Instruction manual

Operational instructions

for digital Multibus

Mass Flow / Pressure instruments

Doc. no.: 9.17.023AD Date: 21-04-2015

ATTENTION

Please read this instruction manual carefully before installing and operating the instrument.

Not following the guidelines could result in personal injury and/or damage to the equipment.

Head Office: Nijverheidsstraat 1a, NL-7261 AK Ruurlo, The Netherlands, Tel. +31 573 458800, info@bronkhorst.com

BRONKHORST®

Disclaimer

Even though care has been taken in the preparation and publication of the contents of this manual, we do not assume

legal or other liability for any inaccuracy, mistake, mis-statement or any other error of whatsoever nature contained

herein. The material in this manual is for information purposes only, and is subject to change without notice.

Bronkhorst High-Tech B.V.

July 2011

Symbols

Important information. Discarding this information could cause injuries to people or damage to the

Instrument or installation.

Helpful information. This information will facilitate the use of this instrument.

Additional info available on the internet or from your local sales representative.

Warranty

The products of Bronkhorst High-Tech B.V. are warranteed against defects in material and workmanship for a period

of three years from the date of shipment, provided they are used in accordance with the ordering specifications

and the instructions in this manual and that they are not subjected to abuse, physical damage or

contamination. Products that do not operate properly during this period may be repaired or replaced at no charge.

Repairs are normally warranted for one year or the balance of the original warranty, whichever is the longer.

See also paragraph 9 of the Conditions of sales:

http://www.bronkhorst.com/files/corporate_headquarters/sales_conditions/en_general_terms_of_sales.pdf

The warranty includes all initial and latent defects, random failures, and undeterminable internal causes.

It excludes failures and damage caused by the customer, such as contamination, improper electrical hook-up, physical

shock etc.

Re-conditioning of products primarily returned for warranty service that is partly or wholly judged non-warranty may

be charged for.

Bronkhorst High-Tech B.V. or affiliated company prepays outgoing freight charges when any party of the service is

performed under warranty, unless otherwise agreed upon beforehand. However, if the product has been returned

collect to our factory or service center, these costs are added to the repair invoice. Import and/or export charges,

foreign shipping methods/carriers are paid for by the customer.

Page 2 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

TABLE OF CONTENTS

1 GENERAL PRODUCT INFORMATION ................................................................................................. 5

1.1 INTRODUCTION ................................................................................................................................................ 5

1.2 MULTIBUS TYPES .............................................................................................................................................. 5

1.3 REFERENCES TO OTHER APPLICABLE DOCUMENTS ..................................................................................................... 6

2 DIGITAL INSTRUMENT ..................................................................................................................... 7

2.1 GENERAL ........................................................................................................................................................ 7

2.2 BASIC DIAGRAM ............................................................................................................................................... 7

2.3 MEASURE AND CONTROL FUNCTIONAL BLOCK DIAGRAM ............................................................................................ 9

2.4 CALIBRATION WITH MATHEMATICAL FUNCTIONS .....................................................................................................10

2.5 MULTI FLUID / MULTI RANGE INSTRUMENTS .........................................................................................................11

3 PARAMETERS AND PROPERTIES ..................................................................................................... 12

3.1 GENERAL .......................................................................................................................................................12

3.2 BRONKHORST SOFTWARE ..................................................................................................................................12

3.3 PARAMETER USE .............................................................................................................................................13

4 NORMAL OPERATION PARAMETERS .............................................................................................. 16

4.1 MEASURE UNIPOLAIR .......................................................................................................................................16

4.2 MEASURE BIPOLAIR .........................................................................................................................................16

4.3 FMEASURE .....................................................................................................................................................16

4.4 SETPOINT ......................................................................................................................................................17

4.5 FSETPOINT .....................................................................................................................................................17

4.6 SETPOINT MONITOR MODE ................................................................................................................................17

4.7 SETPOINT EXPONENTIAL SMOOTHING FILTER .........................................................................................................17

4.8 SETPOINT SLOPE ..............................................................................................................................................18

4.9 ANALOG INPUT ...............................................................................................................................................18

4.10 CONTROL MODE ..............................................................................................................................................18

4.11 SLAVE FACTOR ................................................................................................................................................19

4.12 FLUID NUMBER ...............................................................................................................................................19

4.13 FLUID NAME ...................................................................................................................................................19

4.14 VALVE OUTPUT ...............................................................................................................................................20

4.15 TEMPERATURE ................................................................................................................................................20

4.16 ACTUAL DENSITY .............................................................................................................................................20

4.17 SENSOR TYPE ..................................................................................................................................................20

4.18 CAPACITY 100% .............................................................................................................................................20

4.19 CAPACITY 0% .................................................................................................................................................20

4.20 CAPACITY UNIT INDEX .......................................................................................................................................21

4.21 CAPACITY UNIT ...............................................................................................................................................22

5 CONTROL PARAMETERS................................................................................................................. 23

5.1 PID-KP .........................................................................................................................................................23

5.2 PID-TI ..........................................................................................................................................................23

5.3 PID-TD .........................................................................................................................................................23

5.4 CONTROLLER SPEED .........................................................................................................................................23

5.5 OPEN FROM ZERO RESPONSE .............................................................................................................................23

5.6 NORMAL STEP RESPONSE ..................................................................................................................................24

5.7 STABLE RESPONSE ...........................................................................................................................................24

5.8 SENSOR DIFFERENTIATOR UP .............................................................................................................................24

5.9 SENSOR DIFFERENTIATOR DOWN ........................................................................................................................24

5.10 SENSOR EXPONENTIAL SMOOTHING FILTER ............................................................................................................24

5.11 VALVE SAFE STATE ...........................................................................................................................................25

6 ALARM / STATUS PARAMETERS ..................................................................................................... 26

6.1 GENERAL .......................................................................................................................................................26

6.2 FUNCTIONAL ALARM SCHEMATIC .........................................................................................................................26

6.3 ALARM INFO ..................................................................................................................................................27

6.4 ALARM MODE ................................................................................................................................................27

Page 3 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

6.5 ALARM MAXIMUM LIMIT...................................................................................................................................27

6.6 ALARM MINIMUM LIMIT ...................................................................................................................................27

6.7 ALARM SETPOINT MODE ...................................................................................................................................27

6.8 ALARM NEW SETPOINT .....................................................................................................................................27

6.9 ALARM DELAY TIME .........................................................................................................................................28

6.10 RESET ALARM ENABLE ......................................................................................................................................28

6.11 STATUS .........................................................................................................................................................28

6.12 STATUS OUT POSITION ......................................................................................................................................28

6.13 USING AN ALARM (EXAMPLES) ...........................................................................................................................29

7 COUNTER PARAMETERS ................................................................................................................ 30

7.1 COUNTER VALUE .............................................................................................................................................30

7.2 COUNTER MODE .............................................................................................................................................30

7.3 COUNTER SETPOINT MODE ................................................................................................................................30

7.4 COUNTER NEW SETPOINT ..................................................................................................................................31

7.5 COUNTER LIMIT ..............................................................................................................................................31

7.6 COUNTER UNIT INDEX .......................................................................................................................................31

7.7 COUNTER UNIT ...............................................................................................................................................32

7.8 RESET COUNTER ENABLE ...................................................................................................................................32

7.9 COUNTER CONTROLLER OVERRUN CORRECTION ......................................................................................................33

7.10 COUNTER CONTROLLER GAIN ..............................................................................................................................33

7.11 USING A COUNTER (EXAMPLE) ............................................................................................................................33

8 IDENTIFICATION PARAMETERS ...................................................................................................... 34

8.1 SERIAL NUMBER ..............................................................................................................................................34

8.2 BHTMODEL NUMBER ......................................................................................................................................34

8.3 FIRMWARE VERSION ........................................................................................................................................34

8.4 USERTAG .......................................................................................................................................................34

8.5 CUSTOMER MODEL ..........................................................................................................................................34

8.6 IDENTIFICATION NUMBER ..................................................................................................................................35

8.7 DEVICE TYPE...................................................................................................................................................35

9 SPECIAL PARAMETERS ................................................................................................................... 36

9.1 RESET ...........................................................................................................................................................36

9.2 INIT / RESET ...................................................................................................................................................36

9.3 WINK ...........................................................................................................................................................36

9.4 IOSTATUS .....................................................................................................................................................36

10 SPECIAL INSTRUMENT FEATURES ................................................................................................ 39

10.1 ZEROING .......................................................................................................................................................39

10.2 RESTORE PARAMETER SETTINGS ..........................................................................................................................40

