Page 1

SERVICE MANUAL

FOR

BAS-605

AUTOMATIC

(FOR FLAP ATTACHMENT)

BAS-61 0

LOCK

STITCH

POCKET

SERIES

WELT

SEWER

Page 2

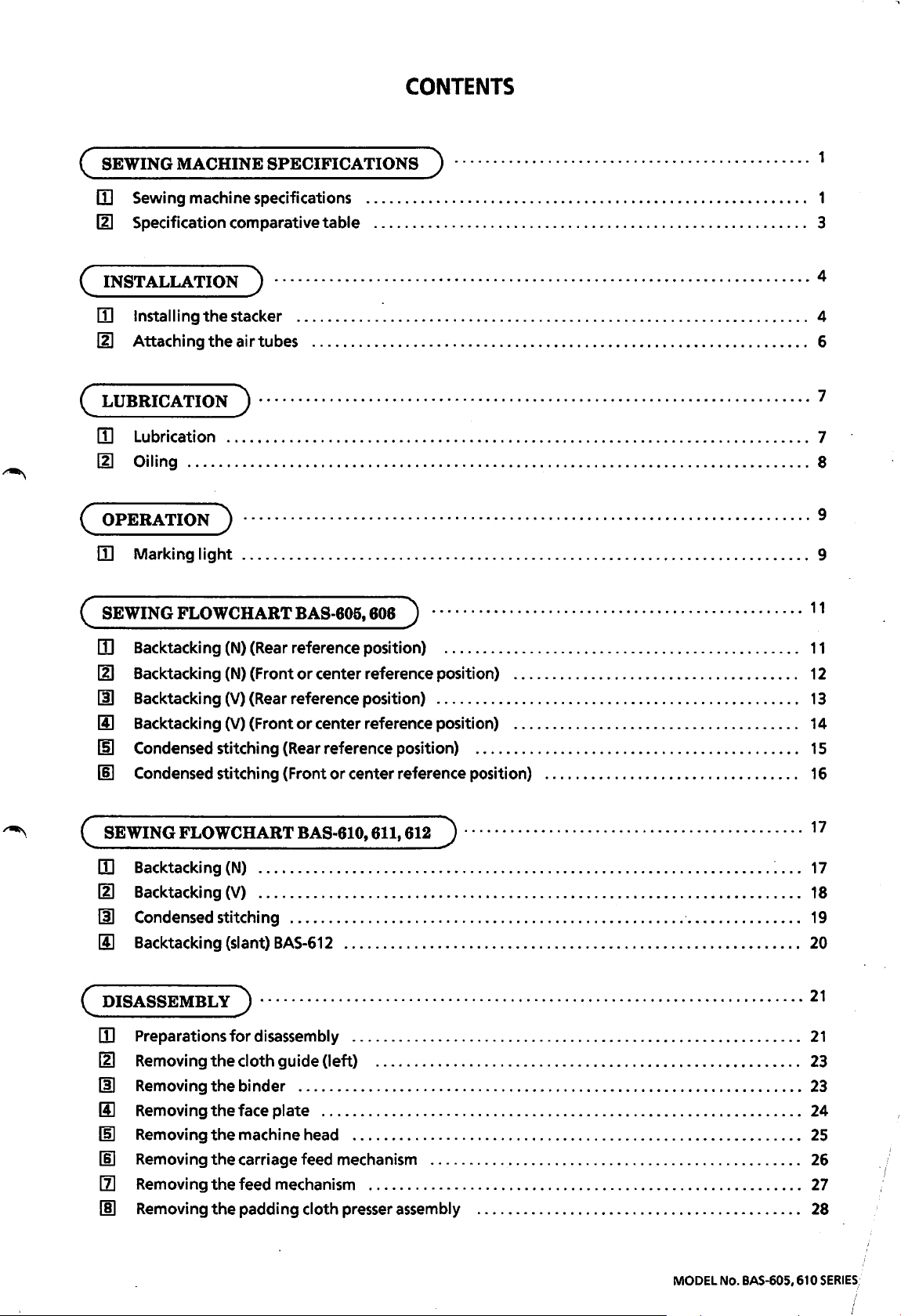

CONTENTS

(

SEWING

I]] Sewing machine specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

~

(

INSTALLATION

rn

~

(

LUBRICATION

I]] Lubrication . . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

~

(

OPERATION

MACHINE

Specification comparative

SPECIFICATIONS

) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 4

Installing

Attachingtheairtubes

the

stacker

..................................................................

................................................................

) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 7

Oiling

................................................................................

)

···························

table

) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

· ·

········ · ········ · ·······

·· ··

··········

· · ·

··

4

6

8

9

I]]

Marking

(

SEWING

[]]

Backtacking (N} (Rear reference position)

~

Backtacking

liD

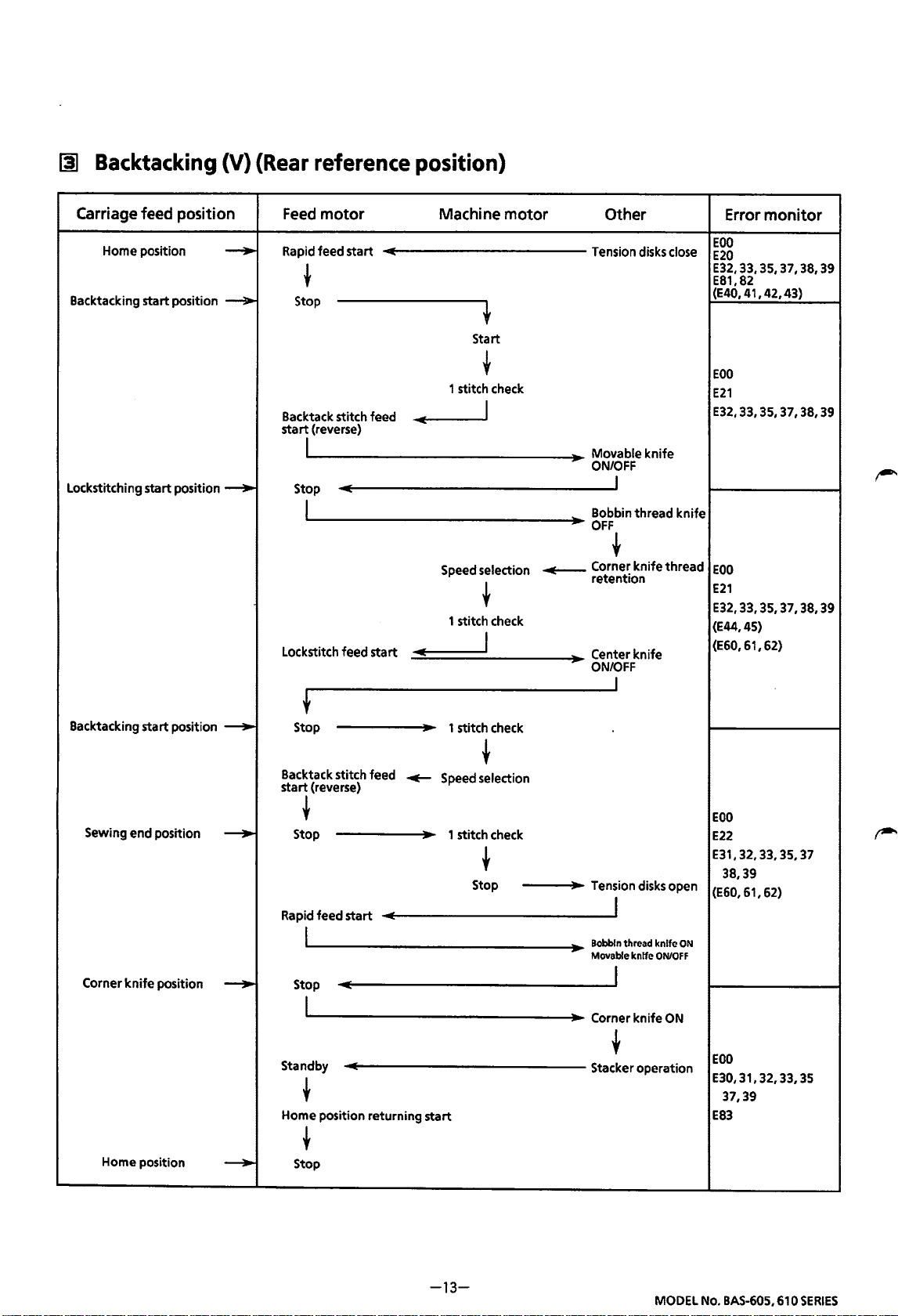

Backtacking (V)(Rear reference position)

1!1

Backtacki

[§] Condensed stitching (Rear reference position)

III Condensed stitching (Front

(

SEWING

I]] Backtacking (N)

~

Backtacki

liD

Condensed stitching

1!1

Backtacking (slant) BAS-612

(

DISASSEMBLY

light

.........................................................................

FLOWCHART

(N)(Front

ng

(V)(Front

FLOWCHART

..................................................................

ng

(V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

BAS-605, 606 ) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

or

center reference position) . . . . . . . . . . . . . . . .

or

center reference position) .

or

center reference position) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BAS-610, 611, 612 ) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

...................................................

...........................................................

..............................................

..

. . .

..

. . .

..

.. . ..

. . .

..

..

..

. . .

..

.. ..

..

. .

..

. .

..

. . .

..

.. . ..

..........................................

..

. . . . . . . .

. . . . .

..

. .

..

. . .

·

...............

.. ..

..

.. ..

. .

. . . . . .

..

. . . . . 14

:

...

9

11

11

12

13

15

16

17

17

19

20

21

I]] Preparations

~

Removing

liD

Removing

1!1

Removing

[§] Removing

III Removing

Removing

Ill

Removing

for

disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

cloth

guide

(left)

the

binder

the

face

the

machine head . . . . .

the

carriage feed mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

the

feed mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

the

padding cloth presser assembly . . . .

.................................................................

plate

..............................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

..

. . . . . . . . . . . . . . . . . . .

..

..

. . . . . . . . . . . .

. . . . . . .

.. . ..

. . . .

..

. . . . . . . . . . . . .

MODEL

.. . ..

No.

..

..

. . .

.. .. . ..

BAS-605,

21

23

24

..

25

. . 28

610

SERIES/

Page 3

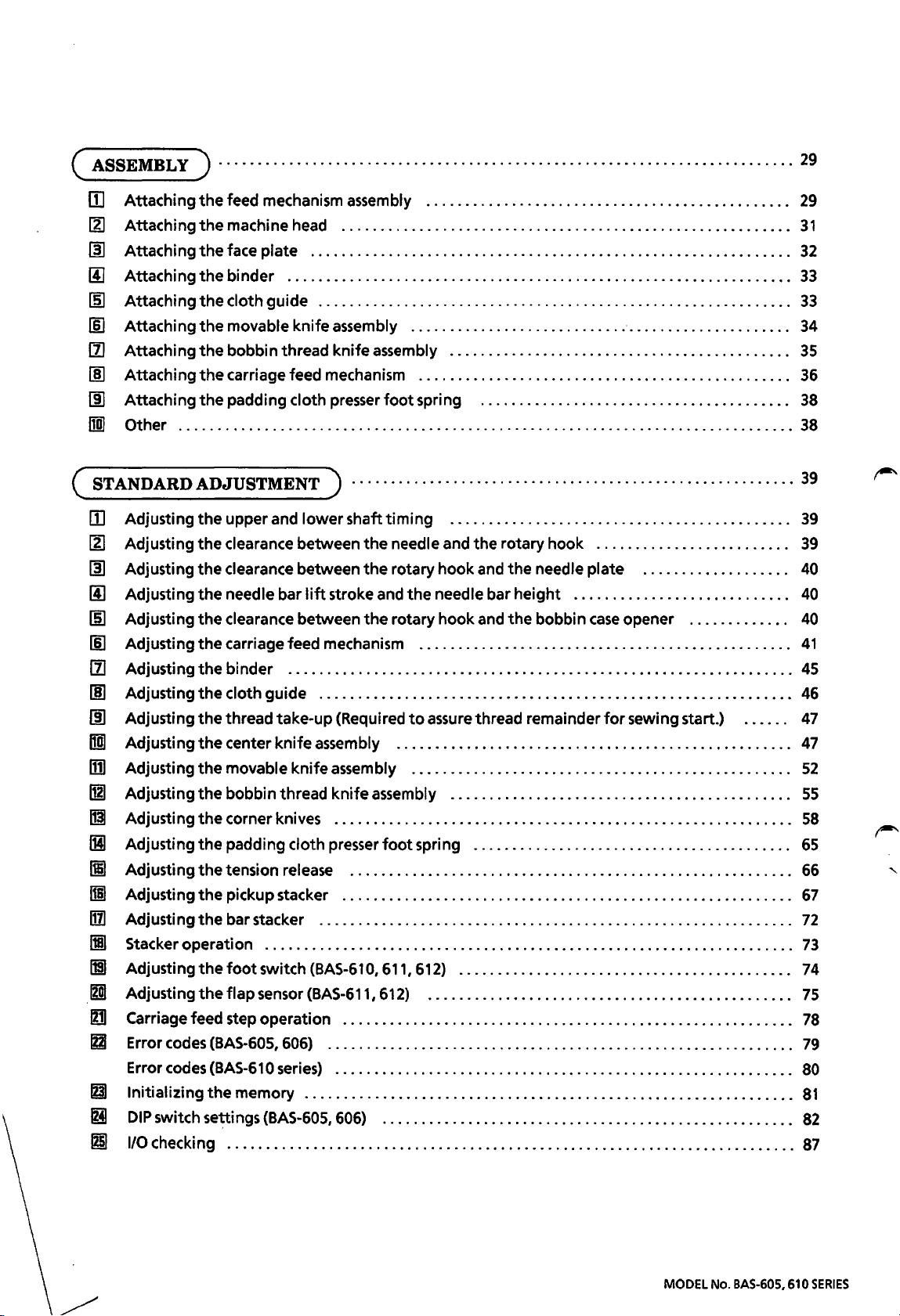

(

ASSEMBLY

) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

29

[I] Attaching

IZ1

Attaching

@1

Attaching

00

Attaching

[§]

Attaching

liD

Attaching

!I1

Attaching

00

Attaching

[11

Attaching

1iDJ

Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

(

STANDARD

[]]

Adjusting

IZ1

Adjusting

@]

Adjusting

00

Adjusting

[§]

Adjusting

liD

Adjusting

!I1

Adjusting

00

Adjusting

[11

Adjusting

liDJ

Adjusting

Ill!

Adjusting

Hi~

Adjusting

~

Adjusting

Ml

Adjusting

H§l

Adjusting

Hm

Adjusting

Ill!

Adjusting

lift!

Stacker operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ill Adjusting

181

Adjustingtheflapsensor(BAS-611,612)

~ Carriage feed step operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IDl

Error codes (BAS-605, 606) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error codes

1211

Initializing

~

DIP

~

110

checking

the

feed mechanism assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

machine head

the

face plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

binder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

doth

guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

movable knife assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

the

bobbin thread knife assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

carriage feed mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

the

padding cloth presser

ADJUSTMENT

the

upper and

the

clearance between

the

clearance between

the

needle bar

the

clearance between

the

carriage feed mechanism

the

binder

the

doth

the

thread take-up (Required

the

center knife assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

movable

the

bobbin thread

the

corner knives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

padding cloth presser

the

tension release

the

pickup stacker . . . . . . . . . . .

the

bar stacker

the

foot

(BAS-61

the

memory

switch settings (BAS-605, 606) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.........................................................................

.................................................................

guide

knife

switch

0 series) . . . . . .

..........................................................

foot

spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

lower

shaft

timing

the

needle and the rotary hook . . . . . . . . . . . . . . . . . . . . . . . . .

the

rotary

lift

stroke and

the

rotary hook and

.............................................................

assembly

knife

assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

foot

..

. . . . . . .

.............................................................

(BAS-61

...............................................................

0,

611, 612)

..

. . . . . . . . . . .

............................................

hook

and

the

needle plate . . . . . . . . . . . . . . . . . . .

the

needle bar height . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

bobbin

................................................

to

assure thread remainder

.................................................

spring .

.. . ..

.. ..

...............................................

.. . ..

..

. . . . . . . . .

..

. . . . . . .

..

..

..

..

. . . . . . . .

.. . .. ..

.. . ..

. .

.. . .. . ..

..

case

opener . . . . . . . . . . . . .

for

sewing start.)

. . .

..

.. .. ..

..

. .

..

. . . . . . . . . . . . . . . . . . .

. . . . .

..

..

..

..

. . . . . . . . .

..

..

..

. . . .

.. . .. ..

. . . .

. . . . .

..

..

..

. .

. . . .

. .

..

..

..

..

. . . . .

..

. . . . . . .

. .

..

.. . ..

..

. . .

..

..

..

. . . 80

29

31

32

33

33

35

39

39

39

40

40

40

41

45

46

47

47

52

55

58

65

66

67

72

73

. 7 4

75

78

79

81

82

87

'

MODEL

No.

BAS-605,

610

SERIES

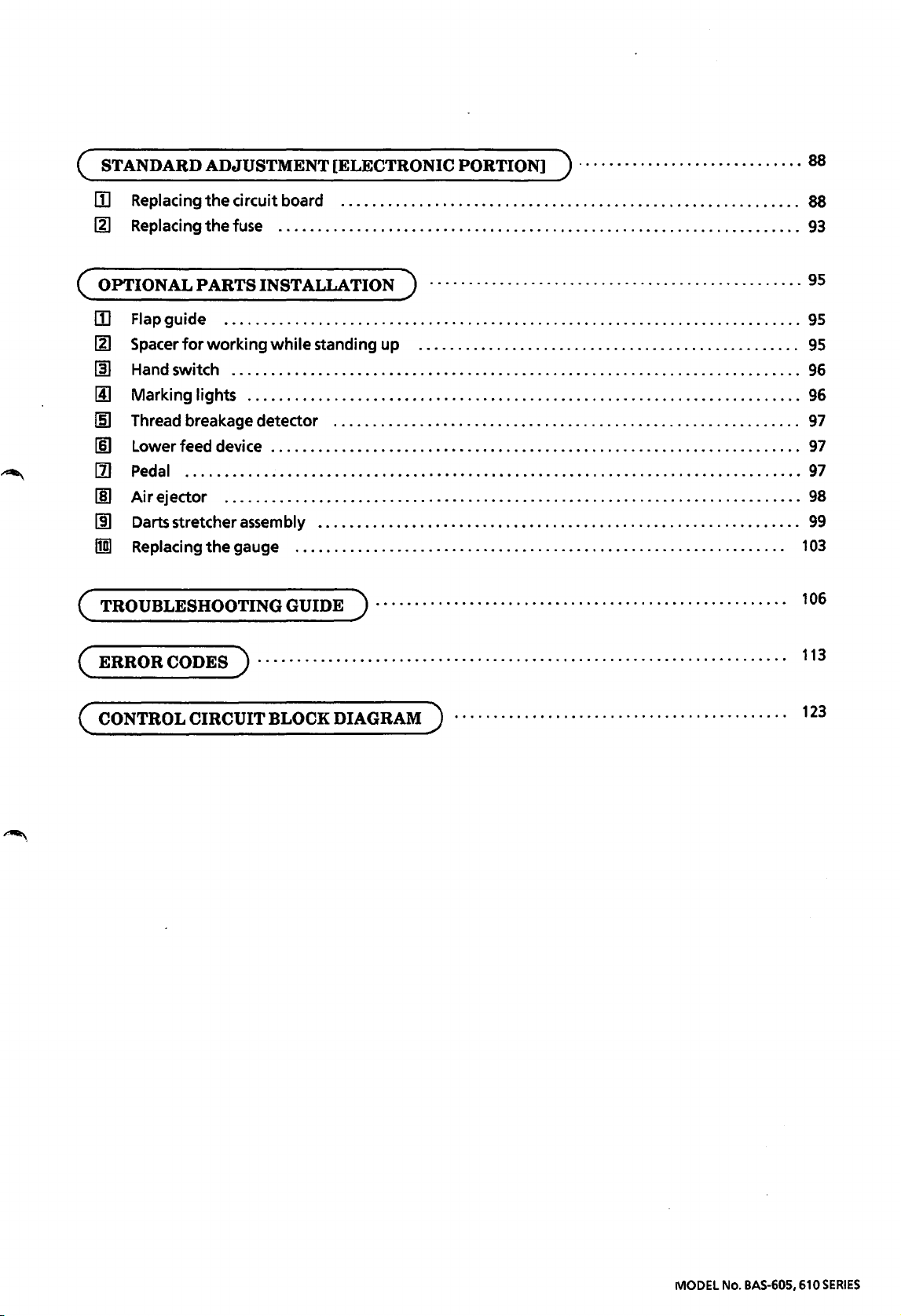

Page 4

( STANDARD ADJUSTMENT [ELECTRONIC PORTION] ) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 88

ill

Replacing

~

Replacing

(

OPTIONALPARTSINSTALLATION)

ill

Flap

~

Spacerfor

00

Hand switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

!!I

Marking

[§]

Thread breakage

[§]

Lower feed device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

111

Pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ill

Air

ejector

~

Darts stretcher assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

!iDl

Replacing

guide

lights

the

circuit board

the

fuse

...................................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

working

the

while

.......................................................................

detector

..........................................................................

gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

...........................................................

