Page 1

SERVICE MANUAL

BAS-311E,311EL

BAS-326E,326EL

Please read this manual before making any adjustments.

PROGRAMMABLE ELECTRONIC PATTERN SEWER

WITH CYLINDER BED

Page 2

This service manual is intended for BAS-311E, 311EL and 326E; be sure to read the BAS-311E, 311EL,

and 326E, 326EL instruction manuals before this manual.

Carefully read the “SAFETY INSTRUCTIONS” below and the whole of this manual to understand this

product before you start maintenance.

As a result of research and improvements regarding this product, some details of this manual may not be

the same as those for the product you purchased.

If you have any questions regarding this product, please contact a Brother dealer.

SAFETY INSTRUCTIONS

z Safety indications and their meanings

This instruction manual and the indications and symbols that are used on the machine itself are provided in

order to ensure safe operation of this machine and to prevent accidents and injury to yourself or other

people. The meanings of these indications and symbols are given below.

Indications

DANGER

CAUTION

Symbols

.................This symbol ( ) indicates something that you should be careful of. The picture

.................This symbol (

.................This symbol (

The instructions which follow this term indicate situations where failure to

follow the instructions will almost certainly result in death or severe injury.

The instructions which follow this term indicate situations where failure to

follow the instructions could cause injury when using the machine or physical

damage to equipment and surroundings.

inside the triangle indicates the nature of the caution that must be taken.

(For example, the symbol at left means "beware of injury".)

) indicates something that you must not do.

) indicates something that you must do. The picture inside the

circle indicates the nature of the thing that must be done.

(For example, the symbol at left means "you must make the ground connection".)

BAS-311E.311EL.326E.326EL

i

Page 3

x Notes on safety

Wait at least 5 minutes after turning off the power switch and disconnecting the power cord from

the wall outlet before opening the face plate of the control box.

Touching areas where high voltages are present can result in severe injury.

DANGER

CAUTION

Installation

Machine installation should only be carried

out by a qualified technician.

Contact your Brother dealer or a qualified

electrician for any electrical work that may

need to be done.

The sewing machine weights more than

BAS-311E60kg,BAS-311EL·326E·

326EL65kg. The installation should be carried out by two or more people.

Do not connect the power cord until installation is complete, otherwise the machine

may operate if the start switch is pressed

by mistake, which could result in injury.

Be sure to connect the ground. If the ground

connection is not secure, you run a high risk

of receiving a serious electric shock, and

problems with correct operation may also

occur.

Sewing

Be sure to wear protective goggles and

gloves when handling the lubricating oil and

grease, so that they do not get into your eyes

or onto your skin, otherwise inflammation can

result.

Furthermore, do not drink the oil or eat the

grease under any circumstances, as they can

cause vomiting and diarrhoea.

Keep the oil out of the reach of children.

Avoid setting up the sewing machine near

sources of strong electrical noise such as

high-frequency welding equipment.

If this precaution is not taken, incorrect machine operation may re

Have two people present to hold the machine

head with both their hands when tilting it back

or returning it to its original position.

This sewing machine should only be used

by operators who have received the

neccessary training in safe use beforehand.

The sewing machine should not be used

for any applications other than sewing.

Attach all safety devices before using the

sewing machine.

If the machine is used without these devices

attached, injury may result.

Turn off the power switch at the following

times, otherwise the machine may operate

if the start switch is pressed by mistake,

which could result in injury.

• When not using the machine

• When leaving the machine unattended

ii

BAS-311E.311EL.326E.326EL

Do not touch any of the moving parts or press

any objects against the machine while sewing, as this may result in personal injury or

damage to the machine.

If an error occurs in machine operation, or if

abnormal noises or smells are noticed, immediately turn off the power switch. Then

contact your nearese Brother dealer or a

qualified technician.

If the machine develops a problem, contact

your nearest Brother dealer or a qualified

technician.

If using a work table which has casters, the

casters chould be secured in such a way so

that they cannot move.

Page 4

CAUTION

Cleaning

Turn off the power switch before starting any

cleaning work, otherwise the machine may

operate if the start switch is pressed by mistake, which could result in injury.

Maintenance and inspection

Maintenance and inspection of the sewing

machine should only be carried out by a

qualified technician.

Ask your Brother dealer or a qualified electrician to carry out any maintenance and

inspection of the electrical system.

Turn off the power switch and disconnect

the power cord from the wall outlet at the

following times, otherwise the machine may

operate if the start switch is pressed by mistake, which could result in injury.

• When carrying out inspection, adjustment

and maintenance

• When replacing consumable parts such

as the rotary hook and knife

Disconnect the air hoses from the air supply and wait for the needle on the pressure

gauge to drop to "0" before carrying out inspection, adjustment and repair of any parts

which use the pneumatic equipment.

Be sure to wear protective goggles and

gloves when handling the lubricating oil and

grease, so that they do not get into your eyes

or onto your skin otherwise inflammation can

result.

Furthermore, do not drink the oil or eat the

grease under any circumstances, as they can

cause vomiting and diarrhoea.

Keep the oil out of the reach of children.

If the power switch and air need to be left on

when carrying out some adjustment, be extremely careful to observe all safety precautions.

Use only the proper replacement parts as

specified by Brother.

If any safety devices have been removed, be

absolutely sure to re-install them to their original positions and check that they operate

correctly before using the machine.

Any problems in machine operation which

result from unauthorized modifications to the

machine will not be covered by the warranty.

Have two people present to hold the machine

head with both their hands when tilting it back

or returning it to its original position.

BAS-311E.311EL.326E.326EL

iii

Page 5

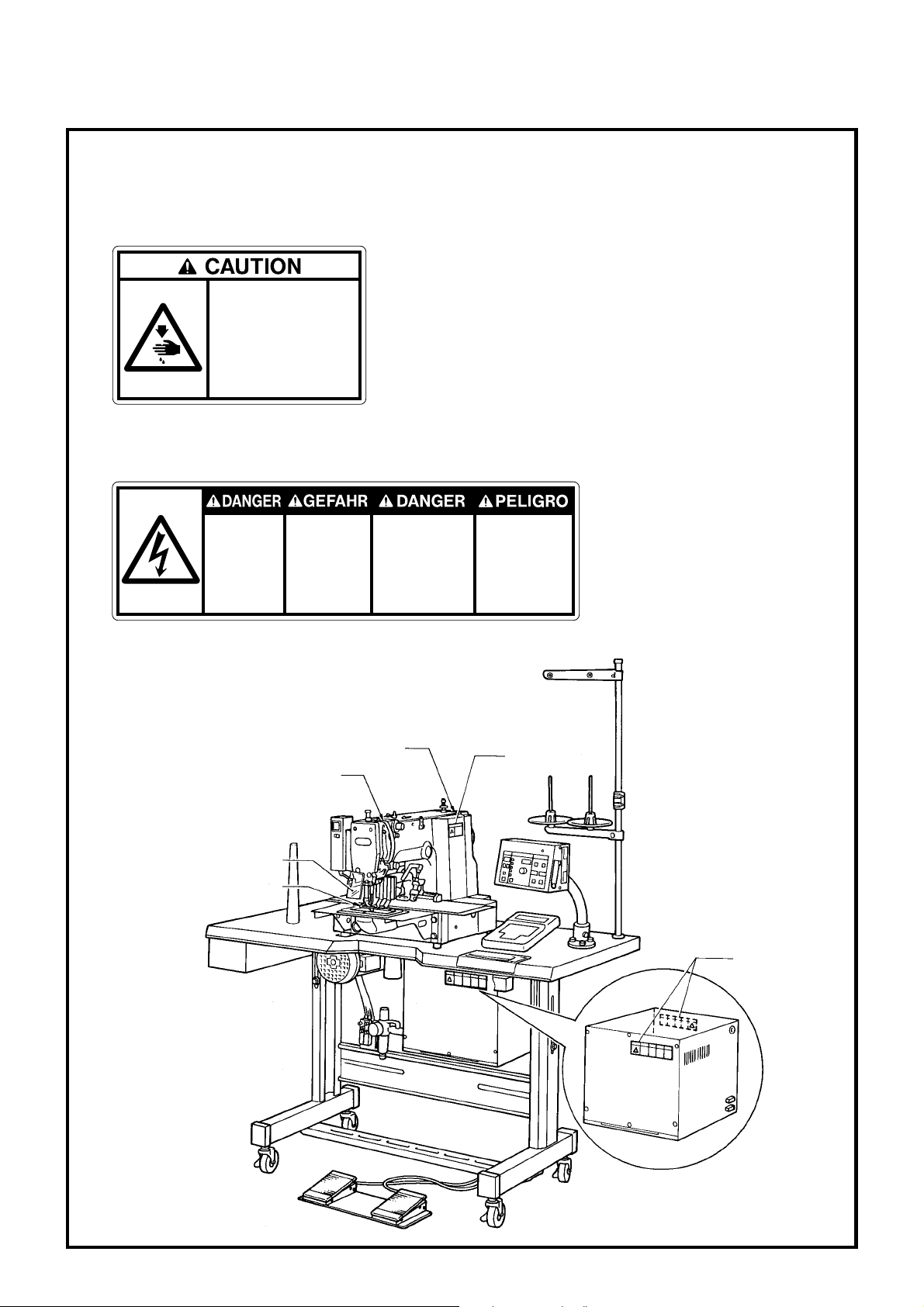

c Warning labels

★The following warning labels appear on the sewing machine.

Please follow the instructions on the labels at all times when using the machine. If the labels have

been removed or are difficult to read, please contact your nearest Brother dealer.

1

Moving parts

may cause injury.

Operate with safety de vices .

Turn off main switch before

threading, changing bobbin

and needle, cleaning etc.

Safety devices: Thread take-up cover,

Eye guard, Belt cover,

Finger guard, etc.

2

Hazardous voltage

will cause injury.

Turn off main

switch and wait 5

minutes before

opening this cover.

Hochspannung

verletzungsgefahr!

Bitte schalten sie den

hauptschalter aus und

warten sie 5 minuten,

bevor sie diese

abdeckung öffnen.

Un voltage non adapté

provoque des blessures.

Eteindrel'interrupteur et

attendre 5 minutes

avantd' ouvrir le capot

Un voltaje inadecuado

puede provocar las

heridas.

Apagar el interruptor

principal y esperar 5

minutos antes de abrir

esta cubierta.

[BAS-311E]

Eye guard

Finger guard

Belt cover

Thread take-up

cover

1

1

2

iv

BAS-311E.311EL.326E.326EL

Page 6

Explanation of models

This manual explains three models

•BAS-311E (Solenoid type, Pnevmatic type), 311EL (Pnevmatic type), 326E, 326EL

(Pnevmatic type)

Explanation for individual model is provided by identifying the model name. Check the

model before useing the machine.

INDEX

Chapter 1. Mechanical description ........................................................... 1

