Page 1

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

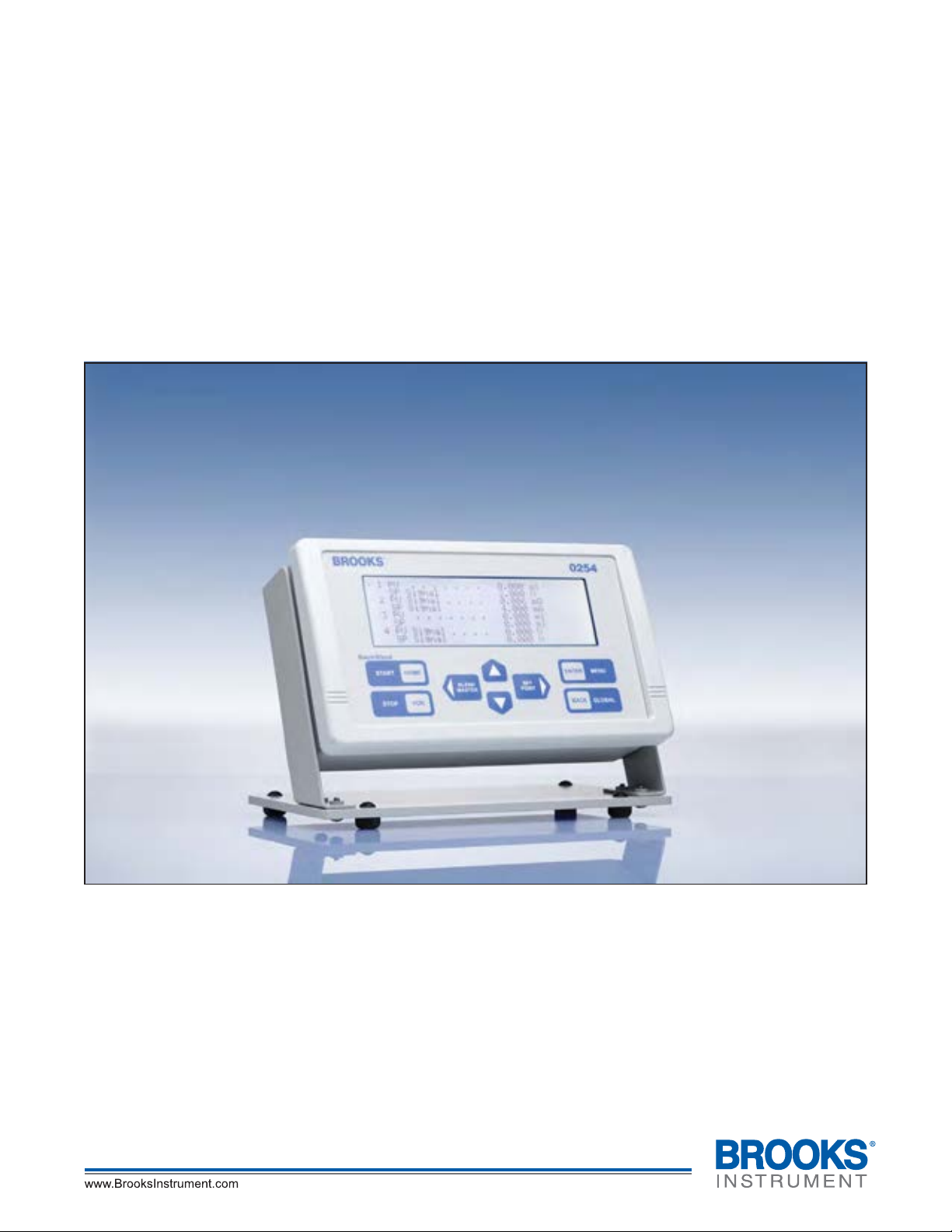

Gas and Liquid Mass Flow

Secondary Electronics

Model 0254

5

Model 0254

Table Top Four Channel

Secondary Electronics

Page 2

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

Model 0254

September, 2010

Essential Instructions

Read before proceeding!

Brooks Instrument designs, manufactures and tests its products to meet many national and international standards. These products must be properly

installed, operated and maintained to ensure they continue to operate within their normal specifications. The following instructions must be adhered to

and integrated into your safety program when installing, operating and maintaining Brooks Instrument products.

• To ensure proper performance, use qualified personnel to install, operate, update, program and maintain the product.

• Read all instructions prior to installing, operating and servicing the product. If this instruction manual is not the correct manual, please see back cover

for local sales office contact information. Save this instruction manual for future reference.

WARNING: Do not operate this instrument in excess of the specifications listed in the Instruction and Operation Manual. Failure to heed

this warning can result in serious personal injury and / or damage to the equipment.

• If you do not understand any of the instructions, contact your Brooks Instrument representative for clarification.

• Follow all warnings, cautions and instructions marked on and supplied with the product.

• Install your equipment as specified in the installation instructions of the appropriate instruction manual and per applicable local and national codes.

Connect all products to the proper electrical and pressure sources.

• Operation: (1) Slowly initiate flow into the system. Open process valves slowly to avoid flow surges. (2) Check for leaks around the flow meter inlet

and outlet connections. If no leaks are present, bring the system up to the operating pressure.

• Please make sure that the process line pressure is removed prior to service. When replacement parts are required, ensure that qualified people use

replacement parts specified by Brooks Instrument. Unauthorized parts and procedures can affect the product's performance and place the safe

operation of your process at risk. Look-alike substitutions may result in fire, electrical hazards or improper operation.

• Ensure that all equipment doors are closed and protective covers are in place to prevent electrical shock and personal injury, except when

maintenance is being performed by qualified persons.

WARNING: For liquid flow devices, if the inlet and outlet valves adjacent to the devices are to be closed for any reason, the devices must

be completely drained. Failure to do so may result in thermal expansion of the liquid that can rupture the device and may cause personal

injury.

European Pressure Equipment Directive (PED)

All pressure equipment with an internal pressure greater than 0.5 bar (g) and a size larger than 25mm or 1" (inch) falls under the Pressure Equipment Directive

(PED).

• The Specifications Section of this manual contains instructions related to the PED directive.

• Meters described in this manual are in compliance with EN directive 97/23/EC.

• All Brooks Instrument Flowmeters fall under fluid group 1.

• Meters larger than 25mm or 1" (inch) are in compliance with PED category I, II or III.

• Meters of 25mm or 1" (inch) or smaller are Sound Engineering Practice (SEP).

European Electromagnetic Compatibility (EMC)

The Brooks Instrument (electric/electronic) equipment bearing the CE mark has been successfully tested to the regulations of the Electro Magnetic

Compatibility (2004/108/EC (EMC directive 89/336/EEC)).

Special attention however is required when selecting the signal cable to be used with CE marked equipment.

Quality of the signal cable, cable glands and connectors:

Brooks Instrument supplies high quality cable(s) which meets the specifications for CE certification.

If you provide your own signal cable you should use a cable which is overall completely screened with a 100% shield.

“D” or “Circular” type connectors used should be shielded with a metal shield. If applicable, metal cable glands must be used providing cable screen

clamping.

The cable screen should be connected to the metal shell or gland and shielded at both ends over 360 Degrees.

The shield should be terminated to an earth ground.

Card Edge Connectors are standard non-metallic. The cables used must be screened with 100% shield to comply with CE certification.

The shield should be terminated to an earth ground.

For pin configuration : Please refer to the enclosed Instruction Manual.

ESD (Electrostatic Discharge)

CAUTION: This instrument contains electronic components that are susceptible to damage by static electricity. Proper handling procedures

must be observed during the removal, installation or other handling of internal circuit boards or devices.

Handling Procedure:

1. Power to unit must be removed.

2. Personnel must be grounded, via a wrist strap or other safe, suitable means before any printed circuit card or other internal device is installed,

removed or adjusted.

3. Printed circuit cards must be transported in a conductive container. Boards must not be removed from protective enclosure until immediately before

installation. Removed boards must immediately be placed in protective container for transport, storage or return to factory.

Comments

This instrument is not unique in its content of ESD (electrostatic discharge) sensitive components. Most modern electronic designs contain components

that utilize metal oxide technology (NMOS, SMOS, etc.). Experience has proven that even small amounts of static electricity can damage or destroy these

devices. Damaged components, even though they appear to function properly, exhibit early failure.

Page 3

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Dear Customer,

We appreciate this opportunity to service your flow measurement and control requirements with a Brooks

Instrument device. Every day , flow customers all over the world turn to Brooks Instrument for solutions to their

gas and liquid low-flow applications. Brooks provides an array of flow measurement and control products for

various industries from biopharmaceuticals, oil and gas, fuel cell research and chemicals, to medical devices,

analytical instrumentation, semiconductor manufacturing, and more.

The Brooks product you have just received is of the highest quality available, offering superior performance,

reliability and value to the user. It is designed with the ever changing process conditions, accuracy requirements

and hostile process environments in mind to provide you with a lifetime of dependable service.

We recommend that you read this manual in its entirety. Should you require any additional information concerning

Brooks products and services, please contact your local Brooks Sales and Service Office listed on the back cover

of this manual or visit www.BrooksInstrument.com

Y ours sincerely ,

Brooks Instrument

Model 0254

Page 4

Model 0254

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

THIS PAGE WAS

INTENTIONALLY

LEFT BLANK

Page 5

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Paragraph Page

Number Number

Section 1 Introduction

1-1 Description .................................................................................................................................1-1

1-1-1 Architecture................................................................................................................................ 1-1

1-1-2 Communication .......................................................................................................................... 1-1

1-1-3 Process Controls ....................................................................................................................... 1-1

1-1-4 Operator Controls and Indicators............................................................................................... 1-2

1-1-5 Diagnostic Capabilities...............................................................................................................1-2

1-2 Specifications............................................................................................................................. 1-2

1-3 Signal Wiring..............................................................................................................................1-6

1-4 Optional Equipment ................................................................................................................... 1-7

1-4-1 Mounting Kit Options..................................................................................................................1-7

1-4-2 Power Supply Output V oltage Options....................................................................................... 1-7

1-4-3 Input/Output Signal Adapters ..................................................................................................... 1-7

Section 2 Installation

2-1 General ...................................................................................................................................... 2-1

2-2 Receipt of Equipment................................................................................................................. 2-1

2-3 Recommended S torage Practice ............................................................................................... 2-1

2-4 Return Shipment........................................................................................................................2-2

2-5 Transit Precautions .................................................................................................................... 2-2

2-6 Removal from Storage ............................................................................................................... 2-2

2-7 Ventilation and Mounting Requirements ....................................................................................2-2

2-8 Cleaning Instructions ................................................................................................................. 2-2

2-9 Cable Requirements .................................................................................................................. 2-3

2-10 Installation Instructions .............................................................................................................. 2-3

2-10-1 Panel Mount Installation Instructions .........................................................................................2-3

2-10-2 Table Top S tand Assembly Instructions...................................................................................... 2-5

2-10-3 Retrofit to Model 0152/0154 Table Top Housing ........................................................................ 2-6

2-10-4 19-in. Rack Assembly and Installation Instructions.................................................................... 2-7

Contents

Model 0254

Section 3 Operation

3-1 Home Screen............................................................................................................................. 3-1

3-2 Operating Controls.....................................................................................................................