····

········

standing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

up

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

········· · ·········

..

. . . . . . . . . . . . . . . . . . .

·····

············

..

. . . . . . . .

88

93

95

95

95

96

96

97

97

97

98

99

103

( TROUBLESHOOTING GUIDE )

(ERROR

CODES)····································································

······

· ·

·········· · ······· · ·······

· ·

··

··········

·····

( CONTROL CIRCUIT BLOCK DIAGRAM ) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

106

113

123

MODEL

No.

BAS-605,

610

SERIES

Page 5

(

SEWINGMACHINESPECIFICATIONS)

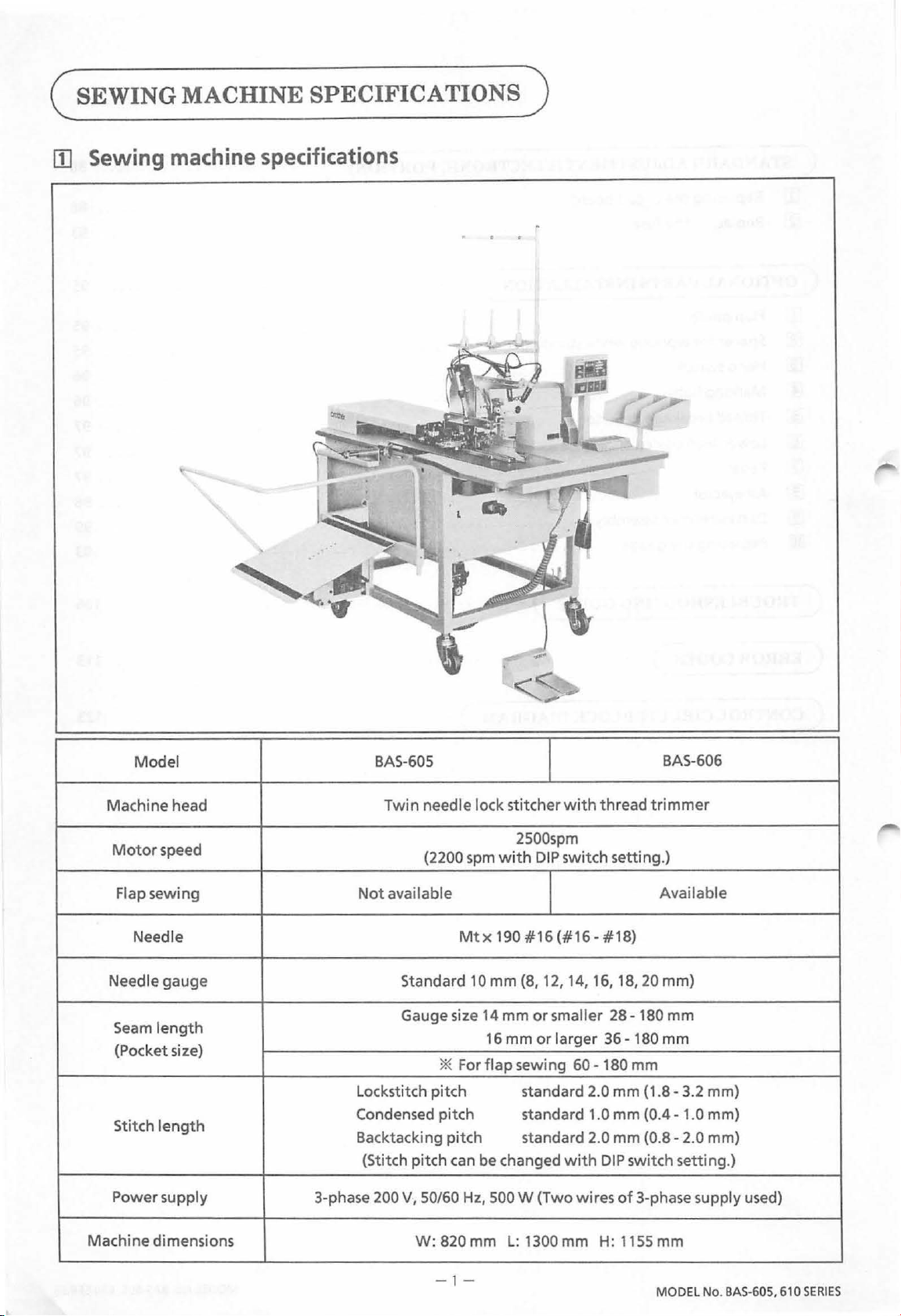

11J

Sewing

machine

specifications

Model

Machine head

Motor

Needle gauge

speed

Flap sewing

Needle

.·

~

' A·

...

Not

BAS-605

Twin needle lock stitcher

2500spm

(2200

spm

with

available

Mtx

190#16(#16-#18)

Standard

10

mm (8,

with

thread t

DIP

switch setting.)

12,

14,

16, 18,

BAS-606

rimmer

Available

20

mm)

Seam

length

(Pocket size)

length

Stitch

Power supply

Machine dimensions

Lockstitch pitch

Condensed pitch

Backtacking pitch

(Stitch pitch

3-phase 200

Gauge size

V,

50/60Hz,

W:

-1-

14

mm

16

mm

*

Forflapsewing

can

be

changed

500

820 mm

L:

or

smaller

or

larger

standard 2.0 mm (1.8-3.2 mm)

standard

standard

with

W (Two wires

1300 mm

28-180

36-

60-180mm

1.0 mm

2.0 mm (0.8-2.0 mm)

DIP

of

H:

mm

180

mm

(0.4-

1.0 mm)

switch setting.)

3-phase supply used)

1155 mm

MODEL No.

BAS-605,

610

SERIES

Page 6

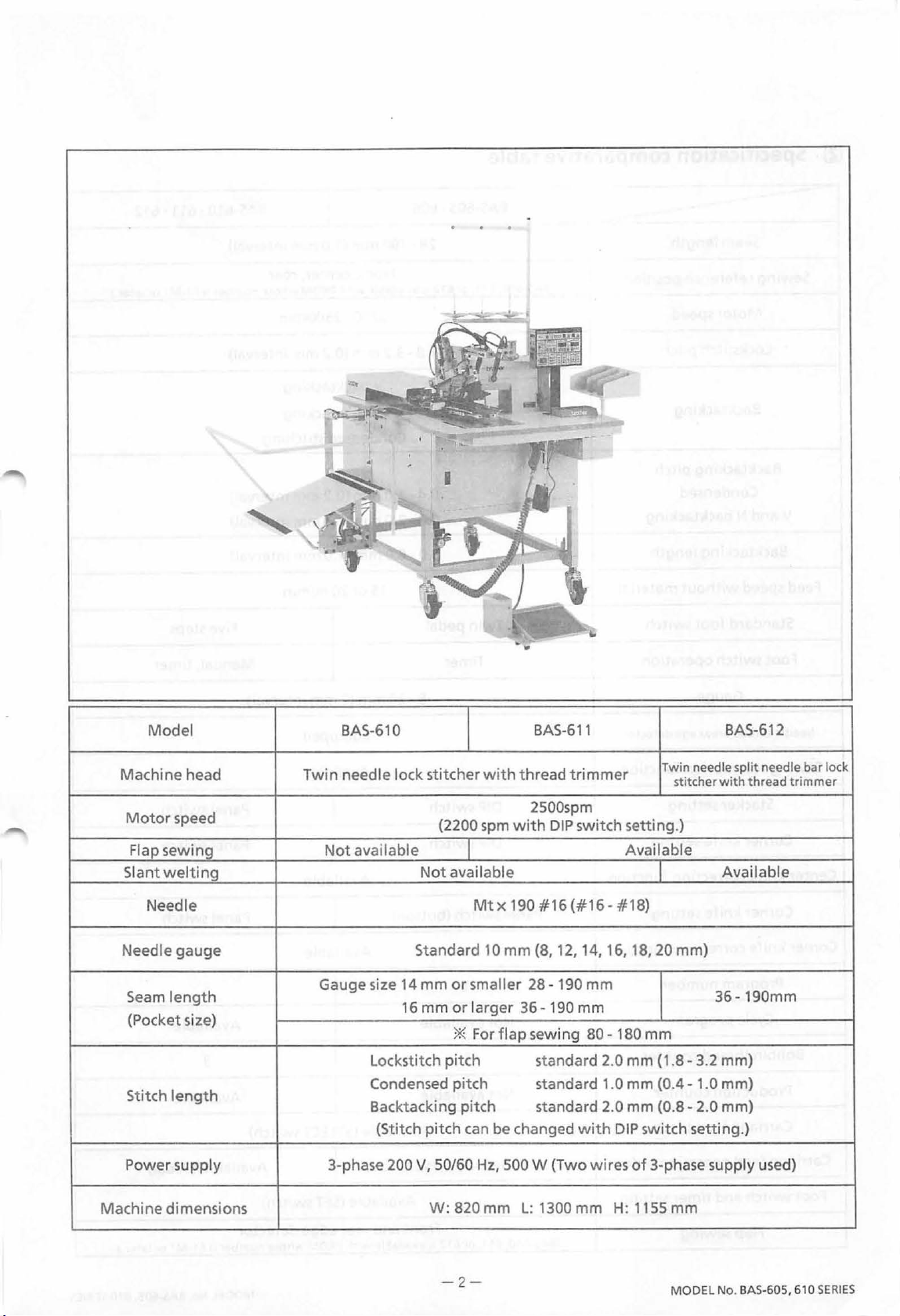

Model

BAS-610

BAS-611

BAS-612

Machine head

Motor

Slant

Needle

Power supply

Machine dimensions

speed

Flap sewing

welting

Needle

gauge

Seam

length

{Pocket size)

Stitch

length

Twin

needle lock stitcher

Not

available Available

Gauge size 14 mm

16 mm

Lockstitch pitch

Condensed pitch

Backtacking pitch

{Stitch pitch

3-phase

200

with

thread

spm

{2200

Not

available

Standard

or

or

*

can

V,

50/60Hz, 500 W (Two wires

W:

820 mm

with

Mt X 190 # 16

10

mm (8, 12,

smaller

larger

36-190

Forflap

be changed

L:

trimmer

2500spm

DIP

switch setting.)

( #

28-

190

mm

sewing

standard

standard

standard

with

1300

mm

Twin needle split needle bar lock

stitcher

16

- #

18)

14,

16, 18, 20 mm)

mm

80-

180 mm

2.0 mm

1.0 mm (0.4- 1.0 mm)

2.0 mm (0.8- 2.0 mm)

(1.8-

3.2 mm)

DIP

switch setting.)

of

3-phase supply used)

H:

1155 mm

with

thread

Available

36-190mm

trimmer

-2-

MODEL No. BAS-605,

610

SERIES

Page 7

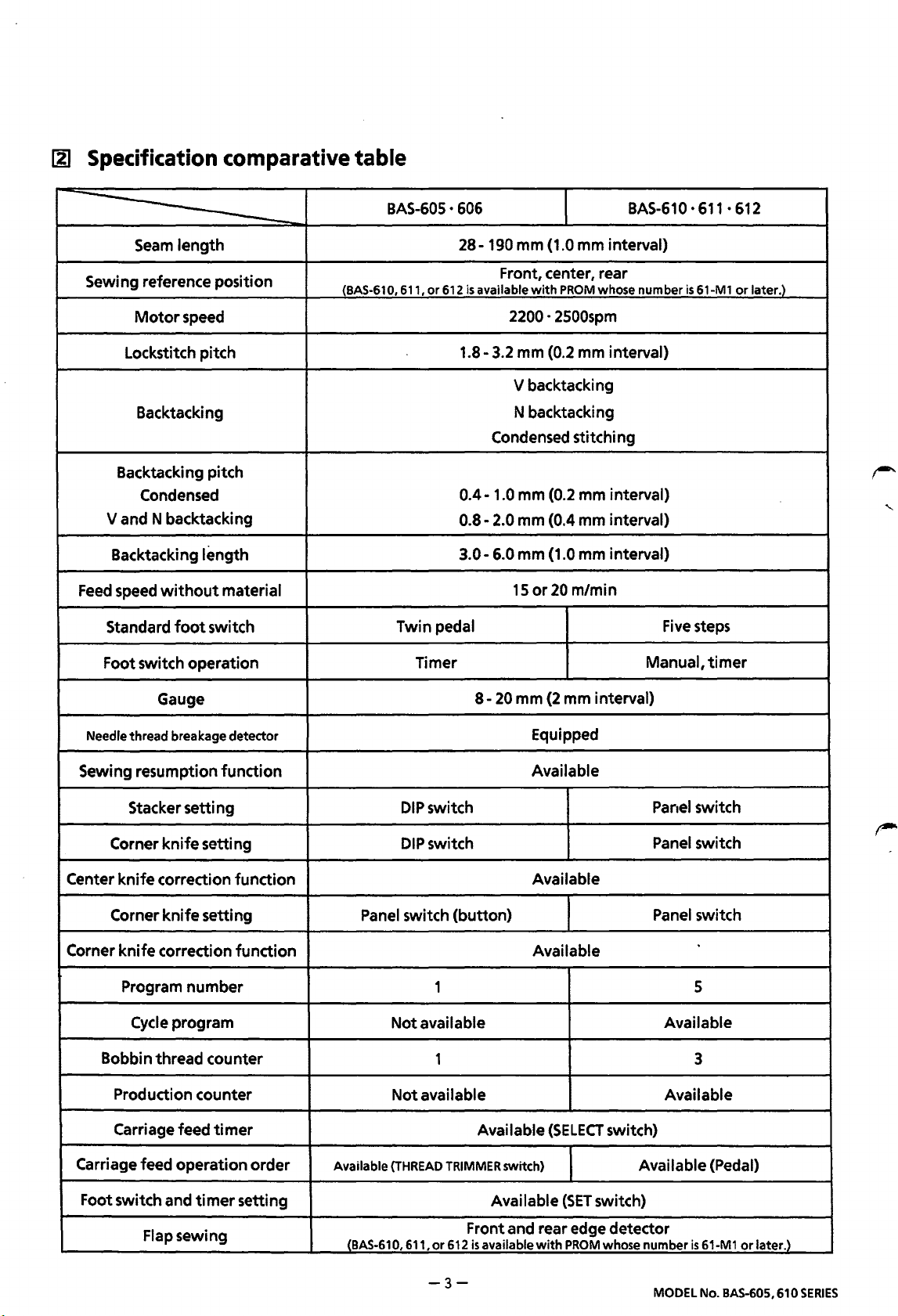

~

Specification comparative table

--------

Sewing reference position

Feed

Seam

length

Motor

Lockstitch pitch

Backtacki ng pitch

V and N backtacking

Backtacking

speed

Standard

Foot switch operation

speed 2200 · 2500spm

Backtacking

Condensed

length

without

foot

material

switch

BAS-605

(BAS-610, 611,

Twin pedal

Timer

or

612

• 606

28-190

is

1.8-3.2

0.4-

0.8-

3.0-6.0

mm (1.0 mm interval)

Front, center, rear

available

with

PROM whose

mm (0.2 mm interval)

V backtacki ng

N backtacking

Condensed stitching

1.0 mm (0.2 mm interval)

2.0 mm (0.4 mm interval)

mm

(1.0 mm interval)

15

or

20m/min

BAS-610 • 611

number

is

61-M1

Five steps

Manual,

timer

• 612

or

later.)

Gauge

Needle

thread

breakage

Sewing resumption

Stacker setting

Corner

Center

Corner

Corner

Bobbin thread counter

Production counter

Carriage feed

knife

knife

correction

knife

knife

correction

Program

Cycle program

detector

function

DIP

switch

DIP

setting

function

setting Panel switch (button)

function

number

timer

switch

1 5

Not

available

1 3

Not available Available

8-20

mm

Equipped

Available

Available

Available

Available

{2

mm interval)

(SELECT

switch)

Panel switch

Panel switch

Panel switch

Available

Carriage feed

Foot switch and

operation

timer

Flap sewing

order

setting Available

Available

(BAS-610,

(THREAD TRIMMER switch) Available (Pedal)

611,or

Front and rear edge detector

612

isavailablewith

(SET

PROM

-3-

switch)

whose

number

is

61-M1

or

later.)

MODEL No. BAS-605, 610

SERIES

Page 8

c

INSTALLATION)

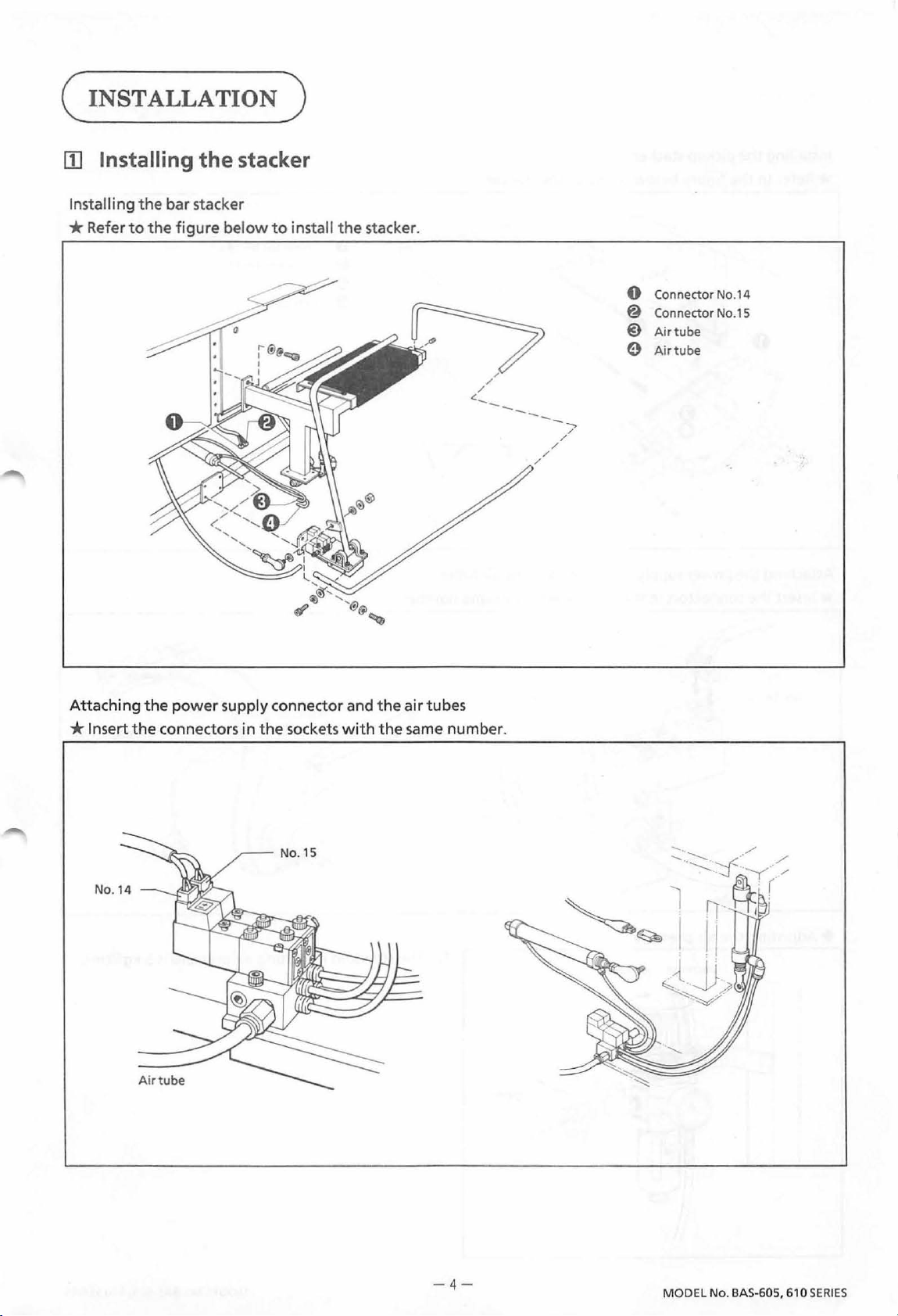

[I]

Installing

In

stalling

*Refer

the

to

the

the

bar

stacker

figure below

stacker

to

install

the

stacker.

