Page 1

INSTALLATION AND USER GUIDE

CENTRAL VACUUM POWER UNITS

!

FOR RESIDENTIAL USE ONLY

!

BQ550 / BQ650 / BQ700 / BQ500KIT

AB0039

MODELS SFDB-DH, SFDB-DI, SFDB-DJ AND SFDB-DT

VENMAR VENTILATION ULC WWW.BROAN.CA 1-877-896-1119

EGISTER YOUR PRODUCT ONLINE AT : WWW.BROAN.CA

R

24007 rev. A

Page 2

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THIS APPLIANCE

When using an electrical appliance, basic precautions should always be followed, including the following:

WARNING

To reduce the risk of fire, electric shock or injury:

1. Do not use on wet surfaces or outdoors.

2. Do not vacuum liquids or fine powders (such as

drywall dust).

3. Do not use to pick up flammable or combustible

liquids such as gasoline or use in areas where they

may be present.

4. Do not pick up anything that is burning or smoking,

such as cigarettes, matches, or hot ashes.

5. Do not allow to be used as a toy. Close attention is

necessary when used by or near children.

6. Use only as described in this manual. Use only

manufacturer's recommended attachments.

7. Keep hair, loose clothing, fingers and all parts of

body away from openings and moving parts.

8. Turn off all controls before unplugging.

9. Use extra care when cleaning on stairs.

10. Do not handle plug or appliance with wet hands.

11. Do not use with damaged cord or plug. If appliance

is not working as it should, if it has been dropped,

damaged, left outdoors, or dropped into water, return

it to a Service Center.

12. Keep your work area well lighted.

13. Connect to a properly grounded outlet only. See

grounding instructions shown on page 9.

14. When performing installation, servicing or cleaning

the unit, it is recommended to wear safety glasses

and gloves.

15. When applicable local regulations comprise

more restrictive installation and/or certification

requirements, the aforementioned requirements

prevail on those of this document and the installer

agrees to conform to these at his own expenses.

!

CAUTION

1. Do not put any object into openings. Do not use with

any opening blocked; keep free of dust, lint, hair and

anything that may reduce air flow.

2. Ensure air flows freely and exhausts unobstructed

from top or side outlet.

3. Do not use without filter (or filters, according to the

model) in place.

4. Do not use to blow leaves or debris.

5. Do not place any object on top of the unit.

6. Do not install the unit horizontally.

7. Do not use the pail as a wash bucket.

8. Do not use the pail as a stool.

9. Avoid picking up sharp objects.

10. This appliance is for use on a standard 120 VAC,

dedicated 15-amp branch circuit. Some brands of

house panel breakers may be more sensitive to

startup current than others (for example, Square

D brand). In the event where nuisance tripping of

the house panel breaker occurs*, we recommend

changing the breaker with an “HM” type of the same

AMP rating.

*after ensuring that the circuit is DEDICATED to the

central vacuum unit, meaning that there is no other

electrical device connected to the central vacuum

unit circuit.

11. Do not unplug the unit by pulling on cord. To unplug,

grasp the plug, not the cord.

12. Store your vacuum cleaner indoors in a clean, dry

area, and away from extreme temperatures.

13. Any servicing other than that recommended in

this manual should be performed by an authorized

service facility.

14. We recommend that your unit be inspected by a

specialized technician once a year.

2

Page 3

TABLE OF CONTENTS

GENERAL INFORMATION .........................................................................................................4

TOOL LISTING .......................................................................................................................................................4

WORKING WITH PLASTIC TUBING......................................................................................................................4

C

UTTING TUBING ......................................................................................................................................................4

MAKING A JOINT ......................................................................................................................................................4

CEMENTING FLEXIBLE TUBING .....................................................................................................................................4

SECURE WIRE TO TUBING ..........................................................................................................................................4

WALL INLET INSTALLATION ....................................................................................................4

MAKING THE WALL INLET CUTOUT ................................................................................................................................4

ATTACHING THE INLET MOUNTING PLATE (V144) ............................................................................................................4

COMPLETING THE INLET ASSEMBLY ..............................................................................................................................4

INSTALLING THE INLET (V111) .................................................................................................................................... 4

V800W CANSWEEP® UNDER CABINET INSTALLATION .................................................... 5-6

V800W CANSWEEP® BASEBOARD WALL INSTALLATION ....................................................7

POWER UNIT INSTALLATION ...................................................................................................8

LOCATING THE POWER UNIT ..............................................................................................................................8

CHANGING INTAKE LINE DIRECTION .................................................................................................................8

MOUNTING THE POWER UNIT ............................................................................................................................9

FITTING MAIN LINE TO POWER UNIT ...............................................................................................................10

GROUNDING INSTRUCTIONS ................................................................................................10

WIRING ................................................................................................................................................................10

OPERATION AND MAINTENANCE .........................................................................................11

WHEN TO CHANGE BAG* OR EMPTY DEBRIS PAIL ........................................................................................ 11

