Page 1

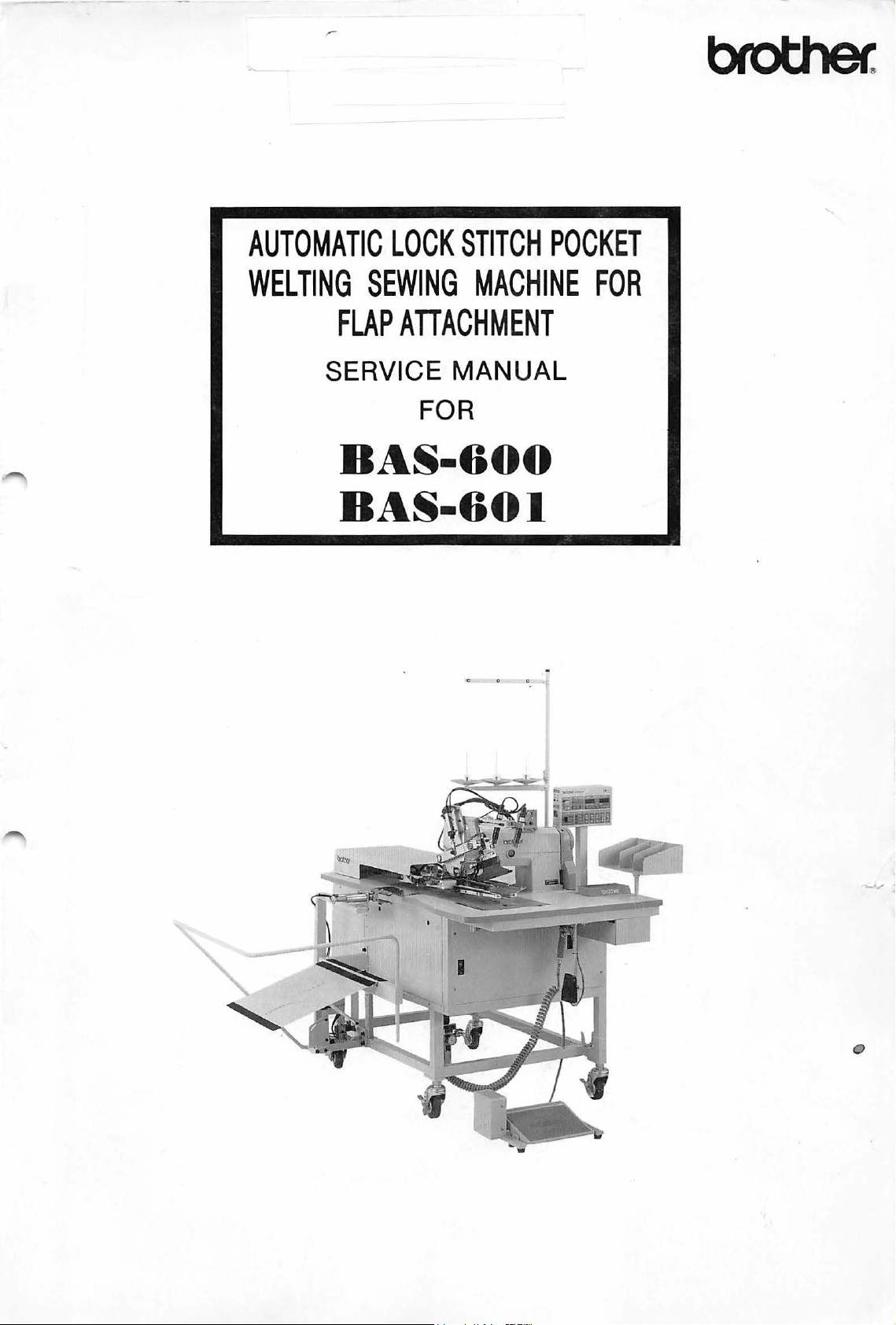

AUTOMATIC

LOCK

STITCH

POCKET

WELTING

SEWING

FLAP

SERVICE

BAS-600

BAS-601

MACHINE

FOR

ATIACHMENT

MANUAL

FOR

•.

Page 2

CONTENTS

SPECIFICATIONS

INSTALLATION . • • . • • • • • • • • • • . • • • • • • • • • • • . • • • • • • • • • . • • • • • • • • • • • • • • . • • • • • 2

1. Setting up

3.

Installing

4.

Installing

2.

Installing

5.

Installing

LUBRICATION

1.

Adding oil

2.

Adjusting

3.

Filling

4.

Regular lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CORRECT

1.

2.

3.

4.

OPERATION

Winding

Threading

Threading

Holding

• . • • • • • • • • . • . • • • • • • • • • • . . • • • • . • . • • . • • • • • • • • • • • • • • • • • • • • • 1

the

table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

the

spool stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

the

material holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

the

treadle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

the

stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. • • . • • • • . . • . • • • • . . • • • • • • • . . . • • • • • • • • • • • • • • • . • • • • • • • • • • • • • • 5

to

the

the

the

the

rotary

the

rotary hook lubrication

arm

top

...•.••.•••••••••••••••••••.•••••••.••••••••

bobbin thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

the

needle thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

the

bobbin thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

needle and bobbin threads . . . . . . . . . . . . . . . . . . . . . . . . .

oil

hook

tank

oil

tank

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

...........................

~

. 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

I • • • • • 7

10

TREADLE

1. Treadle

2.

3. Marking

PROGRAMMING • • . • • . • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 15

1. Entering a standard sewing program . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Entering a flap sewing program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.

4. Operating

5.

6.

7.

8.

ADJUSTMENT • . • • • • . • . • • • . • • • • • • • • • • • • • • • • • • • . • • • • • • • • • • • • • • • • • • • • • • •

1. Adjusting

2.

AND

START

SWITCH

operation

Treadle operation

light

Entering a

Setting

the

Checking

Clearing

9etting

the

the

Adjusting

the

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

cycle

sewing program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

stacker during

bobbin counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

number

work

material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

center knife

the

corner knife position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DESCRIPTION

• • • • • • • • • • • • • • • • • • • • • • • • • • • •

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

for

operation standing up . . . . . . . . . . . . . . . . . . . . .

cycle

sewing . . . . . . . . . . . . . . . . . . . . . . . 19

of

work

pieces . . . . . . . . . . . . . . . . . . . . . . . . . . . .

piece counter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

posit~

on . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

11

12

15

16

18

20

21

21

22

23

23

Page 3

DISASSEMBLY

1. Removing

2.

Removing

3.

Removing

4.

Removing

5.

Removing

6.

Removing

7.

Removing

••••.•••.••••••••••••••••••••••••••••••••••••••••••••••

the

cloth guide (left)

the

binder

the

face plate

the

machine head

the

carriage feed mechanism

the

feed mechanism

the

padding cloth presser assembly

.........................................

......................................

................................

..................................

........................

................................

...................

25

.

27

.

27

.

28

.

29

.

30

.

31

.

32

ASSEMBLY

1.

Attaching

2.

Attaching

3.

Attaching

4.

Attaching

5.

Attaching

6.

Attaching

7.

Attaching

8.

Attaching

9.

Attaching

1

0.

Other

SEWING FLOW CHART

•••.•.•.••..•••••••••••••••••..•••••••••••••••••••••••••••

the

the

the

the

the

(Same

attachment method

the

the

the

the

.......................................................

1. Backtacking

2.

Condensed stitch

3.

Stacker operation

4. 1/0 checking

5.

DIP

switch descriptions (supplement)

6.

Relationship between machine speed and feed speed

to

due

stitch pitch

feed mechanism assembly

machine head

face plate

binder

cloth guide

movable knife assembly

fixed knife assembly

carriage feed assembly

padding cloth presser

•••••••••••••••••••••••••••••••••••••••••••••••••

.................................................

.................................................

.........................................

.............................................

............................................

.........................................

...................................

................................•..•...

for

both

........................

right

..........................

.............................

......................•..•..

foot

...........................

and

left

....................•...

sides)

.......

33

33

.

35

.

36

37

.

37

.

38

.

39

.

~

40

42

42

.

43

43

.

44

.

45

.

46

.

47

.

48

.

STANDARD ADJUSTMENT

1. Adjusting

2.

Adjusting

3.

Adjusting

4.

Adjusting

5.

Adjusting

the

6.

Adjusting

7.

Adjusting

8.

Adjusting

9.

Adjusting retention

(Required

10.

Adjusting

11. Adjusting

12.

Adjusting

the

the

the

the

the

bobbin

the

the

the

the

the

the

(MECHANICAL

upper and

needle and

gap between

needle bar

gap between

case

opener

carriage feed mechanism

binder

cloth guide

to

assure

center knife assembly

movable knife assembly

fixed knife assembly

lower

the

the

lift

the

...................................•.

..........................................

.....................................

thread remainder

PORTION)

shaft timing

rotary

stroke and

hook

rotary

rotary

.............................

••••••••••••••••••••••

.....................

timing

hook

hook

............................

and

the

needle bar

and

........................

for

sewing start.)

..........................

................

the

needle plate

height

.....

.......

..

49

49

.

49

.

so

so

so

.

51

.

55

.

56

.

57

.

58

.

64

.

67

Page 4

13.

Adjusting

14.

Adjusting

15.

Adjusting

16.

Adjusting

17.

Adjusting

18.

Adjusting

19.

Adjusting

the

corner knife . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

padding cloth presser

the

tension release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

the

pickup type stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

bar stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

the

foot

switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the

flap sensor (model

foot

601

. . . . . . . . . . . . . . . . . . . . . . . .

only) . . . . . . . . . . . . . . . . . . . . . . .

70

76

79

85

86

STANDARD

1.

2.

3.

OPTIONAL

1.

2.

3.

4.

5.

TROUBLESHOOTING

ERROR

ADJUSTMENT

Replacing

Replacing

Connecting

PARTS

the

the

the

INSTALLATION • • • • • • • • • • • • • • • • • • • • • • • • • . • • • • • • • • • • • • • 95

Thread breakage detector . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flap guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spacer

for

working

Hand switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Marking lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CODES

• . • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • . • • • • • • • • • • • • • • • • • • • • 1

(ELECTRONIC

PORTION)

. • • • . • • • • . • • • • • • • • • • • • •

circuit board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

solenoid valves and the air lines . . . . . . . . . . . . . . . . . . 94

..

. . . . . . . . . .

while

GUIDE

standing up . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

• • • • . • • • • • • • • • • • • • • • • . • . • • • • • • • • • • • • . • • • • • . • 98

87

87

93

95

95

96

97

OS

Page 5

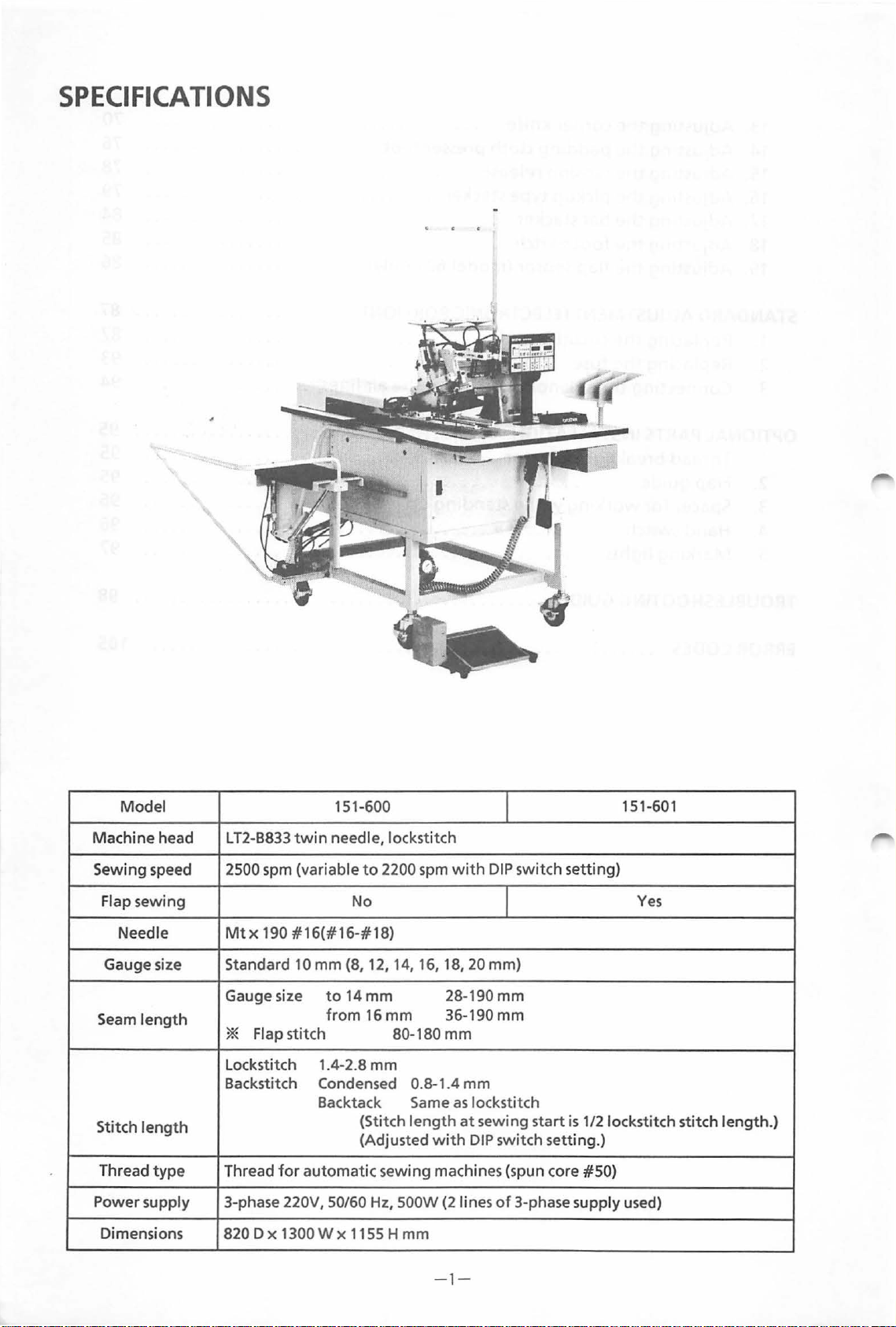

SPECIFICATIONS

Model 151-600

Machine head LT2-B833

Sewing speed

Flap sewing No

Needle

Gauge size

Seam

length

2500 spm (variable

Mtx

Standard

Gauge size

twin

190

#16(#16-#18)

10 mm (8, 12,

Flap stitch

needle, lockstitch

to

2200 spm

14, 16,

to

14mm

from

16

mm

80-180

with

18,20 mm)

28-190 mm

36-190

mm

*

Lockstitch

Backstitch Condensed 0.8-1.4 mm

Stitch

length

Thread

Power supply 3-phase 220V, 50/60Hz, 500W (21ines

Dimensions

type

Thread

820 D X 1300 W X 1155 H mm

1.4-2.8

Backtack Same

for

automatic sewing

mm

(Stitch

(Adjusted

length

as

lockstit

at

sewing

with

DIP

machines (spun core #50)

I

DIP

switch setting)

I

mm

ch

start

is

1/2 lockstitch stitch length.)

switch setting.)

of

3-phase supply used)

151-601

Yes

- 1-

Page 6

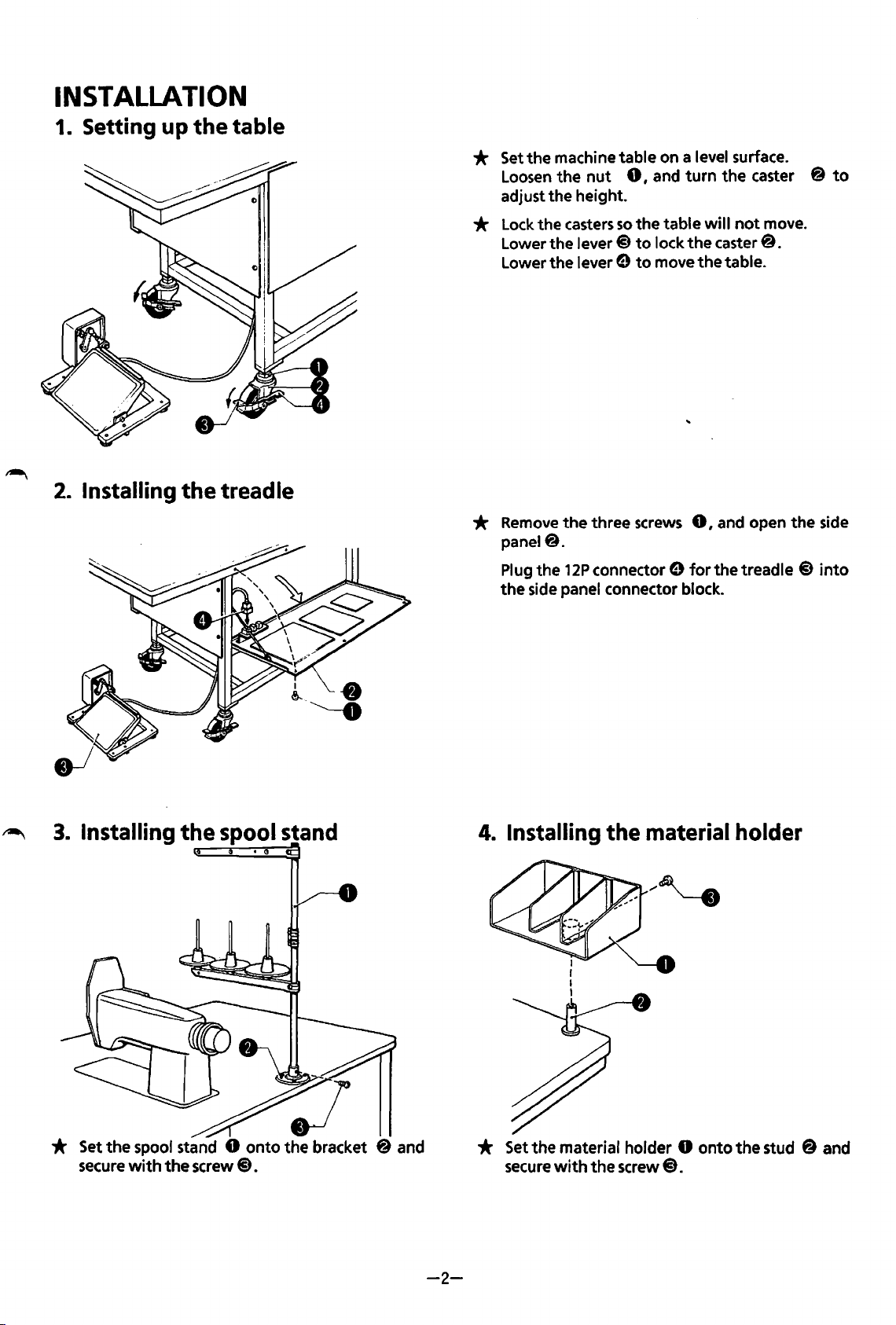

INSTALLATION

1.