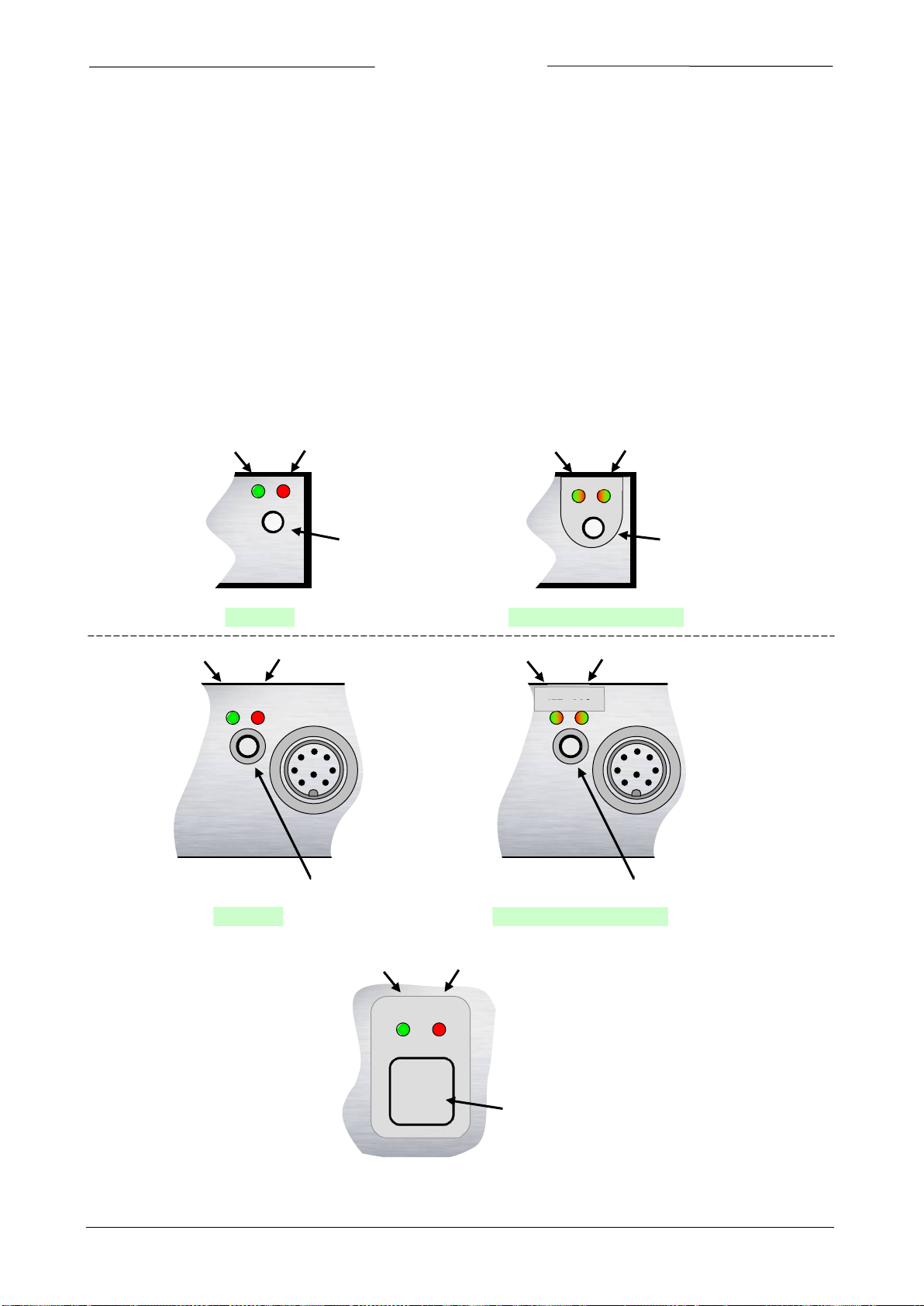

11 MANUAL INTERFACE: MICRO-SWITCH AND LED’S ....................................................................... 41

11.1 GENERAL .......................................................................................................................................................41

11.2 LED’S INDICATIONS .........................................................................................................................................42

11.3 MICRO-SWITCH USE FOR READING / SETTING ADDRESS / MAC-ID AND BAUDRATE ........................................................45

11.4 MICRO-SWITCH USE FOR READING/CHANGING CONTROL MODE: ................................................................................48

12 TESTING AND DIAGNOSTICS ....................................................................................................... 49

13 SERVICE ..................................................................................................................................... 50

Page 4 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

1 GENERAL PRODUCT INFORMATION

1.1 INTRODUCTION

This user guide explains the functioning of Bronkhorst

structure. They are called MULTIBUS instruments because the digital instruments may be fitted with a field bus. At

this moment the following types of field buses are supported: FLOW-BUS, Modbus, DeviceNet, PROFIBUS and

EtherCAT. Therefore included herein is the basic information to operate a digital instrument with optional field bus.

Explained is the functioning of the several parts of a digital system as the measuring system, control settings, alarm

and counter use and identification parameters. For every field bus a separate user guide is available.

1)

digital Multibus instruments features and parameter

1)

Bronkhorst: This includes Bronkhorst High-Tech B.V. , Bronkhorst Cori-Tech B.V. and

M+W Instruments GmbH.

1.2 MULTIBUS TYPES

In 2000 Bronkhorst developed their first digital instruments according to the “multibus” principle. The basic pc-board

on the instrument contained all of the general functions needed for measurement and control, including alarm,

totalizing and diagnostic functions. It had analog I/O-signals and also an RS232 connection as a standard feature. In

addition to this there is the possibility of integrating an interface board with DeviceNet™, Profibus-DP

FLOW-BUS or EtherCAT protocol. The first generation (MBC-I) was based on a 16 bit Fujitsu controller. It was

superseded in 2003 by the Multibus type 2 (MBC-II). This version was also based on

the 16 bit Fujitsu controller but it had several improvements to the MBC-I. One of

them is the current steering of the valve. It reduced heat production and improved

control characteristics. The latest version Multibus controller type 3 (MBC3) is

introduced in 2011. It is build around a 72MHz 32 bit NXP ARM controller. It has AD

and DA controllers on board which makes it possible to measure noise free and

control valves without delays. The internal control loop runs 6 times faster compared

to the MBC-II therefore control stability has improved significantly. It also has several

improved functions like reverse voltage protection, inrush current limitation and

overvoltage protection.

MBC3 instruments can be recognised by the “MBC3” placed on lower left side

of the instrument label (see example).

®

, Modbus ,

Page 5 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

RS232 interface with

FLOW-BUS protocol

Bronkhorst High-Tech

Bronkhorst Cori-Tech

Bronkhorst Cori-Tech

Bronkhorst High-Tech

Document 9.17.022

Document 9.17.050

Document 9.17.044

Document 9.17.023

Document 9.17.024

Document 9.17.025

Document 9.17.026

Document 9.17.035

Document 9.17.027

General instructions

Instrument type based

Operational

instructions

Field bus specific

information

Document 9.17.031

M+W Instruments

Document 9.17.063

1.3 REFERENCES TO OTHER APPLICABLE DOCUMENTS

Manuals and guides for digital instruments are modular. General instructions give information about the functioning

and installation of instruments. Operational instructions explain the use of the digital instruments features and

parameters. Field bus specific information explains the installation and use of the field bus installed on the

instrument.

1.3.1 Manuals and user guides:

General instructions digital Mass Flow / Pressure

General instructions CORI-FLOW

General instructions mini CORI-FLOW

General instructions digital LIQUI-FLOW L30

Instruction manual MASS-STREAM D-6300

Operational instructions

for digital multibus

Mass Flow / Pressure

instruments

FLOW-BUS interface

PROFIBUS–DP interface

DeviceNet interface

Modbus interface

EtherCAT interface

1.3.2 Software tooling:

Page 6 Operational instructions for digital multibus instruments 9.17.023

FlowPlot

FlowView

Flowfix

FlowDDE

All these documents can be found at:

http://www.bronkhorst.com/en/downloads

BRONKHORST®

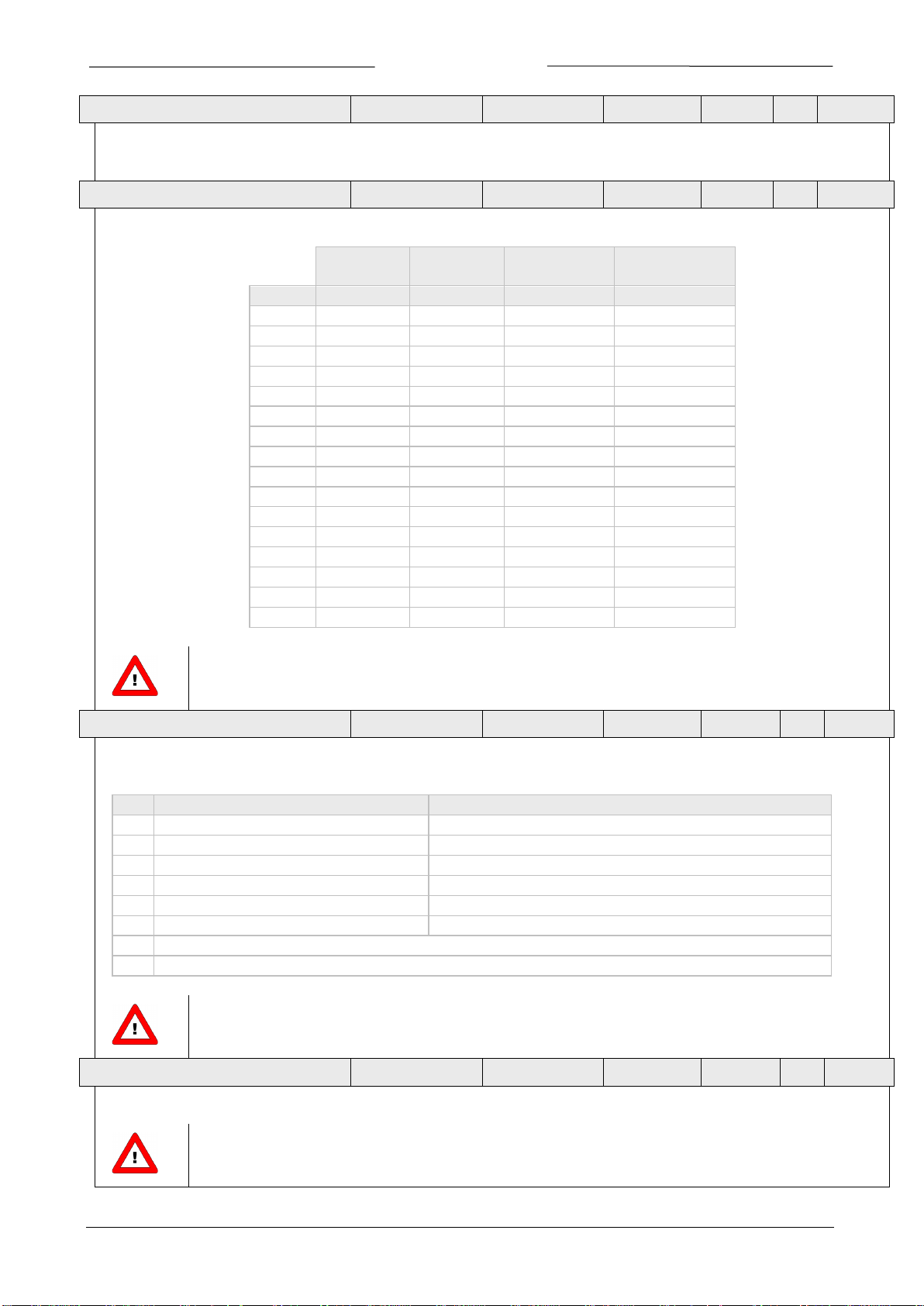

Read and write parameters

FIELD BUS

Sensor

Valve

LED Green

LED Red

Microswitch

PWM

AD

DA AD

Analog

Input

0…5V

4…20mA

Analog

Output

1 Analog Output

DA

AD

2 Analog Input

3 Digital Output

4 Digital Input

RS232/

1

2 3 4

MBC3 type only

0…5V

4…20mA

RS232/

(RS485)

