Page 1

INSTRUCTION

FOR

MANUAL

BROTHER

CB3-B913

Chain

BROTHER

Stitch

INDUSTRIES,

NAGOYA,

Buttoning

JAPAN

Machine

LTD.

Page 2

© FEATURES

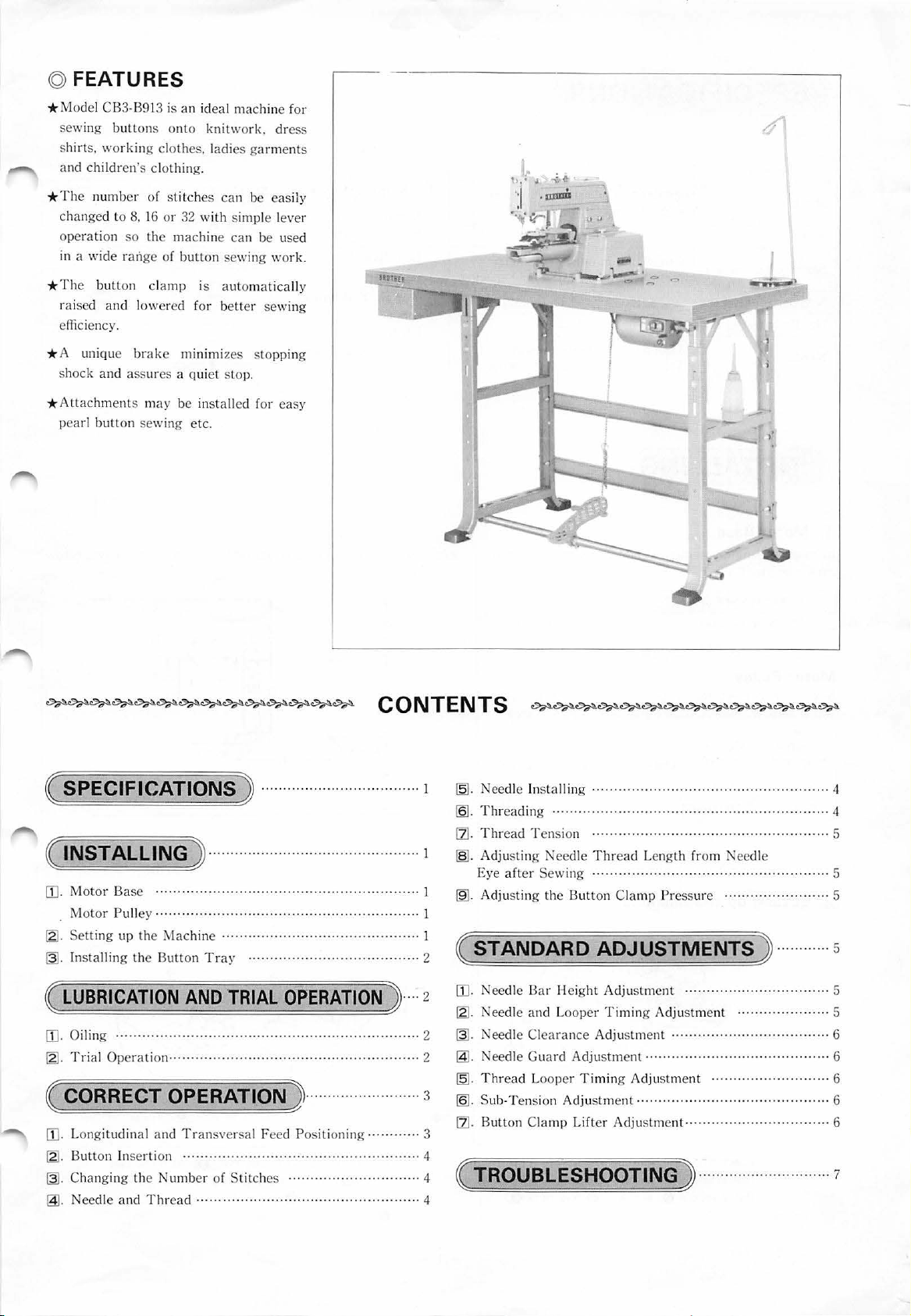

* Model CB3-B913 is

sewing

shirts.

and children's clothing.

The number

*

changed to

ope

in a wide

*T

rai

efficiency.

