Page 1

CBD3 SERIES

CBD3 Series

Register your product online

at: www.broan.com

Range Hoods

READ AND SAVE THESE INSTRUCTIONS

FOR DOMESTIC COOKING ONLY

Page 1

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer at the

address or telephone number listed in the warranty.

2. Before servicing or cleaning unit, switch power off at service

panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten

a prominent warning device, such as a tag, to the service

panel.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction.

4. Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning equipment to prevent backdrafting. Follow the heating equipment

manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA),

and the American Society of Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code authorities.

5. This product may have sharp edges. Be careful to avoid cuts

and abrasions during installation and cleaning.

6. When cutting or drilling into wall or ceiling, do not damage

electrical wiring and other hidden utilities.

7. Ducted fans must always be vented to the outdoors.

8. Use only metal ductwork.

9. Do not use this fan with any solid-state speed control device.

10. As an alternative, this product may be installed with the ULapproved cord kit designated for the product, following instructions packed with the cord kit.

11. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that may ignite. Heat oils slowly on low or medium settings.

2. Always turn hood ON when cooking at high heat or when

flambéing food (i.e. Crepes Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

3. Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate for

the size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid, cookie sheet,

or metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out immediately,

EVACUATE AND CALL THE FIRE DEPARTMENT.

WARNING

2. NEVER PICK UP A FLAMING PAN — You may be burned or

spread the fire.

3. DO NOT USE WATER, including wet dishcloths or towels - a

violent steam explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher, and you

already know how to operate it.

B. The fire is small and contained in the area where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Based on “Kitchen Firesafety Tips” published by NFPA.

CAUTION

1. For indoor use only.

2. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

3. To avoid motor bearing damage and noisy and/or unbalanced impeller, keep drywall spray, construction dust, etc.,

off power unit.

4. Do not use over cooking equipment greater than 60,000

BTU/hr.

5. Your hood motor has a thermal overload which will automatically shut off the motor if it becomes overheated. The motor

will restart when it cools down. If the motor continues to shut

off and restart, have the hood serviced.

6. A maximum height of 24” above the cooktop is recommended for best capture of cooking impurities. The bottom of the

hood MUST NOT BE LESS than 18” above the cooktop.

7. Please read specification label on product for further information and requirements.

NOTE If hood is to be installed non-ducted:

Purchase non-ducted filter (Model BPQTF) from your

local distributor or retailer.

Installer: Leave this manual

with the homeowner.

Homeowner: Cleaning, Maintenance and

Operating instructions on page 2.

Page 2

CBD3 SERIES

Page 2

OPERATION

Always turn the hood ON before cooking in order to establish an

air flow in the kitchen. After turning off the range, let the hood run

for a few minutes to clear the air.

This range hood is equipped with the latest in capacitive touch

technology. The buttons do not move, but are touch sensitive.

When a touch is understood, the control will emit a sound.

FAN

1. Touch fan button to turn fan on to low speed.

2. Touch fan button again for high speed and fan off.

The light ring around the button will illuminate when

fan is on - a dim glow for low speed and a brighter

glow for high speed.

LIGHT

1. Touch light button to turn light on to dim setting.

2. Touch light button again for bright and light off.

The light ring around the button will illuminate when

light is on - a dim glow for dim light setting and a

brighter glow for bright light setting.

FILTER CLEAN

The fan light ring will flash when it is time to clean or replace

the filter, based on your individual use pattern.

To reset filter clean reminder indicator, touch and hold the fan

button for three seconds.

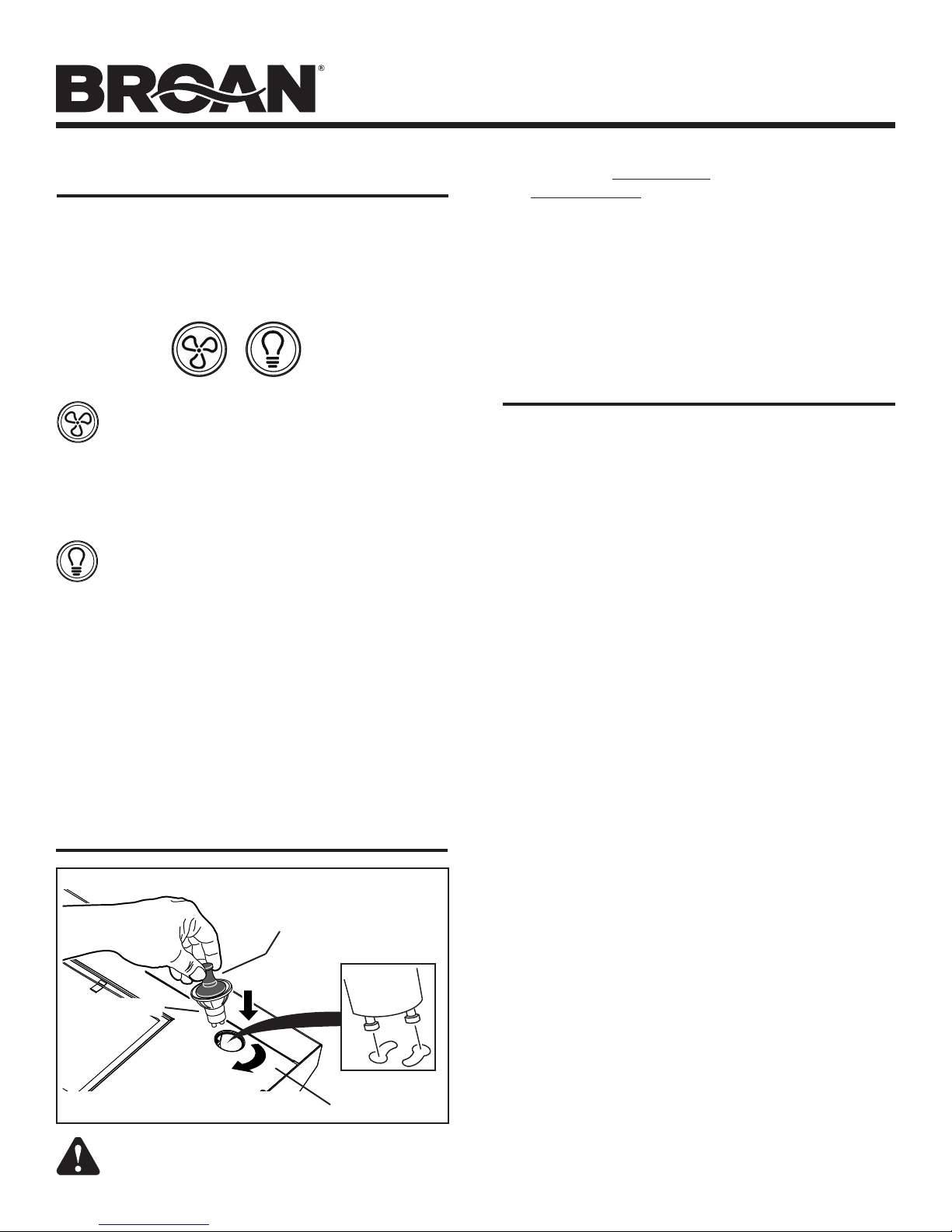

LIGHT BULB REPLACEMENT

SUCTION

CUP TOOL

(1)

HALOGEN

BULB

(2)

ROTATE

CLOCKWISE

CAUTION: Bulbs may be hot. Refer to bulb

packaging for further information.

PUSH IN

LIGHT PANEL

Use 120 V, 35 W, Halogen Bulbs - MR16 with GU10 base.

The Suction Cup Tool (included with hood) can be used to install

and remove light bulbs. Press suction cup tool on to bulb and

rotate counterclockwise to remove bulb or clockwise to install bulb.

Align pins on bulb with large diameter opening on socket, then

push bulb up into socket and rotate clockwise until firmly seated.

The position of the bulb socket (depth) is adjustable and may

require adjustment when:

a) certain brands of bulbs are difficult to install.

b) the bulb protrudes too far below the light panel.

See Step 25 for bracket adjustment detail.

CLEANING & MAINTENANCE

Proper maintenance of the Range Hood will assure proper

performance of the unit.

Motor

The motor is permanently lubricated and never needs oiling. If

the motor bearings make excessive or unusual noise, replace

the motor with the exact service motor. The impeller should also

be replaced.

Grease Filter

The grease filter should be cleaned frequently. Use a warm

dishwashing detergent solution. Grease filter is dishwasher safe.

Clean all-metal filters in the dishwasher using a non-phosphate

detergent. Discoloration of the filter may occur if using phosphate

detergents, or as a result of local water conditions - but this will

not affect filter performance. This discoloration is not covered by

the warranty.

See “INSTALL FILTERS” section for removal and installation

instructions.

Non-ducted Recirculation Filter

The non-ducted recirculation filter should be changed every 3-6

months. Replace more often if your cooking style generates extra

grease, such as frying and wok cooking.

Stainless Steel Cleaning

DO:

• Regularly wash with clean cloth or rag soaked with warm

water and mild soap or liquid dish detergent.

• Alwayscleaninthedirectionoforiginalpolishlines.

• Alwaysrinsewellwithclearwater(2or3times)aftercleaning.

Wipe dry completely.

