Page 1

RANGE AoST oR

RM60000 SERIES

RANGE HOOD

INSTALLATION INSTRUCTIONS

AND USER MANUAL

HBO026

Z_INTENDED FOR RESIDENTIAL USE ONLY/_

_,,1=lr_,_my_,_#Im]l,.,-t!'_,\,A=ll iI-=I =[,,.1=mi#_ / [_|[_ / [o] #_

INSTALLER: LEAVE THIS MANUAL WITH HOMEOWNER.

HOMEOWNER: USE AND CARE INFORMATION ON PAGE 10.

Broan-NuTone LLC, 926 West State Street, Hartford, Wl 53027 (1-800-637-!453)

NuTone, Inc., 4820 Red Bank Road, Cincinnati, OH 45227 (1-800-543-8687)

Broan-NuTone Canada, Inc., 1140 Tristar Drive, Mississauga, ON L5T 1H9 (!-888-882-7626)

V05527 rev. D

Page 2

WARNING WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the

manufacturer, tf you have questions, contact the

manufacturer at the address or telephone number

listed in the warranty.

2. Before servicing or cleaning unit, switch power off at

service panel and lock service disconnecting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be

locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

3. Installation work and electrical wiring must be

done by qualified personnel in accordance with

all applicable codes and standards, including

fire-rated construction codes and standards.

.

Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of

fuel burning equipment to prevent backdrafting.

Follow the heating equipment manufacturer's

guidelines and safety standards such as those

published by the National Fire Protection

Association (NFPA), and the American Society for

Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. Do not use this unit with any additional solid-state

speed control device.

8. To reduce the risk of fire, use only steel ductwork.

9. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE

FIRE:

a) Never leave surface units unattended at high

settings. Boilovers cause smoking and greasy

spillovers that may ignite. Heat oils slowly on low or

medium settings.

b) Always turn hood ON when cooking at high heat or

when cooking flaming foods.

c) Clean ventilating fans frequently. Grease should not

be allowed to accumulate on fan or filter.

d) Use proper pan size. Always use cookware

appropriate for the size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN

THE EVENT OF A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING*:

SMOTHER FLAMES with a close-fitting lid,

cookie sheet or metal tray, then turn off the

burner. BE CAREFUL TO PREVENT BURNS.

IF THE FLAMES DO NOT GO OUT IMMEDIATELY,

EVACUATE AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN - You may

be burned.

3. DO NOT USE WATER, including wet dishcloths or

towels - This could cause a violent steam explosion.

.

Use an extinguisher ONLY if:

A. You own a Class ABC extinguisher and

you know how to operate it.

B. The fire is small and contained in the area

where it started.

C. The fire department has been called.

D. You can fight the fire with your back to an exit.

* Based on "Kitchen Fire Safety Tips" published by NFPA.

CAUTION

1. For general ventilating use only. Do not use to

exhaust hazardous or explosive materials and

vapors.

2. To avoid motor bearing damage and noisy

and/or unbalanced impellers, keep drywall

spray, construction dust, etc. off power unit.

.

Your hood motor has a thermal overload which

will automatically shut off the motor if it

becomes overheated. The motor will restart when

it will be cooled down. If the motor continues

to shut off and restart, have the hood serviced.

.

For best capture of cooking impurities, the bottom of

the hood should be at a minimum of 24" and at a

maximum of 30" above the cooking surface.

5. To reduce the risk of fire and to properly

exhaust air, be sure to duct air outside - Do not

exhaust air into spaces within walls or ceilings

or into attics, crawl spaces or garage.

6. This product is equipped with a thermostat which

may start blower automatically. To reduce the

risk of injury and to prevent power from being

switched on accidentally, switch power off at service

panel and lock or tag service panel.

7. To reduce the risk of fire and electrical shock, the

Rangemaster RM60000 Series hood must be

installed with blower models RM325H, RM326H,

331 H, 332H, 335 or 336 only. Other blowers cannot

be substituted. (Blowers sold separately).

8. Use with approved cord-connection kit only.

9. Please read specification label on product for

further information and requirements.

-2-

Page 3

1,0

2,0

3,0

4,0

5,0

6,0

7,0

8,0

9,0

10,0

11,0

12,0

13,0

14,0

15,0

16,0

17,0

18,0

SELECT BLOWER OPTION AND iNSTALL DUCTWORK ..................................... 5

MEASURE iNSTALLATiON ............................................................ 5

PREPARE THE INSTALLATION ......................................................... 6

INSTALL BACKSPLASH ............................................................... 6

INSTALL WOOD MOUNTHNG STRHP ..................................................... 6

INSTALL THE HOOD ................................................................. 6

INSTALL TRANSHTHON TO ROUGH-HN PLATE .............................................. 7

INSTALL THE ROUGH-HN PLATE TO THE HOOD ........................................... 7

CONNECT THE WHRHNG .............................................................. 7

WHRHNGDHAGRAM .................................................................. 8

INSTALL THE OPTHONAL SOFFHT CHHMNEY .............................................. 8

INSTALL BLOWER .................................................................. 8

INSTALL LHGHT BULBS AND WARMING LAMPS ........................................... 8

INSTALL FILTERS ................................................................... 9

USE AND CARE .................................................................... 10

OPERATION ....................................................................... 10

SERVHCE PARTS .................................................................... 11

WARRANTY ....................................................................... 12

-3-

Page 4

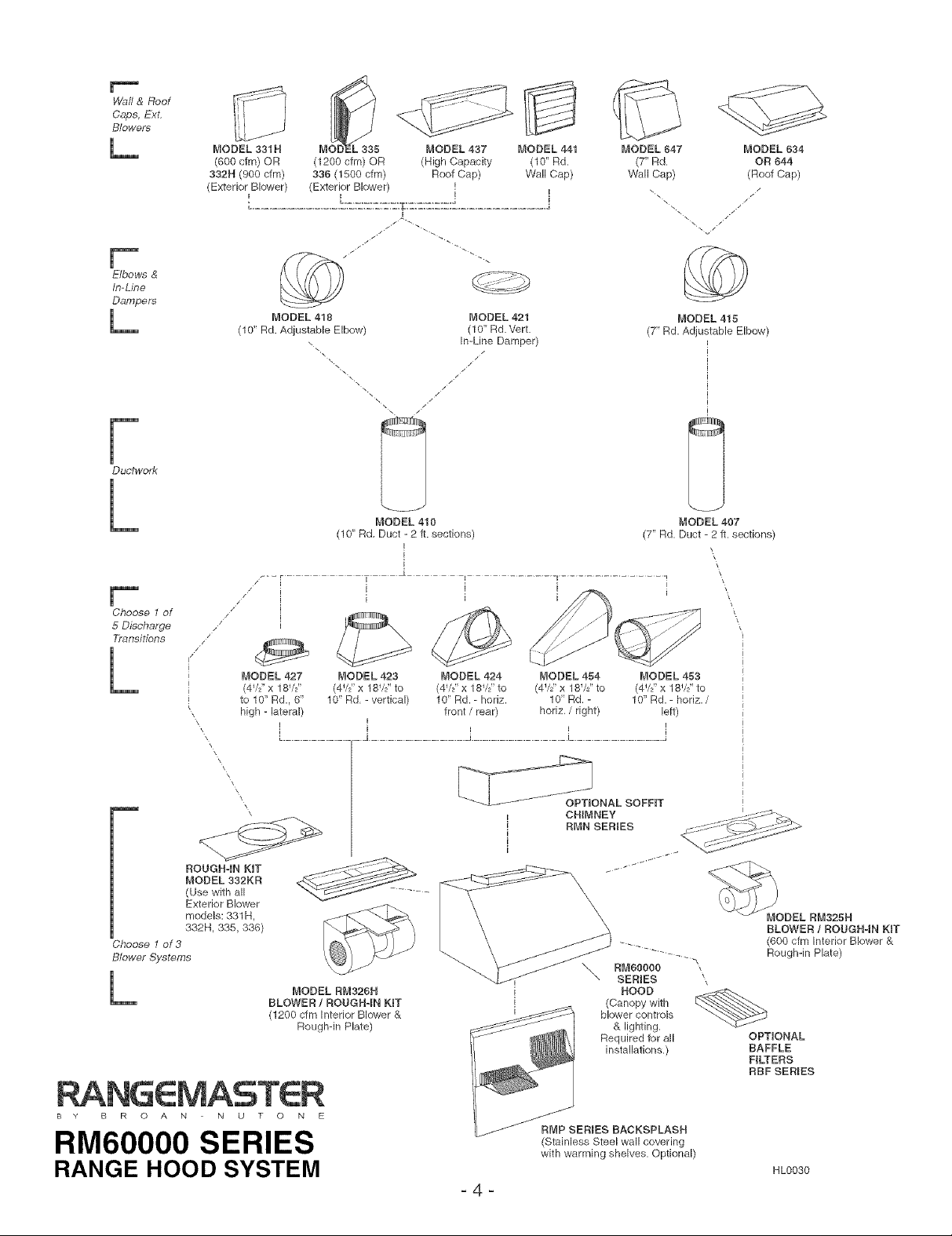

Waft & Roof

Caps, ExL

Blowers

Elbows &

In-Line

Dampers

Ductwork

MODEL 331R M_ 335 MODEL 437 MODEL 441

(600 cfm) OR (1200 cfm) OR (High Capacity (10" Rd.

332R (900 cfm) 336 (1500 cfm) Roof Cap) Wall Cap)

(Exterior Blower) (Exterior Blower) i

I ' i

L..................... _7ZTZTZTZ_"--ITIZLZIZZZZZ_-..................... J

i i i

i z

MODEL 647

(7" Rd.

Wall Cap)

MODEL 418 MODEL 421 MODEL 415

(10" Rd. Adjustable Elbow) (10' Rd. Vert. (7' Rd. Adjustable Elbow)

\ I

\ // i

\ / i

\ /

\

\ / I

\ / i

\ /

\ / !

In-Line Damper) !

MODEL 410 MODEL 407

(10" Rd, Duct - 2 ft. sections) (7" Rd, Duct - 2 ft, sections)

\v/

/

/

1

/

MODEL 634

OR 644

(Roof Cap)

/

z /

Choose 1 of

5 Discharge

7?ansitions

Choose 1 of 3

Blower Systems

MODEL 427

(4Vd x 18W'

to 10" Rd., 6'

high - lateral)

ROUGH-IN }<IT

MODEL 332KR

(Use with all

Exterior Blower

models: 331H,

332H, 335,336)

.... - T i ! .......... q.........................

I I I

i i

MODEL 423

(4W' x 181/2"to (41/2" x 18Vd' to (41/d' x 181/#' to (4Vd' x 181/2"to

10" Rd, - vertical) i 0" Rd.- horiz. 10" Rd. - 10" Rd.- horiz./

I

MODEL 424 MODEL 454 MODEL 453 I

front / rear) horiz, / right) left) I

L................... J ....................... J ....................... L ..................... J

_ONAL SOFFIT

i CHIMNEY

i RMN SERIES

i

i

I

\\ RM6O0O0

MODEL RM326R

BLOWER / ROUGH:IN }(IT

(1200 cfm Interior Blower &

Rough-in Plate)

\ SERIES '_

(Canopy with

blower controls

& lighting.

Required for all OPTIONAL

instaNations.) BAFFLE

MODEL RM325R

BLOWER / ROUGH-iN KIT

-_ ......... _ Rough-in Plate)

(600 cfm Interior Blower &

HOOD

FILTERS

RRF SERIES

BY BROAN NUTONE

RM60000 SERIES

RANGE HOOD SYSTEM

=4 =

RMP SERIES BACKSPLASR

(Stainless Steel wall covering

with warming shelves. Optional)

