Page 1

AUTOMATIC

LOCK

STITCH

POCKET

WELTING

SEWING

MACHINE

INSTRUCTION

FOR

-

-------------l

FLAP

ATTACHMENT

[

MANUAL

..__.______

_ ]

BAS-600

BAS-601

0 ' •

~___I

_

___;

Page 2

Contents

1 • SPECIFICATIONS

2.

CONTROL

3.

INSTALLATION

• Table

1

• Treadle installation · · · · · · · · · · · · · · · · • · · · · · · · · · · · · · · · ·· · · • · · · • • · • · · · • · • · · • · · · · · · ·· · · · · · · · · · · · · · · · · · · · · 6

2

3

• Spool stand installation · · · · · · • · · · · · · · · · · · · · · · · · · · · · · · • · · · · · · · · · · · · · · · · · · · · · · · · · · · • · · · · · · · · · · · · · · · · 6

• Material holder installation .... · · · · • · · · · ...... · · · · · · · · · · · · · · · · · · · · · · · · · · · · .. · • · · · · · · · · · · · .. · • · • • 6

4

5 . Bar

6

• Pickup type stacker installation .... · .. · .... · · · .. · .. · · · · .. ·

• Air pressure adjustment·· ..

7

4.

LUBRICATION··········...................................................................................

< Adding oil > ··

< Regular lubrication > · · · .. · · · · · .. · · · .. · .. · · · • • ...... · .... · · · .... · · · · · .. · · · .. · .. · · · · · · · · .. · · · · · · · · · · 1 0

5.

CORRECT OPERATION

< Winding the bobbin thread >

< Threading the

< Threading the bobbin thread > .... ·

< Holding the

6.

TREADLE AND START SWITCH

< Treadle operation >

PANEL DESCRIPTION

set-up··························································································

type

stacker installation · · · · · • · · • · · · · · · · • · · · • • • · · · · · · • · · · · · · • · · · · • · • • · · · · · • · • • · • · · •

··············•·••·••·····························•····················•··•··•·•••·••·•

·····•·····•·•·······

··•···•····································••····•···················•··········•··•······

.................

needle

needle

·············

· ................................................. ··•·

..............................................................................

.....................................................

thread >

and bobbin threads >

DESCRIPTION................................................

.................................................................................

.........

..........

.. ··· .. ·· ..

................

············•·······•······•••····•··········

......

· .... · · · .... · • · .... · .. · .... · · · 8

·····

.. · .... ·· .. ··· .. · .... •·•···•· .. ·•·• .. ····• 9

......

·•··•···••••·••·

......

...................................

· .. · .. • · · · .. · ... · • · •

..........

..............

.............................. · 14

...........................

·········

·•

• .. · • · • · 7

2

6

6

9

··· · 9

11

11

12

15

16

16

< Setting the material > · · .. · · · • • · · .. · .. · .. · · · · · ... · · · .. · · · · · · .... · · · • · • · · • · • • ·

7.

ADJUSTING THE MARKING LIGHT

8.

PROGRAMMING (Entering a standard sewing program)

9 • PROGRAMMING (Entering a flap sewing program) ..

10.

PROGRAMMING (Entering a cycle sewing program)

<

Checking

11.

PROGRAM CONFIRMATION

12. SEWING

< Setting the bobbin counter > .. • · · • · · · · · · · · · .. · .. · .. · .. · · · · .... · .. · .. · · · ·

<

Checking

< Clearing the

< Stitch tension > · · • · · .. · · · · • · · .. · · .. · · · · · · .. • • · · · .. · · · · .. · .. · · · ...... · · · · · · • · · .... · · · · · • · · · · · · .. · · · · · ·

13.

CENTER KNIFE POSITION ADJUSTMENT

14.

CORNER KNIFE POSITION ADJUSTMENT

15.

< FLAP SENSOR SENSITIVITY ADJUSTMENT (BAS-601) >

16.

TROUBLEooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooo

<UPPER

< BOBBIN EMPTY indicator lights >

< PROGRAMMING ERROR indicator

<EMERGENCY

17. OPERATING THE STACKER DURING CYCLE SEWING

the sewing cycle > · .... · .... · · .. · · ...... · .... · · · ... · · · .. · · · · ...... · · · .. · · · .. · · · .. · · · .. ·

........................................................................

...................................................................................................

the number of

work

THREAD BREAKAGE indicator

STOP>..............................................................................

work

piece

counter display > ..... ...

...............................................................

....................................

.....................

.......................................

pieces

> · .. · · .... · .. ·

..............

......................................................

lights>

............................................................

lights>

............ · ........

..............

..........................

.............................................

................................................

....................................

••

• · .. • • · •

••

• · •

·•

...................

·•

· • · · • · • • · • • · · .... · · · · · ·

· .. · .. ·

........

.........

....................

..............

...........................

· • • · · •

·....

17

18

19

20

22

23

24

25

26

26

26

·.

27

28

29

30

32

32

32

33

33

34

Page 3

18. STANDARD ADJUSTMENTS

········································································

< Needle installation > · ·•· ············ ····· ····· ········· ··· ··· ········· ··············· ·· ·········· ·

< Upper and lower shaft timing adjustment >

< Needle and rotary hook timing adjustment >

[Needle

[Rotary hook to needle plate gap] ·· ······ ······ ············

[Needle

fRotary hook and bobbin case opener gapJ

19. CARRIAGE FEED ADJUSTMENT

to rotary hook point gap]

bar lift stroke and needle bar height] ······ ········· ····· ·····•···· ····· ·•·•··· ···

..................................................................

............................................................

···················································

········

·········

·······•·······························•········

·····

··········

..................................

···

··

...........

35

35

35

35

35

36

36

36

37

< Parallel adjustment of needle and carriage feed > · · · · · · · · · · · · · · • · · · · · · · · · · · · · · • · · · · · · · · ·

< Carriage feed angle adjustment > · · • · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · .. · .. ·

< Carriage feed height adjustment > · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · • · · · · · · · · · · · · · ·

< Folding plate position adjustment > · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · • · • · ·· · · · · · · · · · · · • · ·· • · · ·

< Binder position adjustment > · · · ·· · · · · · · · · · · · · · ·· · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·· · · · · · · · · · · · · ··· · · · ·

20. SENSOR ADJUSTMENT

< Needle thread knife sensor adjustment > · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

< Corner knife

21. STACKER

adjustment>

ADJUSTMENT··············································································

··············································································

··

· · · · · · · · · · · · ·

·······················

···············•················•················

·· · ·..

< Bar stacker > · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · • · · · · · · · · · · · · · · • · ·

< Pickup stacker > · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

22. KNIFE

REPLACEMENT·················································································

··

· · · · ·

··

· · · ·

< Corner knife replacement > · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · • · · · · · · • · · · · · · · · · · · · · · · · ·

< Needle thread trimmer knife replacement > ··········· ···· ·············· ······ ···•····· ····

< Bobbin thread knife replacement > · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · • · · · · · · · · · · · • · • · · · · · · ·

< Center knife replacement > · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · • · · · · • · · · · · · · · · · · · · · · · · · • · · ·

< Fixed knife replacement > · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

23. DOUBLE WELTING--. SINGLE WELTING (DEFORMED WELTING) REPLACEMEMT

< Changing from double to single welting > · · · · · · · · · · · · · · · · · · · • · · · · · · · · · · · · · · · · · • ·· · · · · · · · · · · ·

< Changing from double to deformed welting > · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·· · · • · · · · · · · ·

24. ERROR MESSAGES ···

25.

MAIN

CIRCUIT BOARD DIP SWITCH

···················

···························································

DESCRIPTIONs.......................................

···

37

37

38

38

39

40

40

41

42

42

43

44

44

45

46

47

47

48

48

48

49

50

26. MEMORY INITIALIZATION

27.

TROUBLESHOOTING

···········································································

·················•·······························································

52

53

Page 4

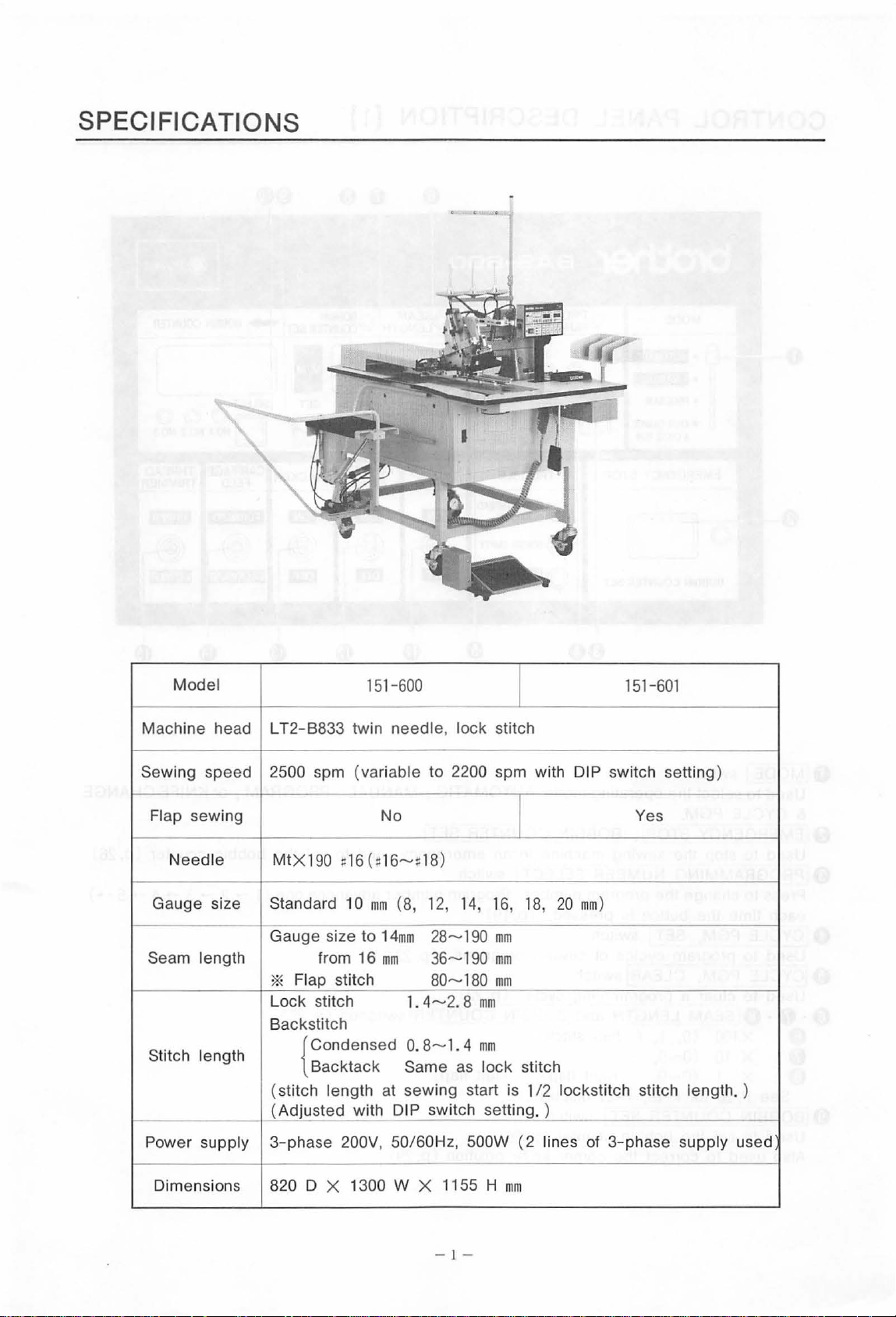

SPECIFICATIONS

Model

Machine he ad LT2

Sewing

Flap sewing No

Gauge size Standard 10

speed

Needle

-·

Seam length from 16

-B833

2500 spm

MtX190

Gauge size to

twin needle,

(varia

~

16

* Flap stitch

Lock

stitch

Backstitch

Stitch length

{ Condensed 0. 8--1 . 4

Backtack

(s

titch length

(Adjusted with DIP switch

151-600

ble

to 2200 spm with

U16--#18

mm

14mm

mm

at

)

(8,

12,

28--190

36--190

80--180

1.

4--2.8

Same

sewing start is 1

I

lock stitch

I

14, 16,

as

18,

mm

mm

mm

mm

mm

lock

stitch

setting.)

15

1-601

DIP switch setting )

Yes

20 mm)

/2

lockstitch stitch length. )

Power supply

Dimensions 820 D X 1300 W X 1155 H

3-phase

200V, 50/60Hz, 500W ( 2 lines of

mm

- 1 -

3-phase

supply used

Page 5

CONTROL

PANEL DESCRIPTION (1]

©

BOBBIN

EMPTY

©~RAMMING

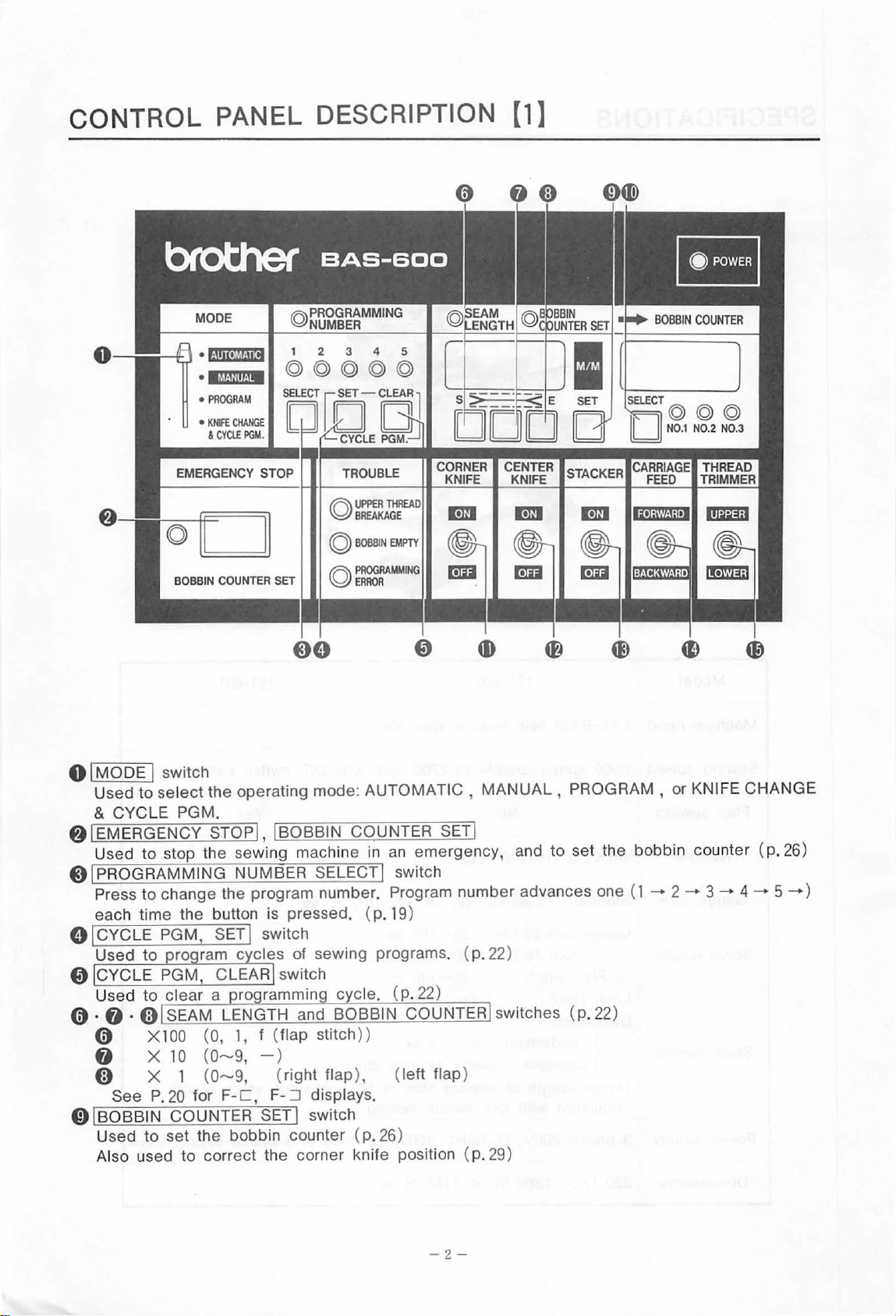

O IMODE I switch

to select

Used

& CYCLE PGM.

f)

I EMERGENCY STOP I, I BOBBIN COUNTER SET!

