Page 1

SERVICE MANUAL FOR

COMPUTERIZED SEWING MACHINE

LOW-END COMPUTER SERIES

CS4000

BC2100

BC2300

RS240

RS250

ES2000

ES2000t

ES2200

ES2010

ES2210

ES2020

ES2220

comfort40E

CE4000

CS6000

CS6000b

CS6000t

CS6000i

BC2500

RS260

XR7700

ES2400

ES2410

ES2420

comfort60E

CS100t

EX-660

BC1000

HS1000

The CD-ROM version of service manual contains movie!

CD-ROM version of service manual contains movies "2. Disassembly"

"3. Assembly".Please click on mark to start the movie.

10.2005.

6.2007.

Page 2

Page 3

1. Outline of Mechanism ........................................................................1 - 1

Main Mechanisms ...........................................................................1 - 2

Driveline ..........................................................................................1 - 3

Positions of electronic components ...................................................................1 - 4

Control system block diagram ...........................................................................1 - 5

Control system block diagram ...........................................................................1 - 6

Operation of other electronic components .........................................................1 - 7

2. Disassembly ........................................................................................2 - 1

Main parts ..........................................................................................................2 - 2

Accessory table removal ....................................................................................................................2 - 3

Bottom cover removal .......................................................................................................................2 - 3

Needle plate B assembly removal ......................................................................................................2 - 4

Needle plate B ASSY disassembly ..............................................................................................2 - 4

Face plate assembly removal .............................................................................................................2 - 5

Face plate A ASSY disassembly .................................................................................................2 - 5

Front cover removal ...........................................................................................................................2 - 6

Thread tension holder assembly and thread take-up holder B removal .............................................2 - 7

Thread tension holder ASSY disassembly ..................................................................................2 - 7

Thread take-up holder B disassembly ...........................................................................................2 - 8

LED lamp removal .............................................................................................................................2 - 8

Operation PCB assembly and SSVR PCB assembly removal ...........................................................2 - 9

Button removal ..................................................................................................................................2 - 9

Front panel and LCD removal ...........................................................................................................2 - 9

SV keytop removal ..........................................................................................................................2 - 10

Base plate rubber removal ...............................................................................................................2 - 10

Upper cover thread guide removal ...................................................................................................2 - 10

Main PCB assembly removal ..........................................................................................................2 - 11

Main PCB ASSY disassembly ...................................................................................................2 - 11

Power PCB assembly removal .........................................................................................................2 - 12

Power PCB ASSY disassembly ................................................................................................2 - 12

Inlet assembly removal ....................................................................................................................2 - 12

FC jack removal ...............................................................................................................................2 - 13

Main motor assembly removal ........................................................................................................2 - 13

Main motor ASSY disassembly ................................................................................................2 - 13

Tension pulley assembly removal ....................................................................................................2 - 14

Tension pulley ASSY disassembly ............................................................................................2 - 14

Feed unit assembly removal ...........................................................................................................2 - 14

Upper shaft assembly removal .........................................................................................................2 - 15

Needle-presser unit removal ............................................................................................................2 - 15

Plate spring removal ........................................................................................................................2 - 15

Bobbin base assembly removal ........................................................................................................2 - 16

Bobbin base ASSY disassembly ................................................................................................2 - 16

Bobbin winder assembly removal ....................................................................................................2 - 16

Spool pin removal ............................................................................................................................2 - 17

Bobbin presser removal ...................................................................................................................2 - 17

Thread guide assembly removal ......................................................................................................2 - 17

Base plate rubber removal ...............................................................................................................2 - 18

Feed unit ..........................................................................................................2 - 19

Needle plate A assembly removal ...................................................................................................2 - 20

i

Page 4

Needle plate A ASSY disassembly ...........................................................................................2 - 20

Spring removal .................................................................................................................................2 - 20

Inner rotary hook bracket assembly removal ...................................................................................2 - 20

Feed dog removal .............................................................................................................................2 - 21

Vertical adjuster screw assembly removal .......................................................................................2 - 21

Outer rotary hook removal ...............................................................................................................2 - 21

Shaft supporter removal ...................................................................................................................2 - 21

Feed bar removal .............................................................................................................................2 - 22

Needle plate supporter shaft B removal ...........................................................................................2 - 22

Feed arm A assembly removal .........................................................................................................2 - 23

Feed arm B ASSY disassembly ................................................................................................2 - 23

Feed adjuster assembly removal ......................................................................................................2 - 24

Feed adjuster disassembly .........................................................................................................2 - 24

Vertical lever removal .....................................................................................................................2 - 24

FPM holder assembly removal ........................................................................................................2 - 25

FPM disassembly .......................................................................................................................2 - 25

Timing pulley D removal .................................................................................................................2 - 25

Lower shaft assembly removal ........................................................................................................2 - 26

Lower shaft bushing removal ..........................................................................................................2 - 26

Needle-presser unit .........................................................................................2 - 27

Threader hook assembly .................................................................................................................2 - 28

LED lamp left assembly removal ....................................................................................................2 - 28

BH switch assembly removal ..........................................................................................................2 - 28

Thread take-up lever and needle bar crank removal ........................................................................2 - 28

Thread take-up lever link removal ...................................................................................................2 - 29

Needle bar assembly removal ..........................................................................................................2 - 29

Needle bar ASSY disassembly ...................................................................................................2 - 29

Needle holder assembly removal .....................................................................................................2 - 30

Needle holder ASSY disassembly .............................................................................................2 - 31

Presser bar removal ..........................................................................................................................2 - 32

Z zigzag lever assembly removal .....................................................................................................2 - 32

Z zigzag lever disassembly .......................................................................................................2 - 33

Z zigzag camp removal ....................................................................................................................2 - 33

Shaft bushing removal .....................................................................................................................2 - 33

Presser foot lifter removal ................................................................................................................2 - 33

Thread release lever removal ...........................................................................................................2 - 34

Lock nut removal .............................................................................................................................2 - 34

Z pulse motor removal .....................................................................................................................2 - 34

Presser switch assembly removal ....................................................................................................2 - 34

3. Assembly .............................................................................................3 - 1

Main parts ..........................................................................................................3 - 2

Base plate rubber attachment .............................................................................................................3 - 3

Thread guide assembly attachment ....................................................................................................3 - 3

Bobbin presser attachment .................................................................................................................3 - 3

Spool pin attachment .........................................................................................................................3 - 4

Bobbin winder assembly attachment .................................................................................................3 - 5

Bobbin base assembly attachment .....................................................................................................3 - 6

Bobbin base ASSY assembly .......................................................................................................3 - 6

Plate spring attachment ......................................................................................................................3 - 6

Needle-presser unit attachment ..........................................................................................................3 - 7

Upper shaft assembly attachment ......................................................................................................3 - 8

Feed unit assembly attachment ..........................................................................................................3 - 9

Upper shaft and lower shat phase matching ......................................................................................3 - 9

Tension pulley assembly attachment ...............................................................................................3 - 10

ii

Page 5

Tension pulley ASSY assembly ................................................................................................3 - 10

Main motor assembly attachment ....................................................................................................3 - 10

Main motor assembly .................................................................................................................3 - 10

FC jack attachment ..........................................................................................................................3 - 11

Inlet assembly attachment ................................................................................................................3 - 11

Power PCB assembly attachment ....................................................................................................3 - 12

Power PCB ASSY assembly .....................................................................................................3 - 12

Main PCB assembly attachment ......................................................................................................3 - 13

Main PCB assembly ..................................................................................................................3 - 13

Upper cover thread guide attachment ..............................................................................................3 - 13

Base plate rubber attachment ...........................................................................................................3 - 14

SV keytop attachment ......................................................................................................................3 - 14

Front panel LCD attachment ............................................................................................................3 - 14

Button attachment ............................................................................................................................3 - 15

Operation PCB assembly and SSVR PCB assembly attachment ....................................................3 - 15

LED lamp attachment ......................................................................................................................3 - 16

Thread tension holder assembly and thread take-up holder B attachment ......................................3 - 16

Thread tension holder ASSY assembly .....................................................................................3 - 16

Thread take-up holder B assembly..............................................................................................3 - 17

Front cover attachment ....................................................................................................................3 - 18

Face plate A assembly attachment ...................................................................................................3 - 19

Face plate A ASSY assembly ...................................................................................................3 - 19

Needle plate B assembly attachment ...............................................................................................3 - 20

Needle plate B ASSY assembly .................................................................................................3 - 20

Base cover attachment .....................................................................................................................3 - 20

Accessory table attachment .............................................................................................................3 - 21

Feed unit ..........................................................................................................3 - 22

Lower shaft bushing attachment ......................................................................................................3 - 23

Lower shaft assembly attachment ....................................................................................................3 - 23

Timing pulley D attachment ............................................................................................................3 - 23

FPM holder assembly attachment ....................................................................................................3 - 24

FPM assembly ...........................................................................................................................3 - 24

Vertical lever attachment .................................................................................................................3 - 25

Feed adjuster assembly attachment ..................................................................................................3 - 26

Feed adjuster ASSY assembly ...................................................................................................3 - 26

Feed arm A assembly attachment ....................................................................................................3 - 27

Feed arm B ASSY assembly ......................................................................................................3 - 28

Needle plate supporter shaft B attachment ......................................................................................3 - 29

FPM gear engagement .....................................................................................................................3 - 30

Feed bar attachment .........................................................................................................................3 - 31

Shaft supporter attachment ..............................................................................................................3 - 31

Outer rotary hook attachment ..........................................................................................................3 - 32

Vertical adjuster screw assembly attachment ..................................................................................3 - 32

Feed dog attachment ........................................................................................................................3 - 32

Inner rotary hook bracket assembly attachment ..............................................................................3 - 33

Spring attachment ............................................................................................................................3 - 33

Needle plate A assembly attachment ...............................................................................................3 - 33

Needle plate A ASSY assembly ................................................................................................3 - 33

Needle-presser unit .........................................................................................3 - 34

Presser switch assembly attachment ................................................................................................3 - 35

Z pulse motor attachment ................................................................................................................3 - 35

Lock nut attachment .........................................................................................................................3 - 36

Thread release lever attachment ......................................................................................................3 - 36

Presser foot lifter attachment ...........................................................................................................3 - 37

Shaft bushing attachment .................................................................................................................3 - 37

iii

Page 6

Z zigzag cam attachment .................................................................................................................3 - 38

Z zigzag lever assembly attachment ................................................................................................3 - 39

Z zigzag lever ASSY assembly .................................................................................................3 - 39

Presser bar attachment .....................................................................................................................3 - 40

Needle holder assembly attachment ...............................................................................................3 - 41

Needle holder ASSY assembly .................................................................................................3 - 42

Needle bar assembly attachment ......................................................................................................3 - 43

Needle bar ASSY assembly .......................................................................................................3 - 43

Thread take-up lever link attachment ..............................................................................................3 - 43

Thread take-up lever and needle bar crank attachment ...................................................................3 - 44

BH switch assembly attachment ......................................................................................................3 - 44

LED lamp left assembly ..................................................................................................................3 - 45

Threader hook attachment ...............................................................................................................3 - 45

4. Adjustment ..........................................................................................4 - 1

Test mode ..........................................................................................................4 - 2

Timing belt tension adjustment ..........................................................................4 - 3

Motor belt tension adjustment ............................................................................4 - 4

Upper thread tension adjustment .......................................................................4 - 5

Three point needle drop adjustment ..................................................................4 - 6

Needle drop position adjustment for needle bar unit and rotary hook unit ........4 - 7

Needle interference left/right adjustment ...........................................................4 - 8

Needle bar rise adjustment ................................................................................4 - 9

Needle bar height adjustment ..........................................................................4 - 10

Needle interference adjustment .......................................................................4 - 11

Adjust the needle thread block ........................................................................4 - 12

Presser bar height and parallel adjustment .....................................................4 - 13

Inner rotary hook (bobbin thread) tension ........................................................4 - 14

Feed forward/reverse adjustment ....................................................................4 - 15

Bobbin winder (uneven bobbin winding and bobbin winding amounts) adjustment

.....4 - 16

BH lever switch position adjustment ................................................................4 - 17

Forward and back adjustment of needle and presser. .....................................4 - 18

Feed dog forward/reverse and left/right adjustment ........................................4 - 19

Feed dog height adjustment ............................................................................4 - 20

Inner rotary hook bracket position adjustment .................................................4 - 21

5. Special Instructions of Wiring ...........................................................5 - 1

iv

LED lamp right supply assy ...............................................................................5 - 2

Operation PCB supply assy and SSVR PCB supply assy .................................5 - 3

Operation PCB supply assy ...............................................................................5 - 4

Lead wire assy, FPM-LE ....................................................................................5 - 5

Page 7

Lead wire assy, Power-LE .................................................................................5 - 6

BH switch assy ..................................................................................................5 - 7

LED lamp left supply assy .................................................................................5 - 8

Needle bar unit ..................................................................................................5 - 9

Upper side of shutter cover ..............................................................................5 - 10

FC jack supply assy .........................................................................................5 - 11

6. Failure Investigation for Electronic Parts .........................................6 - 1

Error message list ..............................................................................................6 - 2

v

Page 8

vi

Page 9

1

Outline of Mechanism

Main Mechanisms .................................................... 1 - 2

Driveline ................................................................... 1 - 3

