movement

rock shaft crank 0

rock shaft@

moves

CID

moves the vertical feed connecting rod

of

the feed rock shaft & .

the

horizontal feed bracket arm

4D

swings the feed

moves

4)

and

moves

the feed

the feed

8)

operates

lifting

of

the

ED,

4D

lifting

lifting

crank~,

the

feed dog @ attached

rock shaft crank 0 attached

rock shaft@.

moving

arrow, the level feed eccentric wheel @

moving the feed bracket

up and down.

the

feed bracket@) up and down.

to

the feed bracket

to

@)

forward and

it.

@).

-7-

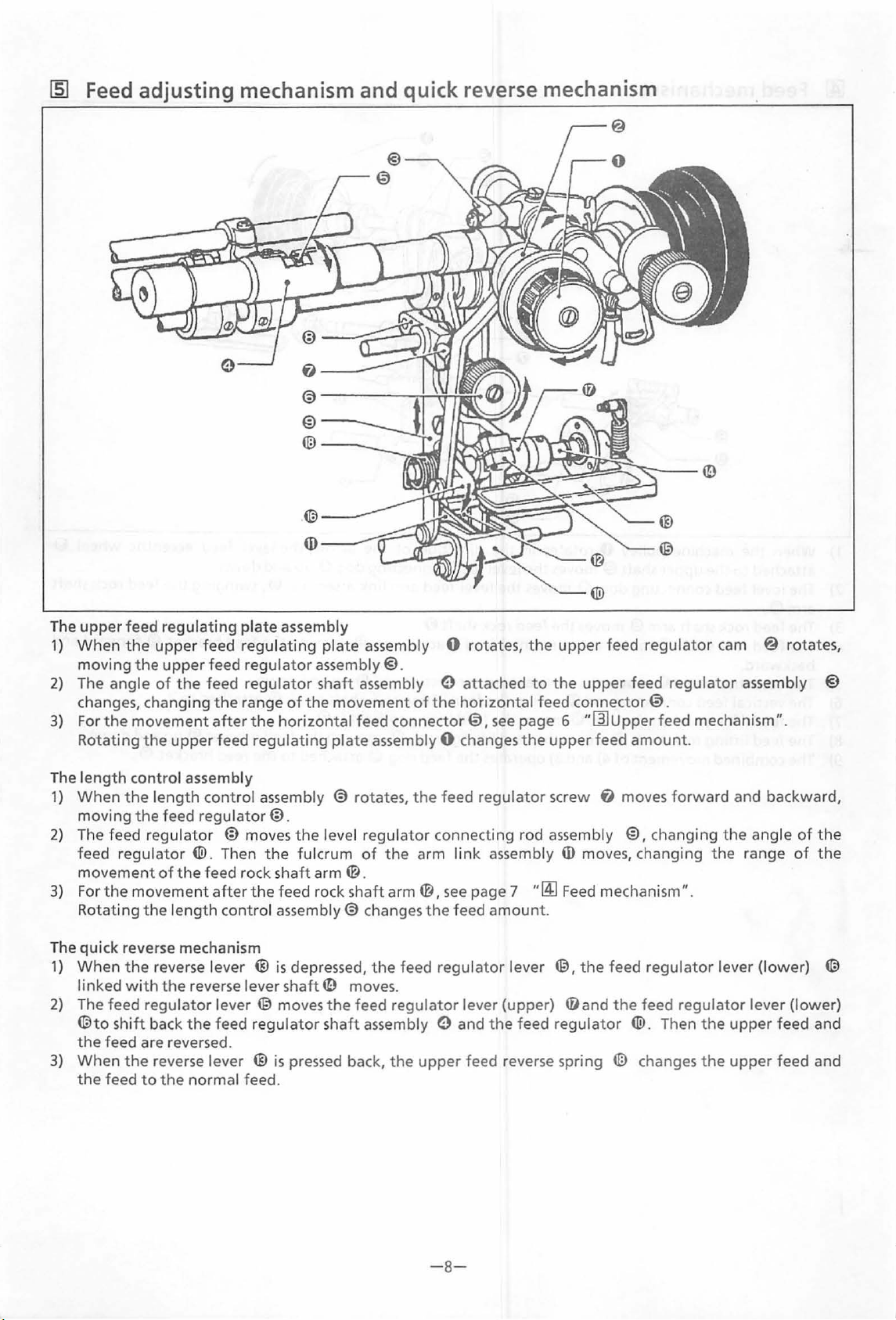

~

Feed adjusting mechanism and quick reverse mechanism

The

upper

feed regulating plate assembly

1)

When

moving

2)

The angle

changes, changing

3)

For

Rotating

The

1)

When

moving

2)

The feed regulato r @ moves

feed

movement

3)

For

Rotating

The quick reverse mechanism

1)

When

linked

2)

The feed

®to shift

the

3)

When

the

the

upper

the

upper

of

the

the

movement

the

upper

length

control assembly

the

length

the

feed

regulator

of

the

movement

the

length

the

reverse lever ®

with

the

regulator

back

feed are reversed.

the

reverse lever ®

feed

to

the

feed

regulating

feed

regulator

feed

regulator

the

range

after

the

feed regula

control assembly @ rotates,

regulator@

@.

Then

the

feed rock shaft arm

after

the

control assembly@ changes

reverse lever shaft

lever

the

feed

regulator

normal feed.

plate

assembly@.

shaft assembly e attached

of

the

movement

horizontal feed

ting

plate assembly 0 changes

.

the

level

the

fulcrum

feed rock

is

depressed,

ID

@moves

is

the

sha

pressed back,

assembly 0 rotates,

of

the horizo

connector@,

the

feed regulator screw

regulator

of

the

connecting rod assembly

arm

lin

k assembly

®.

shaft

arm

®,

see

page 7

the

feed amount.

the

feed regul

moves.

feed

regulator

ft

assembly e and

the

upper

ator

lever (upper) {!)and

feed reverse spring ® changes

ntal feed

see

page 6

the

lever

the

feed

the

upper feed regulator

to

the

upper

connector@.

"[21

upper feed amount.

ID

move

"~

Feed

@,the

regulator

feed

Upper feed mechanism

fJ

moves

@,

s,

changing

mechanism

feed

the

feed

@.

regulator

forward

changing

11

•

regulator

regulator

Then

the

the

cam

@ rotates,

assembly @

II.