Setting up the table

2. Installing

the

treadle

* Set

*

the

Loosen

adjust

Lock

the

Lower

Lower

* Remove

panel@.

Plug

the

the

side panel connector block.

machine table on a level surface.

the

nut 0 I and turn

the

height.

casters so

the

lever@

the

Ievere

the

12Pconnectore

the

to

to

three

screws 0 I and open

table will

lock

move

the

caster @

not

move.

the

caster@.

the

table.

forthetreadle@

the

to

side

into

-2-

4. Installing the material holder

* Set

the

material holder 0 onto

secure with

the

screw@).

the

stud @ and

Page 7

5.

Installing the

stacker

Installing

* Refer

the

to

bar

the

type

figure

stacker

below

to

install

the

stacker.

0 Connector No. 14

@ Connector No.

@)

Airhose

e

Airhose

15

Connecting

* Connect

the

power

the

connectors

supply connector and

as

numbered.

the

air

hoses

-3-

Page 8

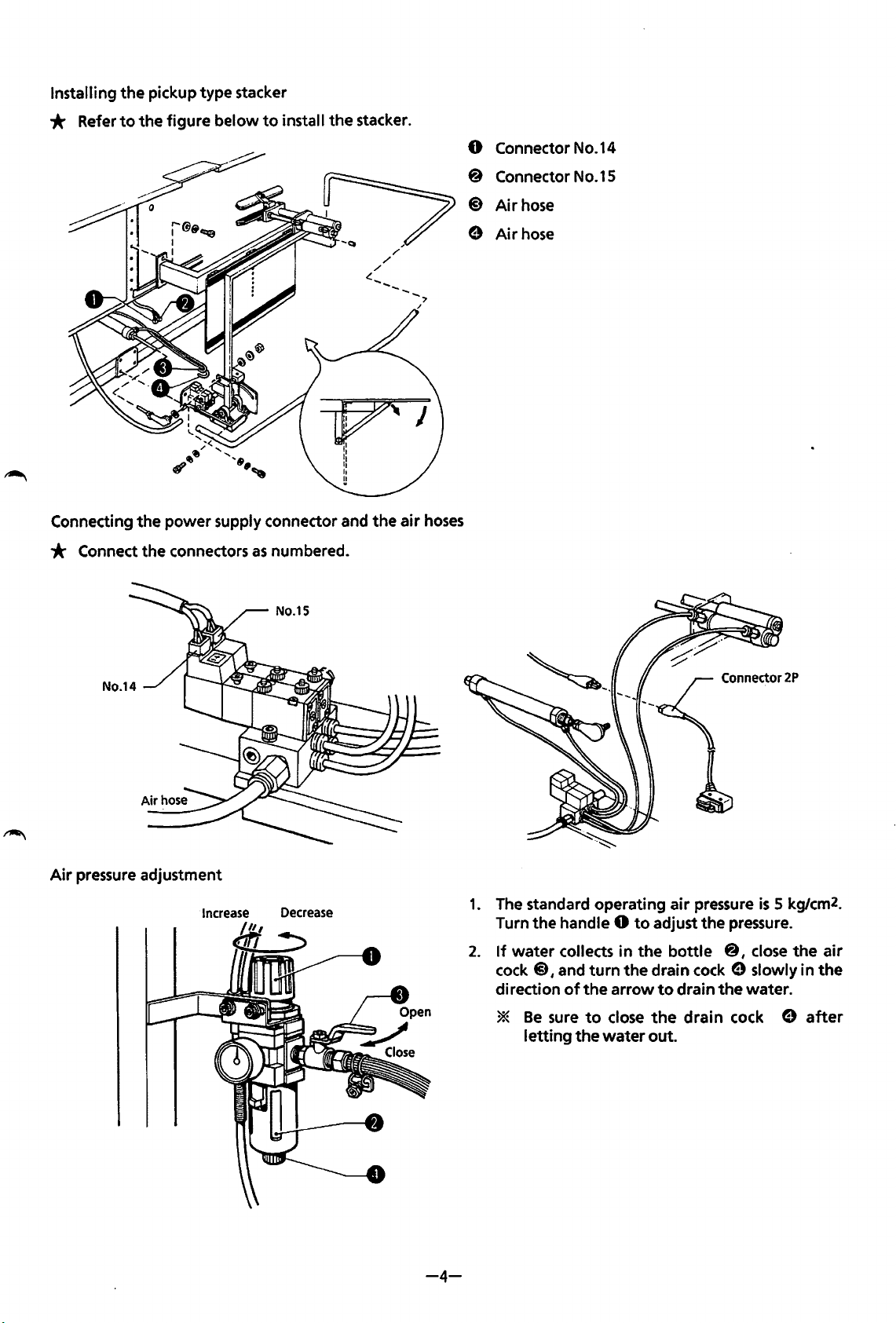

Installing

the

pickup type stacker

* Refer

Connecting

to

the

figure below

the

power supply connector and the

* Connect the connectors

to

install the stacker.

as

numbered.

air

0 Connector No.

@ Connector No.15

@)

Airhose

9 Airhose

hoses

14

Air

pressure adjustment

1.

Increase

Decrease

The standard operating

Turn

the

handle 0

2.

If

water

cock @ 1 and

direction

*

collects in

of

Be

sure

letting

-4-

turn

the

to

the

to

the

the

arrow

close

water

air

pressure

adjust the pressure.

bottle

drain cock e slowly in

to

drain

the

drain

out.

is

@

close

1

the

water.

cock 9

5 kg/cm2.

the

air

the

after

Page 9

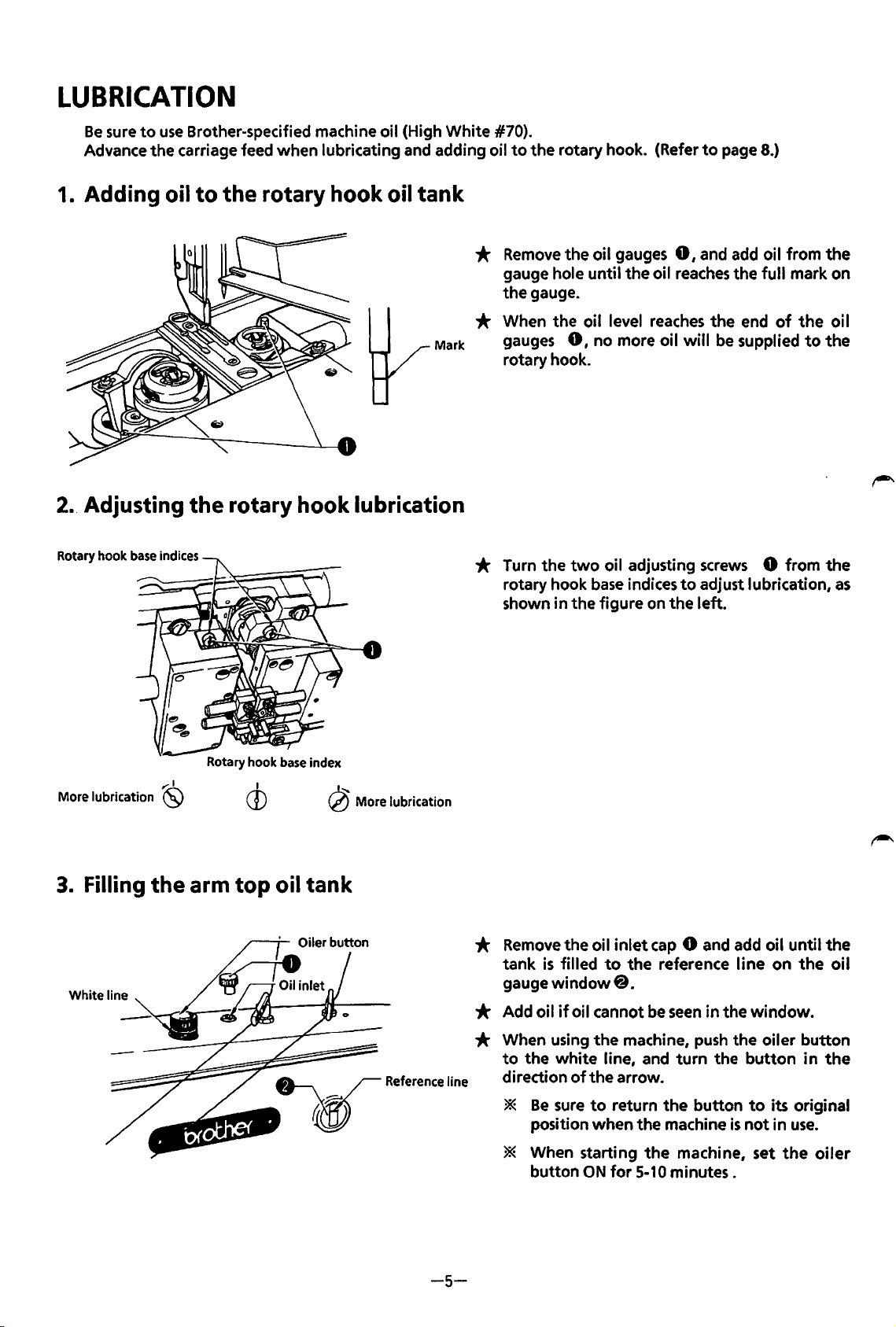

LUBRICATION

Be

sure

to

use

Brother-specified machine oil (High White #70).

Advance the carriage feed when lubricating and adding oil

to

the rotary hook. (Refer

to

page 8.)

1. Adding oil

2. Adjusting

Rotary hook base indices

to

the rotary hook oil tank

the

rotary hook lubrication

*

Remove

gauge hole until the oil

the gauge.

* When the oil level

Mark

gauges

rotary hook.

* Turn the

rotary hook

shown in the figure on the left.

the oil gauges

reaches

0,

no more oil

two

oil adjusting

base

indices

0,

and add oil from the

reaches

will

to

the full mark on

the end

be

screws

adjust lubrication,

of

supplied

0 from the

the

to

oi I

the

as

More lubrication

3. Filling

White

line

Rotary hook base index

..-:1

(SJ

the

arm top oil tank

I

CD

~

More

lubrication

*

Remove

tank

gauge

* Add oil

the oil

is

filled

window@.

if

oil cannot

* When using

to

the white line, and

direction

*

* When starting

of

Be

sure

position when the machine

button

inlet

cap

0 and add oil until the

to

the reference line on

be

seen

the

machine,

the arrow.

to

return the button

the

ON

for

5-10

push

turn

machine, set

minutes.

the

in the window.

the oiler button

the

button

to

is

not

in

its original

in

use.

the

oil

the

oiler

-5-

Page 10

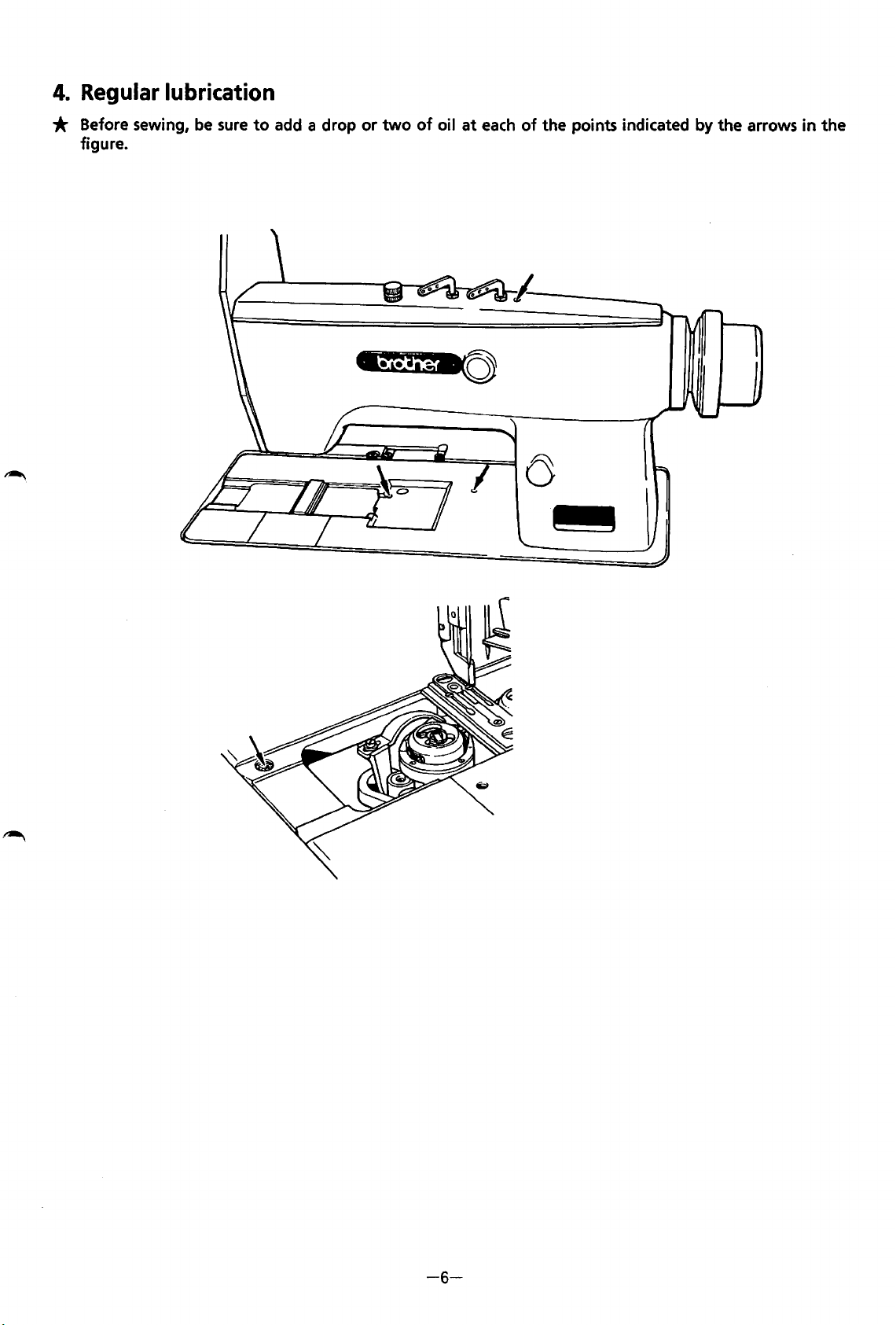

4.

Regular

lubrication

* Before sewing,

figure.

be

sure

to

add

a drop or

two

of

oil

at

each

of

the points indicated by the arrows in the

1------

a

l

..

-6-

Page 11

CORRECT

OPERATION

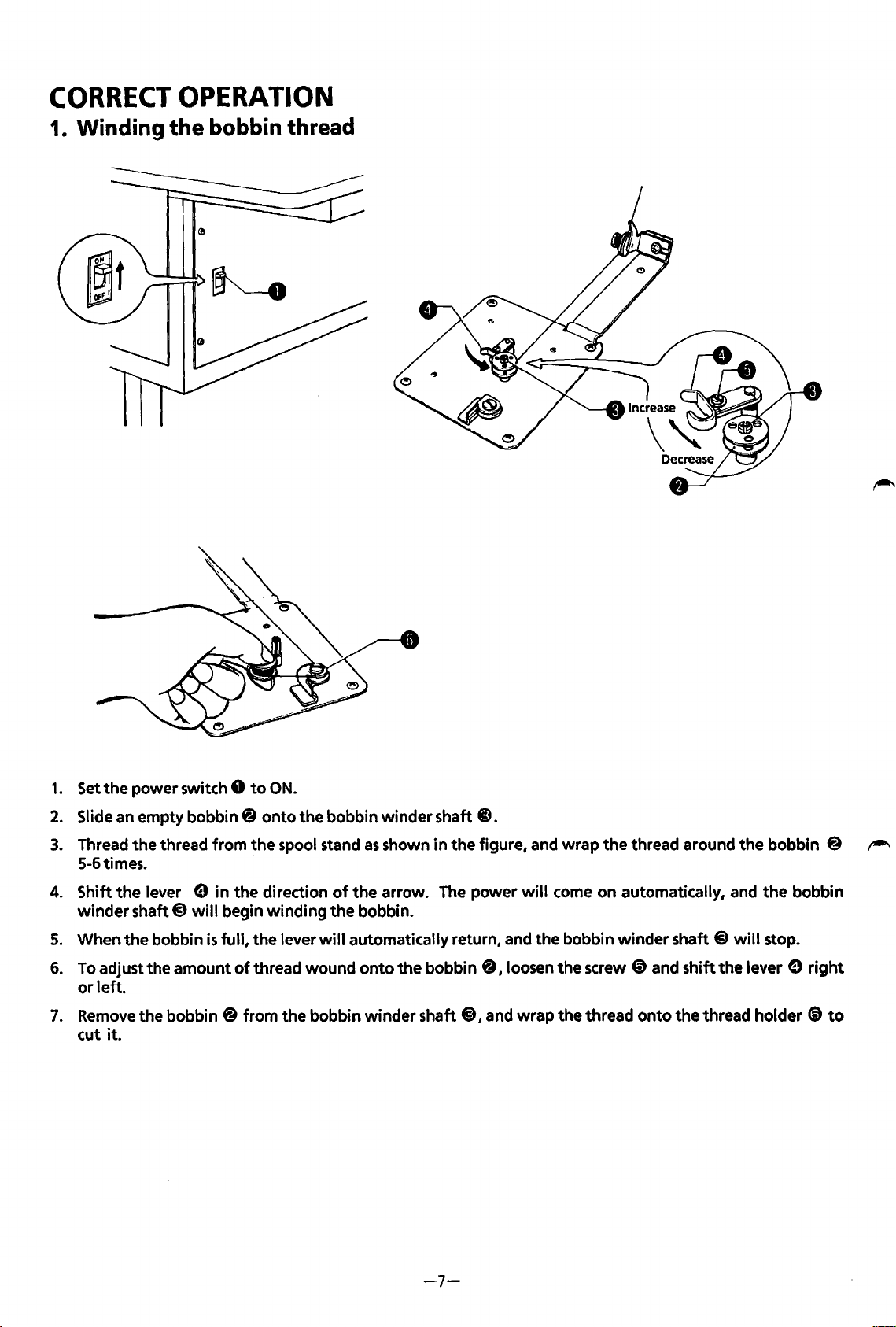

1. Winding the

bobbin

thread

1.

Set

the

power switch 0

2.

Slide an empty bobbin@

3.

Thread

5-6times. ·

4.

Shift

winder

5.

When

6.

To

or

7.

