Broan ERVS100S Installation Manual

INSTALLATION AND USER GUIDE FOR

BROAN ERVS100

VB0231

! !

RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

INSTALLER: LEAVE THIS MANUAL WITH HOMEOWNER

Broan-NuTone LLC; Hartford, Wisconsin www.broan.com 877-862-7626

REGISTER YOUR PRODUCT ONLINE AT: www.broan.com/register

For additional information - visit www.broan.com

22077 rev. 07

ABOUT THIS MANUAL

Please take note that this manual uses the following symbols to emphasize particular information:

!

WARNING

Identifies an instruction which, if not followed, might cause serious personal injuries including possibility of death.

CAUTION

Identifies an instruction which, if not followed, may severely damage the unit and/or its components.

NOTE: Indicates supplementary information needed to fully complete an instruction.

ABOUT THESE UNITS

LIMITATION

For residential (domestic) installation only. Installation work and electrical wiring must be done by a qualified person(s) in accordance with

all applicable codes and standards, including fire-rated construction codes and standards.

!

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSON(S) OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the address or

telephone number listed in the warranty.

2. Before servicing or cleaning the unit, disconnect the power cord from electrical outlet or turn power off at the service panel.

3. This unit is not designed to provide combustion and/or dilution air for fuel-burning appliances.

4. When cutting or drilling into a wall or ceiling, do not damage electrical wiring and other hidden utilities.

5. Do not use this unit with any solid-state speed control device other than following controls:

AUXILIARY CONTROLS ENERGIZED BY UNIT

BROAN VB20W 20-MINUTE LIGHTED PUSH-BUTTON TIMER

STANDARD DRY CONTACT STANDBY SWITCH

6. This unit must be grounded. The power supply cord has a 3-prong grounding plug for your personal safety. It must be plugged into a

mating 3-prong grounding receptacle, grounded in accordance with the national electrical code and local codes and ordinances. Do

not remove the ground prong. Do not use an extension cord.

7. Do not install in a cooking area or connect directly to any appliances.

8. Do not use to exhaust hazardous or explosive materials and vapors.

9. This unit must be protected from the elements.

10. When performing installation, servicing or cleaning these units, it is recommended to wear safety glasses and gloves.

11. When applicable local regulation comprises more restrictive installation and/or certification requirements, the aforementioned

requirements prevail on those of this document and the installer agrees to conform to these at his own expenses.

CAUTION

1. To avoid prematurately clogged filters and chemical attacks on materiel, turn the unit OFF during construction or renovation.

2. Please read specification label on product for further information and requirements.

3. Be sure to duct air outside – Do not intake/exhaust air into spaces within walls or ceiling or into attics, crawl spaces, or garage.

4. Intended for residential installation only in accordance with the requirements of NFPA 90B (for a unit installed in U.S.A.).

5. Do not run any air ducts directly above or closer than 2 ft to any furnace or its supply plenum, boiler, or other heat producing appliance.

If a duct has to be connected to the furnace return plenum, it must be connected as far as possible from this plenum connection to the

furnace.

6. The ductwork is intended to be installed in compliance with all local and national codes that are applicable.

7. When leaving the house for a long period of time (more than two weeks), a responsible person should regularly check if the unit

operates adequately.

2

TABLE OF CONTENTS

1 Safe Installation Zone ................................................................................................3

2 Unit Preparation ......................................................................................................... 4

3 Installation ............................................................................................................4-10

3.1 Positioning the Unit .............................................................................................................................. 4-6

3.2 Combining with an AHU ......................................................................................................................... 7

3.3 Installing the Registers, Ductwork and Hoods ..................................................................................... 8-9

3.4 Connecting the controls ..................................................................................................................... 9-10

3.5 Installing a Tandem

4 Getting the Unit Started ........................................................................................... 11

4.1 Unit Setttings ..........................................................................................................................................11

4.2 Prepare the Unit .....................................................................................................................................11

4.3 Booting Sequence .................................................................................................................................11

5 Maintenance ....................................................................................................... 12-13

5.1 Quarterly Maintenance ..........................................................................................................................12

5.2 Annual Maintenance ..............................................................................................................................13

6 Warranty .................................................................................................................. 13

®

Transition* Kit ........................................................................................................10

7 Wiring Diagram ........................................................................................................14

8 Service Parts ........................................................................................................... 15

9 Troubleshooting ....................................................................................................... 16

