Instruction manual

Digital readout and

control system E-7000

for analog and digital

instruments

Doc. no.: 9.17.004N Date: 25-07-2011

ATTENTION

Please read this instruction manual carefully before installing and operating the instrument.

Not following the guidelines could result in personal injury and/or damage to the equipment.

BRONKHORST HIGH-TECH B.V.

BRONKHORST HIGH-TECH B.V.

Even though care has been taken in the preparation

and publication of the contents of this manual, we do

not assume legal or other liability for any inaccuracy,

mistake, mis-statement or any other error of

whatsoever nature contained herein. The material in

this manual is for information purposes only, and is

subject to change without notice.

Bronkhorst High-Tech B.V.

July 2011

Warranty

The products of Bronkhorst High-Tech B.V. are

warranteed against defects in material and

workmanship for a period of three years from the date

of shipment, provided they are used in accordance

with the ordering specifications and the instructions in

this manual and that they are not subjected to abuse,

physical damage or contamination.

Products that do not operate properly during this

period may be repaired or replaced at no charge.

Repairs are normally warranteed for one year or the

balance of the original warranty, whichever is the

longer.

See also paragraph 9 of the Conditions of sales.

The warranty includes all initial and latent defects,

random failures, and undeterminable internal causes.

It excludes failures and damage caused by the

customer, such as contamination, improper electrical

hook-up, physical shock etc.

Re-conditioning of products primarily returned for

warranty service that is partly or wholly judged nonwarranty may be charged for.

Bronkhorst High-Tech B.V. prepays outgoing freight

charges when any party of the service is performed

under warranty, unless otherwise agreed upon

beforehand.However, if the product has been returned

collect to Bronkhorst High-Tech B.V., these costs are

added to the repair invoice. Import and/or export

charges, foreign shipping methods/carriers are paid

for by the customer.

BRONKHORST HIGH-TECH B.V.

BRONKHORST HIGH-TECH B.V.

TABLE OF CONTENTS

1 Introduction

1.1 General description ............................................................................................................ page 7

1.2 Model configuration ............................................................................................................page 7

1.3 Power supply......................................................................................................................page 8

1.4 In/output signals ................................................................................................................. page 8

1.4.1 Rearpanel connectors ........................................................................................................ page 8

1.4.2 Connection to measuring and controlling devices.............................................................. page 9

1.4.3 Connection to remote equipment ....................................................................................... page 9

1.4.3.1 Analog input/output signals................................................................................................. page 10

1.4.3.2 Relay contacts....................................................................................................................page 10

1.4.3.3 Reset input ......................................................................................................................... page 10

1.4.4 Connection to FLOW-BUS................................................................................................. page 10

1.4.4.1 RJ45 connector .................................................................................................................. page 10

1.4.5 RS232/FLOW-BUS interface.............................................................................................. page 10

1.4.5.1 General description ............................................................................................................ page 10

1.4.6 EMC and cables ................................................................................................................. page 11

1.5 Specifications ..................................................................................................................... page 12

1.5.1 Housings............................................................................................................................. page 12

1.5.2 EMC and housings ............................................................................................................. page 14

1.5.3 Electrical specifications ...................................................................................................... page 14

2 Installation

2.1 General............................................................................................................................... page 15

2.1.1 Receipt of equipment.......................................................................................................... page 15

2.1.2 Return shipment................................................................................................................. page 15

2.1.3 Service................................................................................................................................ page 15

2.1.4 Installation........................................................................................................................... page 15

2.1.5 Configuration ...................................................................................................................... page 15

2.1.6 Equipment storage ............................................................................................................. page 15

3 Operation of analog instruments

3.1 General information............................................................................................................ page 17

3.2 Start-up menu..................................................................................................................... page 18

3.3 Measure menu.................................................................................................................... page 20

3.4 Operation menu.................................................................................................................. page 22

3.5 Reset menu........................................................................................................................ page 24

3.6 Counter menu..................................................................................................................... page 26

3.7 Alarm menu........................................................................................................................ page 28

3.8 Instrument menu ................................................................................................................ page 30

3.9 Local menu.........................................................................................................................page 32

3.10 FLOW-BUS menu .............................................................................................................. page 34

3.11 Calibration with polynomial functions.................................................................................. page 36

3.11.1 General information............................................................................................................page 36

3.11.2 General form....................................................................................................................... page 36

BRONKHORST HIGH-TECH B.V.

3.11.3 Polynomial functions of sensor signal and setpoint............................................................ page 36

3.11.4 Presentation of parameters ................................................................................................ page 37

3.11.5 Using polynomial functions at readout/control unit............................................................. page 37

4 Operation of digital (FLOW-BUS) instruments.............................................. page 39

4.1 General information............................................................................................................ page 39

4.2 Startup and menu selection................................................................................................ page 40

4.3 Measure menu.................................................................................................................... page 42

4.4 Operation menu.................................................................................................................. page 44

4.5 Reset menu........................................................................................................................ page 46

4.6 Counter menu..................................................................................................................... page 48

4.7 Alarm menu........................................................................................................................ page 50

4.8 Instrument menu ................................................................................................................ page 54

4.9 Local menu.........................................................................................................................page 58

4.10 FLOW-BUS menu .............................................................................................................. page 60

4.11 Calibration with polynomial functions.................................................................................. page 63

4.11.1 General information............................................................................................................page 63

4.11.2 General form....................................................................................................................... page 63

4.11.3 Polynomial functions of sensor signal and setpoint............................................................ page 63

4.11.4 Presentation of parameters ................................................................................................ page 63

4.11.5 Using polynomial at readout/control unit............................................................................. page 64

5 Maintenance ................................................................................................................. page 65

6 Troubleshooting......................................................................................................... page 66

Appendices

1 System specific sections (if applicable)

2 Customer system description (if applicable)

BRONKHORST HIGH-TECH B.V.

1 INTRODUCTION

1.1 General description

The Bronkhorst High-Tech B.V. serie E-7000 is a modular digital readout and control system for (analog)

mass flow/pressure sensors and controllers. Basically a system consists of one or more (14 TE) single

channel readout/control modules.

The system can be expanded with additional (14 TE) modules like Ex-proof and heatercontrol for evaporator

systems. (For operation of any of these special functions the appropriate additional manuals should be

consulted).

1.2 Model configuration

(A)

E - 7 N N 0 - NN - NN - NN ..... etc.

Housing Code

½ 19" table top (42 TE)

19" table top (84 TE)

½ 19" rack (42 TE)

19" rack (84 TE)

Table top cassette (14 TE)

Panel mount casset t e (14 TE)

Other/Specifiy

Supply voltage Code

100 ... 240 Vac

220 ... 240 Vac

110 ... 120 Vac

24 Vac

24 Vdc

Other/Specify

Modules with blind front (14 TE) Code

Blind front only

Blind front + power supply (linked to module with mains entrance)

Blind front + power supply + mains ent rance + flow bus (incl. cable)

Blind front + power supply + RJ45 connect or for +15Vdc supply voltage

+ mains entrance (incl. cable)

Blind front + power supply + RJ45 connect or for +15Vdc supply voltage

( linked to module with mai ns entrance)

Modules with single channel Readout/Control panel (14 TE) Code

R/C-panel + power supply + mains entrance (incl. cable) analog model

R/C-panel + power supply (linked to module with mains entrance) analog model

R/C-panel (linked to module with power supply) analog model

R/C-panel + power supply + mains entrance (incl. Cable) digital model

R/C-panel + power supply (linked to module with main entrance) digital m odel

R/C-panel (linked to module with power supply) di gi tal model

Modules with Ex-proof functions (14 TE) Code

R/C-panel + transmitt er supply unit for MFM/EPT (Ex-proof)

R/C-panel + supply for MFM/EPT (Ex-proof) + valve with XB-coil

R/C-panel + supply for MFM/EPT (Ex-proof) + valve with XC-coil

Blind front + transmi tter supply unit for MFM/EPT (E x-proof)

Blind front + supply for MFM/EP T (Ex-proof) + valve with XB-coil

Blind front + supply for MFM/EP T (Ex-proof) + valve with XC-coil

Modules for temperature control for CEM-systems (14 TE) Code

Temp. R/C-panel + 10 W supply for low capacity CEM-sys t em

Temp. R/C-panel + 100 W supply for medium capacity CEM-system

Temp. R/C-panel + excl. supply f or hi gh capacity CEM-system

Temp. R/C-panel + 1000W supply / 230Vac W-303

Temp. R/C-panel + 1000W supply / 120Vac operation for W-303

Blind front + FLOW-BUS/RS232 interface

Blind front + FLOW-B US/PROFIBUS-DP interface

None

Other/Specify

1

2

3

4

5

6

9

0

1

2

3

4

9

(B) (C)

Modules

to be mounted in the

selected housing;

mounting order from

left to right

01

03

04

05

06

10

11

12

13

14

15

20

21

22

23

24

25

33

34

35

36

37

40

41

00

99

9.17.004 page 7

BRONKHORST HIGH-TECH B.V.

c

PE:ground

P

E

Code for external output/input signals :

Sensor output signal Code

0 - 5 Vdc

0 - 10 Vdc

0 - 20 mA dc (Sinking)

4 - 20 mA dc (Sinking)

15 - 20 mA dc

0 - 20 mA (Sourcing)

4 - 20 mA (Sourcing)

FLOW-BUS

Other/Specify

Module output signal Code

0 - 5 Vdc

0 - 10 Vdc

0 - 20 mA (Sourcing)

4 - 20 mA (Sourcing)

Other/Specify

Ext. setpoint/Module input si gnal Code

0 - 5 Vdc

0 - 10 Vdc

0 - 20 mA (Sinking input)

4 - 20 mA (Sinking input)

Other/Specify

A

B

C

D

E

F

G

R

Z

A

B

C

D

Z

A

B

C

D

Z

N N - A A A

Module

(see page 7)

1.3 Power supply

Each E-7000 series housing incorporates one or two power supplies.

