Page 1

BAS H series

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

LCD PANEL / OPERATION PANEL

INSTRUCTION MANUAL

Page 2

CONTENTS

1. USING THE LCD PANEL (BASIC OPERATIONS) ··················· 1

1-1. Name and function of each LCD panel item ·································································1

1-1-1. Main names and functions ·················································································1

1-1-2. Home screen ······································································································1

1-1-3. Sewing operation screen ····················································································2

1-2. Parameter setting method ····························································································4

1-2-1. X/Y-scale, X/Y-offset ··························································································5

1-2-2. Slow start pattern ································································································7

1-2-3. Using the lower thread counter ··········································································8

1-2-4. Using the production counter ·········································································· 10

1-2-5. Split number setting method ············································································ 11

1-3. Copying programs ····································································································· 13

1-4. Checking the sewing pattern ····················································································· 14

1-5. Setting the work clamp lift amount ············································································· 16

1-5-1. For BAS-311H/BAS-326H/BAS-326H-484/BAS-341H/BAS-342H ·················· 17

1-5-2. For BAS-360H/BAS-365H ··············································································· 19

2. USING THE LCD PANEL (ADVANCED OPERATIONS) ·········· 21

2-1. Memory switch setting method ··················································································· 21

2-2. List of memory switch settings ···················································································· 23

2-3. Using cycle programs ································································································· 25

2-4. Direct selection ··········································································································· 29

2-5. Setting the sewing screen display ·············································································· 30

2-6. Initialization method ···································································································· 32

2-7. Maintenance mode ····································································································· 34

3. USING STORAGE MEDIA ························································36

3-1. Notes on handling ········································································································ 36

3-2. Folder structure ············································································································ 36

3-3. Importing and exporting data ······················································································· 37

3-4. Importing items of sewing data separately ·································································· 39

BAS H series

Page 3

1. USING THE LCD PANEL (BASIC OPERATIONS)

1. USING THE LCD PANEL (BASIC OPERATIONS)

CAUTION

To prevent problems, do not use objects with sharp points to operate the LCD panel.

1-1. Name and function of each LCD panel item

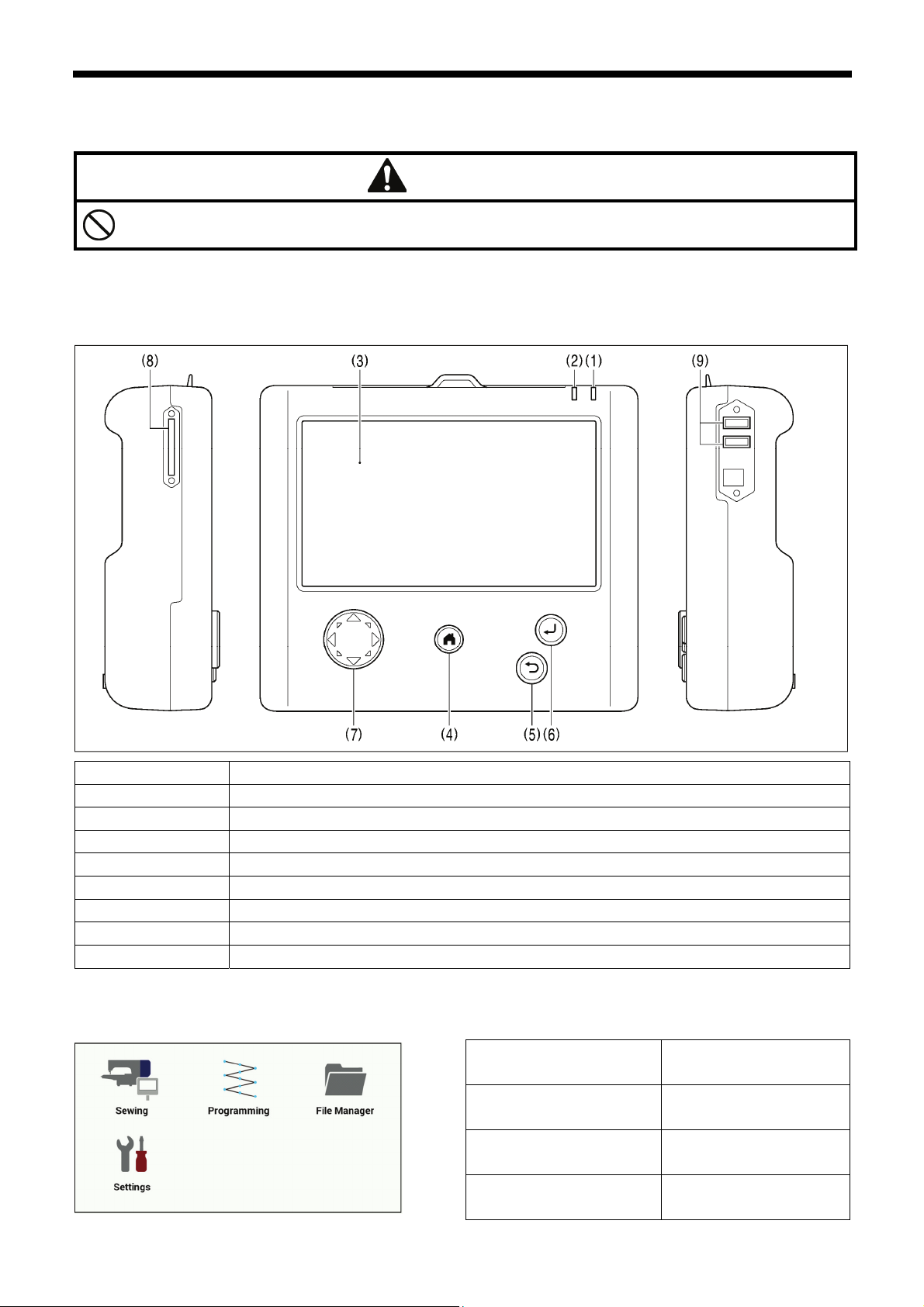

1-1-1. Main names and functions

(1) Power indicator Illuminates when the power is turned on.

(2) Caution indicator Illuminates when an error occurs.

(3) LCD/touch panel This displays messages and touch keys (icons).

(4) HOME key This key is used to return to the home screen.

(5) BACK key This key is used for operations such as returning to the previous step and canceling settings.

(6) ENTER key This key is used for operations such as confirming settings.

(7) JOG key This key is used when programming sewing data.

(8) SD card slot Insert an SD card.

(9) USB port×2 Connect a USB memory or other device.

1-1-2. Home screen

4289B

Press the HOME key to display the home screen.

(1)

(4)

(2)

(3)

(1) Sewing key Touch to switch to the

(2) Programming key Touch to switch to the

(3) File Manager key Touch to switch to the

(4) Settings key Touch to switch to the

BAS H series

sewing operation screen.

programming screen.

file manager screen.

setting menu screen.

