Page 1

PROGRAMMABLE

ELEGTRONIC

PATTERN

SEWER

WITH

- INSTRUCTION

CYLINDER

BED

MANUAL

,,

BAS-311A

Page 2

CONTENTS

~MAIN

~SPECIFICATIONS~

~

~S1r~AnO~

[j]

Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[1]

Installation

rn

Cord connections

[!]

Tilting the sewing machine head

[]]

V-belt

~

LUBRICATION

[j]

Adding

[1]

Oil draining

~

co~

[j]

Needle installation

[1]

Upper

@]

Bobbin thread

[!]

Bobbin case installation and threading

[]]

Thread tension

PAitt!NAMES

~

..... · · · · · · · ·

....................

~

.....................

of

spool stand . . . . . . . . . . . . . . . . . . . . .

...........................

..............

tension

thread threading

...................

AND

oil

...... , ...........................

...............................................................

OIL

oP~1tlo~

.........................................................

....................................................

winding

..............................

.....................................................

· · · · · · · · · · · · f · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

DRAINJNG;t0

~

........................................... .

.......................................

·:

·

·1·

.

: .

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

1

..............................

............................

............................

I

.............................

;-

.............................

I

...........................

1

'

......

· · · · · · · · · · · · · · · · · · · · · · · · ·

.............................

.

2

2

.

2

.

2

.

2

.

3

3

.

3

3

.

4

4

.

4

.

4

.

6

.

6

.

',

__

/

~

OPRRA'fll'iG

[j]

Operation panel

[1]

Using the

@]

Using production

[!]

Using 8,000 stitch sewing

[]]

Using single

[]]

Using the program

[II

Using the STEP BACK

@]

Adjusting

[!]

Using the TEST

[j]] Using

[j]

Shifting a stitch pattern

ll1J

Using bobbin thread

floppy

the

the

emergency

IWO®URE

part

names and

disk

......................................................

counter

split

mode

R/W

switch

sewing

switch

counter

SPEED

.....................................................

stop

~

.......................................

functions

..................................................

mode

.............................................

....................................................

switch

....................................................

..............................................

...............................................

control

switch

...........................................

................................................

....................................

.........................................

~SEWING~·······························································

7

.

.

7

.

8

.

8

.

9

.

9

.

10

.

11

.

11

.

12

.

12

.

13

.

13

14

Page 3

15

[jJ Needle bar height adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

[]]

Needle bar

00

Needle

[!]

Shuttle

00

Shuttle hook thread guide

[ill Two-step

[I]

Movable knife adjustment

[ill Presser

00

Changing the presser

[ID

Wiper adjustment

[j]

Needle and feed timing adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1m

2-step

1m

Changing the thread breakage detection stitch margin setting . . . . . . . . . . . . . . . . . . . .

IHJ

Changing the feed speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

[l]

Changing the speed at the start and end

[ID

Using the

lift

stroke adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

to

shuttle hook point gap adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

driver

needle contact adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

adjustment.........................................

work

clamp adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

.....................

foot

adjustment......................................................

foot

lift

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..............

work

clamp operation adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

memory

switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

:.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of

sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

:.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

15

16

18

18

19

22

22

23

24

24

25

26

27

Page 4

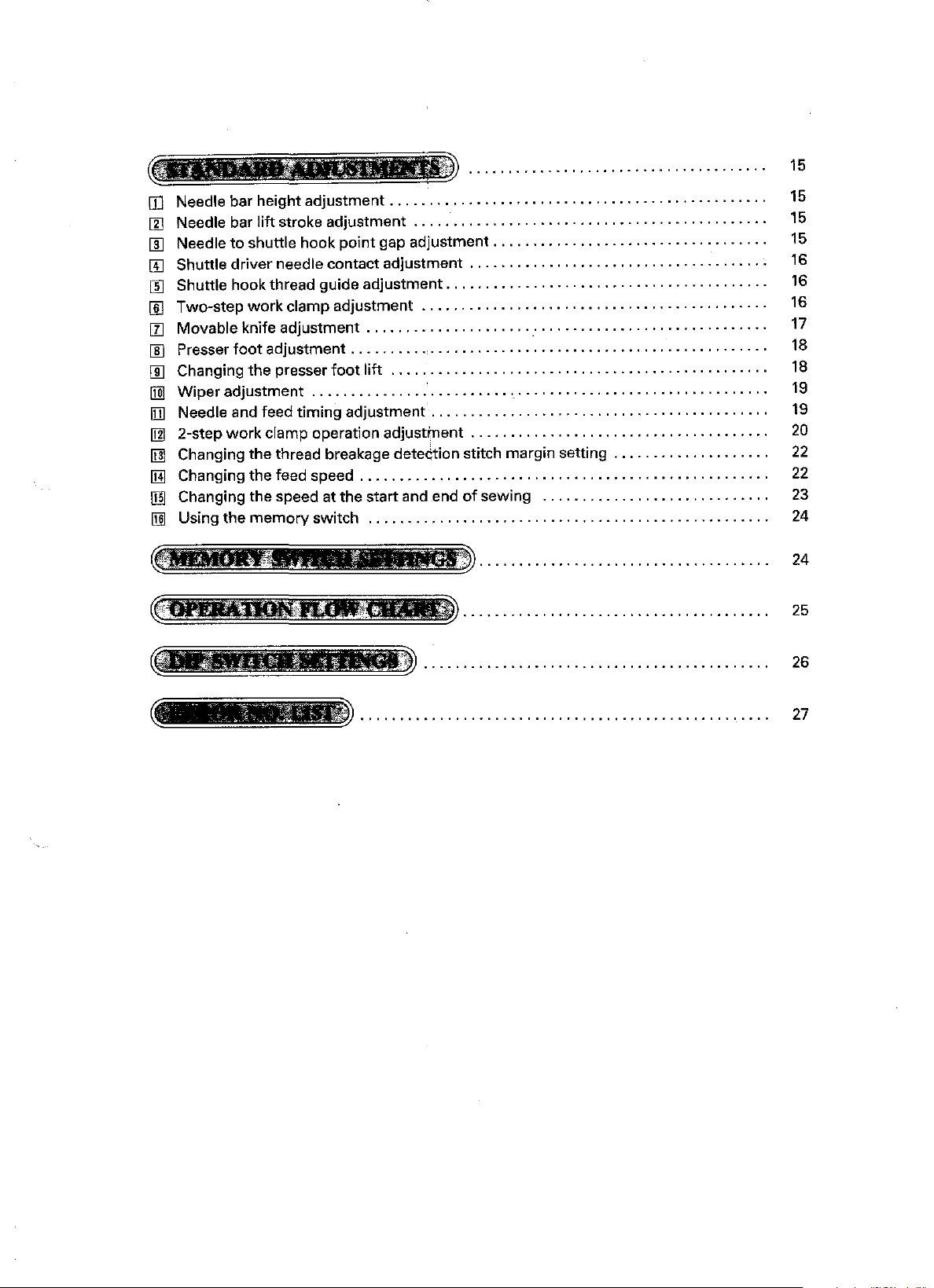

Emergency stop switch

Operation

~~

1

or

Floppy disk

<for pneumatic>

Presser lifter pedal

~-

'SPECIFICADONS

Stitch

type

Sewing

Stitch length and

max. sewing speed

Feed

Max. pattern size 100

Number

Work

2-step

Intermittent

Test function Operation

Safety devices

Machine dimensions

Power

Standard

Power

Motor

machine Lock stitch, pattern tacking sewing machine

format

of

stitches

clamp

lift

stroke

presser

table T-shaped

source

foot

feed

accessories

Starting pedal

--~

1,000-2,000 spm

0.1-3.0

Automatic

mm

Max. 4,000 (one pattern) Max. 8,000 (reading

0,

4, 7 mm

1,200W x 590D x 1140H

1-phase

stop

Single needle, lock stitch

3.1-4.4

750-1,500

Intermittent

mm

18

mm

selectable (factory set

test

function

function

with

intermediate

11

OV,

Three phase induction

mm

spm

wide

(X

axis) and 60

(for

solenoid), 20

Solenoid

provided

for

activation in

stop

mm

for

Floppy disks

200V, 220V,

Starting pedal

Presser

lifter

(with

large shuttle hook)

4.5-6.3

400-1,200

feed, pulse

mm

or

pneumatic

to

4 mm; 10

for

the

function and safety circuits.

