Page 1

&m~a~=

BAS-311E

INSTRUCTION MANUAL

BAS-311EL

BAS-326E

tf:IMJ:t&,iiili(I 7

i:.

Cl.)iltll.ijil~iWC/\1

i:.CI.)iltiijillcl,

INNER CLAMPING DEVICE

Please read this manual before using the machine.

Please keep this manual within easy reach for quick reference.

c1J'

5,

-~~

!P.\-~t:~I~T<:I~IIRbWtt~~Plil~,

-i±*i)

<::iiMJ

<

tc~l,

\o

(FOR

fitiL,

Z:<t::~t,\o

PNEUMATIC)

''

Page 2

A

m;a,oANGER

1.

lltlf'il:t~

1.

Before installation ..... .

iiil~

...

/A •

~

:I

:I

i'D-JIIift~?:AC7)t.JJt-1d:IJUI:t~Bilct~'ftilli:A-1'

~rdJfi::>

7::1J'

5

t.l

J t -1d:HI:t't' <

/A • Wait at least 5 minutes after turning

~

outlet before opening the face plate

result in severe injury.

A

A •

~

A • Turn

~

fFI!O)iiJIC::iUi:A-1'

m::>

't'llfi1d:lli0t:.

•

I7-~ii81{C7)I7-:J~?~Mli

<tct!l,\o

off

the power switch and disconnect the power cord before carrying

the machine

• Close the air cock

the pressure gauge points to ''0".

will

~

7~tJJ

..

E::V:J1J'fFIJJL,

operate

of

the air supply source, and then open the drain cock to bleed the air until the needle

0

if

the treadle is pressed by mistake, which could result in injury.

~71d:tJ.Jtl

tct!

l,

\o

iWiitifEM~I~,J,fl

off

the power switch and disconnecting the power cord from the wall

of

the control box. Touching areas where high voltages are present

~

t:...

:kl:t1J'1d:9

..

tlli:15~·1d:~l,\'~

~

c:

t:.1J'®

5!1\/CAUTION

..

illi:15~·1d:·l,

7:1:t1JtC7)Jm~t:.~O

..

~l.J..(:J:J~?~OI7-~~~

\7::

<

tct!l,

\o

~9

o

..

fE:t.JitO)mtt~

out

troubleshooting, otherwise

..

~C7)fl5

t>

~9

o

can

raJ

IC::l.,'t'

of

1 .

IN

b i'll:t Q

1.

Before installation

1 -1 .

1-1.