1

Page 4

1. USING THE LCD PANEL (BASIC OPERATIONS)

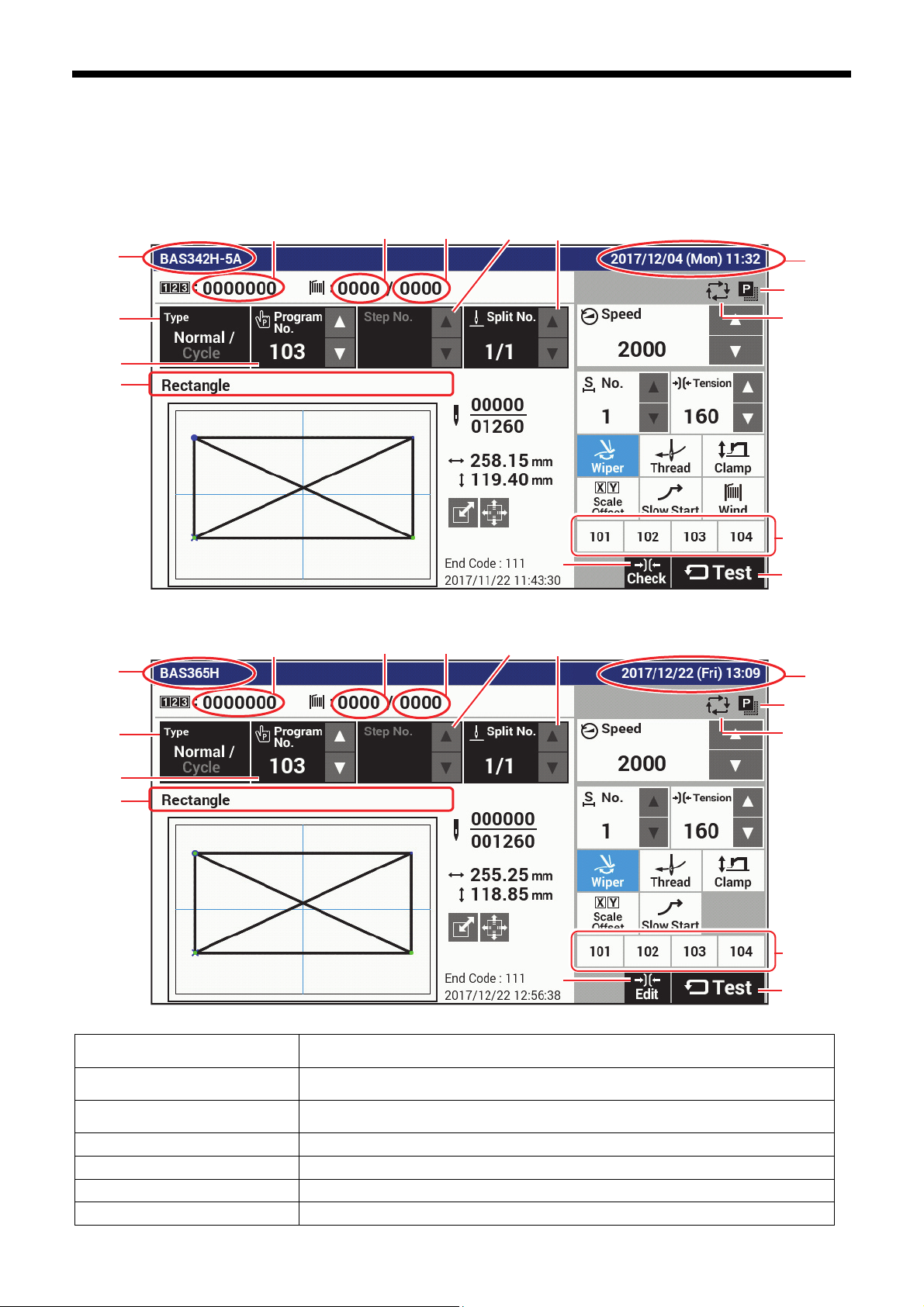

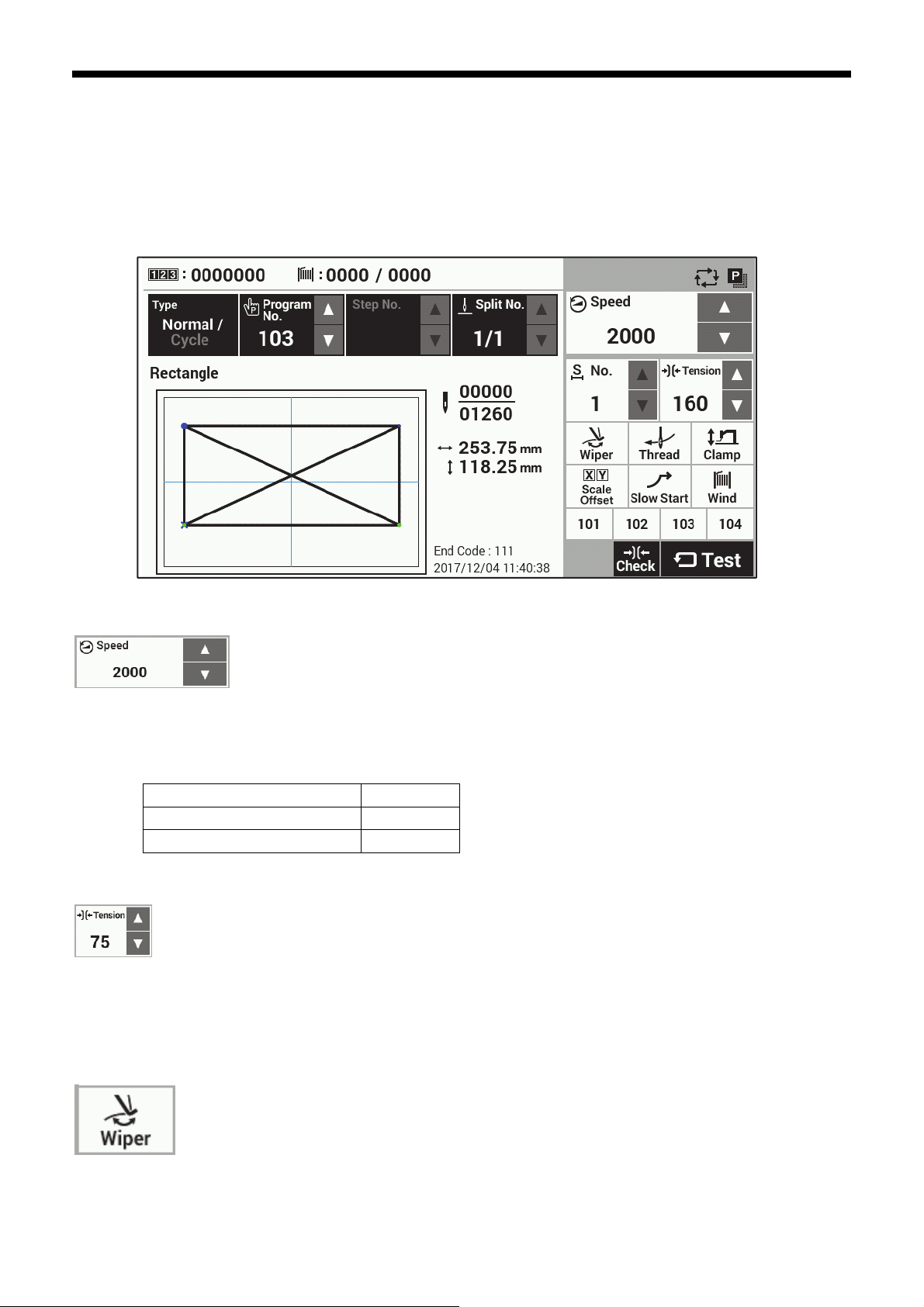

1-1-3. Sewing operation screen

When the power is turned on while the LCD panel is connected to the sewing machine, this screen is displayed

・

automatically.

If any other screen is being displayed, touch the sewing key in the home screen to display this screen.

・

[For BAS-311HN, BAS-326H, BAS-326H-484, BAS-341H and BAS-342H]

(27)

(6)

(7)

(29)

[For BAS-360H and BAS-365H]

(27)

(6)

(7)

(29)

(1) Production counter key

(2) Lower thread counter key

(3) Lower thread setting key

(4) Cycle program key

(5) Copy key

(6) Type key

(7) Program No. keys

2

(25)

(25)

(1)

(1)

This shows the production counter value.

If you keep pressing this key, the display switches to the setting menu screen.

This shows the lower thread counter value.

If you keep pressing this key, the display switches to the setting menu screen.

Displays the lower thread setting value. If you keep pressing this key, the display

switches to the setting menu screen.

Touch to switch to the cycle program editing screen.

Touch to switch to the sewing program copying screen.

Touch to select the program type.

Touch to display/select the current program number.

(2)

(2)

(3)

(24)

(3)

(24)

BAS H series

(8)

(8)

(26)

(26)

(9)

(10)

(11)

(22)

(13)

(23)

(16)

(20)

(9)

(10)

(11)

(22)

(13)

(23)

(16) (17)

(20)

(12)

(14)

(17)

(14)

(15)

(18)

(12)

(15)

(Continued on next page)

(28)

(5)

(4)

(19)

(21)

(28)

(5)

(4)

(19)

(21)

Page 5

1. USING THE LCD PANEL (BASIC OPERATIONS)

(8) Step No. keys

(9) Split No. keys

(10) Speed keys

(11) Section No. keys

(12) Tension keys

(13) Wiper key

(14) Thread key

(15) Clamp key

(16) Scale Offset key

(17) Slow Start key

(18) Wind key

(19) Direct selection keys

(20) Tension operation check key

(21) Test key

(22) Current stitch number

/ Total number of stitches

(23) Sewing area size

(24) Sewing data information

(25) Preview

(26) Scale/Offset key

(27) Model name

(28) Date and time

(29) Comments

(30) Tension editing check key

Touch to display/select the current step number.

Touch to display/select the current split number.

Touch to display/select the sewing speed.

Touch to display/select the section number for the digital tension.

These are not displayed when digital tension is not being used.

Touch to display/select the digital tension value.

These are not displayed when digital tension is not being used.

Touch to switch the thread wiper on/off.

Touch to switch to the threading screen.

Touch to switch to the Adjust Clamp Height setting screen.

Touch to switch to the Scale/Offset setting screen.

Touch to switch to the Slow Start setting screen.

Touch to switch to the thread winding screen.

This is not displayed for the BAS-360H/365H.

You can register normal/cycle program numbers into each of these keys.

When you keep pressing a key, the program assigned to that key is selected.

Touch to switch to the tension operation check mode.

This is not displayed when digital tension is not being used.

Touch to switch to test mode.

Shows the current stitch number and the total number of stitches.

Shows the size of the sewing data area.

Shows information about the sewing data.

Shows a preview of the sewing data.

This is displayed when the Scale/Offset setting values have been changed from the

default setting values.

Touch the key to display the setting value.

Shows the model name and specifications.

Shows the current date and time.

Shows comments about the sewing data.

Touch to switch to digital tension editing mode.

This is not displayed when digital tension is not being used.

BAS H series

3

Page 6

1. USING THE LCD PANEL (BASIC OPERATIONS)

1-2. Parameter setting method

Parameter settings are made at the sewing operation screen.

* For details on the sewing data reading method, refer to "3. Using storage media".

* For details on memory switch setting methods, refer to "2-1. Memory switch setting method".

(3)

(4) (5)

(1)

(2)

Sewing speed

Use the Speed △ and ▽ keys (1) to make the setting.

・Setting range: 200 sti/min to corresponding value in the table below

100 sti/min units Initial value: 2,000 sti/min

Table: Maximum sewing speed for each model

Models other than those below 2800 sti/min

BAS-326H-484 2200 sti/min

BAS-360H/BAS-365H 2700 sti/min

Digital tension

Touch the Tension △ or ▽ key (2) to change the tension value.

・Setting range: 0 to 300 or 0 to 500 (for BAS-360H and BAS-365H)

Initial value: For -3 specifications, 100 For -5 and -7 specifications, 160

Thread wiping

Touch the Wiper key (3) to turn the wiper on or off. (The initial value varies for each model and specification.)

When the setting is on, the key is displayed in blue.

