Bronkhorst Modbus slave interface User Manual

Instruction manual

Modbus slave interface

for digital

Mass Flow / Pressure instruments

Doc. no.: 9.17.035U Date: 16-10- 2014

ATTENTION

Please read this instruction manual carefully before installing and operating the instrument.

Not following the guidelines could result in personal injury and/or damage to the equipment.

Head Office: Nijverheidsstraat 1a, NL-7261 AK Ruurlo, The Netherlands, Tel. +31 573 458800, info@bronkhorst.com

BRONKHORST®

Important information. Discarding this information could cause injuries to people or

Instrument or installation.

Disclaimer

Even though care has been taken in the preparation and publication of the contents of this manual, we do not assume

legal or other liability for any inaccuracy, mistake, mis-statement or any other error of whatsoever nature contained

herein. The material in this manual is for information purposes only, and is subject to change without notice.

Bronkhorst High-Tech B.V.

July 2011

Symbols

damage to the

Helpful information. This information will facilitate the use of this instrument.

Additional info available on the internet or from your local sales representative.

Warranty

The products of Bronkhorst High-Tech B.V. are warranteed against defects in material and workmanship for a period

of three years from the date of shipment, provided they are used in accordance with the ordering specifications

and the instructions in this manual and that they are not subjected to abuse, physical damage or

contamination. Products that do not operate properly during this period may be repaired or replaced at no charge.

Repairs are normally warranted for one year or the balance of the original warranty, whichever is the longer.

See also paragraph 9 of the Conditions of sales:

http://www.bronkhorst.com/files/corporate_headquarters/sales_conditions/en_general_terms_of_sales.pdf

The warranty includes all initial and latent defects, random failures, and undeterminable internal causes.

It excludes failures and damage caused by the customer, such as contamination, improper electrical hook-up, physical

shock etc.

Re-conditioning of products primarily returned for warranty service that is partly or wholly judged non-warranty may

be charged for.

Bronkhorst High-Tech B.V. or affiliated company prepays outgoing freight charges when any party of the service is

performed under warranty, unless otherwise agreed upon beforehand. However, if the product has been returned

collect to our factory or service center, these costs are added to the repair invoice. Import and/or export charges,

foreign shipping methods/carriers are paid for by the customer.

Page 2 Modbus interface 9.17.035

BRONKHORST®

Table of contents

1 GENERAL PRODUCT INFORMATION ................................................................................................. 4

1.1 INTRODUCTION ................................................................................................................................................ 4

1.2 MULTIBUS TYPES .............................................................................................................................................. 4

1.3 REFERENCES TO OTHER APPLICABLE DOCUMENTS ..................................................................................................... 5

1.3.1 Manuals and user guides: ........................................................................................................................... 5

1.3.2 Technical Drawings: .................................................................................................................................... 5

1.3.3 Software tooling: ........................................................................................................................................ 5

1.4 SHORT FORM START-UP ..................................................................................................................................... 6

2 FIELD BUS INSTALLATION ................................................................................................................. 7

2.1 GENERAL ........................................................................................................................................................ 7

2.2 MODBUS CONNECTOR ....................................................................................................................................... 7

2.2.1 Shielded RJ45 modular jack ......................................................................................................................... 7

2.2.2 Shielded a coded M12 connector ................................................................................................................ 8

2.3 MODBUS CABLES AND T-PARTS ........................................................................................................................... 9

2.3.1 RJ45 FTP cables ........................................................................................................................................... 9

2.3.2 M12 DeviceNet drop cables ...................................................................................................................... 10

2.4 TERMINATION ................................................................................................................................................11

2.4.1 Termination resistors ................................................................................................................................ 11

2.4.2 Biasing resistors ........................................................................................................................................ 11

3 CHANGING SLAVE ADDRESS AND BAUD RATE ................................................................................ 13

3.1 VIA ROTARY SWITCHES ON THE SIDE OF THE INSTRUMENT (IF PRESENT) ........................................................................13

3.2 VIA RS232: FLOWFIX ......................................................................................................................................13