-~ifil!l

Sewing

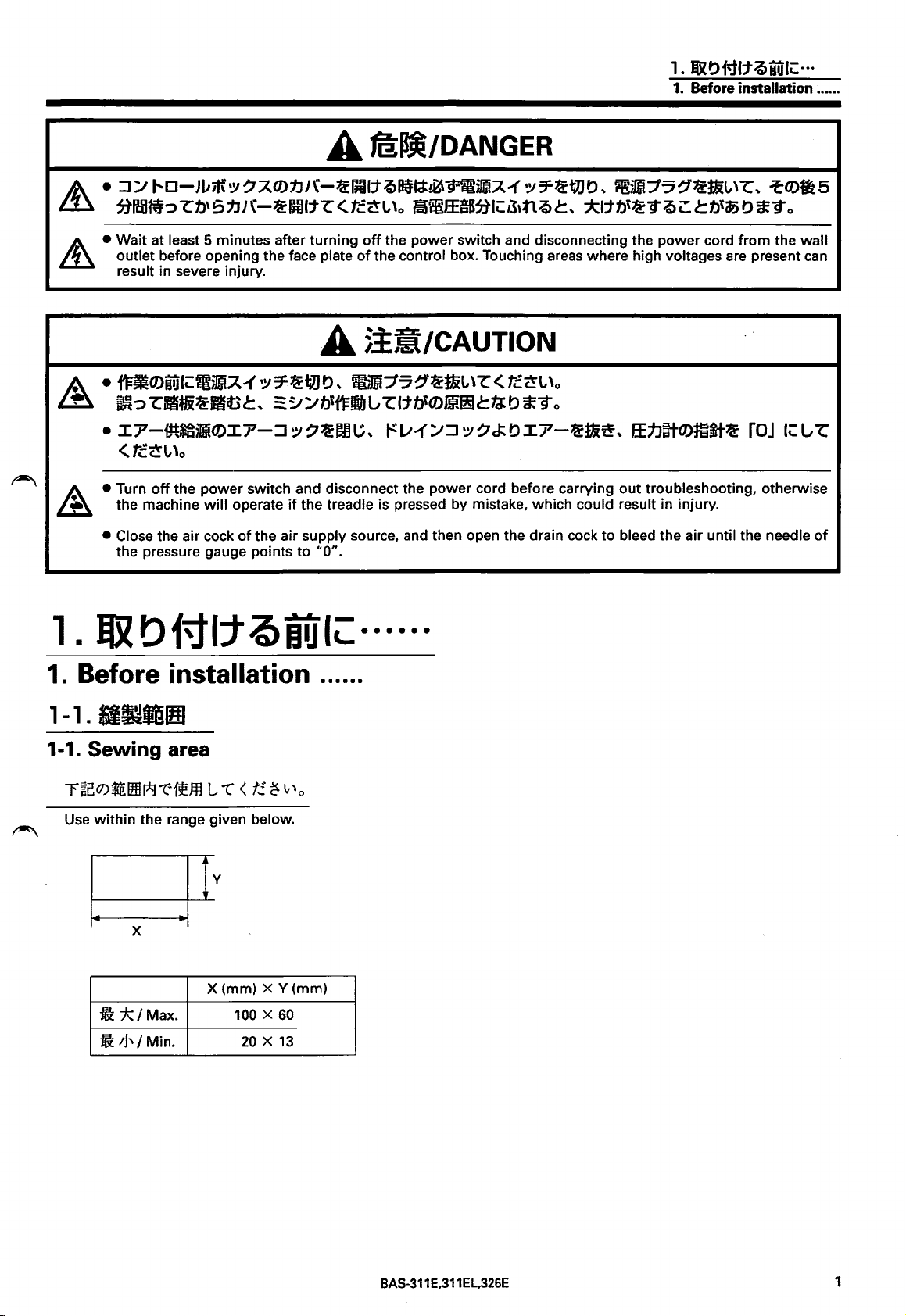

r~cl7)$EIHJJ*rc:1seffl

Use

within the range given below.

ill

*-!Max.

ft

'J'/

Min.

area

L

"C

X (mm) X Y (mm)

100 X 60

rurc:::

<

t!.

~

"'o

20 X 13

· · · · · ·

BAS-311E,311EL,326E

1

Page 3

1 .

IUl

0 Ml:t

i>

iUIC: · ··

1.

Before installation ..•...

1-2. Preparing

the

presser foot

~;t..@O

L,

t.

*i1ftl

2.

