Page 1

MODELS MP100, MP140 & MP200

MULTI-PORT IN-LINE FANS

READ AND SAVE THESE INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the address or telephone number listed below

the warranty.

2. Before servicing or cleaning unit, switch power off at

service panel and lock the service disconnecting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a

tag, to the service panel.

3. Installation work and electrical wiring must be done by

qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction

codes and standards.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fueling

equipment to prevent backdrafting. Follow the heating

equipment manufacturer’s guideline and safety standards such as those published by the National Fire

WARNING

Protection Association (NFPA), and the American Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

6. Ducted fans must always be vented to the outdoors.

7. This unit must be grounded.

CAUTION

1. For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or unbalanced impellers, keep drywall spray, construction dust,

etc. off power unit.

3. If ventilator is installed in an unconditioned space

(such as an attic): Surround the ventilator with thermal

insulation - to minimize possible condensation.

4. Please read specification label on product for further

information and requirements.

PLAN THE INSTALLATION

Adequate ventilation requires that both intermittent and

continuous contamination be controlled.

Intermittent ventilation must be provided in the bathroom

and kitchen. The bathroom requires 8 air changes per hour.

(Multiply bathroom sq. footage by 1.1 for proper fan sizing).

The kitchen requires a minimum of 150 CFM capacity (71

l/s) when a ducted range hood is used. If a kitchen fan is

used, determine fan capacity by multiplying the room's sq.

footage by 2. All are run intermittently to control pollution at

the source.

Continuous ventilation, while the house is occupied, provides the flow of fresh air for good indoor air quality.

This ventilator is intended for continuous operation, supplying fresh air to the entire house.

RECOMMENDED VENTILATOR SIZING

DWELLING SIZE RANGE (Sq. Ftg.)

(include finished basement area)

MODEL

MP100

MP140

MP200

*AC/HR = Air Changes per Hour. Based on 8' ceilings.