and backwa rd,

the

angle

of

the

range

lever (lower) ®

upper

upper

of

lever (lower)

feed and

feed and

the

the

-8-

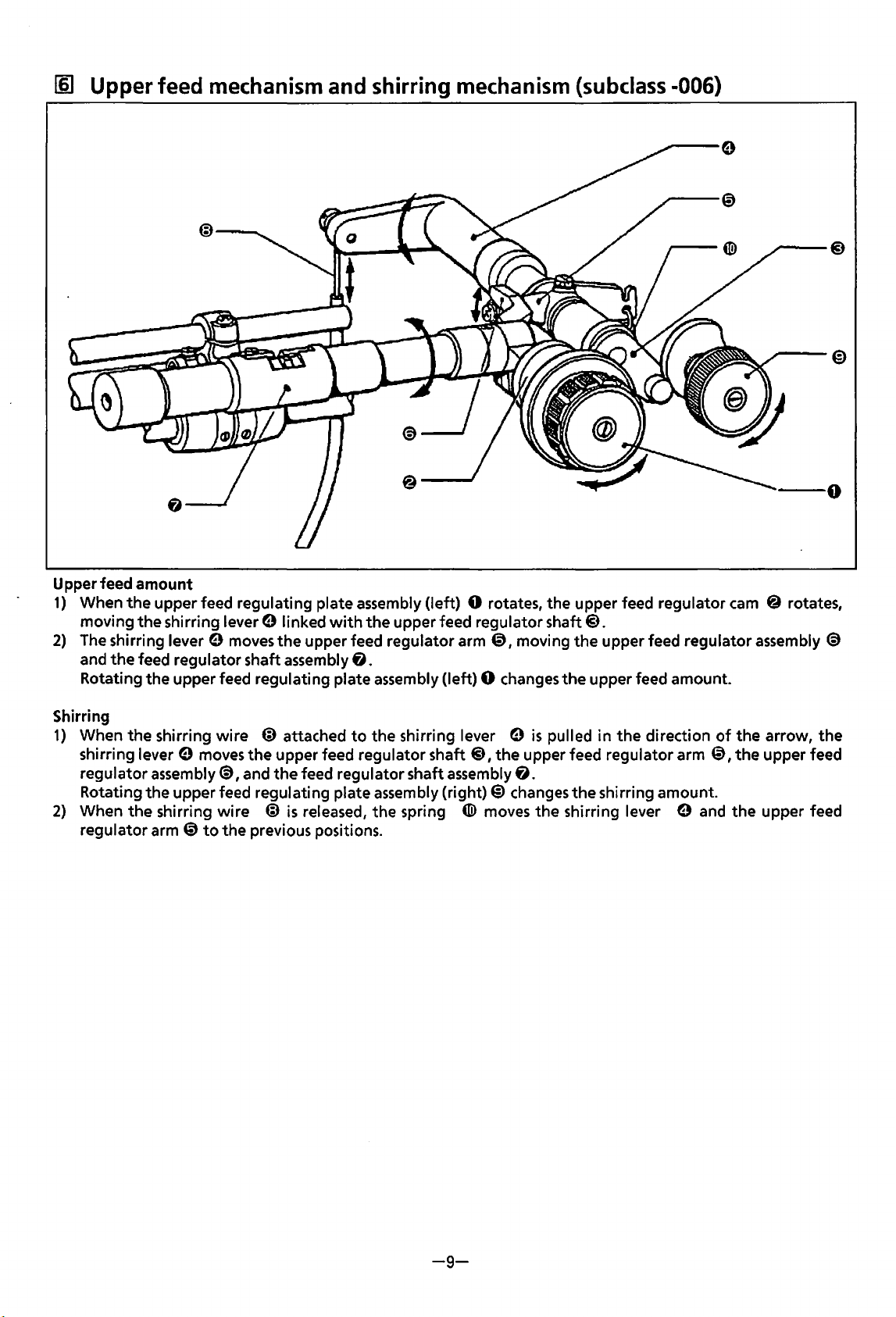

(§]

Upper feed

mechanism

and

shirring

mechanism

(subclass

-006)

Upper feed amount

1)

When

moving the shirring lever

2)

The shirring lever 9 moves the upper feed regulator arm @),moving the upper feed regulator assembly @

and

Shirring

1)

When

shirring lever 9 moves

regulator

Rotating the upper feed regulating plate assembly (right)@) changes

2)

When

regulator

the

upper feed regulating plate assembly (left) 0 rotates, the upper feed regulator

e linked

the

feed regulator shaft assembly

Rotating the upper feed regulating plate assembly (left) 0 changes

the

shirring

assembly@, and

the

shirring

arm@)

wire

@ attached

the

upper feed regulator

the

wire

to

@

the previous positions.

with

the

upper feed regulator shaft@.

e.

to

the shirring lever 9

shaft@,

feed regulator shaft assembly

is

released,

the

spring

([.i)

is

pulled in

the upper feed regulator arm

6.

moves

the

the

upper feed amount.

the

direction

the

shirring amount.

shirring lever 9 and

cam

of

the arrow,

@,the

the

@ rotates,

upper feed

upper feed

the

-9-

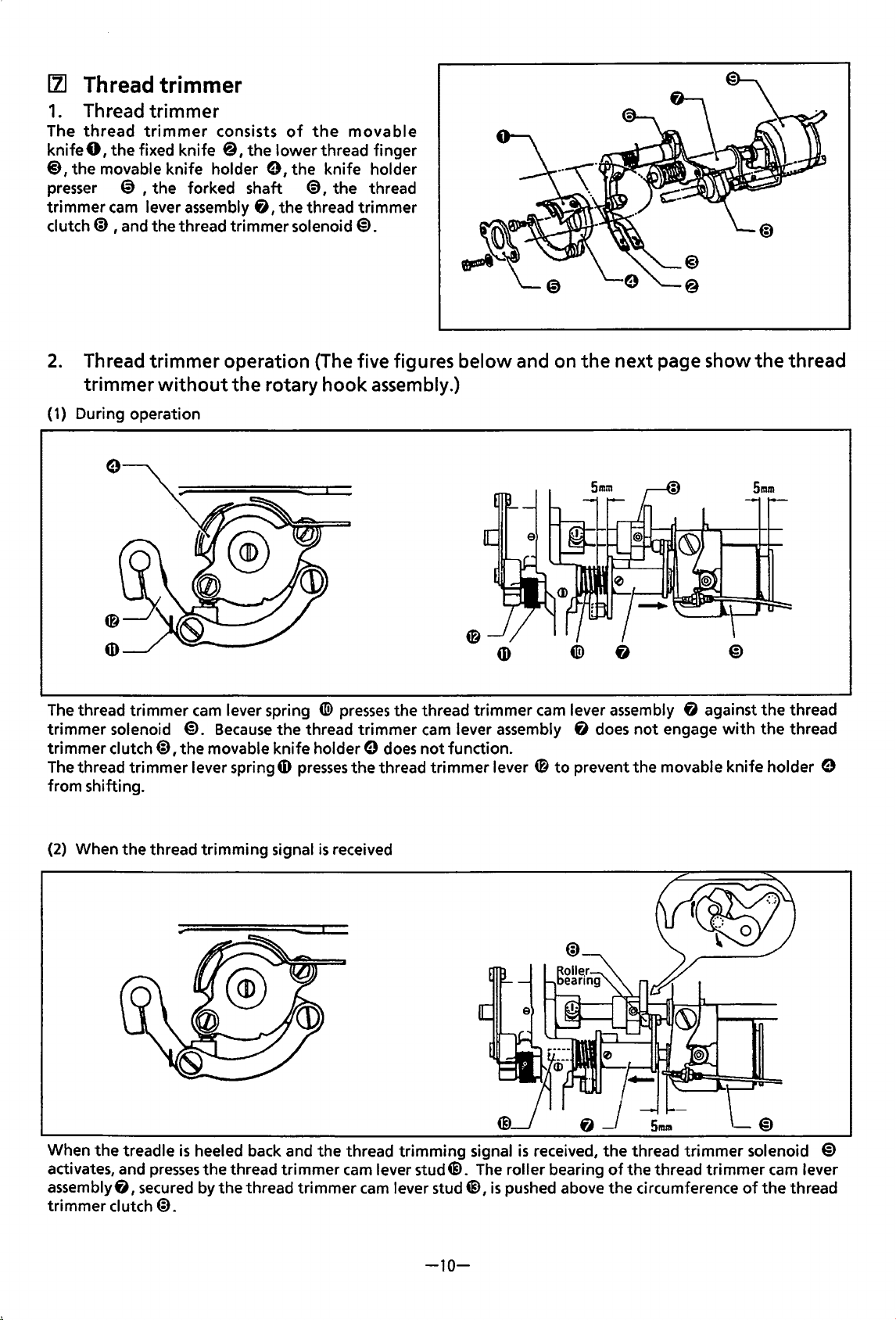

111

Thread trimmer

1.