k:mf.l

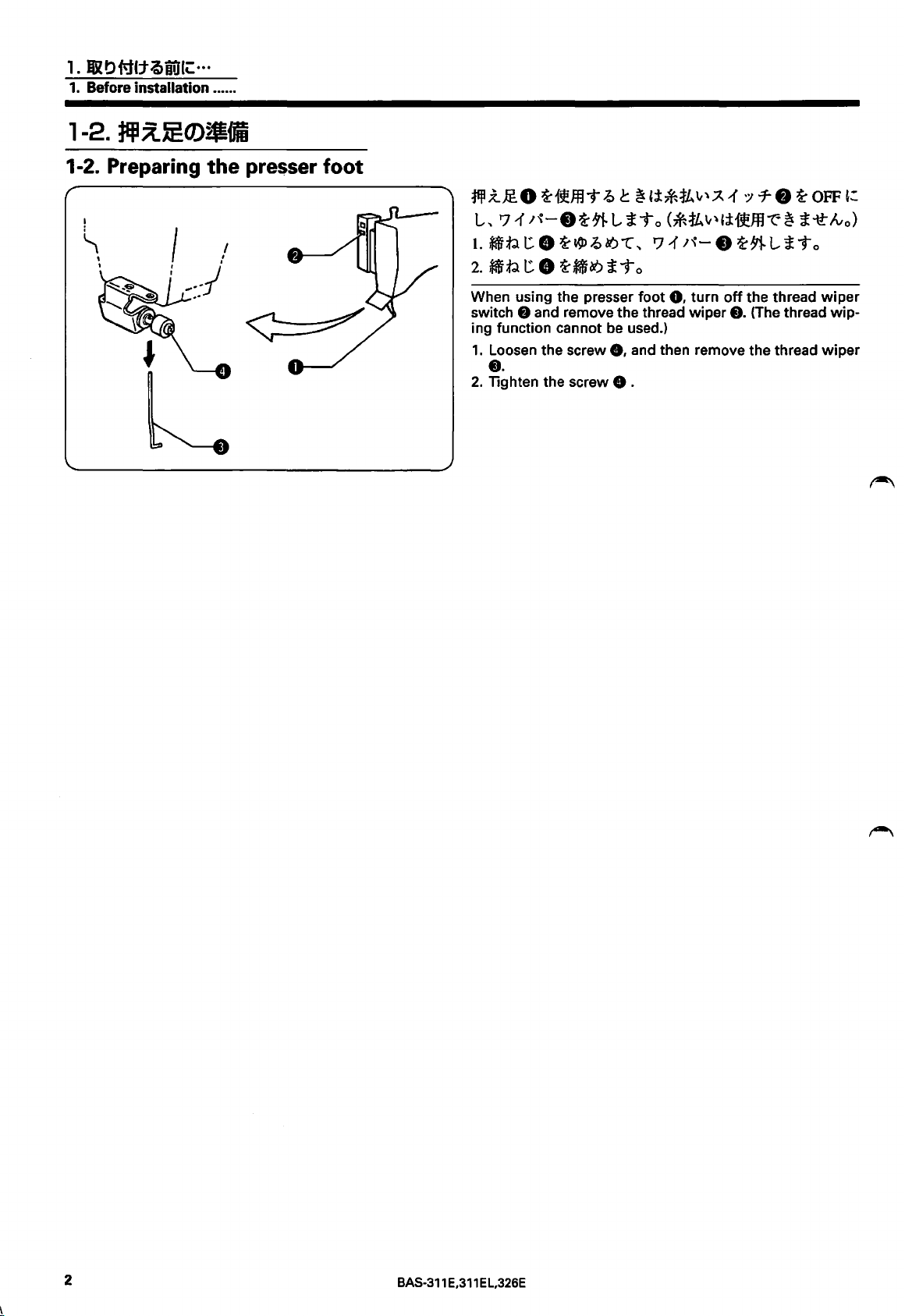

When using the presser foot

switch 8 and remove the thread wiper

ing function cannot be used.)

1.

Loosen the screw

••

2.

Tighten the screw 8 .

~1~.fflT

71

;'\-

8

t:

8

~~.Q&t)"l,

t:

8

~~~iTo

-0

c

~

';J:*fL\t'.A

~~LiTo

<*1k

71

0,

8,

and then remove the thread wiper

;'\-

turn

"'

8

1 -:17-8

li1~.ffl

~~LiTo

off

the thread

f).

~OFF':

"t"'

~

{The

thread wip-

i-tt

lvo)

wiper

2

BAS-311

E,311 E L,326E

Page 4

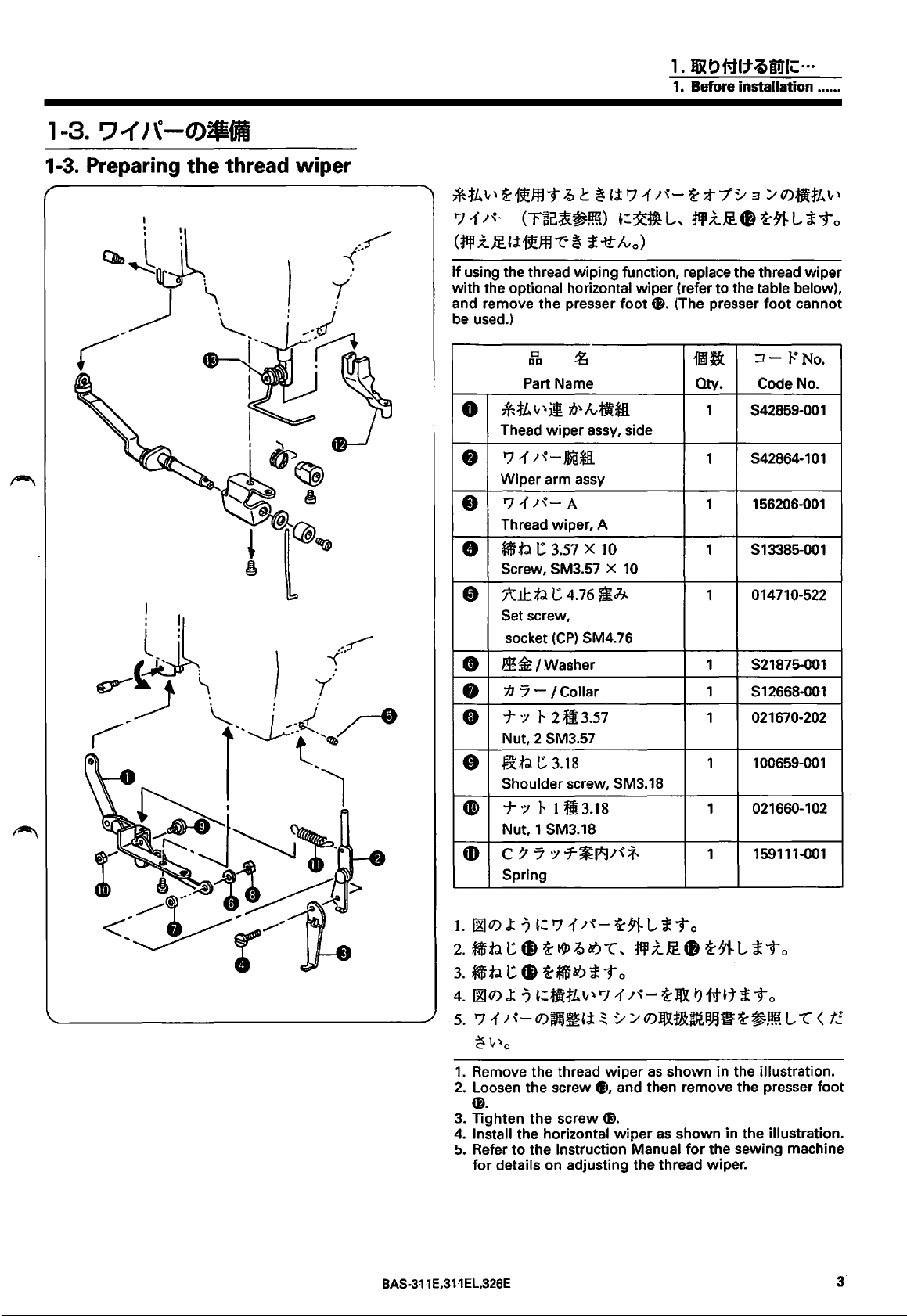

1-3. Preparing the thread wiper

1.

RR~MI:tQiUIC:···

1.

Before installation ..... .

*ikv'

If

with the

and remove the presser

be used.)

a-i5l!ffli"

'71,"-

(liP

.z

.@_

'j:

using the thread wiping function, replace the thread wiper

optional horizontal wiper (refer to the table below),

*iL

0

Thead wiper assy, side

'711'\-JDQU

•

Wiper arm assy

'711'\-

•

Thread wiper, A

f$b

•

Screw, SM3.57 X

J':.IJ:b t 4.76

•

Set screw,

socket

~ c ~

{;t

'711'\-

(rac~~ml)

i5l!ffl""E

Part Name

c

I:U:I

v

'j!!

~

7}~

A

t 3.57 X

':~ilL,

*

-tt

lv

foot

tr

lvftt*li

10

10

0)

tB.

f!Jj.

(CP)

SM4.

76

a-

;t7"~

:JfPX..lf.•

(The presser

i!Mic

Oty.

1

S42859-001

S42864-101

1

1

1

S13385-001

1

3 ;.-Q)•tkv'

a-~

LiTo

foot

cannot

::I-

r"'

No.

Code No.

156206-001

014710-522

https://manualmachine.com/Washer

•

7J

•

0

•

•

•

1.

~Q)

2. $:t.l

3.

$:t.l t 8

4.

5.

1.

Remove the thread

2.

Loosen the screw

••

3. Tighten the screw

4.

Install the horizontal

5.

Refer to the Instruction Manual

for

7 - I Collar

-t

·:;

r

2ft3.57

Nut, 2 SM3.57

~b

t:.

3.18

Shoulder screw, SM3.18

-t

·:;

r

tll3.ts

Nut, 1 SM3.18

c 7 7

Spring

~Q)J:?

'711'\-Q)W!)~{;t

~

\,\0

details on adjusting the thread wiper.

':1

7-~I*J;~

J:

?

':

'711'\-

t:.

8

a-~~&?

a-~&?£

~:ffi'ttLvl'J-{;'\-a-J&JJft'tiTo

;f.

a-~

L £ i" o

-c,

liP

i.l!

i" o

~ ~ ;.tQ)J&fB£~1!JH!t=a-~Jm

wiper

as

CJ),

and then remove the presser foot

ti.

wiper

S21875-001

1

1

S12668-001

1 021670-202

100659-001

1

021660-102

1

1

159111-001

.-

a-;rt.

L t i" o

L

-c

shown in the illustration.

as

shown in the illustration.

for

the sewing machine

<

t!.

BAS-311

E,311

EL,326E

Page 5

1. IUlbiq(:tQil}(\:···

1.

Before installation

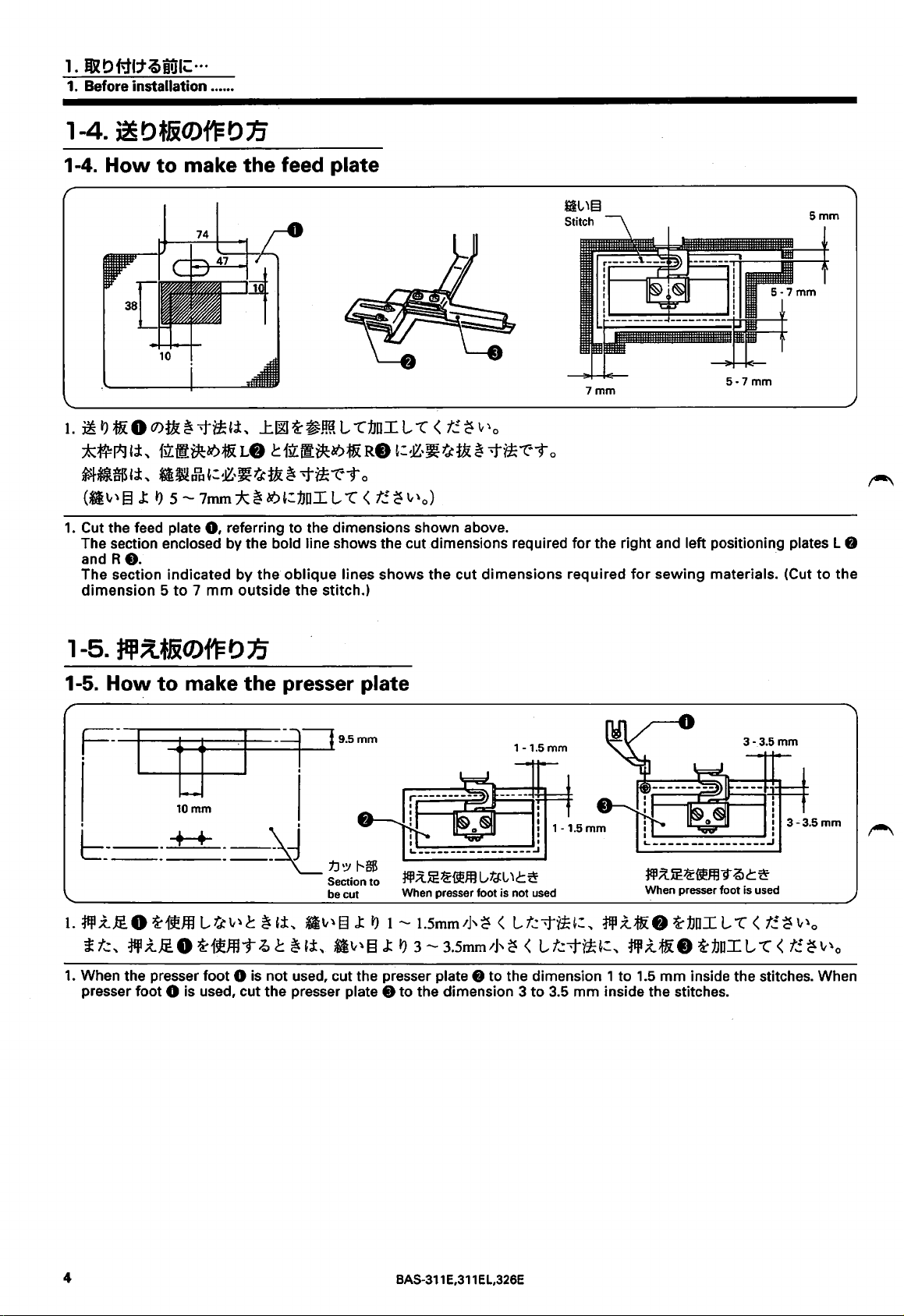

1-4.

How

to make the feed plate

•.•.•.

10

1.

~

l'J

1i 0

O)f!

~

'f~'i,

:i:~I*Hi,

~*lmHi,

(*i"" §

1.

Cut the feed plate

The section enclosed by the bold line shows the cut dimensions required

and R

The section indicated

dimension 5 to 7 mm

flf:tliie&?1&L8 c lli:tl#c&?1&R8

~~Jh~:~-~~t!~

J:

l')

5 -

7mm

0,

8.

J:OO

:k

~

&?

referring

by

the

outside

~~!ffi

L

L"1JDI

L

-c

<

t!.

~:~-~~{!~

-ti*-r'-9 o

':1Jni L

to

oblique

the

-c

<

t!.

~

""o)

the dimensions shown above.

lines shows

stitch.)

the

~

'-'"o

-t~"t"T

cut

dimensions

Jil.,)§

Stitch

7mm

o

for

the right and left positioning plates L 8

required

for

sewing

5-7mm

materials. (Cut

Smm

to

the