3-2-1 Primary Functions ......................................................................................................................3-2

3-2-2 Key Functions ............................................................................................................................3-3

3-3 Navigation .................................................................................................................................. 3-4

3-3-1 Display or Instrument Configuration Screen Selection............................................................... 3-5

3-3-2 User Interface Screen Map........................................................................................................ 3-6

3-4 Process V alues (PV) and Setpoint s (SP)................................................................................... 3-7

3-4-1 PV-SP Measures and S t atus...................................................................................................... 3-7

3-4-2 PV-SP Configuration ..................................................................................................................3-8

3-4-3 Value Programming ...................................................................................................................3-9

3-5 Global Settings.......................................................................................................................... 3-12

3-5-1 Global Information.....................................................................................................................3-12

3-5-2 Global System Power................................................................................................................ 3-13

3-5-3 Global Control Services ............................................................................................................ 3-14

3-5-4 Global Communication..............................................................................................................3-15

3-6 Instrument Configuration and Control ....................................................................................... 3-15

3-6-1 Rate (Setpoint) Control ............................................................................................................. 3-15

3-2

i

Page 6

Contents

Model 0254

Paragraph Page

Number Number

3-6-2 PV Configuration ....................................................................................................................... 3-17

3-6-3 Batch Control ............................................................................................................................ 3-18

Appendix A Engineering Units

Available Engineering Units .......................................................................................................A-1

Appendix B Blending Examples

Examples 1 through 6 ................................................................................................................B-1

Appendix C Serial Communications Protocol

Contents

C-1 Overview ....................................................................................................................................C-1

C-2 Communication Settings............................................................................................................. C-1

C-2-1 RS-232 Port Settings.................................................................................................................. C-1

C-2-2 Hyperterminal Setup ................................................................................................................... C-2

C- 3 Serial Command Organization ....................................................................................................C-4

C-3-1 Command Structures ..................................................................................................................C-4

C-3-2 Command Addressing................................................................................................................. C-5

C- 4 Command Operation................................................................................................................... C-6

C-4-1 General Commands .................................................................................................................... C-6

C-4-1-1 Command Synchronize .............................................................................................................. C-6

C-4-1-2 Menu Command ......................................................................................................................... C-6

C-4-1-3 View Programmed Channel Port Values ..................................................................................... C-7

C-4-1-4 Identify Command....................................................................................................................... C-7

C-4-1-5 Message Serial Character Pacing Controls ................................................................................ C- 8

C-4-1-6 Serial Message Error Control...................................................................................................... C-9

C-4-2 Channel Input Port Commands .................................................................................................. C-10

C-4-2-1 Measured Channel Values Command........................................................................................C-10

C-4-2-2 Send Channel Input Port Programmed V alues........................................................................... C-11

C-4-2-3 Program Channel Input Port V alues........................................................................................... C-12

C-4-2-4 Clear Accumulated Values......................................................................................................... C-12

C-4-3 Channel Output Port Control Commands ................................................................................... C-12

C-4-3-1 Channel Control Output Port V alues .......................................................................................... C-12

C-4-3-2 Batch and Blend Control Commands......................................................................................... C-13

C-4-4 Global Settings Services............................................................................................................C-15

C-4-4-1 Global Setting V alues

C-4-4-2 Set Global Settings Values ........................................................................................................ C-15

C-4-5 Communication Message Basics ..............................................................................................C-15

C-4-5-1 Message Structure ....................................................................................................................C-16

C-4-5-2 Message Format .......................................................................................................................C-16

C- 5 Serial Value Programming ......................................................................................................... C-17

C-5-1 Read a Programmed Value ........................................................................................................C-17

C-5-2 Program a New Value ................................................................................................................C-18

C-5-3 Channel Input Port Values ......................................................................................................... C-19

C-5-4 Channel Output Port Values ...................................................................................................... C-21

C-5-5 Global Setting Values ................................................................................................................ C-22

................................................................................................................C-15

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

ii

Page 7

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Appendix D CE Certification

Essential Instructions .................................................................................................................D-1

Warranty, Local Sales/Service Contact Information...................................................................... Back Cover

Figures

Figure Page

Number Number

1-1 Model 0254 Signal Wiring ..........................................................................................................1-6

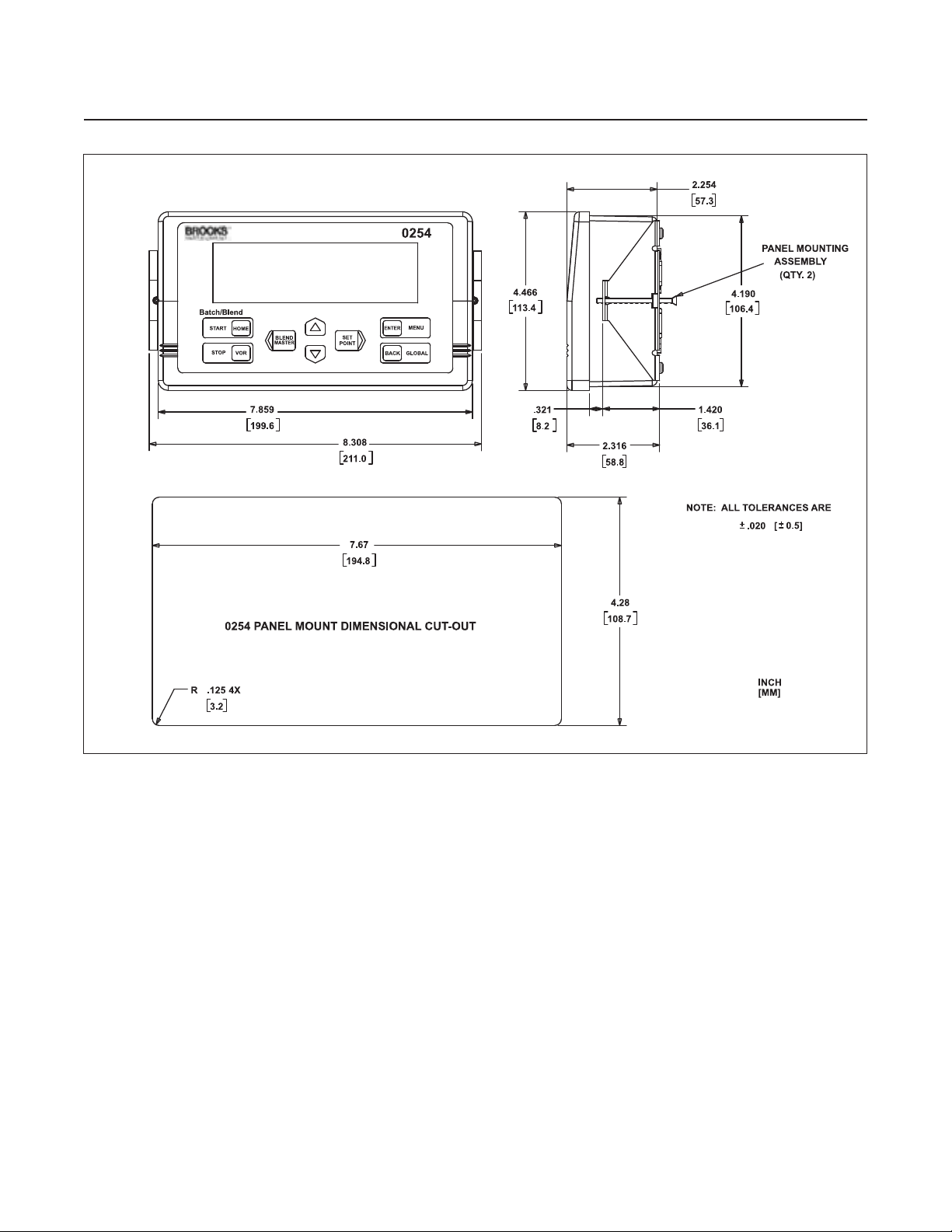

2-1 Panel Mount Cut-Out Dimensions ............................................................................................. 2-4

2-2 T able Top Stand Mount Installation ............................................................................................2-5

2-3 Power Supply Bracket and Bezel ............................................................................................... 2-8

2-4 Rack Installation.........................................................................................................................2-9

3-1 Home Screen............................................................................................................................. 3-1

3-2 User Interface Screen Map ........................................................................................................ 3-6

Contents

Model 0254

Tables

Table Page

Number Number

3-1 Display Home Screen Fields...................................................................................................... 3-2

iii

Page 8

Contents

Model 0254

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

THIS PAGE WAS

INTENTIONALLY

LEFT BLANK

iv

Page 9

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

1-1 Description

Section 1 Introduction

Model 0254

The Brooks Model 0254 is a versatile full-featured measurement and

control process instrument, with precision multiple channel capabilities.

The architecture supports a wide range of operating capabilities organized

to meet the requirements of nearly any high-accuracy measurement and

control application.

This system suits applications requiring advanced multiple channel

operation. It provides control services including rate, batch, and

proportional blending.

The system is all digital, based on microcomputer technology. There is no

power switch to be left off, no feature selection switches or jumpers, and

no analog trimming potentiometers.

It employs surface mount technology and incorporates floating-point digital

signal processing arithmetic. Built-in test capabilities enable simple

installation, and extensive self-tests ensures long-term operating reliability .

The rugged package is modular , providing an ideal solution for use in

demanding applications and tough environments. Options are available for

panel mount, rack mount, and desktop.

1-1-1 Architecture

1-1-2 Communication

1-1-3 Process Controls

The system is built on the basics of a multiple-port based architecture,

modularly organized, which are combined as channels, able to meet

present and future instrumentation requirements.

Channels provide for value measurements and quantity accumulation, rate

measurements, scalar measurements, supported by value scaling for

process voltage and current process signals. Signal acquisition uses digital

signal processing rejecting ambient noise and interference.

The communication facilities provide for data acquisition, command, and

control functions, supporting configuration programming and information

gathering.