(Sitting)-

use sitting

240V

3-phase 220V, 380V, 415V

motor

mm

spm

motor

drive

mm

deep

(Y

two

(for pneumatic)

mm

optionally

use

with

low

event

of

misoperation realized

1,350H

or

mm

standing

400W

6.4-12.7

400-600

axis)

patterns)

available)

speed drive

(Standing)

Power switch

Control

mm

spm

-1-

Page 5

~

INSTALLATION

[j]

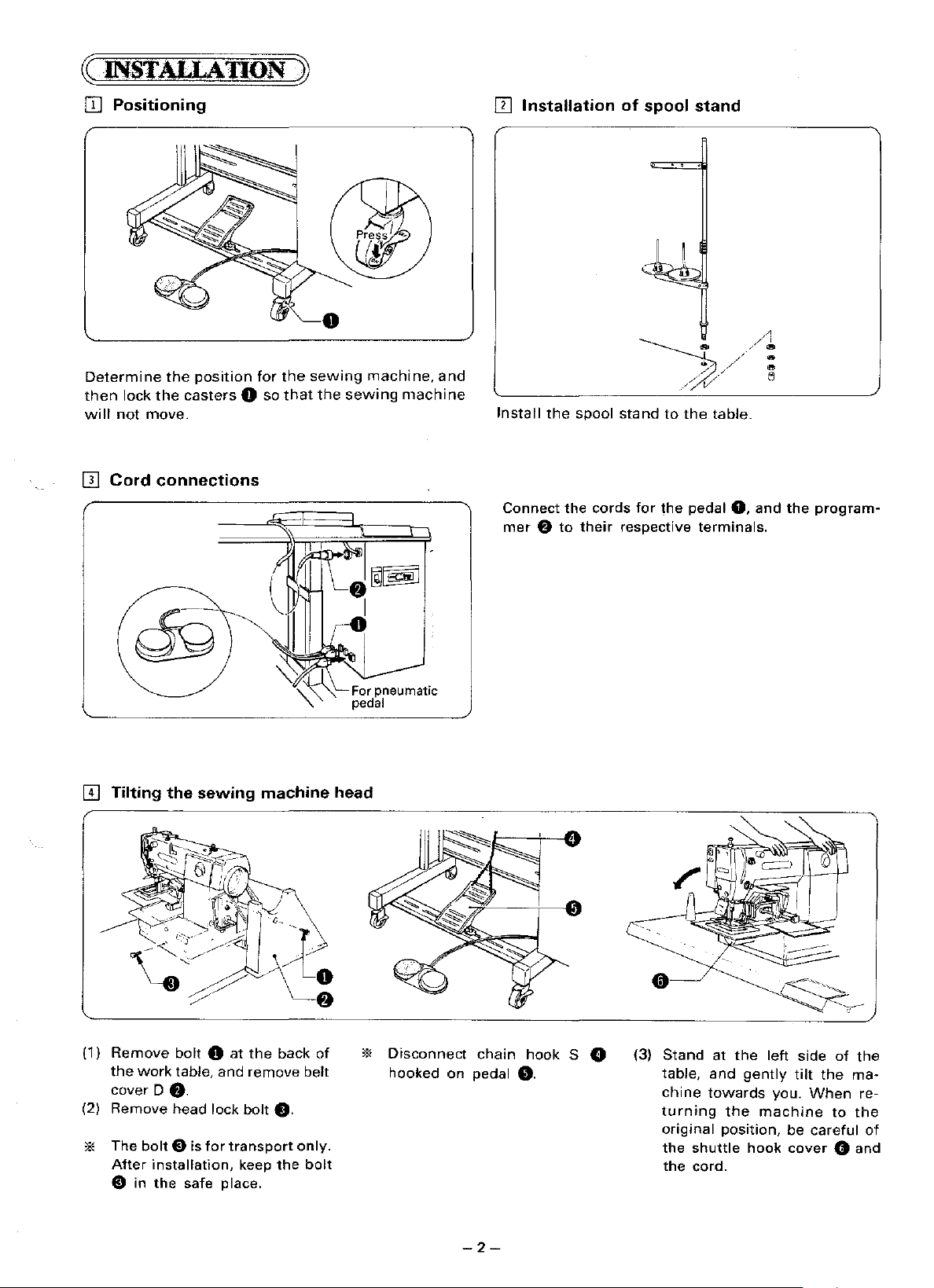

Positioning

·~

ill

Installation

of

spool stand

.lJ

=

Determine

then

will

not

[II

Cord

[I]

Tilting the sewing machine head

the

lock

the

casters

move.

connections

position

0 so

for

the

that

sewing

the

sewing

machine,

machine

For pneumatic

pedal

and

Install

the

Connect the

mer e to

spool

cords

their

stand

to

for

the pedal

respective

the

table.

terminals.

0,

and

the

program-

(1)

Remove

the

cover

(2) Remove head lock bolt

* The

After

e in

bolt 0

work

table. and

D

8.

bolt

E) is

installation,

the

safe place.

at

for

transport

the

remove

f).

keep

back

the

of

belt

only.

bolt

*

Disconnect

hooked

on

chain

pedal

-2-

hook

0.

S 0

(3)

Stand

table,

chine

turning

original position, be careful of

the

the cord.

at

and

towards

the

shuttle

the

gently

machine

hook

left side

tilt

you.

When

cover

of

the

to

0 and

the

ma-

re-

the

Page 6

!}]

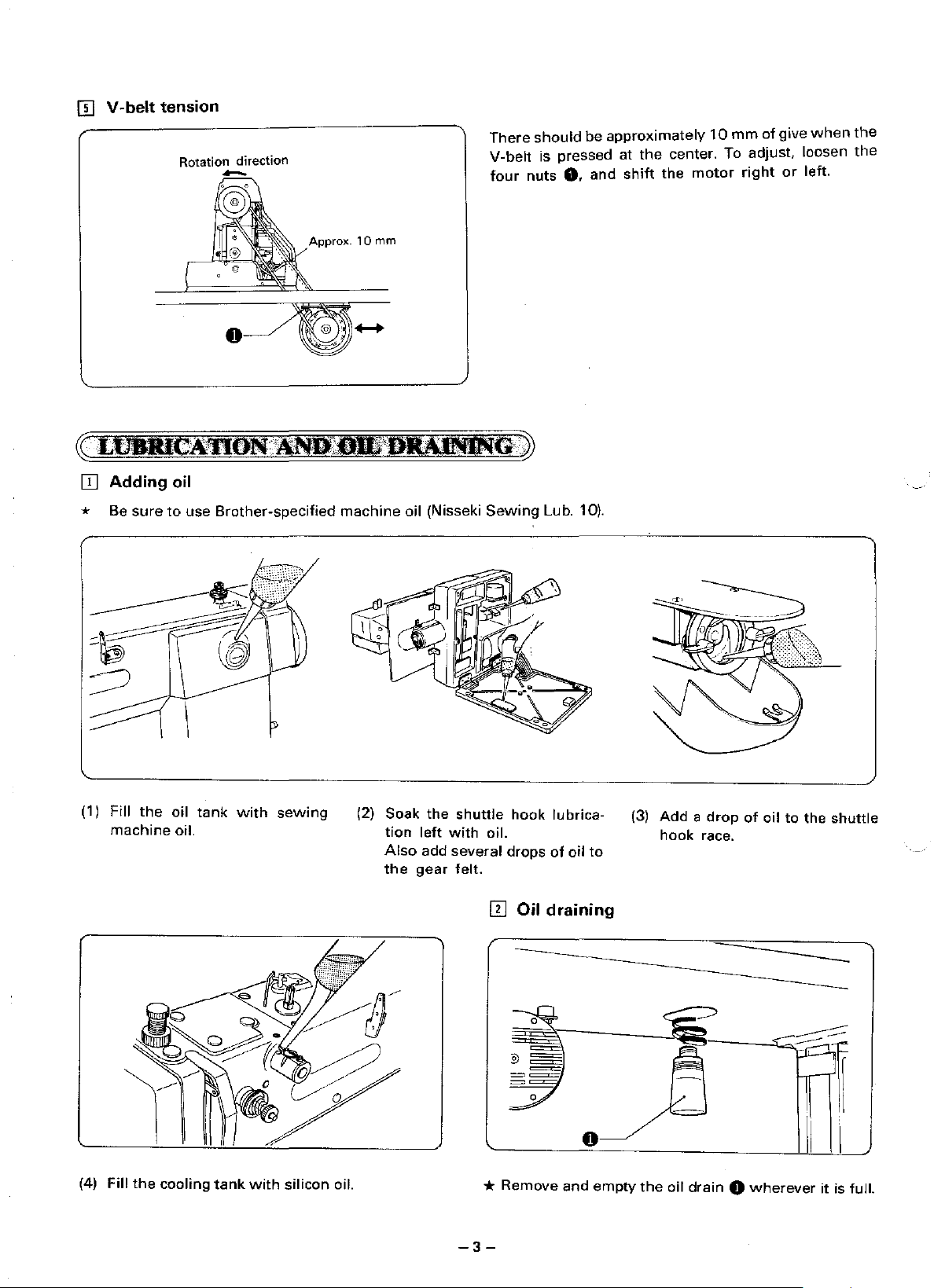

V-belt tension

1Il

Adding oil

Rotation direction

-~-

There

V-belt

four

should

nuts

be

is pressed at

0.

and

approximately

the

center. To adjust. loosen

shift

the

motor

10

mm

right

of

give

or

when

left.

the

the

* Be

(1) Fill

machine oil.

sure

the

to

oil

use

Brother-specified

tank

with

sewing

machine

(2) Soak the

oil (Nisseki

tion

Also

the

left

add

gear

Sewing

shuttle

with

several

felt.

hook

oil.

drops

ffi Oil draining

Lub. 10).

lubrica-

of

oil

to

(3)

Add a drop

hook

race.

of

oil

to

the

shuttle

(4) Fill

the

cooling

tank

with

silicon

oil.

-3-

*

Remove

and

empty

the

oil

drain 0 wherever

it is full.