Positions of electronic components .......................... 1 - 4

Control system block diagram .................................. 1 - 5

Operation of other electronic components ............... 1 - 7

1 - 1

Page 10

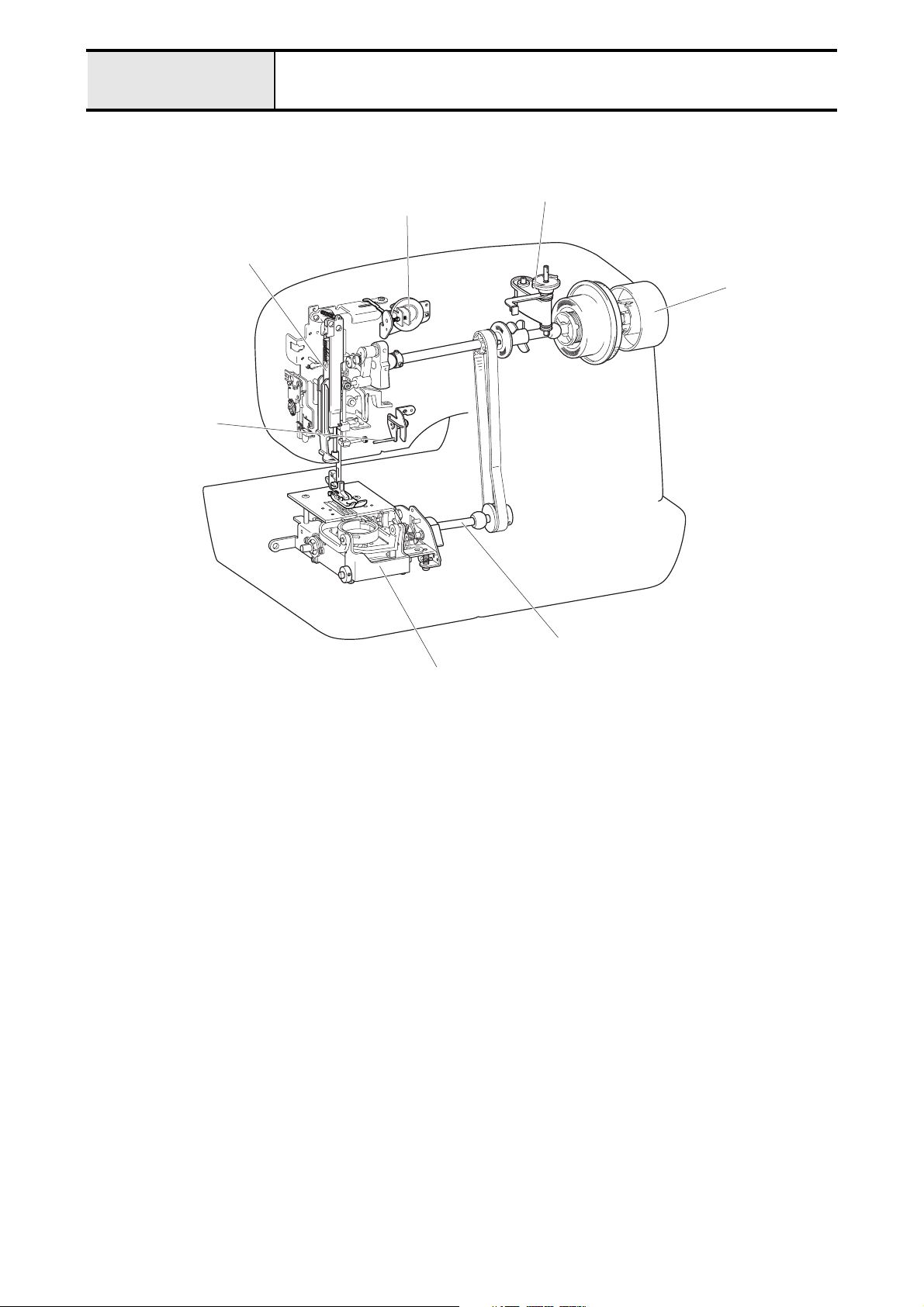

Outline of Mechanism Main Mechanisms

Sewing Machine

Thread guide mechanism

Needle bar /

Presser mechanism

Needle threader

mechanism

Bobbin winder mechanism

Upper shaft

mechanism

Feed / Rotary hook mechanism

Side feed mechanism

1 - 2

Page 11

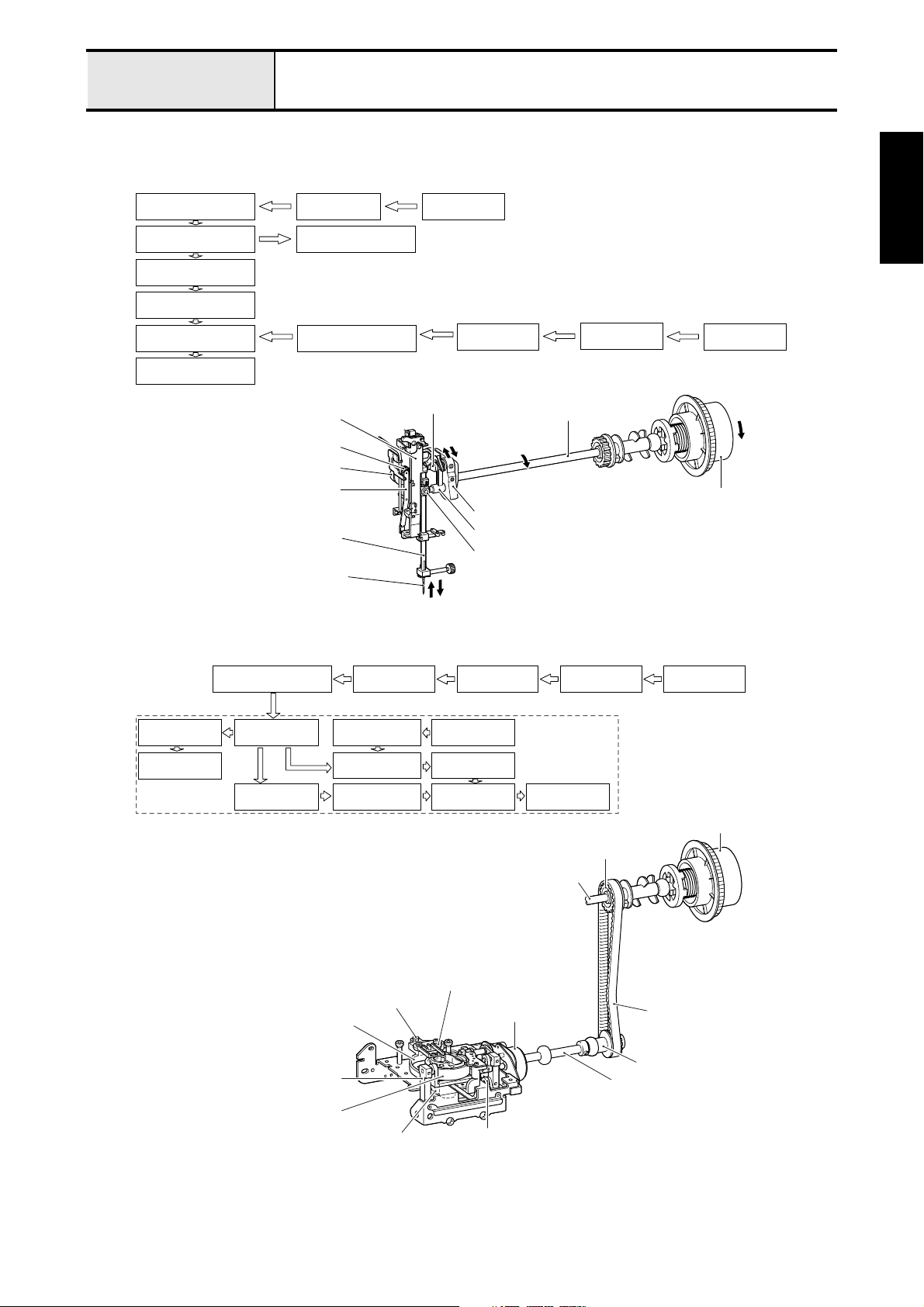

Outline of Mechanism Driveline

A) Up and down movement of needle bar, movement of thread take-up lever and zigzag

mechanism

Thread take-up

counter weight

Needle bar crank

Needle bar crank rod

Needle bar block

Needle bar

Needle

Needle bar supporter assy

Upper shaft

Thread take-up lever

Needle bar supporter

assy

Needle bar crank

Pulley

Z zigzag cam

Z pulse motor

Z zigzag lever

Needle bar

Needle

B) Movement of feed dog and rotary hook

Z zigzag lever

Z zigzag cam

Upper shaft

Thread take-up counter weight

Needle bar crank rod

Needle bar block

Z pulse motor

Pulley

Outline of

Mechanism

Lower shaft

gear

Outer rotary

hook

Timing pulley D Timing belt

Lower shaft

Vertical lever

Feed adjuster

Feed arm b

assy

Vertical

adjusting screw

Vertical adjusting screw

Feed bar

Feed arm A

Outer rotary hook

Lower shaft gear

Upper shaft

pulley

F pulse motor

Feed arm A

Feed bar Feed dog

Upper shaft

Feed dog

F pulse motor

Feed arm b assy

Upper shaft Pulley

Feed module

Pulley

Upper shaft pulley

Timing belt

Timing pulley D

Lower shaft

1 - 3

Page 12

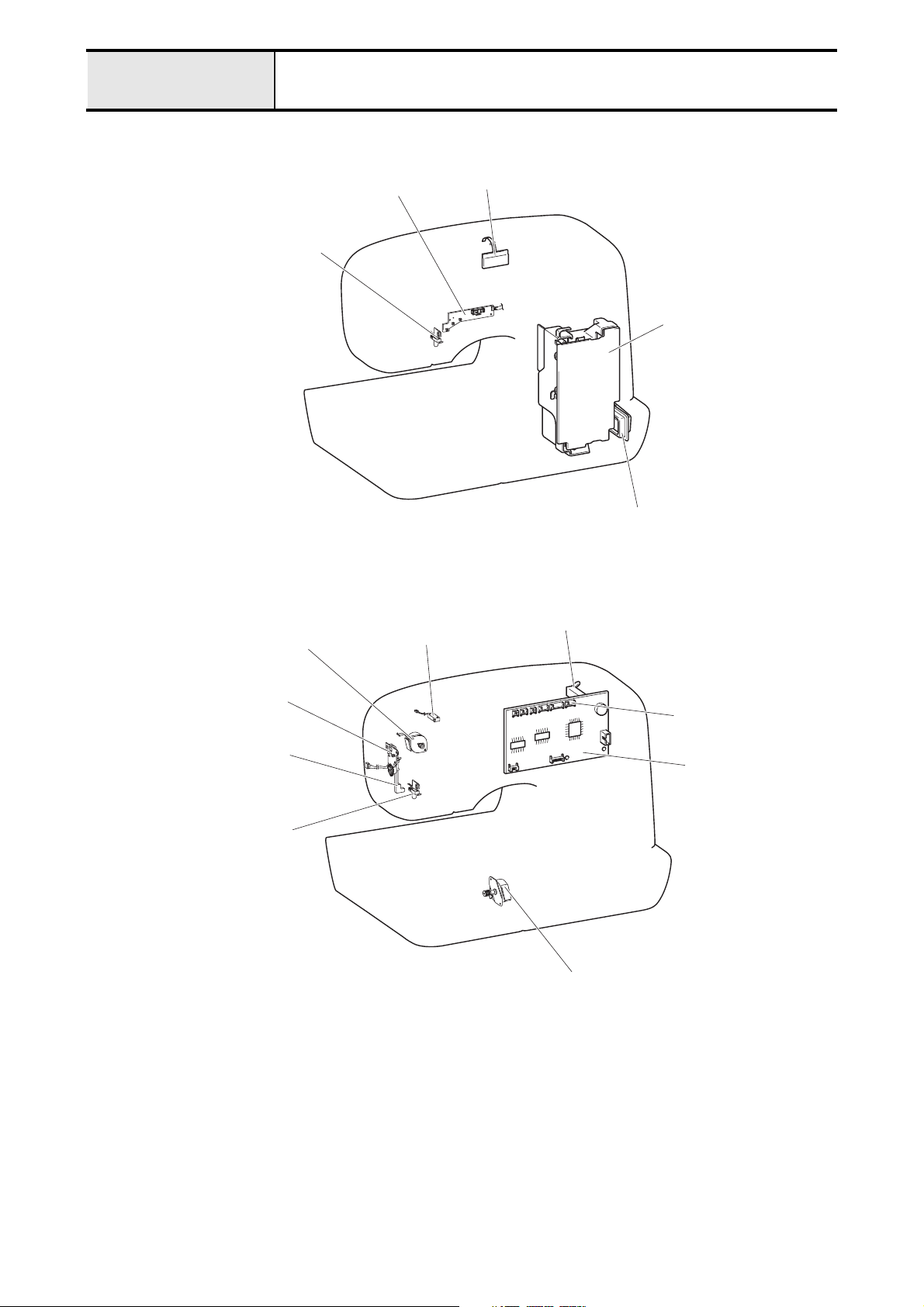

Outline of Mechanism Positions of electronic components

Sewing Machine

SS-VR PCB assy

LED Lamp SR assy

Z pulse motor

LCD PCB assy

Power PC assy

Power switch/Inlet assy

BWSW-S assy

PFSW-S assy

BH change switch assy

BH switch lever

LED Lamp SL assy

NP sensor

Main PCB assy

F pulse motor

1 - 4

Page 13

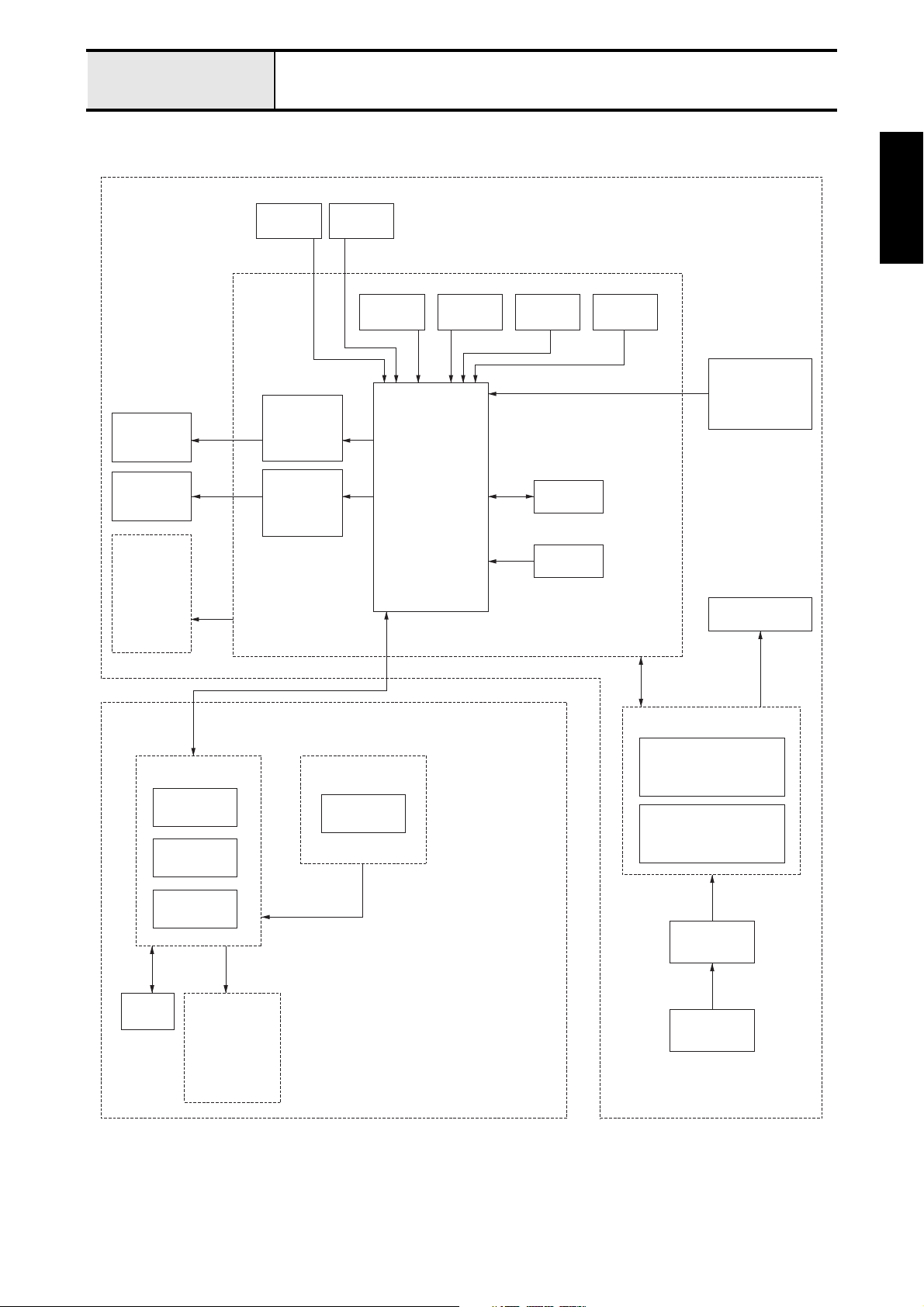

Outline of Mechanism Control system block diagram

CPS33 S34

ZPM

FPM

LED PCB

LIGHT

WHITE COLOR

LED (LEFT)