Totalizer , batch, and proportional blending are readily achieved using the

front panel key controls or serial commands.

1-1

Page 10

Section 1 Introduction

Model 0254

1-1-4 Operator Controls and Indicators

1-1-5 Diagnostic Capabilities

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Operation may be completely controlled from its integral eight-key pad

used to view operation and programmed operating values. Key activations

are single touch with hold-and-repeat capability . The front panel key p ad

provides splash proofing and environment protection.

The 0254 primary indicator is its large back lit liquid crystal graphic display

- visible at a distance even in low light conditions - to view values, support

programming operations, and indicate process state information. A userselectable audio indicator annunciates key activations.

Powerful automatic diagnostics support easy installation and ensure a

trouble-free operating life. Tests include memory facility scans, channel

input-output status, and communication status.

1-2 Specifications

Programmable Control and Measurement Functions

Four independent channels.

Rate, Batch, Blend, Measure: 0.000 to 999999

Blend Ratio Percent: 0.000 to 999.999

T ot alizer: 0.000 to 19,999,999,999

Gas Correction Factor: 0.000 to 999.999

Measurement Engineering Units: Refer to Appendix A.

Time Base: day, hrs, min, sec, none

Decimal Point : X. to X.XXX

1-2

V alve Override: Normal, Open, Closed

Input and Output Signal Selection: Volt s or mA, independent, mix or match

Input and Output Full Scale Setting: Independent, 0.000 to 999,999

Setpoint Source: Keypad or RS232

Page 11

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Section 1 Introduction

Model 0254

Measurement and Setpoint Accuracy

0.090% of Full Scale

Electrical Specifications

Input Electrical Characteristics

V oltage Input: 0–5, 0-10, 1–5, 2–10 V

V olts Input Impedance: 10 K Ohms

Current Input: 0–20, 4–20 mA

Current Input Impedance: 100 Ohms

Output Electrical Characteristics

V oltage Output: 0–5, 0–10, 1–5, 2–10 V

V oltage Output Load: 2 K Ohms minimum

Current Output: 0–20, 4–20 mA

Current Output Load: 0–375 Ohms

Voltage Compensation

Voltage I/O signals are compensated to correct for volt age drop in the power

return circuit of the attached wiring

V alve Override (VOR) Output

Normal: Open circuit

Open: 8.0 V @ 4 mA

Closed: –4.0 V @ 4 mA

Channel Connectors (4)

15-pin female D

Provides signal and power to connected devices

Serial Port

EIA-TIA232D full duplex D9S Load 4.7 K max

Baud Rate = 9600

1-3

Page 12

Section 1 Introduction

Model 0254

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Power for Model 0254 and Connected Equipment

Power Supply Requirements

Required: 12–24 Vdc, 2 Amp s

Additional permitted: –15 Vdc, 1 Amp DC +/- 5%

Supply voltage flucuations up to +/- 10%

Max current draw per channel : 400 mA

Instrument power draw: 0.8 W

Power Connector: 9-pin female D, 5 A rated

Optional Power Supply Modules (available from Brooks)

• +15 Vdc/2 A, –15 Vdc/1 A, 100–240 Vac, 47–63 Hz

• +24 Vdc/2.5 A, 100–240 Vac, 47–63 Hz

Graphic Display

8-line x 40-character LCD display with backlight

Programmable Display Configuration

Two lines per channel

Line 1, Process V ariable: Rate, Total, or Signal

Line 2, Setpoint: Rate, Batch, Blend, or Signal

Off: Unused individual lines can be turned off

Keypad/Display Window

8-Key Metal Dome Tactile with Selectable Audio Beep

Construction: S plash proof and chemically resistant

Hot Keys for Instant Access: Setpoint (rate, batch, blend), VOR,

Emergency Stop

Key Functionality: Full operation and programming capability (refer to

Figure 3-2 on p. 3-6)

Global Settings

1-4

Settings applied to all four channels

Information

V ersion/Check Sum: Factory-installed firmware information

Factory Setting: Allows reset of all channels to factory configuration

System Power

Key selectable power down, power up

Page 13

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Section 1 Introduction

Model 0254

Control Service Settings

Audio Beep: Selectable audible keystroke, 2 kHz

Leading Zero Suppress: Selectable leading zero suppression on display

Power Setpoint Clear: Selectable memory retention for Setpoint/VOR

Network Address

Unique factory set identifier

Environment

Temperature/Humidity

Operating: 32 to 122°F (0 to 50°C); 0 to 95% non-condensing

Ship Storage: –40 to 185°F (–40 to 85°C); 0 to 95% non-condensing

Warm-up

15 min typ to rated accuracy

Data Reliability

Data Retention: Non-volatile RAM/ROM, 100 year retention

Self-Diagnostics: On power up, memory checksum, communications,

system status, display and keypad operation

Enclosure

Material: ABS Cycolac Resin FR23

Weight: 1.4 lbs (635 g)

Panel Cut-Out: 7.67 x 4.275 in., 0.125 in. radius maximum

(194.8 x 108.6 m, 3.2 m radius maximum); 0.25 in. (6.35 mm) maximum

panel thickness with optional panel mount kit

Certifications

CE Mark: EN61326-1

FCC: Part 15 Class A, Part 68

RoHS: EPD 2002/95/EC, 01Jul2006

UL: UL 61010 Electrical Safety for General Purpose

Indoor Use;

Altitude up to 2000 m;

RA TED POLLUTION Degree 2

1-5

Page 14

Section 1 Introduction

Model 0254

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Mounting Options

Panel Mount Kit: Brackets accept panel thickness up to 0.25 in. (6.35 mm)

T able T op Kit: W eighted base with fixed tilt for easy viewing

Rack Mount Kit: Hardware for mounting the Model 0254 and optional power

supply into 19-in. sub-rack.

Rack Mount Kit with 19-in. sub-rack: 19-in. sub-rack included with Rack

Mount Kit

Retrofit Applications, Model 0152/0154: Rack Mount Kit will adapt the

Model 0254 and power supply to the table top enclosure used for the

Model 0152/0154

Communications

Full communications capability for remote readout setpoint, control,

programming, and data acquisition

1-3 Signal Wiring

NOTES:

1) The following nodes are directly connected inside the 0254:

Pin 12 (COM PWR) of each DA15S channel

Pin 5 (GND) of the SERIAL PORT connector

Pins 1,2 and 6 (GND) of the +12-24 Vdc 9-Pin SUB D connector

All hex shield screwlocks for all SUB-D connectors

2) For each DA15S channel, Pins 6 (CMD RTN) and 8 (RATE RTN) are directly connected,

are connected via approximately 10KΩ to Pin 12 (COM PWR)

Pins 6 and 8 are not directly connected between channels

3) For all connectors, all unlisted pins are not internally connected

Figure 1-1 Model 0254 Signal Wiring

1-6

Page 15

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

1-4 Optional Equipment

1-4-1 Mounting Kit Options

1-4-2 Power Supply Options

Section 1 Introduction

Model 0254

The Model 0254 can be mounted using the following kits:

• Panel Mount Kit

• T able Top Kit

• Rack Mount Kit

• Rack Mount Kit with 19-in. Rack

The Model 0254 supports the following power supply options:

1-4-3 Input/Output Pin-Out Adapters

• Factory supplied: +15 Vdc/2 A, –15 Vdc/1 A, 100–240 Vac, 47–63 Hz

• Factory supplied: +24 Vdc/2.5 A, 100–240 Vac, 47–63 Hz

• User supplied: 12–24 Vdc into 9-pin D connector, 5 A rated

The Model 0254 has four 15-pin female D-channel connectors. The pin

configuration is compatible with standard Brooks 0(4)-20 mA cables.

An optional pin-out adapter kit with four adapters is available for use with

Brooks 0(1)-5 Vdc cables.

1-7

Page 16

Section 1 Introduction

Model 0254

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

THIS PAGE WAS

INTENTIONALLY

LEFT BLANK

1-8

Page 17

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

2-1 General

2-2 Receipt of Equipment

Section 2 InstallationInstallation and Operation Manual

Model 0254

This section provides installation instructions for the Model 0254 Gas and

Liquid Mass Flow Secondary Electronics device.

When the instrument is received, the outside packing case should be

checked for damage incurred during shipment. If the packing case is

damaged, the local carrier should be notified at once regarding his liability .

A report should be submitted to your nearest Product Service Department.

Brooks Instrument

407 W. V ine Street

P.O. Box 903

Hatfield, PA 19440 USA

Toll Free (888) 554 FLOW (3569)

Tel (215) 362 3700

Fax (215) 362 3745

E-m ail: BrooksAm @BrooksInstrument.com

www.BrooksInstrument.com

2-3 Recommended Storage Practice

Brooks Instrument Brooks Instrument

Neonstraat 3 1-4-4 Kitasuna Koto-Ku

6718 WX Ede, Netherlands Tokyo, 136-0073 Japan

P.O. Box 428 Tel +81 (0) 3 5633 7100

6710 BK Ede, Netherlands Fax +81 (0) 3 5633 7101

Tel +31 (0) 318 549 300 Email: BrooksAs@BrooksInstrument.com

Fax +31 (0) 318 549 309

E-mail: BrooksEu@BrooksInstrument.com

Remove the envelope containing the packing list. Carefully remove the

instrument from the packing case. Make sure spare part s are not

discarded with the packing materials. Inspect for damaged or missing

parts.

If intermediate or long-term storage of equipment is required, it is

recommended that the equipment be stored in accordance with the

following:

• Within the original shipping container.

• Stored in a sheltered area, preferably a warm, dry, heated warehouse.

• –40 to 185°F (–40 to 85°C); 0 to 95% non-condensing.

• Upon removal from storage, a visual inspection should be conducted to

verify the condition of equipment is "as received".

2-1

Page 18

Section 2 Installation Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

Model 0254

2-4 Return Shipment

Prior to returning any instrument to the factory, cont act your nearest Brooks

location for a Return Materials Authorization Number (RMA#). This can be

obtained from one of the following locations:

Brooks Instrument

407 W. Vi ne Street

P.O. Box 903

Hatfield, PA 19440 USA

Toll Free (888) 554 FLOW (3569)

Tel (215) 362 3700

Fax (215) 362 3745

E- mail: BrooksA m@BrooksInstrument.com

www.BrooksInstrument.com

Brooks Instrument Brooks Instrument

Neonstraat 3 1-4-4 Kitasuna Koto-Ku

6718 WX Ede, Netherlands Tokyo, 136-0073 Japan

P.O. Box 428 Tel +81 (0) 3 5633 7100

6710 BK Ede, Netherlands Fax +81 (0) 3 5633 7101

Tel +31 (0) 318 549 300 Email: BrooksAs@BrooksInstrument.com

Fax +31 (0) 318 549 309

E-mail: BrooksEu@BrooksInstrument.com

September, 2010

2-5 Transit Precautions

To safeguard against damage during transit, transport the instrument to the

installation site in the same container used for transportation from the

factory if circumstances permit.