Page 7

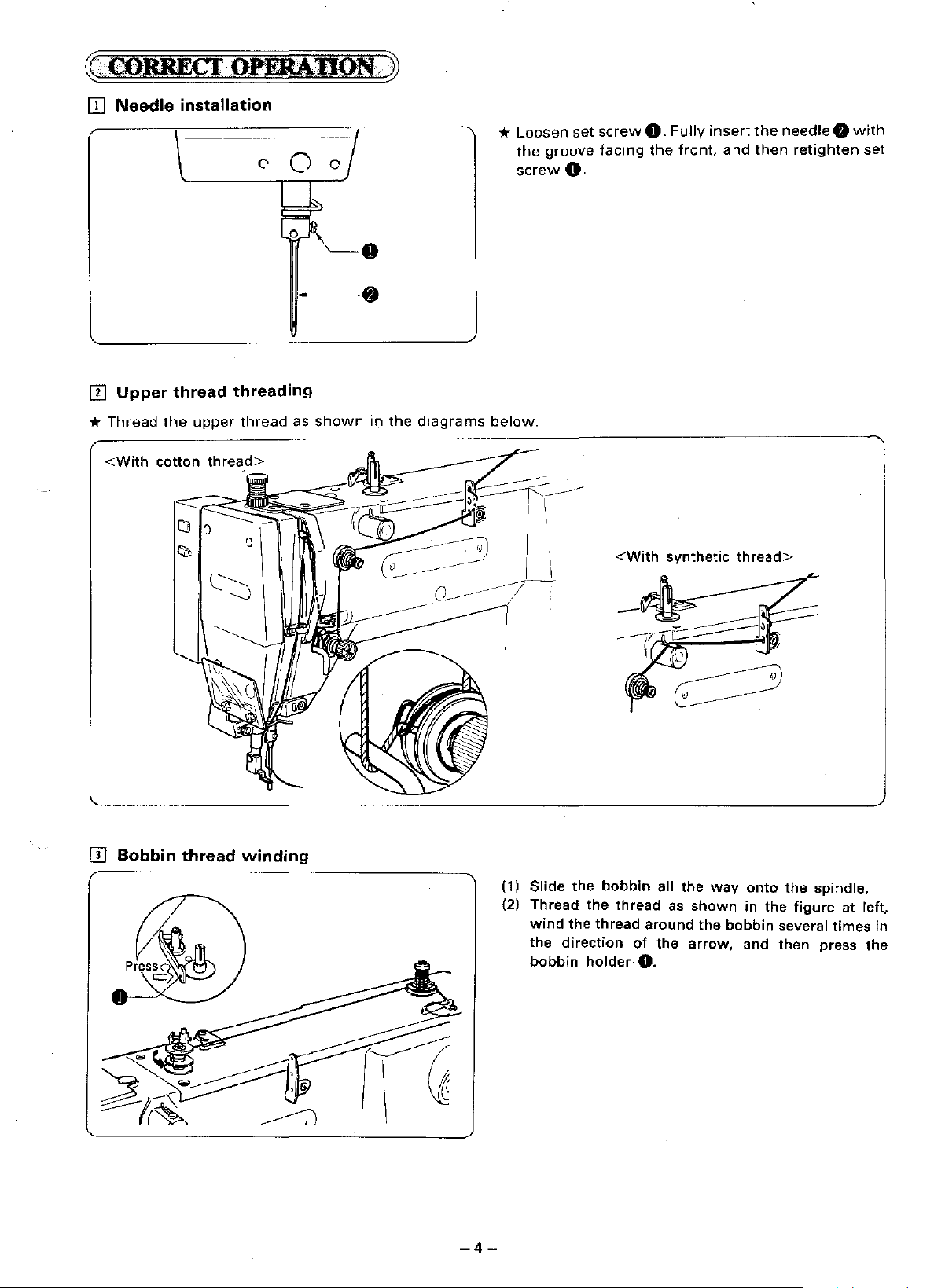

[j]

IIl

*

Thread

Needle

Upper

the

installation

thread

upper

threading

thread

c

~~

0

c~/

o,

!l.

•

@)

as

shown

in

the

diagrams

*

Loosen

the

screw

below.

set

groove

0.

screw

facing

0.

the

Fully

front,

insert

and

the

needle 0 with

then

retighten

set

ITl

Bobbin

thread

winding

(1)

Slide

(2) Thread

wind

the

the

direction

bobbin

the

the

holder

<With

bobbin

thread

thread

all the

around

of

the

0.

synthetic

way

as

shown

the

arrow,

thread>

onto

in

bobbin

and

the

the

several

then

spindle.

figure

press

at left,

times

in

the

-4-

Page 8

.:::<.1:::-f-!

"""'SPEED

.2@)-·

:: , ()

•0:>

,,,_

m•

IOlo

=

t

.AT,;;71b?

STEP BACK

I~

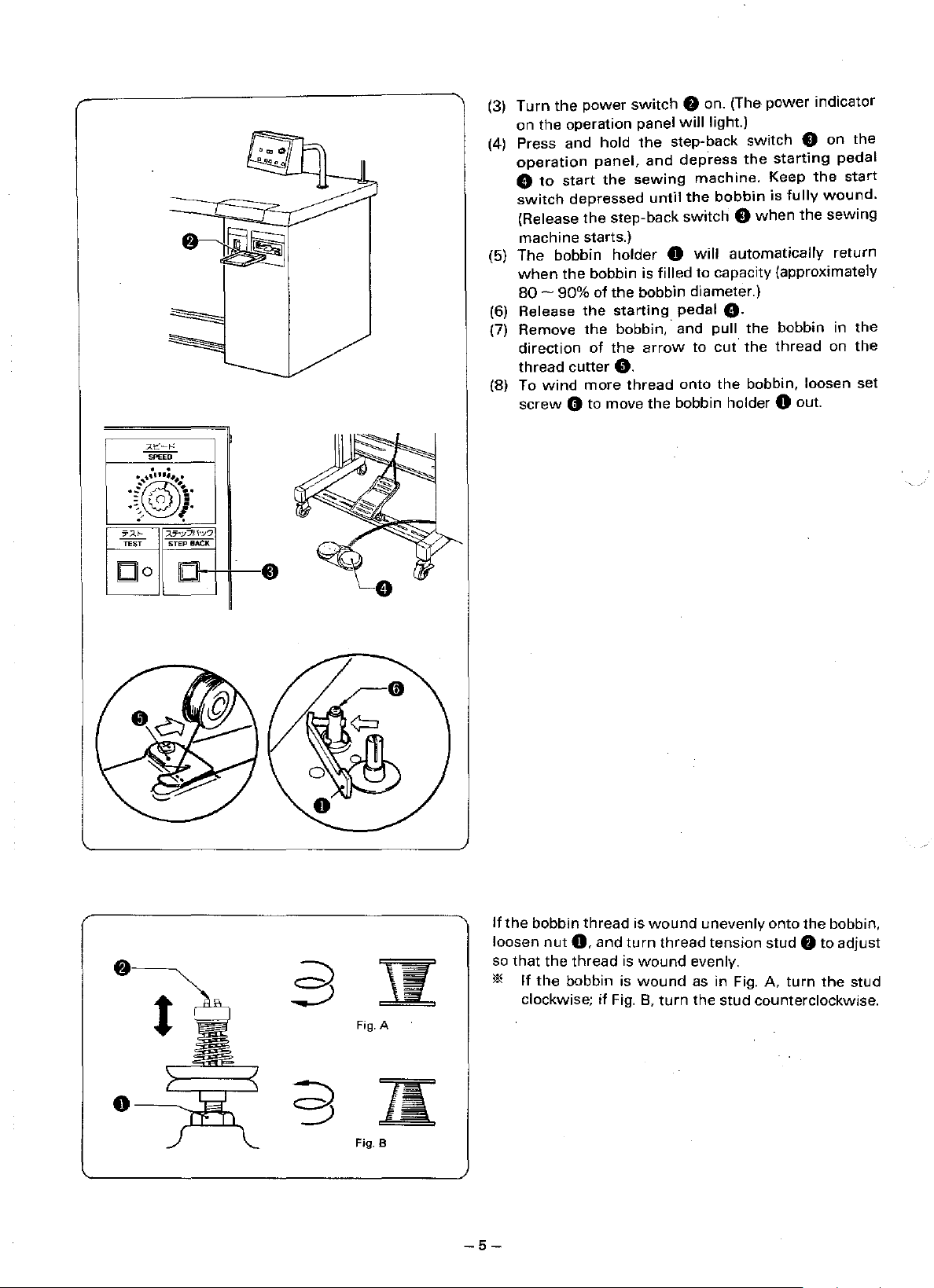

(3)

Turn

the

on

the

operation

(4) Press

operation

8

switch

(5)

The

when

(6)

(7) Remove

(8) To

and

to

start

(Release

machine

bobbin

the

80-

90%

Release

direction

thread

wind

screw e to

power

depressed

the

starts.)

the

cutter

switch

hold

panel,

the

step-back

holder

bobbin is

of

the

starting

the

bobbin,·

of

the

0.

more

thread

move

f)

on. (The

panel

will

light.)

the

step-back

and

dep.ress

sewing

bobbin diameter.)

arrow

the

machine.

until

the

switch 0 when

0

will

filled

pedal

and

to

onto

bobbin holder 0 out.

the

bobbin

automatically

to

capacity (approximately

8·

pull

cut·

the

power

switch

starting

Keep

is

the

bobbin

the

thread

bobbin,

0

fully

the

loosen

indicator

on

the

pedal

the

start

wound.

sewing

return

in

the

on

the

set

~

t

s

!I

Fig. A

1(

Fig. B

-5-

If

the

loosen

so

that

*

If

clockwise;

bobbin

nut

the

the

bobbin is

thread

0,

and

thread

if

is

turn

is

wound

wound

Fig. 8,

wound

thread

turn

unevenly

tension

evenly.

as in Fig.

the

stud

onto

the

bobbin,

stud

f)

to

adjust

A.

turn

the

stud

counterclockwise.