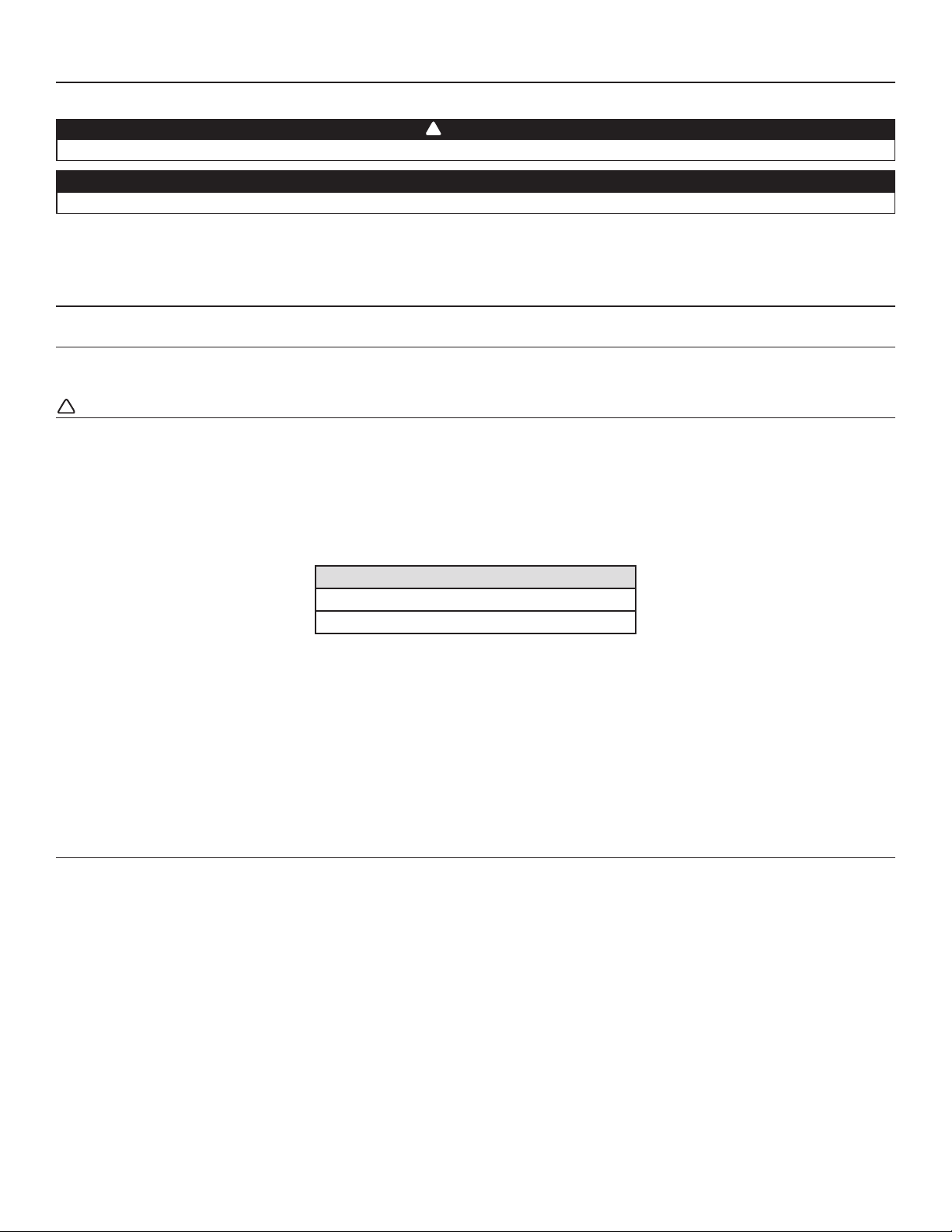

1 Safe Installation Zone

This unit is designed for installlation where temperature is above 14°F throughout the year (zone A on map below). For units installed

in B zone, they must be installed in a conditioned space.

OLYMPIA

SALEM

BOISE

RENO

SACRAMENTO

HELENA

SALT LAKE CITY

PHOENIX

DENVER

SANTA FE

BISMARCK

B

TOPEKA

OKLAHOMA CITY

ST. PAUL

MADISON

DES MOINES

SPRINGFIELD

DETROIT

INDIANAPOLIS

NASHVILLE

ATLANTA

HARRISBURG

COLUMBUS

COLUMBIA

BOSTON

HARTFORD

WASHINGTON

RALEIGH

VN0010

A

AUSTIN

3

BATON ROUGE

2 Unit Preparation

• Inspect the exterior of the unit for shipping damage.

• Unit should never operate while the building is still in construction.

• Unit is shipped with its door covered with a cardboard for protection during construction. Leave the cardboard on until painting.

3 Installation

3.1 Positioning the Unit

• Unit can be installed between 24” on-center trusses, on top of 24” on-center trusses or under the ceiling, using brackets. A set

of 4 brackets is included in the hardware kit, along with the necessary screws.

• A standard 3-prong electrical outlet has to be available within 28” of the unit and must be connected to its own dedicated circuit.

• Allow a 12” clearance for the door, core and filters to be removed for maintenance.