PFSW

MAIN PCB

ZPM

DRIVER

FPM

DRIVER

BHSW

BWSW

CPU

NP

SENSOR 2NPSENSOR 1SPSENSOR

EEPROM

RESET IC

FOOT

CONTROLLER

JACK

MAIN MOTOR

Outline of

Mechanism

FRONT

COVER

OPERATION PCB BK PCB

Z KEY X2

F KEY X2

PATTERN

SELECTION X4

LCD

LED PCB

LIGHT

WHITE COLOR

LED (RIGHT)

BK SW

POWER SUPPLY PCB

SWITCHING POWER

30V / 5V CIRCUIT

MAIN MOTOR

DRIVE CIRCUIT

POWER

SWITCH

INLET

1 - 5

Page 14

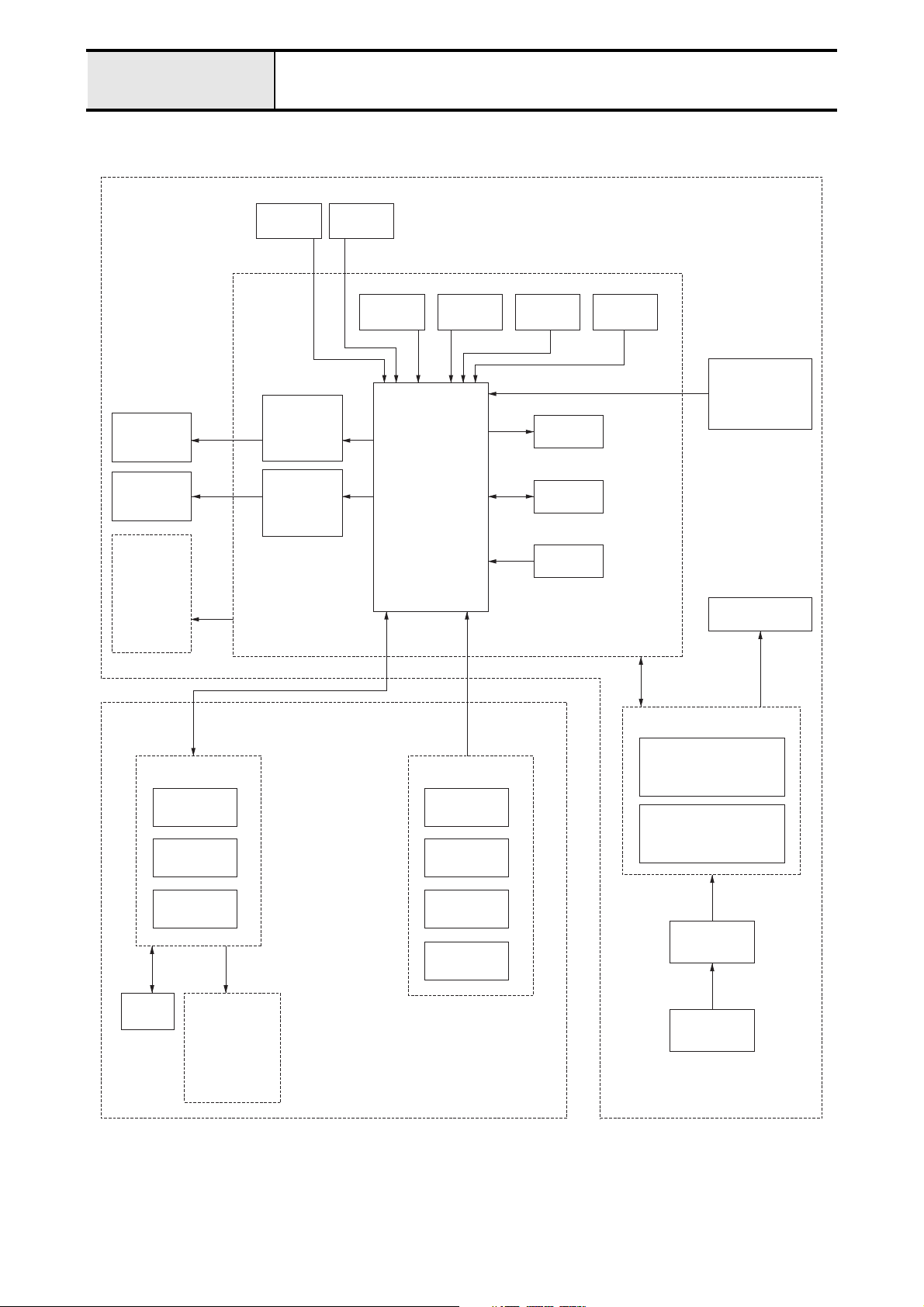

Outline of Mechanism Control system block diagram

CPS36 S37

ZPM

FPM

LED PCB

LIGHT

WHITE COLOR

LED (LEFT)

PFSW

MAIN PCB

ZPM

DRIVER

FPM

DRIVER

BHSW

BWSW

CPU

NP

SENSOR 2NPSENSOR 1SPSENSOR

FOOT

CONTROLLER

JACK

BUZZER

EEPROM

RESET IC

MAIN MOTOR

FRONT

COVER

OPERATION PCB

Z KEY X2

F KEY X2

PATTERN

SELECTION X4

LCD

LED PCB

LIGHT

WHITE COLOR

LED (RIGHT)

SSVR PCB

SS SW

BK SW

NP SW

SPEED VR

POWER SUPPLY PCB

SWITCHING POWER

30V / 5V CIRCUIT

MAIN MOTOR

DRIVE CIRCUIT

POWER

SWITCH

INLET

1 - 6

Page 15

Outline of Mechanism Operation of other electronic components

Start/Stop (SS) Switch . . . . . . . . . . . . . . . . . . . . . . Switch for starting and stopping the sewing machine. The machine

operates at a slow speed while the switch is being held down.

Reverse switch . . . . . . . . . . . . . . . . . . . . . . . This switch is for backtracking or ending a seam. If the switch is

pushed, it makes three to four stitches in that place and stops

automatically. If the switch is held down, it sews at a slow speed

in the reverse direction as long as the switch is held.

Raise needle switch . . . . . . . . . . . . . . . . . . . . This switch toggles the needle between the up and down positions.

Outline of

Mechanism

Operation PCB assembly

BH (buttonhole) switch . . . . . . . . . . . . . . . . This switch is for detecting the forward and rear ends of the

BH (button hole) lever switch . . . . . . . . . . . . . .

NP sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . This sensor detects the drive timing for the pulse motor for

Speed sensor. . . . . . . . . . . . . . . . . . . . . . . . . This sensor detects the rotational speed of the main motor. It

Presser switch. . . . . . . . . . . . . . . . . . . . . . . . This switch detects the vertical position of the presser foot lifter.

BW (bobbin winder) switch . . . . . . . . . . . . . When the bobbin thread is wound, this switch detects whether

. . . . . . . . . . . . . . . . Input for pattern selection and other conditions necessary for sewing.

buttonhole according to the BH presser and lever.

This switch detects whether the BH lever is up or down.

zigzagging and feed, the vertical stop position for the needle. It

detects the upper shaft angle of rotation using a shutter attached

to the upper shaft and an optical sensor.

detects the upper shaft rotational speed using a shutter attached

to the upper shaft and an optical sensor.

the bobbin is set for winding or not.

Foot control jack. . . . . . . . . . . . . . . . . . . . . . . This is the jack for plugging in the foot controller when it is used.

LED lamp SR assy., SL assy. . . . . . . . . . . . . White LED lamps for illuminating the work space.

1 - 7

Page 16

1 - 8

Page 17

2

Disassembly

Main parts........................................ 2 - 2

Feed unit........................................ 2 - 19

Needle-presser unit ....................... 2 - 27

With the CD-ROM version, click to start the movie clip.