HOW TO EMPTY DEBRIS PAIL (BQ650 AND BQ700 POWER UNITS ONLY) ................................................... 11

BQ550 AND BQ500KIT POWER UNITS DETAILED VIEW .................................................................................. 11

DISPOSABLE BAG REPLACEMENT (BQ550 AND BQ500KIT POWER UNITS ONLY) ..................................... 11

PERMANENT FILTER (BQ650 AND BQ700 POWER UNITS ONLY) ..................................................................12

REMOVAL AND INSTALLATION OF PERMANENT FILTER (BQ650 AND BQ700 POWER UNITS ONLY) ........ 12

MOTOR FOAM FILTER (ALL UNITS) ..................................................................................................................12

REMOVING MOTOR FOAM FILTER ................................................................................................................................12

REINSTALLING MOTOR FOAM FILTER ............................................................................................................................ 12

ACCESSORIES (BQ500KIT ONLY) .........................................................................................13

ACCESSORIES INCLUDED ................................................................................................................................13

INSTALLING HOSE HANGER .............................................................................................................................13

TROUBLESHOOTING GUIDE ..................................................................................................14

SERVICE PARTS ......................................................................................................................15

WARRANTY ..............................................................................................................................16

3

Page 4

GENERAL INFORMATION WALL INLET INSTALLATION

TOOL LISTING

Depending on the installation, the use of the following tools

may be required:

Wire strippers, 1/4’’ and 1/2” drill bits, utility knife, putty knife,

2½’’ hole saw, keyhole saw, hammer, cold chisel, level,

flashlight, drill, electrical tape, Phillips no. 2 screwdriver,

wrench, hacksaw, tape measure, safety glasses.

Power tools are recommended to make the installation proceed

quickly. A mask and gloves should be worn when cutting

ducting and using glue.