Thread

The

thread

knife

0,

@)

1 the movable knife holder e I the knife holder

presser

trimmer

clutch@ , and the thread trimmer solenoid@.

2.

Thread

trimmer

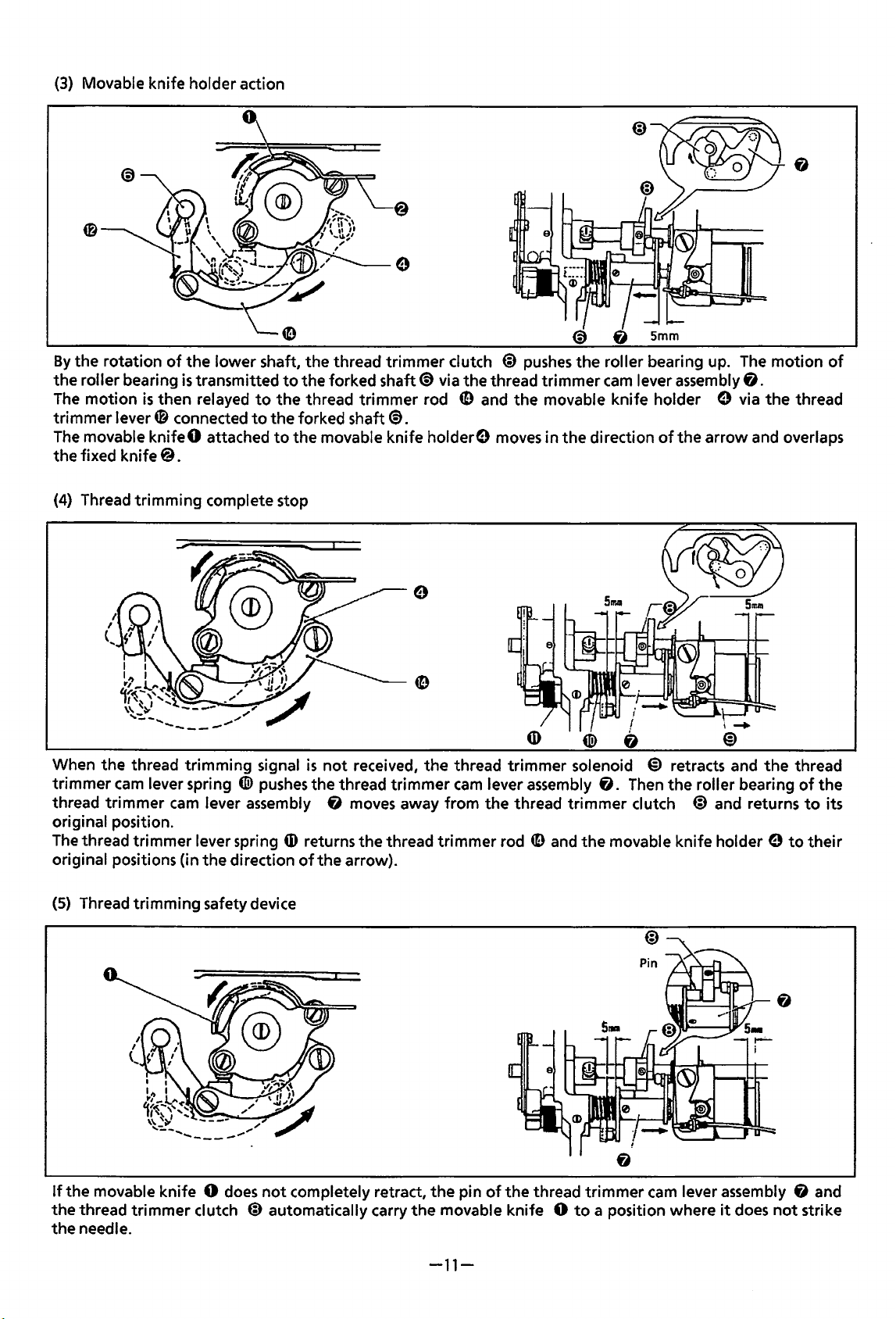

(1)

During operation

trimmer

trimmer

the

fixed knife

@ , the forked shaft

cam

lever assembly

trimmer

without

consists

@,the

operation (The five figures

the

of

lower

f),

the

rotary

the

movable

thread finger

@),

the

thread

thread

trimmer

hook

assembly.)

below

and on

the

next page show

the

thread

The

thread trimmer

trimmer

trimmer clutch@ I

The

from shifting.

(2)

When

activates, and

assembly

trimmer

solenoid @.

thread trimmer lever springiD

When

the

the

treadle

f),

secured by

clutch

cam

Because

the

movable knife holder e

thread trimming signal

is

heeled back and the thread trimming signal

presses

the

the

«D.

lever spring @

the

thread trimmer

presses

is

thread trimmer

thread trimmer

presses

received

cam

the thread trimmer

cam

does

not

the

thread trimmer lever 0

lever stud

cam

lever stud

lever assembly

function.

is

6).

The

roller bearing

6),

is

pushed above

cam

lever assembly

f)

does

not

to

prevent the movable knife holder 9

received,

the

thread

of

the thread trimmer

the

f)