15…24Vdc

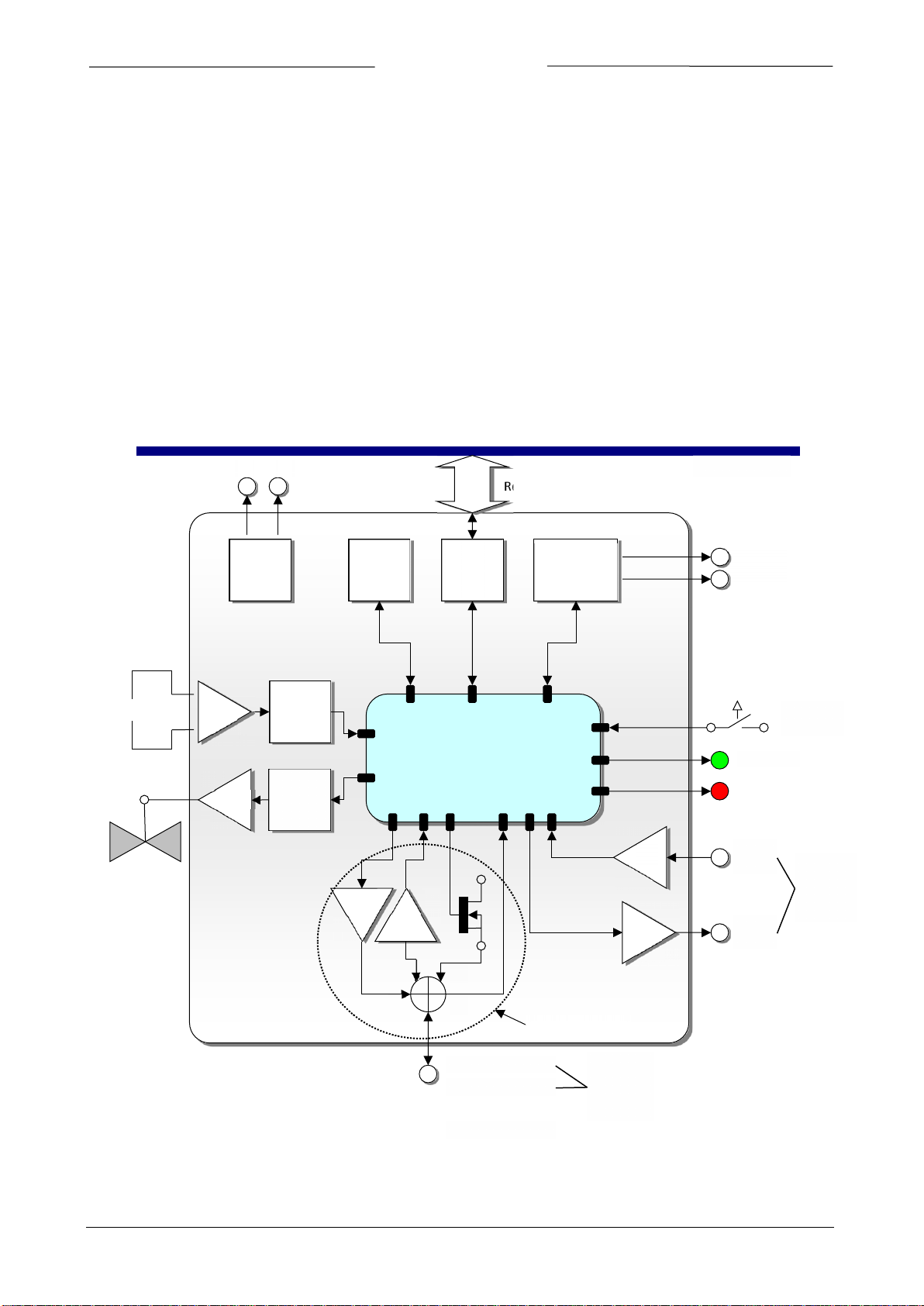

2 DIGITAL INSTRUMENT

2.1 GENERAL

A digital instrument of Bronkhorst is a Mass Flow or Pressure Meter / Controller which is equipped with a digital

electronic Multibus PC board. These electronics consist of a micro-controller with peripheral circuitry for measuring,

controlling and communication. The flow/pressure signal is measured and digitized directly at the sensor and

processed by means of the internal software (firmware). Measured and processed values can be output through the

analog interface and through the digital communication line RS232 (and optional field bus interface). For controllers

the setting for the actuator is calculated by the firmware. Setpoint can be given through the integrated analog

interface or through the digital communication line. Digital instruments have many parameters for settings for signal

processing, controlling and many extra features and therefore they have a wide range in use. Reading and changing of

these settings is possible through field bus or RS232, except for measured value, setpoint and valve output, which is

also possible through the analog interface. (Depending on parameter setting) See operating instructions of Readout

and Control module or PC-program how to read/change parameter values of digital instruments.

2.2 BASIC DIAGRAM

Supply

Voltage

Measure

PID

controller

Data

Memory

FIELD BUS

Interface

Digital Signal

Processing

RS485

Interface

0…10V

0…20mA

Page 7 Operational instructions for digital multibus instruments 9.17.023

0…10V

0…20mA

BRONKHORST®

Digital instruments can be operated by means of:

1. Analog interface. (0...5Vdc/0...10Vdc/0...20mA/4...20mA)

2. RS232 interface (connected to COM-port by means of special cable (Default speed 38400 Baud)

3. FLOW-BUS

4. PROFIBUS-DP

5. DeviceNet

6. Modbus

7. EtherCAT

Option 1 and 2 are always present on Multibus instruments. Option 3, 4, 5 and 6 are optional. Operation via analog

interface, RS232 interface and an optional field bus can be performed at the same time. A special parameter called

“control mode” indicates to which setpoint the controller should listen: analog or digital (via field bus or RS232). The

RS232 interface behaves like a FLOW-BUS interface. When using more digital interfaces at the same time, reading can

be done simultaneously without problems. When changing a parameter value, the last value send by an interface will

be valid.

Also the micro push-button switch and the LED’s on top of the instrument can be used for manual operation of some

options.

• The green LED will indicate in what mode the instrument is active.

• The red LED will indicate info / error / warning situations.

Page 8 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

ADC

Bridge potmeter

ADC scaling

3

Bridge current

Exponential

filter

4

Lookup table

linearization

Polynomial

linearization

Differentiator

5

6 7 8

Differentiator

(MBC-II only)