HLO030

Page 5

1. SELECTBLOWER OPTION

AND INSTALL DUCTWORK

2. MEASUREINSTALLATION

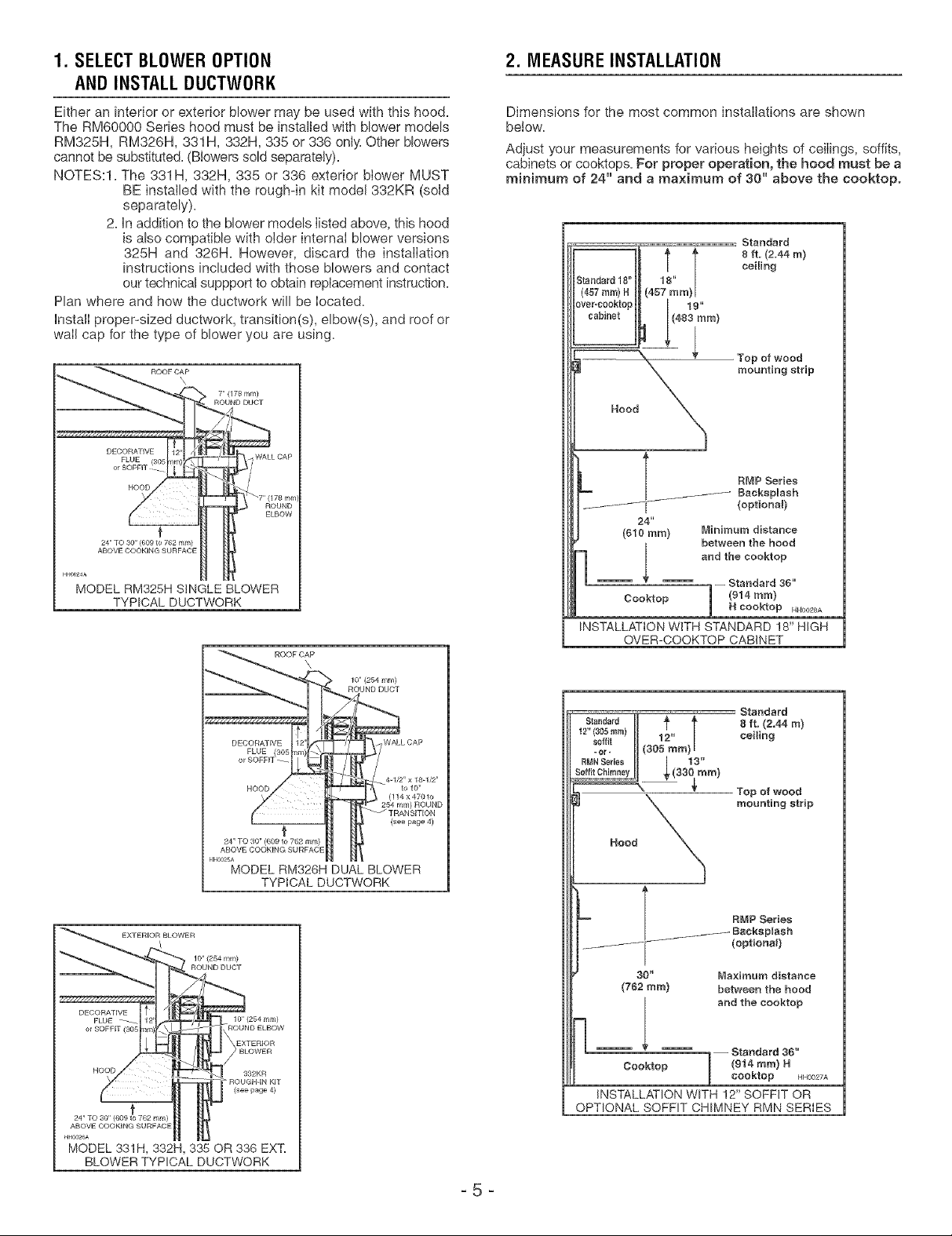

Either an interior or exterior blower may be used with this hood.

The RM60000 Series hood must be installed with blower models

RM325H, RM326H, 331H, 332H, 335 or 336 only. Other blowers

cannot be substituted. (Blowers sold separately).

NOTES:I. The 331 H, 332H, 335 or 336 exterior blower MUST

BE installed with the rough-in kit model 332KR (sold

separately).

2. in addition to the blower models listed above, this hood

is also compatible with older internal blower versions

325H and 326H. However, discard the installation

instructions included with those blowers and contact

our technical suppport to obtain replacement instruction.

Plan where and how the ductwork will be located.

install proper-sized ductwork, transition(s), elbow(s), and roof or

wail cap for the type of blower you are using.

711(178 mm)

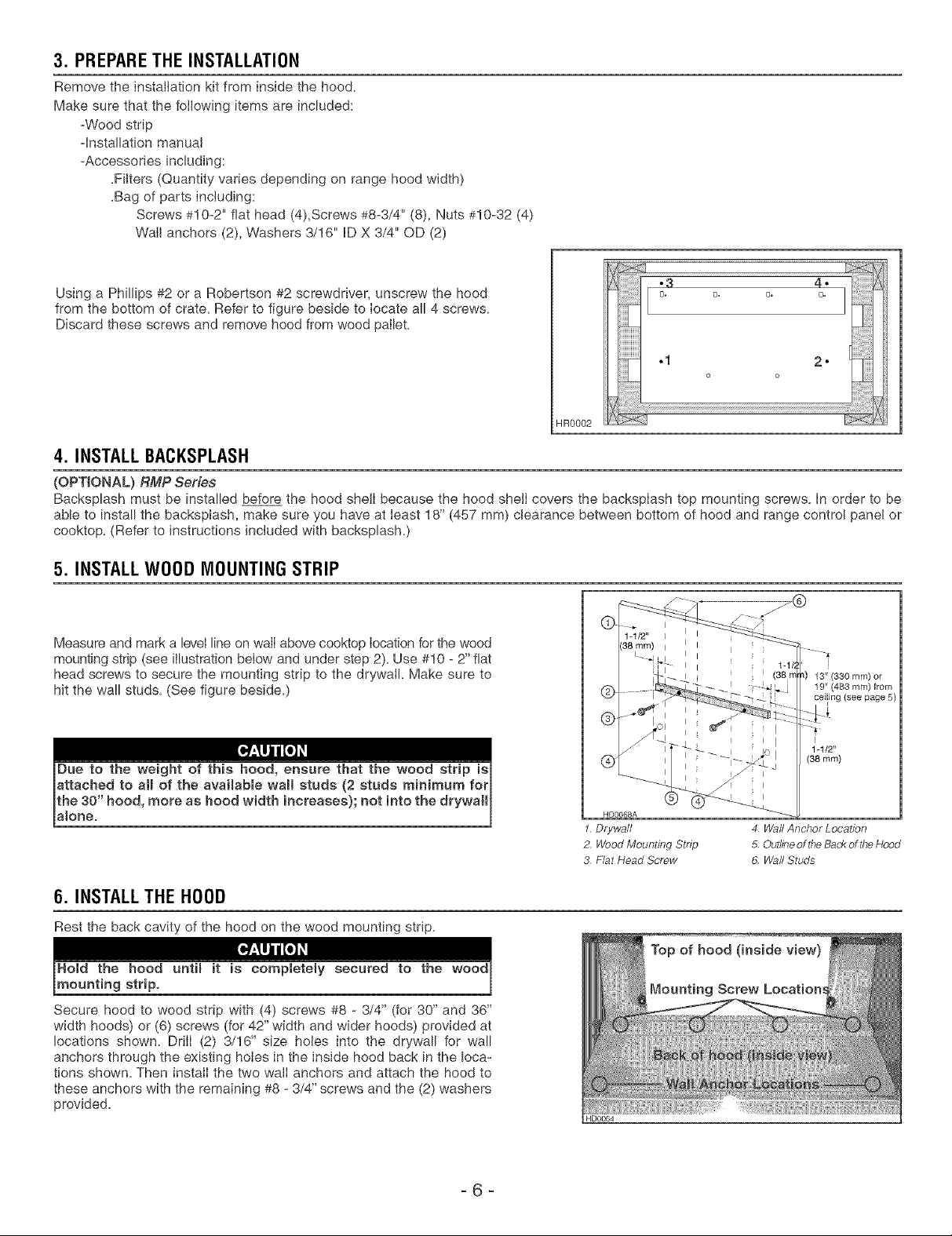

Dimensions for the most common installations are shown

below.

Adjust your measurements for various heights of ceilings, soffits,

cabinets or cooktops. For proper operation, the hood must be a

minimum of 24" and a maximum of 30" above the cooktop.

Standard 18" 18"

(457rnm)H (457 ram)

over'c0okto9 19"

cabinet (483 ram)

Top of wood

mounting strip

RMR Series

--_ BackspUash

24"

({}10 ram) Minimum distance

(optiona0

between the hood

MODEL RM328H SINGLE BLOWER

TYPICAL DUCTWORK

MODEL RM326H DUAL BLOWER

TYPICAL DUCTWORK

10" (254 mill)

10" (254 mm)

BLOWER

ROOFCAP

f

and the eooktop

-- Starldard 36"

Cooktop H cooktop HHOO2SA

(914 ram}

INSTALLATION WITH STANDARD !8" HIGH

OVER-COOKTOP CABINET

\

le'(254 mm)

ROUND DUCT

Stasdard

8 ft. (2,44 m)

ceiling

(33 ram)

(114 x470to

(see page 4)

._ RNP Series

OPTIONAL SOFFIT CHIMNEY RMN SERIES

\ Top of wood

X mounting strip

Hood

_- IBacksplash

30" Maximum distance

(762 tara) between the hood

Cooktop m (914 tara) H

(optional)

and the cooktop

'1-- Standard 36"

j cooktop NH0027A

INSTALLATION WITH !2" SOFFIT OR

HH0026A

MODEL 331H, 332H, 338 OR 338 EXT.

BLOWERTYPICAL DUCTWORK

_5 _

Page 6

3. PREPARETHE INSTALLATION

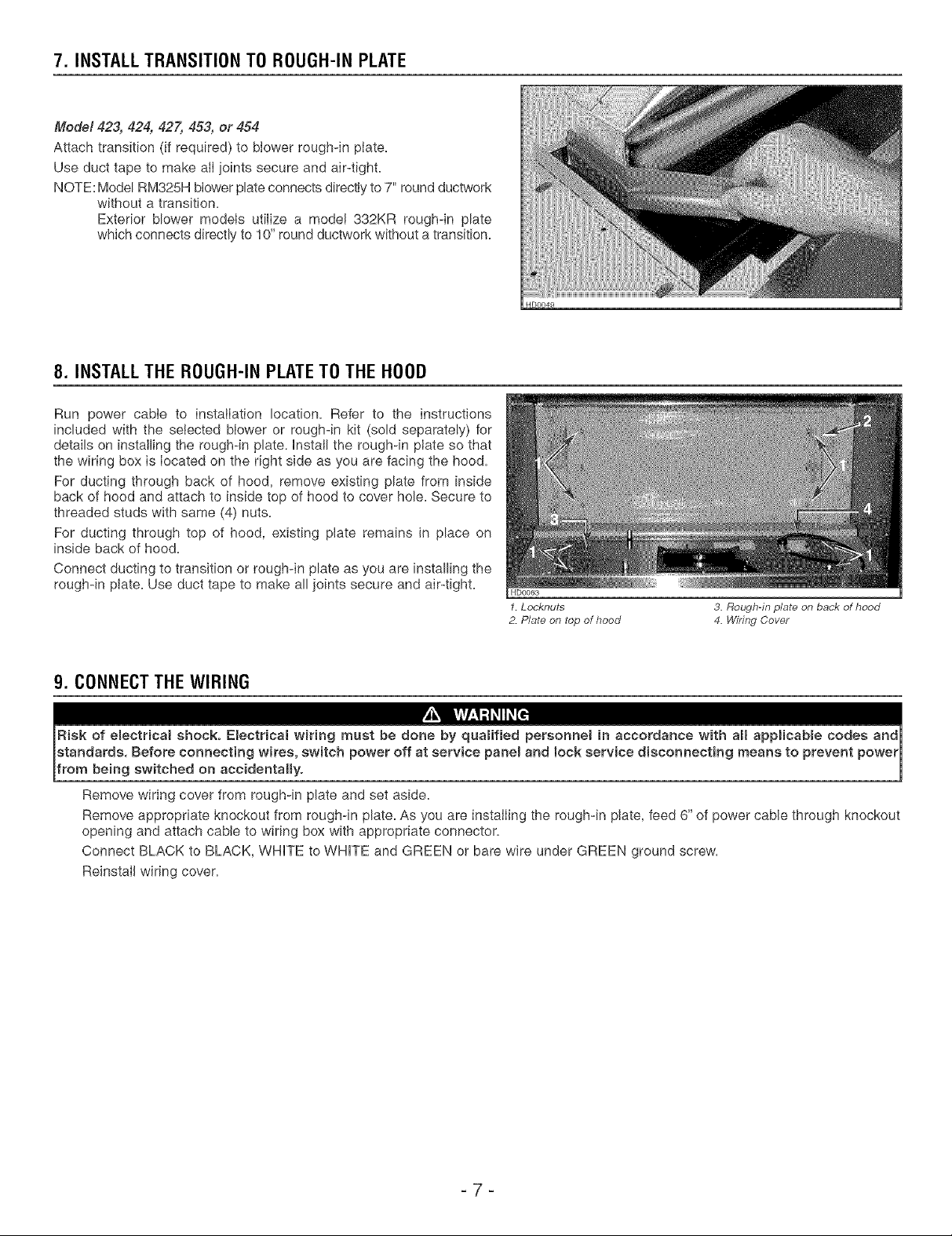

Remove the installation kit from inside the hood.

Make sure that the fotlowing items are included:

+Wood strip

4nstallation manual

+Accessories including:

+Filters (Quantity varies depending on range hood width)

+Bag of parts inciud+ng:

Screws #10-2" flat head (4),Screws #8-3/4" (8), Nuts #10-32 (4)

Wail anchors (2), Washers 3/16" ID X 3/4" OD (2)

Using a Phillips #2 or a Robertson #2 screwdriver, unscrew the hood

from the bottom of crate. Refer to figure beside to locate all 4 screws.

Discard these screws and remove hood from wood pallet.

HR0002

4. INSTALLBACKSPLASH

(OPTIONAL) RMP Serfes

Backsplash must be installed before the hood shelI because the hood shelI covers the backspIash top mounting screws. In order to be

able to install the backsplash, make sure you have at least 18" (457 mm) clearance between bottom of hood and range control panel or

cooktop. (Refer to instructions included with backsplash.)

5. INSTALLWOOD MOUNTING STRIP

Measure and mark a level line on waiI above cooktop Iocation for the wood

mounting strip (see iilustration below and under step 2)+ Use #10 - 2" flat

head screws to secure the mounting strip to the drywall Make sure to

hit the wall studs. (See figure beside.)

6. INSTALLTHE HOOD

Rest the back cavity of the hood on the wood mounting strip.

Secure hood to wood strip with (4) screws #8 - 3/4" (for 30" and 36"

width hoods) or (6) screws (for 42" width and wider hoods) provided at

locations shown. Drill (2) 3/16" size holes into the drywall for wall

anchors through the existing hoies in the inside hood back in the loca-

tions shown. Then instaiI the two walI anchors and attach the hood to

these anchors with the remaining #8 +3/4" screws and the (2) washers

provided.