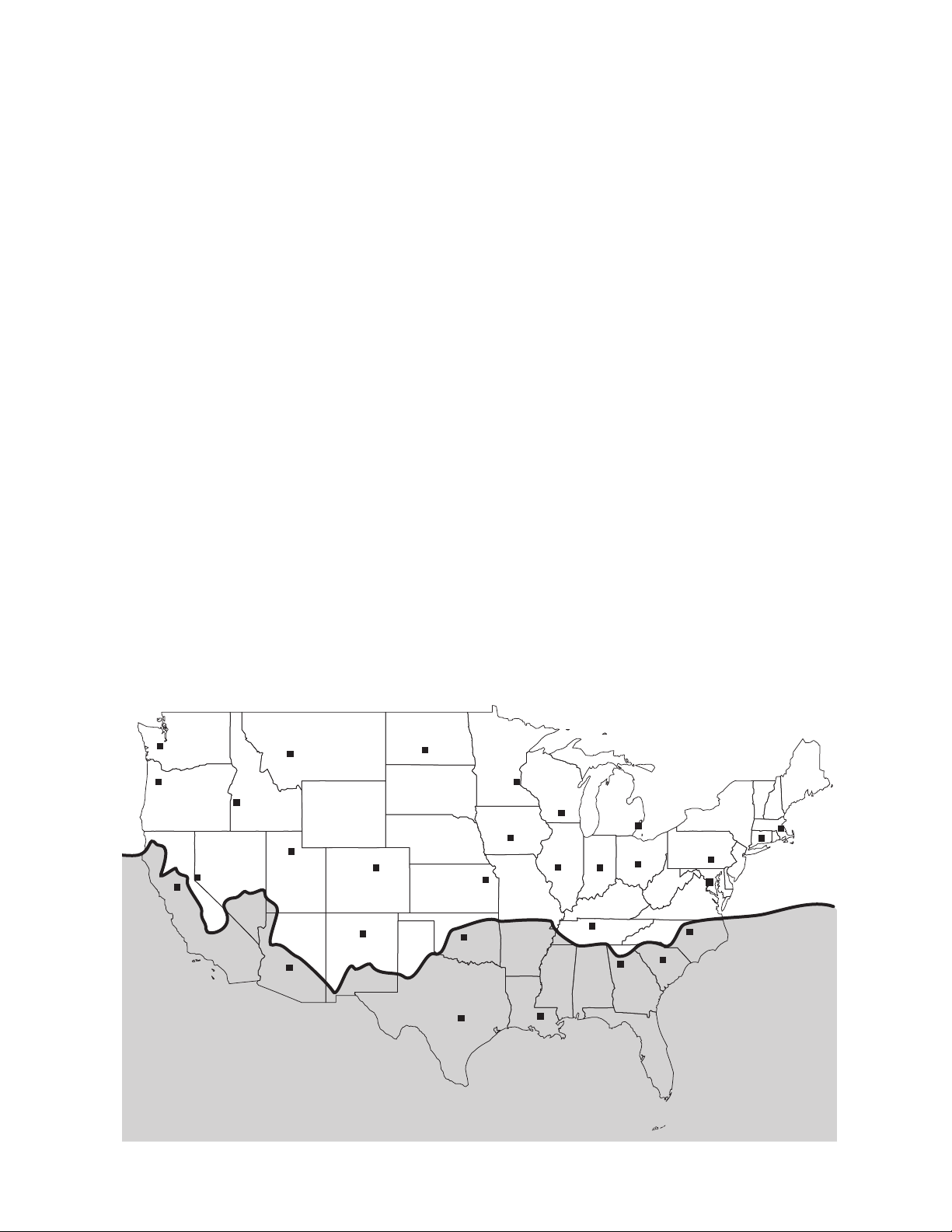

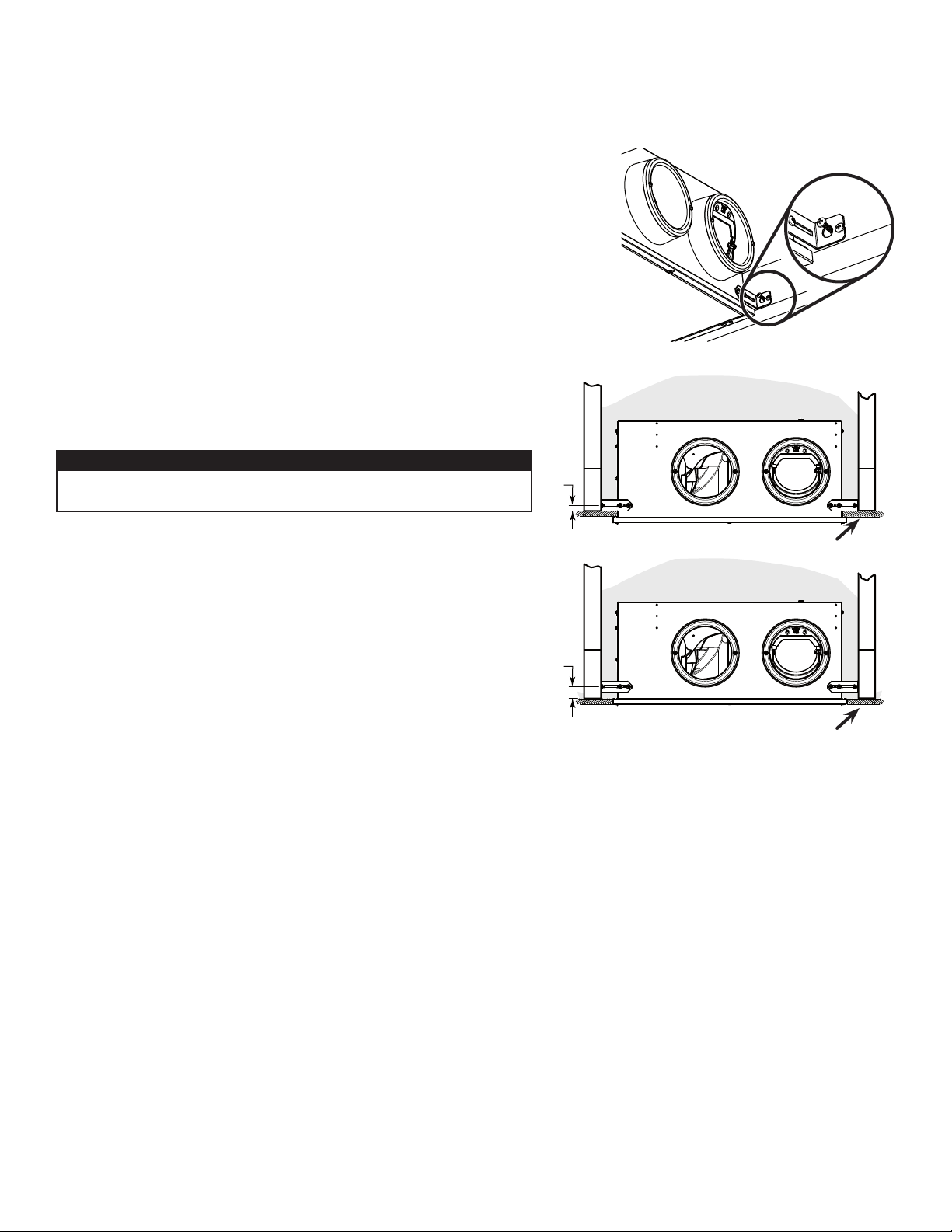

3.1.1 Installation in the ceiling (between 24” on-center trusses)

1. Trace a level line on both trusses, at 1/2” or 1” from the bottom, for

the unit bracket location (1/2” will allow the unit door perimeter to

lay on ceiling material while 1” will result in flush mount installation;

see A and B in next page). On one truss, screw half way on level line

two no. 8 x 1½” provided screws, leaving 23” between each other.

VD0391A

2. Mount the 4 brackets to the unit as illustrated at right,

using two no. 10 x 5/8" screws provided for each

bracket.

TIP: Screw half way the screws to allow adjusment

between trusses, see insets at right (left shows the

minimum distance and right the maximum distance.

3. Hang the lightest side of the unit on the screws mounted on

the truss using the larger holes of the brackets.

4. Lift the other side of the unit and secure it to the other truss

using one no. 8 x 1½” screw per bracket, inserted through

the smaller hole of the brackets.

VD0394

VD0390

4

3 Installation (cont'd)

3.1 Positioning the Unit (cont'd)

3.1.1 Installation in the ceiling (between 24” on-center trusses)

5. Secure the first brackets installed to the truss using one no. 8 x 1½” screw per

bracket, inserted through their smaller hole, then tighten completely the brackets

screws to the unit.

CAUTION

When installed in the attic, insulation must be spread over the

unit.