against

engage

circumference

with

trimmer

of

the

thread

the

thread

solenoid @

cam

lever

the

thread

-10-

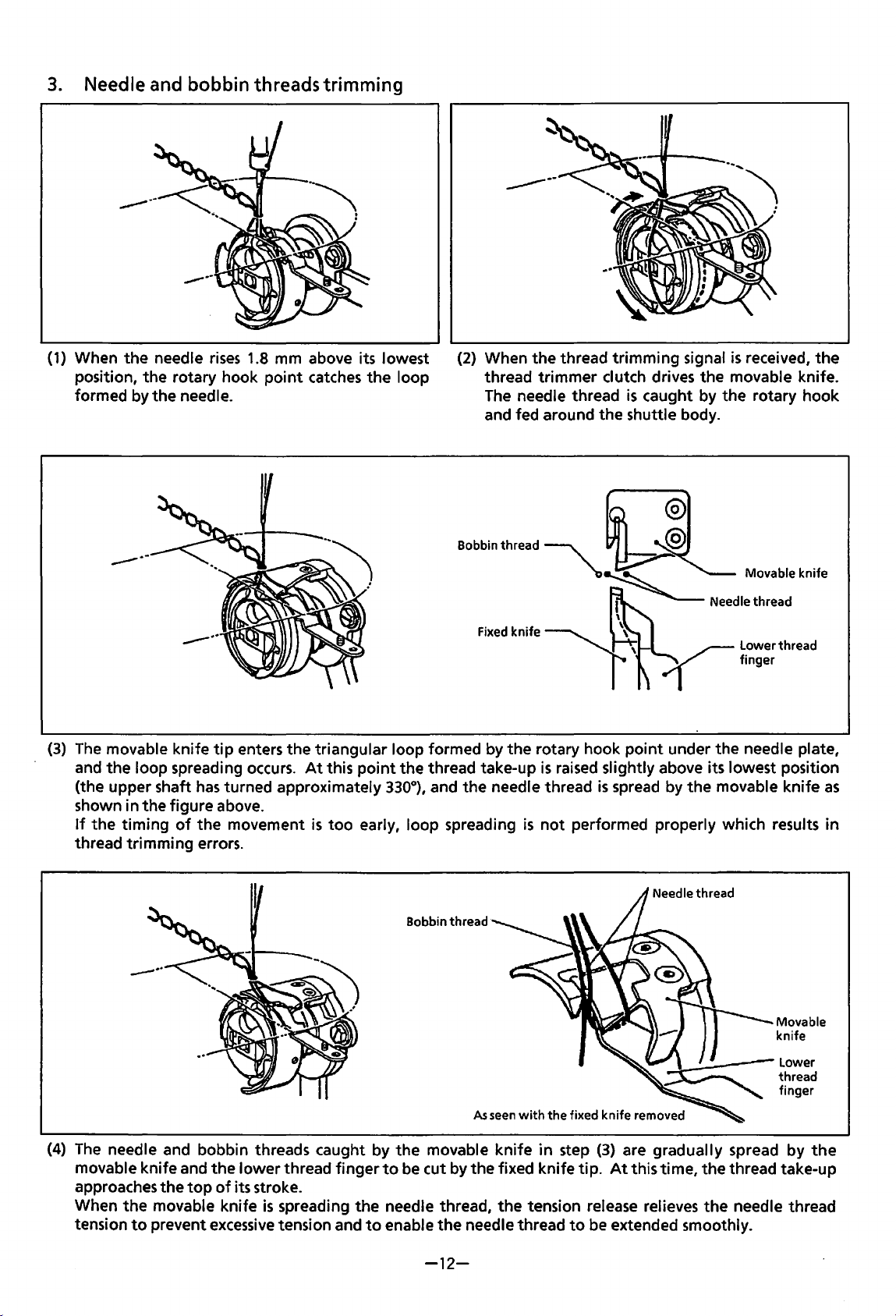

(3)

Movable knife holder action

By

the rotation

the roller bearing

The

motion

trimmer lever

The

movable

the fixed knife

(4)

Thread trimming complete stop

of

the lower shaft, the thread trimmer clutch @

is

transmitted

is

then relayed

4!1

connected

knifeO

@.

attached

to

the forked shaft@ via the thread trimmer

to

the

thread trimmer rod

to

the forked shaft@.

to

the movable knife hold

pushes

49

and the movable knife holder 0 via

ere

moves

the roller bearing up.

cam

lever assembly

in the direction

of

the arrow and overlaps

The

f).

motion

the

thread

of

When the thread trimming signal

trimmer

thread trimmer

original position.

The

original positions (in the direction

(S)

If

the movable knife 0

the thread trimmer clutch

the needle.

cam

lever spring

cam

thread trimmer lever spring

Thread trimming safety device

tiD

pushes

lever assembly

4D

does

not

@ automatically carry

is

not

received, the thread trimmer solenoid @ retracts and

the thread trimmer

f)

moves away from the thread trimmer clutch @ and returns

returns

of

completely retract,

the

thread trimmer rod

the arrow).

the

cam

lever assembly

49

the

pin

of

the thread trimmer

movable knife 0

f).

Then

the roller bearing

and

the movable knife holder 0

cam

lever assembly

to

a position where

it

does

the

not

thread

of

the

to

to

their

f)