2 - 1

Page 18

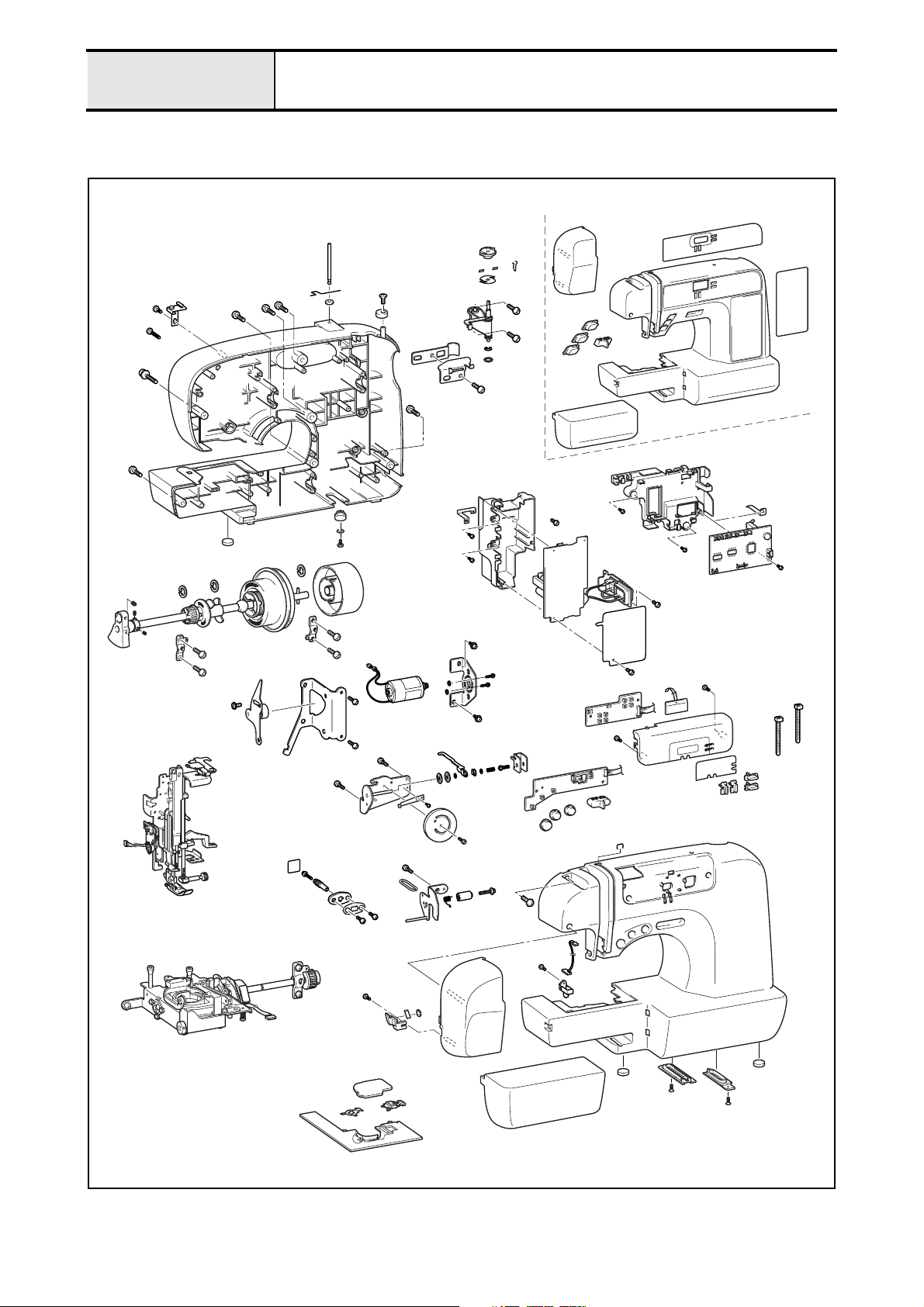

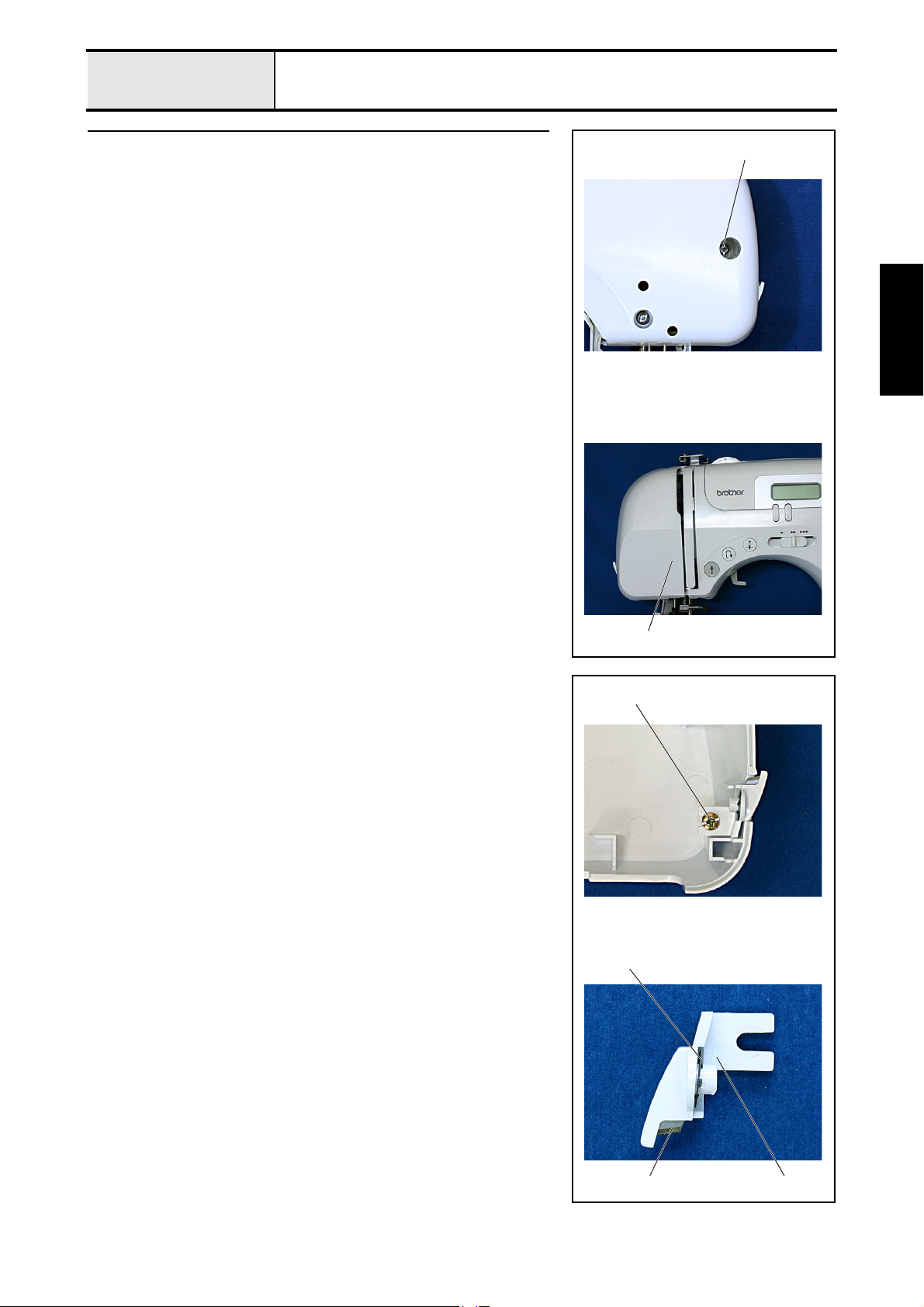

Main unit

Main parts location diagram

2 - 2

Page 19

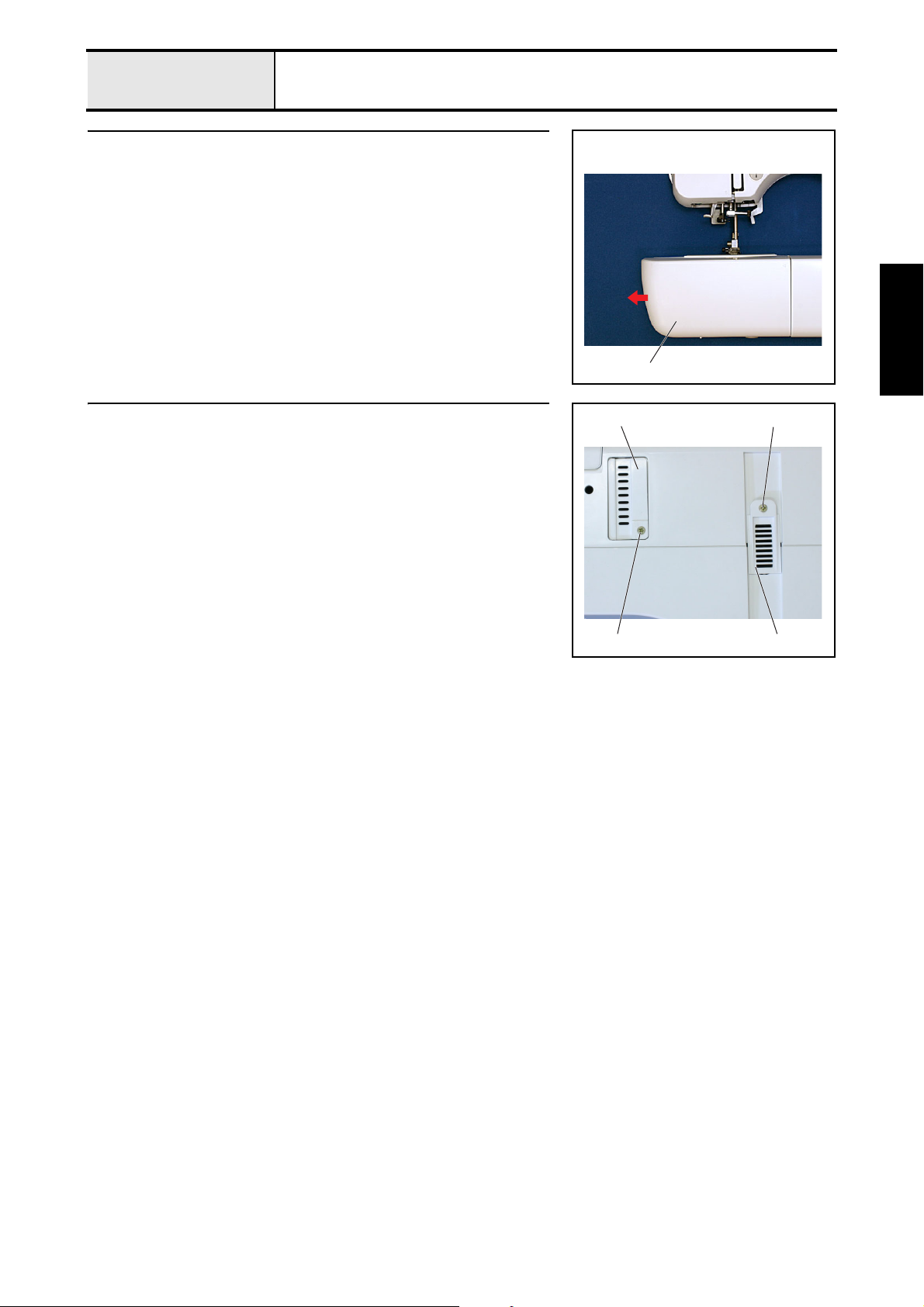

Main unit

1 Accessory table removal

1. Remove the accessory table 1.

Main parts

1

Disassembly

2 Bottom cover removal

1. Remove the screw 1, and then remove the base cover 1.

2. Remove the screw 2, and then remove base cover A 2.

12

1 1

2 - 3

Page 20

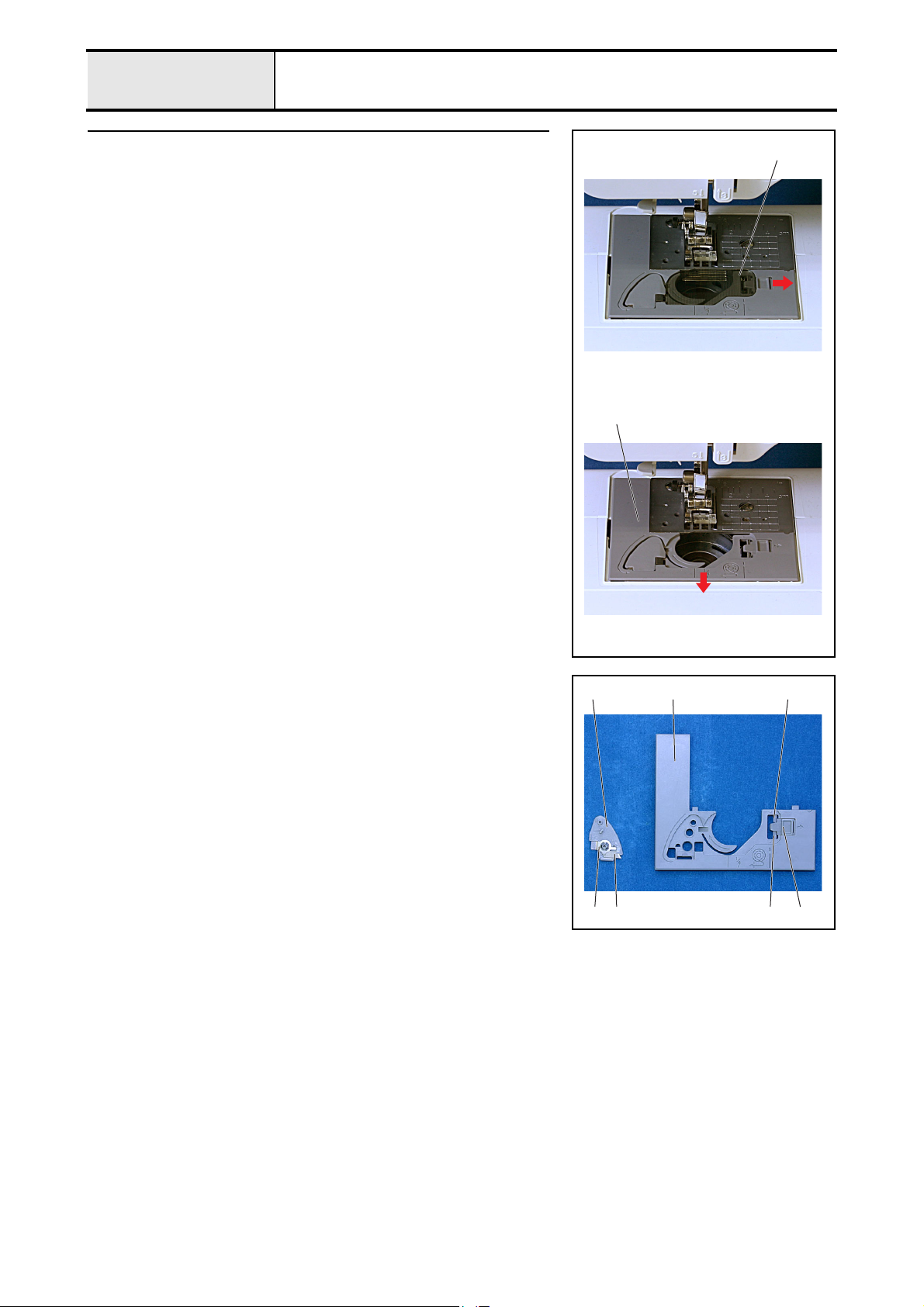

Main unit

Main parts

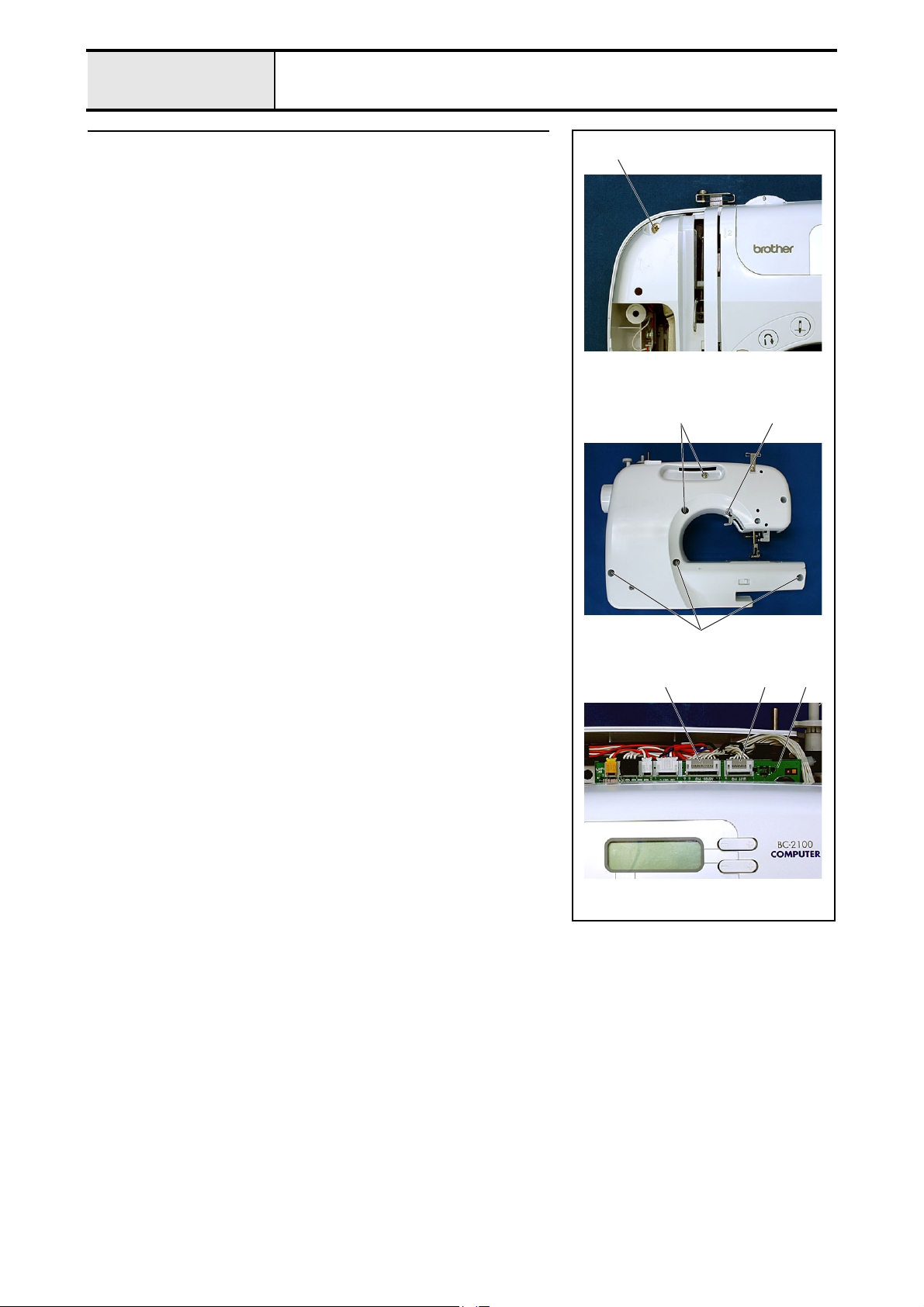

3 Needle plate B assembly removal

1. Remove the needle plate cover 1.

2. Remove the needle plate B assembly 2.

1

2

3-1 Needle plate B ASSY disassembly

1. Remove the cutter cover 2 from the needle plate B assembly 1.

2. Remove the spring plate 3 from the cutter cover 2, and then remove the

NT lower thread cutter 4.

3. Remove the 2 slide button hooks 5, and then remove the slide button 6.

21 5

6543

2 - 4

Page 21

Main unit

Main parts

4 Face plate assembly removal

1. Remove the screw 1, and then remove the face plate assembly 1.

1

Disassembly

4-1 Face plate A ASSY disassembly

1. Remove the screw 1, and then remove the cutter cover assembly 1.

2. Remove the CS retaining ring 2, and then remove the NT lower thread

cutter 3.

1

1

2

31

2 - 5

Page 22

Main unit

Main parts

5 Front cover removal

1. Remove screws 1 (front, 1 pc.), 2 (rear, 1 pc.), and 3 (rear, 5 pcs.), and

then remove the front cover.

*Key point

• Disconnect the SSVR PCB lead wire connector 1 and the

operation PCB lead wire connector 2 from the main PCB

assembly 3 located near the front cover.

1

3

2

3

213

2 - 6

Page 23

Main unit

Main parts

6

Thread tension holder assembly and thread take-up holder B removal

1. Remove the two screws 1.

2. Remove the thread guide A assembly 1.

3. Remove the screw 2.

4. Remove the thread guide B assembly 2.

6-1 Thread tension holder ASSY disassembly

1. Remove the screw 1, and then remove the notch spring 2 from the thread

tension holder assembly 1.

2. Remove the thread dial shaft 3.

*Key point

• Turn the dial clockwise until it stops.

