Page 1

BR N

CBX1 Series

ange oods

FOR DOMESTIC

WARNING

CBX1 SERIES

Page 1

Register your product online !at: www.broan.com

TO REDUCETHE RISK OF FIRE, ELECTRIC SHOCK, OR IN=

JURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufac-

turer, if you have questions, contact the manufacturer at the

address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the ser-

vice disconnecting means cannot be locked, securely fasten

a prominent warning device, such as a tag, to the service

panel.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction.

4. Sufficient air is needed for proper combustion and exhaust-

ing of gases through the flue (chimney) of fuel burning equip-

ment to prevent backdrafting. Follow the heating equipment

manufacturer's guideline and safety standards such as those

published by the National Fire Protection Association (NFPA),

and the American Society of Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code au-

thorities.

5. This product may have sharp edges. Be careful to avoid cuts

and abrasions during installationand cleaning.

6. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

7. Ducted fans must always be vented to the outdoors.

8. Use only metal ductwork.

9. Do not use this fan with any solid-state speed control device.

10.As an alternative, this product may be installed with the UL-

approved cord kit designated for the product, following in-

structions packed with the cord kit.

11.This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may ig-

nite. Heat oils slowly on low or medium settings.

2. Always turn hood ON when cooking at high heat or when

flamb6ing food (i.e. Crepes Suzette, Cherries Jubilee, Pep-

percorn Beef Flamb6).

3. Clean ventilating fans frequently. Grease should not be al-

lowed to accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate for

the size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet,

or metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out immediately,

EVACUATE AND CALLTHE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN --You may be burned or

spread the fire.

3. DO NOT USE WATER, including wet dishcloths or towels - a

violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher, and you

already know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on "Kitchen Firesafety Tips" published by NFPA.

CAUTION

1. For indoor use only.

2. For general ventilating use only. Do not use to exhaust haz-

ardous or explosive materials and vapors.

3. To avoid motor bearing damage and noisy and/or unbal-

anced impeller, keep drywall spray, construction dust, etc.,

off power unit.

4. Do not use over cooking equipment greater than 60,000

BTU/hr.

5. Your hood motor has a thermal overload which will automati-

cally shut off the motor if it becomes overheated. The motor

will restart when it cools down. If the motor continues to shut

off and restart, have the hood serviced.

6. A maximum height of 24" above the cooktop is recommend-

ed for best capture of cooking impurities. The bottom of the

hood MUST NOT BE LESS than 18" above the cooktop.

7. Please read specification label on product for further infor-

mation and requirements.

[_lf hood is to be installed non-ducted:

Purchase non-ducted filter (Model BPQTF) from your

local distributor or retailer.

Installer:Leavethis manual

with the homeowner.

Homeowner:Cleaning, Maintenanceand

Operatinginstructionson page2.

Page 2

BR N

OPERATION

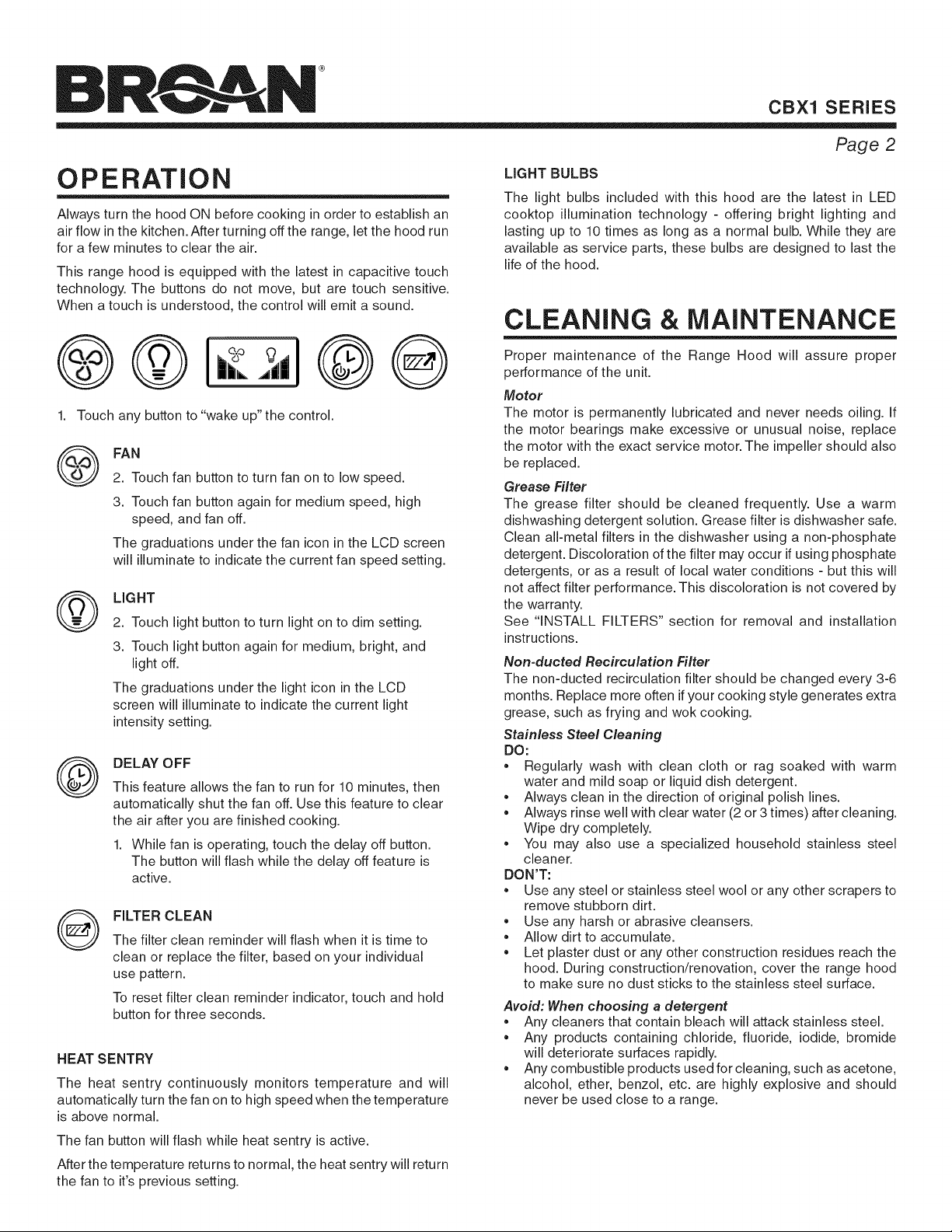

Always turn the hood ON before cooking in order to establish an

air flow in the kitchen. After turning off the range, let the hood run

for a few minutes to clear the air.

This range hood is equipped with the latest in capacitive touch

technology. The buttons do not move, but are touch sensitive.

When a touch is understood, the control will emit a sound.

@©

1. Touch any button to "wake up" the control.

FAN

@

©

@

@

HEAT SENTRY

The heat sentry continuously monitors temperature and will

automatically turn the fan on to high speed when the temperature

is above normal.

The fan button will flash while heat sentry is active.

After the temperature returns to normal, the heat sentry will return

the fan to it's previous setting.

2. Touch fan button to turn fan on to low speed.

3. Touch fan button again for medium speed, high

speed, and fan off.

The graduations under the fan icon in the LCD screen

will illuminate to indicate the current fan speed setting.

LIGHT

2. Touch light button to turn light on to dim setting.

3. Touch light button again for medium, bright, and

light off.

The graduations under the light icon in the LCD

screen will illuminate to indicate the current light

intensity setting.

DELAY OFF

This feature allows the fan to run for 10 minutes, then

automatically shut the fan off. Use this feature to clear

the air after you are finished cooking.

1. While fan is operating, touch the delay off button.

The button will flash while the delay off feature is

active.

FILTER CLEAN

The filter clean reminder will flash when it is time to

clean or replace the filter, based on your individual

use pattern.

To reset filter clean reminder indicator, touch and hold

button for three seconds.

CBX1 SERIES

Page 2

LIGHT BULBS

The light bulbs included with this hood are the latest in LED

cooktop illumination technology - offering bright lighting and

lasting up to 10 times as long as a normal bulb. While they are

available as service parts, these bulbs are designed to last the

life of the hood.

CLEANING & MAINTENANCE

Proper maintenance of the Range Hood will assure proper

performance of the unit.

Motor

The motor is permanently lubricated and never needs oiling. If

the motor bearings make excessive or unusual noise, replace

the motor with the exact service motor. The impeller should also

be replaced.

