Instruction Manual

Vapor Delivery Module

Doc. no.: 9.17.079B Date: 22-01-2015

ATTENTION

Please read this Instruction Manual carefully before installing and operating the instrument.

Not following the instructions could result in personal injury and/or damage to the equipment.

Important information. Discarding this information could cause injuries to people or damage to the Instrument or

installation.

Helpful information. This information will facilitate the use of this instrument.

i

www

Additional info available on the internet or from your local sales representative.

Check the packing list to ensure that you received all of the items.

Do not discard spare or replacement parts with the packing material and inspect the contents for damage.

Bronkhorst®

Disclaimer

The information in this manual has been reviewed and is believed to be wholly reliable. No responsibility, however, is assumed for

inaccuracies. The material in this manual is for information purposes only.

Bronkhorst High-Tech B.V.

January 2015

Symbols

Receipt of equipment

Check the outside packing box for damage incurred during shipment. When the packing box is damaged, then the local carrier must

be notified at once regarding his liability, if so required. At the same time a report should be submitted to your local sales

representative.

Carefully remove the equipment from the packing box. Verify that the equipment was not damaged during shipment. Should the

equipment be damaged, then the local carrier must be notified at once regarding his liability, if so required. At the same time a

report should be submitted to your local sales representative.

Refer to "Removal and return instructions" about return shipment procedures.

Equipment storage

The equipment should be stored in its original packing in a cupboard warehouse or similar. Care should be taken not to subject the

equipment to excessive temperatures or humidity.

Copyright

© 2015 Bronkhorst High-Tech B.V.

All rights reserved. This documentation is protected by copyright.

Subject to technical and optical changes as well as printing errors.

The information contained in this document is subject to change at any time without prior notification. Bronkhorst High-Tech B.V.

reserves the right to modify or improve its products and modify the contents without being obliged to inform any particular

persons or organizations. The device specifications and the contents of the package may deviate from what is stated in this

document.

2

Vapor Delivery Module 9.17.079

i

www

See also paragraph 9 of the Conditions of sales:

http://www.bronkhorst.com/files/corporate_headquarters/sales_conditions/en_general_terms_of_sales.pdf

Bronkhorst®

Warranty

Bronkhorst products are warranted against defects in material and workmanship for a period of three years from the date of

shipment provided they are used in accordance with the ordering specifications and not subjected to abuse or physical damage.

Products that do not operate properly during this period may be repaired or replaced at no charge. Repairs are normally warranted

for one year or the balance of the original warranty, whichever is the longest.

The warranty includes all initial and latent defects, random failures, and undeterminable internal causes.

It excludes failures and damage caused by the customer, such as contamination, improper electrical hook-up, physical shock etc.

Re-conditioning of products primarily returned for warranty service that is partly or wholly judged non-warranty may be

charged for.

Bronkhorst High-Tech B.V. or affiliated company prepays outgoing freight charges when any part of the service is performed under

warranty, unless otherwise agreed upon beforehand, however, if the product has been returned collect to our factory or service

center, these costs are added to the repair invoice. Import and/or export charges, foreign shipping methods/carriers are paid by

the customer.

Safety Precautions

The following safety precautions should be observed before using this product and any associated instrumentation.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read the operating information carefully before using the product.

Before operating, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting cables,

test leads, cracks, or breaks before each use.

The module and accessories must be used in accordance with its specifications and operating instructions otherwise the safety of

the equipment may be impaired.

If required, replace fuses with the same type and rating for continued protection against fire hazard.

Opening of the equipment is not allowed. In case of a defect please return the equipment to Bronkhorst High-Tech.

The symbol on the module indicates that the user should refer to the operating instructions in the manual.

Surfaces near the symbol may be hot.

To maintain protection from electric shock and fire, replacement components must be obtained from Bronkhorst High-Tech B.V..

Standard fuses, with applicable national safety approvals, may be used if the rating and type are simular. Other components that

are not safety related may be obtained from other suppliers as long as they are equivalent to the original component. (Note that

selected parts should be obtained only through Bronkhorst® to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call your local Bronkhorst® representative for support.

9.17.079

Vapor Delivery Module 3

Table of contents

...................................................................................................................................................................... 6

Scope of this manual 1

...................................................................................................................................................................... 61.1 Introduction and intended use

...................................................................................................................................................................... 61.2 References to other applicable documents

...................................................................................................................................................................... 6Related documents 1.2.1

...................................................................................................................................................................... 6Software tooling 1.2.2

...................................................................................................................................................................... 7

Starting up 2

...................................................................................................................................................................... 72.1 Check properties

...................................................................................................................................................................... 72.2 Rated pressure test inspection

...................................................................................................................................................................... 72.3 Install module

...................................................................................................................................................................... 72.4 Model key

...................................................................................................................................................................... 8

Technical specification 3

...................................................................................................................................................................... 83.1 Physical dimensions

...................................................................................................................................................................... 83.2 Environmental conditions

...................................................................................................................................................................... 83.3 Ingress protection class