Used

Q IPROGRAMMING NUMBER SELECT ! switch

each time the button

O ICYCLE PGM, SET I switch

Press

Used

to

to

change the program number. Program number advance s one (1 -+

to

the operating mode:

stop the sewing machine in

is

pressed. ( p.

ro ram c cles of sewing programs. ( p. 22)

AUTOMATIC,

an emerge

19

)

0 CYCLE PGM CLEAR switch

to

clear

Used

0 · 0 ·

«;)

0 X1

0 X

«;)

See

01BOBBIN

to

Used

Also used

a ro ram min c cle. (

SEAM LENGTH and BOBBIN

00

(0, 1, f (flap stitch

10 (0-9,

X 1 (

P.

20

for

COUNTER

set

the bobbin counter (

to

0-9,

correct the corner knife position ( p. 29)

F-C,

- )

(right flap

F-

:::::J

SET!

displays.

switch

))

),

p.

26)

p.

22)

COUNT

(left flap)

MANUAL,

ncy, and to set the bobbin counter (p. 26)

ER

switches (p. 22)

PROGRAM , or KNIFE CHANGE

2-+

3-+

4-+

5-+

)

-2-

Page 6

•

t!11UeJM.)i[j

•l&f-HIINM

•

PROGRAM

•

KNIFE

CHANGE

&

CYCI.f

PGM.

EMERGENCY STOP

A

UPPER

BOBBIN

THREAD

EMPTY

~BREAKAGE

(Q)

©~RAMMING

~!BOBBIN

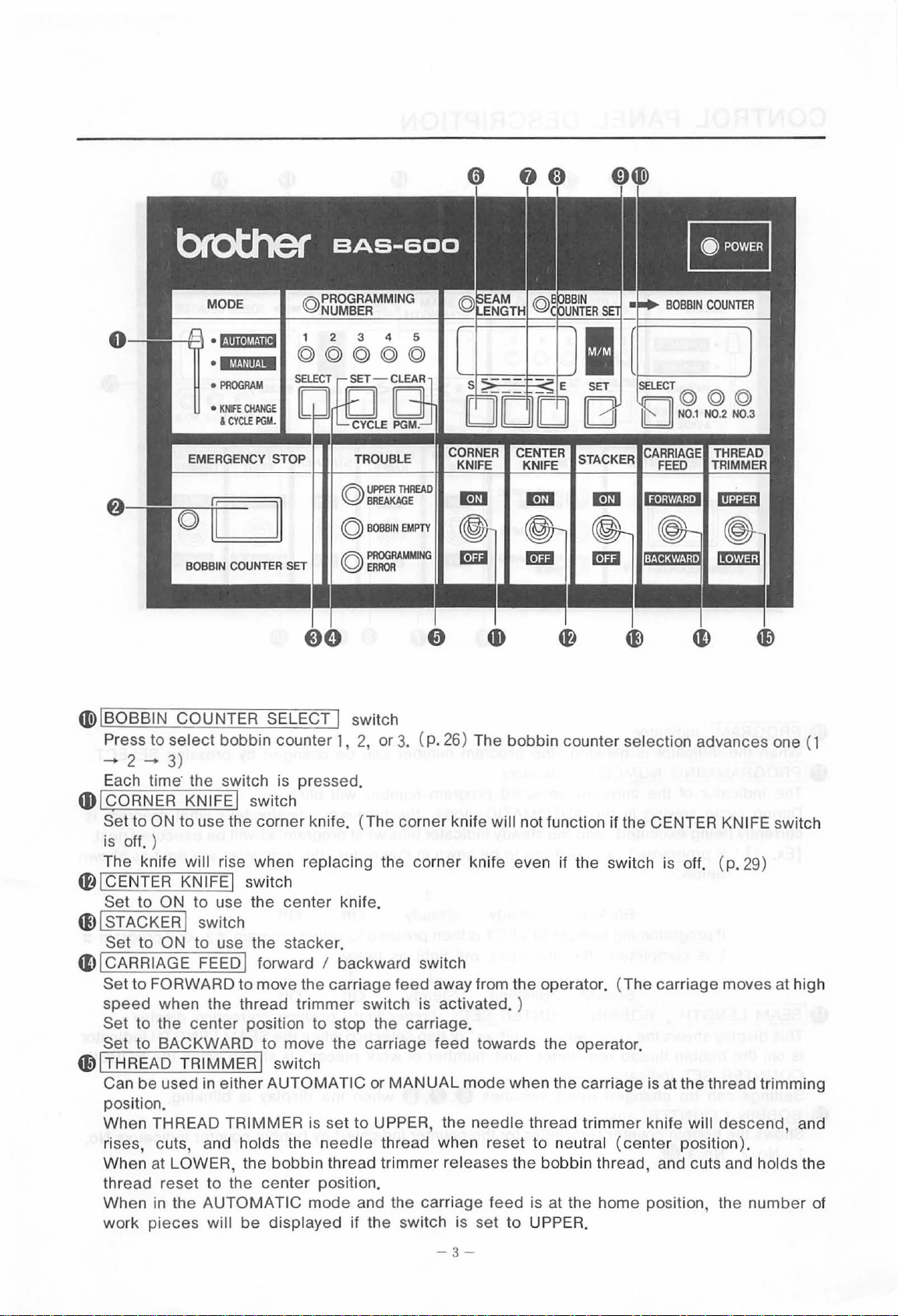

Press to

-

2-

COUNTER SELECT I switch

select

bobbin counter 1, 2, or 3. ( p. 26) The bobbin counter selection advances one ( 1

3)

Each time· the switch is pressed.

Q}ICORNER

KNIFE! switch

Set to ON to use the corner knife. (The corner knife will not function if the CENTER KNIFE switch

is

off. )

Th

e knife will rise when replacing the corner knife even if the switch is off. ( p. 29)

~!CENTER

Set to ON

41)

I STACKER I switch

Set to ON

41)

I CARRIAGE FEED I forward I backward switch

Set to FORWARD

speed

Set

Set to BACKWARD

~~THREAD

Can be used in either AUTOMATIC or

KNIFEj switch

to

use

the

center

to

use the stacker.

to

move the carriage feed away from the operator. (The carriage moves at high

knife.

when the thread trimmer switch is activated. )

to

the

center

position to stop the carriage.

to

move the carriage

feed

TRIMMER! switch

MANUAL

mode when the carriage

towards the operator.

is

at the thread trimming

position.

When THREAD

ri

ses, cuts, and holds the

When at

LOWER, the bobbin thread trimmer releases the bobbin thread, and cuts and holds the

thread reset

When in the

pieces

work

TRIMMER is set

to

the

center

AUTOMATIC mode and the carriage

will

be

displayed if the switch is set to UPPER.

to

needle

position.

UPPER, the

needle

thread when reset

feed

thread trimm

to

neutral

er

knife will

(center

descend,

position).

is at the home position, the

number

and

of

-3

-

Page 7

CONTROL

PANEL DESCRIPTION

•

t!jiiUJl&littl

·IM,UIIHM

•

PROGRAM

•

KNIFE

~

EMERGENCY STOP TROUBLE

4D

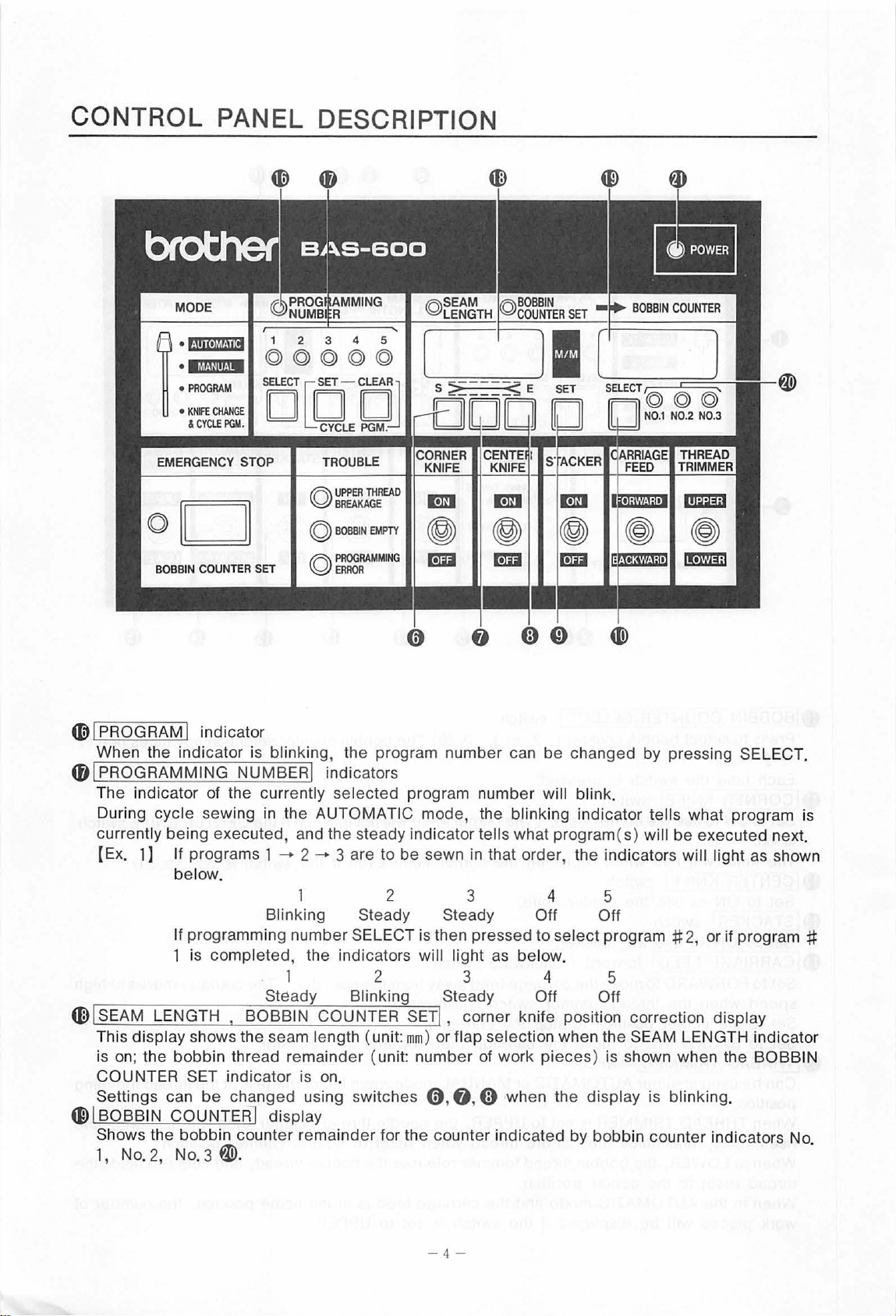

I PROGRAM I indicator

When the indicator is blinking, the program numb

4f#

J PROGRAMMING NUMBERJ indi cators

Th

e indicator of the currently sel

During cycle sewing in the AUTOMATIC mode, the blinking indicator tells what program is

currently being executed, and the steady indicator tells what program

[E

x.

1] If programs 1 -+

4E)

I SEAM LENGTH , BOBBIN COUNTER SETI , corner knife position correction display

This display shows the seam length (unit:

is on; the

COUNT

Settings can

4D

I BOBB IN CO UNT

Shows

1, N

ER

the bobbin counter remainder for the counter ind icated by bobbin counter indicators No.

o.2,

CHANGE

&

CYClE

be

low.

programming number SELECT is then pressed to sel

If

1 is completed, the indicators will light as below.

bobb

in thread remaind

SET indicator is on.

be

No. 3 W.

1 2 3 4 5

©©©©©

PGM.

DCOJOJ

fR\

UPPER

~BREAKAGE

©

2-+

Blinking Steady Steady Off Off

1 2 3 4 5

Steady Blinking Steady Off Off

chang

ed

using switches 0 ,

ER

I display

THREAD

BOBBIN

EMPTY

ected

3 are

er (unit:

er

can

program numb

to

be sew n in that order, the indicators will light as shown

2 3 4 5

mm)

or fl ap selection when the SEAM LEN GTH indicator

number

0,

er

of

work

0 when the display is blinking .

be

changed by pressing SELECT.

will blin

pieces ) is shown when the BOBBIN

k.

(s) will

ect

program #

be executed next.

2,

or if program #

- 4 -

Page 8

.

\.-

~~-

.:-:.;.-

---.