4

BAS H series

Page 7

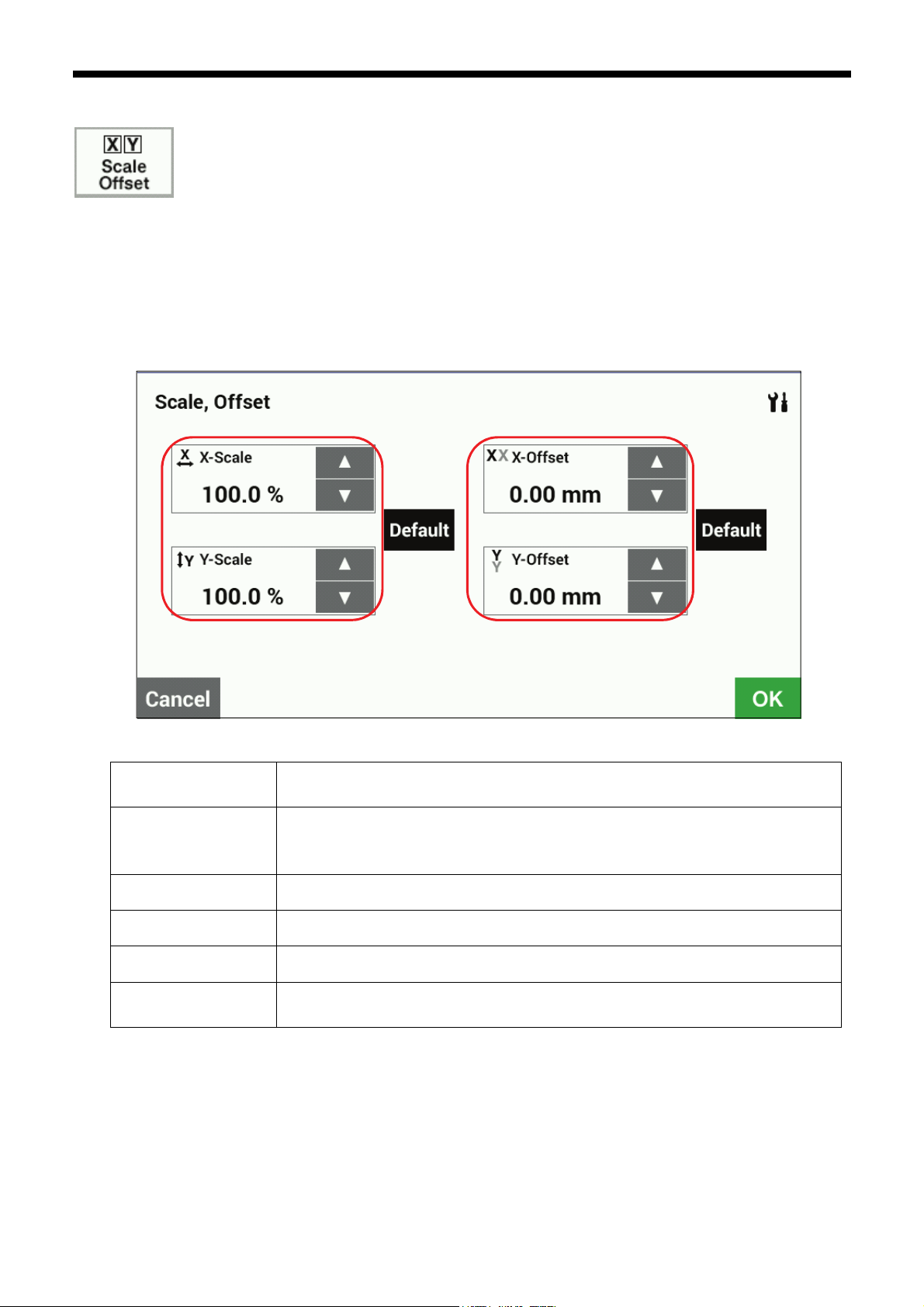

1-2-1. X/Y-scale, X/Y-offset

Touch the Scale Offset key (4) in the sewing operation screen to display the X/Y-scale and X/Y-offset setting

screen.

Use when you would like to enlarge, reduce or move the pattern without changing the sewing data.

* When memory switch no. 400 is set to ON, the X-scale, Y-scale, sewing speed and work clamp height can be

recorded separately for each program number.

[X/Y-scale and X/Y-offset screen]

(1) X/Y-scale

(X-Scale, Y-Scale)

(2) Offset

(X-Offset, Y-Offset)

Limited by available sewing area.

Setting range: 0 to 400%, 0.1% units, initial value: 100%

When activating the offset, first carry out home position detection(*).

Setting range: 0 to 300 mm, 0.05 mm units

Initial value: 0 mm

1. USING THE LCD PANEL (BASIC OPERATIONS)

(1) (2)

(4)

(4)

(6)

(3) (5)

(3) OK key Touch to confirm the setting and return the display to the previous screen.

(4) Default key Touch to return the setting to the initial value.

(5) Cancel key Touch to return to the previous screen without changing the setting.

(6) Setting key

* When the foot switch is depressed to the 2nd step, home position detection is carried out.

(If using a two-pedal foot switch, lower the work clamp before depressing the start switch. For the hand start switch,

use the right switch to lower the feed plate lock cylinder and work clamp, and then press the left and right switches at

the same time.)

Touch to display the screen for setting the center point for scaling and the display units

(% or mm).

BAS H series

5

Page 8

1. USING THE LCD PANEL (BASIC OPERATIONS)

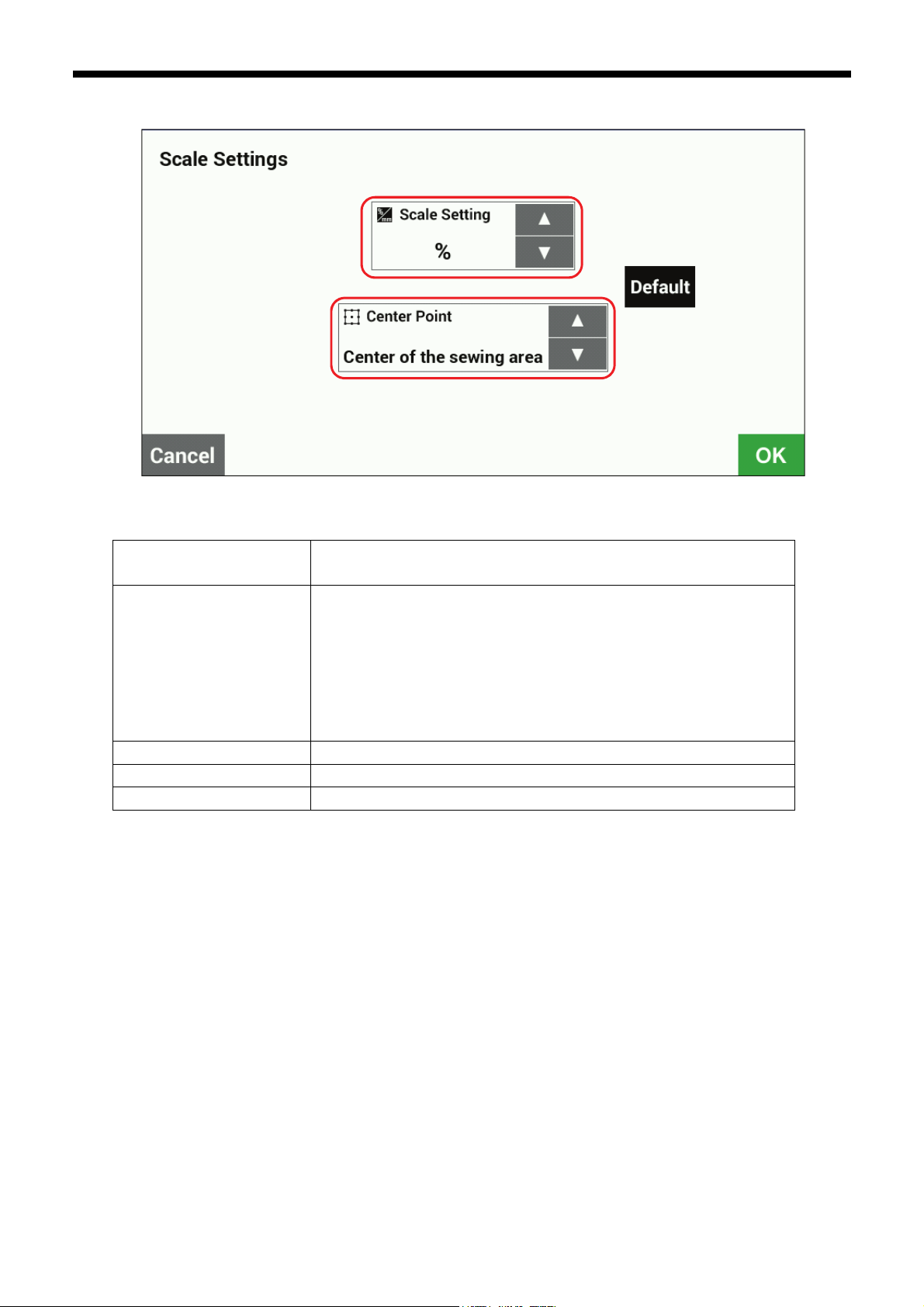

[Scale setting screen]

(11)

(7) Scale setting units Touch to change the scaling units.

Setting range: %, mm, initial value: %

(8) Scaling center point Touch to change the scaling center point.

Setting range: Sewing frame center position, sewing start position, center of

pattern, forward center of pattern, rear center of pattern,

rear-left corner of sewing area, front-left corner of sewing

area, rear-right corner of sewing area, front-right corner of

sewing area

Initial value: Center of sewing frame

(9) OK key Touch to confirm the setting and return the display to the previous screen.

(10) Default key Touch to return the setting to the initial value.

(11) Cancel key Touch to return to the previous screen without changing the setting.