Square Feet x .093 = Square Meters

.50 AC/HR* .35 AC/HR* .30 AC/HR*

1500 2140 2500

2100 3000 3500

3000 4285 5000

Page 2

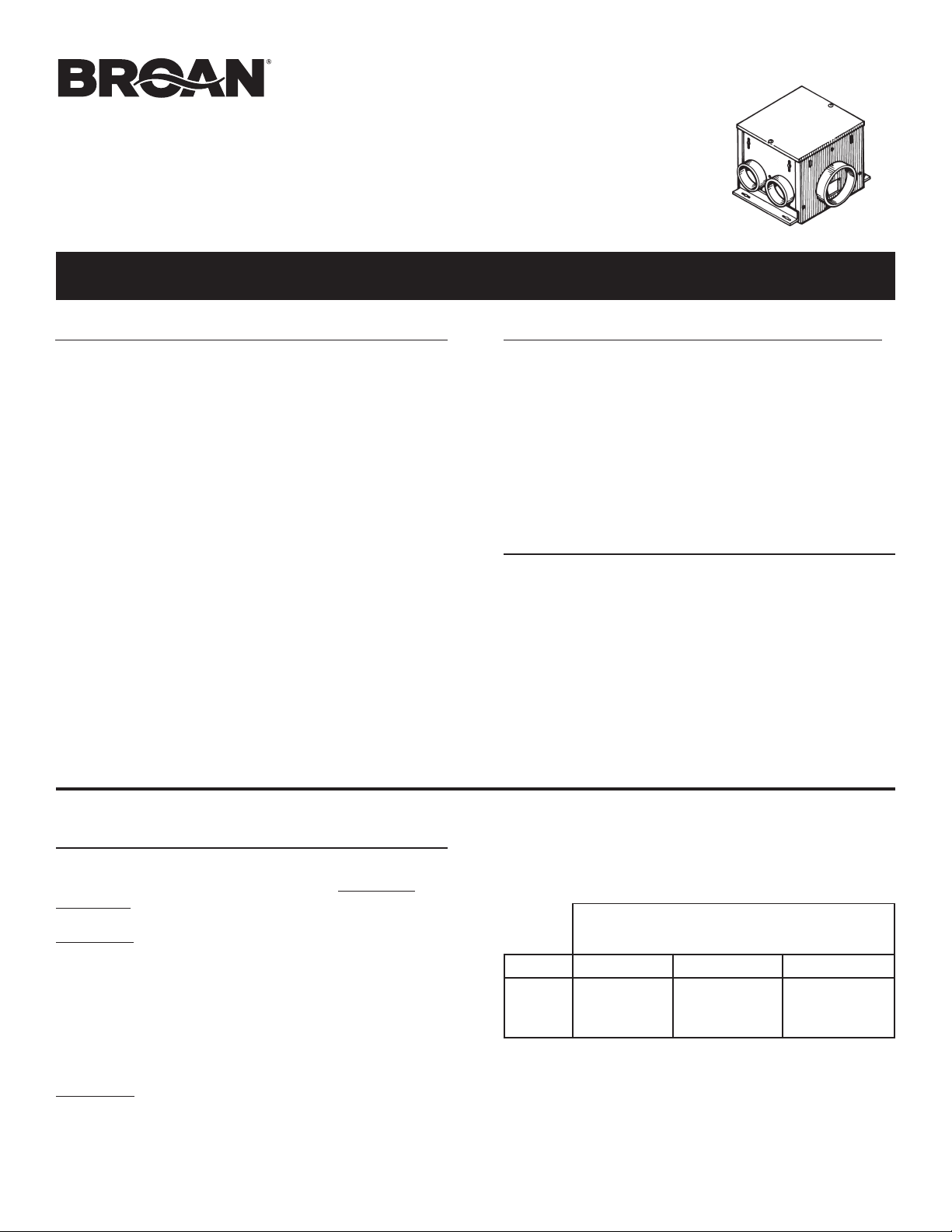

PLAN THE INSTALLATION

STALE

AIR

VENTILATOR

DIFFUSER

FRESH AIR

INLET

LOCATION OF DIFFUSERS & INLETS

SINGLE-STORY HOME

FRESH AIR INLETS

AIR FLOW IN TYPICAL INSTALLATION

VENTILATOR

The ventilator exhausts stale air. There are normally sufficient natural intake openings into a dwelling to admit fresh

outside air to be drawn in to replace the stale air. For better

control, fresh air inlets may be used.

The ventilator should be centrally located to keep ductwork

as short as possible. Locations for the ventilator include:

joists in an attic space or the basement, or a wall away from

the living areas.

EXHAUST

DIFFUSERS

(Available separately)

Exhaust diffusers regulate

the flow of fresh air drawn

through the house.

Exhaust diffusers should

be mounted in the ceilings or high on the wall.

For best performance, exhaust diffusers should be

mounted in a central location. An exhaust diffuser

should not be installed

near a cooking area. (see

figure)

COOKING AREA

Do not install

above or inside

this area

o

45

Cooking

Equipment

o

45

Floor

FRESH

AIR

DUCTED

KITCHEN

RANGE HOOD

DIFFUSER

DIFFUSER

DIFFUSER

DUCTED

BATH FAN

FRESH AIR INLETS

TWO-STORY HOME

FRESH AIR INLETS

DIFFUSER

SECOND

FLOOR

DUCTED

BATH FAN

FRESH AIR INLETS

DUCTED KITCHEN

RANGE HOOD

FRESH AIR INLETS (Available separately)

For best control of fresh air in a room, install a fresh air inlet.

The number of inlet vents depends on the floor plan.

Consider the rooms/areas through which fresh air should

flow toward the exhaust diffuser(s).

Vents should be located in outside walls, preferably near

the ceiling and approximately the same distance from a

diffuser. Vents should be separated from diffusers far

enough to allow fresh air to mix with room air before being

exhausted.