®

®

®

HDOO68A

1. Drywall

2. Wood Mounting Stnp

3 Flat Head Screw

13" (330 mm) or

19" (483 ram) from

ceiiing (see page 5)

(38 ram)

4 [A/allAnchor Location

5. Outline of the Back of the Hood

6. Wall Studs

Page 7

7. INSTALLTRANSITION TO ROUGH-IN PLATE

Model 423, 424, 427, 453, or 454

Attach transition (if required) to blower rough-in plate.

Use duct tape to make aII joints secure and air-tight.

NOTE: Model RM325H blower plate connects directly to 7" round ductwork

without a transition.

Exterior blower models utilize a mode! 332KR rough-in plate

which connects directly to 10" round ductwork without a transition.

8. INSTALLTHE ROUGH-IN PLATETO THE HOOD

Run power cable to installation location. Refer to the instructions

included with the selected blower or rough-in kit (sold separately) for

details on installing the rough-in plate. Instatl the rough-in plate so that

the wiring box is located on the right side as you are facing the hood.

For ducting through back of hood, remove existing plate from inside

back of hood and attach to inside top of hood to cover hole. Secure to

threaded studs with same (4) nuts.

For ducting through top of hood, existing plate remains in place on

inside back of hood.

Connect ducting to transition or rough-in plate as you are installing the

rough-in plate. Use duct tape to make all joints secure and air-tight.

HDO063

1.Locknuts

2. Pluto on top of hood

3. Rough-in plate on back of hood

4. Wiring Cover

9. CONNECTTHE WIRING

Risk of eject with aH appHcabme codes andj

etandarde, Before connecting wires, switch power off at service panem and lock service disconnecting means to prevent powerJ

[from be ng ew tched on ace denta y. j

Remove wiring cover from rough-in plate and set aside.

Remove appropriate knockout from rough-in plate. As you are instalIing the rough-in plate, feed 6" of power cable through knockout

opening and attach cable to wiring box with appropriate connector.

Connect BLACK to BLACK, WHITE to WHITE and GREEN or bare wire under GREEN ground screw.

ReinstaII wiring cover.

H

_7 _

Page 8

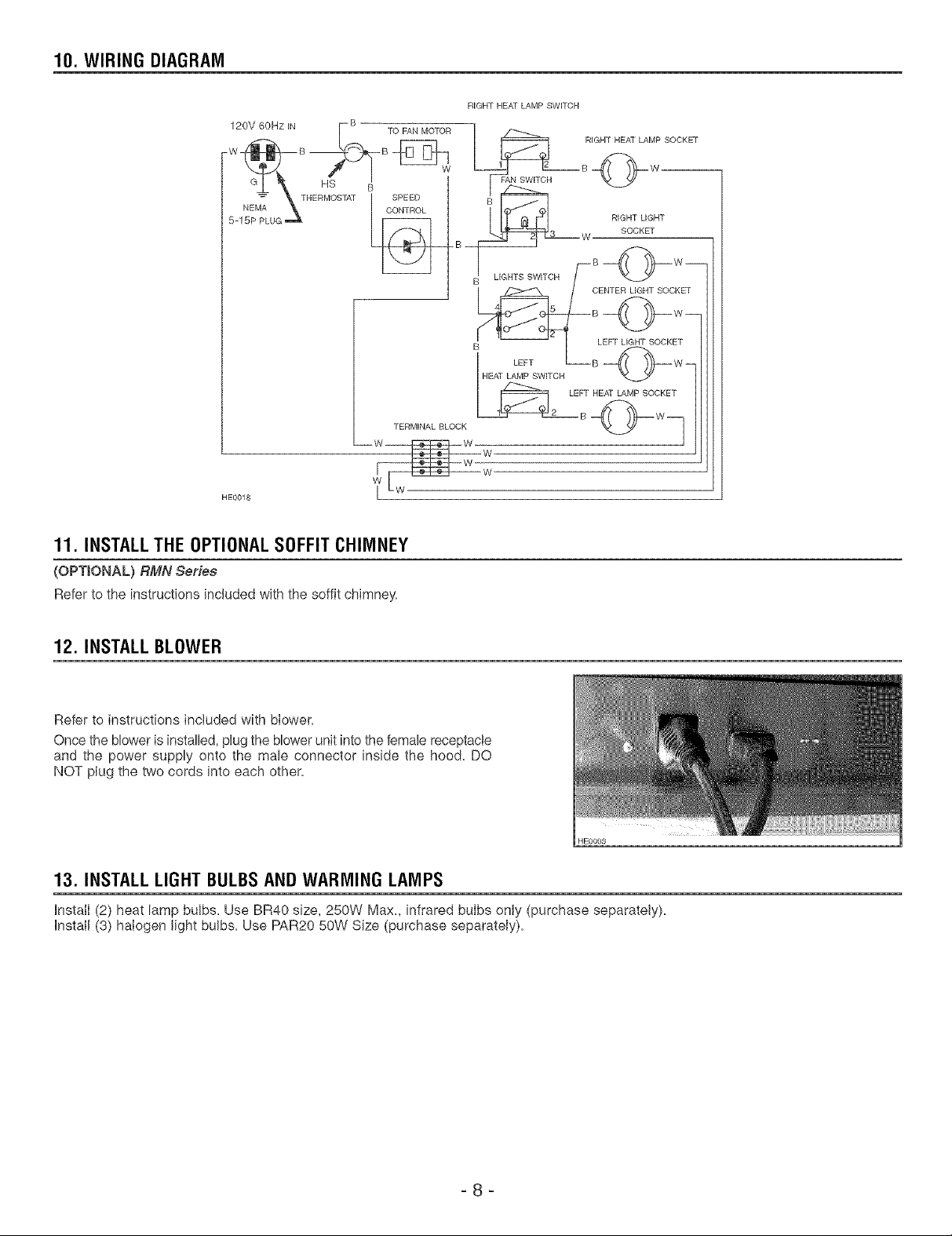

10. WIRING DIAGRAM

RIGHT HEAT LAMP SWITCH

HE0018

11. INSTALLTHE OPTIONAL SOFFIT CHIMNEY

(OPTIONAL) RMN Series

Refer to the instructions included with the soffit chimne_

12. INSTALL BLOWER

Refer to instructions included with blower.

Once the blower is installed, plug the blower unit into the female receptacle

and the power supply onto the male connector inside the hood. DO

NOT plug the two cords into each other.

HE0003

13. INSTALL LIGHT BULBSAND WARMING LAMPS

InstalI (2) heat lamp bulbs. Use BR40 size, 250Vv' Max, infrared bulbs only (purchase separately).

Install (3) halogen light bulbs. Use PAR20 50W Size (purchase separately).

=8 =

Page 9

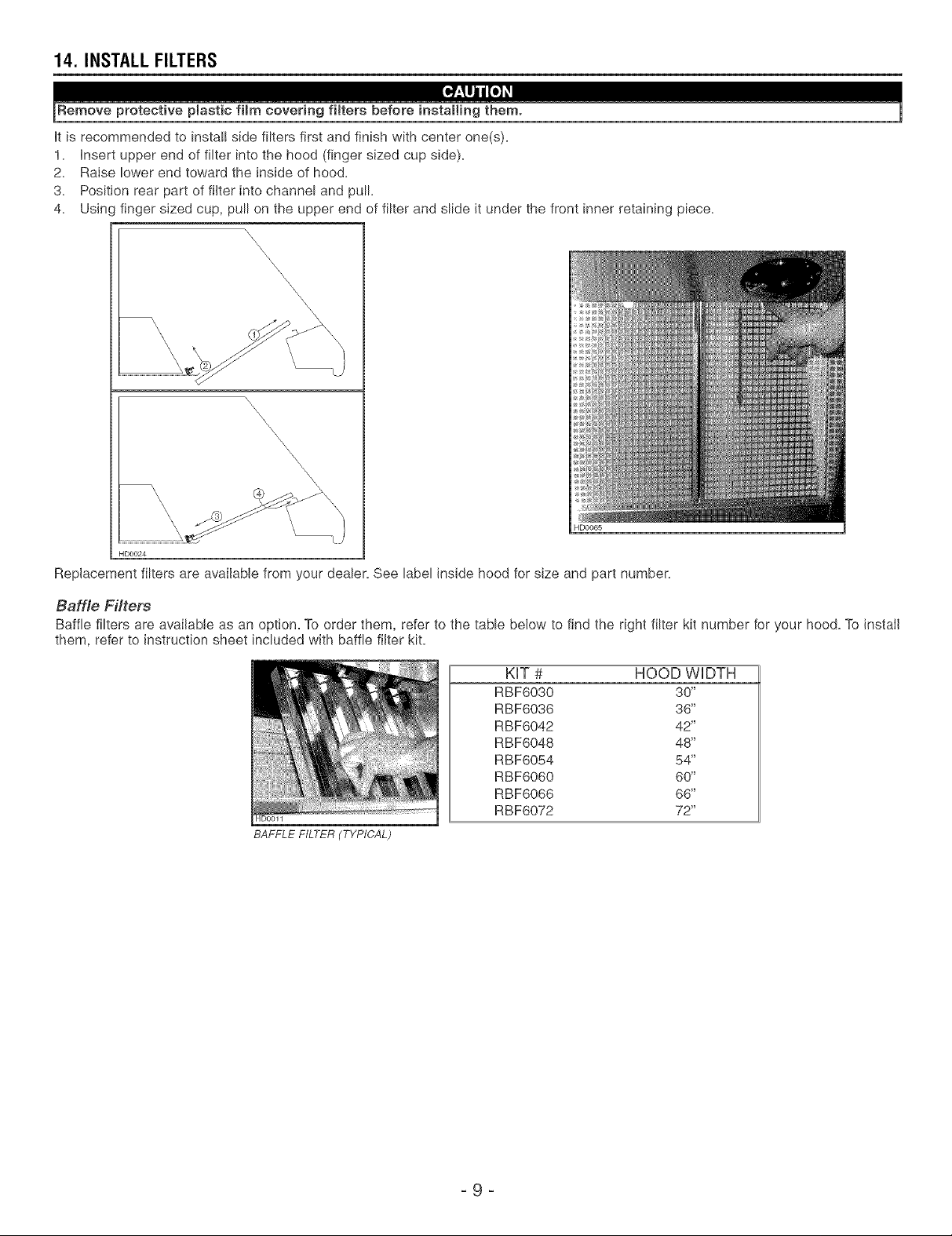

14. INSTALL FILTERS

It is recommended to instal! side filters first and finish with center one(s).

1. Insert upper end of filter into the hood (finger sized cup side).

2. Raise lower end toward the inside of hood.

3. Position rear part of filter into channel and pull.

4. Usin( finger sized cup, pull on the upper end of filter and slide it under the front inner retaining piece.

\\\\

\

\\\\\

HDO065

HD0024

Replacement filters are available from your dealer. See label inside hood for size and part number.

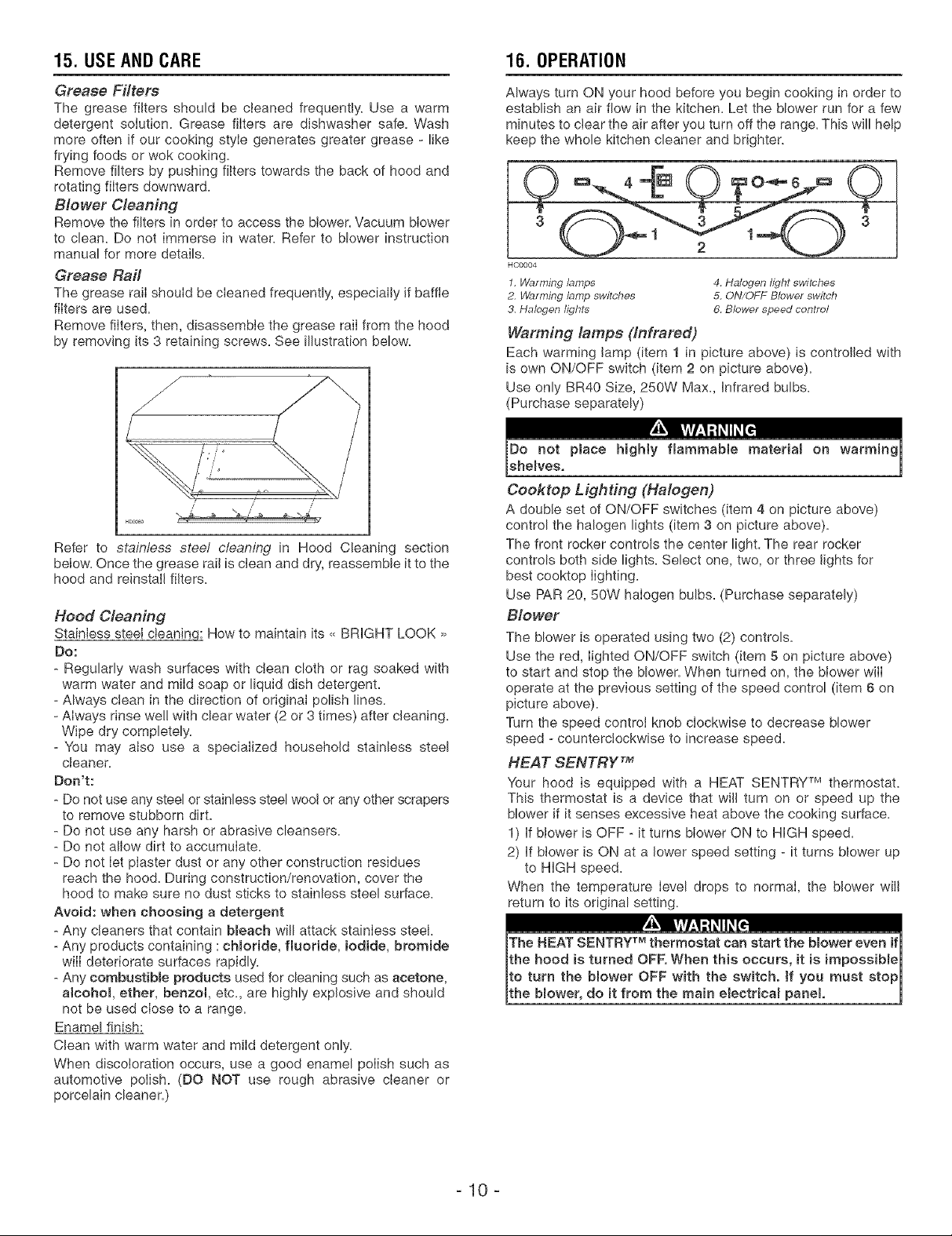

Baffle Filters

Baffle filters are available as an option_ To order them, refer to the table below to find the right filter kit number for your hoe& To install

them, refer to instruction sheet included with baffle filter kit.