...................................................................................................................................................................... 83.4 Fluidic connections

...................................................................................................................................................................... 8General 3.4.1

...................................................................................................................................................................... 8Flow ranges of used components 3.4.2

...................................................................................................................................................................... 9Capacities 3.4.3

...................................................................................................................................................................... 9Pressure rating 3.4.4

...................................................................................................................................................................... 93.5 Piping

...................................................................................................................................................................... 93.6 Electrical connections

...................................................................................................................................................................... 9Mains 3.6.1

...................................................................................................................................................................... 10Tracing 3.6.2

...................................................................................................................................................................... 10Pt100 tracing sensor 3.6.3

...................................................................................................................................................................... 10Communication 3.6.4

....................................................................................................................................................................... 10RS232 / Propar 3.6.4.1

....................................................................................................................................................................... 10FLOW-BUS 3.6.4.2

...................................................................................................................................................................... 113.7 Connector specifications

...................................................................................................................................................................... 11Hook-up diagram 3.7.1

...................................................................................................................................................................... 12

Installation 4

...................................................................................................................................................................... 124.1 Mounting

...................................................................................................................................................................... 124.2 Fluid connections

...................................................................................................................................................................... 124.3 Supply pressure

...................................................................................................................................................................... 124.4 Leak check

...................................................................................................................................................................... 124.5 Seals

...................................................................................................................................................................... 134.6 Purging / filling

...................................................................................................................................................................... 13Startup without using vacuum 4.6.1

....................................................................................................................................................................... 13To fill the system 4.6.1.1

....................................................................................................................................................................... 14To start the process 4.6.1.2

....................................................................................................................................................................... 14To stop the process 4.6.1.3

....................................................................................................................................................................... 14How to leave system overnight 4.6.1.4

....................................................................................................................................................................... 14To empty and purge the system 4.6.1.5

...................................................................................................................................................................... 15Startup with using vacuum 4.6.2

....................................................................................................................................................................... 15To fill the system 4.6.2.1

....................................................................................................................................................................... 15To start the process 4.6.2.2

Bronkhorst®

Vapor Delivery Module 9.17.0794

Bronkhorst®

....................................................................................................................................................................... 16To stop the process 4.6.2.3

....................................................................................................................................................................... 16How to leave system overnight 4.6.2.4

....................................................................................................................................................................... 16To empty and purge the system 4.6.2.5

...................................................................................................................................................................... 17

Operation 5

...................................................................................................................................................................... 175.1 Power- and warm-up

...................................................................................................................................................................... 175.2 User interface

...................................................................................................................................................................... 17Buttons 5.2.1

...................................................................................................................................................................... 17Display 5.2.2

...................................................................................................................................................................... 18Select Instrument 5.2.3

...................................................................................................................................................................... 19Temperature and flow setpoint 5.2.4

...................................................................................................................................................................... 195.3 Operating settings

...................................................................................................................................................................... 20Operation example 5.3.1

...................................................................................................................................................................... 21Vaporpressure of water 5.3.2

...................................................................................................................................................................... 22

Troubleshooting and service 6

...................................................................................................................................................................... 226.1 Troubleshooting

...................................................................................................................................................................... 236.2 Maintenance

...................................................................................................................................................................... 236.3 Service

...................................................................................................................................................................... 24

Removal and return instructions 7

9.17.079

Vapor Delivery Module 5

Bronkhorst®

i

www

Manuals and Software tooling can be found at: http://www.bronkhorst.com/en/downloads

1 Scope of this manual

1.1 Introduction and intended use

The Vapor Delivery Module is a compact integrated system to realize mass flow control of vapor. The Vapor Delivery Module is

intended to generate a predefined vapor flow, accruing from an accurately controlled liquid mass flow injected into an accurately

controlled carrier gas flow with subsequent evaporation inside a temperature controlled chamber.

1.2 References to other applicable documents

Manuals and guides for digital instruments are modular. General instructions give information about the functioning and

installation of instruments. Operational instructions explain the use of the digital instruments features and parameters. Field bus

specific information explains the installation and use of the field bus installed on the instrument.

1.2.1 Related documents

- Instruction manual FLOW-BUS interface (document nr. 9.16.024)

- Instruction manual RS232 interface with FLOW-BUS protocol (document nr. 9.16.027)

- Instruction manual E-8000 Readout and Control System (document nr. 9.17.076)

These documents Contain information for basic and advanced operation, more detailed product information and instructions

for troubleshooting.

1.2.2 Software tooling

For RS232 or FLOW-BUS operation the following Bronkhorst software is available.

FlowDDE Software tool to interface between digital instruments and windows software

FlowView Software tool to operate Bronkhorst digital instruments

Flowfix Software tool for fieldbus connection of digital instruments

FlowPlot Software tool for monitoring and optimizing digital instruments parameters

Vapor Delivery Module 9.17.0796

Bronkhorst®

Before installing a Vapor Delivery Module it is important to read the attached labels

and check:

Model key

Pressure rate

Temperature (ambient)

Power supply

Power

The tested pressure is stated on the module with a RED COLOURED sticker.