3.3 VIA RS232: OTHER PROGRAMS ..........................................................................................................................14

3.4 VIA MICRO-SWITCH AND LED’S ON THE INSTRUMENT (IF PRESENT) .............................................................................14

3.4.1 Readout bus-address/MAC-ID and baud rate: .......................................................................................... 14

3.4.2 Change bus-address and baud rate: ......................................................................................................... 15

3.5 BY USER INTERFACE (IF PRESENT) ........................................................................................................................15

4 FUNCTIONAL DESCRIPTION ............................................................................................................ 16

4.1 GENERAL .......................................................................................................................................................16

4.2 IMPLEMENTATION CLASS ...................................................................................................................................16

4.3 RESPONSE TIME ..............................................................................................................................................17

4.4 SUPPORTED MODBUS FUNCTIONS .......................................................................................................................17

4.4.1 Read Holding Registers (03) ...................................................................................................................... 17

4.4.2 Write Single Register (06) ......................................................................................................................... 17

4.4.3 Write Multiple Registers (16) .................................................................................................................... 17

4.4.4 Diagnostics (08) ........................................................................................................................................ 18

4.4.5 Report Slave ID (17) .................................................................................................................................. 18

4.4.6 Available parameters ................................................................................................................................ 19

5 TROUBLESHOOTING ...................................................................................................................... 21

5.1 VISUAL DIAGNOSTICS .......................................................................................................................................21

5.2 STEP-BY-STEP .................................................................................................................................................21

5.3 BUS DIAGNOSTICS STRING .................................................................................................................................22

6 SERVICE ........................................................................................................................................ 23

Page 3 Modbus interface 9.17.035

BRONKHORST®

The implementation of the Modbus interface is based on the following standards:

[2] Modbus_over_serial_line_V1_02.pdf December 20, 2006

1 GENERAL PRODUCT INFORMATION

1.1 Introduction

This manual covers the Modbus interface, which offers a direct

connection to Modbus for Bronkhorst

meters / controllers. The Modbus instrument will behave as a slave. This

means all communication (instructions / readout) will be performed by a

master device on the same Modbus system. Mostly this will be a PC

controlling a process. This manual explains how to install a Bronkhorst

instrument to your Modbus system.

1)

Bronkhorst: This includes Bronkhorst High-Tech B.V. , Bronkhorst Cori-Tech B.V. and

M+W Instruments GmbH.

More detailed information about Modbus can be found at www.modbus.org or any website of the

(local) Modbus organisation of your country (when available).

1)

digital mass-flow / pressure

[1] Modbus_Application_Protocol_V1_1b.pdf December 28, 2006

1.2 Multibus types

In 2000 Bronkhorst developed their first digital instruments according to the

“multibus” principle. The basic pc-board on the instrument contained all of

the general functions needed for measurement and control, including alarm,

totalizing and diagnostic functions. It had analog I/O-signals and also an

RS232 connection as a standard feature. In addition to this there is the

possibility of integrating an interface board with DeviceNet™, Profibus-DP

Modbus , FLOW-BUS or EtherCAT protocol. The first generation (MBC-I) was

based on a 16 bit Fujitsu controller. It was superseded in 2003 by the

Multibus type 2 (MBC-II). This version was also based on the 16 bit Fujitsu controller but it had several improvements

to the MBC-I. One of them is the current steering of the valve. It reduced heat production and improved control

characteristics. The latest version Multibus controller type 3 (MBC3) is introduced in 2011. It is build around a 72MHz

32 bit NXP ARM controller. It has AD and DA controllers on board which makes it possible to measure noise free and

control valves without delays. The internal control loop runs 6 times faster compared to the MBC-II therefore control

stability has improved significantly. It also has several improved functions like reverse voltage protection, inrush

current limitation and overvoltage protection.

MBC3 instruments can be recognised by the “MBC3” placed on lower left side

of the instrument label (see example).