1

Setpoint

0

Display filter

fmeasure

Measure

PID

controller

2

VALVE

SENSOR

FLOW

MEASURE

CONTROL

Monitor

Valve Out

MBC3

MBC-II

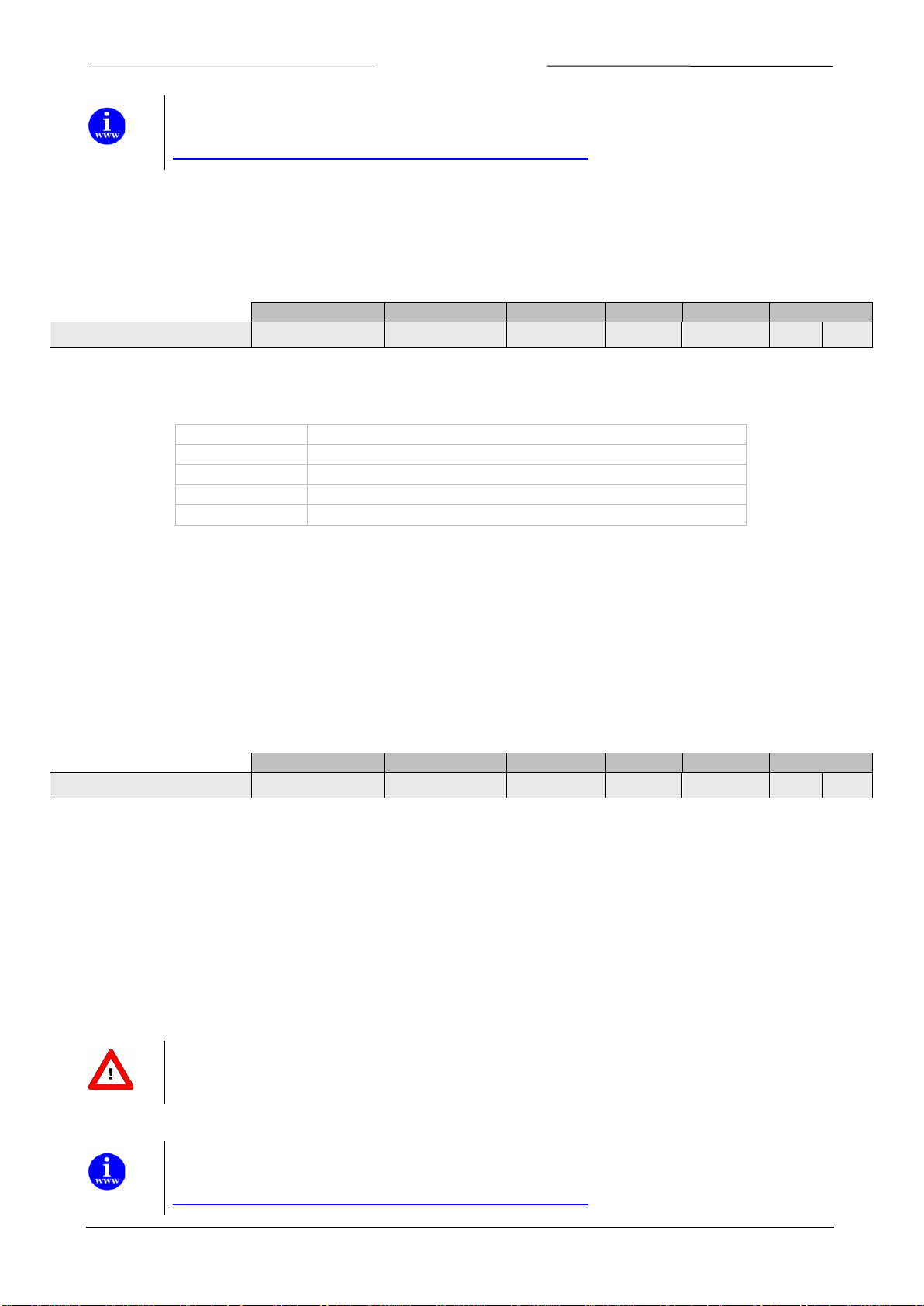

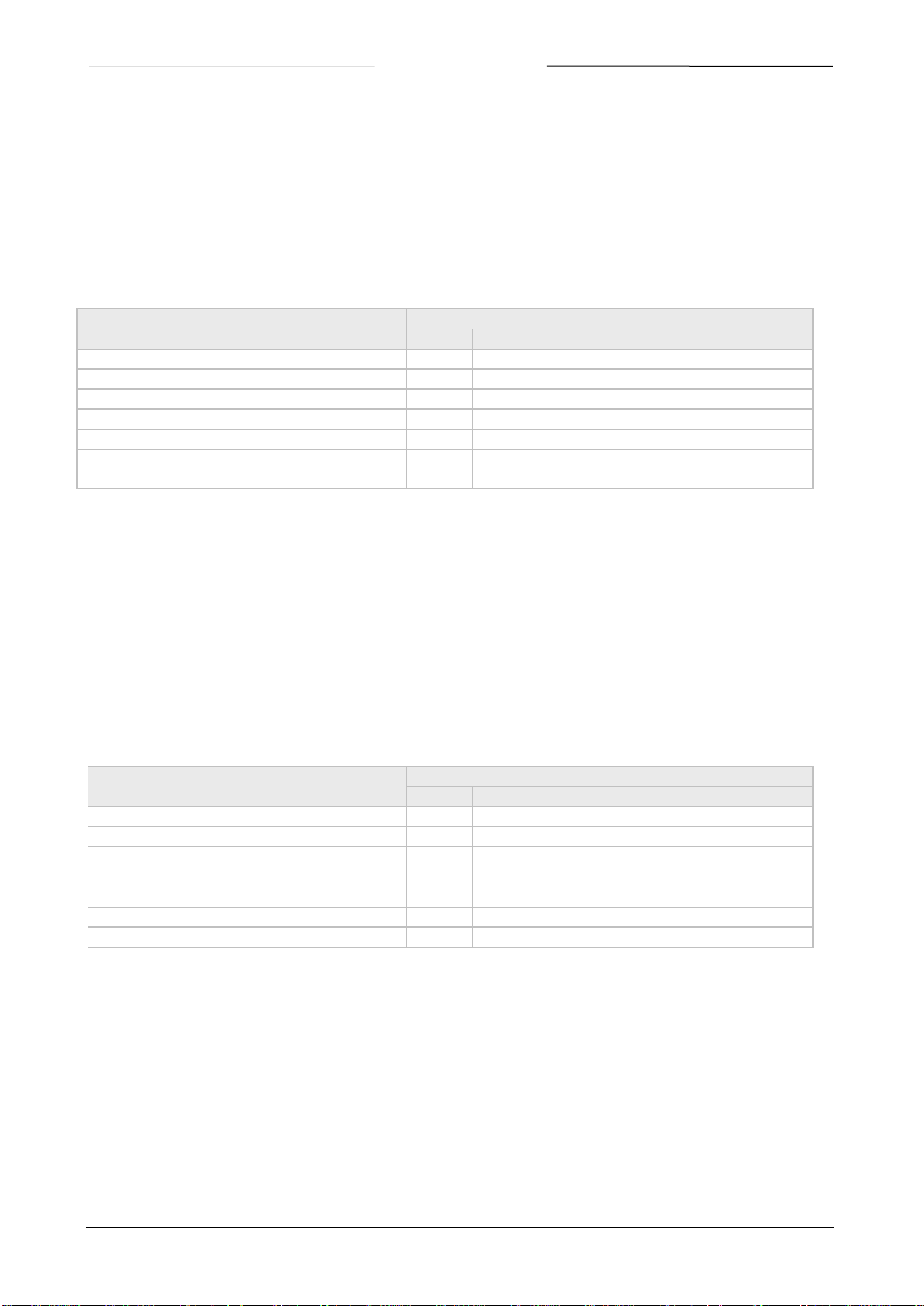

2.3 MEASURE AND CONTROL FUNCTIONAL BLOCK DIAGRAM

The main part of a digital instrument is the measuring stage. The base is a highly accurate Analog to Digital converter.

The measuring signal is than processed trough a couple of stages as shown below. In general the path is: ADC scaling,

filtering, linearization (look-up or polynomial), Differentiation (gas flow sensors only), display filtering. In case of a

control system this signal is used to control a valve. The control loop consists of an enhanced PID controller (See the

chapter “Control parameters”).

Digital mass-flow measure / controller functional block diagram

converter

smoothing

filter

Page 9 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

n

n

XaXaXaXaay ⋅++⋅+⋅+⋅+= .....

3

3

2

210

32

XdXcXbaY ⋅+⋅+⋅+=

index X Y

x0 y

0

x1 y

1

x2 y

2

x3 y

3

…

… n xn y

n

2.4 CALIBRATION WITH MATHEMATICAL FUNCTIONS

2.4.1 General information

Depending on instrument and sensor type an instrument output signal is calculated with one of the following

mathematical methods:

• polynomial function

• look-up table (2 dimensions)

• look-up table with temperature compensation (3 dimensions)

2.4.2 Polynomial functions

By means of a few samples, a polynomial function can be obtained. After determining the polynomial function, the

original calibration points and an infinite amount of values in between, can be calculated with high accuracy. In a

system where pressure- and/or flow meters and -controllers should be readout and set with high accuracy, these

polynomial functions often are used for approximation of their transfer function.

2.4.2.1 General form of a polynomial function

In mathematics, a polynomial is an expression of finite length constructed from variables (also known as in

determinates) and constants. The general form of a polynomial function of the n-th degree is as follows:

n is a non negative integer and 'a

they can be approximated by means of a 'n

' to 'an' are polynomial constant coefficients. When you have 'n + 1' measure-points,

0

th

' degree polynomial function.

2.4.2.2 Polynomial function of sensor signal

By means of a calibration at Bronkhorst several measured calibration points will be used to obtain a polynomial

function. The form of this function of the 3

In which 'Y' is the normalized measured value (0-1) and 'X' is the value of the sensor signal. Characters 'a - d' are

polynomial parameters, which can be obtained by a mathematical program. The polynomial parameters are calculated

in such a way that the fit error between the calibration points and the polynomial function is minimized.

rd

degree is:

2.4.3 Look-up tables

It is also possible to linearize a sensor signal is using a so called look-up table. A look-up table is a table filled with

calibration points. The embedded software inside the digital instrument calculates a continuous smooth function

which fits exactly through these calibration points. Using this method it is possible to describe any monotone rising

sensor signal curve with high accuracy.

2.4.4 General form of 2-dimensional look-up tables

The general form of a 2-dimensional look-up table is as follows:

0

1

2

3

…

In which 'Y' is the real flow value, 'X' is the value of the sensor signal and ‘index’ represents the position in the look-up

table. A Bronkhorst digital instrument can store look-up tables with a maximum of 21 calibration points.

Page 10 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

2.4.5 Using mathematical functions at a digital instrument

Digital instruments are capable of storing 8 different fluid calibrations. Parameters for these calibrations are stored

inside the instrument and can be read or changed through the field bus or the RS232 connection by means of a PCprogram or a digital Readout and Control module. Factory calibration parameters are secured and can not be changed

unless you have special rights to do this. Selection of another fluid is part of operation and therefore not secured.

Digital instruments will need at least 1 fluid set of calibration parameters for operation.

2.5 MULTI FLUID / MULTI RANGE INSTRUMENTS

2.5.1 General information

Multi Fluid / Multi Range (MFMR) instruments are calibrated for standard ranges which can easily be configured for

other fluids and ranges. This applies for both Bronkhorst and its customers. Changing fluid and range can be

performed by means of a simple computer program through the RS232 connection of an instrument. The program can

convert the primal calibration curve inside the instrument to the selected fluid and range.

MFMR instruments can be identified by the text “MFMR” on the instruments identification.

2.5.2 Differences between traditional and MFMR instruments

In traditional digital instruments the parameters capacity, density, unit type, capacity unit etc. are static parameters.

These parameters are used by, for example, read out units or PC-software to convert the measured value in

percentage of the maximum output to a real value in a certain unit.

However in MFMR instruments these parameters are dynamic.

Examples:

An instrument is configured for 2000 ml

Changing the capacity unit from ‘ml

‘2000’ to ‘2’. The 100% output is not affected.

Changing the capacity from ‘2000’ to ‘1000’ effects that the instruments full scale capacity (100% output)

changes to 1000 ml

/min. The instrument is reranged.

n

/min Air.

n

/min’ to ‘ln/min’ effects that the capacity automatically changes from

n

Page 11 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

3 PARAMETERS AND PROPERTIES

3.1 GENERAL

Digital instruments consist of a microcontroller with several processes running simultaneously for:

• Measuring sensor value

• Reading analog input signal

• Digital signal processing

• Driving a valve

• Setting analog output signal

• Communication with the world outside

Each process needs its own specific parameters in order to function correctly. These parameter values are accessible

through the available interface(s) to influence the process behavior (for instance Control behavior or alarm settings).

These parameters can easily be controlled by end-users for more flexible use of the instruments. Bronkhorst offers

special software tooling for these purposes.