KIT # HOOD WIDTH

RBF6030 30"

RBF6036 36"

RBF6042 42"

RBF6048 48"

RBF6054 54"

RBF6060 60"

RBF6066 66"

HD0011

BAFFLE FILTER (TYPICAL)

RBF6072 72"

_9 _

Page 10

15. USEAND CARE 16. OPERATION

Grease Filters

The grease filters should be cleaned frequently. Use a warm

detergent solution. Grease filters are dishwasher safe. Wash

more often if our cooking style generates greater grease - like

frying foods or wok cooking.

Remove filters by pushing filters towards the back of hood and

rotating filters downward.

Blower Cleaning

Remove the filters in order to access the blower. Vacuum blower

to clean. Do not immerse in water. Refer to blower instruction

manual for more details.

Grease Rail

The grease raiI shouId be cIeaned frequently, especiaIly if baffle

filters are used.

Remove filters, then, disassemble the grease raiI from the hood

by removing its 3 retaining screws. See illustration below.

Refer to stainless steel cteanit_g in Hood Cleaning section

below. Once the grease rail is clean and dry, reassemble it to the

hood and reinstalI filters.

Hood Cleaning

Stainless steel cteaningl How to maintain its ,, BRIGHT LOOK >>

Do:

- Regularly wash surfaces with clean cloth or rag soaked with

warm water and mild soap or liquid dish detergent.

- Always clean in the direction of original polish lines.

- Always rinse wel! with clear water (2 or 3 times) after cleaning.

Wipe dry completely.

- You may also use a specialized household stainless steel

cleaner.

Don't:

- Do not use any steel or stainless steel wool or any other scrapers

to remove stubborn dirt.

- Do not use any harsh or abrasive cleansers.

- Do not allow dirt to accumuIate.

- Do not Iet piaster dust or any other construction residues

reach the hood. During construction/renovation, cover the

hood to make sure no dust sticks to stainless steel surface.

Avoid: when choosing a detergent

- Any cleaners that contain b_each will attack stainIess steel.

- Any products containing :cHoride, fluoride, iodide, bromide

will deteriorate surfaces rapidly.

- Any combuetiMe products used for cleaning such as acetone,

atcohoL ether, benzol, etc., are highly explosive and should

not be used cIose to a range.

Enamel finish:

Clean with warm water and miId detergent only.

When discoloration occurs, use a good enamel poIish such as

automotive poIish. (DO NOT use rough abrasive cleaner or

porcelain cleaner.)

Always turn ON your hood before you begin cooking in order to

establish an air flow in the kitchen. Let the blower run for a few

minutes to clear the air after you turn off the range. This will help

keep the whole kitchen cleaner and brighter.

HCO004

1, Warming lamps 4. Halogen light switches

2. Warming lamp switches 5. ON/OFF Blower switch

3. Halogen lights 6. Blower speed control

Warming lamps (Infrared)

Each warming lamp (item 1 in picture above) is controlled with

is own ON/OFF switch (item 2 on picture above).

Use only BR40 Size, 250W Max., Infrared bulbs.

(Purchase separately)

Cooktop Lighting (Halogen)

A double set of ON/OFF switches (item 4 on picture above)

control the halogen lights (item 3 on picture above).

The front rocker controls the center light. The rear rocker

controls both side lights. Select one, two, or three lights for

best cooktop Iighting.

Use PAR 20, 50W halogen bulbs. (Purchase separately)

Blower

The blower is operated using two (2) controls.

Use the red, lighted ON/OFF switch (item 5 on picture above)

to start and stop the blower. When turned on, the blower witI

operate at the previous setting of the speed control (item 6 on

picture above).

Turn the speed control knob cIockwise to decrease blower

speed - counterclockwise to increase speed.

HEAT SENTRY TM

Your hood is equipped with a HEAT SENTRY TM thermostat.

This thermostat is a device that will turn on or speed up the

blower if it senses excessive heat above the cooking surface.

1) If blower is OFF - it turns blower ON to NIGH speed.

2) If blower is ON at a lower speed setting - it turns blower up

to NIGH speed.

When the temperature Ievel drops to normaI, the blower will

return to its original setting.

-10-

Page 11

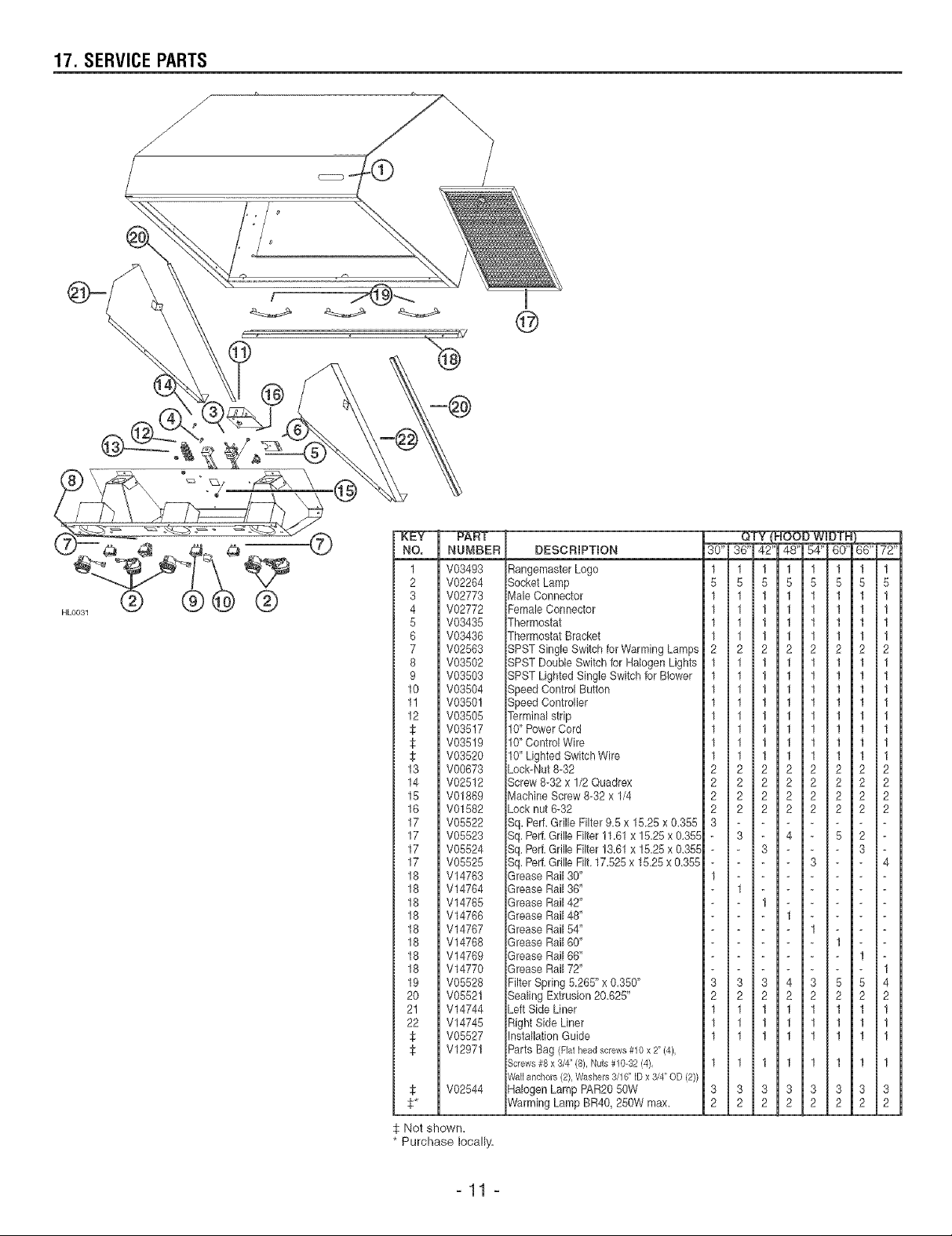

17. SERVICE PARTS

i

@

HLO031

NO.

NUMBER

1

V08493

2

V02284

3

V02773

4

V02772

5

V03435

6

V08436

7

V02583

8

V03502

9

V03503

10

V03504

11

V03501

12

V03505

V08517

V03519

V03520

13

V00673

14

V02612

15

V01889

16

V01582

17

V05522

17

V05523

17

V05524

17

V05525

18

V14763

18

V14764

18

V14765

18

V14768

18

V14767

18

V14768

18

V14769

18

V14770

19

V05528

2O

V05521

21

V14744

22

V14745

V05527

V12971

V02544

: Not shown.

Purchase locally'.

DESCRIPTION

RangemasterLogo

SocketLamp

Male Connector

FemaleConnector

Thermostat

Thermostat Bracket

SPST Single Switch forWarming Lamps

SPST DoubleSwitch for HalogenLights

SPST LightedSingle Switchfor Blower

Speed Control Button

Speed Controller

Terminalstrip

10" PowerCord

10"ControlWire

10" LightedSwitch Wire

Lock-Nut8-32

Screw 8-32x 1/2Quadrex

Machine Screw8-32 x 1/4

Locknut 6-32

Sq. Perf.Grille Filter 9.5 x 1&28 x 0.355

Sq.Pert Grille Filter11.61x 15.25x 0.355

Sq.Perf.GrilleFilter !&61 x !525 x 0.355

Sq.Perf.Grille Filt.17.525x 15.25x &355

GreaseRail 30"

GreaseRail 36"

GreaseRail 42"

GreaseRail 48"

GreaseRail 54"

GreaseRail 60"

GreaseRail 66"

GreaseRail 72"

FilterSpring 5265" x 0.350"

Sealing Extrusion2&625"

LeftSide Liner

Right Side Liner

InstallationGuide

Parts Bag (Flat head screws #10 x 2" (4),

Screws #8 x 3/4" (8), Nuts # 10-32 (4),

Wall anchors (2), Washers 3/16" ID x 3/4" OD (2))

HalogenLamp RAR2050W

WarmingLamp BR40, 250W max.

30" 36'

1 1

5 5

1 1

1 1

1 1

1 1

2 2

1 1

1 1

1

1

1

1

1

1

2

2

2

2

3

1

3

2

1

1

1

1 1

3 3

2 2

1

1

1

1

1

1

2

2

2

2

3

1

3

2

1

1

1

42' 48"

1 1

5 5

1 1

1 1

1 1

1 1

2 2

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

2 2

2 2

2 2

2 2

- 4

3 -

1 -

- 1

3 4

2 2

1 1

1 1

1 1

1 1

3 3

2 2

54" BO" BB" 72"

1 1 1 1

5 5 5 5

1 1 1 1

1 1 1 1

1 1 1 1

1 1 1 1

2 2 2 2

1 1 1 1

1 1 1 1

1 1 1 1

1 1 1 1

1 1 1 1

1 1 1 1

1 1 1 1

1 1 1 1

2 2 2 2

2 2 2 2

2 2 2 2

2 2 2 2

- 5 2 -

3 - - 4

3 5 5 4

2 2 2 2

1 1 1 1

1 1 1 1

1 1 1 1

1 1 1 1

3 3 3 3

2 2 2 2

Page 12

18. WARRANTY

BROANoNUTONE ONE YEAR LBMBTEDWARRANTY

Broan-NuTone warrants to the original consumer purchaser of its products that such products will be free from defects in materials or

workmanship for a period of one year from the date of original purchase. THERE ARE NO OTHER WARRANTES, EXPRESS OR

IMPLED, INCLUDING, BUT NOT LIMITED TO, IMPLED WARRANTES OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without charge, any product or part which is found to be

defective under normal use and service.

This warranty does not cover (a) normal maintenance and service or (b) any products or parts which have been subject to misuse,

negligence, accident, improper maintenance or repair (other than by Broan-NuTone), faulty installation or installation contrary to

recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states and/or provinces

do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE'S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE'S OPTION, SHALL BE THE PURCHASER'S SOLE AND

EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL

OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some states and/or

provinces do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not

apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state, or province to another.

This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address or telephone number below, (b) give the model number

and part identification and (c) describe the nature of any defect in the product or part. At the time of requesting warranty service, you

must present evidence of the original purchase date.

In case of discrepancies between the english version and the french and or spanish version of this warranty, the english version will prevail.