1-5. How to make the presser plate

F-1----+--

b---++

----

1.

~X.JE.

£ t.:,

~

1.

When the presser foot 0 is

presser foot

g-+------1

10mm

__

----~

0

~151!ffl

X.JE.

L ~ ""

0

~151!fflT

-~~·:--J

9.5mm

\Jd'

1J'Y

1---$

Section

to

be cut

c

~

,i,

*~""

13

J:

l'J

1 -

o c

~

,i,

*~""

§

J:

l'J

not

used, cut the presser plate 8 to the dimension 1 to

0 is used, cut the presser plate 8 to the dimension 3

1-1.5

¥J!;UE~ffm

When presser foot is

1.5mm

3-

1],

3.5mm

Gta:L-

'c~

~

< L

1]'

~

not

mm

1------fl-:--"~--t

,

___

L

----------------...1

¥JI;{JE~d"Y"

used

t.:-t~':,

< L t.:-ti*,:,

to

3.5

mm

When presser

~X.1i 8 ~1JDI

~X.1& 8 ~1JDI

1.5

mm

inside the stitches.

I

:

.Q

c

is used

-c

L

~

<

"'C

t!.

I

1

:

<

~

3-3.5mm

""o

t!.

~

""o

__;;,;;

___

foot

L

inside the stitches. When

4

BAS-311

E,311

El,326E

Page 6

2.

&t)MI:tn

2.

INSTALLATION

2.

2-1 .

Q)l

b f'i(jJJ' /INSTALLATION

:tEll;{.

rJ9m

/Presser unit

-

...............

__

I.

1fiJ

.Z

JE

1fiJ

.Z

1&: 0 'd:'

I&

tJ

91-

L

't"

,

1fiJ

.Z

JE

8 (

1fiJ

J&tJ91-LiTo

2. *

t)

1&:8

'd:'

1&

t)

91-

L 't",

1JDI

L

t:.~

t)

1&:'d:'

1&

To

1.

Remove the guide plates

foot 8 together

2.

Replace the feed plate 8

made in accordance with

3.

1fii.Z1&:0

4.

91-1fll

.ZJE8 c

.z

JE

1fiJ

.z

1&:

3.

Attach the presser plate 0 to the presser plate holder

4.

Attach the working

sembly

nents

8

with

with

'd:-1f1J.Z;f&*Jv¥-

1fiJ

~

0 t:

1&

to

the presser

guide plates

0,

the work clamp

7 7

t)

foot

and detach the

with

"How

8

:;,.-

7

LA*-0.0

1t

't

i

.,_

8 and the presser crank LA as-

ar'm

0.

8.

the

feed plate

to

make the feed plate."

~:~&

t)

1t£ti't

'd:'*'

X.Ja8

0

C!),

and fix these ·compo-

.·

work

X.

8)

t)

#£t

clamp

that

o

~:,

'd:'

i

was

1fiJ

8.

--

..

:~

5.

1)l:f1~&?1&:R0

c

1)l:i1~&?1&:L4D

~91-~X.JE&~:l&

1ttt£To

5.

Attach the positioning plate R «!)and the positioning plate

L

tJ)

to

the working

foot

8.

t)

BAS-3 1 1

E,3

1 1 E

L,326E

5

Page 7

2. llit>MI:tn

2.

INSTALLATION

2-2.

IJ7-IJ9ii

2-2. Pneumatic system

1.

.r{Jv

r

7J

;'\-

0,

1ftUiii7J

(

~

~

:/

(J)JD(tj~PJH~F~fflO

1.

Remove the belt cover 0 and the side cover

(Refer to the Instruction Manual for the sewing machine.)

;'\-

8

~1&

t'J

~Li-to

8.

2.

:I*'7·?

3.1[S;'\Jv/f),

4 .

.OC~JfJ

JDl.

s .

.OC~JfJl[ift;'\Jv/*-0.

2.

Push

3.

Remove the solenoid valve 8 and

4.

Install the solenoid valve 8 and

valve assembly

5.

Install the reversal solenoid valve assembly 0 to the leg.

80)@$~~L

l[ift;'\

t'J

#~ti

To

down the

8,

Jv

/*-D.

part®

0.

r~f,

:I*'7?8,

0

~:JD(

t')

0

~

JJI4I

':JD(

of

the connector

:r..7-7-:1.-7·

1:/'T~v-?8,

~Lt.:

t?ta;'\

t'J

1-J·'t i "to

8,

8,

the connectors