and

strike

its

-11-

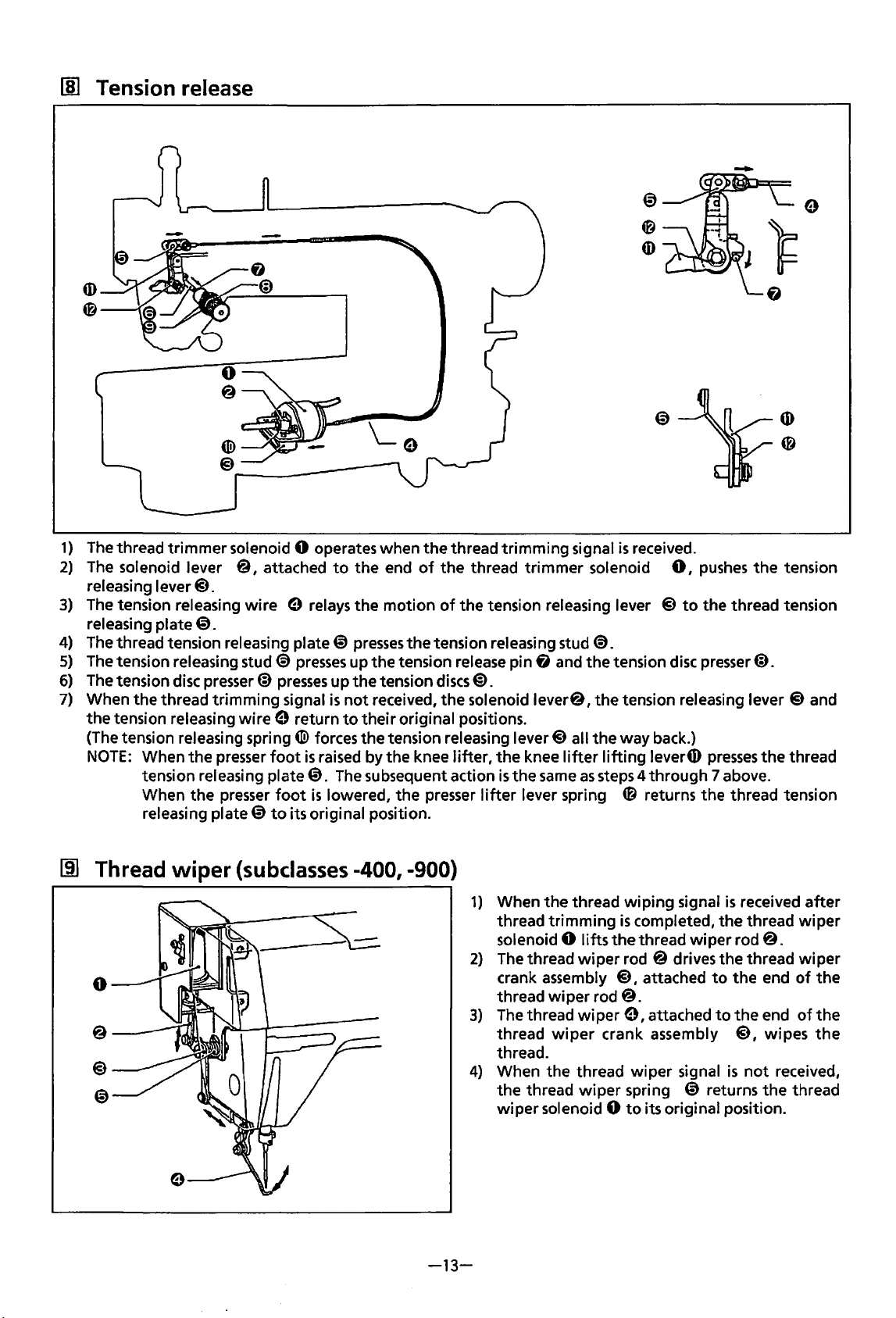

3.

Needle and bobbin threads trimming

(1)

When the needle

position, the rotary hook

formed by the needle.

rises

1.8

mm above its lowest

point

catches

the loop

------

(2)

When the thread trimming signal

thread trimmer

The

needle thread

and fed around the shuttle body.

clutch drives the movable knife.

is

caught by the rotary hook

is

received, the

-----

(3)

The

movable knife

and the loop spreading

(the upper shaft

shown in the figure above.

If

the

timing

thread trimming errors.

has

of

the movement

tip

enters the triangular loop formed by the rotary hook point under the needle plate,

occurs.

turned approximately

At

is

this

point

the thread take-up

330°),

and the needle thread

too

early, loop spreading

Bobbin thread

is

is

raised

slightly above its lowest position

is

spread by

not

performed properly which results in

the

movable knife

Movable

knife

as

As

seen

with

the fixed knife removed

(4)

The

needle and bobbin threads caught by the movable knife in step

movable knife and the lower thread finger

approaches the

When the movable knife

tension

to

top

prevent

of

its stroke.

is

excessive

spreading the needle thread, the tension release relieves

tension and

to

be

cut by the fixed knife tip.

to

enable the needle thread

-12-

(3)

are gradually spread by

At

this time, the thread take-up

to

be

extended smoothly.

the

needle thread

the

liD

Tension release

1)

The

thread trimmer solenoid 0 operates when the thread trimming signal

2)

The

solenoid lever

releasing

3)

The

releasing

4)

The

5)

The

6)

The

7) When the thread trimming signal

the tension releasing wire

(The

NOTE:

m:J

Thread

lever@.

tension releasing wire 0 relays the motion

plate@.

thread tension releasing plate@

tension releasing stud@

tension disc

tension releasing spring

When the

tension releasing

When the

releasing

wiper

@,

attached

presses

presser@)

presses

0 return

4D>

forces the tension releasing lever@ all

presser

presser

plate@

foot

is

plate@.

foot

is

to

its original position.

(subclasses -400, -900)

0

to

the

end

of

the

thread trimmer solenoid

of

the tension releasing lever

presses

up the tension release pin

up

the

is

not

to

raised by the knee lifter,

The

lowered, the presser

the tension releasing stud

tension

received,

their

subsequent action

discs@).

the

solenoid lever@, the tension releasing

original positions.

lifter

1)

2)

3)

4)

is

received.

0,

pushes

@to

the thread tension

@.

fj

and

the

tension

the

way back.)

the

knee

lifter

lifting

is

the

same

as

steps

lever spring 0 returns the thread tension

When the thread wiping signal

thread trimming

solenoid

The

crank assembly

thread wiper rod

The

thread

thread.

When the thread wiper signal

the thread

wiper solenoid

0 lifts the thread wiper rod@.

thread

thread

wiper

is

wiper

@,

@.

wiper

crank assembly @, wipes

wiper

0

disc

presser@).

lever

G)

4 through 7 above.

completed, the thread wiper

rod @ drives the thread wiper

attached

0,

attached

spring @ returns the thread

to

its original position.

the

lever@

presses

to

the

is

received after

the end

to

the

end

is

not

received,

tension

and

thread

of

the

of

the

the

-13-

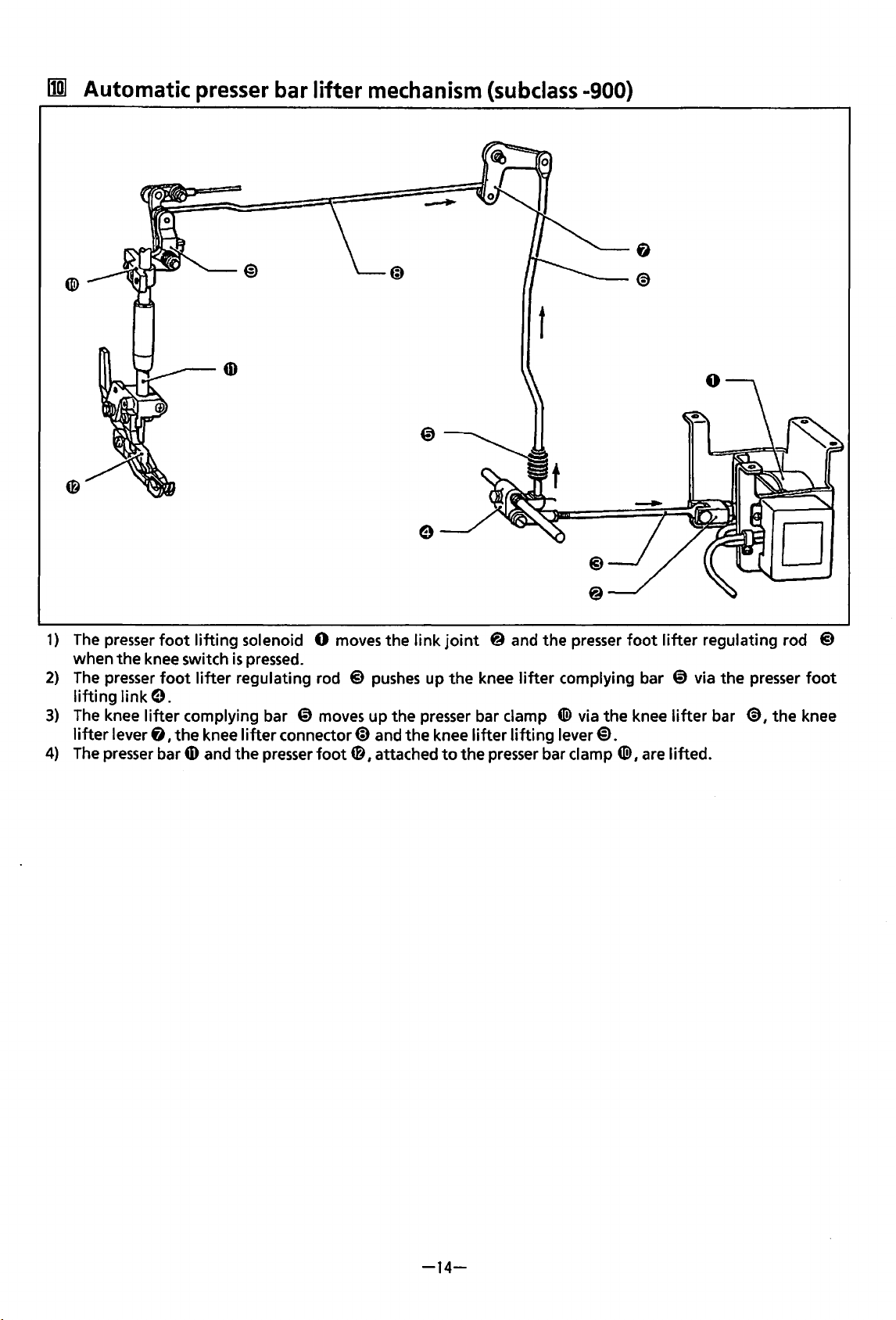

I1W

Automatic

presser

bar lifter

mechanism

(subclass

t

-900)