Grease Filter

The grease filter should be cleaned frequently. Use a warm

dishwashing detergent solution. Grease filter is dishwasher safe.

Clean all-metal filters in the dishwasher using a non-phosphate

detergent. Discoloration of the filter may occur if using phosphate

detergents, or as a result of local water conditions - but this will

not affect filter performance. This discoloration is not covered by

the warranty.

See "INSTALL FILTERS" section for removal and installation

instructions.

Non-ducted Recirculation Filter

The non-ducted recirculation filter should be changed every 3-6

months. Replace more often if your cooking style generates extra

grease, such as frying and wok cooking.

Stainless Steel Cleaning

DO:

• Regularly wash with clean cloth or rag soaked with warm

water and mild soap or liquid dish detergent.

• Always clean in the direction of original polish lines.

• Always rinse well with clear water (2 or 3 times) after cleaning.

Wipe dry completely.

• You may also use a specialized household stainless steel

cleaner.

DON'T:

• Use any steel or stainless steel wool or any other scrapers to

remove stubborn dirt.

• Use any harsh or abrasive cleansers.

• Allow dirt to accumulate.

• Let plaster dust or any other construction residues reach the

hood. During construction/renovation, cover the range hood

to make sure no dust sticks to the stainless steel surface.

Avoid: When choosing a detergent

• Any cleaners that contain bleach will attack stainless steel.

• Any products containing chloride, fluoride, iodide, bromide

will deteriorate surfaces rapidly.

• Any combustible products used for cleaning, such as acetone,

alcohol, ether, benzol, etc. are highly explosive and should

never be used close to a range.

Page 3

BR N

CBX1 SERIES

Page 3

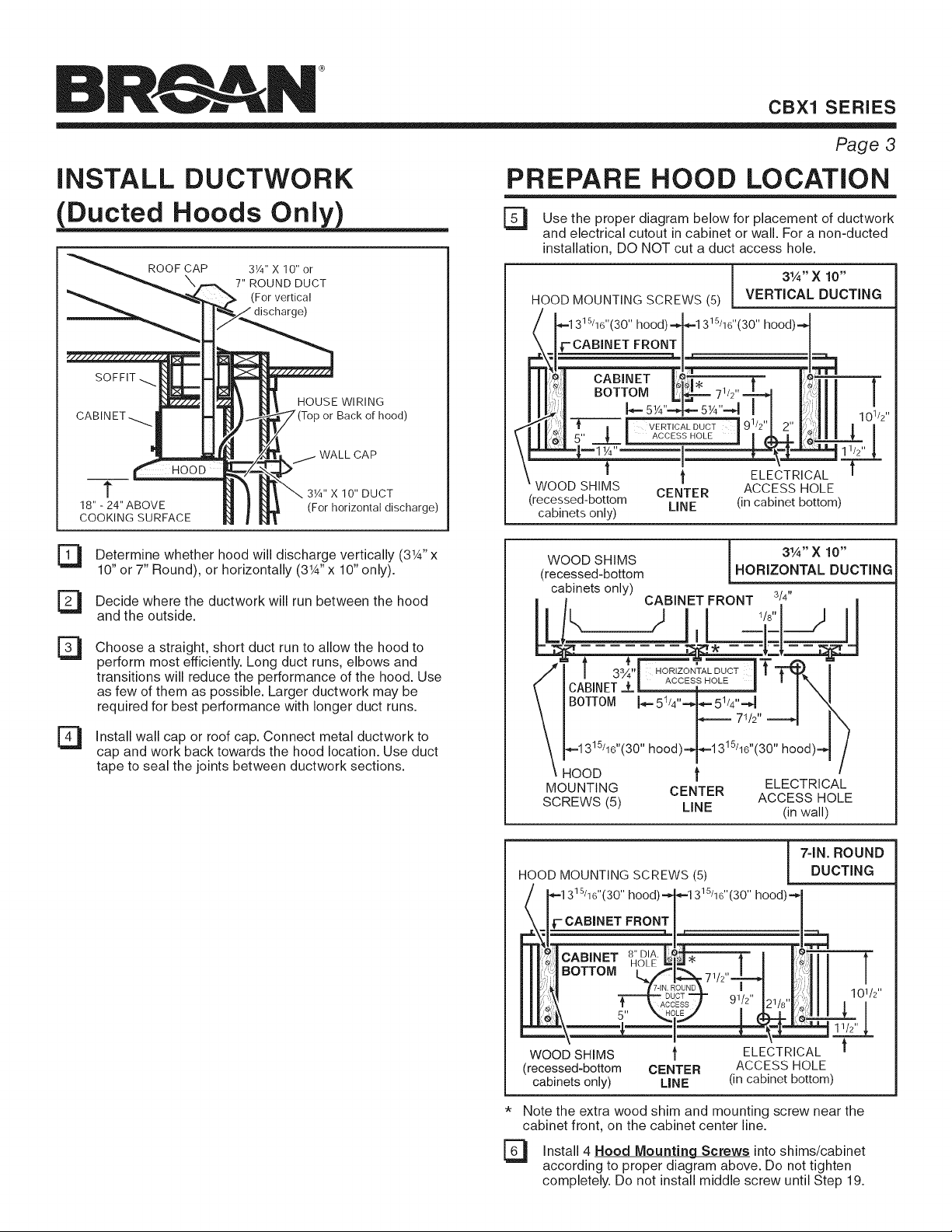

iNSTALL DUCTWORK PREPARE HOOD LOCATION

(Ducted Hoods Only) IZJ

ROOF CAP

CABINET

t

18" - 24" ABOVE

COOKING SURFACE

Determine whether hood will discharge vertically (3W' x

El

10" or 7" Round), or horizontally (3W' x 10" only).

Decide where the ductwork will run between the hood

El

and the outside.

Choose a straight, short duct run to allow the hood to

El

perform most efficiently. Long duct runs, elbows and

transitions will reduce the performance of the hood. Use

as few of them as possible. Larger ductwork may be

required for best performance with longer duct runs.

3¼" X 10" or

7" ROUND DUCT

(For vertical

discharge)

HOUSE WIRING

or Back of hood)

WALL CAP

3¼" X 10" DUCT

(For horizontal discharge)

Use the proper diagram below for placement of ductwork

and electrical cutout in cabinet or wall. For a non-ducted

installation, DO NOT cut a duct access hole.

HOOD MOUNTING SCREWS (5) VERTICAL DUCTING

hood)_,_

BOTTOMi:21#1-7'2

I--Slj4"C!=Slj4,,-4II

[ VERTICALDUC_-7 91/2"1

[ ACCESS HOLE J

--I z.__

WOOD SHIMS _ ELECTRICAL

recessed-bottom CENTER ACCESS HOLE

cabinets only) LINE (incabinet bottom)

WOOD SHIMS _ 3W' X 10"

(recessed-bottom [ HORIZONTAL DUCTING

cabinets only) CABINET FRONT 3/4"

l 314"X 10"

W

101/2"

t

!

/LI

I ">3/,,11 HORIZONTAL DUCT

| ,J/4

CABINET!

BOTTOM

l -ACCESS HOLE

i

[_ Install wall or roof Connect metal ductwork to

cap and work back towards the hood location. Use duct

tape to seal the joints between ductwork sections.

cap cap.

,=1315/16"(30"

HOOD

MOUNTING CENTER ACCESS HOLE

SCREWS (5) LINE (in wall)

HOOD MOUNTING SCREWS (5)

-'=1315/16"(30" hood)--, ,-=1315/16"(30" hood).,-*

r-CABINET FRONT

CABINET 8"D)A.

BOTTOM _

1,2 F

7-1[

ELECTRICAL

7-IN. ROUNDDUCTING

CTs--[" 9V_" 12v_"|i,

,i_

WOOD SHIMS

(recessed-bottom

cabinets only)

* Note the extra wood shim and mounting screw near the

cabinet front, on the cabinet center line.

I_ Install 4 Hood Screws into shims/cabinet

according to proper diagram above. Do not tighten

completely. Do not install middle screw until Step 19.