Remove

cut

the

thread from the spool stand

the

lever e in

shaft@)

the

adjust the amount

left.

the bobbin @ from

it.

will

bobbin

to

ON.

onto

the

direction

begin winding

is

full,

the

lever

of

thread wound

the

the bobbin winder shaft

as

shown

of

the

arrow. The power

the

bobbin.

will

automatically return, and

onto

bobbin winder shaft

the

in

the

bobbin

@),

@.

figure, and wrap

will

come on automatically, and

the

8,

loosen

and wrap the thread onto

the

thread around

bobbin winder shaft

the

screw

@>

the

bobbin 8

the

bobbin

@)

will

stop.

and shift the lever e

the

thread holder ~ to

r-"

right

-7-

Page 12

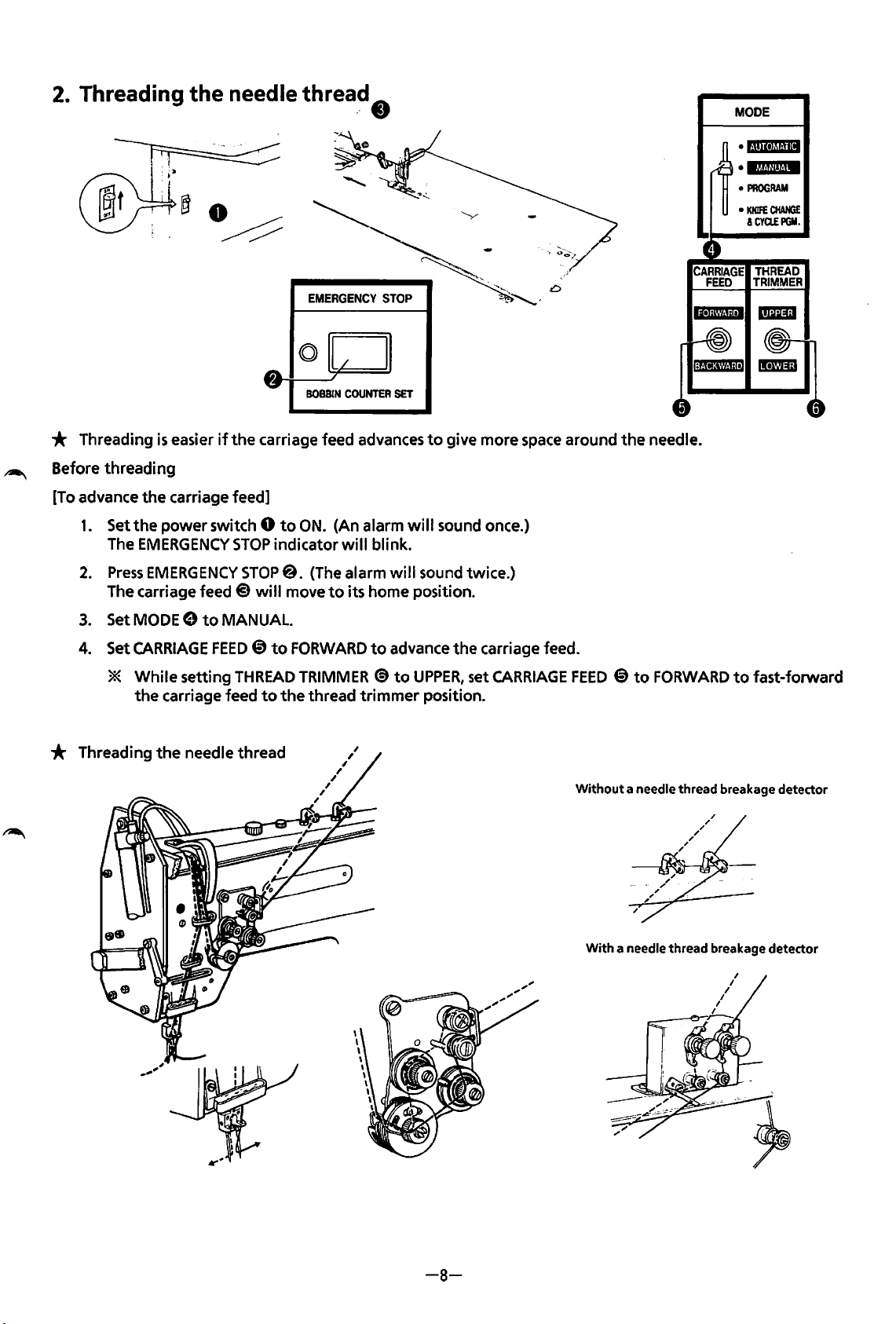

2.

Threading the needle

threa~

t)

MODE

•

«·im•IMiil+

•lf.t.Uiit.iW

•

PROGRAM

•

KNIFE

CHANGE

&CYa.EPGM.

~

* Threading

Before

[To advance

threading

the

1.

Set

the

The

EMERGENCY

2.

Press

The carriage feed

3.

SetMODEe

4.

Set

CARRIAGE

*

While

the

is

easier

carriage feed]

power

EMERGENCY

carriage feed

if

switch 0

to

MANUAL.

FEED@)

setting

the

STOP

BOBBIN

COUNTER

carriage feed advances

to

ON.

(An alarm

indicator

STOP@. (The alarm

@

will

move

to

FORWARD

THREAD

to

the

will

to

its home position.

TRIMMER

thread

trimmer

SET

blink.

will

to

advance

@to

to

give more space around

will

sound once.)

sound twice.)

the

carriage feed.

UPPER,

set

position.

CARRIAGE

the

FEED @ to

CARRIAGE

FEED

needle.

FORWARD

THREAD

TRIMMER

to

fast-forward

* Threading

the

needle thread

Without

a needle thread breakage detector

With

a needle thread breakage detector

-8-

Page 13

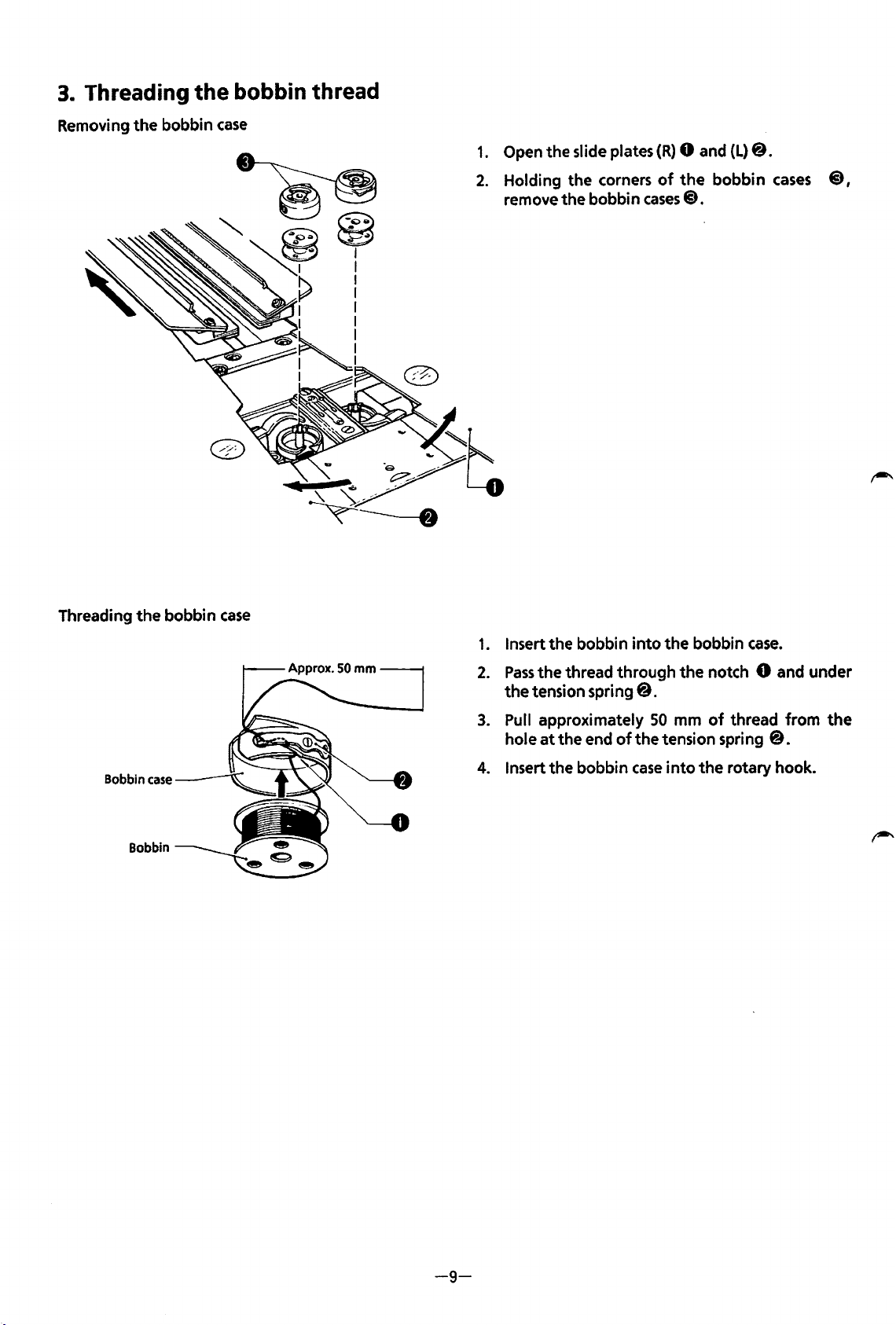

3.

Threading the bobbin thread

Removing the bobbin

case

1.

Open the slide plates

2.

Holding the corners

remove the bobbin

(R)

0 and

of

the

cases@.

(L)

@.

bobbin

cases

@,

Threading

Bobbin

the

case

Bobbin

bobbin

case

1.

Insert the bobbin

2.

Pass

the

thread through

the

tension spring@.

3.

Pull approximately

hole

at

the end

4.

Insert the bobbin

into

the bobbin

the

notch 0 and under

50

mm

of

of

the tension spring

case

into

the

case.

thread from

@.

rotary hook.

the

-9-

Page 14

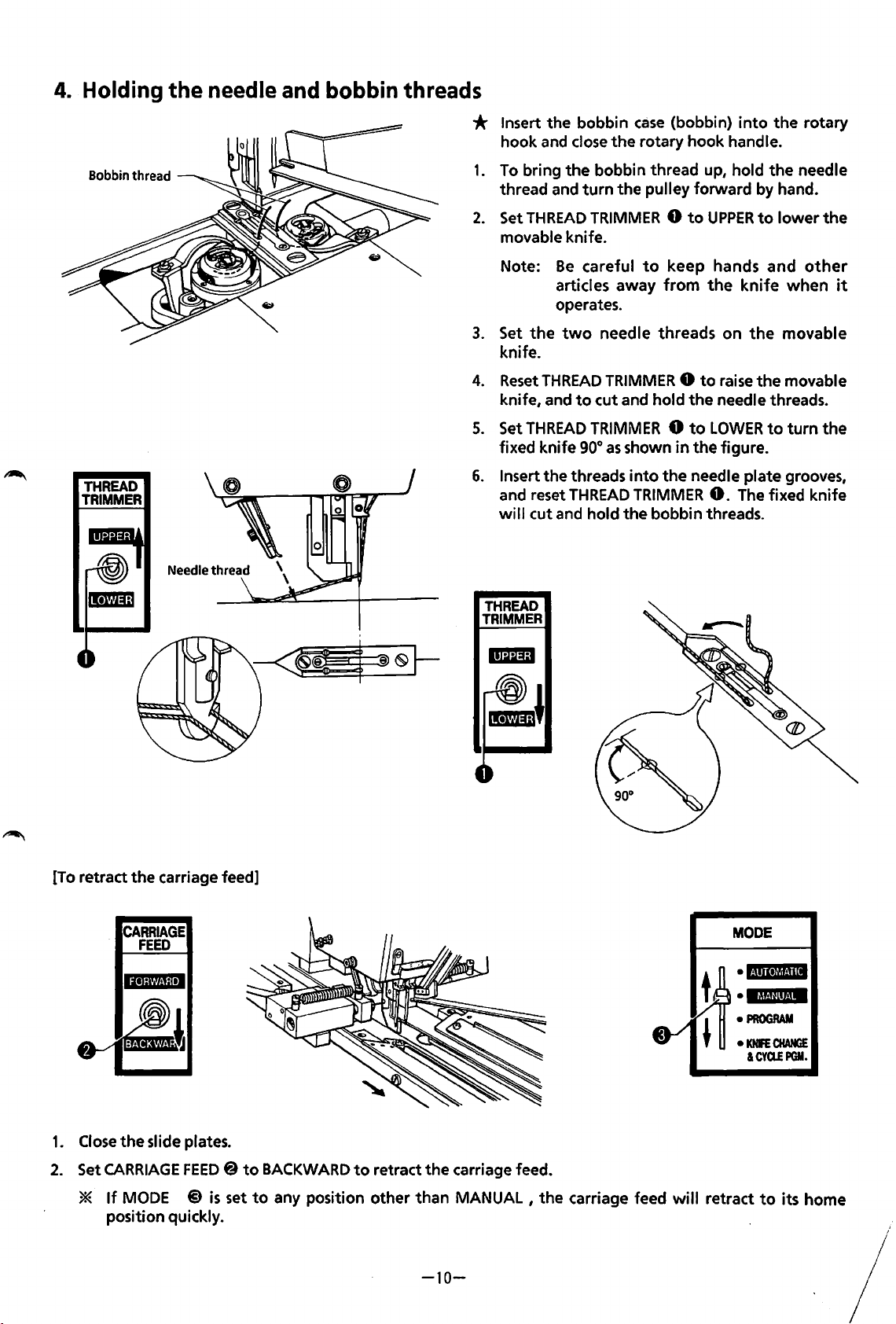

4. Holding

the

needle and bobbin threads

Bobbin thread

THREAD

TRIMMER

* Insert the bobbin

hook

and

close

the rotary hook handle.

1.

To

bring the bobbin thread up, hold

turn

thread and

2.

Set

THREAD

movable knife.

Note:

3.

Set

knife.

4.

Reset

knife,

5.

Set

fixed knife

6.

Insert the threads

and reset

wi

Be

articles away

operates.

the

THREAD

and

THREAD

II

cut

and

two

THREAD

the pulley forward by hand.

TRIMMER 0 to

careful

needle threads on

TRIMMER 0 to

to

cut and hold

TRIMMER 0 to

90°

as

hold the bobbin threads.

case

(bobbin)

to

keep hands and

from

the

shown in the figure.

into

the needle plate grooves,

TRIMMER

into

UPPER

the

0.

to

knife

the

raise

the

needle threads.

LOWER

The

the rotary

the

needle

lower the

other

when

movable

movable

to

turn

fixed knife

it

the

[To

retract the carriage feed]

CARRIAGE

FEED

THREAD

TRIMMER

MODE

•l·iiiitiij.Jil

• 16t.!ilit4M

•

PROGRAM

•

KNfE

CHANGE

&CYa.EPGM.

1.

Close

the

slide plates.

2.

Set

CARRIAGE

*

If

MODE

position quickly.

FEED 8 to

@)

is

set

BACKWARD

to

any position other than

to

retract

the

carriage feed.

MANUAL,

the carriage feed will retract

-10-

to

its home

Page 15

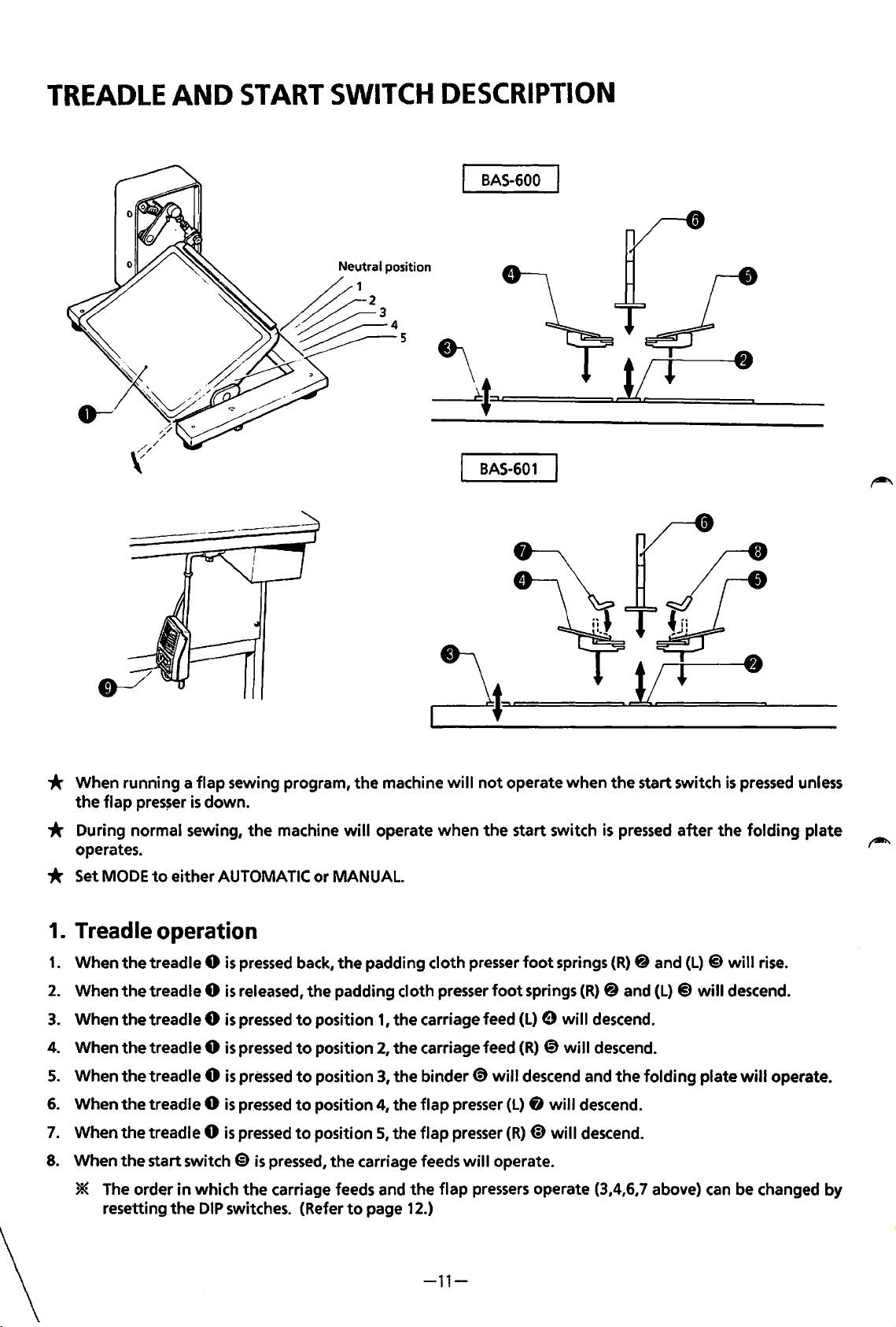

TREADLE

AND

START

SWITCH

DESCRIPTION

BAS-600

BAS-601

* When running a

the

flap

pres~er

flap

sewing program,

is

down.