1)

2)

3)

4)

The

presser

when

The

presser

lifting

The

knee

lifter

The

presser bar

the

knee switch

link

9.

lifter

lever & I

foot

lifting

foot

lifter

complying bar

the

knee

0)

and the presser

solenoid 0 moves the

is

pressed.

regulating rod @

@)

moves up the presser bar clamp

lifter

connector@) and

foot

pushes

4fl

attached

1

link

the

up

knee

to

joint

@ and the presser

the

knee

lifter

lifter

lifting

the

presser bar clamp

foot

complying bar

4ID

via

the

knee

lever

€>.

(@I

are lifted.

lifter

regulating rod @

@)

via the presser

lifter

bar

€)

the

1

foot

knee

-14-

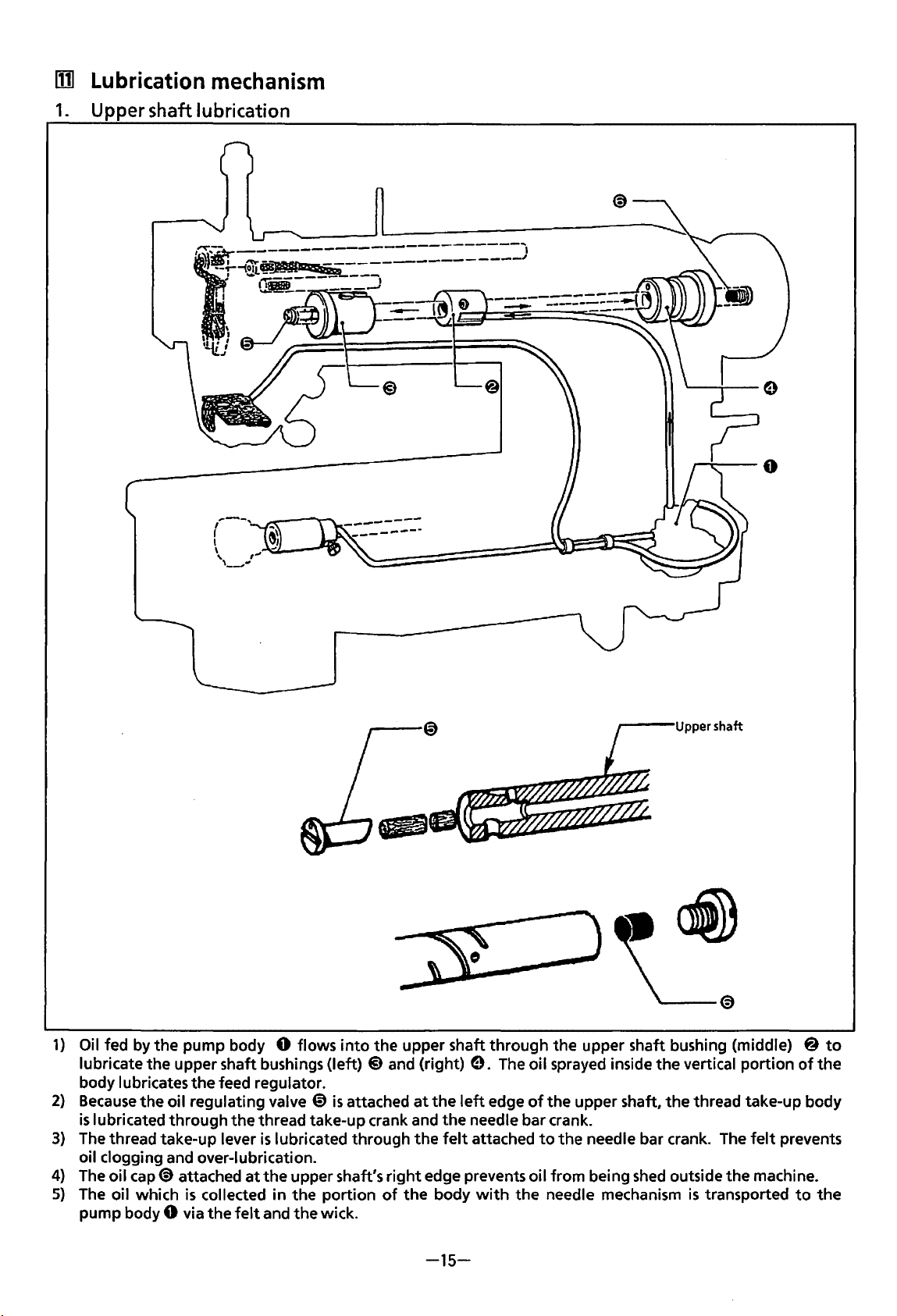

lD1

Lubrication

1.

Upper shaft lubrication

mechanism

1)

Oil fed by the pump body 0 flows

lubricate the upper shaft bushings (left) @ and (right)

body lubricates the feed regulator.

2)

Because

is

3)

The

oil clogging and over-lubrication.

4)

The

5)

The

pump body 0 via the

the oil regulating valve ~ is

lubricated through the thread take-up crank and the needle bar crank.

thread take-up lever

oil cap@ attached

oil which

is

collected in the portion

is

lubricated through the

at

the

upper shaft's right edge prevents oil from being

felt

and the wick.

into

the upper shaft through the upper shaft bushing (middle) @

9.