®

,

Page 4 Modbus interface 9.17.035

BRONKHORST®

RS232 interface with

Bronkhorst High-Tech

Bronkhorst Cori-Tech

Bronkhorst Cori-Tech

Bronkhorst High-Tech

Document 9.17.022

Document 9.17.050

Document 9.17.044

Document 9.17.023

Document 9.17.024

Document 9.17.025

Document 9.17.026

Document 9.17.035

Document 9.17.027

General instructions

Instrument type based

Operational

instructions

Field bus specific

information

Document 9.17.031

M+W Instruments

Document 9.17.063

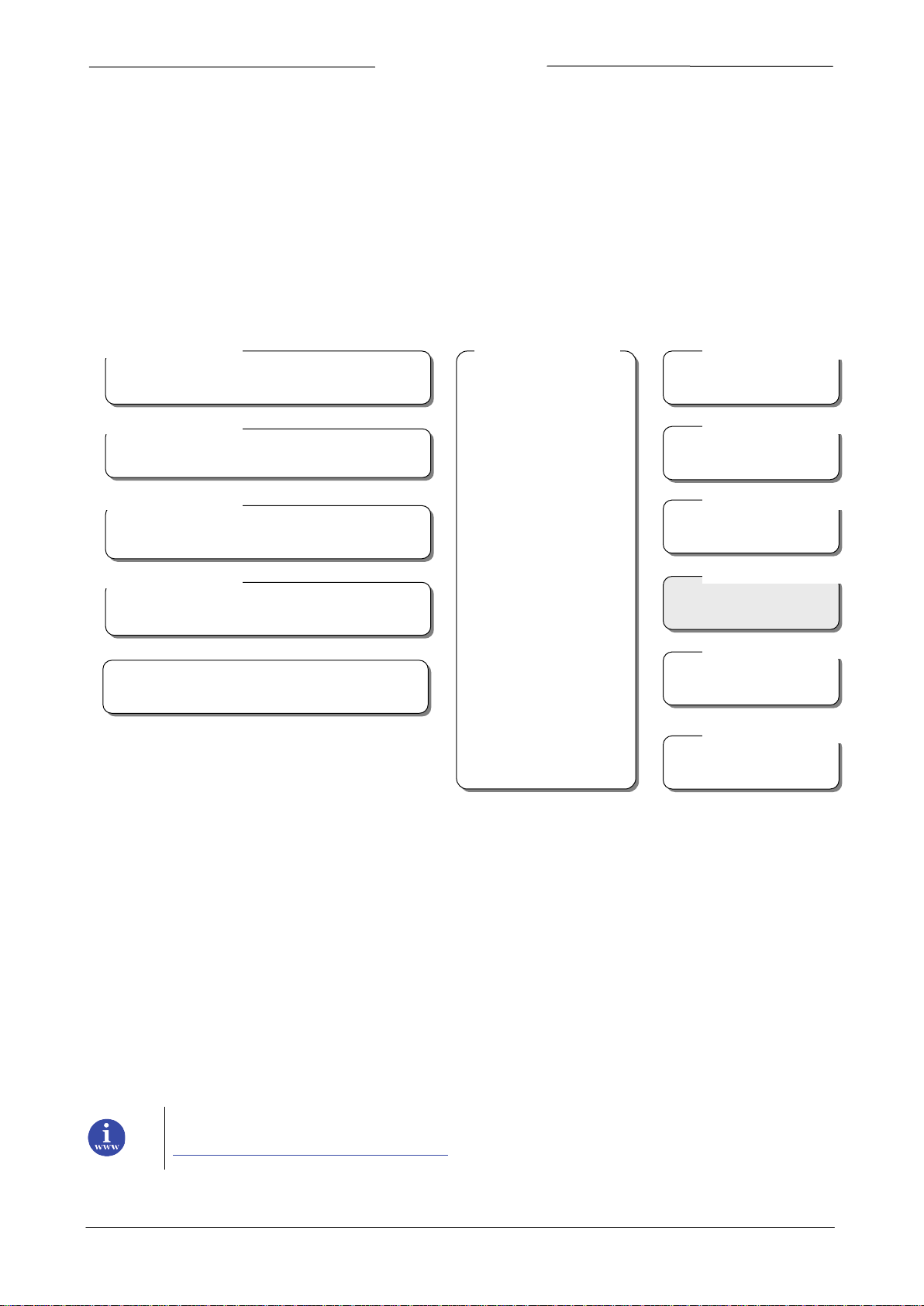

1.3 References to other applicable documents

Manuals and guides for digital instruments are modular. General instructions give information about the functioning

and installation of instruments. Operational instructions explain the use of the digital instruments features and

parameters. Field bus specific information explains the installation and use of the field bus installed on the

instrument.