DIFFUSER

DUCTED

BATH FAN

FRESH AIR INLETS

DIFFUSER

FIRST FLOOR

Page 3

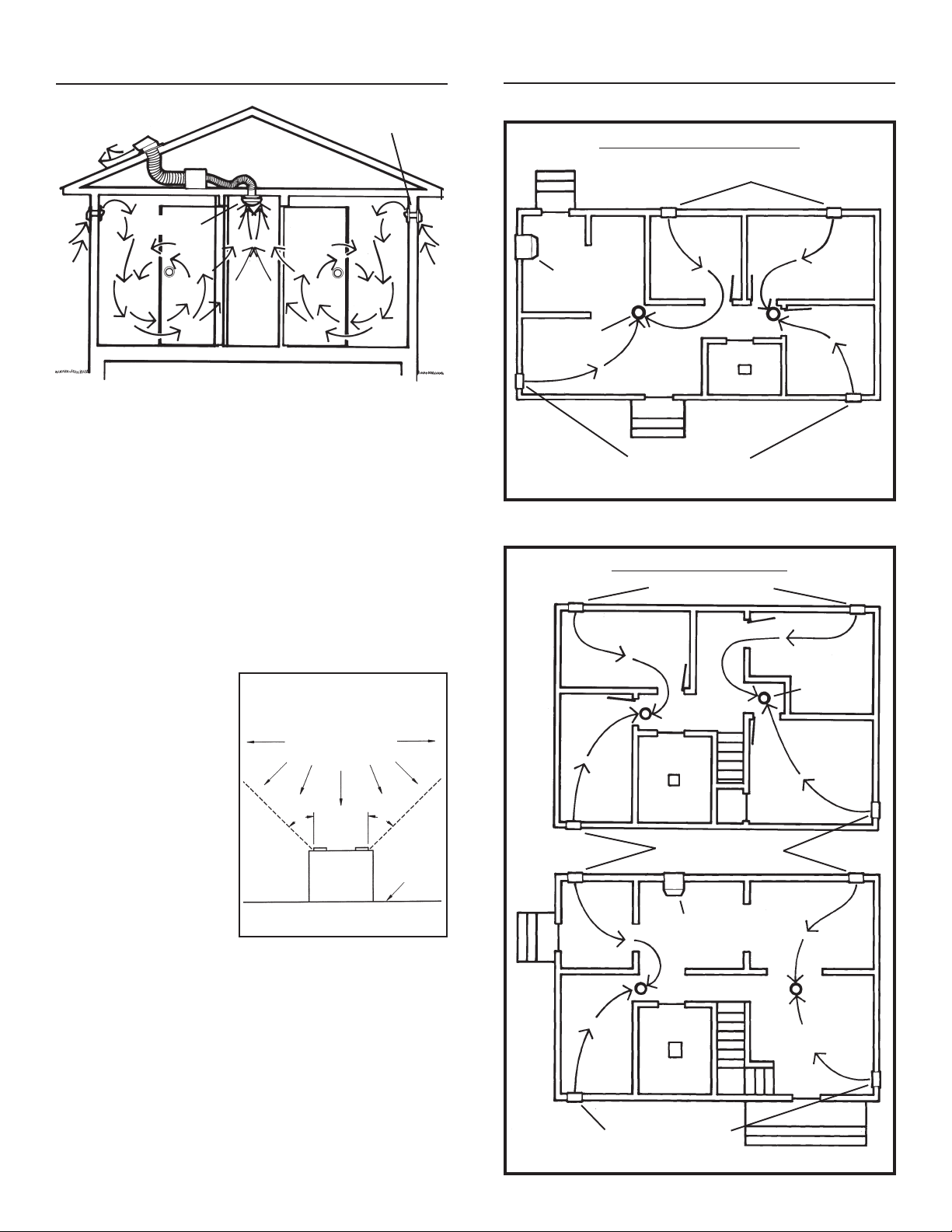

INSTALL FRESH AIR INLETS

CONNECT DUCTWORK

1. Mount all fresh air inlets in chosen locations during

rough-in construction. Follow directions packed with

inlets.

MOUNT THE VENTILATOR

CEILING

JOISTS

FRAMING

OR

FROM

DIFFUSERS

4" ROUND

INSULATED

FLEXIBLE

DUCT

FROM

DIFFUSERS

DUCT

TAPE OR CLAMP

6" ROUND

INSULATED

FLEXIBLE

DUCT

(OUTLET)

TO ROOF OR

WALL CAP

1. Run 4" insulated, flexible ductwork from ventilator inlet

to diffuser location(s) and 6" insulated flexible ductwork

from ventilator outlet to roof or wall cap.Outlet side is

marked with a label.

2. To minimize condensation inside of ductwork in the attic, cover ductwork with additional insulation. Also, avoid

forming condensation traps in the ductwork runs.

3. Seal ductwork to ventilator and roof or wall cap with duct

tape or clamp (available separately).

4.

If some ventilator inlets will not be used:

Place the inlet

cover(s) (provided) over the unused inlet(s) and tape

them in place.

CEILING

JOISTS

FRAMING

1. Add framing to ceiling joists as shown.

2. Set ventilator in place and screw to framing with screws

provided. Ventilator may also be hung from joists or

rafters with hanging straps (available separately).