System setup is such that the instruments that belong to the sytem can be powered.

For other applications or modifications your supplier should be consulted. The power input incorporates an

on/off switch and a fuse. For extra protection each power supply has a separate internal fuse.

1.4 In/output signals

If applicable, connection of cables carrying in- or/and output signals is further explained in the customer

system description (see appendices).

1.4.1 Rear panel connectors

for analog instruments:

FLOWBUS

INSTR

IN/OUT

3

1

2

1: +24Vdc/24 Va

2: 0Vdc/24 Vac

3: not connected

page 8 9.17.004

BRONKHORST HIGH-TECH B.V.

c

PE:ground

P

E

for digital instruments (FLOW-BUS):

FLOW-BUS

IN/OUT

IN/OUT

FLOW-BUS

3

IN/OUT

1: +24 Vdc/24 Va

2: 0 Vdc/24 Vac

3: not connected

2

1

1.4.2 Connection to measuring and controlling devices

The instrument connector (2) is a female sub-miniature 9-pin D-connector. The pin designation is according

to the Bronkhorst High-Tech B.V. standard for analog

instruments.

pinnumber description

1

2

3

4

5

6

7

8

9

not connected

sensor signal

setpoint signal

0 V valve

+ valve

- 15 Vdc supply

+ 15 Vdc supply

0 V/Common

ground (shield)

Sensor- and setpointsignals are also according to one of the Bronkhorst High-Tech B.V. standards.

signal

type sensor setpoint

A

0 - 5 Vdc

B

0 - 10 Vdc

C

0 - 20 mA (sinking)

D

4 - 20 mA (sinking)

F

0 - 20 mA (sourcing)

G

4 - 20 mA (sourcing)

0 - 5 Vdc

0 - 10 Vdc

0 - 5 Vdc

1 - 5 Vdc

0 - 20 mA

4 - 20 mA

1.4.3 Connection to remote equipment

The female in/out (1) (sub-miniature 9-pin) D-connector has the following pin configuration:

pinnumber description

1

2

3

4

5

6

7

8

9

output signal

input signal

0 V (common)

not connected

relay contact MC

relay contact NO

relay contact NC

reset input

ground (shield)

9.17.004 page 9

BRONKHORST HIGH-TECH B.V.

1.4.3.1 Analog input/output signals

Analog input signals should be connected to pin 2 (+) and 0 V/common.

Analog ouput signals are available at pin 1 (+) and 0 V/common.

Signals are according to one of the Bronkhorst High-Tech B.V. standards. The model configuration contains

a code, describing the input/output signals.

Notes:

a. Max. load current output (sourcing) : 375 Ohm

b. Min. load voltage ouput : 10 kOhm

c. Input load resistance (voltage) : 22K4

d. Input load resistance (current) (sinking) : 200 Ohm

e. Input load resistance (current) (sourcing) : 250 Ohm

1.4.3.2 Relay contacts

The (isolated) relay contacts are available at the following pins:

pin 5: common

pin 6: normally open

pin 7: normally closed

Note: contact arrangement during "power on"/"no alarm".

The specifications of the relay contacts are:

Contact arrangement : SPCO (Single Pole Changeover)

Contact rating : Switch voltage : 24 Vac/dc max.

Switch current : 0,2 A ac/dc max.

Switch power : 3 W/3 VA max.

1.4.3.3 Reset input

The reset input signal should be connected to pin 8 (+ V) and pin 3 (0 V/common).

Reset can be achieved by either pulling the + V input (pin 8) to 0 V (pin 3) by means of a contact or a

transistor, or by applying an active low logic signal to pin 8 (+ V) and pin 3 (0 V). The logic signal level should

be 5 V (high) or 0 V (low).

1.4.4 Connection to FLOW-BUS

1.4.4.1 RJ45 connector

The shielded RJ45 modular jack connector has the following pin configuration:

pinnumber description

1

2

3

4

5

6

7

8

+ 15 Vdc supply

0 V (ref to +15Vdc )

Shield

0 V (ref to +15Vdc )

+ 15 Vdc supply

0 V (RS485)

RS485 - B

RS485 - A

1.4.5 RS232/FLOW-BUS interface

1.4.5.1 General description

The RS232/FLOW-BUS interface is an interface between the FLOW-BUS and the RS232 V24 serial

(computer) port.

It will either be supplied as a separate enclosed unit with a FLOW-BUS connector and a RS232 connector or

as an integral 14TE module of your E-7000 readout and control system.

The converter offers communication with a baudrate up to 38,4 kbaud.

Communication software support is available. Consult manual RS232/Flow-Bus interface.

page 10 9.17.004

BRONKHORST HIGH-TECH B.V.

e

1.4.6 EMC and cables

All system setups described in this manual carry the CE-mark.

Therefore they have to comply with the EMC requirements as are valid for this kind of equipment.

However compliance with the EMC requirements is not possible without the use of proper cables and

connector assemblies.

For good results Bronkhorst High-Tech B.V. can provide standard cables. Otherwise follow the guidelines as

stated below. For cables with 9-pin sub D-connectors:

Fold the shield of the cable back over the cable (the shield must be around the cable).

20 mm

Wind a copper tape around the shield

Solder a black wire on the tape and

Connect to pin 9 of connector

copper tape

shielded cable

.g. LAPP LiYCY

8 mm

other wires

black wire

D-connector housing

metalized

connector

(shield)

NOTE:

For FLOW-BUS SFTP data (patch)cable connection to RJ45 connectors follow the instructions of the

supplier. It is important to use shielded twisted pair cables and shielded RJ45 modular jack connectors.

In case the system is electrically connected to another device (e.g. I/O connector to PLC), use shielded

cables.

Be sure not to disturb the integrity of the shielding of the cable, never use open wire terminals.

9.17.004 page 11

1.5 Specifications

1.5.1 Housings

½ 19" table top (42TE)

BRONKHORST HIGH-TECH B.V.

213.4 mm

235.4 mm

19" table top (84TE)

426.8 mm

448.8 mm

m

m

m

m

5

5

.

.

2

2

3

1

1

1

213.4 mm

m

m

m

m

5

5

.

.

2

2

3

1

1

1

m

m

m

m

5

5

.

.

2

8

3

3

2

2

238.5 mm

238.5 mm

m

m

m

m

5

.

0

2

4

3

1

1

m

m

m

m

5

.

0

2

4

3

1

1

426.8 mm

½19" rack mount (42TE)

213.4 mm

235.4 mm

m

m

m

m

5

5

.

.

2

8

3

3

2

2

m

m

m

m

5

5

.

.

2

2

3

1

1

1

213.4 mm

m

m

m

m

5

5

.

.

2

8

3

3

2

2

282.5

m

m

5

.

2

3

1

page 12 9.17.004

19" rack mount (84TE)

426.8 mm

448.8 mm

BRONKHORST HIGH-TECH B.V.

m

m

m

m

5

5

.

.

2

2

3

1

1

1

m

m

m

m

5

5

.

.

2

8

3

3

2

2

282.5

m

m

5

.

2

3

1

426.8 mm

table top cassette (14TE)

m

m

E

H

4

.

3

3

3

1

14 TE

76 mm

m

m

0

6

2

panel mount cassette(96x144mm for 14TE module)

90mm

m

m

5

.

3

3

m

1

m

0

3

2

14TE

96mm

E

4

H

4

1

3

230mm

233mm

m

m

4

.

3

3

1

260 mm

m

m

4

4

1

+0.8

92 mm

PANEL CUT OUT

m

m

0

.

1

+

8

3

1

96mm

9.17.004 page 13

BRONKHORST HIGH-TECH B.V.

1.5.2 EMC and housing

All electronic circuits and modules have been designed to meet the requirements needed to carry the

CE-mark.

However compliance with the (EMC) requirements is not possible without the use of properly

screened housings.