6. Spread the insulation over the unit (and around, as for B at right).

(cont'd)

VD0393

INSULATION

(OVER AND AROUND

THE UNIT)

A

1/2”

1/2" CEILING MATERIAL

INSULATION

(OVER AND AROUND

THE UNIT)

B

1”

VD0386

1/2" CEILING MATERIAL

5

3 Installation (cont'd)

3.1 Positioning the Unit (cont'd)

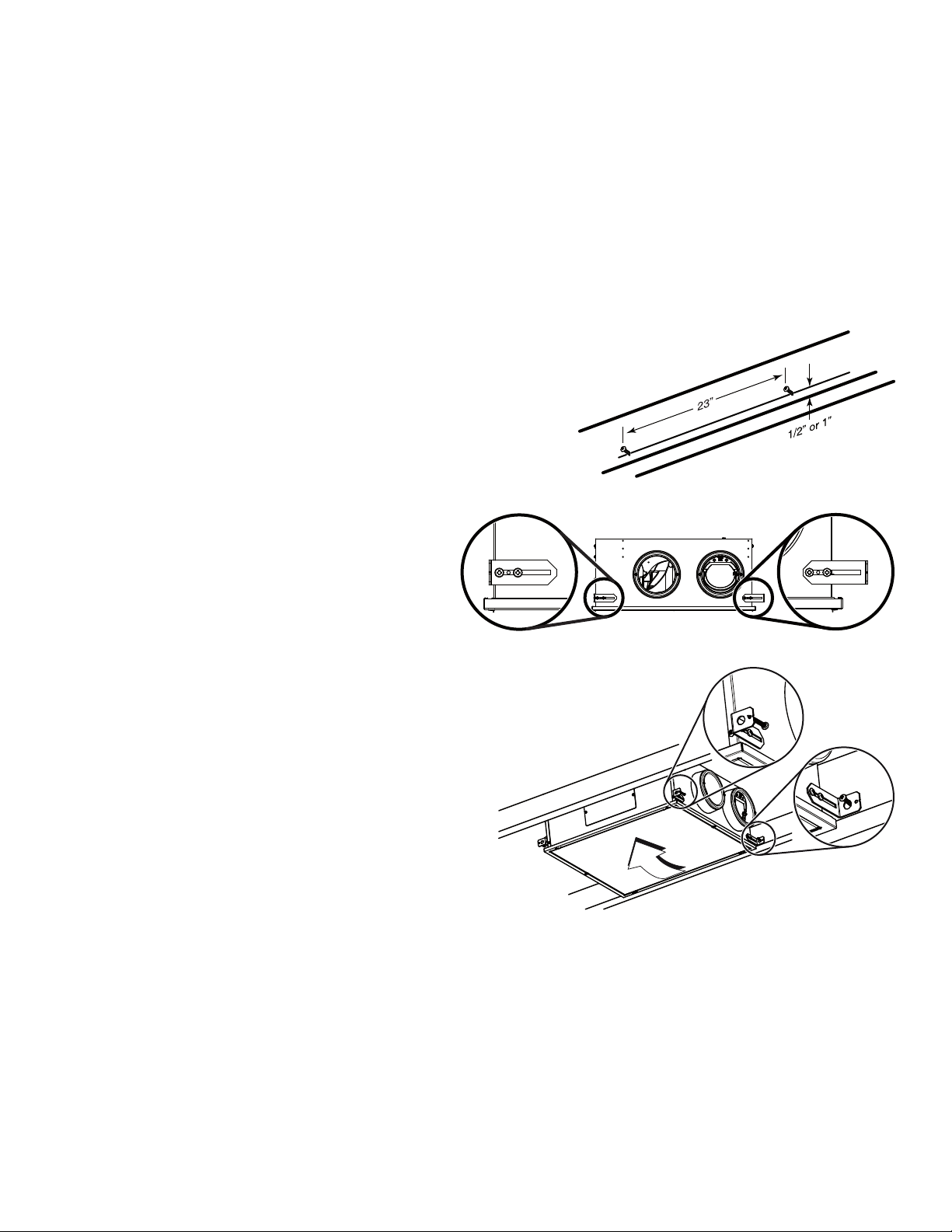

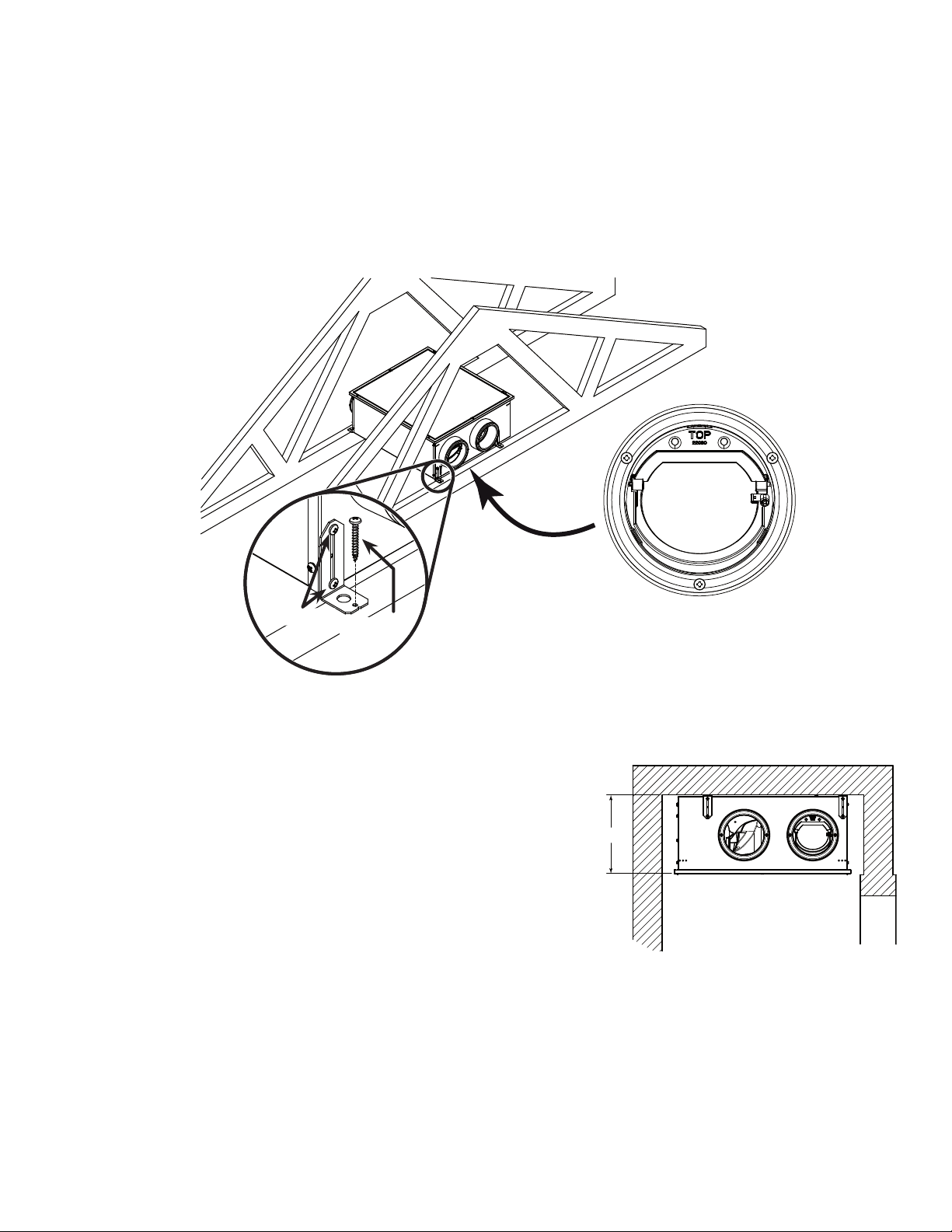

3.1.2 Installation in the attic (unit having its door on top)

1. Rotate the backdraft damper 180° (no tool required) so that it falls in closed position and the word "TOP" engraved on the

damper is up once the unit is in place.

2. Mount the brackets to the unit as illustrated below using two no. 10 x 5/8" screws provided for each bracket.

3. Secure the unit to the trusses using one no. 8 x 1½" screw provided for each bracket.

4. IMPORTANT: If the attic is not ventilated and without radiant barrier sheathing, insulation material must be added around and

over the unit. Ensure access is kept for product maintenance.