* A

shock

*

Attachments may

pearl

buttons on

workin

ration

so

ran

he

button clamp

sed

and lowered

unique

and ass

button sewing

g c

lothe

of stitches ca

8.

16

or

the

machine can

ge

of

brake

ure

s a qui et stop.

an

ideal ma

to

s, l

32

with

butt

on sewing

I S

for

minimi

be installed fo r

etc.

chine fo r

knitw

ork.

adies gar

n be easily

simple le

be used

automatically

bett

er sewi

zes

stopping

dre

ss

ment

ver

work.

ng

easy

s

,:{l

.~

·-,·~J

u"

-i~

~

·

""'

( SPECIFICATIONS )

( INSTALLING )

[I].

Motor Base ......

Mot

or

Pull

ey

......

~

-

Sett

ing up

the Machine

~-

Install

ing the

(

LUBRICATION

[I]

. Oiling

[2]

.

Trial

Operati

........

Button

.. .. ..... ·

on

......... · ·

....

· · ..

.............

Tray ........................ · .. · ...........

AND

..... · .................... · ........

......

··

............ · .............................

.............

........

........

.....................

.. ·

.................

....

.....

....................................

TRIAL

OPERATION , ....

( CORRECT OPERATION )

. Longitudinal

~-

Button Inserti

~-

Chang

@.

Needle and

and

Tran

on

·· · ........

ing the Number

Thr

ead ...... ·

sversa

l Feed Positioning ·

· · · · ··· · .. · · · ·

of

Stitch

es

......

. ·

........

..............................

....

.....

...

.....

· · ........ · .... · ......

· .. ·· ·

.. · ........

·· .. ··

...... · ........

. ·· · .. · ·

...

.................

..........

.......

· ·

.. · ....

· .. · ·

....... ·

.......... · .....

......

......

........

....... 2

.....

....

· ... 4

· ·

1

~-

Needle Installing .

[Q].

T

hreading

[1]

.

Thread

. 1

~-

Adjusting ·

E

I

~

-

Adjust ing the

I

I

( STANDARD ADJUSTMENTS )

2

[D . Needle

2

~

-

Needle and Looper

2

~

-

Needle

@ . Needle

~

-

Thread

3

[Q].

Su

[1]

. Button C

( TROUBLESHOOTING )

··

. 3

4

4

ye

after

b-T

T ension

Sew

Bar

Clea

Guard

Looper

ension

lamp

......

...

................................... ····

.....

· · ..

.................

........ · .............. · ........

eed

le

Thre

ing · ·

.......

Button

Cla

Hei

ght

Adjus

Timing

ran

ce

Adjustme

Adjustment ................................

Timing

Adjustme

Lift

er

Adjustme

... ·

ad

Length fr om Needle

·· · · ·

......

mp Pressu

tment

Adjus

nt

......

Adjus

tment

nt

.........................................

nt

...........

· ... · · ·

......................

........................

···

.... · ......

·· ·

.........

··

· ... · · ·

.....

re

... · ....... · ..... · ......

tment

···

..................

· · · ....... · · ·

........................

..........

....

...........

. ·

·· ··· 4

·· ... ... 4

· .. ·

..

· ... 5

· ... · .. · · · ··· 5

............

.. ····

·· ..

· ..... 6

· .. · ...... 6

... 6

... 6

.........

···

·· .