1.3.1 Manuals and user guides:

General instructions digital Mass Flow / Pressure

General instructions CORI-FLOW

General instructions mini CORI-FLOW

General instructions digital LIQUI-FLOW L30

Instruction manual MASS-STREAM D-6300

Operational instructions

for digital multibus

Mass Flow / Pressure

instruments

FLOW-BUS interface

PROFIBUS–DP interface

DeviceNet interface

Modbus interface

FLOW-BUS protocol

EtherCAT interface

1.3.2 Technical Drawings:

Hook-up diagram laboratory-style Modbus (document nr. 9.16.064)

Hook-up diagram industrial style Modbus (document nr. 9.16.065)

Hook-up diagram CORI-FLOW Modbus (document nr. 9.16.066)

Hook-up diagram LIQUI-FLOW L30 digital Modbus (document nr. 9.16.075)

1.3.3 Software tooling:

FlowPlot

FlowView

FlowFix

FlowDDE

Page 5 Modbus interface 9.17.035

All these documents can be found at:

http://www.bronkhorst.com/en/downloads

BRONKHORST®

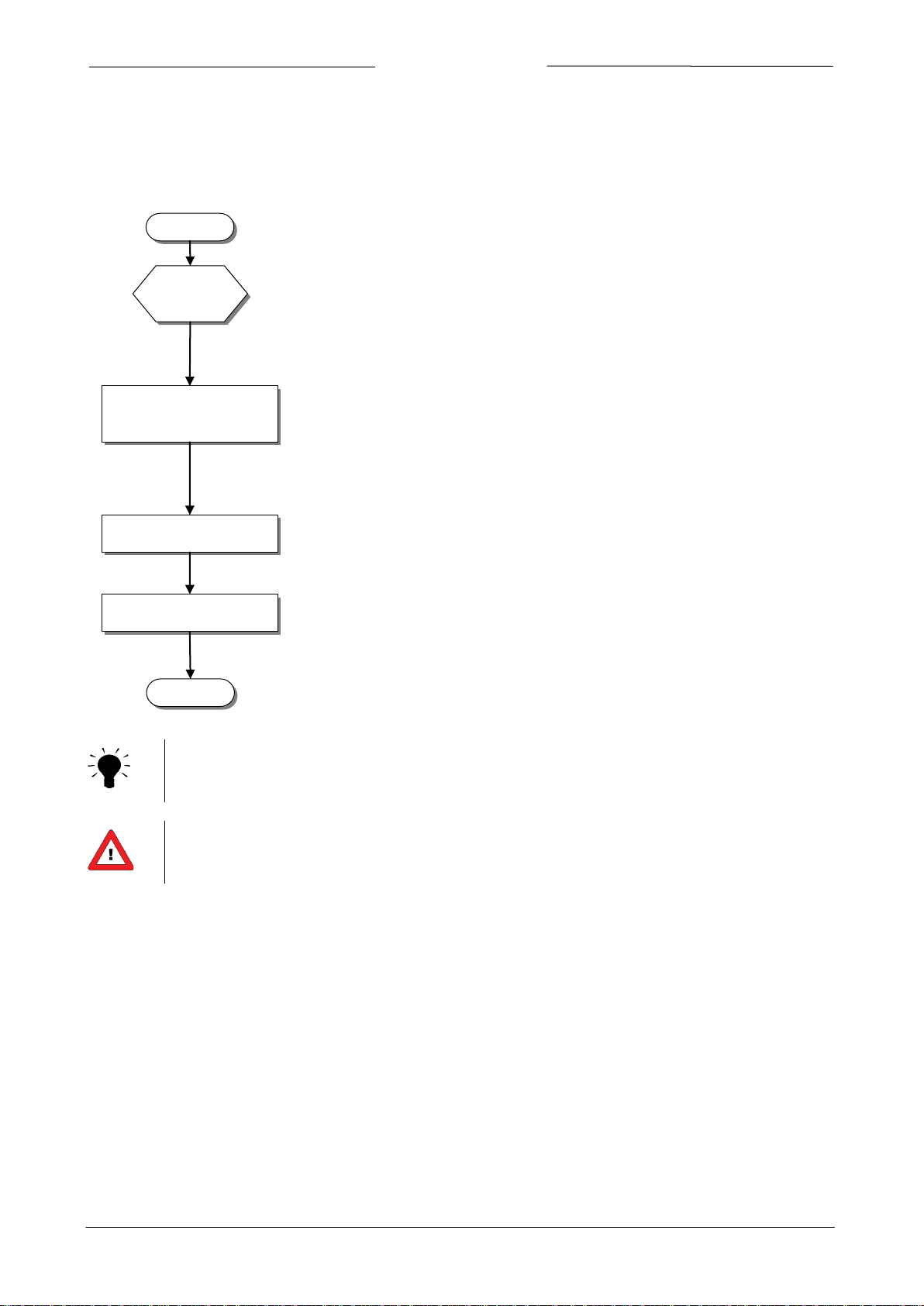

START

Master

present

Set Slave address and

baud rate of instrument

Make sure your Modbus master has been installed to the system

Instruments will be delivered to customers on address 1 and with a baud rate of

19200 baud.

switches on the instrument. Also y

address and baud rate via the RS232 connectio

instrument to apply the changes). Slave address and baud rate can also be changed

using the button (if present) on the instrument.

Connect instrument

Physically connect the instrument to the Modbus network.

Test

Test communication between your master and the instrument(s)

Ready

1.4 Short form start-up

All necessary settings for this module are already performed at Bronkhorst.

To follow next steps carefully is the quickest way to get this module operational in your own Modbus environment.

The easiest way to change the slave address is by use of the rotary

ou can use the FLOWFIX program to change Slave

n (it may be needed to restart the

Instruments with combined RS232 / RS485 signal lines and no user interface automatically detect the

bus type at start-up.

Warning: this device uses a vendor specific pin layout on the RJ45 connector that differs from the

Modbus recommended pin layout.

Page 6 Modbus interface 9.17.035

BRONKHORST®

1 8

The implementation of the Modbus interface is based on the following standards:

[2] Modbus_over_serial_line_V1_02.pdf December 20, 2006

Physical layer and communication protocol are detected automatically upon reception of messages.

protocol. After every power-up the communication detection mode is active.