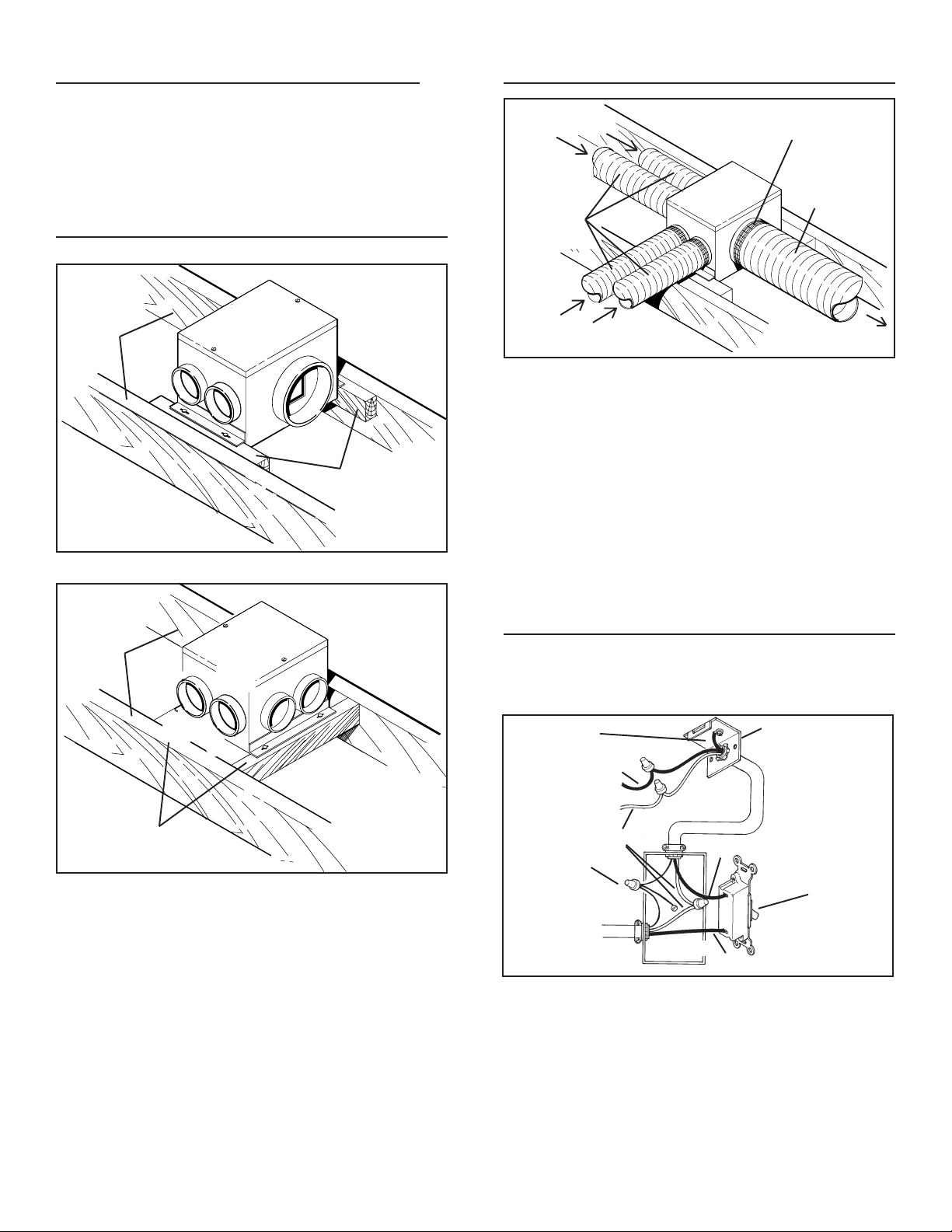

WIRE THE VENTILATOR

WARNING: DISCONNECT POWER AT SERVICE

ENTRANCE AND LOCK OUT SERVICE PANEL TO

PREVENT POWER FROM BEING SWITCHED ON

ACCIDENTALLY.

GROUND

WIRE

BLACK

WHITE

GROUND

(Green or

Bare Wires)

120 VAC

LINE IN

BLACK

BLACK

Use an ON/OFF switch to control the in-line ventilator.

Accessory timers and humidity controls are also available.

1. Remove the wiring adapter plate.

2. Attach power cable to wiring adapter plate using U.L./

CSA approved connector.

3. Connect black to black, white to white, and green or bare

wire to green ground screw.

4. Replace wiring adapter plate. Make sure tab on housing

slides through slot in plate.

WIRING ADAPTER

PLATE

ON/OFF

SWITCH

Page 4

INSTALL EXHAUST DIFFUSERS

USE AND CARE

WARNING: DISCONNECT ELECTRICAL POWER AND LOCK

OUT SERVICE PANEL BEFORE CLEANING OR SERVICING

THIS UNIT.

CLEANING

A continuously operating in-line ventilator needs to be cleaned

once a year to assure proper performance.

TO

VENTILATOR

4" ROUND

INSULATED

FLEXIBLE DUCT

DUCT

TAPE

OR

CLAMP

Remove cover and carefully vacuum blower and inside of housing. Be careful not to bend or otherwise damage blower wheel.

CEILING

DRYWALL

DIFFUSER

Follow instructions packed with diffuser(s). General instructions:

1. Cut hole(s) in ceiling drywall and install diffuser(s).

2. Connect insulated ductwork to diffuser(s) and use duct tape or

Diffusers and intake vents can be vacuumed and/or wiped clean

with a damp cloth.

MOTOR LUBRICATION

The motor is permanently lubricated. Do not oil or disassemble

motor.

clamp (available separately) to seal connection(s).

3. Rotate center of diffuser(s) counterclockwise to fully open for

maximum air flow. Reduce air flow by rotating center of

diffuser(s) clockwise to desired opening. A balancing damper

(available separately) can be used to adjust airflow.

SERVICE PARTS

Models MP100, MP140 & MP200

KEY

NO.

* Standard Hardware - May be purchased locally.

** Not shown assembled. Always order replacement parts by “Part No, - not by “Key No.”

Broan warrants to the original consumer purchaser of its products that such products will be free from defects in materials or workmanship for a period of one year from the date of original purchase. THERE

ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan will, at its option, repair or replace, without charge, any product or part which is found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERS AND TUBES. This warranty does not cover (a) normal maintenance and service or (b) any products or parts which have

been subject to misuse, negligence, accident, improper maintenance or repair (other than by Broan), faulty installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

BROAN’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN’S OPTION, SHALL BE THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN SHALL NOT BE

LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE. Some states do not allow the exclusion

or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan, (b) give the model number and part identification and (c) describe the nature of any defect in the product or part. At the time of requesting warranty

service, you must present evidence of the original purchase date.