........ 7

5

5

. 5

5

6

Page 3

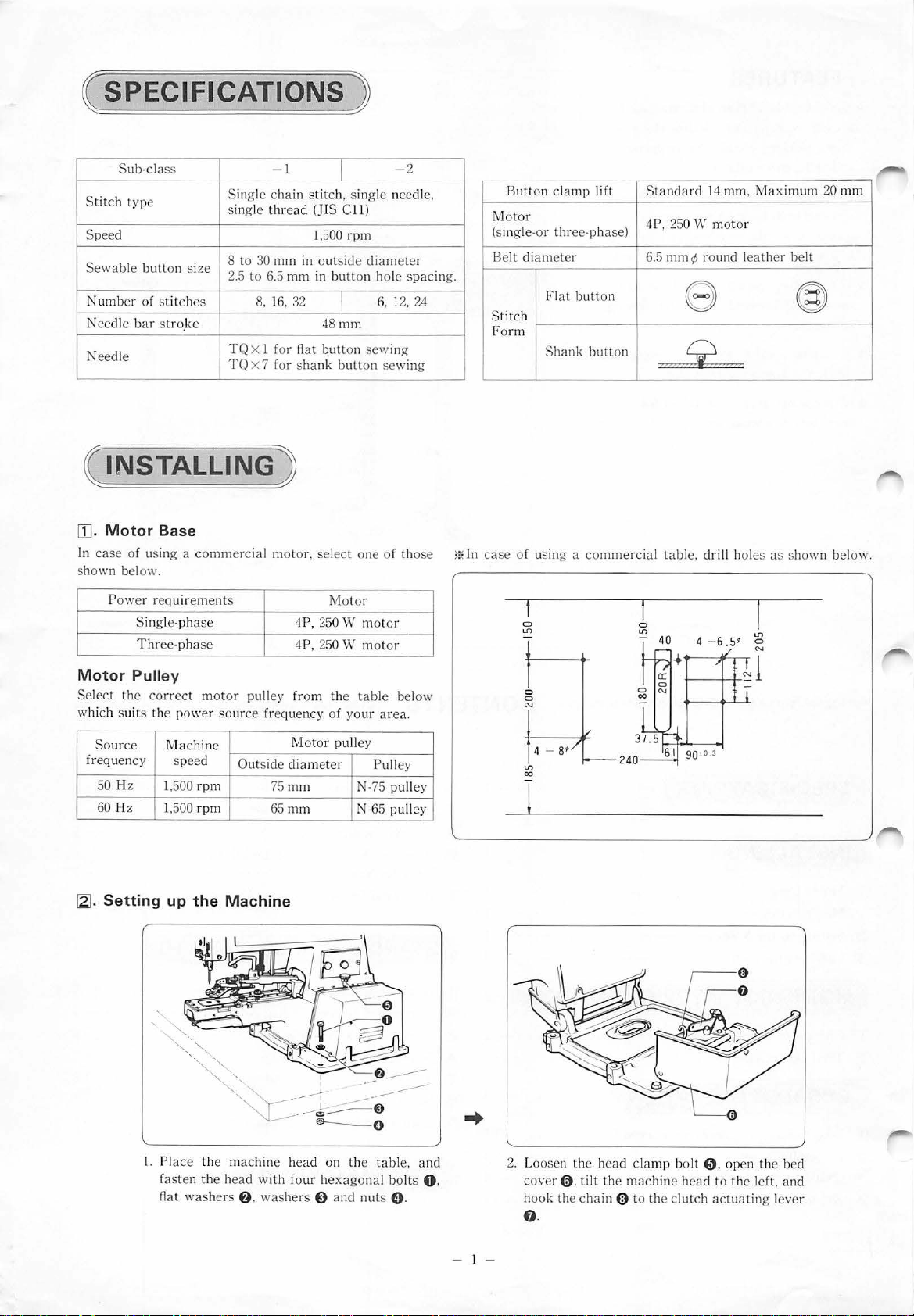

( SPECIFICATIONS J

Sub-clas

Stitc

h type

Speed

Sewable

Numbe

Nee

dl e

Nee

dle

s - 1

button

size

r of stitches

bar

stro.ke

Single ch

single

8 to

2.5

TQ

TQ

ain

thread

30

mm in outside

to

6.5 mm in b

8, 16,

32

X 1 for A at button s

X 7 for

( INSTALLING J

[I]

.

Motor

In

case

shown below.

Power requirement

Base

of

using a comm

Single-ph

Three-pha

ase

se

ercial

s

motor,

I

stitch, single needle,

(JIS C

1,500 r

utton

I

48

mm

shank

butt

select one

Motor

4P,

250

W mot

4P,

250

W m

-2

ll)

pm

diam

eter

hole

6, 12,

ewing

on

se\\'ing

of those * In

or

oto

r

spac

24

ing.

Motor

(s

ingle-or

Belt

S

tit

Form

case

Button

cla

mp

lift S

thr

ee-phase)

diameter

Fla

t bu

tton

ch

Sha

nk

button

of

using a co mmercial table. dr

0

Lf)

4P, 250 W mo

6.5

0

U')

tandard

mm

¢ round

e

2

14

mm,

tor

ill

Maximum

leather

hol

belt

es

as shown below.