Before installation, make sure that the test pressure is in accordance with

normal safety factors for your application.

If there is no Pressure Testing Sticker on the module or if the test pressure is

not complying with your pressure requirements, the equipment should not

be mounted in the process line and be returned to the factory.

2 Starting up

2.1 Check properties

2.2 Rated pressure test inspection

Each Vapor Delivery Module is pressure tested to at least 1.5 times the working pressure of the process conditions stipulated by the

customer, with a minimum of 8 bar. Each Module is helium leak tested to at least 2•10-9 [mbar l/s] Helium outboard.

2.3 Install module

See chapter 4 for detail installation instructions.

Before switching on power, please check if all external electrical and communication (if necessary) connections are properly

connected.

2.4 Model key

9.17.079

Vapor Delivery Module 7

Bronkhorst®

i

www

For overall dimensions please consult supplied dimensional drawing 7.05.901. This documents is available on:

http://www.bronkhorst.com/en/downloads or can be obtained by contacting our local sales & service

representatives

For exact information on the fitting, please contact Swagelok for further instructions or documentation.

Always check your system for leaks, before applying fluid pressure. Especially if toxic, explosive or other dangerous

fluids are used.

Model

Heater

model

Thermal

power

Max. capacity

1

Max temp.

SW-10n

W-100A

10 W

1...30 g/h liquid

0.1...4 ln/min gas

200°C

SW-20n

W-200A

100 W

10...120 g/h liquid

0.2...10 ln/min gas

200°C

3 Technical specification

3.1 Physical dimensions

3.2 Environmental conditions

• Ambient temperature : 5°C - 40°C.

• Relative humidity : Maximum relative humidity 80%, for temperatures up to 31°C decreasing linearly

to 50% relative humidity at 40°C.

• Height altitude : Up to 2000 m.

3.3 Ingress protection class

IP20, according IEC standard 60529.

3.4 Fluidic connections

3.4.1 General

The Vapor Delivery Module gas and liquid supply are equipped with compression type or face-seal-fittings. Normally these fittings

are BSP parallel threads types which have to be used in combination with elastomeric O-rings to seal to the Vapor Delivery Module.

Occasionally fittings are orbital welded to the VDM-Series.

For leak tight installation of compression type fittings be sure that the tube is inserted to the shoulder in the fitting body and that

no dirt or dust is present on tube, ferrules or fittings.

3.4.2 Flow ranges of used components

1

Depends on liquid and process pressure; table based on water at 1 atmosphere.

For other liquids or pressure conditions please consult the manufacturer or your local sales representative.

Vapor Delivery Module 9.17.0798

Bronkhorst®

Be sure that piping is absolutely clean!

CAUTION - DO NOT install small diameter piping on high flow rates.

CAUTION - DO NOT mount abrupt angles directly to the inlet or outlet, especially for high flow rates.

Model

Power

supply

(Vac)

Maximum power

(included tracing

§3.6.2)

Fuse primary heater

Fuse secondary

heater

Fuse main

SW-10n-n-50-a-nn-a

110 … 120

250VA 50-60 Hz

T2A I2t >30A

Littelfuse 0213002.MXP*

T4A

T2A

SW-10n-n-51-a-nn-a

110 … 120

550VA 50-60 Hz

T2A I2t >30A

Littelfuse 0213002.MXP*

T4A

T2A

SW-20n-n-50-a-nn-a

110 … 120

250VA 50-60 Hz

T2A I2t >30A

Littelfuse 0213002.MXP*

T4A

T2A

SW-20n-n-51-a-nn-a

110 … 120

550VA 50-60 Hz

T2A I2t >30A

Littelfuse 0213002.MXP*

T4A

T2A

SW-10n-n-30-a-nn-a

220 … 240

250VA 50-60 Hz

T1A I2t >10A

Littelfuse 0213001.MXP*

T4A

T1A

SW-10n-n-31-a-nn-a

220 … 240

550VA 50-60 Hz

T1A I2t >10A

Littelfuse 0213001.MXP*

T4A

T1A

SW-20n-n-30-a-nn-a

220 … 240

250VA 50-60 Hz

T1A I2t >10A

Littelfuse 0213001.MXP*

T4A

T1A

SW-20n-n-31-a-nn-a

220 … 240

550VA 50-60 Hz

T1A I2t >10A

Littelfuse 0213001.MXP*

T4A

T1A

3.4.3

Figure 1: Capacity SW-100 Vaporizer Figure 2: Capacity SW-200 Vaporizer

Capacities

3.4.4 Pressure rating

• Gas supply = max. 10 bar(g)

• Liquid supply = max. 10 bar(g)

• Vapor pressure = atmospheric

3.5 Piping

For optimal performance of the system it is recommend to have at least 10 pipe diameters distance between the angle and the

equipment inlets. The purge is rarely used in production environments, except for installation.