(7)

(10)

(8)

(9)

6

BAS H series

Page 9

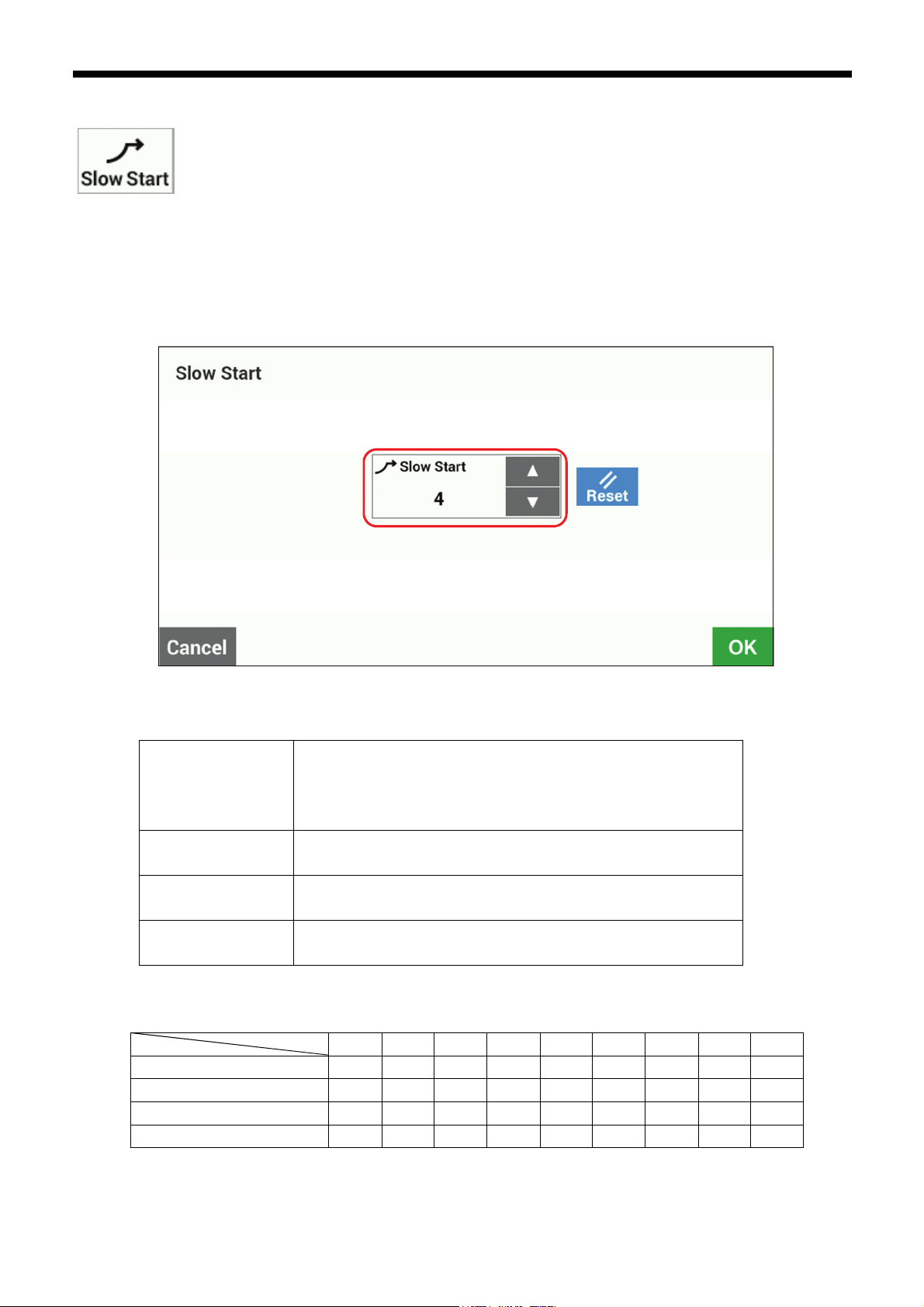

1-2-2. Slow start pattern

Set memory switch No. 100 to ON and then touch the Slow Start key (5) in the sewing operation screen to display

the slow start setting screen.

This is used to stop the thread from pulling out at the sewing start, and at times when skipped stitches might easily

occur.

* When memory switch no. 400 is set to ON, slow start patterns can be recorded separately for each program

number.

Slow Start (1) Touch the △ or ▽ key to adjust the starting-up speed at the sewing

OK key (2) Touch to confirm the setting value and return to the sewing operation

Cancel key (3) Touch to return to the sewing operation screen without changing the

Reset key (4) Touch to return the value to the value which was first displayed when

Table Setting values and starting-up speeds

Sewing speed for 1st stitch 200 200 300 400 400 400 400 600 800

Sewing speed for 2nd stitch 200 300 400 400 500 600 800 1000 1200

Sewing speed for 3rd stitch 300 400 500 600 800 1000 1200 1600 *1

Sewing speed for 4th stitch 500 600 700 900 1200 1400 *1 *1 *1

*1 Sewing will be carried out at the sewing speed which is set by the “Sewing speed” parameter.

start.

* The smaller the number, the slower the start.

* Refer to the following table for the speed setting values.

screen.

setting value.

you switched to the setting screen.

Lo 1 2 3 4 5 6 7 8 9

BAS H series

1. USING THE LCD PANEL (BASIC OPERATIONS)

(1)

(4)

(2) (3)

7

Page 10

1. USING THE LCD PANEL (BASIC OPERATIONS)

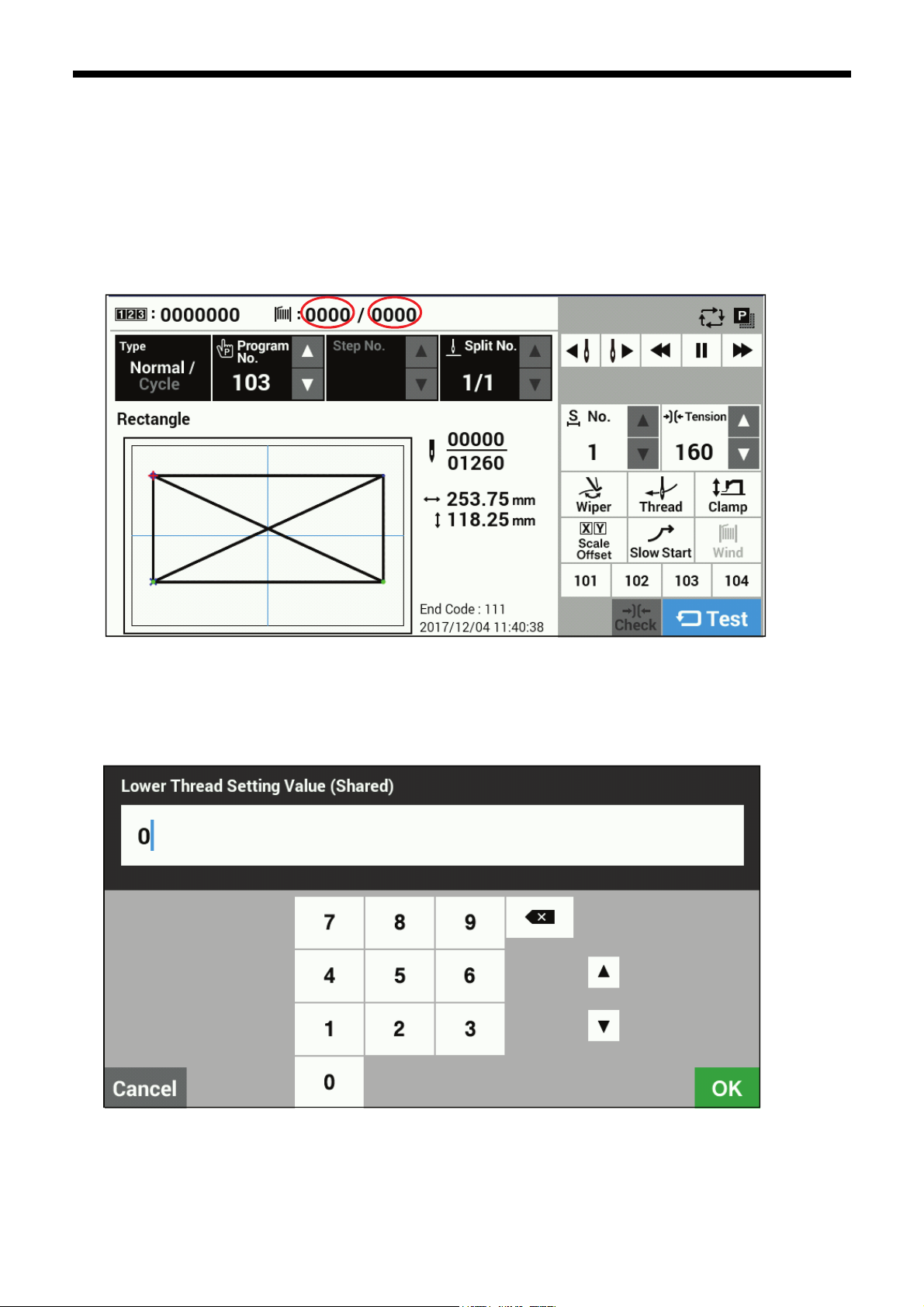

1-2-3. Using the lower thread counter

If you use the lower thread counter to set the number of articles which can be sewn with the amount of lower thread available,

you can stop the lower thread running out in the middle of sewing a pattern.

<Setting the lower thread setting value>

If you keep pressing the lower thread setting key (1) in the sewing operation screen, the screen will switch to the input

screen for the lower thread setting value.

[Sewing operation screen]

(2)

(1)

(1)

(2)

Enter the value and then touch the OK key (3) to confirm the value.

When the lower thread setting value has been set, the same value will appear as the lower thread counter value (2).

f the value is set to "0000", the lower thread counter will not operate.

・ I

The lower thread setting value can be set to "0"-"9999".

8

BAS H series

(3)

Page 11

1. USING THE LCD PANEL (BASIC OPERATIONS)

<Setting the lower thread counter value>

If you keep pressing the lower thread counter key (2) in the sewing operation screen, the screen will switch to the input

screen for the lower thread counter value.

Enter the value and then touch the OK key (5) to confirm the value.

Touch the Reset key (4) to set the lower thread setting value as the lower thread counter value.

The lower thread counter value can be set from "0" to the lower thread setting value.

(4) (5)

<Lower thread counter operation>

If the initial value for the lower thread counter is set to a value other than "0", the lower thread counter will operate.

The counter value decreases by 1 each time sewing of an item is completed, and when it reaches "0", a message screen

is displayed and the buzzer sounds.

When this happens, the sewing machine cannot be operated.

Touch the Reset key (6) to return the lower thread counter value to the initial value, and then sewing will be possible

again.