3.2 BRONKHORST SOFTWARE

FlowDDE is software which allows users to communicate with digital instruments in a standard way. It uses the RS232

interface on the instrument which is linked to a computer with a standard Bronkhorst cable. It converts the

instrument parameters to DDE commands. DDE (Dynamic Data Exchange) is a technology for communication between

multiple applications under Microsoft Windows.

FlowView and FlowPlot use FlowDDE as a server. In short:

FlowView :Windows application for the readout and/or control of 12 instruments (default), configurable up to

99 instruments.

FlowPlot :Windows application for monitoring and optimizing. (Value versus time on screen)

Page 12 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

These programs are on the support CD or can be downloaded from:

http://www.bronkhorst.com/en/products/accessories/software_tools/

End-users are also free to use their own software using either:

FlowDDE : DDE-server for data exchange with Microsoft Windows applications

FLOWB32.DLL : Dynamic Link Library for Microsoft Windows applications

RS232 interface : Protocol for instructions with ASCII HEX or Binary telegrams

3.3 PARAMETER USE

In general each parameter has its own properties, like data-type, size, reading/writing allowance, security.

Parameters can be protected in general:

• Parameters used for operation of instruments are not secured (read / write is allowed).

(e.g..: measure, setpoint, control mode, setpoint slope, fluid number, alarm and counter)

• Parameter for settings and configuration are secured (reading is allowed/ writing is not allowed).

(e.g..: calibration settings, controller settings, identification, network/field bus settings)

Parameters for settings are secured. They can be read-out, but can not be changed without knowledge of special keyparameters and knowledge of the instrument.

Reading/changing parameter values via FlowDDE offers the user a different interface to the instrument. Besides the

server name: ‘FlowDDE’ or ‘FlowDDE2’ there is only need of:

• topic, used for channel number: ‘C(X)’ (x = channel number)

• item, used for parameter number: ‘P(Y)’ (y = parameter number)

A DDE parameter number is a unique number in a special FlowDDE instruments/parameter database and not the

same as the parameter number from the process on an instrument. Node address and process number will be

translated by FlowDDE to a channel number.

When not using FlowDDE for communication with the instrument, each parameter value needs:

• node address of instrument on FLOW-BUS

• process number on instrument

• parameter number on instrument

Page 13 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

Document “917027--Manual RS232 interface” explains in more detail the use of RS232 communication

http://www.bronkhorst.com/en/downloads/instruction_manuals/

Data Type

Range

read/write

Secured

DDE

Proc/par

Valve output

unsigned long

0…16777215

RW Y

55

114

1

Unsigned char

1 byte integer

Unsigned int

2 bytes integer, MSB first

Unsigned long

4 bytes integer, MSB first

Float

4 bytes IEEE 32-bit single precision numbers, MSB first

Unsigned char []

array of characters (string)

Data Type

Range

read/write

Secured

DDE

Proc/par

Fluid name

unsigned char[10]

a…Z, 0…9

RW Y

25

1

17

More information can be found in the manual “917030 Manual FlowPlot”

http://www.bronkhorst.com/en/downloads/instruction_manuals/

This document can be found at:

Example of a parameter and the explanation:

unsigned long = one of the data types below.

RW = R - parameter can be read, W – parameter can be written.

Secured = Y =Parameter is secured. N= Parameter not secured.

0…16777215 = Parameter range.

DDEpar. = 55 = FlowDDE parameter number

Proc. = 114 = Process number

Par. = 1 = process parameter number

Another example is:

unsigned char[10] = Data type Unsigned char[], array of characters. [10] = number of characters.

RW = R - parameter can be read, W – parameter can be written.

Secured = Y =Parameter is secured. N= Parameter not secured.

a...Z = characters which can be used in the string

0...9 = numbers which can be used in the string

DDEpar. = 25 = FlowDDE parameter number

Proc. = 1 = Process number

Par. = 17 = process parameter number

secured parameter:

To enable secured parameter, see chapter 9 SPECIAL PARAMETERS 9.2 INIT/RESET.

This document can be found at:

Page 14 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

Page 15 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

Data Type

Range

read/write

Secured

DDE

Proc/par

4.1 MEASURE UNIPOLAIR

unsigned int

0…41942

R

N 8 1/0

4.2 M

unsigned int

0…65535

R

N 8 1/0

4.3 F

float

-3.40282E+38 …

3.40282E+38

R

N

205

33/0

Depending on the type of instrument, measured value indicates the amount of mass flow or pressure metered by the

ng floating point notation. The

Not used

( )

capacity0%capacity0%capacity*

32000

measure

fmeasure +

−=

4 NORMAL OPERATION PARAMETERS

EASURE BIPOLAIR

MEASURE

instrument. Sensor signals at digital instruments will be digitized at the sensor bridge by means of highly accurate ADconverters. Digitized signals will be internally processed by the microcontroller usi

sensor signal will be differentiated, linearized and filtered.

At the digital output measured values can be presented in three ways:

1. For Unipolair mode the signal of 0...100% will be presented in a range of 0...32000.

For the instruments, maximum signal to be expected is 131.07 %, which is: 41942.

0 32000 41942 65535

0% 100% 131.07%

2. For Bipolair mode the signal of 0...100% will be presented in a range of 0...32000.

Maximum signal is 131.07 %, which is: 41942, minimum signal is -73.73 %, which is 41943

0 32000 41942 41943 65535

0% 100% 131.07% -73.73% -0.003%

3. Fmeasure is a different parameter as Measure. It represents the internal floating point version of the variable

Value is calculated as follows:

measure as mentioned before.

The users will read-out the measured value in the capacity and capacity unit for which the instrument has

been calibrated. These settings depend on variables: capacity, capacity unit, sensor type and capacity 0%.

Fmeasure is a read-only float on (FLOW-BUS) proc 33, par 0.

in text

Page 16 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

4.4 S

unsigned int

0…32000

RW

N 9 1/1

4.5 FSETPOINT

float

1e-10…1e+10

RW

N

206

33/3

32000

capacity0%capacity

capacity0%fsetpoint

setpoint •

−

−

=

Reading back actual values of Fsetpoint is also possible. When a value has been send to proc1, par1

capacity and unit

4.6 SETPOINT MONITOR MODE

unsigned char

0…255

RW Y

329

115/23

This parameter makes it possible to visualize the internal setpoint value.

Value

Description

0

Setpoint

1

Internal setpoint after Setpoint Exponential Smoothing filter

2

Internal setpoint after slope function

4.7 S

SMOOTHING FILTER

float

0…1

RW Y

73

117/3

This factor is used for filtering the setpoint before it is further processed.

filter) exp. Setpoint(1filter exp. SetpointxY

00

−•+•=

1

y

ETPOINT

Setpoint of the instrument can be operated by two parameters at the same time:

1. Setpoint is used to tell the PID controller in the instrument what the wanted amount of mass flow or pressure

is. Signals are in the same range as the measured value, only setpoint is limited between 0 and 100 %.

Setpoint can be given either via optional field bus or RS232 or via the analog interface. The parameter control

mode selects the active setpoint for the controller. See that paragraph for more detailed information.

2. With the use of parameter Fmeasure, also Fsetpoint is often needed. This parameter is R/W as variable in

FLOW-BUS proc33, par3. Fsetpoint is a float (in the capacity in which the instrument was calibrated, see also

Fmeasure). The last received setpoint by the instrument will be valid. It is not advised to use setpoint and

Fsetpoint at the same time.

Relation between setpoint and Fsetpoint is calculated as follows:

in text

(integer setpoint), then this will be converted to the float setpoint for direct reading in the right

ETPOINT EXPONENTIAL

It filters according the following formula:

Default value = 1 (off)

This filter is in the control loop so it affects the response time.

For MBC-II type of instruments this parameter affects the analog setpoint signal.

For MBC3 type of instruments this parameter affects both analog and digital setpoint signals.

Page 17 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

4.8 S

unsigned int

0…30000

RW

N

10

1/2

Digital instruments can establish a smooth setpoint control using the setpoint slope time. The setpoint will be linear

=•

−

slope

100

oldspnewsp

610

100%

20%80%

=•

−

4.9 ANALOG INPUT

unsigned int

0…65535

R

N

11

1/3

Depending on the analog mode, 0...5Vdc / 0…10Vdc / 0...20mA / 4...20mA is converted to 0…32000.

4.10 CONTROL MODE

unsigned char

0…255

RW

N

12

1/4

For switching between different functions of a digital meter or controller several modes are available.

Mode

Instrument action

Setpoint source

Master source

Slave factor

0

BUS/RS232

Controlling

BUS/RS232

1

Analog input

Controlling

analog input

controlling as slave from other

instrument on the bus

FLOW-BUS * slave

factor /100%

slave factor

(proc33,par 1)

3

Valve close

close valve

stand-by on BUS/RS232

freezes in current position

5

Testing mode

testing enabled (factory only)

6 Tuning mode

tuning enabled (factory only)

7

Setpoint 100%

controlling on 100%

100%

8

Valve fully open

purge valve

9 Calibration mode

calibration enabled (factory only)

controlling as slave from other

instrument on analog input

Analog input * slave

factor /100%

proc33,par 1

(slave factor)

12

setpoint 0%

controlling on 0%

0%

controlling as slave from other

with signal on analog input

FLOW-BUS * analog

/100%

18

RS232

Controlling

valve stearing

(valve = setpoint)

Setpoint is redirected directly to

Valve Out with the controller idle

analog valve stearing

(valve = analog input)

Analog input is redirected directly to

Valve Out with the controller idle

22

valve safe state

See parameter Valve Safe State

IOStatus.

ETPOINT SLOPE

increased in time from old setpoint to new setpoint value. A value between 0 and 3000 seconds, with a resolution of

0.1 seconds, can be given to set the time for the integrator on the setpoint signal.

Setpoint will reach its end value after:

seconds

Sample; When slope = 10 seconds how long will it take to go from 20% to 80%?

seconds

Analog input signals (digitized) are in the same range as measured values (0...32000 = 0...100%).

This input can be used to give setpoint or slave factor, depending on the value of control mode.

2 FLOW-BUS slave

4 Controller idle

controlling is stopped / Valve Out

FLOW-BUS

10 Analog slave

13 FLOW-BUS analog slave

20

21

instrument on bus, slave factor is set

input * slave factor

analog input

FLOW-BUS *

analog input

Analog input= external input= pin 3 on DB 9 connector.