3.6 Electrical connections

3.6.1 Mains

* Littelfuse or equivalent

9.17.079

Vapor Delivery Module 9

Bronkhorst®

Model

Power supply (Vac)

Maximum tracing power

Fuse tracing heater

SW-10n-n-51-a-nn-a

110 … 120

300 VA 50-60 Hz

T2,5A

SW-20n-n-51-a-nn-a

110 … 120

300 VA 50-60 Hz

T2,5A

SW-10n-n-31-a-nn-a

220 … 240

300 VA 50-60 Hz

T1,25A

SW-20n-n-31-a-nn-a

220 … 240

300 VA 50-60 Hz

T1,25A

Warning! Be sure that the temperature sensor is properly mounted with the tracing wire,

otherwise no temperature control is possible and hazardous situations may occur.

i

www

For further instructions about the RS232 interface see manual 9.17.027 Manual 'RS232 interface with FLOW-BUS

protocol for digital instruments'. This manual is available at the download section of our website:

http://www.bronkhorst.com/files/downloads/manuals_english/917027manual_rs232_interface.pdf

i

www

For further instructions about the FLOW-BUS interface see manual 9.17.024 Manual 'FLOW-BUS interface for digital

instruments'. This manual is available at the download section of our website:

http://www.bronkhorst.com/files/downloads/manuals_english/917024manual_flowbus_interface.pdf

For mains connection, use appropriate cabling with IEC 60320-1/C19 connector:

Power cable with Euro Plug (EU) – Schurter #6051.2043 (art.nr.1.15.242)

•

• Power cable with Switzerland Plug (CH) (art.nr.1.15.243)

• Power cable with North America Plug (USA) – Schurter #6051.2041 (art.nr.1.15.244)

• Power cable with United Kingdom Plug (UK) – Schurter #6051.2048 (art.nr.1.15.245)

3.6.2 Tracing

Optionally, the Vapor Delivery Module can be provided with a trace temperature control. In this case, the VDM-Series is provide

with a tracing output IEC 60320-2-2 / C13 female connector. This connector is intended for connecting tracing tape, which is not

supplied. The voltage at this tracing output is equal to the supply voltage of the Vapor Delivery Module.

For tracing connection, use appropriate cabling with IEC 60320-2-2/C14 plug (art.nr. 1.09.594). Make sure cabling is double

isolated.

The table below shows the maximum tracing power and the fuse amperage for the various models.

3.6.3 Pt100 tracing sensor

Optionally, the Vapor Delivery Module can be provided with a trace temperature control. In this case, the VDM-Series is provide

with a Pt100 inlet 4-pin M12 A-coded male connector. This connector is intended for connecting a two, three or four-wire Pt100.

Measurement current through the sensor is 0,5 mA.

For Pt100 connection, use appropriate cabling with M12 4-pin female connector (art.nr. 1.09.593).

3.6.4 Communication

3.6.4.1 RS232 / Propar

3.6.4.2 FLOW-BUS

Vapor Delivery Module 9.17.07910

3.7 Connector specifications

3.7.1 Hook-up diagram

Bronkhorst®

9.17.079

Vapor Delivery Module 11

4 Installation

The mounting position of the equipment is upright (Figure 1). Please take attention:

Avoid installation in close proximity of mechanic vibration and/or heat sources.

Avoid contact between hot surfaces of the enclosure with electrical cables and fluidic hoses/pipes.

Ventilation requires a minimum distance of 100 mm space from each side to a wall.

Make use of the protective earth pin (paragraph 3.7.1 connector 3) for grounding the connected tubing.

Use an appropriate cable.

Mount the equipment in such a way, that cables and mains switches can easily be reached and disconnected.

Figure 1

Please be aware when using Oxygen (O2) that the fittings mounted in the gas line should be absolutely oxygen clean.

Check the system for leaks before applying (fluid) pressure. Especially if toxic, explosive or other dangerous fluids are

used!

Bronkhorst® has gathered a material compatibility chart from a number of sources believed to be reliable. However,

it is a general guide only. Operating conditions may substantially change the accuracy of this guide. Therefore there

is no liability for damages accruing from the use of this guide. The customer’s application will demand its own

specific design or test evaluation for optimum reliability. So check order documentation if the used seals are correct

for the process.

4.1 Mounting

Bronkhorst®

4.2 Fluid connections

For exact information on the fittings, please contact Swagelok for further instructions or documentation.

4.3 Supply pressure

Do not apply pressure until electrical connections are made. When applying pressure to the system, make sure that the pressure is

increased gradually and avoid pressure shocks in the system.

4.4 Leak check

4.5 Seals

Vapor Delivery Module 9.17.07912

4.6 Purging / filling

Procedure:

Actions:

A1

Purge all lines

Close V2, V3 and V7

Open V1, V4, V5 and V6

Give setpoint 100% to MFC

Give setpoint 0% to LFC

Purge for a long time.

A2

Setup carrier gas supply

Close V4

Open V3

A3

Fill the system with liquid.

Close V1

Open V2 briefly; allow mixing valve VDM to fill.