The

oil sprayed inside the vertical portion

attached

of

at

the

the

felt

body

left

edge

attached

with

of

the upper shaft, the thread take-up body

to

the needle bar crank.

the needle mechanism

-15-

shed

outside

is

transported

The

the

of

felt

prevents

machine.

to

to

the

the

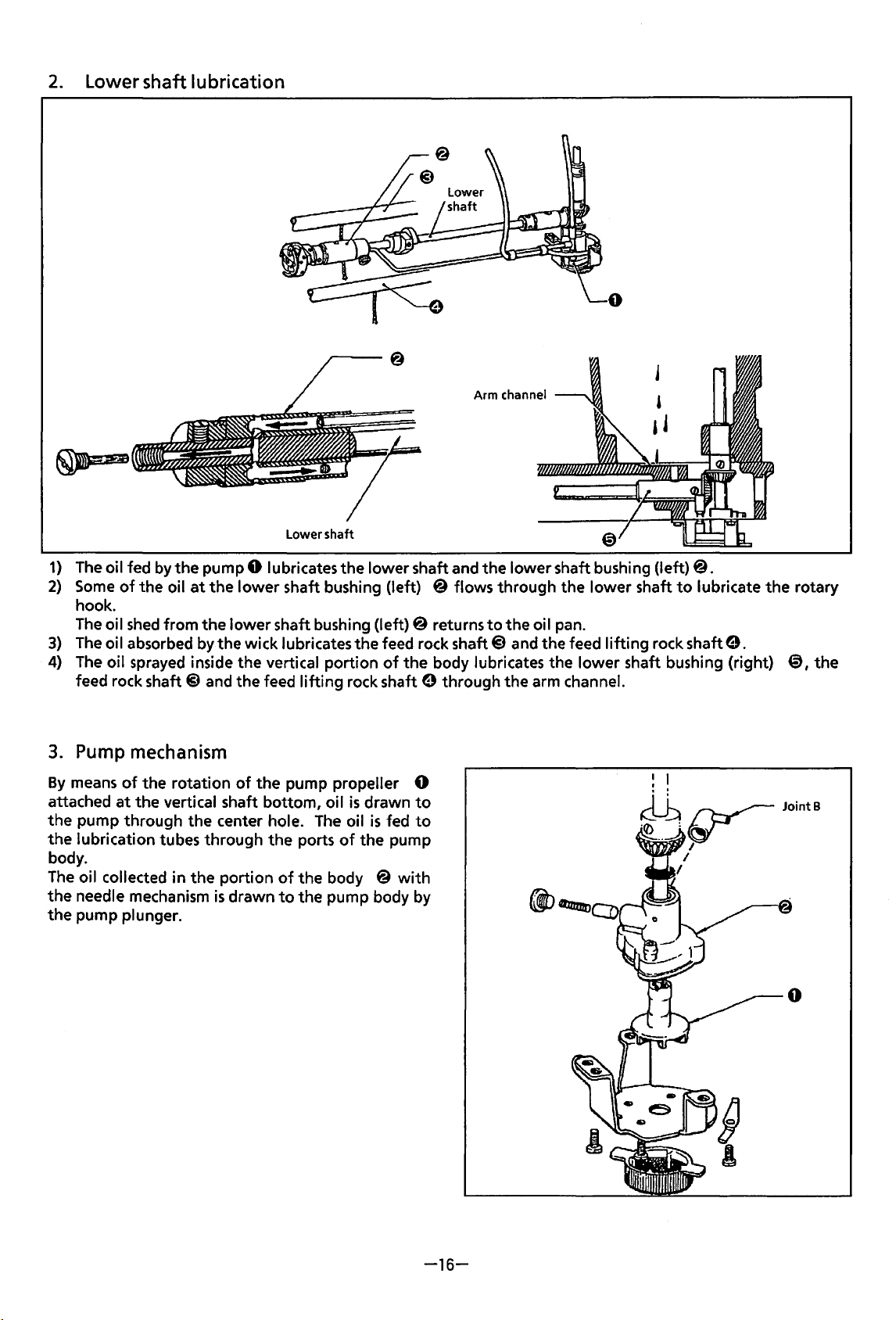

2.

Lower shaft lubrication

0

Arm channel

Lower shaft

1)

The

oil fed

2)

Some

hook.

The

oil

3)

The

oil absorbed by the wick lubricates the feed rock shaft@ and the feed

4)

The

feed rock

3.

Pump mechanism

By

means

attached

the pump through the center hole.

the lubrication tubes through the ports

body.

The

oil collected in the portion

the needle mechanism

the pump

by

the pump 0 lubricates the lower shaft and the lower shaft bushing (left)@.

of

the oil

shed

oil sprayed inside the vertical portion

of

the rotation

at

the vertical shaft bottom, oil

plunger.

at

the

lower shaft bushing (left) @ flows through the lower shaft

from the lower shaft bushing (left)@ returns

shaft@ and the feed

of

is

drawn

lifting

the pump propeller 0

The

of

the body @

to

the pump body by

to

the oil pan.

of

the body lubricates the lower shaft bushing (right)

rock shaft e through the arm channel.

is

drawn

oil

of

the pump

is

fed

with

to

to

lifting

to

lubricate

rock shaft

e.

the

rotary

8,

the

-16-

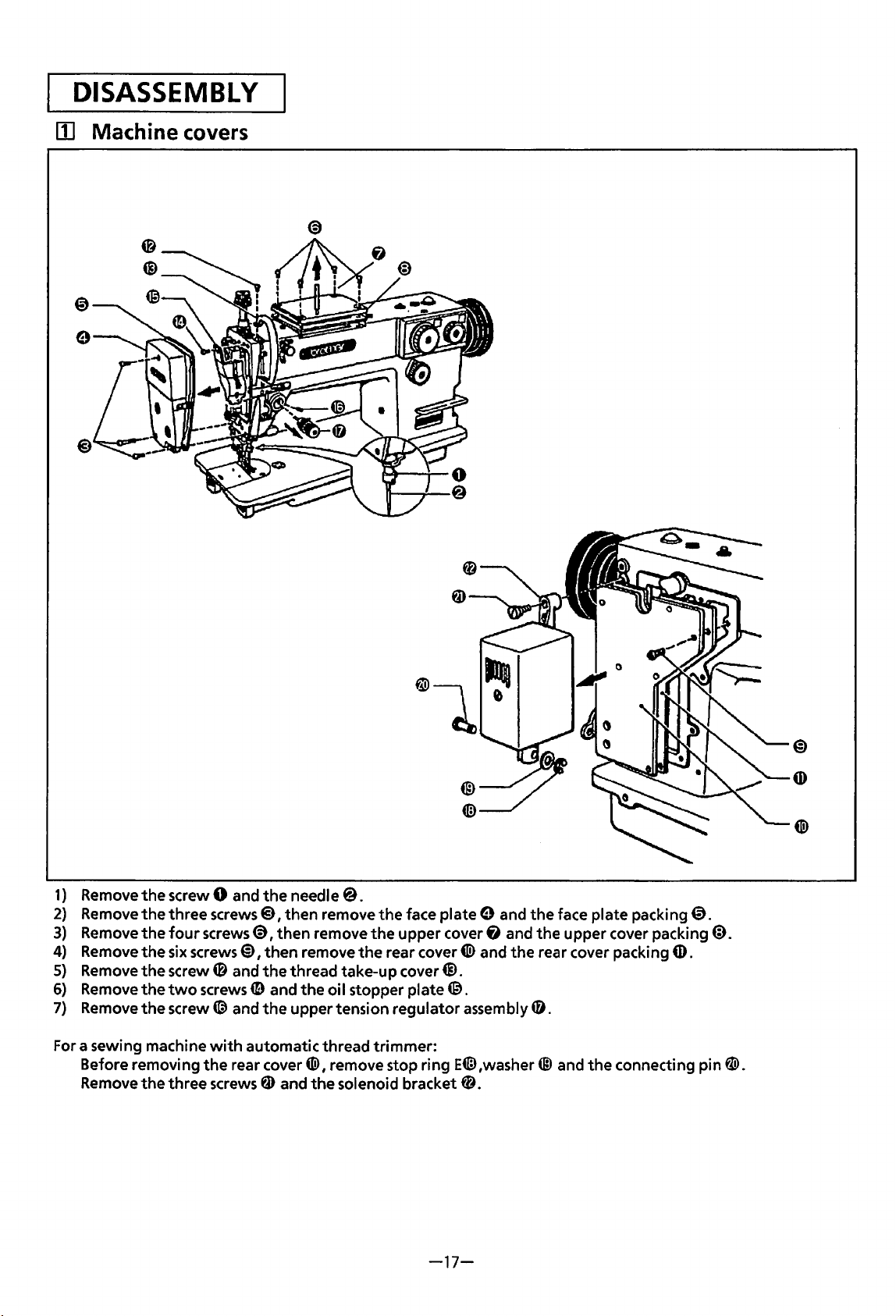

DISASSEMBLY

[]]