2-6 Removal from Storage

Upon removal from storage, a visual inspection should be conducted to

verify the condition of the equipment is “as received.”

2-7 Ventilation and Mounting Requirements

Because of the low power consumption of the Model 0254, it does not

have ventilation requirements. However , the ambient temperature

surrounding the Model 0254 should not exeed 122°F (50°C). The optional

power supply modules are also ventilation-free and limited to an ambient

temperature of 122°F (50°C).

2-8 Cleaning Instructions

Do not use cleaning agents other than water because this might affect

color and marking of the equipment.

2-2

Use a clean, soft and damp cloth for cleaning.

Page 19

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

2-9 Cable Requirements

2-10 Installation Instructions

Section 2 InstallationInstallation and Operation Manual

Model 0254

For compliance with the EMC directive 89/336/EEC, the equipment has to

be installed with shielded signal cables which are overall completely

screened with a shield of at least 80%. Sub-D connectors used must be

shielded with a metal shield. The cable screen should be connected to the

metal shell and shielded at both ends over 360°. The shield should be

terminated to earth ground.

The optional power supplies available from Brooks are always supplied

with a power cord that meets all agency certifications and has a protective

conductor for grounding purposes. Any replacement cords must have

similar construction and be certified by a recognized nartional test

laboratory.

Do not use cleaning agents other than water because this might affect

color and marking of the equipment.

2-10-1 Panel Mount Installation Instructions

1. Cut a hole according to the cut-out dimensions shown in Figure 2-1 on

p. 2-4.

2. Pass the Model 0254 enclosure through the cut-out.

3. Position one of the two brackets included in the Panel Mount kit on the

side of the enclosure, while aligning the two holes at the top and bottom

of the bracket flange with the holes at the corners of the back of the

enclosure. Secure the bracket to the enclosure with two of the screws

provided in the kit.

Do not over-tighten these attachment screws.

4. Secure the second bracket to the other side of the enclosure.

5. Tighten the panel mounting screws in the middle of both brackets to

secure the enclosure to the panel.

CAUTION

!

CAUTION

!

Do not over-tighten these attachment screws.

6. Connect the power supply cable with the D-connector to the power

connector on the back of the enclosure.

7. Connect the power supply AC cord to a power outlet.

8. Connect the cables to the RS-232 and Channel connectors, as

approprate for the application.

2-3

Page 20

Section 2 Installation Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

Model 0254

September, 2010

Figure 2-1 Panel Mount Cut-Out Dimensions

2-4

Page 21

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

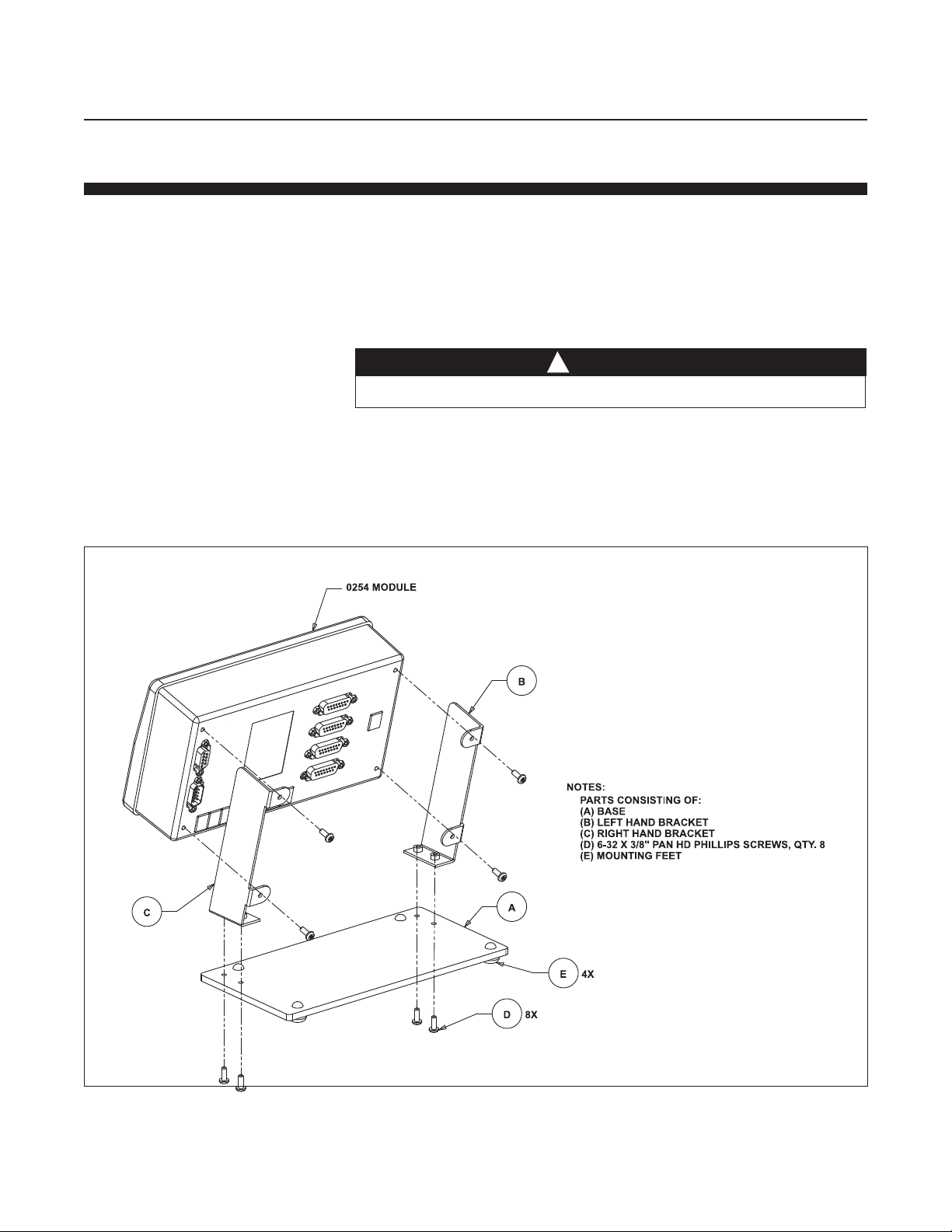

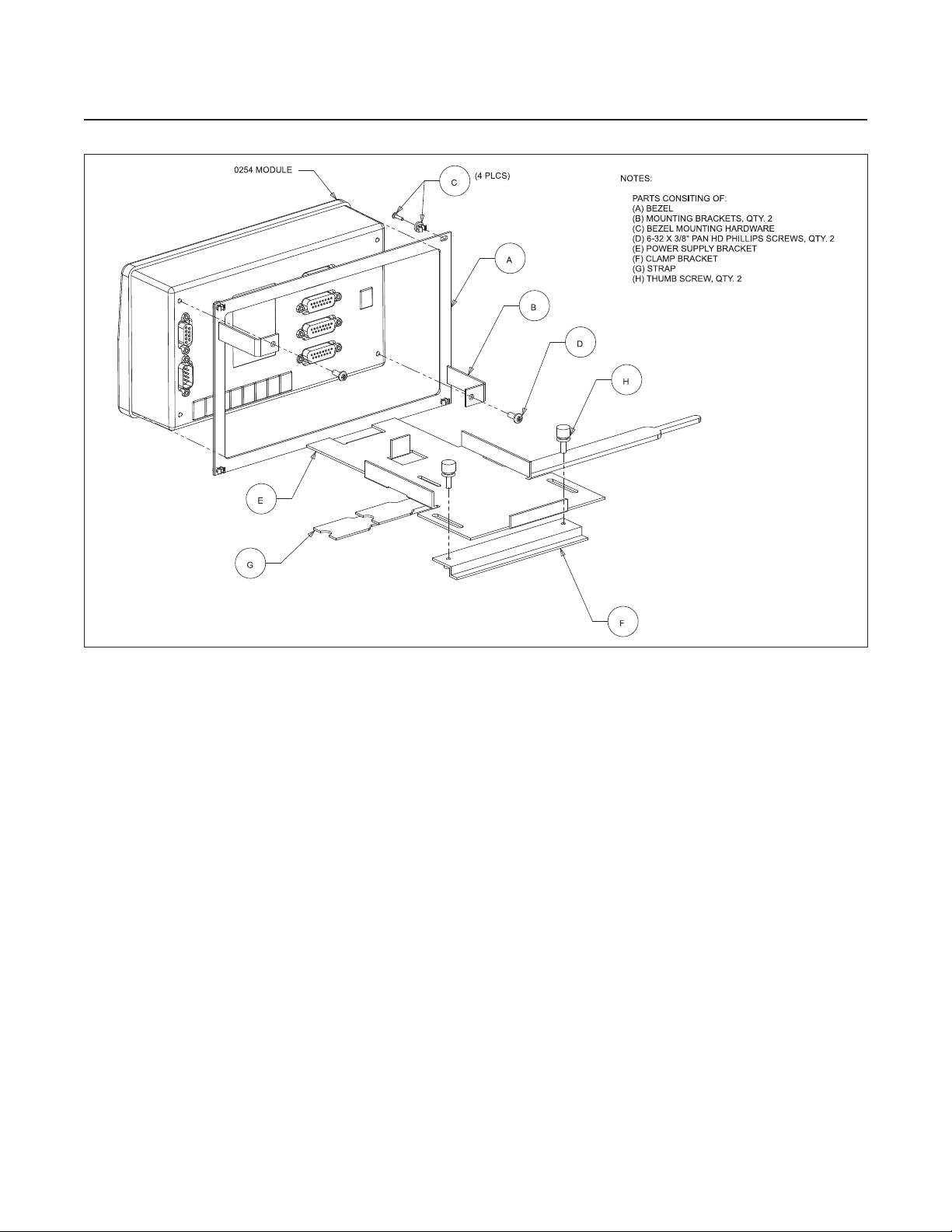

2-10-2 T able T op S t and Assembly Instructions

1. Attach the four rubber mounting feet to the base, as shown in

Figure 2-2.

2. Use four of the provided screws to attach the two brackets to the base.

3. Slide the Model 0254 enclosure into the brackets.

4. Use four screws to secure the enclosure to the brackets.

Do not over-tighten these attachment screws.