3. Remove the thread tension dial 4 and the thread tension plate assembly

5.

4. Remove the spring 6, washer 7, tension disc washer 8, thread release

plate 9, washer 7, tension disc B ;, and then tension disc A A in this

order from the caulking shaft of the thread tension holder assembly 1.

5. Remove the thread tension adjusting screw B from the thread tension plate

assembly 5.

0

9

A

1

221

Disassembly

5

6

8

B

7

4

1

2

1

3

2 - 7

Page 24

Main unit

Main parts

6-2 Thread take-up holder B disassembly

1. Remove the screw 1.

2. Remove the thread catching spring case 2 from thread take-up holder B

1.

3. Remove the thread take-up spring 3 from the thread catching spring case

2.

4. Remove the thread guide wire 4 from thread take-up holder B 1.

1

32

1

2

7 LED lamp removal

1. Disconnect the LED lamp connector 2 from the operation PCB 1.

2. Remove the screw 1, and then remove the LED lamp 3.

4

1

12

2 - 8

1 3

Page 25

Main unit

Main parts

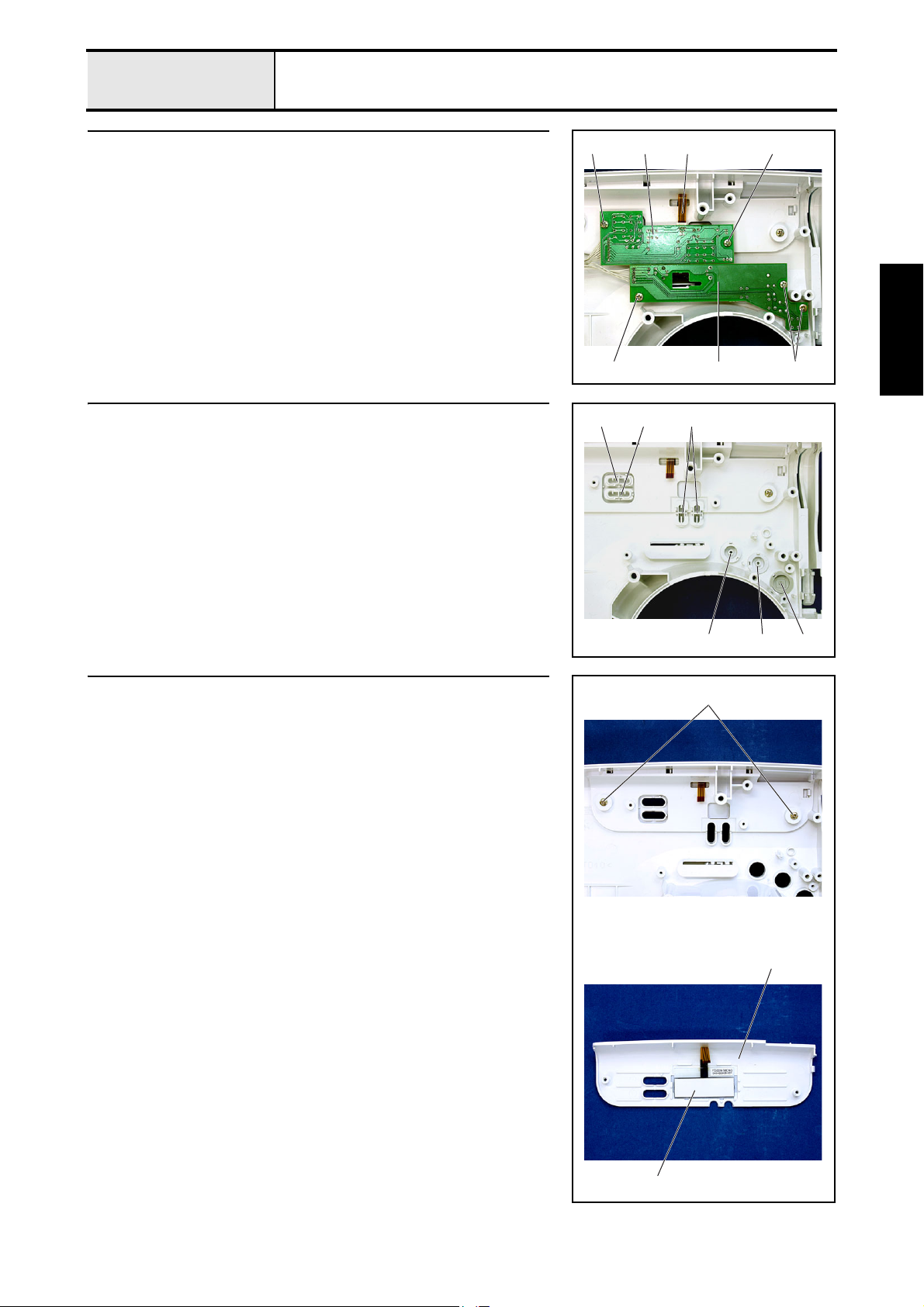

8

Operation PCB assembly and SSVR PCB assembly removal

1. Remove the 2 screws 1, and then remove the operation PCB assembly 1.

2. Disconnect the LCD cable 2 from the operation PCB assembly 1.

3. Remove the 3 screws 2, and then remove the SSVR PCB assembly 3.

*Key point

• Remove the bands (2 locations) securing the cords of the

operation PCB assembly 1 and the SSVR PCB assembly 3.

9 Button removal

1. Remove the 2 selecting buttons 1.

2. Remove manual button A 2 and manual button B 3.

3. Remove the SS button 4, the backstitching button 5, and the NP button

6.

1

12

23 1

3

1

22

Disassembly

10 Front panel and LCD removal

1. Remove the 2 screws 1.

2. Remove the front panel 1 and the LCD 2.

654

1

1

2

2 - 9

Page 26

Main unit

Main parts

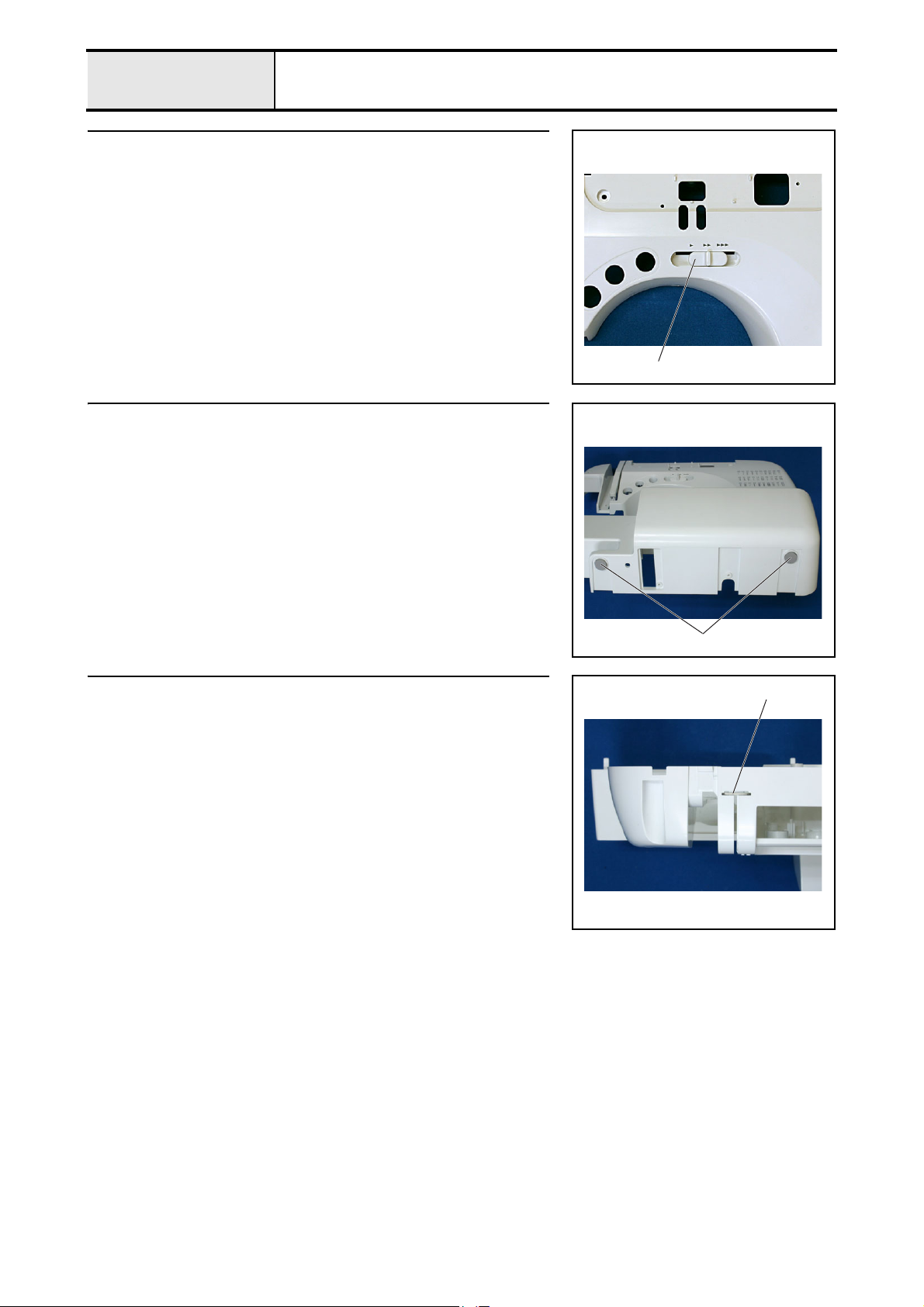

11 SV keytop removal

1. Remove the SV keytop 1.

*Key point

• Press the SV keytop hooks (2 locations) from the inside of the

front cover to remove the SV keytop.