• You may also use a specialized household stainless steel

cleaner.

DON’T:

• Useanysteelorstainlesssteelwooloranyotherscrapersto

remove stubborn dirt.

• Useanyharshorabrasivecleansers.

• Allowdirttoaccumulate.

• Letplasterdustoranyotherconstructionresiduesreachthe

hood. During construction/renovation, cover the range hood

to make sure no dust sticks to the stainless steel surface.

Avoid: When choosing a detergent

• Anycleanersthatcontainbleachwillattackstainlesssteel.

• Any products containing chloride, fluoride, iodide, bromide

will deteriorate surfaces rapidly.

• Anycombustibleproductsusedforcleaning,suchasacetone,

alcohol, ether, benzol, etc. are highly explosive and should

never be used close to a range.

Page 3

CBD3 SERIES

Page 3

INSTALL DUCTWORK

(Ducted Hoods Only)

ROOF CAP

SOFFIT

CABINET

HOODHOOD

18" - 24" ABOVE

COOKING SURFACE

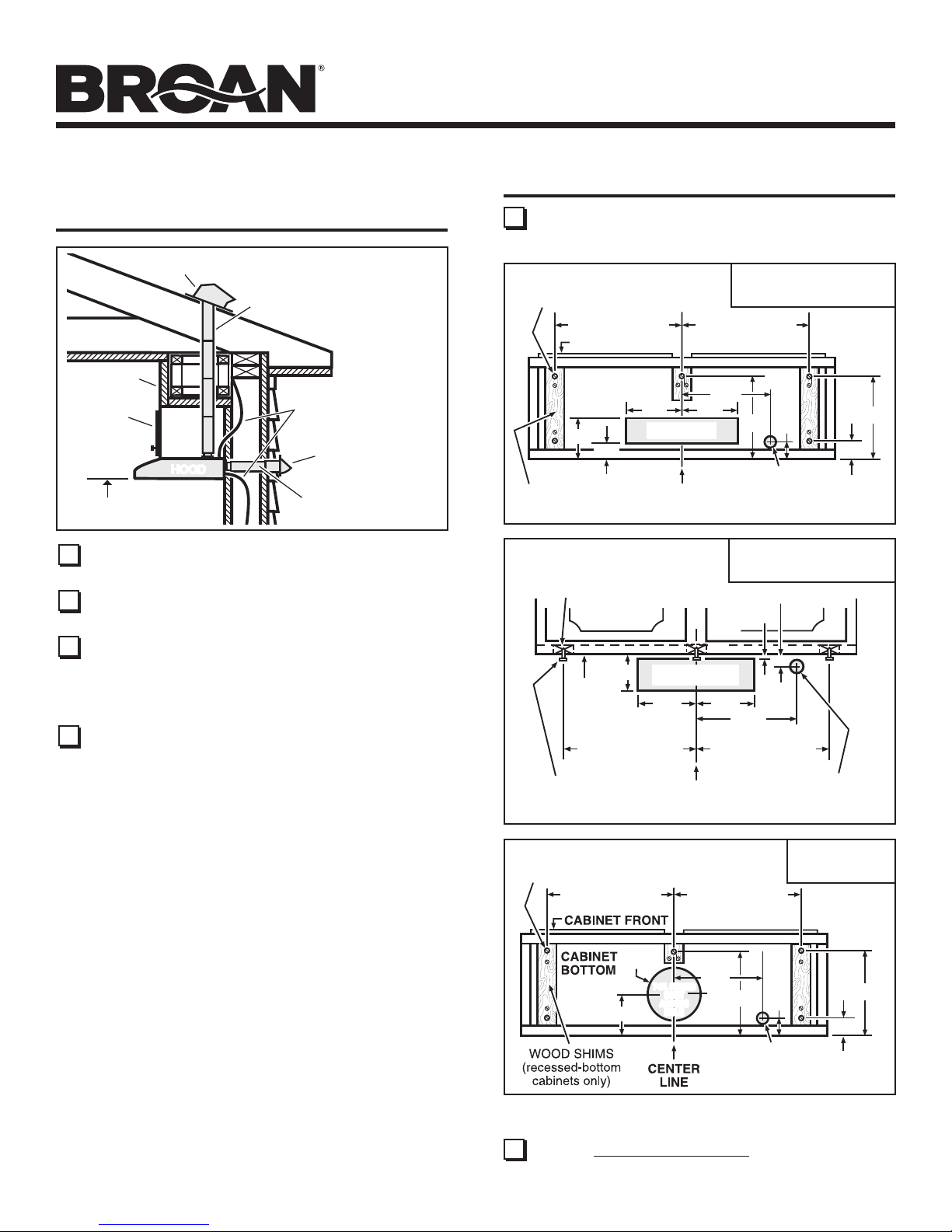

1 Determine whether hood will discharge vertically (3¼” x

10” or 7” Round), or horizontally (3¼” x 10” only).

2 Decide where the ductwork will run between the hood

and the outside.

3¼" X 10" or

7" ROUND DUCT

(For vertical

discharge)

HOUSE WIRING

(Top or Back of hood)

WALL CAP

3¼" X 10" DUCT

(For horizontal discharge)

PREPARE HOOD LOCATION

5 Use the proper diagram below for placement of ductwork

and electrical cutout in cabinet or wall. For a non-ducted

installation, DO NOT cut a duct access hole.

3¼” X 10”

HOOD MOUNTING SCREWS (5)

15

/

13

"(30" hood)

16

13

CABINET FRONT

CABINET

BOTTOM

*

5¼"

VERTICAL DUCT

5"

ACCESS HOLE

1¼"

WOOD SHIMS

(recessed-bottom

cabinets only)

CENTER

LINE

WOOD SHIMS

(recessed-bottom

cabinets only)

CABINET FRONT

VERTICAL DUCTING

15

/

"(30" hood)

16

1

/

7

"

2

5¼"

1

/

9

"

2

2"

ELECTRICAL

ACCESS HOLE

(in cabinet bottom)

3¼” X 10”

HORIZONTAL DUCTING

3

/4"

1

/8"

1

/

10

1

/

"

2

1

"

2

3 Choose a straight, short duct run to allow the hood to

perform most efficiently. Long duct runs, elbows and

transitions will reduce the performance of the hood. Use

as few of them as possible. Larger ductwork may be

required for best performance with longer duct runs.

4 Install wall cap or roof cap. Connect metal ductwork to

cap and work back towards the hood location. Use duct

tape to seal the joints between ductwork sections.

HORIZONTAL DUCT

CABINET

BOTTOM

15

/

13

3¾"

"(30" hood)

16

ACCESS HOLE

1

/

"

5

4

HOOD

MOUNTING

SCREWS (5)

CENTER

LINE

HOOD MOUNTING SCREWS (5)

15

/

13

"(30" hood)

16

8" DIA.

HOLE

5"

7-IN. ROUND

7-IN. ROUND

DUCT

DUCT

ACCESS

ACCESS

HOLE

HOLE

13

*

*

1

/

5

"

4

71/2"

15

/

"(30" hood)

16

13

ELECTRICAL

ACCESS HOLE

15

/

"(30" hood)

16

71/2"

91/2"

21/8"

ELECTRICAL

ACCESS HOLE

(in cabinet bottom)

(in wall)

7-IN. ROUND

DUCTING

1

1

/2"

10

1

/2"

Note the extra wood shim and mounting screw near the

*

cabinet front, on the cabinet center line.

6 Install 4 Hood Mounting Screws into shims/cabinet

according to proper diagram above. Do not tighten

completely. Do not install middle screw until Step 20.