5. Connect the power supply cable with the D-connector to the power

connector on the back of the enclosure.

6. Connect the power supply AC cord to a power outlet.

CAUTION

!

Section 2 InstallationInstallation and Operation Manual

Model 0254

7. Connect the cables to the RS-232 and Channel connectors, as

approprate for the application.

Figure 2-2 Table Top Stand Mount Installation

2-5

Page 22

Section 2 Installation Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

Model 0254

2-10-3 Retrofit to Model 0152/0154 T able Top Housing

It is possible to retrofit the Model 0254 into a table top box that was used

for the Model 0152/0154.

1. Slide the flange on the front of the power supply bracket, shown in

Figure 2-3 on p. 2-8, under the rear channel rail of the box. For an

illustration of the rail engagement, refer to Figure 2-4 on p. 2-9.

2. Use the two thumbscrews at the back of the power supply bracket to

slide the back flange under the front channel rail of the box. Finger

tighten the two thumbscrews.

3. Place the power supply onto the bracket, with the AC cord receptacle

facing the back of the box.

4. Secure the power supply to the bracket using the Velcro strap.

5. Install the four plastic screw retainers into the bezel, then add the bezel

screws.

September, 2010

6. Slide the bezel over the back of the Model 0254 enclosure. Secure the

bezel to the enclosure by threading two screws through the holes in the

bezel mounting brackets and tightening them.

CAUTION

!

Do not over-tighten these attachment screws.

7. Connect the power supply cable with the D-connector to the power

connector on the back of the enclosure.

8. Connect the cables to the RS-232 and Channel connectors, as

approprate for the application.

9. Slide the enclosure into the box until the bezel is flush with the front of

the box.

10. Secure the bezel to the front of the box using the bezel screws.

1 1.Connect the power supply AC cord to a power outlet.

2-6

Page 23

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

2-10-4 19-in. Rack Assembly and Inst allation Instructions

Use these instructions whether you are installing the Model 0254 into your

own rack or into the optional 19-in. rack assembly from Brooks Instrument.

1. The optional 19-in. rack comes with a blind front plate covering half of

the rack. This plate can be removed or repositioned, depending on the

application, such as installing two Model 0254 modules side by side.

2. Slide the flange on the front of the power supply bracket, shown in

Figure 2-3 on p. 2-8, under the rear channel rail of the rack.

3. Use the two thumbscrews at the back of the power supply bracket to

slide the back flange under the back channel rail of the rack. Finger

tighten the two thumbscrews.

4. Place the power supply onto the bracket, with the AC cord receptacle

facing the back of the box.

5. Secure the power supply to the bracket using the Velcro strap.

Section 2 InstallationInstallation and Operation Manual

Model 0254

6. Install the four plastic screw retainers into the bezel, then add the bezel

screws.

7. Slide the bezel over the back of the Model 0254 enclosure. Secure the

bezel to the enclosure by threading two screws through the holes in the

bezel mounting brackets and tightening them.

CAUTION

!

Do not over-tighten these attachment screws.

8. Connect the power supply cable with the D-connector to the power

connector on the back of the enclosure.

9. Connect the cables to the RS-232 and Channel connectors, as

approprate for the application.

10. Place the enclosure into the rack until the bezel is flush with the

front of the rack.

1 1.Secure the bezel to the front of the rack using the bezel screws.

12. Connect the power supply AC cord to a power outlet.

Figure 2-4 on p. 2-9 shows a completed rack installation.

2-7

Page 24

Section 2 Installation Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

Model 0254

September, 2010

Figure 2-3 Power Supply Bracket and Bezel

2-8

Page 25

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Section 2 InstallationInstallation and Operation Manual

Model 0254

Figure 2-4 Rack Installation

2-9

Page 26

Section 2 Installation Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

Model 0254

September, 2010

THIS PAGE WAS

INTENTIONALLY

LEFT BLANK

2-10

Page 27

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September , 2010

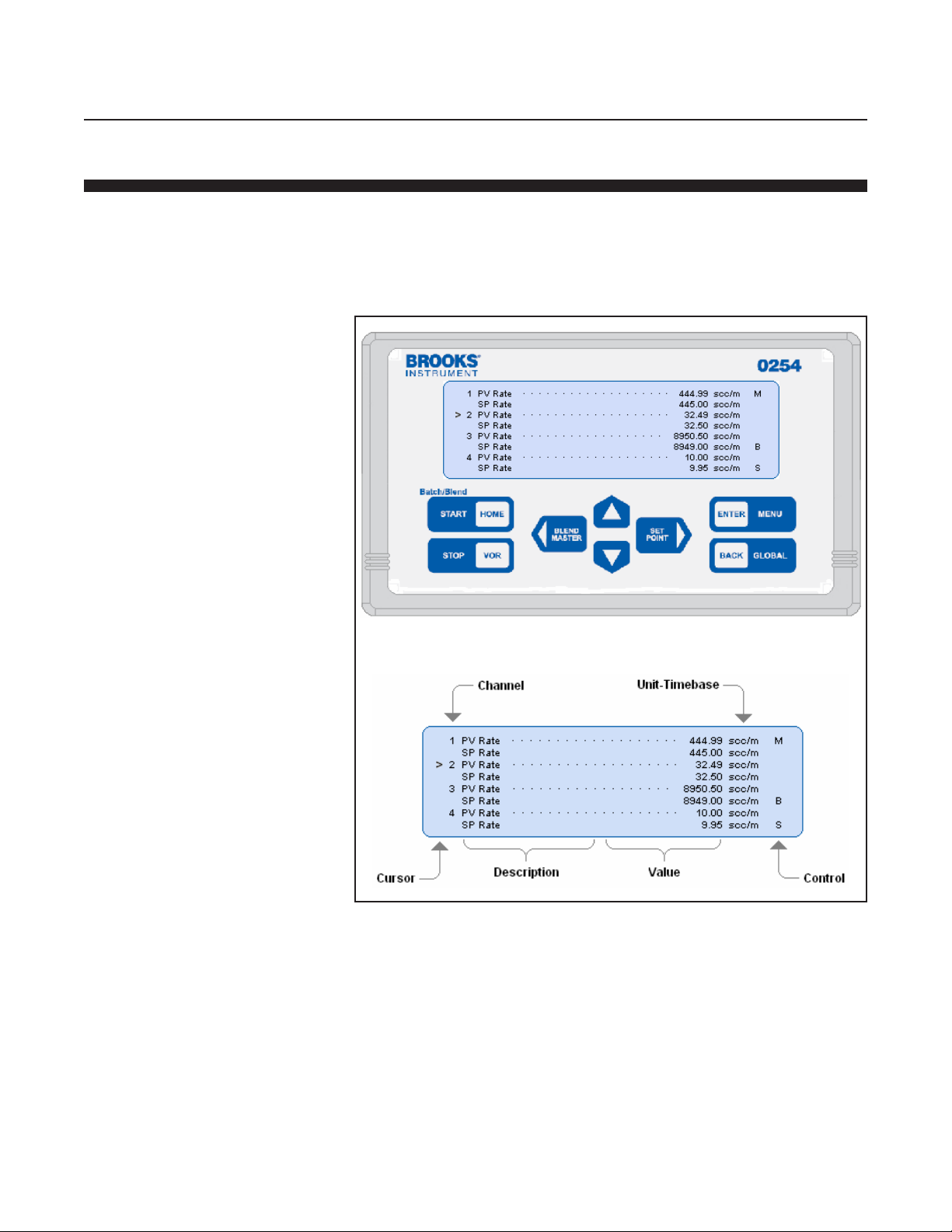

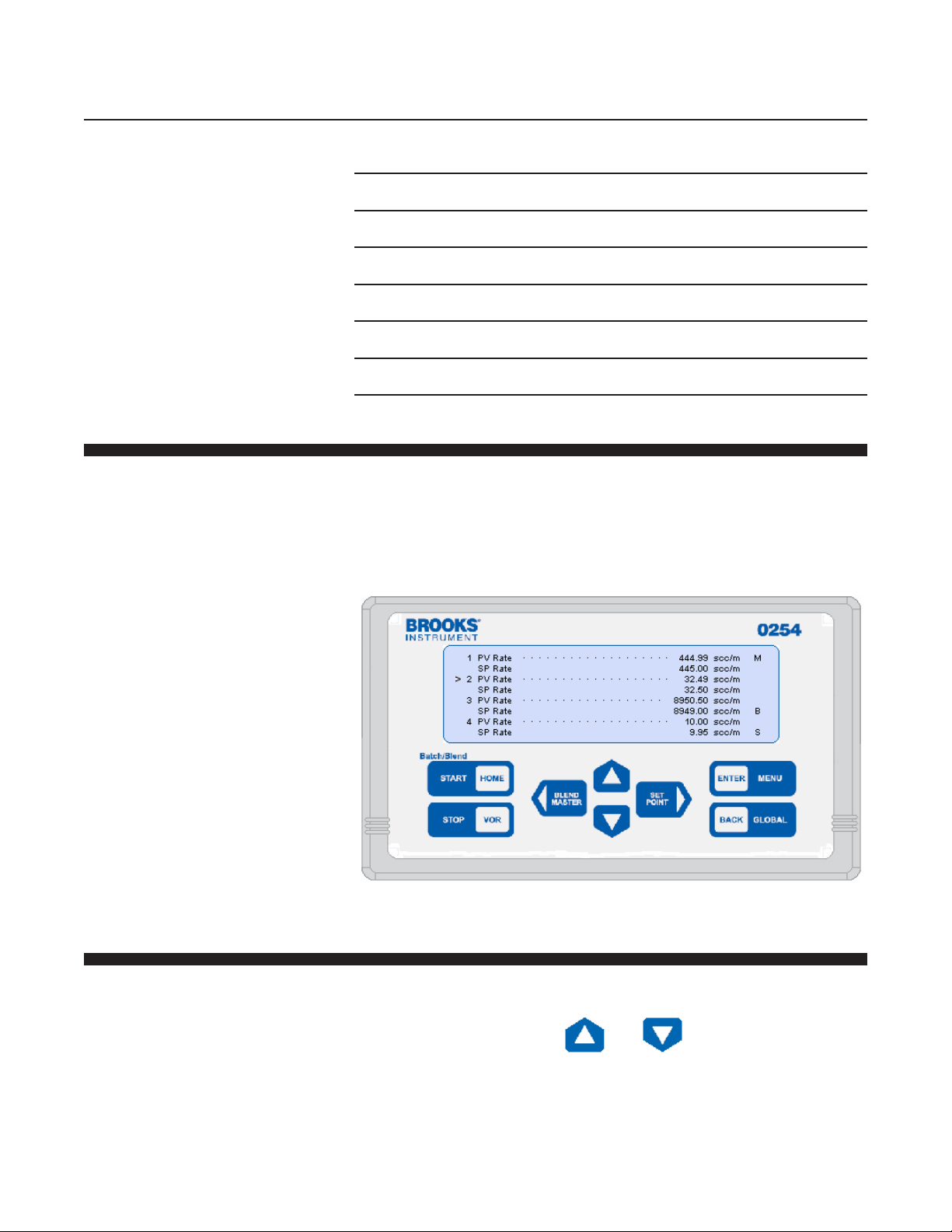

3-1 Home Screen

Section 3 Operation

Model 0254

The Model 0254 home screen is the instrument's central information and

navigation indicator. The home screen displays following initial power

application, and automatically follows the make-model screen banner. It

provides an overall view of the instrument's operation. Table 3-1 on p. 3-2

describes the main elements of the home screen.