12 Base plate rubber removal

1. Remove the 2 base plate rubbers 1.

1

13 Upper cover thread guide removal

1. Remove the upper cover thread guide 1.

1

1

2 - 10

Page 27

Main unit

Main parts

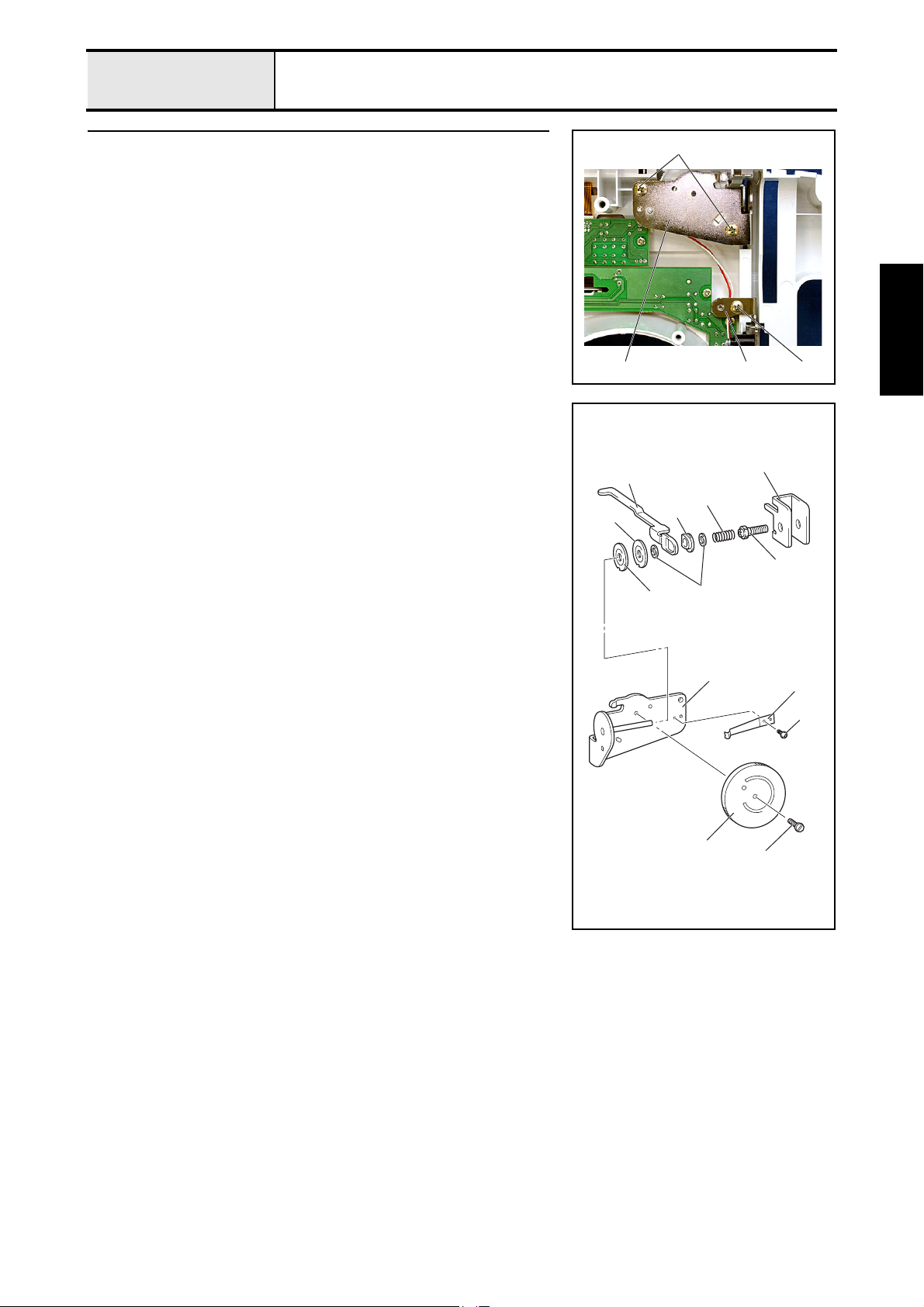

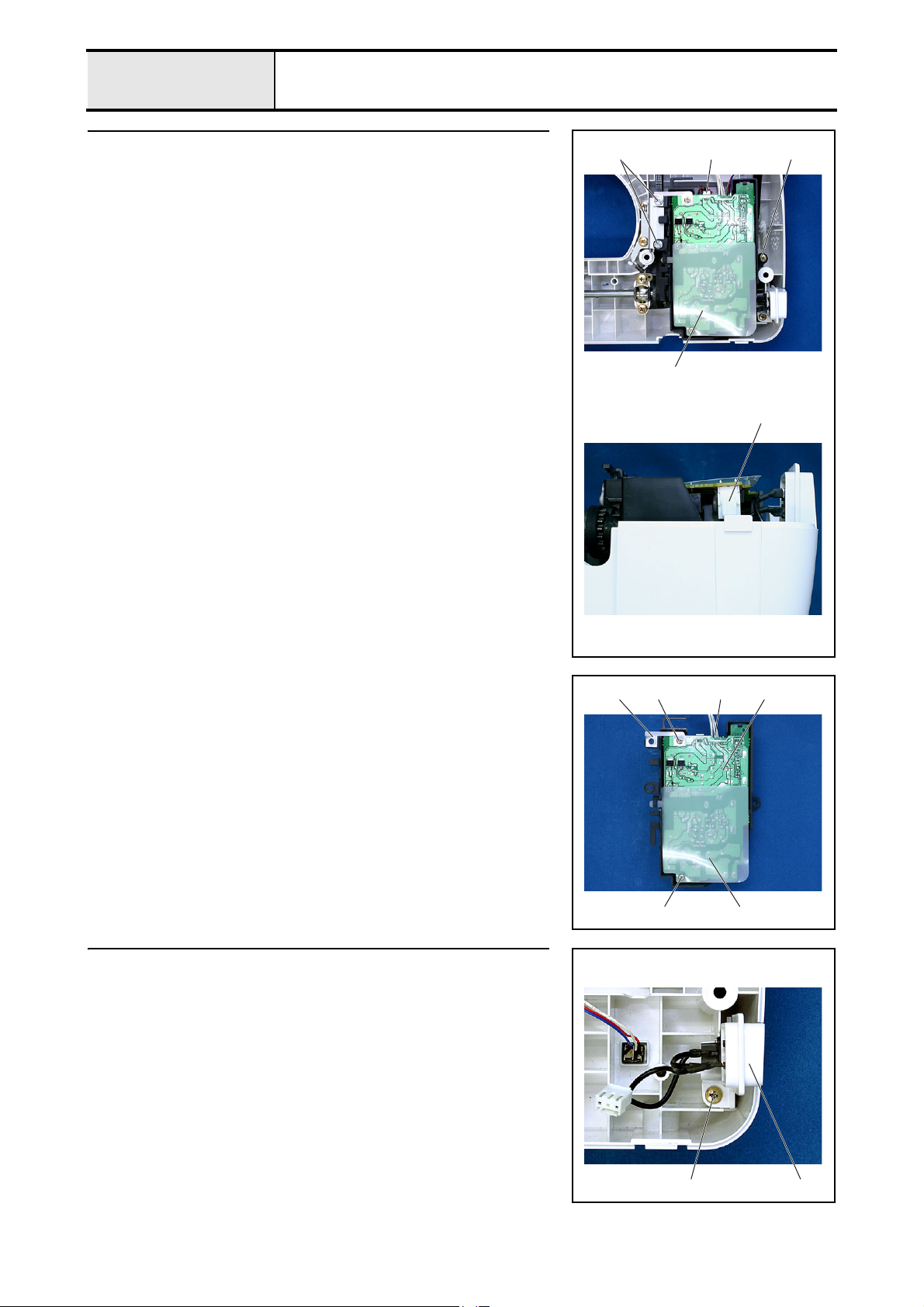

14 Main PCB assembly removal

1. Remove the 2 screws 1.

2. Remove the main PCB assembly 1.

14-1 Main PCB ASSY disassembly

1. Remove the screw 1.

2. Remove the main PCB plate spring 1, and then remove the main PCB 2.

1

1

1

Disassembly

1

2

2 - 11

Page 28

Main unit

Main parts

15 Power PCB assembly removal

1. Remove screws 1 and 2 (2 pcs. /1pc.), and then remove the power PCB

assembly 1.

2. Disconnect the main motor lead wire 2 and the inlet assembly connector

3.

*Key point

• Hold the hook on the inlet assembly connector 3 and pull it

out.

1 2 2

1

3

15-1 Power PCB ASSY disassembly

1. Disconnect the power lead wire assembly connector 1.

2. Remove the screw 1, and then remove the power plate spring 2.

3. Remove the screw 2, and then remove the insulator sheet 3.

4. Remove the power PCB 4.

16 Inlet assembly removal

1. Remove the screw 1, and then remove the inlet assembly 1.

121

2 3

4

2 - 12

1 1

Page 29

Main unit

Main parts

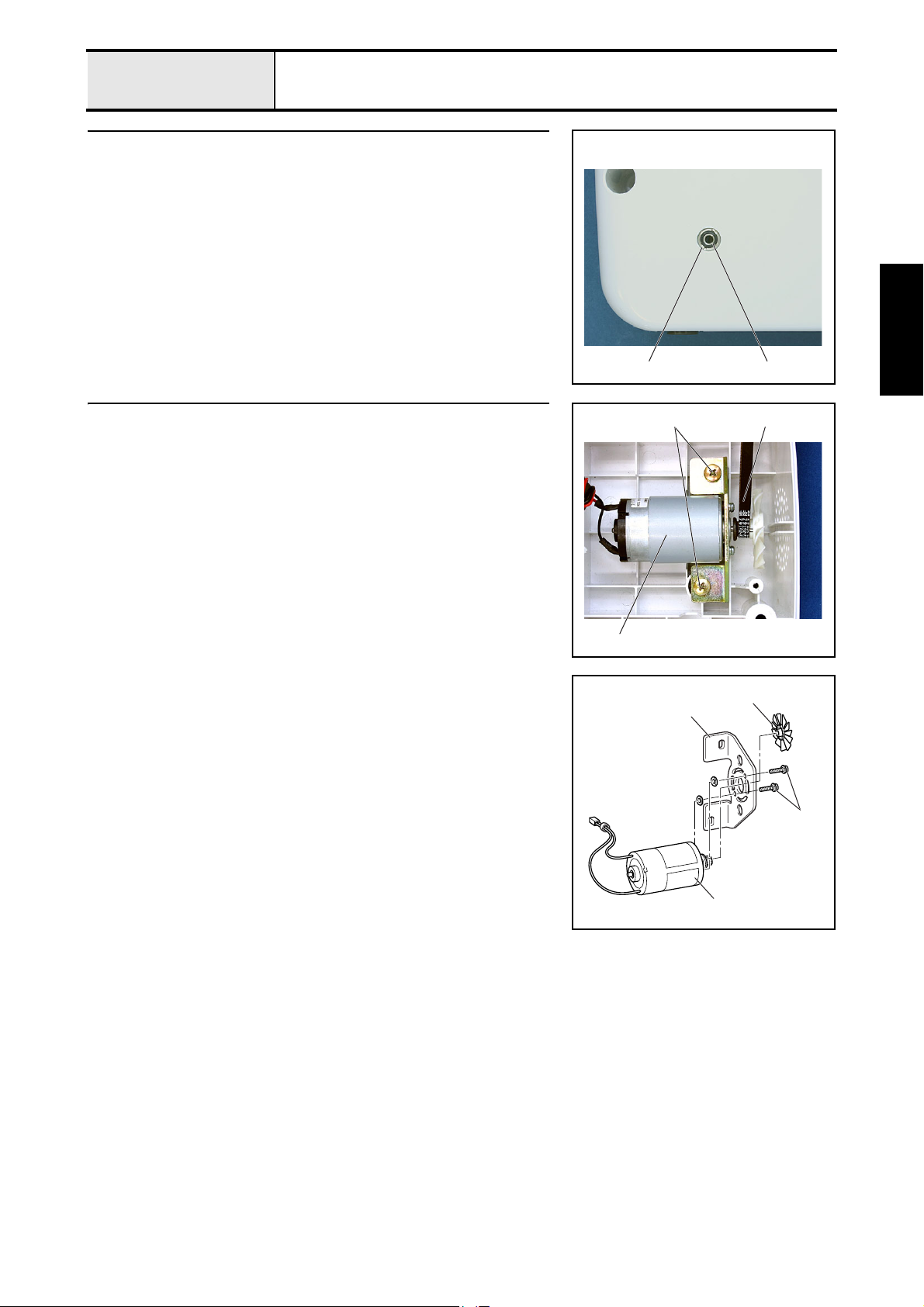

17 FC jack removal

1. Remove the jack nut 1, and then remove the FC jack assembly 2.

12

Disassembly

18 Main motor assembly removal

1. Remove the 2 screws 1, and then remove the main motor assembly 1.

2. Remove the motor belt 2 from the main motor assembly 1.

18-1 Main motor ASSY disassembly

1. Remove the motor fan 1.

2. Remove the 2 screws 1, and then remove the main motor 3 from the

motor holder 2.

1 2

1

1

2

1

3

2 - 13

Page 30

Main unit

Main parts

19 Tension pulley assembly removal

1. Remove spring .

2. Remove the 2 screws 1, and then remove the tension pulley assembly 1.

19-1 Tension pulley ASSY disassembly

1. Remove the screw 1, and then remove the tension pulley holder 2 from

the tension pulley assembly 1.

S09

1 1

S09

1

20 Feed unit assembly removal

1. Remove the 2 screws 1, and then remove the upper shaft bearing presser

1.

2. Remove the 2 screws 2, and then remove the feed unit assembly 2.

2

1

1

1

2

2 - 14

2

Page 31

Main unit

Main parts

21 Upper shaft assembly removal

1. Remove the screw 1.

2. Remove the 4 screws 2, and then remove the 2 upper shaft bearing

pressers 1.

3. Remove the upper shaft assembly 3 from the needle bar crank 2, and

then remove timing belt 420-5GT-6 4 and timing belt 372-2GT-6 5.

22 Needle-presser unit removal

1. Peel the label, and then remove the screw 1.

2. Remove the 2 screws 2, and then remove the needle-presser unit 1.

1 1 2 1

23 4 5

Disassembly

1

23 Plate spring removal

1. Remove the adjusting screw 1.

2. Remove the 2 screws 1, and then remove the adjusting plate 2 and the

plate spring 3.

1

2

1

213

2

3

1

2 - 15

Page 32

Main unit

Main parts

24 Bobbin base assembly removal

1. Remove the bobbin base assembly 2 from the bobbin winder shaft 1.

24-1 Bobbin base ASSY disassembly

1. Remove the bobbin thread cutter holder 2 from the bobbin base assembly

1, and then remove the NT lower thread cutter 3.

12

1

2

25 Bobbin winder assembly removal

1. Remove the screw 1, and then remove the bobbin winder shaft stopper 1

and the bobbin winder spring 2.

2. Remove the 2 screws 2, and then remove the bobbin winder assembly 3.

3. Remove the rubber ring 4 from the bobbin winder pulley.

3

1243

1

2

2 - 16

Page 33

Main unit

Main parts

26 Spool pin removal

1. Remove the spool pin spring 1 and pull out the spool pin 2.

2. Peel the spool pin stand 3.

2

1

Disassembly

3

27 Bobbin presser removal

1. Remove the screw 1, and then remove the bobbin presser 1.

28 Thread guide assembly removal

1. Remove the screw 1, and then remove the thread guide assembly 1.

11

1

1

2 - 17

Page 34

Main unit

Main parts

29 Base plate rubber removal

1. Remove the screw 1, and then remove the plain washer (M 3.5) 1 and

rubber cushion A 2.

2. Remove the base plate rubber 3.

3

1

12

2 - 18

Page 35

Main unit

Feed unit location diagram

Disassembly

2 - 19

Page 36

Main unit

Feed unit

1 Needle plate A assembly removal

1. Remove the 2 screws 1, and then remove the needle plate A assembly 1.

1-1 Needle plate A ASSY disassembly

1. Remove the screw 1, and then remove the F gear stopper plate 1.

2. Remove the screw 2, and then remove the stopper plate 2.

1 1

21

2 Spring removal

1. Remove the spring .

S10

3 Inner rotary hook bracket assembly removal

1. Remove the screw 1, and then remove the inner rotary hook bracket

assembly 1.

21

S10

2 - 20

11

Page 37

Main unit

Feed unit

4 Feed dog removal

1. Remove the 2 screws 1, and then remove the feed dog 1.

5 Vertical adjuster screw assembly removal

1. Remove spring .

2. Remove the M5 nut 1

3. Remove the vertical adjuster screw assembly 2.

S10

1

1

Disassembly

1

6 Outer rotary hook removal

1. Remove the screw 1, and then remove the outer rotary hook shaft 1,

washer 6 2, outer rotary hook assembly 3, spacer 4, and washer 6 2 .

7 Shaft supporter removal

1. Remove the 2 screws 1, and then remove the shaft supporter 1 and the

collar 2.

2

S04

2

1

3

4

1

2

11

1

2 - 21

Page 38

Main unit

Feed unit

8 Feed bar removal

1. Remove the retaining ring (CS4).

2. Remove the polyester slider 1, feed bar 2, and polyester slider 1 in this

order.

Start movie clip (CD-ROM version only)

9 Needle plate supporter shaft B removal

1. Remove nut 1 (M3) 1.

2. Remove needle plate supporter shaft B 2, and feed arm supporter 3.

*Key point

• Press the hook on the feed arm supporter 3 from the rear of

the feed bar to remove the supporter.

3. Remove the feed arm supporter 3 from the needle plate supporter shaft B

2.

2

1

Retaining ring CS4

2

1

2

3

3

2

2 - 22

3

Page 39

Main unit

Feed unit

10 Feed arm A assembly removal

1. Remove the screw 1, and then remove the set collar 1 and the thrust

wafer 2 in this order.

2. Remove the screw 2, and then remove the horizontal feed shaft 3.

3. Remove the feed arm A assembly 4 and the thrust wafer 2.

Start movie clip (CD-ROM version only)

10-1 Feed arm B ASSY disassembly

1. emove the retaining ring (CSTW-3.5), and then remove the feed arm B

assembly 1 and the polyester slider 2.

2. Remove the screw 1, and then remove the feed supporting plate 4 and

feed supporting plate B 5 from the feed arm B 3.

1

3

2

1

2

Retaining ring CSTW-3.5

4

2

Disassembly

1

2

3

4

15

2 - 23

Page 40

Main unit

Feed unit

11 Feed adjuster assembly removal

1. Remove the feed adjuster assembly 1, polyester slider 2, and spring

in this order.

Start movie clip (CD-ROM version only)

11-1 Feed adjuster disassembly

1. Remove spring , and then remove the F gear 2 from the feed adjuster

1.

S05

S06

S06

S05

1

2

12 Vertical lever removal

1. Remove the 4 retaining rings (E3).

2. Pull out the vertical feed shaft 1, and then remove the plain washer (L4)

2, spring , vertical lever 3, and drop knob 4.

Start movie clip (CD-ROM version only)

S07

12

S05

4

2

3

S07

Retaining ring E3

Retaining ring E3

1

Retaining ring E3

2 - 24

Page 41

Main unit

Feed unit

13 FPM holder assembly removal

1. Remove the screw 1, and then remove spring .

2. Remove the screw 2, and then remove the FPM holder assembly 1.

13-1 FPM disassembly

1. Remove the lead wire assembly (FPM-LE) 1.

2. Remove the 2 screws 1, and the remove the FPM 2.

3. Remove the rubber 3.

S08

211

S08

Disassembly

2

14 Timing pulley D removal

1. Remove the 2 screws 1, and then remove timing pulley D 1.

2. Remove the retaining ring (E6), and then pull out the lower shaft bushing

2.

