Page 1

AUTOMATIC

SLEEVE

EASING

MACHINE

INSTRUCTION

MANUAL

BAS-150

--·•n.••

r

.,

-

--

...

IJ

-

L____

_

Page 2

~FEATURES

OF THIS

MACHINE)

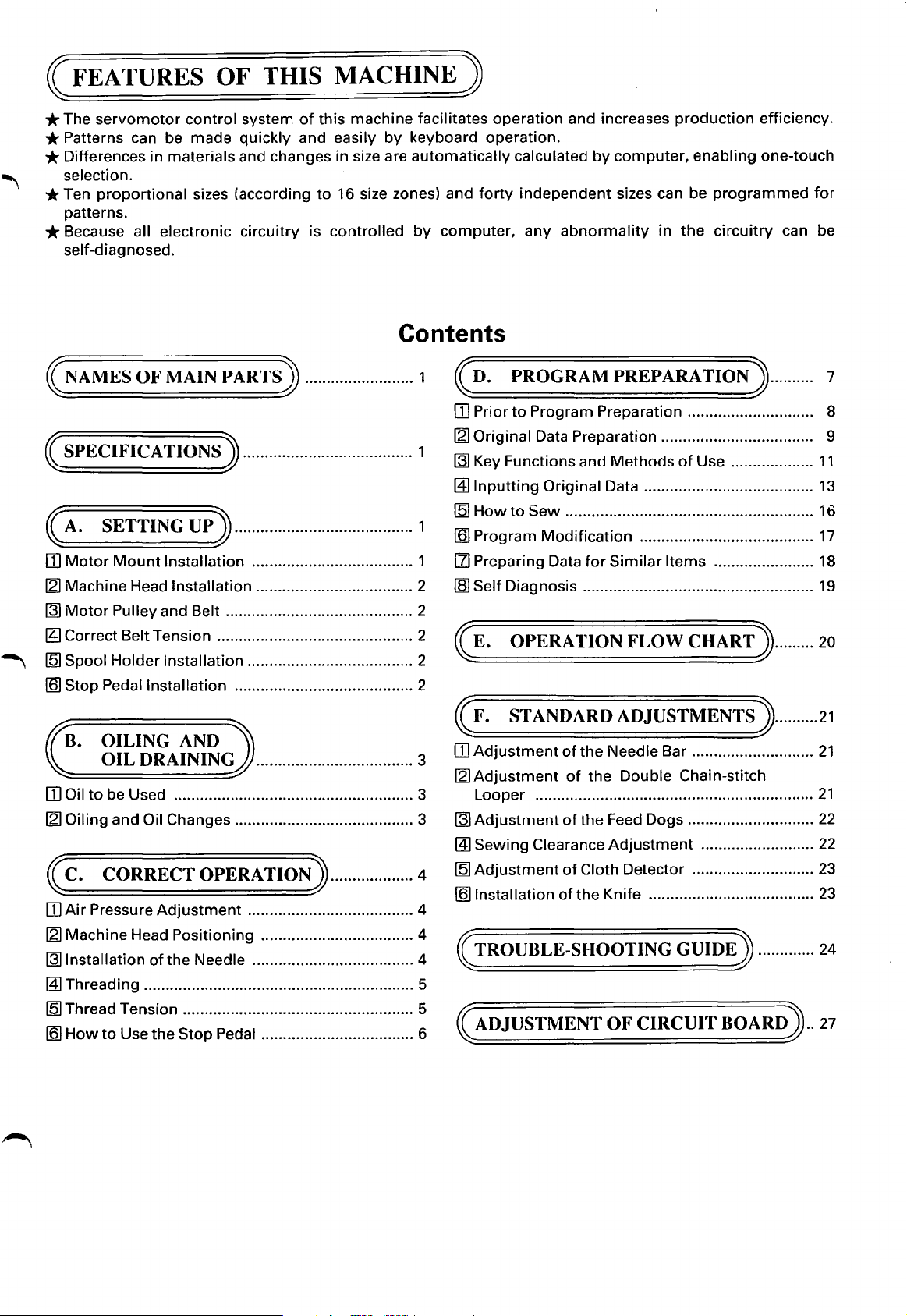

*The

*Patterns

*Differences

*Ten

*Because

~NAMES

{SPECIFICATIONS)

~A.

1Il

121

[3]

servomotor

can be

selection.

proportional

patterns.

all electronic

self-diagnosed.

OF

control

made

in materials and changes in size are

sizes (according

MAIN

system

quickly and easily

circuitry

PARTS)

of

this machine facilitates

to

is

controlled

......................... 1

16 size zones) and

....................................... 1

SETTING

Motor

Machine Head Installation .................................... 2

Motor

Mount

Pulley and Belt ........................................... 2

UP)

......................................... 1

Installation ..................................... 1

operation

by

keyboard operation.

automatically

forty

by

computer,

Contents

~D.

1Il

Prior

121

Original Data Preparation ................................... 9

[31

Key Functions and

~Inputting

[5]

How

[QJ

Program

[1]

Preparing Data

[8] Self Diagnosis ..................................................... 19

and increases

calculated

independent

any

by

abnormality

computer,

sizes can be

production

enabling one-touch

programmed

in

the

circuitry

efficiency.

for

can be

PROGRAM PREPARATION)......... 7

to

Program Preparation ............................. 8

Methods

Original Data ....................................... 13

to

Sew

......................................................... 16

Modification

for

Similar

of

Use ...................

........................................

Items ....................... 18

11

17

~Correct

~

[5]

Spool Holder Installation ...................................... 2

!61

Stop Pedal Installation ......................................... 2

B.

1Il

Oil

121

Oiling and Oil Changes ......................................... 3

~C.

IIl

Air

121

Machine Head Positioning ................................... 4

[31

Installation

~Threading

·~Thread

!61

How

Belt Tension ............................................. 2

OILING

OIL

DRAINING .................................... 3

to

be Used ....................................................... 3 Looper ................................................................

CORRECT

Pressure

of

.............................................................. 5

Tension ..................................................... 5

to

Use

the

AND

OPERATION)

Adjustment

the

Needle ..................................... 4

Stop

...................................... 4

Pedal ................................... 6

.................. 4

~E.

~F.

1Il

121

[31

~Sewing

~Adjustment

IQ]

~TROUBLE-SHOOTING

~ADJUSTMENT

OPERATION FLOW

CHART)

STANDARD ADJUSTMENTS ) .........

Adjustment

Adjustment

Adjustment

Installation

of

the

Needle Bar ............................

of

the

Double Chain-stitch

of

the Feed Dogs .............................

Clearance

of

Adjustment

of

Cloth Detector ............................ 23

the

Knife ......................................

.......................... 22

GUIDE)

OF

CIRCUIT

BOARD)

.........

.............

20

21

21

21

22

23

24

..

27

Page 3

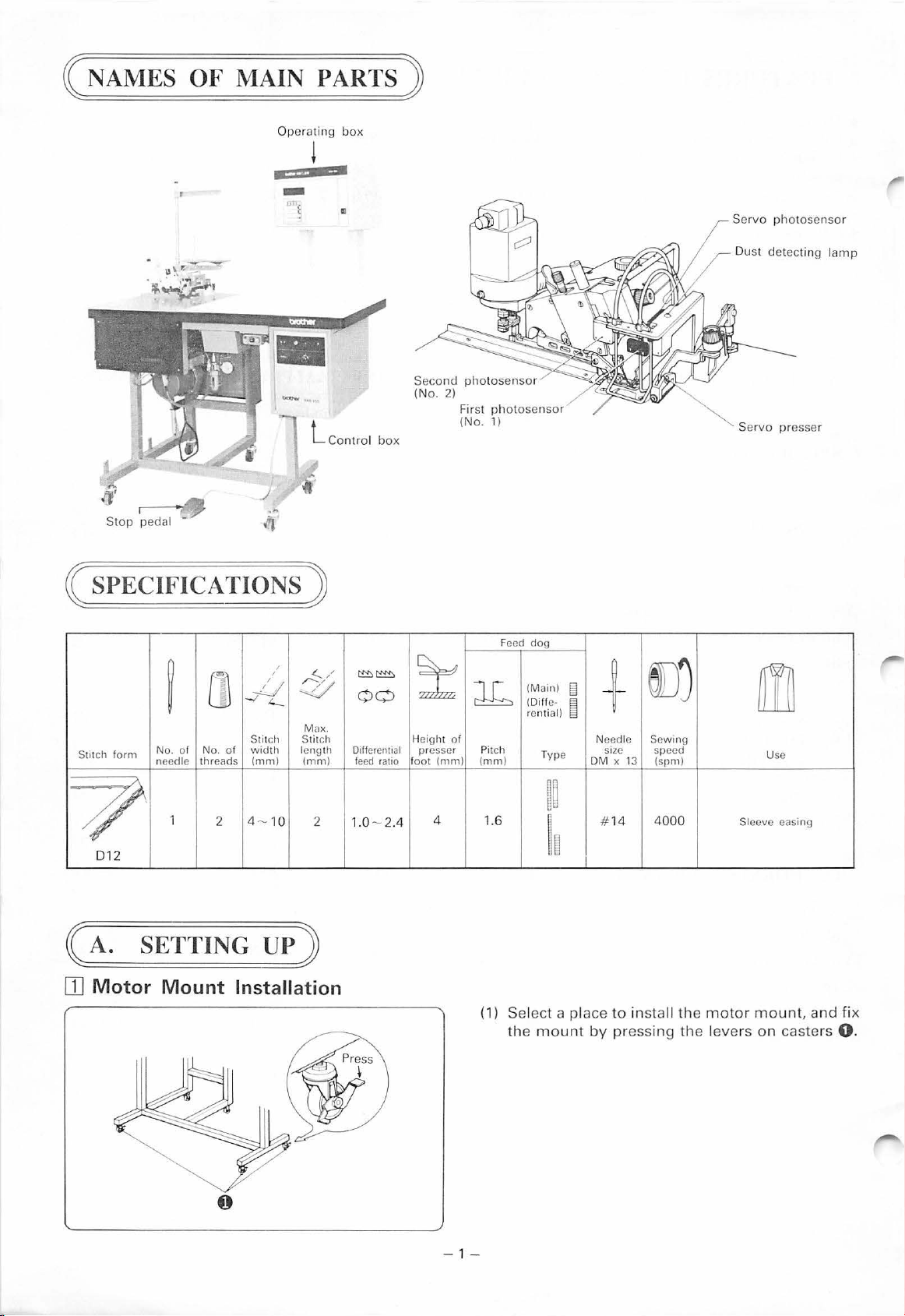

( NAMES

OF

MAIN PARTS )

Op

era

ting

~

•

' t

-

•

box

ll

Ser

vo photosensor

Dust

det

ecting

lamp

-··

l Cont rol

.....

fJ'

Stop

~

( SPECIFICATIONS )

/

/

10

~/

4

Max.