DOOR

NO. 10 X 5/8"

VH0111

NO. 8 X 1½"

3.1.3 Installation under the ceiling (in a living area)

1. Mount the brackets to the unit as illustrated above using two no. 10 x 5/8”

screws provided for each bracket.

2. Secure unit to the ceiling using two no. 8 x 1½” screws provided for each

bracket, making sure not to secure it into drywall alone.

24"-DEEP CLOSET

9¼”

6

Stale air from home

connected to return

ducting of AHU

Distribution

of fresh air

using plastic grille

AHU

AHU supply ducting

and grille to home

Stale air

to outdoors

damper

Fresh air

from outdoors

VH0113A

ERV

3 Installation (cont'd)

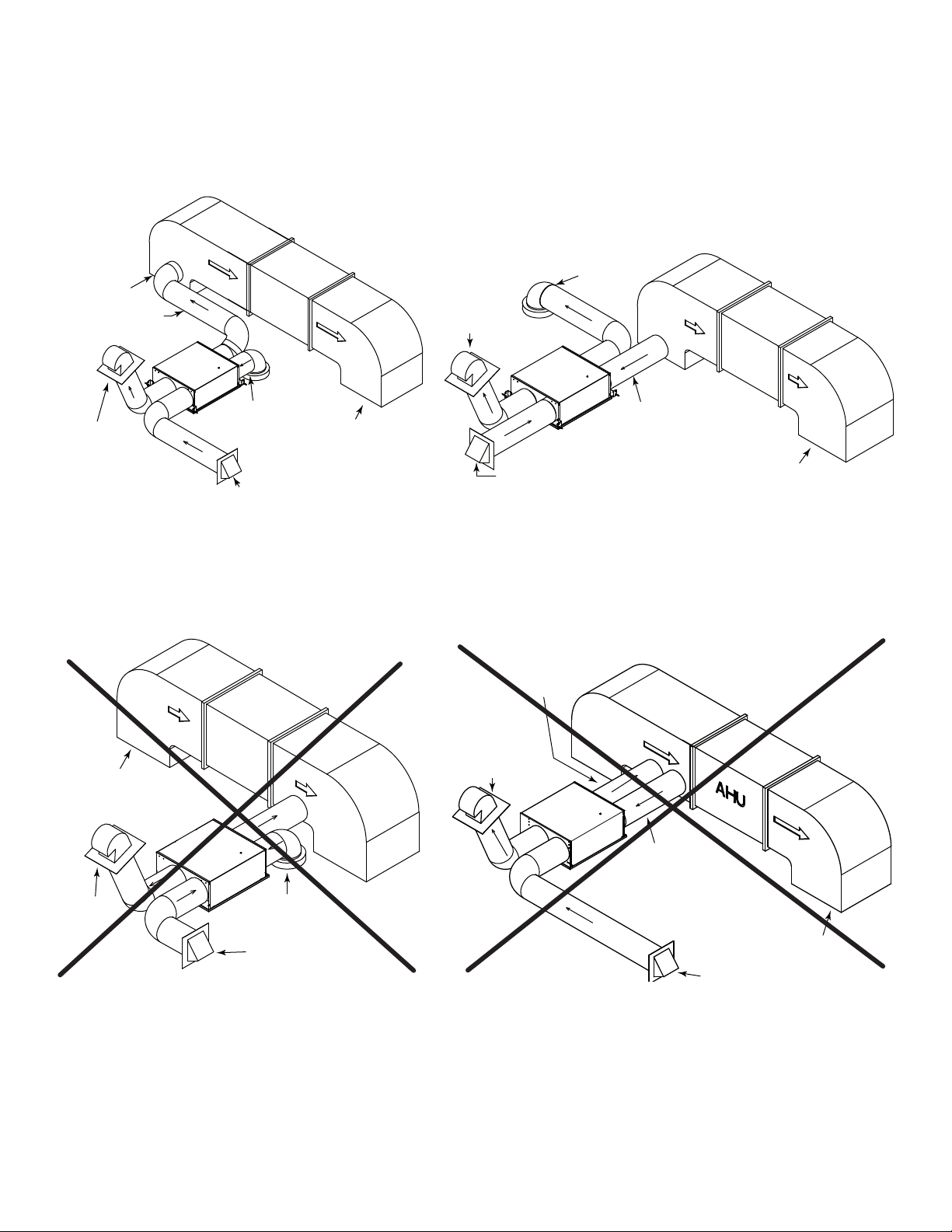

3.2 Combining with an AHU

3.2.1 Recommended configurations

When the distribution of fresh air from the ERV is connected to the return of an AHU (such as in the image below, on the left),

the connection should be done as close as possible from one AHU return grille to ensure proper functionning of the built-in

fresh air damper.