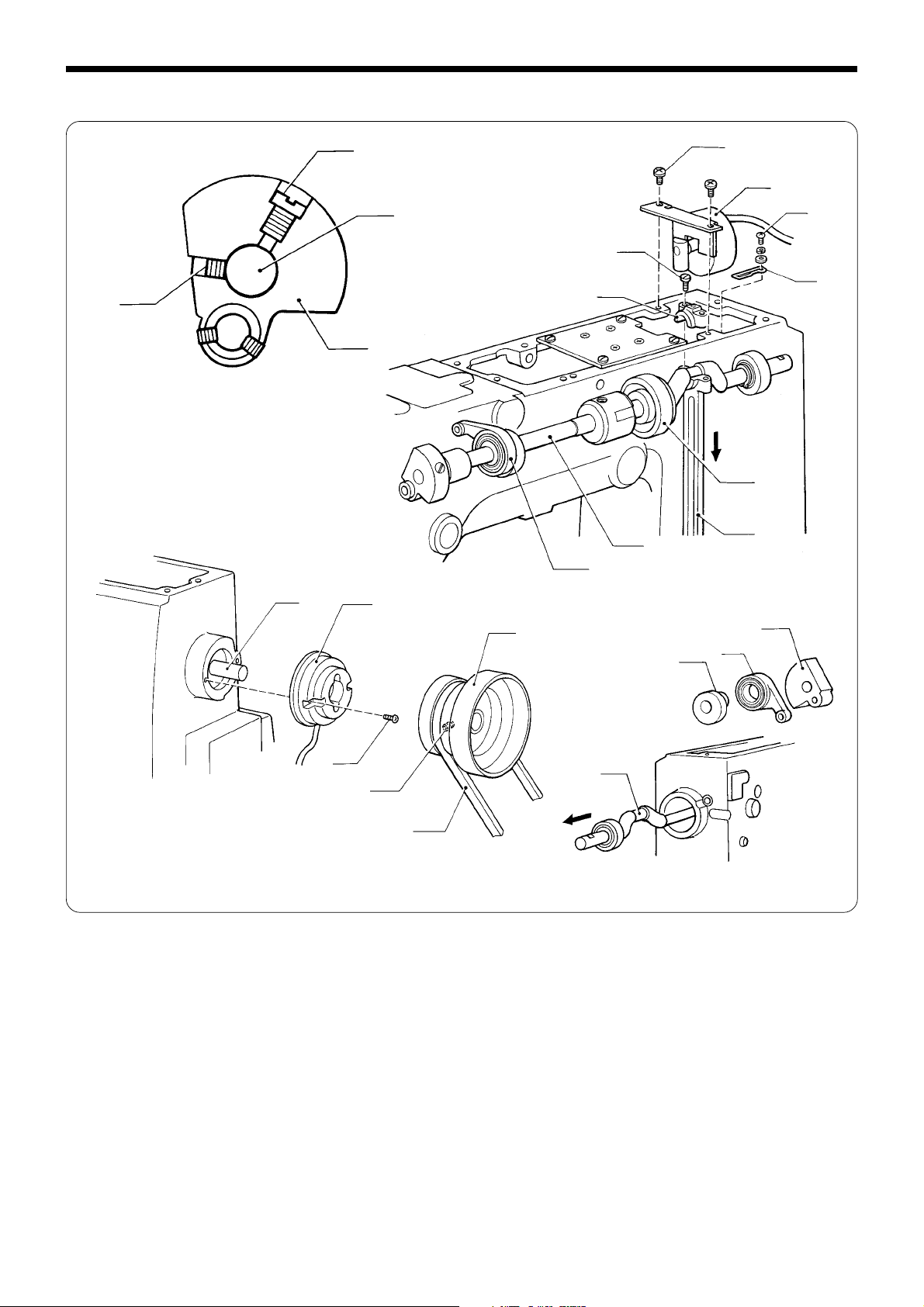

1. Needle bar, thread take-up, lower shaft and shuttle hook mechanism................. 1

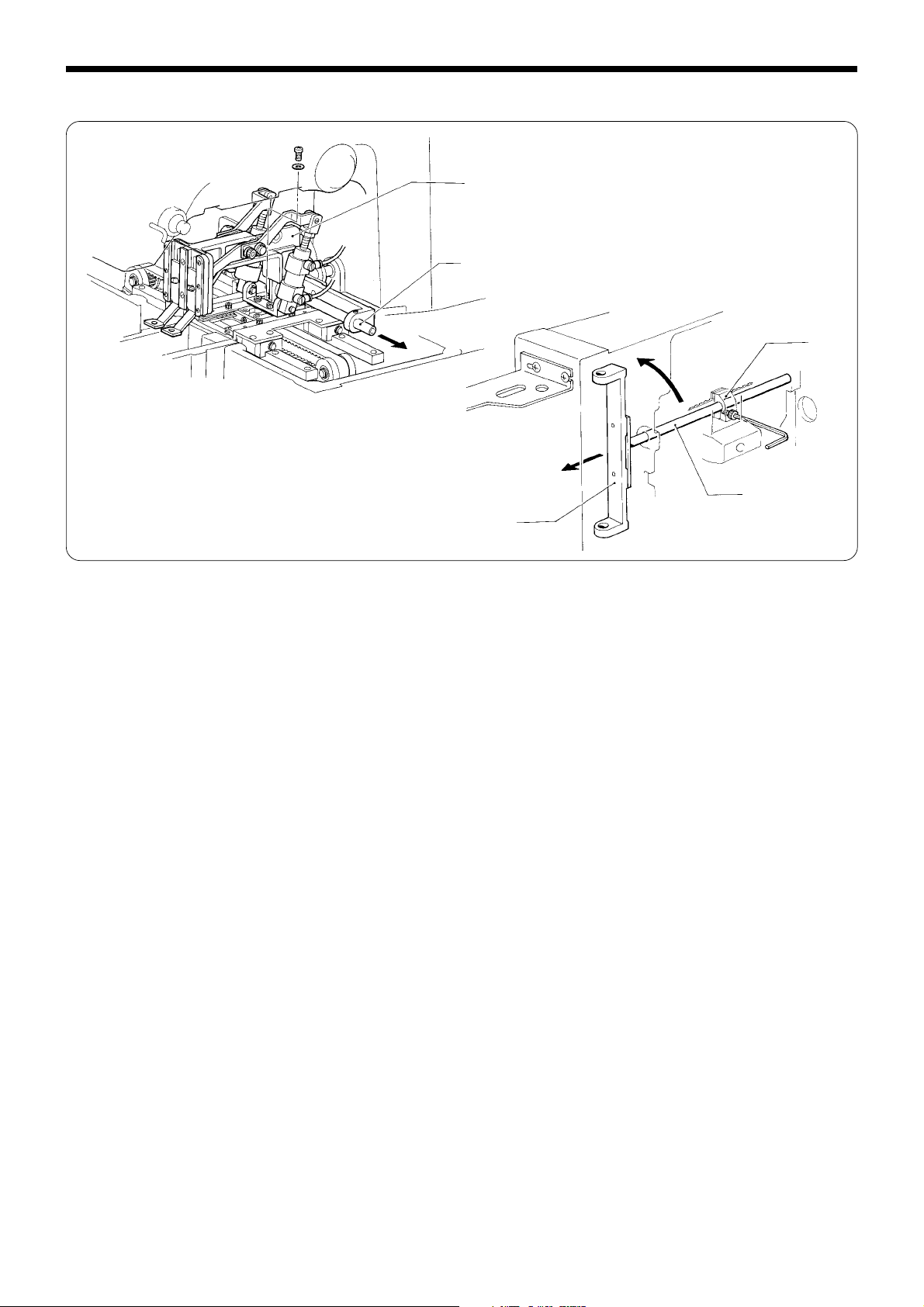

2. Work clamp lifting mechanism (1)(2) ....................................................................... 2

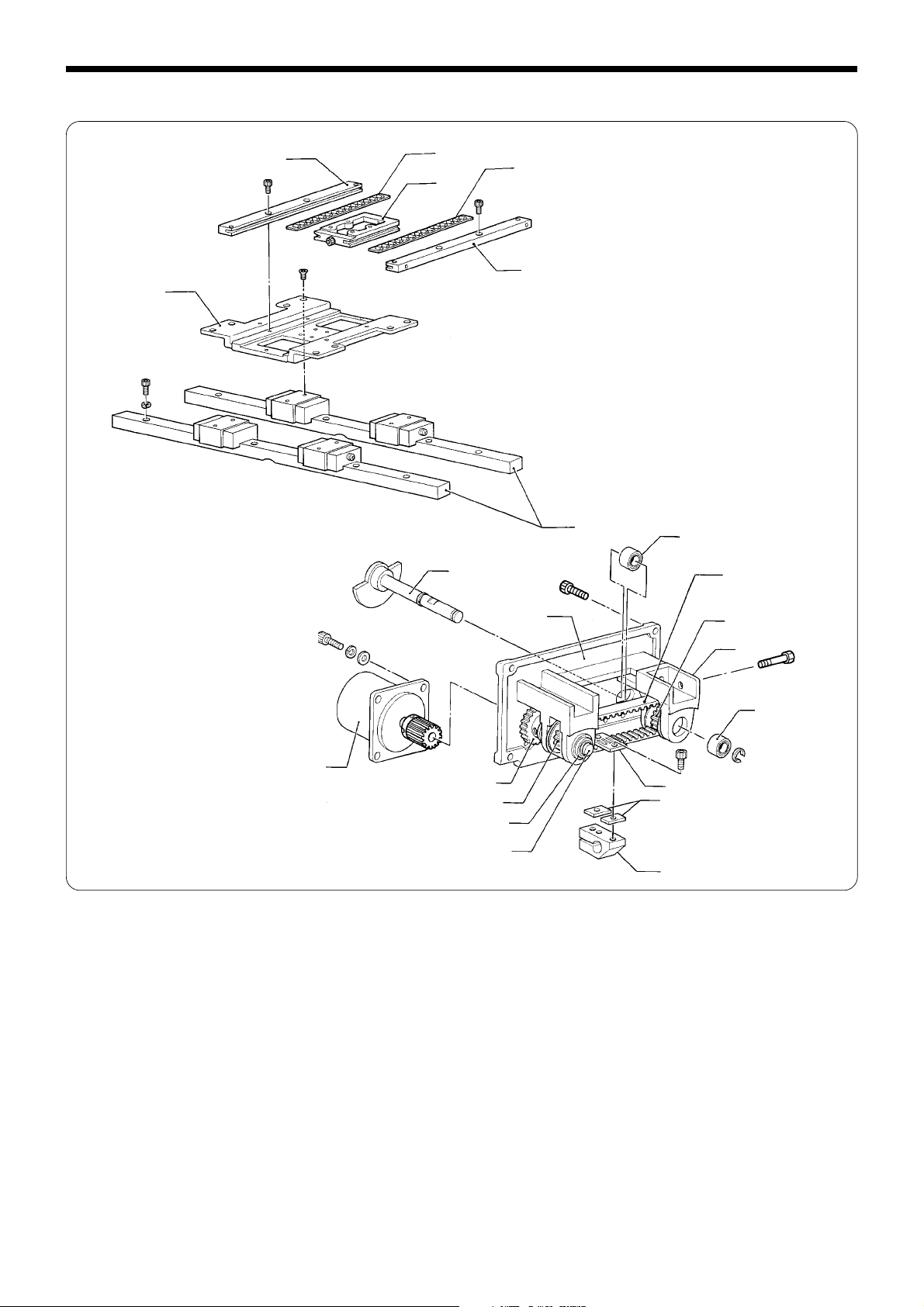

3. Feed mechanism (X axis) .......................................................................................... 4

4. Presser foot mechanism (1)(2) .................................................................................. 6

5. Thread trimmer mechanism ..................................................................................... 8

6. Thread nipper (1)(2) when presser foot rises ......................................................... 9

7. Thread wiper (1) (2).................................................................................................... 10

Chapter 2. Disassembly ............................................................................. 11

1. Covers (1)(2)(3) ........................................................................................................... 11

2. Feed mechanism ........................................................................................................ 13

3. Presser foot mechanism ............................................................................................ 14

4. Needle bar mechanism.............................................................................................. 15

5. Upper shaft mechanism ............................................................................................ 16

6. Feed mechanism (Y axis)(1)(2)(3) ............................................................................. 17

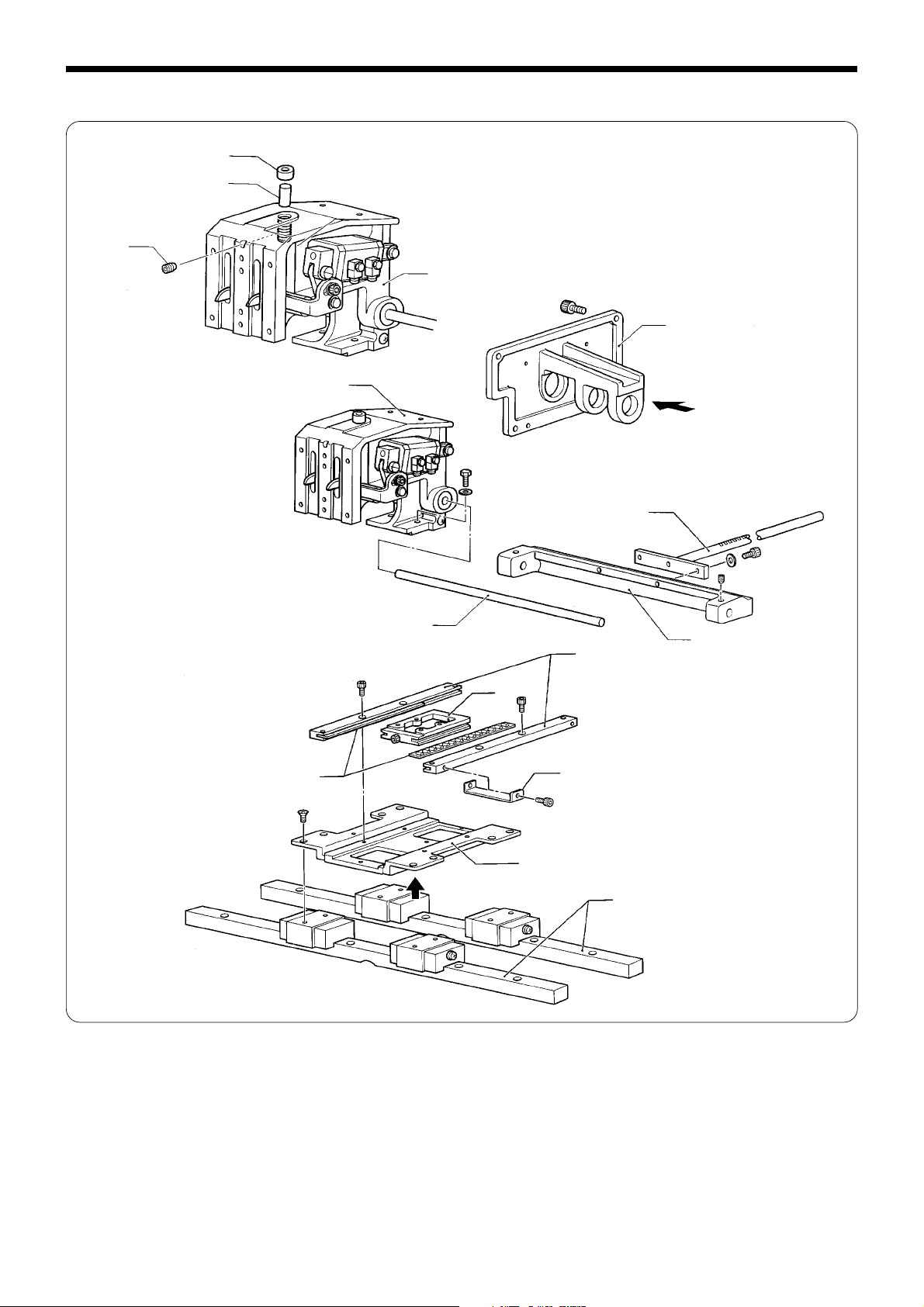

7. Feed mechanism (X axis)(1)(2) ................................................................................. 20

8. Lower shaft mechanism ............................................................................................ 22

9. Work clamp lifter (Solenoid type) ............................................................................. 23

10. Thread nipper mechanism ........................................................................................ 24

11. Thread trimmer mechanism .................................................................................... 25

Chapter 3. Assembly .................................................................................. 26

1. Thread trimmer mechanism (1) ................................................................................ 26

2. Thread nipper mechanism ........................................................................................ 27

BAS-311E.311EL.326E.326EL

Page 7

3. Work clamp lifter mechanism .................................................................................. 29

4. Feed mechanism (X axis) .......................................................................................... 31

5. Feed mechanism (Y axis) .......................................................................................... 35

6. Upper shaft mechanism ............................................................................................ 39

7. Needle bar mechanism.............................................................................................. 40

8. Presser foot mechanism ............................................................................................ 41

9. Lower shaft mechanism (1) ....................................................................................... 43

10. Lower shaft (Rotary hook) (2).................................................................................... 44

11. Thread trimmer mechanism ..................................................................................... 45

12. Feed guide mechanism (Home position adjustment: X ) ....................................... 46

13. Covers ......................................................................................................................... 49

Chapter 4. Adjustments ............................................................................. 51

1. Adjusting the needle bar height adjustment ........................................................... 51

2. Adjusting the needle bar lift amount........................................................................ 51

3. Adjusting the needle clearance................................................................................. 52

4. Adjusting the driver needle guard ............................................................................ 52

5. Adjusting the shuttle race thread guide ................................................................... 52

6. Adjusting the two-step work clamp lift amount ...................................................... 53

7. Adjusting the movable knife ..................................................................................... 55

8. Adjusting the lowest point of the presser foot ........................................................ 58

9. Changing the presser foot lift ................................................................................... 59

10. Wiper adjustment....................................................................................................... 60

11. Adjusting the home position..................................................................................... 61

12. Adjusting the tension of the timing belt .................................................................. 64

13. Adjusting backlashes ................................................................................................. 66

14. Adjusting the driving lever stopper position ........................................................... 67

15. Adjusting the thread trimmer driving lever position .............................................. 67

16. Work clamp lift components for manual operation (Solenoid type) ..................... 68

17. Adjusting the presser foot height ............................................................................. 68

18. Adjusting the needle up step position ..................................................................... 69

BAS-311E.311EL.326E.326EL

Page 8

Chapter 5. How to make up the work clamp........................................... 70

1. How to make up clamping type work clamp ........................................................... 70

2. How to make up cassette type work clamp ............................................................. 71

Chapter 6. Power supply and electrical parts adjustment ..................... 73

1. Precautions at the time of adjustment ..................................................................... 73

2. Components inside the control box ......................................................................... 73

3. Fuse explanation ........................................................................................................ 74

4. Connectors.................................................................................................................. 75

5. DIP switches ............................................................................................................... 82

6. Changing special functions using the memory switches ....................................... 86

7. Checking the input sensor and DIP switch input ..................................................... 90

8. Checking the input voltage........................................................................................ 91

9. Clearing all memory settings .................................................................................... 91

10. Confirming software version .................................................................................... 92

11. Error codes ................................................................................................................. 93

Chapter 7. Trouble shooting ..................................................................... 95

Flowchart .................................................................................................................... 95

Problem solution and measures ............................................................................... 101

Chapter 8. 1. Gauge parts list according to subclasses .......................... 112

Chapter 9. Gauge parts list........................................................................ 113

Chapter 10. Option parts ............................................................................. 123

Control Block diagram ............................................................................................... 140

BAS-311E.311EL.326E.326EL

Page 9

Chapter 1. Mechanical description

Chapter 1. Mechanical description

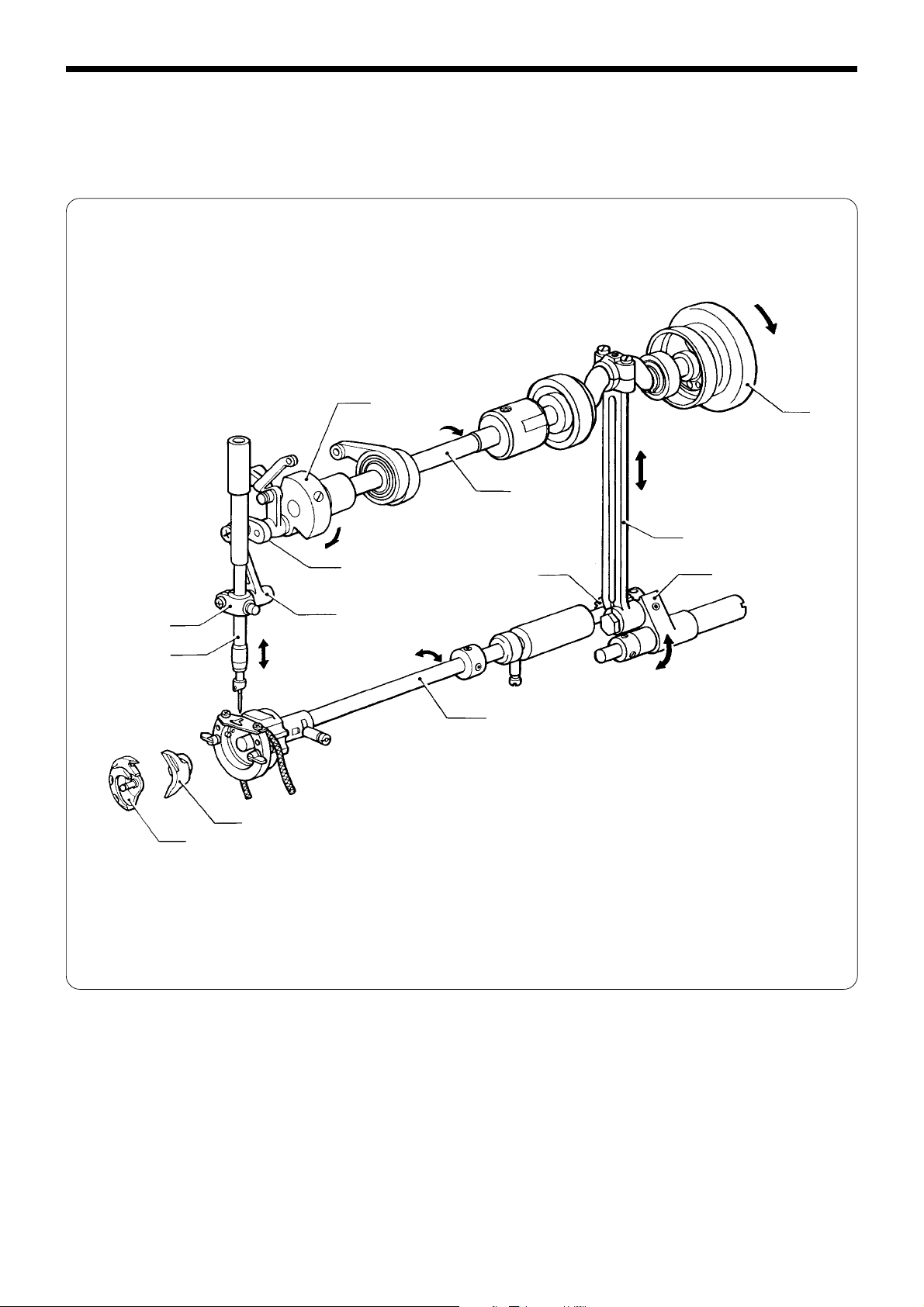

1. Needle bar, thread take-up, lower shaft and shuttle hook mechanism

y

u

!3

!2

t

r

e

!1

w

!0

q

i

o

1. When the machine pulley q rotates in the direction of the arrow, the upper shaft w rotates, then it rotates the thread

take-up crank e.

2. The needle bar crank r, attached to the thread take-up crank e, moves the thread take-up lever t.

3. The needle bar u attached to the needle bar clamp y is moved up and down.

4. When the machine pulley q rotates in the direction of the arrow, the crank rod i attached to the upper shaft w moves

up and down.

5. The crank rod i oscillates the attached rock gear o.

6. The rock gear o oscillates the lower shaft !1 through the lower shaft gear !0. The lower shaft !1 oscillates the attached

driver !2 and inner rotary hook !3 in the shuttle hook mechanism.