Figure 3-1 Home Screen

3-1

Page 28

Section 3 Operation

Model 0254

3-2 Operating Controls

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Table 3-1 Display Home Screen Fields

Cursor Points to channel even when channel is Off.

Channel Numbers 1-4.

Description Process value text.

Value Numeric process value.

Unit / Time-base Combined measure units and rate time-base.

Control Process control state indicators.

The primary instrument control is supported by eight front panel tactile

snap-action keys, and alternatively by serial communications. Every

function that can be accomplished by using the keys can also be

simultaneously be accomplished by serial communication commands. The

serial communication functions are described more fully in Section D.

3-2-1 Primary Functions

3-2

Primary functions performed from the Home screen are as follows:

• Select a channel using the and keys

• Enter the configuration selection menu

• Enter the Global System Settings selection menus

Page 29

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September , 2010

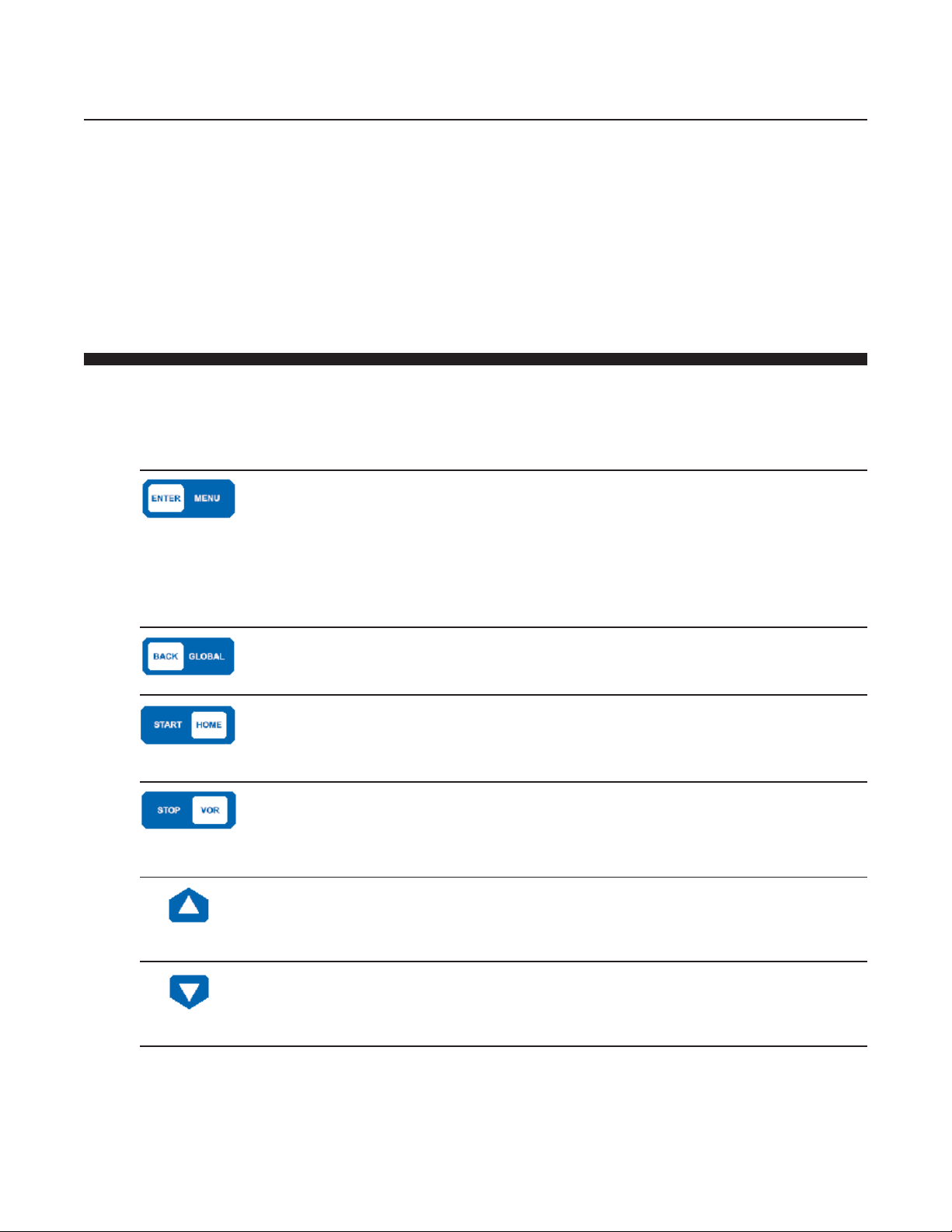

3-2-2 Key Functions

Key Present Location System Response

Home Screen Navigates to channel configuration screen.

Section 3 Operation

Model 0254

• Quickly navigate to setpoint or valve override functions

• Start and stop control functions

• Select a blend control master

• Execute the emergency stop function

Instructions for the using the above are described in their respective

subsections throughout this section.

The control function of the keys is dependant on the context of the function

that has been requested to be accomplished as follows:

Function Select Screen Selects viewing configuration or programming

configuration.

Display Configuration Screen Selects the home screen value.

Input Configuration Screen Programs the value that the cursor points to and

saves the value.

Home Screen Press three times to enter Global System Settings.

All Other Screens Navigates immediately to previous screen.

Home Screen Press three times to start batch and/or blend controls

operation.

Power Down Condition Press to restore power.

Home Screen Terminates operating controls if any. Otherwise HOT

navigates to change channel VOR state. This key can

be used to power down the system when pressed for

3 seconds.

All Screens Move cursor up to desired item.

All Screens: Selected Item Increase blinking program selection to succeeding

choice.

All Screens Move cursor down to desired item.

All Screens: Selected Item Decrease blinking program selection to preceding

choice.

3-3

Page 30

Section 3 Operation

Model 0254

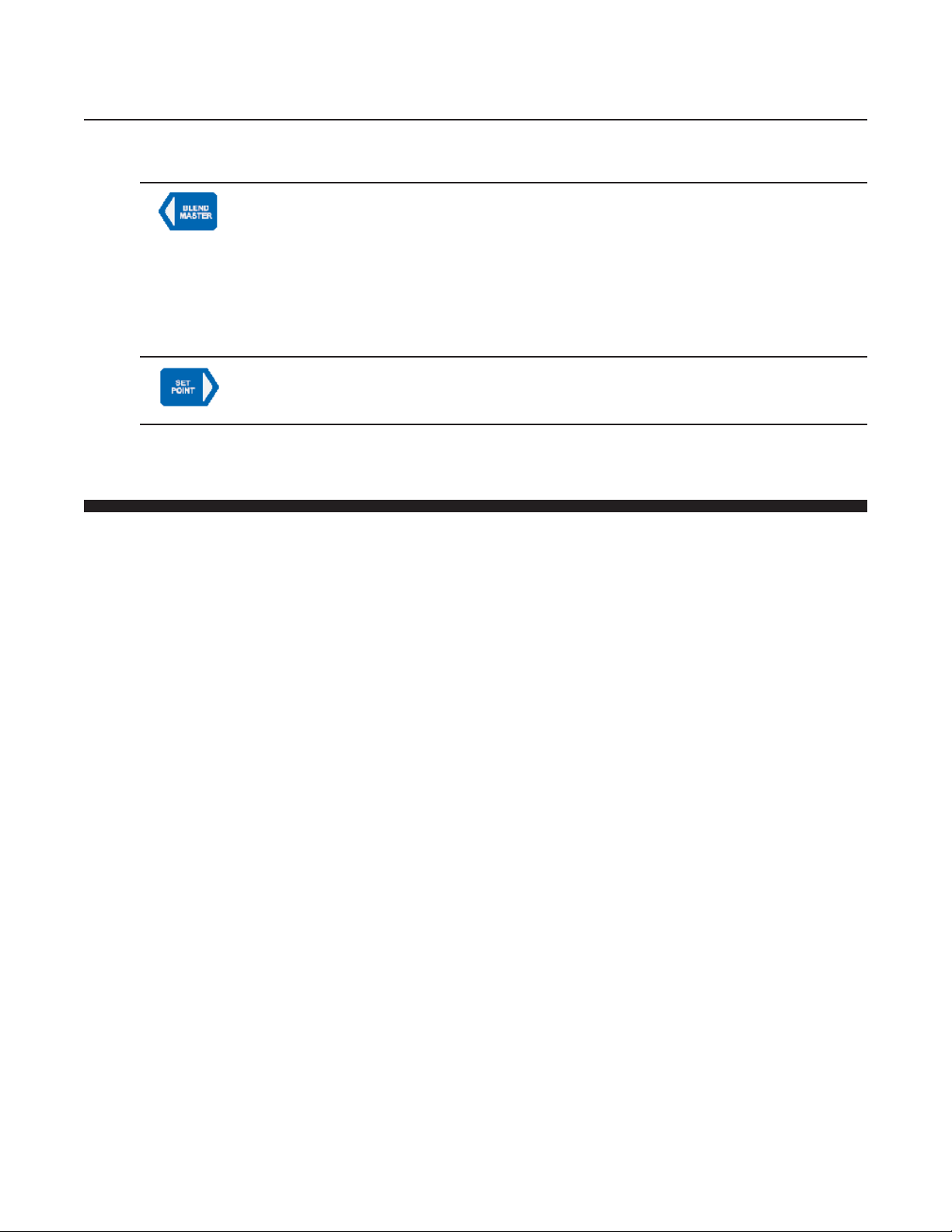

Key Present Location System Response

3-3 Navigation

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

All Screens: Selected Item Move cursor left.