Stitc

length

(mm)

Stitch

f

orm

0

~

No.

of N

o.

of

threads

needle

1

2

_j__/

-./4._

Stitch

width

(mm)

4 -

7

012

h

2

box

~:!:!::>~

00

Differential

feed

ratio

1.0- 2.4

Second

(No. 2)

~

H

foot (mm)

First ph

(

eight

of

presser

4 1.6

photosenso

No.1)

l6

(mm)

Pitch

r

otosenso

Feed

r

dog

(Main)

(Oiffe· e

rential)

Type

~~

~8

[§

Ne

OM

I

~

+

edle

x 13

14

Sewing

speed

(spm)

400

SIZe

#

Se

J

0

Sleeve easing

rvo

presser

m

Use

OJ

SETTING

Motor

Mount

UP

)

Installation

0

(1) S

elect

a place

the

mount

-

1-

to

by

pressing

inst

all

the

the leve

motor

rs

moun

on

t, and fix

casters

0.

Page 4

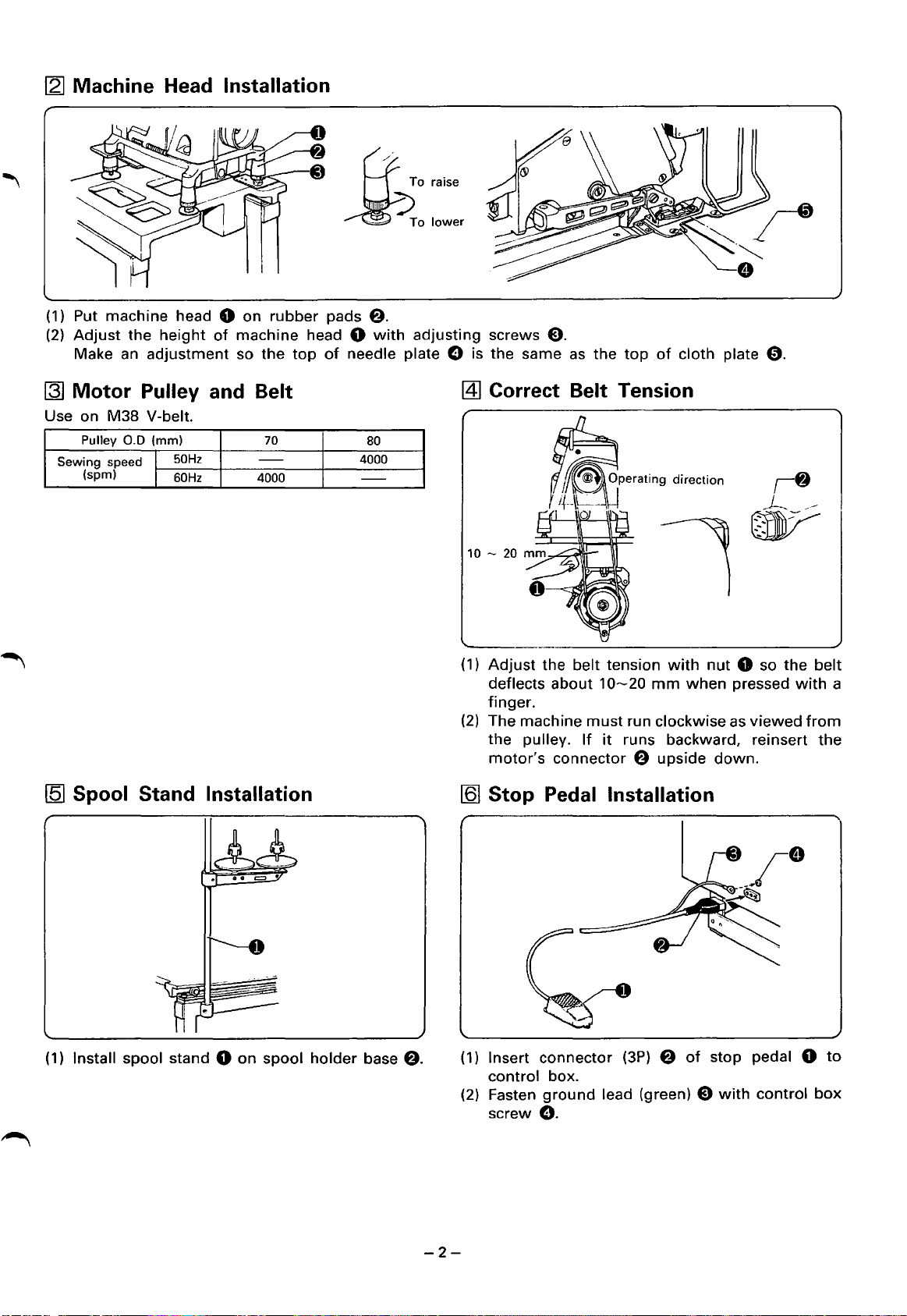

[2]

Machine Head Installation

(1)

Put machine head 0 on

(2)

Adjust

Make an

~

Motor

Use on

Sewing

the

Pulley and Belt

M38

Pulley

0.0

speed I

(spm) 1

height

adjustment

V-belt.

(mm)

of

50Hz

60Hz

machine head 0

so

the

-

4000

rubber

top

70

pads

8.

with

adjusting

of

needle plate 0 is

80

4000

-

screws

the

[4]

Correct Belt Tens ion

0.

same

as

the

top

of

cloth plate

0.

~

Spool Stand Installation

(1)

Install spool stand 0

on

spool

holder

base

f).

(1)

Adjust

deflects

finger.

(2)

The machine

the

motor's

[Q]

Stop Pedal Installation

(1) Insert connector

control box.

(2) Fasten

screw

the belt tension

about

pulley. If

ground

10~20

must

run clockwise as

it

runs backward, reinsert

connector 8 upside

(3P)

lead (green) 0

0.

mm

with

8

nut

0 so

when

of

pressed

viewed

down.

stop pedal 0

with

control

the

with

belt

a

from

the

to

box

-2-

Page 5

(B.

OILING

AND

OIL

DRAINING)

[I] Oil

The Brother oil included

lZI

to

be

Used

with

Oiling and Oil Changes

the machine should be used.