Page 9

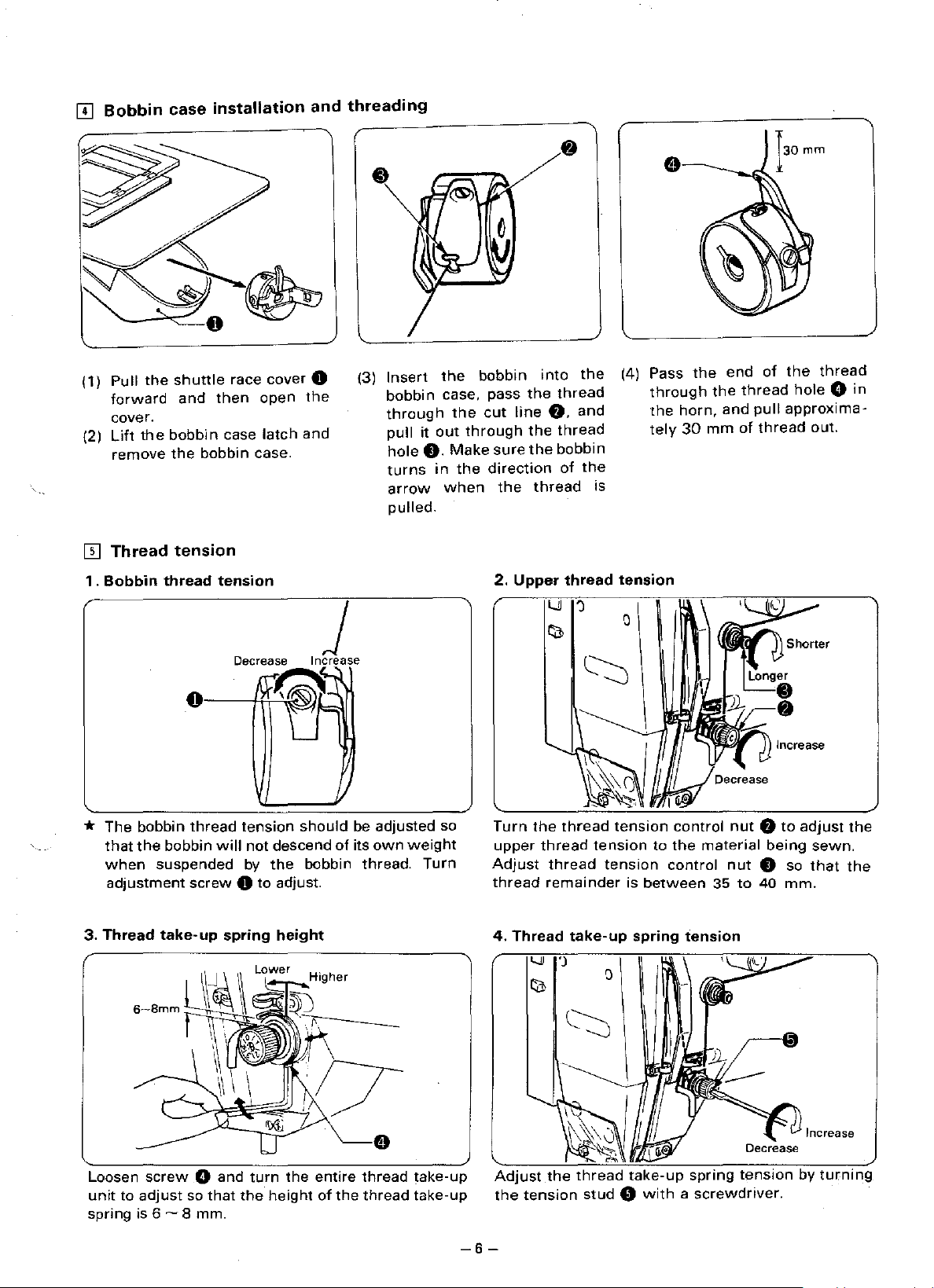

(1) Pull

(2)

III

1.

the

shuttle

forward

cover.

Lift

remove

Thread

Bobbin thread tension

the

and

bobbin

the

bobbin

tension

then

race cover 0

open

case

latch

and

case.

the

(3)

Insert

bobbin

through

pull

it

hole

0.

turns

arrow

pulled.

the

bobbin

case, pass

the

cut

out

through

Make

sure

in

the

direction

when

the

2.

into

the

line

0,

the

the

thread

Upper

the

thread

and

thread

bobbin

of

the

is

thread

(4) Pass

through

the

tely

tension

the

horn,

30

mm

end

the

and

of

thread

pull

of

thread

the

thread

hole G in

approxima-

out.

* The bobbin

that

the

bobbin

when

adjustment

3.

Thread

suspended

take-up

0

thread

will

screw

~

J

9

Decrease Increase

A

{~~'j

'--

tension

not descend

by

should

the

bobbin thread.

0 to adjust.

spring

height

Lower

/.,

be adjusted so

of

its

own

weight

Turn

Turn

upper

Adjust

thread

4.

Thread

the

thread

thread

thread

remainder

take-up

tension

tension

tension

to

is

between

spring tension

control

the

material

control

nut 0 to

nut

35

to

being

0 so

40

mm.

adjust

sewn.

that

the

the

Loosen

unit

spring is 6 ~ 8 mm.

to

screw

adjust

G and

so

that

turn

the

the

height

entire

of

the

thread

thread

take-up

take-up

-6-

Adjust

the

tension

the

thread

take-up

stud 0 with a screwdriver.

spring

Page 10

~

..

OIIBA!MG·PROQ.HJJ)(Jt'·~

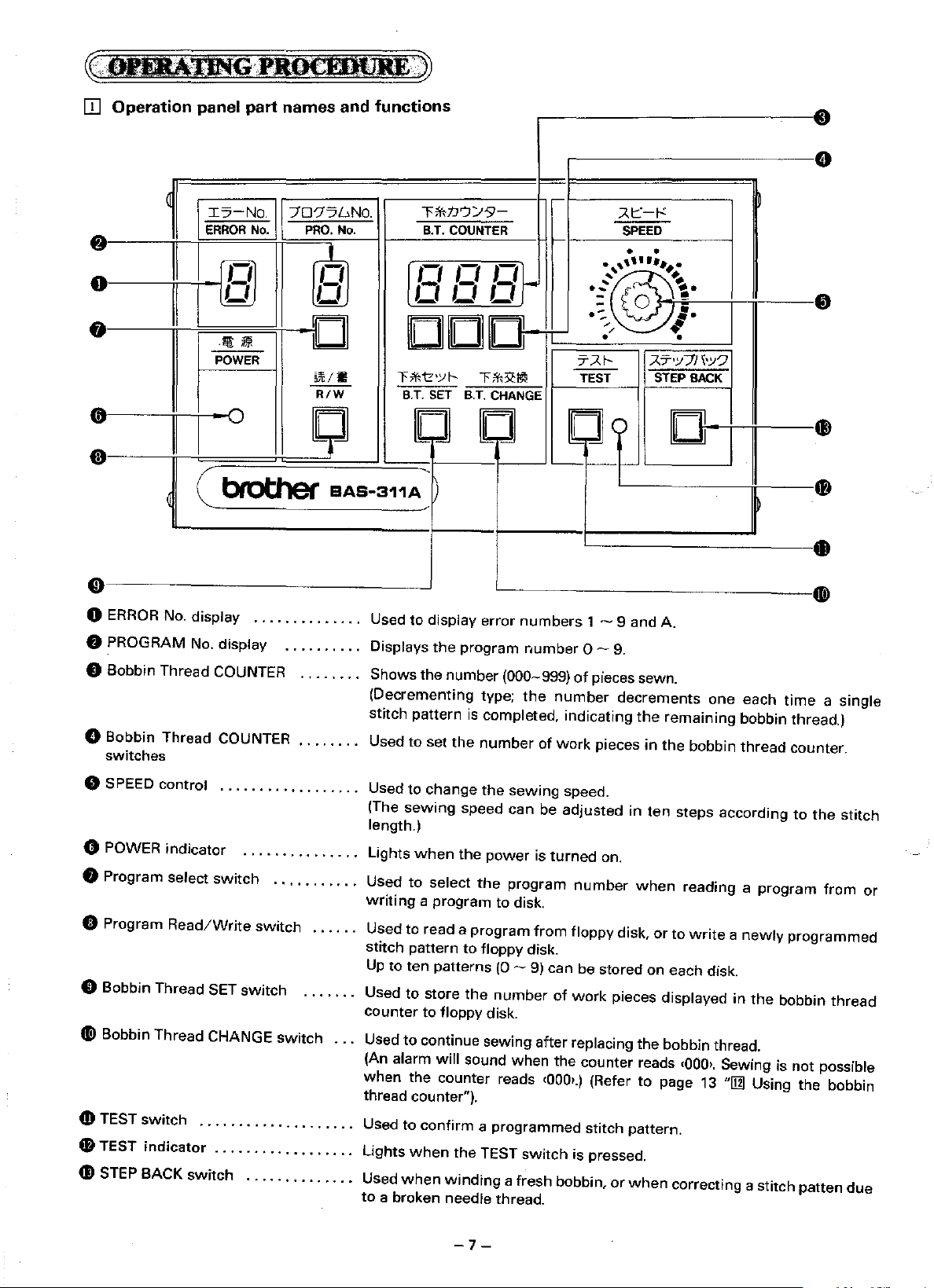

[j]

Operation panel part names and functions

....

""'

•

Ic:>-No.

ERROR

No.

70'7?wNO.

PRO.

No.

,_,

0

li

II

[@

Ll

I

.

!Jt

POWER

•0

I

l>i

II

(@

n

-

D

511:/W

R/W

[]

LILIU

CllCllD-

T;\'<'\z•yf-

B.T. SET B.T. CHANGE

[]

'

(

bf'ot:her

0

ERROR

0 PROGRAM No. display . . . . . . . . . . Displays

No. display

..............

BAS·311A

Used

to

T;\'<tJ')Y9-

COUNTER

B.T.

,_,

,_,

T;\'<:R:Ill

[J

~

display error

the

program

'

f-

1-

i-

' .

.....

: ;

~-

·:.

TAf-

--

TEST STEP BACK

[]o

'----

numbers

number 0-9.

1 - 9 and A.

).t:::

SPEED

• •

1-'

~

~·

,.

•

AT'Y71b?