BAS-311E.311EL.326E.326EL

1

Page 10

Chapter 1. Mechanical description

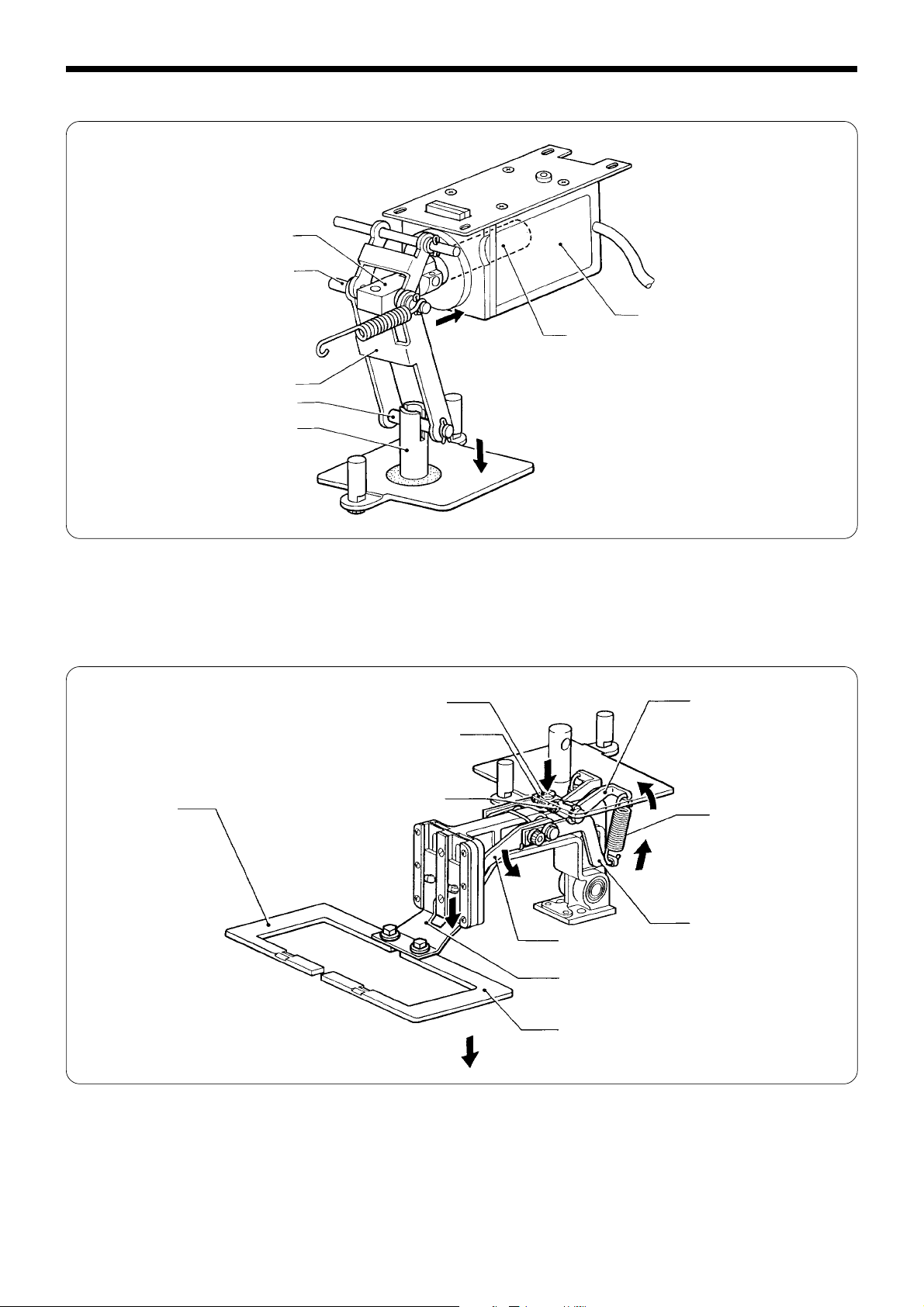

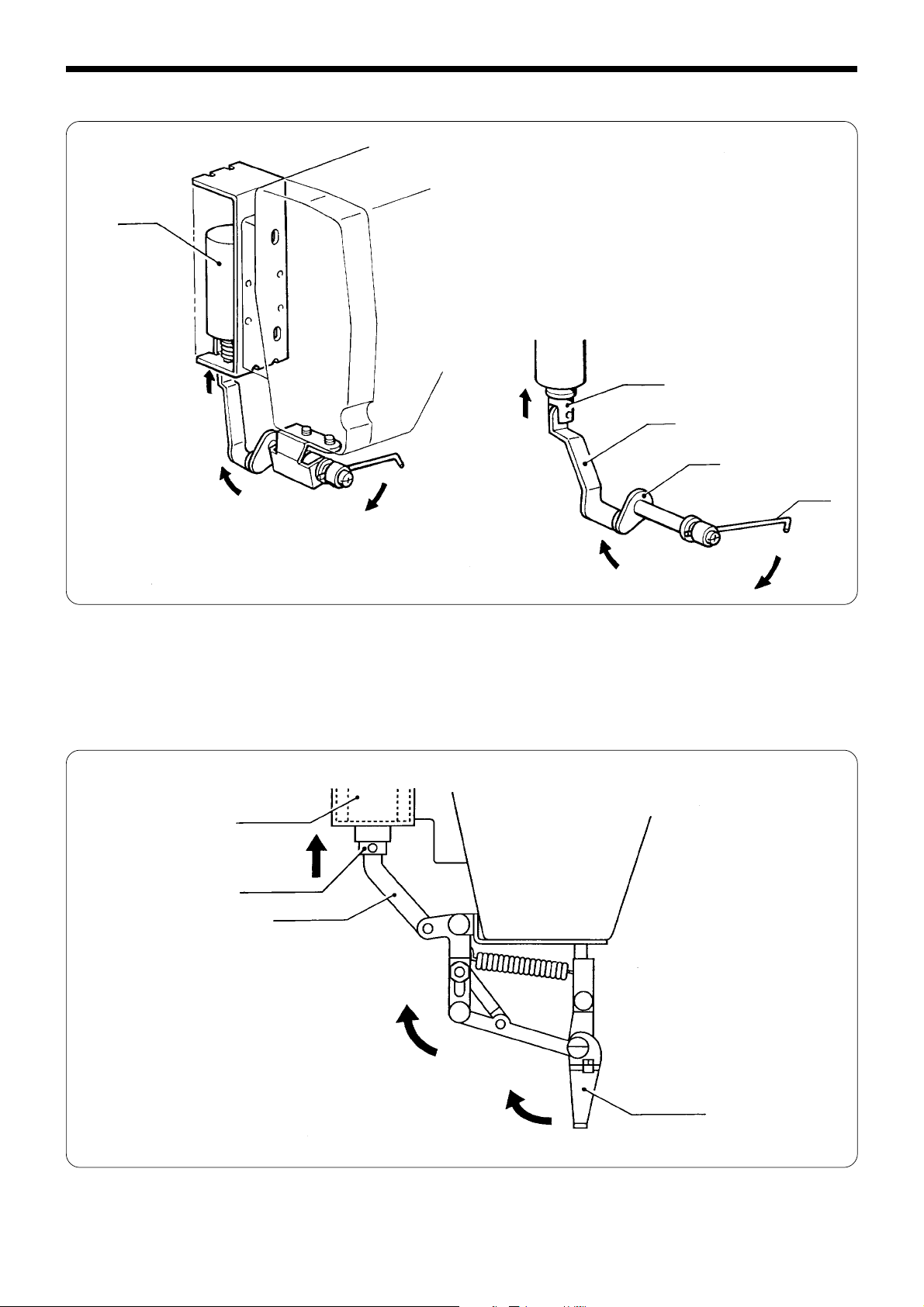

2. Work clamp lifting mechanism (1) (Solenoid type), 311E

e

r

q

w

t

y

u

1. When the presser signal is on, the presser solenoid q operates.

2. The plunger w operates in the direction of the arrow and moves link (B) t through link (C) e and link shaft (A) r.

3. Link (B) t presses down the presser plate u through the link shaft (C) y.

i

!1

o

!6

!0

!2

!3

!4

!5

!7

4. When the work clamp plate operates, the slider i and the slider support o are pressed down. When they are pressed,

work clamp lifter lever R. !1 is raised through the slider support shaft !0.

5. The spring !2, the work clamp arm lever (RR) !3 and (F) !4 which are linked to presser bar lifter lever (R) !1 operate in the

direction of the arrow.

6. Work clamp (UN) !5 and presser foot (L) !6 ·(R) !7 are pressed down through work clamp lever (F) !4.

2

BAS-311E.311EL.326E.326EL

Page 11

Chapter 1. Mechanical description

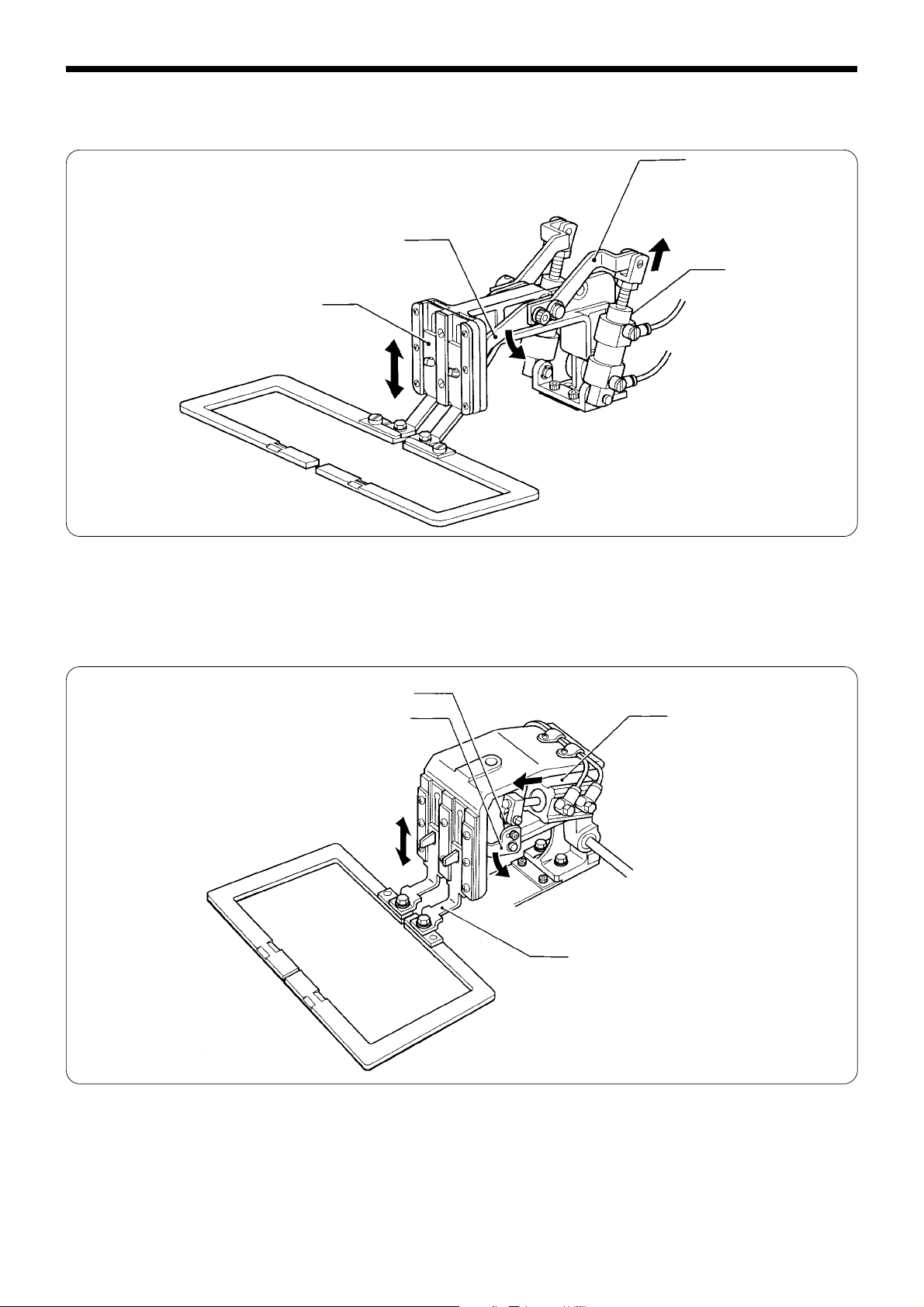

Work clamp lifting mechanism (2) 311E, 311EL

(Pneumatictype)

e

r

w

q

1. When the air cylinder q operates in the direction of the arrow, work clamp arm levers R w and F e also operate in the

direction of the arrow.

2. Work clamp SE r is moved vertically via work clamp arm lever F e.

Work clamp lifting mechanism 326E

w

e

r

q

1. When the air cylinder q operates in the direction of the arrow, work clamp lifter lever D w and lever U e also operate

in the direction of the arrow.

2. Work clamp SE r is moved vertically via knee lifter lifting lever U e.

BAS-311E.311EL.326E.326EL

3

Page 12

Chapter 1. Mechanical description

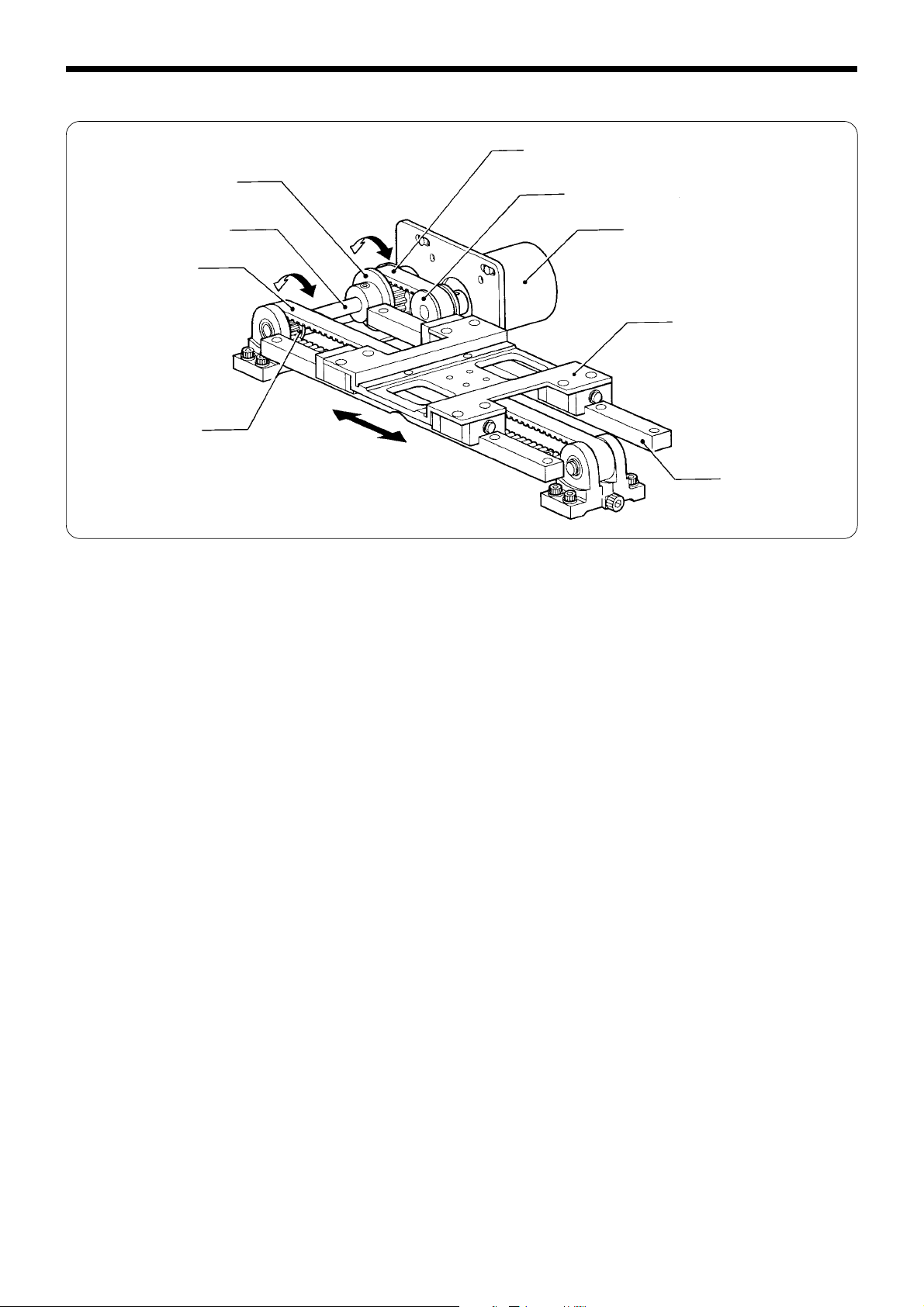

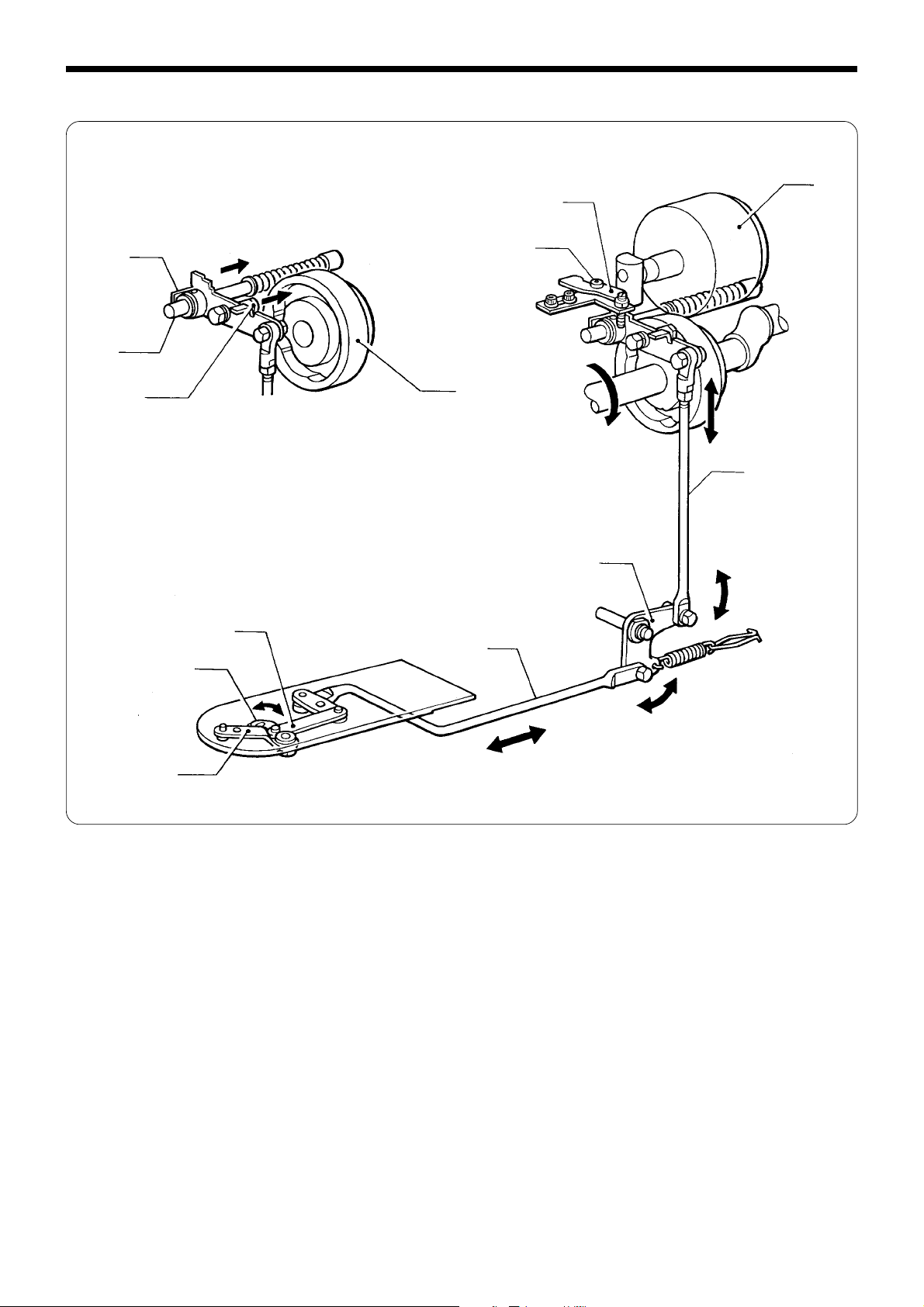

3. Feed mechanism (X axis) 311E, 311EL, 326E, 326EL

e

r

t

u

y

1. When X-timing pulley A326 w attached to the X-pulse motor q moves, its motion is transmitted to X-timing pulley

B311 r via X-timing belt A311 e.