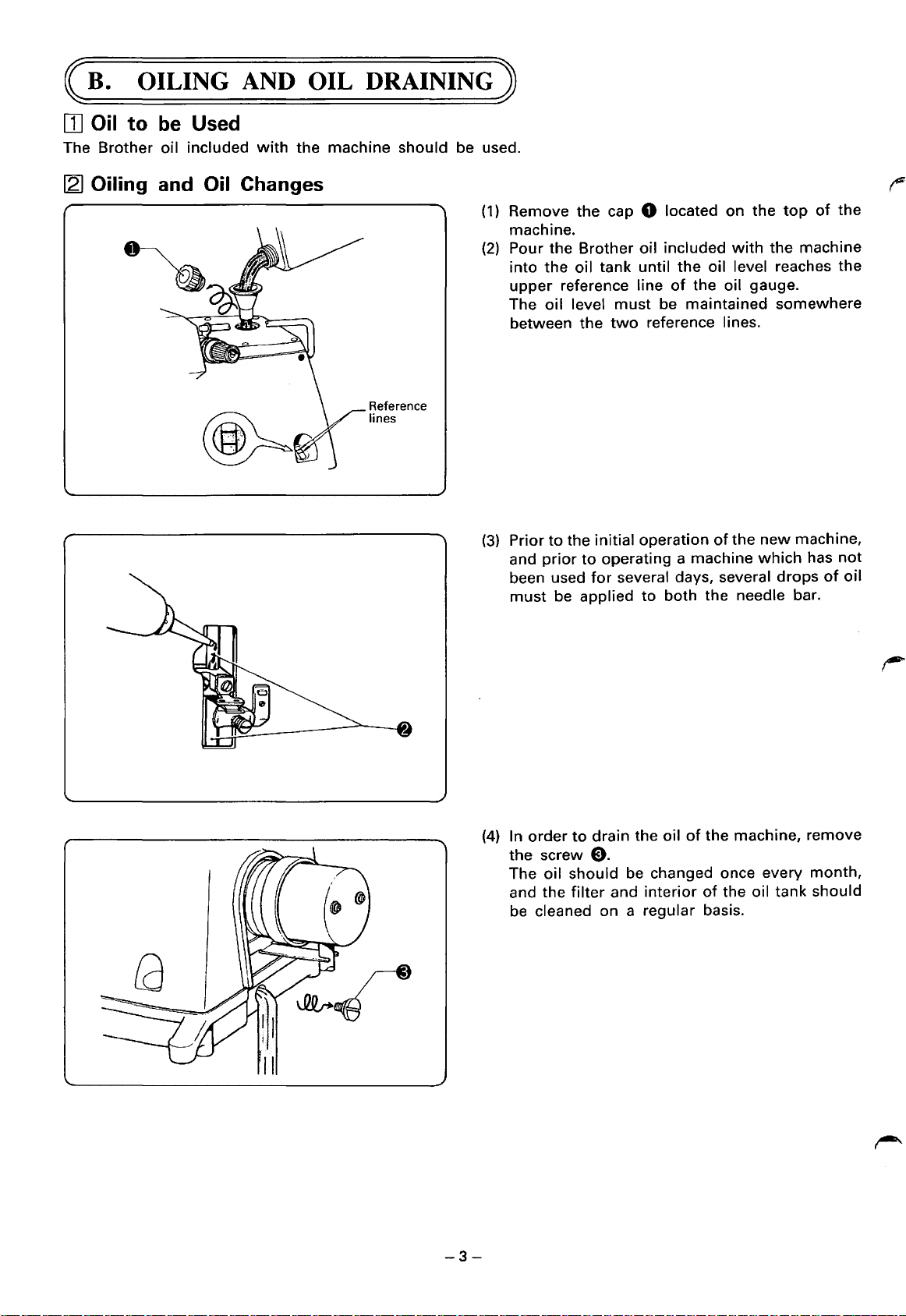

(1)

Remove the cap 0 located on the

machine.

(2)

Pour the Brother oil included

into the

upper reference line

The oil level

between the

Reference

lines

(3)

Prior to the initial operation

and

been used

must

top

with

the machine

oil tank until the oil level reaches the

of

the oil gauge.

must

be maintained somewhere

two

reference lines.

of

the

new

prior

to

operating a machine

for

several days, several drops

be applied to both the needle bar.

which

of

the

machine,

has

not

of

oil

-3-

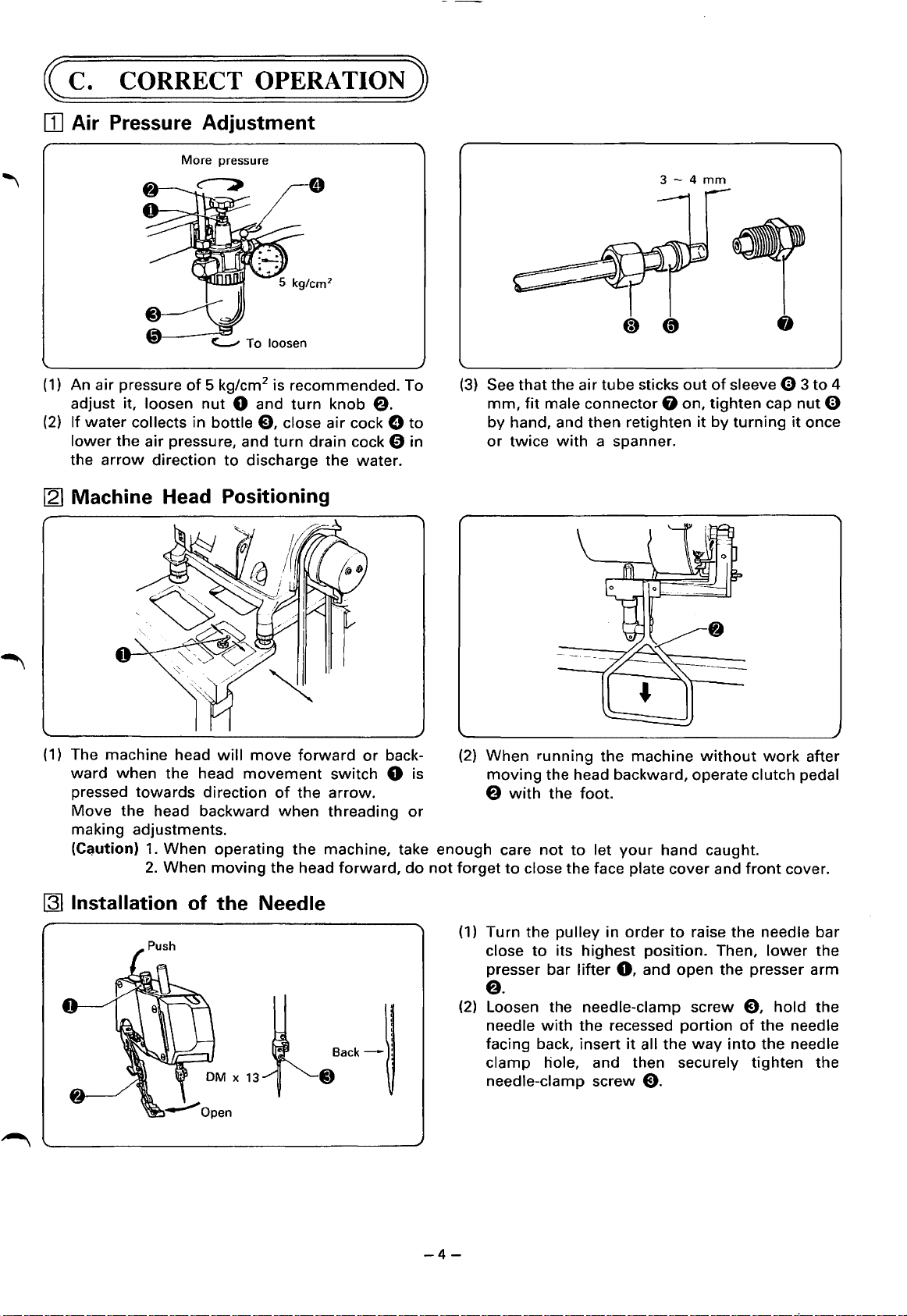

(4)

In order

the screw

The oil should

and the

be

cleaned on a regular basis.

to

drain the oil

0.

be

filter

and interior

of

the machine, remove

changed once every month,

of

the oil tank should

Page 6

~C.

OJ

Air Pressure Adjustment

CORRECT

More

pressure

OPERATION)

3-4

mm

~To

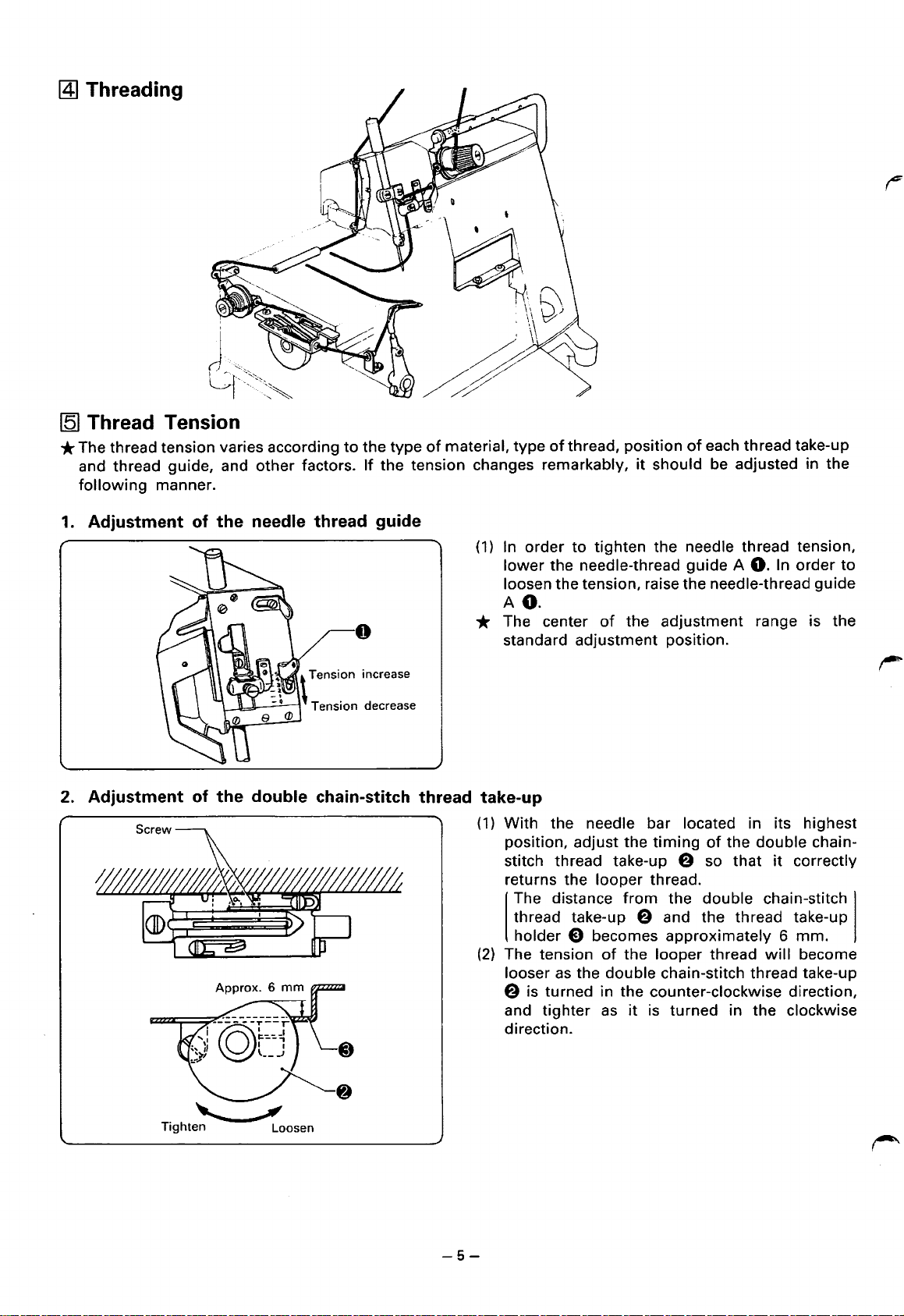

(1)

An

air

pressure

adjust it,

(2)

If

water

collects in bottle E), close

lower

the

arrow

the

[2]

Machine Head Positioning

(1)

The machine head

ward

when

pressed

Move

making adjustments.