---

~

0

~

1-1--ll--~

1--L--'t:::::::::~

~-

0

>.-=-=<

iJ---~i

600

~

:

~---

~

---

:

~::

~~

---

-

~

-~-

0 9 9 0

- --

~~

~~

601

--

-n--

--

~

~

Seam length display

@

~~~TH @g~~

I

,-,

,

,_,

[

S

;? ____

_

DODD

Flap displ

@

ay

t~~~TH

@

,-,

11

,_,

0:;:

E

SET

gg:~

SET

SET

-+

BOBBIN COUNTER

(

SELECT

D@@

N0.1 N0.2 N0.3

-+

BOBBIN COUNTER

)'

@

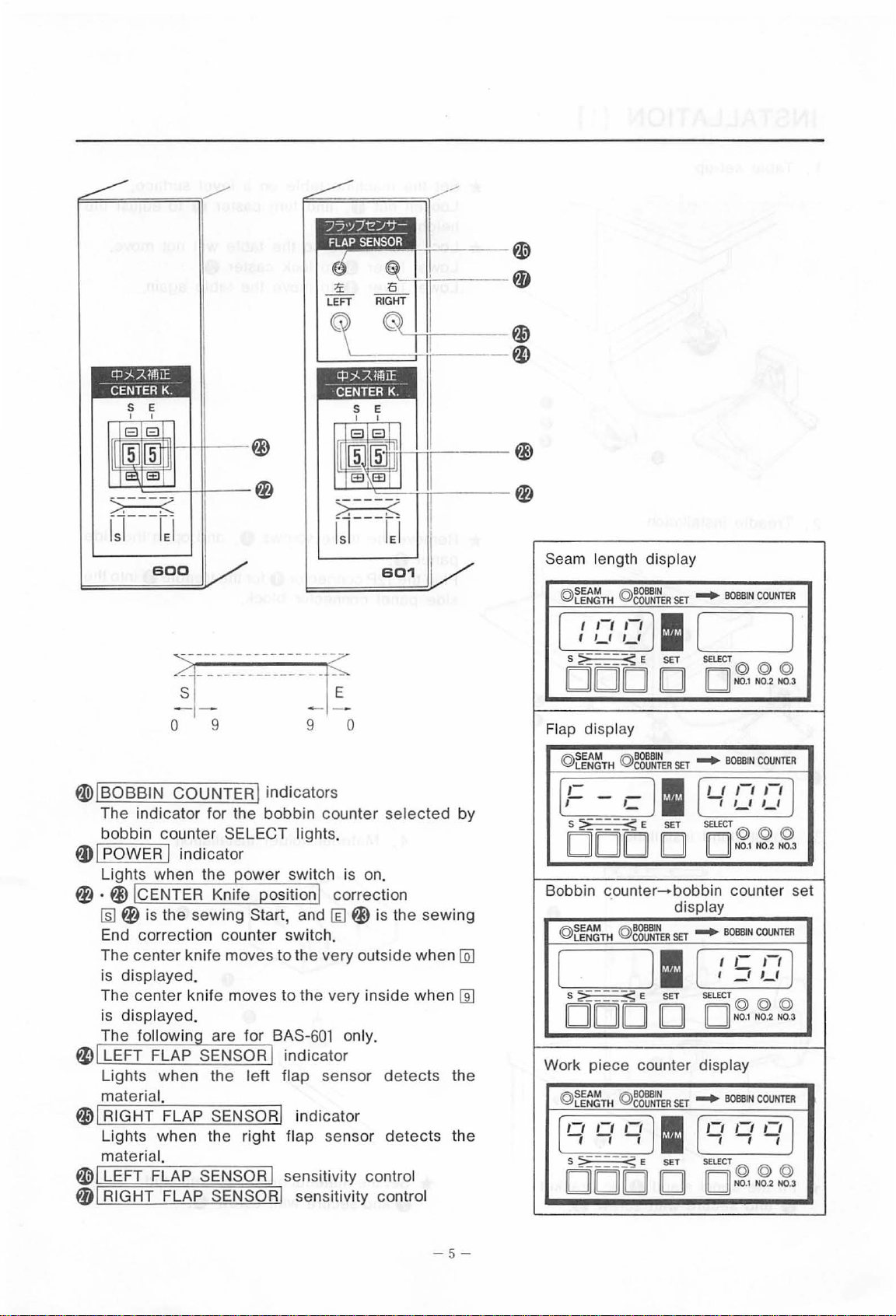

W IBOBBIN COUNTER! indicators

Th

e indicator for the bobbin counter

bobbin

tDI

POWER I indi cator

Lights when the ower switch is

0 ·

~

~

End correcti

The center knife moves to the very outside when

is displayed.

The center knife moves

is displayed.

The followin are for BAS

~

LEFT FLAP SENSOR indicator

Lights when

material.

~~RIGHT

Lights when the right

material.

~~

LEFT FLAP SENSOR I sensitivity control

01

RI

co

unt

er SELECT lights.

CENTER Knife osition correction

0

is

the sewing Start, and [ill ~ is the sewing

on

count

er

switc

h.

to

the very inside when

-601 on

th

e l

eft

flap sensor

FLAP SENSOR! indicator

flap sensor detects the

GHT FLAP SENSOR! se nsitivity control

selec

on

.

ly.

detects

ted by

[ill

Eru

the

- -l I f u

(

:-

S ;? _

DODD

Bobbin

@

t~~~TH

[

S ;?

DODD

Work piece counter display

@

SEAM @80681N

LEN

[

'7

S

DODD

I_

___

_

~

E

counter-bobbin

@

~JeR

_____

GTH

'i

;? _____

ll

<:;:

E

COUNTER

I:

ll

~

E

SET

SET

SET

SE

displ

SET

T

I 1_1 1_1

SElECT

D@@

counter set

ay

-+

BOBBIN

I

I

_t

(

SELECT

D@@

N0

-+

BOBBIN

(

'7

SELEC

T@

IDI

N0

,-,-,

N0.1 N0.2 N0.3

,-

,-:

l

@

COUNTER

1-1 )

1_1

@

.1 N0.2 N0.3

COUNTER

'7

)

@@

.1 N0.2 N0.3

-

5-

Page 9

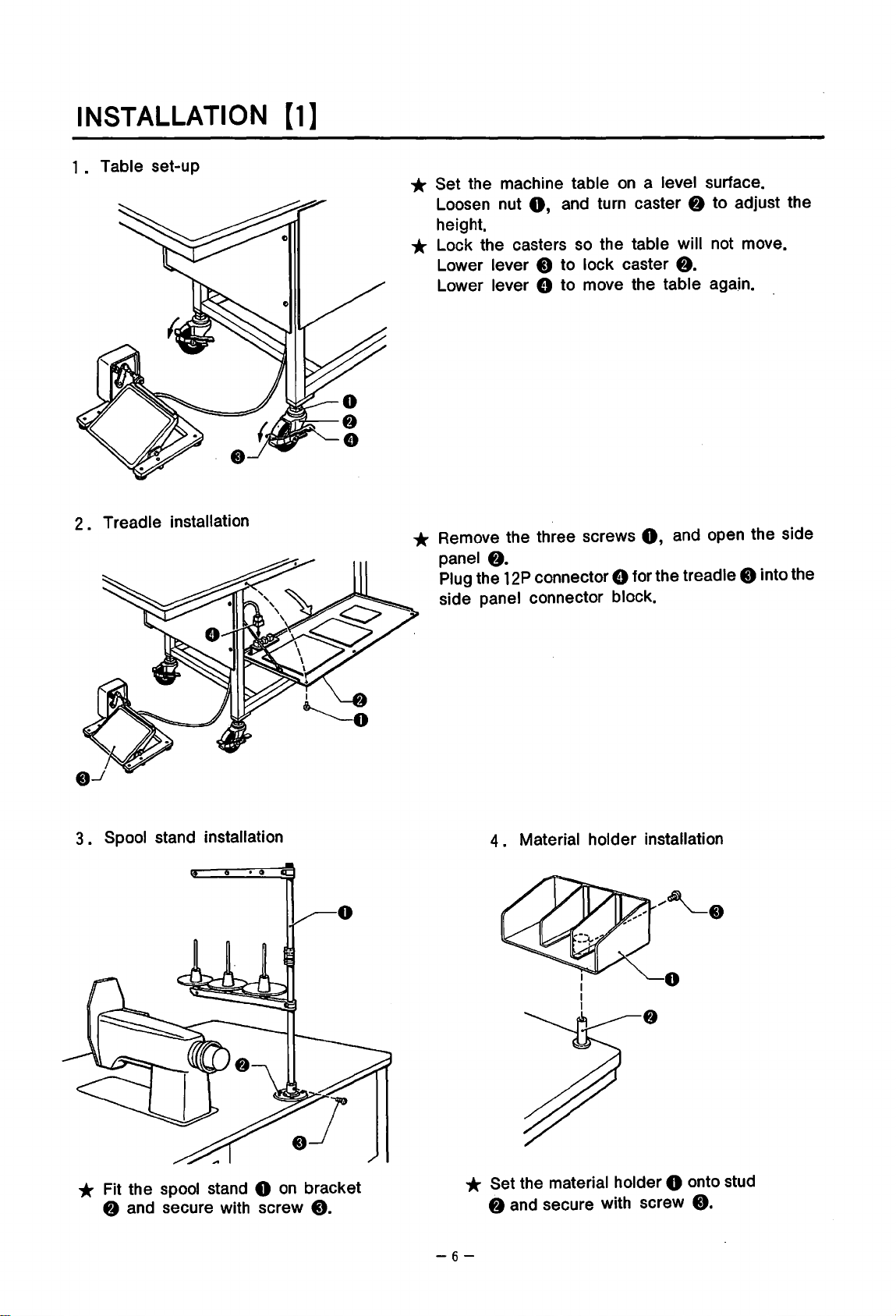

INSTALLATION

1 . Table set-up

2

• Treadle installation

[1]

* Set the machine table

0,

Loosen nut

height.

and turn caster

on

a level surface.

f)

to adjust the

* Lock the casters so the table will not move.

Lower

Lower lever 8 to move the table again.

lever 0 to lock caster

* Remove the three screws

panel

Plug the

side

f).

12P

connector 8 for the treadle 0 into the

panel connector block.

f).

0,

and open the side

3.

Spool stand installation

* Fit the spool stand 0

f)

and secure with screw

on

bracket

0.

4 • Material holder installation

* Set the material holder 0 onto stud

t)

and secure with screw

-6-

0.

Page 10

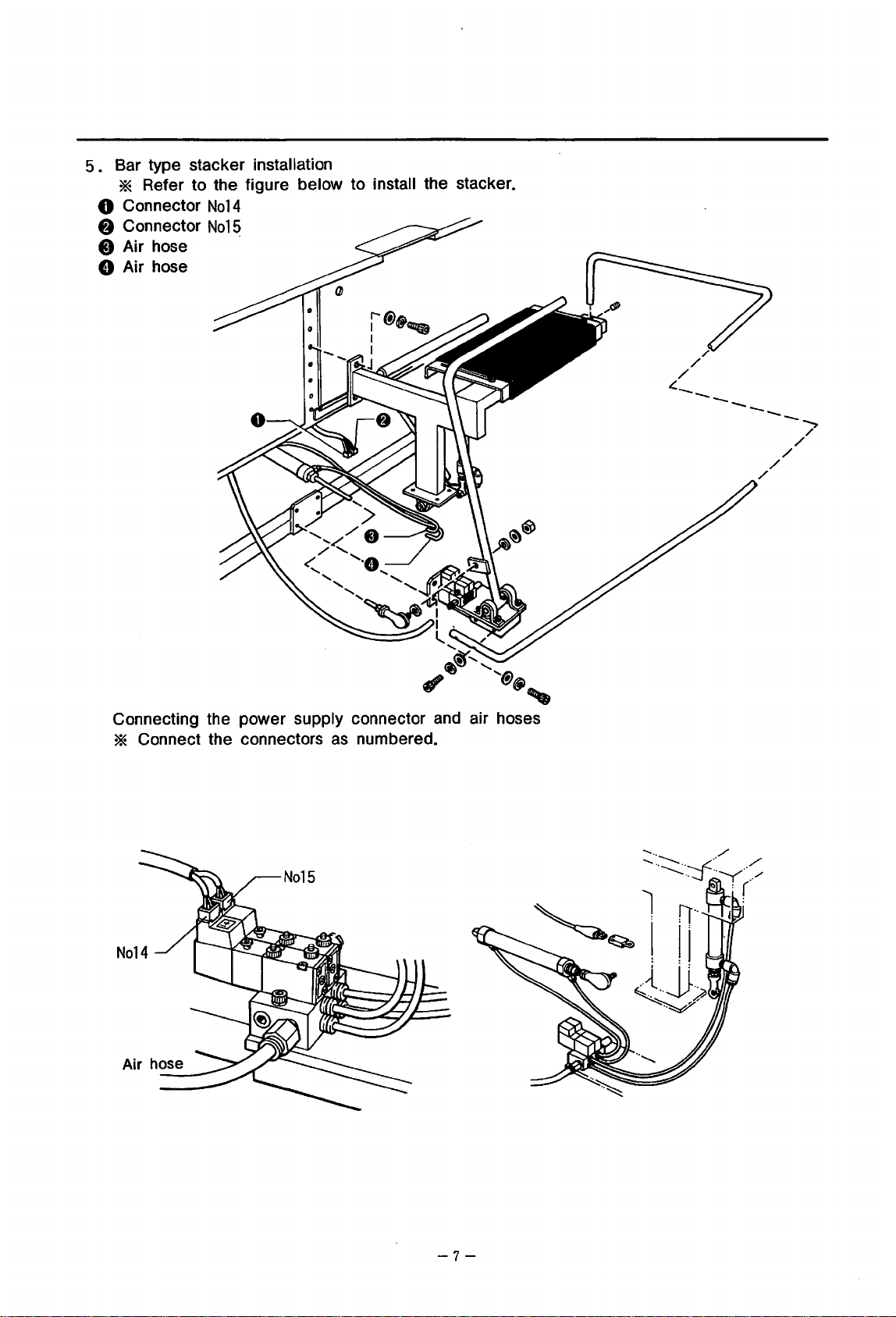

5 • Bar type stacker installation

* Refer to the figure below to install the stacker.

0 Connector

8 Connector

0 Air hose ·

8 Air hose

No14

No

15

4(-

/

/

/

--

---

/

/

-"""->

/

/

/

Connecting the power supply connector and air hoses

* Connect the connectors

Air

hose

as

numbered.

-7-

Page 11

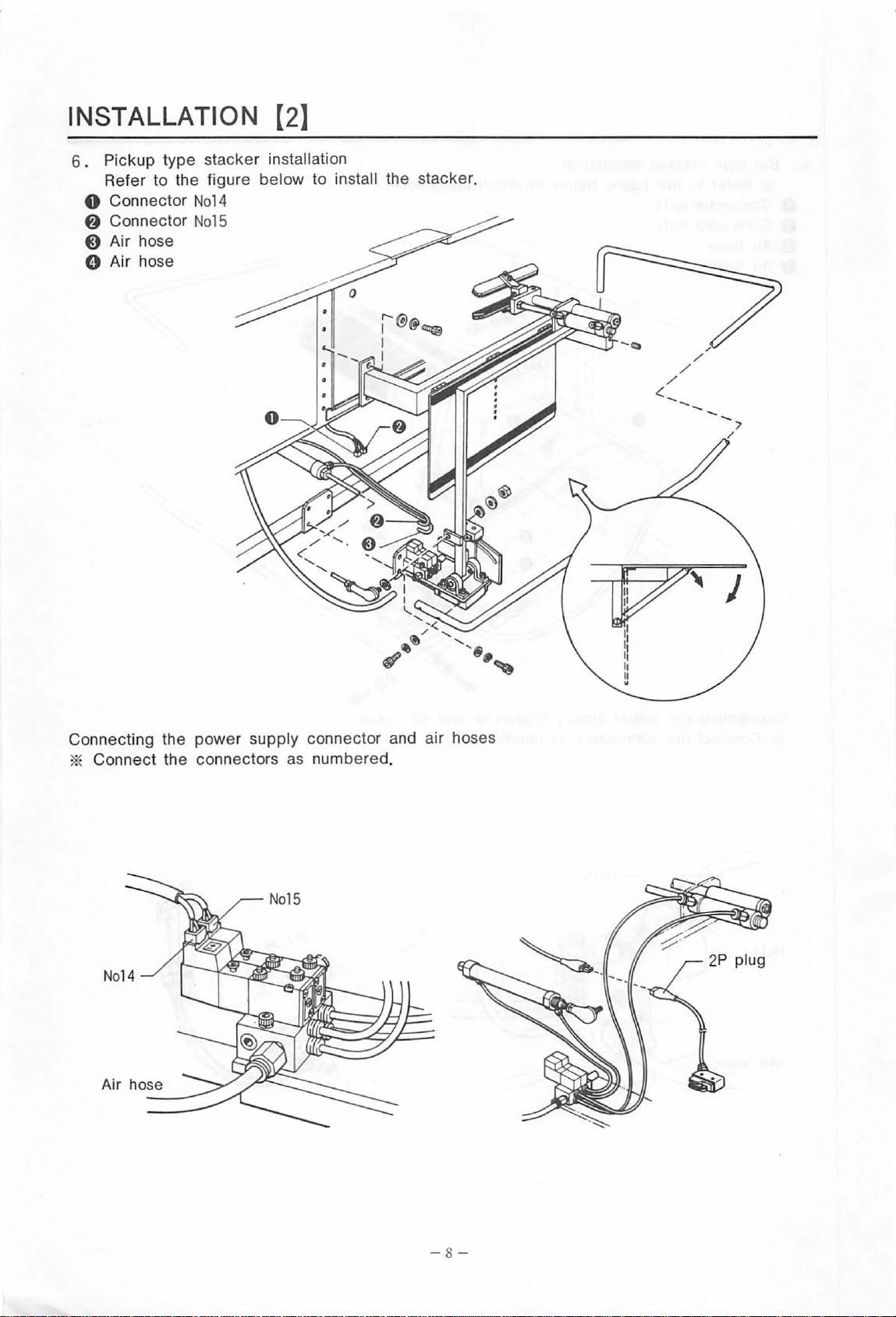

INSTALLATION [2]

6.

Pickup type stacker installation

Refer to the figure

0 Connector

f)

Connector

No14

No15

0 Air hose

0 Air hose

below

to install the stacker.

/

.::::

__

/

/

/

--.

Connecti ng the power supply conn

*

Co

nnect the connectors as numbered.

15

No

Air hose

ector

and air hoses

-8-

Page 12

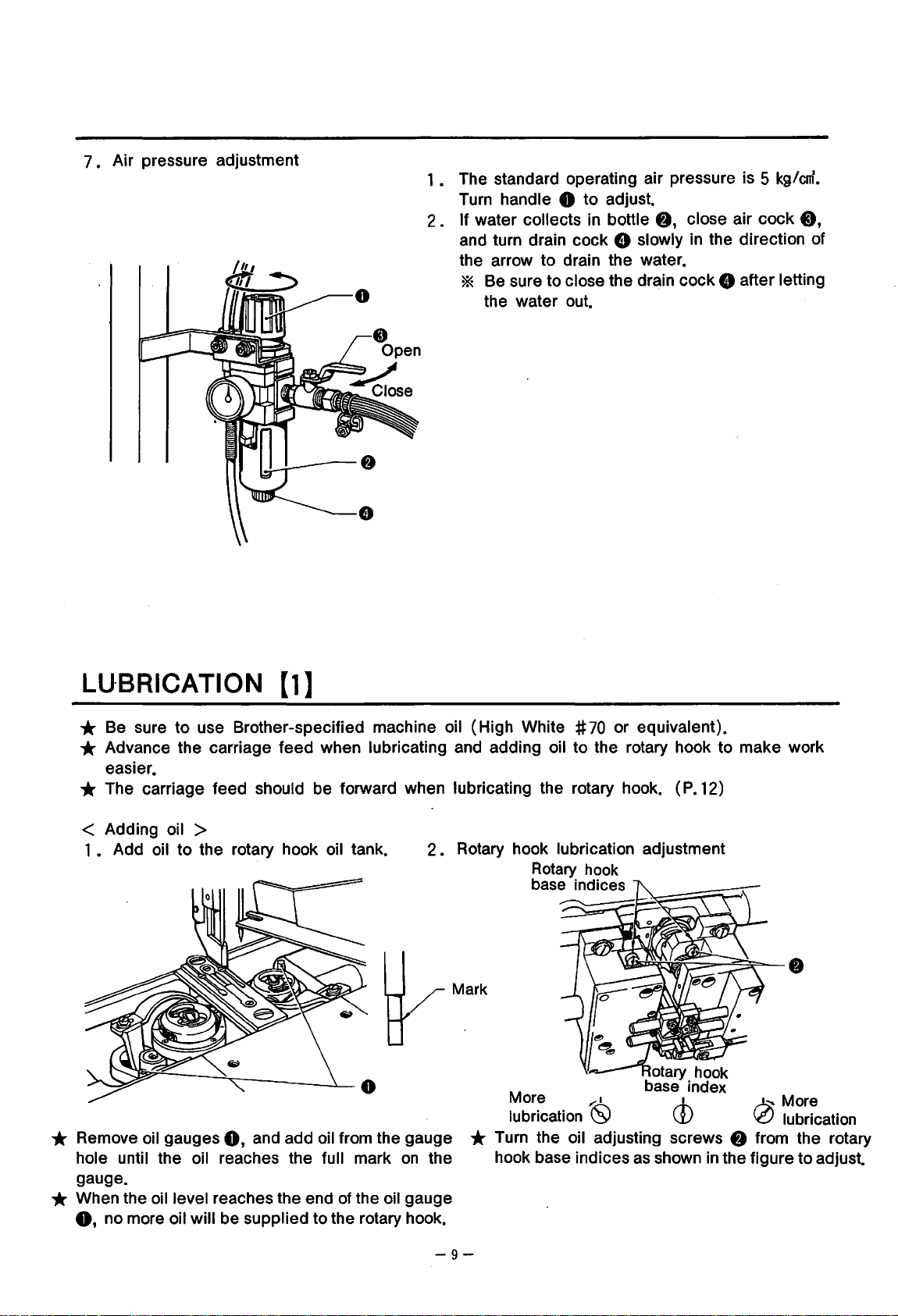

7 • Air pressure adjustment

1 • The standard operating air pressure is 5

Turn handle 0 to adjust.

2 • If water collects

and turn drain cock 8 slowly

the arrow to drain the water.

in

bottle

8,

close air cock

in

the direction of

* Be sure to close the drain cock 8 after letting

the water out.

kg/em.

0,

LU·BRICATION

* Be sure to use Brother-specified machine oil (High White #

[1]

70

or equivalent).

* Advance the carriage feed when lubricating and adding oil to the rotary hook to make work

easier.

* The carriage feed should be forward when lubricating the rotary hook. (

P.

12)

< Adding oil >

1 • Add oil to the rotary hook oil tank.

2 • Rotary hook lubrication adjustment

Rotary

base

hook

indices

YMark

* Remove oil gauges

hole until the oil reaches the

gauge.

0,

and add oil from the gauge

full mark

on

the

* When the oil level reaches the end of the oil gauge

0,

no more oil will be supplied to the rotary hook.

More

lubrication

,::1 •

(S)

CD

* Turn the oil adjusting screws 8 from the rotary

as

hook base indices

shown

in

~More

\0

the figure to adjust.

lubrication

-9-

Page 13

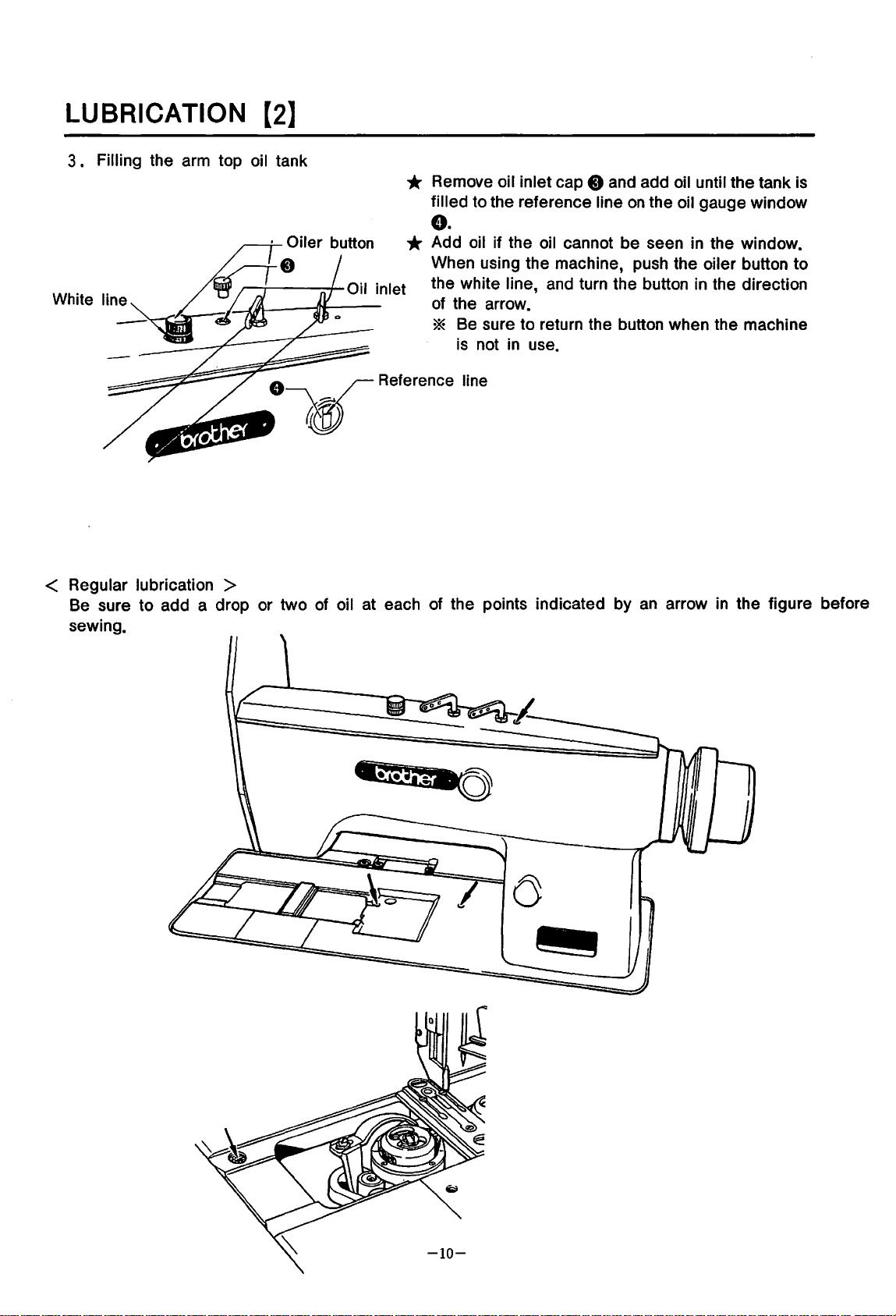

LUBRICATION (2]

3 • Filling the arm top oil tank

* Remove oil inlet cap 8 and add oil until the tank

filled to the reference line

e.

* Add oil if the oil cannot be seen

When using the machine, push the

line,

and

the white

of the arrow.

* Be sure to return the button when the machine

is

not

in

use.

turn the button

on

the oil gauge window

in

the window.

oiler button to

in

the direction

is

< Regular lubrication >

Be sure to add a drop or two

sewing.

of

oil at each of the points indicated by

an

arrow

in

the figure before

Page 14

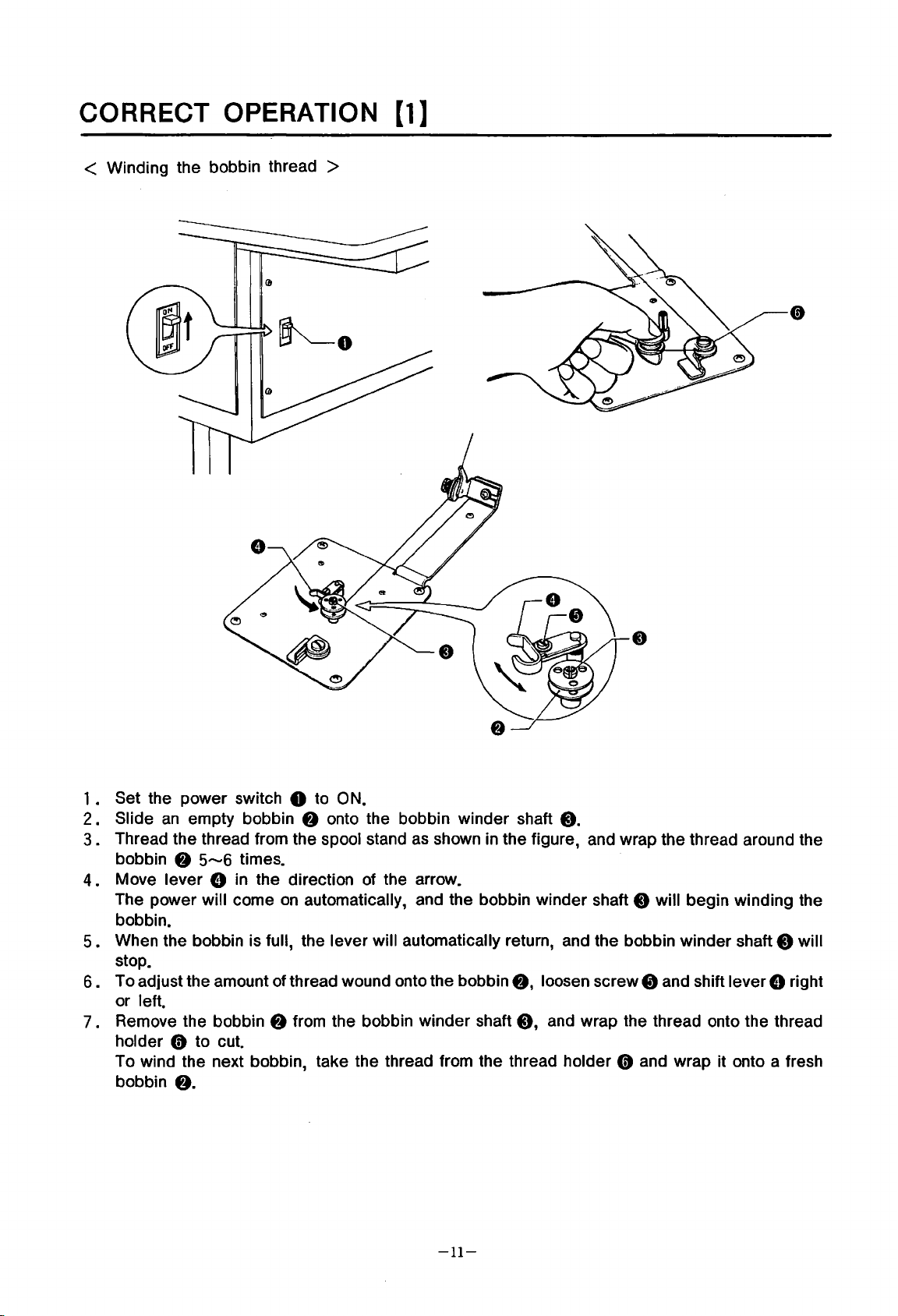

CORRECT OPERATION

< Winding the bobbin thread >

(1]

1 • Set the power switch 0 to ON.

2.

Slide

3.

Thread the thread from the spool stand

bobbin

4.

Move lever 8

The power will come

bobbin.

5.

When the bobbin is full, the lever will automatically return, and the bobbin winder shaft 0 will

stop.

6.

To adjust the amount of thread wound onto the bobbin

or left.

7 . Remove the bobbin

holder

To wind the next bobbin, take the thread from the thread holder

bobbin

an

empty bobbin

f)

5--6

in

0 to cut.

f).

f)

times.

the direction

on

automatically, and the bobbin winder shaft 0 will begin winding the

f)

from the bobbin winder shaft

onto the bobbin winder shaft

as

of

the arrow.

shown

in

the figure, and wrap the thread around the

f),

loosen screw 8 and shift lever 8 right

0,

-11-

8.

and wrap the thread onto the thread

0 and wrap it onto a fresh

Page 15

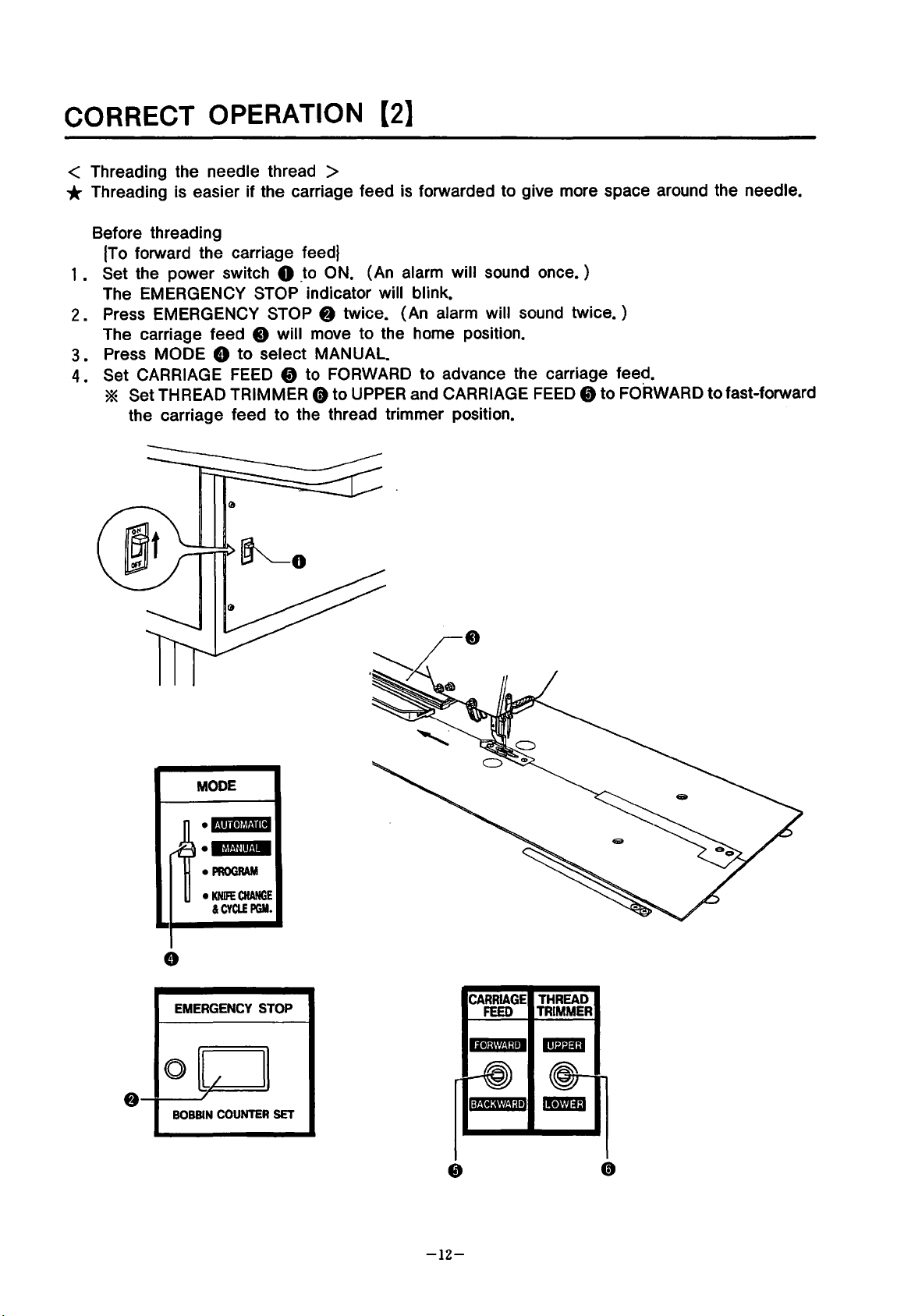

CORRECT OPERATION

[2]

< Threading the needle thread >

* Threading is easier if the carriage feed is forwarded to give more space around the needle.

Before threading

(To

forward the carriage

1 • Set the power switch 0

The EMERGENCY STOP indicator will blink.

2.

Press EMERGENCY STOP 8 twice. (An alarm will sound twice. )

The carriage feed

3.

Press MODE 8 to select MANUAL.

4.

Set CARRIAGE

0 will move to the home position.

FEED

* Set THREAD TRIMMER 0 to

the carriage feed to the thread trimmer position.

feedJ

_to

ON. (An alarm will sound

t)

to FORWARD to advance the carriage feed.

UPPER

and CARRIAGE

once.)

FEED

t)

to FORWARD to fast-forward

MODE

.c.!lfleit,l.ni

•

il,t.Jflif.!M

•

PROGRAM

•

KNIFE

&CYCLEPGM.

8

EMERGENCY

ol

BOBBIN

/

COUNTER

CHANGE

STOP

II

SET

CARRIAGE

FEED