PART

NO.

1 99150591 Screw, #10 x 7/8" (4 required)*

2 97011410 Housing Assembly (includes Key No. 7)

3 98005512 Wiring Adapter Plate

4 99150471 Ground Screw, #10-32 x 1/2"

5 97008575 Wiring Harness

6 99260477 Whiz Nut, 1/4-20 (2 required)*

7 99420470 Grille Nut (2 required)

8 98005513 Outlet Box Cover

9 99400035 Strain Relief Bushing

10 97011394 Blower Wheel (MP100)

97011395 Blower Wheel (MP140)

97011396 Blower Wheel (MP200)

11 97011361 Blower Housing (MP100)

97011362 Blower Housing (MP140)

97011363 Blower Housing (MP200)

12 99100412 Motor Mounting Rubber (2 required)

13 97011400 Motor (MP100) (includes Key No. 16)

97011411 Motor (MP140) (includes Key No. 16)

97011402 Motor (MP200) (includes Key No. 16)

14 95000963 Motor Cup

15 99170245 Screw, #8 x 3/8" (10 required)*

16 97011403 Capacitor (MP100)

97011412 Capacitor (MP140)

97011405 Capacitor (MP200)

17 97011406 Cover

18 99110942 Inlet Cover (covers unused inlet ports)

** 97011407 Blower Assembly Complete (MP100)

** 97011413 Blower Assembly Complete (MP140)

** 97011409 Blower Assembly Complete (MP200)

DESCRIPTION

(includes Key No.s 10 thru 16)

(includes Key No.s 10 thru 16)

(includes Key No.s 10 thru 16)

BROAN ONE YEAR LIMITED WARRANTY

In Canada, contact: Broan-NuTone Canada, Inc., 1140 Tristar Drive, Mississauga, Ontario L5T 1H9 (1-888-882-7626)

15

17

13

12

14

12

6

10

16

11

9

8

5

15

7

2

1

18

In the U.S., contact: Broan-NuTone LLC, 926 West State Street, Hartford, WI 53027 (1-800-637-1453)

15

4

3

99041951J

15

Page 5

VENTILATEUR À PRISE

D'AÉRATION MULTIPLE

MODÈLES MP100, MP140 & MP200

LISEZ ET CONSERVEZ CES INSTRUCTIONS

AVERTISSEMENT

POUR RÉDUIRE LE RISQUE D'INCENDIE, DE CHOC

ÉLECTRIQUE OU DE BLESSURES PERSONNELLES,

OBSERVEZ CE QUI SUIT:

1. Utilisez cette unité seulement de la façon prévue par le

fabricant. Pour d'autres renseignments, contactez le

fabricant

trouvent au bas de la garantie.

2. Avant de réparer ou de nettoyer l'appareil, éteindre ce

dernier au panneau de service afin d'éviter sa remise en

marche accidentelle. Si le panneau de service ne peut être

verrouillé, y fixer un avertissement en évidence.

3. L'installation et la pose des fils électriques doivent

effectuées par une ou des personnes qualifi

conform

incluant les codes et normes de construction en rapport

aux incendies.

4. Il faut suffisament d'air pour une combustion appropriée et

l'évacuation des gaz par le tuyau de la cheminée de

l'équipement br

contre-courant. Suivez les instructions du fabricant de

l'equipmement de chauffage et les normes de sécurité

telles que celles publi

Association (NFPA) et l'American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE)

et les autorités du code local.

à l'adresse ou au numéro de téléphone qui se

être

ées

ément à tous les codes et normes applicables,

ûlant du combustible, pour prévenir un

ées par la National Fire Protection

AVERTISSMENT

5. Lors de la coupe ou du perçage dans un mur ou un plafond,

prenez soin de ne pas endommager les fils

les autres utilités dissimulées.

6. La décharge des ventilateurs

toujours se faire

7. Cette unité doit être mise à la terre.

à l'extérieur.

à conduit par l'évent doit

électriques et

ATTENTION

1. Pour ventilation générale seulement. Ne l'utilisez pas pour

évacuer les vapeurs ou matériaux dangereux ou qui

peuvent exploser.

2. Pour éviter d'endommager les coussinets du moteur et

des turbines bruyantes et/ou mal équilibrées, asurez que

l'unité motrice est exempte de poussi

murs en pierres s

3. Si le ventilateur est installé dans un endroit non con-

ditionné (tel qu’un grenier): Entourez le ventilateur d’un

isolant thermique afin de réduire toute condensation éventuelle.

4. Lisez l'étiquette de spécifications sur le produit pour

d'autres renseignements et exigences.

èches et la construction.

ère provenant des

PROJETEZ L'INSTALLATION

Pour une ventilation adéquate la contamination intermittente

et continue doit être contrôlée.