(C~ution)

towards

the head backward

of

5 kg/cm2 is recommended. To

loosen

air

direction

1.

2.

nut

0 and

pressure, and

to

will

the

head

direction

When operating

When

moving

discharge the water.

move

movement

loosen

turn

knob

air

turn

drain cock 0 in

forward

switch

of

the

arrow.

when

the

threading

the

machine, take

head

e.

cock 0

or

back-

0 is

forward,

to

or

do

(3)

(2) When

enough

not

forget

See

that

mm,

fit

by

hand, and

or

twice

moving

e

with

care

to

close

the

air

tube

sticks

out

of

sleeve 0 3

male

connector

then

with

a spanner.

running

the head backward, operate clutch pedal

the

not

the

foot.

to

let

the

face plate

0 on,

retighten

machine

your

hand caught.

cover

tighten

it

by

turning

without

and

cap

work

front

nut

it

once

after

cover.

to

4

0

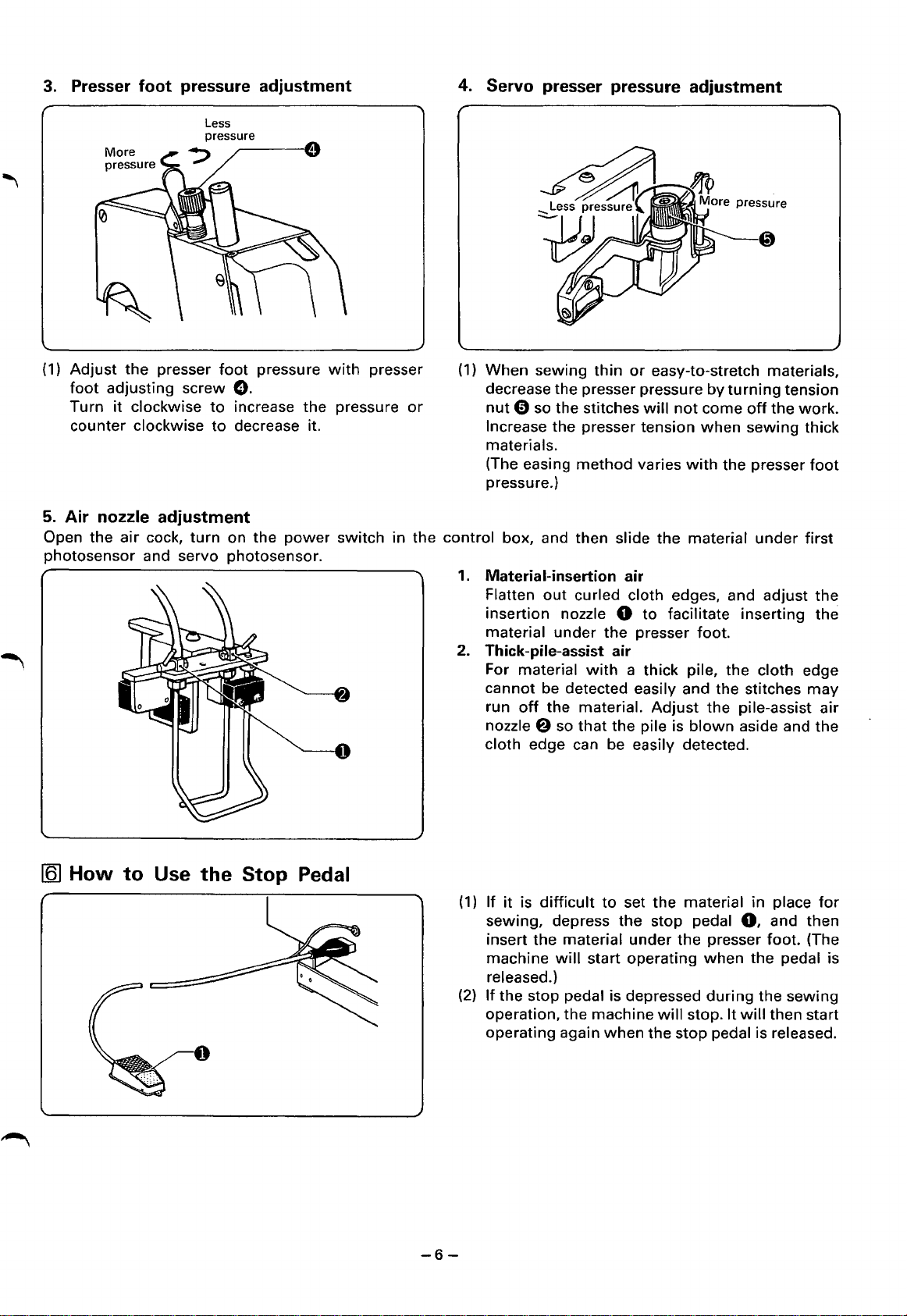

[3]

Installation of the Needle

CJBack-~

-4-

(1) Turn

the

pulley

close

to

its

presser bar

in

highest

lifter

0,

order

to

raise

position. Then,

and

open

e.

(2)

Loosen the needle-clamp screw E),

needle

facing back, insert

clamp

needle-clamp

with

the

recessed

it

hole, and then securely

screw

all

E).

portion

the

way

the

the

into

needle

lower

presser

hold

of

the

the

tighten

bar

the

arm

the

needle

needle

the

Page 7

~Threading

J~

1-

~···-.~~'

~r---.·;,

[5]

Thread Tension

*The

1.

thread tension varies according

and thread guide, and

following

manner.

other

to

factors.

Adjustment of the needle thread guide

the

type

of

material,

If

the tension changes remarkably,

type

of

thread, position

(1)

In

order

to

lower

the needle-thread

loosen the tension, raise

AO.

* The center

standard

adjustment

of

each thread take-up

it

should be adjusted in the

tighten the needle thread tension,

guide

the

of

the adjustment range is the

position.

A

0.

In

order

needle-thread

to

guide

2. Adjustment of the double chain-stitch thread take-up

(1)

With

position, adjust the

stitch thread take-up

returns the

The distance

thread take-up

holder

(2)

The tension

looser

e is turned in the counter-clockwise direction,

and

direction.

-~

Tighten

Loosen

the needle bar located in its highest

timing

looper

thread.

from

8 and

e becomes

of

the

looper

as

the double chain-stitch thread take-up

tighter

as

it

is

of

the

double

e so

the double chain-stitch

approximately 6 mm.

turned

that

the

thread take-up

thread

in the clockwise

it

will

chain-

correctly

become

-5-

Page 8

3. Presser

(1)

Adjust

foot

Turn

counter clockwise

5.

Air

Open

the

photosensor

foot

the

adjusting screw

it

clockwise

nozzle

air

pressure

Less

presser

adjustment

foot

pressure

0.

to

increase

to

decrease it.

adjustment

cock,

turn

on

the

and servo photosensor.

the

power

with

presser

pressure

switch

in

4.

Servo

(1)

When sewing

decrease

or

the

nut

Increase

materials.

(The easing

pressure.)

control box, and then slide the material

1.

Material-insertion air

Flatten

insertion

material

presser pressure

thin

or

the

presser pressure

0 so the stitches

the

presser tension

method

out

curled cloth edges, and

nozzle 0

under

the

easy-to-stretch materials,

will

varies

to

facilitate

presser foot.

2. Thick-pile-assist air

For material

cannot be detected easily and

run

off

nozzle

cloth edge can be easily detected.

f)

with

a thick pile,

the material.

so

that

the

Adjust

pile is

adjustment

by

turning

not

come

when

with

the

inserting

the

the

the

pile-assist

blown

aside and

tension

off

the

work.

sewing

presser

under

cloth edge

stitches

thick

first

adjust

foot

the

the

may

air

the

[§]

How

to

Use

the

Stop

Pedal

-6-

(1)

If

it

is

difficult

sewing, depress

insert the material

machine

released.)

(2)

If

the stop pedal is depressed

operation,

operating again

will

to

start operating

the

machine

when

set

the

under

the

stop

will

the

material

pedal

the

when

stop. It

stop

in

0,

presser

the

during

will

pedal is released.

place

and

then

foot.