Page 4

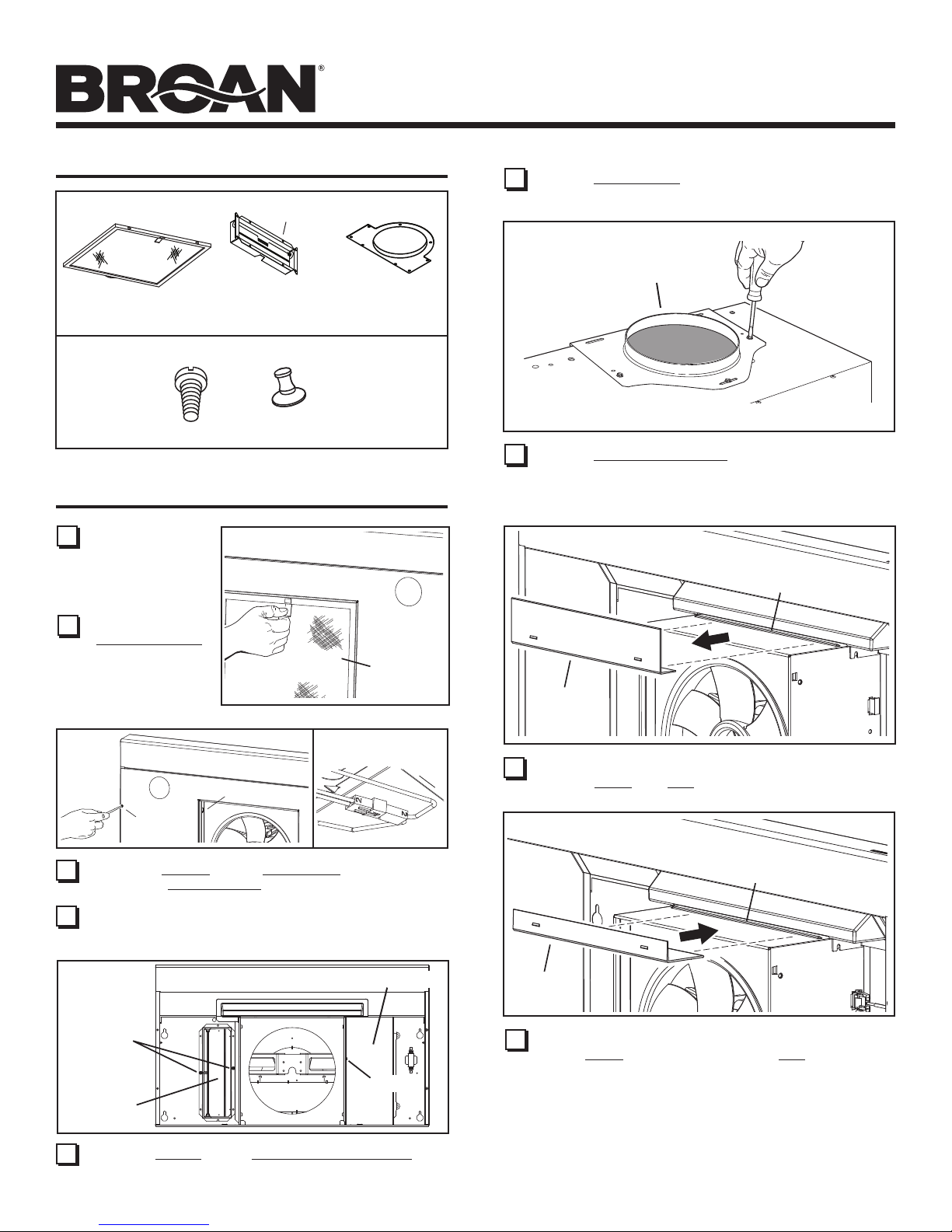

CONTENTS

(1) GREASE

FILTER

(1) PARTS BAG** CONTAINING:

(5) #10 X 5/8”

RD. HD.

MOUNTING

SCREWS

* FIND INSIDE

OF HOOD

(1) 3¼” X 10”

DAMPER / DUCT

CONNECTOR*

(1) BULB SUCTION

** FIND PARTS BAG

INSIDE OF BOTTOM PANEL.

(1) 7” ROUND

CONNECTOR

CUP TOOL

CBD3 SERIES

Page 4

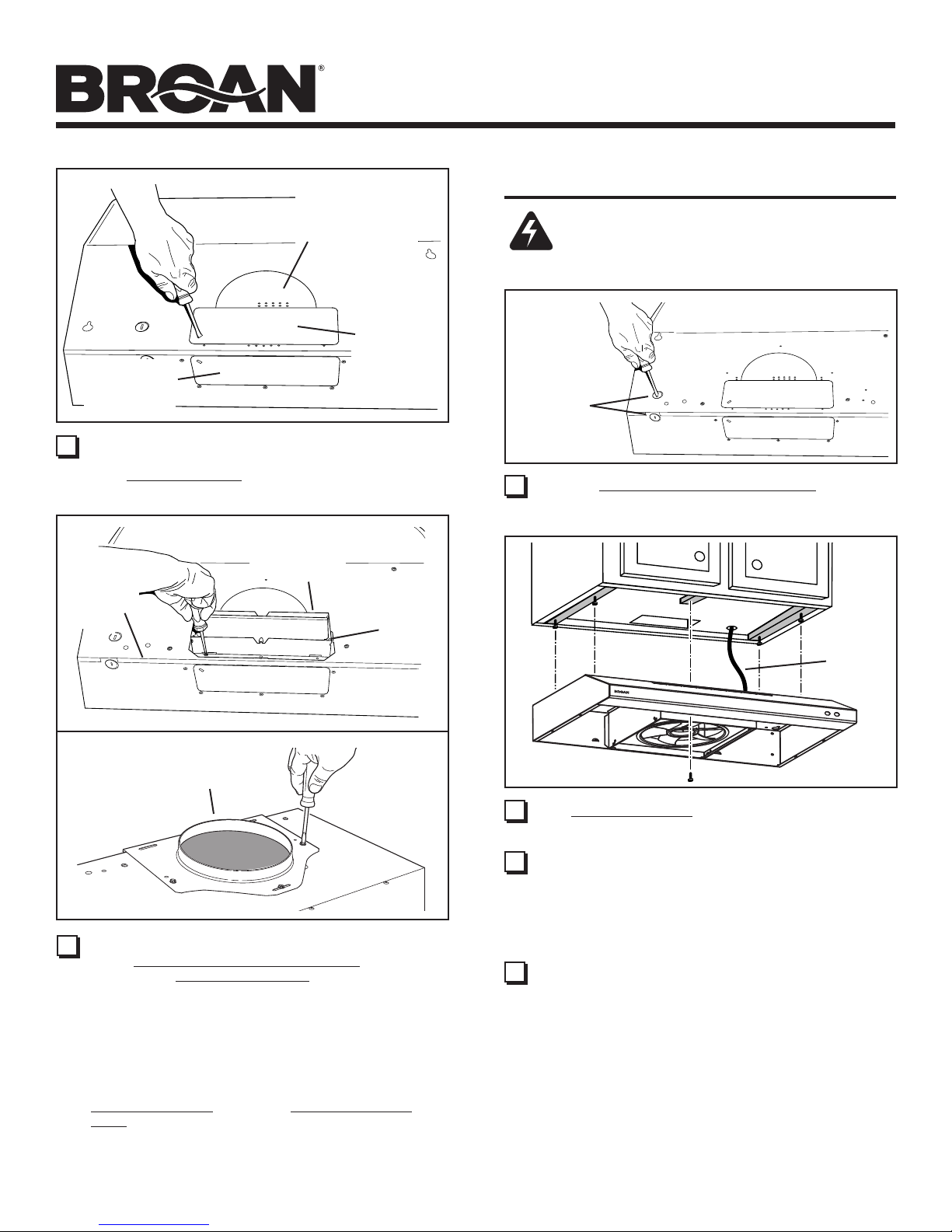

12 Remove Wiring Cover from inside of hood Set cover and

screw aside.

7” ROUND

DUCT

PLATE

DUCT

13 Remove 7” Round Duct Plate from top/back of hood.

PREPARE THE HOOD

7 Remove all

protective polyfilm

from the hood

(stainless steel

hoods only).

8 Remove the

Aluminum Filter

from the hood by

pulling the tab

down and lifting

filter out.

(4)

9 Remove 8 Screws holding Bottom Pan to hood.

Disconnect Light Harness.

10 Remove parts bag included with the hood. (Parts bag is

inside the hood.)

(4)

(2)

LIFT

OUT

ç

(1)

PULL

DOWN

ç

ALUMINUM

FILTER

ç

FOR NON-DUCTED INSTALLATIONS - Skip to

“INSTALL THE HOOD”.

SLOT

BAFFLE

14 DUCTED INSTALLATION ONLY:

Remove Baffle from Slot above air box.

ç

SLOT

SCREWS

DAMPER /

DUCT

CONNECTOR

11

Remove 2 Screws holding Damper / Duct Connector to

hood. Remove damper/duct connector from inside the hood.

WIRING COVER

SCREW

BAFFLE

15 DUCTED INSTALLATION ONLY:

Rotate Baffle and insert long side into Slot above air

box. Baffle is inserted properly when you feel a positive

stop.

Page 5

CBD3 SERIES

Page 5

7” ROUND

KNOCKOUT

PLATE (also

remove 3¼” x 10”

vertical plate)

KNOCKOUT

3¼” X 10”

HORIZONTAL

KNOCKOUT

PLATE

16 DUCTED INSTALLATION ONLY:

Remove 3¼” x 10 vertical, 3¼” x 10” horizontal, or 7-inch

round knockout plate(s) as appropriate for your ducting

method.

3¼” X 10”

DAMPER /

DUCT

CONNECTOR

TOP/BACK

EDGE OF

HOOD

3¼” X 10”

VERTICAL

PLATE

DAMPER

FLAP

PIVOT

INSTALL THE HOOD

WARNING

To reduce the risk of electrical shock, switch power off

at service panel. Lock or tag service panel to prevent

power from being switched on accidentally.

ELECTRICAL

POWER

CABLE

KNOCKOUT

18 Remove Electrical Power Cable Knockout from top or

back of hood.

HOUSE

POWER

CABLE

7” ROUND

DUCT

PLATE

17 DUCTED INSTALLATION ONLY:

Attach 3¼” x 10” Damper/Duct Connector (if using 3¼”

x 10” duct) or 7” Round Duct Plate (if using 7-inch round

duct) over the knockout opening.

Notes:

To accomodate off-center ductwork, the 3¼” x 10”

damper/duct connector or the 7” round duct plate can be

installed up to ½” on either side of the hood center.

Install the 3¼” x 10” Damper/Duct Connector with the

Damper Flap Pivot nearest the Top/Back Edge of

Hood.

For 7” round duct, install a 7” round damper (#97010792 purchase separately).