1.5.3 Electrical specifications

Input: see model configuration for input voltage

Supply voltage: 100 ... 240 Vac : 50 ... 60 Hz

220 ... 240 Vac : 50 ... 60 Hz

110 ... 120 Vac : 50 ... 60 Hz

24 Vac : ± 5 %/50 ... 60 Hz

24 Vdc : ± 5 %

Outputs of one power supply:

Mains powered and : + 15 Vdc/2A

24 Vac/dc powered - 15 Vdc/0,5A

+ 5 Vdc/1A nominal 30W

Temperature

Operating range : 0 ... + 50°C

Storage range : - 20 ... + 60°C

Fuse : consult system label

Note :

Never block ventilation holes.

Operation at high ambient temperatures over extended periods may lead to reduction of the operating

lifetime of your power supply / readout system

page 14 9.17.004

BRONKHORST HIGH-TECH B.V.

2 INSTALLATION

2.1 General

2.1.1 Receipt of equipment

Check the outside packing for damage incurred during shipment.

Should the packing box be damaged, then the local carrier must be notified at once regarding his liability, if

so required.

At the same time a report should be submitted to

BRONKHORST HIGH-TECH B.V.

RUURLO HOLLAND

Remove the envelope containing the packing list; carefully remove the equipment from the packing box.

Do not discard spare or replacement parts with the packing material and inspect the contents for damaged or

missing parts.

2.1.2 Return shipment

When returning material always describe problem and if possible the work to be done in a covering letter.

Important:

Do clearly note, on top of the package the custom clearance number of Bronkhorst High-Tech B.V.,

namely:

NL801989978B01

2.1.3 Service

If this equipment is not properly serviced, serious personal injury and/or damage to the equipment could

result. It is therefore important that servicing is performed by trained and qualified service personnel.

Bronkhorst High-Tech B.V. has a trained staff of servicemen available.

2.1.4 Installation

Before switching on power, please check if all external electrical connections with sensor/controllers and

FLOW-BUS (if necessary) are properly connected (consult Customers System Description).

If you receive a readout unit including sensor/controllers, the total system has been tested in full operation

under the nearest process-conditions.

For the electrical connection between sensor/controller and readout unit it is recommended to use the

standard Bronkhorst HI-TEC cable, which is an eight conductor shielded cable, complete with connectors.

2.1.5 Configuration

All readout and control modules are factory set, for the used Bronkhorst High-Tech sensors/controllers, as

described in your customer system description (see appendices).

2.1.6 Equipment storage

The equipment should be stored in its original packing in a cupboard warehouse or similar. Care should be

taken not to subject the equipment to excessive temperatures or humidity.

9.17.004 page 15

BRONKHORST HIGH-TECH B.V.

page 16 9.17.004

BRONKHORST HIGH-TECH B.V.

3 Operation of analog instruments

3.1 General information

Before operating your sytem be sure that it is setup to readout and control analog instruments.

Check: Model configuration; sensor output signal.

Use 'cursor' keys to scroll through the menu-structure and to select the required menu level.

The 'enter' key is used to acknowledge a selected setting and to enter a edited value and/or text.

Editing can be performed by using the 'cursor' keys to select the character to be edited ( ← / → ) and to scroll

through the available character set or units ( ↑ / ↓ ).

After power-up the display will show the usual start-up sequence for some seconds.

FLOW-BUS

analog instrument

9.17.004 page 17

BRONKHORST HIGH-TECH B.V.

3.2 Startup and menu selection

(8000 0000)

FLOW-BUS MENU

(7000 0000)

LOCAL MENU

(6000 0000)

INSTRUMENT MENU

ALARM MENU

COUNTER MENU

RESET MENU

(5000 0000)

(4000 0000)

(3000 0000)

(2000 0000)

OPERATION MENU

(0000 0000)

Loading

Parameters ...

Bronkhorst Hi-Tec

(0001 0000)

Checking flowbus

Please wait ...

(0002 0000)

(0003 0000)

SINGLE CHANNEL

STYLE D Vx.xx

MEASURE MENU

(1000 0000)

page 18 9.17.004

BRONKHORST HIGH-TECH B.V.

Menu descriptions

0001 0000 Startup screen showing company name

0002 0000 Startup screen showing communication check with FLOW-BUS in progress. Takes a short time

(few seconds), depending on system size. If the FLOW-BUS address of the module is occupied,

you can reinstall the module on a new address.

0003 0000 Startup screen showing software revision level

1000 0000 Measure menu or ‘Readout Display’ for reading the amount of flow/pressure, setpoint and/or

counter value. When there is an alarm- or counter limit reached it will be shown here. For editing

the setpoint/slave factor go down one level.

2000 0000 Operation menu for selecting setpoint source (and master/slave), fluidset and setpoint slope for

the device to be operated. Also for editing setpoint offset.

3000 0000 Reset menu for quick reset of counter and alarm by keyboard. Also password input location to

enable advanced use of this module.

4000 0000 Counter menu for configuration of all counter options. This menu is secured by means of a

password.

5000 0000 Alarm menu for configuration of all alarm options. This menu is secured by means of a

password.

6000 0000 Instrument menu for configuration of the instrument to be operated, such as instrument type,

capacity, sensor type, identification and fluid sets with calibration values. This menu is secured

by means of a password.

7000 0000 Readout menu for configuration of the measure menu. You can select the wanted information for

your display.

8000 0000 FLOW-BUS menu to install module on the FLOW-BUS or start/stop communication with the bus.

This menu is secured by means of a password.

9.17.004 page 19

3.3 Measure menu

BRONKHORST HIGH-TECH B.V.

(1200 0000)

EDIT SETPOINT:

xxx.xx (cursor)

MEASURE MENU

(1000 0000)

(1100 0000)

EDIT SETPOINT:

xxx.xx (step)

(1400 0000)

CHANGE SETPOINT:

SETPOINT ZERO

(1300 0000)

CHANGE SETPOINT:

SETPOINT FULL

page 20 9.17.004

BRONKHORST HIGH-TECH B.V.

Menu descriptions

1100 0000 Stepsize editor for editing setpoint/slave-factor by a 0.1% step up or down. By holding down

UP/DOWN key continuously, the step size will increase. Changes are used by the controller

immediately. What is displayed here in this menu depends on the selection of the setpoint

source. Analog setpoints can not be edited.

1200 0000 Cursor editor for editing setpoint/slave-factor by entering the exact (new) value. After pressing

'enter', the changes will be used by the controller. Could be used for large setpoint steps. What is

displayed here in this menu depends on the selection of the setpoint source. Analog setpoints

can not be edited.

1300 0000 Setpoint full. After pressing 'enter', setpoint for controller will be 100% unconditionally (controller

valve will be opened in almost all situations).

1400 0000 Setpoint zero. After pressing 'enter', setpoint for controller will be zero unconditionally (controller

valve will be closed in almost all situations). You will return to the readout display now. Setpoint

will not respond to selected source again until 'enter' has been pressed in menu 1000.

NOTE:

Measured values could be readout up to 110.0%.

Sensor signals > 110.0% will be cut-off.

Setpoint can be entered up to 100.0%. However, setpoint signals can, just like sensor signals, be

corrected by means of polynomial calculation.

Also you can use setpoint offset correction to eliminate cable offsets in your system (see

operation menu).

9.17.004 page 21

3.4 Operation menu

BRONKHORST HIGH-TECH B.V.

(2180 0000)

CONTROL MODE

SETPOINT 0%

(2170 0000)

CONTROL MODE

SETPOINT 100%

OPERATION MENU

(2400 0000)

SETPOINT OFFSET

(2300 0000)

OFFSET CORRECT.

SETPOINT ZERO

(2410 0000)

(2310 0000)

OFFSET CORRECT.

VALUE: xxx.x %

(2411 0000)

CONTROL MODE

CONTROL MODE

CONTROL MODE

FB, ANALOG SLAVE

FLOW-BUS SLAVE

FLOW-BUS

(2160 0000)

MASTER: xxxxxxx

xxxxxxxxxxxxxxxx

(2150 0000)

MASTER: xxxxxxx

xxxxxxxxxxxxxxxx

(2140 0000)

(2130 0000)

(2161 0000)

(2151 0000)

OPERATION MENU

SETPOINT SLOPE

EDIT SLOPE

OPERATION MENU

(2000 0000)

OPERATION MENU

OPERATION MENU

FLUIDSET [nr]

CONTROL MODE

(2200 0000)

(2100 0000)

FLUIDSET SELECT

TIME: xxxx.x Sec

(2210 0000)

NR: x (edit)

CONTROL MODE

CONTROL MODE

CONTROL MODE

ANALOG SLAVE

(2120 0000)

ANALOG INPUT

(2110 0000)

KEYB. & FLOW-BUS

page 22 9.17.004

BRONKHORST HIGH-TECH B.V.

Menu descriptions

2100 0000 Operation mode. Here you can change the source of the setpoint for the operating instrument

2110 0000 This option selects a setpoint change with the keyboard or by means of a FLOW-BUS device

(operation module or Personal Computer).