Une ventilation intermittente doit être fournie dans la salle

de bain et la cuisine. La salle de bain requiert 8 changements

d' air par heure. (Multipliez le nombre de pi. ca. de la salle

de bain par 1.1 pour un ventilateur approprié.) La cuisine

requiert une capacité minimale de 150 PCM (71 l/s)

lorsqu'une hotte de cuisinière à conduit est utilisée.

Lorsqu'un ventilateur de cuisine est utilisé, déterminez la

capacité du ventilateur en multipliant le nombre de pi. ca.

de la pièce par 2. Ils sont tous opérés par intermittence

pour contrôler la pollution à la source.

Une ventilation continue, lorsque la maison est occupée,

fournit une circulation d' air frais de bonne qualité à

l'intérieur.

Ce ventilateur est prévu pour une opération continue,

fournissant de l'air fraise dans toute la maison.

VENTILATOR RECOMMANDÈ

DIMENSION DE LA MAISON (pi. ca.)

(incluant l'aire du sous-sol fini)

MODÈLE

MP100

MP140

MP200

*CA/HRE=Changements d'air par heure. Se basant sur des

plafonds de 8'.

Pieds carrés x .093 = Mètres carrés

0.50 /HRE* 0.35 CA/HRE* 0.30 CA/ HRE*

1500 2140 2500

2100 3000 3500

3000 4285 5000

Page 6

PROJETEZ L' INSTALLATION

EMPLACEMENTS DES

DIFFUSEURS & ENTRÉES

AIR VICIÉ

VENTILATEUR

DIFFUSEUR

AIR

FRAIS

PRISE D'AIR

FRAIS

AIR

FRAIS

CIRCULATION D'AIR DANS UNE INSTALLATION TYPIQUE

VENTILATEUR

Le ventilateur aspire l' air vicié. Il y a normalement suffisamment

d'ouvertures naturelles dans une maison pour laisser p

l'air frais de l'ext

meilleur contr

Le ventilateur doit

érieur pour remplacer l'air vicié. Pour un

ôle, des prises d'air frais peuvent être utilisées.

être installé dans un endroit central pour

que les conduits de ventilation soient aussi courts que possible. Le ventilateur peut

grenier ou un sous-sol, ou sur un mur

être installé sur les solives dans un

éloigné de l'aire

d'habitation.

énétrer

HOTTE DE

CUISINIÈRE À

CONDUIT

DIFFUSEUR

MAISON À DEUX ÉTAGES

MAISON À UN ÉTAGE

PRISES D'AIR FRAIS

DIFFUSEUR

VENTILATEUR DE SALLE DE

BAIN À CONDUIT

PRISES D'AIR FRAIS

PRISES D'AIR FRAIS

DIFFUSEURS ASPIRANT (Disponibles séparément)

Les diffuseurs aspirant

règlent la circulation d'air

frais tiré dans la maison.

Les diffuseurs aspirant

doivent être montés dans

AIRE DE CUISSON

Ne pas installer au-

dessus ou à l' intérieur

de cette aire.

les plafonds ou sur le haut

d'un mur.

Pour le meilleur rendement,

o

45

o

45

les diffuseurs aspirant

doivent être montés dans

un endroit central. Un

diffuseur aspirant ne doit

Équipement

de cuisson

Plancher

pas être installé près d'une

aire de cuisson (vuir ill.).

PRISE D'AIR FRAIS (Disponibles séparément)

Pour le meilleur contr

une prise d'air frais.

Le nombre de prises d'air dépend du plan du plancher.

Considérez les pièces/endroits dans lesquels l'air frais doit

circuler pour rejoindre le ou les diffuseurs aspirant.

Les prises d'air doivent

préférablement près du plafond et à approximativement la

m

ême distance à un diffuseur. Les prises d'air doivent être

assez éloignées des diffuseurs pour permettre

se mélanger avec l'air de la pièce avant d'être aspiré.

ôle de l'air frais dans une pièce, installez

être installées dans les murs extérieurs,

à l'air frais de

DIFFUSEUR

PRISES D'AIR FRAIS

DEUXIÈME

ÉTAGE

VENTILATEUR

DE SALLE

DE BAIN À

CONDUIT

PRISES D'AIR FRAIS

HOTTE DE

CUISINÈRE A

CONDUIT

DIFFUSEUR

VENTILATEUR

DE SALLE

DE BAIN À

CONDUIT

DIFFUSEUR

DIFFUSEUR

PREMIER ÉTAGE

Page 7

INSTALLEZ DES PRISES D'AIR FRAIS

1. Installez toutes les prises d'air frais aux endroits choisis

pendant les travaux préparatoires de construction. Suivez

les instructions emballées avec les prises d'air.

MONTEZ LE VENTILATEUR

SOLIVES DE

PLAFOND

SUPPORTS

OU

2. Pour minimiser la condensation à l'intérieur du conduit de

ventilation dans le grenier, couvrez le conduit de ventilation

avec un isolant suppl

émentaire. Évitez aussi de former des

collecteurs de condensation dans le conduit de ventilation.