Return grille

of AHU

Distribution of

fresh air in AHU

ERV

Stale air

to outdoors

with backdraft

damper

VH0112A

AHU

Stale air

from home

Fresh air

from outdoors

AHU supply ducting

and grille to home

OPTION 2OPTION 1

with backdraft

VH0114A

3.2.2 Prohibited configurations

Distribution of fresh air from the ERV in the distribution ducting from the AHU (such as in the image below, on the left) may cause

condensation issues during cooling season and must be avoided.

Connecting both distribution of fresh air from the ERV and stale air exhaust in the AHU return ducting (such as in the image

below, on the right) must be avoided.

Return grille

of AHU

Stale air

to outdoors

damper

ERV

AHU

Stale air

from home

Fresh air

from outdoors

Distribution

of fresh air

connected to return

ducting of AHU

Stale air

to outdoors

with backdraft

damper

ERV

Stale air from home

connected to return

ducting of AHU

AHU supply ducting

and grille to home

Fresh air

7

3 Installation (cont'd)

3.3 Installing the Registers, Ductwork and Hoods

3.3.1 Registers

!

WARNING

Never install a stale air exhaust register in a closed room where a combustion device operates, such as a gas

furnace, a gas water heater or a fireplace.

Refer to applicable building codes to plan where the stale air exhaust registers and fresh air distribution registers should be

installed. Below are some general recommendations.

Stale air exhaust registers:

• Install the stale air exhaust registers where the contaminants are produced: bathroom (up to 2), kitchen, living room, etc.

Position the registers as far from the stairway as possible and in such a way that the air circulates in all the lived-in spaces in

the house.

• If a register is installed in the kitchen, it must be located at least 4 feet away from the cooking applicances.

• Install the registers on an interior wall, 6 to 12 inches below the ceiling OR in the ceiling.

Fresh air distribution registers (Option 2 in 3.2.1):

• Install the fresh air distribution registers in bedrooms, dining rooms, living rooms and basement, if applicable.

• Keep in mind that the fresh air registers must be located as far as possible from the ERV stale air registers.

• Install the registers on an interior wall, 6 to 12 inches below the ceiling OR in the ceiling.

• If a register must be floor installed, direct the airflow up the wall.

3.3.2 Ductwork

!

WARNING

When performing duct connections, always use approved tools and materials. Respect all corresponding laws

and safety regulations. Please refer to your local building code.

CAUTION

If ducts have to go through an unconditioned space (e.g.: attic), always use insulated ducts.

• All units ports should be connected to 6” ducts, but can be connected to larger ducts using an appropriate transition.

• If you have to connect rigid ducts to the unit, use a short lenght (approximately 6”) of flexible duct to avoid transmission of

vibrations. Use a tie wrap and foil tape to connect the flexible duct to the port and to the rigid duct.

• Never use screws to connect rigid ducting to the ports.

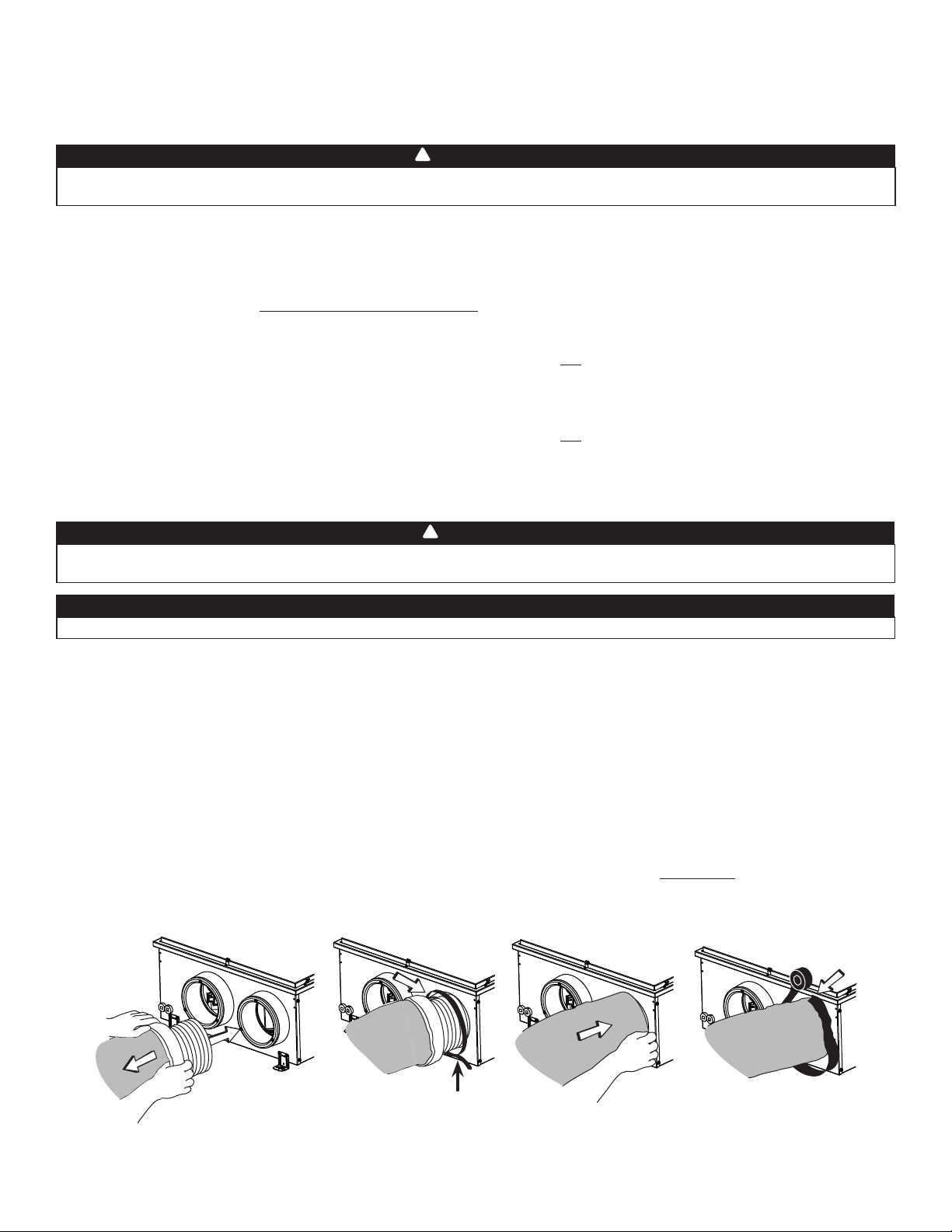

Connecting insulated flexible ducts to the ports:

1. Pull back the insulation to expose the flexible duct.

2. Attach the flexible duct to the port using a tie wrap; ensure tie wrap is tighten to its maximum strength.

3. Pull the insulation over the joint, then pull the vapor barrier (shaded part in illustrations below) over the insulation. Make sure

that the vapor barrier does not tear due to manipulation to avoid condensation within the ducts.