CENTER

LiNE

Mounting

ELECTRICAL

ACCESS HOLE

(in cabinet bottom)

2"

Page 4

BR N

CBX1 SERIES

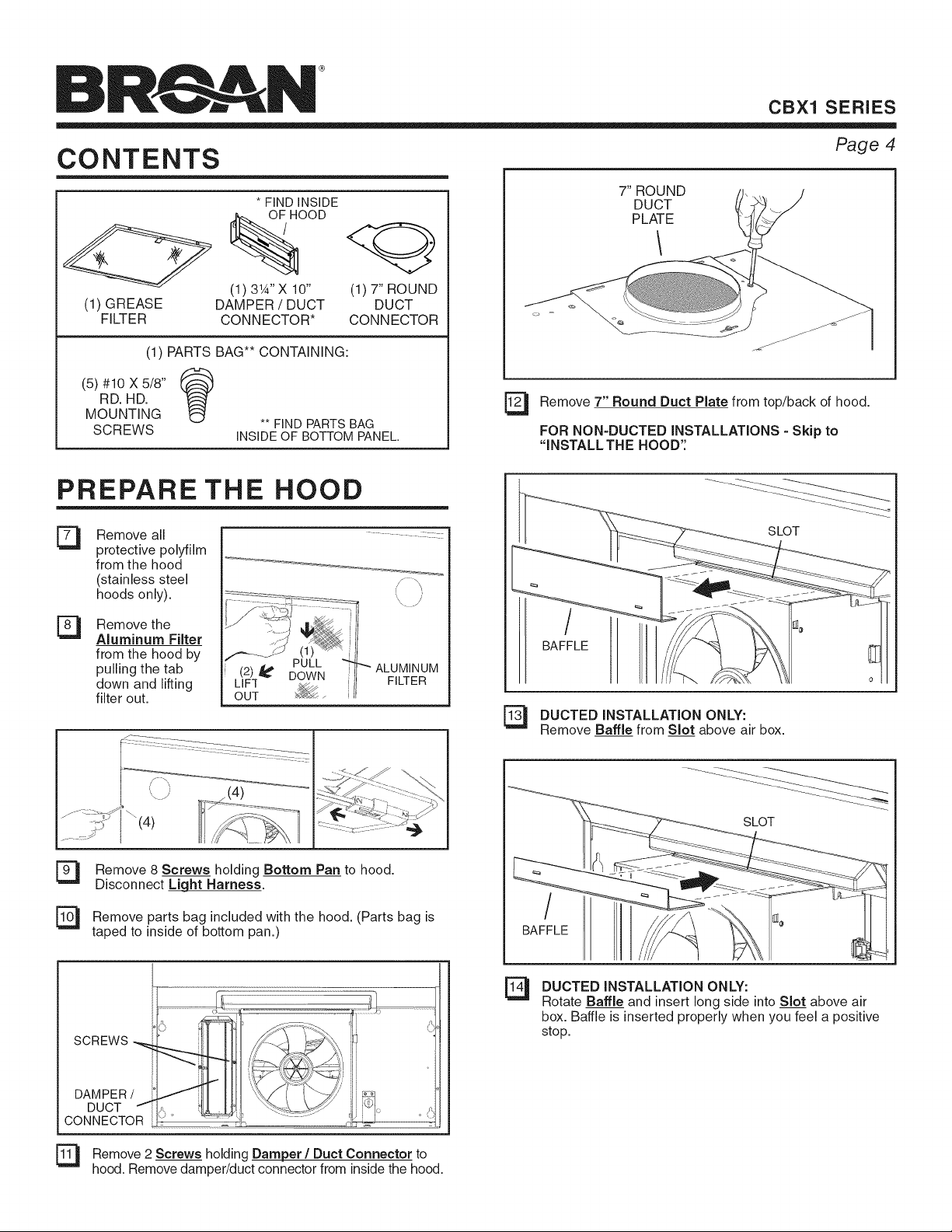

CONTENTS

* FIND INSIDE

00D

(1) GREASE DAMPER / DUCT DUCT

FILTER CONNECTOR* CONNECTOR

(1) PARTS BAG** CONTAINING:

(5) #10 x 5/8"

RD. HD.

MOUNTING

SCREWS ** FIND PARTSBAG

(1) 31A"X 10'' (1) 7" ROUND

INSIDEOF BOTTOM PANEL.

PREPARE THE HOOD

Remove all

E3

protective polyfilm

from the hood

(stainless steel

hoods only).

Remove the

O

Aluminum Filter

from the hood by

pulling the tab

down and lifting

filter out.

PULL

DOWN

........... :zzz:

'\ /

FILTER

7" ROUND

DUCT

PLATE

Remove 7" Round Duct Plate from top/back of hood.

FOR NON-DUCTED INSTALLATIONS =Skip to

"INSTALL THE HOOD':

SLOT

/

BAFFLE

[_ DUCTED INSTALLATION ONLY:

Remove Baffle from Slot above air box.

Page 4

\(4)

Remove 8 Screws holding Bottom Pan to hood.

Disconnect Ljght Harness.

Remove parts bag included with the hood. (Parts bag is

taped to inside of bottom pan.)

SCREWS

DAMPER /

DUCT

CONNECTOR

El Remove 2 Screws holding Damper / Duct Connector to

hood. Remove damper/duct connector from inside the hood.

SLOT

/

BAFFLE

DUCTED INSTALLATION ONLY:

El

Rotate Baffle and insert long side into Slot above air

box. Baffle is inserted properly when you feel a positive

stop.

Page 5

BR N

CBX1 SERIES

Page 5

7" ROUND

KNOCKOUT

PLATE (also

remove 3W' x 10"

vertical plate)

r') _ 314''X 10"

KNOCKOUT

314''X 10" PLATE

KNOCKOUT

PLATE

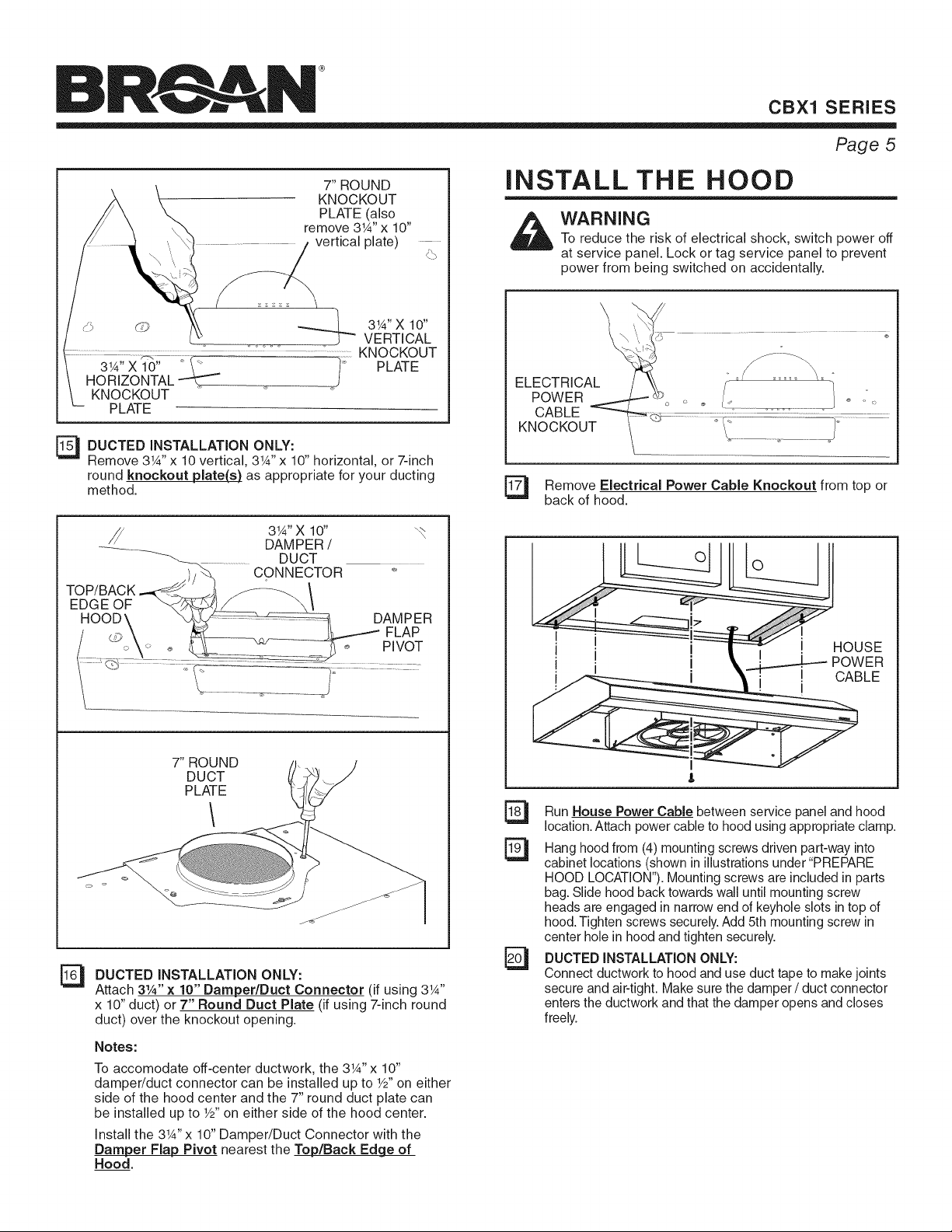

[_ DUCTED INSTALLATION ONLY:

Remove 314'' x 10 vertical, 314'' x 10" horizontal, or 7-inch

round knockout plate(s) as appropriate for your ducting

method.