2. When X-timing pulley B311 r moves, timing pulley A y linked to the X-timing pulley shaft t moves X-timing belt

B311 u left and right.

3. Feed bracket X i secured to X-timing belt B311 u moves via linear guide 311 o in the X direction (left and right).

w

q

i

o

4

BAS-311E.311EL.326E.326EL

Page 13

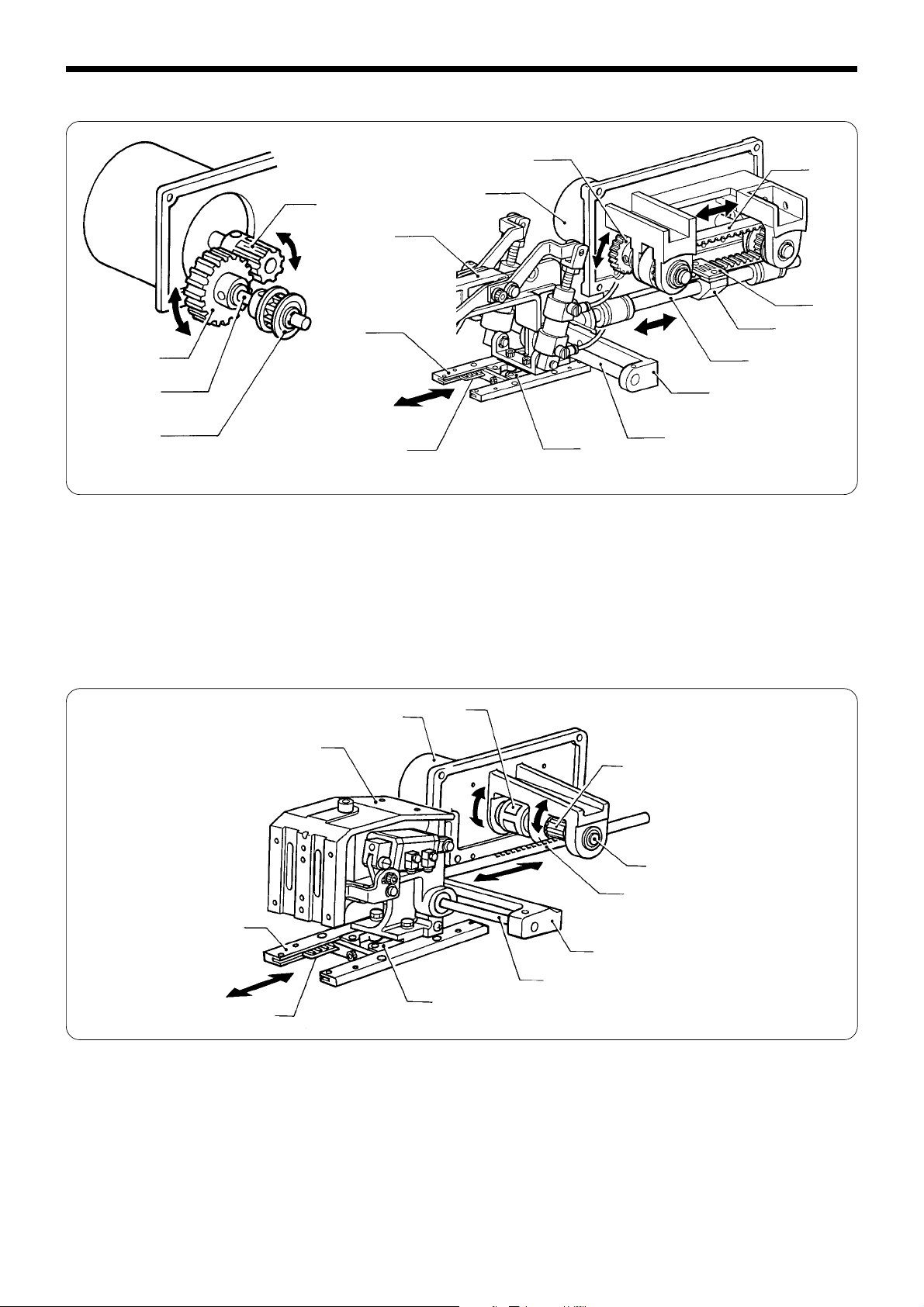

Feed mechanism (Y axis) 311E and 311EL

Chapter 1. Mechanical description

e

w

!2

!5

e

r

t

!4

1. The driving gear w attached to the Y-pulse motor q oscillates the idle gear e.

2. When the idle gear e oscillates, the Y-timing belt y moves forward and backward through timing pulley (A)t attached

to Y-pulley shaft (A)r.

3. The belt holder u and the Y-driving shaft holder i which are fixed to the Y-timing belt y operate the Y-driving shaft o.

4. The X-feed shaft support !0 and the X-feed shaft !1 are attached to the Y-driving shaft o. The presser arm assembly !2

is attached to the Y-feed bracket !3.

5. The Y-feed bracket !3 operates in the Y-direction (moves longitudinally) via the Cross roller !4 and the Y-feed guide !5.

q

!3

o

!0

!1

y

u

i

Feed mechanism (Y axis) 326E, 326EL

q

i

!1

!0

1. When the Y-pulse motor q operates, its motion is transmitted to the driving gear r attached to the Y-driving gear shaft

e via the coupling w.

2. The driving gear r is engaged with the rack of the Y-driving shaft t, and the Y-driving shaft t moves back and forth.

3. The work clamp arm assy i is attached to the Y-feed bracket o via X-feed shaft support 326 y attached to the Y-

driving shaft t and the X-feed shaft u.

4. The Y-feed bracket o operates in the Y-direction (back and forth) via cross roller 326 !0 and Y-feed guide 326Y !1.

w

r

e

t

y

u

o

BAS-311E.311EL.326E.326EL

5

Page 14

Chapter 1. Mechanical description

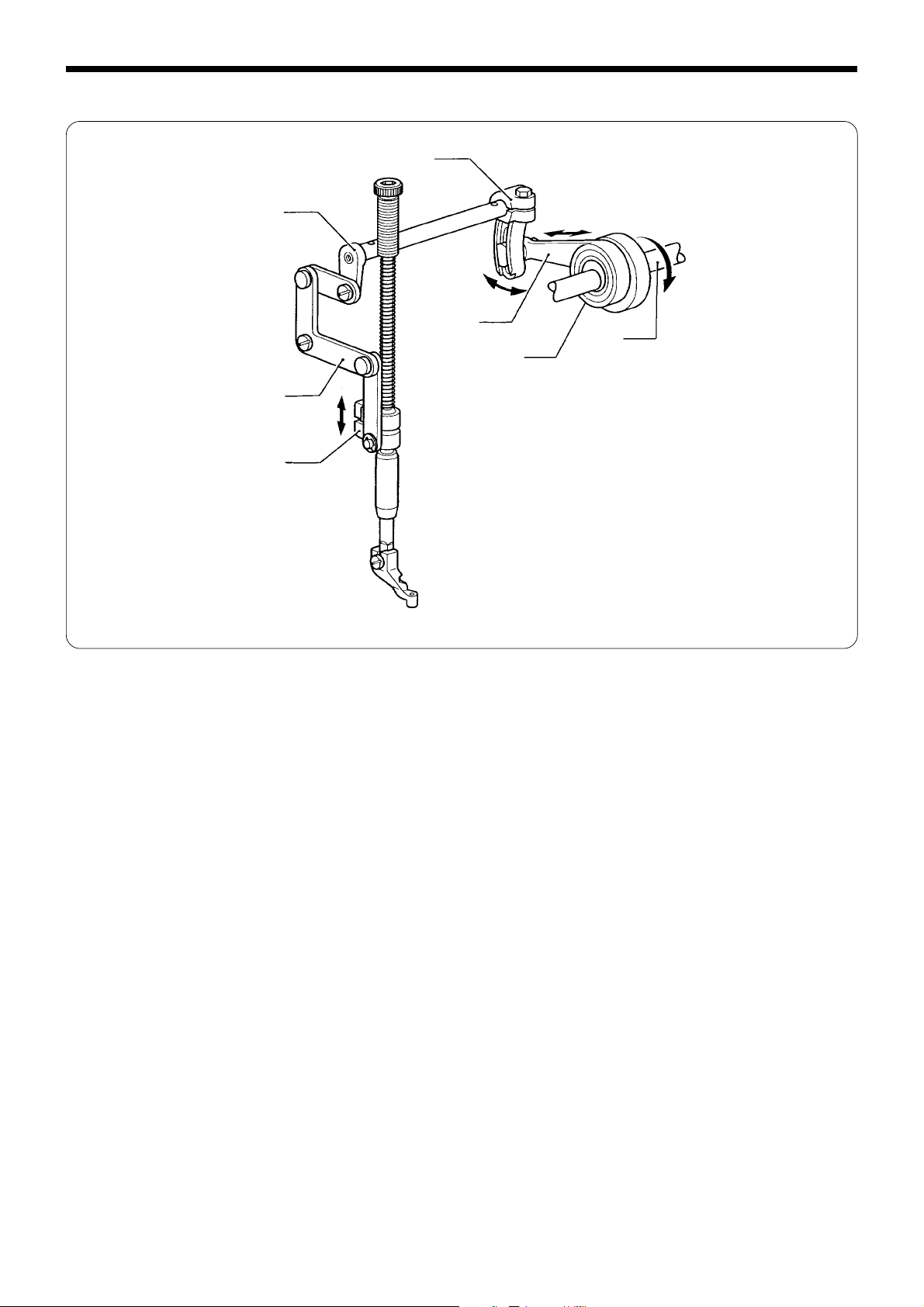

4. Presser foot mechanism (1)

r

t

y

u

e

q

w

1. When the upper shaft q rotates, the stepping work clamp cam w moves eccentrically, and the stepping work clamp

connecting rod e oscillates stepping work clamp arm R r.

2. The oscillation of stepping work clamp arm R r is transmitted to stepping work clamp arm F t, and the stepping link

assy y moves the presser bar lifter u up and down.

6

BAS-311E.311EL.326E.326EL

Page 15

Presser foot mechanism (2)

r

Chapter 1. Mechanical description

e

q

1. When the stepping work clamp signal is on, the stepping solenoid q operates the lifter lever w.

2. The lifter lever w operates the work clamp lifter lever assy r via the work clamp lifter wire e.

Note: When the machine stops, the stepping solenoid q operates, and the presser foot rises as soon as the work clamp

rises. At this time, tension releasing is performed.

w

BAS-311E.311EL.326E.326EL

7

Page 16

Chapter 1. Mechanical description

5. Thread trimmer mechanism

q

w

t

r

y

e

u

i

o

!1

!0

!2

!3

1. When the thread trimmer signal is on, the thread trimming solenoid q pushes the pushing lever driving lever w.

2. The pushing lever driving lever w pushes the thread trimmer driving lever r in the direction of the arrow, pivoting on

the shoulder screw e. The pushing lever driving lever w slides along the driving lever shaft t.

3. The roller y attached to the thread trimming driving lever r fits into the groove of the thread trimmer cam u, and

operates the thread trimmer rod i.

4. As the thread trimmer lever o is linked to the thread trimmer rod i, the connecting rod lever !0 operates.

5. When the thread trimmer connecting rod !1 linked to the connecting rod lever !0 operates, the fixed knife !2 and the

movable knife !3 fit into each other and perform thread trimming.