Broan-NuTone LLC, 926 West State Street, Hartford, WI 53027

(1-800-637-1453)

NuTone, _nc., 4820 Red bank Road, Cincinnati, OH 45227

(1-800-543-8687)

BroamNuTone Canada, 8nc., 1140 Tristar Drive, Mississauga, ON L5T 1H9

(1-888-882-7626)

_12 _

Page 13

RANGE AoST oR

GUIDE D'INSTALLATION

ET D'UTILISATION

DES HOTTES DE CUISINII_RE

SI_RIE RM60000

HBO026

/_kCONQUES POUR LA CUISSON DOMESTIQUE SEULEMENTZ_,

ilI;=_I=i=IIIE*{ ]_'_l=l;,_'J=l;,i*]=l[_'iIl_'_"]III;,t [*,]IIIE ]_'_,

INSTALLATEUR "LAISSER CE GUIDE AU PROPRI#TAIRE.

PROPRI#TAIRE "INSTRUCTION D'UTILISATION ET D'ENTRETIEN EN PAGE 22.

Broan-NuTone LLC, 926 West State Street, Hartford, WI 53027 (1-800-637-!453)

NuTone, Inc., 4820 Red Bank Road, Cincinnati, OH 45227 (1-800-543-8687)

Broan-NuTone Canada, Inc., 1140 Tristar Drive, Mississauga, ON L5T 1H9 (!-888-882-7626)

o_ • _ | o_

V05527 rev. D

Page 14

/%, AVERTISSEMENT

AVERTISSEMENT

AFIN DE REDUIRE LES RISQUES D'INCENDIE,

D'I_LECTROCUTION OU DE BLESSURES CORPORELLES,

SUIVEZ LES INSTRUCTIONS SUIVANTES :

N'utilisez cet apparel! que de la fa£on prevue par le

manufacturier. Si vous avez des questions, contactez

le manufacturier a I'adresse et au numero de tel6phone

indiques sur la garantie.

2.

Avant de reparer ou de nettoyer I'appareil, couper

I'alimentation 6Jectrique en verrouillant le panneau de

service afin d'eviter sa remise en marche accidentelle.

Si le panneau de service ne peut 6tre verrouille, y fixer un

avertissement en evidence.

3,

Les travaux d'installation et de raccordement electrique

doivent 6tre effectues par une personne qualifiee, conformement

aux codes et standards de construction, incluant ceux concernant

le feu.

4,

Une quantite d'air adequate est requise afin d'assurer une

bonne combustion et I'evacuation des gaz par la cheminee

darts le cas des equipements alimentes au gaz, afin de

prevenir les retours de cheminee. Conformez-vous aux

instructions et aux standards de securit6 des manufacturiers

d'equipement de chauffage, tels que publies par le National

Fire Protection Association (NFPA) et I'American Society for

Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), ainsi que les responsables des codes Iocaux.

Lorsque vous coupez ou perforez un mur ou un plafond,

prenez garde de ne pas endommager les ills electriques ou

tout appareil caches.

6,

Les ventilateurs avec conduits doivent toujours ¢tre ventiles

& I'exterieur.

7,

Ne pas utiliser cet appareil avec une commande de vitesse

semi-conducteur additionnelle.

8,

Afin de reduire les risques d'incendie, n'utilisez que des

conduits de metal.

9, Cet appareil dolt ¢tre mis a la terre.

AFIN DE RF:DUIRE LES RISQUES DE FEU DE CUISINIERE :

a) Ne jamais laisser les appareils de cuisson sans surveillance

Iorsqu'ils sent r6gles & feu vif. Les debordements engendrent de

la fumee et des deversements graisseux pouvant s'enflammer.

Chauffez I'huile lentement, & feu doux ou moyen.

b) Toujours mettre la hotte en marche Iorsque vous cuisinez a feu

vif ou que vous cuisinez des mets flambes.

c) Nettoyez regulierement la (les) roue(s) du ventilateur. Ne

laissez pas la graisse s'accumuler sur le ventilateur ou les filtres.

d) Utilisez le bon format de casserole. Servez-vous toujours de

casseroles et d'ustensiles appropries a la dimension de la

surface chauffante.

AFIN D'EVITER TOUT RISQUE DE BLESSURES DANS LE GAS

D'UN FEU DE CUlSINIERE, SUIVEZ CES INSTRUCTIONS* :

1. Etouffez les flammes avec un couvercle hermetique, une

tSle a biscuits ou un plateau metallique et ensuite, eteindre

le brt31eur. PRENEZ SOIN D'EVITER LES BROLURES. SI

LES FLAMMES NE S'ETEIGNENT PAS

IMMEDIATEMENT, EVACUEZ LES LIEUX ET APPELEZ

LES POMPIERS.

2. NE PRENEZ JAMAIS UNE CASSEROLE EN FLAMMES

DANS VOS MAINS - Vous pourriez subir des brQlures.

3. N'UTILISEZ PAS D'EAU, incluant linge a vaisselle ou serviette

mouilles - ceci pourrait occasionner une violente explosion.

4. N'utilisez un extincteur QUE DANS LE CAS O0 :

A. Vous savez qu'il s'agit d'un extincteur de classe ABC

et que vous en connaissez le fonctionnement.

B. l_incendie est petit et limite a I'endroit oQ il a debut6.

C. Les pompiers ont et6 avises.

D. Vous pouvez combattre I'incendie en ayant acces &

une sortie de secours.

* Tirees du "Kitchen Fire Safety Tips" publie par la NFPA.

ATTENTION

Pour usage domestique seulement. Ne pas utiliser pour

evacuer des vapeurs ou des produits dangereux

ou explosifs.

Afin d'eviter tout dommage au moteur et de debalancer

ou de rendre bruyante la roue du moteur, garder votre

appareil a I'abri des poussieres de placopl_tre et de

construction/renovation, etc.

Le moteur de votre hotte possede une protection

thermique qui eteindra automatiquement le moteur s'il

devient surchauffe. Le moteur repartira automatiquement

une lois refroidi. Si le moteur continue & arr6ter et &

repartir, faites-le verifier.

Pour une meilleure evacuation des odeurs de cuisine, le

bas de votre hotte devrait 6tre & un minimum de 24" et un

maximum de 30" au-dessus de la surface de cuisson.

Afin de reduire les risques d'incendie, assurez-vous

d'evacuer Fair & I'exterieur - Ne pas evacuer Fair dans

des espaces restreints comme I'interieur des murs ou

plafond ou dans le grenier, faux plafond ou garage.

Ce produit est 6quipe d'un thermostat pouvant faire

demarrer le ventilateur automatiquement. Afin de reduire

le risque de blessure, couper le courant & partir du

panneau electrique et verrouillez ou apposez un avertissement

sur le panneau afin de prevenir que la hotte soit mise en

marche automatiquement.

Afin de reduire les risques d'incendie et d'electrocution,

la hotte de cuisiniere Rangemaster Serie RM60000 dolt

6tre installee uniquement avec un des ventilateurs suivants :

RM325H, RM326H, 331H, 332H, 335 ou 336 (vendus

separement). Aucun autre ventilateur ne dolt 6tre utilise.

8,

Cette hotte ne dolt 6tre utilisee seulement qu'avec un

ensemble de cordon d'alimentation approuve.

9.

Veuillez consulter I'autocollant appose & I'interieur de la

hotte pour plus d'informations ou autres exigences.

-14-

Page 15

1,0

2,0

3,0

4,0

5,0

6,0

7,0

8,0

9,0

10,0

11,0

12,0

13,0

14,0

15,0

16,0

17,0

18,0

CHOISIR L:OPTION VENTILATEUR ET iNSTALLER LES CONDUITS ............................ 17

MESURER L:INSTALLATION ........................................................... 17

PRO:PARER EINSTALLATION ........................................................... 18

iNSTALLER LE DOSSERET ........................................................... 18

iNSTALLER LA LISIERE DE BOIS ....................................................... 18

iNSTALLER LA HOTTE ............................................................... 18

iNSTALLER LA TRANSiTiON ,_ LA PLAQUE VENTHLATEUR ................................... 19

iNSTALLER LA PLAQUE VENTHLATEUR SUR LA HOTTE ..................................... 19

BRANCHEMENT €:LECTRHQUE ......................................................... 19

SCHC:MA €:LECTRIQUE .............................................................. 20

iNSTALLER LE COUVREoCONDUHTS .................................................... 20

iNSTALLER LE VENTHLATEUR ......................................................... 20

iNSTALLER LES AMPOULES ET LES LAMPES CHAUFFANTES ............................... 20

iNSTALLER LES FHLTRES ............................................................. 21

ENTRETIEN ....................................................................... 22

FONCTIONNEMENT ................................................................. 22

PIECES DE REMPLACEMENT ......................................................... 23

GARANTIE ........................................................................ 24

_15 _

Page 16

Capuchons de

mur ou toit.

Ventilateurs

ext6fieurs

L_

Coudes et

volet

int6rieur

Conduits

MODELE 331H M( 335 MODELE 437

(Ventilateur ext.) (Ventilateur ext.) (Capuchon de toit

(600 pcm) OU (1200 pcm) OU & haut rendement)

332H (900 pcm) 336 (1500 pcm) !

t..................... _:::z:::zz::]_:::::::::::! ..................... ]

MOD#LE 418 MOD#LE 421

(Coude ajustabb 10" ronc (Vobt int6rieur vertical

\\ //

\\ z

• //

\

\ /

10" rond)

z

MODELE 441

(Capuchon de

toit 10" rond)

MODELE 647

(Capuchon de

mur 7" rend)

\ /

MODELE 415

(Coude ajustabb 7" rend)

MODELE 634 OU 644

(Capuchon de toit)

I

I

i

Choisir 1 des

5 transitions

PLAQUE VENT_LATEUR

MOD#LE 332KR

(& utiliser avec tousles

modebs de ventilateur exL :

//

/

\\

331 H, 332H, 335 et 336)

Choisir 1 des 3

syst#mes de ventilateur

(Conduit rend 10"- Sections de 2 pieds)

MODELE 410

/ I I I

/

/

/

J

MODELE 427 NIODELE 423 NODELE 424

(4'/2" x 18W' (4V2" x 18'/;' & 10" (4'/;' x 18V2" a

10" rond, 6" rond - verticab) 10" rond - horiz.

haut - lat6rale) avant / arri6re)

h................... J ....................... J....................... L ..................... J

\\

\

\

\

I I

MODELE 454 MOD#LE 453

(4W' x 18V;' a (4W'x 18V;' &

10" rond - 10" rond - honz

horiz, / droke) / gauche)

I I I

__VRE=CONDUITS

SE_R_ERMN

_ HOTTE _" (Ventiiateur int6rieur de 600 pcm

MODELE RM326H

VENTJLATEUR /

PLAQUE VENTILATEUR

(Ventilateur int6rieur de 1200 pcm

et pJaque ventiJateur)

(Conduit rond 7"- Sections de 2 pieds)

MODELE 407

i

i

MOD#LE RM325H

VENTILATEUR /

--- - _ _ _ PLAQUE VENT_LATEUR

SERIE

'_ & plaque ventilateur)R_60000

ventilateur et

(Avec contr61e

6clairage. Requis

pour toutes les

installations) FILTRES A CHICANES

OPT_ONNELS

SE_R_ERBF

B Y B R O A N - N U T O N E

SI RIE RM60000

SYSTI ME DE HOTTE

DE CUlSINII RE

=16=

DOSSERET S¢:R_E R_P

(Recouvrement de mur en acier inoxydabb

avec support assiettes. Facultatif)

HLO030

Page 17

1. CHOISIR L'OPTION VENTILATEUR

ET INSTALLERLES CONDUITS

2. MESURER L'INSTALLATION

La hotte de cuisini@e S@ie RM60000 fonctionne autant avec

un ventiIateur exterieur qu'int@ieur, Ella dolt _tre instalI_e

uniquement avec un des ventilateurs suivants : RM325H,

RM326H, 331H, 332H, 335 ou 336 (vendus s6par6ment),

Aucun autre ventilateur ne dolt 6tre utiJis&

NOTES : 1, Le ventiIateur exter[eur 331H, 332H, 335 ou 336

DOlT _tre [nsta!le avec Ia ptaque ventilateur modele

332KR (vendue separ6ment),

2, En pIus des modeles de ventiIateurs 6num@6s

cFdessus, cette hotte est aussi compatible avec

les anciennes versions de modeles de ventiiateurs

internes, soit Ies 325H et 326H, Si ces ventiIateurs

sent utiIises, jeter les instructions d'instalIation

comprises avec ces ventiJateurs, VeuiIIer contacter

notre soutien technique afin d'obtenir les nouvelIes

instructions d'installation,

Determiner&queIendroit etde quelle fagonlesconduits seront Iocalis6s,

Installer des conduits de dimension appropri_e, transition(s),

coude(s) et capuchon de toit ou de tour, au moteur utilis&

Les dimensions pour Jes JnstaIlations Jes plus courantes sent

indiqu_es plus bas,

Ajustez vos mesures pour Ies diff@entes hauteurs de plafond,

soffite, armoires ou surfaces de cuisson, Afin d"assurer un

meilleur fonctionnement, mahotte doit _tre aun minimum de

24" ({}10 ram) eta un maximum de 30" (762 ram) au=dessus

de masurface de cu[sson.