[Message screen]

(6)

BAS H series

9

Page 12

1. USING THE LCD PANEL (BASIC OPERATIONS)

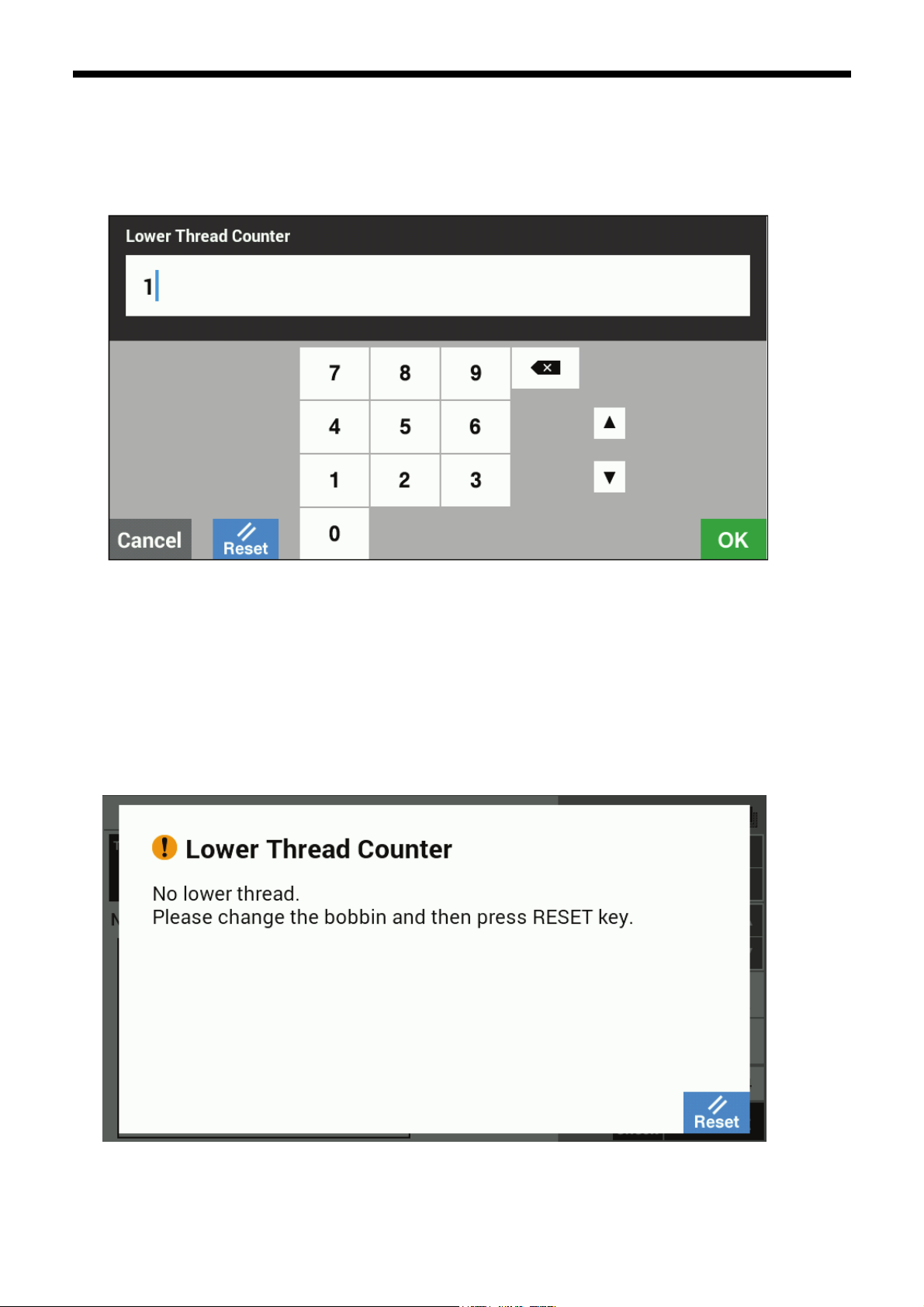

1-2-4. Using the production counter

<Setting the counter value>

If you keep pressing the production counter key (1) in the sewing operation screen, the screen will switch to the input

screen for the production counter.

The counter value can be set to a value from "0" to "9999999".

If you would like to return the value to "0", touch the Reset key (2) and then touch the OK key (3).

After doing this, the display will return to the sewing operation screen.

Touch the Cancel key (4) to return to the sewing operation screen without changing the value.

<Production counter operation>

The production counter always operates, and it increases by 1 each time sewing of an item is completed.

(1)

(2) (4)

(3)