8

BAS-311E.311EL.326E.326EL

Page 17

Chapter 1. Mechanical description

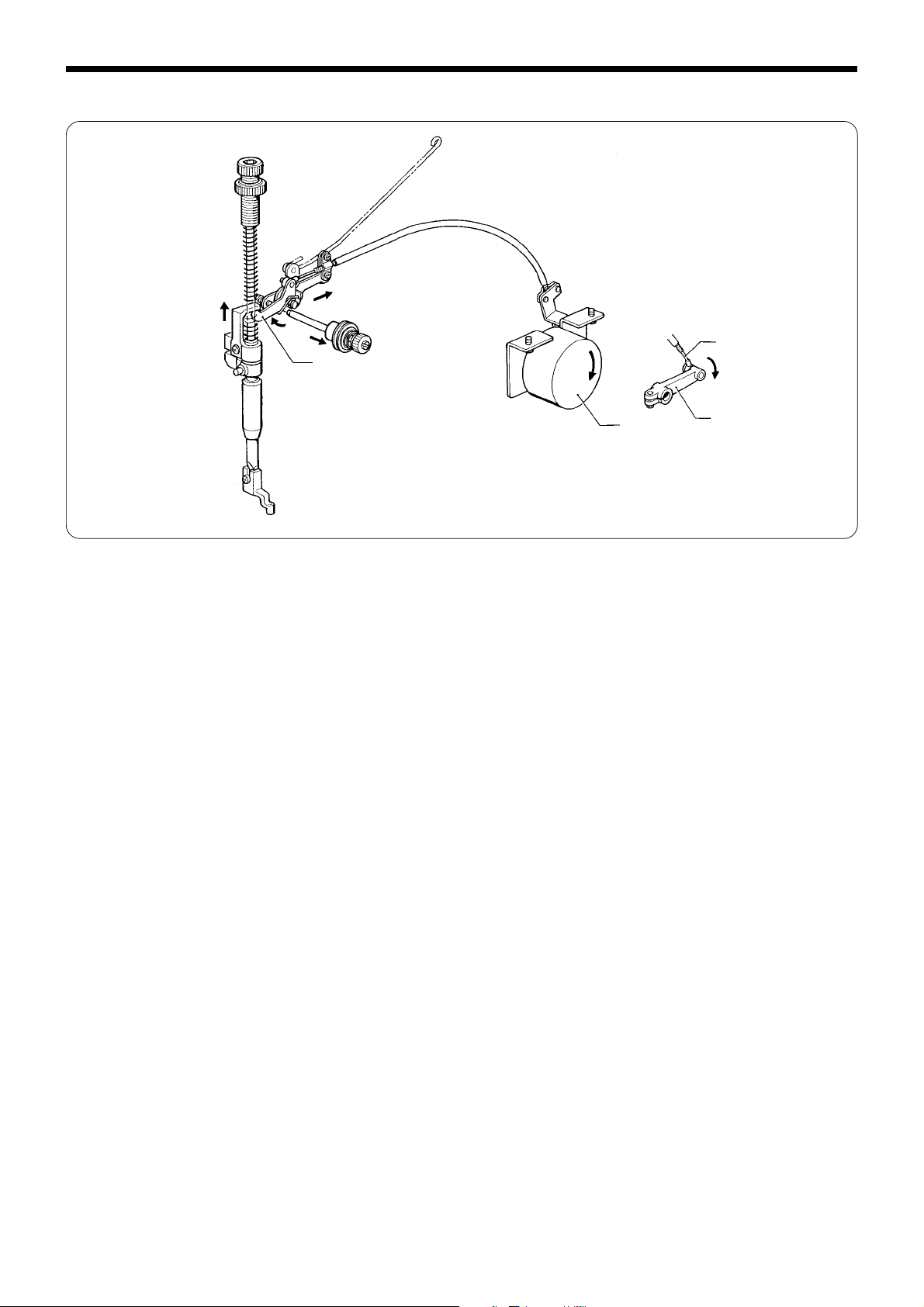

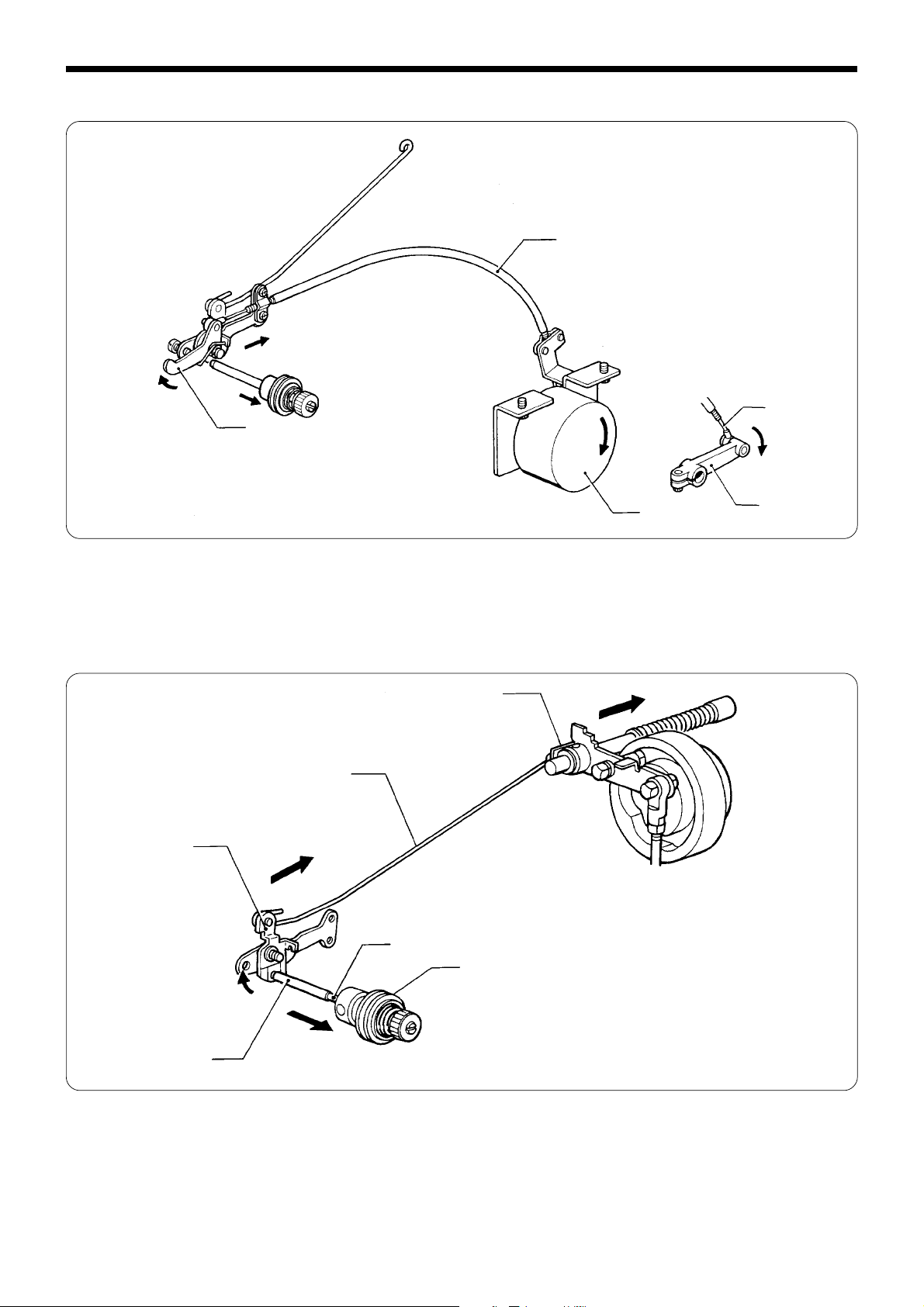

6. Thread nipper (1) when presser foot rises

r

e

r

q

1. When the machine stops, the stepping solenoid q operates, and the presser foot rises as soon as the work clamp rises.

2. The stepping solenoid q operates the lifter lever w, and the work clamp lifter lever assy e via the work clamp lifter

wire r.

w

Thread nipper (2) during thread trimming

q

w

e

t

y

r

1. When the thread trimming signal is on and the thread trimming solenoid operates, the thread trimmer driving lever q

is pushed in the direction of the arrow.

2. The thread trimmer driving lever q moves the tension release lever e via the tension release rod w.

3. The tension release lever e pushes the tension release bar r.

4. The end of the tension release bar r pushes the pin t and the tension disk opens y.

BAS-311E.311EL.326E.326EL

9

Page 18

Chapter 1. Mechanical description

7. Thread wiper (1) (vertical wiper: standard)

q

w

e

r

t

1. After thread trimming, the thread wiper signal is on and the thread wiper solenoid q operates.

2. When the plunger w operates in the direction of the arrow, the thread wiper crank assembly r attached to the end of

the thread wiper connecting rod e operates.

3. The wiper t attached to the thread wiper crank assembly r operates.

Thread wiper (2) (horizontal wiper: optional)

q

w

e

r

1. After thread trimming, the thread wiper signal is on and the thread wiper solenoid q operates.

2. When the plunger w operates in the direction of the arrow, T-wiper connecting rod assy S e also operates.

3. Thread wiper A r attached to T-wiper connecting rod assy e operates.

10

BAS-311E.311EL.326E.326EL

Page 19

Chapter 2. Disassembly

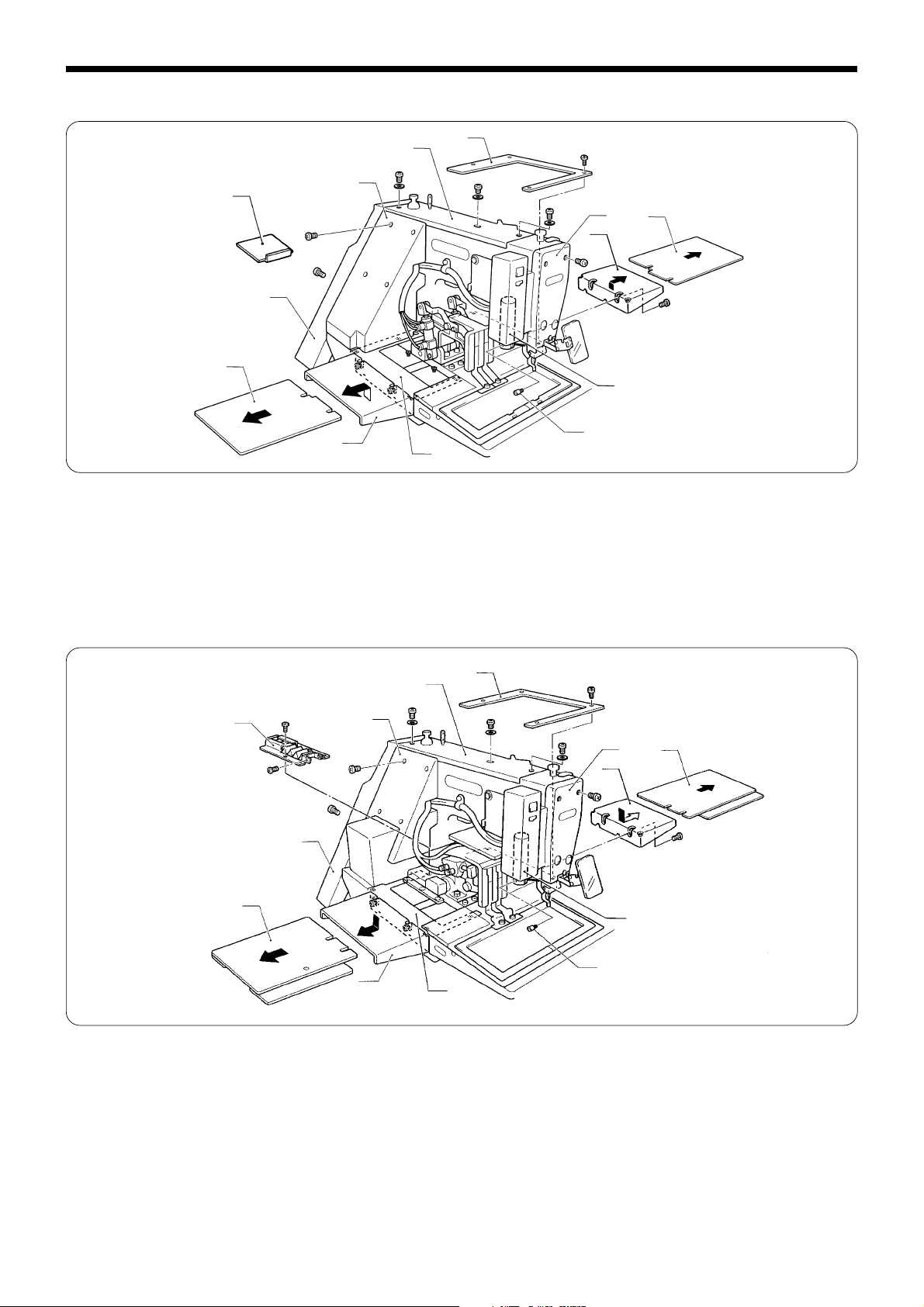

1. Covers (1) 311E

q

w

r

Chapter 2. Disassembly

y

e

!2

o

!0

i

u

t

!1

!0

o

!3

1. Remove the screw, the top cover q, the belt covers w and the rear cover e.

2. Loosen shoulder screw r and remove the work clamp lifter connect rod t.

3. Remove the plunger pin u from the plunger y.

4. Remove the screw and the face plate i.

5. Remove the screw and the X-feed bracket covers o on the right and left and cover spacer !0 Y-feed bracket cover !1.

6. Remove the screw and XY-feed base covers (L) !2 and (R) !3.

BAS-311E.311EL.326E.326EL

11

Page 20

Chapter 2. Disassembly

Covers (2) 311EL

!0

!1

o

t

y

u

r

q

e

i

w

u

o

1. Remove the screws, the top cover q, the belt cover w, and the frame side cover e.

2. Remove the plunger pin t from the plunger r.

3. Remove the screws, and the faceplate y.

4. Remove the screws, and X-axis feed bracket covers L and R u and Y- feed bracket cover i.

5. Loosen the screws, and remove the left and right feed bracket cover supports o in the direction of the arrow.

6. Remove the screws, and X-Y feed bracket covers L !0 and R !1.

Covers (3) 326E, 326EL

!0

!1

o

t

y

i

r

q

u

w

i

1. Remove the screws, the top cover q, the belt cover w, and the frame side cover e.

2. Remove the plunger pin t from the plunger r.

3. Remove the screws, and the faceplate y.

4. Remove the screws, and the bellows assy u.

5. Remove the screws and X-axis feed bracket cover assemblies L and R i.

6. Loosen the screws, and remove the left and right feed bracket cover supports o in the direction of the arrow.

7. Remove the screws, and X-Y feed bracket covers L !0 and R !1.

e

o

12

BAS-311E.311EL.326E.326EL

Page 21

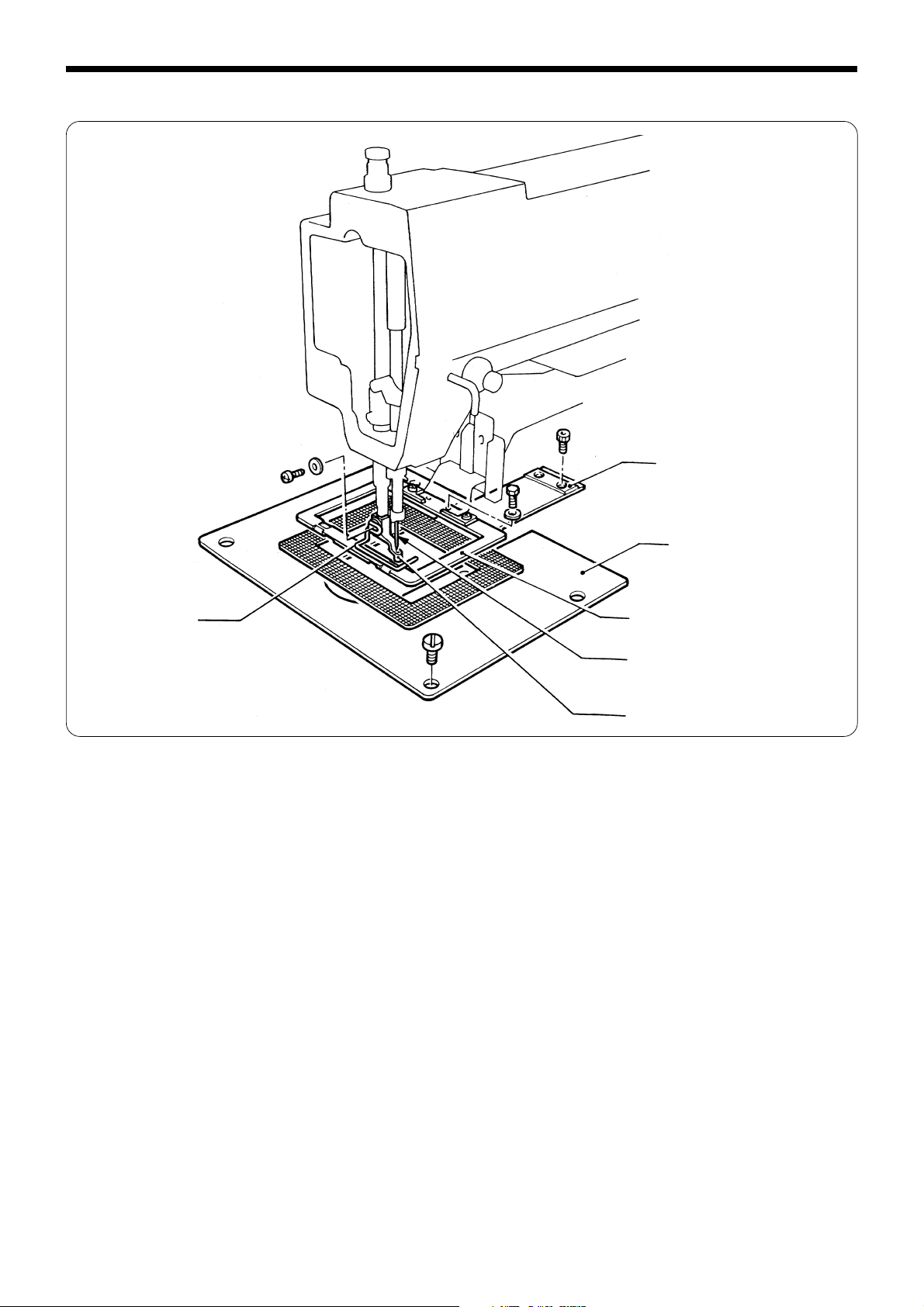

2. Feed mechanism

Chapter 2. Disassembly

t

e

1. Remove the screw, the needle q and the presser foot w and finger guard e.

2. Remove the bolt and the work clamp r.

3. Remove the screw, the feed plate t and the needle sub plate y.

y

r

q

w

BAS-311E.311EL.326E.326EL

13

Page 22

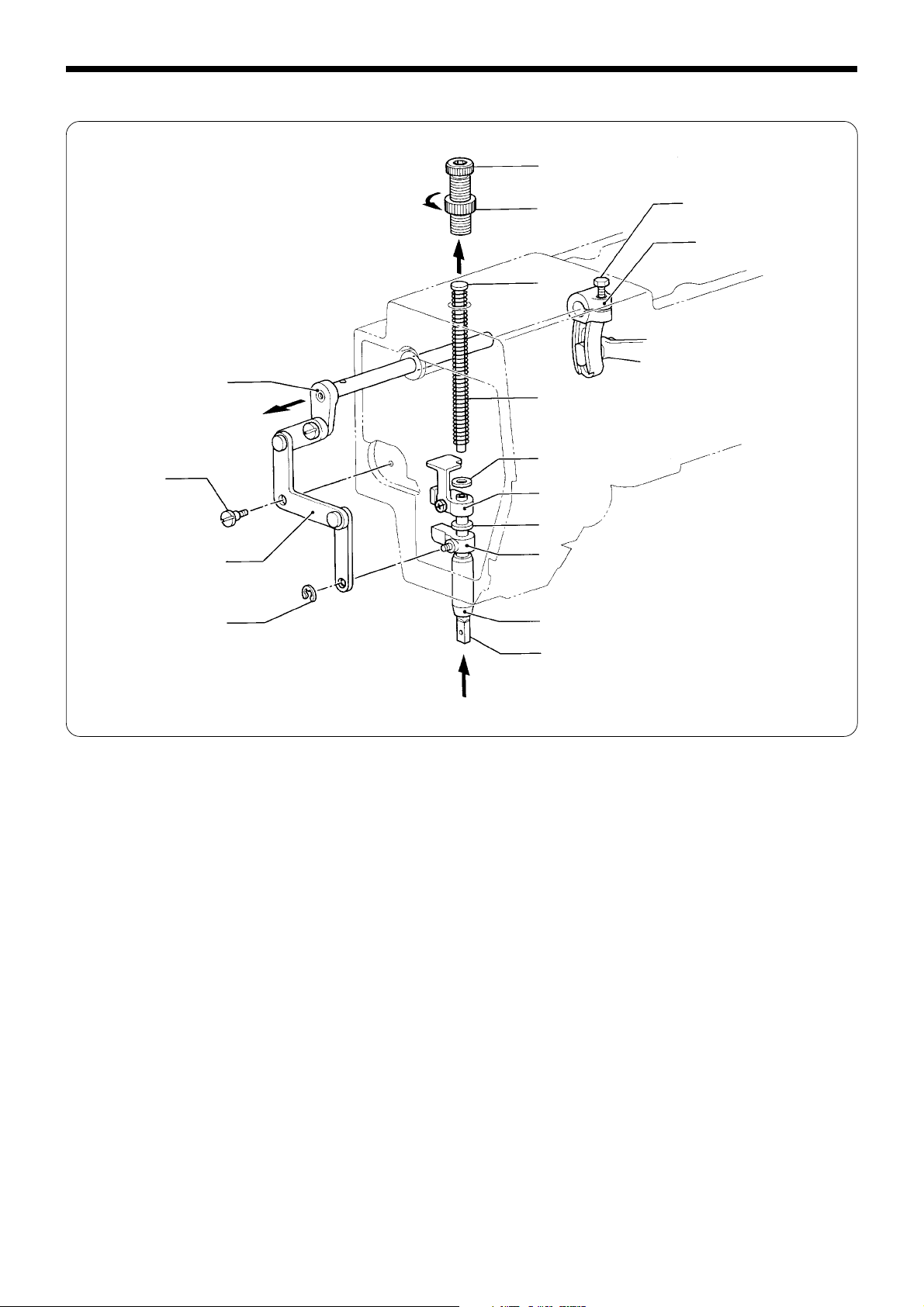

Chapter 2. Disassembly

3. Presser foot mechanism

w

i

!1

!2

!0

q

e

r

t

!6

!5

o

!4

u

y

!3

1. Loosen the nut q, remove the adjust screw w, the spring guide e, and the spring r by lifting them from above of the

machine, and remove the washer t.