20

@

mm

Motor

Select the corr

which s

~

Source

frequen

50

Hz

60Hz

-

Setting

Pulley

ui

ts the power sour

cy

ect

motor pull

Machi

ne

speed

1,500

rpm

1,500 rpm

up

the

ey from

ce

frequency

Outside di

75

65

Machine

the table below

of

Mo

tor pull

ameter

mm

mm

your

area.

ey

Pulley

N-75 pulley

N-65 pulle y

0

0

N

1.

-,.

U')

co

l.

Pl

ace

the

machin e

faste

n the head with four h

n

at

washe

rs

f)

.

was

head

her

s 0

on the t

exagonal bolt

and

nut

able

s 0 .

, and

s 0 .

- I -

2. Loosen

cover

ook th

h

f)

.

0 . tilt

the

head

clamp

the machine head

e chain (l) to the c

bolt 0 .

lut

ch

actuat

open th

to

the

e bed

left, and

ing l

ever

Page 4

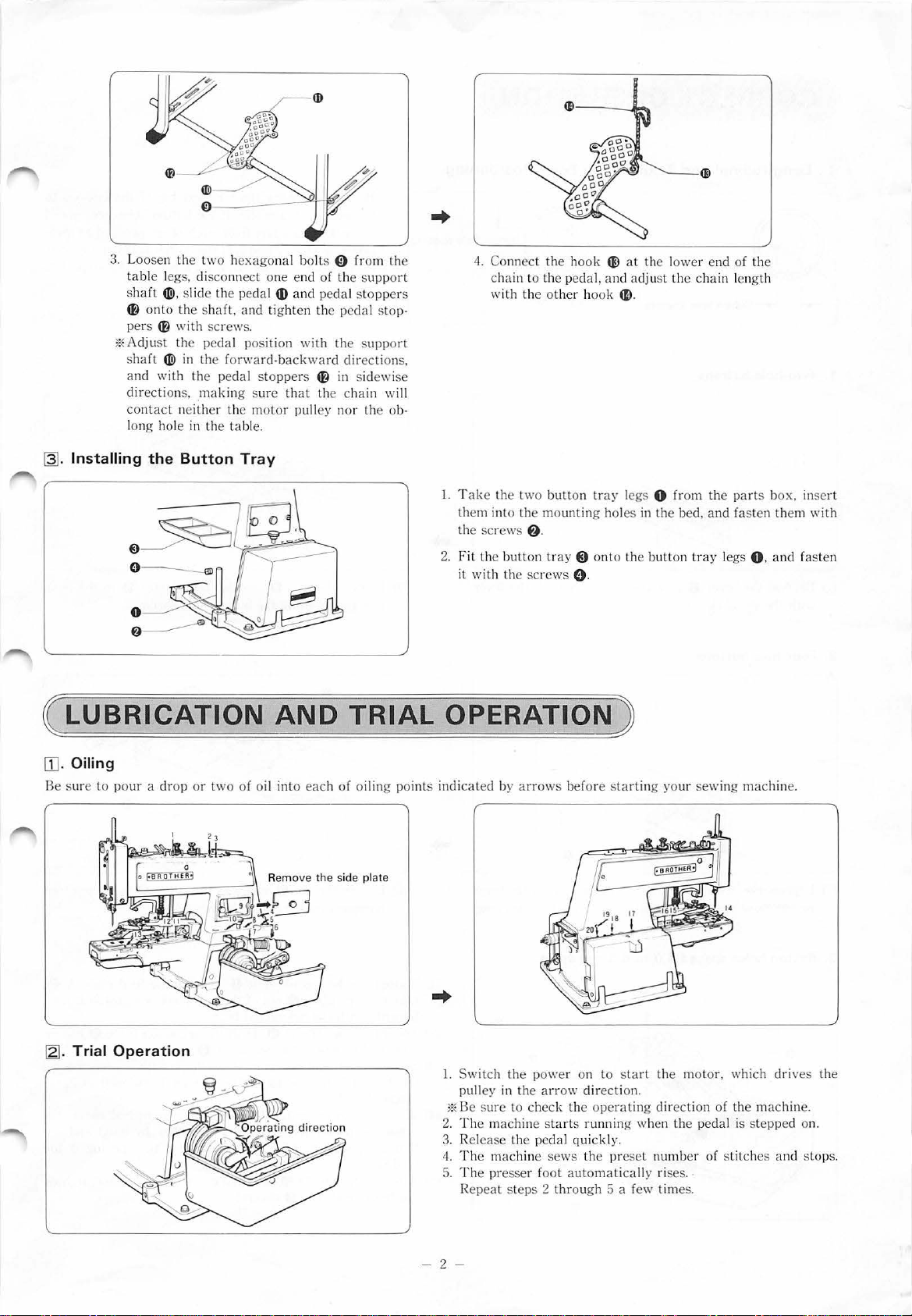

~

-

Installing

3.