8,

the connectors

Jv

/8,

and pull out the air tubes

(4*)

8,

8

~51~!!~

.:r..7--:<77-8~l&t'J~Li"to

(t,

:I

*' 7 ?

8,

the integrator 8 and the air muffler

the integrator 8 and the air muffler 8 to the reversal solenoid

8,

(4

iTo

1

pes)

:/

7

8.

~

v-

?

8,

8.

.:r..

7

--:<

7

7-

8

~

6

BAS-311 E,311EL,326E

Page 8

~

6.

::1;;

r

o-

7.

J~Jv:fJ\-

s.

.OC~Jfl

:fb:#

tift;~

iTo

Jv~

'J 7 .A(J)jf

*'.A

(12P)

Jv

:141)

(~lil&1tli)

CD>~~~

(J) ~ ;;

? -

iTo

~

"T

Jv

(

ttilt

~

IJJHti

1::.-:'

;;

To

(

,

41ft: ~ ;; )

~

~;,.,

(J)J&fll~I~Jl&$Jm)

~;

~

Jv

:1;

\-

*'

.A

8

(J)

::1

*'

2.

IIROMI:t1J

2. INSTALLATION

7 ? ttl=..

41=

~:

£

L.

6.

Open the control box cover (circuit board installation plate). (Refer

7. Disconnect the

8.

Insert the pin terminals

2-a.

2-3.

~m

Piping

valve harness

(#11,

(12P)

Cl>.

#4)

of

the reversal solenoid valve

to

the Instruction Manual

tD

into connectors

for

the sewing machine.)

#11

and #4 on the valve harness

Cl>.

1.

Connect each air tube

to

the locations with identical numbers.

BAS-311

E,311 E L,326E

7

Page 9

2.

u

t>

i'il:tn

2.

INSTALLATION

1

2 .

.&!Iii~

3.

""'Jv

2.

Bind the air tubes from the reversal cylinder with a spiral tube.

3.

Install the belt cover 0 and the side cover

) "'./

~-(J):r_

~

7.7

;'\-

o

..

ili~W

71-

:J..-7·"1i:

7.7

;'\-

8

Al'L{

"li:

~

7'Jv1-

tJ

1t~t

f).

.:r..

-7"1:'*tJ

~-to < ~

(Refer

~ / (J)~t.&~sti!IH!t=~Jm)

to

the Instruction Manual

~-to

for

the sewing machine.)

2-4. 7-'(

2-4. DIP

switch

':1

-:17..-1

':1

70)tJJ

selection

bli;{.

(C::j:£10

71

·:;"'/A 1

<

f!.

~

v"o

1.

71

·:;

L~To

*

.&!lii~tl

No.3 t No.6

[Caution]

Be

sure to turn

DIP

switch settings.

1.

Turn the selectors No.3, No.4 and No.6 on the

@to

"ON".

* When the reversal crank device is

selectors No.3 and No.6 on the

"'/;A

·:;

7-(J)~J!(J)~~:

1

·:;

7-@

(J)

No.3, No.4 t

"li:15f!ffl

L

1j:

""

"li:

"OFF"

off

the power before changing any

'

t

~

~:

,i,

,i,

71

L "( <

DIP

1l--r~ili.~ID

t!.

not

'?

"(

No.6~

~

switch to "OFF".

"ON".':

7 "'/A 1

':J

v"o

of

DIP

switch

used, turn the

1-(J)

the

~

8

BAS-311

E,311 E L,326E

Page 10

3.~~

3.

ADJUSTMENT

3.~~

3.

ADJUSTMENT

3-1 .

g;g~J±O)~~

3-1. Adjustment of air pressure

I.

~Jn.EE

<~~JJ)~)

'j:, 0.49MPa (

1

/77·v-~

Q

5kgf

O)J\/

2

/cm

-r-f~ffll

)

r·Jvf)~51~

';t

To

..

tJfl"il't?

!Hill"{Tlj:v'';tTo

w.l~f.fTi~'i,J\/

!-"Jvf)~r""'-:ttfll-co-;;7l;t

T o

2.

JX!Piffl

x.

t::.

:,-

e:

~ ~=,

'J

:;..-

1'0)~3n_EE,i,

~P

x.

7 7

:;..-

7

o

:flll

.:t.W:O-r-~~!}o/.1

n~

&!Pi-t

.Q

!lm!W

~:flll

~

1*1

~=

l

;t

T o

<~~JJ)~)

:r..

7-

v.::r;J.

v-

~

0

0);\

:;..-

r·

Jv

0

~51

~..tffl"

il'

t?

@J

ll"{Tv,

fful~*~