10

BAS H series

Page 13

1. USING THE LCD PANEL (BASIC OPERATIONS)

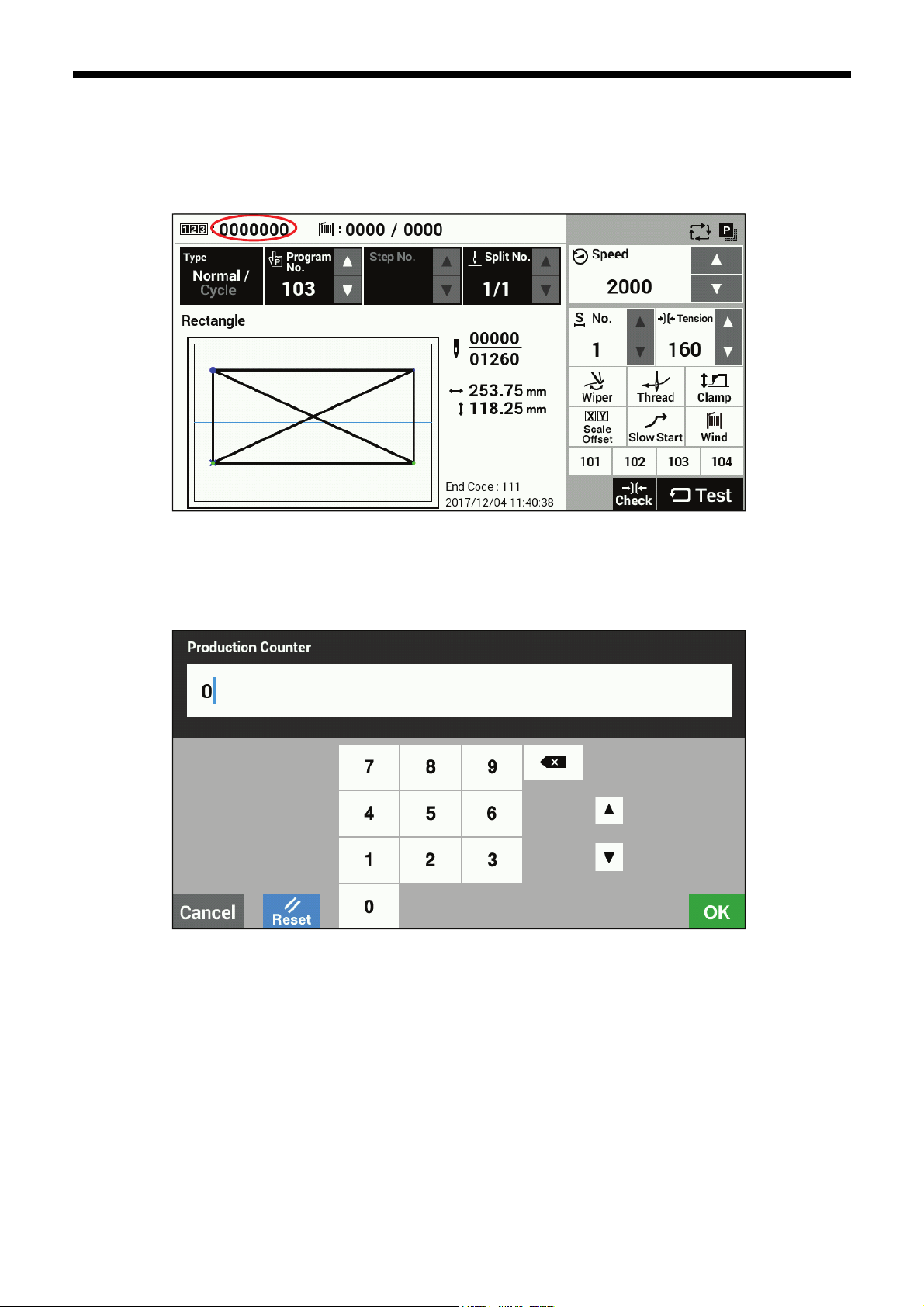

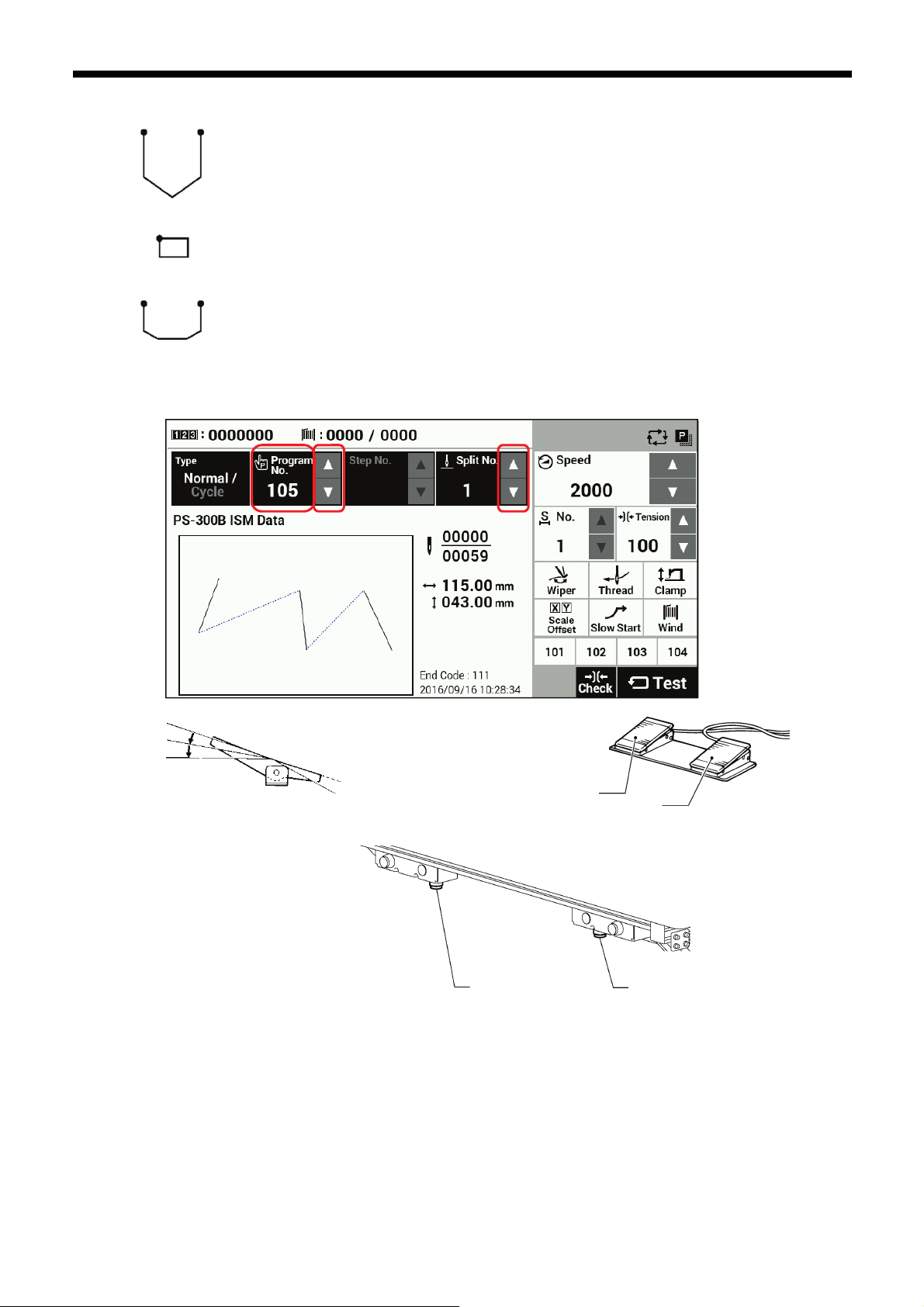

1-2-5. Split number setting method

If split codes (sewing interrupt data) exist in one program, the number which indicates

the pattern which has been divided by the split codes is called the split number.

Pattern 1

Pattern 2

4964Q

[Sewing operation screen]

Pattern 3

Pattern 1: Split No. 1

Pattern 2: Split No. 2

Pattern 3: Split No. 3

(1) (2) (3)

2nd step

4441Q

Work clamp switch (2-step)

Start switch

4923Q

Left switch

Right switch

4169B

1.

Touch the "Program No." △ or ▽ key (1) to select the program number which includes the split code.

The "Program No." value (2) will flash.

・

Depress the foot switch to the 2nd step to carry out home position detection.

2.

(If using a two-pedal foot switch, lower the work clamp before depressing the start switch. For the hand start switch, use

the right switch to lower the feed plate lock cylinder and work clamp, and then press the left and right switches at the same

time.)

* The feed mechanism will move to the home position and the program number will be confirmed. (The “Program No.”

setting (2) will stop flashing and illuminate steadily.)

Use the "Split No." △ or ▽ key (3) to select the split number.

3.

BAS H series

11

Page 14

1. USING THE LCD PANEL (BASIC OPERATIONS)

p

The setting for memory switch No. 403 lets you select the split mode.

[Continuous split]

Memory switch No. 403 = 0

Sewing is carried out each time in the order of steps 1 → 2 → 3 → 1 (for example, if there are two split codes).

・

[Independent split]

Memory switch No. 403 = 1

・The

attern for the displayed split number is sewn independently.

12

BAS H series

Page 15

1-3. Copying programs

[Sewing operation screen]

1. USING THE LCD PANEL (BASIC OPERATIONS)

(1)

Touch the Copy key (1) to switch to the program copy screen.

[Program copy screen]

Select the copy source program No. and the copy destination program No.

Touch the OK key to carry out copying. After copying, the display will return to the previous screen.

Touch the Cancel key to return to the previous screen without copying.

* The number which is selected as the copy destination program number will flash only if sewing data already exists in a

program assigned to that number.

BAS H series

13

Page 16

1. USING THE LCD PANEL (BASIC OPERATIONS)

1-4. Checking the sewing pattern

Use test feed mode to operate the feed mechanism in order to check the needle movement.

Check that the needle hole does not come out from the frame of the work clamp.

1

The Test key is displayed in blue.

[Sewing operation screen]

2

Continuous test feed

2nd step

(1)

Work clamp switch (2-step)

Start switch

1. Touch the Test key at the sewing operation

screen.

2. Press the △ or ▽ key (1) to set the program

number that you would like to check.

1. Depress the foot switch to the 2nd step (for a

2-pedal foot switch, lower the work clamp and

then depress the start switch. For the hand

start switch, press the right switch to lower the

feed plate lock cylinder and work clamp, and

then press the left and right switches at the

same time.) Furthermore, if you touch the

continuous feed key (2), the feed mechanism

will start moving continuously one stitch at a

time.

(The current stitch number in the stitch number

display will increase by 1 each time.)

14

Left switch

Right switch

(5)

BAS H series

2. When the feed reaches the end of the pattern,

it stops.

・ If you would like to stop the feeding operation,

touch the continuous feed stop key (3).

・ If you touch the continuous feed key (4), the

feed mechanism will start moving continuously

in the direction of the sewing start position one

stitch at a time.

・ Touch the Move to sewing start key (5) to

return to the sewing start.

4441Q

4923Q

4169B

Page 17

3

[For BAS-311HN, BAS-326H, BAS-326H-484, BAS-341H

and BAS-342H]

Single stitch check

[For BAS-360H and BAS-365H]

Checking the specified number of stitches

(7) (8)

(6)

(8) (7)

(4)

(3) (4)

(3)

(2)

(2)

1. USING THE LCD PANEL (BASIC OPERATIONS)

1. If you touch the stitch forward key (7) or the

stitch back key (8), the feed mechanism will

move by the specified number of stitches.

・ Touch the Move to sewing start key (5) to

return to the sewing start.

2. At the specified number of stitches, touch the +

or - key (6) to specify the number of stitches to

move.

3. If you touch the stitch forward key (7) or the

stitch back key (8), the feed mechanism will

move by the specified number of stitches

・ If you would like to stop the feeding operation,

touch the continuous feed stop key (3).

・ Touch the Move to sewing start key (5) to

return to the sewing start.

BAS H series

15

Page 18

1. USING THE LCD PANEL (BASIC OPERATIONS)

1-5. Setting the work clamp lift amount

The settings for the work clamp and intermittent presser foot lift amounts can be changed at the sewing operation screen.

* For pneumatic work clamp specifications, only intermittent presser foot height setting mode will be available.

[Sewing operation screen]

(1)

Touch the Clamp key (1) to display the Adjust Clamp Height setting screen.

16

BAS H series

Page 19

1. USING THE LCD PANEL (BASIC OPERATIONS)

1-5-1. For BAS-311H/BAS-326H/BAS-326H-484/BAS-341H/BAS-342H

(6)

・Work clamp height setting (can only be selected for motor driven-type work clamp)

- Use the Type keys (2) to select "Work Clamp Height".

- If you use the Height keys (3) to change the Height value, the sewing machine's work clamp will move.

(setting range: 15 - 25 initial value: 20)

- Touch the OK key (4) to confirm, or touch the Cancel key (6) to return to the sewing operation screen

without changing the setting.

- Touch the Reset key (5) to return the value which currently appears in the display to the value which was

first displayed when you switched to the setting screen. The sewing machine's work clamp will operate

according to this value.

・Intermediate work clamp height setting (can only be selected for motor driven-type work clamp)

Selection is only possible when memory switch No. 003 is set to "2".

- Use the Type keys (2) to select "Intermediate Work Clamp Height".

- If you use the Height keys (3) to change the Height value, the sewing machine's work clamp will move.

(setting range: 1 - 15 initial value: 7)

- Touch the OK key (4) to confirm, or touch the Cancel key (6) to return to the sewing operation screen

without changing the setting.

- Touch the Reset key (5) to return the value which currently appears in the display to the value which was

first displayed when you switched to the setting screen. The sewing machine's work clamp will operate

according to this value.

・Intermittent presser foot height setting

- Use the Type keys (2) to select "Intermittent Presser Foot Height".

- If you use the Height keys (3) to change the Height value, the sewing machine's intermittent presser foot

will move.

(setting range: 0.0 - 10.0 initial value: 5.0)

- Touch the OK key (4) to confirm, or touch the Cancel key (6) to return to the sewing operation screen

without changing the setting.

- Touch the Reset key (5) to return the value which currently appears in the display to the value which was

first displayed when you switched to the setting screen. The sewing machine's intermittent presser foot

will operate according to this value.

(2)

(5)

(3)

(4)

BAS H series

17

Page 20

1. USING THE LCD PANEL (BASIC OPERATIONS)

NOTE:

When setting the work clamp height and the

intermediate work clamp height, check that slider (1) is

touching the work clamp lifter plate assembly (2).

3091B

Intermittent presser foot operation

Doing standby

When lowered

1 Intermittent presser foot lift amount

2 Intermittent presser foot height stroke drop

position

3 Intermittent presser foot stroke amount

* After the presser foot has been replaced, it

will be necessary to make corrections to the

intermittent stroke drop position.

Ask the place of purchase for information on

the correction method.

When sewing

5033Q

18

BAS H series

Page 21

1. USING THE LCD PANEL (BASIC OPERATIONS)

1-5-2. For BAS-360H/BAS-365H

Adjust the intermittent presser foot height by setting the intermittent stroke drop position and the intermittent stroke amount.

[Stroke drop position setting]

(2)

[Stroke amount setting]

(6)

Type (1) Touch the △ or ▽ key to select the item to change.

(1)

(3)

(9)

(10)

(4) (5)

(7)

(8)

Touch the △ or ▽ key to change the stroke drop position.