D

•

O Bobbin Thread COUNTER . . . . . . . . Shows

(Decrementing type;

stitch pattern

C) Bobbin Thread COUNTER

switches

0 SPEED control

0 POWER indicator

8 Program select

0 Program

0 Bobbin Thread SET

II

Bobbin Thread CHANGE

4D

TEST

ID

TEST

Read/Write

switch

indicator

..................

...............

switch

switch

switch

. . . . . . . . . . . . . . . . . . . . Used to

. . . . . . . . . . • . . . . . . . Lights

...........

. . . . . . Used to read a

. . . . . . . Used

switch

Used to set

Used to change

(The

length.)

Lights

Used

writing

stitch pattern

Up

to

counter

. . . Used

(An

alarm will sound when the counter reads

when

thread

the

number (000-999)

the

is

completed, indicating

the

number

the

sewing

sewing

when

to

ten

to

to

the counter reads

counter").

when

speed can be

the

power

select

a program to disk.

store

to floppy disk.

continue sewing after replacing the bobbin thread.

confirm a programmed

the

program

to

floppy disk.

patterns

the

the

TEST

program

(0-

number

switch

of

pieces sewn.

number

of

work

speed.

adjusted

is

turned

from

floppy disk,

9) can be stored on each disk.

of

•000>.)

decrements

the

pieces

number

work

(Refer

stitch pattern.

is pressed.

in

in

ten

on.

when

pieces displayed

to

one

remaining

the

bobbin

steps according

reading a

or

to

write a newly

•000>.

page

13

each

time

a single

bobbin thread.)

thread

in

Sewing is not possible

"[j]

counter.

to

the

stitch

program

the

Using the bobbin

from

programmed

bobbin

thread

or

G)

STEP BACK

switch

..............

Used

when

winding

to

a broken needle thread.

-7-

a fresh bobbin,

or

when

correcting a stitch patten

due

Page 11

[I]

Using

the

* Programs

disk.

floppy disk

for

up

to

ten programs each containing up to a

maximum

4,000 stitches

can

be stored on each

floppy

(1)

Turn

the

power

(2) Hold

(3) To eject

* Slide

'*

*

the

disk 0

click

into

the

the

accidental erasure of the disk contents.

Inserting the disk into the drive upside

writing

Be

telephones,

exposure

of

sure to store your disks

place.

disk, press

write

data.

and

of

the

switch

with

protector 0 on

disk

other

to

0 on.

the

label up and

the

eject

devices.

oil

or

dust.

~~

the

metal

shutter

button

away

Magnetism

G.

the

back

of

the

down

or

backwards

from any magnets or magnetic sources, including radios, televisions,

can erase or damage disk contents. Also, be careful to prevent

disk

to

up

the

(the

may

'

!"

!

front,

window

damage

Unlocked, writing possible

Locked,

writing

and

insert

the

disk

into

the

opens)

the drive and will prevent reading

to

lock

the

disk and prevent

impossible

drive

O.

It

will

or

[]]

Using production counter

.-----,,-----~,.----

7D-7:JL!No

PRO.

No.

·x~~

·..

• ·-

~

·,

~in9

p!OOucliOQ

am

not be done while displaying the PRODUCTION counter.

""F*1J'")::JS'-

B.T.

COUNTER SPI

counter

Will

be displayed only after step

.At=:

...

.,

®

Both

PRO.

NO.

and B.T. COUNTER displays are available

for

the

four-digit

(1)

While pressing the TEST switch

SET

switch @. The test lamp 8 will light to display

the production count on both

COUNTER displays .

(j) Press the

TION

® Using the

be set from 0000

(2)

Press the TEST switch

out and all displays will return

play.

PRODUCTION counter .

BT

CHANGE switch @.The PRODUC-

counter will display 0000.

keys®,

the PRODUCTION counter

to

9999.

0.

(1).

0,

press the

PRO.

NO.

and

The test lamp 8 will

to

their

former

B.T.

B.T.

can

go

dis-

-8-

Page 12

[!]

Using

* By successively reading the

ches.

(1)

Set the DIP

(Refer

(2)

While pressing the EMERGENCY STOP switch,

The stitch pattern stored in the machine

(3)

In

(4)

When

stitch pattern.

put

8,000

stitch

SW@

to

page 26, "DIP SWITCH SETTINGS".) .

two

stitch patterns successively.

stepping

sewing

No.2

on

the starting switch, the second stitch pattern

to

ON. This

mode

two

stitch patterns

will

in

8,000 stitch sewing mode,

enter 8,000 stitch sewing mode.

turn

on

the

will

be erased.

power,

then release the EMERGENCY STOP sw1tch.

input

it

is possible

will

be sewn directly after the first

to

sew

up

to

8,000

stit-

input

NOtE:

[]]

Using

* By

using

.NOTE:

.

(1

I Set the DIP

(Refer

to

(2) Turn on

"1"

will

will

be

(Ex)

When

order.

(3)

*

When

When

pressing

(The

Pressing

stepping

reading

PRO.

The

rl\ao~

the

*tcond

single

single

As to spHt sewing, refer

grammer"

SW

page 26, "DIP SWITCH SETTINGS".)

the

be

displayed

displayed

the

the

NO.

the

will

jump

stitch

from

stitch J!llltt&m; · :

split

mode

split

mode,

(a

separate volume). .

@ No.1

power,

new

step back switch.

R/W

input

on

in

order.

three

patterns are

on

the

stitch patterns into

display

switch

it

IQ

to

ON.

the

the

PRO.

starting

switches

and

the

is

possible

th@

illstru~on

This

pattern

NO.

display.

programmed

switch,

from

displayed

the

final stitcll

to

change

will

enter

programmed

When

only

the

the

machine

1,

2 ...

stitch pattern

1]1anual

single

pressing the

with

split

pattern

from

to

9, 0.)

ofthe

fn-s~

up

to 9 patterns

of

.the

"e~.tromc

split

mode.

with

split

sewing,

displayed

the

floppy disk, press

will

Stitch pattern 'i,nj)Uno

immediately.

"1

'

'\ ' -:

,,-,

'-'

q '

··

· . • . ., _ . •

switch,

switches 1, 2, 3, 1, 2 ... in

PRO.

NO.

the

program select switch

read

into

sewing.

program

the

display

on

be

newly

P~'1'ammabl&

select

the

the

~rtlng

,•;,

. ·

'-

--' --

PatterQ

the

display

the

~et

program

can be sewn.

machine.

point

of

- - -

prq-

numbers

while

.•

that

-9-

Page 13

[ID

Using

the

program

R/W

{Read/Write)

switch

I5-No.

ERROR

•

POWER

0

No.

l.!R

7D-75L>No.

PRO.

No.

!Iii/&

R/W

* Programmed

can

be

patterns

storage and later recall.

(1)

Insert

the

contain

(2-

1)

To

Press the

play the number

PRO.

the

program number, press the

indicator

the

PRO.

When the

out

and the

the

number of the stitch pattern, reading is completed.

play @ will blink. Blinking will stop after the home

position is detected.

(2

- 2) To WRITE a pattern to

Press the

lect

the

ing the pattern

R/W

the

and a "P." will be displayed on the

while

the data is being read .

Pattern

sounds and the indicator 0 goes

NO.

display returns

completed.

stitch

patterns stored on floppy disk

read into

can be

the

memory,

written

floppy disk 8

programmed stitch pattern.

and

newly

to

disk

containing

programmed

for

permanent

or

which

READ a pattern to memory

PRO.

NO.

8 on the operation panel

of

the programmed stitch pattern in

NO.

display @.

0 will light, and a

NO.

display while the data

alarm sounds and the indicator 0 goes

"P"

on the

At

this time, the

After

R/W

"P"

PRO.

NO.

number

selecting the desired

switch

0.

will be displayed on

is

being read.

display changes to

on the

PRO.

disk

PRO.

NO.

8 on the operation panel to se-

desired program number.

with

the stitch programmer, press

switch

writing

0.

The drive indicator 0 will light,

onto disk will start

to

its

former

After

PRO.

when

out

and the

display,

programm-

NO.

is to

to

dis-

The drive

NO.

dis-

display

the

alarm

PRO.

writing

is

-

10-

*

If

an error

If

an error message code

the

Press the emergency stop switch 0 on the

the machine

then refer

ERROR

message

No.

to

to

and

is displayed

(1 -9,

display

stop sewing machine operation, and

follow

0.

and alarm will sound.

the

error code list on page

27.

A) is displayed in

front

of

Page 14

[I]

Using

the

STEP BACK switch

:TA-l-

TEST

A.7'Y7/I'Y?

STEP

BACK

* This

(1

I Press the emergency

(21

(3)

(41

(51

*

switch

at a time

resewing in the

bin thread runs

return

out. This is

chine is running.

emergency

Press the emergency

emergency

Press the

reverse one stitch at a

switch

When

position, release the step back switch.

clamp is stopped

back switch again

movement.

The machine

pedal (!) is pressed.

Turn

pedal(!)

forward. The

units

is used

in

the reverse sewing direction to enable

to

the

especially useful

stop

stop

STEP

is

depressed.

the

presser

the TEST switch 0 on and press the starting

to

move

if

the

STEP

to

move

the machine one stitch

event

the thread breaks

out

in mid-pattern. Use this switch

point

where

All

lamp

lamp

BACK

foot

too

to

will

start sewing

the presser

work

clamp

BACK switch is pressed at this time.

the thread broke

with

stop

switch 0

operations

will illuminate.

stop

switch 0 once again. The

will

go

out.

switch

0.

time

as

has returned

soon,

resume reverse

foot

will

or

the

bob-

or

run

large patterns.

while

the

ma-

will

stop and the

The

work

clamp

will

long

as

the step back

to

the

des~red

If

the

work

simply

press the step

work

clamp

when

the starting

one stitch at a

advance in 100 stitch

time

to

l

[[]

Adjusting

the

sewing SPEED control

A.t::-r-:

SPEED

(1

I The actual sewing speed can be adjusted in ten

steps

stitch

(21

Refer

speeds.