Machine covers

1)

Remove

2)

Remove

3)

Remove

4)

Remove

5)

Remove

6)

Remove

7)

Remove

For a sewing machine

Before removing

Remove

the

screw 0 and

the

three screws@), then remove

the

four

screws@,

the

six screws@),

the

screw@ and

the

two

screws

the

screw(;) and

with

the

the

three screws ~ and

the

needle@.

then

then

remove

the

thread take-up cover@.

49

and

the

the

upper tension regulator assembly

automatic thread

rear cover

4ID,

the

the

remove

the

oil stopper

face plate e and

the

upper cover

rear cover

plate®.

4ID

and

fl

the

and

the

the

rear cover packing {I).

49.

trimmer:

remove stop ring E® ,washer@ and

solenoid bracket

fD.

face plate packing@.

upper cover packing@.

-17-

the

connecting pin

W.

111

Presser

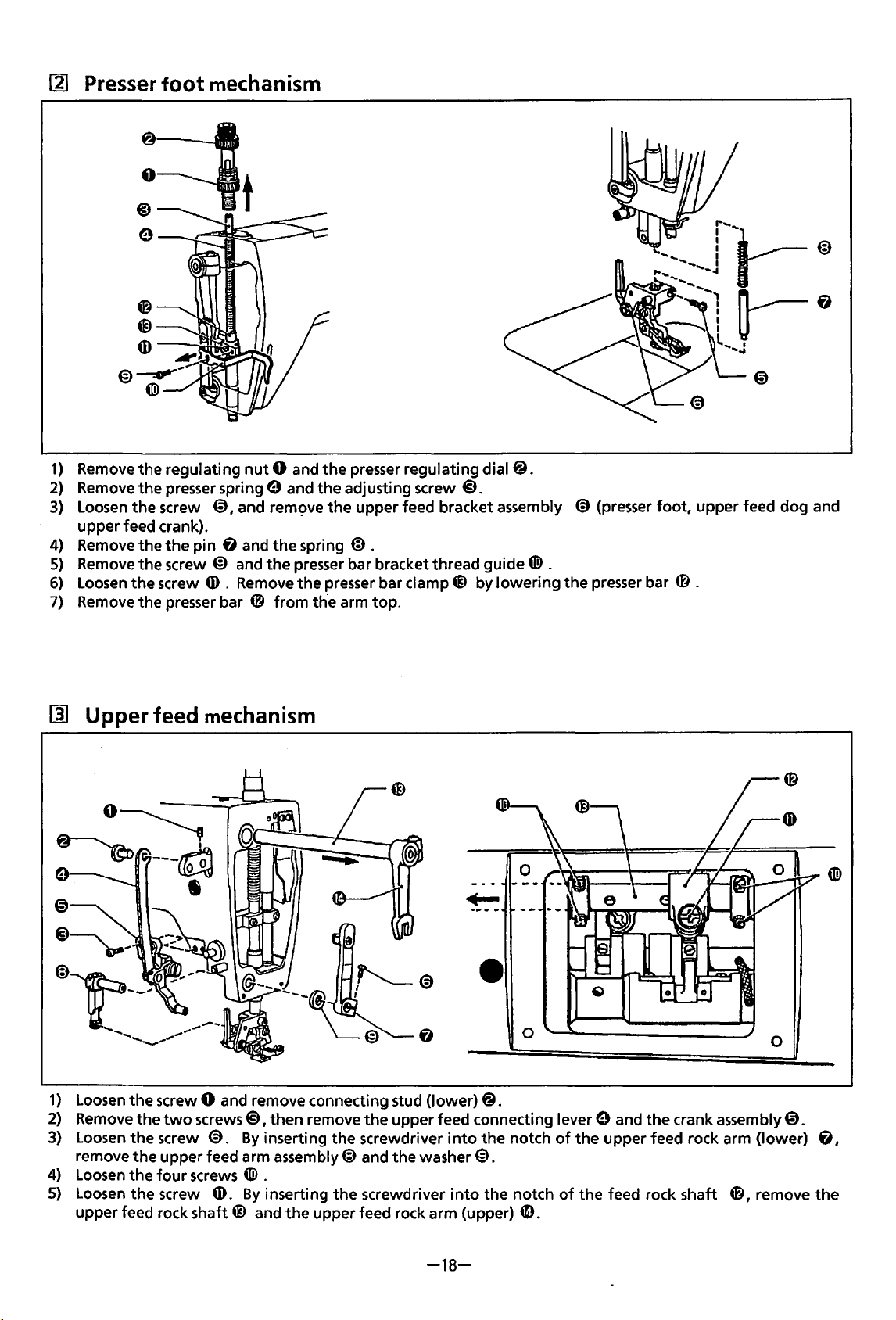

1)

Remove

2)

Remove

3)

Loosen

upper feed crank).

4)

Remove

5)

Remove

6)

Loosen

7)

Remove

the regulating

the presser spring 9 and the adjusting screw

the

the

the screw @ and

the

the presser bar 0 from the arm top.

foot

screw @, and

screw

mechanism

nut

0 and

rem~:>Ve

the

pin 6 and the spring @ .

the

presser

ID

.

Remove

the

presser

the

upper feed bracket assembly

bar bracket thread guide

the presser bar clamp@ by lowering

regulating

@).

dial@.

4ID

.

@)

(presser foot, upper feed dog and

the

presser bar 0 .

llJ

Upper feed

1)

Loosen

2)

Remove

3)

Loosen

remove

4)

Loosen

5)

Loosen

upper feed rock

mechanism

the

screw 0 and remove connecting stud (lower)@.

the

two

screws@),

the screw

the

upper feed arm assembly@ and the washer@).

the

four

the

screw (D.

@).

screws

shaft~

then remove

By

inserting

4ID

.

By

inserting the screwdriver

and

the

upper feed rock arm (upper)

the

the

screwdriver

upper feed connecting lever 9 and the crank assembly@.

into

into

0

the notch

the notch

~.

of

the

upper feed rock arm (lower) & ,

of

the feed rock shaft

0,

0

remove

the

-18-

Loading...

Loading...