Loosen

table legs, di

sh

~

pers ~ with screw

*A

s

and

direction

contact

l

ong

the

aft

4Ji)

, slide

o

nto

the shaft. and tig

dju

st the pedal position

haft

4Ji)

in

with

the

s,

.ma

neither the m

hole in the

the

Button

- Y

two hexagonal bolts 0 fro m

sconnect one

th

e pedal

s.

the

forward·backward

ped<

tl stoppe

kin

g s

tab

Tray

end

4D

and

hten

with the suppo

rs ~ in sidewise

ure

that

oto

r pulley nor the

le.

of the su

pedal stoppers

the p

edal stop·

directions,

the chain wi

the

pport

rt

ob·

ll

..

4.

Connect the hook

chain to the p

with

l.

T

ake the two b

them into the mo

the scr

2.

Fit the bu

th the sc

it wi

th

ews

tton

eda

e other hoo

utton tray legs

unting holes

f)

.

tray@ on

rew

s 0 .

til

at the lower end of

l, and

adjust

the c

k

41)

.

0 f

in

the

to

the

butt

on tr

hain lengt

rom the

bed,

and

ay legs

the

h

parts

box, inse

fas

ten

O. and fas

them

rt

with

te

n

( LUBRICATION

[1

].

Oiling

Be sure

~

-

Trial

to

pour

a dr

Operation

op

or

two

of o

AND

il into each

TRIAL

of

oiling poin

OPERATION)

ts

indi

cated

by

arrows before startin

1.

Switch

pulley in

*Be sur

2. The machine starts running when

3.

Release the p

4.

The machine

5. The presser fool

R

the powe

the arrow direc

e to check the op

epea

t steps 2

r on

eda

l quickl y.

sews

automaticall

thr

ough 5 a f

to start

the

tion.

erat

preset

g yo

ur sewing machine.

the m

oto

ing direc

ew

the

number

y ri

ses

times.

tion

. .

r, which dri ves

of the machine.

pedal is

of sti

step

tch

es and stops.

the

ped on.

- 2 -

Page 5

( CORRECT OPERATION)

[

[].

Longitudinal

and Transversal

Feed

Positioning.

1 .

Two-hole

(1

) Depress the l

with the

Button hole spacing

button

s

ever

0 and align the

©mari

e

arr

ow on the lever

Be sure to check the hole spacing of th e but

be sew n on

2.5 to

tioned in steps 1 and 2. If the

4.0 to 6.5 mm a

and 3.

(2) Loosen the nut

tion representing the bu

to

4.0 mm a

a fabric.

part

from

par

t from

f)

, and

If

the bu

tto

eac

h other. proceed as men·

butt

each ot

set

the pointer $ to the posi-

tto

n hole spacing.

ton

s to

n hol

es

are spaced

on holes are sp

her. take steps 1, 2

ace

d

2. Four-hole

(1) Depress the lever 0 and move

to th e posit ion representing the bu

3.

Button

buttons

holes spaced 4 .0

to

th

e arrow on the lever

tt

on hole spacing.

6.5

mm

apart

.

..

(2

) Loosen the

pr

esenting th e button hole spaci ng.

re

(1) Loosen the he

tak

e the feed pl

porarily with the he

(2

) Loosen the set screw 0 . push the adjusting plate 0 a

wa

y,

and retighten the set screw 0 .

(3

) Set the lever and the poin ter to the positions representing

the button hole sp

gra

phs 1 and 2.

4)

With the power switch

(

press the pedal,

that the needle wi

feed

pl

ate.