Stitch length

through

length. Turn

to

0.1-3.0

3.1-4.4

4.5-6.3

6.4-12.7

the sewing speed ranger

SPEED

the table

(mml

control 0

below

for

Sewing speed (spml

for

to

adjust.

allowable sewing

1,000-2,000

750-1,500

400-1,200

400-600

each

-11-

Page 15

w Using the TEST switch

77..1--

TEST

7..7'Y71b?

STEP

BACK

* Use the TEST

desired

thread runs out.

(1)

Press the emergency

ing machine is running. (All operations will stop, and

an

alarm

(2)

Press the

thread

(3)

Press the starting pedal ft.

The

work

ing

start position.

(4)

Press the TEST switch

light.

(5)

Press the starting pedal ft. (The needle

stationary as the

pattern at

presser

clamp

switch 0

time.)

(6)

When

press the TEST switch

and the

clamp

8 again

(7)

Sewing

pressed.

* The

work

by

pressing the STEP BACK switch 0

TEST

switch

0

to

fast forward.)

switch

point

when

will

sound.)

emergency

cutter

will

clamp

low

lifter

pedal 0

was

stopped

to

advance the

the

work

test

indicator 0

was

stopped

to

proceed.

will

start

clamp can be

8 is on. (Press the presser

to

begin sewing again

the thread breaks

stop

switch 0

stop

switch 0 again. (The

operate and the alarm will stop.)

will

move

automatically

$.

The test indicator 0 will

work

clamp advances

speed one stitch

to

fast

forward.

too

late, press the STEP BACK

work

clamp one stitch at a

clamp

reaches

8.

The

work

will

too

early, press the TEST switch

when

the starting pedal 8 is

forwarded

or

the bobbin

while

to

will

through

at

a time. Press the

If

the

desired position,

clamp

go out.

If

in 100 stitch units

lifter

from

any

the sew-

the

sew-

remain

the

work

will

stop,

the

work

when

pedal

the

the

[j]J

Using the emergency stop switch

(3)

If

a

problem

If

an

abnormal

activated, all

emergency

occurs

load

operations

stop

mode.

is

applied

stop,

or a problem

and

the

alarm

occurs

during

sounds. Press

-12-

* Press

(1)

*

(2)

The

sewing,

the

emergency

stop the sewing machine during actual sewing or

when

in

the

test mode.

If

the

emergency

sewing.

All

operations

Correct

switch

emergency

alarm

There

is pressed

on

If

the

All

when

the

0 again. The

will

will

(the

alarm

the

emergency

test

mode.

operations

emergency

the

the

the

will

problem,

stop

stop.

be no response

when

is sounding).

will

emergency

emergency

emergency

stop

stop

switch

stop,

and

and

press

thread

function

the

stop

stop function

will

emergency

switch

stop.

and

stop

switch 0 is

stop

stop

switch 0 to

when

function

switch

to

0 is pressed

an

alarm

the

emergency

cutter

will

be cancelled,

either

stop

0 is pressed

an

alarm

will

be

is

automatically

immediately

will

operate.

foot

switch

will

pressed.

cancel

while

sound.

stop

the

and

the

switch

0 is

during

sound.

cancelled

the

Page 16

[j]

Shifting a stitch pattern

r

I

7D?7L..No

PRO.

No.

-

fJJ

D

t.l'&;a

R/W

[J

1

~

T*-1J'J"J9

B.T. COUNTER

·n

l

DEllG

"'F*"t''Yf-

B.T. SET B.T. CHANGE

---tj

.--------,

®

' '

...

: 1

I I

L---;;-

l

;zt::

SPf

•

.

-I

LU

Ttf.::~~

L_

,,,.

~

...

',.......-,

.

-::,

·~;~

',

•

r::Zt-

TEST

-~...-

....

I-

8

[l-1:'

~

... ©

•

...

®

__ J

.@

* The relative position

stitch pattern

(1)

Press and hold

R/W

switch

<

,:;

..:;

<))

Press bobbin thread counter switch ®

pattern 1

@ Press bobbin thread counter switch ®

pattern 1

® Press bobbin thread

tern 1

pulse

@)

Press bobbin thread CHANGE switch @

pattern 1

*

At

this time, the

synchronizer and the home position sensor which

are operating.

Y~home

X-home

(2)

position

position

After

fine adjustment

pleted above, press the TEST switch

dicator

and the stitch pattern shift mode will be cancelled.

can

8.

> will appear in the bobbin thread counter

pulse

pulse

(0.1

pulse

sensor-------t

sensor

0 and bobbin thread counter 0 will go out,

of

a previously programmed

be shifted

the

TEST switch 0 and press

The test indicadtor 0

(0.1

mm) left .

(0.1

mm) right.

mm) up.

(0.1

mm) down.

PRO.

up/down

SET

switch ©

NO.

display 0 will indicate the

~Needle

._w..

I U Timing signal

(synchronizer)

"(f

----1.-r-e

....,....

...

Needle down

L__

(synchronizer) ·

of

the

pattern position is com-

and right/left.

will

to

to

to

shift the pat-

to

up

stop

(synchronizer)

stop

0.

The test in-

the

light, and

0.

shift the

shift the

shift the

signal

signal

[j]

Using the bobbin thread counter

T7f<1Y:>>9-

B.T.

COUNTER

,-,

,-,

0

C.t

C.t

DDD}t--•

T

i\\t?

'Y

t--

Ti\\:\Zill!

B.T.

SET

B.T.

CHANGE

-

•

DJ

-

D

,-,

•

-

""

* Set the bobbin thread counter

of

pieces

with

running

tern.

(1)

Press the bobbin thread counter switches 0 to display the

counter8.

the

out

number

of

the selected pattern which

amount

of

thread on the bobbin to avoid

of

bobbin thread in the middle

of

work

to

display the number

can

be sewn

of

a pat-

pieces in the bobbin thread

* The bobbin thread counter can be set to any number

from

<

001 > to

< 000

>,

sewing continues irrespective

amount

(2)

Insert the

SET

record the

bin thread counter

(3)

The

one each

the

sewn, the counter 8

will

the start switch is pressed.)

(4)

Press the bobbin thread change switch 0 and re-

place the bobbin. The alarm will stop, and the number

again in the bobbin thread counter

of

bobbin thread remaining.

floppy

switch

number

number

time

number

sound. (The sewing machine will not start even

of

work

< 999

>.

If the counter is set

of

the

disk and press

0.

An alarm will beep twice. This will

of

work

8

to

the disk.

shown in the counter 8 will decrease

the stitch pattern

of

patterns shown in the counter

will

read <

pieces set in step

the

bobbin thread

pieces shown in the bob-

is

completed. When

000

>,and

(2)

will be displayed

8.

an

alarm

to

is

if

-13-

Page 17

(1)

Turn

the

power

(2)

Insert the

(3)

Press the

(4)

Press

(The

the data is being read.

will

(5)

Step

(6)

Insert

the clamp.

floppy

PRO.

R/W

switch

floppy

go

on

disk drive indicator

out, then the

the presser

the

work

switch

0 on. The

disk

f,J.

No. selection switch 8

power

0.

will

When

reading

piece

program

lifter

under

no. display

switch 0 to

the

work

:10'.75/..>No.

PRO.

Iii/a

indicator on the operation panel

to

select the desired

light

and the

is

completed, an alarm

will

raise the presser foot.

clamp, and press the presser

No.

R/W

program

blink the

program

no. display

program

will

light.

number.

will

show

a P

will

sound and the indicator

number.)

lifter

pedal 0

to

while

lower

*

*

(7)

(8)

(9)

Shuttle

When

working

quired, press the manual

piece, and then press presser

Press the starting pedal

to

the

sewing

gram

is

sewing.)

Press the starting pedal 0 again

After

sewing is completed, the thread

clamp

will

of

sewing can be continued since

time.

hook

lubrication

with

small pieces

work

0.

(The

start position and blinking

rise.

When

the

power

which

are hard

clamp lifter pedal

lifter

pedal0.

work

clamp

will

to

start sewing.

cutter

is

turned

on

the

machine still stores the sewing data

to

position,

(i)

(This is convenient

will

return

stop. This is only required the

will

automatically operate, then the

after

once being

or

when

precise sewing is re-

for

precise positioning

when

sewing

to

the origin, and will then advance

turned

off, the same pattern

while

first

from

of

time

the

work

sitting.)

a pro-

work

the last

(1) Pull

forward

remove

the

to

the

shuttle

bobbin case.

hook

open.

and

cover

then

(2)

Slide

of

the

shuttle

tle

hook

the

tab 0 in

arrow, and

race

e.

body 0

-14-

the

direction

remove

and

the

shut-

(3)

Clean

pieces

shuttle

race.

After

add a

any

from

hook

cleaning

drop

of

dust

the

driver

thread

is

oil

to

and

thread

0.

the

guides

completed,

the

and

race.

Page 18

~

STANDARD

*Turn

[I]

Turn

needle

bottom

*

[I]

the

Needle

{DPx

the

pulley

bar

of

Align

Needle

machine

bar

a

5)

so

that

the

the

top

bar

pulley

height

to

completely

reference

needle

reference

lift

stroke

AWUSTMENTS

by

hand

adjustment

lower

line®,

bar

bushing

line

adjustment

®,

when

the

the

0.

with

making

needle

second

the

bar.

from

bottom

»

any

Remove

bott.om

adjustments

cap

reference

of

the

needle

f),

loosen

line

bar

set

screw

on

the

bushing

Q,

needle

when

and

vertically adjust

bar, is aligned

using

needle

the

with

the

DP x 5.