Height (2)

Reset key (3)

OK key (4) Touch to confirm the setting value and return to the sewing operation screen.

Cancel key (5) Touch to discard the setting value and return to the sewing operation screen.

Stroke (6)

If you change the value, the sewing machine's intermittent presser foot will move.

Setting range: 0.5 to 7.0 mm, 0.1 mm units, initial value: 2.0 mm

Touch to return the value which currently appears in the display to the value which was first displayed

when you switched to the setting screen. The sewing machine's intermittent presser foot will move

according to this value.

Touch the △ or ▽ key to change the stroke amount.

If you change the value, the sewing machine's intermittent presser foot will move.

Setting range: 0.0 to 10.0 mm, 0.1mm units, initial value: 3.0 mm

BAS H series

19

Page 22

1. USING THE LCD PANEL (BASIC OPERATIONS)

Stroke Up key (7)

Stroke Down key (8)

Intermittent presser

foot height (9)

Stroke drop position

(10)

Touch to raise the intermittent presser foot.

However, the key is disabled while the intermittent presser foot is rising.

Touch to lower the intermittent presser foot.

However, the key is disabled while the intermittent presser foot is lowering.

Displays the sum of the value set for the stroke drop position and the value set for the stroke amount.

(“Intermittent presser foot operation” (2))

Displays the value set for the stroke drop position.

(“Intermittent presser foot operation” (3))

Intermittent presser foot operation

Doing standby

When lowered

1 Intermittent presser foot lift amount

2 Intermittent presser foot height stroke drop

position

3 Intermittent presser foot stroke amount

* After the presser foot has been replaced, it

will be necessary to make corrections to the

intermittent stroke drop position.

Ask the place of purchase for information on

the correction method.

When sewing

4170B

20

BAS H series

Page 23

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

CAUTION

To prevent problems, do not use objects with sharp points to operate the LCD panel.

2-1. Memory switch setting method

Press the HOME key to switch to the home screen.

[Home screen]

Touch the Settings key (1) to switch to the setting menu screen.

[Setting menu screen]

(1)

Select “Memory Switch”.

BAS H series

21

Page 24

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

[Memory switch selection screen]

(3)

Select the number of the memory switch that you would like to change the setting for.

・

When you touch the number of the memory switch you would like to change the setting for, the display will

change to the memory switch editing screen.

・

Touch the OK key (4) to return to the setting menu screen.

・

Modified (2): This displays the numbers of memory switches that have been changed from default settings.

・

All (3): This displays all memory switches.

[Memory switch editing screen]

(8)

(6)

This lets you change memory switch values.

(2)

(4)

(5)

(7)

(9)

22

Number ( ) keys (5): These change the memory switch number.

・

Value ( ) keys (6): These change the memory switch setting value display (ON/OFF, number).

・

・

Reset key (7): This displays the initial value.

・

Cancel key (8): This returns the display to the memory switch selection screen without confirming the value.

OK key (9): This confirms the value and then returns the display to the memory switch selection screen.

・

BAS H series

Page 25

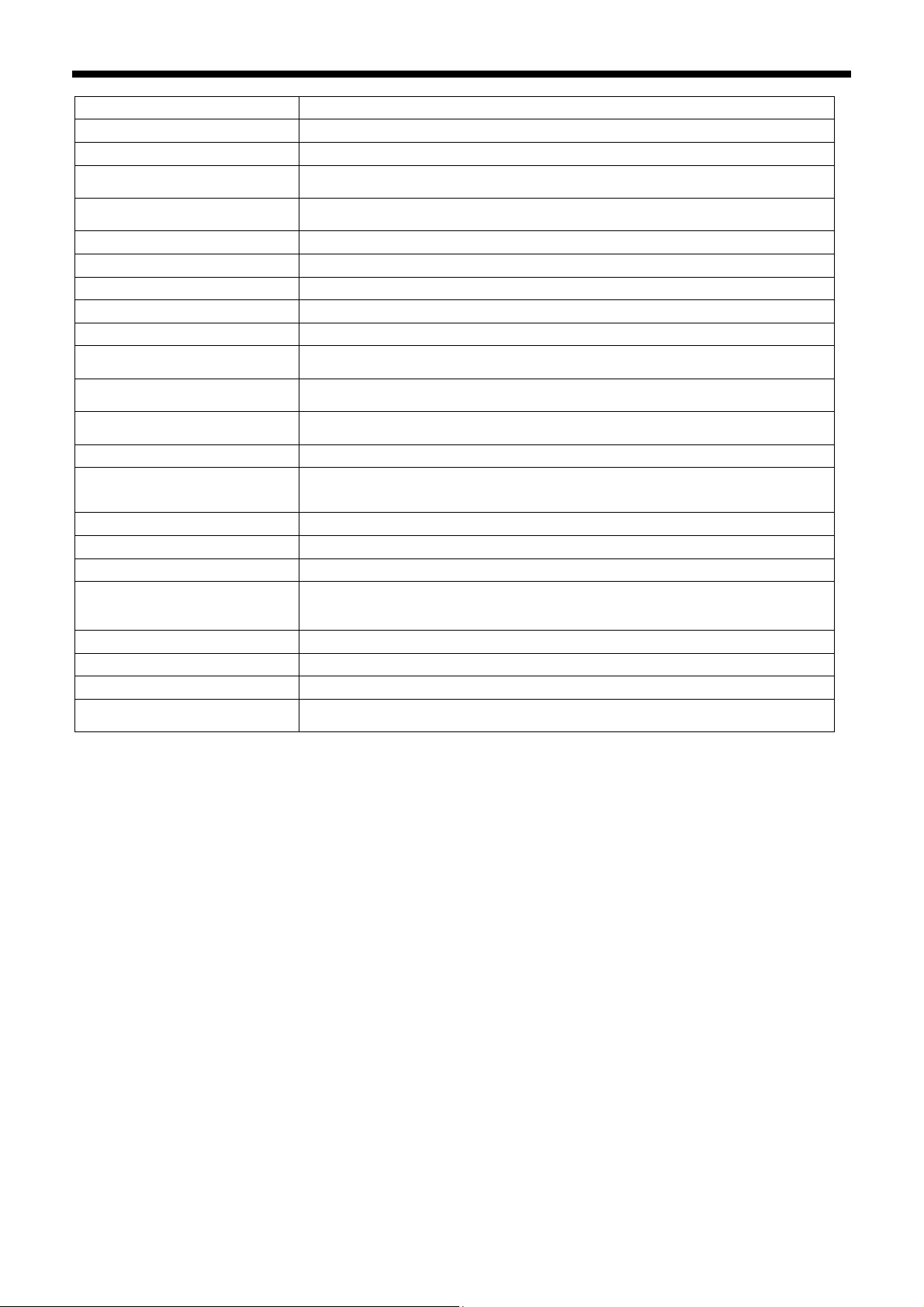

2-2. List of memory switch settings

No.

001

002

003

100

200

400

403

Setting

range

Work clamp lift timing after sewing is completed

0 Work clamp is not raised automatically.

1 Work clamp is raised at the final stitch position.

2 Work clamp is raised after moving to the home position.

Work clamps lowering operation (Models other than pneumatic work clamp specifications/BAS341H/BAS342H) (*2)

0 Left and right work clamps are lowered at the same time.

1 Work clamps are lowered in order left > right.

2 Work clamps are lowered in the order right > left.

Work clamp lowering operation (BAS341H/BAS342H only) (*2)

0 Work clamp dropping in one step

1 Work clamp dropping in two steps (*1)

2 Do not use this setting.

Work clamp lowering operation (Motor-driven work clamp specifications only)

Analog lowering: Work clamp is lowered in direct proportion to the pedal

0

1

2

Slow start method

OFF

ON

Single-stitch test feed

OFF

ON

Sewing condition detail settings

OFF Parameters which are common to all programs are used.

ON Parameters can be set separately for each program.

Split mode selection

0 Continuous split mode

1 Single split mode

depression amount, and sewing starts when the pedal is fully depressed.

* This operation is only possible for foot switch specifications; for two-pedal foot

switch specifications, operation is the same as for a 2-step work clamp.

1-step work clamp: Work clamp is lowered when pedal is depressed to the 1st step,

and sewing starts when pedal is depressed to the 2nd step.

2-step work clamp: Work clamp is lowered to intermediate height when pedal is

depressed to the 1st step, and work clamp is fully lowered and sewing starts when

the pedal is depressed to the 2nd step.

The sewing speed for the first 5 stitches will be in accordance with the setting for

memory switch Nos. 151 to 155. (Ask the place of purchase for details on memory

switch Nos. 151 to 155.)

The sewing speed for the first 4 stitches can be selected from the nine slow start

patterns “1” to “9”. (Refer to Slow start pattern in “1-2. Parameter setting method”.)

Initial value of slow start pattern: 4

Test feed starts when the foot switch (start switch) is depressed, and it continues

automatically until the final stitch.

Test feed starts when the foot switch (start switch) is depressed, and it moves

forward by one stitch each time the switch is depressed.

In addition, after test feed starts, test feed will move forward one stitch at a time

when the machine pulley is turned by hand.

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

Function name

Setting details Initial value

2

0

0

2

OFF

OFF

OFF

0

(*1) The position of the work clamp stopper must be set.

(*2) This is not displayed for the BAS-360H/365H.

BAS H series

(Continued on next page)

23

Page 26

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

No.

407

408

409

410

Setting

range

Assignment to direct selection key 1

OFF No program number is assigned to direct selection key 1.

1 - 999 The program number is assigned.

C01 - C30 The cycle program number is assigned.

Assignment to direct selection key 2

OFF No program number is assigned to direct selection key 2.

1 - 999 The program number is assigned.

C01 - C30 The cycle program number is assigned.

Assignment to direct selection key 3

OFF No program number is assigned to direct selection key 3.

1 - 999 The program number is assigned.

C01 - C30 The cycle program number is assigned.

Assignment to direct selection key 4

OFF No program number is assigned to direct selection key 4.