Attaching

*

Ins

ert

the

power

the

connectors in

supply connector

the

sockets with

and

the

air

tubes

the

same number.

/

.::

__

/

/

--

---/

Connector

0

@

Connector

@)

Air

Air

e

/

/

No.14

No.15

tube

tube

- 4 -

MODEL No. BAS-605,

610

SERIES

Page 9

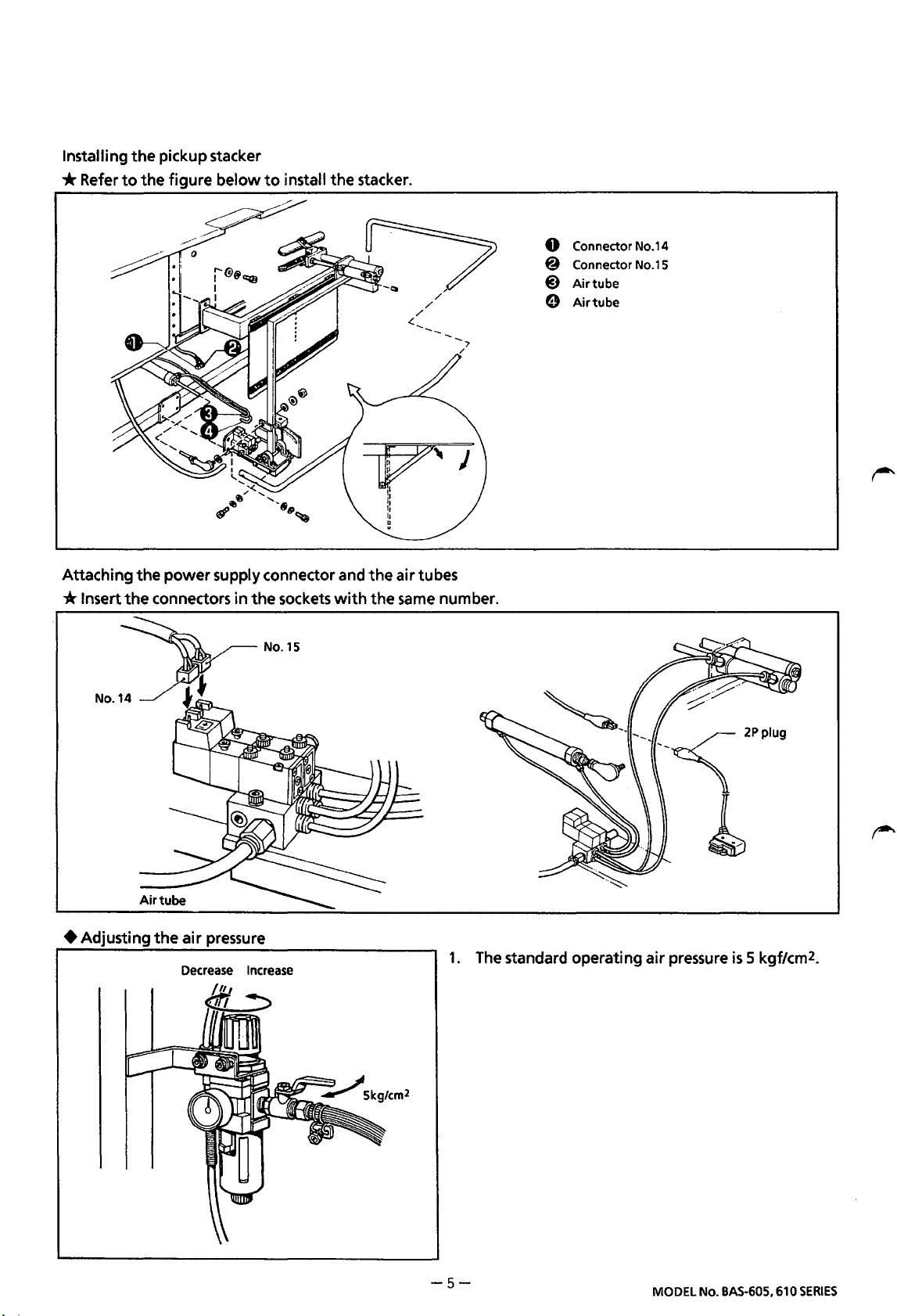

Installing

* Refer

the

pickup stacker

to

the

figure

below

to

install

the

stacker.

0 Connector No.14

@ Connector No.15

@)

Airtube

0

Airtube

Attaching

*Insert

+Adjusting

the

the

power

connectors in

the

air

Decrease Increase

supply connector and

the

sockets

pressure

with

the

the

air

tubes

same

number.

1.

The

--~

k

standard operating air pressure

2Ppl"g

is

5 kgf/cm2.

-5-

MODEL No. BAS-605, 610

SERIES

Page 10

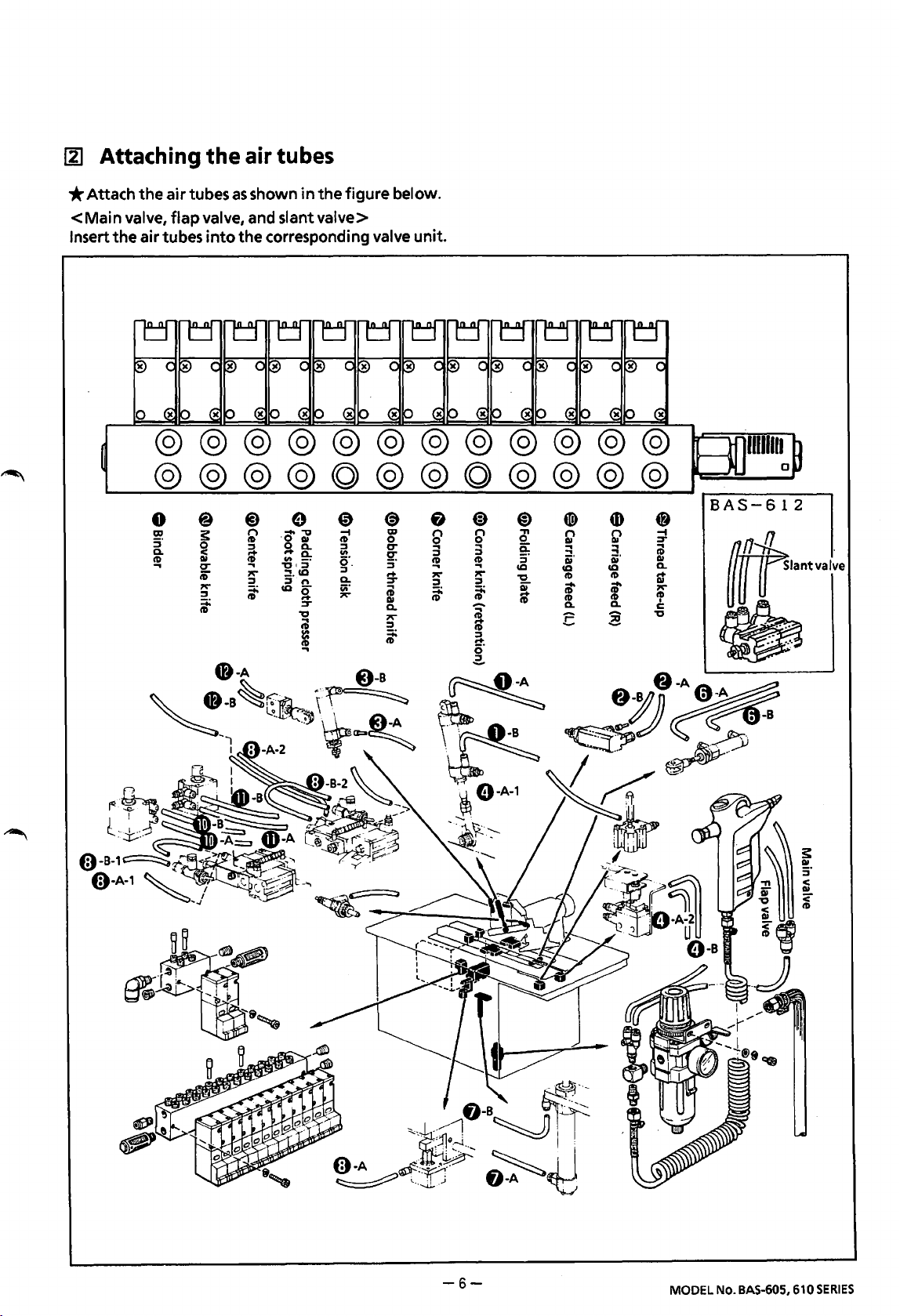

~

Attaching

the

air tubes

*Attach

<Main

Insert

the

the

valve,

air tubes

0

air

tubes

as

shown

flap

valve, and slant valve>

into

the corresponding valve unit.

in

the

figure below.

BAS-612

If''"'"''"

~

~

-6-

MODEL No. BAS-605, 610

SERIES

Page 11

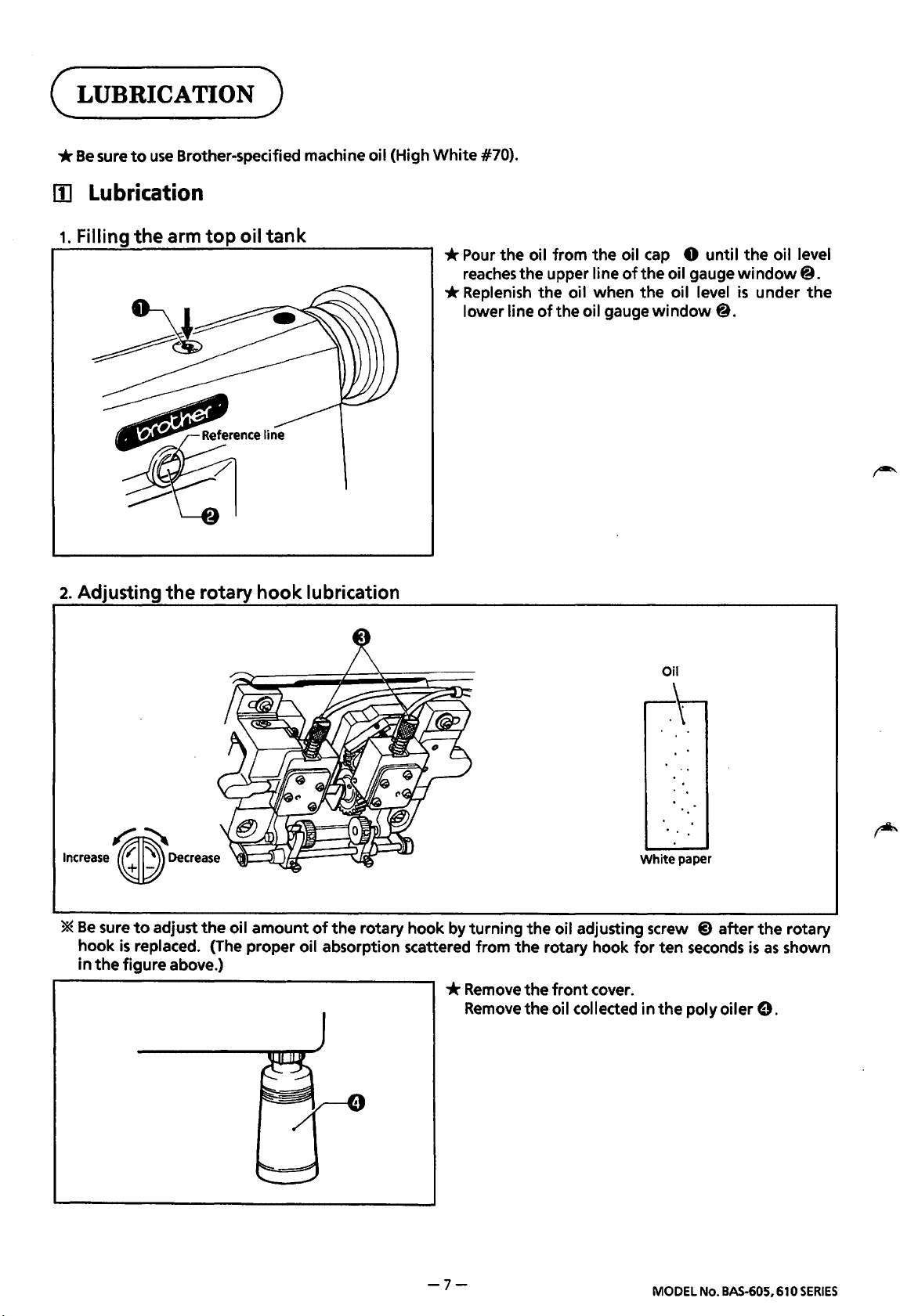

c

LUBRICATION)

*Be

sure

to

use

Brother-specified machine oil (High White #70).

[lJ

Lubrication

1.

Filling

the

arm

top

oil

tank

*Pour

*Replenish

the oil from

reaches

lower line

the upper line

the

oil

cap

0 until

of

the oil gauge

the oil when the oil level

of

the oil gauge

window@.

the

oil level

window@.

is

under

the

2.

Adjusting

*Be

sure

hook

in

the

the

rotary

to

adjust

is

replaced. (The proper oil absorption scattered from

figure above.)

the

hook

oil amount

lubrication

of

the rotary hook by turning the oil adjusting screw @)after the rotary

*

Remove

Remove

the

rotary hook

the

front

cover.

the oil collected

Oil

_\

·\

White paper

for

ten

seconds

in

the

poly oiler

is

as

0.

shown

-7-

MODEL No.

BAS-605,

610

SERIES

Page 12

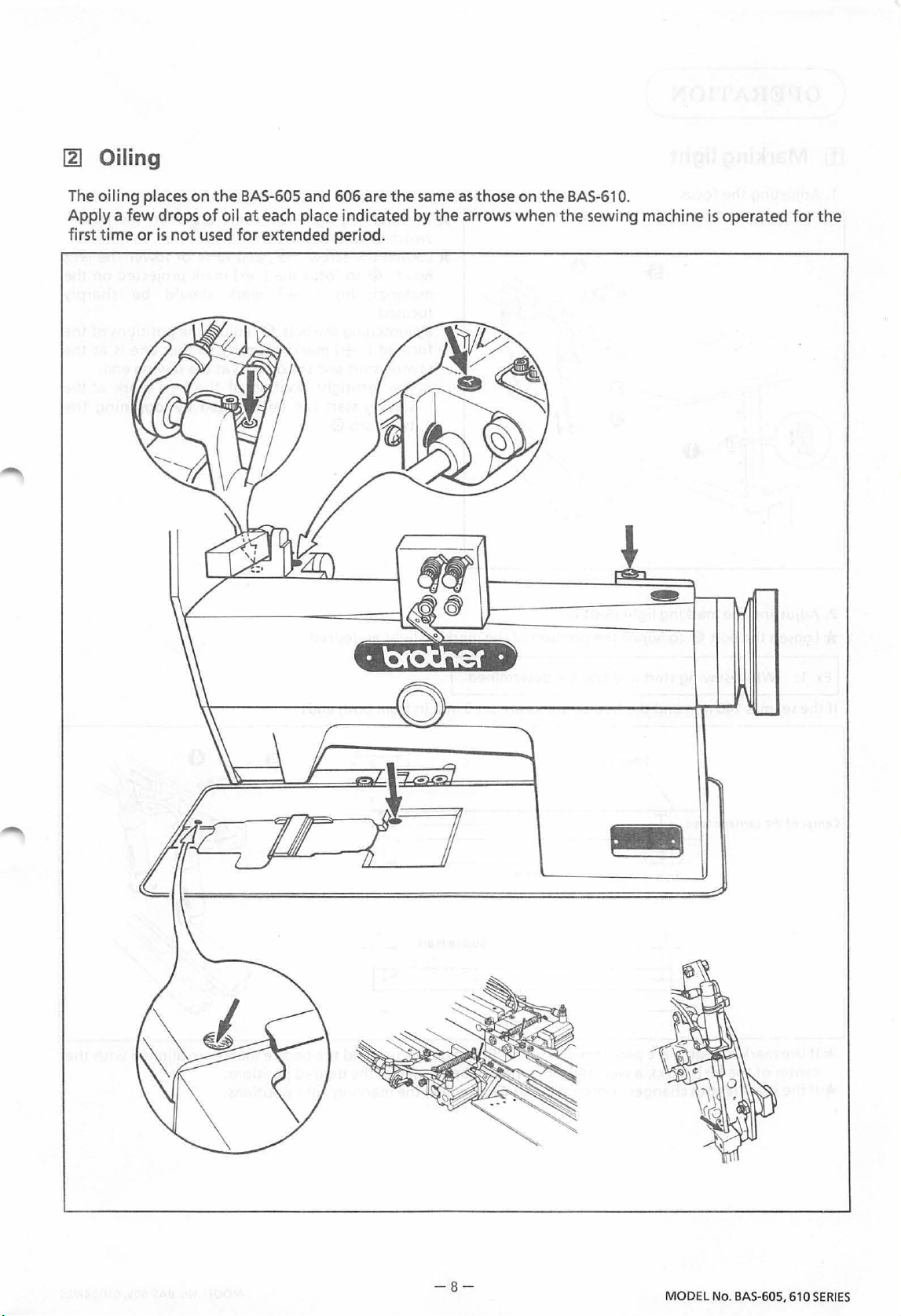

~

Oiling

The

oiling

Apply a few

first

time

or

places on

drops

is

not

used

the

BAS-605 and 606 are

of

oil

at

each place indicated by

for

extended period.

the

same

the

as

those on

arrows

the

when

BAS-61

the

0.

sewing machine

is

operated

for

the

-8-

m

MODEL No.