(The

pedal is

the

sewing

then start

for

Page 9

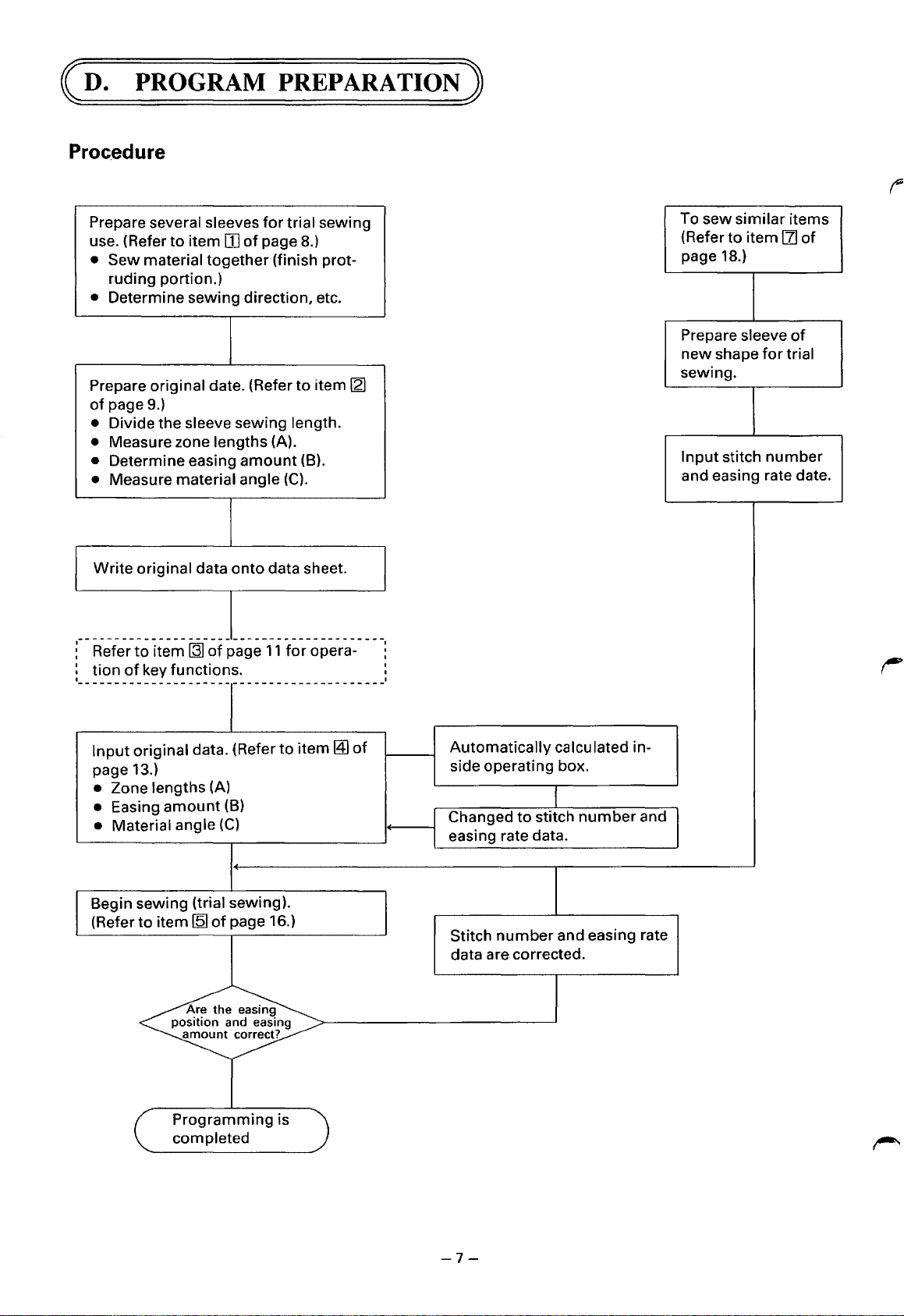

(D.

PROGRAM

Proc.edure

PREPARATION)

Prepare several sleeves

use. (Refer

•

Sew

ruding portion.)

• Determine sewing direction, etc.

Prepare

of

page 9.)

• Divide the sleeve sewing length.

Measure zone lengths (A).

•

• Determine easing

• Measure material angle

to

item

material

original date. (Refer

together

I Write original data

----------------------------------------

Refer

to

tion

item~

of

key functions.

of

III

of

amount

onto

page

for

trial sewing

page 8.)

(finish prot-

to

item

(B).

(C).

data sheet.

11

for

opera-

[21

To sew

(Refer

page 18.)

Prepare

new

sewing.

Input

and easing rate date.

similar

to

item

sleeve

shape

stitch

items

111

of

of

for

trial

number

Input

original data. (Refer

page 13.)

• Zone lengths (A)

• Easing

• Material angle

Begin sewing (trial sewing).

(Refer

amount

to

item

[Q]

Are

position

amount

Programming

completed

(B)

(C)

of

page 16.)

the

and easing

to

easing

correct?

is

item~

of

Automatically

side operating box.

Changed

easing rate data.

Stitch

number

data are corrected.

calculated in-

to

stitch

and easing rate

number

and

-7-

Page 10

[I]

Prior

to

Program Preparation

© Prepare 2 - 3 sleeves

1.

This machine can tack

side together.

for

trial sewing.

while

the material is laid

out

flat. Sew either the upper sleeve side

or

lower

sleeve

Upper sleeve

side

2.

As

for

the sewing direction, select the side which is least likely

amount

3.

When the joined edges are

to

as

the side

temporarily

secure the side

for

sewing to end.

Sewing

direction

to

be

tacked

from

sleeve

Lower

side

to

disturb the easing position and easing

or

pressed in order to keep them flat, use a heat-sealing adhesive

which

sewing

will

begin.

4.

Cut

off

protruding material whenever possible. If

material, which

5.

Make the left and right sleeves

will

make insertion, under the servo roller and presser

between the left and right sleeves

For materials such

programs

for

as

suede, etc., where one surface is raised and

the left and

Temporary stitch

by

sewing on the back and

can

be

right

sleeves.

Heat-sealing

adhesive

it

is folded

over

and tacked, a thick step

front

of

the material, respectively. Variations

foot

difficult.

decreased by making the sewing direction

difficult

to sew, prepare separate

will

uniform

result in the

in this way.

-8-

Page 11

121

Original Data Preparation

1.

Prepare a standard size pattern paper.

2. Draw

3.

finishing

Measure the intervals between points, and calculate the easing amount.

stitch lines

for

the

sleeves and body.

4. Divide the sleeve sewing length,

to

F).

(1)

By using points in this

simplified.

(2)

Consider each

(3)

Also, consider

changes in angle

5.

Measure each zone length (A).

portion

portions

way

which

which

as

one zone.

as zone markers, the calculation

including

has

the

have

only

an

allowance

same easing

small

Zone Order

for

stitching,

amoutn

6.

Determine

into a maximum

of

the easing position and easing

as

one zone.

the

easing

of

amount

16 zones (from 0

(8)

amount

for

each zone.

is

7.

Measure

finishing

zone. Measure these

vals.

the

material angle

stitch line and grain line

material angles in

(C)

between the

from

each

5o

inter-

-9-

Finishing

stitch line

~45°

Grain line

Page 12

8.

Write the original data

Zone No.

Zon_e

Easmg

length

amount

Finishing

stitch

1

line

4

0

onto

Material

angle

the data sheet.

Point

@]I

33

4

[§]

38

4

Grain line

Original Data

Zone

No.

0 14

1 48

2

3 14

4 34

Zone

Length

A (mm) B (mm)

Easing

Amount

0 45

4

40 4

0 90

5

5 33 4

6 38 4 25

7 86 2

8

9

A

8 72

65

65

0 65

2 85

67 4 40

5

Material

Angle

c (

0)

50

65

65

40

20

40

Data Sheet

Calculated Data

Stitch

Number

Easing

Rate

Modified

Stitch Easing

Number

Data

Rate

Remark

c

D

E

F

TOTAL

8 0

40

~

~

-10-

~

Page 13

[3]

Key Functions and

1.

Material

Key: Used

Methods

to

adjust

for

of

the

Use

difficulty

of

easing

for

each

type

of

material.

Considering the

-

[Q].

2.

Pattern Key: Used

Size key: Used

© Relationship

(1)

When patterns

standard pattern size. Centering on

increased

calculated.

~

0 I 2 3 4 5 6

of

or

decreased 2%

(The sewing pitch is fixed at 2

to

adjust

to

adjust

the

Pattern Key and Size Key

from

0 - 9 are selected and

0

I v

number~

0

Materials easily

eased

for

the

design

for

the size

this

for

each succeeding

~~

8 9 A B C D E F

v

key

to

be

2@.1456

Stan-

dard

oE-

of

the sleeve.

of

the

sleeve.

programmed,

standard size

mm.)

the

standard degree

Materials eased

--,)

size 7 is automatically memorized

7,

the stitch

number

or

of

easing, select a key

with

difficulty

number

letter and each size is automatically

for

the

sewing length is

* The

program

(designated

gram)

automatically memorized.

The data

than size 7

cannot

of

each pattern is

for

yet

from

as

for

size 7

~

in

the

sizes

other

[0-6,

be changed.

8-F]

[Q]

the

dia-

5

6 Stitch

~--+-finished

1---7-+-

is decreased 2% per

8 numbfer.