THREAD

TRIMMER

-12-

Page 16

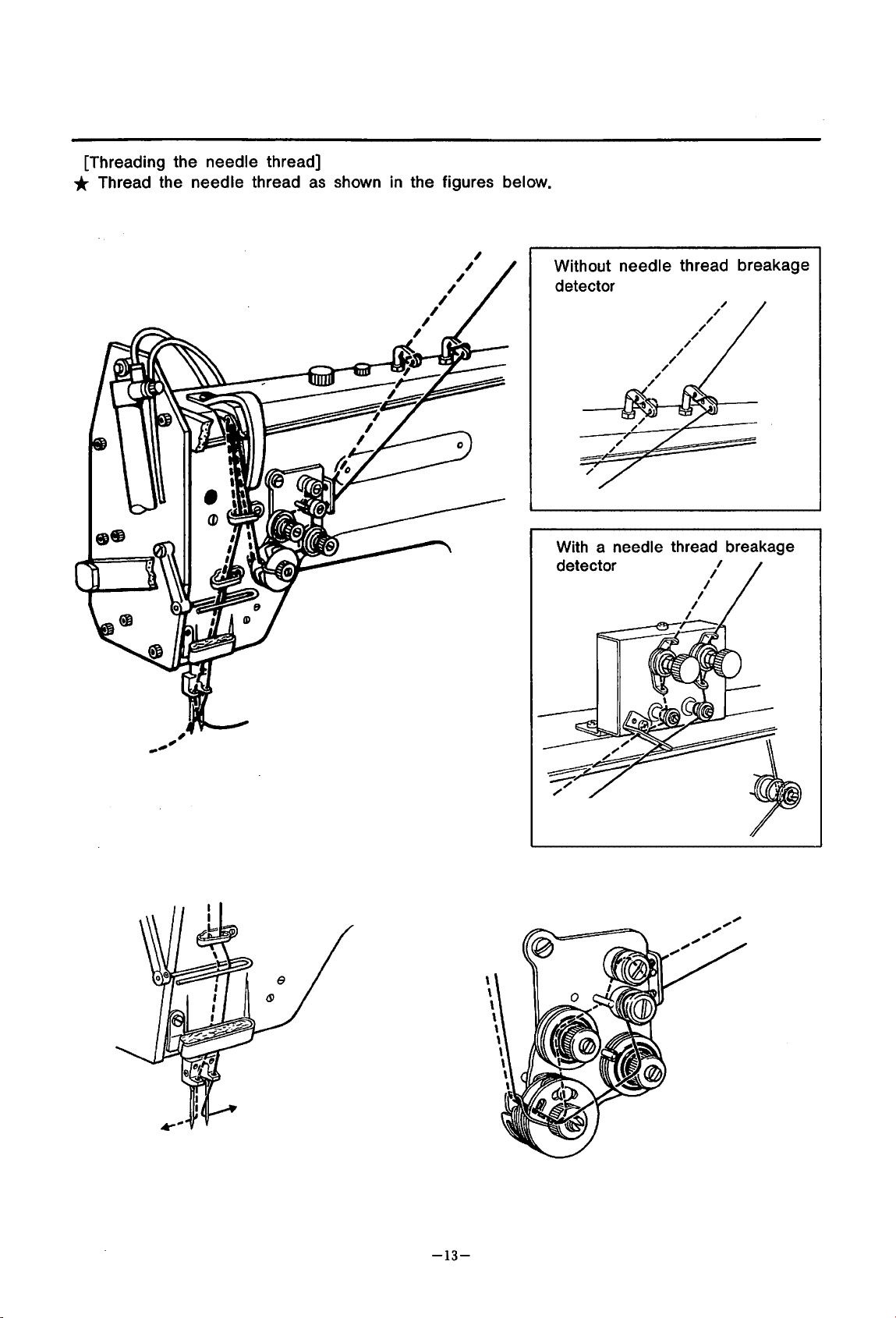

[Threading the needle thread]

* Thread the needle thread

as

shown in the figures below.

,

,

,

,

,

,

,

,

Without needle thread breakage

detector

With a needle thread breakage

detector

-13-

Page 17

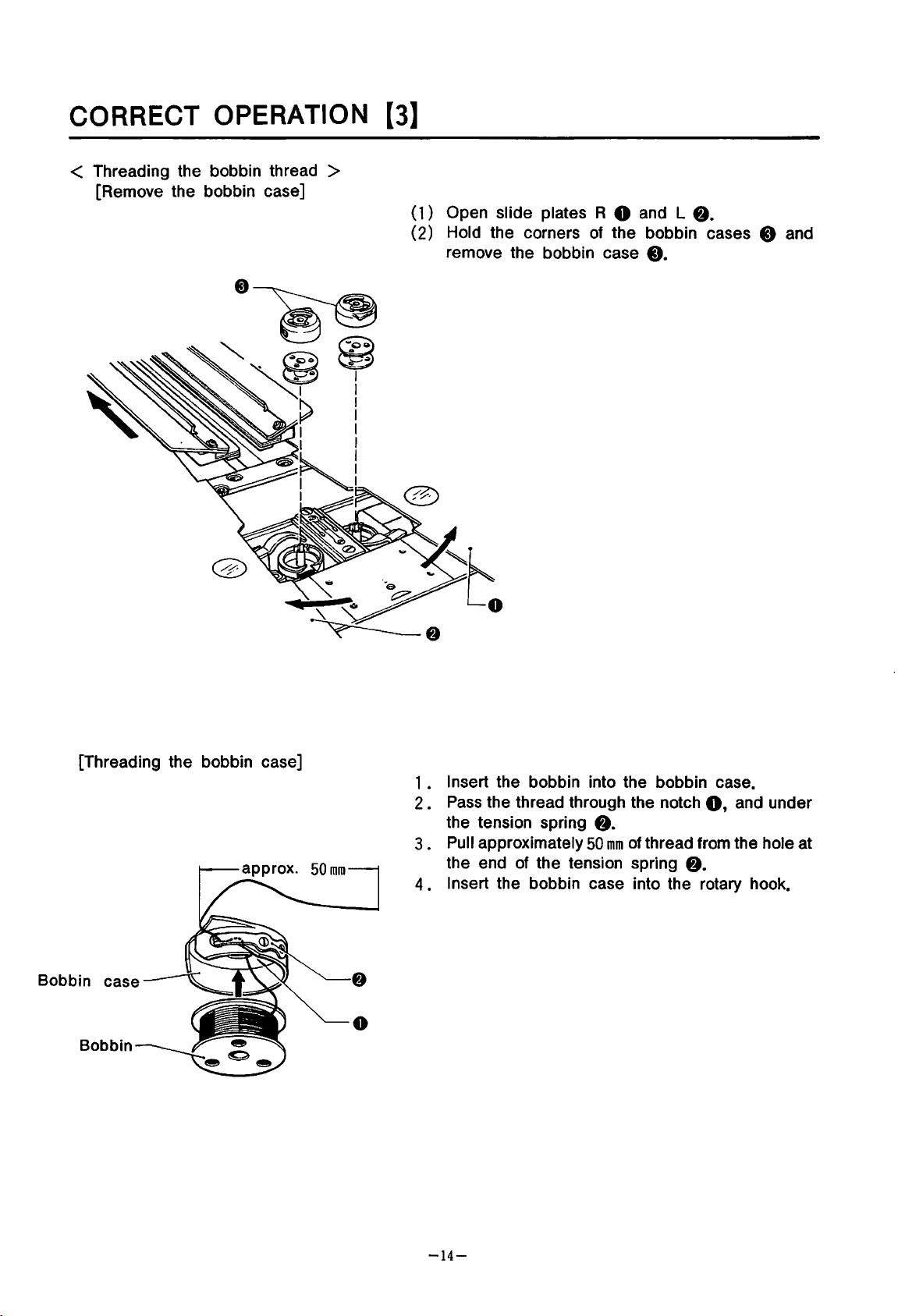

CORRECT OPERATION

< Threading the bobbin thread >

[Remove the bobbin case]

[3]

( 1 ) Open slide plates R 0 and L

(2) Hold the corners of the bobbin cases 0 and

remove the bobbin case

8.

0.

[Threading the bobbin case]

Bobbin case

Bobbin

•

1 • Insert the bobbin into the bobbin case.

•

Pass

2

3 • Pull approximately

4.

the thread through the notch

the tension spring

the end of the tension spring

Insert the bobbin case into the rotary hook.

8.

50

mm

of thread from the hole at

8.

0,

and under

-14-

Page 18

< Holding the needle and bobbin threads >

* Insert the bobbin case (bobbin) into the rotary hook, and close the handle.

• Hold the needle thread by hand, and turn the

1

pulley by hand to bring the bobbin thread up.

2.

Set THREAD TRIMMER 0 to NEEDLE to lower

the needle thread trimmer knife.

Note.

Bobbin thread

THREAD

TRIMMER

Needle

thread

Be careful to keep the hands and other articles

away from the knife when it operates.

3.

Set the two needle threads

trimmer knife.

4.

Return THREAD

thread trimmer knife and

threads.

5.

Set THREAD TRIMMER 0 to LOWER to turn the

bobbin thread knife

below.

• Insert the thread into the groove

6

plate, and reset THREAD TRIMMER 0 to cut

and hold the bobbin thread with the bobbin

thread knife.

THREAD

TRIMMER

TR_IMMER

90°

as

on

the needle thread

0 to raise the needle

hold the needle

shown

in

the figure

in

the needle

0

{To

reverse the carriage feed}

1 . Return the slide plates.

2.

Set CARRIAGE

* If MODE 0 is set to any position other than MANUAL, the carriage feed will retract to the

home position quickly.

CARRIAGE

FEED

FEED

DlBI

~

0

8 to BACKWARD to retract the carriage feed.

MODE

•l·nlielf&Jii

•

MM"fllt·!M

•

PROGRAM

•

KNIFE

CHANGE

&CYa.EPGM.

-15-

Page 19

TREADLE AND START SWITCH DESCRIPTION

* When running a flap sewing program, the machine will not operate when the start switch is

pressed

* During normal sewing, the machine will operate when the start switch

plate

unless the flap presser is down.

operates.

is

pressed after the folding

* Set MODE to either AUTOMATIC or MANUAL.

< Treadle operation >

1 • When the treadle 0

presser foot spring L 0 will rise.

• When the treadle 0 is released, padding cloth presser foot spring R

2

presser foot spring L 0 will descend.

3

• When the treadle 0 is pressed to position

4

• When the treadle 0 is pressed to

5.

When the treadle 0 is pressed to position

operate.

* The folding plate will operate

6 • When the treadle 0

7.

When the treadle 0 is pressed to position

• Press the start switch 0

8

* When MODE is at MANUAL, the carriage feed will move without actually sewing.

* The order in which the carriage feed and flap pressers operate (3,

changed by resetting the

is

pressed, padding cloth presser foot spring R

1,

carriage feed ( L) 8 will descend.

positio~

0.

25-0.

is

pressed to position

and

the carriage feed will operate. ·

DIP switches. (p.

2,

carriage feed (

3,

binder 8 will descend, and the folding plate will

35

sec. after the binder

4,

flap presser ( L) 0 will descend.

5,

flap presser (

50)

R)

f)

and padding cloth

f)

and padding cloth

R)

8 will descend.

~perates.

0 will descend.

4,

6,

7 above) can be

I

BAs-6YY]

Neutral

(center)

position

-~45

0\

~t~==~~==~---

lsAS-601

-16-

Page 20

< Setting the material >

* When running a flap sewing program, the machine will not operate when the start switch is

is

in

down.

place.

0.

25,.....,0.

is

pressed after the folding

,.....,3

are unnecessary.

1,

carriage feed (

35

sec. after the binder operates.

4,

flap presser ( L) • will descend.

5,

flap presser (

L)

0 will descend.

R)

0 will descend.

pressed unless the flap presser

* During normal sewing, the machine will operate when the start switch

plate operates.

1 . When the treadle 0 is pressed, padding cloth presser foot spring R 8 and padding cloth

presser foot spring

2 • Set the padding

3 . When the treadle 0 is released, padding cloth presser foot spring R 8 and padding cloth

presser foot spring L

* If the padding

4 . Set the bodice

5 . When the treadle 0 is pressed to position

6.

When the treadle 0 is pressed to position 2, carriage feed ( R) 8 will descend.

7 • Set the welting

8 . When the treadle 0 is pressed to position 3, binder C) will descend, and the folding plate will

operate.

(The binder

C) will descend to hold the welting, and the welting will then be folded. )

L 0 will rise.

(or

material)

0 will descend to secure the padding.

is

sewn to the material already, steps 1

in

place.

in

place.

* The folding plate will operate

9 . Set one of the flaps, right or left.

10.

When the treadle 0

11.

When the treadle 0

12.

This completes material setting.

is

pressed to position

is

pressed to position

1 • Padding presser

• Welting material

3

2.

4.

Bodice

Flap

-17-

~ding

plate

Page 21

ADJUSTING THE MARKING LIGHT

Adjust the focus before setting the material

Focus adjustment

1

• The marking light will come

2 • Loosen screw 8

material are sharply focused.

Loosen

start· and sewing end positions.

bolt 0 and adjust the crosshairs

and

raise or lower the lens hood 0 so that the crosshairs

on

when the power switch 0

in

place.

is

set to ON.

rffiJ

so that they are focused precisely at the sewing

* Use Allen bolts 8 to adjust the sewing start position forward or back.

rt±tJ

projected

on

the

* Three marking lights

can

be installed with option

-18-

808367-000.

Page 22

PROGRAMMING(Entering

a standard sewing program)

* Set MODE to PROGRAM. The PROGRAMMING NUMBER and SEAM LENGTH indicators will

blink~

* Flap sewing is selected if

< Entering a standard sewing program >

Change the seam length

1 • Set MODE 0 to PROGRAM.

2 • Press SELECT 8 so that programming number indicator 1 lights.

3 • Enter the seam length for the standard sewing program.

Press switches

4.

Change MODE 0 to any position other than PROGRAM.

* Changes

turned off before resetting MODE, the changes will not be stored

5.

Set MODE 0 to AUTOMATIC to sew.

0 to change the seam length display from 1

in

the program settings are stored when the MODE switch is reset. If the power

F-

:J

or

F-C are displayed.

of

programming number 1 from 1

Program

00

to

125.

00

to

125.

in

the program.

is

MODE

•l·!•ll•lt~!·!lll

•lht.Ji!ft.IM

•

PROGRAM

•