2. Loosen the bolt u of stepping work clamp arm R y, remove the shoulder screw i and the retaining ring !0 of the

presser bar lifter o from the faceplate, and then remove stepping work clamp arm F !1 and stepping link assy !2.

3. Push up the presser bar !3, and separate it from the presser bar bush !4.

(The presser bar lifter o, the cushion !5, and the needle bar clamp !6 will come off as a set.)

14

BAS-311E.311EL.326E.326EL

Page 23

4. Needle bar mechanism

t

Chapter 2. Disassembly

q

e

i

!1

!0

o

!5

!4

r

!7

u

y

!2

y

!6

r

w

!2

!3

!3

1. Remove the rubber cap q.

2. Remove the needle bar thread guide w from the needle bar e.

3. Loosen the screw of the needle bar clamp r, and remove the needle bar e through the machine top.

4. Remove the needle bar clamp r from the thread take-up lever t.

(Remove the needle bar guide slide block u from the needle bar guide y.)

5. Remove the rubber cap i, loosen the set screw o, and remove the thread take-up support stud !0.

6. Remove the oil cap !1, loosen the set screw !3 of the counter weight !2, and remove the thread take-up lever !4.

(The thread take-up assembly !5 will come off.)

7. Remove the rubber cap !6, the screw !7, and the needle bar guide y.

(Do not remove them if possible to prevent the machine from overheating due to needle bar rubbing.)

BAS-311E.311EL.326E.326EL

15

Page 24

Chapter 2. Disassembly

5. Upper shaft mechanism

e

w

q

r

!0

!1

o

r

t

y

u

i

!2

!0’

r

!6

!7

!5

r

!2

q

!1

!4

!3

1. Loosen the screw w and the set screw e of thread take-up crank q.

(The screw w should be loosened until its end comes off the upper shaft r.)

2. Remove the screw t, and the thread trimming solenoid y.

3. Remove the screw u, and the wick support i.

4. Remove the screw o, and the crank rod !0.

(At this time, lower the crank rod !0’ in the direction of the arrow.)

5. Loosen the set screws of the stepping work clamp cam !1 and the thread trimmer cam !2.

6. Remove the V belt !3, loosen the set screw !4, and remove the pulley !5.

7. Remove the screw !6 and the synchronizer !7.

8. Remove the upper shaft r in the direction of the arrow.

After that, remove the thread take-up crank q, the stepping work clamp cam !1, and the thread trimmer cam !2 from

the upper shaft r, in this order.

16

BAS-311E.311EL.326E.326EL

Page 25

6. Feed mechanism (Y axis) (1) 311E and 311EL

w

q

Chapter 2. Disassembly

e

r

t

1. Loosen the set screw and remove the X-feed shaft q.

2. Remove the screws and the work clamp arm w.

3. Tilt the machine head until it stops.

4. Remove the bolt of the Y-driving shaft holder e, the Y-driving shaft r and the X-feed shaft support t.

5. Raise the machine head.

BAS-311E.311EL.326E.326EL

17

Page 26

Chapter 2. Disassembly

Feed mechanism (Y axis) (2)

r

q

w

e

!3

w

q

t

!6

!5

y

!2

!4

!6

u

i

o

!8

!9

!1

!0

!7

1. Remove the bolts, the Y-feed guide assembly q, the cross roller w, and the Y-feed bracket e.

2. Remove the screws, the X-feed bracket r, and the linear guide t.

3. Remove the bolts and the Y-driving pulse motor bracket y.

4. Remove the bolts and the Y-pulse motor u.

5. Loosen the set screws of the idle gear i and timing pulley A o, and remove Y-pulley shaft A !0 along with the retaining

rings. (The idle gear i, timing pulley A o, and the ball bearing !1 will come off.)

6. Loosen the set screw of timing pulley A !2, and remove the two retaining rings and Y-pulley shaft B !3.

7. Remove the bolts, the Y-driving pulse motor bracket !4, timing pulley A !2, the Y-timing belt !5, and micro bearings !6.

* To remove the Y-driving shaft holder !7, remove the bolt, the belt holder !8, the timing belt spacer, !9, and the Y-

timing belt !5.

18

BAS-311E.311EL.326E.326EL

Page 27

Feed mechanism (Y axis) (3) 326E, 326E

r

w

e

q

q

Chapter 2. Disassembly

u

!1

i

t

y

!0

!2

o

!3

!4

1. Secure the slider support shaft w of the work clamp assy q using the supplied set screw e.

(To prevent the slider support shaft w and the slider r from suddenly protruding, be sure to do this job.)

2. Loosen the set screw, and remove the X-feed shaft t.

3. Remove the two bolts, and the work clamp assy q.

4. Remove the two bolts, and X-feed shaft support 326 y.

5. Remove the four bolts, the Y-feed pulse motor bracket u, and the Y-driving shaft i.

6. Remove the two bolts, and Y-feed bracket cover F o.

7. Remove the four bolts, Y-feed guide assy 326 !0, cross roller 326 !1, and the Y-feed bracket !2.

8. Remove the eight set screws, the X-feed bracket !3, and the linear guide !4.

BAS-311E.311EL.326E.326EL

19

Page 28

Chapter 2. Disassembly

7. Feed mechanism (X axis) (1) 311E

q

y

t

w

e

!0

r

!5

!6

i

y

!4

!3

!1

i

o

!2

!0

u

1. Remove the rubber cap q.

2. Loosen the set screws of X-timing pulley B311 w and timing pulley A e, and remove the X-timing pulley shaft t and

retaining ring r. (X-timing pulley B311 w and timing pulley A e, and the two ball bearings y will come off.)

3. Loosen the set screw of timing pulley B u, and remove the retaining ring i and X-pulley shaft B o.

(Timing pulley B u, X-timing belt B311 !0, and the two ball bearings !1 will come off.)

4. Remove the bolts !2 from adjustment holes, and separate X-pulley base B !3.

5. To remove the X-feed bracket !4, remove the eight set screws, the belt holder !5, the timing belt spacer !6, and X-timing

belt B311 !0.

20

BAS-311E.311EL.326E.326EL

Page 29

Chapter 2. Disassembly

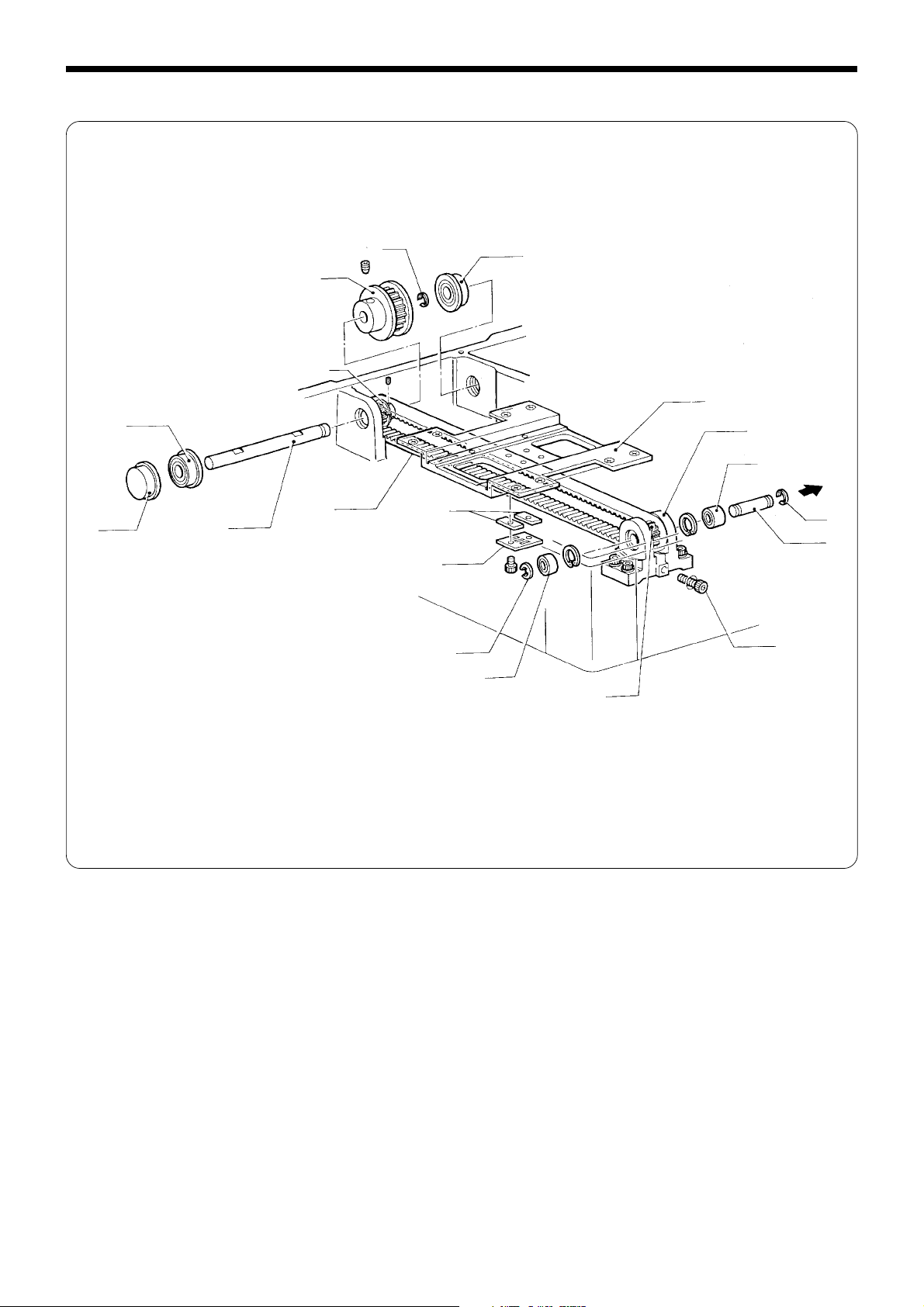

Feed mechanism (X axis) (2) 311EL and 326E, 326EL

@3

o

!1

!0

!3

!6

!2

!5

!4

!7

!8

y

u

!9

q

r

!7

r

w

e

@6

@2

@0

@5

@4

@1

t

@2

i

1. Remove the bolt w and the washer e of X-pulley bracket L q, and the adjust bolt r.

2. Remove the bolt y and the washer u of X-pulley bracket R t, and the adjust bolt i.

3. Remove X-timing belt A326 o.

4. Loosen the set screw !1 of X-timing pulley B326 !0, and the set screw !3 of timing pulley A !2, and remove the back

retaining ring !5 of the X-timing pulley shaft !4, and pull out the X-timing pulley shaft !4 in the direction of the arrow.

(At this time, timing pulley !2, X-timing belt B326 !6, X-timing pulley B326 !0, X-timing belt A326 o, and the two micro

bearings !7 will come off.)

5. Loosen the set screw !9 of timing pulley B !8, remove the front retaining ring @1 of X-pulley shaft R @0, and pull out X-

pulley shaft R @0 in the direction of the arrow.

(At this time, X-timing belt B326 !6, timing pulley B !8, and the two micro bearings @2 will come off.)

6. Remove the bolt @4 on the back of the X-feed bracket @3, the belt holder @5, the timing belt spacer @6, and X-timing belt

B326 !6.

BAS-311E.311EL.326E.326EL

21

Page 30

Chapter 2. Disassembly

8. Lower shaft mechanism

u

y

w

t

r

q

e

!2

!1

!0

o

i

1. Tilt the machine head until it stops.

2. Remove the bobbin case q and the shuttle hook w.

3. Loosen the bolt e, and remove the driver r and the retaining ring t.

4. Loosen the set screw of the set screw collar y, and remove the lower shaft assembly u from the rear of the machine.

5. Loosen the set screw i.

6. Loosen the set screw of the set screw collar o, and remove the rock gear shaft !0 from the rear of the machine.

7. Remove the set screw collar o, the rock gear !1, and the crank rod !2.

8. Raise the machine head.

22

BAS-311E.311EL.326E.326EL

Page 31

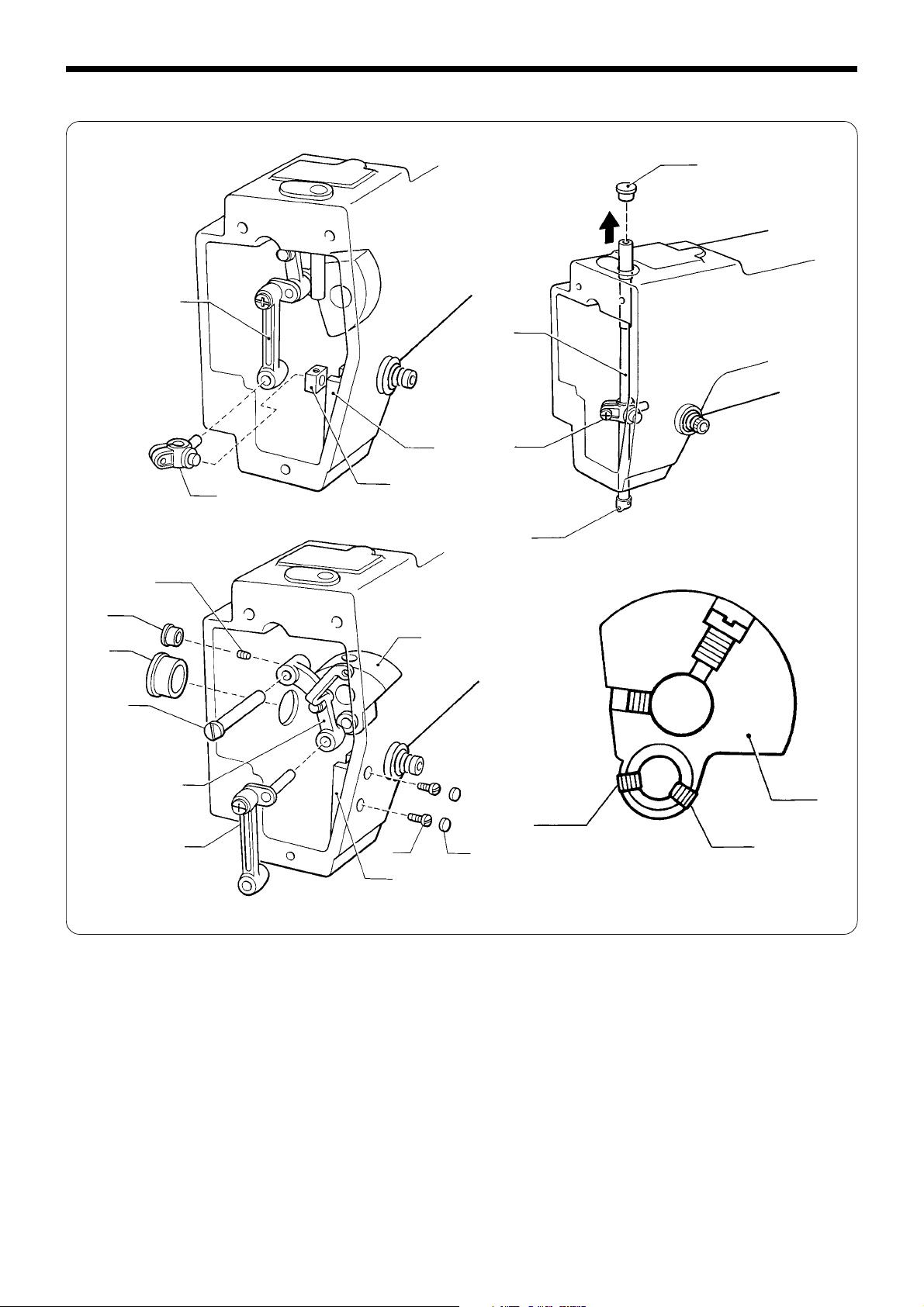

9. Work clamp lifter (Solenoid type)

e

Chapter 2. Disassembly

w

u

o

i

!1

!3

!0

q

t

u

q

!0

!2

e

r

y

i

r

!5

!4

1. Remove the spring q.

2. Remove the screw w, and the presser solenoid e from the plunger r by lifting the latter from above.

Be sure to hold the plunger r securely so that it does not fall.

3. Remove the snap pin t and the rod y.

4. Loosen the set screw u, and remove the snap pin i, link shaft A o, and the washer !0.

5. Remove the rubber cap !1, the snap pin !2, and link shaft C !3.

Be sure to hold the presser plate !4 and the presser bar lifter lever rubber !5 so that they do not fall.

6. Remove all parts connected to the plunger r by lifting them upward.

o

BAS-311E.311EL.326E.326EL

23

Page 32

Chapter 2. Disassembly

10. Thread nipper mechanism

r

r

t

y

i

e

t

r

w

q

u

y

o

!2

!3

!1

!0

1. Remove the set screw, the thread tension q, the pin w, and the tension release bar e.

2. Remove the shoulder screw r and the tension release rod t.

3. Remove the screw and the tension release assembly y.

4. Remove the screw, the cable support u, and the cord holder i.

5. Tilt the machine head until it stops.

6. Remove the extension spring o and the SOL oil pan !0.

7. Remove the screw and the wire support !1.

8. Loosen the bolt, and remove the work clamp lifter lever !2.

9. Loosen the set screw of the work clamp lifter lever !2, and remove the flanged shaft !3.

10.Return the machine head to its original position.

24

BAS-311E.311EL.326E.326EL

Page 33

11. Thread trimmer mechanism

Chapter 2. Disassembly

@1

t

q

y

r

w

e

i

!1

@2

o

!2

!0

u

!6

!9

!4

@0

!3

!7

!7

!5

!8

1. Remove the screws q, the flat screws w and the needle plate e.

2. Remove the rubber cap r, loosen the set screw t, and remove the connecting rod lever shaft y.

3. Remove the oil cap u, loosen the set screw i, and remove the retaining ring o.

4. Remove the driving lever shaft !0 by pulling it in the direction of the arrow. Then remove the cushion !1 and the spring

!2 from the shaft.