1 - 999 The program number is assigned.

C01 - C30 The cycle program number is assigned.

Function name

Setting details Initial value

101

102

103

104

24

BAS H series

Page 27

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

2-3. Using cycle programs

Sewing patterns that have been recorded in user programs can be saved in up to 30 cycle programs.

One cycle program can contain up to a maximum of 50 steps.

When sewing the sewing patterns in a certain order, it can be useful to save them in a cycle program beforehand.

* If memory switch No. 400 is set to OFF, cycle program setting and selection cannot be carried out.

<Registration method>

This describes the procedure using an example in which program number 106 is registered as the 1st step,

program number 200 is registered as the 2nd step and program number 252 is registered as the 3rd step of cycle

program number C01.

1. Touch the cycle program key in the sewing operation screen to switch to the cycle program editing screen.

* To edit a cycle program which has already been created, first select the desired cycle program number and then

touch the cycle program key.

[Sewing operation screen]

2. Touch the add step key (1) in the cycle program editing screen to switch to the add step screen.

[Cycle program editing screen]

(6)

(5)

(1)

(2)

(3)

(4)

(7)

BAS H series

25

Page 28

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

Descriptions of keys

(1) Add step Switches to the screen for selecting a program to add.

(2) Delete step Deletes the program which is currently selected.

(3) Move step (forward) Moves the currently-selected program one step toward the start.

(4) Move step (backward) Moves the currently-selected program one step toward the end.

When saving a new program:

(5) Save

(6) Save as ... Switches to the cycle program save screen.

(7) OK Switches to the sewing operation screen.

Switches to the cycle program save screen.

When saving an existing cycle program that has been edited:

The save program dialog box is displayed.

3. Select "Program No." in the add step screen and then touch the OK key to add that program number. The display will

then return to the cycle program editing screen.

* If you touch the multiple select key (8), you can select multiple files.

[Add step screen]

(8)

[Cycle program editing screen]

(5)

(6)

(1)

(2)

(3)

(4)

(7)

26

BAS H series

Page 29

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

4. Repeat the operations in steps 2. and 3. to create the desired cycle program, and then touch the Save key (5) or Save

as ... key (6) to switch to the cycle program save screen.

5. Enter the cycle program number, and then touch the OK key. The cycle program will be saved and the display will

return to the cycle program editing screen. Numbers from C01 to C30 can be saved.

[Cycle program editing screen]

(5)

(6)

[Cycle program save screen]

6. Touch the OK key (7) in the cycle program editing screen to return to the sewing operation screen.

BAS H series

27

Page 30

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

<Method of use>

When cycle programs have been registered, you can select the cycle program numbers from the sewing operation screen.

[Sewing operation screen]

(9)

(10)

(11)

(12)

(13)

Descriptions of keys

(9) Type key Select "Cycle".

The currently selected cycle program number is displayed.

(10) Program No. keys

(11) Step No. keys

(12) Section No. keys

(13) Tension keys

Touch the ▽△ keys to select the cycle program number that you would like to

use.

The currently selected step number is displayed.

Touch the ▽△ keys to select the step number.

The currently selected section number is displayed.

Touch the ▽△ keys to select the section number.

The tension value of the currently selected section number is displayed.

Touch the ▽△ keys to select the tension value.

28

BAS H series

Page 31

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

2-4. Direct selection

You can use the direct selection keys to directly select program numbers and cycle program numbers.

[Sewing operation screen]

<Recording method>

This is carried out using memory switch Nos. 407 to 410.

Setting range: OFF, 001 - 999, C01 - C30

Direct selection

1 key

Corresponding memory

switch number

Initial value 101 102 103 104

407 408 409 410

Direct selection

2 key

・ If there are no program numbers registered in a direct selection key (i.e. it is OFF), "---" will be displayed and the

display will become inactive.

・ If a program number (sewing pattern) which has been registered in a direct selection key cannot be loaded, the

display will be inactive and the key cannot be selected.

・ If you keep pressing a direct selection key, the display will switch to the settings for the program number displayed

with this key.

Direct selection keys

1 to 4

Direct selection

3 key

Direct selection

4 key

BAS H series

29

Page 32

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

2-5. Setting the sewing screen display

This lets you set whether the codes which are displayed in the sewing screen preview are displayed or not displayed.

1. Press the HOME key to switch to the home screen.

Touch the Settings key (1) to switch to the setting menu screen.

[Home screen]

(1)

2.

Select "Sewing Screen".

[Setting menu screen]

BAS H series

30

Page 33

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

3. Select "Display Setting of Sewing Data Preview".

[Sewing Screen]

4. The codes which can be switched between displayed and not displayed in the sewing screen preview are displayed in a

list.

If you would like the codes to be displayed, select the corresponding check box.

If you would like the codes to be not displayed, unselect the corresponding check box.

* These settings are not applied during digital tension editing mode.

BAS H series

31

Page 34

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

2-6. Initialization method

Press the HOME key to switch to the home screen.

[Home screen]

(1)

Touch the Settings key (1) to switch to the setting menu screen.

[Setting menu screen]

Select "Data Management".

Select "Format".

32

BAS H series

Page 35

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

The following five items will be displayed for initialization.

- Sewing data, cycle program, user parameter

- Cycle program, user parameter

- Memory Switch Settings

- Panel settings, programmer settings, sewing settings

- Extended option program

Place a check mark against the items you would like to initialize, and then touch the OK key (2) to start the

initialization.

When initialization is finished, the finished message screen will be displayed.

(2)

BAS H series

33

Page 36

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

2-7. Maintenance mode

If you switch to maintenance mode, you can then move the machine head to the to the edge when carrying out adjustment,

etc.

[Home screen]

Press the HOME key to switch to the home screen.

(1)

[Setting menu screen]

Select "Sewing Machine Adjustment".

34

[Sewing Machine Adjustment Screen]

Select "Maintenance".

BAS H series

Page 37

[Maintenance Screen]

Press the left switch and the right switch simultaneously. The machine head will then move

Remove both work clamp frame and feed plate, and turn off the power.

2. USING THE LCD PANEL (ADVANCED OPERATIONS)

BAS H series

35

Page 38

3. USING STORAGE MEDIA

3. USING STORAGE MEDIA

CAUTION

Do not connect anything to the USB port other than the USB memory. If this is not observed, problems with

operation may result.

To prevent problems, do not use objects with sharp points to operate the LCD panel.

3-1. Notes on handling

【SD】

Compatible cards: SD (max. 2 GB), SDHC (max. 32 GB)

-

Compatible file formats: FAT16, FAT32

-

【USB Memory】

-

Compatible file formats: FAT16, FAT32

Max. size: 32 GB

-

3-2. Folder structure

Data type File name Folder name

ISMS0***.SEW

Sewing data

Memory switch memorysw.db Same as above

ISMS0***.EMB

(*** is the program number.)

\BROTHER\ISM\ISMDH**\

\BROTHER\ISM\ISMDH**\ (For BAS-360H and

BAS-365H)

(The sewing machine's ID code appears in the **

part.)

(Ask the place of purchase for details on the method

of changing the settings.)

User parameter userparam.db Same as above

ISMCYC**.SEW

Cycle program

Panel setting values settings.db Same as above

Extended option data

Error log

(** is the cycle program

number.)

ISMSEQ**.SEQ

(** is the extended option

number.)

e*******.csv

m*******.db

(******* is the serial number.)

Same as above

Same as above

\BROTHER\ISM\ISMLDT\

36

BAS H series

Page 39

3-3. Importing and exporting data

[

1

SD card slot

2

Home screen]

(1)

[Setting menu screen]

USB port

3. USING STORAGE MEDIA

Insert an SD card or USB memory.

NOTE:

・

Make sure that the media is facing the

correct way when inserting it.

Always be sure to keep the cover closed

・

except when inserting and removing the

media, otherwise dust may get inside and

cause problems with operation.

・ Press the HOME key to switch to the home

screen.

・ Touch the Settings key (1) to switch to the

setting menu screen.

4290B

3593B

・

If you select "Data Management" > "Import

(Storage Media to Panel)", the display

switches to the import screen. If you select

"Data Management" > "Export (Panel to

Storage Media)", it switches to the export

screen.

BAS H series

37

Page 40

3. USING STORAGE MEDIA

3

[Import screen]

[Export screen]

(2)

Select the items to be imported or exported,

and then touch the OK key (2).

[Items to import]

Sewing data (all)

Cycle program, user parameter

Memory switch settings

Panel settings, programmer settings

Extended option program

* To select and import only part of the

sewing data, refer to the procedure in 3-4.

[Items to export]

Sewing data (all)

Cycle program, user parameter

Memory switch settings

Panel settings, programmer settings

Extended option program

Error log

(2)

38

BAS H series

Page 41

3-4. Importing items of sewing data separately

3. USING STORAGE MEDIA

If you would like to import sewing data separately, do it from the file manager screen. Folders are not specified.

1

SD card slot USB port

2

[Home screen]

(1)

Insert an SD card or USB memory.

NOTE:

・ Make sure that the media is facing the

correct way when inserting it.

・ Always be sure to keep the cover closed

except when inserting and removing the

media, otherwise dust may get inside and

cause problems with operation.

・

Press the HOME key to switch to the

home screen.

・

If you touch the File manager key (1), the

display will switch to the file manager

screen.

[File manager screen]

・

Touch the media key in the top-left corner

to select "SD Card" or "USB Memory".

The display will switch to the respective

main folder.

4290B

3593B

3

* For details on other functions, please contact the place of purchase.

BAS H series

(2)

・ Select the files to be imported and then

touch the import key (2) .

* If you would like to select multiple files,

you can select files in multiple select

mode.

Touch to switch between multiple

select and single select mode.

39

Page 42

INSTRUCTION MANUAL

* Please note that the contents of this manual may differ slightly from the actual product purchased as a result of product improvements.

© 2015, 2016, 2018 Brother Industries, Ltd. All Rights Reserved.

This is the original instructions.

BAS H series

I8041230B E

2018.04.B (1)

Loading...

Loading...