(5

) Aft

er

the feed p

the h

exago

xago

nal bo

nut

f)

, and set the pointer 8 to the pos

nal bolt 0 . remove the feed plate A

ate

8 out of the pa

xag

onal bolt.

ac

ing in the manner mentioned in Para·

OFF

turn

the machine pulley by hand and

ll

not hit the edges of the opening in the

lat

e 8 h

as

been correctly positioned, tighten

lt

0 sec

urely.

rt

s box,

, open the

rig

and

ht

install

bed

cov

it

ion

f)

it

tem·

ll

the

er, de·

see

,

- 3 -

Page 6

IZJ.

Button Insertion

3.

1 . Two-hole buttons.

2.

Four-hole buttons.

Sewing

continually.

on

same-sized buttons

•

0

0

(1) When the cam plate 0 is pushed, the button clamp 8 opens. Insert a button into the button clamp,

(2)

Insert a button into the clamp in the correct direction as shown above, and re- and make sure

lease the cam plate

0.

securely gripped. With the button gripped by the clamp, loosen the set screw

•.

pull the adjusting plate e toward

yourself until there is a clearance of

about

0.5

ing plate e and the screw

Then tighten the set screw

to

1.0

that

the button has been

mm

between the adjust-

•.

@).

~-

Changing the Number of Stitches.

Turn the power switch OFF

a desired number of stitches

~-

Needle and Thread

Needle

Size of thread Kind of thread

#

100

to

80

60

40

30

30

to

to

to

to

to

;1:80

#60

#40

#30

#24

;!:

16

# 9

#11

#14

#16

#18

#20

#

#

#

#

#

at

the normal machine stop position, open the left bed cover, and depress the pedal

as

follows.

Cotton, silk

II

II

II

II

,

II

II

II

II

II

~-

Needle Installing

as

you select

1 . 8 stitches

The figure

2.

1 6 stitches

at

left shows the case of 8 stitches.

Pull the stitch select knob 0 toward yourself and

in

move it

3.

32

(1) Pull the stitch select knob 0 toward yourself

the arrow direction.

stitches

and move it in the arrow direction.

(2)

Loosen the hexagonal bolt

@)

in

lever

the hexagonal bolt

1§1.

the arrow direction, and retighten

fj.

Threading

fj,

push down the

Pull the thread whtJe pressmg the button.

Select a needle and thread by referring

to the above table.

3*

Use a TQ X 1 needle for sewing flat

buttons on ; a TQ

X 7 needle for

shank buttons.