5. Tilt the machine head until it stops.

6. Remove the thread trimmer return spring !3 and the spring hook !4.

7. Remove the nut !5, the shoulder screw !6, and the washer !7.

8. Loosen the set screw !8, and remove the lever shaft !9 and the thread trimmer lever @0.

9. Return the machine head to its original position, and remove the connecting rod lever @1 and the thread trimmer

driving lever @2.

BAS-311E.311EL.326E.326EL

25

Page 34

Chapter 3. Assembly

Chapter 3. Assembly

1. Thread trimmer mechanism (1)

y

r

e

!5

t

w

u

q

!3

!5

i

!0

!9

@7

o

@3

@6

@5

@4

!1

r

y

e

1. Insert the driving lever shaft q into the machine. Place the spring w, the thread trimmer driving lever e, and the

cushion r on the shaft in this order.

2. Put the retaining rings t on the shaft. Press the thread trimmer driving lever e against the retaining rings t. Tighten

the set screw y on the screw flat.

3. Attach the oil cap u.

4. Insert the connecting rod lever i into the machine, lightly press the connecting rod lever shaft o against the former,

then secure them using the set screw !0.

5. Attach the rubber cap !1.

6. Tilt the machine head until it stops.

7. Pass the lever shaft !3 with the washer and the retaining ring, through the thread trimmer lever !2, and tighten the set

screw !4 on the screw flat.

8. Attach the thread trimmer rod !5 and the connecting rod lever i to the thread trimmer lever !2 using the washer !6,

plain washer 4.37 (t=0.8) !7, washer 4.76 (t=0.5) !8, the stud screw !9, and the nut @0.

9. Attach the spring hook @1 to the inside of the machine, and connect the thread trimmer return spring @2 to it.

10.Return the machine head to its original position.

11.Fit the thread cutter connecting rod @3 on connecting lever pin @4 , and install needle plate @5 using the flat screws @6

and screws @7 (First tighten the flat screws @6 and screws @7 ).

t

!2

i

!8

!7

!4

@0

!6

@2

@1

26

BAS-311E.311EL.326E.326EL

Page 35

2. Thread nipper mechanism

q

u

y

Chapter 3. Assembly

1. Pass the tension release assembly q from the bottom of

the machine to the top.

2. Attach the wire support w to the solenoid set plate e

with the bolt r.

3. Temporarily attach the lifter lever t to the shaft of the

stepping solenoid y. At this time, align the end face of

the lifter lever t with the end face of the stepping solenoid y.

4. Attach the SOL oil pan u using the screw.

5. Raise the machine head.

e

!0

i

y

t

t

!1

Align

w

r

6. Attach the cable support i to the machine body.

7. Attach the thread trimmer rod o to the tension release

assembly q with the shoulder screw !0.

8. Attach the other end of the tension release rod o to the

thread trimmer driving lever !1 using the shoulder screw

!0.

q

!0

o

!3

BAS-311E.311EL.326E.326EL

27

Page 36

Chapter 3. Assembly

!2

9. Attach the tension release assembly q to the machine

body with the screw !2.

10.Attach the cord holder !3 to the machine body.

q

11.Attach the tension release bar !4, the pin !5 and the

thread tension assembly !6 to the machine. Fit the set

screw !7 in the groove of the thread tension assembly

!6, then tighten it.

@0

!7

!9

@1

@2

t

!4

!8

!5

!6

12.Turn the stepping solenoid !8 fully in the direction of

the arrow. Move the lifter lever t so that there is no

clearance (0 mm) between work clamp lifter lever !9

and the presser bar clamp @0, remove the slack from the

work clamp lifter wire @1, and tighten the bolt @2.

28

@0

!9

BAS-311E.311EL.326E.326EL

Page 37

3. Work clamp lifter mechanism

Chapter 3. Assembly

!6

@4

t

!5

!7

@3

y

!4

!0

w

i

o

@0

u

q

@0

!1

!3

e

@2

i

@1

!2

e

r

!3

@0

!7

!8

!7

!9

!4

79.0mm

1. Attach the presser plate q to the presser bar lifter lever rubber w, and insert them from the bottom of the arm. Insert

the parts r linked to the plunger e from the top of the arm, and fit them on link shaft C t, link B y, and the presser

plate q.

2. Fit the snap pins u on both ends of link shaft C t.

3. Insert link shaft A i into the machine, and pass it through the washer o and link A !0.

4. Fit the snap pins !1 on both sides of link shaft A i and outside the washer o.

5. Attach the presser solenoid !2 to the top of the arm so as to cover the plunger e. Secure link shaft A i using the set

screw !4 so that link B y is centered in the bush !3.

6. Slide the presser solenoid !5 until it has reached 19.0 mm from the end of the arm, where the plunger e easily moves,

and tighten the screw !6.

7. Attach the spring !7 to link shaft B !8 and the pin !9.

8. Hang the rod @0 on the shoulder screw @1, and insert the former into link shaft B @2, and secure it using the snap pins @3.

9. Attach the rubber cap @4.

!1

BAS-311E.311EL.326E.326EL

29

Page 38

Chapter 3. Assembly

Make sure that work clamp easily moves up and down, and apply grease to sliding portions to assemble parts.

t

i

1. Sliding portions of link shaft C q and link B w.

2. Sliding portions of link shaft B e, link B w, link A r, and

link C t.

3. Sliding portions of link shaft A y and link A r.

4. Sliding portions of link shaft D u, link C t, and plunger

i.

u

r

y

t

e

i

u

w

q

q

1. Sliding portion of the work clamp q (Apply small

amount of grease).

2. Sliding portions of the work clamp arm lever shaft w

and work clamp arm levers R and L e.

e

w

30

BAS-311E.311EL.326E.326EL

Page 39

4. Feed mechanism (X axis) 311E

1. Fit the ball bearings q on X-pulley bracket L, and pass

q

e

t

y

u

q

Chapter 3. Assembly

the X-timing pulley shaft w from the front of X-pulley

bracket L through timing pulley A e, X-timing belt B311

r, X-timing pulley B326 t, and X-timing belt A326 y.

Place the two retaining rings u on both ends of the Xtiming pulley shaft w by pressing them against the ball

bearings q, adjust timing pulley A e so that there is no

looseness in the X-timing pulley shaft w, and secure it

using the set screws.

e

w

r

i

t

o

!2

!3

2. Secure X-timing pulley B326 t on the screw flat using

the set screw.

3. Loop the X-timing belt B i around timing pulley (B) !1.

Pass X-pulley shaft (B) !0 through timing pulley (B) !1,

and the micro bearing !2. Secure them to the X-pulley

base B o using the retaining ring !3.

!0

!3

!2

!1

!4

4. Place timing pulley (B) !1 at the middle of X-pulley base

!1

o

BAS-311E.311EL.326E.326EL

(B) o, then tighten the two set screws !4.

31

Page 40

Chapter 3. Assembly

!7

i

!6

!7

Reference

area

!6

!5

5. Attach the linear guide !5, the X-feed bracket !6, and the

X-feed guide !7 to the bed using the three bolts !8.

Note: Adjust the X-feed guide !7 so that the X-feed

bracket !6 can easily move left or right.

Adjustment procedure

1. Position the front linear guide !9 in the reference area

for installation on the front of the bed, and secure it

using the six bolts @0 and six washers.

2. Attach the rear linear guide @1 to the rear of the bed

using the five bolts @2 and five washers. Keep in

mind that the linear guide can move easily.

3. Attach the X-feed bracket !6 to the linear guide !5 us-

ing the eight screws.

4. Adjust the rear linear guide @1 so that the X-feed

bracket !6 can easily move left and right, and tighten

the five bolts @2 on the rear linear guide.

5. Place X-timing belt B i between the two timing belt

spacers !9 on the back of the X-feed bracket !6. Align

a rectangular slot of the belt holder !8 with a tooth of

X-timing belt B i. and secure them using the belt @0.

9.8N

(1kgf)

!9

!8

i

@0

6. Move the X-feed bracket !6 to the left end and apply a

load of 9.8N (1 kgf) to the center of the X-timing belt B i.

Then adjust the X-timing belt B i with the adjust screw

@1 to produce a deflection of 3 mm.

!6

3mm

@1

80mm

32

BAS-311E.311EL.326E.326EL

Page 41

Feed mechanism (X axis) 311EL, 326E

q

!2

!6

Chapter 3. Assembly

w

!3

!5

e

!4

!7

o

!1

!4

r

i

u

t

i

!0

1. Place X-timing belt B326 w between the two timing belt spacers e on the back of the X-feed bracket q. Align a

rectangular slot of the belt holder r with a tooth of X-timing belt B326 w, and secure them using the bolt t.

2. Fit timing X-timing belt B326 w in X-pulley bracket R y, pass X-pulley shaft R u through the micro bearing i, timing

pulley B o, and the micro bearing i, and attach the retaining ring !0.

3. Place X-timing belt B326 w and X-timing belt A326 !2 on X-pulley bracket L !1, pass the X-timing pulley shaft !3

through the micro bearing !4, timing pulley A !5, X-timing pulley B326 !6, and the micro bearing !4, and attach the

retaining ring !7.

y

BAS-311E.311EL.326E.326EL

33

Page 42

Chapter 3. Assembly

Feed mechanism (X axis) 311EL and 326E

@3

@7

!6

@7

!8

!9

@4

!1

!3

!5

2mm

2.5mm

!2

w

@2

o

@1

@0

@6

@5

u

y

@8

4. Position X-timing pulley B326 !6, which is attached to X-pulley bracket L !1 via the X-timing pulley shaft !3, so that there

is a 2 mm clearance between the top of X-timing pulley B326 !6 and end A of X-pulley base L !1. Position timing pulley

A !5 so that there is a 2.5 mm clearance between the bottom of timing pulley A !5 and end B of X-pulley base L !1. Then

secure X-timing pulley B326 !6 and timing pulley A !5 to the X-timing pulley shaft !3 using the set screws !8 and !9.

5. Position timing pulley B o attached to X-pulley bracket R y so that clearances C and D are equal, then secure it to Xpulley shaft R u using the set screw @0.

6. Loop X-timing belt A326 !2 around X-timing pulley A311 (A326) @2 of X-pulse motor @1 and X-timing pulley B326 !6.

Temporarily attach X-pulley bracket L !1 to the bed using the bolt @3 and washer @4.

7. Loop X-timing belt B326 w around timing pulley A !5 of X-pulley base L !1 and timing pulley B o of X-pulley base R y.

Temporarily attach X-pulley bracket R y to the bed using the bolt @5 and washer @6.

8. Insert the bolt @7 that is used to adjust the tension of X-timing belt A326 !2 from the left side of the bed, into X-pulley

bracket L !1.

9. Insert the bolt @8 that is used to adjust the tension of X-pulley belt B326 w from the right side of the bed, into X-pulley

bracket R y.

34

BAS-311E.311EL.326E.326EL

Page 43

Feed mechanism (Y axis) 311E and 311EL

1. Loop the Y-timing belt q around the Y-driving pulse motor bracket w, and pass Y-pulley shaft B e through the

Y-driving pulse motor bracket w, timing pulley A r, and

the micro bearing t. Attach the retaining ring y to hold

them.

2. Insert Y-pulley shaft A i into the Y-driving pulse motor

base u, passing it through timing pulley A o, the ball

bearing !0, and the idle gear !1. Position the idle gear !1

so that there is no end play with it.

3. Secure timing pulley A r with a clearance of 0.5 mm

from the Y-driving pulse motor bracket w left.

4. Secure timing pulley A o with the set screw !2 to provide a 0.5 mm clearance with the Y-driving pulse motor

base u.

q

o

!1

!0

!0

e

i

0.5mm

t

r

u

t

w

y

u

0.5mm

Chapter 3. Assembly

!3

u

!5

!4

!1

r

w

!6

q

!2

u

!8

!7

o

w

!9

5. Lightly pressing the driving gear !4 of the Y-pulse motor

!3 against the idle gear !1, attach the Y-pulse motor !3 to

the Y-driving pulse motor base u.

Note: Make sure that there is no backlash between the

idle gear !1 and the driving gear !4.

6. Temporarily attach the Y-driving pulse motor bracket w

to the Y-driving pulse motor base u using the bolts !5.

7. Sandwich the timing belt spacers !7 between the Y-tim-

ing belt q and the Y-driving shaft holder !6, place the

belt holder !8 on the Y-timing belt q, and secure the Ytiming belt q to the Y-driving shaft holder !6.

8. Lightly pressing the assembled Y-driving pulse motor

base u against end A of the machine, secure it with the

screws.

“A”

BAS-311E.311EL.326E.326EL

35

Page 44

Chapter 3. Assembly

@3

@9

#2

@8

9. Attach the Y-axis feed guide @0 to the left of the X-feed

bracket @1, pressing the former against the latter.

10.Attach the Y-axis feed bracket @2, the cross roller @3, and

the right of the Y-axis feed guide @4 right of the to the Xfeed bracket @1.

Note: When attaching the Y-axis feed guide @4 to the

right of the X-feed bracket @1, lightly push it to the

left so that there is no looseness in the Y-axis feed

guide @2, and tighten the set screw @5.

#0

w

@0

@2

Parallel

@8

@6

@1

q

@4

!6

@6

@5

Line

#1

@9

!6

@7

11.Tilt the machine head until it stops.

12.Pass the Y-driving shaft @6 through the Y-driving shaft

holder !6.

Align the reference line on the Y-driving shaft @6 with the

end of the Y-driving shaft holder !6.

Then, tighten the bolt @7.

Note: Be sure to make the X-feed shaft support @8 paral-

lel to the top of the bed to prevent timing belt (Y)

q from being damaged or cut.

13.Raise the machine head.

14.Temporarily attach the presser arm @9 to the Y-feed

bracket @2 with the screw #0.

15.Pass the X-feed shaft #1 through the X-feed shaft support @8 and the presser arm @9, then secure it with the set

screw #2.

16.Loosen the bolt !5 of the driving P motor bracket w.

When the power is turned off, adjust the driving P motor

bracket w with the adjust bolt !5 so that timing belt (Y)

q is not slack and the presser arm @9 moves smoothly

forwards and backwards. Then power on the machine

and adjust the tension of timing belt (Y) q with the adjust bolt #3 so that there is no looseness of the presser

arm @9.

17.After adjustment, tighten the bolt !5 of the driving P motor bracket w.

36

#3

!5

BAS-311E.311EL.326E.326EL

Page 45

Feed mechanism (Y axis) 326E

q

Chapter 3. Assembly

r

w

e

Rack

25 - 44N (2.5 - 4.5kgf)

1. Engage the driving gear w embedded in the Y-feed pulse motor bracket q with the rack of the Y-driving shaft e.

2. The engagement load between the driving gear w embedded in the Y-feed pulse motor bracket q with the rack of the

Y-driving shaft e should be 25 - 44 N ( 2.5 - 4.5 kgf) or less (so that the load will not fluctuate sharply). Move the Y-feed

pulse motor bracket q vertically to adjust the load, and secure it using the bolts r.

t

i

o

o

!0

y

u

!1

3. Attach the Y-axis feed guide t to the left of the X-feed bracket y, pressing the former against u the latter.

4. Attach the Y-feed bracket i, the cross roller o, and the right Y-feed guide !0.

When attaching the right Y-feed guide !0 to the right of the X-feed bracket y, lightly pushing it to the left so that there

is no looseness in the Y-feed bracket i, and tighten the bolt and set screw !1.

BAS-311E.311EL.326E.326EL

37

Page 46

Chapter 3. Assembly

!5

!2

e

!3

!4

i

5. Temporarily attach the work clamp Arm !2 to the Y-feed bracket i using the bolts and washers.

6. Temporarily attach the X-feed shaft support !3 to the Y-driving shaft e using the bolts and washers.

7. Pass the X-feed shaft !4 through the X-feed shaft support !3 and the work clamp Arm !2, and secure the X-feed shaft

support !3 and the X-feed shaft !4 using the set screws.

8. Move the work clamp Arm !2 left and right to make sure that there is no inclination in X-feed shaft !4. Then securely

tighten the bolts of Y-driving shaft e and the X-feed shaft support !3.

9. Remove the set screw of the slider support shaft !5 from the front of the work clamp Arm !2.

38

BAS-311E.311EL.326E.326EL

Page 47

6. Upper shaft mechanism

Chapter 3. Assembly

e

i

q

w

!0

t

y

r

e

q

y

t

q

r

o

!1

0.5mm

!1

u

!0

q

w

!0

i

1. Insert the upper shaft q from the rear of the machine, and place the thread trimmer cam w and the stepping work

clamp connecting rod e on the shaft.

* Apply adhesive (equivalent of Three Bond 1401) around the area which the bearing in the machine goes into. Also,

apply grease to grooves on the thread trimmer cam w.

2. Pass the thread take-up crank r from the face plate side over the upper shaft q, and tighten the screw t and the set

screw y.

3. Place the upper shaft bush between the thread take-up crank r and the stepping work clamp connecting rod e, and

secure the upper shaft q so that there is no looseness. (At this time, do not securely tighten the set screw of the

stepping work clamp conncting rod e.)

4. Press the thread trimmer conncting rod w against the crank of the upper shaft q. Adjust the set screw u that comes

first when rotating to the screw flat, and tighten it.

5. Attach they synchronizer i to the machine using the screw o.

6. Attach the pulley !0 leaving a 0.5 mm clearance from the protrusion of the synchronizer i, tighten the set screw !1 that

comes later when rotating to the screw flat.

BAS-311E.311EL.326E.326EL

39

Page 48

Chapter 3. Assembly

7. Needle bar mechanism

t

!7

!6

u

!8

e

i

r

!2

y

o

w

q

u

!9

aDP×5

!3

!2

!1

!0

!4

ADP×17

q

!3

!1

!5

!3

@0

!4

Cut section

1. Temporarily tighten the screw w of the needle bar guide q.

2. Pass the thread take-up support stud e through the thread take-up assembly r, lightly press the former, and secure

them using the set screw t.

3. Pass the needle bar crank y through the thread take-up assembly r and the counter crank u, adjust the set screw i

to the screw flat, and tighten the set screws i and o.