* During normal sewing,

operates.

* Set MODE

1. Treadle operation

1.

When

2.

When

3.

When

4.

When

5.

When

6.

When

7.

When

8.

When

* The order

resetting

to

the

treadle 0

the

treadle 0

the

treadle 0

the

treadle 0

the

treadle 0

the

treadle 0

the

treadle 0

the

start switch

either AUTOMATIC

is

pressed back,

is

released,

is

pressed

is

pressed

is

pressed

is

pressed

is

pressed

€)

in

which

the

the

DIP

switches. (Refer

the

machine

to

to

to

to

to

is

pressed,

carriage feeds and

will

or

MANUAL.

the

the

padding cloth presser

position

position

position 3,

position 4,

position

the

to

the

machine

operate

padding cloth presser

1,

the

2,

the

the

the

5,

the

carriage feeds

page 12.)

will

not

when

the

carriage feed

carriage feed

binder@

flap

presser

flap

presser

will

the

flap

pressers

operate

start switch

foot

will

(L) 8 will

(R)@)

operate.

when

the

start switch

is

pressed

foot

springs

springs

(L) 9 will

(R)

@)

will

descend and

will

operate (3,4,6,7 above) can be changed by

(R)

(R)

@ and

descend.

descend.

the

descend.

descend.

after

@ and

(L) @ will

folding

is

pressed unless

the

folding

(L) @ will

descend.

plate will operate.

plate

rise.

-11-

Page 16

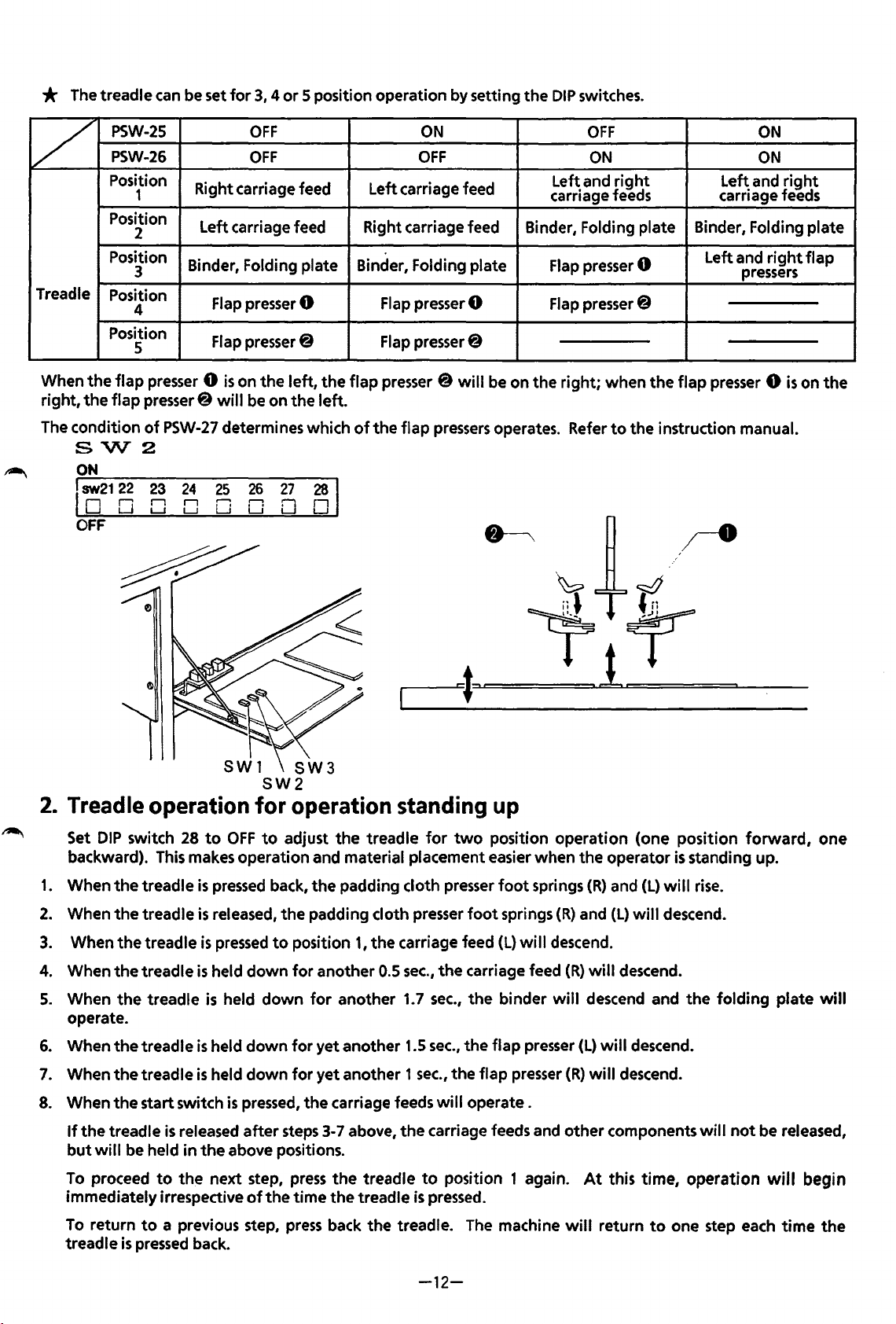

* The treadle can be set

for

3, 4 or

5 position operation by setting

the

DIP

switches.

/

Treadle

When

right,

The condition

~

the

the

SW2

PSW-25

PSW-26

Position

1

Position

2

Position

3

Position

4

Position

5

flap

presser 0

flap

presser@

of

PSW-27

23

r1

L...J L...J u

~

OFF

OFF

Right carriage feed Left carriage feed

Left carriage feed Right carriage feed

Binder, Folding plate Binder, Folding plate

Flap presser 0 Flap presserO Flap presser@

Flap presser@ Flap presser@

is

on

the

left,

the

flap

will

be on

the

left.

determines which

25

0

26

,.......,

24

r1

27

0

28

n

L...J

of

the

ON

OFF

presser @

flap

pressers

Binder, Folding plate Binder, Folding plate

will

be on

operates. Refer

Left and

carriage feeds carriage feeds

Flap presser 0

the

right;

~

~

OFF

ON ON

right

Left and

when

the

flap

presser 0

to

the

instruction manual.

ON

Left and

pressers

,r-8

~

right

right

is

flap

on

the

2. Treadle operation

~

Set

DIP

switch 28

backward). This makes operation and material placement easier when

1.

When

the

treadle

2.

When

the

treadle

3.

4.

5.

6.

7.

8.

When

When

When

operate.

When

When

When

the

treadle

the

treadle

the

treadle

the

treadle

the

treadle

the

start switch

to

OFF

is

pressed

is

released,

is

pressed

is

held

is

held

is

held

is

held

is

SW2

for

to

adjust

back,

the

to

down

down

down

down

pressed,

.--------=rl===..=:!:::::L=!

operation standing up

the

treadle

the

padding cloth presser

padding cloth presser

position

for

for

for

the

1,

the

another 0.5

for

another 1.7

yet

another

yet another 1

carriage feeds

for

two

foot

carriage feed

sec.,

the

carriage feed

sec.,

the

1.5

sec.,

the

sec.,

the

flap presser

will

operate .

position

foot

springs

(L)

binder

flap

~t=

=:::::::a..__

operation

springs

wi

II

descend.

will

presser

the

(R)

(R)

and

(R)

descend and

(L)

(R)

operator

and

(L)

will

descend.

will

will

descend.

(one

position

is

(L)

will

will

descend.

descend.

forward,

standing up.

rise.

the

folding

plate

one

will

If

the

treadle

but

will

To proceed

immediately irrespective

To

return

treadle

is

released

be held

is

pressed back.

in

to

the

to

a previous step,

after

the

above positions.

next step,

of

the

steps 3-7 above,

press

the

treadle

time

the

treadle

press

back

the

the

carriage feeds and

to

position 1 again.

is

pressed.

treadle. The machine

other

will

-12-

components

At

this

return

will

time,

operation

to

one step each

not

be released,

will

begin

time

the

Page 17

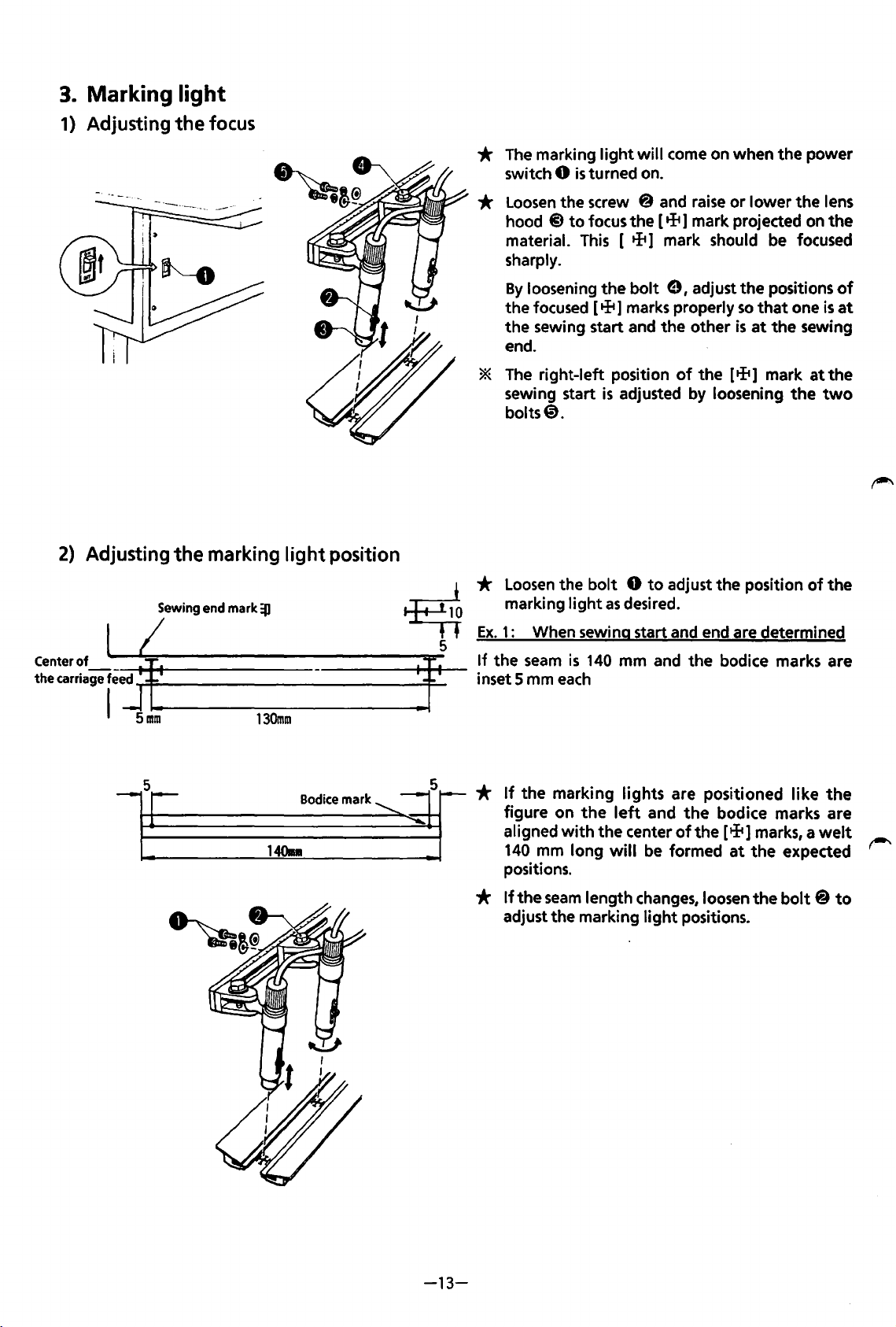

3.

Marking light

1) Adjusting

2)

Adjusting

the

the

focus

marking

light

position

*

The

marking

switch

*

Loosen

hood @

material.

sharply.

By

loosening the

the focused [ + 1 marks properly

the sewing start and the other

end.

*

The

right-left position

sewing start

bolts@.

light

will come on when the power

0

is

turned on.

the screw @ and

to

focus the [ + 1 mark projected on

This

[ + 1 mark should

bolt

e I adjust the positions

is

adjusted by loosening

raise

or lower the lens

so

is

at

of

the [ tft 1 mark

be

that

the

the

focused

one

is

sewing

at

the

the

two

of

at

Centerof

thecarriagef.!j

I 5

.,.

_____________

mm

*

Loosen

marking

Ex.

1:

If

~

--tj

130mm

5

Bodicemark~

1408

the

inset 5 mm

If

the marking lights are positioned like

*

figure on

aligned

140

positions.

*

If

the

adjust the marking

the

bolt 0 to

light

as

When sewing start and end are determined

seam

is

140

mm and the bodice marks are

each

the

left

with

the center

mm long

seam

will

length

adjust the position

desired.

and

the

of

the

be

formed

changes,

light

loosen the

positions.

of

bodice marks are

[tli1

marks, a

at

the expected

welt

bolt @ to

the

the

-13-

Page 18

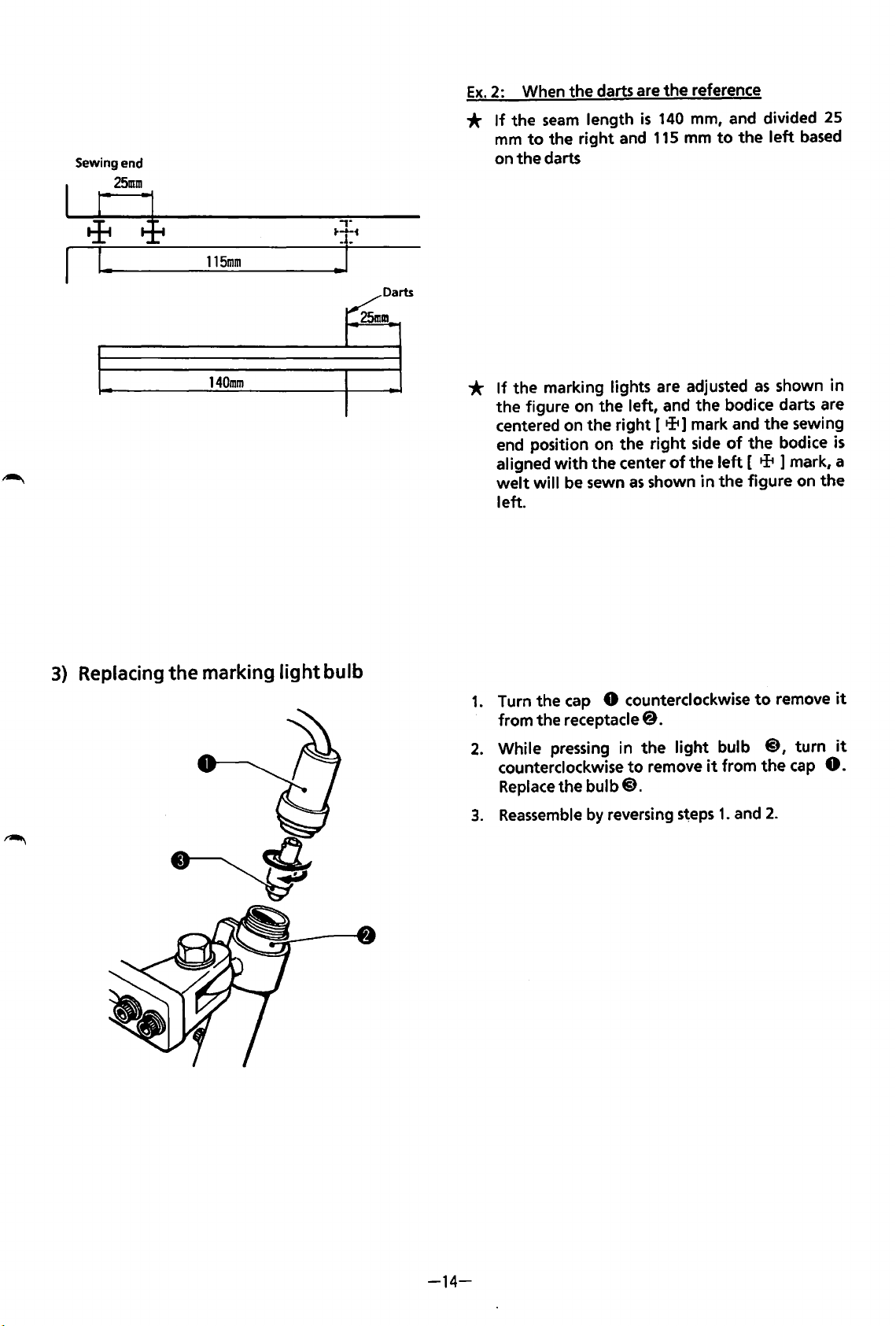

Sewing end

25mm

4 l

I.

115mm

,.

J

Darts

~~

Ex.