3. Scellez le conduit de ventilation au ventilateur et au capuchon

de toit ou de mur avec du ruban

à conduit ou un collier

(disponible séparément).

Lorsque des orifices d'admission du ventilateur ne sont pas

4.

utilisés:

Placez le ou les couvercles des orifices d'admission

(fournis) sur les orifices d'admission non utilisés et rubanezles en place.

POSEZ LES FILS DU VENTILATOR

AVERTISSEMENT: COUPEZ LE COURANT AU

PANNEAU DE SERVICE ET BARREZ LE PANNEAU

DE SERVICE POUR EMPÊCHER QUE LE COURANT SOIT RÉTABLI PAR ACCIDENT.

FIL DE MISE À LA

TERRE

NOIR

PLAQUE D'

ADAPTATION DES

FILS

SOLIVES DE

PLAFOND

SUPPORTS

1. Ajoutez des supports aux solives de plafond tel qu'illustré.

2. Placez le ventilateur et vissez-le au support avec les vis

fournies. Le ventilateur peut aussi

être supendu des solives

du plafond ou chevrons avec des courroies de suspension

(disponibles séparément).

RACCORDER LES CONDUITS DE

VENTILATION

DES

DIFFUSEURS

CONDUIT

ROND

FLEXIBLE

ISOLÉ 4"

RUBAN À

CONDUIT OU

COLLIER

CONDUIT

ROND

FLEXIBLE

ISOLÉ 6"

MISE À LA

BLANC

TERRE (Fils

vert ou nu)

120 VCA

EN LIGNE

NOIR

NOIR

INTERRUPTEUR

MARCHE/

ARRÊT

Utilisez un interrupteur MARCHE/ARRÊT pour contrôler le

ventilateur en ligne. Des minuteries et des contrôles

d'humidité sont aussi disponibles.

1. Enlevez la plaque d'adaptation des fils.

2. Attachez le câble d'énergie à la plaque d'adaptation des

fils en utilisant une connexion approvée par U.L./ACNOR.

3. Connectez le fil noir au noir, blanc au blanc, et vert ou nu

à la vis verte de mise à la terre.

4. Replacez la plaque d'adaptation des fils. Assurez que

languette sur le boîtier glisse dans la fente dans la

plaque.

DES

DIFFUSEURS

1. Faites passer le c

onduit de ventilation flexible, isolé, de 4"

AU CAPUCHON DE

TOIT OU DE MUR

à partir de l'orifice d'admission du ventilateur jusqu' à ou

aux emplacements du ou des diffuseurs et le conduit de

ventilation flexible de 6"

à partir de la sortie du ventilateur

jusqu'au capuchon de toit ou de mur. Une étiquette identifie

le c

ôté de la sortie.

Page 8

INSTALLEZ LES DIFFUSEURS ASPIRANT

CONDUIT ROND

FLEXIBLE ISOLÉ 4"

AU

VENTILATEUR

PLAFOND MUR

EN PIERRES

SÈCHES

Suivre les instructions emballées avec le ou les diffuseurs.

Instructions générales:

1. Coupez un ou des trous dans le plafond mur en pierres

RUBAN

DE

CONDUIT

OU

COLLIER

DIFFUSEUR

UTILISATION ET SOIN

AVERTISSEMENT: COUPEZ LE COURANT AU PANNEAU

DE SERVICE ET BARREZ LE PANNEAU DE SERVICE AVANT

DE NETTOYER OU DE RÉPARER CETTE UNITÉ.

NETTOYAGE

Un ventilateur en ligne opérant continuellement doit être nettoyé

une fois par année pour assurer un bon fonctionnement.

Enlevez le couvercle et passez doucement l'aspirateur sur le

ventilateur et dans le boîtier. Prenez soin de ne pas courber ou

endommager autrement la roue du ventilateur.

Les diffuseurs et les orifices d'admission peuvent être nettoyés

à l'aspirateur et/ou essuyés avec un chiffon humide.

sèches et installez le ou les diffuseurs.

2. Raccordez le conduit de ventilation isolé au ou aux diffuseurs

et utilisez du ruban

à conduit ou un collier (disponible

séparément) pour sceller le ou les raccords.

3. Tournez complètement le centre du ou des diffuseurs dans

LUBRIFICATION DU MOTEUR

Le moteur est lubrifié en permanence. Ne huilez pas ou ne

désassemblez pas le moteur.

le sens contraire des aiguilles d'une montre pour une

circulation d'air maximale. R

tournant le centre du ou des diffuseurs

aiguilles d'une montre. Un registre basculant (disponible

séparément) peut être utilisé pour régler la circulation

d'air.

PIÈCES DE RECHANGE

Modéles MP100, MP140 & MP200

NO DE

REP

*Ferrure standard - Peut être achetée localement.