2120 0000 This option selects a setpoint change coming from an analog input.

2130 0000 This option selects a setpoint change coming from an analog input, multiplied by a slave-factor

(analog master/slave).

2140 0000 This option selects a setpoint change by means of a FLOW-BUS device (operation module or

Personal Computer).

2150 0000 This option selects a setpoint change coming from an output signal of a master device, via

FLOW-BUS, multiplied by a slave-factor (FLOW-BUS master-slave).

2151 0000 Choose a master channel. With LEFT/RIGHT you can search for the master device on the

FLOW-BUS. Your instrument module will be slave.

Each time a possible master device has been found on the bus, the type and identification

number will be displayed. When ‘----‘ is displayed, this means that no master could be found.

With UP you can stop the search, and with 'enter' you select the currently displayed device.

Slave factor must be entered at the position where setpoint is normally entered

2160 0000 This option selects a setpoint change coming from an output signal of a master device, via

FLOW-BUS, multiplied by a slave-factor (FLOW-BUS master-slave), coming from an analog

input.

2161 0000 Choose a master channel. With LEFT/RIGHT you can search for the master device on the

FLOW-BUS. Your instrument module will be slave.

Each time a possible master device has been found on the bus, the type and identification

number will be displayed. When ‘----‘ is displayed, this means that no master could be found.

With UP you can stop the search, and with 'enter' you select the currently displayed device.

Slave factor must be entered at the position where setpoint is normally entered

2170 0000 This function sets a setpoint of 100%

2180 0000 This function sets a setpoint of 0%

2200 0000 Fluidset selection. Here you can change the actual fluidset. Your current settings will be saved

and the settings of the selected fluidset will become the new active settings for your instrument.

When fluidset changes, the instrument will use the calibration settings in the memory for sensor

signal/setpoint adjustments for that fluid.

2210 0000 Select the active fluidset by selecting a number from 1 to 8. Settings will be active after pressing

'enter'. This is for selection fluidsets only. For changing fluid calibration settings use Instrument

menu.

2300 0000 Setpoint Slope. Here you can enter a setpoint slope for this device. When the setpoint has been

changed and not overruled by counter limit or an alarm, the setpoint will (smoothly) increase to

the set value.

2310 0000 Edit the setpoint slope time.This is the time it will take for the setpoint value to increase from 0%

to 100% (and vice versa). The value can be entered from 0...3000.0 seconds.

2400 0000 Setpoint offset correction. Here you can enter a setpoint offset. This could be used to remove

cable offsets.

2411 0000 Edit setpoint zero offset. A value can be entered from -2.5%...+2.5%.

9.17.004 page 23

3.5 Reset menu

BRONKHORST HIGH-TECH B.V.

(3300 0000)

RESET MENU

PASSWORD

(3200 0000)

RESET MENU

RESET COUNTER

(3000 0000)

RESET MENU

(3100 0000)

RESET MENU

RESET ALARM

(3310 0000)

PASSWORD:

_

(3220 0000)

RESET COUNTER?

YES

(3210 0000)

RESET COUNTER?

NO

(3120 0000)

RESET ALARM?

YES

(3110 0000)

RESET ALARM?

NO

page 24 9.17.004

BRONKHORST HIGH-TECH B.V.

Menu descriptions

3100 0000 Reset Alarm.

Here you can reset an alarm if it is active. This will result in removing the alarm situation defined

to take place at the potential free contact and/or at the (temporary) alarm setpoint. If the alarm

condition is still present, the alarm will activate again after a few seconds until alarm condition is

removed (flow/pressure input signal into save area again) or when alarm mode will be changed.

3200 0000 Reset Counter.

Here you can reset the counter. This will result in setting the counter to value 0 and evt. removing

the alarm situation defined to take place at the potential free contact and/or at the (temporary)

alarm setpoint. Counter will proceed when counting mode has not been changed.

3300 0000 Password input location.

Here you can enter a password to be allowed to edit the counter, alarm, instrument and FLOW-

BUS configurations. The password consists of 5 characters and can not be changed. Cursor can

be controlled with LEFT/RIGHT keys. Characters can be selected with UP/DOWN keys. When

password has been entered correctly, you have access to all menu's and it is possible to change

settings for an instrument. Without password input it is only possible to operate an instrument.

Password will be erased and access to settings-menu's will be denied when:

1) Module has been switched-off and on again (at power-up).

2) A wrong password has been entered.

3) Automatically after 3 minutes when no key has been pressed.

Password is: ABABC and can not be changed.

9.17.004 page 25

3.6 Counter menu

BRONKHORST HIGH-TECH B.V.

SETP. AT LIMIT:

NEW SETPOINT

(4600 0000)

COUNTER MENU

LIMIT SETPOINT

SETP.AT LIMIT:

NO CHANGE

(4500 0000)

COUNTER MENU

RELAY

(4400 0000)

(4620 0000)

COUNTER LIMIT

SETP: xxx.xx%

(4610 0000)

(4410 0000)

(4621 0000)

COUNTER RELAY:

CONTINUOUS

COUNTER RELAY:

PULSE

COUNTER RELAY:

OFF

(4230 0000)

(4530 0000)

(4520 0000)

(4510 0000)

(4140 0000)

(4141 0000)

COUNTER MENU

LIMIT

COUNTER MENU

UNIT

COUNTER MENU

MODE

(4000 0000)

COUNTER MENU

COUNTER MENU

RESET

CNTR LIMIT COUNT

xxxxxxx.x [unit]

(4300 0000)

(4200 0000)

(4100 0000)

(4310 0000)

EDIT CNTR UNIT:

_

COUNTER MODE:

UP TO LIMIT

(4220 0000)

COUNTER MODE:

UP

(4210 0000)

COUNTER MODE:

OFF

RESET COUNTER

AUTO

RESET COUNTER

AUTO:EN/DIS

(4130 0000)

RESET COUNTER

FLOW-BUS

RESET COUNTER

FB: En-/Disabeld

(4120 0000)

RESET COUNTER

EXTERNAL

RESET COUNTER

EXT: En-/Disable

(4110 0000)

RESET COUNTER

KEYBOARD

RESET COUNTER

KEYB: En-/Disabled

(4131 0000)

(4121 0000)

(4111 0000)

page 26 9.17.004

BRONKHORST HIGH-TECH B.V.

Menu descriptions

4100 0000 Counter Reset Enable.

Here you can enter how the counter may be reset.

4110 0000 Keyboard Reset. Here you can enable/disable a counter reset by the keyboard.

4120 0000 External Reset. Here you can enable/disable a counter reset by an external signal.

4130 0000 FLOW-BUS Reset. Here you can enable/disable a counter reset via the FLOW-BUS by means of

f.i. a Personal Computer.

4140 0000 When the counter unit is reached, the counter is reset.

4200 0000 Counter Mode.

Here you can select how the counter must behave.

4210 0000 This option will disable the counter.

4220 0000 This option will let the counter count-up*.

4230 0000 This option will let the counter count-up, and check if a limit has been reached.

4300 0000 Edit Counter Unit.

Here you can change the unit for the counter to display the counter value.

4310 0000 Counter Unit Editor.

With UP/DOWN you can change the unit to be counted with.

4400 0000 Edit Counter Limit.

Here you can edit at which value the counter will reach its limit.

4410 0000 Counter Limit Editor.

With UP/DOWN you can change the number at the cursor, and with LEFT/RIGHT you go to

another cursor position.

4500 0000 Relay At Limit.

Here you can enter what you want the relay to do when a limit has been reached.

4510 0000 This option will disable a relay action at a counter limit.

4520 0000 This option will let the relay pulse at a counter limit.

4530 0000 This option will let the relay be continuously on at a counter limit.

4600 0000 Limit Setpoint.

Here you can configure what to do with the setpoint at a limit. You can make the setpoint go to a

predefined value temporarily until reset situation.

4610 0000 This option wil not change the setpoint.

4620 0000 This option will change the setpoint to the entered value.

4621 0000 Setpoint At Counter Limit Editor.

Here you can enter the setpoint value to be active until reset.

NOTE:

Counter will be disabled when sensor type of instrument is set on either ‘Pressure’ or ‘Other’.

in COUNTER MENU RELAY the relay is turned on (pulse or continuous) Every time the

* If

limit or its multiple is reached, a pulse is given.

9.17.004 page 27

BRONKHORST HIGH-TECH B.V.