Wait until all gas bubbles left the system via Purge out

and V5, then close V5.

Make sure that the carrier gas is always flowing when the

liquid flow is on. Preferably, let always gas flow in the

carrier gas line when the system is filled with liquid.

A4

The system is now ready for use.

Bronkhorst®

4.6.1 Startup without using vacuum

4.6.1.1 To fill the system

9.17.079

Vapor Delivery Module 13

Bronkhorst®

Procedure:

Actions:

B1

Set the heater at right temperature

Give set point to the heater; wait until the temperature is

stabilized

B2

Start gas flow

Give setpoint to MFC

Make sure that the carrier gas is always flowing when the

liquid flow is on. Preferably, let always gas flow in the

carrier gas line when the system is filled with liquid.

B3

Start liquid flow

Give setpoint LFC, wait until stabilization

Close supply pressure of the liquid vessel during the process.

The pressure controller of the inert gas supply can influence

the stability of the liquid flow controller.

B4

Connect process

Open V7, close V6

Procedure:

Actions:

C1

Disconnect process

Open V6, close V7

C2

Stop liquid flow

Give setpoint = 0 to LFC

C3

Optional: Stop gas flow

Give setpoint = 0 to MFC

Make sure that the carrier gas is always flowing when the

liquid flow is on. Preferably, let always gas flow in the

carrier gas line when the system is filled with liquid.

Procedure:

Actions:

D1

Relief the supply pressure from the liquid- and

carrier gas lines

Close V2 and V3

Procedure

(1,2)

:

Actions:

E1

Relief the supply pressure from the liquid- and

carrier gas lines

Close V2 and V3

E2

Purge liquid out of lines

Open V1 and V5

E3

Purge lines with inert gas

Open V4, V6

Close V7

Give setpoint to MFC

E4

Optional: purge wit inert liquid

Connect inert liquid to inert gas supply, Proceed according

to E2

E5

Optional: Alter E3 and E4 for a few times

(1)

If the liquid is reactive or aggressive, be sure to remove air (and water vapor) carefully, before introducing

liquid in the system.

(2)

If the liquid is reactive, aggressive, poisonous, toxic, or flammable, beware that the system is purged fully

(preferably with inert liquid, E3, E4, E5) before opening the system.

- In case of non-pure liquids, place a filter upstream the liquid flow controller.

- Mount the Vapor Delivery Module upright.

4.6.1.2

To start the process

4.6.1.3 To stop the process

4.6.1.4 How to leave system overnight

4.6.1.5 To empty and purge the system

Vapor Delivery Module 9.17.07914

Bronkhorst®

Procedure:

Actions:

A1

Evacuate the lines “Vacuum”

Start pumps

A2

Evacuate all lines

Close: V1, V2, V3, V4, and V6

Make sure that “waste” and “process” are vacuum

Connect inert gas on carrier gas inle.

Open : V5 and V8

Give setpoint to gas and liquid control (the control valves

of the LFC and MFC open)

Pump for a long time

Remark: if the system is not completely dry follow

procedure of E3, E4, (E5)

A3

Purge line between inert gas source and valve V1

Open valve V1 briefly for some seconds.

A4

Purge line between process gas source and gas MFC

Give setpoint = 0 to LFM (mix valve closes)

Open valve V3 briefly for some seconds

A5

Pump down liquid supply

Open V2 for some time

Close V2

A6

Setup carrier gas

Close V8

Open V3

A7

Fill the system with liquid

Close V1

Open B2 briefly; allow mixing valve VDM to fill

Close V5

Make sure that the carrier gas is always flowing when the

liquid flow is on. Preferably, let always gas flow in the

carrier gas line when the system is filled with liquid.

A8

Optional: degassing mixing valve

Open V5, a needle valve will be best, to avoid too much

liquid be pumped away

A9

The system is now ready for use

Procedure:

Actions:

B1

Set the heater at right temperature

Give setpoint to the heater, wait until temperature is

reached

B2

Start gas flow

Give setpoint to MFC

Make sure that the carrier gas is always flowing when the

liquid flow is on. Preferably, let always gas flow in the

carrier gas line when the system is filled with liquid.

B3

Start liquid flow

Give setpoint LFC, wait until stabilization

Close supply pressure of the liquid vessel during the process.

The pressure controller of the inert gas supply can influence

the stability of the liquid flow controller.

B4

Connect process

Open V7, close V6

4.6.2

Startup with using vacuum

4.6.2.1 To fill the system

4.6.2.2 To start the process

9.17.079

Vapor Delivery Module 15

Bronkhorst®

Procedure:

Actions:

C1

Disconnect process

Open V6, close V7

C2

Stop liquid flow

Give setpoint = 0 to LFC

C3

Optional: Stop gas flow

Give setpoint = 0 to MFC

Make sure that the carrier gas is always flowing when the

liquid flow is on. Preferably, let always gas flow in the

carrier gas line when the system is filled with liquid.