VERTICAL

INSTALL THE HOOD

_ ARNING

[_ Remove Electrical Power Cable Knockout from top or

To reduce the risk of electrical shock, switch power off

at service panel. Lock or tag service panel to prevent

power from being switched on accidentally.

back of hood.

7" ROUND

DUCT

PLATE

DUCTED INSTALLATION ONLY:

Attach 31,4'' × 10" Damper/Duct Connector (if using 314''

x 10" duct) or 7" Round Duct Plate (if using 7-inch round

duct) over the knockout opening.

Notes:

To accomodate off-center ductwork, the 3X"x 10"

damper/duct connector can be installed up to Y2"on either

side of the hood center and the 7" round duct plate can

be installed up to W' on either side of the hood center.

Install the 3W'x 10" Damper/Duct Connector with the

Damper Flap Pivot nearest the Top/Back Edge of

Hood.

HOUSE

POWER

CABLE

[_ Run House Power Cable between service and hood

location. Attach power cable to hood using appropriate clamp.

El Hang hood from (4) mounting screwsdriven into

cabinet locations (shown inillustrationsunder "PREPARE

HOOD LOCATION"). Mounting screws are includedin parts

bag. Slide hood back towards wall until mounting screw

heads are engaged innarrow end of keyhole slots in top of

hood. Tighten screws securely. Add 5th mounting screw in

center hole in hood and tighten securely.

DUCTED INSTALLATION ONLY:

Connect ductwork to hood and useduct tape to makejoints

secure and air-tight. Make sure the damper/duct connector

enters the ductwork and that the damper opens and closes

freely.

panel

part-way

Page 6

BR N

CONNECT THE WiRiNG

GROUND

SCREW

HOUSE

POWER CABLE

CBX1 SERIES

Page 6

El Connect House Power Cable to hood wiring -

BLACK to BLACK, WHITE to WHITE, and GREEN or

BARE WIRE to Ground Screw.

Re-connect lamp wire harness and re-attach bottom panel

with (8) screws as shown in Step 9.

[_ DUCTED INSTALLATION ONLY:

Re-install aluminum filters removed in Step 8.

NON-DUCTED INSTALLATION ONLY:

Purchase a non-ducted filter (Model BPQTF) from your

local distributor or retailer. Attach the non-ducted filter fol-

lowing instructions packed with the non-ducted filter.

range

Page 7

BR N

SERVICE PARTS

CBX1 SERIES

Page 7

3

17 12/

/

13

\

10

KEY

NO. DESCRIPTION PART NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

BOTTOM PANEL, STAINLESS STEEL (includes hardware)

SCREW PACKAGE FOR BOTTOM PANEL & AIR DUCT

#8-18 X 3/8 (10 REQ.) (2 SCREWS IN BAG)

LAMP WIRE HARNESS

MOTOR WIRE HARNESS (includes power harness)

LED LIGHT (2 REQ.) (includes hardware)

AIR CHUTE (includes chute, baffle and hardware)

CONTROL ASSEMBLY (includes control board, user interface and hardware)

FAN BLADE (INCLUDES HAIRPIN CLIP)

HAIRPIN CLIP

MOUNTING SCREWS (4 REQ.)

FILTER ALUMINUM

7" ROUND DUCT PLATE (includes mounting hardware)

3-1/4" X 10" DAMPER ASSEMBLY (includes mounting hardware)

MOTOR

CABLE CLIP, WIRE HARNESS

CAPACITOR

CONTROL COVER

NON-DUCTED FILTER

97018653

R602534

99271468

97019363

97019364

97018660

97019365

R531076

R99420635

97019040

R610092

R680508

R740014

99080666

99680044

99271481

99111574

99010317

* Not illustrated. Purchase separately.

Order replacement parts by PART NO. - not by KEY NO.

Page 8

BR N

CBX1 SERIES

Page 8

WARRANTY

Limited Warranty

Warranty Period and Exclusions: Broan-NuTone LLC (the "Company") warrants to the original consumer purchaser of its product

("you") that the product (the "Product") will be free from material defects in the Product or its workmanship for a period of one (1) year

from the date of original purchase. The warranty on the light bulbs provided with the Product is one (1) year and does not cover lamp/

bulb breakage.

The limited warranty period for any replacement parts provided by the Company and for any Products repaired or replaced under this

limited warranty shall be the remainder of the original warranty period.

This warranty does not cover fluorescent lamp starters, tubes, halogen and incandescent bulbs, fuses, filters, ducts, roof caps, wall caps

and other accessories for ducting that may be purchased separately and installed with the Product.This warranty also does not cover

(a) normal maintenance and service, (b) normal wear and tear, (c) any Products or parts which have been subject to misuse, abuse,

abnormal usage, negligence, accident, improper or insufficient maintenance, storage or repair (other than repair by the Company),

(d) damage caused by faulty installation, or installation or use contrary to recommendations or instructions, (e) any Product that has

been moved from its original point of installation, (f) damage caused by environmental or natural elements, (g) damage in transit,

(h) natural wear of finish, (i) Products in commercial or nonresidential use, or (j) damage caused by fire, flood or other act of God. This

warranty covers only Products sold to original consumers in the United States by the Company or U.S. distributors authorized by the

Company.

This warranty supersedes all prior warranties and is not transferable from the original consumer purchaser.

No Other Warranties: This Limited Warranty contains the Company's sole obligation and your sole remedy for defective products.

The foregoing warranties are exclusive and in lieu of any other warranties, express or implied. THE COMPANY DISCLAIMS AND

EXCLUDES ALL OTHER EXPRESS WARRANTIES, AND DISCLAIMS AND EXCLUDES ALL WARRANTIES IMPLIED BY LAW,

INCLUDING WITHOUT LiMiTATION THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. To the

extent that applicable law prohibits the exclusion of implied warranties, the duration of any applicable implied warranty is limited to the

period specified for the express warranty above. Some states do not allow limitations on how long an implied warranty lasts, so the

above limitation may not apply to you. Any oral or written description of the Product is for the sole purpose of identifying it and shall not

be construed as an express warranty.

Whenever possible, each provision of this Limited Warranty shall be interpreted in such manner as to be effective and valid under

applicable law, but if any provision is held to be prohibited or invalid, such provision shall be ineffective only to the extent of such

prohibition or invalidity, without invalidating the remainder of such provision or the other remaining provisions of the Limited Warranty.

Remedy: During the applicable limited warranty period, the Company will, at its option, provide replacement parts for, or repair or

replace, without charge, any Product or part thereof, to the extent the Company finds it to be covered by and in breach of this limited

warranty under normal use and service. The Company will ship the repaired or replaced Product or replacement parts to you at no

charge. You are responsible for all costs for removal, reinstallation and shipping, insurance or other freight charges incurred in the

shipment of the Product or part to the Company. If you must send the Product or part to the Company, as instructed by the Company,

you must properly pack the Product or part--the Company is not responsible for damage in transit. The Company reserves the right to

utilize reconditioned, refurbished, repaired or remanufactured Products or parts in the warranty repair or replacement process. Such

Products and parts will be comparable in function and performance to an original Product or part and warranted for the remainder of

the original warranty period.

Exclusion of Damages: THE COMPANY'S OBLIGATION TO PROVIDE REPLACEMENT PARTS, OR REPAIR OR REPLACE, AT

THE COMPANY'S OPTION, SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY AND THE

COMPANY'S SOLE AND EXCLUSIVE OBLIGATION. THE COMPANY SHALL NOT BE LIABLE FOR INCIDENTAL, INDIRECT,

CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH THE PRODUCT, ITS USE OR

PERFORMANCE.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you. This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state.

This warranty covers only replacement or repair of defective Products or parts thereof at the Company's main facility and does not

include the cost of field service travel and living expenses.

Any assistance the Company provides to or procures for you outside the terms, limitations or exclusions of this limited warranty will not

constitute a waiver of such terms, limitations or exclusions, nor will such assistance extend or revive the warranty.