BUS = any available field bus

At power-up the control mode will be set by the jumper or dip switch setting on the PC-board of the instrument (only

for the control mode values 0, 1, 9 or 18). If the actual control mode is not equal to 0, 1, 9 or 18, it will not be

overruled by jumper or dip switch setting on the PC-board of the instrument. For more information see parameter

Page 18 Operational instructions for digital multibus instruments 9.17.023

analog input

BRONKHORST®

When operating a controller (reading measured value and sending setpoint) for proper operation it is important that

4.11 SLAVE FACTOR

float

0…500

RW

N

139

33/1

Depending on the Setpoint/control mode a slave factor can be set.

100%

factor slavealOutputsign

setpoint

(master)

(slave)

•

=

These options are available for FLOW-BUS or RS232 instruments only.

Slave factors can also be changed via RS232.

4.12 FLUID NUMBER

unsigned char

0…7

RW

N

24

1/16

Fluid number is a pointer to the set of calibration parameters. Each selectable fluid has its own set of calibration

4.13 F

unsigned char[10]

a…z / 0…9

RW Y

25

1/17

Fluid name consists of the name of the fluid of the actual selected fluid number. Up to 10 characters are available for

4.10.1 Dual interface operation

the controller gets its setpoint from the right source. Setpoints may come from different sources: analog input, field

bus interface, RS232 interface or may be overruled by close valve or open valve (purge) commands. Therefore it is

important to know what the setpoint source of the controller is. This can be set by means of parameter control mode

(DDE parameter 12).

In some cases it is possible that the setpoint may come from 2 sources at the same time. The last setpoint send will be

valid and send to the controller. This is the case in control mode = 0, when setpoints may come through any field bus

interface or RS232. However, there could be situations where control over the instrument seems impossible. This is

the case when the instrument comes into a safe-state e.g. when field bus communication is disturbed or disconnected.

The valve will be forced to a safe state automatically: closed (NC) or fully open (NO).

In case you want to get control back via RS232 operation, you have to change the control mode. When control mode

gets value 18, safe state will be overruled and sending setpoints via RS232 interface will have effect on the controller

again. ‘Control Mode’ value 18 will be lost after power off and power on of the instrument.

4.10.2 Tuning, test and calibration mode

These are special modes to prepare the instrument for either a tuning, test or calibration action. These modes are used

by Bronkhorst service personnel only and are not meant for customer use.

In master/slave or ratio control the setpoint of an instrument is related to the output signal of another instrument.

Digital instruments offer possibilities for master/slave control via the FLOW-BUS. The output value of any instrument

connected to the FLOW-BUS is automatically available to all other instruments (without extra wiring). When

master/slave control is wanted the instrument can be put in control mode 2 or 13, depending on how the slave factor

should be set (see table above). Through FLOW-BUS an instrument can be told that it should be a slave, who should be

its master (DDEpar. 158 ‘Master Node’) and what should be the slave factor to follow the master with. It is possible to

have more masters and more slaves in one system. A slave can also be a master itself for other instruments.

Output signals from master can be received via FLOW-BUS only.

Master/slave is meant here for controlling purposes and has nothing to do with master and slave behavior on field bus

networks.

parameter values. Fluid number is an unsigned char parameter (DDEpar. 24 ‘Fluid number’) in the range of 0...7, where

0 = fluid1 and 7 = fluid8. Up to 8 fluids can be stored in one instrument. Default value = 0 (fluid 1).

LUID NAME

storage of this name. This parameter is secured and read-only for normal users (it is written during calibration at the

factory). Default value is “Air”.

Page 19 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

4.14 V

unsigned long

0…16777215

RW Y

55

114/1

This parameter is the signal coming out of the controller, going to the DAC for driving the valve. 0...16777215

4.15 T

float

-250…500

RW

N

142

33/7

In MBC3 type of instruments the temperature surrounding the sensor is shown.

4.16 A

float

-3.40282E+38 …

3.40282E+38

R

N

270

116/15

This parameter shows the Actual Density measured by the (mini) CORI-FLOW. It is not used in other instruments.

4.17 S

unsigned char

0…255

RW Y

22

1/14

Unsigned char used to select proper set of units for certain sensor, together with Counter unit (MBC-II type).

Value

Description

Controller/Sensor

0

pressure (no counting allowed)

1

liquid volume

2

liquid/gas mass

3

gas volume

4

other sensor type (no counting allowed)

128

pressure (no counting allowed)

129

liquid volume

130

liquid/gas mass

131

gas volume

132

other sensor type (no counting allowed)

4.18 C

100%

float

1e-10…1e+10

RW Y

21

13

Capacity is the maximum value (span) at 100% for direct reading in readout units. The readout unit will be determined

4.19 CAPACITY 0%

float

1e-10…1e+10

RW Y

183

33/22

This is the capacity zero point (offset) for direct reading in readout units. The readout unit will be determined by the

ALVE OUTPUT

corresponds with approximately 0...300mAdc. Maximum output voltage is the supply voltage and therefore in practice

300 mAdc may not be reached.

EMPERATURE

For (mini) CORI-FLOW type of instruments this parameter shows the temperature of the tubes.

It is not used in other instruments.

CTUAL DENSITY

ENSOR TYPE

Default setting is 3.

APACITY

by the capacity unit index / string. For each fluid (number) capacity will be stored separately.

capacity unit index / string. For each fluid (number) capacity will be stored separately.

Controller

Sensor

Page 20 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

4.20 C

unsigned char

0…4

RW Y

23

1/15

capacity unit index (limited unit table)

0 1 2 3 4 5 6 7 8

9

0

bar

mbar

psi

kPa

cmH2O

cmHg

atm

kgf/cm2

1

l/min

ml/h

ml/min

l/h

mm3/s

cm3/min

2

kg/h

kg/min

kg/s

g/h

g/min

g/s

mg/h

mg/min

mg/s

3

ln/min

mln/h

mln/min

ln/h

m3n/h

mls/min

mls/h

ls/min

ls/h

m3s/h

4

usrtype

usrtype

usrtype

APACITY UNIT INDEX

This parameter gives access to the limited unit table which is available for MBC-II and MBC3 type of

instruments.

Capacity unit index is a pointer to select an actual readout unit (see list below). For FLOW-BUS instruments all capacity

units are available for direct reading. Other field busses (eg. DeviceNet) are limited in options for direct reading

facilities.

Sensor

Type

name description

sensor type Indicator for type of sensor in instrument in relation with a list of units for direct reading

capacity unit index Points to the capacity unit for direct reading in list of available units

Example:

If you want to readout your instrument in ln/min, then make sure parameter “sensor type” is set to value 3 and

parameter “capacity unit index” is set to value 0. By means of parameter “capacity unit” the unit string can be readback as a 7 character string.

Page 21 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

4.21 C

unsigned char[7]

see table

RW Y/N

129

1/31

For MBC3 type of instruments this parameter can be read and written.

table below in capacity unit.

Extended unit table

Pressure

A

mbar(a)

bar(a)

gf/cm2a

kgf/cma

psi(a)

torr(a)

Pa(a)

hPa(a)

kPa(a)

MPa(a)

atm(a)

mmH2O(a)

cmH2Oa

mH2O(a)

"H2O(a)

ftH2Oa

mmHg(a)

cmHg(a)

"Hg(a)

Pressure

G

mbar(g)

bar(g)

gf/cm2g

kgf/cmg

psi(g)

torr(g)

Pa(g)

hPa(g)

kPa(g)

MPa(g)

atm(g)

mmH2Og

cmH2Og

mH2O(g)

"H2O(g)

ftH2Og

mmHg(g)

cmHg(g)

"Hg(g)

D

mbar(d)

bar(d)

gf/cm2d

kgf/cmd

psi(d)

torr(d)

Pa(d)

hPa(d)

kPa(d)

MPa(d)

atm(d)

mmH2Od

cmH2Od

mH2O(d)

"H2O(d)

ftH2Od

mmHg(d)

cmHg(d)

"Hg(d)

ug/h

ug/min

ug/s

mg/h

mg/min

mg/s

g/h

g/min

g/s

kg/h

kg/min

kg/s

ul/h

ul/min

ul/s

ml/h

ml/min

ml/s

l/h

l/min

l/s

cc/h

cc/min

cc/s

mm3/h

mm3/m

mm3/s

cm3/h

cm3/min

cm3/s

m3/h

m3/min

m3/s

cfh

cfm

cfs

Normal

Flow

uln/h

uln/min

uln/s

mln/h

mln/min

mln/s

ln/h

ln/min

ln/s

ccn/h

ccn/min

ccn/s

mm3n/h

mm3n/m

mm3n/s

cm3n/h

cm3n/m

cm3n/s

m3n/h

m3n/min

m3n/s

scfh

scfm

scfs

sccm

slm

Standard

Flow

uls/h

uls/min

uls/s

mls/h

mls/min

mls/s

ls/h

ls/min

ls/s

ccs/h

ccs/min

ccs/s

mm3s/h

mm3s/m

mm3s/s

cm3s/h

cm3s/m

cm3s/s

m3s/h

m3s/min

m3s/s

APACITY UNIT

This parameter gives access to the extended unit table which is available for MBC3 type of instruments

only.

For MBC-II type of instruments this parameter can only be read.

Only if sensor type = 4 (other sensor type) this parameter can be written

The easiest way to change a unit in the MBC3 type of instrument is to fill in the unit needed from the

The “Capacity unit” displays the unit name set by “Capacity unit index”. A valid “Capacity unit”(for example ln/min) can

also be entered here which changes the “Capacity unit index”. In MBC3 type of instruments the parameter is not

secured.

Pressure

Mass Flow

(Custom)

Volume

Flow

Volume

Volume

Due to compatibility the maximum string length is limited to 7 characters. Therefore unit names may

be truncated. For instance mm3n/m means mm3n/min.

Page 22 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

Data Type

Range

read/write

Secured

DDE

Proc/par

5.1 PID-KP

float

0…1E+10

RW Y

167

114/21

PID controller response, proportional action, multiplication factor.