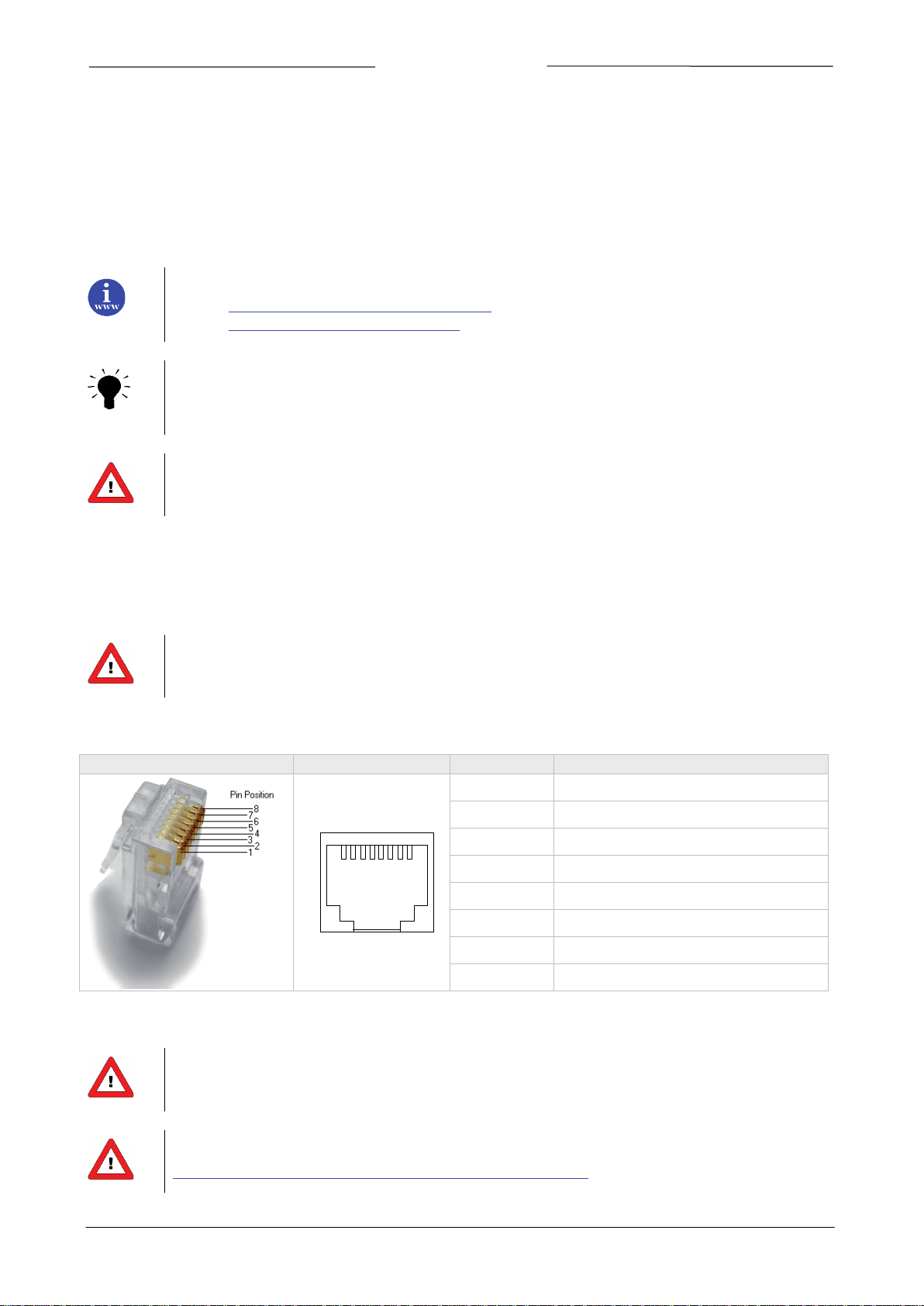

RJ45 Connector

Receptable

Pin number

Description

2 FIELD BUS INSTALLATION

2.1 General

Modbus is a 3-wire, RS485-based field bus communication system for parameter value exchange. In this system each

instrument / device is equipped with a micro-controller for its own dedicated task but also for exchanging parameter

value information with other instruments / devices connected to the same Modbus system.

[1] Modbus_Application_Protocol_V1_1b.pdf December 28, 2006

These messages must be sent using the correct combination of physical layer and communication

Bronkhorst advices not to use more as 127 instruments in one bus system.

2.2 Modbus connector

2.2.1 Shielded RJ45 modular jack

Warning: this device uses a vendor specific pin layout on the RJ45 connector that differs from the

Modbus recommended pin layout.

The shielded RJ45 modular jack connector (for non IP65 applications) has the following pin configuration:

1 +15…24Vdc supply

2 0V

3 Shield

4 0V

5

6 0V (Modbus common)

7 D0 Modbus (A/A')

8 D1 Modbus (B/ B')

+15…24Vdc supply

The maximum contact rating for RJ45 connectors is 1.5A.

For MASS-VIEW instrument see manual 9.17.051 for pin layout.

Page 7 Modbus interface 9.17.035

http://www.bronkhorst.com/en/downloads/instruction_manuals/

Loading...

Loading...