The Company will not reimburse you for any expenses incurred by you in repairing or replacing any defective Product, except for those

incurred with the Company's prior written permission.

How to Obtain Warranty Service: To qualify for warranty service, you must (a) notify the Company at the address or telephone

number stated below within seven (7) days of discovering the covered defect, (b) give the model number and part identification and

(c) describe the nature of any defect in the Product or part. At the time of requesting warranty service, you must present evidence of

the original purchase date. If you cannot provide a copy of the original written limited warranty, then the terms of the Company's most

current written limited warranty for your particular product will control. The most current limited written warranties for the Company's

products can be found at www.broan.com.

Broan-NuTone LLC 926 West State Street, Hartford, Wl 53027 www.broan.com 800-637-1453

99045146B

Page 9

BR N

Campanas

Serie CBX1 [

Registte su producto en el i

sitio web www.broan.com

SERIE CBX1

P_gina 9

i

SOLAMENTE PARA

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO, DESCARGA EL¢CTRICA

O LESIONES CORPORALES, OBSERVE LO SIGUIENTE:

1. Use la unidad s61o de la manera indicada por el fabricante. Si tiene

preguntas, comuniquese con el fabricante a la direcci6n o al numero

telef6nico que se incluye en la garantia.

2. Antes de dar servicio a la unidad o de limpiarla, interrumpa el

suministro electrico en el panel de servicio y bloquee los medios de

desconexi6n del servicio para evitar que la electricidad se reanude

accidentalmente. Cuando no sea posible bloquear los medios de

desconexi6n del servicio, fije firmemente una seSal de advertencia

(como una etiqueta) en un lugar visible del panel de servicio.

3. Una o mAs personas calificadas deben realizar el trabajo de

instalaci6n y el cableado electrico siguiendo todos los c6digos y

normas correspondientes, incluidos los c6digos y las normas de

construcci6n especificos para incendios.

4. Se necesita suficiente aire para que se Ileve a cabo una combusti6n

y una extracci6n adecuadas de los gases a traves del tubo de

humos (chimenea) del equipo quemador de combustible, con el fin

de evitar el contratiro. Siga las directrices y las normas de seguridad

del fabricante del equipo de calefacci6n, como las publicadas pot

la Asociaci6n Nacional de Protecci6n contra Incendios (National

Fire Protection Association, NFPA), y la Sociedad Americana de

Ingenieros en Calefacci6n, Refrigeraci6n y Aire Acondicionado

(American Society of Heating, Refrigeration and Air Conditioning

Engineers, ASHRAE), y las autoridades de los c6digos locales.

5. Este producto podria tener hordes afilados. Trabaje con cuidado

para evitar cortes y abrasiones durante la instalaci6n y la limpieza.

6. AI cortar o perforar a traves de la pared o del techo, tenga cuidado

de no daSar el cableado electrico ni otros servicios ocultos.

Z Los ventiladores en conductos siempre deben ventearse hacia el

exterior.

8. Utilice unicamente conductos metb,licos.

9. No use este ventilador junto con ningun dispositivo de control de

velocidad de estado s61ido.

10. Como alternativa, se puede instalar este producto con el juego de

cable de alimentaci6n aprobado pot UL y diseSado para el producto,

siguiendo las instrucciones incluidas con el cable.

11. Esta unidad debe estar conectada a tierra.

PARA REDUCIR EL RIESGO DE INCENDIO PROVOCADO POR

GRASA PRESENTE EN LA ESTUFA:

1. Nunca deje desatendidas las unidades de la superficie cuando

esten en ajustes altos de calor. Los alimentos en ebullici6n provocan

derrames grasosos y con humo que se pueden incendiar. Caliente

el aceite lentamente en ajustes de calor bajo o medio.

2. Siempre ENClENDA la campana cuando este cocinando a altas

temperaturas o flamee alimentos (pot ejemplo crepas Suzette,

cerezas Jubilee, bistec con pimienta flameado).

3. Limpie frecuentemente los ventiladores. No permita la acumulaci6n

de grasa en el ventilador ni en el filtro.

4. Use una cacerola del tamaSo adecuado. Siempre use utensilios

de cocina que sean apropiados para el tamaSo del elemento de la

superficie.

COClNAR EN CASA

ADVERTENCIA

PARAREDUClR EL RIESGO DELESIONES A LAS PERSONAS ENCASO DE

UN INCENDIO PRODUCIDO POR GRASA EN UNA ESTUFA, OBSERVE

LOSIGUIENTE*:

1. APAGUE LAS LLAMAS con una tapa de ajuste exacto, una charola para

galletas ouna bandeja de metal,y despues apagueel quemador. PROCEDA

CONCUIDADO PARAEVlTAR QUEMADURAS. Si las llamas no se apagan

inmediatamente, EVACUE ELAREA Y LLAME A LOS BOMBEROS.

2. NUNCA LEVANTE UNA CACEROLA INCENDIADA porque podria sufrir

quemaduras o propagarel incendio.

3. NO USE AGUA, incluidos trapos o toallas de cocina mojados; puede

producirse una explosi6n violenta de vapor.

4. Use un extintor SOLO si:

A. Sabe que tiene un extintor clase ABC, y ya sabe c6mo usarlo.

B. El incendio es pequeSoy esta confinado alArea en la que se inici6.

C. Se estAIlamando al Departamento de Bomberos.

D. Puedecombatir el incendioteniendola espalda orientadahacia una salida.

*Basado en "Consejos 0tiles de seguridad en incendios en la cocina" ("Kitchen

Fire Safety Tips"), publicado pot NFPA.

PRECAUCION

1. S61odebe usarse bajo techo.

2. S61o para usarse como medio de ventilaci6n general. No debe

usarse para la extracci6n de materiales o vapores peligrosos o

explosivos.

3. Para evitar daSos a los cojinetes del motor y rotores ruidosos o

desbalanceados, mantenga la unidad electrica al resguardo de

rociados de yeso, polvo de construcci6n, etc.

4. No use equipo para cocinar mayor de 60,000 BTU/hr.

5. Este motor de campana tiene una protecci6n contra sobrecargas t6rmicas

que automaticamente apagara el motor en caso de sobrecalentamiento.

El motor reanudarA su funcionamiento cuando se enfr[e. Si el motor

continua apagAndose y encendi_ndose, solicite servicio para la campana.

6. Una altura maxima de 24" por encima de la superficie de cocci6n se re-

comienda para limpiar mejor las impurezas al cocinar. La parte inferior

de la campana no debe set inferior a 18" por encima de la superficie de

cocci6n.

Lea la etiqueta de especificaciones que tiene el producto para ver

informaci6n y requisitos adicionales.

Si la instalar sistema sin conductos:

campana se va a en un

Compre un filtro sin conductos (Modelo BPQTF) con su

distribuidor o tienda minorista local.

Avisoal instalador:Deje este manual

conel duenode la casa.Avisoal due o

de la casa:Enla p gina 10 encontrar

lasinstruceionesde limpieza,

mantenimiento y funcionamiento.

Page 10

BR N

SERIE CBX1

P4gina 10

FUNCIONAlVllENTO LllVIPIEZAY IVIANTENllVllENTO

ENCIENDA siempre la campana antes de comenzar a cocinar, con el fin de

establecer un fiujo de aire en la cocina. Despues de apagar la estufa, deje

que la campana funcione durante unos cuantos minutos para despejar el aire.

Esta campana est,. equipada con IoQltimo en tecnologfa t_ctil capacitiva. Los

botones no se mueven, pero son sensibles al tacto. Cuando un contacto es

interpretado, el control emitir_, un sonido.

@@

1. Toque cualquier bot6n para"despertar" el control.

VENTILADOR

@

@

@

@

CONTROLADOR DE CALOR

El controlador de calor continuamente monitorea la temperatura y

autom_ticamente enciende el ventilador a alta velocidad cuando la

temperatura est,. per encima de Io normal.

El bot6n del ventilador destellar_,mientras el centinela calor est,. activa.

Despues de que la temperatura vuelve a la normalidad, el controlador de

calor apaga el ventilador y la memoria de control devuelve el ventilador a su

valor anterior.

2. Toque el bot6n del ventilador para encender el ventilador a

baja velocidad.

3. Toque de nuevo el bot6n del ventilador para velocidad media,

velocidad m_xima y apagado.

Las graduaciones en el icono del ventilador en la pantalla LCD

se iluminar_ para indicar elajuste de velocidad del ventilador

actual.

LUZ

2. Toque el bot6n de luz para encender la luz en el ajuste

oscuro,

3. Pulse el bot6n de nuevo para luz media, brillante o apagada.

Las graduaciones en el icono de luz en la pantalla LCD se

iluminar_, para indicar el ajuste de intensidad de luz actual.