BAS

-605, 610

SERIES

Page 13

c

OPERATION)

III

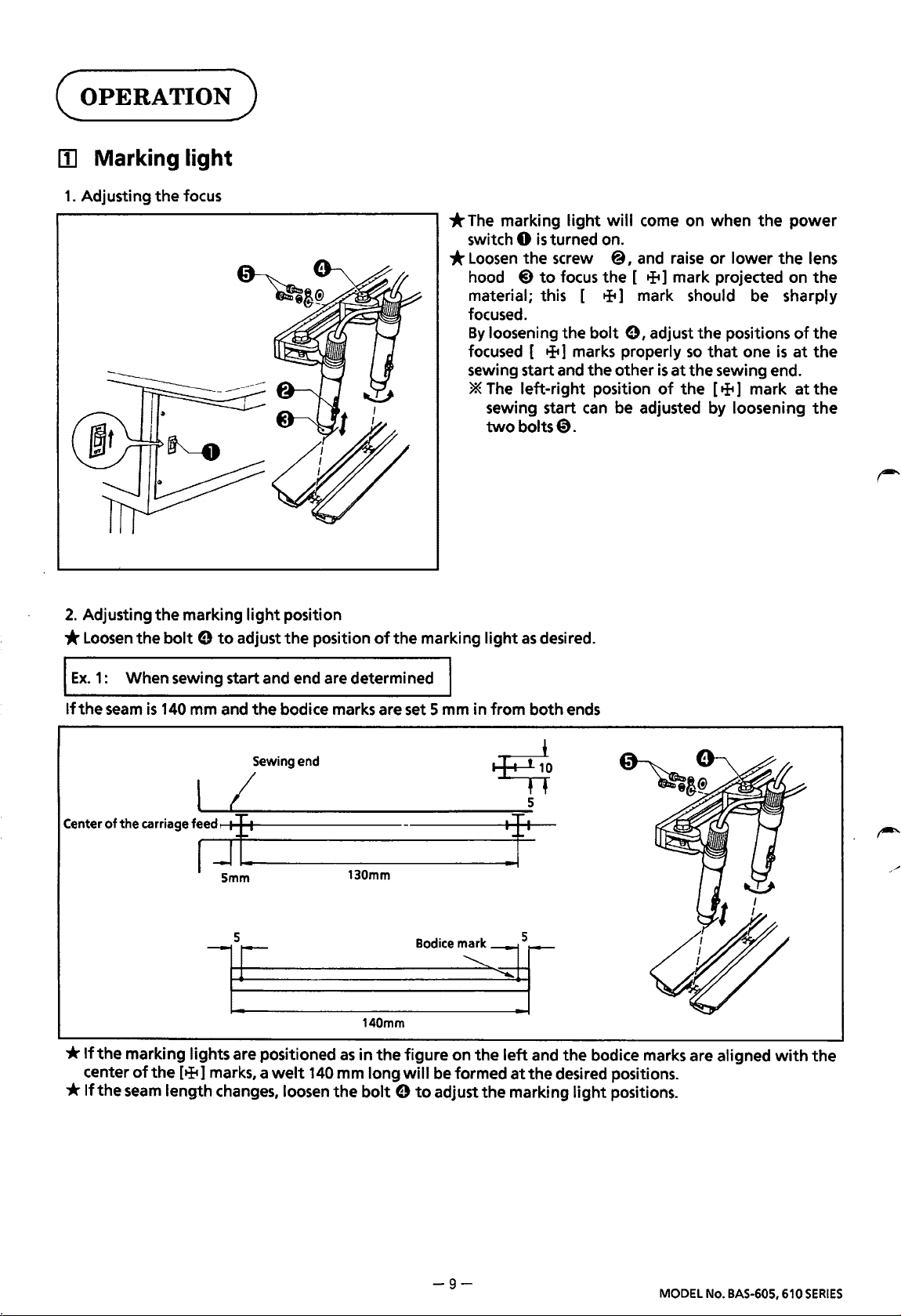

Marking light

1.

Adjusting the focus

*The

*Loosen

marking

switch

hood @

material; this [ tit] mark should be sharply

focused.

By loosening the

focused [

sewing start and the other

0

*

The

sewing start

twobolts0.

light

will

come on when the power

is

turned on.

the screw

to

focus the [

tit

1 marks properly

left-right position

@,

and

bolt

e I adjust the positions

can

be adjusted by loosening

raise

or lower

tit

1 mark projected on

so

that

one

is

at

the sewing end.

of

the [ tit] mark

the

is

of

at

at

lens

the

the

the

the

the

2.

Adjusting the marking

*Loosen

Ex.

If

the

the

bolt 9 to

1:

When sewing start and end are determined

seam

is

140 mm and

light

position

adjust

the

position

the

bodice marks are set 5

Sewiogeod

of

the marking

light

as

mm

in from both ends

~

desired.

L 5

centerofthecarriagefer,'-J,.t:r:----------...:::;jr-'

5mm 130mm

5

l5

140mm

*If

the

center

*If

marking lights are positioned

of

the

[tit 1 marks, a

the

seam

length changes, loosen

welt

as

in

the

140 mm long

the

bolt 9 to

figure on the

will

be formed

adjust the marking

left

and the bodice marks are aligned

at

the desired positions.

light

positions.

with

the

-9-

MODEL No. BAS-605, 610

SERIES

Page 14

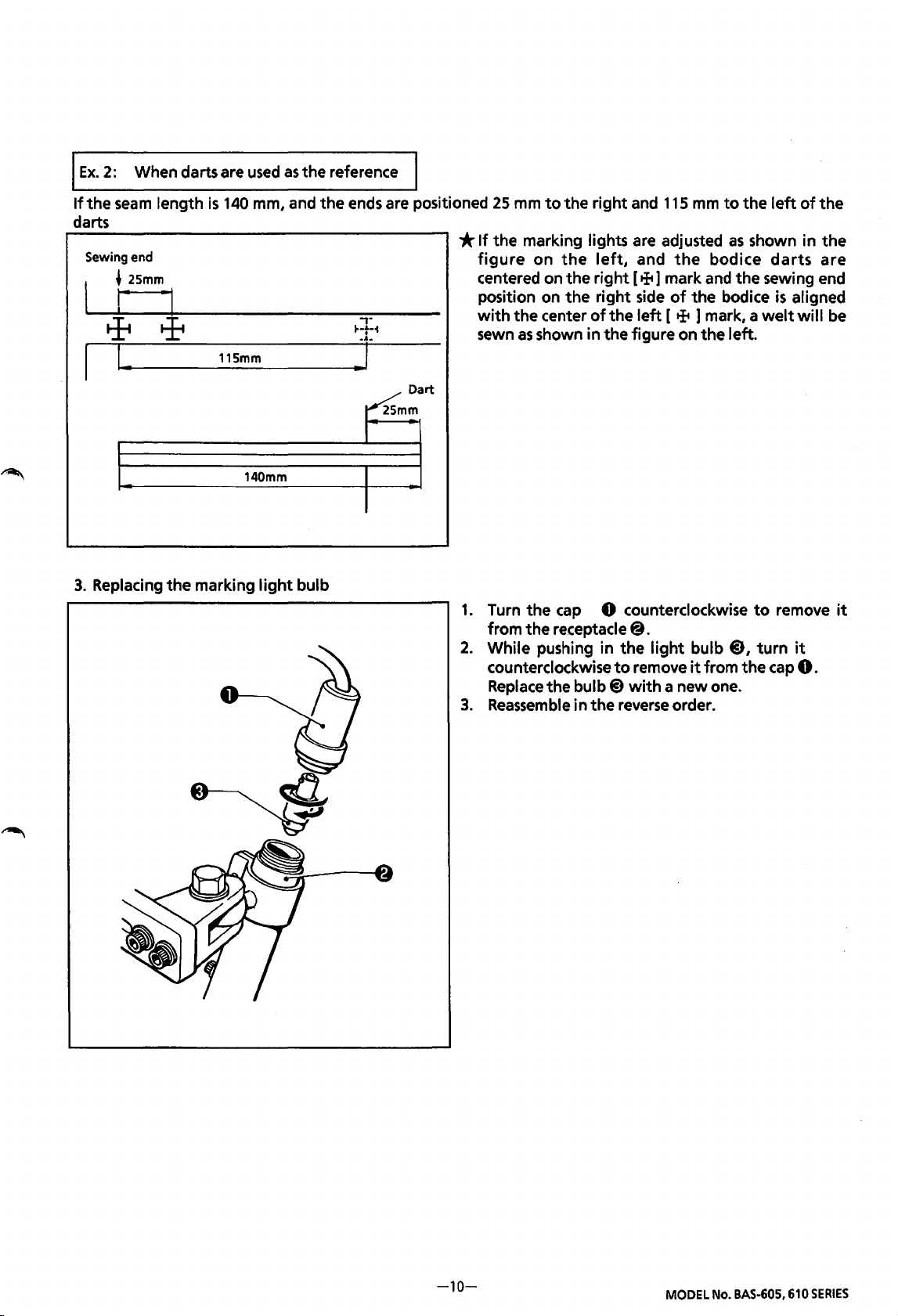

I

Ex.

2:

If

the

darts

Sewing end

3.

Replacing

When darts are

seam

length

~

25mm

r·

·1

!

..

the

marking

used

as

the reference

is

140

mm, and the ends are positioned

115mm

~mm

140mm

light

bulb

Dart

25

mm

to

the right and

*If

the marking lights are adjusted

figure

centered on the right [

position on

with

sewn

1.

2.

3.

on

the

left,

and

the

right

side

the center

as

shown in the figure on the left.

Turn the

from the receptacle

While pushing in the

counterclockwise

Replace

Reassemble

of

the

cap

0 counterclockwise

to

the bulb@)

in the

left

@.

remove

with

reverse

+]

115

mm

the

bodice

mark

and

of

the bodice

[ + ] mark, a

light

bulb

it

from

a new one.

order.

to

the

left

of

as

shown in the

darts

the sewing end

is

aligned

welt

will

to

remove

@J,

turn

it

the

cap

0.

the

are

be

it

-10-

MODEL

No.

BAS-605,

610

SERIES

Page 15

c

SEWING

FLOWCHART

BAS-605, 606 )

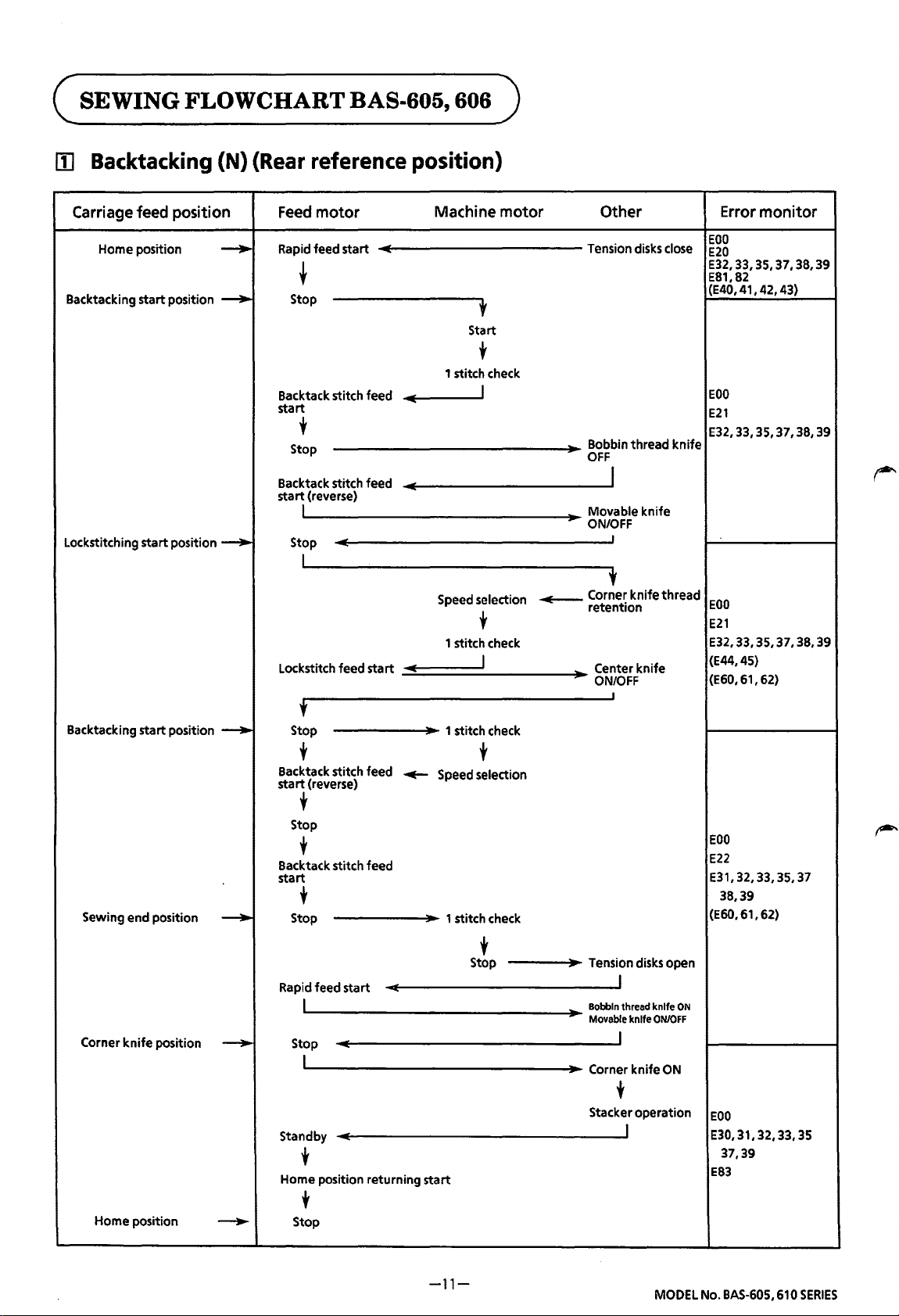

IIl Backtacking (N) (Rear reference position)

Carriage feed position

Home

position

Backtacking

Lockstitching

start

start

position

position

---..

---..

---..

Feed

motor

Rapid feed

start

t

Stop

Backtack stitch

start

•

Stop

Backtack stitch feed

startl (reverse)

Stop

I

Lockstitch

feed

feed

start

Machine

1 stitch check

IIIIi

Speed selection

1 stitch check

IIIIi

t

Start

t

I

t

I

motor

..,___

Other Error

Tension disks close

Bobbin

thread

OFF

EOO

E20

E32,33,35,37,38,39

E81,82

(E40,

EOO

E21

E32,33,35,37,38,39

knife

I

Movable

ON/OFF

Cor!er

retention

Center

ON/OFF

knife

knife

knife

thread

EOO

E21

E32,33,35,37,38,39

(E44,45)

(E60, 61, 62)

monitor

41, 42, 43)

Backtacking

Sewing

Corner

knife

start

end

position

position

position

---..

---..

~

t

Stop

Backtack stitch

•

start

(reverse)

t

Stop

Backtack stitch

•

start

t

Stop

Rapid feed

start

I

Stop

I

Standby

t

Home

position

feed

~

feed

returning

1 stitch check

t

Speed selection

1 stitch check

t

Stop

start

Tension disks open

I

Bobbin

thread knife

Movable knife

ON

ON/OFF

I

Corner

knife

ON

•

Stacker

operation

I

EOO

E22

E31,32,33,35,37

38,39

(E60, 61, 62)

EOO

E30,31,32,33,35

37,39

E83

Home

position

---..

•

Stop

-11-

MODEL No. BAS-605, 610

SERIES

Page 16

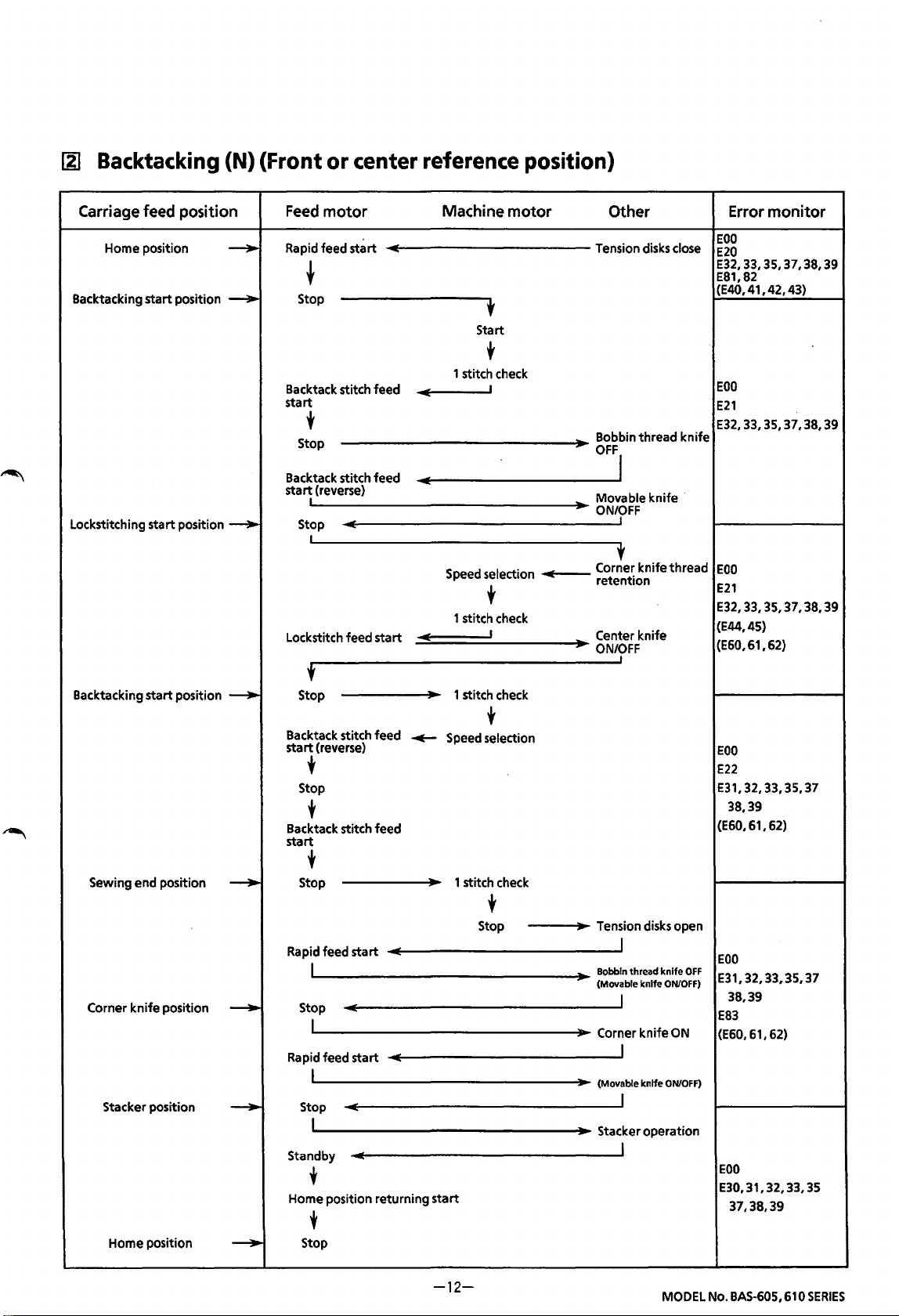

IZI

Backtacking (N) (Front

or

center reference position)

Carriage feed position

Home position

start

start

position

position--..

Backtacking

Lockstitching

--..

__.

Feed

motor

Rapid feed

sti~rt

t

Stop

Backtack stitch feed

start

t

Stop

Backtack stitch feed

sta~

(reverse)

Stop

I

Lockstitch feed

start

Machine

1 stitch check

.,

Speed selection

1 stitch check

...,

t

Start

t

I

t

I

motor

IIIIi

Other Error

Tension disks close

Bobbin

thread

OFF'

Movable

ON/OFF

Cor!er

retention

Center knife

ON/OFF

knife

knife

thread

EOO

E20

E32,33,35,37,38,39

E81,82

(E40,41,42,43)

EOO

E21

E32,33,35,37,38,39

knife

EOO

E21

E32,33,35,37,38,39

(E44,45)

(E60,61,62)

monitor

Backtacking

Sewing end position

Corner

start

knife

position

Stacker position

Home position

position

---+-

----..