Plafoad

Armoire

standard

18"(457mrs)

au°dessus

de la surface

l J standard

I8"

(457 rara}

19"

(483 ram)

24" Distance minimate entre la

(610 rnm) hotte et Ussurface de cuisson

8 pL (2,44 ra)

Deasus de Ja

lisi_re de bois

Dosseret

S_.rie RMP

(facuUtatif)

MODELE RM325H A 1 VENTILATEUR

CONDUITS STANDARDS

MODELE RM326H ,&,2 VENTILATEURS

CONDUITS STANDARDS

VENTI/ATEUR EXTERIEUR

CAPUOHON DE TOIT

\

254 _fm)

(voir page 16)

l Surface de

-- standard

Surface de caisson hauteur

suisaon

36" (914 ram)

INSTALLATIONSOUS DES-ARMOIRES

STANDARDDE 18" HAUT

Plafond

Soffite standard _ t standard

12" 305 t#r_ ou 12' | 8' (2,44 ra)

Serie RMN (305 rara)E

CSernJ.eesoffite[j | 13"

€(33orara)

la liai_re

de boia

Dosaeret

S_rie RMP

(facultatif)

30" Distance ma×iraaUe

(762 ram) entre Is hotte et Ua

surface de cuisson

HN0028F

=17 =

J Surface de

" _ caisson staadard

Surface de caisson hauteur

36" (914 ram)

HH0027F

INSTALLATION AVEC UN SOFFITE DE 12" OU

LE COUVRE-CONDUITS OPT. SE_RiE RMN

Page 18

3. PRI_PARERL'INSTALLATION

Retirer Ia trousse d'instalIation de I'interieur de la hotte.

S'assurer que les items suivants soient presents :

-Lisiere de bois

-Guide d'installation

-Accessoires incluant :

.Les filtres (la quantite varie selon la largeur de la hotte)

.Sac de quincailIerie incJuant :

Vis #10 - 2" & t_te plate (4), Vis #8 - 3/4" (8), E_crous#10 - 32 (4)

Ancrages de gypse (2), Rondelles 3/16" DI X 3/4" DE (2)

A I'aide d'un tournevis Phillips #2 ou d'un Robertson #2, retirer les

vis retenant Ia hotte au fond de Ia caisse. Voir Jafigure ci-contre pour

Iocaliser les 4 vis. Jeter ces vis et retirer la hotte de la caisse.

HR0002

4. INSTALLERLE DOSSERET

(Facultatif) Serie RMP

Le dosseret dolt _tre instalIe avant Ia hotte puisque ce!Ie-ci couvre Ies vis d'installation du dossereL Afin de pouvoir installer Ie dosseret,

s'assurer d'avoir au moins 18" (457 ram) entre Ie dessus de la hotte et le panneau de contr61e de la cuisini@e ou de la surface de

cuisson (Voir les instructions fournies avec le dosseret.)

5. INSTALLERLA LISII:RE DE B01S

Mesurer puis tracer une ligne drolte, au-dessus de la surface de cuisson,

pour Ia Iocalisation de la Iisi@e ce bois. ,&,I'alde des vis a tSte plate

#10 - 2", fixer Ia Iisi@e de bois au tour en vous assurant d'atteindre les

montants. (Voir I'illustration de l'6tape 2 et celle c[-contre.)

6. INSTALLERLA HOTTE

En appuyant la hotte au rnur, ins@er la lisiere de bois dans la cavit6

arrJ_re de Jahotte.

HDOO68F

1. Mur

2. Lisigre de bois

3 Visa t#te fraisee

13" (330 ram) ou

19" (483 ram) du

plafond (volr page 17)

1-1/2"

(38 ram)

4. Locatisation des ancrages de gypse

5 Trace de I'arrigre de/a hotte

6 Montants

Fixer la hotte & la Iisi@e de bois & I'aide de (4) vis #8 - 3/4" (pour les

hottes de 30" et 36") ou (6) vis (pour les hottes de 42" et plus) fournies,

aux endroits indiques. En se servant des trous existants dans la hotte,

percer lemur de (2) trous de 3/16" pour Ies ancrages de gypse, aux

endroits indiqu6s. Puis, ins@er Ies deux ancrages de gypse et fixer Ia

hotte & ces ancrages avec les (2) vis restantes #8 - 3/4" et les (2)

rondelles fournies.

_18 _

Page 19

7. INSTALLERLA TRANSITION A LA PLAQUE VENTILATEUR

Meddles 423, 424, 427, 453 eu 454

Fixer la transition (s[ requise) & Ja plaque vent[lateur.

Sceller tous Ies joints avec du ruban a conduits.

NOTE : La plaque ventilateur du modele RM325N a un ventilateur se

branche directement a un conduit rend de 7", sans transition.

Les ventilateurs exter[eurs utilisent Ia plaque ventilateur 332KR;

elle se branche dlrectement b.un conduit rend de 10",sans transition.

8. INSTALLERLA PLAQUEVENTILATEUR SUR LA HOTTE

Amener Ie c&ble d'aJimentation a la Iocal[sation de la hotte. Pour les

d6ta[Is concernant I'installation de Ia plaque ventilateur, voir les

instructions comprises avec celle-ci (vendue s@arement). Installer Ia

plaque de facon & ce que son boi'tier 6lectrique soit a dro[te, Iorsque

vous fa[tes face a Ia hotte.

Si vous choisissez !'evacuation par I'arriere, retirer la plaque de I'arriere

de Ia hotte et !'installer sur le dessus pour couvr[r I'ouverture. Fixer b.

la hotte avec les m_mes 6crous denteles.

Pour une evacuation par Ie dessus, Iaisser Ia plaque a I'arri@e de la hotte.

Relier les conduits a la transition ou a la plaque ventilateur. Util[ser du

ruban a conduit afin d'assurer I'etanch6ite de tousles joints.

HDO063

1.E-crous denteles

2. Plaque sur le dessus de la hotte

3. Plaque ventilateur 8 I'arriere de la hotte

4. Couvemle du boPtier electrique

9. BRANCHEIVIENTItLECTRIQUE

Risque de chocs emectriques. Le raccordement eBectrique doit _tre effectue par du personnem quaHfie conformement au× codes 1

jet standards. Avant d effectuer le branchement coupez JaJimentation emectrique au panneau de service et verrouiHezde pour

[ev ter une mse en rnarche ace dente eo j

Ret[rer le couvercie du bo_tier electrique de Ia plaque ventHateur et mettre de c6te.

Retirer Fouverture pr6-amorc6e du bo_tier eIectdque. En instaIIant Ia pIaque Ventilateur, ins6rer une Iongueur de 6" de cb.ble

d'aHmentation darts le bo_t[er _lectr[que par son ouverture et brancher Ie c&ble en utiIisant le connecteur appropr[e.

Connecter le fiI NOIR au NOIR, Ie BLANC au BLANC et JefHVERT ou d_nud6 a Jav[s VERTE de m[se b.Jaterre.

ReinstaJJer Jecouvercle du boi'tier 61ectrique.

_19 _

Page 20

10. SCHI_IVIAI_LECTRIQUE

INTER. LAMPE CHAUF. DROITE

DOUILLE LAMPE CHAUF. DROITE

IN'[ER. VEN]',LA]'EUR N -_ B

5-15P

BORNIER

HEO018

11. INSTALLER LE COUVRE-CONDUITS OPTIONNEL

(OPTtONEL) S#de RMN

Voir les instructions incluses avec le couvre*conduits optionneL

12. INSTALLER LEVENTILATEUR

3 B--

" N__t¢

N D'ECLA, AGE

N DOUILLE AMPOULE GAUCHE

I CHAOF.GAUCHE _

DOUILLE AMPOULE DROITE

DOUILLE AMPOULE CENTRALE

DOUILLE LAMPE CHAUF, GAUCHE

Pour installer le ventilateur, voir les instructions fournies avec celui-cL

Une lois install6, brancher le ventilateur et Ie cordon de Ia bo_te

electrique aux prises, a I'interieur de la hotte. NE PAS brancher

ensemble les deux cordons.

HEO003

13. INSTALLER LESAIVIPOULESETLAIVIPESCHAUFFANTES

InstaIIer deux lampes chauffantes. Utiliser des infrarouges de format BR40, 250W maximum (non incluses).

Installer trois ampoules halogenes. Utiliser des ampoules de format PAR 20, 50W (non incluses).

20

Page 21

14. INSTALLER LES FILTRES

HJest recommande d'instalIer d'abord Ies flltres s[tues aux extr_m[t6s et de term[ner par Je(s) fiJtre(s) du centre.

1. Ins@er Ia pattie sup@ieure du filtre dans la hotte (c6te de la poign6e).

2. Falre p[voter Ia pattie inferieure vers I'[nt@ieur de la hotte.

3. Placer Ie f[Itre sous I'attache s[tuee au fond de Ia hotte.

4. En util[sant la poignee, gl[sser Jef[Itre sous Ja )i_ce de retenue int@ieure.

\\\\\

\

\\\\\

\\

\ HD0065

HD0024

Des filtres de remplacement sent disponlbles chez votre detaillant. Consulter J'etiquette s[tuee & J'[nt@ieur de Jahotte pour Je num@o

de pJ6ce et le format.

Filtres # chfcane

Ces filtres sent dispon[bles en option. Pour Ies commander, se ref@er au tableau ci-dessous pour trouver Je num@o de kit correspondant

& Jahotte. Pour Jes installer, se ref6rer & JafeuilJe d'instruct[on incluse darts Je kit de filtres b.chicane).

KIT # LARGEURDE HOTTE

RBF6030 30"

RBF6036 36"

RBF6042 42"

RBF6048 48"

RBF6054 54"

RBF6060 60"

RBF6066 66"

HDO011

FtLTRE A CHICANE (TYPtQUE)

RBF6072 72"

_21

Page 22

15. ENTRETIEN

16. FONCTIONNEMENT

Filtres

Les filtres doivent 6tre nettoy6s fr6quemment. Utiliser une solution

d'eau chaude et de d_tergent. Les fiItres sont Iavables au

lave-vaisselle. Les filtres doivent _tre laves plus souvent sJ vos

habitudes de cuisson g6n@ent pJus de graisse - comme par

exemple de la friture ou des aliments sautes au wok.

Pour retirer les filtres, pousser chaque filtre vers Ie bas en utiJisant

la poign6e afin des d6gager de Ia piece de retenue. PuJs,

pousser vers I'int6rieur de Ia hotte et les retirer.

Nettoyage du ventilateur

RetJrer Ies fiItres pour acceder au ventilateur. Passer I'aspirateur

pour Ie nettoyer ; ne pas I'immerger dans I'eau. Pour pJus de

d6tails, consuJter Je guide d'Jnstruction du ventilateur.

Goutde_e

La goutti@e dolt 6tre nettoyee fr6quemment, sutout sJdes filtres

&chicanes sont uti!is_s. Retirer Ies filtres, puis desassembler Ia

gouttiere de Ia hotte en d6vissant ses 3 vis de retenue. Voir

I'illustration ci-dessous.

Consulter la section nettoyage de I'acier inoxydable dans la section

nettoyage de la hotte ci-dessous. Une lois Ia goutti_re propre et

seche, la r_assembler sur la hotte et r6installer les filtres.

Nettoyage de la hotte

Acier inox_dabte : Comment preserver son

,_APPARENCE CTINCELANTE 7,

A faire :

- Laver r6guli@ement les surfaces _ I'aided'un chiffon ou linge propre

imbib6 d'eau tilde et de savon doux ou d_tergent _ vaisselle.

- Toujours nettoyer dans Ia direction des lignes de grains (direction

du polissage).

- Toujours bien rincer avec de I'eau propre (2 ou 3 lois) et

essuyer compl_tement.

- Vous pouvez 6galement utiliser un nettoyant domestique

congu sp6cialement pour J'acier inoxydable.

_, ne pas faire :

- N'utilisez aucune Iaine d'acier ou d'acier inoxydable ou tout

autre grattoir pour enlever Jasalete tenace.

- N'utilisez aucune poudre nettoyante abrasive ou rugueuse.

- Ne laissez pas Ia salete s'accumuler.

- Ne pas laJsser Ia poussiere de platte ou tout autre r6sidu de

construction/r6novation atteindre Ia hotte. Couvrir Ia hotte pour

la dur_e des travaux pour s'assurer qu'aucune poussi_re ne

colic &tla surface de I'acier.

_, _,viter moredu choix d'un detergent :

- Tous produits nettoyants qui contiennent des agents de

blanchiment ;ils attaqueront I'acier inoxydable.

- Teus produits contenant du chlorure, fluorure, lode ou

bromure ;ils det6rioreront rapidement Ies surfaces.

- Tous produita cornbuetiMes utilJs6s pour le nettoyage :acetone,

alcooL ether, benzol etc. :iIs sont hautement expIosifs et ne

devraient iamais 6tre utilis6s pros d'une cuisini@e.

Surfaces peintes :

Nettoyer avec de I'eau chaude additionnee seulement d'un

d6tergent doux. S'il y a d6coIoration, utiIisez une bonne cire

peinture telIe qu'une cire d'automobiJe. (NE PAS UTlUSER de

nettoyant abrasif ou de nettoyant a porcelaine.)

Touiours mettre en marche la hotte avant de commencer Ia

cuisson afin d'etablir une circulation d'air dans Ia cuisine. Aussi,

laisser la hotte fonctionner quelques minutes apr@s I'arr@t de Ia

cuisini6re afin de nettoyer Fair. Ceci aidera _ garder la cuisine

plus propre et plus claire.

HO0004

1.Lampes r_chauds 4. Interrupteurs de la mpes halog_nes

2. Interrupteurs de lampes rAchauds 5. Interrupteur Marche/Arr_t du ventilateur

3. Lampes halog_nes 6. ContrSle de la vitesse du venfilateur

Lampes rechauds

Chaque lampe rechaud (item 1de I'illustration ci-dessus) poss_de

son propre interrupteur Marche/Arr@t(item 2 de I'illustrationci-dessus).