4. Fit the chamfering side of the needle bar guide slide block !0 into the groove on the needle bar guide q, and insert the

shafts of the needle bar clamp !1 into the needle bar connecting rod !2 and the needle bar guide slide block !0, as

shown in the figure.

5. Insert the needle bar !3 from the top of the machine into the needle bar clamp !1.

6. Turn the pulley to set the needle bar !3 at its lowest position. Move the needle bar vertically so as to align the second

lowest reference line A (for using needle DP ✕ 17) or the highest reference line a (for using needle DP ✕ 5) on the

needle bar !3 with the lower end of needle bar bush (D) !4. Tighten the screw !5 with the cut section of the needle bar

facing the front.

7. Find the position of the needle bar guide q so that the pulley rotates easily, and tighten the screw w.

8. Attach the oil cap !6 and the rubber caps !7, !8, and !9.

9. Fit the needle bar thread guide @0 on the needle bar !3.

40

BAS-311E.311EL.326E.326EL

Page 49

8. Presser foot mechanism

Chapter 3. Assembly

o

!5

!1

!6

!7

!2

!0

u

y

i

t

r

e

q

w

!4

!3

32mm

1. Insert the presser bar w into the presser bar bush q. Pass the presser bar lifter e, the cushion r, and the needle bar

clamp t through the presser bar w in that order.

2. Secure the needle bar clamp t with the screw.

3. Insert the spring y and the spring guide u from the top of the arm, pass the spring guide u through the washer i and

the presser bar w, and attach the presser adjusting screw o.

Note: Position the presser adjusting screw o using the presser adjusting nut !0 so that there is approx. 32 mm from the

top of the presser adjusting screw o to the top of the machine.

4. Pass stepping work clamp arm F !1 through spreader shaft bushes (L) and (R) !2, then insert it into stepping work clamp

arm R !3.

5. Attach the stepping link assy !6 to the arm using the shoulder screw !5, and to the presser bar lifter e using the

retaining ring !7.

BAS-311E.311EL.326E.326EL

41

Page 50

Chapter 3. Assembly

V notch

t

!1

!1

!6

0.5 - 1mm

!4

e

q

6. Turn the pulley to align the needle bar with the shuttle

hook. At this time, turn the stepping work clamp connecting rod !8 to turn stepping work clamp arm F !1 in

the direction of the arrow and move the stepping link

assy !6 in the direction of the arrow. When the presser

foot is at the lowest position, secure the stepping work

clamp connecting rod !8 to the upper shaft @0 using the

set screw !9.

Adjust the lift stroke of presser foot A to 3-5 mm, and 5-8

mm. When the clearance between the presser bar lifter

e and the presser bar bush q is 0.5 - 1 mm, tighten the

bolt !4 of stepping work clamp arm R !3. (At this time,

the match mark of stepping work clamp arm F !1 will be

almost aligned with that of arm.)

Note: Make sure that stepping work clamp arm F !0 has

no end play.

!3

Align

w

@1

w

!9

!8

@3

@2

@0

w

@1

@2

7. Secure the needle bar clamp t using the screw so that

when the presser bar w is at the lowest position. The

distance between the bottom of the presser bar w and

the top of the needle plate should be 23 mm. (22 mm for

311EL.)

Attach the presser foot @1 to the presser bar w so that

the top of the presser foot @1 is aligned with the top of

the screw that holds the presser foot @2.

8. Attach the needle @2 to the needle bar @3.

9. Turn the pulley to insert the needle @2 into the hole of the

presser foot @1. Turn the presser bar w so that the

needle @2 is in the center of the hole of the presser foot

@1, and tighten the screw of the needle bar clamp t.

10.Turn the pulley to set the presser bar w at its lowest position. Adjust the height of the presser foot @1 so that

there is a 0.5 mm clearance from the top of the material

to be sewn.

42

@1

0.5mm

BAS-311E.311EL.326E.326EL

Page 51

9. Lower shaft mechanism (1)

Chapter 3. Assembly

!4

!3

!3

!3

e

!5

Matching mark

w

!6

r

w

q

!1

!0

u

!2

!7

q

0.05 - 0.12mm

y

o

i

t

u

!1

1. Tilt the machine head until it stops.

2. Insert the rock gear shaft q from the rear of the machine, pass the rock gear w, the set screw collar e over the shaft,

bring them close together without any clearance, and tighten the set screw r.

3. Insert the lower shaft t from the rear of the machine, pass the set screw collar y over it, and engage the lower shaft

gear u with the rock gear w.

4. Sandwich the lower shaft bush i between the lower shaft gear u and the set screw collar y without any clearance,

and tighten the set screw o.

5. Fit the retaining ring !0 on the lower shaft t, press the driver !1 against the retaining ring !0, and tighten the bolt !2.

6. Return the machine head to its original position.

7. Fit the crank rod !3 over the crank of the upper shaft !4, align the matching mark of the crank rod !3 with that of the

upper shaft !4, and tighten the screw !5.

8. Tilt the machine head until it stops.

9. Turn the pulley !6 to move the rock gear w right and left until the pulley rotates easily. Turn the rock gear shaft q to

allow 0.05 - 0.12 mm play of the driver !1. Then tighten the set screw !7.

10.Return the machine head to its original position.

BAS-311E.311EL.326E.326EL

43

Page 52

Chapter 3. Assembly

10. Lower shaft (Rotary hook) (2)

1. Fit the inner rotary hook in the large shuttle hook.

2. Turn the pulley to raise the needle bar from its lowest

t

3. Turn the pulley to align the inner rotary hook point with

ADP × 17

w

DP × 5

q

r

y

e

u

position until the second highest reference line on the

needle bar q aligns with the end of needle bar bush (D)

w. Turn the shuttle driver e so that the inner rotary

hook point is aligned with the center of needle r, then

tighten the bolt t.

the center of the needle. Loosen the set screw y so that

the clearance between the needle r and the inner rotary hook point is 0.01 - 0.08 mm, then rotate the shuttle

hook adjust stud u to adjust.

r

r

0.01 - 0.08mm

r

e

4. Turn the pulley to align the inner rotary hook point with

the center of the needle r.

Loosen the set screw and adjust the shuttle hook adjust

stud i so that the needle r lightly contacts the needle

receiver of the shuttle driver e.

5. Remove the needle r.

i

44

!2

!1

!0

o

6. Attach the large shuttle hook o to the large shuttle hook

body !0.

7. Insert the bobbin !1 into the bobbin case !2, then attach

them to the inner rotary hook !3.

!3

BAS-311E.311EL.326E.326EL

Page 53

11. Thread trimmer mechanism

Chapter 3. Assembly

r

!2

0.5mm

w

t

e

q

o

y

i

u

e

!4

V notch

A

!0

i

!1

o

1. Fit the hole of the thread trimmer connecting rod q over the pin of the connecting rod lever w. Secure the needle plate

e using the screws r and t so that the hole on the needle plate is centered at the needle position.

2. Turn the pulley y until the mark u has slightly passed over the horizontal line.

(Adjust the position of the pulley to the position where the cam gooves on the thread trimmer cam do not fluctuate.)

3. Attach the thread trimming solenoid i using the screw o. At this time, the plunger !0 of the thread trimming solenoid

i must be fully pressed (the same status as when the thread trimming solenoid i is turned on), and a 0.5 mm

clearance must be provided between the thread trimmer driving lever !1 and the driving lever stopper !2.

4. Make sure that the thread trimmer driving lever !1 moves smoothly when the plunger !0 is pressed and released.

5. Tilt the machine head until it stops.

6. Loosen the nut !3, move the connecting rod lever w to the left and right to align the V notch A of the movable knife !4

with the mark on the needle plate e, and tighten the nut !3.

7. Return the machine head to its original position.

!3

w

BAS-311E.311EL.326E.326EL

45

Page 54

Chapter 3. Assembly

12. Feed guide mechanism (Home position adjustment: X )

311E, 311EL, and 326E

1. Secure the large shuttle hook cover q with the two

shoulder screws w.

2. Secure the needle sub plate e with the screw r.

r

e

t

w

q

i

3. Remove the presser foot t.

4. Remove the screws u, tlat screws o and the work

clamp guide brackets A y, B i and replace the work

clamp !0 with the H-position standard plate !1.

Note: Securely attach the H-position standard plate !1

using the work clamp guide brackets A y, B i

and the flat screws o.

o

u

!2

y

!3

!1

P key

!0

Parallel

X-reference

line

!5

!4

!6

!1

5. Connect the programmer !2 to the operation panel !3.

6. Plug the cord into the wall socket, and turn on the power of the machine.

7. Step on the foot switch to lower the H-position standard plate !1.

8. Press the P key on the programmer !2.

9. Attach the needle !4.

10.Turn the pulley to bring the needle !4 close to the H-position standard plate !1.

11.Press the jog key ( vu ) to adjust the work clamp arm !5 until its X-direction motion is parallel to the X-reference line

of the H-position standard plate !1. Securely tighten the screws !6.

46

BAS-311E.311EL.326E.326EL

Page 55

!1

Chapter 3. Assembly

0.1 - 0.5mm

!4

!8

H - position

(X=0, Y=0)

12.Press the P key and adjust the X-sensor setting plate !7 so that the needle !4 is aligned with the home position (X=0,

Y=0) of the H-position standard plate !1.

13.Press the P key again to make sure that the needle !4 is aligned with the home position (X=0, Y=0) of the H-position

standard plate !1.

14.Secure the X-sensor setting plate !7 using the screw.

15.Remove the needle !4.

16.Press the P key to be out of the program mode, and turn off the power.

17.Replace the H-position standard plate !1 with the work clamp.

Note: When adjusting the X home position, be sure to set the clearance between the X-home position dog !8 and the

surface where the sensor is activated to 0.1 - 0.5 mm. If the clearance is too great, an error in home position

detection may occur because the temperature of the sewing machine rises during sewing operation.

!7

BAS-311E.311EL.326E.326EL

47

Page 56

Chapter 3. Assembly

Feed guide mechanism (Home position adjustment: Y )

311E and 311EL

r

e

q

e

t

w

H - position

(X=0, Y=0)

1. Press the P key on the programmer, and adjust the Y-home position dog e so that the needle q is aligned with the

home position (X=0, Y=0) of the H-position standard plate w.

2. Press the P key again to make sure that the needle q is aligned with the home position (X=0, Y=0) of the H-position

standard plate w.

3. Secure the Y-home position dog e using the set screw r.

4. Remove the needle q.

5. Press the P key to be out of the program mode, and turn off the power.

6. Replace the H-position standard plate w with the work clamp.

Note: When adjusting the Y home position, be sure to set the clearance between the Y-home position dog e and the

surface where the sensor t is activated to 0.1 - 0.5 mm. If the clearance is too great, an error in home position

detection may occur because the temperature of the sewing machine rises during sewing operation.

t

0.1 - 0.5mm

Feed guide mechanism (Home position adjustment: Y )

326E and 326EL

P key

q

w

H - position

(X=0, Y=0)

1. Press the P key on the programmer, and adjust the Y-sensor setting plate e so that the needle q is aligned with the

home position (X=0, Y=0) of the H-position standard plate w.

2. Press the P key again to make sure that the needle q is aligned with the home position (X=0, Y=0) of the H-position

standard plate w.

3. Attach the Y-sensor setting plate e to the Y-home position bracket r using the bolt t.

4. Remove the needle q.

5. Press the P key to be out of the program mode, and turn off the power.

6. Replace the H-position standard plate w with the work clamp.

Note: When adjusting the Y home position, be sure to set the clearance between the Y-driving shaft y and the surface

where the sensor u is activated to 0.1 - 0.5 mm. If the clearance is too great, an error in home position detection

may occur because the temperature of the sewing machine rises during sewing operation.

r

y

t

u

0.1 - 0.5mm

e

48

BAS-311E.311EL.326E.326EL

Page 57

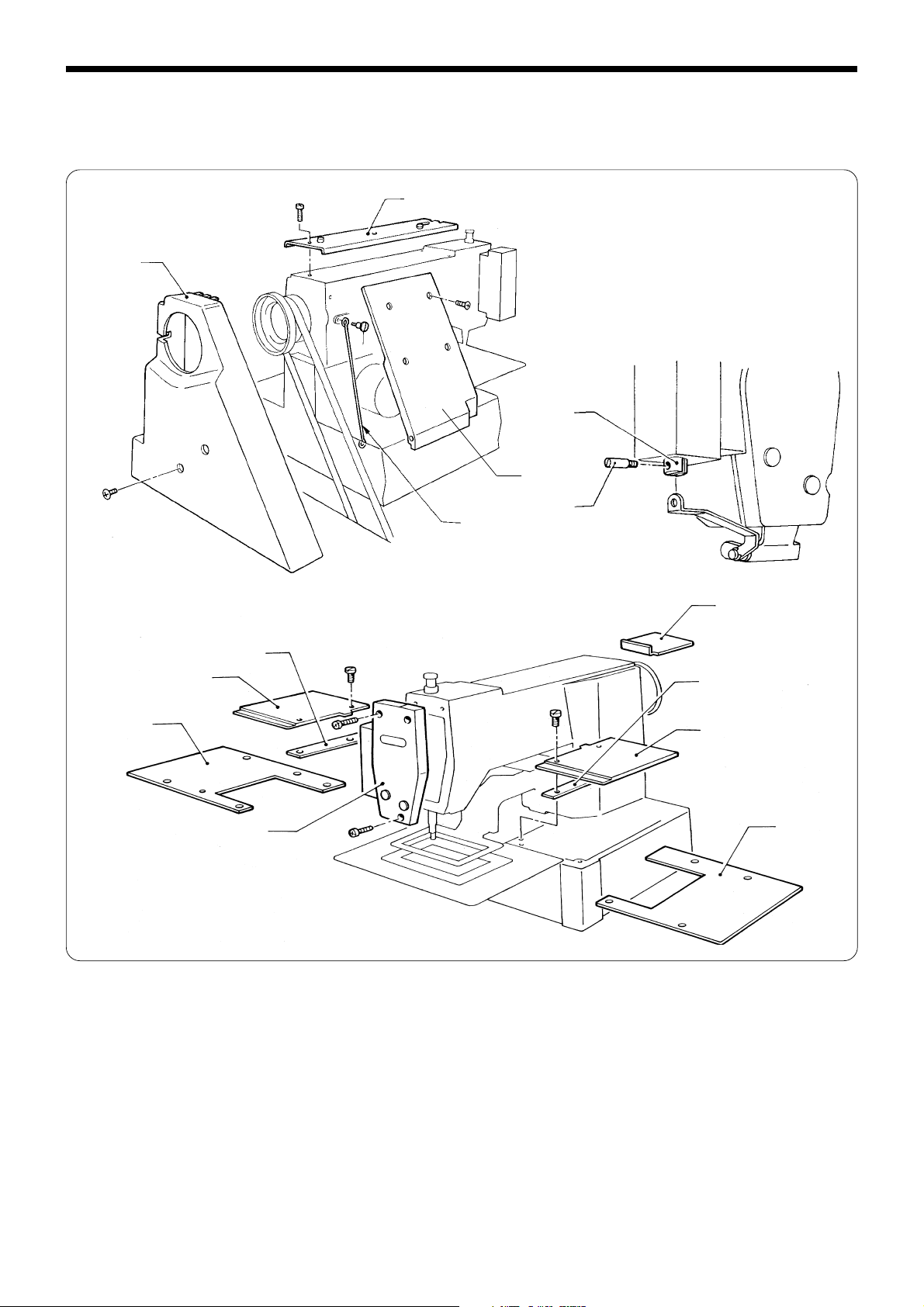

13. Covers 311E

e

q

u

y

t

r

Chapter 3. Assembly

1. Secure XY-feed base covers (L) q and (R) w with the

screws e.

2. Attach Y-feed bracket cover (B) r to Y-feed bracket

cover (A) t.

Secure the right and left X-feed bracket covers (L),(R) y

with the screws u.

y

o

!0 i

!1

!2

u

w

e

3. Attach the thread wiper connecting rod i to the plunger

!0 with the plunger pin o, then secure the face plate !1

with the screw !2.

4. Attach the presser foot !3 and the needle !4 in place and

attach the feed plate !5 to the feed bracket !6 with the

screw.

@2

@1

!3

@0

!4

!5

!7

!6

5. Attach the top cover !7, and the side cover !8 with the

screws.

6. Set the V belt !9 over the pulley @0, then secure belt

cover @1 with the screws @2.

!8

!9

BAS-311E.311EL.326E.326EL

49

Page 58

Chapter 3. Assembly

311EL

t

t

e

u

y

w

i

o

!1

r

!0

q

e

1. Attach the XY-feed bracket covers L q and R w using the screws.

2. Insert the left and right feed bracket cover supports e in the direction of the arrow, and tighten the screws.

3. Attach the X-axis feed bracket covers t using the screws.

4. Attach the faceplate t using the screws.

5. Attach the plunger pin y to the plunger u.

6. Attach the top cover i, the belt cover o, and the frame side cover !0 using the screw.

326E · 326EL

o

t

!0

q

1. Attach the XY-feed bracket covers L q and R w using the screws.

2. Insert the left and right feed bracket cover supports e in the direction of the arrow, and tighten the screws.

3. Attach the X-axis feed bracket covers r using the screws. (Use the front screws.)

4. Attach the bellows assy t to the work clamp arm and the X-axis feed bracket covers r using the screws.

5. Attach the faceplate y using the screws.

6. Attach the plunger pin u to the plunger i.

7. Attach the top cover o, the belt cover !0, and the frame side cover !1 using the screws.

!1

e

r

yw

e

i

u

r

50

BAS-311E.311EL.326E.326EL

Page 59

Chapter 4. Adjustments

1. Adjusting the needle bar height adjustment

q

Chapter 4. Adjustments

w

a(DPx5)

Turn the machine pulley to move the needle bar to the lowest position. Then remove the rubber cap w, loosen the screw

e and then move the needle bar up or down to adjust so that the second reference line from the bottom of the needle

(reference line A) is aligned with the lower edge of the needle bar bush q.