____..,

----..

----..

t

Stop

Backtack stitch feed

start

(reverse)

~

t

Stop

t

Backtack stitch feed

start

t

Stop

Rapid feed

start

I

Stop

I

Rapid feed

start

I

Stop

I

Standby

t

Home position returning

t

Stop

1 stitch check

t

Speed selection

1 stitch check

t

Stop Tension disks open

Bobbin

(Movable

Corner

(Movable

Stacker operation

start

I

thread

I

I

I

I

knife

knife

knife

knife

ON/OFF)

ON

ON/OFF)

EOO

E22

E31,

38,39

(E60,61,62)

EOO

OFF

E31,32,33,35,37

38,39

E83

(E60, 61,

EOO

E30, 31, 32,

37,38,39

32, 33,

62)

35,37

33,35

-12-

MODEL No. BAS-605, 610

SERIES

Page 17

~

Backtacking

(V)

(Rear

reference position)

Carriage feed position

Home position

Backtacking

Lockstitching

start

start

position

position

--+-

_..,.

--+-

Feed

motor

Rapid feed

start

Machine

motor

Other

Tension disks close

t

Stop

t

Start

t

1 stitch check

Backtack stitch feed

stal

(reverse)

Stop

Ollf

I Bobbin thread

I

Movable

ON/OFF

_I

OFF

t

Speed selection

~

Corner

retention

t

1 stitch check

Lockstitch feed

start

Ill!

I

Center

ON/OFF

J

knife

knife

knife

knife

thread

Error

monitor

EOO

E20

E32,33,35,37,38,39

E81,

82

(E40, 41, 42,

EOO

E21

E32,33,35,37,38,39

EOO

E21

E32,33,35,37,38,39

(E44,45)

(E60,61,62)

43)

Backtacking

Sewing end position

Corner

start

knife

position

Home position

position ----+

--+-

--+

--+

Stop

'

Backtack stitch feed

start

(reverse)

t

Stop

Rapid feed

start

I

Stop

I

Standby

t

Home position returning

t

Stop

~

1 stitch check

t

Speed selection

1 stitch check

t

Stop

start

Tension disks open

J

Bobbin

thread knife

Movable knife

ON

ON/OFF

I

Corner

knife

ON

t

operation

Stacker

EOO

E22

E31,32,33,35,37

38,39

(E60,61,62)

EOO

E30,31,32,33,35

37,39

E83

-13-

MODEL No. BAS-605, 610

SERIES

Page 18

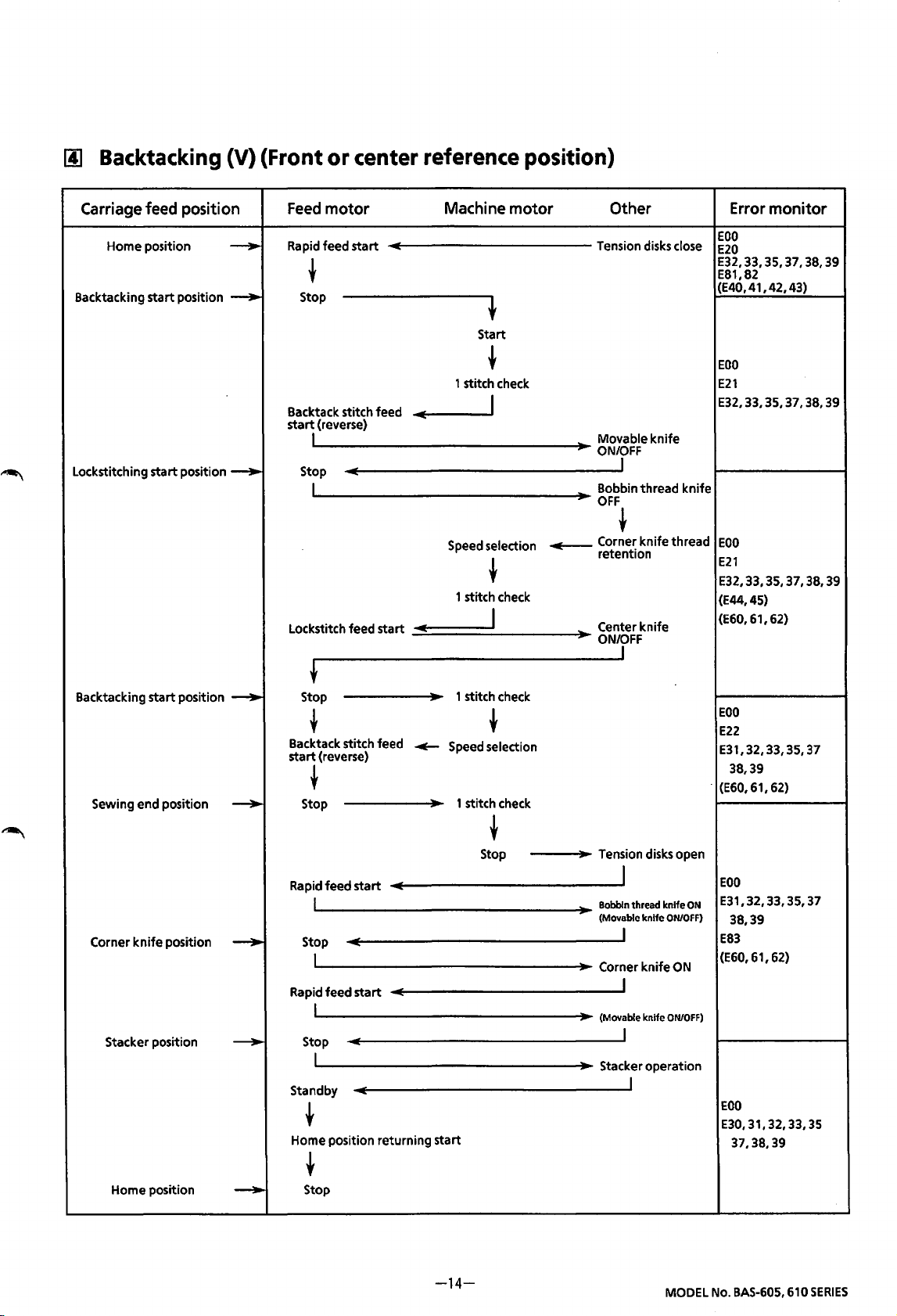

~

Backtacking

(V) (Front or center reference position)

Carriage feed position

Home

position

8acktacking

Lockstitching

start

start

position

position

--...

--..

--..

Feed

motor

Rapid

feed

start

t

Stop

Backtack stitch

sta~

(reverse)

Stop

I

Lockstitch feed

feed

start

Machine

1 stitch check

...

Speed selection

1 stitch check

...

l

Start

t

I

t

I

motor

..---

Other Error

Tension disks close

Movable

ON/?FF

Bobbin

OFF

knife

thread

EOO

E20

E32,33,35,37,38,39

E81,82

(E40,41,42,43)

EOO

E21

E32,33,35,37,38,39

knife

t

Corner

knife

retention

Center

knife

ONfFF

thread

EOO

E21

E32,33,35,37,38,39

(E44,45)

(E60,61,62)

monitor

Backtacking

Sewing

Corner

knife

Stacker position

start

end

position

position

position

--..

__..

__..

__..

t

Stop

t

Backtack stitch feed

start

(reverse)

t

Stop

Rapid

feed

start

I

Stop

I

feed

I

I

position

start

returning

Rapid

Stop

Standby

t

Home

1 stitch check

-4--

Speed selection

1 stitch check

start

t

t

Stop Tension disks open

I

Bobbin

thread

knife

knife

ON/OFF)

knife

ON

knife

ON/OFF)

operation

ON

(Movable

I

Corner

I

(Movable

I

Stacker

I

EOO

E22

E31,

32, 33, 35, 37

38,39

. (E60, 61, 62)

EOO

E31,32,33,35,37

38,39

E83

(E60, 61,

EOO

E30,

31, 32, 33,

37,38,

62)

39

35

t

Stop

Home

position

__..

-14-

MODEL No. BAS-605, 610

SERIES

Page 19

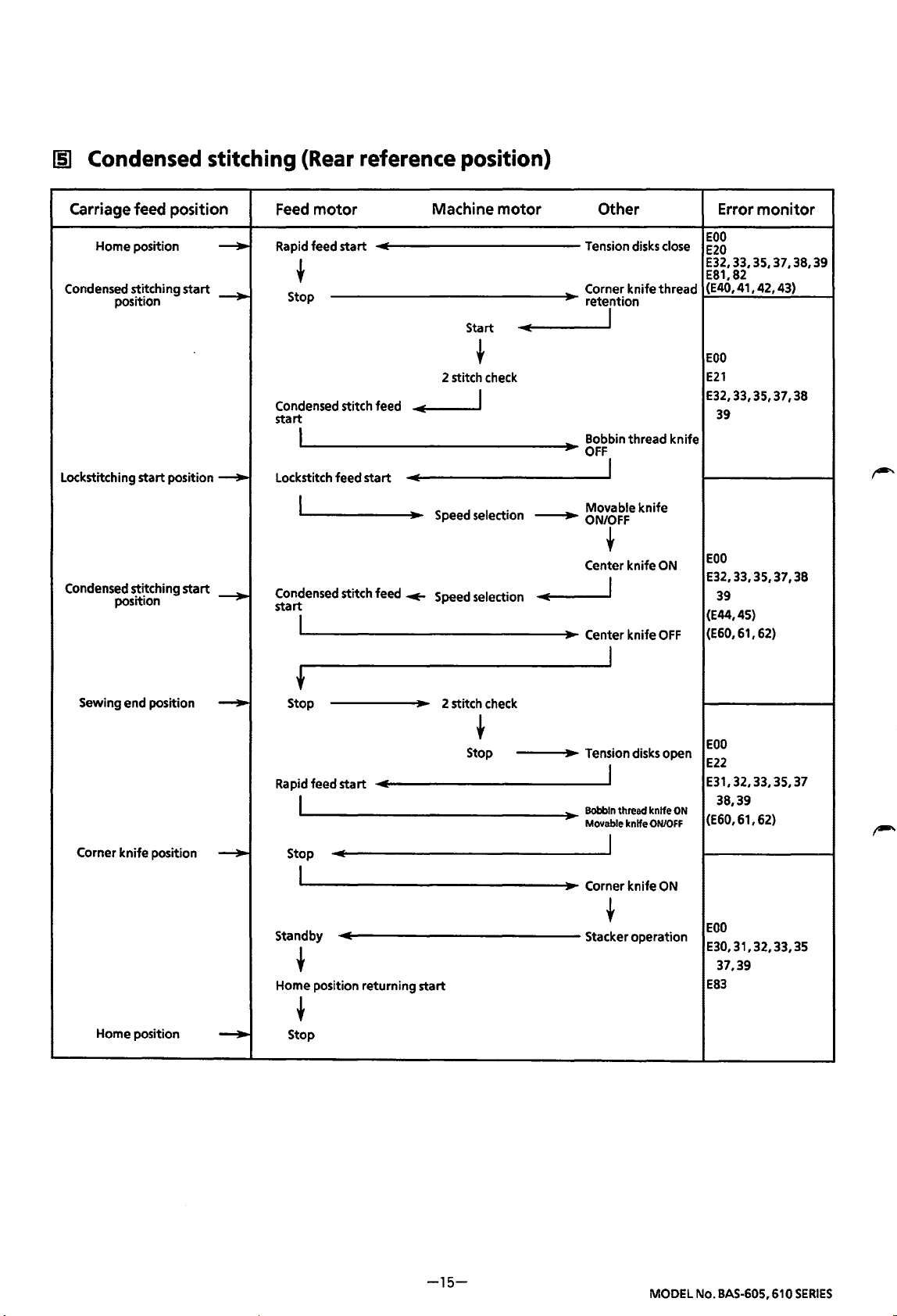

~

Condensed

stitching

(Rear

reference position)

Carriage feed position

Home

position

Condensed

Lockstitching

Condensed

s_ti.tching

posrtron

start

s_ti.tching

positron

start

position

start

____.,

____.,

----..

____.,

Feed

motor

Rapid feed

start

t

Stop

Condensed stitch feed

start

I

Lockstitch

Condensed stitch feed

start

I

I

feed

start

Machine

2 stitch check

Oil!

)I

Speed selection

.._

Speed selection

Start

t

I

motor

Oil!

____.

IIIIi

Other Error

Tension disks close

knife

Corner

retention

thread

EOO

E20

E32,33,35,37,38,39

E81,82

(E40,41,42,43)

I

EOO

E21

E32, 33, 35,

39

Bobbin

thread

knife

OFFJ

Movable

ON/OFF

Center

Center

t

I

knife

knife

knife

ON

OFF

EOO

E32,33,35,37,38

39

(E44,45)

(E60, 61, 62)

I

monitor

37,38

Sewing

end

Corner

knife

Home position

position

position

__.,.

__.,.

__.,.

+

Stop

Rapid feed

I

Stop

I

Standby

t

Home

position

t

Stop

start

returning

2 stitch check

start

t

Stop

Tension disks

I

Bobbin

thread knife

Movable

knife

ON/OFF

I

Corner

knife

t

Stacker

operation

open

ON

ON

EOO

E22

E31,

32, 33, 35,

38,39

(E60,61,62)

EOO

E30,

31, 32, 33, 35

37,39

E83

37

-15-

MODEL No. BAS-605,610

SERIES

Page 20

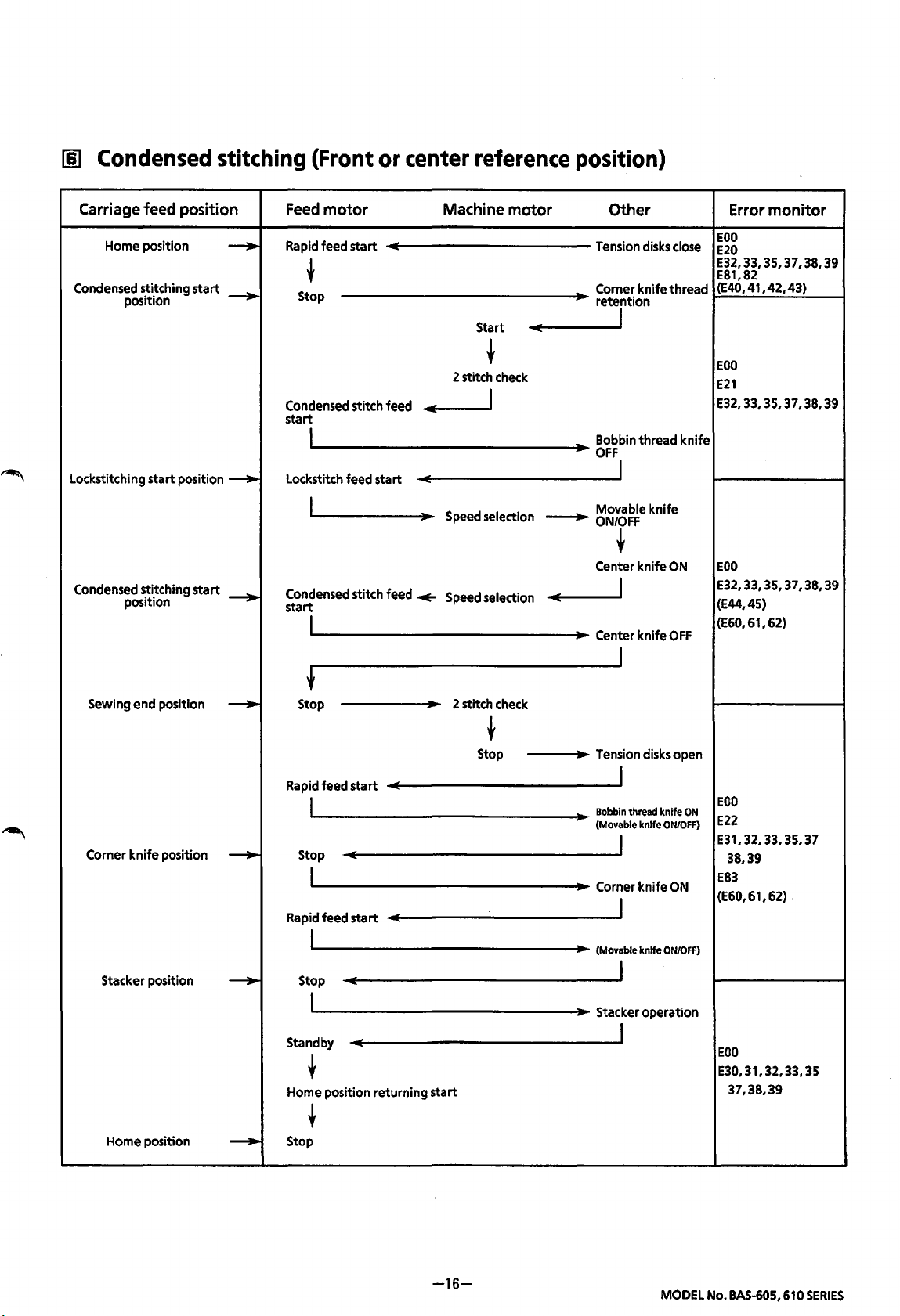

Iii

Condensed

stitching

(Front

or

center

reference

position)

Carriage feed position

Home

position

Condensed

Lockstitching start position

Condensed

stitching start

position

stitching start

position

......

_...,

---..

_...,

Feed

motor

Rapid

feed start

t

Stop

Condensed

start

Lockstitch feed start

Condensed

start

stitch feed

I

I

stitch feed

I

Machine

..,

...

_.

2 stitch

Speed

Speed

motor

Start

~

check

I

selection

selection

llf

____,.

Other

Tension

Corner

retention

Bobbin thread knife

OFF

Movable knife

ON/OFF

Center knife

II!

Center knife

disks

knife thread

I

I

~

I

I

close

ON

OFF

monitor

Error

EOO

E20

E32,33,35,37,38,39

E81,82

(E40,

41,42,43)

EOO

E21

E32,33,35,37,38,39

EOO

E32,33,35,37,38,39

(E44,45)

(E60,

61,

62)

Sewing end position

Corner

knife position

Stacker position

Home

position

......

---.

---.

......

+

Stop 2 stitch

Rapid

feed start

I

Stop

I

Rapid

feed start

I

Stop

I

Standby

t

Home

position returning start

t

Stop

check

~

Stop

Tension

disks

open

I

Bobbin

thread knife

(Movable knife

_I

Corner knife

I

(Movable knife

I

Stacker operation

I

ON

ON/OFF)

ON

ON/OFF)

EOO

E22

E31,

32, 33,

35,37

38,39

E83

(E60,

61,

62)

EOO

E30,31,32,33,35

37,38,39

-16-

MODEL

No.