5.2 PID-TI

float

0…1E+10

RW Y

168

114/22

PID controller response, integration action in seconds.

5.3 PID-TD

float

0…1E+10

RW Y

169

114/23

PID controller response, differentiation action in seconds.

5.4 C

(Kspeed)

float

0…3.40282E+38

RW Y

254

114/30

This parameter is the controller speed factor. PID-Kp is multiplied by this factor.

5.5 OPEN FROM ZERO RESPONSE

unsigned char

0…255

RW Y

165

114/18

,

Zero) from Open(128

1.05*response oldresponse New

−

=

S

+

Sensor

Control Valve

Flow

Setpoint

P

I

D

+ + +

5 CONTROL PARAMETERS

The controlling algorithm for the valve handled by the micro-controller consists of several parameters which can be

set via the BUS/RS232. Although many parameters could be accessed via BUS/RS232, Bronkhorst advises not to

change these parameters because during manufacturing they have got optimal values for their purposes. Changing of

controller settings should be performed by or under supervision from trained service personnel only.

The picture below shows the basic controller diagram of the digital instrument. It consists of a standard PID controller

with a number of add-ons.

K

open

K

speed

Basically, when a faster or slower controller response is needed, only the controller speed (Kspeed) or PID-Kp has to

be changed.

Kp

K

normal

K

stable

ONTROLLER SPEED

Controller response when starting-up from 0% (K

Value 128 is default and means: no correction.

Otherwise controller speed will be adjusted as follows:

Kp multiplication factor when valve opens).

open

Page 23 Operational instructions for digital multibus instruments 9.17.023

5.6 N

ORMAL STEP RESPONSE

unsigned char

0…255

RW Y

72

114/5

,

Step) Normal(128

1.05*response oldresponse New

−

=

5.7 S

unsigned char

0…255

RW Y

141

114/17

,

response) Stable(128

1.05*response oldresponse New

−

=

5.8 S

float

0…1E+10

RW Y

51

1/12

Sensor time constant (upwards).

5.9 S

DOWN

float

0…1E+10

RW Y

50

1/11

Sensor time constant (downwards).

5.10 S

SMOOTHING FILTER

float

0…1

RW Y

74

117/4

This factor is used for filtering the signal coming from the sensor circuitry before it is further processed.

filter) exp. Sensor(1filter exp. SensorxY

00

−•+•=

1

y

Response

Factor setting

Slow

0.05

Normal

0.1

Fast

0.2

Very fast

0.5...1.0 (not advised)

Controller response during normal control (K

normal

TABLE RESPONSE

Controller response when controller is stable (K

ENSOR DIFFERENTIATOR UP

ENSOR DIFFERENTIATOR

BRONKHORST®

Kp multiplication factor at setpoint step)

Kp multiplication factor within band of 2%)

stable

ENSOR EXPONENTIAL

It filters according the following formula:

For EL-FLOW types of instruments it will be the “slow” (not differentiated), non-linearized sensor signal. Only in case of a

noisy sensor signal this value will have another value than 1.0. Advise: do not give a value much lower than 0.8, otherwise it

would slow down sensor response too much. Best setting: 1.0.

For (mini) CORI-FLOW instruments it will influence the amount of averaging of the “bare” values. The smaller this value

gets, the slower a (mini) CORI-FLOW instrument will get a sensor signal, but less noise will be on the signal.

This filter is in the control loop so it affects the response time.

Page 24 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

5.11 V

Unsigned char

0…255

RW

N

301

115/31

The controller module will go to a safe state in the following situations:

Decimal value

Description

0

Deactivate valve (0mA)

1

Activate valve (max current)

2

Close valve

3

Open valve

4

Hold valve in current position

5

Hold valve at safe value

If Initreset = 73 the fail safe state mode will always be “hold valve in current position”

“Hold valve at safe value” can only be used with DeviceNet instruments.

ALVE SAFE STATE

• If bus communication is lost and control mode = 0 (DeviceNet and PROFIBUS only)

• if initreset = 73

• if control mode = 22 (new safe state control mode)

In fail safe state the green LED will be blinking (0.1 s on, 2 sec off).

The valve will react to the fail safe state according to the table below.

Page 25 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

Alarm

mode 0..3

Alarm delay

time 0..255

Alarm new

Alarm setpoint

mode 0,1

Reset alarm

enable 0..15

80%

15%

Minimum alarm

limit 4800 = 15%

Maximum alarm

limit 25600 = 80%

Measure

0…32000

+3%

-4%

Minimum alarm limit

= 1280 = 4%

Maximum alarm

limit = 960 = 3%

Measure

0…32000

Setpoint

0…32000

Off

Power-up

Max

Min

Min

Max

Hardware

alarm

Master/

Slave alarm

Batch

counter limit

Warning

message

Error

message

+

Old Setpoint

Setpoint

Automatic

External

Keyboard/

Micro-switch

After Reset

alarm will still

during “Alarm

Reset

alarm

Setpoint

0…32000

bit[0]

bit[1]

bit[4]

bit[6]

bit[7]

Reset

Response

alarm

Min/Max

alarm

Alarm

info 0..7

Min. Alarm

Max. Alarm

Power-up

Response

bit[2]

bit[3]

bit[5]

bit[5]

bit[0]

bit[1]

bit[2]

bit[3]

Min/max

Response

Alarm must

External

Parameter

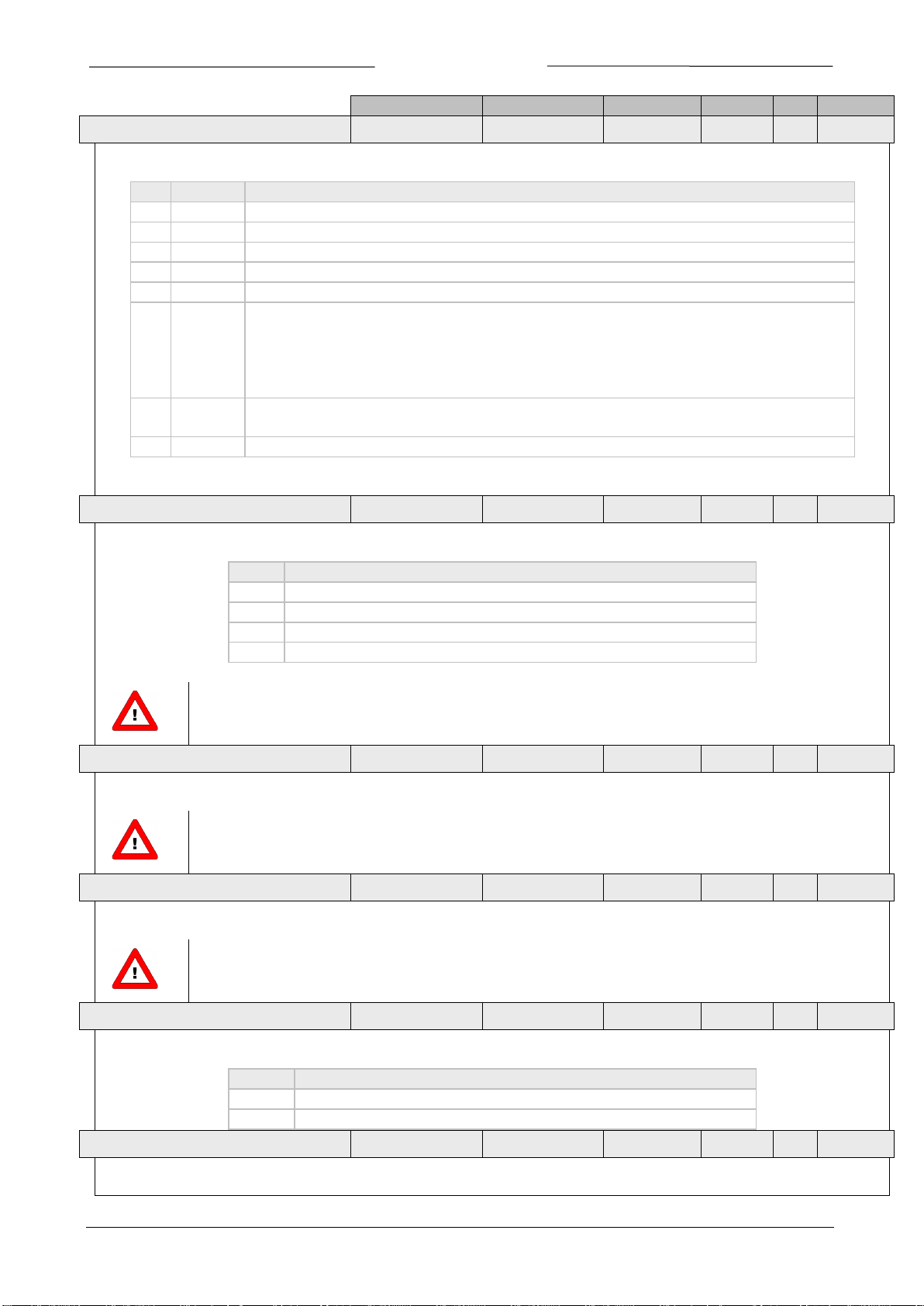

6 ALARM / STATUS PARAMETERS

6.1 GENERAL

Bronkhorst digital instruments have a build in alarm function. It is used to indicate several types of alarms:

• System errors

• System warnings

• Min/max alarms

• Response alarms

• Batch alarm

• Master slave alarms

The alarm can be read out using parameter alarm info. After an alarm a setpoint change can be set. This means the

setpoint will go to the set value after an alarm occurs. A delay can be set to prevent reaction to glitches in

measurement or power. How an alarm can be reset is controlled by the parameter “reset alarm enable”. It can bitwise be set to automatic, reset, external or keyboard/micro-switch. After the reset the alarm stays present during the

alarm delay time. In the functional schematic below the basic alarm function is explained.