19 Run House Power Cable between service panel and hood

location. Attach power cable to hood using appropriate clamp

(not included).

20 Hang hood from (4) mounting screws driven part-way into

cabinet locations (shown in illustrations under “PREPARE

HOOD LOCATION”). Mounting screws are included in parts

bag. Slide hood back towards wall until mounting screw

heads are engaged in narrow end of keyhole slots in top of

hood. Tighten screws securely. Add 5th mounting screw in

center hole in hood and tighten securely.

21 DUCTED INSTALLATION ONLY:

Connect ductwork to hood and use duct tape to make joints

secure and air-tight. Make sure the damper / duct connector

enters the ductwork and that the damper opens and closes

freely.

Page 6

CBD3 SERIES

Page 6

CONNECT THE WIRING

GROUND

SCREW

HOUSE

POWER CABLE

22 Connect House Power Cable to range hood wiring -

BLACK to BLACK, WHITE to WHITE, and GREEN or

BARE WIRE to Ground Screw.

23 Replace wiring cover.

24 Re-connect lamp wire harness and re-attach bottom panel

with (8) screws as shown in Step 9.

INSTALL LIGHT BULBS

LAMP SOCKET

BRACKET

SCREWS

To change the depth of bulb sockets:

- Remove bottom panel (See Step 9).

- Disconnect light harness.

- Loosen 2 Screws holding Lamp Socket Bracket to

Light Panel.

- Adjust socket/bracket to desired depth.

- Re-tighten screws securely.

- Re-attach light harness and replace bottom panel.

26 DUCTED INSTALLATION ONLY:

Re-install aluminum filters removed in Step 8.

NON-DUCTED INSTALLATION ONLY:

Purchase a non-ducted filter (Model BPQTF) from your

local distributor or retailer. Attach the non-ducted filter following instructions packed with the non-ducted filter.

SUCTION

CUP TOOL

(1)

HALOGEN

BULB

(2)

ROTATE

CLOCKWISE

CAUTION: Bulbs may be hot. Always allow bulbs

to cool before removing them.

25 Install (2) Halogen Bulbs. Use 120 V, 35 W, shielded

halogen bulbs - MR16 with GU10 base.

NOTE: Suction Cup Tool (included with hood) can be

used to install and remove light bulbs.

Align pins on bulb with large diameter opening on socket,

then push bulb up into socket and rotate clockwise until

firmly seated.

The position of the bulb socket (depth) is adjustable and

may require adjustment when:

a) certain brands of bulbs are difficult to install.

b) the bulb protrudes too far below the light panel.

PUSH IN

LIGHT PANEL

Page 7

SERVICE PARTS

CBD3 SERIES

Page 7

13

3

5

6

14

2

7

8

15

18

4

11

10

9

16

17

1

12

2

KEY

NO. DESCRIPTION PART NO.

1 BOTTOM PANEL, WHITE, 30” 97018651

BOTTOM PANEL, BLACK, 30” 97018652

BOTTOM PANEL, STAINLESS STEEL, 30” 97018653

BOTTOM PANEL, WHITE, 36” 98010876

BOTTOM PANEL, BLACK, 36” 98010877

2 SCREW PACKAGE FOR BOTTOM PANEL & AIR DUCT R602534

#8-18 X 3/8 (10 req.) (2 screws in a bag)

3 LAMP WIRE HARNESS 97018656

4 WIRE HARNESS 99271466

5 LIGHT BRACKET HARDWARE BAG 97018665

6 BAFFLE 99111539

7 AIR CHUTE 99111538

AIR CHUTE ASSEMBLY (includes Key Nos. 6, 7 and hardware) 97018660

8 CONTROL ASSEMBLY, WHITE 97019322

CONTROL ASSEMBLY, BLACK 97019323

CONTROL ASSEMBLY, STAINLESS STEEL 97019324

9 FAN BLADE (INCLUDES HAIRPIN CLIP) R531076

10 HAIRPIN CLIP R99420635

11 PARTS BAG ASSEMBLY 97018623

12 FILTER ALUMINUM R610092

13 7” ROUND DUCT PLATE (includes mounting hardware) R680508

14 3-1/4” X 10” DAMPER ASSEMBLY (includes mounting hardware) R740014

15 MOTOR 99080666

16 CABLE CLIP, WIRE HARNESS 99680044

17 WIRING COVER 98009816

18 TRANSFORMER 99271478

* 7-IN. ROUND DAMPER 97010792

* NON-DUCTED FILTER 99010317

* BULB, 120V, 35W, MR16 GU10 BASE HALOGEN (2 req.) 99526798

* Not illustrated. Purchase separately.

Order replacement parts by PART NO. - not by KEY NO.

Page 8

CBD3 SERIES

Page 8

WARRANTY

Limited Warranty

Warranty Period and Exclusions: Broan-NuTone LLC (the “Company”) warrants to the original consumer purchaser of its product

(“you”) that the product (the “Product”) will be free from material defects in the Product or its workmanship for a period of one (1) year

from the date of original purchase. The warranty on the light bulbs provided with the Product is one (1) year and does not cover lamp/

bulb breakage.

The limited warranty period for any replacement parts provided by the Company and for any Products repaired or replaced under this

limited warranty shall be the remainder of the original warranty period.

This warranty does not cover fluorescent lamp starters, tubes, halogen and incandescent bulbs, fuses, filters, ducts, roof caps, wall caps

and other accessories for ducting that may be purchased separately and installed with the Product. This warranty also does not cover

(a)normal maintenance and service, (b)normal wear and tear, (c)any Products or parts which have been subject to misuse, abuse,

abnormal usage, negligence, accident, improper or insufficient maintenance, storage or repair (other than repair by the Company),

(d)damage caused by faulty installation, or installation or use contrary to recommendations or instructions, (e)any Product that has

been moved from its original point of installation, (f)damage caused by environmental or natural elements, (g)damage in transit,

(h)natural wear of finish, (i)Products in commercial or nonresidential use, or (j)damage caused by fire, flood or other act of God. This

warranty covers only Products sold to original consumers in the United States by the Company or U.S. distributors authorized by the

Company.

This warranty supersedes all prior warranties and is not transferable from the original consumer purchaser.

No Other Warranties: This Limited Warranty contains the Company’s sole obligation and your sole remedy for defective products.

The foregoing warranties are exclusive and in lieu of any other warranties, express or implied. THE COMPANY DISCLAIMS AND

EXCLUDES ALL OTHER EXPRESS WARRANTIES, AND DISCLAIMS AND EXCLUDES ALL WARRANTIES IMPLIED BY LAW,

INCLUDING WITHOUT LIMITATION THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. To the

extent that applicable law prohibits the exclusion of implied warranties, the duration of any applicable implied warranty is limited to the

period specified for the express warranty above. Some states do not allow limitations on how long an implied warranty lasts, so the

above limitation may not apply to you. Any oral or written description of the Product is for the sole purpose of identifying it and shall not

be construed as an express warranty.

Whenever possible, each provision of this Limited Warranty shall be interpreted in such manner as to be effective and valid under

applicable law, but if any provision is held to be prohibited or invalid, such provision shall be ineffective only to the extent of such

prohibition or invalidity, without invalidating the remainder of such provision or the other remaining provisions of the Limited Warranty.

Remedy: During the applicable limited warranty period, the Company will, at its option, provide replacement parts for, or repair or

replace, without charge, any Product or part thereof, to the extent the Company finds it to be covered by and in breach of this limited

warranty under normal use and service. The Company will ship the repaired or replaced Product or replacement parts to you at no

charge. You are responsible for all costs for removal, reinstallation and shipping, insurance or other freight charges incurred in the

shipment of the Product or part to the Company. If you must send the Product or part to the Company, as instructed by the Company,

you must properly pack the Product or part—the Company is not responsible for damage in transit. The Company reserves the right to

utilize reconditioned, refurbished, repaired or remanufactured Products or parts in the warranty repair or replacement process. Such

Products and parts will be comparable in function and performance to an original Product or part and warranted for the remainder of

the original warranty period.

Exclusion of Damages: THE COMPANY’S OBLIGATION TO PROVIDE REPLACEMENT PARTS, OR REPAIR OR REPLACE, AT

THE COMPANY’S OPTION, SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY AND THE

COMPANY’S SOLE AND EXCLUSIVE OBLIGATION. THE COMPANY SHALL NOT BE LIABLE FOR INCIDENTAL, INDIRECT,

CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH THE PRODUCT, ITS USE OR

PERFORMANCE.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you. This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state.

This warranty covers only replacement or repair of defective Products or parts thereof at the Company’s main facility and does not

include the cost of field service travel and living expenses.

Any assistance the Company provides to or procures for you outside the terms, limitations or exclusions of this limited warranty will not

constitute a waiver of such terms, limitations or exclusions, nor will such assistance extend or revive the warranty.

The Company will not reimburse you for any expenses incurred by you in repairing or replacing any defective Product, except for those

incurred with the Company’s prior written permission.