Procedure:

Actions:

D1

Relief the supply pressure from the liquid- and

carrier gas lines

Close V2

Open V8 for some seconds

Procedure

(1,2)

:

Actions:

E1

Relief the supply pressure from the liquid- and

carrier gas lines

Close V2 and V3

E2

Purge liquid out of lines

Open V1 and V4

E3

Purge lines with inert gas

Open V4 and V6

Close V7

Give setpoint to MFC

E4

Evacuate liquid lines (cont.)

Close V1

Open V8

E5

Optional: Repeat last two steps for a few times

(1)

If the liquid is reactive or aggressive, be sure to remove air (and water vapor) carefully, before introducing

liquid in the system.

(2)

If the liquid is reactive, aggressive, poisonous, toxic, or flammable, beware that the system is purged fully

(preferably with inert liquid, E3, E4, E5) before opening the system.

- In case of non-pure liquids, place a filter upstream the liquid flow controller.

- Mount the Vapor Delivery Module upright.

4.6.2.3

To stop the process

4.6.2.4 How to leave system overnight

4.6.2.5 To empty and purge the system

Vapor Delivery Module 9.17.07916

5 Operation

Before switching on the power, be sure that:

System is checked for leakage of gases and liquids

All connections have been made

Flow-set points are zero

No liquid has been spilled into the equipment

Switch on and then:

Allow 30 minutes (from switching on) to warm up (common for thermal flow controllers)

Wait until pre-set temperatures are reached. When the LED indicators turn blue,

temperatures are reached.

Make sure that the carrier gas is always flowing before the liquid flow setpoint is applied.

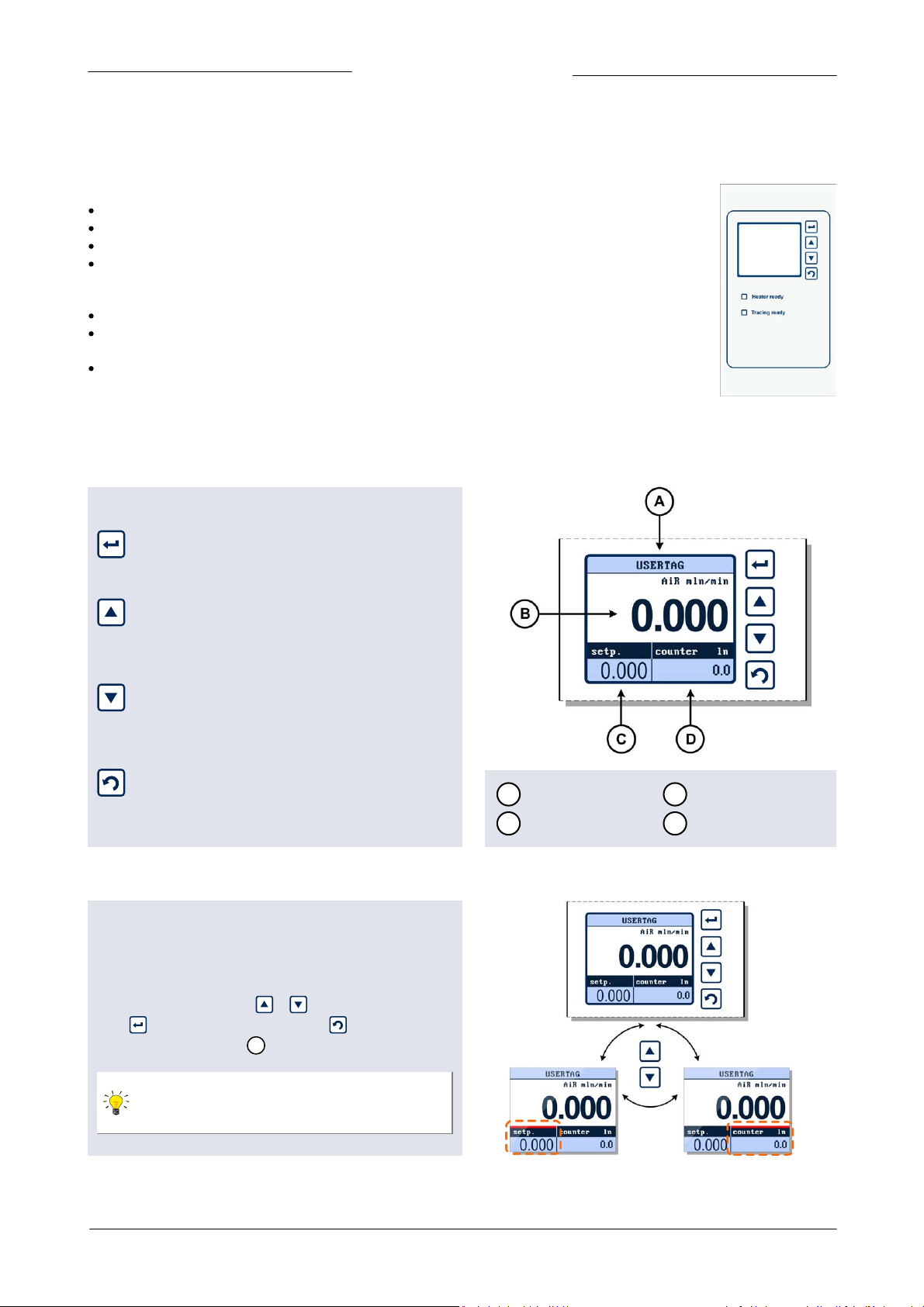

The buttons have the following functions:

- Enter selected menu

- Enter edit mode

- Confirm selection/changes

- Menu selection up

- Select information field

- Next character in edit mode

- Up in table

- Menu selection down

- Select information field

- Previous character in edit mode

- Down in table

- Return to previous screen

- Undo, cancel and exit edit mode

- Switch content in the 'Custom readout 2' field

A

Top line

C

Custom readout 1

B

Measure readout

D

Custom readout 2

The display is divided into 4 areas, ‘Measure readout’,

‘Custom readout 1’, ‘Custom readout 2’ and the 'Top line'.

The information in these areas can be configured by the user.

If an area contains a parameter which can be set or reset by

the operator, you can press

or

to select this parameter.

Press

to enter the edit mode or press

to return to the

‘Measure readout’ screen B.

If ‘Custom readout 1’ is disabled, you can only

switch between ‘Measure readout’ and ‘Custom

readout 2’.

5.1 Power- and warm-up

5.2 User interface

5.2.1 Buttons

Bronkhorst®

5.2.2 Display

9.17.079

Vapor Delivery Module 17

5.2.3 Select Instrument

The Vapor Delivery Modules contains liquid and gas flow

controllers. Also a temperature controller for evaporation and

optional trace heating is provided. These integrated

instruments have unique node addresses. Factory default

node addresses are:

Node address

Instrument

2

Readout and control (Display)

3

Temp. controlled evaporation device

4*

Trace heating temperature control

5

Liquid flow supply

6

Carrier gas supply

7*

Second carrier gas supply

8*

Dilution gas supply

* = if applicable

To enter the 'instrument' mode, press the button until the

red line appears above 'Custom readout 2' than press to

activate this field.

Security settings can be set to avoid unauthorised

access to this option.

The number of displays that have the same

instrument selected must not exceed 3.

The integrated Instruments will be indicated with their node

addresses. Press or to search for an instrument on the

bus. While the message “search” is displayed, the VDM is

searching for a valid node address and it will not show any

specific instrument info until an active node is found.

When an active node address is found, the VDM will show the

corresponding USERTAG or Serial Number in the 'Top line'. It

will also show the actual measure and, if applicable, the actual

setpoint.

Press to select this instrument to be operated by the VDM

or press to return to the previous selected instrument.

Bronkhorst®

Vapor Delivery Module 9.17.07918

Bronkhorst®

Setpoint can only be edited when the setpoint parameter is

displayed in 'Custom readout 1' or 'Custom readout 2'.

To edit the setpoint press to select the readout area in

which this parameter is displayed. Press to enter the edit

mode, the first digit will lighten.

Security settings can be set to avoid unauthorised

access to the setpoint parameter.

Use or to change the digits, press to confirm and

select the next digit.

You can change the setpoint edit mode into 'step'.

This enables you to change the setpoint using fixed

steps. See section 'Customize display info' in the

E-8000 manual (9.17.076) for more detailed

information.

After the last digit is confirmed by pressing , the setpoint

will be sent to the instrument.

If the entered setpoint is ignored, check controller

mode. See section 'Controller mode' in the E-8000

manual (9.17.076) for more detailed information.

The button can be used to exit the edit mode

and cancel the changes.

i

www

This chapter explains the most important user interface options. For more information please check the E-8000

manual 9.17.076 at: http://www.bronkhorst.com/en/downloads

Especially for tracing, the temperature is only controlled at a single location, while inadequate insulation may

introduce cold-spots at which condensation may occur.

5.2.4

Temperature and flow setpoint

5.3 Operating settings

Make sure that the tracing and heating temperatures are well above the dew point of the desired vapor flow at the process

conditions.

Be aware that the temperatures (both heater and tracing) depend on the location of the sensor. Therefore, it is advised to set the

heater temperature approximately 20°C above the theoretical temperature.

In addition, it is advised to set the tracing temperature another 10°C higher.

9.17.079

Vapor Delivery Module 19

Bronkhorst®

i

www

FLUIDAT® on the Net: Bronkhorst High-Tech's interactive Flow Calculations and routines generating Physical

Properties. Visit www.fluidat.com

Assumptions: Consider water vapor as an ideal gas, 1 mole of ideal gas at normal

conditions = 22.4 l, 1 mole of water is 18 g and 1 hour is 60 min.

1 atm. = 1013.25 mbar.

The MoleRatio:

So in a gas flow of 2 ln/min, the saturated vapor flow (100% r.h.) is:

[ln/min]

and in [g/h]:

[g/h]

The MoleRatio:

so in a gas flow of 2 ln/min, the saturated vapor flow (50% r.h.) is:

and in [g/h]

[g/h]

Result: at 50% r.h., the water flow is 29.41 g/h.