**Non illustré assemblé. Commandez toujours les pièces de rechange par le "no de pièce " - non pas le "no de rep."

Broan garantit à l’acheteur consommateur original, de ses produits qu’ils sont exempts de défauts dans les matières premières ou la main-d’oeuvre pour une période d’un an à compter de la date d’achat

original. IL N’Y A PAS D’AUTRES GARANTIES, EXPRIMÉES OU IMPLICITES, INCLUANT LES MAIS NON PAS LIMITÉ AUX GARANTIES IMPLICITES POUR FIN DE COMMERCIALISATION ET DE

CONVENANCE DANS UN BUT PARTICULIER.

Pendant cette période d’un an, Broan, à son choix, réparera ou remplacera, gratuitement, tout produit ou pièce qui s’avère défectueux sous utilisation et service normaux.

CETTE GARANTIE NE COUVRE PAS LES STARTERS DE LAMPES FLUORESCENTES ET LES TUBES. Cette garantie ne couvre pas (a) l’entretien et le service normaux ou (b) tout produit ou pièce

endommagé par suite de mauvais usage, négligence, accident, entretien inapproprié ou réparation (autre que par Broan), mauvais installation ou installation contraire au mode d’installation recommandé.

La durée de toute garantie implicite est limitée à une période d’un an tel que spécifié pour la garantie exprimée. Certains états ne permettent pas la limitation de la durée d’une garantie implicite, la limitation

ci-dessus peut donc ne pas s’appliquer à vous.

L’ENGAGEMENT DE BROAN DE RÉPARER OU DE REMPLACER, AU CHOIX DE BROAN, SERA LA SEULE OBLIGATION EXCLUSIVE SOUS CETTE GARANTIE. BROAN NE SE TIENDRA PAS

RESPONSABLE DES DOMMAGES DIRECTS, INDIRECTS OU SPÉCIAUX SURVENANT À CAUSE DE OU EN RAPPORT À L’UTILISATION OU LA PERFORMANCE DE SES PRODUITS.

Certains états ne permettent pas l’exclusion ou la limitation des dommages directs ou indirects, la limitation ou l’exclusion ci-dessus peut donc ne pas s’appliquer à vous.

Cette garantie vous donne des droits légaux spécifiques et il se peut que vous ayez d’autres droits qui varient d’un état à un autre. Cette garantie annule toutes les garanties précédentes.

Pour le service sous garantie, vous devez (a) aviser Broan, (b) donner le numéro du modèle et l’identification de la pièce et (c) décrire la nature de tout défaut dans le produit ou la pièce. Au temps de

demander le service sous garantie, vous devez présenter une preuve de la date d’achat original.

NO DE

PIÈCE

1 99150591 Vis, #10 x 7/8" (4 requises)*

2 97011410 Ensemble du boîtier (inclut no. de rep. 7)

3 98005512 Plaque d'adaptation des fils

4 99150471 Vis de mise à la terre, #10-32 x 1/2"

5 97008575 Harnais de fils

6 99260477 Ècrou, 1/4-20 (2 requis)*

7 99420470 Ècrou de grille (2 requis)

8 98005513 Couvercle de boîte de sortie

9 99400035 Coussinet réduisant la tension

10 97011394 Roue de ventilateur (MP100)

97011395 Roue de ventilateur (MP140)

97011396 Roue de ventilateur (MP200)

11 97011361 Boîter du ventilateur (MP100)

97011362 Boîter du ventilateur (MP140)

97011363 Boîter du ventilateur (MP200)

12 99100412 Caoutchouc pour le montage du moteur (2 requis)

13 97011400 Moteur (MP100) (inclut no de rep. 16)

97011411 Moteur (MP140) (inclut no de rep. 16)

97011402 Moteur (MP200) (inclut no de rep. 16)

14 95000963 Godet de moteur

15 99170245 Vis #8B x 3/8" (10 requises)*

16 97011403 Condensateur (MP100)

97011412 Condensateur (MP140)

97011405 Condensateur (MP200)

17 97011406 Couvercle

18 99110942 Couvercle d'orifice d'admission (couvre les orifices d'

** 97011407 Ensemble complet du ventilateur (MP100) (inclut nos

** 97011413 Ensemble complet du ventilateur (MP140) (inclut

** 97011409 Ensemble complet du ventilateur (MP200) (inclut nos

admission non utilisés)

de rep. 10 à l16)

nos de rep. 10 à 16)

de rep. 10 à 16)

éduisez la circulation d'air en

dans le sens des

DESCRIPTION

Au Canada, communiquez avec: Broan-NuTone Canada, Inc., 1140 Tristar Drive, Mississauga, Ontario L5T 1H9 (1-888-882-7626)

15

10

1

18

GARANTIE LIMITÉE D’UN AN DE BROAN

Aux É.U. communiquez avec: Broan-NuTone LLC, 926 West State Street, Hartford, WI 53027 (1-800-637-1453)

17

13

12

14

12

6

16

11

9

8

5

15

7

2

15

4

3

99041951J

15

Loading...

Loading...