BAS-605,

610

SERIES

Page 21

(SEWING

[j]

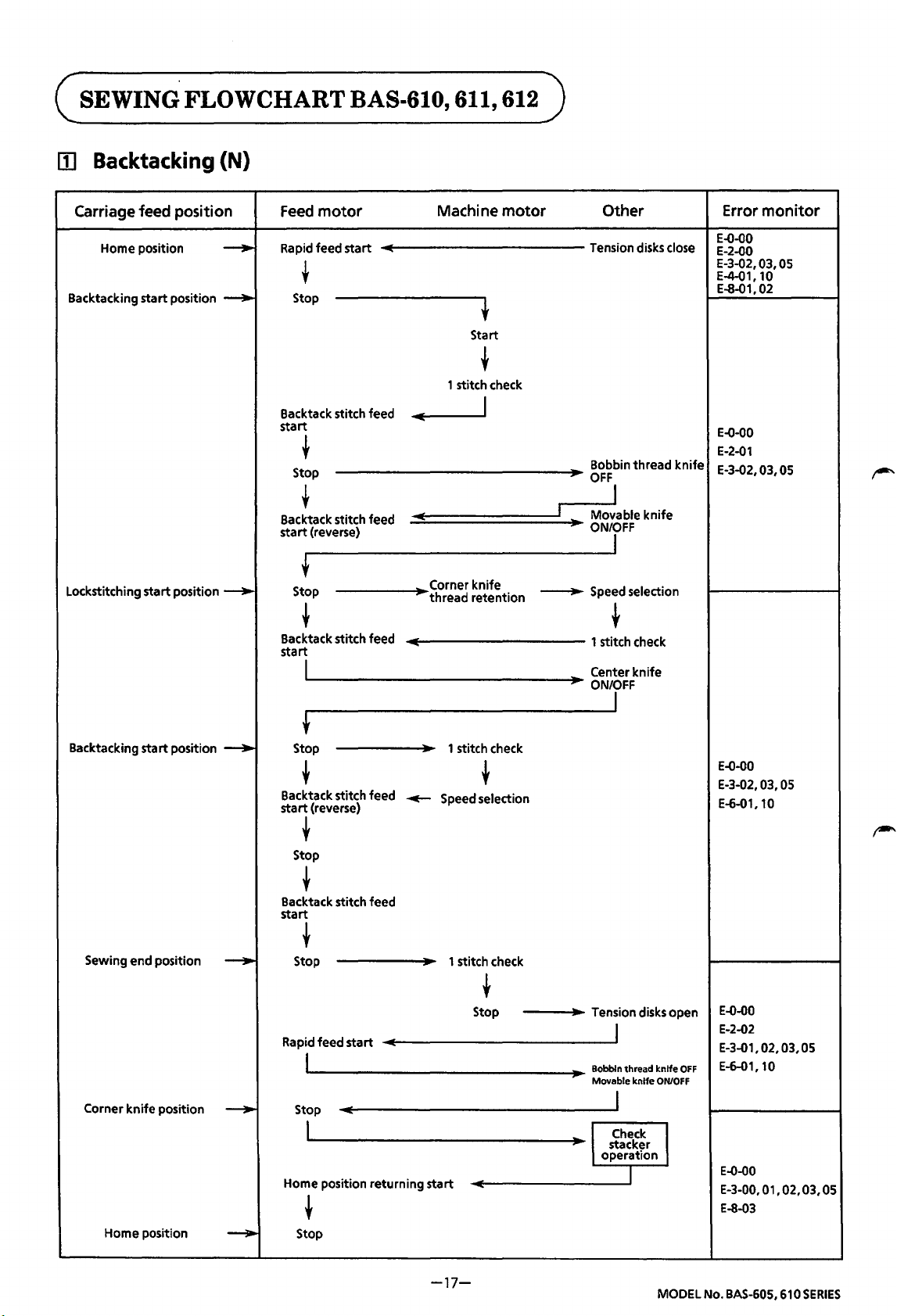

Backtacking

FLOWCHART BAS-610, 611,

(N)

612)

Carriage feed position

Home position

Backtacking

Lockstitching

start

start

position

position

--...

--...

--...

Feed

motor

Rapid feed

start

t

Stop

Backtack stitch feed

start

t

Stop

t

Backtack stitch feed

start

(reverse)

t

Stop

t

Backtack stitch feed

start

I

Machine

~

OlliE

Corner

thread

motor

t

Start

t

1 stitch check

I

knife

retention

~

Other

Tension disks close

Bobbin

,

OFF

I

I

Movable

ON/OFF

I

Speed selection

t

1 stitch check

Center

ON'IFF

thread

knife

knife

knife

Error

monitor

E-0-00

E-2-00

E-3-02, 03,

E-4-01, 10

E-8-01, 02

E-0-00

E-2-01

E-3-02, 03,

OS

OS

Backtacking start position

Sewing

end

position

Corner

knife

position

Home

position

--...

--...

--...

---..

f

Stop 1 stitch check

t

Backtack stitch

start

(reverse)

feed

~

t

Speed selection

t

Stop

t

Backtack stitch

start

feed

t

Stop

1 stitch check

t

Stop Tension disks open

Rapid feed

start

I

Stop

I

Home position

returning

start

t

Stop

I

Bobbin

thread

knife

knife

ON/OFF

Movable

J

I Check I

stacker

operation

I

E-0-00

E-3-02, 03,

E-6-01, 10

E-0-00

E-2-02

E-3-01, 02, 03,

E-6-01,10

OFF

E-0-00

E-3-00, 01, 02, 03,

E-8-03

OS

OS

OS

-17-

MODEL No. BAS-60S, 610

SERIES

Page 22

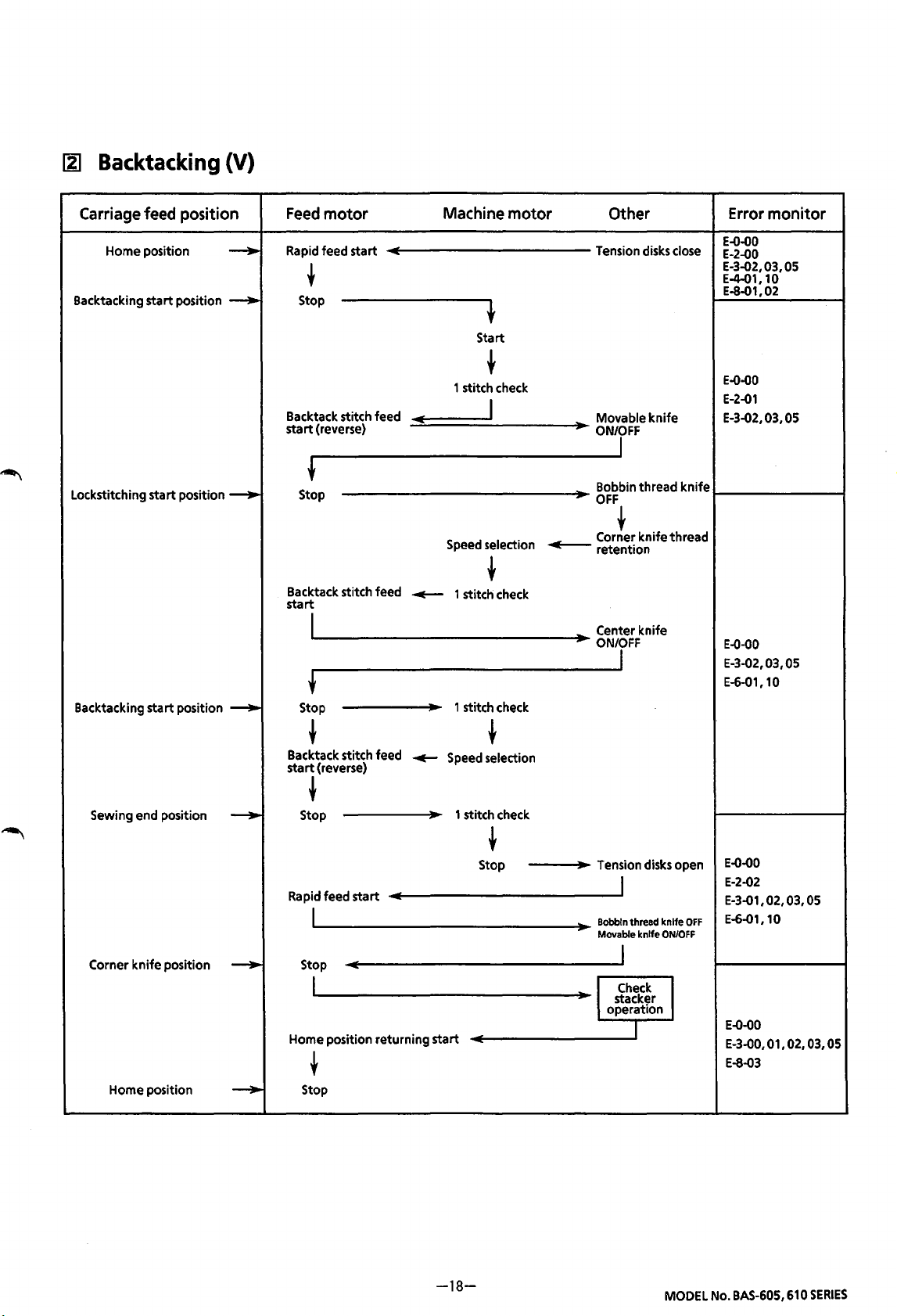

~

Backtacking

(V)

Carriage feed position

Home position

Backtacking

Lockstitching

Backtacking

start

start

start

position

position

position

--+-

--+-

--+-

~

Feed

motor

Rapid feed start Tension disks close

Machine

motor

Other Error

t

Stop

t

Start

~

1 stitch check

Backtack stitch feed

start

(reverse)

+

Stop

Backtack stitch feed

start

I

+

Stop

~

....--

I

Speed selection

~

1 stitch check

1 stitch check

...,___

Movable

ON'IFF

Bobbin

OFF

Corner knife

retention

Center knife

ON/rF

knife

thread

~

knife

thread

monitor

E-0-00

E-2-00

E-3-02, 03,

E-4-01, 10

E-8-01,02

E-0-00

E-2-01

E-3-02, 03,

E-0-00

E-3-02, 03,

E-6-01, 10

OS

OS

OS

Sewing end position

Corner

knife

position

Home position

--+-

~

--+-

~

Backtack stitch feed

start

(reverse)

......

~

Stop

Rapid feed

start

I

Stop

I

Home position returning

t

Stop

~

Speed selection

1 stitch check

~

Stop Tension disks open

Bobbin

Movable knife

~

start

I

thread knife

I

Check

stacker

operation

I

OFF

ON/OFF

_I

E-0-00

E-2-02

E-3-01, 02, 03,

E-6-01, 10

E-0-00

E-3-00, 01, 02, 03,

E-8-03

OS

OS

-18-

MODEL No. BAS-605, 610

SERIES

Page 23

~

Condensed

stitching

Carriage feed position

Home position

Condensed

Lockstitching start position

Condensed

stitching start

position retention

~i~ching

positiOn

start

~

__,.

--..

__..

Feed

motor

Rapid

feed start

~

Stop

Condensed

start

stitch feed

~

Stop

~

Lockstitch feed start

Condensed

stal

stitch feed .,._

--...

Machine

2 stitch

..,

Speed

Speed

motor

Start

~

check

I

selection

selection

..,

~

Other

Tension

Corner knife thread

Bobbin thread knife

OFF

Movable knife

ON/OFF

Center knife

..,

Center knife

disks

I

I

~

I

J

close

ON

OFF

Error

monitor

E-0-00

E-2-00

E-3-02,

03,

E-4-01,

10

E-8-01,02

E-0-00

E-2-01

E-3-02,

03,

E-0-00

E-3-02,

03,

E-6-01,

10

OS

OS

OS

Sewing end position

Corner knife position

Home position

~

__,..

~

+

Stop

Rapid

feed start

I

Stop

L

Home position returning start

t

Stop

2 stitch

Stop

check

~

Tension

I

Bobbin

thread

Movable

J

l

Check

stacker

operation

knife

I

disks

knife

ON/OFF

open

J

ON

E-0-00

E-2-02

E-3-0

1,

E-6-01,

E-0-00

E-3-00,

E-8-03

02, 03,

OS

10

01, 02, 03,

OS

-19-

MODEL

No.

BAS-60S,

610

SERIES

Page 24

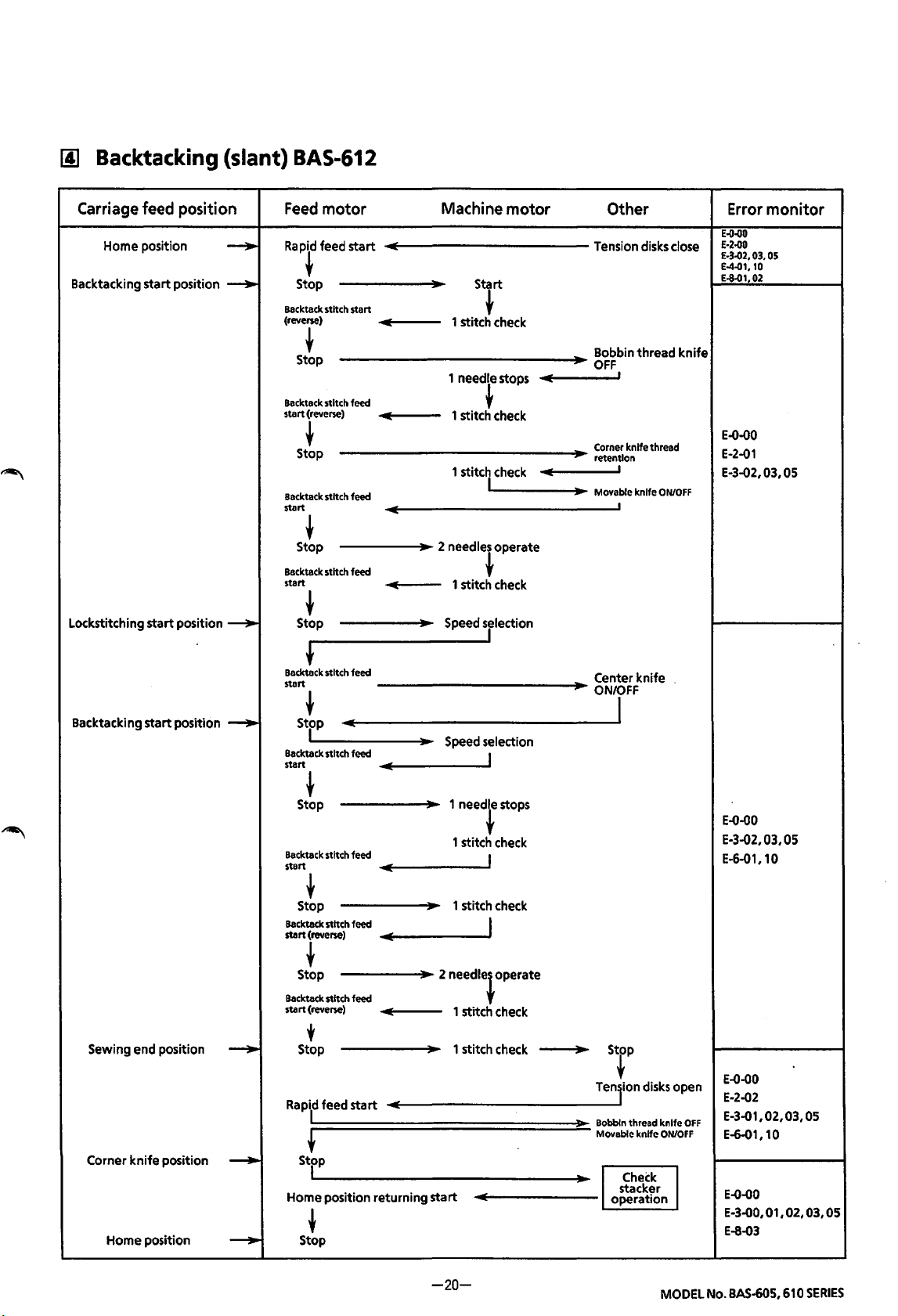

lj] Backtacking (slant)

BAS-612

Carriage feed position

Home position

Backtacking start position

Lockstitching start position

Backtacking start position

~

~

---...

---...

Feed

motor

Rap~d

feed

start

Stop Start

Backtack

stitch start

(reverse)

~

Stop

Backtack

stitch feed

start (reverse)

~

Stop

Backtack

stitch feed

start

~

Stop

Backtack

stitch feed

start

~

Stop

t

Backtack

stitch feed

start

Machine

1 stitch

1 needle

1 stitch

1 stitc,

2

needle~

1 stitch

Speed

~

strp

Becktack

start

stitch feed

Speed

motor

~

check

stops

~

check

check

operate

check

sjlection

selection

I

Other Error

Tension

disks

close

Bobbin thread knife

OFF

1

Corner knife thread

reten:lon

...

Movable knife

Center knife

ON,FF

ON/OFF

I

E-!1..00

E·2..00

E-3..02,

03,

E-4-01,10

E-8-01,02

E-0-00

E-2-01

E-3-02,

monitor

OS

03,

OS

Sewing

end

Corner

knife position

Home position

position

~

~

~

~

Stop

Backteck

stitch feed

start

~

Stop 1 stitch

Backteck

stitch feed

~

Stop

Backteck

stitch feed

(reverse)

start

Stop

.,

.,

1

1 stitch

2

needle~

1 stitch

1 stitch

'

Rapild

feed start

f

strp

Home

position returning start

~

Stop

.,

needr

I

I start (reverse)

stops

check

check

operate

check

check

)lo

Tenjion

Bobbin

Movable knife

I

Slp

disks

thread knife

Check

stacker

operation

open

OFF

ON/OFF

I

E-0-00

E-3-02,

03,

E-6-01,

10

E..()-00

E-2..()2

E-3-01,

02, 03,

E-6-01,10

E..()..()O

E-3..()0,

01,

E-8..()3

OS

OS

02, 03,

OS

-20-

MODEL

No.

BAS-605,

610

SERIES

Page 25

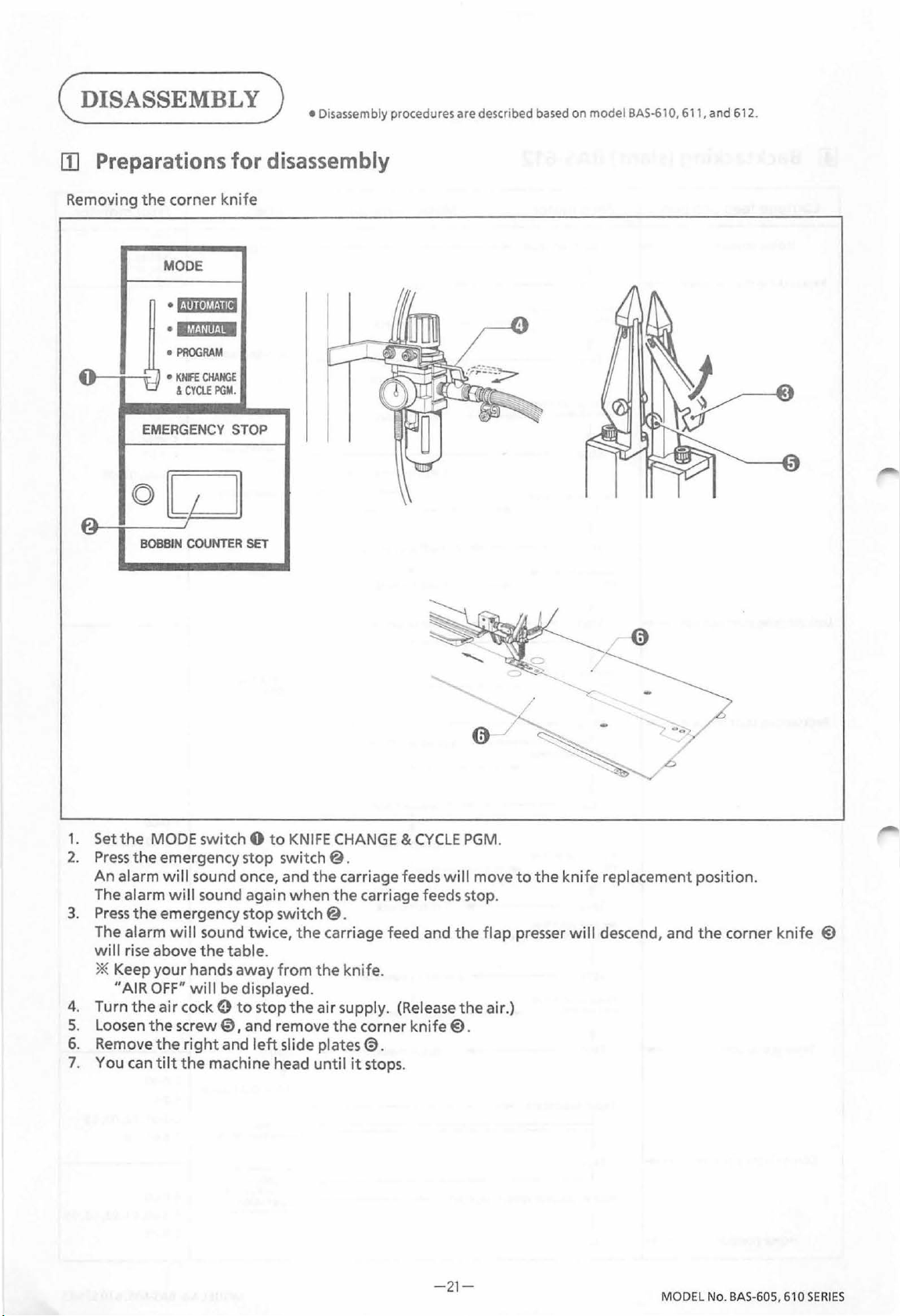

(DISASSEMBLY)

• Disassembly procedures are descnbed

based

on model

BAS-61

0, 611, and 612.