RETARDO

Esta caracterfstica permite que el ventilador funcione durante 10

minutes y luego se apaga autom_.ticamente. Utilice esta funci6n

para limpiar el aire despues de que su cocci6n haya terminado.

1. Mientras el ventilador est_ funcionando, toque el bot6n de

desactivaci6n de retardo. El bot6n parpadear& mientras la

funci6n de retardo de apagado est& active.

LIMPIEZA DEL FILTRO

El recordatorio de limpieza del filtro parpadear& cuando sea

el momento de limpiar o reemplazar el filtro, basado en su

modalidad de uso.

Para poner a cero el indicador de limpieza de filtro, toque y

mantenga presionado el bot6n durante tres segundos.

El mantenimiento correcto de la campana de la estufa asegurar_ el

funcionamiento adecuado de la unidad.

Motor

El motor est_ permanentemente lubricado y nunca necesitar_,ponerle aceite.

Si los cojinetes del motor estAn haciendo ruido excesivo o inusual, reemplace

el motor con el motor deservicio exacto. Tambien debe reemplazar el impulsor.

Filtro de grasa

El filtro de grasa se debe limpiar con frecuencia. Utilice una soluci6n tibia de

detergente para plates. El filtro de grasa se puede lavaren lavaplatos. Limpie

los filtros completamente met_.licos en la lavaplatos con un detergente sin

fosfatos. Elfiltro se puede decolorar si se utilizan detergentes con fosfatoo como

resultado de lacondici6n del agua local, pero esto no afectar_ el desempe_o

del filtro. Esta decoloraci6n no est,. cubierta pot la garantfa.

Consulte la secci6n "INSTALACION DE LOS FILTROS" para vet las

instrucciones de instalaci6n y desmontaje.

Filtro de recirculacidn para sistemas sin conductos

El filtro de recirculaci6n para sistemas sin conductos se debe cambiar cada

3-6 meses. C_.mbielo con mAs frecuencia si su estilo de cocinar genera m_.s

grasa, come freir los alimentos o cocinar en un wok. CensuRe las instrucciones

para quitar e instalar en el paso 15de la p_.gina 18.

Limpieza del acero inoxidable

COSAS QUE PUEDE HACER:

• Regularmente, lave con una tela o trapo limpio remojado con agua tibia y

jab6n o detergente liquido para plates.

• Siempre limpie en la direcci6n de las lineas originales de pulido.

• Siempre enjuague bien con agua limpia (2 o 3 veces) despu6s de la

limpieza. Deje totalmente seco.

• Tambien puede usar un limpiador casero especializado para acero

inoxidable.

COSAS QUE NO DEBE HACER:

• Usar lana de acero o acero inoxidable ni alg_n otro tipo de raspador para

quitar mugre dificil de sacar.

• Usar limpiadores fuertes ni abrasivos.

• Dejar que se acumule la mugre.

• Dejar que el polvo forme plastas ni que quede en la campana algQn

otro residuo de la construcci6n. Durante la construcci6n o la renovaci6n,

cubra la campana para estar seguro de que el polvo no se pegue a la

superficie de acero inoxidable.

Evite: AI elegir un detergente

• Todo limpiador que contenga blanqueador, pues atacar& al acero

inoxidable.

• Productos que contengan cloruro, fluoruro, yoduro, bromuro, pues

deteriorar_n las superficies r@idamente.

• Todo producto combustible utilizado para la limpieza, como acetona,

alcohol, 6ter, benzol, etc., pues son altamente explosivos y nunca se

deben usar cerca de una estufa.

LAMPARAS

Las lamparas incluidas con esta campana son Io _ltimo en tecnologia

de iluminaci6n LED de estufa - que ofrece una iluminaci6n brillante y

duran hasta 10 veces m_.s que una I_.mparanormal. Mientras que estAn

disponibles como piezas de repuesto, estas I_.mparasest_.ndise_adas para

durar toda la vida de lacampana.

Esta campana estA equipada con IoOltimo en tecnologia t_ctil capacitiva.

Los botones no se mueven, pero son sensibles al tacto. Cuando un contacto

es interpretado, el control emitir_, un sonido.

Page 11

BR N

SERIE CBX1

P_gina 11

INSTALEEL SISTEIVlA

DECONDUCTOS(S61ocampanas

para sistemas con conductos)

TAPA DE TECHO

PLAFON

1"

DE 18a 24 PULG.

(45.7 a 61 CM) POR ENCIMADE

LA SUPERFICIE DE COCINADO

Determine si la descarga de la campana va a ser vertical

rq

(conducto de 31Ax 10 pulg. [8.3 x 25.4 cm] o redondo

de 7 pulg. [17.8 cm]) u horizontal (sOlo conducto de

31Ax 10 pulg. [8.3 x 25.4 cm]).

Decida dOnde instalara el conducto entre la campana y

el exterior.

Elija un conducto recto y corto para permitir que la

campana funcione mas eficientemente. Los tramos

largos de conductos, codos y transiciones reduciran

el desempero de la campana. Use tan pocos de

ellos como sea posible. Es posible que se requieran

conductos mb,s grandes para un mejor funcionamiento

con tramos mas largos de conductos.

Instale la tapa para pared o para techo. Conecte un

El

conducto metb,lico en la tapa y trabaje hacia atras,

hacia la ubicaciOn de la campana. Use cinta para

conductos para sellar las uniones entre las secciones

de conductos.

CONDUCTO DE

3¼ x 10 pulg. (8.3 x 25.4 cm) o

CONDUCTO REDONDO

de 7 pulg. (17.8 cm)

(para descarga vertical)

CABLEADO ELECTRICO

DE LA CASA

_erior o

posterior de la campana)

CONDUCTO DE

3¼ x 10 pulg.

(8.3 x 25.4 cm)

(para descarga horizontal)

CONDUCTOVERTICALDE

TORNILLOSDEMONTAJE 31AX 10PULG.(8.3 X25.4CM

DE LACAMPANA(5)

/ l_i,=13q5/16puig (354cm) ._=1315116pulg ([¢54 cm)

I (c_lrnpana do 30 pulg/Z6 2 cm) I (campana de 30 pulg 176 2 cm)

\ I FRENTEOELGABINETEI

II,,: j ........ I::;1111

r i 574 pulg 5¼ pulg 0 ¼1)

-¢P(,IW __;f,m,',,11<_7"o'7,,_ ',111 ,<_G;,m,

II"lii<'S';_'_ _ I_._!!:t-l;_ /

CUNAS DE MADERA t ORIFICIO DE ACCESO '

(s01ogabinetes LJNEA PARA CABLES ELECTRICOS

de parte inferior empotrada) CENTRAL (en la parte inferior del gabinete)

i CONDUCTOHORIZONTALDE

CUNAS DE MADERA 131_X!OPULG:!8:3X25.4CM

(sologabinetes de parte FRENTE DEL 3/4pulg.

inferiorempotrada) GABINETE 1, (1._om)

t_.b ore) CONDUCTO HORIZONTAL

/ ±! °°N°H°T, 1

PARTE 5 V4 pulg. I 5 V4 pulg. I

INFERIOR'1"i3.3cr_,_

DEL GABINETE 17 '12pulg.(19.1

1315/16 pulg. (35.4 cm) _ 1315/16 pulg. (35.4 cm)

campana de 30 pulg./76.2 cm) _(carnpana de 30 pulg

TORNILLOS DE LINEA ACCESO PARA

MONTAJE DE CABLES ELECTRICOS

LACAMPANA (5) CENTRAL (en la pared)

TORNILLOS DE MONTAJE

DE LA CAMPANA (5)

13 15/16 pulg (35 4 cm)

::'JZ:::°'US

,,¢ DE DIAM

":'1 PARTE INFERIOR

DEL GABINETE

),_,,' 5p. _°

,__ 13 15/16 pulg (354 cm) .._

(campana de 30 pulg/76 2 cm)

CTDE _(191 ore) I - I

NSOoTo 9 7_ pulg 2 pulg

18 pulg.

ORIFICIO DE

CONDUCTO REDONDO

DE 7 PULG. (17.8 CM)

PREPARE EL LUGAR DONDE SE

VAA INSTALAR LA CAiVlPANA

Gufese pot el diagrama correspondiente (a continuaciOn)

El

para colocar los conductos y hacer el corte exacto para

la conexiOn elOctrica en el gabinete o en la pared. Para

instalaciones en sistemas sin conductos, NO haga

ningQn orificio de acceso para conducto.