KNIFE

CHANGE

&CYa.EPGM.

0

.ROGRAMMING

UMBER

1

2

@©)@@@

4

3

5aECT[EfDJ

CYCLE

PGM.

J

CD)

MODE

i •

H•ii~tiill

•

IM.nlrt.!M

•

PROGRAM

•

KNIFE

CHANGE

&CYa.EPGM.

PROGRAMMING

NUMBER

4

1 2

~@@@©)

3

DCQCJ

I~-------.

5

125

-EAM

NGTH

I

f

----tJ

(Q)BOBBIN

COUNTER

,-,

II

,_,

,_,

SET

I

s~---~E

DOD

__

EAM

<

~ENGTH

5

I

'·

S

>-----~

@BOBBIN

-,

,-

c

='

DOD

SET

D

COUNTER

SET

I

SET

E

D

-19-

Page 23

PROGRAMMING(Enterlng

a flap sewing program)

* Flap sewing programming is not possible

* Set MODE to PROGRAM. The PROGRAMMING NUMBER

blink.

* Flap sewing

F-:J indicates right flap, F-C indicates left flap sewing.

is

selected if

F-::J

or

F-[

on

BAS-600.

are displayed.

and

SEAM

LENGTH indicators will

* Correct the sewing start position (correction data).

< Entering a flap sewing program >

Change programming number 2 to right flap sewing, and correct the sewing start position.

• Set MODE 0 to PROGRAM.

1

2.

Press SELECT 8

3

• Select flap sewing

Press switch

Press switch 8 ( 1 's place) to display

4 . Set the flap. (See page

5 . Press the start switch

0

so

that programming number indicator 2 lights.

and

either right or left flap.

(100s

place) to display

:::J

17

for setting the flap. )

8.

F.

•

A

0

MODE

•l·l!il•lt!!·lll

•

16!Mft.!M

•

PROGRAM

•

KNifE

CHANGE

&CYa.EPGM.

~PROGRAMMING

NUMBER

CYCLE

4 5

PGM.

1 2 3

@(f)@@@

SELECT

[OfDJ

-~~~TH

[F

@~:eR

- c

Jl

SET

...

BOBBIN

I I 1-1

,

SELECT

0@@@

COUNTER

,-,

,_,

,_,

N0.1

N0.2 N0.3

~9--Q

-20-

Page 24

6 • The flap sensor will detect the flap edge, and the carriage feed will move forward

stop.

The distance moved after

display:40.

7.

Set CARRIAGE

flap edge is at the sewing start (needle) position. ·

the

The carriage feed can be moved

8

• Press

The carriage feed will return to the home position, and the correction data shown

COUNTER display will

If EMERGENCY STOP 0

return to the home position but the correction data will not be stored.

9.

Changes

PROGRAM.

* Changes

is turned off before resetting

0.

FEED

SET

switch 8 after the sewing start position is located.

in

the program will be stored when MODE switch 0 is reset to any position other than

in

the program settings are stored when the MODE switch 0 is reset. If the power

material edge detection will appear in the BOBBIN COUNTER

switch 0 to FORWARD or BACKWARD to move the carriage feed so that

in

0.

2

mm

steps.

be stored.

is

pressed without pressing

MODE, the seam length will not be changed.

SET

switch

8,

the carriage feed will

40

in

the BOBBIN

* If the only change to be made is the right or left flap selection, steps 4_,8 can be skipped.

mm

and

EMERGENCY

0

~

BOBBIN

COUNTER

STOP

I

SET

CARRIAGE

FEED

~

I

~40mm]

)

~

~-----------------)

I

I

~~-..

I

-21-

Page 25

PROGRAMMING(Entering

a cycle sewing program)

* CYCLE

order.

* See the preceding pages to set a standard or flap sewing program

PGM

allows up to six selections from

any

of program numbers

1-5

in

< Entering a cycle sewing program >

Set a 1

1

• Set MODE 0 to KNIFE CHANGE & CYCLE

2.

Press CYCLE PGM. CLEAR

3 • Press SELECT 0 to select program number

4.

Press CYCLE PGM.

5 • Press SELECT 0 to select program number

6.

Press CYCLE PGM.

7 • Press SELECT 8 to select program number

8.

Press CYCLE PGM.

9 • Press SELECT 8 to select program number

10.

Press CYCLE PGM.

11.

Reset MODE 0 to any position other than KNIFE CHANGE & CYCLE PGM.

© If stacker operation

© If stacker operation

© See page

* The changes

* If a mistake

-+ 2 -+ 1 -+

after the last program number (3 above) to program stacker operation at that time.

last program number (3 above) to program stacker operation at that time.

34

sewing cycle

3 sewing cycle.

PGM.

f).

1.

SET

0 to store program number

2.

SET

0 to store program number

1.

SET

0 to store program number

3.

SET

0 to store program number

is

not programmed, stacker operation will be automatically programmed

is

not programmed, a period

to operate the stacker independently.

in

the sewing cycle are stored when MODE 0 is reset. No changes

will be stored if the power is turned off without resetting MODE.

is

made

in

the order, press CLEAR

1.

2.

1.

3.

".

" will be automatically entered after the

f)

and reprogram from the beginning.

to be combined

program numbers

in

any

1-5.

in

the

-22-

Page 26

MODE

.ROGRAMMING

UMBER

(Q)SEAM

LENGTH

(Q)BOBBIN

COUNTER

SET

_.

BOBBIN

COUNTER

•I·!•II•M!·III

·•M.u&IHM

•

PROGRAM

~

•

KNIFE

CHANGE

&CYCLEPGM.

1 2 3

@@@(Q)@

4

5

[-

-

s~---~E

DODD

~J

I

•

Cycle

1-+2-+1-+3

t

< Checking the sewing cycle >

1 • Set MODE 0 to KNIFE CHANGE & CYCLE PGM.

The order of the program cycle

sewn

Sewing order

repeatedly

will be displayed •

-ll

© Program number

(-

SET

1 2 3 4 5

.8.©©

-

SELECT@

II

II

N0.1

-]

@@

N0.2 N0.3

•

MODE

•1·!111•1~!·11

•

MM.Jfl*HM

•

PROGRAM

'

~

•

KNIFE

&CYCLEPGM.

0

II

CHANGE

ROGRAMMING

-

UMBER

1 2 3

@@@@@

O[EfCLEARU

CYCLE

4 5

PGM

(Q}~~~TH

I

[

•C

S

?----~

DOD

-23-

@~g~~~R

-,

:

ll

SET

E

SET

D

The period

stacker operation.

_.

BOBBIN

COUNTER

-,

-=~-

SELECT

@@@

N0.1

D

N0.2 N0.3

"."

after the 3 indicates

-

I

Page 27

PROGRAM CONFIRMATION

* The carriage feed can be moved to check the sewing operation without actually sewing.

1

• Set MODE 0 to MANUAL.

• Press SELECT 8 to select program number 1

2

Set STACKER 8 to

Set STACKER 8 to OFF if stacker operation

Set the material in place.

3 .

4 •

Press·

The carriage feed will advance to the sewing start position.

• Press the start switch 8 again.

5

The carriage feed

shortened)

• Continue pressing the start switch 8 to advance the carriage feed to the next step.

6

the start switch

or

backstitch seam.

* If the start switch 8 is pressed at the

backstitch sewing, the carriage feed will move to the corner knife position.

7.

The carriage feed, flap presser, and binder will rise, and the stacker will operate.

The stacker

8.

Press the start switch 8 again.

The carriage feed

will not operate if STACKER 8

* If EMERGENCY STOP

stop and return to the home position.

ON

to operate the stacker.

8.

will advance to the end point of the condensed seam (stitch length

5th

will return to the home position.

C)

is

pressed between steps 5 and 7 above, the carriage feed will

stitch

is

"'5.

i&

not necessary.

in

condensed seam sewing or the

off.

7th

stitch

is

in

MODE

•

!·!liie!M5i!i

•

Mf&UIW•·

•

PROGRAM

•

KNIFE

&CYa.EPGM.

0

EMERGENCY

Ov

/

BOBBIN

COUNTER

CHANGE

STOP

I

/A\

PROGRAMMING

'@II

NUMBER

1 2 3 4 5

@)(Q)(Q)@(Q)

SELECT