T1~'j:;

;t

\

/

-t

o

r:·

Jv

0

~

r

""-:fill

L

-co

-;;

7 L ;t

To

3. 1

:;..-

-r

7·

v-

~

0

0)

*.

r

;~-ti*J

~=71<1.1{t::_

1/~-;;7Q~~~O)~~~@ll"7J<~~~';tT

1.

Air

pressure should

The

air

pressure can

ing

the co

ntr

ol knob

After adjustment is complete, push the

downw

2. Adjust the

within such a

versely wh

su

For adjustment, pull up and,

the

Aft

to

3.

If

drain cock

drain the water.

ard

to

air

en

re plate

air

er adjustment is complete, push the handle 0

lock it.

wat

er stands in the

pressing the sewing material

0.

regulator

f)

be

0.49 MPa [5 kg/cm

be

adjusted by pulling up and turn-

f)

on the

lock it.

pressure

ra

nge that the presser crank G rotates re-

0.

in the direc

for

bott

integrat

the reversal cyli

turn

the control knob 0 on

le of the integrator 0 ,

tion

indicated

;t ·:d.:: t?,

2

).

or

0.

contro

nder

wit

by

an a

r·

v

o

l knob

f)

to

stay

h the pres-

down

turn

the

rrow

to

BA

S-311 E,311EL,326E 9

Page 11

3.~~

3. ADJUS

TMENT

3-2. Adjustment of

3-3. Adjustment of

the

positioning plates

1.

*'lv'EI

~l~~.-~c8~~~~-z:-~

L,

iT

it.:,

~

C 8

1.

Loosen the screws

sitioning

out

betw

Nex

t, loosen the screws

positioning

evenly laid o

the

presser crank horizontal position

<fiJI

;t?

5:;?

1

JX~i

~

~~.

When

Loosen the nut 0 and push in or pull o

0 so

reversal cy linder pl

)

~

'

:jifl

;Z

#Jv

the

that

(A)

7'P7~J

v01

:Ml"Z:"IVri~:1JioJi1t:!S)~I:~

•~

~•R•~••

o

:tc:ti:1JioJii*1

~ ~ ~ ~ "Z:"

plate R

een the

plate L 0 so

ut

tJ

/ .y

{/)

7 7 / 7 8

~ G~l±ll.Ahl"Z:"RJlliTo

presser

the presser crank

v'EI

(

f

}[:Ji;'R:~

f),

and adjust the

f)

so

that

the label 0 can be evenly la

front

and back seams (A).

8,

that

between the le

':EifflU(J)

-j'

7 /

-/.){7](

crank

unger

t:

:;

.if 1:

is

0 is

~

-\'

in

f)

>

0

B)

iJf:lSJ~I:~~

-

L0

~--l

position

and adjust the posi

the presse r plate can be

ft

and

right

~

:ti""'"'

~

~ l ~

1:'

the

right

position

ed

ut

hor

to th

can be

mov

l

seams

-?

I

fit'

-j-

·:;

the a

djusting bolt

izontal

e ri

ght

~

iT

of

tion

l±l

~ 8 ~

when

extreme.

1:,.

o

the

of the

(B)

L,

t.:

po-

id

.

C:

~

the

tJta:l'le(

D

DO

~

R/ W

BA

0

~~

0~

:>.~-·

05PEEQ

0

IAtJ?

B.T.

COUNTER

0

:>.7'•J·~~N

SPUT NO.

D

S-3

:~=...,

:.-9-

00E

r!tNU

I

O.

series

un

l

@~

(

til~)

I.

77.

~

.

il

0

POWE

R

;fffi

*

2.

:Jifi;Z

*:Jifl

3.

-T.A

Verification

1.

Whil

sw

*

2. Tread th e presser li

* Make s

3.

Press th e test switch again to e

7.1·:;-T0~

liT

o

3!Vf-i1'

_Uf~.YJ

:Jifl

X..

(

7 8

X..

~

-?

~.A1

e press

itch

Th

e indi

Verify th

(

tr

od, the presser cran k

pr

esser plate 0 and the pos

( C

_t

1 f

~

.Y

il{:tc:ti

7 7 / 7 8

"("