6.2 FUNCTIONAL ALARM SCHEMATIC

be present

during

“Alarm

delay time“

before

activation

be present

delay time“

&

Page 26 Operational instructions for digital multibus instruments 9.17.023

setpoint 0…32000

BRONKHORST®

Data Type

Range

read/write

Secured

DDE

Proc/par

6.3 A

unsigned char

0…255

R

N

28

1/20

This parameter contains 8 bits with status information about some (alarm) events in the instrument.

Bit

low (0)

High (1)

0

no error

An error occurred: Alarm register 2 contains an error

1

no error

A warning occurred: Alarm register 1 contains a warning

2

no error

Minimum alarm: Sensor signal < minimum limit

3

no error

Maximum alarm: Sensor signal > maximum limit

4

no error

Batch counter: Reached its limit

5

no error

This bit only: Power-up alarm (probably power dip occurred)

(bit 2 or bit 3 indicate if difference is positive or negative)

6

no error

Master/slave alarm: master output signal not received or slave factor out of

limits (> 100%)

7

no error

Hardware alarm: check hardware

6.4 A

unsigned char

0…3

RW

N

118

97/3

Available alarm modes for device:

Bit

Description

0

Off 1 alarm on absolute limits

2

alarm on limits related to setpoint (response alarm)

3

alarm when instrument powers-up (e.g. after power-down)

6.5 A

unsigned int

0…32000

RW

N

116

97/1

Maximum limit for sensor signal to trigger alarm situation (after delay time).

6.6 A

unsigned int

0…32000

RW

N

117

97/2

Minimum limit for sensor signal to trigger alarm situation (after delay time).

6.7 A

unsigned char

0…1

RW

N

120

97/5

Available alarm setpoint modes for device:

Value

Description

0

no setpoint change at alarm

1

new/safe setpoint at alarm enabled (set at alarm new setpoint)

6.8 ALARM NEW SETPOINT

unsigned int

0…32000

RW

N

121

97/6

New/safe setpoint during alarm situation until reset.

LARM INFO

Together wit bit 2 or bit 3: Response alarm message

(setpoint-measure too much difference)

LARM MODE

Not all modes are available for all field busses. E.g. for DeviceNet only mode 0 and 1 are available.

LARM MAXIMUM LIMIT

Minimum limit ≤ Maximum limit ≤ 100%

LARM MINIMUM LIMIT

0% ≤ Minimum limit ≤ Maximum limit

LARM SETPOINT MODE

Page 27 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

6.9 A

unsigned char

0…255

RW

N

182

97/7

Time in seconds alarm action will be delayed when alarm limit has been exceeded.

6.10 RESET ALARM ENABLE

unsigned char

0…15

RW

N

156

97/9

Available alarm reset options:

Automatic

Reset

par 114

External*

Keyboard/

micro-switch

Value

bit[3]

bit[2]

bit[1]

bit[0]

0 0 0 0 0 1 0 0 0

1 2 0 0 1

0 3 0 0 1

1 4 0 1 0

0 5 0 1 0

1 6 0 1 1

0

7 0 1 1 1 8 1 0 0

0 9 1 0 0

1

10 1 0 1 0

11 1 0 1 1

12 1 1 0 0

13 1 1 0 1

14 1 1 1 0

15 1 1 1 1

6.11 STATUS

unsigned char

0…255

R

N

This parameter is a special byte for monitoring PROFIBUS communication. It contains 8 bits with information about certain

Bit

Low (0)

High (1)

0

no error in communication with channel

error in communication

1

no parameter process error

a parameter process error has occurred

2

no parameter error

a parameter error has occurred

3

no parameter type error

a parameter type error has occurred

4

no parameter value error

a parameter R value error has occurred

5

no error

a parameter process claim or command error has occurred

6

Reserved

7

Reserved

6.12 S

unsigned char

0…255

R

N

Index pointing to the first byte in the PROFIBUS output data for which the above status bits applies (only for PROFIBUS).

LARM DELAY TIME

Also time in second’s automatic reset will be delayed when sensor signal reaches safe level again.

*External is not used in MBC-II and MBC3 type instruments.

(alarm) events.

This parameter cannot be read via FlowDDE.

TATUS OUT POSITION

This parameter cannot be read via FlowDDE.

Page 28 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

Send following parameter values:

Action

Parameter

Value

Maximum alarm on 90%.

send to

Alarm maximum limit

28800

Minimum alarm on 10%.

send to

Alarm minimum limit

3200

No new setpoint wanted at crossing alarm limit.

send to

Alarm setpoint mode

0

Reset alarm enable *

12

Delay on action at output should be 10 seconds.

send to

Alarm delay time

10

Reset should be automatically, when signal

comes into safe area again or via FLOW-BUS.

send to

Alarm mode

1

Send following parameter values:

Action

Parameter

Value

Maximum alarm limit on setpoint + 3%.

send to

Alarm maximum limit

960

Minimum alarm limit on setpoint – 0.9%.

send to

Alarm minimum limit

288

send to

Alarm setpoint mode

1

send to

Alarm new setpoint

0 send to

Reset alarm enable *

5

Delay on action at output should be 2 minutes.

send to

Alarm delay time

120

Reset via keyboard or BUS/RS232.

send to

Alarm mode

2

6.13 USING AN ALARM (EXAMPLES)

Using the alarms will take three steps:

1. Preparing the instrument (setting correct values for mode, limits etc.)

2. Monitoring the alarm info byte (gives info which alarm has occurred)

3. Resetting the alarm (will re-initialize the alarm and set output to normal values again)

6.13.1 Using maximum and minimum alarm

This alarm will check if the measured signal crosses the maximum or minimum limit set by the user.

Example

*) Default all reset inputs are enabled, so this command isn’t really necessary

Now the alarm will be active.

Alarm status can be monitored by means of parameter alarm info.

Resetting the alarm will need the following command reset = 0 and then reset = 2.

To inactivate the alarm, put it in alarm mode “off”. This will also reset your outputs.

This can be done sending command: alarm mode = 0.

6.13.2 Using instrument with response alarm

This alarm will check if the measured value will come within an area limited by maximum limit and minimum limit,

related to the setpoint, within a certain delay-time.

Example

Setpoint wanted at crossing alarm limit = 0%.

*) Default all reset inputs are enabled, so this command isn’t really necessary

Now the alarm will be active.

Alarm status can be monitored by means of parameter alarm info.

Resetting the alarm will need the following command reset = 0 and then reset = 2.

To inactivate the alarm, put it in alarm mode “off”. This will also reset your outputs.

This can be done sending command: alarm mode = 0.

Page 29 Operational instructions for digital multibus instruments 9.17.023

7 COUNTER PARAMETERS

Data Type

Range

read/write

Secured

DDE

Proc/par

7.1 C

float

0…10000000

RW

N

122

104/1

Actual counter value in units selected at Counter unit. Value is a float in IEEE-754 32-bits single precision notation.

7.2 COUNTER MODE

Unsigned char

0…2

RW

N

130

104/8

Available counter modes for device:

Value

Description

0

Off 1 counting upwards continuously

2

counting up to limit (batch counter)

7.3 C

Unsigned char

0…1

RW

N

126

104/5

Setpoint change enable during counter limit/batch situation (until reset). Default = 0.

Value

Description

0

no setpoint change at batch limit allowed

1

setpoint change at batch limit allowed

Counter

mode 0..2

Counter new

setpoint 0…32000

Counter setpoint

Reset counter

enable 0..15

time

Measure

0…32000

time

Counter limit

Measure

0…32000

Off

Old Setpoint

Setpoint

Automatic

External

Keyboard/

Micro-switch

Reset

Reset

UP to limit

UP

bit[0]

bit[1]

bit[2]

bit[3]

Up

Up to limit

Parameter

Counter

value

Counter

value

BRONKHORST®

mode 0,1

counter

OUNTER VALUE

Default value = 0.

OUNTER SETPOINT MODE

&

Page 30 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

7.4 C

Unsigned int

0…32000

RW

N

127

104/6

New/safe setpoint at counter limit/batch situation (until reset). See measure for range.

7.5 COUNTER LIMIT

float

0…9999999

RW

N

124

104/3

Counter limit/batch in units selected at Counter unit. Value is a float in IEEE-754 32-bits single precision notation. Default

7.6 COUNTER UNIT INDEX

Unsigned char

0…13

RW

N

123

104/2

counter unit index table (limited unit table)

0 1 2 3 4 5 6 7 8 9 10

11

12

13

1 l mm3

ml

cm3

ul

m3 2 g

mg

ug

kg

3

ln

mm3n

mln

cm3n

uln

dm3n

m3n

uls

mm3s

mls

cm3s

ls

dm3s

m3s

nr

Sensor type

0

pressure (no counting allowed)

1

liquid volume

2

liquid/gas mass

3

gas volume

4

other sensor type (no counting allowed)

OUNTER NEW SETPOINT

Normally this value is set to 0%.

setting is 0 ln.

This parameter gives access to the limited unit table which is available for MBC-II and MBC3 type of

instruments.

Counter unit index is a pointer to select an actual readout unit (see list below).

Sensor

Type

Sensor type number explanation:

Page 31 Operational instructions for digital multibus instruments 9.17.023

BRONKHORST®

7.7 C

unsigned char[4]

string

RW

N

128

104/7

For MBC3 type of instruments this parameter can be read and written.

table below.

Extended counter unit table

Mass

ug

mg g kg

Custom volume

ul

ml l mm3

cm3

dm3

m3

Normal volume

uln

mln

ln

mm3n

cm3n

dm3n

m3n

Standard volume

uls

mls

ls

mm3s

cm3s

dm3s

m3s

7.8 RESET COUNTER ENABLE

Unsigned char

0…15

RW

N

157

104/9

Available counter reset options:

Automatic

Reset

par 114

External*

Keyboard/

micro-switch

Value

bit[3]

bit[2]

bit[1]

bit[0]

0 0 0 0 0

1 0 0 0 1 2 0 0 1

0

3 0 0 1 1 4 0 1 0

0 5 0 1 0

1

6 0 1 1 0 7 0 1 1

1

8 1 0 0 0 9 1 0 0

1

10 1 0 1 0

11 1 0 1 1

12 1 1 0 0

13 1 1 0 1

14 1 1 1 0

15 1 1 1 1

OUNTER UNIT