Hold the needle with its long groove

side

0 facing

sert the needle into the needle

hole all the way, and clamp

the screw

in

8

your direction,

it

in-

bar

with

-4-

Page 7

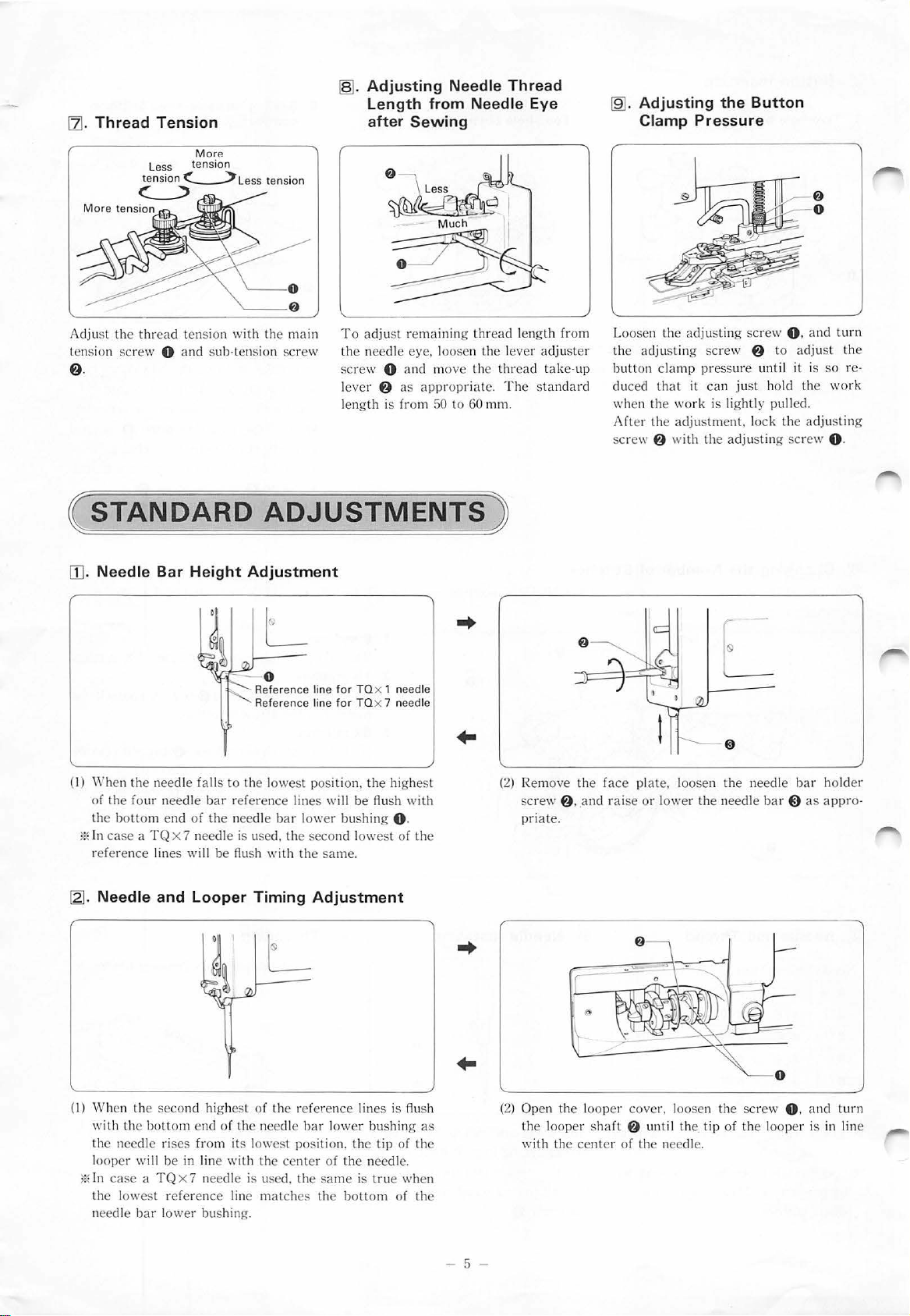

[ZJ

.

Thread

CJ

Tension

ss

Le

tension

MorP.

tension

<.____>L

ess tension

~a~.

Adjusting

Length

after

Needle

from

Sewing

Thread

Needle

Eye

~.

Adjusting

Clamp

the

Button

Pressure

@

0

Adju

st the

thread

tension with the main

tension screw 0

f).

(

sTANDARD

[[]. Needle

(I)

When the needle falls

of the four

the

bott

l?<

In case a TQ

refere

nce

and

Bar

Height

nee

dle

om end of the need le bar lower bushing 0 .

X 7

ne

lines will

sub·ten sion sc

ADJUSTMENTS

Adjustment

L

·-

o

Reference line

Re

ference line for TQx 7 needle

to

the lowest position.

bar

reference lin

edle is used,

be

flu

sh with the same.

To

adju

rew

the

needle

screw 0 an

lever

length is from

for

TQ x 1 needle

the

es

will

be

the second lowe

st

f)

high

flu

sh with

st

remaining

eye

. loosen the l

d move the

as ap

propr

50

est

of

the

thread

thread

iate. The st

to

60 mm.

)

(2

up

d

.. and

Loosen the

the

b

utt

on cl

duc

ed

when the

After

sc

rew 8 with

rai

se

len

gth from

ever adjuster

take·

andar

) Remove the face plate, loosen the needle

scr

ew

f)

priate.

adjusting

adjusting

amp pressure

that

work

the adju

or l

ower

scr

ew

it

can

just

is lightly pulle

stment. l

the

adjusting scr

the

needle

screw

f)

to

unt

hold

ock the

bar~

il it is

0 ,

and

adju

st

so

the

work

d.

adjusting

ew

0 .

bar holder

as

appro·

turn

the

re·

12]

.

(I)

When the

wi

th

ooper

l

mIn ca

th

need le b

Needle

th

e needle ri

e lowe

and

Looper

second

the bott

se a TQ

om

end

ses

from its l

will be in line wi

x 7 needle is used.

st

reference line

ar lower

Timing

highest of the ref

of the needle b

owes

t pos

th

the cent

match

bushing.