i(f[jl

~CYCLE

SET

PGM.!!J

STACKER

8

-24-

\,

Page 28

SEWING

* If the temperature

work pieces before beginning regular operation.

1 • Set the power switch 0 to ON.

2.

Press EMERGENCY STOP

3.

Set MODE 0 to AUTOMATIC.

To use the corner knife, turn CORNER KNIFE 0 and CENTER KNIFE 8

To use the center knife, turn CENTER KNIFE 8

* When CENTER KNIFE 8

is

on.

4.

To use the stacker, turn STACKER 0

If the stacker

* When

• Set the material

5

6 • Press the start switch

The selected automatic sewing procedure will begin.

in

selected program number is not one included

is

below

5°C,

sewing machine operation will be sluggish at first. Test sew

8.

on.

is

off, the corner knife will not operate even if CORNER KNIFE 0

on.

is

not used, turn STACKER 8 off.

the cycle sewing mode, the stacker will not operate even if STACKER e

in

the sewing cycle. (See

in

place. ·

0.

MODE

1

•l·l•il•lt~!·lil

•

1~!·!11•!·1•

•

PROGRAM

•

KNifE

CHANGE

&CYCLEPGM.

on.

p.

is

22,

on

2-3

if the

34.

)

EMERGENCY

~

0~

ll

OBBIN

COUNTER

STOP

SET

CORNER

KNIFE

* The carriage feed can be moved to provide more working space

in

material

* When DIP switch

returns to the home position after sewing

the start switch

* If the treadle

carriage feed can be returned to the home position with the start

ON-OFF setting of the above DIP switch.

place.

3-3

on

the main circuit board is

is

completed is regulated by the start switch

0.

is

pressed back when the carriage feed

-25-

on,

the timing at which the carriage feed

is

at the corner knife position, the

CENTER

KNIFE

on

the table when setting the

STACKER

0.

switc.h,

regardless of the

Press

Page 29

< Setting the bobbin counter >

1 • Set MODE 0 to AUTOMATIC.

2.

Press SELECT 8 to select the bobbin number

3.

Press BOBBIN COUNTER SET

The number of work pieces previously set for that bobbin

SET

COUNTER

• Use switches 8 to change the setting.

4

• Press SET 0 when the changes are completed or if no changes are made.

5

(The number shown

COUNTER

BOBBIN COUNTER

The

display.

display. )

in

the BOBBIN COUNTER

SET

0.

The BOBBIN COUNTER

indicator will go

1-3.

SET

out.

SET

indicator will blink.

will be shown

display will appear

in

the BOBBIN

in

the BOBBIN

MODE

~

•l·!lll•ltu.llll

•

16f.Uilt·1M

•

PROGRAM

•

KNIFE

&CYCLEPGM.

CHANGE

@PROGRAMMING

NUMBER

1 2 3

@@@@©

4

DCOLCJ

(Q)SEAM

LENGTH

5

'''''-'_!II''~'~

:::'1

~I

::

..

f

~

......

,,,,,"''''

S

~----<:

DOD

'

•

< Checking the number of work pieces >

1 • Set MODE 0 to AUTOMATIC.

2.

Set THREAD TRIMMER

The counter will increase by one each time a piece

can be counted.

MODE

rB

•l·!lll•lt~l·lill

•IMUIIHM

•

PROGRAM

•

KNlfE

CHANGE

&CYCLEPGM

@PROGRAMMING

NUMBER

1 2

@@@@@

DCQCJ

•

f)

to NEEDLE.

4 5

3

@~~~TH

,-,

fff

S

DOD

.BBIN

.

OUNTER

SET

C:

-·--

I

SET

E

~~

v

.

8

:?----~

J

is

completed. From

@~g~:eR

,-,

,-,

E

...

BOBBIN

(

SELECT@

SET

I

SET

D

COUNTER

EMERGENCY

l

(Q) (Q)

N0.1

NOHO~

0-999,

-+

BOBBIN

,-,

,-,

,,,

SELECT@

II

II

N0.1

.~~

BOBBIN

999

COUNTER

,-,

@ @

N0.2 N0.3

STOP

I

COUNTER

work pieces

SET

THREAD

TRIMMER

•

< Clearing the work piece counter display >

1 . Set MODE 0 to AUTOMATIC.

2.

With THREAD TRIMMER

be set to

MODE

kj

•l·l•ll•ltJ!·Iil

•

•MMIH•

•

PROGRAM

•

KNIFE

&CYCLEPGM.

0.

CHANGE

(Q)SEAM

LENGTH

[

S

DOD

•

f)

set to UPPER, press BOBBIN COUNTER

(Q)BOBBIN

COUNTER

Jl

?----~

E

SET

SET

D

-+

(

SELECT

0©>

-26-

BOBBIN

N0.1

N0.2 N0.3

COUNTER

")

'-'·

©> ©>

SET

EMERGENCY

v

~

BOBBIN

COUNTER

0.

The counter will

STOP

l

SET

THREAD

TRIMMER

l!liBI

r£f

I

Page 30

< Stitch tension >

1 • Bobbin thread tension

2

• Needle thread tension

* The bobbin thread tension varies with material and

thread. Turn adjusting screw

tension.

Standard tension is

materials when working with a

thick

yarn.

40..-.,;50

0 to adjust the

g for medium-thick t6

#50

spun

• Thread take-up spring

3

* Turn tension control nut

Greater

Smaller f'-.....:_ 0 a

• w

f)

to adjust the needle

thread tension.

Once the bobbin tension has been adjusted,

adjustment of the

provide a

clean, even seam.

0

needle thread tension alone can

~

:ip

4

Evenly tensioned seam

Needle thread tension is

too

high,

thread tension is too low.

/? Needle thread tension is

! too low, or bobbin thread

tension

Is

or

bobbin

too high.

\

\

\_.

* Range of thread take-up spring operation

of

Standard range

To adjust the range of thread take-up spring 8 operation, adjust stopper

thread take-up spring operation is

* Thread take-up spring tension

Standard thread take-up spring tension is

To adjust, loosen screw 8 and turn tension stud

20..-.,;40

-27-

7..-.,;10

g.

fj.

mm.

8.

Page 31

CENTER KNIFE POSITION ADJUSTMENT

* Adju stment of the

E

1 .

2.

x.

The hi

p

gher the number of the center knife pos ition, the fa

os

itioned.

Change the sewing start [ill value fr om 5 to 6, and the sewing end ~ value from 5

Pr

ess the switch 0 for

Pr

ess the swi

* If

the abo

l1J)l.AlifiiE

-----

CENTER K.

ce

nter knife position should be done

th

e sewing start [ill position

tc

h 8 for

ve chan

th

e sewing start ~ position

ge

is made

bef

ore sewing start

acco

rding

to

rth

er

to

chan

ge

to

chan

ge

s,

the machine may

the thickness of the materia

inside

the 5 to a 6.

the 5 to a

the

be

..

corner knife is

to

7.

in any mode.

l.

7.

601

601

Sewing start Sewing end

~-----------

-~---

-

s

o---

-9

---

----~

-------

----

-

-

E

9

--0

-28-

Page 32

CORNER KNIFE POSIT.ION ADJUSTMENT

* Adjustment of the corner knife position should be done according to the thickness of the material.

The higher the number

_ positioned.

Ex.

Change the sewing start value from 5 to

1 • . Set MODE 0 to PROGRAM.

2 • Press SET·

The corner knife position will be shown

3.

Press SEAM LENGTH switch 0 to display a

4.

Press SEAM LENGTH switch 8 to display a

5.

The new corner knife position will be stored when

other position from PROGRAM.

If the power is turned off without pressing

not be stored.

8.

* The corner knife will not operate when the center knife is off (even if the corner knife switch

is on).

of

the corner knife position, the farther inside the corner knife is

6,

and

the sewing end value from 5 to

in

the display.

6.

7.

SET 8 is

SET

or changing the MODE position, the change will

pressed

or

MODE 0

is

reset to

7.

any

MODE

j •IIIIIGil

1•

0

s

o-

•IMU!it·!M

PROGRAM

•

KNIFE

CHANGE

&CYa.E

PGM.

-9

@PROGRAMMING

NUMBER

1 2 3

@@@@@

4 5

(Q)SEAM

LENGTH

,-

-

~

S

~---~

(Q)BOBBIN

,-

='

0[0LEO.J