2:

*

If

the

mm

on the darts

When the darts are the reference

seam

to

the right

length

and

is

140

115

mm,

mm

to

and

the

divided 25

left

based

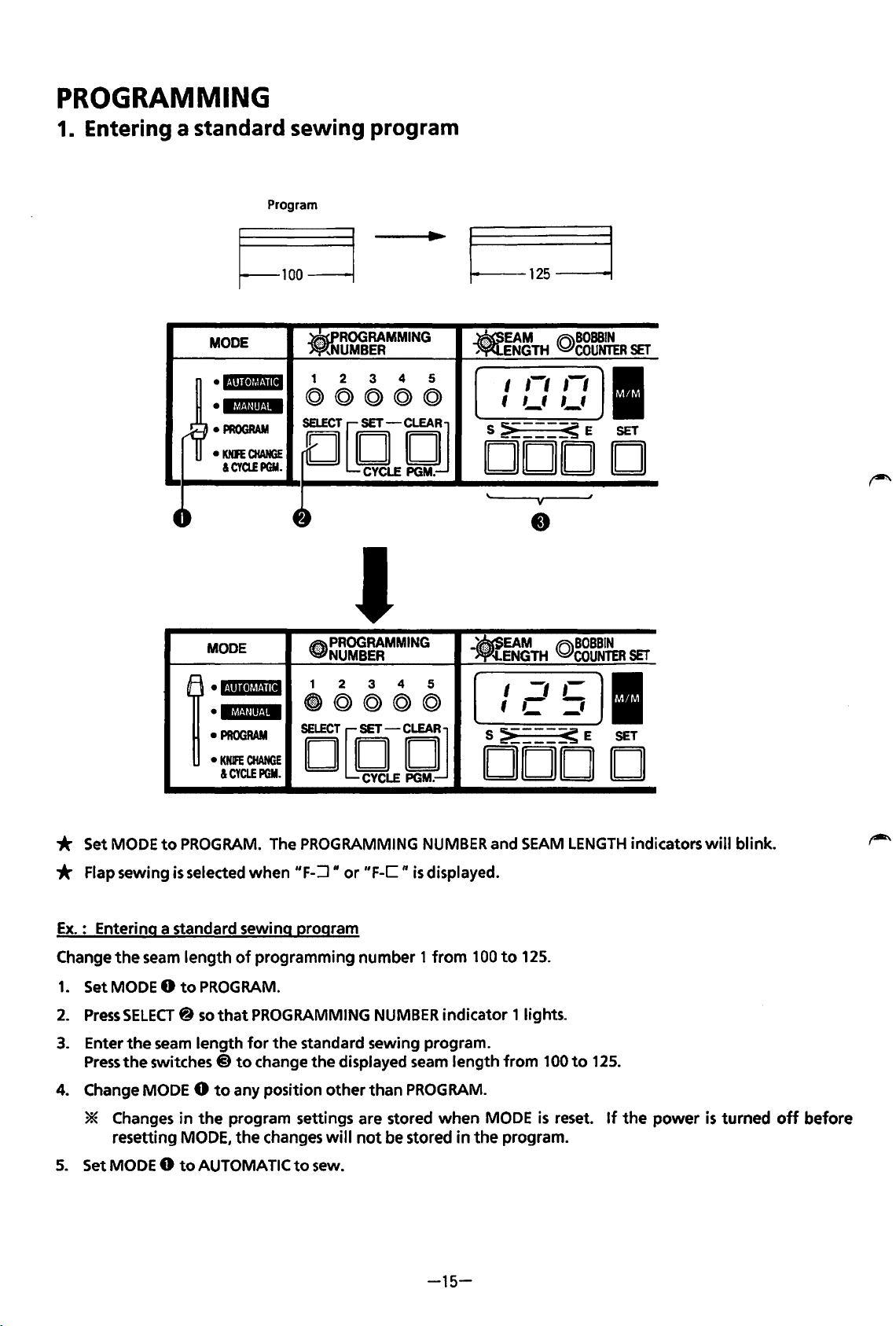

3)

Replacing

the

140mm

marking

light

bulb

*

If

the marking lights are adjusted

the figure on the left,

centered on the right

end

position

aligned

welt

will

left.

1.

Turn the

from the receptacle@.

2.

While

counterclockwise

Replace

3.

Reassemble

on

the right

with

the center

be

sewn

cap

8 counterclockwise

pressing

the bulb@.

in the

by

reversing s'eps

as

shown in the figure on the

to

remove

as

and

the bodice darts are

[tit]

mark

and

side

of

the bodice

of

the

left

[ tit 1 mark, a

to

light

bulb

it

from the

1.

and

shown in

the sewing

is

remove

@,

turn

cap

0.

2.

it

it

-14-

Page 19

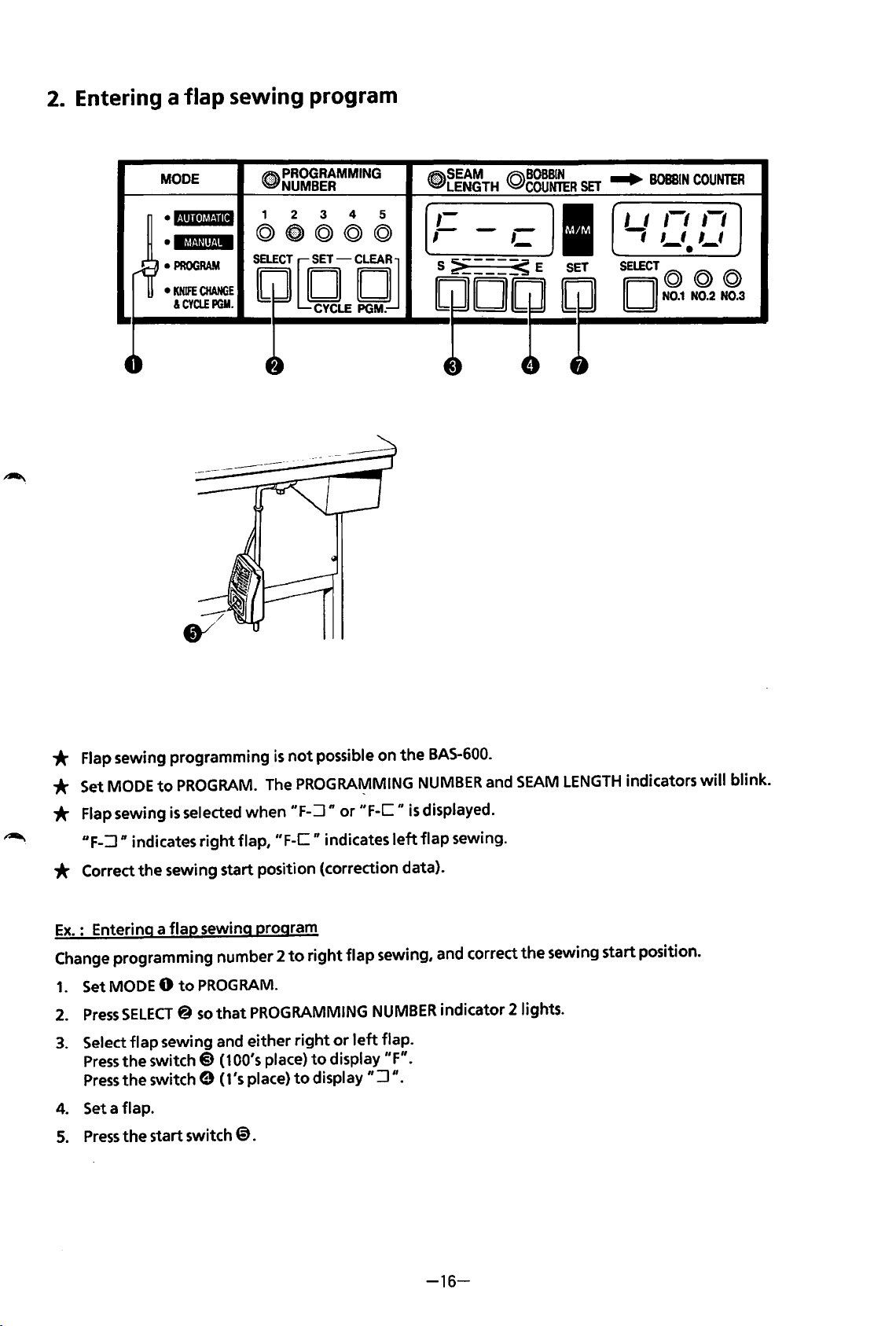

PROGRAMMING

1. Entering a standard sewing program

Program

I~-------.

MODE

•I·~!II•JII·!ill

el.f,t@if.jM

•

PROGRAM

•

KNFE

CHANGE

&CYQ!PGM.

.ROO

1 2

©@@(Q)@

sruCT[O-DJ

RAMMING

UMBER

3

CYCLE

.EAM

4 5

PGM.

J

MODE

1

•lllli~~Hil

•

'MUI*t.IM

•

PROGRAM

•

KNIFE

CHANGE

&CYCLEPGM.

~PROGRAMMING

NUMBER

1 2

@)@@@©

4

3

iEJ[{jLEtjJ

__

5

125

-----~~

ENGTH

I

f

S

~----<

(Q)BOBBIN

,-,

,-,

,_,

,_,

COUNTER

E

DOD

EAM

.<·

~ENGTH

I

1 C

S

:>

@BOBBIN

-,

,-

='

_____

< E

COUNTER

DOD

SET

I

SET

D

SET

I

SET

D

* Set MODE

* Flap sewing

Ex.: Entering a standard sewing program

Change

1.

Set MODE 0

2.

Press

3.

Enter

Press

4.

Change MODE 0

* Changes

resetting

5.

Set MODE 0

to

the

seam

SELECT@

the

seam

the

switches @

PROGRAM.

is

selected

length

to

in

MODE,

to

of

PROGRAM.

so

that

length

to

to

any position

the

program settings are stored

the

AUTOMATIC

The PROGRAMMING

when

"F-:J"

programming

PROGRAMMING

for

the

change

changes

to

or

standard sewing program.

the

displayed seam

other

will

sew.

NUMBER

"F-C"

number 1 from

not

is

NUMBER

than

PROGRAM.

be stored

displayed.

indicator 1 lights.

length

when

-15-

in

and

100

MODE

the

to

SEAM

125.

from

100

is

reset.

program.

LENGTH

to

125.

If

indicators

the

power

will

is

turned

blink.

off

before

Page 20

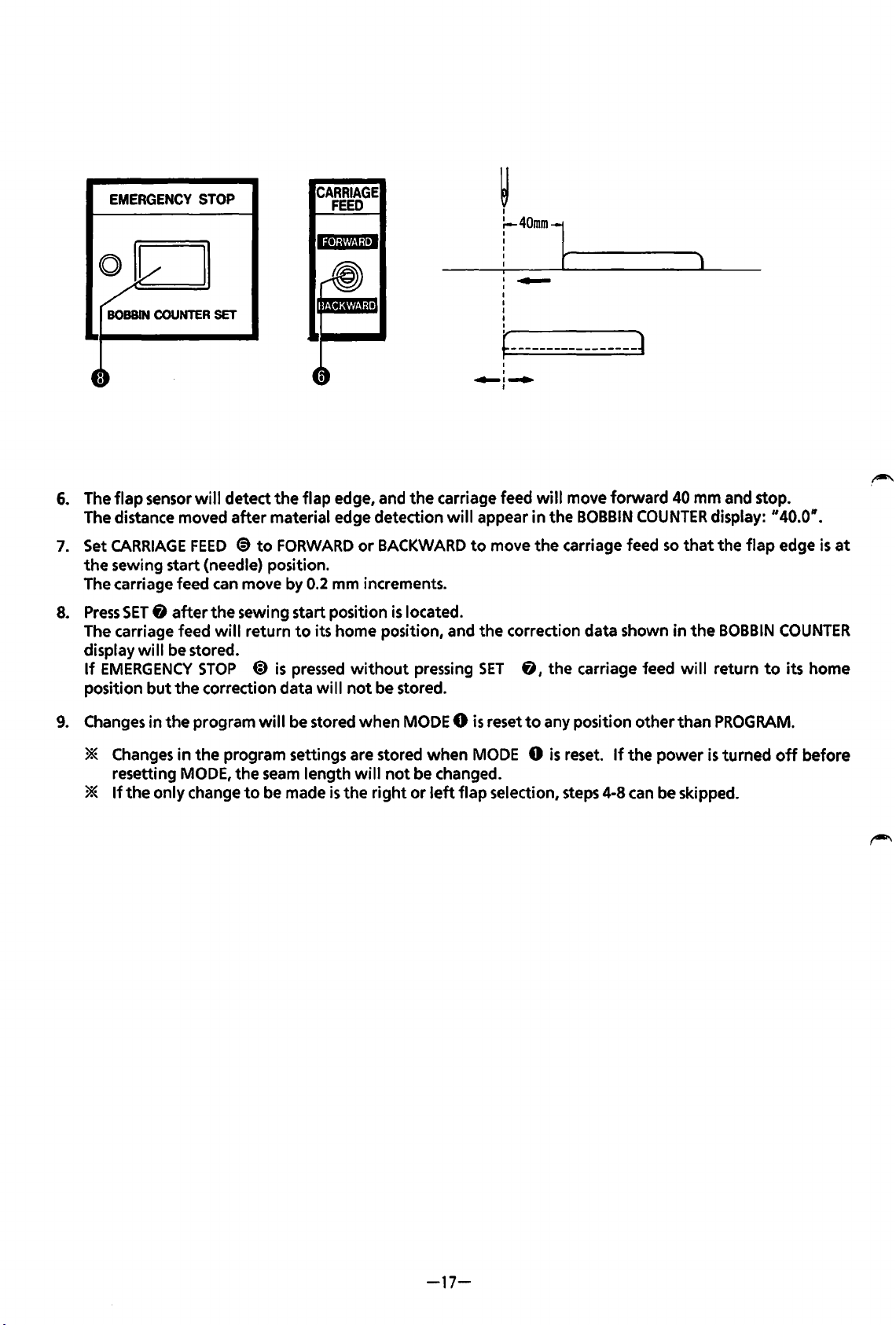

2.

Entering a

flap

MODE

sewing program

12\\

PROGRAMMING

~NUMBER

~SEAM

WPLENGTH

©BOBBIN

COUNTER

SET

...

BOBBIN

COUNTER

•

l·nmJbt.Ui

•

lt't("f!tt.!M

•

PROGRAM

•

KNIFE

CHANGE

&CYCLEPGM.

1 2 3 4 5

©~@©©

SELECT

1[f[j1

~CYCLE

PGM.!J

I I 1-1

-;

,-,

,_,

,_,

•

SELECT©

II

II

N0.1

© ©

N0.2

N0.3

* Flap sewing programming

* Set MODE

* Flap sewing

UF-:J

* Correct

Ex.

: Entering a

Change programming number 2

1.

SetMODEO

2.

Press

3.

Select

Press

Press

4. Set a flap.

5.

Press

to

PROGRAM.

is

selected

n indicates

the

SELECT@

flap

the

switch@

the

switch 9 (1's place)

the

start switch

right

sewing start position (correction data).

flap

sewing program

to

PROGRAM.

so

that

sewing and

The PROGRAMMING

when

flap,

PROGRAMMING

either

(100's place)

@).

is

not

"F-:J n

"F-C

to

right

to

possible

or

II

indicates

right

flap

or

to

display

display

on

the

BAS-600.

NUMBER

"F-C

II

is

displayed.

left

flap

sewing.

sewing, and correct

NUMBER

left

flap.

"F".

":J

".

indicator

and

2lights.

SEAM

LENGTH

the

sewing start position.

indicators

will

blink.

-16-

Page 21

EMERGENCY

0

/

BOBBIN

STOP

COUNTER

SET

«:)

6.

The

flap

sensor

The distance moved

7.

Set

CARRIAGE

the

sewing start (needle) position.

The carriage feed can move by

8.

Press

SET 8 after

The carriage feed

display

If

position

will

EMERGENCY

be stored.

but

the

will

detect

after

FEED

€)

the

sewing start position

will

STOP

correction data

CARRIAGE

FEED

the

flap edge, and

material edge detection

to

FORWARD

return

@

is

0.2

to

pressed

or

BACKWARD

mm increments.

its home position, and

without

will

not

be stored.

the

is

located.

pressing

I

.....

I

I

I

I

I

t-----------------]

I

I

.... I_,.

I

carriage feed

will

appear

to

move

the

correction data shown

SET

0,

will

move

in

the

BOBBIN

the

carriage feed

the

carriage feed

forward

COUNTER

so

40

that

in

will

mm

display:

the

return

and stop.

the

flap

BOBBIN

to

"40.0".

edge

is

COUNTER

its home

at

9.

Changes in

* Changes

*

the

program

in

the

resetting MODE,

If

the

only

change

will

be stored

program settings are stored

the

seam

length

to

be made

is

when

will

the

MODE 0

not

right

be changed.

or

when

left

flap

is

reset

to

any position

MODE 0

selection, steps 4-8 can be skipped.

is

reset.

If

other

the

than

power

PROGRAM.

is

turned

off

before

-17-

Page 22

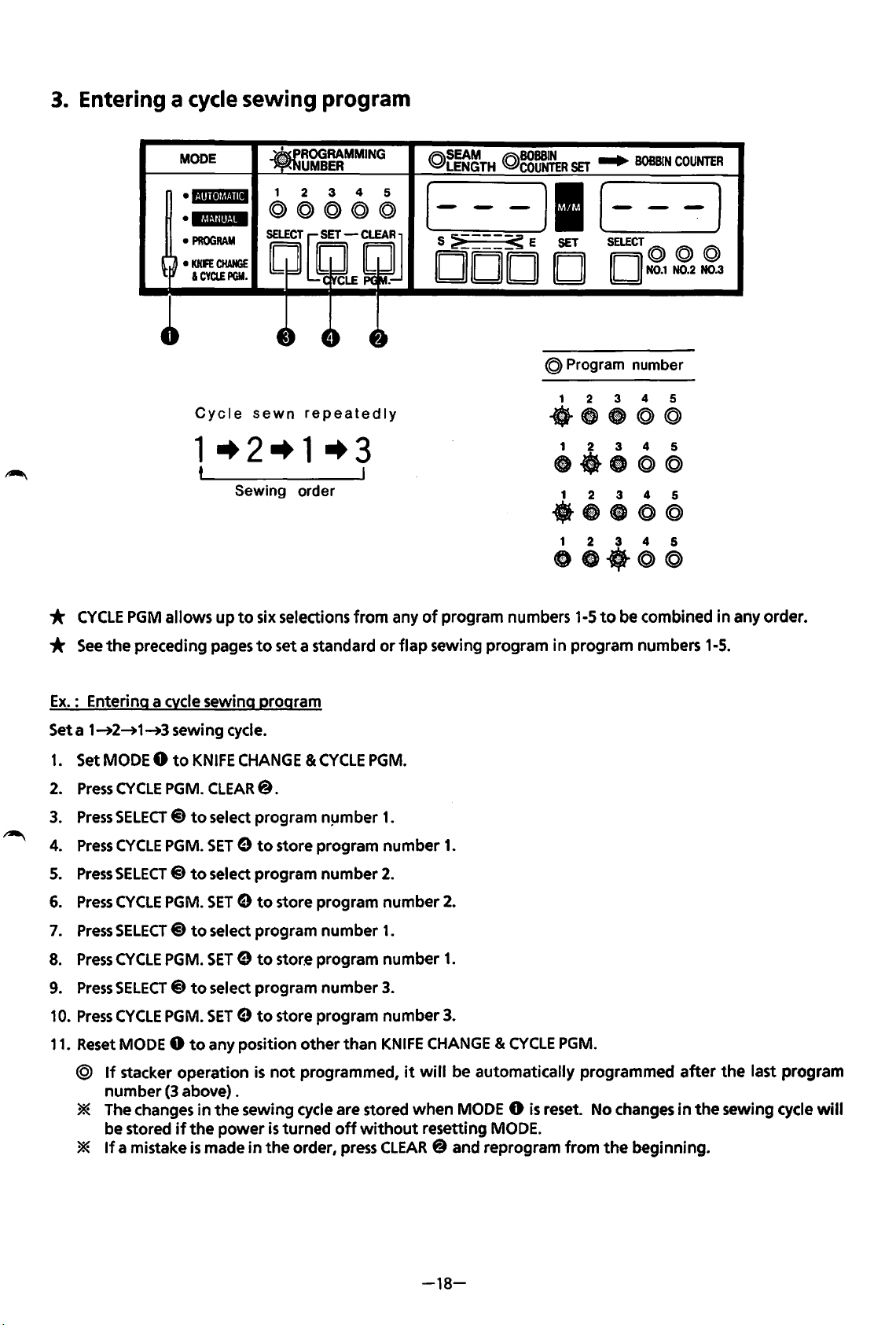

3.