[I] Preparations for

Removing

~

'-="'

the

corner

MODE

•

·l~~~·!~ll!iJ.

•

8'

•

EMERGENCY STOP

(Q)

II

BOBBIN

knife

lil'ii·J~~·n~a

PROGRAM

KNfl:

CHANGE

&

CYClE

PGM.

I I

COUNTER

SET

disassembly

1. Set the MODE switch 0

2.

Press

the

emergency stop switch @ .

An

alarm

will

sound once, and

alarm

will

The

3.

Press

the

The alarm will sound twice,

will

rise above

sound again

emergency stop switch

the

table.

* Keep your hands away

"AIR

OFF"

will

be displayed.

4.

Turn

the

air

5. Loosen

6. Remove

7. You can

the

the

tilt

cock 0

screw

right

the

to

0,

and remove

and

machine head

to

KNIFE

the

when

the

from

the

stop

the

air supply. (Release

left

slide plates@.

until

~

CHANGE & CYCLE

carriage feeds

the

carriage feeds stop.

@.

carriage feed and

knife.

the

corner kni

it

stops.

fe@.

will

the

the

0

PGM

move

.

-'~

:<,

.

to

the knif

flap presser

air.)

0

-

. '>)

~-....../b

e replacement position.

will

descend, and the corner k

nife

@

-2

1-

MODEL No.

BAS-605,

610

SERIES

Page 26

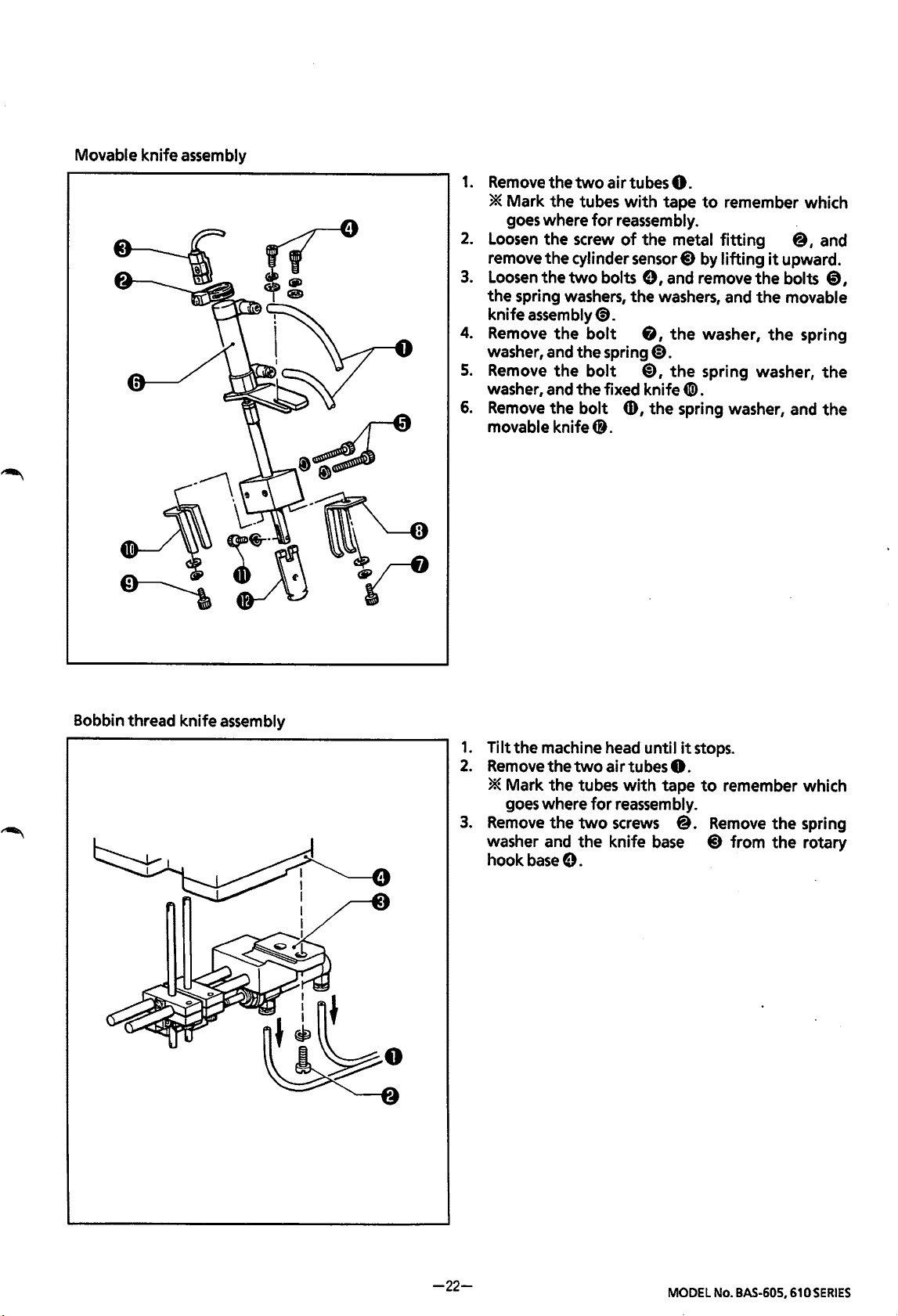

Movable knife assembly

1.

RemovethetwoairtubesO.

* Mark the tubes

goes

where

2.

loosen the screw

remove the cylinder

3.

loosen the

the spring

knife

4.

Remove

washer, and the spring

5.

Remove

washer, and the fixed knife

6.

Remove

movable knife 4i.

two

washers,

assembly

the

the

the

for

reassembly.

bolts

<9.

bolt

bolt

bolt

with

of

CD,

tape

to

remember which

the metal

sensor

e,

and remove the bolts

the washers, and the movable

&,

the

(D.

(i),

the

fitting

8 by

lifting

washer,

spring washer,

@,

it

upward.

the

spring

and

0,

the

4I!>.

the spring washer, and the

Bobbin thread knife assembly

1.

Tilt the machine

2.

Remove

the

* Mark the tubes

goes

where

3.

Remove

washer

hook

the

and

base

two

for

two

the knife

e.

head

until

air tubes

with

tape

reassembly.

screws

base

it

8.

@.

stops.

to

remember which

Remove

8 from

the spring

the

rotary

-22-

MODEL

No.

BAS-605,

610SERIES

Page 27

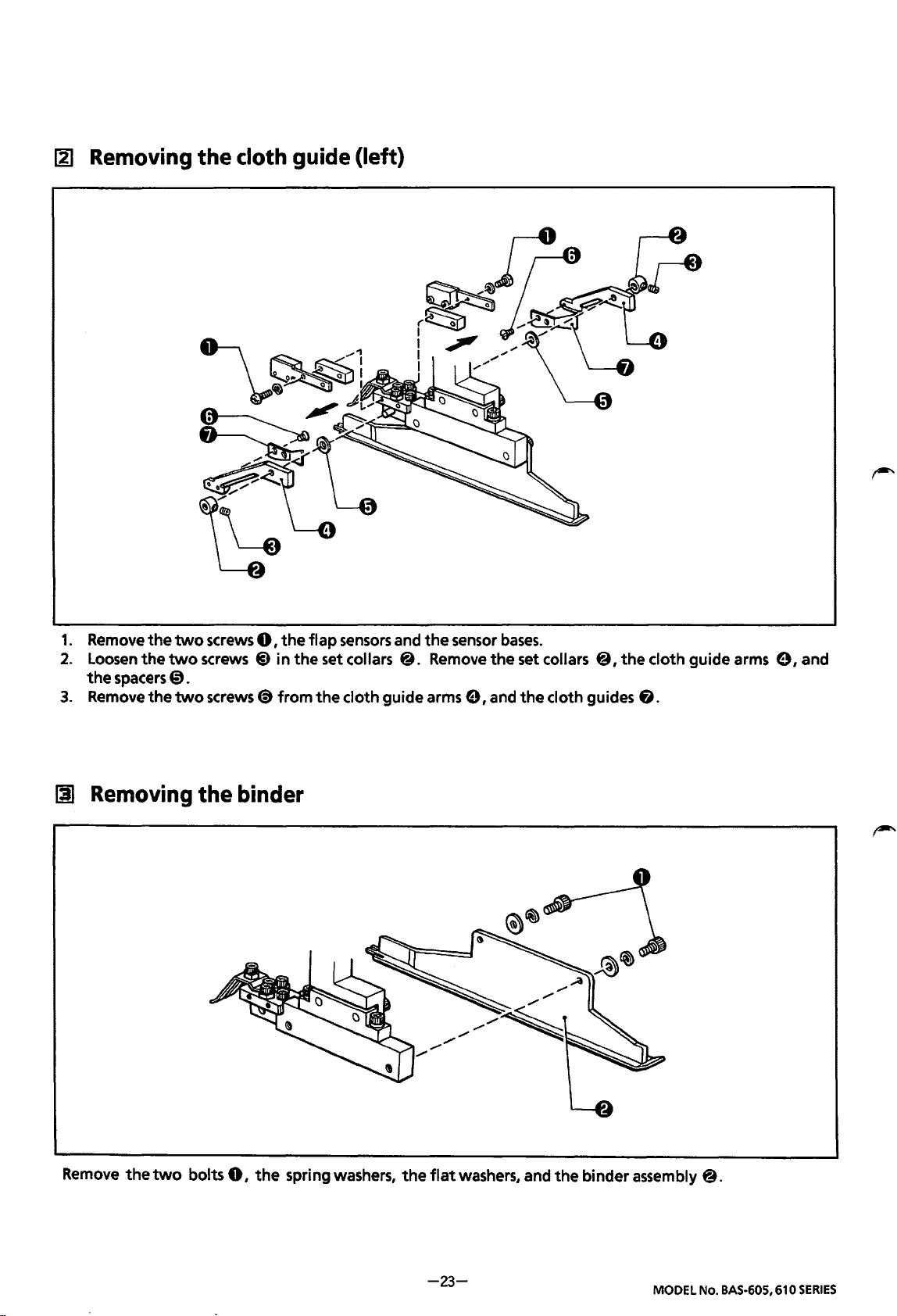

1:2]

Removing

the

cloth

guide (left}

1.

Remove

2.

Loosen

the

spacers

3.

Remove

[I

Removing

the

the

the

two

screws

two

screws

0.

two

screws

the binder

0,

@)

<9

the

flap

sensors

in

the

set collars @. Remove

from

the

cloth guide arms e, and

and

the

sensor

bases.

the

set collars

the

@,the

cloth guides & .

cloth guide arms e, and

Remove

the

two

bolts

0,

the

spring washers,

the

flat

washers, and

-23-

the

binder assembly @.

MODEL No.

BAS-605,

610

SERIES

Page 28

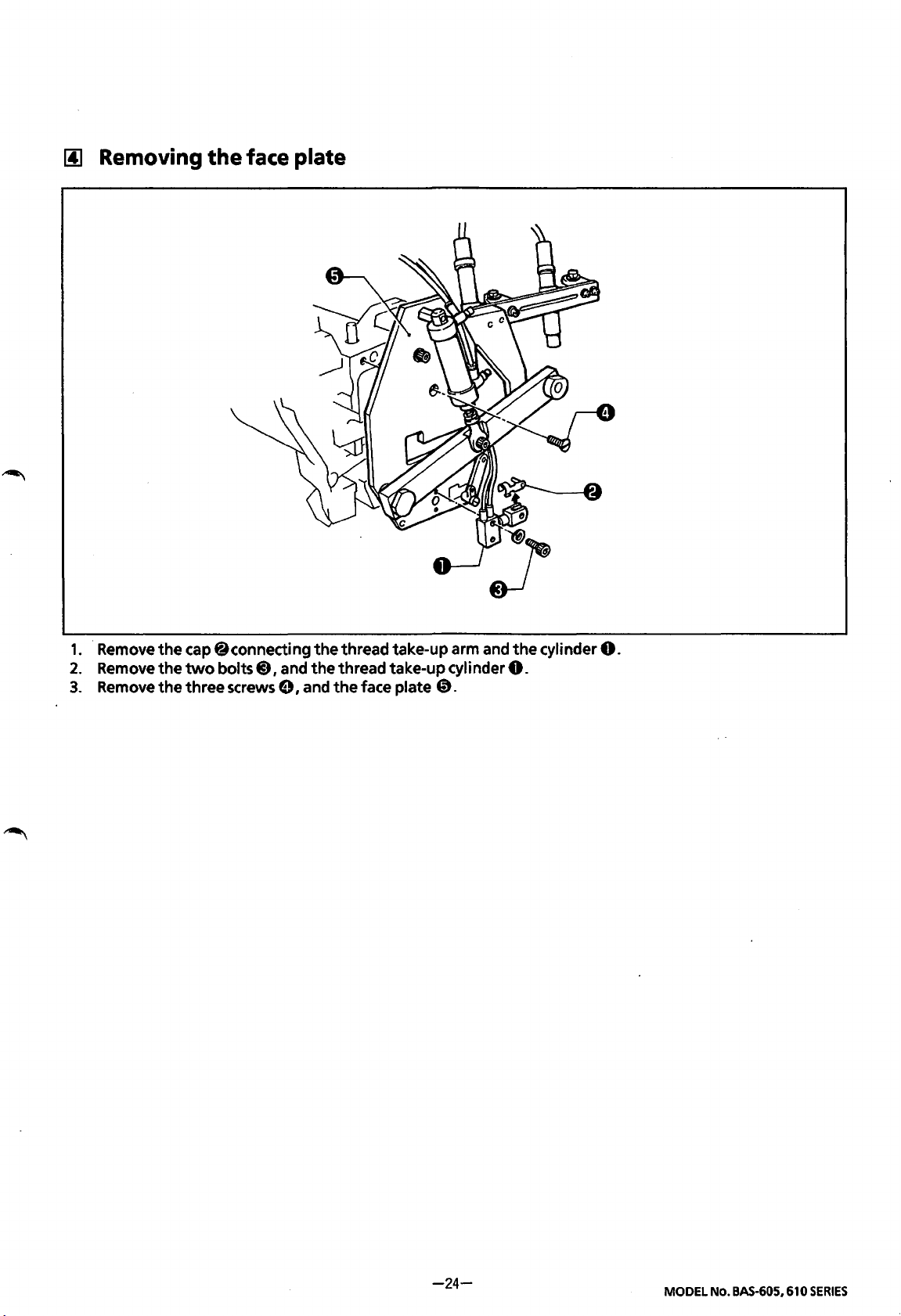

1!1

Removing

the

face plate

1.

2.

3.

Remove

Remove

Remove

the

cap @connecting

the

two

bolts@) I and

the

three screws e I and

the

thread take-up arm and

the

thread take-up cylinder

the

face plate

0.

the

0.

cylinder

0.

-24-

MODEL No. BAS-605, 610

SERIES

Page 29

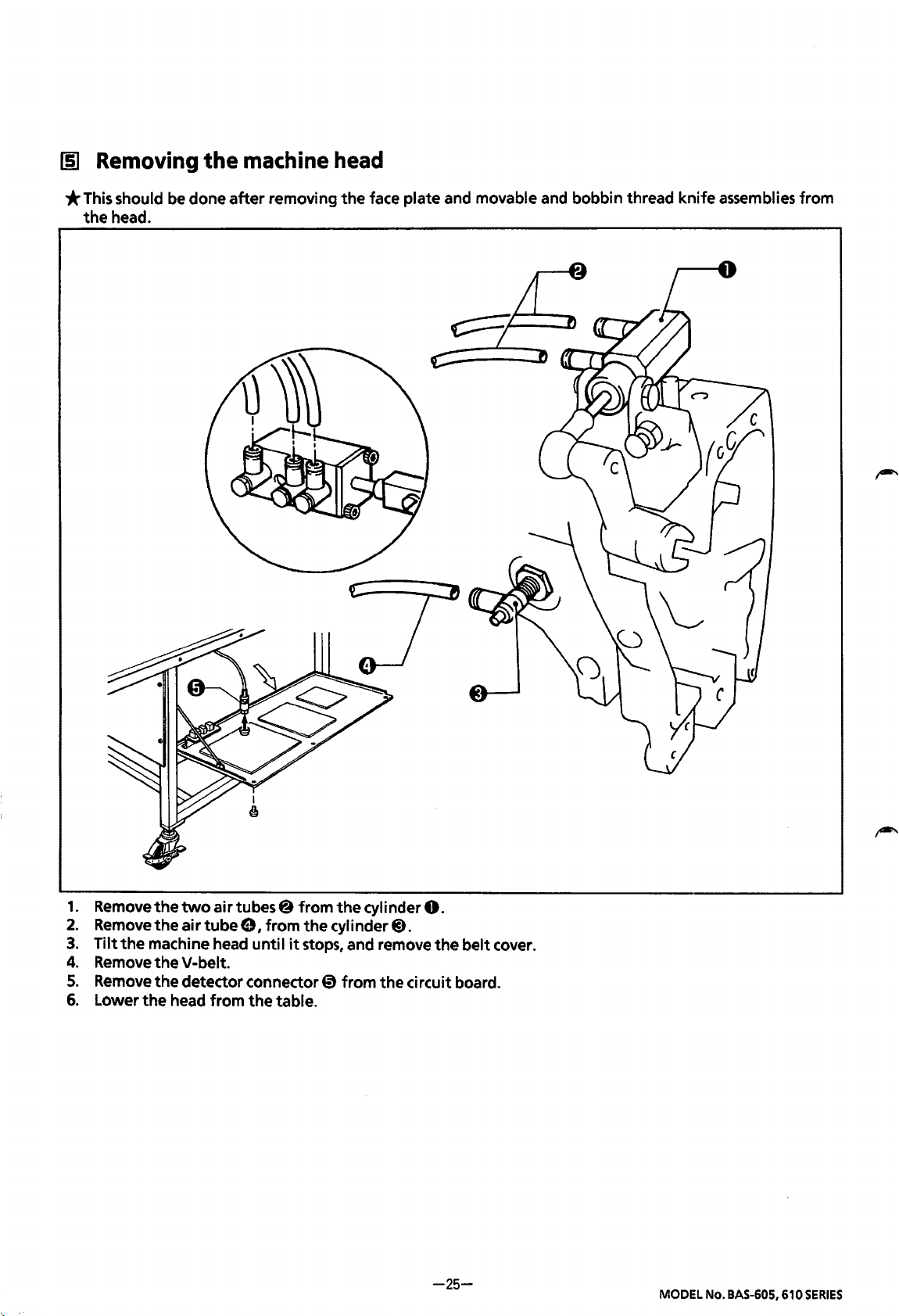

[§]

Removing

the

machine head

*This

the

should

head.

be

done

after

removing

the

face plate and movable and bobbin thread knife assemblies from

1.