"'

~

v'

>'T0~

ing the test swit

0.

cator shows

at

whenever

ure th

:Jifl

l.,~i1{t.>~/m:.A

,:;

)

C: ~ iJ iTo

v f)

~lf6}j.i-f

Jv

8

~

1:

JX~i

~

-1.1''.

:Jifl

il'lii

-/.)

>

~

:Jifl

-tC:Ml~~hiT

lf6

tr

<

iJ

~ l

X...

"("

< t

ch

.::

o

C:

9

:.

0,

C ~ .

fte

r pedal 8 .

the

presser

f)

flip

s le

at the presser crank

itioning

nd the test

1·:;-T0

1: , :Jifl

~

;Z

7 7 / )

i-t

o

C:

f}[:R

;'R:~-

"'

0

press the read/write

lift

er pedal 8 is

ft

or right.

f)

does

plate R

o

not

mod

R0

hit the

0.

e.

~

1:

10

BAS-311 E,3

11

E L,326E

Page 12

3-4. Adjustment of the presser plate lifting speed

t.

~tmr\Jv 7 0)~~~~

t:.

8

a-lill

...tfHUO)n~1n:*f

0)~~~*!

•

tm;~

• iftiQ;

1.

Loosen the nut 0 on the exhaust air throttle valve

Slower

the solenoid valve, and turn the adjusting screw 8

adjust the presser plate lifting speed.

The upper exhaust air throttle valve adjusts the presser

plate ascending speed,

throttle valve adjusts the descending speed.

· Solenoid valve

· Solenoid valve ®

3.1111

3. ADJUSTMENT

t'J

1f0)

7-

7 r 0

L

"t"ftv~

t'J

#'±:f11J..t7.1{r7.1{~

Jv

7

~

Jv

7·

iTo

t'J

#tt:f11J..t

7.1f...t7.1f.Q

c

Q}·····:f111

®· · ··

..ttim

·

·1ll:tl~~tim

while

<D

••••••

for

the presser plate

......

for

the positioning plates

a-~

c

~

0)~

~

O))l~

the

lower

.Q

~,

im.Jftil

~a-,

'l:~~

LiTo

exhaust

h

r·nm

for

to

air

'

BAS-311

E,311

EL,326E

,.,

Page 13

4.11!1

4.

·NOTES

TO

SEWING

OPERATIONS

4. NOTES TO SEWING OPERATIONS

1.

~

Lllv'Q)~IHHi,

Reference point

1.

Reverse stitching is possible within 4.5

from the reference point.

*lv'MlN'JQ)£~.~J:

mm

l'J

ti:;f:i~:

left and right

:{pO)J!jl(b

Thickness

of

material

ll~~tJ{fJv'jj.g.,

2.

oc~T

.Q

c

~, ~tc

~~+

~:;iHj§£,~

t.:.

t!.

L,

:i!!)!!t~tJ{ft~jt

~

1~Q)jf*'1.J{~·~W.J:J:~

-Jil/J,ffi!M~:

(~$Q)jf*'~~

2.

For thick materials, provide a shunting point at the last

needle position in the program to prevent the presser

crank

pleted.

If

the shunting point is

tion, the needle thread after thread trimming may be too

long.

tance from the last stitch position.

~~

0 from striking the needle after sewing is com-

Set the shunting point at the shortest possible dis-

ilv'~t> ~ 1~~:;f1JJ

~t.:.

~

~"'

J:-?

~::to

a-~~t""C

L

""C

,i,

(

f!.

~

v'o

J:

l'J

~tt~

<

~

<

t!.

~

v'o

35-

40mm

too

far from the last stitch posi-

.Q.::

"t"'T

c

~·""C

.:t

7 7 ~ 7

~7 A Q)~

"'

.Q

tJ{~

tJ

"£

o)

c,

TQ)'t",

OiJ{

r-'\

*W

12

BAS-311E,311EL,326E

Page 14

••

••

77t:t-J:IIfli"tGf.l:

um~B.ijlf

INSTRUCTION MANUAL

BROTHER

=f467-8562

Printed

INDUSTRIES,L

~i!imiflliMii~}D.J~-

in

Japan

TO.

NAGOYA,JAPAN

TEll

Ill~

TEL(052)824-2392

151-Vll,V12,V26

S93Vll-221

1999.03

BCD

Loading...

Loading...