Turn

the

bottom

shuttle

*

Align

DP

1Il

Needle

the

X 5.

{DPx5)

pulley

hook

the

@

to

of

the

point

second

to

shuttle

raise

the

needle

is

aligned

from

hook

--ict-~-

needle

bar

bushing

with

top

reference

001-0.08

"--®

DPx

bar

from

the

point

0

17

the

0.

Now,

needle

line

gap

adjustment

mm

lowest

center.

@,

loosen

with

needle

Allen

the

bottom

position

screw

of

and

49

the

align

and

needle

turn

the

the

bar

bottom

shuttle

bushing

reference

driver

E) so

when

line®,

using

with

that

needle

the

Turn

the

pulley

connecting

and

link

stud e to

align

the

shuttle

adjust

hook

the

point

needle

with

to

shuttle

the

-15-

needle

hook

center. Loosen set

point

gap

to

0.01-0.08

screw 0 and

mm.

turn

the

eccentric

Page 19

IT]

Shuttle

Turn

the

pulley

connecting

will

result

point

will

[}]

Shuttle

driver

needle

0

and

align

the

link

stud

0 so

that

in skipped stitches.

interrupt

hook

the

needle, resulting

thread

contact

shuttle

the

shuttle

Also,

guide

adjustment

hook

point

with

driver

if

the

needle does

in

abnormal

adjustment

the needle center. Loosen set

meets

the

needle

not

sufficiently

abraison.

Adjust

thread

thread

8.

Note

so

that

guide

guide

contact

8 is

lightly

screw

that

excessive needle

the

shuttle

the needle

at

the

center

in, and then

Oand

driver,

groove

of

turn

the

eccentric

to

driver

contact

the

shuttle

of

the

shuttle

the needle, slide

retighten

the screws.

hook

hook

the

ffi

Two-step

Maximum

stopped.

(1)

Lower

plate 0 to

Now

(2)

Lift

presser

to

the

work

the

presser

tighten

work

0 mm,

work

clamp adjustment (independent presser

clamp 0 lift

plate

and

screw G and

plate 0 again,

clamp

0 is

f).

then

18

is

18

Loosen

tighten

nut

O.

and

loosen

mm.

mm

from

screw G and

screw

Q.

nut

the

needle

nut 0 to

Spring 8 will

0.

Adjust

-16-

plate

guide

top

adjust

be

minimally

stud

toot

solenoid type)

to

the

work

the

gap

0 so

that

clamp 0 when

between

tensioned at

the

the

height

work

this

from

the

machine

clamp 0 and

time.

the

needle plate

is

feed

top

Page 20

0 Movable knife adjustment

Loosen

the index on the needle plate

<{Replacing the movable and fixed knives}>

(1) Remove

nut@

screws

disconnect

and

the

move

connecting

f),

and remove feed

thread

cutter

rod L 8

when

the

machine is stopped.

plate

connecting rod 0

right

or

f).

left

so

Remove

from

stud

that

the

V-notch

screws 0 and

f).

@of

G.

the

movable

and

remove needle plate

knife 0 is even

e.

with

Now

Movable knife -------c;;t

washer

(2) Remove

new

the

necessary, use

to

the

movable knife.

movable

adjust

the

;-:::---~

~

movable knife,

Now

knife 0 and

the

provided movable knife

knives so

check

that

and

the

they

replace it

the

cutting

fixed knife

cut

properly.

with

edge of

0.

washer

~-

a

If

-17-

(3) Install

hole plate

the

fixed

G).

knife 0 0.5

mm

away

from

needle

Page 21

I1J

Presser

foot

adjustment

(4) Fit

*

the

thread

ing

lever

When

the

*

(1)

*

(2)

fitting

ing

lever

and

e.

bit

to

confirm

connecting

Turn

the

the

down

below.

Loosen

8

lightly

screwO.

If

the

presser

will

shift

too

high, skipped

Turn

the

enters the center of the needle hole

foot

f).

of

the

needle

and

turn

cutter

connecting

pin

o.

and

install

the

connecting

pin

0 and before

move

the

needle

that

rod

pulley

by

position,

screw

0.

against

foot

when

sewing.

stitches

pulley

by hand,

If

the

needle

hole,

the

presser foot (presser bar)

plate

the

movable knife 0 is

e.

hand

to

and

then

set

the

bottom

the

work

is

lowered

Also,

and

is

not

remove

may

rod 0 on

needle

lower

capo.

plate

rod 0 on

tightening

back

and

the

proceed.with

of

the

piece,

and

too

far,

if

the

occur.

make

sure

aligned

with

loosen

connect-

e.

the

connect-

screws

forth a little

pulled

presser

the

presser

then

tighten

the

work

presser

the

in

the presser

the

screw

to

adjust.

0

by

foot

to

steps

foot

piece

foot

is

needle

center

e.

[[]

Changing the presser

*

Maximum

mm.

4 mm presser 0

foot lift

standard

0

(1) To

(2) If vertical

change

intermittent

(There are

movement

the

presser

two

presser

lift

of

the

foot

indexes, 4

of

foot

presser

cam

and

the

presser

lift

foot

C)

7, on

lift

foot.

over.

the

foot

is 4

mm.

~I

remove

cam. The

is

Presser

0

7

mm

foot lift

nut

(small)

number

not

required, remove

-18-

foot

lift

on

presser

0.

nut

of

the

this

(large)

index

the

machine

8.

indicates

cam

e.

can be set

and

washer

the

0.

lift in

to

either 4 mm

and

then

millimeters.)

0

turn

or

the

7

Page 22

[jQ]

Wiper

adjustment

iapprox.

15mm

(1)

When the thread

the needle center. Loosen screws 8 and shift the entire solenoid bracket 0 up

* The standard

(2)

When

the

[ill

needle

Loosen

not strike

Needle

19

Needle

mm

tip

screw

the

and

up

wiper

solenoid plunger 0 is driven

height

wiper

should be approximately 2

presser foot 0

feed

position

from

the

solenoid bracket G bottom to

f)

is operated and aligned

0 and move

timing

Material

the

or

adjustment

wiper

needle.

~eed

Feed

e

mm.

f)

in

operating

stopped

with

or

out

;\:Y

to

the

center of

to

adjust. As

,

C\!J

the full stroke, the

the

needle plate

the

shown

~

2

mm

wiper

needle bar,

in Fig. A, make

Rotation

8 should be

or

down

top

is

approximately 131 mm.

the

distance

direction

to

sure

Fig.

adjust.

from

the

A

15

mm

the

wiper

wiper

0

in front

f)

f)

does

of

to

(1)

*

Adjust

Turn

Adjust

needle

material.

reflector 0 so

clockwise

the

has

to

needle

been

removed

that

lower,

and

the

needle

counterclockwise

feed

timing

from

the

with

material,

tip

is

19

mm

to

raise

synchronizer 8 so

and

so

-19-

1

above

that

the

the

the

stop

needle plate

position.

the

feed

-feed

mechanism

when

the

mechanism

stops

needle is in

begins

before

to

the

the

operate

needle

up

position.

after

enters

the

the

Page 23

IJ1I

"DIP

2-step

switch

work

clamp operation adjustment

®-1"

ON

=m

ON

=m

When

OFF;

The presser

When ON;

The presser

sewing

Dip switches

foot

foot

is

completed.

Turn the

operation panel.

(1)

will

rise automatically when sewing is completed.

will

rise when

power

Presser

settings

the

presser lifter pedal is pressed

off, then open the side cover

foot

of

motion

DIP

can be adjusted

switches®

1,

2,

3,

by

changing

4, 5 and

after

7.

of

the

the

«DIP switch

~~

®-2,

ON

ON

3,

4»

2:0N

3:0FF

First switch

Second switch

2:0FF

First switch

Second switch

2:0N

First

switch

Second switch

ON:-----'Work

3:0N

ON:-----'Work

3:0N

4:0N

ON:-----'Work

First

switch~

Second

switch

For

clamp left fJ, and the presser foot 8 will

neously.

will appear

pedal

*For

OFF.

4:0N

clamp right 0 descends.

ON: Work clamp

4:0N

clamp left 8 descends.

ON:

ON: Presser

Work clamp right 0 and presser

clamp right 0 and

o

pneumatic type, after sewing work clamp right

The

work

clamp (right and left} and the presser foot

as

below

when

they

is a two

solenide type, DIPSW

foot

position switch.)

left

8 and presser

0 descends.

work

descend. (The presser lifter

®-2,3

and 4

should

foot

0 descend.

foot

0 descend.

clamp left 8 descend.

all

rise

be

8,

work

simulta~

all

set

to

2:0N

3:0N

4:0FF

First

switch

Second switch

Start

switch

ON:-----Work

ON: No

ON: Presser

-20-

clamp

right

movement

foot

0 descends.

0 and left 8 descend.

Page 24

«DIP switch

®-5»

ON

The sening

ation

of

the

of

DIP

switch ® < 5 > determines the oper-

work

clamp during split

mode

operation.

Work clamp

cally during split mode oper-

ation.

«DIP switch

rises

®-7»

Normal

automati-

Work clamp

presser lifter pedal

during

Single pedal operation

rises

split mode operation.

when the

is

pressed

DIP

switch®

ation.

<7>

is used

to

select single pedal oper-

When the start switch is pressed, the

matically

drops, and sewing starts when the switch is re-

leased.

work

clamp auto-

-21-

Page 25

@]

Changing

uDIP switch

the

thread breakage detection stitch margin setting

®-5»

<Normal: 8 stitches>

1--1-...-.-j:::::

,__.__,o

<

14

stitches>

The thread breakage detection stitch margin setting

be set to either 8 or

of

DIP

switch®-< 5 >.