CUKIASDEMADERA

(s01o gabinetes de

parte inferior empotrada)

* Observe la curia de madera adicional y el tornillo de

montaje cerca del frente del gabinete, sobre la linea central

del gabinete.

7 Instale 4 tomillos de de la

lascalzas/gabinete,de acuerdocon eldiagrama

correspondiente.No aprietetotalmente.No instaleel

tornillode en medio hastaelpaso 19.

LINEA

CENTRAL

montaie

ORIFICIODEACCESO

PARACABLES ELECTRICOS

(enla parteinferiordel gabinete)

campan8

t

en

Page 12

BR N

SERIE CBX1

CONTENIDO

* ENCUENTRA EN EL INTERIOR

DE LA CAMPANA.

(1) FILTRO CONDUCTO DE 31A X 10 REDONDO DE

DE GRASA PULG. (8.3 X 25.4 CM)* 7 PULG. (17.8 CM)

(1) BOLSA DE PIEZAS** QUE CONTIENE:

(5) TORNiLLOS DE

MONTAJE DE CABEZA

REDONDA #10 X

5/8 PULG.

** ENCUENTRA LA BOLSA DE PIEZAS

AL INTERIOR DEL PANEL INFERIOR.

PREPARE LA CAIVIPANA

Quite todo el forro

El

de pl_.stico protector

de la campana

(QnJcamente

campanas de

acero inoxJdable).

Retire el fiitro de

O

aiuminio de la

campana jalando

la lengOeta hacia

abajo y levantando

el filtro.

'\ /

FILTRO DE

ALUMINIO

P4gina 12

PLACA DEL

CONDUCTO

REDONDO

DE 7 PULG.(1X8 CM)

[_ etire la placa del conducto redondo de 7 pulg. (17.8 cm)_

de la parte superior/trasera de la campana.

RANURA

DEFLECTOR

Quite los 8 tornillos que sostienen el recipiente inferior a la

campana. Desconecte el arn_s de las luces.

Retire la boJsa de piezas incluida con la campana. (Bolsa de

piezas se pega al interior del recipiente inferior.

A

TORNILLOS ._<

CONECTOR DEL

REGULADOR_

DETIRO/

CONDUCTO

El Quite los 2 tornillos sujetan el conector del regulador de

tiro/conducto a la campana. Quite el conector del regulador de

tiro/conducto del interior de la campana.

que

_i ¸_._

0NICAMENTE EN INSTALACIONES CON CONDUCTOS:

Retire el deflector de la ranura arriba de la caja de aire.

RANURA

DEFLECTOR

0NICAMENTE EN INSTALACIONES CON CONDUCTOS:

Gire el deflector e inserte el lado largo en la ranura arrJba

de la caja de aire. El deflector se inserta adecuadamente

cuando siente un tope positivo.

Page 13

BR N

SERIE CBX1

P4gina 13

PLACA REDONDA DE

ORIFICIO CIEGO DE 7

PULG. (17.8 CM) (TAMBIEN

DESMONTE LA PLACA

VERTICAL DE 31/4X 10 PULG.

[8.3 X 25.4 CM])

PLACA HORIZONTAL

ORIFICIO CIEGO

DE 3_A X 10 PULG.

PLACA VERTICAL

DE 3_A X 10 PULG.

(8.3 X 25.4 CM)

0NICAMENTE EN INSTALACIONES CON CONDUCTOS:

Retire las placas de orificio cie&o_ vertical de 3 ¼ x 10 pulg.

(8.3 x 25.4 cm), horizontal de 31A x 10 pulg. (8.3 x 25.4 cm),

o redonda de 7 pulg. (17.8 cm), segQn corresponda a su

m6todo de conductos.

CONECTOR PARA

REGULADOR DE TIRO/

CONDUCTO DE 31A X 10 PULG. .....................................

SUPERIOR/ _/I J "_ .

.;/\ <83x254cM> o

(8.3 X 25.4 CM)

1

POSTER,OROE \

LA CA PIVOTE DE LA

/ _ \ _ REGULADOR

_J

ALETA DEL

DE TIRO

INSTALE LA CAIVlPANA

_hb DVERTENCIA

Para reducir el riesgo de una descarga el6ctrica,

desconecte el suministro el6ctdco en el panel de

servicio. BIoquee el panel de servicio o p6ngale una

etiqueta de seguridad para evitar que alguien conecte

accidentalmente la energia el6ctrica.

\

ORIFICIO

CIEGO DEL_

CABLE

ELECTRICO

El Quite el orificio ciego del cableado el6ctrico desde la

parte superior o trasera de la campana.

I

i

i

CABLE

ELECTRICO

DE LA CASA

PLACA DEL CONDUCTO

REDONDO

DE 7 PULG.(17.8 CM)

0NICAMENTE EN INSTALACIONES CON CONDUCTOS:

El

Acople el conector del regulador de tiro/conducto

de 3_A_8.3 x 25.4 cm} (si estdt usando

el conducto de 31A pulg. x 10 pulg. [8.3 x 25.4 cm]) o la

placa redonda de 7 p_ (si estdt usando el

conducto redondo de 7 pulg. [17.8 cm]) por la abertura del

orificio ciego.

Notas:

Paraacomodar los conductos descentrados: el conector del regulador

de tiro/conducto de 3_Ax 10 pulg. (8.3 x 25.4 cm) puede instalarse

a una distancia hasta de 1/2 pulg. (1.27 cm) desde el centro de la

campana hacia cualquier lado, y la placa del conducto redondo de

7 pulg. (17.8cm) puede instalarse a 1/2 pulg. (1.27cm) desde el centro

de la campana hacia cualquier lado.s

Instaleel conector del regulador de tiro/conducto de 3_Ax 10 pulg.

(8.3 x 25.4 cm) con el pivote de aleta del regulador mas cercano al

borde superior/trasero de la campana.

Tienda el cable el6ctdco de la casa entre el panel de servicio

y la campana. Conecte el cable el6ctrJco a la campana con la

abrazadera apropiada.

Cuelgue la campana de los (4) orificios de montaje insertados

parcialmente en las posiciones del gabinete (mostrado en

las ilustraciones de "PREPARE EL LUGAR DONDE SE VA A

INSTALAR LA CAMPANA'). La bolsa de piezas contiene los

tornillos de montaje. Deslice la campana hacia la pared hasta

que las cabezas de los tornillos de montaje queden conectadas

en el extreme angosto de los orificios tipo bocallave que est_.n

en la parte superior de la campana. Apriete bien los tornillos.

Agregue el quinto tornillo de montaje en el orificio central de la

campana y apriete con firmeza.

0NICAMENTE EN INSTALACIONES CON CONDUCTOS:

Conecte el sistema de conductos a la campana y ponga

cinta para conductos en las uniones para fijarlas y sellarlas.

AsegQrese de que el conector del regulador de tiro/conducto

entre a los conductos y que el regulador de tiro pueda abfirse y

cerrarse libremente.

Page 14

BR N

CONECTE EL CABLEADO

TORNILLO

CABLE ELECTRICO

DE LA CASA

El onecte el cable el_ctrico de la casa al cableado de

la campana: cable NEGRO con NEGRO, BLANCO con

BLANCO y VERDE o SIN FORRO al tornillo de tierra.

[_ Reconecte el arn6s de cables de la I_.mpara y vuelva a

conectar el panel inferior con ocho (8) tornillos, como se

muestra en el paso 9.

SERIE CBX1

P_gina 14

INSTALACI6N CON TUBERIA 0NICAMENTE:

El

Vuelva a instalar los filtros de aluminio retirados en elpaso 8.

0NICAMENTE EN INSTALACIONES SIN

CONDUCTOS:

Compre un filtro sin conductos (Modelo BPQTF) con su

distribuidor o tienda minorista local. Conecte el filtro sin

conductos siguiendo las instrucciones incluidas con el

filtro.

Page 15

BR N

PIEZAS DE SERVlClO

/

13

\

10

SERIE CBX1

P_gina 15

_ 3

CLAVE

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

* No se ilustra. Se compra por separado.

AI pedir piezas de repuesto, indique el No. de pieza, no el No. de Clave.