Entering a cycle sewing program

MODE

• i·iliitjij.flli

•

l.jlaU!it·iM

•

PROGRAM

•

KNFE

CHANGE

I

CYClEPGM.

Cycle

sewn

repeatedly

1-+2-+1-+3

t

Sewing order

IR\SEAM

~LENGTH

IR\BOBSIN

Q.,COUNTER

SET

....

BOBBIN

[---)1(---]

S :;i

____

~

E

SET

DOD D D

@ Program number

1 2 3 4 5

-~-@@

1 2 3 4 5

ct-8©@

·~-@@

1 2 3 4 5

•••

SELECT@

N0.1

1 2 3 4 5

@©

COUNTER

@ @

N0.2 N0.3

*

CYCLE

*

See

Ex.

: Entering a cvcle sewing program

Seta

1.

Set MODE 0

2.

Press

3.

Press

4.

Press

5.

Press

6.

Press

7.

Press

8.

Press

9.

Press

10.

Press

11.

Reset MODE 0

@

* The changes

*

PGM

allows

the

preceding pages

1~2~1~3

CYCLE

SELECT@

CYCLE

SELECT@

CYCLE

SELECT @ to

CYCLE

SELECT@

CYCLE

If

stacker

number

be stored

If

a mistake

sewing cycle.

to

PGM. CLEAR@.

PGM.

PGM.

PGM.

PGM.

operation

(3 above) .

if

up

to

six selections

to

KNIFE

CHANGE & CYCLE

to

select program n!Jmber

SET 9 to

to

select program

SET 9 to

select program

SET 9 to

to

select program

SET 9 to

to

any position

is

in

the

sewing cycle are stored

the

power

is

made

in

from

any

of

program numbers 1-5

set a standard

store program

number

store program

number

store program

number

store program

other

not

programmed,

is

turned

the

order, press CLEAR@ and reprogram

than

off

or

flap

PGM.

1.

number

2.

number

1.

number

3.

number

KNIFE

it

without

sewing program in program numbers 1-5.

1.

2.

1.

3.

CHANGE & CYCLE

will

be automatically programmed

when

MODE 0

resetting MODE.

to

be combined

PGM.

is

reset. No changes

from

the

beginning.

in

any order.

after

the

in

the

sewing cycle will

last program

-18-

Page 23

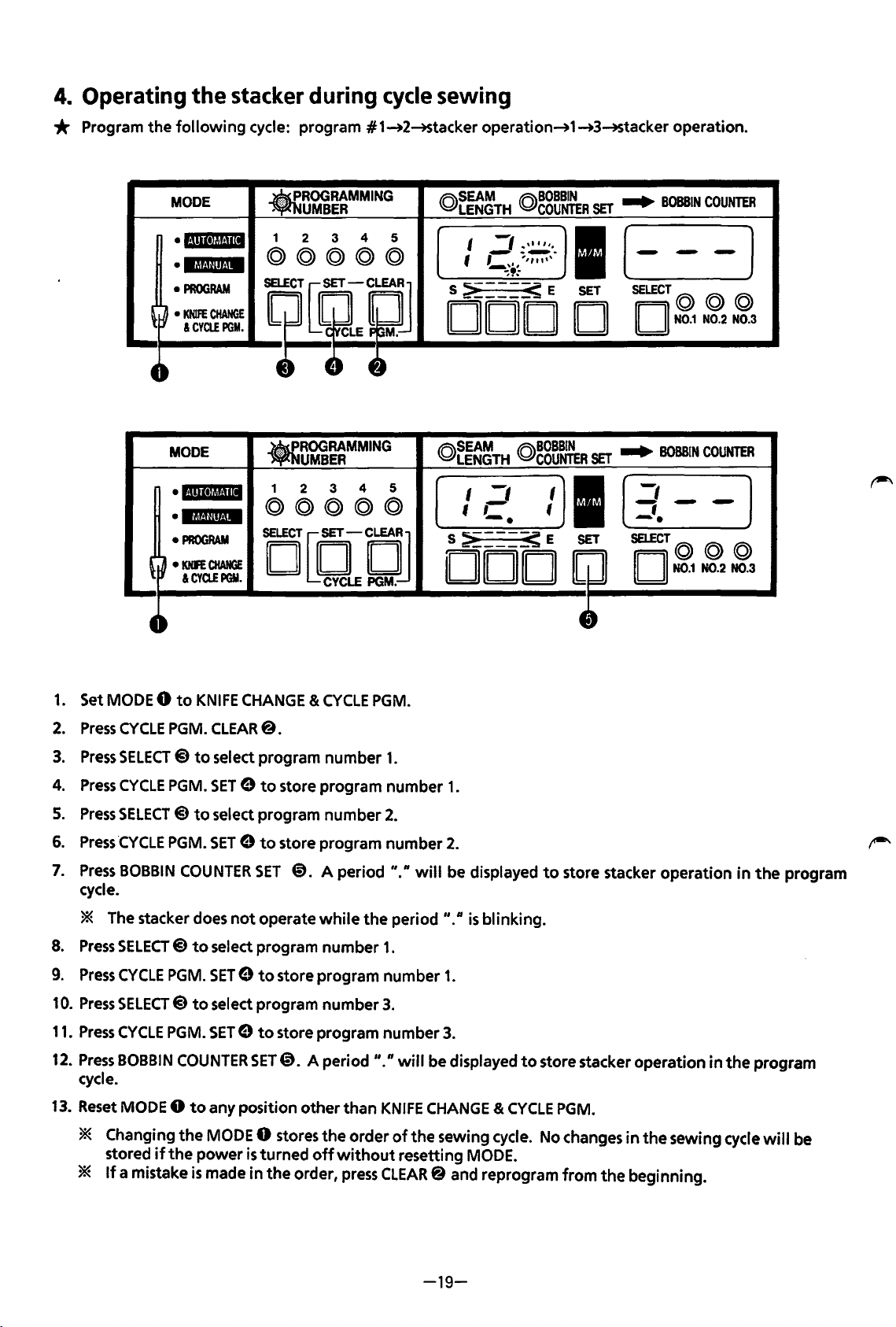

4.

Operating

the

stacker during cycle sewing

* Program

the

following

MODE

·l·!•ll·l~~!·mt

•13!-'fllf.!M

•

PROGRAM

~

~

•

KNIFE

&CYCLEPGM.

cycle: program #1_.2-+Stacker operation_.1_.3-+Stacker

•

ROGRAMMING

UMBER

4

3

CHANGE

1

2

©©@@@

il~?J

--

MODE

•l·l!ll•lt!!·lll

•

lf&Uilto!M

•

PROGRAM

~

~

•

KNFE

&CYa.EPGY.

CHANGE

.ROO

1

©©©©@

DQQCJ

RAMMING

UMBER

2 3

4 5

(Q)~~~TH

5

I

._,1

~

'

~\.,

~,

S

~---_s

DOD

©~~~~TH

I

-,

tC

>-_

•

___

S

DOD

operation

(Q)~g~~R

_,,,

''·

-~-

,,,,

,,,

..

©~g~~R

_s

E

I

'

E

SET

I

SET

D

SET

I

SET

..

BOBBIN

(-

SELECT©

II

..

BOBBIN

[

-,

-;-

-·

SELECT©

II II

-

II

N0.1

N0.1

.

COUNTER

-]

© @

N0.2 N0.3

COUNTER

-]

©@

N0.2 N0.3

4~

1.

Set MODE 0

2.

Press

CYCLE

3.

Press

SELECT@

4.

Press

CYCLE

5.

Press

SELECT @ to

6.

Press

·cYCLE

7.

Press

BOBBIN

cycle.

* The stacker does

8.

Press

SELECT@)

9.

Press

CYCLE

10.

Press

SELECT@

11.

Press

CYCLE

12.

Press

BOBBIN

cycle.

to

KNIFE

CHANGE &

PGM. CLEAR@.

to

select program

PGM.

SET 9 to

select program

PGM.

SET 9 to

COUNTER

to

PGM.

to

PGM.

COUNTER

SET

not

operate

select program

SET 9 to

select program

SET 9 to

SET@. A period

CYCLE

number

store

program

number

store

program

@.

A

period"."

while

the

number

store program

number

store

program

PGM.

1.

number

2.

number

period

1.

number

3.

number

II.

n

will

1.

2.

will

be displayed

"."

is

blinking.

1.

3.

be displayed

4~

to

store stacker

to

store stacker

operation

operation

in

in

the

the

program

program

,-..

13.

Reset MODE 0

* Changing

stored

*

If

a mistake

if

to

any position

the

MODE 0 stores

the

power

is

made

is

turned

in

the

other

than

KNIFE

CHANGE & CYCLE

the

order

of

the

sewing cycle. No changes

off

without

order, press CLEAR@ and reprogram

resetting MODE.

-19-

PGM.

from

in

the

the

beginning.

sewing cycle

will

be

Page 24

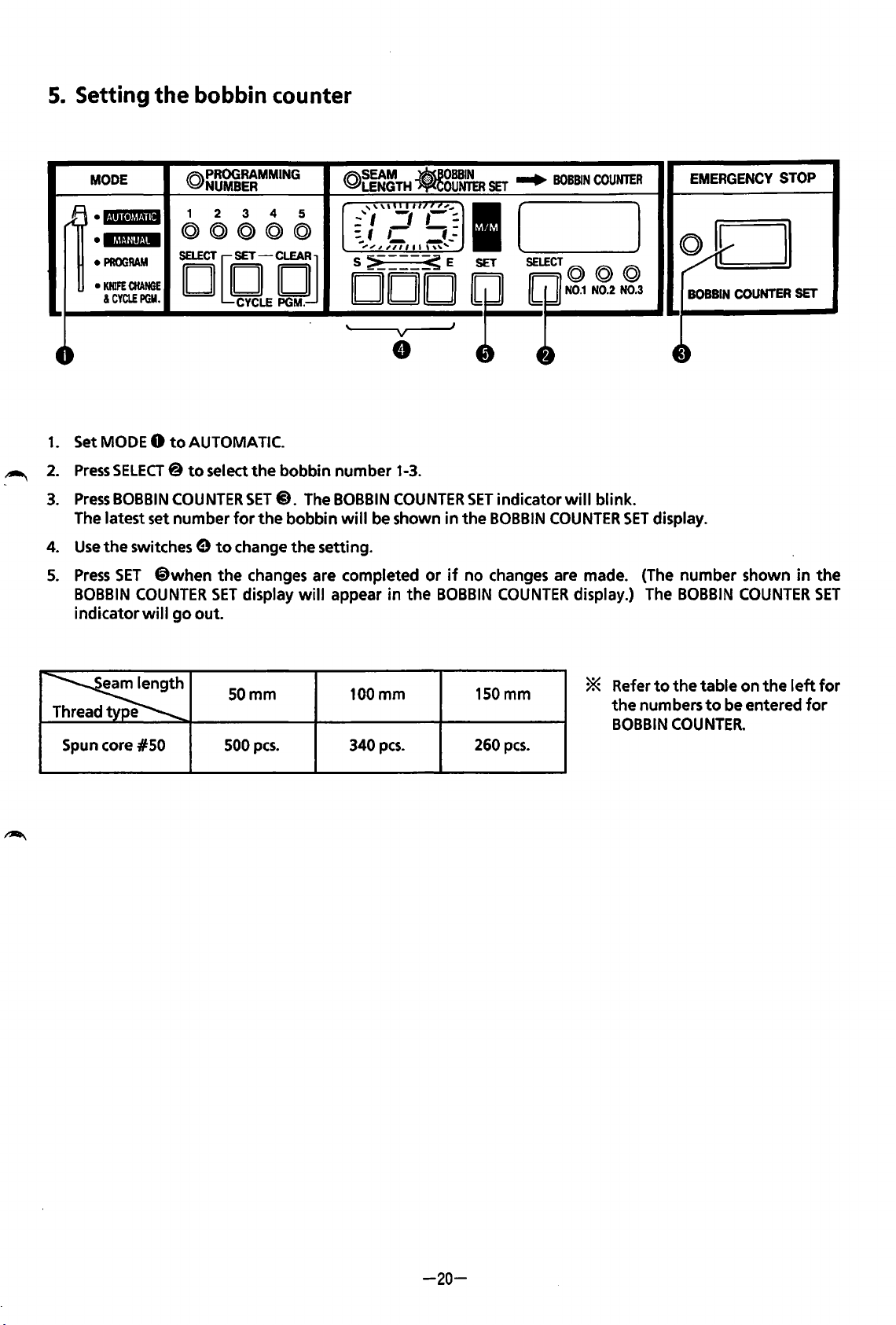

5.

Setting

the

bobbin counter

~

MODE

B

·1·!'11•1!!·!111

•IMU!IHM

•

PROGRAM

•

KNIFE

&CYCLE

4,

1.

Set MODE 0

2.

Press

3.

Press

The latest set

4.

Use

the

5.

Press

BOBBIN

indicator

CHANGE

PGM.

to

SELECT@

BOBBIN

SET

COUNTER

number

switches 9

@when

COUNTER

wi

II

go

@PROGRAMMING

NUMBER

1 2

@@@©@

4

3

ocetCJ

@~g~TH

5

,,,,._

...

'I

: f

,-

,..

,_,,,,,,,. ,,.,

s~---~E

DOD

'

..!'''''''"

-,

~

v

e

AUTOMATIC.

to

select

the

to

SET

out.

bobbin

SET@. The BOBBIN

for

the

bobbin

change

the

changes are completed

display

the

will

number

will

setting.

appear

1-3.

COUNTER

be shown

in

the

.83W~

,-

-;:

~-

or

BOBBIN

SET

...

~

..

in

if

J

SET

the

no

(

I

~~2£2

indicator

BOBBIN

changes are made. (The

COUNTER

BOBBIN

COUNTER

will

blink.

COUNTER

display.) The

l

SET

EMERGENCY

~~

BOBBIN

COUNTER

~-

display.

number

BOBBIN

COUNTER

STOP

shown

SET

in

the

SET

~

Spun core

e

#50

SOmm

500

pes.

100mm

340

pes.

150mm

260

pes.

* Refer

the

numbers

BOBBIN

to

the

table

COUNTER.

on

to

be entered

the

left

for

for

-20-

Page 25

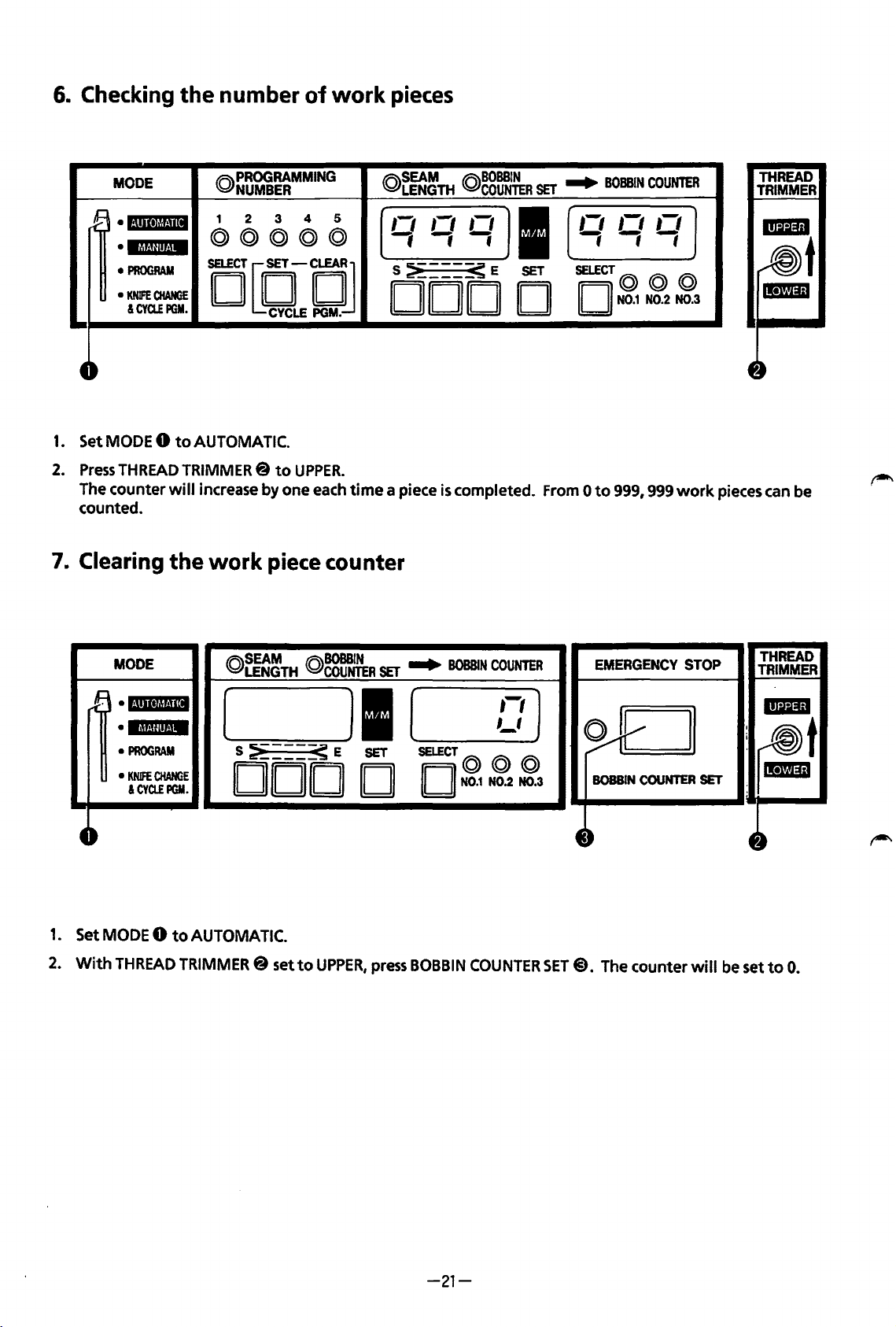

6.

Checking

the

number

of

work

pieces

rB

t-

1.

Set

2.

Press

The

counted.

7.

Clearing

MODE

·l·!•ll•lrll·llll

•IM!Jin·iM

•

PROGRAM

•

KNIFE

CHANGE

&CYCLEPGM.

MODE 0 to

THREAD

counter

TRIMMER@

will

the

@PROGRAMMING

NUMBER

1 2 3

@@@@@

4 5

DCClCJ

AUTOMATIC.

to

UPPER.

increase by one

work

each

piece counter

@r~~TH

,-,

fff

s~---~E

DOD

time a piece

@gg~~R

,-,

,,

I

SET

D

is

completed.

SET

...

,-,

-,-,-;

SELECT@

II II

From 0 to

BOBBIN

COUNTER

,-,

N0.1

N0.2 N0.3

999,

999

,-,

@ @

work

pieces

THREAD

TRIMMER

can

be

1.