How to Obtain Warranty Service: To qualify for warranty service, you must (a)notify the Company at the address or telephone

number stated below within seven (7)days of discovering the covered defect, (b)give the model number and part identification and

(c)describe the nature of any defect in the Product or part. At the time of requesting warranty service, you must present evidence of

the original purchase date. If you cannot provide a copy of the original written limited warranty, then the terms of the Company’s most

current written limited warranty for your particular product will control.The most current limited written warranties for the Company’s

products can be found at www.broan.com .

Broan-NuTone LLC 926 West State Street, Hartford, WI 53027 www.broan.com 800-637-1453

99045076C

Page 9

SERIE CBD3

Página 9

Campanas

Registre su producto en el

sitio web www.broan.com

Serie CBD3

LEA Y CONSERVE ESTAS INSTRUCCIONES

SOLAMENTE PARA COCINAR EN CASA

ADVERTENCIA

PARA REDUCIR EL RIESGO DE INCENDIO, DESCARGA ELÉCTRICA

O LESIONES CORPORALES, OBSERVE LO SIGUIENTE:

1. Use la unidad sólo de la manera indicada por el fabricante. Si tiene

preguntas, comuníquese con el fabricante a la dirección o al número

telefónico que se incluye en la garantía.

2. Antes de dar servicio a la unidad o de limpiarla, interrumpa el

suministro eléctrico en el panel de servicio y bloquee los medios de

desconexión del servicio para evitar que la electricidad se reanude

accidentalmente. Cuando no sea posible bloquear los medios de

desconexión del servicio, fije firmemente una señal de advertencia

(como una etiqueta) en un lugar visible del panel de servicio.

3. Una o más personas calificadas deben realizar el trabajo de

instalación y el cableado eléctrico siguiendo todos los códigos y

normas correspondientes, incluidos los códigos y las normas de

construcción específicos para incendios.

4. Se necesita suficiente aire para que se lleve a cabo una combustión

y una extracción adecuadas de los gases a través del tubo de

humos (chimenea) del equipo quemador de combustible, con el fin

de evitar el contratiro. Siga las directrices y las normas de seguridad

del fabricante del equipo de calefacción, como las publicadas por

la Asociación Nacional de Protección contra Incendios (National

Fire Protection Association, NFPA), y la Sociedad Americana de

Ingenieros en Calefacción, Refrigeración y Aire Acondicionado

(American Society of Heating, Refrigeration and Air Conditioning

Engineers, ASHRAE), y las autoridades de los códigos locales.

5. Este producto podría tener bordes afilados. Trabaje con cuidado

para evitar cortes y abrasiones durante la instalación y la limpieza.

6. Al cortar o perforar a través de la pared o del techo, tenga cuidado

de no dañar el cableado eléctrico ni otros servicios ocultos.

7. Los ventiladores en conductos siempre deben ventearse hacia el

exterior.

8. Utilice únicamente conductos metálicos.

9. No use este ventilador junto con ningún dispositivo de control de

velocidad de estado sólido.

10. Como alternativa, se puede instalar este producto con el juego de

cable de alimentación aprobado por UL y diseñado para el producto,

siguiendo las instrucciones incluidas con el cable.

11. Esta unidad debe estar conectada a tierra.

PARA REDUCIR EL RIESGO DE INCENDIO PROVOCADO POR

GRASA PRESENTE EN LA ESTUFA:

1. Nunca deje desatendidas las unidades de la superficie cuando

estén en ajustes altos de calor. Los alimentos en ebullición provocan

derrames grasosos y con humo que se pueden incendiar. Caliente

el aceite lentamente en ajustes de calor bajo o medio.

2. Siempre ENCIENDA la campana cuando esté cocinando a altas

temperaturas o flamee alimentos (por ejemplo crepas Suzette,

cerezas Jubilee, bistec con pimienta flameado).

3. Limpie frecuentemente los ventiladores. No permita la acumulación

de grasa en el ventilador ni en el filtro.

4. Use una cacerola del tamaño adecuado. Siempre use utensilios

de cocina que sean apropiados para el tamaño del elemento dela

superficie

.

ADVERTENCIA

PARA REDUCIR EL RIESGO DE LESIONES A LAS PERSONAS EN CASO DE

UN INCENDIO PRODUCIDO POR GRASA EN UNA ESTUFA, OBSERVE

LO SIGUIENTE*:

1. APAGUE LAS LLAMAS con una tapa de ajuste exacto, una charola para

galletas o una bandeja de metal, y después apague el quemador. PROCEDA

CON CUIDADO PARA EVITAR QUEMADURAS. Si las llamas no se apagan

inmediatamente, EVACUE EL ÁREA Y LLAME A LOS BOMBEROS.

2. NUNCA LEVANTE UNA CACEROLA INCENDIADA porque podría sufrir

quemaduras o propagar el incendio.

3. NO USE AGUA, incluidos trapos o toallas de cocina mojados; puede

producirse una explosión violenta de vapor.

4. Use un extintor SÓLO si:

A. Sabe que tiene un extintor clase ABC, y ya sabe cómo usarlo.

B. El incendio es pequeño y está confinado al área en la que se inició.

C. Se está llamando al Departamento de Bomberos.

D. Puede combatir el incendio teniendo la espalda orientada hacia una salida.

*Basado en “Consejos útiles de seguridad en incendios en la cocina” (“Kitchen

Fire Safety Tips”), publicado por NFPA.

PRECAUCIÓN

1. Sólo debe usarse bajo techo.

2. Sólo para usarse como medio de ventilación general. No debe

usarse para la extracción de materiales o vapores peligrosos o

explosivos.

3. Para evitar daños a los cojinetes del motor y rotores ruidosos o

desbalanceados, mantenga la unidad eléctrica al resguardo de

rociados de yeso, polvo de construcción, etc.

4. No use equipo para cocinar mayor de 60,000 BTU/hr.

5. Este motor de campana tiene una protección contra sobrecargas térmicas

que automáticamente apagará el motor en caso de sobrecalentamiento.

El motor reanudará su funcionamiento cuando se enfríe. Si el motor

continúa apagándose y encendiéndose, solicite servicio para la campana.

6. Una altura máxima de 24” por encima de la superficie de cocción se recomienda para limpiar mejor las impurezas al cocinar. La parte inferior

de la campana no debe ser inferior a 18” por encima de la superficie de

cocción.

7. Lea la etiqueta de especificaciones que tiene el producto para ver

información y requisitos adicionales.

NOTA Si la campana se va a instalar en un sistema sin conductos:

Compre un filtro sin conductos (Modelo BPQTF) con su

distribuidor o tienda minorista local.

Aviso al instalador: Deje este manual

con el dueño de la casa.Aviso al dueño

de la casa: En la página 10 encontrará

lasinstrucciones de limpieza,

mantenimiento y funcionamiento.

Page 10

FUNCIONAMIENTO

SERIE CBD3

Página 10

ENCIENDA siempre la campana antes de comenzar a cocinar, con el fin de

establecer un flujo de aire en la cocina. Después de apagar la estufa, deje

que la campana funcione durante unos cuantos minutos para despejar el aire.

Esta campana está equipada con lo último en tecnología táctil capacitiva. Los

botones no se mueven, pero son sensibles al tacto. Cuando un contacto es

interpretado, el control emitirá un sonido.

VENTILADOR

1. Toque el botón del ventilador para encender el ventilador a

baja velocidad.

2. Toque de nuevo el botón del ventilador para velocidad máxima

y apagado.

El anillo de luz alrededor del botón se iluminará cuando el

ventilador este encedido - un tenue brillo para velocidad baja y un

brillo mas fuerte para alta velocidad.

LUZ

1. Toque el botón de luz para encender la luz en el ajuste oscuro.

2. Pulse el botón de nuevo para luz brillante o apagada.

El anillo de luz alrededor del botón se iluminará cuando la luz

esté encendida - un tenue brillo para luz baja y brillo mas fuerte

para luz brillante.

LIMPIEZA DEL FILTRO

El anillo de ventilador del ventilador destellará cuando sea tiempo de limpiar

o reemplazar el filtro, basado en su patrón individual.

Para poner a cero el indicador del filtro recordatorio de limpieza, presione y

mantenga presionado el botón del ventilador durante tres segundos.

REEMPLAZO DE LAS BOMBILLAS

HERRAMIENTA

DE VENTOSA

(1)

EMPUJAR

HACIA

BOMBILLA DE

HALÓGENO

(2)

(2)

GIRAR EN SENTIDO

GIRAR EN SENTIDO

DE LAS AGUJAS

DE LAS AGUJAS

DEL RELOJ

DEL RELOJ

PRECAUCIÓN: Las bombillas podrían estar

calientes. Consulte la información adicional en los

paquetes de las bombillas.

Utilice bombillas de halógeno de 120 V, 35 W (MR16 con base GU10).

La herramienta de ventosa (incluida con la campana) sirve para instalar

y quitar bombillas. Prensa herramienta de ventosa a la bombilla y girar a la

izquierda para quitar la bombilla o hacia la derecha para instalar la bombilla.

Alinee las clavijas de la bombilla con la abertura de diámetro grande en el

receptáculo, empuje la bombilla para arriba en el zócalo y luego gire hacia la

derecha hasta que esté firmemente asentada.

La posición del receptáculo de la bombilla (profundidad) es ajustable, y podría

necesitar ajuste cuando:

a) Ciertas marcas de bombillas sean difíciles de instalar.

b) La bombilla sobresalga demasiado por debajo del panel de la bombilla.