2.

3.

4.

5.

6.

Remove

Remove

Tilt

Remove

Remove

Lower

the

two

air

the

air

tube

the

machine head until

the

V-belt.

the

detector connector 0 from

the

head from

tubes@ from

e I from

the

the

it

stops, and remove

table.

the

cylinder

cylinder

the

0.

8.

the

circuit board.

-25-

belt cover.

MODEL No.

BAS-605,

610

SERIES

Page 30

111

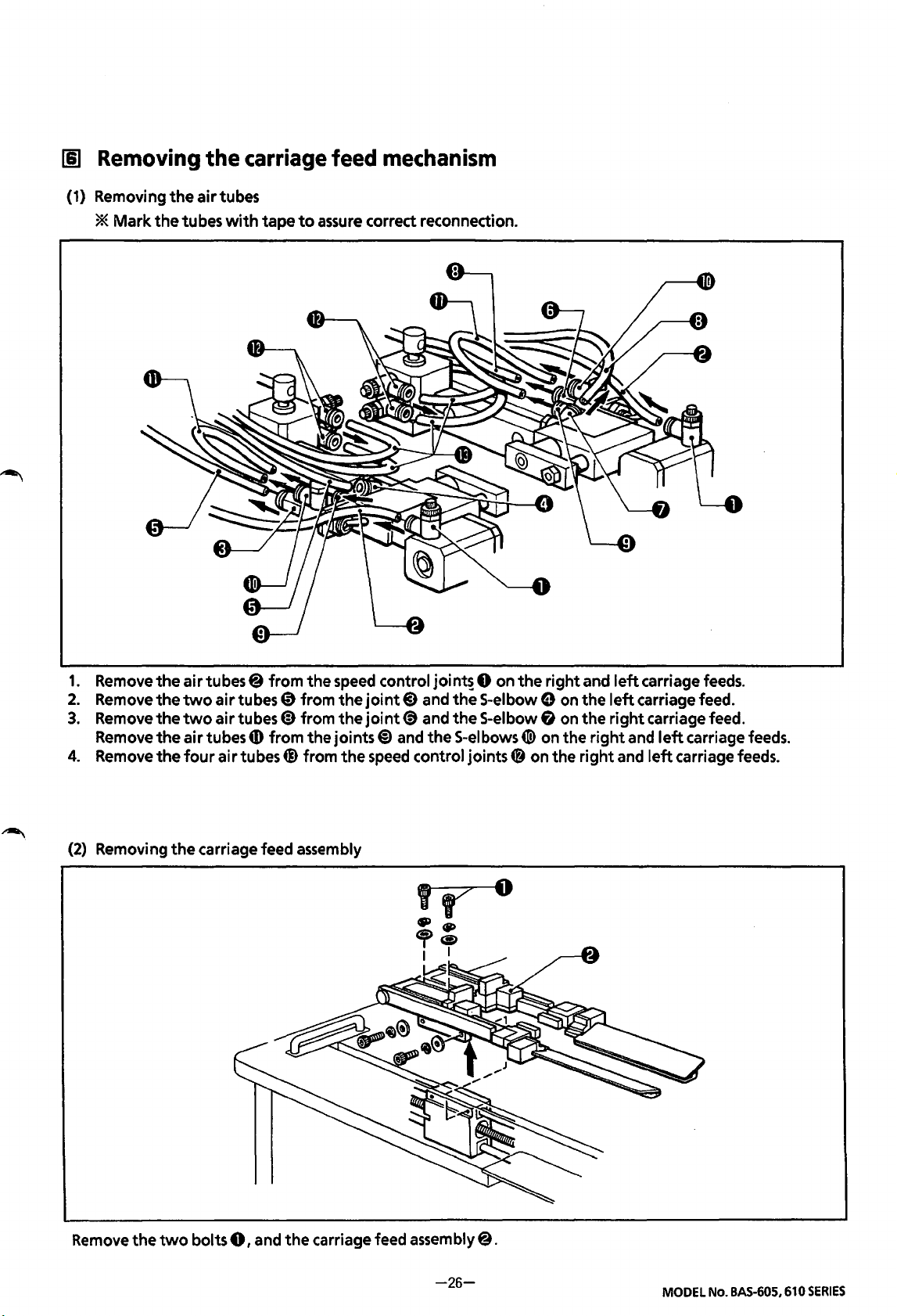

Removing

(1) Removingtheairtubes

*

Mark

the

the

tubes

with

carriage

tape

to

assure

feed

mechanism

correct reconnection.

1.

Remove

2.

Removethetwoairtubes@

3.

Remove

Remove

4.

Remove

(2)

Removing

the

air

tubes@ from

the

two

air

the

air tubes

the

four

air tubes@) from

the

carriage feed assembly

the

speed

from

thejoint8

tubes

(D

from

the

41)

from the joints@) and

the

control

joint(§) and

speed

joint~

and

the

control

0 on

the

the

S-elbow0

the

S-elbow8

S-elbows

joints~

4D)

on

right and

on the

on the

on the

the

right

right and

left

carriage feeds.

left

carriage feed.

right

carriage feed.

and

left

left

carriage feeds.

carriage feeds.

Remove

the

two

bolts

0,

and

the

carriage feed assembly@.

-26-

MODEL

No.

BAS-605,610

SERIES

Page 31

[1]

Removing

the feed

mechanism

(1) Removing the

(2)

Removing the corner knife cylinder assembly

DC

motor assembly

1.

Remove

assembly 0 from the circuit board.

2.

Loosen

belt0.

3.

Remove

washers,

1.

Loosen

sensor@

2.

Remove

3.

Remove

washers, and

the

two

connectors @

the

two

bolts

the

two

and the

the

screw

by sliding

the air tubes@ and

the

two

the

@,and

bolts

DC

motor assembly

0,

and remove

it

downward.

bolts

@,

corner knife cylinder assembly

@).

remove the

@,

the

0.

the

washers,

of

flat

the

0.

DC

motor

timing

and spring

the

cylinder

the

spring

(3)

Removing

the

corner knife adjusting

base

1.

Remove

2.

Remove

washers, and the corner knife adjusting

-27-

the spring

the

two

0.

bolts

@,the

MODEL

flat

No.

BAS-605,

and spring

base

@).

610

SERIES

Page 32

(4)

Removing

* Do

[I]

Removing

not

the

feed mechanism assembly

remove

or

disassemble

the

padding

the

feed mechanism unless

1.

2.

cloth

presser

absolut~ly

Remove

Remove

mechanism assembly@).

*

the

the

Be

careful

assembly@).

air

tube

four

not

necessary.

to

assembly

0.

bolts

drop

@I

and

the

feed mechanism

the

feed

(1) Removing padding cloth presser

1.

Remove

2.

Loosen

3.

Remove

(2)

Removing padding cloth presser

1.

Remove

2.

Remove

3.

Loosen

the

the

the

the

the

the

two

air

tubes

0.

two

screws@ 1 and remove padding cloth presser

two

bolts 0 I and remove

air

tube(¥).

two

screws & 1 and remove padding cloth presser

two

screws

@)I

and remove

foot

foot

I

I

I

oJ

spring

spring

(R)

the

cylinder assembly 0

(L)

the

cylinder assembly

foot

from

foot

4ID

spring

spring

from

the

the

(R)

@).

table.

(L)

@)from

table.

the

table.

-28-

MODEL No. BAS-605, 610

SERIES

Page 33

(ASSEMBLY)

[!]

Attaching the feed

(1)

Attaching

1.

Attach the feed mechanism

frame

2.

lnserttheairtube@) into the S-elbow

*The

adjusted later.

the

feed mechanism

with

the

four bolts

carriage feed

8.

position

mechanism

assembly

assembly 0 to

0.

needs

to

assembly

(2)

Attaching the corner knife adjusting

1.

the

be

Attach the corner knife adjusting

ball

the

2.

Mount the spring 0

screw

flat

*The

needs

base

base

support

and

spring

corner knife adjusting base

to

be

(R)

@)

with

washers.

on

the spring hook

adjusted later.

the

two

0

to

bolts

@,

0.

position

(3)

Attaching

the

corner knife cylinder

assembly

1.

Insert the pins @ into the channel in the corner

0.

knife lifting plate

cylinder

with

*At

assembly

flat

and

spring

this time, make

plate 0

pin

pulled

sure

original position

@.

to

that

is

not

If

it

is,

the

left

the slider

@)

pushed

the slider

Attach the corner knife

to

ball

screw

support

washers

by hand and

with

and

two

sure

the corner knife

too

far

back

~may

~

smoothly returns

the

pressure

stick when

released.

bolts

towards the

ofthe

&.

Check

that the pins @ do

the

channel in

because

2.

Connect the air tube

connect the air tube

3.

Insert the cylinder

fitting, and temporarily tighten the screw

*The

later.

they are not inserted properly.

corner knife

corner knife

41!>

to

sensor

sensor

not

come

lifting

@)

to

the

joint

the half union G).

4f}

into the metal

needs

to

be

out

plate 0

(R)

e

0.

lifting

it

is

Make

to

its

spring

of

the

@),

and

(D.

adjusted

~

(;----

---- --------

~--:J

X

-29-

MODEL

No.

BAS-605,

610

SERIES

Page 34

{4)

Attaching

the

DC

motor

assembly

0.05-0.25mm

2.5-3.Smm

1.

Attach the

2.

Insert the key 0

clearance between pulley B 0 and the motor shaft

screws~.

3.

Attach the

DC

motor

DC

assembly 0

into

the

motor assembly 0

to

the

motor bracket@

key way on the

to

support L 6 using

with

the

DC

motor shaft, and then slide pulley B @ on.

bush

to

0.05-0.25 mm, and tighten

each

two

then temporarily tighten them.

[Adjusting

4.

Mount

there

5.

Insert

the

timing

the

timing

is

2.5-3.5 mm

the

two

belt

of

belt @)on the

of

give when a

connectors

the

fD

DC

of

motor

timing

600

the

DC

assembly]

pulley

±50

g load

@and

is

applied

motor assembly

-30-

pulley B

to

0.

0.

the center

four washers and bolts@.

Set

the

the

two

set

washers, spring washers, and bolts @,

Firmly tighten

of

the

the

timing

MODEL

bolts

belt@).

No.

BAS-605,

@so

610

that

SERIES

Page 35

00

Attaching the

machine

0

head

~

I

I

I

I

1.

Set

the

head 0

* Make sure

not

more

2.

Loop

the

The V-belt @ tension should

that

sure

the

four

bolts

3.

Attach

4.

Position slide plates

that

(D)

the

the

clearances on

and fulcrum pin guides

onto

the

that

the

than

a 0.3 mm step, and

V-belt@ over

the

centers

C9,

air

tubes and

of

and slide

(R)

table

@.

bed surface

the

machine pulley e and

the

the

the

and

(L)

the

right

(R)

of

the

that

allow

15-20 mm

machine pulley e and

motor G to

detector connector.

@)

so

that

and

left

and

(L)

tD

head 0 and

the

machine head does

the

of

give when

motor

adjust

the

there

is

no clearance

sides

of

the

so

that

there

-31-

the

top

of

the

not

motor

alignment.

slide plates are equal. Adjust

is

pulley

the

belt @ is

pulley 0 are aligned.

at

the

no play either front-back

table @ are flush

wobble.

0.

pressed

front

of

the needle plate @),and

or

MODEL

or

that

there

by hand. Also make

If

they are not, loosen

the

positioning bolts

left-right.

No.

BAS-605,

610

SERIES

is

so

Page 36

jjJ

Attaching the

face

plate

1.

2.

3.

Attach

Attach

Attach

the

face plate 0

the

thread take-up cylinder@)

the

thread take-up arm and

to

the

machine head using

to

the face plate 0 using the

the

cylinder using

-32-

the

three screws@.

the

cap

0.

two

bolts

9.

MODEL No.

BAS-605,

610

SERIES

Page 37

1!1

Attaching the binder

00

Attaching the

cloth

guide

1.

Attach

plate using

bolts.

2.

Make

adjusting

slide plate.

the

binder assembly 0

the

two

the

binder and

the

height between

to

the

ruler

springs,

the

flat

washers, and

needle plate parallel by

the

binder and

fitting

the

1.

Attach

2.

Put

3.

Place

screws

up and

4.

Attach

* Refer

the

left

the

spacers

the

cloth guide arms

f)

so

that

down

the

flap

to

page 46,

and

right

e on

the

there

(down by

spacers@)

"00

cloth guides 0

fulcrum shaft@).

@)

and

is

no

play

left-right

the

spring pressure). ·

and

the

sensor

Adjusting

the

to

the

cloth guide arms

The

number

the

set collars ~ onto

in

the

cloth guide arm

bases@)

cloth guide."

using

-33-

@)

of

the

spacer 9 must match

the

fulcrum shaft

the

screws

using

@)

4ID.

two

and

screws

that

@ each.

the

gauge

@),

and tighten

the

arm moves smoothly

MODEL

No.

size.

BAS-605,

the

610

two

SERIES

Page 38

[§)

Attaching

the

movable

knife

assembly

1.

Insert the movable knife 0

with

that

of

the

knife bar@. Tighten the washer and bolt

2.

Secure

washers, and

3.

Check

and

*

4.

Attach the movable knife

Be

cylinder rod

*The

5.

Insert the cylinder

fitting

6.

Connectthetwoairtubes@

the fixed knife 0 and

bolts~

that

the knife bar @ moves both smoothly and easily, up and down. Adjust the fixed knife e

the

thread retainer spring@

lfthe

angle

of

the thread retaining spring 0

the

bolts~

sure

the

pressure should be adjusted

If

the

0)

and 8 are tightened

cylinder rod

4lD

moves easily

thread

is

to

adjust the

not

sensor

into

the

slot

of

the knife bar @, and align the hole

the

thread retainer spring @ temporarily using the washers, spring

and

8.

so

that

the thread retainer spring 0 touches the movable knife

too

much,

assembly@)

4lD

and the knife bar @ are straight and

and

cut properly, increase the

41

into

sensor.

to

using the washers, spring washers, and

does

not

strike the

to

as

little

as

the metal

the

cylinderS-elbows.

fitting

@).

is

incorrect, the thread

the

knife operation

head

when moved up and down by hand.

will

cut the thread.

pressure

slightly.

ID,

then temporarily tighten

will

of

the movable knife 0

will

not

be

properly held. Also,

become

not

too

stiff.

four

bolts@).

twisted. Also, make

the

screw

0.

sure

of

the metal

if

the

-34-

MODEL

No.

BAS-605,

610

SERIES

Page 39

[1]

Attaching

the

bobbin thread knife assembly

1.

Remove slide plates

2.

Align

the

two

bobbin thread knives @

the

insert

3.

Attach the knife

*The

knives@.

position

0.

4.

Move the cylinder rod 8

5.

6.

Connect

Return

*The

the

two

the

machine head

bobbin thread knife position needs

(R)

and

base 9 to

will

not

air

tubes@)

(L),

then

tilt

the

machine head until

of

knife holder

rotary hook

change when

left

or

right

to

the cylinder@).

to

its original position, and attach slide plates

base

the

knife

by hand

to

(R)

0 using

base 9 is

to

be adjusted later.

(L) 0 with

the

make sure

two

fitted

it

moves smoothly and easily.

it

stops.

the holes

screws@.

against

of

the

needle plate

the

step in rotary hook

(R)

and

(L).

8,

base

then

(R)

-35-

MODEL

No.

BAS-605,

610

SERIES

Page 40

[I] Attaching the

(1)

Carriage feed

carriage

feed

mechanism

~

IS\IJ>

~®

I I

I I

l

1.

Attach

washers and

2.

Make sure there

assembly and

carriage feed assembly 0

after

*After

(2)

Air

the

carriage feed assembly 0

bolts@) each.

the

the

carriage feed assembly 0

attachment, make sure

at

the

aligned

tubes

sewing end position. ·

to

the

carriage feed

is

a uniform 1 mm clearance between both the

carriage feed assembly.

right

or

is

that

If

the

left

to

adjust

removed, and

the

needle and the

clearance

the

it

fitting

is

incorrect, loosen

clearance.

is

not

usually needed.

left

and right carriage feed reference lines are

Reference

plate @ using

left

and right

the

This

adjustment

lines

the

two

flat

and spring

sides

of

the

bolts @),and shift

will

be

required only

binder

the

1.

Connect

2.

Connect

feed.

Connect

3.

Connect the air tubes@)

4.

Connect

the

the

the

the

air

tubes@

two

two

two

to

air tubes

air

tubes 0

to

air tubes

the

flap presser cylinders 0 on both carriage feeds.

@to

the

folding plate cylinders

to

the joint@) and

the

folding plate cylinder

4I!)

to

the carriage feed

the

S-elbow 9 on the

(S)

lifting

-36-

@)

and the S-elbows 9 on

and

the

cylinders

5-elbow

@).

right

carriage feed.

6.

MODEL

the

No.

left

BAS-605,

carriage

610

SERIES

Page 41

(3) Flap presser assembly

(if

not

attached)

1.

2.

3.

Remove

Lift

Attach

up

the

two

the

carriage feed

the

flap

bolts 0 and

presser assembly e

@).

the

connecting shaft supporter@.

to

the

left

carriage feed 0 using

@.

* Make sure

1 mm clearance

4.

Repeat

5.

Gently

6.

Attach

7.

Attach

*Adjust

8~

Connect

that

when

the

flap

at

the

rear

of

the

same steps

tilt

the

carriage feed.

the

connecting shaft supporter@

the

flap

stopper@)

the

flap

the

air

tube $ to

for

the

right

to

the

stopper@) according

the

cylinder assembly

presser assembly e makes contact

flap

presser

carriage feed.

carriage

to

feed@

to

the'

(L)

6.

the

carriage feed movable

using

the

washer and spring washer, and screw

flap

shape.

0.

-37-

the

with

base@)

two

spring washers and bolts

the

carriage feed

using

the

two

MODEL

No.

BAS-605,

0,

bolts

there

0.

4Ii).

610

is

a

SERIES

Page 42

00

Attaching

the

padding cloth presser

foot

spring

(1) Padding cloth presser

1.

Attach

boltsO.

2.

Attach padding cloth presser

3. Connect

(2) Padding cloth presser

1.

Set

@).

2.

Attach

3.

Attach padding cloth presser

4.

Connect

1m!

Other

1.

Make sure

tight,

2.

Turn on

3.

Set a piece

the

Check

adjust

Carriage feed".

4.

Attach

5.

Check

switch

6.

Sew and correct any improperly adjusted

the

cylinder assembly

the

two

the.top

carriage feed

end

the

cylinder@)

the

air

that

there

and

that

operation

the

air

and

of

material under

that

the

needle

the

clearance between

the

corner knives.

the

sewing operation. Next, set

to

ON, and sew.

foot

spring

@to

foot

air

tubes@

foot

of

the padding cloth pusher @)to

tube@)

is

the

to

the

to

spring (L)

to

the

table using

foot

to

the

speed control

no

excessive

is

normal.

power, and set

the

sewing end position.

is

aligned

the

(R}

the

table using

spring

the

spring

carriage feed, and operate the treadle.

with

carriage feed and the binder

(R} 9 to

cylinder speed control joints

the

two

(L)

0)

joint

play in any parts,

the

MODE

the

left

the

center knife switch

places.

the

two

washers, spring washers, washer

the

spring

55

spring washers and

to

the

table using the

fitting

mm above the

tD.

that

parts do

switch

and

Refer

to

MANUAL.

right

reference lines on the carriage feed.

to

the

sewing

shaft 8 using

f).

not

to

1 mm, referring

to

ON,