5.3.1 Operation example

Application

The Vapor Delivery Module can be used for generating certain humidity in a gas stream. Carrier gas and liquid (water) are

controlled to regulate the humidity. The water is mixed with the gas and consequently evaporated. The humidity at a certain

temperature corresponds with a certain ratio of gas and water, this ratio can be set by the flow controllers which are part of the

Vapor Delivery module.

Calculation example for setting of relative humidity

At atmospheric pressure, at 80°C, 2 ln/min Air has to be moistened. Which water flow is needed for a r.h. of 50%. The vapor

pressure of water at 80°C is 473.3 mbar according to FLUIDAT®.

At 100% r.h., the (Mole)Ratio between gas and water is:

At 50% r.h., the (Mole)Ratio between gas and water:

Vapor Delivery Module 9.17.07920

Bronkhorst®

5.3.2

Vaporpressure of water

9.17.079

Vapor Delivery Module 21

Bronkhorst®

Symptom

Possible cause

Action

No heating of heater, everything else works

(no ready heater LED after 10 minutes)

1. Mains switch turned off

Turn on mains switch

2. Fuse may be blown

Replace fuse

(check mains and heater fuse)

3. Defective temperature sensor

Return equipment

4. Heater defective

Return equipment

No heating of tracing, everything else works

(no ready heater LED after 30 minutes)

1. Fuse blown

Replace fuse

(check mains and tracing fuse)

2. Defective temperature sensor

Replace sensor

3. Defective tracing

Replace tracing

4. Inadequate insulation resulting

in thermal power loss

Improve insulation

No Liquid flow

1. Wrong controller mode LFC

Check controller mode LFC

2. No setpoint

Give Setpoint

No Gas flow

1. Wrong controller mode MFC

Check controller mode MFC

2. No Setpoint

Give Setpoint

No vapor stream

1. No gas supply

Check gas supply

2. No liquid supply

Check liquid supply

Liquid in process chamber

1. Mixture saturated, condensation

1. Increase setpoint Heater

2. Increase setpoint Tracing

3. Increase carrier gas flow

4. Decrease liquid flow

5. Any combinations of the

actions 1 – 4

2. No proper insulation of the

outlet piping

Improve insulation of piping

Irregular vapor stream

Significant pressure variations

on inlets

Reduce pressure variations by e.g.

adding pressure regulators or buffers

6 Troubleshooting and service

6.1 Troubleshooting

In case of not functioning equipment: De-installation and returning of the equipment is recommended. See section 7 for the

relevant details.

Do not open or disassemble the equipment.

Vapor Delivery Module 9.17.07922

Bronkhorst®

6.2

Maintenance

No routine maintenance is required. In case of (other) maintenance which requires de-installation of the equipment, purge the

system first as specified in Section 4.6.1.5

Cleaning

For cleaning the exterior use a soft damp cloth.

Maintenance

6.3 Service

For current information on Bronkhorst High-Tech B.V. and service addresses please visit our website:

http://www.bronkhorst.com

Do you have any questions about our products? Our Sales Department will gladly assist you selecting the right product for your

application. Contact sales by e-mail:

sales@bronkhorst.com

For after-sales questions, our Customer Service Department is available with help and guidance.

To contact CSD by e-mail:

support@bronkhorst.com

No matter the time zone, our experts within the Support Group are available to answer your request immediately or ensure

appropriate further action. Our experts can be reached at:

+31 573 45 88 39

Bronkhorst High-Tech B.V.

Nijverheidsstraat 1A

NL-7261 AK Ruurlo

The Netherlands

9.17.079

Vapor Delivery Module 23

Bronkhorst®

i

www

The declaration on contamination form is available at the Bronkhorst download site:

http://www.bronkhorst.com/files/support/safety_information_for_returns.pdf

7 Removal and return instructions

Instrument handlings:

Purge gas lines

When toxic or dangerous fluids have been used, the customer should pre-clean the instrument

Remove instrument from line

The instrument must be at ambient temperature before packaging

Insert the instrument into a plastic bag and seal the bag

Place the bag in a appropriate shipping container

Add documentation:

Reason of return

Failure symptoms

Contaminated condition

Declaration on Contamination form: 9.17.032

When returning material, always describe the problem and if possible the work to be done, in a covering letter.

It is absolutely required to notify the factory if toxic or dangerous fluids have been metered with the instrument!

This to enable the factory to take sufficient precautionary measures to safeguard the staff in their repair department. Take proper

care of packing, if possible use the original packing box.

Contaminated instruments must be dispatched with a completely filled in 'declaration on contamination form'. Contaminated

instruments without this declaration will not be accepted.

Important:

Clearly note, on top of the package, the customer clearance number of Bronkhorst High-Tech B.V., namely:

NL801989978B01

If applicable, otherwise contact your distributor for local arrangements.

Vapor Delivery Module 9.17.07924

Loading...

Loading...