Vea el paso 25 para el detalle soporte de ajuste.

ADENTRO

PANEL DE

ILUMINACIÓN

LIMPIEZA Y MANTENIMIENTO

El mantenimiento correcto de la campana de la estufa asegurará el

funcionamiento adecuado de la unidad.

Motor

El motor está permanentemente lubricado y nunca necesitará ponerle aceite.

Si los cojinetes del motor están haciendo ruido excesivo o inusual, reemplace

el motor con el motor de servicio exacto. También debe reemplazar el impulsor.

Filtro de grasa

El filtro de grasa se debe limpiar con frecuencia. Utilice una solución tibia de

detergente para platos. El filtro de grasa se puede lavar en lavaplatos. Limpie

los filtros completamente metálicos en la lavaplatos con un detergente sin

fosfatos. El filtro se puede decolorar si se utilizan detergentes con fosfato o como

resultado de la condición del agua local, pero esto no afectará el desempeño

del filtro. Esta decoloración no está cubierta por la garantía.

Consulte la sección “INSTALACIÓN DE LOS FILTROS” para ver las

instrucciones de instalación y desmontaje.

Filtro de recirculación para sistemas sin conductos

El filtro de recirculación para sistemas sin conductos se debe cambiar cada

3-6 meses. Cámbielo con más frecuencia si su estilo de cocinar genera más

grasa, como freír los alimentos o cocinar en un wok. Consulte las instrucciones

para quitar e instalar en el paso 15 de la página 18.

Limpieza del acero inoxidable

COSAS QUE PUEDE HACER:

• Regularmente,laveconunatelaotrapolimpioremojadoconaguatibiay

jabón o detergente líquido para platos.

• Siemprelimpieenladireccióndelaslíneasoriginalesdepulido.

• Siempre enjuague bien con agua limpia (2 o 3 veces) después dela

limpieza. Deje totalmente seco.

• También puede usar un limpiador casero especializado para acero

inoxidable.

COSAS QUE NO DEBE HACER:

• Usarlanadeacerooaceroinoxidablenialgúnotrotipoderaspadorpara

quitar mugre difícil de sacar.

• Usarlimpiadoresfuertesniabrasivos.

• Dejarqueseacumulelamugre.

• Dejar que el polvo forme plastas ni que quede en la campana algún

otro residuo de la construcción. Durante la construcción o la renovación,

cubra la campana para estar seguro de que el polvo no se pegue a la

superficie de acero inoxidable.

Evite: Al elegir un detergente

• Todo limpiador que contenga blanqueador, pues atacará al acero

inoxidable.

• Productos que contengan cloruro, fluoruro, yoduro, bromuro, pues

deteriorarán las superficies rápidamente.

• Todo producto combustible utilizado para la limpieza, como acetona,

alcohol, éter, benzol, etc., pues son altamente explosivos y nunca se

deben usar cerca de una estufa.

Page 11

SERIE CBD3

Página 11

INSTALE EL SISTEMA

DECONDUCTOS (Sólo campanas

para sistemas con conductos)

TAPA DE TECHO

PLAFÓN

GABINETE

CAMPANACAMPANA

DE 18 a 24 PULG.

(45.7 a 61 CM) POR ENCIMA DE

LA SUPERFICIE DE COCINADO

1 Determine si la descarga de la campana va a ser vertical

(conducto de 3¼ x 10 pulg. [8.3 x 25.4 cm] o redondo

de 7 pulg. [17.8 cm]) u horizontal (sólo conducto de

3¼ x 10 pulg. [8.3 x 25.4 cm]).

2 Decida dónde instalará el conducto entre la campana y

el exterior.

3 Elija un conducto recto y corto para permitir que la

campana funcione más eficientemente. Los tramos

largos de conductos, codos y transiciones reducirán

el desempeño de la campana. Use tan pocos de

ellos como sea posible. Es posible que se requieran

conductos más grandes para un mejor funcionamiento

con tramos más largos de conductos.

4 Instale la tapa para pared o para techo. Conecte un

conducto metálico en la tapa y trabaje hacia atrás,

hacia la ubicación de la campana. Use cinta para

conductos para sellar las uniones entre las secciones

deconductos.

CONDUCTO DE

3¼ x 10 pulg. (8.3 x 25.4 cm) o

CONDUCTO REDONDO

de 7 pulg. (17.8 cm)

(para descarga vertical)

CABLEADO ELÉCTRICO

DE LA CASA

(parte superior o

posterior de la campana)

TAPA DE PARED

CONDUCTO DE

3¼ x 10 pulg.

(8.3 x 25.4 cm)

(para descarga horizontal)

PREPARE EL LUGAR DONDE SE

VA A INSTALAR LA CAMPANA

TORNILLOS DE MONTAJE

DE LA CAMPANA (5)

13-15/16 pulg. (35.4 cm)

(campana de 30 pulg./76.2 cm)

FRENTE DEL GABINETE

PARTE INFERIOR

DEL GABINETE

5 pulg.

(12.7 cm)

1 ¼ pulg.

(3.2 cm)

CUÑAS DE MADERA

(sólo gabinetes

de parte inferior empotrada)

CUÑAS DE MADERA

(sólo gabinetes de parte

inferior empotrada)

3¾ pulg.

(9.5 cm)

PARTE

INFERIOR

DEL GABINETE

15

/

13

pulg. (35.4 cm)

16

(campana de 30 pulg./76.2 cm)

TORNILLOS DE

MONTAJE DE

LA CAMPANA (5)

TORNILLOS DE MONTAJE

DE LA CAMPANA (5)

CUÑAS DE MADERA

parte inferior empotrada)

13-15/16 pulg. (35.4 cm)

(campana de 30 pulg./76.2 cm)

FRENTE DEL GABINETE

8 pulg. (20.3 cm)

PARTE INFERIOR

DEL GABINETE

(12.7 cm)

(sólo gabinetes de

Orificio de

DE DIÁM.

5 pulg.

13-15/16 pulg. (35.4 cm)

(campana de 30 pulg./76.2 cm)

7 ½ pulg.

(19.1 cm)

5¼ pulg.

(13.3 cm)

ORIFICIO DE ACCESO PARA

CONDUCTO VERTICAL

*

5¼ pulg.

(13.3 cm)

LÍNEA

CENTRAL

PARA CABLES ELÉCTRICOS

(en la parte inferior del gabinete)

FRENTE DEL

GABINETE

ORIFICIO DE ACCESO PARA

CONDUCTO HORIZONTAL

5 ¼ pulg.

(13.3 cm)

*

5 ¼ pulg.

(13.3 cm)

7 ½ pulg. (19.1 cm)

13

(campana de 30 pulg./76.2 cm)

LÍNEA

CENTRAL

13-15/16 pulg. (35.4 cm)

(campana de 30 pulg./76.2 cm)

*

7 ½ pulg.

(19.1 cm)

ORIFICIO DE

ORIFICIO DE

ACCESO

ACCESO

PARA CONDUCTO

PARA CONDUCTO

REDONDO DE 7 pulg.

REDONDO DE 7 pulg.

(17.8 cm)

(17.8 cm)

LÍNEA

CENTRAL

9 ½ pulg.

(24.1 cm)

PARA CABLES ELÉCTRICOS

(en la parte inferior del gabinete)

CONDUCTO VERTICAL DE

3¼ X 10 PULG. (8.3 X 25.4 CM)

10 ½ pulg.

1 ½ pulg.

(3.8 cm)

(26.7 cm)

9 ½ pulg

2 pulg

(24.1 cm)

(5.1 cm)

ORIFICIO DE ACCESO

CONDUCTO HORIZONTAL DE

3¼ X 10 PULG. (8.3 X 25.4 CM)

3

/4 pulg.

(1.9 cm)

1

/8 pulg.

(0.32 cm)

15

/

pulg. (35.4 cm)

16

ORIFICIO DE

ACCESO PARA

CABLES ELÉCTRICOS

(en la pared)

CONDUCTO REDONDO

DE 7 PULG. (17.8 CM)

2 pulg.

(5.1 cm)

ORIFICIO DE ACCESO

10 ½ pulg.

(26.7 cm)

1 ½ pulg.

(3.8 cm)

5 Guíese por el diagrama correspondiente (a continuación)

para colocar los conductos y hacer el corte exacto para

la conexión eléctrica en el gabinete o en la pared. Para

instalaciones en sistemas sin conductos, NO haga

ningún orificio de acceso para conducto.

* Observe la cuña de madera adicional y el tornillo de

montaje cerca del frente del gabinete, sobre la línea central

del gabinete.

6 Instale 4 tornillos de montaje de la campana en

las calzas/gabinete, de acuerdo con el diagrama

correspondiente. No apriete totalmente. No instale el

tornillo de en medio hasta el paso 20.

Page 12

CONTENIDO

SERIE CBD3

Página 12

* ENCUENTRA EN EL INTERIOR

DE LA CAMPANA.

(1) FILTRO

DE GRASA

(1)

CONECTOR

PARA REGULADOR/

CONDUCTO DE 3¼ X 10

PULG. (8.3 X 25.4 CM)*

PARA CONDUCTO

7 PULG. (17.8 CM)

(1)

CONECTOR

REDONDO DE

(1) BOLSA DE PIEZAS** QUE CONTIENE:

(5) TORNILLOS DE

MONTAJE DE CABEZA

REDONDA #10 X

5/8 PULG.