DESCRIPCION

PANEL INFERIOR, ACERO INOXIDABLE (incluye piezas)

PAQUETE DE TORNILLOS PARA PANEL INFERIOR Y DUCTO DE AIRE

# 8-18 x 3/8 (10 req.) (2 tornillos en bolsa)

ARNES DE CABLES DE LAMPARA

ARNES DE CABLES DE MOTOR (incluye cables de alimentaci6n)

LUCES DE LED (2 req.) (Incluye piezas)

CONDUCTO DE AIRE (induye conducto, el deflector y las piezas)

CONTROL DE CIRCUITOS (incluye tarjeta de control, interfaz de usuario y piezas)

ASPA DEL VENTILADOR (incluye pasador de horquilla)

PASADOR DE HORQUILLA

TORNILLOS DE MONTAJE (4 req.)

FILTRO DE ALUMINIO

PLACA DE DUCTO REDONDO DE 7" (incluye piezas de montaje)

3-1/4 "X 10" REGULADOR DE TIRO DE ENSAMBLE (incluye piezas de montaje)

MOTOR

SUJETADOR DE CABLES, ARNES DE CABLES

CAPACITOR

TAPA DEL CONTROLADOR

FILTRO DE CARBON

NO. PARTE

97018653

R602534

99271468

97019363

97019364

97018660

97019365

R531076

R99420635

97019040

R610092

R680508

R740014

99080666

99680044

99271481

99111574

99010317

Page 16

BR N

SERIE CBX1

P_gina 16

GARANTiA

Garantia limitada

Periodo y exciusiones de la garantia: Broan-NuTone LLC (la "CompaGia") garantiza al consumidor comprador original de su producto

("usted")que el producto (el "Producto") estara,libre de defectos en materiales o en mano de obra, por unperiodo de un (1) ago a partir de la

fecha de compra original. La garantia en las bombillas provista con el Producto es de un (1) ago y no cubre el rompimiento de las bombillas/

la.mparas.

El periodo de garantia limitada para cualquier pieza de repuesto proporcionada por la compaGia y para cualquier Producto reparado o

reemplazado bajo esta garantia limitada debe ser Ioque reste del periodo de garantia original.

Esta garantia no cubre arrancadores de lamparas fluorescentes, tubos, bombillas de hal6geno e incandescentes, fusibles, filtros, conductos,

tapas de techo, tapas de pared ni otros accesorios que pudieran ser comprados por separado e instalados con el producto. Esta garantia

tampoco cubre (a) mantenimiento y servicio normal, (b) uso y desgaste normal, (c) Productos o piezas sujetos a real uso, abuso, uso anormal,

negligencia, accidente, mantenimiento inadecuado o insuficiente, almacenamiento o reparaci6n (que no sea reparaci6n por parte de la

CompaGia), (d) daGos causados por instalaci6n defectuosa, o bien instalaci6n o uso contrario alas recomendaciones o instrucciones, (e)

cualquier Producto que se haya movido de su punto de instalaci6n original, (f) daGos ocasionados por el medio ambiente o los elementos

naturales, (g) daGos en transito, (h) desgaste natural del acabado, (i) Productos en uso comercial o no residencial, o (j) daGos ocasionados

por incendio, inundaci6n u otro caso fortuito. Esta garantia cubre solamente Productos vendidos a clientes originales en los Estados Unidos

por la CompaGia o a distribuidores de EE. UU. autorizados por la CompaGia.

Esta garantia sustituye todas las garantias anteriores y no es transferible del comprador consumidor original.

No hay otras garantias: Esta garantia limitada contiene la unica obligaci6n de la CompaGia y su unico recurso anteproductos defectuosos.

Las garantias anteriores son exclusivas yen lugar de cualquier otra garantia, expresa o implicita. LA COMPANIA NIEGA Y EXCLUYE

CUALQUIER OTRA GARANT|A EXPRESA, Y NIEGA Y EXCLUYE TODAS LAS GARANTIAS IMPLtCITAS POR LEY, INCLUYENDO,

ENTRE OTRAS, LAS DE COMERCIALIZACION Y APTITUD PARA UN PROPOSITO EN PARTICULAR. Hasta el grado en que la ley

aplicable prohiba la exclusi6n de las garantias implicitas, la duraci6n de cualquier garantia implicita aplicable esta. limitada al periodo

especificado para la garantia expresa antes mencionada. Algunos estados no permiten limitaciones en la duraci6n de una garantia implicita,

asi que la limitaci6n anterior tal vez no aplique en su caso. Cualquier descripci6n verbal o escrita del Producto es para el Onicoprop6sito de

identificarlo y no debera, considerarse como una garantia expresa.

Siempre que sea posible, toda disposici6n de esta garantia limitada debera ser interpretada de tal forma que sea efectiva y v_.lida de

conformidad con la ley aplicable, pero si alguna disposici6n fuera considerada prohibida o invalida, quedara sin efecto solo en virtud de dicha

prohibici6n o invalidez, sin invalidar el resto de dicha disposici6n o las demas disposiciones restantes de la garantia limitada.

Recurso: Durante el periodo de garantia limitada aplicable, la CompaGia, a su opci6n, suministrara, piezas de repuesto, o reparara, o

reemplazara., sin cargo alguno, cualquier Producto o pieza del mismo, hasta el grado en que la CompaGia Io encuentre cubierto bajo esta

garantia limitada yen incumplimiento de la misma en condiciones normales de uso y servicio. La CompaGia le enviara, el Producto reparado

o reemplazado o las piezas de repuesto sin cargo. Usted es responsable de todos los costos de retiro, reinstalaci6n y envio, seguro u otros

cargos de flete incurridos en el envio del Producto o pieza a la CompaGia. Si debe enviar el Producto o la pieza a la CompaGia, tal como

Io indique la CompaGia, debe empaquetar adecuadamente el Producto o la pieza: la CompaGia no se hace responsable por los daGos en

tra.nsito. La CompaGia se reserva el derecho de utilizar Productos o piezas reacondicionados, renovados, reparados o refabricados en el

proceso de reemplazo o reparaci6n de garantia. Dichos Productos y piezas sera.ncomparables en funci6n y desempeGo a un Producto o una

pieza original y tendran garantia durante el resto del periodo de la garantia original.

Exclusi6n de da_os: LA OBLIGACION DE LA COMPANiA DE SUIVIINISTRAR PIEZAS DE REPUESTO, O DE REPARAR O

REEiVlPLAZAR, A OPCK:)N DE LA COMPANiA, SER_SU UNICO Y EXCLUSIVO RECURSO BAJO ESTA GARANT|A LllVllTADA,Y LA

UNICA Y EXCLUSIVA OBLIGACION DE LA COMPANIA. LA COMPANiA NO SER.& RESPONSABLE POR DANOS INCIDENTALES,

INDIRECTOS, RESULTANTES O ESPECIALES QUE SURJAN POR EL USO O DESEIVlPENO DEL PRODUCTO, O EN RELACION CON

EL IVllSMO.

Algunos estados no permiten la exclusi6n o limitaci6n de daGos incidentales o resultantes, por Io que la limitaci6n antes mencionada podria

no aplicarse a usted. Esta garantia le otorga derechos legales especificos, y usted podria tener otros derechos que varian de un estado a otro.

Esta garantia cubre Onicamente el reemplazo o la reparaci6n de Productos defectuosos o piezas de los mismos en la planta principal de la

CompaGia, y no incluye el costo del viaje para el servicio de campo ni los via.ticos.

Cualquier asistencia que proporcione o procure la CompaGia para usted fuera de los terminos, limitaciones o exclusiones de esta garantia

limitada no constituira, una renuncia a dichos terminos, limitaciones o exclusiones, ni dicha asistencia extendera, o renovar_,la garantia.

La CompaGia no le reembolsara ningun gasto en el que usted haya incurrido al reparar o reemplazar cualquier Producto defectuoso, excepto

los incurridos con el permiso previo por escrito de laCompaGia.

C6mo obtener el servicio cubierto por la garantia: Para tener derecho al servicio cubierto por la garantia, usted debe (a) notificar a la

CompaGia a la direcci6n o numero de tel6fono que aparecen abajo en un plazo de siete (7)dias despues de descubrir el defecto cubierto, (b)

proporcionar el numero de modelo y la identificaci6n de la pieza y (c) describir la naturaleza de cualquier defecto en el Producto o la pieza.

En el momento de solicitar el servicio cubierto por la garantia, debe presentar un comprobante de la fecha de compra original. Si usted no

puede presentar una copia de la garantia limitada original por escrito, entonces regir_n los terminos de la garantia limitada por

escrito m_s actualizada de la compa_ia para su producto en particular. Las garantias limitadas por escrito m_s actualizadas para

los productos de la Compa_ia se pueden encontrar en www.broan.com.

Broan-NuTone LLC 926West State Street, Hartford, Wl 53027 www.broan.com 800-637-1453

99045146B

Loading...

Loading...