I I

number

sewing length

1 1

1

of

9

Example: The

following

is the result

em.

em x

50

Size----Finished

~~~~;:spending

armhole

_2_

100 1 em

sewing

- 43··.· .. ·48

length)

i/

1/

" I I I I

~

~v·u;

-~

~

"C

~

00

I

of a program

em (Length is increased

=

1

o

......

Stitch

~~finished

-;-

is

number

I I I I I I

1

for

s 6

49

.

number

sewing length

increased 2% per

or

letter.

in

which

the

finished sewing length (armhole length) is

or

s g

51

decreased

or

letter.)

......

52···· ..

each

[1]

50

number

--

of

-f--

-f--

50

F

58

-11-

Page 14

(2}

When patterns

(ten sizes

automatically done.}

from

from

0 -

A-

D are

to

be selected and

9}.

(Totalling 40 kinds

programmed,

of

programs

they

must

are possible

be

programmed

to

be memorized

for

while

each size

it

is

not

3.

Zone

Key:

lzonej

4.

Number/Letter

[Q]rv[EJ

5.

Data Mode

loataj

6.

Diagnosis

Used

Key:

Key:

* Programs can be memorized in each

portions

to

store and display data (stitch number, easing rate}

Keys:

Used

malfunctioning

Used

Marked

to

for

with

input,

self diagnosis

the

numbers

modify,

location. (Refer

or

display original data, stitch number, and easing rate.

in

the

0 - 9 and letters A -

event

of

a circuit malfunction, and

to

page 19.)

designated~.

for

16 zones.

F.

for

a check

of

of

the

the

7.

Input 1

8.

Run

9.

Input 2

10. Causes for the warning sound:

Key:

Key:

r:=1

~

Key:

(lnp21

Used

for

8, etc.)

Used

to

data

portion

Note: If

(A

Used

each item

to

input

original data (A, 8,

change

the

warning

to

from

of

the

display.)

stitch

number

sound

memorize corrected

of

input

C).

Press once

the data

data.

1.

2.

3.

4.

mode

to

the

data

for

zone 0 is

will

be produced.)

or

input

data

Incorrect key operation.

Input

value is outside prescribed range.

Malfunction

Completion

(Ideally, the

almost

found

of

completion

simultaneous.)

for

each

sewing mode. (

"00",

the

unit

for

stitch

number

in diagnostic mode.

program

during

of

sewing and

item

of

input

data (once

GO

will

sewing.

"GO"

is indicated in the

not

enter

the

sewing mode.

and easing rate. Press once

the

warning

for

A, once

for

sound are

-12-

Page 15

~

Inputting Original Data

© The Number/Letter Keys are displayed

as

shown

below.

Key

Display

Material Pattern Size Zone (Stitch) (Easing rate)

©

Input

the

1. When a

,-

J

6

,-

0

0

,,

Ll

I

2

, ,

I

I

c

3 4 5

LJ

J

\IIIII[IJ[IJ\

Data

7

Data

Dia

lnp1

Run

lnp2

Mat

c

8

4 5 6

0

original data

pattern

from

Pat

Size Zone

D E F

9 A B

1 2 3

from

the data sheet. (For

0 - 9 is selected:

7 8 9

,,

,,

,

I

D

J

Power

@]

information

8

l

0

c

D E

,-

L 0

Zone

No.

0

1 48 4

2

the

,-

I

c

Data Sheet

Zone

Length Amount Angle

A (mm) 8 (mm)

14

40 4 65

.......--

data sheet, refer

Original

A

,,

,-,

concerning

* Portions flashing on and

F

,-

,-

Data

Material

Easing

c (

.,

45

0

50

--..._

to

page 1

off

can be changed.

\

0.)

Procedures

<D

Turn on the

operating box. power switch was

power

switch

of

the

Key

Operation Display

The

same

information that

IYI~I=tlt

®Press

the

@Press the Data Key.

@Press the Zone Key, and then the

Number

*The

the Pattern Key,

Number

above step is

if

"0"

in the zone position.

Key

"0".

Key

"0".

not

is

already being displayed

and then

necessary

EJ

t

[Q]

(oataJ

jzoneJ

t

IYIYiul

1

Ylal

l3lttl11'''•

"Sta~ard"

displayed

I

-Ill

last turned off will

).

Flashe

on

Yiul

{umbers

till

)

was

''

rn

rn

and

off

rn

t

Flashe

on

rn

Flashe

on

displayed before the

be

displayed.

1u1u1

It

dttl

It

dt

11

rn

Data

is

displayed.

and

off

rn

and

off

[Q]

®Press

the

Input

1 Key.

(

lnp1J

-13-

l=lltllllal

'~''tllluliRI

rn

rn

1

rn

Flashe

on

t

and

off

Page 16

Procedures

@Input

the sewing length 1114

in the data A position, and then

press the Input 1 Key.

mm"

Key

Operation

Display

I.__

l....__.ul....__l_u

I

rmJ

[mJ

https://manualmachine.com/

14mm~~

easing

11

0"

(f)

Input

the easing

data 8 position, and then press the

Input

1 Key.

amount

;1

K[>;ot

®Input

the data C position.

the material angle 1145"

in the

in

@]

!

Flashe on and

11o11u1mrn

L--.....1...-____._____ Flashe on and

1

lL-...1..-1

L-.~-

1

I

IOI

l-_.....L.:..:----1...-.--

I

IOI

1

___._I

L_

1 m I a I a I

lui

[ill

lull!

I

rn

Flashe on and

off

11'1151

off

off

~

j Grain line

®Repeat

zones 1 --C.

@)When data

zone D stitch

automatically displayed.

@Press

steps ®

input

is

number

the Start Key.

through ® for

compl~~ed:,

00

t~e

IS

I

lol

The next zone (1)

1

1o1

Indicates that the program has been completed.

I3IOI7Ial

Ill [ffi]

1s

automatically displayed.

ldllalal

[0

rn

Flashe on and

rn

_,

IGial

off

-14-

Page 17

2.

When a pattern

from

A - D is selected:

Procedures

CD

Turn on the

operating box.

® Press

the

@Press the Size Key, and then the

Number

the

Letter Key

n

~

A

8

power

Pattern Key,

"A".

"0".

Key

I

0

~~

\

\

Program here

switch

2

of

the

and then

Key

B

~

[K]

I Size I

~

[QJ

Operation

The

same

information that

power switch

I

I

[I

I

IRI

I

IR[I

I

IHIOI

I

Display

was

last turned off will

I

I

I

LFiashe

on and

I

LFiashe

was

displayed before the

be

displayed.

IDJDJ

IDJDJ

off

IDJDJ

IDJDJ

on and

off

IDJDJ

@)

Press the Data Key.

®For

®Press

0

1.

2.

0

1.

the

following

items

procedure on page

If

If

If

llnp11

If

Press I Zone

@ - @

the Run Key.

a mistake is made

data has been

data has been

, and then

a mistake is discovered after all

steps, refer

of

input

input

input

I--')

I

Number/Letter

the

"0 -9"

13.

while

up

to

up

once again

to

inputting

data A

to

data

or

Key

loatal

EJ

data:

data

B,

press l Data

C,

press lzonel--') !Previous Zone Number/Letter Kevl--') !Datal--')

from

data A.

the

data has been

of

mistaken

I

~

I3IHIUI

t

Standard numbers

displayed

Input

data A,

B,

I3IRIOIOI

I--')

~and

input:

I Data

I--')

then

j1np1l

IBDJ

Flashe on and

c.

OJ

input

once again

.

t Data is displayed

off

IGIOI

from

data

A.

(Note)

1.

If

the

machine is

prevent this,

2.

Input

data

may

the

machine.

not

used

the

power

be affected

for

a long period

to

the machine

by

lightning.

of

should

If

lightning

time

-15-

(one

month

be

turned

occurs in the vicinity, disconnect

on

or

for

more), the

1 - 2

input

hours

data

every

the

may

month.

power

be lost. To

plug

of

~

Page 18

[Q]

How

,

J

to

,,

Ll

Sew

,

,,

I

u

rn

,-

,,

Ll Ll

(1)

Open air cock

pressure is 5 kg/cm

(2)

Push the

(3)

Push control box

(4)

Push operating box

(5)

Confirm that the material, pattern, and size are

correct.

(6)

Put the machine into the sewing mode.

0,

motor's

and make sure

2

•

power

power

switch 8 ON.

switch

power

switch 0 ON.

6)

that

ON.

the air

0 Chain Length Adjustment

POWER

CHAIN LENGTH

@

shorter

stitch " stitch

ON

~a

(][]m

Longer

OFF

(7)

Insert the

and servo presser. The machine

sew.

Confirm that the

simultaneously

indicate

pleted.

(8)

The thread cutter

final chain stitch.

(9)

The machine

(about one second later) and enter the sewing

mode again.

(1)

After sewing the work, adjust the chain lengths

off

Knob is used

operating

The larger the

chain length.

the

work

smoothly

warning

with

that

the program has been com-

will

will

work

at the beginning and end.

for

timing.

number

under

sound is produced

the end

then operate

return

to

adjusting the chain cutter

the longer

the presser

will

of

sewing

to

the

first

will

foot

begin

program

to

to

cut the

be the

-16-

Page 19

[Q]

Program Modification (Easing Position and Amount)

1.

Write

the stitch

Data

Input Operation

number

and easing rate data calculated inside the operating box

B

l

8

1

[Q)

1

OJ

1

[[)

lnll''l'll''lnl

~u

'uu

JJJI2121m

J2]

[JIBJ

lOlBI

onto

the data sheet.

~

[9

l

[QJ

!

[ID

l

~

Zone No.

0

1 48 4

2

Zone Easing Material

length

A (mm)

14

40

14

~~~

c

--

c::r

2

Jr]

-od

_jQJ

IOIYIIOIOI

lunlunllu''lu''l

- the final zone.

IEII3ISIIOIYI

)

IFIIJI5IIOISI

Data Sheet

Original Data Calculated Data

Amount

B (mm)

0 45

4

0

~

0 40 04

Angle

c (

0)

50

65

~~

Stitch

Number

07

22

18

Easing Stitch Easing

Rate

00

06

08

~

00

11

The

00" stitch

If

data is

ignored.

Modified

Number

~

input

number

after the

Data

Rate

-:::::::::--

here indicates

"00"

indication,

Remark

~

that

cis

it

is

~

D

E

F

TOTAL

2.

Modifying

(1)

If

the easing

~

<

the Easing Position and

00

---1

~

.-....

amount

[§] (Select when easing

is entirely

0 J (Select when easing

~

too

00

Amount

small

amount

amount

~

or

too

-17-

00

great,

is

too

is

too

modify

great.)

small.)