** ENCUENTRA LA BOLSA DE PIEZAS

AL INTERIOR DEL PANEL INFERIOR.

(1) HERRAMIENTA

DE VENTOSA PARA

LAS BOMBILLAS

PREPARE LA CAMPANA

7 Quite todo el forro

de plástico protector

de la campana

(únicamente

campanas de

aceroinoxidable).

8 Retire el filtro de

aluminio de la

campana jalando

la lengüeta hacia

abajo y levantando

elfiltro.

(2)

LEVANTAR

HACIA

FUERA

ç

ç

(1) JALAR

HACIA

ABAJO

FILTRO DE

ALUMINIO

12 Retire la cubierta de cables desde el interior de la cubierta

de la campana y el tornillo a un lado.

PLACA DEL

CONDUCTO

REDONDO

DE 7 PULG. (17.8 CM)

13 Retire la placa del conducto redondo de 7 pulg. (17.8 cm)

de la parte superior/trasera de la campana.

RANURA

DEFLECTOR

(4)

(4)

9 Quite los 8

tornillos

campana. Desconecte el

que sostienen el

arnés de las luces.

ç

recipiente inferior

ç

a la

10 Retire la bolsa de piezas incluida con la campana. (La bolsa

de piezas está dentro de la campana.)

CUBIERTA DE CABLES

TORNILLOS

CONECTOR DEL

REGULADOR

DE TIRO/

CONDUCTO

TORNILLO

11 Quite los 2 tornillos que sujetan el conector del regulador de

tiro/conducto a la campana. Quite el conector del regulador de

tiro/conducto del interior de la campana.

14 ÚNICAMENTE EN INSTALACIONES CON CONDUCTOS:

Retire el

DEFLECTOR

deflector

de la

ranura

arriba de la caja de aire.

RANURA

15 ÚNICAMENTE EN INSTALACIONES CON CONDUCTOS:

Gire el

deflector

e inserte el lado largo en la

ranura

arriba

de la caja de aire. El deflector se inserta adecuadamente

cuando siente un tope positivo.

Page 13

SERIE CBD3

Página 13

PLACA REDONDA DE

ORIFICIO CIEGO DE 7

PULG. (17.8 CM) (TAMBIÉN

DESMONTE LA PLACA

VERTICAL DE 3¼ X 10 PULG.

[8.3 X 25.4 CM])

PLACA HORIZONTAL

DE ORIFICIO CIEGO

DE 3¼ X 10 PULG.

PLACA VERTICAL

DE ORIFICIO CIEGO

DE 3¼ X 10 PULG.

(8.3 X 25.4 CM)

(8.3 X 25.4 CM)

16 ÚNICAMENTE EN INSTALACIONES CON CONDUCTOS:

Retire las placas de orificio ciego vertical de 3¼ x 10 pulg.

(8.3 x 25.4 cm), horizontal de 3¼ x 10 pulg. (8.3 x 25.4 cm),

o redonda de 7 pulg. (17.8 cm), según corresponda a su

método de conductos.

CONECTOR PARA

REGULADOR DE TIRO/

BORDE

SUPERIOR/

POSTERIOR DE

LA CAMPANA

CONDUCTO DE 3¼ X 10 PULG.

(8.3 X 25.4 CM)

PIVOTE DE LA

ALETA DEL

REGULADOR

DE TIRO

INSTALE LA CAMPANA

ADVERTENCIA

Para reducir el riesgo de una descarga eléctrica,

18 Quite el

desconecte el suministro eléctrico en el panel de

servicio. Bloquee el panel de servicio o póngale una

etiqueta de seguridad para evitar que alguien conecte

accidentalmente la energía eléctrica.

ORIFICIO

CIEGO DEL

CABLE

ELÉCTRICO

orificio ciego del cableado eléctrico

parte superior o trasera de la campana.

desde la

PLACA DEL CONDUCTO

REDONDO

DE 7 PULG. (17.8 CM)

17 ÚNICAMENTE EN INSTALACIONES CON CONDUCTOS:

Acople el conector del regulador de tiro/conducto

de 3¼ pulg. x 10 pulg. (8.3 x 25.4 cm) (si está usando

elconducto de 3¼ pulg. x 10 pulg. [8.3 x 25.4 cm]) o la

placa redonda de 7 pulg. (17.8 cm) (si está usando el

conducto redondo de 7pulg. [17.8 cm]) por la abertura del

orificio ciego.

Notas:

Para acomodar los conductos descentrados, el amortiguador/

conducto de 3¼” x 10” o la placa del conducto redondo de 7” se

pueden instalar hasta ½” a cada lado del centro de la campana.

Instale el conector del regulador de tiro/conducto de 3¼ x 10 pulg.

(8.3 x 25.4 cm) con el pivote de aleta del regulador más cercano

al borde superior/trasero de la campana.

Para el ducto redondo de 7”, instale un amortiguador redondo de 7”

(#97010792 - comprar por separado).

CABLE

ELÉCTRICO

DE LA CASA

19 Tienda el cable eléctrico de la casa entre el panel de servicio

y la campana. Conecte el cable eléctrico a la campana con la

abrazadera apropiada (no incluye).

20 Cuelgue la campana de los (4) orificios de montaje insertados

parcialmente en las posiciones del gabinete (mostrado en

las ilustraciones de “PREPARE EL LUGAR DONDE SE VA A

INSTALAR LA CAMPANA”). La bolsa de piezas contiene los

tornillos de montaje. Deslice la campana hacia la pared hasta

que las cabezas de los tornillos de montaje queden conectadas

en el extremo angosto de los orificios tipo bocallave que están

en la parte superior de la campana. Apriete bien los tornillos.

Agregue el quinto tornillo de montaje en el orificio central de la

campana y apriete con firmeza.

21 ÚNICAMENTE EN INSTALACIONES CON CONDUCTOS:

Conecte el sistema de conductos a la campana y ponga

cinta para conductos en las uniones para fijarlas y sellarlas.

Asegúrese de que el conector del regulador de tiro/conducto

entre a los conductos y que el regulador de tiro pueda abrirse y

cerrarse libremente.

Page 14

SERIE CBD3

Página 14

CONECTE EL CABLEADO

TORNILLO

DE TIERRA

CABLE ELÉCTRICO

DE LA CASA

22 Conecte el cable eléctrico de la casa al cableado de

la campana: cable NEGRO con NEGRO, BLANCO con

BLANCO y VERDE o SIN FORRO al tornillo de tierra.

23 Reemplazar la cubierta de cables.

24 Reconecte el arnés de cables de la lámpara y vuelva a

conectar el panel inferior con ocho (8) tornillos, como se

muestra en el paso 9.

INSTALE LAS BOMBILLAS

HERRAMIENTA

DE VENTOSA

SOPORTE DEL

RECEPTÁCULO

DE LA LÁMPARA

TORNILLOS

Para cambiar la profundidad de los receptáculos de las bombillas:

- Quite el panel inferior (vea el paso 9).

- Desconecte el arnés de las luces.

- Afloje los 2 tornillos que sostienen el soporte del

receptáculo de la lámpara al panel de iluminación.

- Ajuste el receptáculo/soporte a la profundidad deseada.

- Vuelva a apretar los tornillos con firmeza.

- Vuelva a colocar el arnés de las luces y el panel inferior.

26 INSTALACIÓN CON TUBERIA ÚNICAMENTE:

Vuelva a instalar los filtros de aluminio retirados en el paso 8.

ÚNICAMENTE EN INSTALACIONES SIN

CONDUCTOS:

Compre un filtro sin conductos (Modelo BPQTF) con su

distribuidor o tienda minorista local. Conecte el filtro sin

conductos siguiendo las instrucciones incluidas con el

filtro.

(1)

EMPUJAR

HACIA

BOMBILLA DE

HALÓGENO

(2)

(2)

GIRAR EN SENTIDO

GIRAR EN SENTIDO

DE LAS AGUJAS

DE LAS AGUJAS

DEL RELOJ

DEL RELOJ

PRECAUCIÓN: Las bombillas podrían estar calientes.

Siempre permita que se enfríen las bombillas antes

de cambiarlas.

25

Instale las (2) bombillas de halógeno. Utilice bombillas de

halógeno con escudo protector de 120 V, 35 W (MR16 con base

GU10).

NOTA: La herramienta de ventosa (incluida con la campana)

sirve para instalar y quitar bombillas.

Alinee las clavijas de la bombilla con la abertura de diámetro

grande en el receptáculo, empuje la bombilla para arriba en el

zócalo y luego gire hacia la derecha hasta que esté firmemente

asentada.

La posición del receptáculo de la bombilla (profundidad) es

ajustable, y podría necesitar ajuste cuando:

a) Ciertas marcas de bombillas sean difíciles de instalar.

b) La bombilla sobresalga demasiado por debajo del panel de la

bombilla.