3.7 Alarm menu

(5520 0000)

SETP. AT LIMIT:

NEW SETPOINT

(5510 0000)

SETP. AT ALARM:

NO CHANGE

(5320 0000)

ALARM DELAY

TIME: 003 SEC

ALARM MENU

SETPOINT

ALARM MENU

RELAY

(5610 0000)

(5500 0000)

(5400 0000)

(5600 0000)

ALARM MENU

DELAY

(5521 0000)

ALARM SETPOINT:

SETP: xxx.xx%

(5321 0000)

ALARM RELAY:

ALARM RELAY:

ALARM RELAY:

CONTINUOUS

PULSE

OFF

(5430 0000)

(5420 0000)

(5410 0000)

(5240 0000)

ALARM MODE

POWER-UP ALARM

(5230 0000)

(5140 0000)

(5141 0000)

ALARM LIMIT

MAXIMUM LEVEL

MAXIMUM LIMIT:

xxx.xx%

(5300 0000)

ALARM MENU

LIMIT

(5200 0000)

ALARM MENU

MODE

(5000 0000)

ALARM MENU

ALARM MENU

(5100 0000)

RESET

ALARM LIMIT

MINIMUM LEVEL

(5310 0000)

(5311 0000)

MINIMUM LIMIT:

xxx.xx%

ALARM MODE

RESPONSE ALARM

(5220 0000)

ALARM MODE

ON

(5210 0000)

ALARM MODE:

OFF

RESET ALARM

AUTO

RESET ALARM

AUTO:En-/Disable

(5130 0000)

RESET ALARM

FLOW-BUS

(5120 0000)

RESET ALARM

EXTERNAL

(5110 0000)

RESET ALARM

KEYBOARD

RESET ALARM

RESET ALARM

RESET ALARM

FB:En-/Disable

EXT:En-/Disable

KEYB:En-/Disable

(5131 0000)

(5121 0000)

(5111 0000)

page 28 9.17.004

BRONKHORST HIGH-TECH B.V.

Menu descriptions

5100 0000 Alarm Reset Enable.

Here you can enter which way the alarm may be reset.

5110 0000 Keyboard Reset.

Here you can enable/disable an alarm reset by the keyboard.

5120 0000 External Reset.

Here you can enable/disable an alarm reset by an external signal.

5130 0000 FLOW-BUS Reset.

Here you can enable/disable an alarm reset via the FLOW-BUS by means of f.i. a Personal

Computer.

5140 0000 Auto Reset.

Here you can enable/disable an automatic reset of an alarm. This reset will be activated after

a few seconds when the cause of the alarm has been removed.

5200 0000 Alarm Mode.

Here you can enter how the alarm-process must react.

5210 0000 This option will disable the alarm.

5220 0000 This option will enable the alarm.

5230 0000 Response Alarm. This option will enable the alarm to detect if the measured value exceeds a

minimal or maximal limit related to the setpoint. If the measured value exceeds these limits for a

given time, the alarm will be activated. The time can be set with the option Alarm Delay.

5240 0000 Power-up Alarm. This alarm will enable the alarm to detect if the instrument had a power failure.

At power-up this alarm will be active. The alarm-setpoint can be used to give a setpoint at power-

up. The delay time can only be used in combination with auto-reset and the Limit settings have

no effect.

5300 0000 Edit Alarm Limit.

Here you can edit at which values the alarm will go off.

5310 0000 Alarm Minimum Level. Select minimum value for the alarm.

5311 0000 Edit Minimum Level.

Here you can change the minimum percentual value for the alarm. Value could be: 2% ≤

minimum limit ≤ maximum limit - 0.1%. Values under 2% are not possible.

5320 0000 Alarm Maximum Level. Select the maximum value for the alarm.

5321 0000 Edit Maximum Level.

Here you can change the maximum percentual value for the alarm. Value could be: minimum

limit + 0.1% ≤ maximum limit ≤ 100%. Values under 2% are not possible.

NOTE: If minimum or maximum limit should not be in use, make limit = 0%. In that case it will be

inactive.

5400 0000 Relay At Alarm.

Here you can enter what you want the relay to do at an alarm situation.

5410 0000 This option will disable a relay action at an alarm.

5420 0000 This option will let the relay pulse at an alarm.

5430 0000 This option will let the relay be continuously on at an alarm.

5500 0000 Limit Setpoint.

Here you can configure what to do with the setpoint at an alarm. You can make the setpoint go to

a predefined value temporarily until reset situation.

5510 0000 This option will not change the setpoint.

5520 0000 This option will change the setpoint to the entered value.

5521 0000 Setpoint At Alarm Editor.

Here you can enter the setpoint value to be active until reset.

5600 0000 Alarm delay.

Here you can edit the delay in seconds before an alarm message will be given or disappear.

9.17.004 page 29

POLYNOMIAL CONST

3.8 Instrument menu

BRONKHORST HIGH-TECH B.V.

INSTRUMENT MENU

INSTRUMENT MENU

INSTRUMENT MENU

(6700 0000)

FLUIDSET x

(6600 0000)

POLYNOMIAL x

(6500 0000)

FLUID NAME 1

(6400 0000)

POLYNOMIAL

POLYNOMIAL

(6680 0000)

H1 x.xxxxxx

(6610 0000)

A1 x.xxxxxx

(6710 0000)

FLUIDSET SELECT

NR: 1

(6510 0000)

FLUID NAME 1:

xxxx

(6410 0000)

POLYNOMIAL CONST

(6681 0000)

H1: x.xxxxxx

(6611 0000)

A1: x.xxxxxx

SENSOR:

OTHER

SENSOR: FLOW

GAS VOLUME

(6250 0000)

0%, 100% measure

and unit name

(6240 0000)

GAS VOLUME FLOW

UNIT1: xxxx

(6230 0000)

(6251 0000)

(6241 0000)

(6231 0000)

INSTRUMENT MENU

(6000 0000)

INSTRUMENT MENU

INSTRUMENT MENU

INSTRUMENT MENU

INSTRUMENT MENU

SENSR CAPACITY 1

(6300 0000)

CAPACITY 0%

(6200 0000)

SENSOR TYPE

(6100 0000)

INSTRUMENT TYPE

CAPACITY 1:

xxxxxx [unit]

CAPACITY 0%:

xxxxxx [unit]

(6310 0000)

SENSOR: FLOW

LIQUID/GAS MASS

(6220 0000)

SENSOR: FLOW

LIQUID VOLUME

(6210 0000)

SENSOR:

PRESSURE

LIQ/GAS MASSFLOW

UNIT1: xxxxx

(6221 0000)

LIQ VOLUME FLOW

UNIT1: xxxx

(6211 0000)

PRESSURE

UNIT1: xxxx

INSTRUMENT TYPE:

CONTROLLER

INSTRUMENT TYPE:

SENSOR

(6120 0000)

(6110 0000)

page 30 9.17.004

BRONKHORST HIGH-TECH B.V.

Menu descriptions

6100 0000 Instrument Type. Here you can change if the instrument will control or only measure mass flow or

pressure.

6110 0000 This will only let you measure the process. You can`t give setpoints.

6120 0000 This will let you control the process. You can edit the setpoint.

6200 0000 Sensor Type. Here you can select the used sensor type from the device.

This is mainly to obtain correctly direct reading in absolute values. Together with the capacity you

can define what 100% signal means. For example: sensortype ‘Gas volume’ gives readout units

like: ‘mln/min’, ‘ln/min’, ‘m3s/h’ etc.

After ‘UNIT’ the selected fluid number will be shown on the display.

6210 0000 Pressure sensor. This prepares module for readout in pressure units. In this mode the counter is

not available.

6211 0000 Select the pressure sensor readout unit with UP/DOWN key.

After unit selection choose: ‘a’ (absolute), ‘g’ (gauge), ‘d’ (differential) or ’. ‘ (no extension)

6220 0000 Liquid Volume Sensor. This prepares module for readout in liquid volume units.

6221 0000 Select the liquid volume readout unit with UP/DOWN key.

6230 0000 Liquid/Gas Mass Sensor. This prepares module for readout in mass flow units.

6231 0000 Select the liquid/mass flow sensor unit with UP/DOWN key.

6240 0000 Gas Volume Sensor. This prepares module for readout in gas volume (mass) units.

6241 0000 Select the gas volume readout unit with UP/DOWN key.

6250 0000 Other Sensor Type. This prepares module for readout in customized units. In this mode the

counter is not available, and you can not enter a capacity.

6251 0000 Here you can define your own sensor type. In order, you must enter the zero scale value (0%),

the full scale value (100%) and the unit type.

6300 0000 Sensor Capacity 0%. Here you can enter the capacity at 0%. This is the value which goes with

0% signal.

6310 0000 Edit the capacity at 0%.

6400 0000 Sensor Capacity. Here you can enter the sensor capacity. This is the value which goes with

100% signal at the selected readout unit.

6410 0000 Edit the sensor capacity.

6500 0000 Fluid Name. Here you can edit the fluid name (max. 10 characters).

6510 0000 Edit the fluid name.

6600 0000 Polynomial Constants. Here you can change the polynomial correction constants for this

instrument Normally these factors are obtained at calibration and represent a 3rd grade

polynomial function.

6610 0000 Here you can edit the polynomial constant A for selected fluidnr.

6611 0000 Edit constant A. (6520 to 6581 likewise for constants B...D or B…H, depending on the instrument

to be operate).