-------

the material data.

Page 20

(2)

If

*

Example:

If

(3)

stitch

the

The

rate

The

the

easing

easing

number

maximum

easing

number

amount

amount

is increased.

easing rate

Changing

from

10

position

data.

to

is

will

the

13.

is

partially

increase as

number

easing rate

not

correct,

Zone 4 stitch

18 stitch

too

the

modify

small

in

or

easing

is 28.

zone 4

the

number : 15 -18

too

great,

correct

the

easing rate.

rr

Zone

No.

4

5

6

Changes

Data Sheet

Calculated Data

Stitch

Number

Easing Stitch

Rate

10 18

15

15

08

17

08

to

the next zone

Modified Data

Easing

Number

Rate

12

17

13

08

08

B-B-~-B-COOO-B-CO~-B-CO[ID-8

(Stitch number) 1 (Easing rate) J (Stitch number)

If this data is

2 Key.

* The display changes successively each

the Input 2 Key is pressed.

not

to

be

changed, press the

Input

time

111

Preparing Data for Similar Items

© If a

1.

2.

program

prepared,

Select

Write

the

Example: Display

for

sample-sewn

program

is

it

can be easily

the

program

data

to

of

be

the

made

that

new

for a pattern

done

is closest

program

by

to

l

I

Data

I

1

EJ~

1

8[ID

1

which

using

the

new

into

is

the

pattern

the

only

slightly

program

data

Because

the

Return

for

in

material,

calculation

the

material and size

to

original

different

the

machine

from

previous

size, etc., and use

column

has been

become

program

one

which

pattern as a base.

of

the

put

standard.

has

it

to

data sheet.

into

already

sew

the

been

a sample. , /

data

mode,

-18-

Page 21

IYI!I9IDI

1....-------r-

y

l---.--119......,........1

OJ

Write

data contents onto data sheet

II

OJ

OJ

OJ

Number

3.

Modify

the data sheet. (Refer

4.

Input

the

changes.

key

last zone

the stitch

new

program

of

number

and easing rate data

to

page 18.)

into

an

unused pattern,

as

required, and

or

input

it

into

a previously used pattern and

EJ-D-8-@J-B-DD-8-DD-8-

turn

of

Input

rate data

on the

the

control

during

(Number key

from

0 -

9)

[B]

Self Diagnosis

© Investigates the problem area

control circuitry.

1.

Move

2.

Turn

operating

power

3.

Close

box.

the machine head backward

off

the

switch again.

the

Display

power

lever 0

air cock, and then

during

switch

from

correct

of

the

turn

operation

loataJ

~

Input stitch

data

if

something abnormal occurs in the

from

the table.

the operating box, disconnect the

power

switch, and then

off

the

power

switch

Display

write

this

in the

easing

abnormality

modified

Input

final zone -

data

up to

Malfunction location

column

write

in

1()1

~

(Stitch data

of

next zone)

of

the

\

8

!

lr-[ ,...------,1

h

1.-------.E

,____,[

I

OJ

(CHECK)

IPIRislsl

(PASS) ! (RAM)

!

OJ

IPIRISISIOJI,

(PASS) i (ROM)

The operating lever moves and the

turns

on. i

ISIYiniCI

(SYNCHRONIZER) !

OJ

IOili213IIYISIIhl!l

(0

- 7 is successively displayed, one

time

each

1.-----.P

I Display returns

the pulley is rotated.)

i

1.-------.R

,----5,--S

(PASS) i (ALL)

II

to

original condition I

It

rn

power

OJ

digit

I R II!

IR

I

lUI

switch

at a time,

,,

I

I

IEI,Jr-IOJrn

I

IEir

1.

The pulse

2.

The pulse

IIIIIOJOJ

(ERROR)

(ERROR)

motor

motor

Warning sound is produced.

Jr

I

OJ

Warning sound is produced.

does

will

not

(No display)

I'

not

operate.

stop operating.

!Ill

Memory

and circuit board

Memory

and circuit board

1.

2.

Synchronizer and

cord

(RAM-TC5516)

(ROM-2532)

Origin switch, cord

and connector

Origin switch

I

-19-

Page 22

OPERATION FLOW

CHART)

Open the

Motor

Control

ON

Operating

switch

Insert the material

the No.1 photosensor

Insert the material

the servo photosensor

air

power

box

box

ON

cock

switch ON

power

switch

power

under

under

The servo presser rises

clutch

motor

The

power

The

control

The

play

illuminates

The material-insertion air

is

The servo presser and

presser

The servo roller rotates

The machine operates

box

power

ofthe

emitted

foot

rotates

lamp

of

illuminates

lamp

operating

the

and dis-

lowers

box

Confirm

pressure is 5 kg/cm

The presser

Confirm

is in the sewing

(Press

The material insertion

stops

The synchronizer begins

stitch

that

foot

that

the

Run Key.)

number

the air

2

rises

the

machine

mode

detection

air

Insert the material

the No.2 photosensor

material moves away

The

from

the No.1 photosen-

sor

The material moves away

from

the servo photosen-

sor

material moves away

The

from

the No.2 photosen-

sor

under

program

The

*

If

a long period

moves

operates and the material insertion air is emitted.

The servo presser rises

The machine stops

The sewing

completion

sounds at the same

that

the

The

time

before the chain cutter operates varies according

The chain

begins

of

below

program

cutter

time

the No.2 photosensor,

program

signal

time

finishes

operates

passes before

* The sewing

The

ted

the

the

The servo roller stops

The synchronizer finishes

stitch

should ideally

with

the end

of

pile-assist

material

chain

number

the

chain stitch length control.

air

cutter

detection

program

sound

of

sewing.

is

emit-

compeltion

simultaneously

to

the

adjustment

signal

The presser

-20-

foot

rises

The material insertion

is

emitted

air

Page 23

TANDARD ADJUSTMENTS

Adjustment of the Needle Bar

9

mm

(1)

Adjust

when

Adjust

center

[21

Adjustment of the Double Chain-stitch Looper

the distance between

the needle is located at its highest position.

by

rotating the needle bar around the

of

the hole in the needle plate.

the

tip

of

the

needle and the

double

top

surface

chain-stitch needle is located directly above

of

the needle plate

should

be 9

mm

the

1

1

(1)

Install the double chain-stitch

it

all

the

way

into

the

double

holder.

of

The angle

contact

inclination is determined by the

point

on the shaft.

~0-

(3)

Set the machine so

chain-stitch

chain-stitch needle

and then make the necessary

the

clearance between

chain-stitch

needle is

If

the

the

tip

contacts the double chain-stitch needle and

pushes

looper

looper

0 - 0.05

machine skips stitches, adjust

of

the double chain-stitch

it

0.05 -

that

is aligned

as

the needle travels

and

mm.

0.1

looper

chain-stitch

0.05

mm

the

tip

of

with

adjustment

the

tip

of

the

double chain-stitch

mm.

by

inserting

looper

the double

the double

upward,

so

that

the

double

it

so

that

looper

(2)

Adjust

chain-stitch

there is 2

chain-stitch

chain-stitch needle.

(4)

With

in item (3), push the

with

0,

between

tip

Also provide a clearance

between the double chain-stitch needle and the

front

as

necessary so that,

looper

mm

looper

the machine set in the

the back

and

provide

the

of

the

double

double

is at its farthest left position,

between the

and the center

double

double

double

chain-stitch needle guard

chain-stitch needle guard

a clearance

chain-stitch needle and the

chain-stitch looper.

when

tip

condition

chain-stitch needle

of

the

of

the double

of

the

of

0 - 0.05

0.3 - 0.5

described

double

double

mm

mm

~

e.

-21-

Page 24

[31

Adjustment of the Feed Dogs

~

Stitch Width Adjustment

© Close

the

air cock before making

1.3

this

adjustment.

mm

(1)

Turn

the

pulley

uppermost

Then, adjust the

0

to

above the upper surface

then secure.

(2)

Adjust

the teeth are at the same

the differential feed dog

position.

be 1.3

the height

mm

Needle center

front

to

raise

the

feed dog

of

the differential feed

(for

medium-thick

of

the

needle plate, and

of

the main feed dog 8 so

height

as

the

0.

to

its

dog

materials)

that

teeth

of

(

1)

Loosen the screw

(2)

Loosen the screw @, move the

(3)

Position the presser

(4)

Insert the material

position

photosensor

lower

If the servo photosensor 0 is positioned closer

sewn

may become

(5)

If

the

where

knife.

curled

dust

detection

0.

foot

F 0 so

under

it

stops. Then, loosen

the

0 back and forth

or

with

an increase in

loose

or

even come

lamp

0 illuminates, clean

lower

that

it

first

0 and servo photosensors

until

the

the

off

knife 8

lightly

edge

cutting margin.

the

to

a suitable position, and then tighten the screw @.

contacts the

Side A

the

adjusting screws 0 and adjust

of

the

material is approximately 0.5

to

the

work.

the

Stitch

4-10

mm

•

lower

knife

8,

and then tighten the screw

Reflecting tape

0,

and

put

the servo roller 0

by

moving

mm

from

pulley side than mentioned above, the

If

it

is positioned closer

glass above the reflecting tape

to

the front, the stitches

with

width

into

the servo

side A

work

a cloth.

of

will

0.

the

the

be

-22-

Page 25

[5]

Adjustment of Cloth Detector

··~

·•

:~,,-~

.·~.