~~~

9--0

E

(Q)SEAM

LENGTH

,-

o-

S

~-----c;

DODD

@BOBBIN

-,

COUNTER

SET

I

E

SET

COUNTER

f

I(

E

SET

SET

...

BOBBIN

COUNTER

(

SELECT@

II

,,

...

BOBBIN

N0.1

l

@@

N0.2 N0.3

COUNTER

l

SELECT

D@@@

N0.1

N0.2 N0.3

-29-

Page 33

FLAP SENSOR SENSITIVITY ADJUSTMENT

< Adjusting flap sensor sensitivity >

1 • Set MODE 0 to PROGRAM, and set a seam length of

2.

Set MODE 0 to MANUAL.

3

• Set a piece of material

wear.

• Press the start switch

4

The carriage feed will move to the sewing start position,

sensitivity

• Move the carriage feed by

5

will be monitored.

8 for the flap sensor is under the sensor

Sensor sensitivity can now be adjusted

page.

6

• Move the carriage feed by hand from position A to B (the full length of the sensor window), and

make sure the FLAP SENSOR indicators

7.

When adjustment is completed, press EMERGENCY

The carriage feed will return to the home position.

in

place

f).

so

the rubber padding

hand

forward from the position at which it stopped so that the window

e.

as

described under "Sensitivity adjustment"

e,

& do not light.

190

mm.

on

the back of the carriage feed does not

and

flap sensor e (both right and left)

.

on

the next

STOP

0.

MODE

fi

•1·!111•1~tHUI

)

~.

·~t!ll!!·!·

•

PROGRAM

•

KNFE

CHANGE

&CYCLEPGM.

0

EMERGENCY

(Q)

v

BOBBIN

STOP

COUNTER

SET

@~~~TH

@~:m

I I

,-,

-;

,-,

,_f,

! f

S

~----~

SET

I

E SET

DODD

•

•

8 A

,..,..

______

I I

,

•

-30-

Page 34

< Sensitivity adjustment >

1 . With the reflector positioned

SENSOR indicators 0 and 0 are

2. Turn the controls another

3 .

Set a

lights.

piece

of material over the reflector now, and make sure the FLAP SENSOR indicator

-H----0

'--~---0

below

45•

clockwise

the sensor, turn sensitivity controls 0 and 0 so that FLAP

between

on

and off.

from this position.

L__--':::::======l-

Be sure

sewing.

to

Flap

sensor

lamp

~Hl--

clean the lamp behind the flap sensor and the reflector (folding plate) top before

---0

-tt---

0

Reflector

(f

olding plate )

-3

1-

Page 35

TROUBLE

* The machine will stop automatically if trouble develops while sewing.

·<

UPPER

THREAD BREAKAGE indicator lights >

EMERGENCY

~

BOBBIN

*

0

STOP

COUNTER

SET

TROUBLE

•

UPPER

THREAD

BREAKAGE

©)BOBBIN

EMPTY

©~

1 • Press EMERGENCY STOP

will advance.

2

• Thread the needle thread.

01

1

0 Left thread

0.

Right thread

< BOBBIN EMPTY indicator lights >

• Set MODE 0 to AUTOMATIC, and set the number of work pieces for the bobbin

1

SET

COUNTER

2.

Set MODE 0 to MANUAL.

3.

Set CARRIAGE

4

• Replace the bobbin with a full bobbin.

* See page

0 display. (p. 26)

FEED

26

8 to FORWARD. The carriage feed will advance.

for resetting the bobbin counter.

The carriage feed

in

the BOBBIN

MODE

i)

•l·llii•JII'Iill

• lti!·!llll·!·

•

PROGRAM

•

KNFE

&CYa.EPGM.

0

EMERGENCY

oil

BOBBIN

COUNTER

CHANGE

STOP

II

SET

'"'''''''-"''""'''

~I

1-1

:,,,,,:

,,,,,I

s?

____

II:

ll~lllll~''"

~E

DOD

TROUBLE

©:~

•

BOBBIN

EMPTY

©~

I (

SET

__

SELECT

0

CARRIAGE

FEED

-----..JJ

@@@

N0.1

N0.2

N0.3

-32-

Page 36

< PROGRAMMING

ERROR

indicator lights >

* If the sewing range exceeds 28-190

50

mm,

re-enter the correct value. (Range

* If the indicator lights

is

an

There

error

in

the AUTOMATIC

in

the data. Re-enter the data

mm

while programming,

is

36,..,.,

or

MANUAL mode

or

if the flap seam is set to more than

190

mm

for a gauge width of

in

the PROGRAM mode.

16......,20

mm.

)

MODE

.

«·mi•JM@i

•

MM"fflf.!M

•

PROGRAM

t

•

KNIFE

&CYCLEPGM.

CHANGE

EMERGENCY

oil

BOBBIN

STOP

II

COUNTER

SET

< EMERGENCY STOP >

Press EMERGENCY STOP 0 to stop carriage feed movement.