4. Apply foil tape to the joint, making an airtight seal. Avoid compressing the insulation when pulling the tape tightly around the

joint. Compressed insulation loses its R value and causes water dripping in cold climates due to condensation on the exterior

surface of the duct.

NOTE: If sealant mastic has to be used over the foil tape as an extra sealing layer, use water based mastic to ensure material

compatibility with the port.

VJ0134

TIGHTEN TIE WRAP TO ITS

MAXIMUM STRENGTH!

8

3 Installation (cont'd)

3.3 Installing the Registers, Ductwork and Hoods (cont'd)

3.3.3 Hoods

Refer to applicable building codes to plan where the stale air exhaust hood and fresh air distribution hood should be installed.

Below are some general recommendations.

!

WARNING

Make sure the intake hood is at least 6 feet away from any of the following:

• Dryer exhaust, high efficiency furnace vent, central vacuum vent

• Gas meter exhaust, gas barbecue-grill

• Any exhaust from a combustion source

• Garbage bin and any other source of contamination

• There must be a minimum distance of 6' between the hoods to avoid cross-contamination.

• Hoods must be at least 18" above the ground.

• Exhaust hood must have a backdraft damper.

3.4 Connecting the Controls (energized by unit, low voltage)

• Controls are not included with this unit.

• Unit may be connected to a dry contact Standby switch if desired. In such case, unit remains powered on, but is put in Standby

mode when the switch is turned on.

• This ERV can replace up to 2 bath fans. Where this is the case, unit should be connected to a 20-minute override control in

each bathroom.

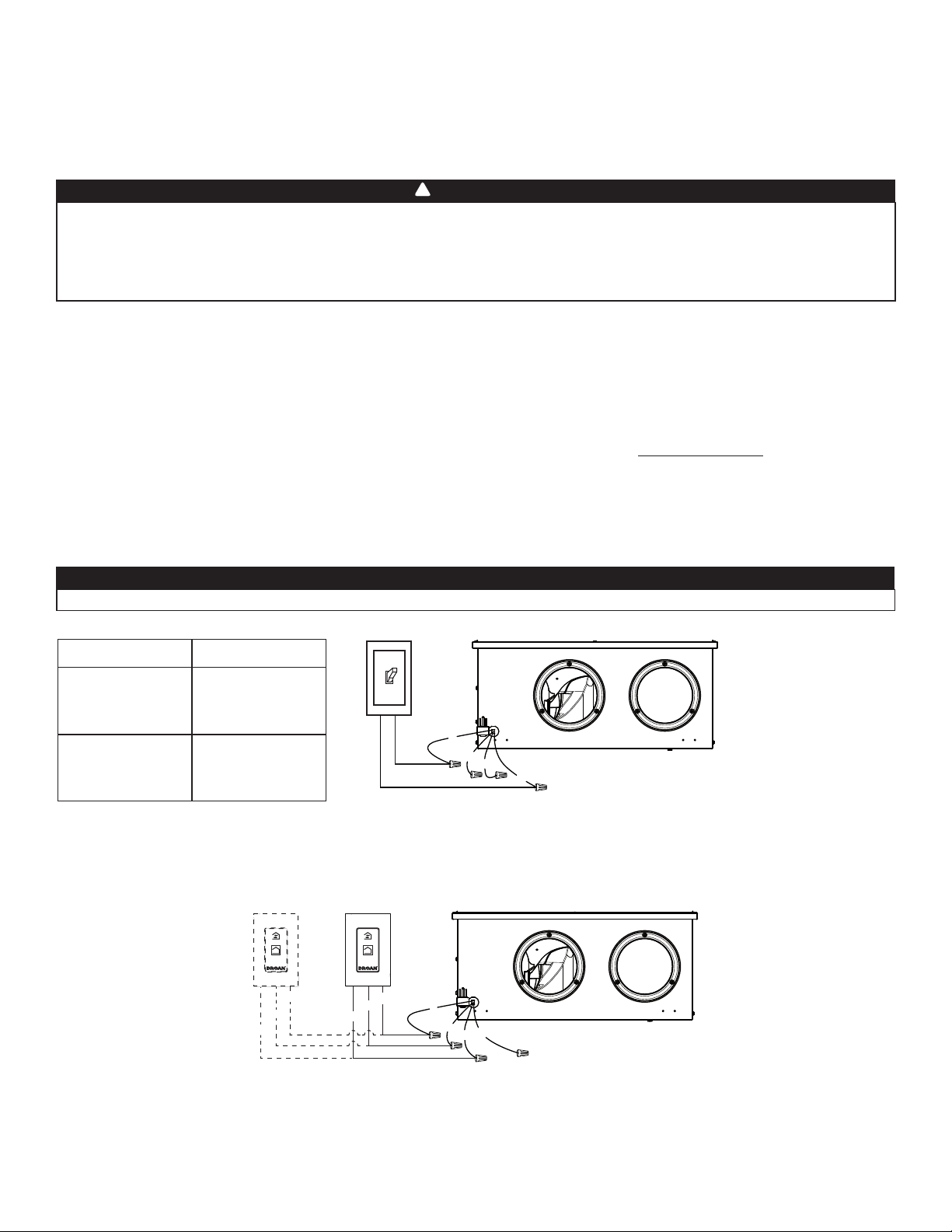

3.4.1 Connecting unit to a Standby switch

Install the dry contact Standby switch in a convenient place and connect it to unit as follows.

Ensure all unused wires are capped off.