1

Retaining ring E6

1

3

1

12

2 - 25

Page 42

Main unit

Feed unit

15 Lower shaft assembly removal

1. Remove the retaining ring (E6), and then remove the thrust washer 1.

2. Remove the lower shaft assembly 2.

*Key point

• Push down the lower shaft assembly 2 to remove it.

• Check that the gear does not contact the base plate.

3. Remove the 2 screws 1, and then remove the thrust wafer 1 and the set

collar 3.

1

Retaining ring E6

2

3

1

2

16 Lower shaft bushing removal

1. Remove the 3 screws 1.

2. Remove bushing presser B 1 and the lower shaft bushing 2.

2

1

1

1

2 - 26

Page 43

Main unit

Needle-presser unit location diagram

Disassembly

2 - 27

Page 44

Main unit

Needle-presser unit

1 Threader hook assembly

1. Pull the needle thread slider 1 toward you, and then remove the threader

hook assembly 2.

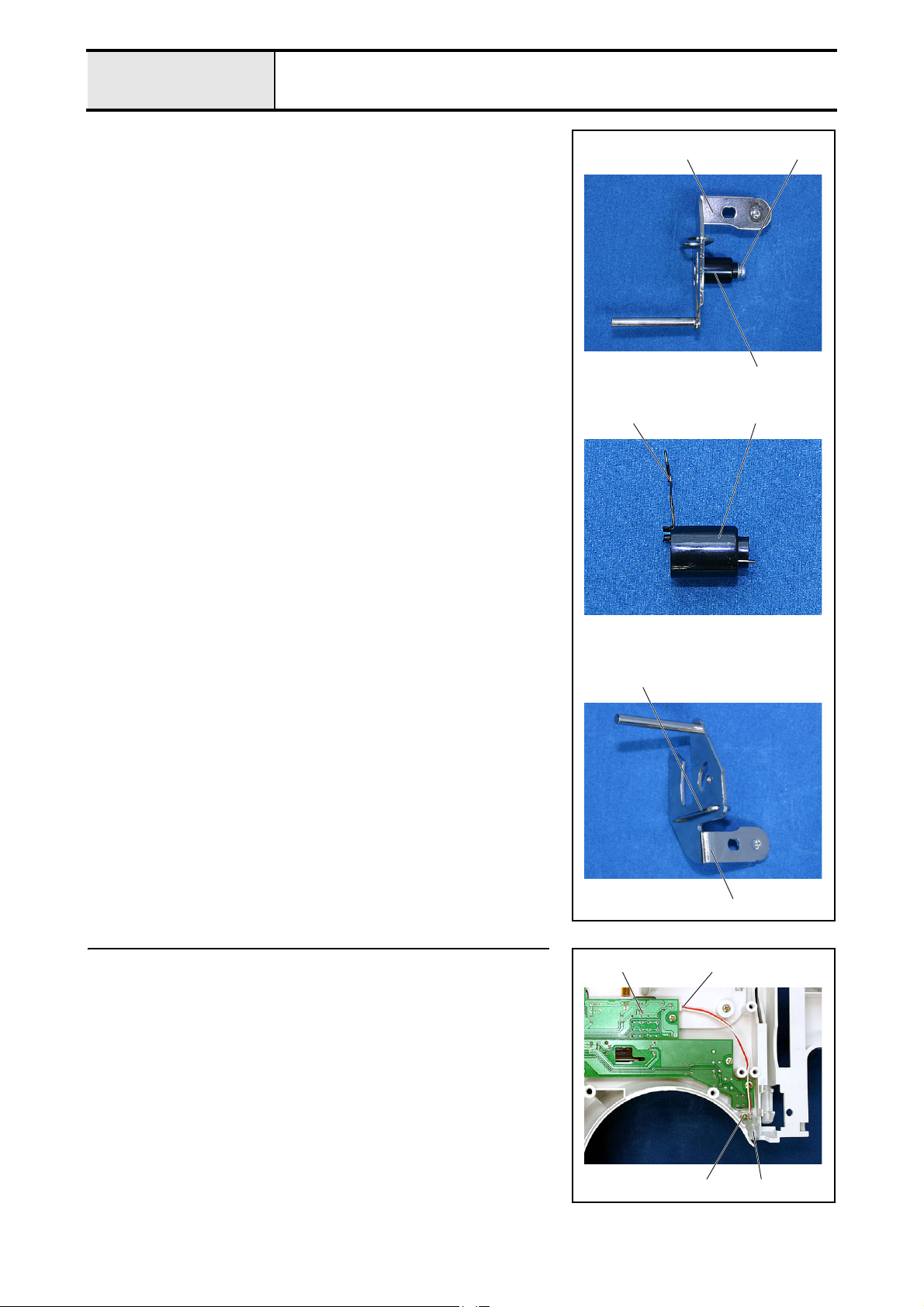

2 LED lamp left assembly removal

1. Remove the screw 1, and then remove the LED lamp left assembly 1.

1

2

1

3 BH switch assembly removal

1. Remove the screw 1, and then remove the BH switch assembly 1.

4 Thread take-up lever and needle bar crank removal

1. Remove the needle bar crank rod 1.

2. Remove the screw 1, and then remove the needle bar crank 3 from the

thread take-up lever 2.

1

1

1

1

2

3

2 - 28

1

Page 45

Main unit

Needle-presser unit

5 Thread take-up lever link removal

1. Remove the retaining ring (E5) and spring washer 1, and then remove the

thread take-up lever link 3 from the shaft 2.

2. Remove the screw 1, and then pull the shaft 2 out of the base holder.

Start movie clip (CD-ROM version only)

6 Needle bar assembly removal

1. Loosen the screws 1 and 2, and then pull the needle bar 1 down and

remove the needle thread block 2 and the needle bar block 3.

Start movie clip (CD-ROM version only)

1 2

Retaining ring E5

3

1232

1

Disassembly

6-1 Needle bar ASSY disassembly

1. Remove the screw 1, and then remove the needle block assy 1.

1

11

2 - 29

Page 46

Main unit

Needle-presser unit

7 Needle holder assembly removal

1. Remove springs and .

2. Remove the screw 1, and then remove the shaft 1, needle holder block

2, and needle holder assembly 3.

*Key point

• Pull out the needle holder assembly from the top.

Start movie clip (CD-ROM version only)

S02 S03

S02

2

1

1

S03

3

2 - 30

Page 47

Main unit

Needle-presser unit

7-1 Needle holder ASSY disassembly

1. Remove spring .

2. Remove the screw 1, and then remove the plate 1.

3. Remove the screw 2. Pull out the shaft 2, and then remove needle holder

shaft A 3.

4. Remove the screw 3, and then remove the zigzag adjusting nut 4.

Start movie clip (CD-ROM version only)

S01

1

3

2

S01

1

2

Disassembly

34

2 - 31

Page 48

Main unit

Needle-presser unit

8 Presser bar removal

1. Remove the screw 1. Pull out the presser bar 1, and then remove the

spring 2 and the presser bar clamp 3.

*Key point

• Remove the presser bar 1 and the presser feed holder

assembly 4.

2. Remove the J foot 5 from the presser feed holder assembly 4.

3. Remove the screw 2, and then remove the presser feed holder assembly

4.

Start movie clip (CD-ROM version only)

1

23

9 Z zigzag lever assembly removal

1. Remove the retaining ring (E4), and then remove the Z zigzag lever 1.

2. Remove the polyester slider 2.

Start movie clip (CD-ROM version only)

2154

Retaining ring E4

1

2 - 32

2

Page 49

Main unit

Needle-presser unit

9-1 Z zigzag lever disassembly

1. Pull out the Z zigzag cap 2 from the Z zigzag lever 1.

10 Z zigzag camp removal

1. Remove the retaining ring (E3), and then remove the Z zigzag cam 1.

2. Remove the rubber 2.

Start movie clip (CD-ROM version only)

1

Retaining ring E3

1

2

Disassembly

11 Shaft bushing removal

1. Remove the 2 screws 1, and then remove the shaft bushing 1.

12 Presser foot lifter removal

1. Remove the retaining ring (E4), and then remove the presser foot lifter 1.

2

1

1

Retaining ring E4

1

2 - 33

Page 50

Main unit

Needle-presser unit

13 Thread release lever removal

1. Remove the retaining ring (CS4), and then remove the thread release lever

1 and the spring 2.

14 Lock nut removal

1. Remove the lock nut 1, and then remove the screw 1.

2

Retaining ring CS4

11

1

15 Z pulse motor removal

1. Remove the 2 screws 1, and then remove the Z pulse motor 1.

16 Presser switch assembly removal

1. Remove the screw 1, and then remove the presser switch 1.

1

1

1

2 - 34

1

Page 51

3

Assembly

Main parts........................................ 3 - 2

Feed unit........................................ 3 - 22

Needle-presser unit ....................... 3 - 34

With the CD-ROM version, click to start the movie clip.

3 - 1

Page 52

Main unit

Main parts location diagram

3 - 2

Page 53

Main unit

Main parts

1 Base plate rubber attachment

1. Attach the base plate rubber 1 to the arm bed cover.

• Attach rubber cushion A 2 and the plain washer (M3.5) 3 to the

arm bed cover with the screw 1.

1

Taptite, Pan B

M3X12

Color; Silver

2 Thread guide assembly attachment

1. Attach the thread guide assembly 1 to the arm bed cover.

2. Temporarily tighten the screw 1.

*Key point

• Tighten the screw after performing "4 - 16 Bobbin winder

(uneven bobbin winding and bobbin winding amounts)

adjustment"

Torque

0.59 – 0.78 N

·m

1

1

32

1

Assembly

1

3 Bobbin presser attachment

1. Attach the bobbin presser 1 with the screw 1.

*Key point

• Place the bobbin presser with the smaller end facing the rear.

• Tighten the screw after performing "4 - 16 Bobbin winder

(uneven bobbin winding and bobbin winding amounts)

adjustment"

1

Giza Tite

4X12

Color; Gold

Taptite, Pan B (S/P washer)

M3X12

Color; Silver

Torque

0.88 – 1.18 N

Torque

0.39 – 0.78 N

·m

·m

1

11

3 - 3

Page 54

Main unit

Main parts

4 Spool pin attachment

1. Attach the spool pin stand 1 so that it does not protrude from the

attachment section.

2. Insert the spool pin 2 into the arm bed cover. Insert the pin from the

grooved end.

3. Attach the spool pin spring 3 to the arm bed cover.

*Key point

• Check that the spool pin 2 moves lightly.

1

2

3

3 - 4

Page 55

Main unit

Main parts

5 Bobbin winder assembly attachment

1. Attach the rubber ring 1 to the bobbin winder pulley.

2. Insert the bobbin winder shaft 2 into the groove on the arm bed cover, and

secure the shaft with the 2 screws 1.

3. Insert the BW switch lever 3 into the bobbin winder shaft stopper 4.

4. Set the bobbin winder spring 5 and then the bobbin winder shaft stopper

4 to the stopper attachment section of the arm bed cover, and secure them

with the screw 2.

*Key point

• Check that the bobbin winder spindle base passes over the

bobbin winder spring when the bobbin winder is switched.

• Check that the bobbin winder spring returns to the original

position when the bobbin winder is switched.

1

14

Assembly

1

2

Giza Tite

5X16

Color; Gold

Torque

1.18 – 1.57 N

·m

2

54 6

2

3 - 5

Page 56

Main unit

Main parts

6 Bobbin base assembly attachment

1. Attach the bobbin base assembly 1.

6-1 Bobbin base ASSY assembly

1. Attach the 2 NT lower thread cutters 2 and the bobbin thread cutter holder

3 to the bobbin base assembly 1.

1

1

3

7 Plate spring attachment

1. Attach the adjusting plate 1 and then the plate spring 2 from the inside of

the arm bed cover with the 2 screws 1.

2. Tighten the adjusting screw 3 to the plate spring 2.

1

Taptite, Bind B

M4X10

Color; Gold

Torque

0.78 – 1.18 N

·m

3

2

231

1

2

1

3 - 6

Page 57

Main unit

Main parts

8 Needle-presser unit attachment

1. Attach the needle-presser unit 1 to the arm bed cover with screws 1 and

2 (1 pc. and 2 pcs. respectively).

*Key point

• Lift the presser foot lifter 2 and insert it into the hole on the

arm bed cover 3 to set the needle-presser unit 1 to the

attachment position.

Start movie clip (CD-ROM version only)

1

Screw, Pan

M3X25

Color; Silver

Torque

0.78 – 1.18 N

1

2

Assembly

·m

2

Giza Tite

5X20

Color; Gold

Torque

1.18 – 1.57 N

·m

1

2

3 - 7

Page 58

Main unit

Main parts

9 Upper shaft assembly attachment

1. Pass timing belt 420-5GT-6 (timing belt) 2 and timing belt 372-2GT-6

(motor belt) 3 to the upper shaft assembly 1.

2. Attach the needle bar crank 5 to the thread take-up lever crank 4.

3. Set the upper shaft bushing 6 to the arm bed cover attachment position.

4. Attach the 2 upper shaft bearing pressers 78 with the 4 screws 1.

*Key point

• Check that the bobbin base assembly is on the left side.

• Attach the left upper shaft bearing presser 7 so that the

projecting part of 7 is positioned at the upper right. And attach

the right upper shaft bearing presser 8 so that the projecting

part of 8 is positioned at the lower shaft.

5. Apply 1 or 2 drops of OILER to the matching section of the upper shaft

and the upper shaft bushing.

6. Align the D-cut face of the needle bar crank with the screw hole on the

thread take-up lever crank, and tighten the screw 2.

Apply OILER to the matching section of the upper shaft

and the upper shaft bushing.

1 - 2 drops

XZ0206***

1

23

54

1

Giza Tite

5X16

Color; Gold

Torque

1.18 – 1.57 N

·m

6

7 1 8

66

D cut face

D cut face

2

2

3 - 8

2

Set Screw, Socket (FT)

M5X5

Color; Black

Torque

1.18 – 1.57 N

·m

Page 59

Main unit

Main parts

10 Feed unit assembly attachment

1. Fit the feed unit 1 to the arm bed cover attachment position, and secure

them with the 2 screws 1.

2. Fit the lower shaft bushing 2 to the arm bed cover attachment position, set

the lower shaft bearing presser 3, and secure them with the 2 screws 2.

*Key point

• Set the lower shaft bearing presser 3 so that the projecting

part of 3 is positioned at upper right.

3. Apply 1 or 2 drops of OILER to the matching section of the lower shaft 4

and the lower shaft bushing 2.

Apply OILER to the matching section of the lower shaft

and the lower shaft bushing.

1

Giza Tite

5X16

Color; Gold

1 - 2 drops

XZ0206***

Torque

1.18 – 1.57 N

1

1

2

Assembly

·m

2

Giza Tite

5X16

Color; Gold

Torque

1.18 – 1.57 N

11 Upper shaft and lower shat phase matching

1. Rotate the upper shaft 1 until the trench on the upper shaft pulley 2 is at

the front.