2.

MODE

rB

•l·llll•lt!!·llll

•

MMU!it·IM

•

PROGRAM

•

KNifE

&CYCLEPGM.

4-

Set

MODE 0 to

With

THREAD

CHANGE

AUTOMATIC.

TRIMMER@

(Q)SEAM

LENGTH

@BOBBIN

COUNTER

[

S

~---~

E

DOD

set

to

UPPER,

SET

Jl

SET

D

press

...

B0BB1

(

SELECT@

II

II

N0.1

BOBBIN

COUNTER

N

COUNTER

,-,)

,_,

@@

N0.2 N0.3

~

4~

SET@).

EMERGENCY

v

BOBBIN

COUNTER

The

counter

STOP

SET

will

THREAD

TRIMMER

-

:

rm!t

:I!Di1

4~

be

set

to

0.

-21-

Page 26

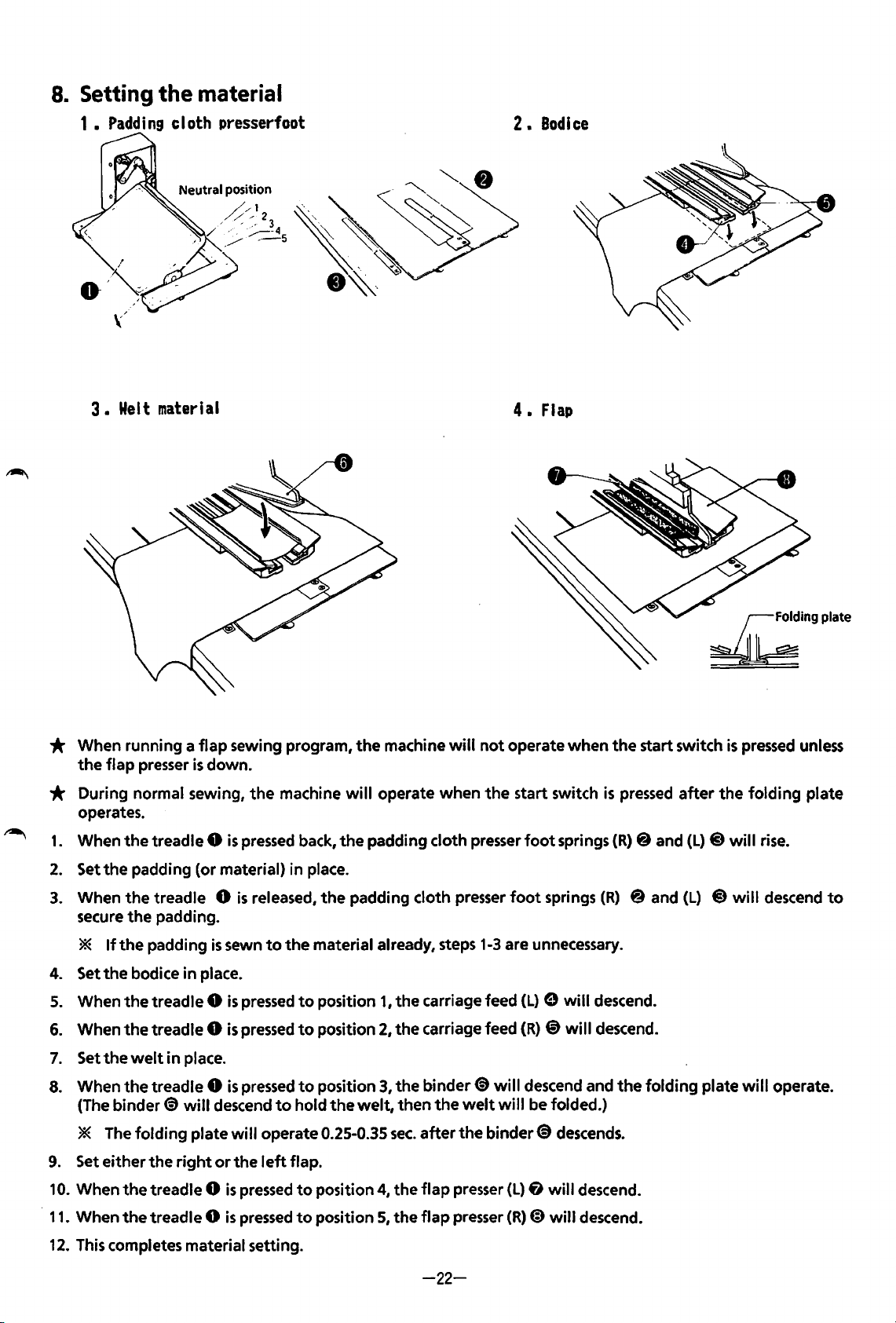

8.

Setting

1 •

Padding

3 •

Wei t material

the

material

cloth presserfoot

2.

4.

Bodice

Flap

* When running a

the

flap

presser

flap

sewing program,

is

down.

* During normal sewing,

operates.

1.

When

the

treadle 0

2.

Set

the

padding (or material) in place.

3.

When

secure

*

4. Set

5.

When

6.

When

7.

Settheweltinplace.

the

treadle 0

the

If

the

padding

the

bodice in place.

the

treadle 0

the

treadle 0

padding.

is

is

sewn

is

is

the

pressed

is

released,

to

pressed

pressed

the

machine

machine

the

to

to

will

operate when

back,

the

padding cloth presser

the

padding cloth presser

material already, steps

position 1 I

position

2,

the

the

will

not

the

1-3

are unnecessary.

carriage feed

carriage feed

operate

start switch

foot

when

foot

springs

springs

(L) e will

(R)

@)

will

the

start switch

is

pressed

(R)

@ and

(R)

@and

descend.

descend.

£ingplate

is

after

the

(L) @ will

(L)

@will

pressed

folding

rise.

descend

unless

plate

to

8.

When

9.

Set either the

10.

When

·

11.

When

12.

This completes material setting.

the

(The

binder~

* The

folding

the

the

treadle 0

will

plate

right

treadle 0

treadle 0

is

pressed

descend

will

operate 0.25-0.35

or

the

left

is

pressed

is

pressed

to

to

hold

flap.

to

to

position

the

welt,

position

position

3,

the

binder~

then

the

sec.

after

4,

the

flap

5,

the

flap

will

descend and

welt

will

be folded.)

the

binder~

presser

presser

(L)

(R)

fJ

@)

descends.

will

will

-22-

the

descend.

descend.

folding

plate

will

operate.

Page 27

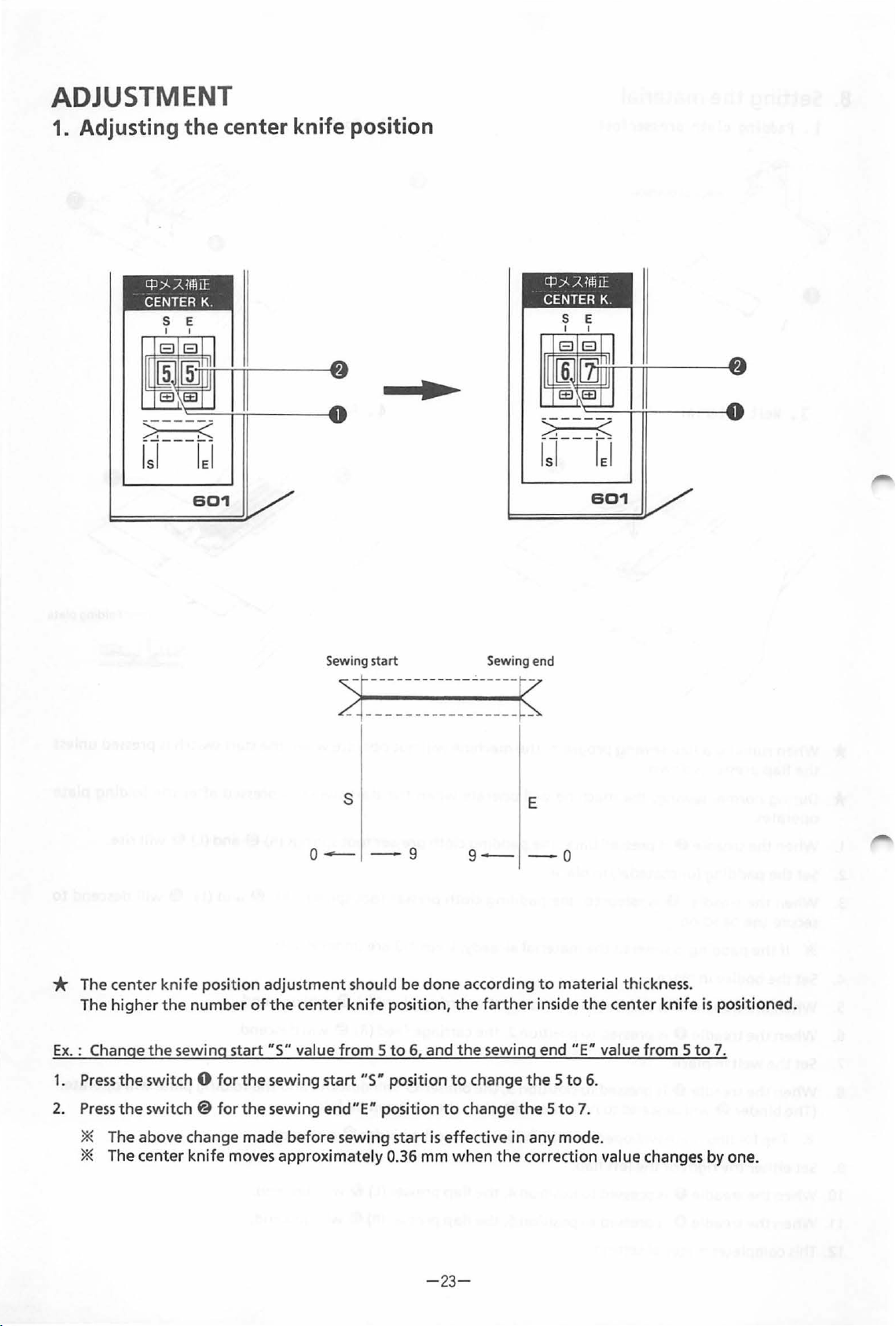

ADJUSTMENT

1. Adjusting

cp

;>(.

CENTER K.

the

.:;z

Uli

center knife position

iE

601

..

cp

)I.

:;z

1fli

iE

CENTER K.

601

* The center

high

The

Ex.

: Change

1.

Press

2.

Press

er

the

switch 0

the

switch@

the

Sewing

sta

rt

~------------~-

-

-------

--------

s

o

---

knife

position adjustment should be done according

the

number

sewing start

for

for

of

the

center

"5"

value

the

sewing start

the

sewing end"E" position

-9

knife

position,

from 5 to

"5"

position

6,

and

to

Sewing

--

9-

the

farther

the

sewing end

to

change

change

end

--~

--

-

E

-o

to

inside

the 5 to

the 5 to

material thickness.

the

"E"

6.

7.

center

value

knife

from 5 to

is

positioned.

7.

* The above change made before sewing start

* The center

knife

moves approximately 0.36 mm

is

effective

when

-

23-

in

any mode.

the

correct

ion

value changes by one.

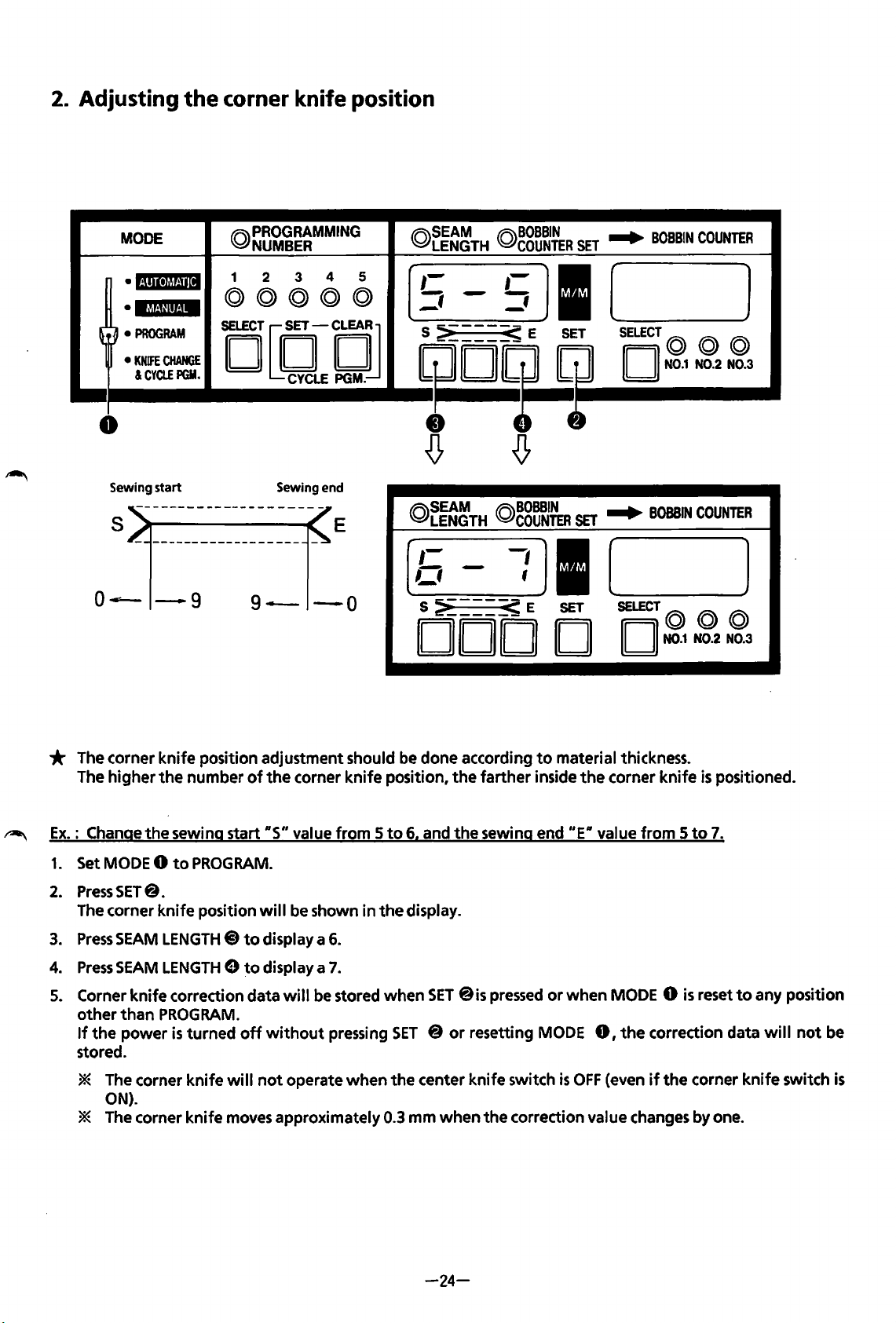

Page 28

2.

Adjusting the

corner

knife

position

MODE

•

l·!lll•lt*l~·!il

•IMUIIJ.!M

(~

•

PROGRAM

~

•

KNIFE

CHANGE

&CYCLEPGM.

l

@PROGRAMMING

NUMBER

1

2 3

©)@@©@

iD[DfDJ

CYCLE

0

Sewing

start

S E

o~

-9

9-

Sewing

end

-o

4 5

PGM.

@SEAM

LENGTH

,-

-,

-

S

~----~

@BOBBIN

,-

_,

- -

COUNTER

I

SET

E

4JD

'

@~~~TH

_,;

S

~---~

DODD

@~8~~

__

: I [

E

SET

SET

...

B

0

BBIN

CO

UNTER

(

SELECT

~

SET

...

II

(Q) (Q)

II

N0.1

BOBBIN

@

N0.2

N0.3

COUNTER

_____

SELECT

(Q)

II II

N0.1

@@

N0.2

N0.3

)

)

* The corner

~

Ex.: Change

1.

2.

3.

4.

5. Corner

knife

The

higher

Set MODE 0

Press

The corner

Press

Press

other

If

the

stored.

the

SET@.

knife

SEAM

SEAM

knife

than

power

the

sewing start

to

LENGTH@)

LENGTH 8 to

correction data will be stored

PROGRAM.

is

* The corner

ON).

* The corner

position adjustment should be done according

number

PROGRAM.

position

turned

knife

knife

of

the

corner

RS"

value

will

be shown

to

display a

display a 7.

off

without

will

not

operate

moves approximately 0.3

knife

from 5 to

in

the

6.

pressing

when

position,

when

SET @ or

the

the

6. and

display.

SET

center

mm

when

farther

the

sewing end

@is pressed

resetting MODE

knife

the

to

material thickness.

inside

the

corner

"ER

value

or

when

MODE 0

0,

switch

correction value changes by one.

is

OFF

(even

knife

from 5 to

is

the

correction data

if

the

corner

is

positioned.