DIP

switch ®-< 5 > is normally set

(In

this position,

margin is 8 stitches.)

When this switch is set to

14

stitches.

NOTE:

NOTE:

If

the

thread breakage detector misoperates, set

the thread breakage detection stitch margin

stitches.

If

the

thread

breakage detector senses thread breakage,

ping the machine upon the third stitch regardless

of

the setting

14

stitches by changing the setting

to

OFF.

the

thread breakage detection stitch

ON, the stitch margin will be

is

broken during sewing, the thread

of

DIP

switch®-< 5 >.

can

to

14

stop-

[j]

Changing the feed speed

uDIP switch

®-8»

<Normal

ON

~1--1--i

speed>

....

....

0

The feed speed

of

DIP

switch®-< 8 >.

DIP

switch®-<

(Feed

speed: approx.

When this switch is set to

material at high speed.

(Feed

speed: approx.

can

be

changed by changing the setting

8 > is normally set

15

em/sec.)

ON, the machine can feed

25

em/sec.)

to

* If the material slips, set the switch

OFF.

to

OFF.

the

-22-

Page 26

[iiD

Changing

the

speed

at

the

start

and end of sewing

Be

sure

to

turn

off

the

power

before opening the control

box.

(1) The sewing starting and en?ing speeds

changed according

< 1 > and

«DIP switch

<2>.

©-1n

When

to

the settmg

OFF:

It

the first stitch.

of

DIP

will

be approx. 600 spm

~ON

ON:

It

will

When

be approx. 260 spm

the first

two

stitches.

~ON

?an

sw1tch

be

©-

for

for

(2)

By changing the setting

at its highest position since the upper shaft

«DIP switch

4 3 2 1 When

©-3»

of

OFF:

The machine

DIP

switch©-<

will

«DIP switch

4 3 2 1 When

- the last

©-2»

OFF:

It will be approx. 400 spm

two

[]__WoN

When ON: It will be approx. 260 spm

the

last

two

3 > on the

is

stop

motor

circuit board,

rotated in the reverse direction after the thread is trimmed.

with

the needle

at

its normal position.

the

machine can

be

stopped

stitches.

stitches.

with

for

for

the needle

mON

1

4 3 2

~ON

NOTE:

All

When ON: The machine

of

DIP

switch

©is

factory preset

will

stop

to

OFF.

with

the needle

-23-

at

its highest position.

Page 27

Jj]J

Using the memory switch

The

memory

memory

switch settings can be used

switch settings)

e

0

to

customize the

I-;;

~

lBl

70'1-::>L...No

NO

PRO. No.

I I

~

D

R

~~~

R/W

D

r:J

work

clamp's operation. (Refer

to

the

following

table

0

AI::'

""F:*1J'J/-9

B.T. COUNTER

[,'

I I I

n n

q~

1_1

DDD

Tii'<i?'~'~'-

T:'i':3Hi.!!

TAC

TEST

r.:

SPEED

. .

·,(@)

.~@

= 0 :

.-_>

~·

~·

J..7'V7! \•;;'?

STEP

BACK

D

8

.·~-to

of

the

(1)

While pressing

No.O

will appear on the

memory

the

(j)

"on"

or "oFF" will appear on the

® When the

order

of

switch

®

All

® Insert a

disk.

NOTE:

(2)

Press the

The TEST lamp E)

NOTE:

~

MEMQRX

The following are special uses. All

NO.

9-F

number

of

the

floppy

When memorizing

when the program including

All

of

Also, when the

switch are set

0 When moving

1

2

3

4

5

6

7

8 Presser crank flips over after

the

TEST switch

PRO.

switch number.

PRO.

No. switch 0 is pressed,

0,

1,

2,

...

9,

A, b,

will appear on the

memory

TEST

the

switch

disk, and press

the

switch

memory

$.

will

go

switch is factory preset

power

to

OFF.

SWITCH

When moving the sewing start

When moving

When moving the sewing start

The home position is changed

direction and then the X direction, and then reversely.

NOTE: When using the

OFF

Upon emergency stoppage, the machine stops

At

the sewing end position, the feeder passes through

At

the sewing end position, the

The presser foot remains lowered.

NOTE: The cycle

OFF

0.

No.

displayO,

B.T.

...

F,

0,

1,

will

be set

the

current

your

out, and the indication on each display will I be returned

is

turned on while pressing the EMERGENCY

SKt'llNGS

of

to

to

e o o

press the

COUNTER display 0 alternately when the

and simultaneously the

B.T.

to

B.T.

SET

memory

STEP

BACK switch@. The TEST

and

"on"

or

"oFF" will appear on the

the

memory

COUNTER display.

"oFF'

when the

switch E). The current

switch setting on the

setting is read

switch number on

from

to

OFF.

memory

B.T.

CHANGE switch 0 is pressed.

the

floppy

4~

lampE)

B.T.

the

PRO.

switch function corresponding

memory

floppy

switch setting

disk, this setting will appear automatically

disk drive.

STOP

switch, all the settings

will light, the

COUNTER display@ according to

STEP

BACK switch 8 is pressed.

No. display 0 will change in the

will

be stored on the

to

its original state.

~

the

memory

the home position, the feeder moves in the X direction, then

the home position, the feeder moves in

time

will

switch

position,

position,

to

work

clamp

work

be shortened

1/4

is

usually set

When

it

moves in

it

moves in the X direction, then

the forward position and

for

attaching buttons, set this switch

clamp rises, and moves to the sewing start position.

when

of

a pattern is sewn, and flips back after

-24-

to

OFF.

ON

theY

direction, then the X direction.

theY

direction, then

theY

the

feeder moves first in

to

with

the needle at its highest position.

the

first home position.

the

program includes many feed points.

3/4

ON.

memory

to

its

of

theY

direction.

the

X direction.

direction.

theY

is sewn.

switch

memory

floppy

the

memory

Page 28

Press

Press

Depress

Power

Insert

the

presser

switch

floppy

PRO No.

the

R/W

lifter

Test

switch.

switch.-

pedal. -

switch

START

on

disk

on-

-

-

-

- Reads

+--

program

Set the work piece.

+--Work clamp descends.

+--Test

lamp

illuminates.

from

disk.

Press the

Select

number.

Press

Press

the

(if

the

work

Power

switch

PRO

No.

the

program

the

R/W

presser

lifter

clamp is down).

To

change

on

switch -

switch.-

pedal

pattern

-

+-Read

-Work

__..

'*Replace

* Set material

program

clamp

plate;

confirm

descent.

from

rises.

presser

in

place.

disk.

foot,

needle

feed

Depress starting pedal -

Depress

starting

pedal -

Test

switch

off-

Depress starting pedal - -

-Presser

start

-Feed

(confirm

presser

operation.)

-Feed

+--Test

Machine,

} Max.

foot stops at

position.

drive

(pulse

needle

foot

and

stop

lamp

goes

feed

2.000

motor)

descent.

work

out.

operate.

spm.

sewing

clamp

Depress presser

Press

emergency

swtich.

Press

emergency

switch.

lifter

pedal.

When

bobbin

stop

stop

__..

thread

thread

__..

__..

breaks

runs

-Machine

sounds.

-*Remove

-Thread

alarm

or

out

cutter

stops.

)

stops,

problem

operates,

alarm

I

One

pleted

machine

+--Stop--thread

cycle

com-

Work

I

cutting

I

clamp

rises

-25-

Press

Press

step

step

back

back

switch.

__..

switch.__..

Work

-

stitch at a

direction.

-Work

clamp moves one

time

in reverse

clamp stops.

Page 29

« DIP SWITCH SEI'llNGS

~

0

Ot::J

®

@

NO.

1

2

3

4

5

6

7

8

®

When ON

Work clamp does not

Right

- left

two-step

Left - right

When the switches

and presser

Work

Presser crank

(Inner clamping device is optional.)

Single pedal operation possible using the starting pedal

Activates thread breakage

two-step

foot

clamp does

of

rise

when sewing completed

work

clamp (refer

work

clamp (refer

2,

3 and 4 are on,

will

descend

not

rise

inner clamping device

with

during

detector

left

two

split mode operation.

(Thread breakage detector is optional)

to

P.20)

to

P.20)

and right

positions. (refer

turns

to

the

work

other

©

[MMJI

clamps will descend at one time,

to

P.20)

side

NO.

1 Single

2

3 Thread

4

5 Thread breakage detection stitch margin setting can be set

6

7

8

split

mode

possible

8000-stitch sewing

trimming

Needle cooler can be used. (Needle cooler device

OFF

OFF

High feed speed

mode

possible

does not function

When

when

ON

emergency

©

NO.

1

2

3

4

The first

The last

The

with

OFF

two

stitches are sewn at

two

stitches are

upper

shaft

turns

the needle at its highest position.

sewn

in the reverse direction after thread breakage, and the machine stops

at

When

ON

low

speed (approx. 260 spm).

low

speed (approx. 260 spm).

-26-

stop

is

optional.)

switch is pressed.

to

either 8

or

14 stitches.

Page 30

·

..

•

NO.

1

2

3

4

5

6

7

8

9

A

Emergency stop switch pressed

Trouble

Over-area

Floppy disk not inserted,

Floppy disk is locked (write protected).

No program registered

Error occurred in program mode.

Thread breakage detected

Protection network activated because

No

with

the

motor

or synchronizer/Motor stopped

or

cable not properly connected

usable pattern data on disk

Cause

of

abnormal voltage

when

voltage dropped

-27-

Page 31

Page 32

BROTHER

INDUSTRIES, L TO.

NAGOYA.

JAPAN

151·311A

883Z11·002

1993,04,L~

Printed in Japan

Loading...

Loading...