6700 0000 Fluidset Select. Here you can change the actual fluidset.

Your current settings will be saved and the settings of the selected fluidset will be the active

settings.

6710 0000 Select the active fluidset with UP/DOWN keys.

The fluidname will be displayed also (when filled-in).

9.17.004 page 31

3.9 Local menu

BRONKHORST HIGH-TECH B.V.

(7360 0000)

MFR. CONFIG.:

[xxxxxxxx]

(7350 0000)

VERSION:

VX.XX

(7340 0000)

MODEL NUMBER:

[xxxxxx]

(7330 0000)

DEVICE TYPE:

[xxxxxx]

(7400 0000)

LOCAL MENU

RESTORE BACKUP

(7300 0000)

(7410 0000)

RESTORE BACKUP

[ ] to restore

(7320 0000)

SERIAL NUMBER:

[xxxxxxxxxxxxxxxx]

(7310 0000)

(7311 0000)

READING MODE:

PERCENTAGE BAR

(7230 0000)

(7220 0000)

(7160 0000)

DISPLAY MODE:

LARGE SENSOR

(7150 0000)

DISPLAY MODE:

SENSOR BAR

(7140 0000)

DISPLAY MODE:

SETPOINT/SENSOR

(7130 0000)

LOCAL MENU

IDENTIFICATION

(7200 0000)

LOCAL MENU

READING MODE

(7000 0000)

LOCAL MENU

(7100 0000)

LOCAL MENU

DISPLAY MODE

USER TAG:

[xxxxxx]

USER TAG:

[xxxxxx] (edit)

READING MODE:

ACTUAL

(7210 0000)

READING MODE:

PERCENTAGE

DISPLAY MODE:

DISPLAY MODE:

DISPLAY MODE:

COUNTER/SENSOR

TAG/FLUID/COUNTR

TAG/FLUID/SENSOR

(7120 0000)

(7110 0000)

page 32 9.17.004

BRONKHORST HIGH-TECH B.V.

Menu descriptions

7100 0000 Display Mode.

Here you can change the values that will be displayed on the Readout Display.

7110 0000 This option will display the usertag, the fluidname and the measured value in the measure

menu readout screen.

7120 0000 This option will display the usertag, the fluidname and the counter value.

7130 0000 This option will display the counter value and the measured value

7140 0000 This option will display the setpoint and the measured value.

7150 0000 This option will display the measured value in a percentage bar from 0 to 100%.

7160 0000 This option will display the measured value with large characters.

7200 0000 Reading Mode. Here you can switch between direct/percentage reading.

7210 0000 Switch to percentage reading.

7220 0000 Switch to direct reading in absolute values. Absolute values can be selected at sensor type and

capacity of the instrument menu.

7230 0000 Switch to percentage bar reading.

7300 0000 Local Identification. Here you can change the User Tag and check the hard- and software

identification settings of this module.

7310 0000 User Tag. Here you can view the user tag of this module.

7311 0000 User Tag. Here you can change the user tag.

7320 0000 Serial number. Here you can view the serial number of this single channel module. The

Bronkhorst High-Tech B.V. serial number is a unique identification for FLOW-BUS modules/

instruments.

7330 0000 Device Type. Here you can view as which type the device is configured.

7340 0000 Model Number. Here you can view the model number of the module.

7350 0000 Version. Here you can view the software version.

7360 0000 Manufacture Configuration. Here you can view the manufacture configuration

7400 0000 Restore Backup. This function restores the backup (the factory settings) which was made after

the final test in de factory.

7410 0000 Press ‘enter’ to restore backup.

9.17.004 page 33

3.10 FLOW-BUS menu

BRONKHORST HIGH-TECH B.V.

FLOW-BUS MODE:

FLOW-BUS MODE:

(8140 0000)

STOP COMMUNIC.

(8130 0000)

START COMMUNIC.

FLOW-BUS MENU

(8000 0000)

FLOW-BUS MENU

FLOW-BUS MENU

SETTING

MODE

(8200 0000)

(8100 0000)

SETTINGS PNA: XXX

NNA: XXX LNA : XXX

(8210 0000)

(8211 0000)

FLOWBUS SETTINGS

NEW ADDRESS: xxx

(8120 0000)

FLOW-BUS MODE:

REMOTE INSTALL

(8110 0000)

FLOW-BUS MODE:

AUTO INSTALL

page 34 9.17.004

BRONKHORST HIGH-TECH B.V.

Menu descriptions

8100 0000 FLOW-BUS Mode.

Here you can install this module on the FLOW-BUS or start/stop the communication.

8110 0000 Auto install.

Press 'enter' to install this module on the FLOW-BUS. It will search for a free address on the bus

by itself and install there.

8120 0000 Remote Install.

Press 'enter' to let this module get into INIT mode so it can be installed to the bus by an external

device (operation module or PC). You have one minute now to perform the installation

procedure.

8130 0000 Start Communication.

When you press 'enter' in this menu communication with the bus will be (re)started (use after

stopping communication temporarily). When the device is properly installed, it will start

communication at power-up and after a reset automatically.

8140 0000 Stop Communication.

When you press 'enter' in this menu communication with the bus will be stopped until ‘Start

communication' will be selected or at a reset of the module.

8200 0000 Check Settings. Here you check FLOW-BUS settings of this module.

8210 0000 PNA means Primary Node Address of module on the FLOW-BUS.

NNA means Next Node Address. This address points to the next module on the FLOW-BUS and

will be changed automatically if a new module is add to the FLOW-BUS behind this module. If

the module is the last module on the FLOW-BUS, its NNA points to zero.

8211 0000* Here you can change the PNA of the module. If you give a new address, the module will restart

the communication. The NNA is default set to PNA+1. During communication NNA values may

change automatically because FLOW-BUS optimises it self for optimum communication speed.

NOTE 1:

Normally installation on the FLOW-BUS has to be performed only one time. Mostly this will be

done at Bronkhorst High-Tech B.V. when your module has been built and tested. The address on

the bus for this module will be stored when the module powers-off. At future power-on situations,

it will be part of the FLOW-BUS on the same address each time. However, there can be

situations you have to install your module on the bus again. For example:

1) When you want to rebuild your FLOW-BUS system.

2) When you want to add this module to another FLOW-BUS system.

3) When, at the check at start-up, the module finds out that its address to be on the FLOWBUS is occupied already by another module. You will get a message on your display That

you have to re-install the module on the bus.

NOTE 2:

Make sure this module has been switched-off before connecting it to the FLOW-BUS.

First make FLOW-BUS connection, then switch-on the power. Only in this order the module is

able to perform its communication checkings properly.

How to install the E-7000 modules on the FLOW-BUS network, see manual 9.17.024.

* LNA means last Node Address. This is an indication of the size of the FLOWBUS network.

The next module added to the network should have a PNA below this LNA. When a module is

automatic installed on the network, this LNA will be changed automatically.

9.17.004 page 35

BRONKHORST HIGH-TECH B.V.

3.11 Calibration with polynomial functions

3.11.1 General information

A normally calibrated device will have linearized transfer functions. This means that real flow/pressure and

setpoint are proportional to the output signal (0-5 V, 0-10 V, 0-20 mA or

4-20 mA).

A polynomial function is a method of approximation which mathematically describes a continues transfer

function.

By means of a few samples, a polynomial function can be obtained.

After determining the polynomial function, the original calibration points and an infinite amount of values in

between, can be calculated with high accuracy.

In a system where pressure- and/or flow meters and -controllers should be readout and set with high

accuracy, these polynomial functions often are used for approximation of their transfer function. For instance

the function which describes the relation between output voltage and measured flow.

3.11.2 General form

The general form of a polynomial function of the n-nd degree is as follows:

Y = a0 + a1 · X + a2 · X

Where 'a0' to 'an' are polynomial parameters, which can be calculated.

When you have 'n + 1' measure-points, they can be approximated by means of a 'n-nd' degree polynomial

function.

3.11.3 Polynomial functions of sensor signal and setpoint

By means of a calibration at Bronkhorst High-Tech B.V. several measure points will be used to obtain a

polynomial function.

The form of this function is:

Y = a + b · X + c · X

In which 'Y' is the measured value in correct unit (e.g. flow in [ln/min]) and 'X' is the value of output signal in

correct unit (e.g. Uout in [V]).

Characters 'a - d' are polynomial parameters, which can be obtained by a mathematical program. These

parameters can be filled in and the polynomial function is completed.

Now a flow can be calculated out of the sensor output signal of the device.

When a controller is calibrated, also a polynomial function for setpoint is calculated.

This will be the inverse function of the polynomial function of the sensor signal.

The form of this function is:

Z = e + f · Y + g · Y

In which 'Y' is the measured value in correct unit again (e.g. flow in

signal in the correct unit (e.g. [V]).

Characters 'e - h' are parameters, which can be filled in.

Now the desired setpoint signal can be calculated out of the amount of flow at which the controller has to

operate.