Home Screen Select channel pointed to by cursor as blend master

unless the channel is already the master, in which

case the existing master is deselected and no master

is chosen.

Display Configuration Screen Zero PV Total when cursor points to PV Total.

Program Screen Move blinking program selection to next left choice.

All Screens: Selected Item Move cursor right.

Home Screen HOT navigates to change channel setpoint value.

This subsection provides an overview of the various values that are

available to set up the various program values, which determine how the

instrument is desired to perform. It also describes the performance

operating states.

Navigation is primarily performed using the keypad controls described in

"3-2-1 Primary Functions" on p. 3-2. The same operating characteristics

set using the keypad are also fully supported by serial communication. The

serial communication functions are described more fully in Section D.

A complete map of the user interface screens is provided to support the

overview of the instrument. It shows the entire organization of all of the

instrument process values (PV), all setpoint (SP) values, and all system

global settings.

3-4

Page 31

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September , 2010

3-3-1 Display or Instrument Configuration Screen Selection

Pressing the menu button from the Home screen provides a secondary

navigation layer for the operator to specify whether PV-SP Display

Configuration or PV-SP Instrument Configuration is desired for a channel.

The screen shown below is displayed as a result of having pressed the

ENTER key while viewing the home screen.

This screen shown is for Channel 2. Use the cursor keys to point to either

Display Configuration to show the present PV Measurements and SP

Status, or Instrument Configuration to program PV and SP values, and

then press ENTER to proceed to the desired selection.

Section 3 Operation

Model 0254

3-5

Page 32

Section 3 Operation

Model 0254

3-3-2 User Interface Screen Map

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

The following diagram showing the screen mapping from the home page to

the channel values.

Figure 3-2 User Interface Screen Map

3-6

Page 33

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September , 2010

3-4 Process Values (PV) and Setpoint s (SP)

This subsection provides a detailed description of the various system map

values that are used to set up the instrument's desired operating

characteristics. These characteristics establish how the instrument is

desired to perform. The subsection also covers the various process values,

which are the outcome of the setup, that show the operating state.

3-4-1 PV-SP Measures and S t atus

Section 3 Operation

Model 0254

The present PV and SP values shown on the home screen are indicated by

an asterisk (*) prefix.

To change the PV displayed on the home screen, point the cursor to the

desired PV value and press the ENTER key.

To change the SP displayed on the home screen, point the cursor to the

desired SP value and press the ENTER key.

For both PV and SP, note that the star indicator is now prefixed to a new

PV or SP value.

PV Rate

This value is either a Rate, defined as quantity per unit time, or None,

which is a scalar value not having a time associated attribute. The Rate

and Time base are configured in the Channel Instrument Configuration

screen. A Time base value must be configured for the totalizer function to

operate. The value displayed is updated in real time as the value changes.

PV T otal

This is a quantity accumulator for a rate value. The quantity values are

displayed when the channel time base is NOT programmed for None. PV

Total quantity is not accumulated for None values, and no PV Total will be

shown on the screen. The value displayed is updated in real time as the

value changes.

To clear an accumulated quantity to zero, point the cursor to PV Total and

press the key. Note the value becomes zero.

3-7

Page 34

Section 3 Operation

Model 0254

3-4-2 PV-SP Configuration

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

PV Signal

This value is the measured electrical value being input into the instrument

channel. It may be used to provide assistance in system installations, and

is used to support instrument calibration. The value displayed is updated in

real time as the value changes.

SP Setpoints

Separate setpoints are provided for rate control (SP Rate), Batch quantity

(SP Batch), and Blend proportion (SP Blend). The specific setpoint shown

on the screen is dependant on the SP Function control type that has been

selected. The value displayed is updated in real time as the value changes.

SP Signal

This value is the output signal being sent form the instruments channel,

and is expressed in the appropriate analog signal type units of V olts or mA.

The PV and SP channel configuration allows you to program the channel

values to determine how signal inputs and outputs are displayed,

calculated, operated, and scaled. These values are programmed in the

Channel Instrument Configuration screen. For more information, refer to

"3-6 Process Controls" on p. 3-15, which describes in greater detail the

setup, configuration, operation, and termination of control processes.

The PV and SP program values are used to determine the following

channel attributes:

• Gas type service

• Channel override signal

• PV signal type and full scale range

• SP signal type and full scale range

• Channel service function

• Channel override signal

• SP values

• SP programming source

The PV and SP values are static and are updated only after a value has

been changed and saved.

3-8

Page 35

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September , 2010

3-4-3 Value Programming

Section 3 Operation

Model 0254

Program a value by pointing the cursor to its line and pressing the ENTER

key . Note a character or string (character string) will be blinking, ready to

be edited.

Edit the character string as follows:

1. Change character string to next value key or previous value key.

2. Move blinking character-string edit field left keyor right key

3. Press the ENTER key to save the changed value (any other key causes

the edited value to be ignored and not saved) and the original value to

be edited will remain unchanged.

When editing a character field that is blinking, the program state will be

terminated if a key is not detected within 30 seconds of the last detected

key . In this case, the value edited will not be saved, and the original value

to be edited will remain unchanged.

Measure Units

Measure units are a combination of symbols used to identify a physical

engineering measurement. The measure units may be selected from a

fixed set of customary strings. Measure Units have no arithmetic affect.

Supported measure units are listed in Section A.

Time Base

This selection is used to set the quantity per unit time (rate) measurement

as either Sec, Min, Hrs, or Days and None. The None, or scalar, time base

selection is presumed not to have a time-quantity association and does not

perform quantity accumulation.

3-9

Page 36

Section 3 Operation

Model 0254

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Decimal Point

The decimal point for values may be freely selected for none, one, two, or

three places. The decimal sets the number of measurement value digits

that are to the right of the decimal point. Setting the decimal has an

arithmetic function that, when changed, automatically multiplies or divides

an existing value so values continue to retain their power-of-ten value. The

values so affected include PV and SP Full Scale, SP Rate, SP Batch.

Gas Factor

This value is a unit-less factor by which measured PV Signals are

compensated by multiplication, and SP Signals corrected by division. This

instrument performs the arithmetic compensation using the Gas Factor.

This capability makes it possible to compensate other gases that are not

the calibration gas. However, the existing Gas Factor must be known and

then methodically changed. By knowing the present factor for the

calibration gas, and desiring to control known gases for which an attached

TMF has not been calibrated, then just divide the new gas factor by the

previously known calibrated gas factor. The result becomes the new Gas

Factor.

Log T ype (Future Option)

All logging option selections should be set to Off.

PV-SP Signal T ypes

Signal Selections May be set for full scale ranges which include

0–20 mA, 4–20 mA, 0–5 V, 1–5 V, 0–10 V,

2–10 V, or OFF.

OFF selection Suspends service for either or both channel PV

and SP signals. Inactive OFF is indicated on the

home screen as a blank line.

PV- SP Full Scale

This value sets the maximum engineering unit range over which the Signal

Type is valid. The minimum is always presumed to be zero.

SP Function

The allowable setpoint Functions are Rate, Batch, or Blend.

Rate The value set in SP Rate is converted to a

corresponding analog signal, which is directly

sent to the channel analog signal output. Refer to

"3-6-1 Rate Control/Setpoint Control" on p. 3-15

for more details.

3-10

Page 37

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September , 2010

Section 3 Operation

Model 0254

Batching Batching is a discontinuous control process that

delivers the quantity set in the SP Batch. This

process is started using either the keypad or a

serial communication command. Batching is

terminated when the desired batch quantity has

been delivered, or any time before delivery is

complete by pressing the STOP. Refer to "3-6-3

Batch Control" on p. 3-18 for more details.

Blending Blending is a continuous control process after

having been started that delivers a rate

proportion set in the SP Blend register, which is

referred to as the prevailing Blend Master input

rate. This process is started using either the

keypad or a serial communication command.

Blending is terminated any time by pressing the

STOP key from the home screen. Refer to "3-6-4

Blend Control" on p. 3-19 for more details.

SP VOR (Valve Override)

This value is set to Normal for standard TMF operation. VOR Normal

causes a VOR signal output voltage to be disconnected (i.e., floating). The

VOR function is used in TMF applications to override the normal analog

command signals, and is used for installation and system diagnostic

purposes.

Valve Open The VOR output signal is connected and

provides a voltage > 8.0 Vdc, causing the TMF

valve to be fully open.

Valve Closed The VOR output signal is connected and

provides a voltage < –4.0 Vdc, causing the TMF

valve to be fully closed.

SP Source

This control enables selection of the source from which setpoints may be

entered as either Keypad or Serial. When set for Serial,changing a setpoint

using the keypad is prohibited.

3-11

Page 38

Section 3 Operation

Model 0254

3-5 Global Settings

3-5-1 Global Information

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Global settings are the various system wide variables used to set up and

review the overall operating characteristics that establish how the entire

instrument will perform. The values include those provided only for viewing,

those that can be selected, and those that invoke immediately action.

To access the Global Settings screen, press the BACK/GLOBAL key three

times from the Home screen.

This screen contains system information values and configuration states.

These values are not programmable, with the only exception being the

Factory Set immediate action selection described below , which erases

present programmed values and replaces them with factory default values.

NOTE: The Clk Install, Wan Install, and Lan Install settings are not available for use.

Unit Serial Number

This is a factory-entered manufacturing serial number and does not relate

directly to the device serial number.

Version

This is the date the firmware was last upgraded represented as year,

month, and day , and is only for viewing.

3-12

Page 39

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September , 2010

3-5-2 Global System Power

Section 3 Operation

Model 0254

Check Sum

This value is the hexadecimal double word sum of the instruction read-only

memory used for factory quality assurance, and is only for viewing.

Factory Set

When the cursor is pointing to Factory Set, a pop-up warning displays

“WARNING - ENTER erases program values” at the bottom of the display.

Pressing ENTER will cause all user program values to be erased and overwritten with factory standard default values. Factory Set does NOT erase

factory pre-set calibration values, which continue to be retained.

To enter the System Power function, point the cursor to System Power on

the Global Settings screen and press the ENTER key . This is an immediate

action selection.

The System Power functions causes power to equipment connected to the

instrument to placed in an Off state, allowing the user to conduct

installation services and diagnostics. The power-of f state is also useful for

placing the instrument and connected equipments in an un-powered

dormant state when the instrument is expected to remain unused for

extended periods.

The pop-up at the bottom of the display is shown on the screen only when

the cursor is pointing to System Power .

Power OFF Press the ENTER key with the cursor pointing to

System Power. This will cause entry into the

power down state, the screen to become blank

with its back-light off, and all signals and power

to be removed from connected equipment.