N'utiliser que des ampoules infrarouges BRA0, 250W max.

(non incluses).

Eclairage (Halogene)

Les interrupteurs doubles Marche/Arr_t (item 4 de I'iIIustration

ci-dessus) contr6ient Ies lampes halog@nes (item 3 de I'illustration

ci-dessus).

LJinterrupteur avant contr61e Ia lampe centrale. LJinterrupteur

arri6re contr61e Ies deux lampes de c6te. Choisir une, deux ou

trois Iampes selon vos pref6rences d'6cIairage.

Utiliser des ampoules haIogenes PAR 20, 50W (non incluses).

Vendlateur

Le ventilateur est contr61e par (2) commandes.

Utiliser I'interrupteur Iumineux rouge (Marche/Arr6t) (item 5 de

I'illustration ci-dessus) pour actJonner ou arr@er le moteur. Une

lois mis en marche, le ventiIateur fonctionnera & la vitesse pre-

selectionn6e par Ia commande de vitesse (item 6 de I'iIIustration

ci-dessus).

Pour augmenter la vitesse du ventilateur, toumer le bouton de

contr61e de Ia vitesse dans le sens horaire -dans le sens

anti-horaire pour ralentir la vitesse.

HEAT SENTRY _

Votre hotte est munie d'un thermostat HEAT SENTRY Mc, Ce

thermostat est un dispositif qui actionnera ou augmentera la

vitesse du ventiIateur s'il d6tecte une chaleur excessive

au-dessus de Ia surface de cuJsson.

1) S[ Ie ventilateur n'est pas en marche - il actionnera le

ventiIateur en haute vitesse.

2) S[ Ie ventilateur fonctionne en basse vitesse - le ventilateur

tournera en haute vitesse.

Lorsque Ia temperature revient & la normale, le ventilateur

retourne & sa vitesse d'origine.

- 22 -

Page 23

17. PIF:CESDE REMPLACEMENT

i

@

HLO031

NO.DE NO. _E LA

REE P ECE

1 V03493

2 V02264

3 V02773

4 V02772

5 V03435

6 V03436

7 V02563

8 V03502

9 V03503

10 V03504

11 V03501

12 V03505

$ V03517

$ V035!9

$ V03520

13 V00673

14 V025!2

15 V01869

16 V01582

17 V05522

17 V05523

17 V05524

17 V05525

18 V14763

18 V14764

18 V14765

18 V14766

18 V14767

18 V14768

18 V14769

18 V14770

19 V05528

20 V05521

2! V14744

22 V14745

$ V05527

$ V12971

$ V02544 Ampoule halogene RAR20 50W 3 3 3 3 3 3 3

$* Ampoule chauffante BR40, 250W max_ 2 2 2 2 2 2 2

_: Non illustr_

* S'approvisionner [ocalement

DESCRIPTION

LogoRangemaster 1 1 1 1 1 1 1

Douille 5 5 5 5 5 5 5

Connecteurm_le 1 1 1 1 1 1 1

Connecteurfemelle 1 1 1 1 1 1 1

Thermostat 1 1 1 1 1 1 1

Support pourthermostat 1 1 1 1 1 1 1

Inter.simple UPSTpourlampechauffante 2 2 2 2 2 2 2

Inter.doubleUPST pour lampe halogene 1 1 1 1 1 1 1

Inter.simple illumine UPSTventilateur 1 1 1 1 1 1 1

Boutoncontr61edevitesse

Contr61ede vitesse

Plaque_ bornes

Cordond'alimentation10"

Fil de contr61e!0"

Fil interrupteurillumine 10"

Ecrou dentele8°32

Visquadrex 8°32x 1/2

Vismecanique 8°32x 1/4

Ecrou dentele6°32

Filtre_ grillecarree 9,5 x 15,25 x 0,355 3

Filtre_ grillecarree 11.61x 15.25x 0.355 - 3 4 5 2

Filtre&grille carrie 13.61x !525 x 0,355 - 3 3

Filtregrillecarr6e 17_525x 1525 x 0,35[

Goutti@e30"

Geutti@e36"

Geutti@e42"

Goutti@e48"

Goutti_re54"

Geutti@e60"

Goutti@e66"

Goutti@e72"

Ressort de filtre 5.265" x 0.350"

Extrusiond'etancheite 20,625"

Paroiinterieure gauche

Paroiint@ieure @oRe

Guided'installation

Sacd'installation (VisL,t@e plate #10 x 2" (4),

Vis#8 x 3/4"(8), @rous #10-32(4),Ancragesde 1 1 1 1 1 1 1

gyp,se(2),Rondelles3/16"DI x3/4"DE(2))

1 1 1 1 1 1 1

1 1 1 1 1 1 1

1 1 1 1 1 1 1

1 1 1 1 1 1 1

1 1 1 1 1 1 1

1 1 1 1 1 1 1

2 2 2 2 2 2 2

2 2 2 2 2 2 2

2 2 2 2 2 2 2

2 2 2 2 2 2 2

3

1

1

1

1

1

3 3 3 4 3 5 5

2 2 2 2 2 2 2

1 1 1 1 1 1 1

1 1 1 1 1 1 1

1 1 1 1 1 1 1

1

1

23

Page 24

18. GARANTIE

GARANT+E LIM+TEE D'UN AN DE BROAN+NUTONE

Broan-NuTone garantit & I'acheteur consommateur initialde ses produits qu'ils sent exempts de tous d6fauts dans Ies matieres premieres

eu Ia main-d'_uvre pour une p6rlode d'un an _ compter de la date d'achat par le consommateur initial. IL N'Y A PAS D'AUTRES

GARANTIES, EXPRIMEES OU IMPLICITES, INCLUANT, MAIS NON LIMITE'._ESAUX GARANTIES IMPLICITES POUR FIN DE

COMMERCIALISATION ET DE CONVENANCE DANS UN BUT PARTICULIER.

Durant cette periode d'un an, Broan-NuTone, _ sa discretion, r6parera ou remplacera gratultement, tout prodult ou piece qui s'avere

defectueux et ayant 6t_ utilise nomalement et d'une maniere non abusive.

Cette garantle ne couvre pas (a) I'entretien et Ie service normal ou (b) tout prodult ou pl_ce endommage par suite de mauvals usage,

negligence, accident, entretJen lnapproprl_ ou reparation (autre que par Broan-NuTone), mauvaise lnstallatlon ou

installation non conforme au mode d'installation recommande.

La dur6e de toute garantie lmpllclte est limit6e _ une p6rlode d'un an tel que specifi6 pour la garantle exprimee.

L:ENGAGEMENT DE BROAN-NUTONE DE RE'PARER OU DE REMPLACER, AU CHOIX DE BROAN-NUTONE, SERA LA SEULE

OBLIGATION EXCLUSIVE SOUS CETTE GARANTIE. BROAN-NUTONE NE SE TIENDRA PAS RESPONSABLE DES DOMMAGES

DIRECTS, INDIRECTS OU SPE_CIAUX SURVENANT ,_ CAUSE DE OU EN RAPPORT ,A.EUTILISATION OU LA PERFORMANCE DE

SES PRODUITS.

Cette garantie vous donne des drolts legaux sp_cifiques et iI se peut que vous ayez d'autres drolts qui varient d'un _tat b. un autre, ou

d'une province a I'autre. Cette garantie annule toutes les autres garantles pr6c_dentes.

Pour Ie service sous garantie, vous devez (a) aviser Broan-NuTone a J'adresse ou au numero de t61ephone mentionne plus bas, (b) donner

le numero du modele et I'identificatlon de la piece et (c) d6crire Ia nature de tout defaut dans le produit ou Ia pi6ce. Au moment de Ja

demande de service sous garantie, vous devez presenter une preuve de la date d'achat initial du dlt prodult.

En cas de divergences entre Ia version anglalse de cette garantie et la version frangalse eb]ou espagnole, Javersion anglaise pr6vaudra.

Broan+NuTone LLC, 926 West State Street Hartford, WI 53027

(1-800-637-1453)

NuTone, Inc., 4820 Red Bank Road, Cincinnati, OH 45227

(1+800-543-8687)

Broan+NuTone Canada, Inc., 1140 Tdstar Drive, M[ss[ssauga, ON LST 1H9

(1-888-882-7626)

+24 +

Page 25

RANGE AoST oR

MANUAL DE INSTALACION

Y UTILIZACION DE LAS

CAMPANAS SERIE RM60000

HB0026

/_CONCEBIDO SOLO PARA USO DOMESTICO/_

INSTALADOR: DE JAR ESTE MANUAL AL PROPRIETARIO

PROPRIETARIO: INSTRUCClONES DE UTILIZAClON Y MANTENIMIENTO EN LA P/_,GINA 34

Broan-NuTone LLC, 926 West State Street, Hartford, WI 53027 (1-800-637-!453)

NuTone, Inc., 4820 Red Bank Road, Cincinnati, OH 45227 (1-800-543-8687)

Broan-NuTone Canada, Inc., 1140 Tristar Drive, Mississauga, ON L5T 1H9 (!-888-882-7626)

V05527 rev. D

Page 26

ADVERTENCIA ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO, DESCARGA

ELECTRICA, O LESIONES A PERSONAS, CUMPLA LOS

SIGUIENTES PUNTOS :

1. Solamente use esta unidad de la manera propuesta por

el fabricante. Si tiene alguna pregunta, communiquese

con el fabricante en la direccion o telefono anotados en

la garantia.

2. Antes de limpiar o poner en servicio la unidad, apague

el interruptor en el panel de servicio, y asegure el panel de

servicio para evitar que se encienda accidentalmente.

Cuando el dispositivo para desconectar el servicio electrico

no puede ser cerrado con algOn tipo de traba, sujete

fuertemente al panel de servicio, una etiqueta de

advertencia prominente.

3. El trabajo de instalaci6n y el alambrado electrico deben

Ilevarse a cabo por personal calificado de acuerdo con

todos los codigos y las normas aplicables, incluyendo

los codigos y normas de construccion contra incendios.

4. Se requiere una cantidad de aire suficiente para la

combustion y escape de gases por la chimenea del

equipo de quemado de combustible para evitar salirse

de las especificaciones y estandares de seguridad del

fabricante, tales como los publicados por la Asociaci6n

nacional de proteccion contra incendios (NFPA pot sus

siglas en Ingles), y la Sociedad americana de ingenieros

de calefaccion, refrigeraci6n y aire acondicionado

(ASHRAE por sus siglas en Ingles), y los codigos de las

autoridades locales.

5. Cuando corte o taladre en una pared o techo, no daSe

los cables electricos, ni otras instalaciones ocultas.

6. Los ventiladores con conductos deben siempre ventilar

hacia el exterior.

7. No use esta unidad con ningQn otro control de velocidad

de estado s61ido.

8. Para reducir todo riesgo de incendio, use solamente

conductos en metal.

9. Esta unidad se debe conectar a tierra.

PARA REDUCIR EL RIESGO DE INCENDIO DE GRASA EN

LA SUPERFICIE DE LA ESTUFA:

a) No deje nunca los aparatos de cocer sin vigilancia a

fuego vivo. Los desbordamientos producen humo y

derrames grasiendos que pueden inflamarse. Caliente el

aceite despacio, a fuego lento o mediano.

b) Ponga en marcha siempre la campana al cocinar a

temperaturas elevadas o al cocinar alimentos flameados.

c) Limpie los ventiladores con frecuencia. No deje que la

grasa se acumule en el ventilador ni en el filtro.

d) Utilice cacerolas de tamaSo apropiado. Emplee siempre

un recipiente adecuado para el tamaSo de la placa.

- 26 -

PARA EVITAR RIESGO DE LESIONES PERSONALES EN

CASO DE INCENDIO DE GRASA EN LA SUPERFICIE DE LA

ESTUFA, OBSERVE LO SIGUIENTE :*:

1. Cubra y sofoque las llamas con una tapa ajustada,

azafate de hornear galletas, o azafate de metal, y luego

apague el calentador. TENGA CUIDADO PARA EVITAR

QUEMADURAS. Si la llamas no se apagan inmediatamente,

HAY QUE EVACUAR Y LLAMAR LOS BOMBEROS.

2. NUNCA ALCE UNA SART#:N QUE TENGA LLAMAS -

Usted se puede quemarse.

3. NO USE AGUA, incluyendo trapos, lavaplatos mojados o

toallas- puede que ocurran explosiones de vapor violentas.

4. Use un extintor SOLAMENTE si :

A. usted sabe que tiene un extintor ABC y sabe usarlo.

B. El incendio es pequeSo y esta restringido al &rea

donde empezo.

C. Se esta Ilamando los bomberos.

D. Usted puede tratar de apagar el fuego teniendo

una salida detr&s suyo.

* Basado en "Kitchen Fire Safety Tips" publicado por la

Asociaci6n National de protecci6n contra Incendios (NFPA).

PRECAUCION

1. Solo para uso de ventilacion general. No se use para

extraer materiales o vapores peligrosos o explosivos.

2. Para evitar daSos al cojinete del motor y/o impulsore ruidosos

o desequilibrados, mantenga la fuente de potencia lejos

de rocios de pared seca, de polvo de construccion, etc.

3. El motor de la campana tiene un dispositivo contra

sobrecargas termicas que apaga el motor en forma

autom&tica si este se sobrecalienta. El motor volver&

arrancar cuando se enfrie. Si el motor sigue apag&ndose,

haga verificar la campana.