2

+ a3 · X3 + ……+ an · Xn

2

+ d · X3

2

+ h · Y3

[I / minn] and Z is the value of the setpoint

page 36 9.17.004

BRONKHORST HIGH-TECH B.V.

3.11.4 Presentation of parameters

Parameters 'a - d' and 'e - h' are polynomial function parameters, which can be obtained with a mathematical

program out of measured calibration points.

All parameters will be printed on the calibration certificate.

They will be presented in scientific notation with 5 significant digits, where the last digit is obtained by

rounding-off.

Example (unscaled):

a = -2.7458 · 10

b = +9.5452 · 10-1 f = +1.0892

c = -1.2714 · 10-1 g = +1.7832 · 10-2

d = +1.8464 · 10

-3

-1

e = -2.5396 · 10

h = -1.1417 · 10

-4

-1

Polynomial function for sensor signal:

Y = -2.7458 · 10

-3

+ 9.5452 · 10-1 · X - 1.2714 · 10-1 · X2 + 1.8464 · 10-1 · X

3

Polynomial function for setpoint:

Z = -2.5396 · 10

-4

+ 1.0892 · Y + 1.7832 · 10-2 · Y2 - 1.1417 · 10-1 · Y3

3.11.5 Using polynomial functions at readout/control unit

The parameters for the polynomial functions are stored at the readout and control-module and can be

changed from the keyboard.

Normally both transfer functions of sensor signal and setpoint are linear Y = X, the transfer function of the

setpoint signals is Z = Y.

The connected device will have linearized transfer functions after (normal) calibration.

The accuracy however, will be ≤ 1 % full scale.

When a special polynomial function calibration is wanted, the parameters 'a-h' will be destillated and printed

on the calibration certificate. In the 'INSTRUMENT'-menu you just have to enter these values.

Now you can connect and operate the concerned device.

Note:

Only this device will operate correctly; if you want to connect an other device to this channel, first change the

polynomial function parameters.

9.17.004 page 37

BRONKHORST HIGH-TECH B.V.

page 38 9.17.004

BRONKHORST HIGH-TECH B.V.

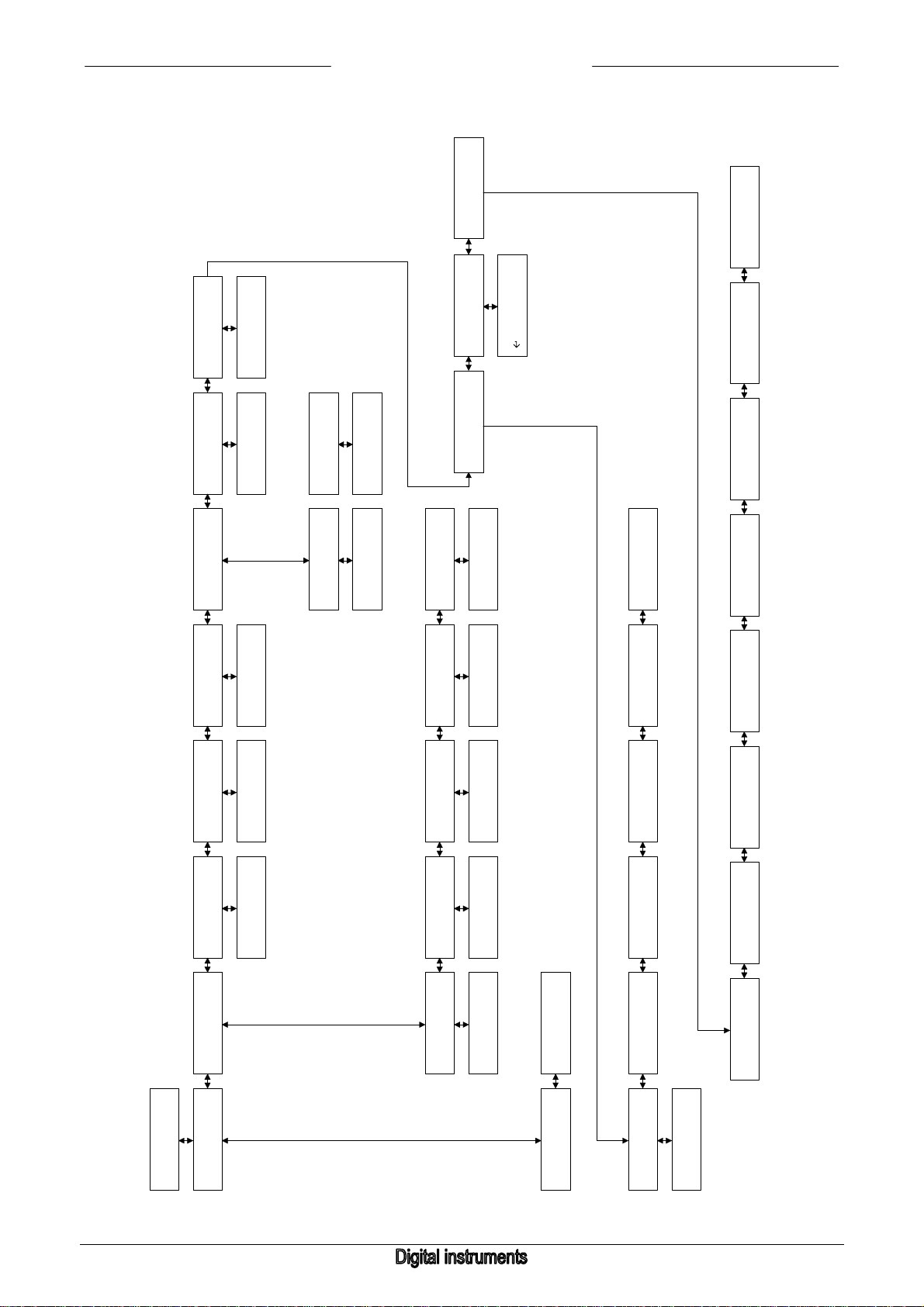

4 Operation of digital (FLOW-BUS) instruments

FLOW-BUS

digital instrument

4.1 General information

Before operating your system be sure that it is setup to readout and control digital (FLOW-BUS) instruments.

Check: model configuration; sensor output signal. The code should be “R”

Use 'cursor' keys to scroll through the menu-structure and to select the required menu level.

The 'enter' key is used to acknowledge a selected setting and to enter a edited value and/or text.

Editing can be performed by using the 'cursor' keys to select the character to be edited ( ← / → ) and to scroll

through the available character set or units ( ↑ / ↓ ).

After power-up the display will show the usual start-up sequence for some seconds.

9.17.004 page 39

BRONKHORST HIGH-TECH B.V.

4.2 Startup and menu selection

(8000 0000)

FLOW-BUS MENU

(7000 0000)

LOCAL MENU

(6000 0000)

INSTRUMENT MENU

(5000 0000)

ALARM MENU

(4000 0000)

COUNTER MENU

(3000 0000)

RESET MENU

(2000 0000)

OPERATION MENU

(0000 0000)

(0001 0000)

(0002 0000)

(0003 0000)

(0004 0000)

(0005 0000)

(1000 0000)

HI-TEC

BRONKHORST

Loading

Parameters...

Checking flowbus

Please wait...

SINGLE CHANNEL

STYLE D Vx.xx

Searching instr.

Please wait

[device]:[usertag]

[serialnumber]

MEASURE MENU

(F000 0000)

[device]:[usertag]

[serialnumber]

page 40 9.17.004

BRONKHORST HIGH-TECH B.V.

Menu descriptions

0000 0000 Startup screen showing message loading parameters.

0001 0000 Startup screen showing company name.

0002 0000 Startup screen showing communication check with FLOW-BUS in progress. Takes a short time

(few seconds), depending on system size. If the FLOW-BUS address of the module is occupied,

you can reinstall the module on a new address.

0003 0000 Startup screen showing software revision level

0004 0000 Startup screen checking operating instrument. If there is no instrument found on the current

instrument node and the MULTI CHANNEL mode is activated, the E7000 module starts

searching for an other instrument on the bus.

0005 0000 Startup screen showing operating instrument if available.

1000 0000 Measure menu or ‘Readout Display’ for reading the amount of flow/pressure, setpoint and/or

counter value. When there is an alarm- or counter limit reached it will be shown here. For editing

the setpoint/slave factor go down one level.

2000 0000 Operation menu for selecting setpoint source (and master/slave), fluidset and setpoint slope for

the device to be operated. Also for editing setpoint offset.

3000 0000 Reset menu for quick reset of counter and alarm by keyboard. Also password input location to

enable advanced use of this module.

4000 0000 Counter menu for configuration of all counter options. This menu is secured by means of a

password.

5000 0000 Alarm menu for configuration of all alarm options. This menu is secured by means of a

password.

6000 0000 Instrument menu for configuration of the instrument to be operated, such as instrument type,

capacity, sensor type, identification and fluid sets with calibration values. This menu is secured

by means of a password.