Power ON Press the START key to restore normal system

operation.

3-13

Page 40

Section 3 Operation

Model 0254

3-5-3 Global Control Services

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

To enter the Control Services screen, point the cursor to Control Services

on the Global Settings screen and press the ENTER key .

These Control Service settings are programmable but are not updated in

real time. They establish operation of the several system level operating

controls.

Audio Beep When this control is selected ON, allows normal

audio annunciation for alarms and key

activation. Otherwise, all audio indications

remain disabled.

Zero Suppress When this control is selected ON, numeric

measured values are displayed with leading

zeros suppressed.

Pwr SP Clear When this control is selected ON, power

restoration causes every channel SP value to

be erased and made zero. Any VOR setting will

be returned to normal.

3-14

Page 41

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September , 2010

3-5-4 Global Communication

Section 3 Operation

Model 0254

To enter the Communications service screen, point the cursor to

Communications on the Global Settings screen and press the ENTER key .

The Network Addr (address) is shown on the service screen. The Network

Address is a unique identification for the instrument operating in a network

environment. It is factory pre-set and not customer programmable.

3-6 Instrument Confugration and Control

This subsection provides a detailed description of the instrument's Rate,

Batch, and Blend control functions, and the channel configuration for the

SP and PV signals.

3-6-1 Rate (Setpoint) Control

Rate control is a continuous process performed on a channel-by-channel

basis.

To configure Rate control:

1. Position the cursor pointing towards the appropriate channel on the

2. Press the Enter/Menu key , and select Instrument Configuration by

3. Once in the Instrument Configuration screen, scroll down to the SP

Home screen.

pressing the Enter/Menu key .

Function option and select Rate.

3-15

Page 42

Section 3 Operation

Model 0254

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

4. Scroll down to the SP Rate option and select the flow rate setpoint that

is desired. This control type causes an SP Rate signal programmed by

the operator to be output to a controller . The setpoint can also be

programmed by the Setpoint hot key .

Start Rate Control

To start rate control, a setpoint must be provided. To set setpoint, use the

Setpoint hot key or the Instrument Configuration screen.

Home Screen

The delivery process can be monitored as shown on the real-time updated

screens above and below . Observing that the SP Rate is the same as the

monitored PV Rate.

3-16

Page 43

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September , 2010

3-6-2 PV Configuration

Section 3 Operation

Model 0254

T erminate Rate Control

When the channel SP Rate is set to zero, the process is off.

To set setpoint to zero, use the Setpoint hot key or the Instrument

Configuration screen.

Independently , the controller's output signal is monitored and indicated as

the channel PV Rate, PV Signal, or PV Total, as selected in the Display

Configuration screen. The PV Signal Type and PV Full Scale values are

configured in the channel instrument configuration. Rate is a continuous

process performed on a channel-by-channel basis.

To configure the PV Signal Type and PV Full Scale values:

1. Position the cursor pointing towards the appropriate channel on the

Home screen.

2. Press the ENTER/MENU key.

3. Select Instrument Configuration by pressing the ENTER/MENU key .

4. Once in the Instrument Configuration screen, scroll down to the PV

Signal Type and PV Full Scale options and select the applicable PV

Signal Type and PV Full Scale values that are desired.

3-17

Page 44

Section 3 Operation

Model 0254

3-6-3 Batch Control

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Batch processing is a non-continuous process that is started, conducted,

and terminated when a desired quantity has completed delivery . You can

stop batch delivery at any time prior to completion.

Setup

The following items must be programmed as follows:

SP Function Select Batch

SP Rate Set desired batch delivery rate

SP Batch Set desired delivery quantity

Start Batch

Return to the home screen. Note that the home screen indicates a ‘B’

control indicator for all channels selected to perform batching.

Home Screen

Press the ST AR T key three times. ‘B’ indicators will be blinking to indicate

channels with batch now in process.

3-18

The delivery process can be monitored as shown on the screen below by

observing that the PV Total increases toward the SP Batch amount, and

verifying that the PV Rate properly indicates the desired delivery rate. The

values in this screen are updated in real time. If the SP Function is set for

Batch, the SP Batch quantity appears on this screen.

Page 45

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September , 2010

Section 3 Operation

Model 0254

T erminate Batches

Batching for each channel set for batch will automatically terminate when

each batch channel PV Total has reached or exceeded its programmed SP

Batch setpoint.

Y ou can terminate any channels that continue with batching remaining in

process by first returning to the home screen, then pressing the STOP key

once. Note that the ‘B’ control indicators on the home screen stop blinking,

indicating that all batch processes are stopped. Pressing the ST AR T key

three times will always reset all batch totals to zero before starting the

process.

3-6-4 Blend Control

Blending is a continuous process that, when started, causes slave SP

Rates to be a proportion of the actual rate being delivered by the master

rate.

NOTE: Blend parameters are saved when power is lost, allowing blending to continue

after power is restored unless Pwr SP Clear is selected to be ON. Refer to "3-5-3

Global Control Services" on p. 3-14.

Select a master channel and set its delivery SP Rate. One or more slave

channels are then selected, and the process is started from the home

screen. Once started, blending will continue and may ONLY be terminated

by an operator.

3-19

Page 46

Section 3 Operation

Model 0254

3-6-4-1 Blend Control Setup

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

Program the above values for master and slave channels desired to

perform blending.

Select Blend Master

From the home screen, point to a channel desired to be the master and

press the master blend key. This causes the home screen to show an

‘M,’ indicating master channel. If you press the master key again at that

moment, the ‘M’ control indicator will no longer be present—no master is

then selected—and blending will not be conducted.

To de-select a blend master, point to the present master channel and press

the master blend key. Note that the ‘M’ control indicator is no longer

present and the master has been de-selected.

Home Screen

Master Channel Setup

It is recommended that you wait until after the blending setup is complete

before selecting the desired flow rate setpoint to the Master Channel (refer

to "3-6-4-2 Start Blend" on p. 3-21).

To configure the Master Channel for blending:

1. Position the cursor pointing towards the appropriate channel on the

Home screen.

2. Press the ENTER/MENU key.

3. Select Instrument Configuration by pressing the ENTER/MENU key .

4. Once in the Instrument Configuration screen, scroll down to the SP

Function option and select Rate.

5. Scroll down to the SP Rate option and input a zero flow rate setpoint (or

via the Setpoint hot key).

NOTE: If you input a flow rate setpoint other than zero, the Master Channel will

immediately respond to that setpoint and will start to flow.

3-20

Page 47

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September , 2010

Section 3 Operation

Model 0254

Slave Channels Setup

Navigate to each desired slave channel and set each SP Function to

Blend, then set the desired SP Blend rate percentage referenced to the

master channels actual delivery rate. Note that the home screen shows ‘S,’

indicating selected blend slave channels.

NOTE: Once a slave channel is set to Blend, SP Rate programming is prohibited for

both keypad and serial command.

3-6-4-2 Start Blend

1. Return to the Home screen.

2. Press the ST ART key three times. Note the 'M' and 'S' suffix now

blinking to indicate channels with blend now in process.

3. Navigate to the Master Channel Instrument Configuration screen (or via

the Setpoint hot key) and set the Master SP Rate to the desired value.

The blending process is visible on the Home screen, observing that the SP

Rate of the slave channels is the programmed proportion of the master

rate. If desired, the Home screen can be reconfigured to replace SP Rate

of the slave channels with SP Blend ratio, as described in "3-4-1 PV -SP

Measures and Status" on p. 3-7.

3-21

Page 48

Section 3 Operation

Model 0254

3-6-4-3 T erminate Blend In-Process

Once blending has started, it will continue unless manually terminated.

To terminate blending:

1. Return to the Home screen, if not already there, and press the STOP

2. Observe that the 'M' and 'S' process indicators no longer blink.

3. To resume blending, press the START key three times and re-enter the

3-6-5 SP VOR (Valve Override) Function

The SP VOR function is typically used in Mass Flow applications to

override the normal analog command signals for installation and system

diagnostic purposes.

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September, 2010

key. This resets the master channel SP Rate to zero, which stops all

flow.

setpoint of the master channel, as described in "3-6-4-2 S tart Blend" on

p. 3-21.

The SP VOR function allows operators to either open or close the Mass

Flow Control (MFC) valve independent of the current setpoint value.

The SP VOR function has three available settings.

• The Normal setting is for normal MFC operation in which the valve is

controlled by the selected Setpoint values.

• The Open setting causes the valve to be fully open regardless of

setpoint. This allows operators to purge the system or to force

maximum flow through the MFC.

• The Closed setting causes the valve to be fully closed regardless of

setpoint.

To activate one of the SP VOR function modes:

1. Position the cursor pointing towards the appropriate channel on the

Home screen.

2. Press the ENTER/MENU key.

3. Select Instrument Configuration by pressing the ENTER/MENU key .

4. Once in the Instrument Configuration screen, scroll down to the SP

VOR Function option and select the mode that is desired (Normal,

Open, or Closed). The SP VOR selection can also be accessed directly

by the VOR hot key.

3-22

Page 49

Installation and Operation Manual

X-SE-0254-eng

Part Number: 541B129AAG

September , 2010

Section 3 Operation

Model 0254

Once activated, the SP VOR function mode is shown on the appropriate

channel display to indicate which VOR function mode is active. The setting

of the SP VOR Valve override function is memorized. After power down

and power up, the memorized SP VOR function mode will remain in the

previous mode until it is changed by the operator .

3-6-6 T ot alization

To return to Normal operation after activating one of the SP VOR function

modes:

1. Position the cursor pointing towards the appropriate channel on the

Home screen.

2. Press the ENTER/MENU key.

3. Select Instrument Configuration by pressing the ENTER/MENU key .

4. Once in the Instrument Configuration screen, scroll down to the SP

VOR Function option and select the Normal mode. The SP VOR

selection can also be accessed directly by the VOR hot key .

The Totalizer function is used to provide a total of a selected channel's PV

Output Rate over time. The total is based on the Rate and Time base that

is configured in the particular channel's Instrument Configuration screen. A

Time base value must be configured for the Totalizer function to operate.

To display the Totalizer value:

1. Position the cursor pointing towards the appropriate channel on the

Home screen.

2. Press the ENTER/MENU key.

3. Select Display Configuration by pressing the ENTER/MENU key .

4. Once in the Display Configuration screen, scroll down and select the

PV T ot al option.

3-23

Page 50

Section 3 Operation

Model 0254

3-6-7 Emergency Off

Installation and Operation Manual

X-SE-0254-eng