·~·

(1)

The cloth detector detects

second

The

(a)

(b) Then

(c)

[Q)

Installation of the Knife

photo

first

and second

Turn the

goes out.

turn

In case

emitting

from

of

the

extinguish~m4

@ 1 9

sensor ~ (for the cutter). (The cloth detector is located on the side

screw

the

thick materials,

diode

has lit. In case

position

~

2 8

0

whether

photo

counterclockwise

screw clockwise

where

sensors can be adjusted in

turn

the

Turn

from

full position

~lighted

one-half

from

position

111

s a

lights

7

10

there is a cloth

with a screwdriver

until

the

the

screw clockwise 2 degrees

of

very

thin materials,

light

emitting

light

diode

under

emitting

(1)

to

one

the

•----~n-

·-~~,....,.-

the

first

photo

the

same

until

the

diode

further

turn

the

screw clockwise

has lit.

When the knives have been replaced,

lower

imately

knife 0

light

0.01

sensor 0

way

emitting

lights.

from

to

mm

(for

machine start) and

of

the control box.)

as

follows:

diode

(LED)

the

position

about

make a clearance

with

the

where

1 degree

upper

on

the

right

the

light

further

adjust

of

knife shaft.

the

approx-

(2)

Adjust

* Make sure

rack e and

Approx. 1

rack 8

with

that

pinion

mm

nuts

upper

Q so

knife 8 has a vertical

0 freely

upper

move

knife 8 engages

in

play

proper

-23-

lower

of

less than

engagement.

knife 0

approximately

by

approximately 1 mm.

0.3

mm

at

the

tip

and

that

Page 26

(TROUBLESHOOTING

GUIDE)

~-----T_r_o_u_b_le------~~~

~-------c_a_u_se

Wrong

______

threading.

~

~-----•n_s_p_e_c_ti_o_n

Threading.

~

Excessive tension disc

pressure.

H

1-

Poor-quality thread.

t--

Tension disc pressure.

Thread quality.

____

~ll

f---

~------R--em

See paragraph on threadin g.

Adjust

ure.

Use thread

ty.

__

e_d_v

to

proper press-

of

good

______

quali-

~IP_a_g_e~~

5

lLJ

L

Thread break

I

Thread is

r--

needle eyelet.

Needle

~

rectly.

Needle groove and needie eyelet finished poorly.

H

Needle, loopers and

thread takeups

-

tioned properly

another.

too

thick

for

installed incor-

not

posi-

to

one

-

1---

t---

Needle size.

Direction and height

needle.

Needle groove and needie eyelet.

Clearance between needie and looper; position

of

thread takeups.

of

Use needle

f---

of

thread

count.

See

1---

installing.

Replace

1---

die.

See

adjustment

-

double chain-stitch looper and thread tension.

of

correct size

of

correct

paragraph on needle

with

good

nee-

paragraphs on

of

needle bar,

4

4

4

21

5

Stitches

skip

Needle, loopers, needle

plate, thread passage

---

have flaws.

r---

Wrong

threading.

Excessive tension disc

pressure. ure.

H

Needle installed incorrectly.

i

Needle

point

blunt

not

to

or

have incor-

r--

'--

bent.

Needle, loopers and

thread takeups

tioned properly

1-

another,

rect clearance.

Needle and needle

not

1-

positioned properly

to

one another.

or

posi-

one

guard

-

1---

H

H Needle

r--

1--

Flaws

of

ers, needle plate, thread

passage.

Threading.

Tension disc pressure.

Direction and height

needle.

Clearance between needie and loopers. Timing. Thread takeup

position.

Clearance between needie and needle guard.

needle, loop-

point

and bend.

of

Smooth

-

buff.

See paragraph on thread-

1---

ing.

Adjust

to

See

paragraph on needle

installing.

H

Replace

y

See

paragraphs on

adjustment

1---

1---

double

and

looper.

See

paragraphs on

adjustment

chain-stitch looper.

will

oil stone

proper press-

with

new needle.

of

needle bar

chain-stitch

of

double

or

I

5

v

4

4

21

5

21

Looper

point

down.

~

hangs

-24-

Looper point.

Correct

replace

with

oil stone,

with

new looper.

or

~

Page 27

L_

____

~------T-ro_u_b_l_e

______

~ll

L

________

c_a_u_s_e

______

~

l_n_s_p_e_~_i_o_n

____

_JI

LI

_______

R_e_m_e_d_v

______

~IP_a_g_e~~

Needle break

Doesn't

!cloth.

(Double-chain

work

well

stitch

without

sewing)

Needle installed incor-

,....-

rectly.

~

Needle bent.

1-

Needle and loopers positioned

1-

L-

.....--

f-

~

1--

improperly

another.

Needle and needle guard

positioned

one another.

Wrong

threading.

Tension

looper threads are

great

Needle thread

positioned incorrectly.

of

or

too small.

to

improperly

needle and

too

guide

one

to

1---

1---

-------

-------

-------

1---

1---

Direction and height

needle.

Needle bend.

Clearance between needie and loopers,

timing.

Clearance between needie and needle guard.

Threading.

Tension disc pressure.

Thread

guide

of

their

position.

See paragraph on needle

1---

installing.

Replace

with

t-

See paragraphs on

adjustment

1---

and double chain-stitch

looper.

See paragraphs on

adjustment

1---

and double chain-stitch

looper.

See paragraph on thread-

....___

in g.

Adjust

1----

~

to

sions.

See paragraph on adjustment

of

stitch needle thread

guide.

double-chain

new

needle.

of

needle bar

of

needle bar

correct ten-

4

4

21

21

5

v

5

When

the

power

turned

on,

in

the

Material, Pattern,

Size, and Zone displays.

No

response

pressed.

"0"

is indicated

when

switch

keys are

is

Wrong

I-

'---

,.......

1--

L..-

1--

L-

timing

chain stitch thread takeup

assembly.

Main and differential feed

dogs are

one another.

The

turned

through

and the

indication is displayed.

The data back-up battery

is depleted.

A key has

its original position.

not

power

off

self-diagnosis,

"

of

level

has been

midway

Sl.fn(

not

returned

double-

with

(Sync.)"

I---

1---

f---.

to

-------

Thread takeup

Feed dog height.

Check data.

Return key.

timing.

See paragraph on adjustment

of

1---

stitch thread takeup and

thread guide.

1----

1---

1----

double-chain

See paragraph on feed

adjustment.

Press the Data Key.

Replace the circuit board.

Turn on the

again. Press the Diagno-

for

sis Key

Fix on correct position.

power

switch

self-diagnosis.

5

22

19

v

19

v

-25-

Page 28

"\

Machine

Trouble

won't

start.

I

I

First photosensor's

too

is

Cause

strong.

light

I

I

Inspection

First photosensor's

light

intensity.

I I

Adjust

Remedy

cloth detector.

I

Pagel

Servo

motor

won't

The machine starts

as

the

power

is

turned

Servo

motor

only.

Machine

Cutter

Cutter

should

runs one

won't

won't

operate.

operates

not.

stop.

where

start.

as

soon

on.

way

it

Fuse is blown.

1--

Either the material plate

surface under the first

1--

photosensor is dusty

the sensor

weak.

1--

Fuse is blown.

First photosensor and

second photosensor's

-

light

are

too

First photosensor's

1--

is

too

weak.

Cutter operating

r-

wrong.

Second photosensor's

f-1.--

light

is

too

light

is

weak.

strong.

or

too

light

timing

1--

-

~

-

1--

is

1--

1--

Fuse.

Dust on the materialplate surface

strength

sensor light.

Fuse.

First photosensor and

second photosensor's

light

are intensity.

Second photosensor's

light

intensity.

Cutter

Second photosensor's

light

intensity.

of

first photo-

timing.

or

Replace the fuse in the

r--

circuit panel.

Clean the material-plate

surface.

-

detector.

Replace the fuse in the

1----

circuit panel.

Adjust cloth detector.

-

1---

Adjust cloth detector.

r--

Adjust control box screw.

Adjust

1---

Adjust

cloth detector.

the cloth

v

23

v

23

23

16

23

-26-

Page 29

~ADJUSTMENT

OF CIRCUIT

BOARD)

@ Close the air cock and push the control box power switch ON.

Feeding direction

STP

~

..,._

(Vide A) (Vide

+ H

~~~c.n

a;

~

e(9

< L e (5 V) "'0

~~

o

±0

V C2DC1DDDCP

B)

@@

CLOSE

V)

OPEN

~

DO

DOoo

(Vide

C)

1.

Right/Left Balance & Output Adjustment of Servo

board (right end in above figure) beforehand].

(1)

Put the edge

and set

(2)

Take measure

adjust in such a

(vide

C).

Also, when removing

2.

Adjustment of Dust Sensor

(1)

Take measure

tester.

(2)

Make adjustment by

between

of

material in

it

at the position

of

the voltage between

way

(0.4-1

±0

V terminal and

the

midst

where

that

it

will

be 5 V

the

material

V)

of

the voltage between

turning

volume

DD

of

light

LED

"PHM"

±0 V terminal

by

turning

out

(vide A),

DD so

terminal

of

that

(-).

Motor

photo

sensor (vide

just

illuminates

and ANP terminal by AC

volume

turning

±0 V terminal

the

"CLOSE"

amount

[Please remove the fuse

or

volume

and

of

voltage

B)

and

turn

the

servo balance

just

puts off.

50

V range

when

inserting the material

"OPEN" and adjust

CP

terminal

will

be

(+)

half

by

DC

of

it

above

on

circuit

"BAL"

of

tester and

forward

to

be 9

1 V range

amount

V.

of

r-".

-27-

Page 30

BROTHER

INDUSTRIES, L TO.

NAGOYA,

JAPAN

...

r

I

I

151-150

192150-0-02

8512

<D

Printed in Japan

Loading...

Loading...