7.

reset

to

any position

will

not

knife

switch

be

is

-24-

Page 29

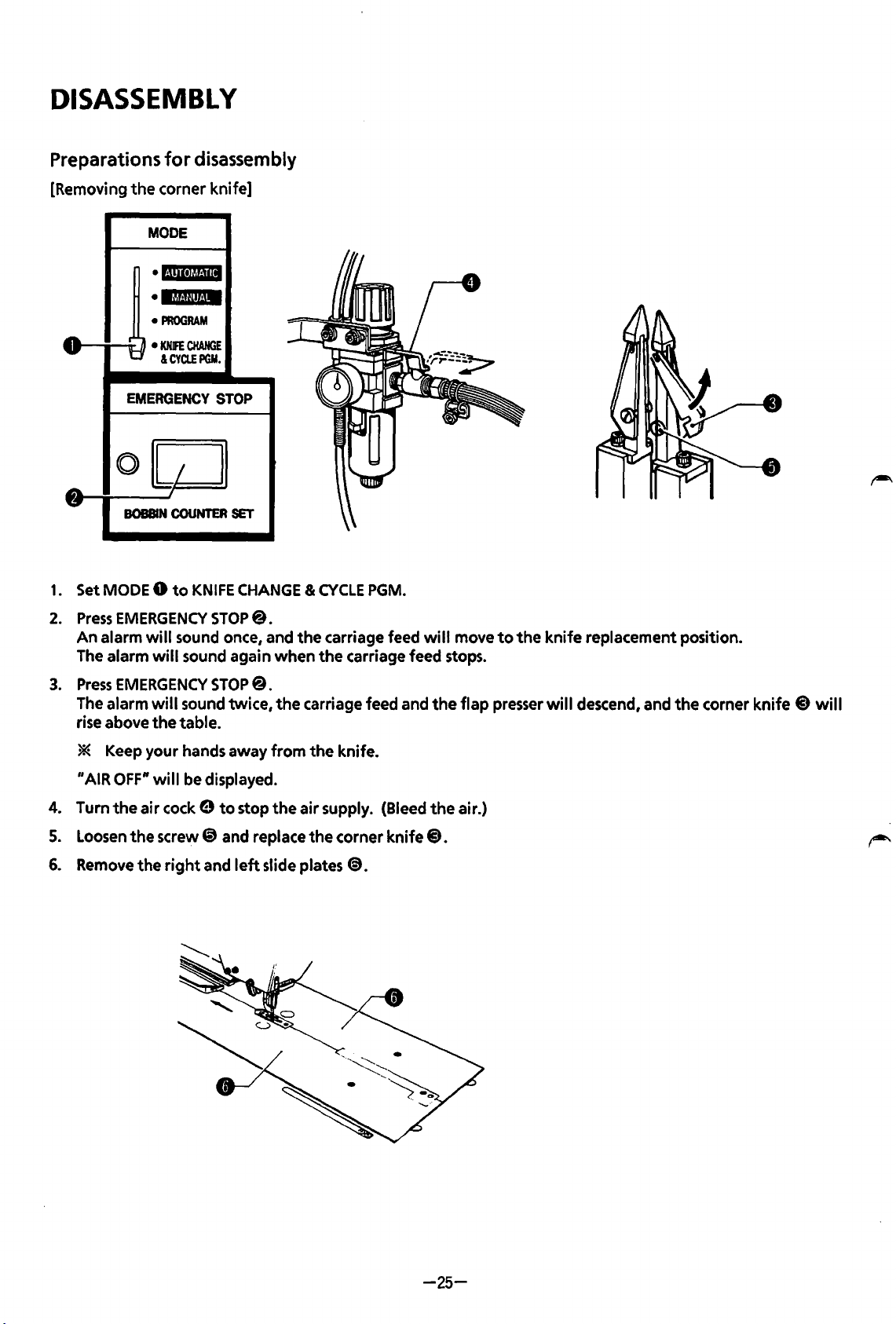

DISASSEMBLY

Preparations

[Removing

the

MODE

•1·!111·1~!·111

• ltl!·llll!·l·

•

..

v

· 9 •

EMERGENCY

0

~

""

1.

Set MODE 0

BOBBIN

for

disassembly

corner

PROGRAM

KNIFE

&CYa.EPGM.

knife]

CHANGE

I I

I

COUNTER

to

KNIFE

STOP

SET

CHANGE & CYCLE

PGM.

2.

Press

An

alarm

The alarm

3.

Press

The alarm

rise above

* Keep

"AIR OFF"

4. Turn

5.

Loosen

6.

Remove

EMERGENCY

will

sound once, and

will

sound again

EMERGENCY

will

sound

the

table.

your

hands away

will

be displayed.

the

air

cock 9

the

screw@) and replace

the

right

and

STOP@.

STOP@.

twice,

to

stop

left

slide plates

the

carriage feed

when

the

carriage feed stops.

the

carriage feed and

from

the

knife.

the

air

supply. (Bleed

the

corner

8.

knife

will

the

the

8.

move

flap

air.)

to

the

presser

knife

replacement position.

will

descend, and

the

corner

knife @ will

-25-

Page 30

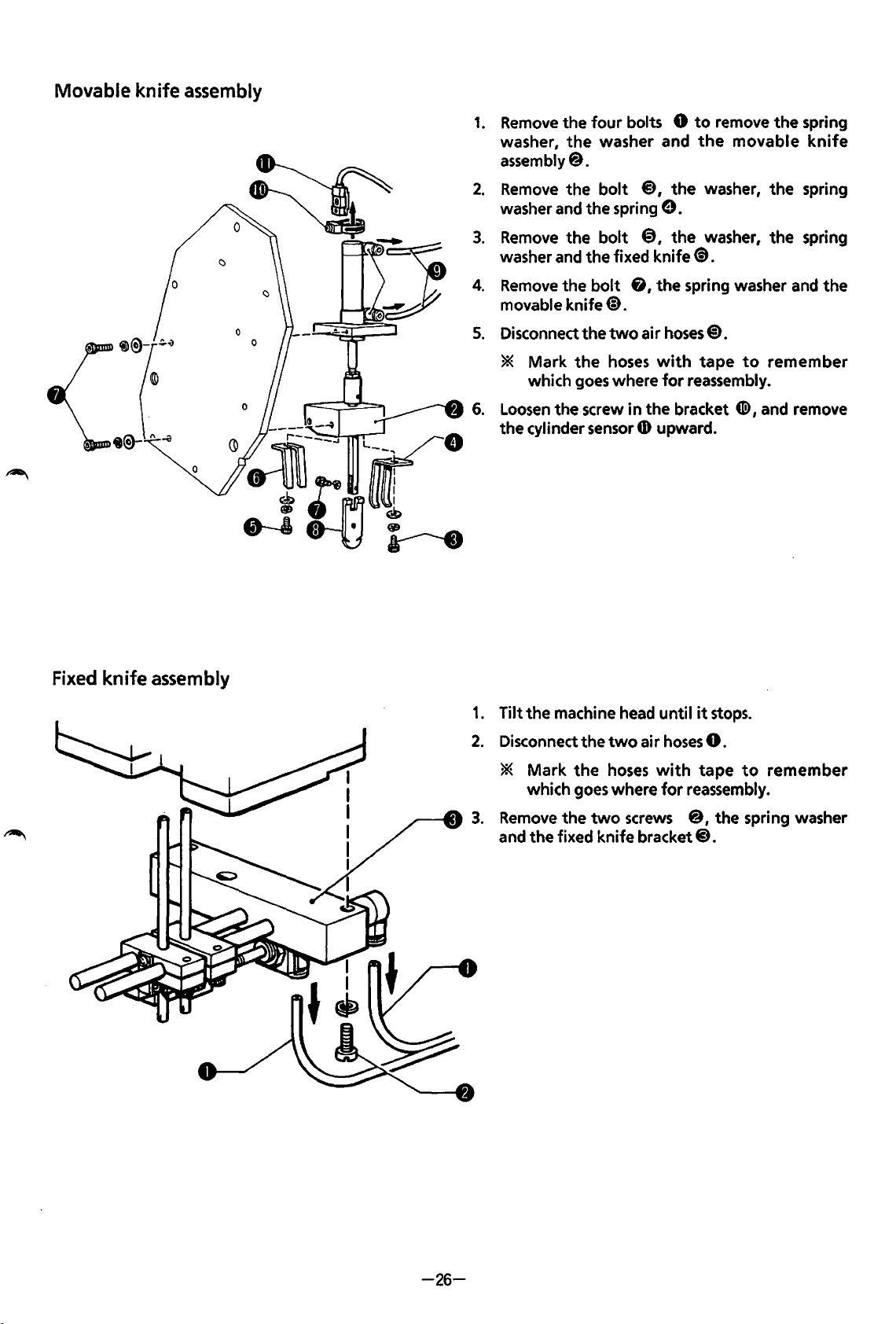

Movable

knife

assembly

1.

Remove

washer,

assembly@.

2.

Remove

washer

3.

Remove

washer

4.

Remove

movable knife@.

5.

Disconnect the

the four bolts 8

and

and

the

the

washer and

the

bolt

@,

the spring

the bolt

the fixed knife(!).

bolt

two

e.

@,

&, the spring washer

air

hoses@).

to

remove the spring

the

movable

the washer, the spring

the washer, the spring

knife

and

the

Fixed

knife

assembly

* Mark the

which

6.

Loosen

the

1.

Tilt the machine

Disconnect the

the

cylinder

* Mark the

which

Remove

and the fixed knife

the

goes

screw

sensor

goes

two

hoses

two

hoses

with

where

where

for

in the bracket

4D

upward.

head

until

air

hoses

with

for

screws

bracket@.

tape

to

reassembly.

4D>,

it

stops.

8.

tape

to

reassembly.

@,the

spring washer

remember

and remove

remember

-26-

Page 31

1.

Removing

the

cloth

guide (left)

1.

Remove

2.

Loosen

spacer@.

3.

Remove

2.

Removing

the

the

the

two

screws

two

screws

two

screws

the binder

8

@)

€}

the

flap sensor and

1

in

the

set collar @.

in

the

cloth guide arm e I then remove

the

sensor bracket.

Remove

the

1.

set collar

the

cloth guide & .

Remove

washers and

two

@I

the

cloth guide arm e and

bolts 01 the

the

binder assembly@.

spring and

the

flat

-:-27-

Page 32

3.

Removing

the

face

plate

~

1.

2.

Remove

Loosen

the

the

bolt

bolt@

0

1

and remove

* When removing the ruler

Remove

3.

Remove the bearing

4.

fulcrum shaft

5.

Loosen

6.

Disconnect

Disconnect the

7.

Remove the three bolts

8.

*

the

nut

the

bolt

the

If

the

arm

spring and

8.

step

e, then remove the fulcrum shaft@), bearing

@).

4B

and remove

two

air

two

air

is

not

flat

washers. Turn

the

spring washer and

the

fitting

cover~,

hoses® from

hoses

4£3,

disassembled,

CD

the

two

the

from

three

the

the

two

washers.

ruler

fitting

plate

washers

connecting shaft Q).

the

the

flat

lift

the

cylinder assembly

plate @

@I

make sure

@),

bearing @),and arm

cylinder

center knife drive cylinder

and spring washers, then remove

4D.

arm and

tie

to

it

the

so

the

right.

does

not

cover~

cam

with

that

the

touch

other

parts.

and arm

fj,

washer

@.

a string, then remove

bolts

the

4£3

can

fj

to

the

«<D

and bearing

face plate

be loosened, and perform

left.

@.

CD

the

from

bolt,

the

the

-28-

Page 33

4. Removing

the

machine head

* This should be done

* Follow

removed.)

the

procedures below

after

removing

if

the

the

face plate and fixed knife assemblies from

face plate assembly

is

attached. (The fixed knife assembly

the

head.

has

been

1.

Disconnect

2.

Loosen

3.

Disconnect

4.

Disconnect

5.

Disconnect

6.

Remove the

7.

Tilt

the

8.

Remove

9.

Disconnect

10.

Lower the head from

the

two

air

the

screw@)

the

two

air hoses@ from

the

two

air

the

connector

two

bolts

machine head

the

V-belt.

the

detector connector @ from

hoses

@ from

and remove

hoses@)

Cli>

at

4D

and the lamp bracket@.

until

it

stops.

the

table.

the

the

cylinder sensor

the

and@)

the

from

back of

two

S-elbows

0.

e.

twoS-elbows@.

the

two

cylinder assemblies

the

machine head.

the

PCB.

-29-

~

~

f).

\

0

Page 34

5.

Removing

the carriage feed

mechanism

(1) Removing

*

Mark

the

the

hoses

air

with

hoses

tape

to

assure

correct reconnection.

1.

Disconnect

2.

Disconnect

3.

Disconnect

Disconnect

hoses

do

not

4.

Disconnect

(2) Removing

the

air

hoses@

the

two

air

the

two

air

the

air

hoses

have

to

the

four

air

the

carriage feed

from

the

speed control joints 0 on

hoses@)

hoses@)

be disconnected.)

hoses

4D

from

from

from

Q)

from

the

the

the

joints

the

the

right

joint@

joint~

speed control joints 0 on the

and

the

S-elbow 8 on

and

the

S-elbow & on

€)

and S-elbows 0 on

the

and

the

the

right

right

left

carriage feeds.

left

carriage feed.

right

carriage feed.

and

left

and

left

carriage feeds. (The

carriage feeds.

·

1.

Remove

the

two

bolts 0 and

the

carriage feed assembly

8.

-30-

Page 35

1.

Disconnect

2.

Loosen

3.

Remove

the

the

the

two

connectors@ in

two

bolts@ and remove

two

bolts@,

the

the

DC

motor

the

timing

flat

and spring washers, and

belt

assembly

9.

the

0.

DC

motor

assembly

0.

(2) Removing

(3) Removing

(4) Removing

the

corner

the

corner knife adjusting

the

feed mechanism assembly

knife

cylinder assembly

base

1.

Loosen

sensor@ downward.

2.

Disconnect

3.

Remove

washer and

the

screw 0 and remove

the

the

@.

* Mark

1.

Remove

2.

Remove

washers, and

the

reconnecti on.

the

the

the

air hoses@ and

two

bolts @),the washer,

the

corner knife cylinder assembly

hoses

with

spring

0.

two

bolts

the

corner knife adjusting

tape

@,

the

9.

to

flat

assure

and spring

cylinder

the

spring

correct

base

@.

,~

* Do

1.

2.

not

mechanism unless absolutely

Disconnect

Remove

mechanism

*

Be

sure

assembly@.

-31-

remove

the

air

hose

the

four

assembly@.

not

to

or

disassembly

necessary.

0.

bolts @ and

drop

the

feed mechanism

the

the

feed

feed

Page 36

7.

Removing

the padding

cloth

presser

I

I

I

•J

assembly

(1) Removing

1.

Disconnect

2.

3.

Loosen

Remove

the

the

(2) Removing

1.

Disconnect

2.

3.

Remove

Loosen

the

the

the

padding cloth presser

the

two

air

hoses

0.

two

screws@ and remove

two

bolts 9 and remove

the

padding cloth presser

the

air

hose

<D.

two

screws 8 and remove

two

screws@)

and remove

foot

spring

the

padding cloth presser

the

cylinder

the

padding cloth presser

the

cylinder assembly

assembly~

foot

spring (L)

(R)

foot

from the table.

foot

tiD

from the table.

spring

spring

(R)

(L)

8.

@)from

the

table.

-32-

Page 37

ASSEMBLY

1. Attaching

1.

Attach the feed

with

frame

2.

Insert the air hose@ into the S-elbow

*

The

adjusted later.

the

feed mechanism assembly

mechanism

the four bolts@.

carriage feed position needs

assembly 0 to

e.

to

the

be

(2) Attaching

1.

Attach the corner knife adjusting

ball

screw

the flat and spring

2. Mount the

*

The

needs

the

corner knife adjusting

support

springe

corner knife adjusting

to

(R) @ with

washers.

on

be

adjusted later.

the

the spring peg

base

base 0 to

two

bolts

@).

base

position

the

@,

(3) Attaching

the

corner

~;~

knife

cylinder assembly

1.

2.

3.

Insert the pin @ into the channel in the corner

0.

knife lifting plate

cylinder

(R)

bolts@.

*

Connect the air

connect the air

Insert the cylinder

plate,

assembly

e

with

the

two

At

this time, make sure the corner knife

lifting plate

towards the pin

might stop on the way when

the

left

the slider

position by the

Check

that the pin

the channel in the corner knife lifting plate

0

because

properly.

and

tighten the

0

by hand and

€)

smoothly returns

the pin @

hose

hose

Attach the corner knife

@to

the ball screw support

flat

and spring

is

not inserted

@.

If

released.

pressure

@is

@)

to

«@

to

the half union

sensor

screw~

it

of

0 into the

washers

too

is,

the slider

it

is

to

the spring & .

not removed from

is

not

the

joint

temporarily.

and

far

back

€)

pulled

Make

its original

to

sure

inserted

@)

and

4D.

fitting

9J

~--------------------

~-~

* The

corner

adjusted later.

X

-33-

knife

sensor needs

to

be

Page 38

(4)

Attaching

the

DC

motor

assembly

1.

Attach

2.

Insert

and

3. Attach

then

[Adjusting

4.

Mount

3.5

5.

Connect

the

DC

motor assembly 0

the

timing pulley B 9 and

the

motor shaft bush

the

DC

motor assembly 0

tighten temporarily.

the

timing belt

the

timing belt

mm

of

give when a 600

the

two

connectors G)

to

the

motor bracket @ with

the

key

@)

to

0.05-0.25 mm, and tighten

to

the

support L 8 with

of

the

DC

motor assembly]

@)

on

the

timing pulleys

±50

g load

of

the

is

applied

DC

motor assembly

into

4ID

-34-

the

and B

to

the

the

DC

motor shaft. Set

the

two

screws

the

two

9.

Firmly

center of

the

0.

four washers and bolts

tighten

timing belt

@.

the

gap between

@.

washers, spring washers and bolts

the

bolts

@).

@)

so

the

that

pulley B $

there

is

@),

2.5-

Page 39

2. Attaching

the

machine head

V-belt tension

1.

Set

the

head 0

* Make sure

more than a

2.

Mount

The V-belt

that

hex bolts@ and slide

3.

Connect

4.

Positions

that

the

the

the

centers

the

the

gaps on

fulcrum pin guides

onto

the

table

8.

that

the bed surface

0.3

mm step, and

V-belt@) on

@)

tension should

of

hall element cord assembly from

the

slide plates

the

machine pulley 8 and

the

machine pulley e and

the

motor

(R)

and

the

right

and

(R)

and

allow

f)

(L)

left

(L)

4D

of

that

15-20 mm

to

@)

sides

so

the

head 0 and

the

machine head does

the

of

give when

motor

adjust

the

alignment.

the

pulley

so

that

there

of

the

slide plates are equal. Adjust

that

there

is

the

top

of

the

not

wobble.

motor

pulley @ are aligned.

is

no play front-back

pulley

the

to

J26

no gap

belt

on

at

@).

the

the

-35-

table 8 are flush

@)

is

pressed

circuit board. (Refer

front

or

right-left.

by hand. Also make sure

If

they

are not, loosen

of

the

needle plate

the

positioning

or

that

to

there

is

the

page 87.}

@),

and

bolt

ClD

not

four

so

and

Page 40

3.

Attaching

the

face plate

1.

Attach

2.

Insert

3.

Insert

4.

Connect

5.

Place

the arm

6.

Insert

7.

Attach the

8.

Tighten

9.

Place

When

any parts.

the

face plate 8

the

connecting shaft@

the

air

hoses

the

two

air

the

two

washers

CD.

Place

the

the

fulcrum shaft

cylinder~

the

fulcrum shaft

the

ruler

fitting

the

cam

follower

to

the

head

with

the

three washers, spring washers and bolts

into

the hole

fl

and@)

hoses

two

plate ~ on the ruler fulcrum shaft 0 I then tighten

into

the center knife drive

CID

to

the

4D

and

the

bearing ® on the fulcrum shaft

washers~

6)

into

the

screw-hole

with

the

bolt@

6)

and the

@)

is

placed on

cylinder@).

of

the

bearing®

1

and

the

nut ® so

the

grooved

the

selector

of

the

spring washer and washer.

that

there

lever$

cylinder~.

and the bearing cover

face plate 8 I and

is

no play right-left in the arm G).

cam

fD

I

be

careful

and tighten the

CD,

-36-

then insert

(D

on

tighten

that

the

the

bolt

the

8.

bolt

@.

the

fulcrum shaft

the

fulcrum shaft G).

nut

@ temporarily.

fD.

cam

follower

does

4D

not

into

hit

Page 41

4. Attaching

1.

While

lifting

fitting

2.

Make

plate.

5.

Attaching

plate

the

binder and

with

the