ADENTRO

PANEL DE

ILUMINACIÓN

Page 15

PIEZAS DE SERVICIO

SERIE CBD3

Página 15

14

13

11

3

5

6

7

2

8

15

18

4

10

9

16

17

1

12

2

CLAVE

NO. DESCRIPCION NO. PARTE

1 PANEL INFERIOR, BLANCO 97018651

PANEL INFERIOR, NEGRO 97018652

PANEL INFERIOR, ACERO 97018653

2 PAQUETE DE TORNILLOS PARA PANEL INFERIOR Y DUCTO DE AIRE R602534

#8-18 X 3/8 (10 req.) (2 tornillos en una bolsa)

3 ARNES DE LAMPARA 97018656

4 ARNES 99271466

5 BOLSA DE PIEZAS DE SOPORTE DE LUZ 97018665

6 DEFLECTOR 99111539

7 CONDUCTO DE AIRE 99111538

CONJUNTO DE CONDUCTO DE AIRE (incluye clave no. 6, 7 y piezas) 97018660

8 CONTROL DE CIRCUITO (incluye tarjeta de control, interface de usuario y piezas) 97019365

9 ASPA DEL VENTILADOR (INCLUYE SUJETADOR DE HORQUILLA) R531076

10 SUJETADOR DE HORQUILLA R99420635

11 BOLSA DE PIEZAS DE MONTAJE 97018623

12 FILTRO DE ALUMINIO R610092

13 7” PLACA DE CONDUCTO REDONDO (incluye piezas de montaje) R680508

14 3-1/4” X 10” AMORTIGUADOR DE MONTAJE (incluye piezas de montaje) R740014

15 MOTOR 99080666

16 SUJETADOR DE CABLE, ARNES 99680044

17 CUBIERTA DE CABLES 98009816

18 TRANSFORMADOR 99271478

* AMORTIGUADOR REDONDO DE 7” 97010792

* FILTRO PARA CAMPANA SIN DUCTO 99010317

* BOMBILLA 120V, 35W MR16, GU10 BASE DE HALÓGENO (2 req.) 99526798

* No se ilustra. Se compra por separado.

Al pedir piezas de repuesto, indique el No. de pieza, no el No. de Clave.

Page 16

SERIE CBD3

Página 16

GARANTÍA

Garantía limitada

Periodo y exclusiones de la garantía: Broan-NuTone LLC (la “Compañía”) garantiza al consumidor comprador original de su producto

(“usted”) que el producto (el “Producto”) estará libre de defectos en materiales o en mano de obra, por un periodo de un (1) año a partir de la

fecha de compra original. La garantía en las bombillas provista con el Producto es de un (1) año y no cubre el rompimiento de las bombillas/

lámparas.

El periodo de garantía limitada para cualquier pieza de repuesto proporcionada por la compañía y para cualquier Producto reparado o

reemplazado bajo esta garantía limitada debe ser lo que reste del periodo de garantía original.

Esta garantía no cubre arrancadores de lámparas fluorescentes, tubos, bombillas de halógeno e incandescentes, fusibles, filtros, conductos,

tapas de techo, tapas de pared ni otros accesorios que pudieran ser comprados por separado e instalados con el producto. Esta garantía

tampoco cubre (a) mantenimiento y servicio normal, (b) uso y desgaste normal, (c) Productos o piezas sujetos a mal uso, abuso, uso anormal,

negligencia, accidente, mantenimiento inadecuado o insuficiente, almacenamiento o reparación (que no sea reparación por parte de la

Compañía), (d) daños causados por instalación defectuosa, o bien instalación o uso contrario a las recomendaciones o instrucciones, (e)

cualquier Producto que se haya movido de su punto de instalación original, (f) daños ocasionados por el medio ambiente o los elementos

naturales, (g) daños en tránsito, (h) desgaste natural del acabado, (i) Productos en uso comercial o no residencial, o (j) daños ocasionados

por incendio, inundación u otro caso fortuito. Esta garantía cubre solamente Productos vendidos a clientes originales en los Estados Unidos

por la Compañía o a distribuidores de EE. UU. autorizados por la Compañía.

Esta garantía sustituye todas las garantías anteriores y no es transferible del comprador consumidor original.

No hay otras garantías: Esta garantía limitada contiene la única obligación de la Compañía y su único recurso ante productos defectuosos.

Las garantías anteriores son exclusivas y en lugar de cualquier otra garantía, expresa o implícita. LA COMPAÑÍA NIEGA Y EXCLUYE

CUALQUIER OTRA GARANTÍA EXPRESA, Y NIEGA Y EXCLUYE TODAS LAS GARANTÍAS IMPLÍCITAS POR LEY, INCLUYENDO,

ENTRE OTRAS, LAS DE COMERCIALIZACIÓN Y APTITUD PARA UN PROPÓSITO EN PARTICULAR. Hasta el grado en que la ley

aplicable prohíba la exclusión de las garantías implícitas, la duración de cualquier garantía implícita aplicable está limitada al periodo

especificado para la garantía expresa antes mencionada. Algunos estados no permiten limitaciones en la duración de una garantía implícita,

así que la limitación anterior tal vez no aplique en su caso. Cualquier descripción verbal o escrita del Producto es para el único propósito de

identificarlo y no deberá considerarse como una garantía expresa.

Siempre que sea posible, toda disposición de esta garantía limitada deberá ser interpretada de tal forma que sea efectiva y válida de

conformidad con la ley aplicable, pero si alguna disposición fuera considerada prohibida o inválida, quedará sin efecto solo en virtud de dicha

prohibición o invalidez, sin invalidar el resto de dicha disposición o las demás disposiciones restantes de la garantía limitada.

Recurso: Durante el periodo de garantía limitada aplicable, la Compañía, a su opción, suministrará piezas de repuesto, o reparará o

reemplazará, sin cargo alguno, cualquier Producto o pieza del mismo, hasta el grado en que la Compañía lo encuentre cubierto bajo esta

garantía limitada y en incumplimiento de la misma en condiciones normales de uso y servicio. La Compañía le enviará el Producto reparado

o reemplazado o las piezas de repuesto sin cargo. Usted es responsable de todos los costos de retiro, reinstalación y envío, seguro u otros

cargos de flete incurridos en el envío del Producto o pieza a la Compañía. Si debe enviar el Producto o la pieza a la Compañía, tal como

lo indique la Compañía, debe empaquetar adecuadamente el Producto o la pieza: la Compañía no se hace responsable por los daños en

tránsito. La Compañía se reserva el derecho de utilizar Productos o piezas reacondicionados, renovados, reparados o refabricados en el

proceso de reemplazo o reparación de garantía. Dichos Productos y piezas serán comparables en función y desempeño a un Producto o una

pieza original y tendrán garantía durante el resto del periodo de la garantía original.

Exclusión de daños: LA OBLIGACIÓN DE LA COMPAÑÍA DE SUMINISTRAR PIEZAS DE REPUESTO, O DE REPARAR O

REEMPLAZAR, A OPCIÓN DE LA COMPAÑÍA, SERÁ SU ÚNICO Y EXCLUSIVO RECURSO BAJO ESTA GARANTÍA LIMITADA, Y LA

ÚNICA Y EXCLUSIVA OBLIGACIÓN DE LA COMPAÑÍA. LA COMPAÑÍA NO SERÁ RESPONSABLE POR DAÑOS INCIDENTALES,

INDIRECTOS, RESULTANTES O ESPECIALES QUE SURJAN POR EL USO O DESEMPEÑO DEL PRODUCTO, O EN RELACIÓN CON

EL MISMO.

Algunos estados no permiten la exclusión o limitación de daños incidentales o resultantes, por lo que la limitación antes mencionada podría

no aplicarse a usted. Esta garantía le otorga derechos legales específicos, y usted podría tener otros derechos que varían de un estado a otro.

Esta garantía cubre únicamente el reemplazo o la reparación de Productos defectuosos o piezas de los mismos en la planta principal de la

Compañía, y no incluye el costo del viaje para el servicio de campo ni los viáticos.

Cualquier asistencia que proporcione o procure la Compañía para usted fuera de los términos, limitaciones o exclusiones de esta garantía

limitada no constituirá una renuncia a dichos términos, limitaciones o exclusiones, ni dicha asistencia extenderá o renovará la garantía.

La Compañía no le reembolsará ningún gasto en el que usted haya incurrido al reparar o reemplazar cualquier Producto defectuoso, excepto

los incurridos con el permiso previo por escrito de la Compañía.

Cómo obtener el servicio cubierto por la garantía: Para tener derecho al servicio cubierto por la garantía, usted debe (a) notificar a la

Compañía a la dirección o número de teléfono que aparecen abajo en un plazo de siete (7) días después de descubrir el defecto cubierto, (b)

proporcionar el número de modelo y la identificación de la pieza y (c) describir la naturaleza de cualquier defecto en el Producto o la pieza.

En el momento de solicitar el servicio cubierto por la garantía, debe presentar un comprobante de la fecha de compra original. Si usted no

puede presentar una copia de la garantía limitada original por escrito, entonces regirán los términos de la garantía limitada por

escrito más actualizada de la compañía para su producto en particular. Las garantías limitadas por escrito más actualizadas para

los productos de la Compañía se pueden encontrar en www.broan.com.

Broan-NuTone LLC 926 West State Street, Hartford, WI 53027 www.broan.com 800-637-1453

99045076C

Loading...

Loading...