2. Turn the lower shaft 3 to the point where the mark on the outer rotary

hook 4 is at the front, the larger feed cam 5 is at the rear, and the hole on

the lower shaft 6 is at the top.

3. Pull the timing belt 7 and hang it over the timing pulley D 8.

Start movie clip (CD-ROM version only)

·m

8

1

4

2

24

7

3

3

7

6

5

3

3 - 9

Page 60

Main unit

Main parts

12 Tension pulley assembly attachment

1. Attach the tension pulley assembly 1 to the arm bed cover with the 2

screws 1.

2. Attach spring .

*Key point

• Perform "4 - 3 Timing belt tension adjustment.

1

S09

12-1 Tension pulley ASSY assembly

1. Align the boss 3 on the tension pulley holder 2 with the hole on the

tension pulley assembly 1, and secure the tension pulley assembly with

the screw 1.

S09

19.8

Giza Tite

5X16

Color; Gold

5

Torque

1.18 – 1.57 N

SPRING

XC2538***

1 1

·m

S09

2

1

1

Screw, Pan (S/P washer)

M4X8DA

Color; Silver

Torque

1.18 – 1.57 N

13 Main motor assembly attachment

1. Hang the motor belt 2 over the main motor assembly 1.

2. Attach the main motor assembly 1 to the arm bed cover assembly with the

2 screws 1.

*Key point

• Perform "4 - 4 Motor belt tension adjustment.

1

Giza Tite

5X16

Color; Gold

13-1 Main motor assembly

1. Attach the main motor 2 to the motor holder 1 with the 2 screws 1.

2. Attach the motor fan 3.

Torque

0.29 – 0.49 N

·m

·m

3

1

1 2

1

3

1

3 - 10

1

Screw, Pan (S/P washer)

M3X8DB

Color; Silver

Torque

0.59 – 0.78 N

·m

1

2

Page 61

Main unit

Main parts

14 FC jack attachment

1. Insert the FC jack assembly 1 from the inside of the arm bed cover

assembly.

2. Attach the jack nut 2 from the outside of the arm bed cover assembly.

*Key point

• Pass the lead wire of the FC jack assembly 1 through the

rear of the main motor.

15 Inlet assembly attachment

1. Attach the inlet assembly 1 with the screw 1.

21

Assembly

1

Taptite, Bind B

M4X10

Color; Gold

Torque

0.78 – 1.18 N

·m

1 1

3 - 11

Page 62

Main unit

Main parts

16 Power PCB assembly attachment

1. Attach the power unit assembly 1 with screws 1 and 2 (1 pc. and 2 pcs.

respectively).

*Key point

• Attach the power plate spring 3 to the upper screw 2.

2. Attach the main motor lead wire assembly connector 4 to the power PCB

2.

3. Attach the inlet assembly connector 5 to the power PCB 2.

1

Taptite, Bind B

M4X10

Color; Gold

Torque

0.78 – 1.18 N

21243

1

52

·m

2

Screw, Bind

M4X8

Color; Silver

Torque

1.18 – 1.57 N

16-1 Power PCB ASSY assembly

1. Attach the power PCB 2 and the insulator sheet 3 to the insulation cover

1 with the screw 1.

2. Attach the power plate spring 1 with the screw 2.

1

2

Taptite, Bind B

M3X8

Color; Gold

Torque

0.39 – 0.78 N

·m

·m

1

24

1 3

2

3 - 12

Page 63

Main unit

Main parts

17 Main PCB assembly attachment

1. Insert the bobbin winder switch of the main PCB 2 into the slot on the

bobbin winder stopper plate 1, and then insert the boss on the arm bed

cover into the screw hole on the shutter cover 3.

2. Main PCB assembly 4 with the 2 screw 1.

*Key point

• Refer to "5 - 1 Special Instructions of Wiring" for wiring details.

1

3

2

4

Assembly

1

Taptite, Bind B

M4X10

Color; Gold

Torque

0.78 – 1.18 N

17-1 Main PCB assembly

1. Attach the main PCB plate spring 2 and the main PCB 3 to the shutter

cover 1 with the screw 1.

1

Taptite, Bind B

M3X8

Color; Gold

Torque

0.39 – 0.78 N

18 Upper cover thread guide attachment

1. Attach the upper cover thread guide 1.

·m

·m

1

12

1 3

1

3 - 13

Page 64

Main unit

Main parts

19 Base plate rubber attachment

1. Attach the 2 base rubber plates 1.

20 SV keytop attachment

1. Attach the SV keytop 1.

1

21 Front panel LCD attachment

1. Attach the LCD 1 and the front panel 2 with the 2 screws 1.

*Key point

• Insert the LCD cable 3 into the hole in the upper section of

the front cover.

1

2

1

1

3 - 14

1

Taptite, Bind B

M3X8

Color; Gold

Torque

0.39 – 0.78 N

·m

3

Page 65

Main unit

Main parts

22 Button attachment

1. Attach the SS button 1, the backstitching button 2, and the NP button 3.

2. Attach manual button A 4, manual button B 5, and 2 selecting buttons

6.

123

456

45 6

Assembly

23

Operation PCB assembly and SSVR PCB assembly attachment

1. Attach the operation PCB assembly 1 with the 2 screws 1.

2. Attach the SSVR PCB assembly 2 with the 3 screws 2.

*Key point

• Insert the speed dial of the SSVR PCB assembly 3 into the

slot on the SV keytop 4.

3. Connect the LCD cable 5 to the operation PCB assembly 1.

*Key point

• Bind the operation PCB cord and SSVR PCB cord, and secure

these with two bands. <Refer to "5 - 1 Special Instructions of

Wiring" for wiring details.>

1

321

15

2

3

1

22

1

1

2

Taptite, Bind B

M3X8

Color; Gold

Torque

0.39 – 0.78 N

·m

4

2

3 - 15

Page 66

Main unit

Main parts

24 LED lamp attachment

1. Attach the LED lamp 1 with the screw 1.

2. Attach the LED lamp connector 2 to the operation PCB 3.

*Key point

• Secure the LED lamp lead wire 1 to the rib on the front cover.

• <Refer to "5 - 1 Special Instructions of Wiring" for wiring

details.>

1

25

Thread tension holder assembly and thread take-up holder B attachment

1. Attach the thread tension holder assembly 1 with the 2 screws 1.

2. Attach the thread take-up holder B 2 with the screw 2.

*Key point

• Insert the wire of the thread tension holder assembly B 2 into

the groove on the front cover, and then insert the boss into the

hole on the front cover.

Taptite, Bind B

M3X8

Color; Gold

Torque

0.39 – 0.78 N

·m

32

1 1

1

1

2

Taptite, Bind B

M4X14

Color; Gold

Torque

0.78 – 1.18 N

25-1 Thread tension holder ASSY assembly

1. Attach tension disc A 2, tension disc B 3, washer 4, thread release plate

5, tension disc washer 6, washer 7, and spring 8 in this order to the

caulking shaft of the thread tension holder assembly 1.

2. Attach the thread tension adjusting screw ; to the thread tension plate 9.

3. Engage the ridge of the thread tension plate 9 with the groove on the

thread tension dial A, insert them into the caulking shaft of the thread

tension holder assembly 1, and secure them with the tension dial shaft B.

4. Attach the notch spring C to the thread tension holder assembly 1 with

the screw 1.

*Key point

• Hold the notch spring with the ridge side up, and insert it into

the lower thread tension dial A. Align the round hole with the

boss on thread tension holder assembly 1.

·m

3

5

2

6

4

8

1

7

221

9

;

C

1

3 - 16

1

Screw, Pan

M3X4

Color; Silver

Torque

0.78 – 1.18 N

·m

A

B

Page 67

Main unit

Main parts

25-2 Thread take-up holder B assembly

1. Attach the wire 2 to thread take-up holder B assembly 1.

2. Insert the tip of the thread take-up spring 3 into the second hole from the

bottom on the thread catching spring case 4, secure 9.7 to 10.7 mm from

the top of the groove on thread take-up holder B assembly 1 to the ridge

of the thread hanging section on the thread take-up spring, and attach the

thread take-up spring to thread take-up holder B assembly 1 with the

screw 1.

*Key point

• Attach the thread hanging section on the thread take-up spring

to the section between the ribs of the thread catching spring

case.

• Insert the 2 ribs of the thread catching spring case into the slot

on thread take-up holder B 1.

2

1

34

Assembly

1

Screw, Pan (S/P washer)

M3X18DA

Color; Silver

Torque

0.59 – 0.78 N

·m

1

9.7-10.7mm

2

4

3

1

4

3 - 17

Page 68

Main unit

Main parts

26 Front cover attachment

1. Connect the SSVR PCB connector 1 and the operation PCB connector 2

to the main PCB 3.

*Key point

• Pass the lead wires to the hook section of the shutter cover 4

while preventing them from lifting or disconnecting.

<Refer to "5 - 1 Special Instructions of Wiring" for wiring

details.>

2. Attach the front cover to the arm bed cover with screws 1 (front, 1 pc.), 2

(rear, 1 pc.), and 3 (rear, 5 pcs.).

213

1

1

2

3

Giza Tite

4X12

Color; Gold

Giza Tite

4X25

Color; Gold

Giza Tite

5X16

Color; Gold

Torque

0.88 – 1.18 N

Torque

0.88 – 1.18 N

Torque

1.18 – 1.57 N

·m

·m

·m

3

2

3

3 - 18

Page 69

Main unit

Main parts

27 Face plate A assembly attachment

1. Attach the face plate A assembly 1 with the screw 1.

1

1

Assembly

1

Taptite, Cup P

M4X20

Color; Silver

Torque

0.78 – 1.18 N

27-1 Face plate A ASSY assembly

1. Attach the NT lower thread cutter 2 to the cutter cover 1, and then attach

the CS retaining ring 3.

*Key point

• Insert the narrow edge of the NT lower thread cutter 2 into

the cutter cover 1 first.

• Align the tab of the CS retaining ring with the groove on the

shaft of the cutter cover 1.

2. Attach the cutter cover assembly to face plate A 4 with the screw 1.

·m

3

21

1

1

Taptite, Bind B

M3X8

Color; Gold

Torque

0.39 – 0.78 N

·m

3 - 19

Page 70

Main unit

Main parts

28 Needle plate B assembly attachment

1. Attach the needle plate B assembly 1.

2. Attach the needle plate cover 2 to the needle plate B assembly 1.

1

2

28-1 Needle plate B ASSY assembly

1. Attach the slide button 1 to needle plate B 2.

2. Attach the NT lower thread cutter 3 and the spring plate 4 to the cutter

cover 5.

3. Attach the cutter cover to needle plate B 2.

29 Base cover attachment

1. Attach the base cover 1 with the screw 1.

2. Attach base cover A 2 with the screw 2.

52

134

12

3 - 20

1

Screw, Flat B

M3X8

Color; Gold

Torque

0.39 – 0.78 N

·m

2 1

Page 71

Main unit

Main parts

30 Accessory table attachment

1. Attach the accessory table 1.

1

Assembly

3 - 21

Page 72

Main unit

Feed unit location diagram

3 - 22

Page 73

Main unit

Feed unit

1 Lower shaft bushing attachment

1. Attach the lower shaft bushing 2 and bushing presser B 3 to the base

plate assembly 1 with the 3 screws 1.

1

Taptite, Bind B

M3X6

Color; Gold

Torque

0.39 – 0.78 N

2 Lower shaft assembly attachment

1. Temporarily tighten the 2 screws 1 to the set collar 1, and attach the set

collar to the lower shaft assembly 2.

*Key point

• Set the set collar with the machined surface facing out.

2. Insert the thrust washer 3 into the lower shaft assembly 2, and attach

them to the lower shaft bushing 4.

3. Insert the thrust washer 5 into the lower shaft assembly 2, and attach the

retaining ring (E6).

4. Push the lower shaft assembly 2 from the retaining ring side, move the set

collar 1 to the lower shaft bushing 4, and then secure them with the 2

screws 1.

Start movie clip (CD-ROM version only)

·m

3

2

1

2

1

1

31

Assembly

1

Set Screw, Socket (CP)

M4X4

Color; Black

Torque

0.78 – 1.18 N

·m

3 Timing pulley D attachment

1. Insert the upper shaft bushing 2 into the lower shaft assembly 1, and

attach the retaining ring (E6).

Insert the timing pulley D 3 into the lower shaft assembly 1, and secure

them with the 2 screws 1.

1

Set Screw, Socket (CP)

M5X5

Color; Black

Torque

1.18 – 1.57 N

·m

4

5

Retaining ring E6

1

Retaining ring E6

2

2

3

1

3 - 23

Page 74

Main unit

Feed unit

4 FPM holder assembly attachment

1. Insert the FPM holder assembly 1 into the feed adjuster shaft 3 of the

base plate assembly 2.

2. Insert spring between the base plate assembly 2 and the FPM holder

assembly 1, and secure them with the screw 1.

*Key point

• Tighten the screw 1 until the tip of the screw protrudes 7 mm.

3. Attach the screw 2.

Start movie clip (CD-ROM version only)

1

2

S08

Bolt, Socket

M4X25

Color; Black

Screw

M3X8

Color; Black

Torque

0.59 – 0.78 N

·m

2

S08

1

21

23

S08

21

5

SPRING

XC2537***

4-1 FPM assembly

1. Attach the rubber 2 to the caulking shaft of the FPM holder assembly 1.

2. Attach the FPM 3 with the 2 screws 1.

3. Apply 1 or 2 drops of FBK OIL RO 100 to the shaft bushing of FPM 3.

4. Attach the lead wire assembly (FPM-LE) 4.

Apply FBK OIL RO 100 to the shaft bushing of FPM.

1 - 2 drops

XC8388***

1

1

2

3

3 - 24

1

Screw, Bind

M3X4

Color; Silver

Torque

0.78 – 1.18 N

·m

1

4

Page 75

Main unit

Feed unit

5 Vertical lever attachment

1. Insert the vertical feed shaft 1 into the inside of the drop knob 2, and

then insert the plain washer (L4) 3, spring , vertical lever 4, and

drop knob 5 in this order.

*Key point

• Determine which end of the vertical feed shaft 1 is closer to

the retaining ring and hold this end, and insert the shaft from

the left side of the base plate assembly.

2. Attach the 2 retaining rings (E3).

3. Place the groove on the vertical feed shaft 1 inside the base plate

assembly 6, and attach the retaining ring (E3).

4. Move the vertical feed shaft to the left, and attach the retaining ring (E3).

Start movie clip (CD-ROM version only)

S07

2

4

S07

Retaining ring E3

5

Retaining ring E3

3

1

Retaining ring E3

S07

11

5.7

SPRING

XC2550***

Assembly

3 - 25

Page 76

Main unit

Feed unit

6 Feed adjuster assembly attachment

1. Insert the polyester slider 2 into the shaft of the feed adjuster assembly 1,

and then attach spring .

*Key point

• Insert the spring from the smaller end.