4. Para Iograr una mejor captura de las impurezas

producidas al cocinar, la parte inferior de la campana

deber& estar a un minimo de 24 y un m&ximo de 30

sobre el nivel la superficie para cocinar.

5. A fin de reducir los riesgos de incendio y para bien evacuar el

aire de salida, asegQrese de evacuar el aire al exterior - No

evacue el aire en espacios limitados como el interior de

las paredes o del techo o en el desv&n, falso techo o garaje.

6. Este producto est& equipado de un termostato que

puede hacer partir el ventilador autom&ticamente. Para

evitar los riesgos de da5o, apague la corriente del panel

electrico y cierre con candado o afiche una advertencia

en el panel para prevenir que la campana funcione

autom&ticamente.

Para reducir el riesgo de incendio y descarga electrica,

esta campana Rangemaster RM60000 serie debe ser

instalada con ventilador modelo RM325H, RM326H,

331 H, 332H, 335 o 336 solamente. Otros ventiladores no

pueden reemplazar a este ventiladores. (Ventiladores

vendidos separadamente.)

8,

Utilice solo con un conjunto autorizado de conexion con

cordon.

9.

Lea la etiqueta de especificaciones en el producto para

mayor informacion y requisitos.

Page 27

1,0

2,0

3,0

4,0

5,0

6,0

7,0

8,0

9,0

10,0

11,0

12,0

13,0

14,0

15,0

16,0

17,0

18,0

SELECCIONE LA OPTION VENTILADOR Y INSTALE LOS CONDUCTOS ......................... 29

MIDA LA INSTALAClON ............................................................... 29

PREPARE LA INSTALACION ........................................................... 30

INSTALE LA PLACA PARA SALPICADURAS ............................................... 30

INSTALAClON DE LA TIRA DE MADERA ................................................. 30

INSTALE LA CAMPANA ............................................................... 30

INSTALE LA TRANSICION EN PLACA DEL VENTILADOR .................................... 31

INSTALE LA PLACA DEL VENTILADOR EN LA CAMPANA .................................... 31

CONECCION ELC:CTRICA ............................................................. 31

ESQUEMA ELC:CTRICO .............................................................. 32

INSTALE LA CHIMENEA DE iNTRADOS OPCIONAL ........................................ 32

INSTALE EL VENTILADOR ............................................................ 32

INSTALE LOS BOMBILLAS Y LAMPARAS TERMOGENA ..................................... 32

INSTALE LOS FILTROS ............................................................... 33

MANTENIMIENTO ................................................................... 34

FUNCIONAMENTO .................................................................. 34

REPUESTOS ....................................................................... 35

GARANTiA ........................................................................ 36

27

Page 28

Tapas del

muro o techo

Ventiladores

exterior

L_

Codes y

compuerta

de tire

Conductos

MODELO 331N MODELO 437 MODELO 441

(Ventilador ext.) (Ventilado ext.) (Tapa de techo de (Tapa de techo

(600 pcm) O (1200 pcm) O Mta capacidad) redondo 10")

332N (900 pcm) 336 (1500 pcm) !

t..................... _::rz::zz2%:::::::::::! ..................... ]

!

MODELO 418 MODELO 421

(Codo ajustado de 10" redondo) (Compuerta de tiro en

\\ //

\\ /

• //

\

\ /

I[nea vertical redondo 10")

z

MODELE 647

(Taps de muro

redondo 7')

MODELO 634 O 644

\ /

MODELO 415

(Codo ajustado de T' redondo)

I

I

i

(T3pa de techo)

Seleccione 1 de 5

transicidns

PLACA DEL VENTJLADOR

MODELO 332KR

(Utilizar con todos los modeios

de ventiladores ext : 331 H

332H, 335 et 336)

Seleccione 1 de 3

systemas de ventiladores

(Conducto redondo de 10" - Secciones de 2 pies)

MODELO 410

(Conducto redondo de 10" - Secciones de 2 pies)

MODELO 407

...................... T........ _.............. !....... q - ]

I I

NODELO 427 NODELO 423 MODELO 424 NODELO 454 NODELO 453

(4VP'x 18'/#' a (4W' x 18'/2" a (4'/P' x 18W' a 10" (4'/f' x 18W' a (4W' x 18'/P' a

10" redondo - 10" redondo - redondo - horiz. 10" redondo - 10" redondo -

6" altura -lateral) vertical) frente / atr_s) horiz. /der.) horiz. / izq.)

I I

h................... J ....................... J....................... h ..................... J

i i i !

__ENEAS DE

INTRADOS OPCiONAL

RMN SERIE

MODELO RM326N

VENTILATOR / PLACA

VENTILADOR

(1200 pcm ventiiador interior

y placa ventilador)

controies dei

(Pabeii6n con

ventiiador y

iluminaci6n.

Se requiere para FtLTROS DE ZiG ZAG

todas las instMaciones) SERiE RBF

- --- - _ _ _ VENTILADOR

MPANA ' interior y placa ventilador)

RIE R_,_60000 _

-_. (600 pcm ventiiador

_x

1

i

i

MODELO RM325N

VENTILADOR / PLACA

OPOEONAL

BY BROAN_NUTONE

SERIE RM60000

SYSTEMA DE CAMPANA

= 28 =

PLACA PARA SALPICADURAS

RMP SERIE

(Cubierta para pared, de acero inoxidable

con estantes para cMentamiento.

Opcional )

HLO030

Page 29

1. SELECCIONELA OPTIONVENTILADORY INSTALE

LOSCONDUCTOS

2. MIDA LA INSTALACION

La campana Serie RM60000 funciona tanto con un ventllador

exterior como interior. Esta campana debe ser instalada con

ventilador mode!o RM325H, RM326H, 331H, 332H, 335 o 336

solamente. Otros ventiladores no pueden reemplazar a este

ventiladores.

NOTAS: 1. El ventilador exterior 331H, 332H, 335 o 336 debe

ser instalado con la placa del ventilador modeto

332KR (vendida separadamente).

2. Adem_s de modelos de ventiladores Iista arriba, este

campana es tambJen compatible con antiguo modelos

de ventiladores intemos: 325H y 326H. Si este ventHadores

son utilizados, descartar las instrucciones de instataci6n

incluyes con este ventiladores. Oontactar con nuestro

soporte t6cnico por obtener Ias nuevas instrucciones

de instalaci6n.

Planifique d6nde y come se van a colocar los conductos.

Instale ductos, transiciones, codes y remate de pared o de

techo de tamale adecuado para el tipo de ventilador que este

usando.

REMATE DE TECHO

\

24' A 30" (609 A 762 mm)

SOBRE EL NiVEL DE LA

SUPERFICIE PARA COCINAF{

f

MODELORM325H CON 1 VENTILADOR

CONDUCTOSTIPJCOS

A continuaci6n se muestran las dimensiones para las

instalaciones m_s comunes.

A]uste sus medidas para Ias diversas alturas de techos,

intrad6s, gabinetes o superficies para cocinar. Para mograr un

funeionamiento adeeuado, Baparte inferior de _a eampana

debera eatar entre 6!0 y 762 mm (24 y 30 pumg,) sobre el

nivel de masuperficie para cocinar.

Teeho

Gabinete 8' (2,44 m)

estandar de

18" (457ram)

Jeaitura sobre 19"

la supetficie (483 ram)

pata cocinar

"_- _ Parte superior

Cam

est_ndar de

de Uatira de

madera de

montaje

C

7_- Placa para

24" (opcional)

(810 ram) Distar_Jamir_imaentreJacarnpana

INSTALACIONDEBAJO UNA ARMARIO

EST,_,NDARDE 18" DE ALTURA

.... salpicaduras

serie RMP

y la superficie para cocinar

SuperfJc_e

para cocinar

est_ndar de

-- 36" (914 ram)

de aitura

HHO028E

MODELO RM326HCON 2VENTtLADOR

CONDUCTOSTIPICOS

VEN1 kLADOR EXTERIOR

10"(254mm)

CODO

REDONDO

PLACA DEL

f

MODELO 331H, 332H, 335 O 336

VENTILADOR EXT. CONDUCTOS TIPICOS

10'(114×470 a

254 ram)

(vet p_glna 28)

Techo

est_ndar de

8' (2,44 m)

Pa_e superior

de Jatira de

madera de

montaje

....... sa_picaduras

30" Distancia m4xima entre la

(762 ram)

Superficie para cociRar 36" (914 ram)

Plata para

ser_e RMP

(optional)

campana y la superficie

para cocinar

Superficie

para cocinar

estandar de

de altura

HH0027E

INSTALACiONCON INTR_,DOS ESTANDARDE

12"O CHIMENEA DE INTRADOS SERE RMN

29

Page 30

3. PREPARELA INSTALACION

Quite e! estuche de instaIaci6n de dentro de la campana.

AsegQrese que Ios art[culos siguientes estAn incluidos:

-Tira de madera

-Manual de instaIaci6n

-Complementos incluyendo:

.Los filtros (la cantitad varia conforme a Ios dimensi6nes de la campana)

.Bolsa de piezas inctuyendo:

Tornillos #10 - 2" con pIana cabeza, (4), TornilIos #8 - 3/4" (8),

Tuercas #10 - 32 (4), Anclas de la pared (2), Arandelas 3/18" Di X 3/4" De (2)

Usando un destornillador Phillips #2 o un Robertson #2, destornille

la campana del fondo de Ia canasta. Refierase a la figurar para

Iocalizar Ios 4 tornillos. Tire los tornillos y quite la campana de la

paleta de madera.

HR0002

4. INSTALELA PLACAPARASALPICADURAS

(Opcionat) Serie RMP

La placa para saIpicaduras se debe instalar antes que Ia campana debido a que este cubre los tornilIos de montaje de la placa para

salpicaduras. Para instaiar la placa para saipicaduras, asegQrese de tenet 18" (487 mm) entre debajo de la campana y el panel de

control de la cocina o encima de la cocina (Vea las instrucciones incluidas con la placa para salpicaduras.)

5. INSTALACIONDE LATIRA DE IVIADERA

En la pared, mida y marque una I[nea de nivel para Ia tira de montaje

de madera pot encima de Ia posici6n de la superficie para cocinar (yea

las dimensiones en Ias ilustraciones del paso 2 y debajo). Usando los

tornilIos con plana cabeza #10 - 2", asegure la tira de montaje a Ia

pared de manera de alcanzar los traversafios de la pared. (Vea figura

aI lade.)

6. INSTALELA CAMPANA

Para instalar la campana en su lugar, use la tira de madera para

apoyar la cavidad de la parte de atrAs de la campana.

1-I/2" :

38 mm I I

"I _ I t-l/

HDOO68E

1. Pared

2. Tira de madera

3 Tomillosde cabeza avellanar 6 Traversados

4. Locallzacion de las anctas de la pared

5. Atras de/a campana

19" (483 ram) de

techo (yea p&gina 29)

!

1_1/2"

(38 ram)

Segure la campana a Ia tira de Ia montura con los 4 tornillos

#8 - 3/4"(para una campana de 30" o 38" larga) o 6 tornillos (para las

campanas de 42" y mas Iarga) incUdos en Iugar indicado. Perfora (2)

aguieros de 3/18" de largo en Ia pared para las anclas de pared en

lugar indicado. Entonces, instale las 2 anctas de la pared y asegure la

campana con los 2 Oltimos tornillos #8 - 3/4" y las 2 arandellas.

- 30 -

Page 31

7. INSTALELA TRANSIClON EN LA PLACADEL VENTILADOR

Modelos 423, 424, 427, 453, o 454

Monte la transicion en la placa del ventilador.

Use cinta para ductos para que todas las juntas sean seguras y

hermeticas.

NOTA: La placa de un solo ventilador del modelo RM325H se conecta

directamente al conducto redondo de 7", sin transicion.

Los ventiladores exterior usan el modelo de la placa del ventilador

332KR que se conecta directamente al conducto redondo de

10", sin transicion.

8. INSTALE LA PLACA DEL VENTILADOR EN LA CAMPANA

Tienda el cable de energia al sitio de la instalacion. Por detalles referente

a la instalacion de la placa del ventilador, vea las instrucci6nes incluida

con esa (vendida separadamente). Instale la placa de tal forma que la

caja de cableado este fuera a la derecha, cuando ustedes hace frente

a la campana.

Si usted seleccione escape por detras, quite la placa de detras de la

campana y instale la placa sobre encima. Asegure la placa ventilador

al interior de la campana, usando 4 tuercas #10-32 (inclusos en la

bolsa de pieza).

Si usted seleccione escape por ecima, quite la placa de encima de la

campana y instale la placa sobre detr&s.

Conecte el ducto redondo a la transici6n o la la placa del ventilador.

Use cinta para ductos para que todas las juntas sean seguras y hermeticas.

1. Tuercas 3. Placa ventilador a detras de la campana

2. Placa sobre encima de la campana 4 Cubierta de la caja de cableado

9. CONEXION ELI_CTRICA

j_ll_*1 e_vj::i:_ I ::l_[e,]f._

Peligro de choque el_ctrico. La instalacibn el_ctrica debe ser hecha por personal calificado de acuerdo con todos los cbdigos

aplicables y normas. Antes de efectuar el empalme, cortar la alimentaci6n el_ctrica del interruptor y cerrar con securidad para

preven r una a mentac 6n acc denta.

Retire la cubierta del cableado de la placa del ventilador y poner a un lado.

Abra el agujero ciego en la caja de cableado de la placa del ventilador. Mientras instale la palca del ventilador, tienda 6" del cable de

energia y conecte el cable a la caja de cableado usando el conector adecuado.