7000 0000 Readout menu for configuration of the measure menu. You can select the wanted information for

your display.

8000 0000 FLOW-BUS menu to install module on the FLOW-BUS or start/stop communication with the bus.

This menu is secured by means of a password.

F000 0000 Searching instruments. One can search on the bus for instruments with the ↑ and ↓ keys. An

instrument can be selected by pressing enter. This option is only available when the MULTI

CHANNEL mode is activated.

NOTE:

When you press ‘enter’ in one of the above menu-options, the module jumps to startup screen ‘0004 0000’

and checks the communication with the operating instrument and shows its serial number.

The MULTI CHANNEL mode can be activated in LOCAL MENU - TERMINAL MODE.

9.17.004 page 41

4.3 Measure menu

BRONKHORST HIGH-TECH B.V.

if available

*

*

*

xxx.xx (cursor)

EDIT SETPOINT:

(1200 0000)

EDIT SETPOINT:

CHANGE SETPOINT:

CHANGE SETPOINT:

(1100 0000)

xxx.xx (step)

(1400 0000)

SETPOINT ZERO

(1300 0000)

SETPOINT FULL

(1610 0000)

TEMPERATURE

(1600 0000)

DENSITY

(1000 0000)

MEASURE MENU

page 42 9.17.004

BRONKHORST HIGH-TECH B.V.

Menu descriptions

1100 0000 Stepsize editor for editing setpoint/slave-factor by a 0.1% step up or down. By holding down

UP/DOWN key continuously, the step size will increase. Changes are used by the controller

immediately. What is displayed here in this menu depends on the selection of the setpoint

source. Analog setpoints can not be edited.

1200 0000 Cursor editor for editing setpoint/slave-factor by entering the exact (new) value. After pressing

'enter', the changes will be used by the controller. Could be used for large setpoint steps. What is

displayed here in this menu depends on the selection of the setpoint source. Analog setpoints

can not be edited.

1300 0000 Setpoint full. After pressing 'enter', setpoint for controller will be 100% unconditionally (controller

valve will be opened in almost all situations).

1400 0000 Setpoint zero. After pressing 'enter', setpoint for controller will be zero unconditionally (controller

valve will be closed in almost all situations). You will return to the readout display now. Setpoint

will not respond to selected source again until 'enter' has been pressed in menu 1000.

NOTE:

Measured values could be readout up to 110.0%.

Sensor signals > 110.0% will be cut-off.

Setpoint can be entered up to 100.0%. However, setpoint signals can, just like sensor signals, be corrected

by means of polynomial calculation.

Also you can use setpoint offset correction to eliminate cable offsets in your system (see operation menu).

9.17.004 page 43

4.4 Operation menu

BRONKHORST HIGH-TECH B.V.

(21E0 0000)

LOCAL SETP. MODE

ANALOG SETPOINT

(2400 0000)

(2420 0000)

(2410 0000)

(2170 0000)

CONTROL MODE

TUNING MODE

(2160 0000)

CONTROL MODE

TESTING MODE

(2150 0000)

CONTROL MODE

CONTROLLER IDLE

(2140 0000)

(2171 0000)

CONTROL MODE

[ ] to auto-tune

(2161 0000)

TESTING MODE

[ ] to start

CONTROL MODE

FB, ANALOG SLAVE

(21D0 0000)

CONTROL MODE

SETPOINT 0%

(21C0 0000)

CONTROL MODE

KEYB. & FLOW-BUS

(21B0 0000)

OPERATION MENU

LOCAL SETP. MODE

OPERATION MENU

SETPOINT SLOPE

OPERATION MENU

SELECT FLUID [nr]

(2000 0000)

LOCAL SETP. MODE

KEYBOARD SETP.

(2300 0000)

EDIT SLOPE

TIME: xxxx.x Sec

(2200 0000)

SELECT FLUID

NR: x (edit)

(2100 0000)

(2310 0000)

(2210 0000)

CONTROL MODE

VALVE CLOSE

(2130 0000)

CONTROL MODE

FLOW-BUS SLAVE

MASTER: xxxxxxx

xxxxxxxxxxxxxxxx

(2120 0000)

CONTROL MODE

ANALOG INPUT

(2110 0000)

(2131 0000)

CONTROL MODE

ANALOG SLAVE

(21A0 0000)

CONTROL MODE

CALIBRATION MODE

CALIBRATION MODE

[ ] to auto zero

(2190 0000)

CONTROL MODE

VALVE FULLY OPEN

(2180 0000)

CONTROL MODE

SETPOINT 100%

(21A1 0000)

OPERATION MENU

OPERATION MENU

CONTROL MODE

CONTROL MODE

FLOW-BUS

page 44 9.17.004

BRONKHORST HIGH-TECH B.V.

Menu descriptions

2100 0000 Operation mode. Here you can change the source of the setpoint for the operating instrument

2110 0000 This option selects a setpoint change by means of a FLOW-BUS device (operation module or

Personal Computer).

2120 0000 This option selects a setpoint change coming from an analog input.

2130 0000 This option selects a setpoint change coming from an output signal of a master device, via

FLOW-BUS, multiplied by a slave-factor (FLOW-BUS master-slave).

2131 0000 Choose a master channel. With LEFT/RIGHT you can search for the master device on the

FLOW-BUS. Your instrument module will be slave.

Each time a possible master device has been found on the bus, the type and identification

number will be displayed. When ‘----‘ is displayed, this means that no master could be found.

With UP you can stop the search, and with 'enter' you select the currently displayed device.

Slave factor must be entered at the position where setpoint is normally entered

2140 0000 This option close the valve of the instrument independent of the setpoint.

2150 0000 This function disables all functions of the instrument except the FLOW-BUS communication.

2160 0000 This function selects the testing mode of the instrument.

2161 0000 Activate the testing mode by pressing ‘enter’

2170 0000 This function selects the tuning mode of the instrument.

2171 0000 Activate the auto-tuning mode by pressing ‘enter’

2180 0000 This function sets a setpoint of 100%

2190 0000 This option opens the valve of the instrument independent of the setpoint.

21A0 0000 This function selects the calibration mode of the instrument.

21A1 0000 Activate the auto-zero mode by pressing ‘enter’.

21B0 0000 This option selects a setpoint change coming from an analog input, multiplied by a slave-factor

(analog master/slave).

21C0 0000 This option selects a setpoint change with the keyboard or by means of a FLOW-BUS device

(operation module or Personal Computer).

21D0 0000 This function sets a setpoint of 0%

21E0 0000 This option selects a setpoint change coming from an output signal of a master device, via

FLOW-BUS, multiplied by a slave-factor (FLOW-BUS master-slave), coming from an analog

input.

21E1 0000 Choose a master channel. With LEFT/RIGHT you can search for the master device on the

FLOW-BUS. Your instrument module will be slave.

Each time a possible master device has been found on the bus, the type and identification

number will be displayed. When ‘----‘ is displayed, this means that no master could be found.

With UP you can stop the search, and with 'enter' you select the currently displayed device.

Slave factor must be entered at the position where setpoint is normally entered

2200 0000 Fluidset selection. Here you can change the actual fluidset. Your current settings will be saved

and the settings of the selected fluidset will become the new active settings for your instrument.

When fluidset changes, the instrument will use the calibration settings in the memory for sensor

signal/setpoint adjustments for that fluid.

2210 0000 Select the active fluidset by selecting a number from 1 to 8. Settings will be active after pressing

'enter'. This is for selection fluidsets only. For changing fluid calibration settings use Instrument

menu.

2300 0000 Setpoint Slope. Here you can enter a setpoint slope for this device. When the setpoint has been

changed and not overruled by counter limit or an alarm, the setpoint will (smoothly) increase to

the set value.

2310 0000 Edit the setpoint slope time.This is the time it will take for the setpoint value to increase from 0%

to 100% (and vice versa). The value can be entered from 0...3000.0 seconds.

2400 0000 Local Setpoint mode.

2410 0000 This option selects the local keyboard for setpoint input.

2420 0000 This option selects the local analog input for setpoint input.

NOTE:

Slave factor can be entered up to 500%.

9.17.004 page 45

4.5 Reset menu

BRONKHORST HIGH-TECH B.V.

(3300 0000)

RESET MENU

PASSWORD

(3200 0000)

RESET MENU

RESET COUNTER

(3000 0000)

RESET MENU

(3100 0000)

RESET MENU

RESET ALARM

(3310 0000)

PASSWORD:

_

(3220 0000)

RESET COUNTER?

YES

(3210 0000)

RESET COUNTER?

NO

(3120 0000)

RESET ALARM?

YES

(3110 0000)

RESET ALARM?

NO

page 46 9.17.004

BRONKHORST HIGH-TECH B.V.

Menu descriptions

3100 0000 Reset Alarm.

Here you can reset an alarm if it is active. This will result in removing the alarm situation defined

to take place at the potential free contact and/or at the (temporary) alarm setpoint. If the alarm