EMERGENCY

BOBBIN

COUNTER

STOP

SET

TROUBLE

©UPPER

©

THREAD

BREAKAGE

BOBBIN

EMPTY

·~lNG

0

Resetting after

* When EMERGENCY STOP

move to the thread trimming position, and the carriage feed will rise. The needle and bobbin

thread trimmer knives can be operated

Press EMERGENCY

the home position.

an

emergency stop

STOP again, and press the start switch

Sewing

is

pressed again, the needle thread will be cut, the carriage feed will

at this time.

on.

The carriage feed will return to

is

possible.

EMERGENCY

BOBBIN

STOP

COUNTER

SET

-33-

Page 37

OPERATING THE STACKER DURING CYCLE SEWING

Ex.

Program the following cycle: program # 1 --+ 2

operation.

Set MODE 0 to KNIFE CHANGE & CYCLE PGM.

1 .

2.

Press CYCLE PGM. CLEAR

3 • Press SELECT 8 to select program number

4. Press CYCLE PGM.

5 • Press SELECT 8 to select program number

6.

Press CYCLE PGM.

7 • Press bobbin counter

program cycle.

SET

SET

SET

f).

8 to store program number

8 to store program number

8.

A period

".

" will be displayed to store stacker operation

* The stacker does not operate while the period

• Press SELECT 8 to select program number

8

9.

Press CYCLE PGM.

10.

Press SELECT 8 to select program number

11.

Press CYCLE PGM. SET 8 to store program number

12.

Press bobbin counter

program cycle.

13.

Reset MODE 0 to any position other than KNIFE CHANGE & CYCLE PGM.

SET

8 to store program number

SET

8.

A period

"."

will be displayed to store stacker operation

1.

2.

1.

3.

--+

stacker operation --+ 1 --+ 3

1.

2.

".

" is blinking.

1.

3.

--+

* Changing the MODE 0 selection stores the order of the sewing cycle. No changes

sewing cycle

* If a mistake

will be stored if the power

is

made

in

the order, press CLEAR

is

turned off without resetting MODE.

f)

and reprogram from the start .

stacker

in

the

in

the

in

the

MODE

•

I·""'W·ii'

•

'·'Mfiit·iM

•

PROGRAM

'

~

•

KNIFE

CHANGE

&CYCLEPGM.

0

MODE

•

11111•!!·!11

•

1!!·!111!·!·

•

PROGRAM

~

~

•

KNIFE

CHANGE

&CYCLEPGM.

0

•

ROGRAMMING

UMBER

1

2

4

3

5

©©©©@

~~;JJ

.ROO

1

©©©©©

RAMMING

UMBER

2 3

4 5

@~~~TH

I

f

S

:?----~

©~Jrm

~,.,

..

~

,

~;;:

,,,

_....._,*

,,,.

,,.

E

DOD

@~~~TH

I

fl

@~~~R

-,

-.

I

f

SET

I

SET

D

SET

I

_.

(-

SELECT©

II

_.

(9.-

SELECT©

DCQCJ

Do0f5

-r

II

BOBBIN

-

II

N0.1

BOBBIN

,,

N0.1

N0.2 N0.3

COUNTER

-]

© ©

N0.2 N0.3

COUNTER

-]

©@

-34-

Page 38

STANDARD

ADJUSTMENTS<sewing

< Needle installation >

machine head)

* Loosen Allen screw

•

Long

groove

•

< Upper and lower shaft timing adjustment >

the way

an

Use

0,

and insert the needle 8 all

in

with the long groove to the inside.

MtX

190

needle •

1 • Remove the needle.

2.

Tilt the machine and remove the timing belt

3.

Align marker A

4 • Without moving the upper shaft, align the arrow

line, and remount the timing belt.

5 . Right the machine and install the needle.

on

the pulley with the red index.

0.

on

the lower belt 8 with the arm bed reference

< Needle and rotary hook timing adjustment >

[Needle to rotary hook point gap]

Needle

Rotary

hook

point

-H---

Max.

0.05

mm

1 • The gap between the needle and rotary hook point should be

and ©, and shift the rotary hook base 0 right

• The gap between the rotary hook base 0 inside and the lower shaft gear

2

0.

2

mm.

approximately

Shift the lower shaft gear

or

left to adjust.

f)

right or left to adjust.

0.

05

mm.

Loosen screws ®, @,

* Be sure that the screw stop does not change when screws © are tightened to gear

f)

should be

f).

-35-

Page 39

[Rotary hook to needle plate gap]

* The gap between the rotary hook 8 and needle plate 8 shouid be

and raise or lower rotary hook 8 to adjust.

[Needle bar

0

lift stroke and needle bar height]

~Needle

0.

6-0.

9

mm.

Loosen screw 0

I

1 , 1

-1.

:I

I I

I I

ll

1/

Needle bar lift stroke

• The rotary hook point should be aligned with the needle center when the needle is raised

1

from the bottom point. Loosen screw 8 and turn rotary hook 8 to adjust.

Needle bar height

• The gap between the top

1

the rotary hook point is

needle bar to adjust.

5mm

2.4mm

of

the needle hole and the rotary hook point should be

aligned with the needle center. Loosen screw 8 and raise or lower the

1-1.

5

2.

mm

4

mm

when

[Rotary hook and bobbin case opener gap]

* The rotary hook 0 to bobbin case opener 0 gap

should be

is shifted all the way

Loosen screw

opener

-36-

0.

2

mm

0,

0 right or left to adjust.

when the bobbin case opener 0

in

the direction

and shift the bobbin case

of

the arrow.

Page 40

CARRIAGE FEED ADJUSTMENT

< Parallel adjustment of needle and carriage feed >

1 • Set the carriage feed to the stop position.

Move the carriage feed and make sure the needle and carriage feed are

the figure below.

parallel

as

shown

in

Adjustment

Loosen screws

Place a piece of material below carriage feed arms 8 and

clamp the

material at front and back.

e and

material. Now pull

0,

and adjust the angle of carriage feed arms 8 and left

on

the material to make sure the carriage feed evenly clamps the

< Carriage feed angle adjustment >

* Make sure the carriage feed angle

Adjustment

Loosen screws

e and

0,

and adjust the angle

is

properly adjusted for the material

• •

r-----

l

8,

and lower the carriage feed to

in

use.

of

carriage feed arms 8 and left

---

-----

----

_

___,

---

__

...._,

8.

8.

>????????????22???????2??22??2?2??{?????2???22?222?222??2??2?22??2

-37-

Page 41

< Carriage feed height adjustment >

* The front edge of the carriage feed should be approximately

20mm

..

-----.r--------~-----------qr

:

"'

I

20mm]

20

mm

high at the home position.

Adjustment

0,

Loosen nut

Loosen bolt

Before adjusting, turn the power switch off, move the carriage feed forward and back by hand,

and make sure the flap presser does not strike the machine.

and adjust bolt

fj

to raise the carriage feed, tighten the bolt to lower the carriage feed.

fj.

•

< Folding plate position adjustment >

Move the carriage feed, and make sure the edge of the carriage feed and the edge

plate are flush.

Also, the gap between the

folding plate is fully extended.

folding plate and needle should be approximately 1

of

the folding

mm

when the

* Move the carriage feed, and make sure the gap between the folding plate and needle is

approximately 1

mm.

-J

o~-------r~

o

________

1

mm

_

1

mm

Adjustment

o Loosen bolts

carriage feed

plate.

o Loosen nut

stroke of the folding

Loosen nut 8 to increase the stroke

Tighten nut

0,

and bring the edge of the

flush with the edge of the folding

8,

turn nut

plate.

8,

and adjust the

8 to decrease the stroke.

-38-

Page 42

< Binder position adjustment >

•

0

5mm

approx.

1 • When the binder 0 is down, the gap between the edge of the binder 0 and the edge of the

carriage feed

parallel.

Adjustment

( 1 ) Loosen

parallel.

(2) Loosen bolt 8 and adjust the gap between the edge of the binder 0 and the edge of the

carriage feed

2

• When the binder 0

slide plate

Adjustment

Loosen nut

the slide plate

3 . The gap between the bottom of the

approximately

Adjustment

Loosen nut

height.

lift the material guide arm

Now

pressure.

8 should be approximately 1

bolt 8 and adjust the binder 0 so the edge of the binder and carriage feed

fJ

to approximately 1

is

down, the gap between the bottom of the binder 0 and the top of the

t)

should be approximately 1

0,

and turn shaft 0 so the gap between the bottom of the binder 0 and the top of

t)

is

approximately 1

1

mm.

0,

and adjust bolts

mm.

The gap at both ends of the binder 0 must be the same.

cloth guides G and the top of the binder 0 should be

CD.

Tighten bolts

4D

by hand to make sure the arm is returned by the spring

mm

mm

(on both sides).

mm.

1mm

(on both sides), and the edges should be

fJ

are

CD

to raise, loosen the bolts to lower the

-39-

Page 43

SENSOR ADJUSTMENT

< Needle thread knife sensor adjustment >

1 • Set MODE 0 to PROGRAM.

Set a seam length of

2.

Set MODE 0 to MANUAL.

3 . Set a piece of material

4 • Press the start switch

The carriage feed will move to the sewing start position.

5.

Set THREAD TRIMMER 0 to

The needle thread trimmer knife 8 will descend.

Adjust the timing at which the thread trimmer becomes off with

6.

Slide needle thread knife sensor 8 up or down and secure where the needle thread trimmer

8 will not strike the flap presser (folding plate).

knife

·*

When the needle thread trimmer knife 8 is off, the needle thread trimmer knife 8 will not

operate if the needle thread trimmer knife sensor indicator

150

mm.

in

place so the cushion

8.

UPPER.

on

the back

of

the carriage feed does not wear.

needle thread knife sensor

8

is

already

on.

8.

MODE

•l·!•ii•M~·!ill

•IM'f!lt·!M

Jf

•

PROGRAM

•

KNIFE

CHANGE

&CYCLEPGM.

.ROGRAMMING

UMBER

3

2

1

©)@©)@@

oco-oJ

CYCLE

•

MODE

~

•IPII•I~HIIil

) •

·~~!·!Ill!·!·

•

PROGRAM

•

KNIFE

CHANGE

&CYCLEPGM.

0

THREAD

TRIMMER

4

PGM

-~~TH

5

,

S

;?

•

DOD

I

,-

='

____

@gg~~R

II

,_.

~

E

SET

I

SET

D

....

(

SELECT@

II

BOBBIN

COUNTER

II

N0.1

N0.2

l

@@

N0.3

-40-

Page 44

< Corner knife adjustment >

1 • Set MODE 0 to AUTOMATIC.

2.

Set CORNER KNIFE

3 . Set a piece of material

4.

When the corner knife operates after sewing, adjust the position of the sensor 8 where the

alarm stops.

Make sure the

If the sensor position

The amount cut by the corner knife

the gauge. Make sure there

f)

and CENTER KNIFE 8 to ON.

in

place, and press the start switch

blade of the corner knife cuts the material at this time.

is

too low, the corner knife will not rise enough.

is

is

a 1

dimension

mm

allowance inside the seams.

B,

approximately 2

8.

mm

less than dimension A of

MODE

jJ

•l·!•ll•bU·!III

•

~~~!·!Ill!·!·

•

PROGRAM

•

KNIFE

CHANGE

&CYa.E

0

@PROGRAMMING

1

@@@©@

DCOLCJ

PGM.

NUMBER

3

2

4 5

CORNER

KNIFE KNIFE

El

CENTER

El

t

t

•

-41-

Page 45

STACKER ADJUSTMENT

< Bar stacker >

Make sure the stacker bar does not extend beyond the table.

A

Adjust

stacker

height with

bolts

Adjust the stacker stop position with nut

the

0.

Loosen

the

the stacker

f).

Cushion adjustment when stopping towards A

Tighten speed

stop speed.

Loosen speed

stop speed.

Cushion adjustment when stopping towards B

Tighten speed

stop speed.

Loosen speed

stop speed.

controller screw 8 to decrease the

controller screw 8 to increase the

controller screw 8 to decrease the

controller screw 8 to increase the

bolt 8

material drapes evenly over

and

plate.

adjust

so

* Adjust so that the recoil of the stacker bar does

not cause the bar to strike the machine when

stops.

that

it

Speed adjustment

Screw valve speed control screw 0

Loosen to increase the speed.

Speed adjustment

Adjust

valve speed control screw 0

in

direction A

in

direction B

in

(turn right) to decrease air cylinder speed.

as

above.

* If the stacker bar returns before the end of the cylinder 8 stroke when the stacker is operated

in

the AUTOMATIC or MANUAL mode, increase the speed so that the bar travels all the way to

the end of the stroke.

-42-

Page 46

< Pickup stacker >

Adjust

stacker

height with

bolts

0.

Flush

I

the

Loosen

just the chuck open-

nut 8 to ad-

opening

is

~:i:ll:li.'Sm

Adjust the stacker stop position with

of

the edge

flush.

the table

and

the edge

nut

f)

so

of

the chuck are

that

Adjust screw 0 to ad-

just the material release timing.

Cushion adjustment when stopping towards A

Tighten speed

stop speed.

Loosen speed controller screw

stop speed.

Cushion adjustment when stopping towards 8

Tighten speed controller screw

stop speed.

Loosen speed

stop speed.

controller screw C) to decrease the

C) to increase the

0 to decrease the

controller screw 0 to increase the

Speed adjustment in direction A

Screw valve speed control screw 0

Loosen to increase the speed.

Speed adjustment in direction 8

Adjust valve speed control screw

G

in

(turn right) to decrease air cylinder speed.

as

above.

-43-

Page 47

KNIFE REPLACEMENT

< Corner knife replacement >

1 . Set MODE 0 to KNIFE CHANGE & CYCLE PGM.

2.

Press EMERGENCY STOP

An

alarm will sound once, and the carriage feed will move to the knife replacement position.

alarm will sound once more when the carriage feed stops.

The

3.

Press EMERGENCY STOP 8 once more.

alarm will sound twice, the carriage feed and flap presser will descend, and the corner

The

will rise above the table.

knife

8.

* Keep your hands away from the knife.

AIR

OFF will be displayed.

4 • Turn air cock 8 to stop the air supply. (Bleed the air line. )

The corner knife

• Loosen screw

5

* Align the edge of the corner knife 8 with the edge of the knife bracket

6.

After replacing the knife, turn air cock 8 to restore the air supply.

7.

Press EMERGENCY STOP 8 again.

alarm will sound twice, the carriage feed and flap presser will rise, and the corner knife will

The

descend.

The carriage feed

MODE

will be locked in the up position.

8,

and replace corner knife