Switch position Unit mode

Unit will run in the

Dry contact opened

selected mode

Refer to 4.1

Dry contact closed

Unit is kept in

Standby mode

3.4.2 Connecting unit to 1 or 2 Broan VB20W 20-minute push-button control(s)

1. Install the 20-minute push-button control in the bathroom(s) following instructions included with the control.

2. Connect it to unit as follows.

ON ON

I

OC

OL

OL

VE0357A

OC

CAUTION

R RED

Y YELLOW

B BLACK

G GREEN

R

Y

B

G

R RED

Y YELLOW

B BLACK

G GREEN

I

Y

G

R

B

VE0358A

9

3 Installation (cont'd)

3.4 Connecting the Controls (energized by unit, low voltage) (cont'd)

3.4.3 Connecting unit to a Standby switch AND 1 or 2 Broan VB20W 20-minute push-button control(s)

1. Install the 20-minute push-button control in the bathroom(s) following instructions included with the control.

2. Install the Standby switch in a convenient place.

3. Connect both with the unit as follows.

BROAN VB20W

MIN.

Switch position Unit mode

Unit will run in the

Dry contact opened

Dry contact closed

selected mode

Refer to 4.1

Unit is kept in

Standby mode

20-

PUSH-BUTTON CONTROL

OC

OL

VE0359A

ON

I

OL

ON

OC

R RED

Y YELLOW

B BLACK

G GREEN

I

DRY CONTACT

S

TANDBY SWITCH

Y

G

R

B

This connection allows the operation of VB20W push-button controls even if the dry contact standby switch is turned off.

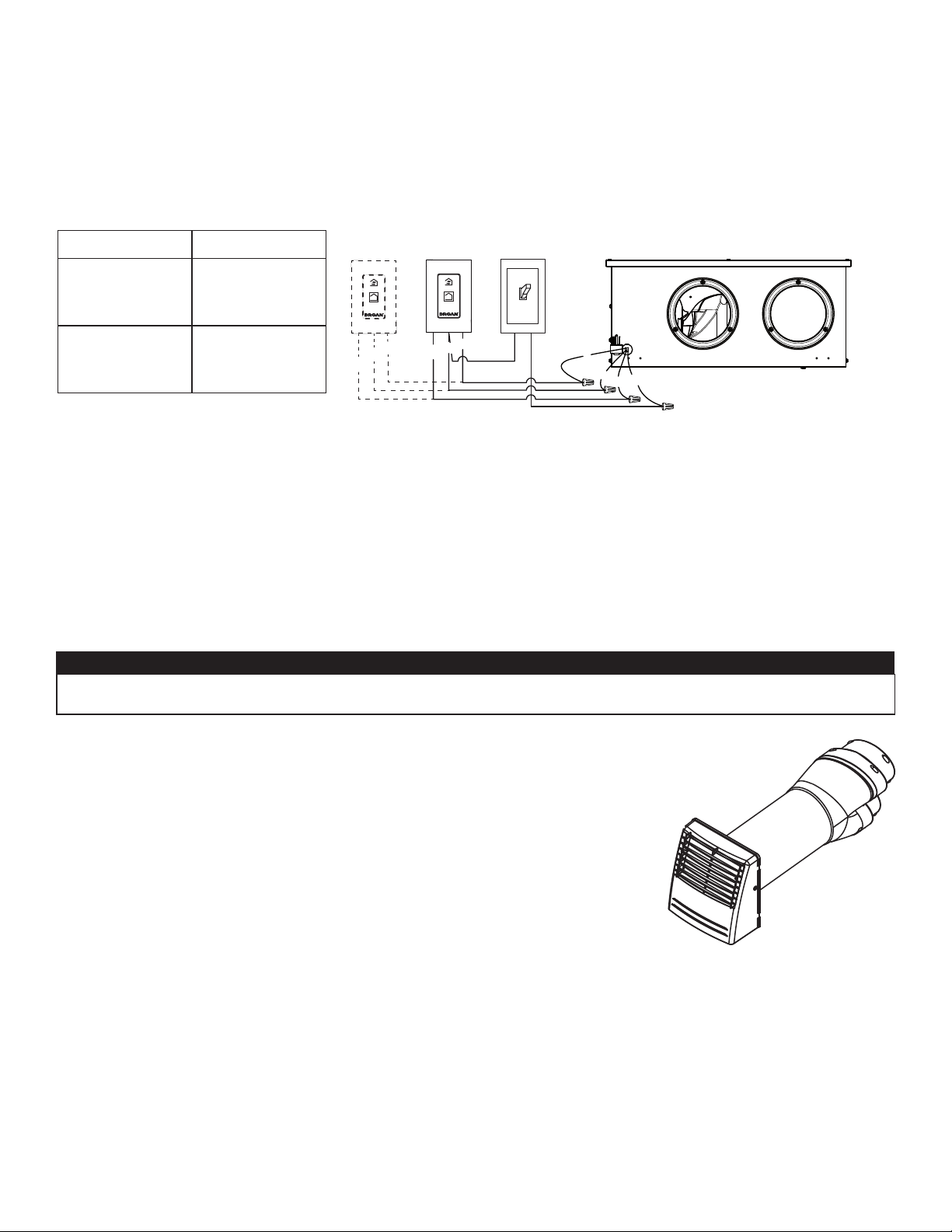

3.5 Installing a Tandem® Transition* Kit

CAUTION

If using a Tandem Transition, a backdraft damper must be installed on the stale air to outdoors duct. If this causes an

interruption in the duct insulation, insulation must be added around the backdraft damper to avoid condensation.

If desired, a Tandem transition kit can be used instead of 2 exterior hoods.

• An additional backdraft damper (not included) must be installed on the stale air to

outdoors duct following common best practice. Should the backdraft damper cause

an interruption in the insulation of the stale air to outdoors duct, make sure that

insulation is added around the backdraft damper to avoid condensation.

• The joist opening needed to install the Tandem

maximum height of the Tandem transition is 8¾”.

• To connect the insulated flexible ducts to the Tandem transition (Exhaust air to

outdoors and Fresh air from outdoors), follow the instructions included with the

Tandem transition kit (part no. VTYIK1).

*Patented.

®

transition must be 9¾” minimum. The

VR0003

Tandem transition kit

10

Loading...

Loading...