Adjustment

erence

lines is

ar lower

ition.

the

er

of

the need

the same

es

is true when

the bott

bushing

tip

of the

le.

om

of

flu

sh

as

the

- 5 -

(2)

Open the looper cover, loosen the screw 0 . and turn

the looper shaft

the

with

center

f)

until th

e.

of the needle.

tip

of

the

looper is

in

line

Page 8

~-

Needle Clearance

Adjustment

Loosen the set collar screw 0 and move

the looper to adjust the clearance

tween the needle arid the tip of the looper

to

0.03

to

0.08

mm when the tip of the

in

looper is

needle.

line with the center of the

be-

~-

Needle Guard Adjustment

Loosen the screw

guard

0 to adjust the clearance between

the needle and the needle guard

about

0.1

mm.

f)

and move the needle

0 to

~-Thread

Looper Timing

Adjustment

1.

Loosen the screw

reference line on the groove cam

with

that

on the looper shaft

2.

Loosen the screw

reference line on the thread looper

triangle cam

shaft

f).

8 with

O.

and align the

8.

and align the

that

on the looper

f).

8

!§].

Sub-Tension Adjustment

Reference line

1.

Check to see

on the needle

matches the reference line on the

needle

these reference lines

make an adjustment by loosening the

hexagonal bolts

that

bar

bar

drive lever shaft

8 and

the reference line

drive lever 0

are

unaligned,

8.

f).

If

0

0

2.

Turn

the pulley by hand to raise the When raising

needle

bar

until the top of the needle clamp by means of the pedal.

bar

0 is

44

to

48

end of the needle

0.

At

this time, the tension disc must

begin to float. Loosen the screw

and turn the sub-tension stud G until

the above-mentioned timing

tained.

*In

case a TQ X 7 needle is used, the

tension disc must begin floating when

the top of the needle

58

mm above the top of the needle

upper bushing.

To decrease

mm above the top

bar

upper bushing hole

bar

is

IZJ.

Button Clamp Lifter

Adjustment

----~-=--a.:~~

·-~~

or

lowering the button

1.

Remove the screw

f),

and retighten the screw

2.

Hook the chain 8 into the hole

8

is

ob-

54

to

bar

button clamp connecting rod

*The

pedal and chain

0.

move it into the

are

optional.

e.

in

0.

the

-6-

Page 9

{

TROUBLES~OOTIN

_

G )

Trouble

Needle breaks.

Stitches ski p.

I

Cause

I

Button ins

improperly.

Longitudinal

and point

improperly.

Wrong

timing. timing.

Wrong nee

l

ooper

T

oo

between nee

looper.

Need le

incorrect.

T

oo

be

tween need

needle

erted

feed

er pos

ition

thread loop

dle and Needle and looper Adju

timing. timing. looper timing.

g r

·eat a clearance

dle

and

bar

hei

ght

g reat a c le

guar·d.

le a

aranc

lever

er

nd

I

ed

e

Check point

I

Button hole

Longitudin al feed l

and pointer positions.

Thr

ead looper

Needle

Needle

Clea rance between

needle

dir

clearanc

bar

height.

and

needle guard.

ection. h

timing.

e.

ever

I I

Inse

oles are

direction.

Adju

f

eed

to butt

Adjust

Adjust

betwe

l

oope

Adjust needle ba r

height.

Adju

Remedy

rt

button

so

in

the

st lo n g

itudin

lever and poin

o n hole s p

thread

loop

st needle and

c le

aran

needle

ce

gua

e n needle and

r.

st

its

correct

a l

ter

acing.

er

rd.

I

Page

l

Stitch

es

Thr

ead breaks.

loose.

Remaining

length too short. length.

Sub-tension di

improperl

Sub

-tension too weak. Sub-tension tensio

Needle installed

inc

orrectly.

Sub-tension di

timing

Needle too thin for

thread.

thread

sc

floats

y.

sc float

wr

ong. timin g.

Remai ning thread

Ten

Needle

Tension disc

Need le

sion di

dire

and thea

sc

ction.

float.

flo

at

cl.

Adjust remainin g

t

hread len

Adjust s

float.

n.

Adju

tension.

Install needle

long g r·

fron

Adju

R

efer

for need le

gth

ub-tension disc

st

sub-tension

oove

t.

st

facin

sub-tens ion.

to inst

ructions

and

.

with

thr

g

its

ead

.

-

7-

Page 10

~--·

•.

118-913

192913-1-02

Printed in Japan

Loading...

Loading...