WORKING WITH PLASTIC TUBING

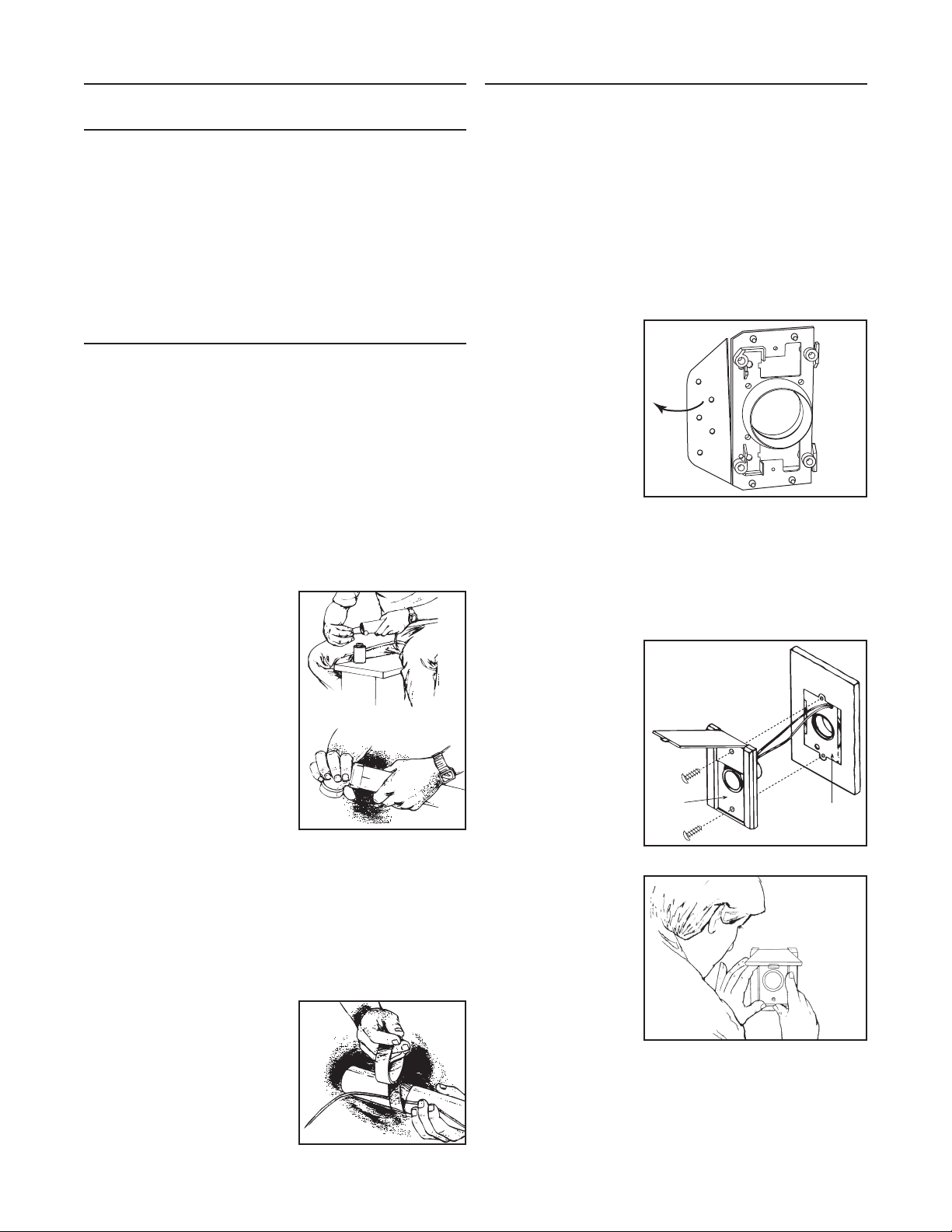

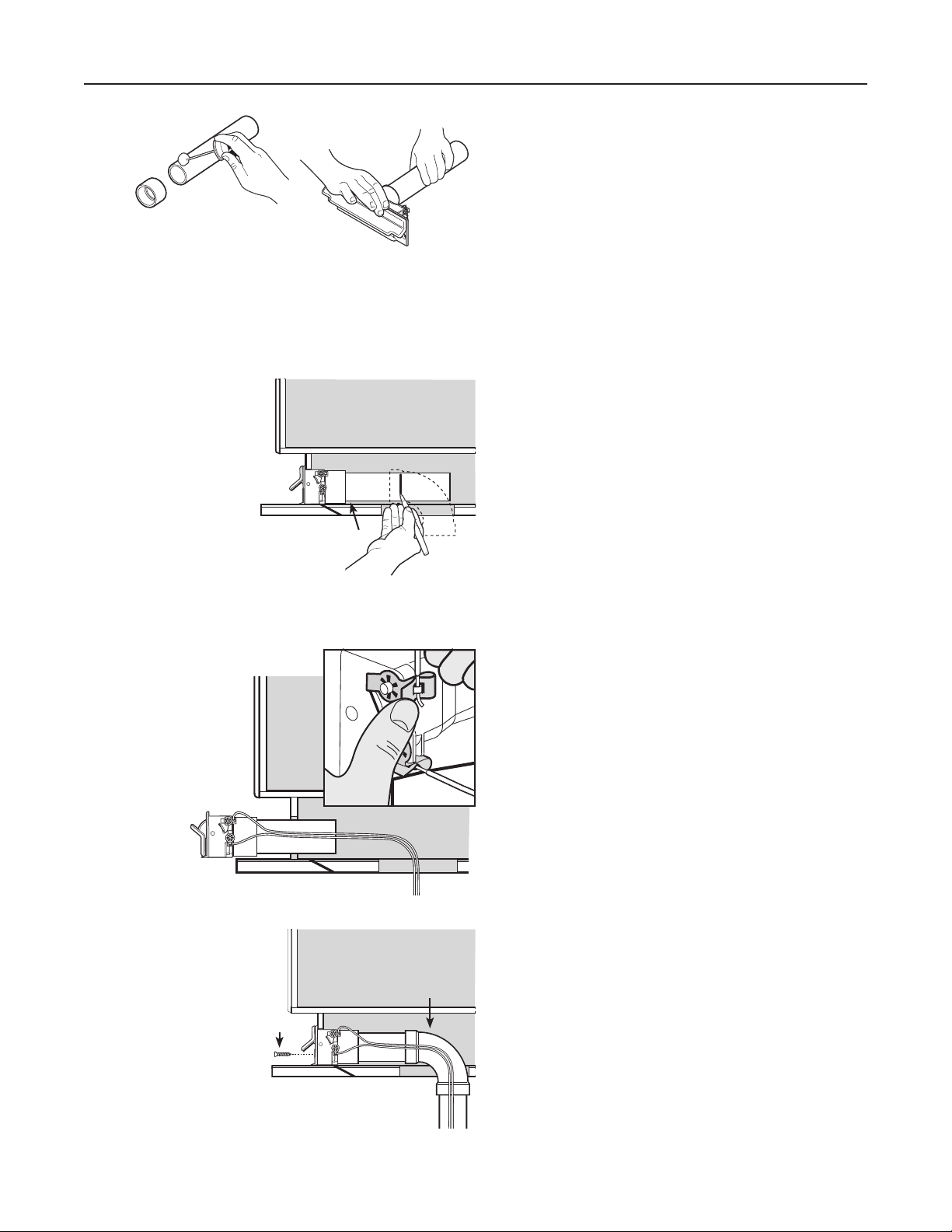

CUTTING TUBING

Measure the length of tube needed. Allow 5/8” of tubing for

inserting into fittings and 1½” for placing into flexible tubing.

Cut the plastic tubing with a hacksaw, ensuring that the cut

is exactly square. Use wire cutters or tin snips to cut flexible

tubing, 8” lengths of flexible tubing should not be cut.

Use a small knife or steel wool to remove any burrs from the

inside of the tube.

Use a file to slightly bevel the outside of the tube so that it will

easily slide into the fitting. Use steel wool or a light grained

sandpaper to buff the surface of the tube which will be glued.

MAKING A JOINT

Insert the tube into the fitting,

aligning both parts as they will be

installed. Mark the tube and the

fitting to quickly realign the joint.

Apply cement in an inch-wide

band to the outside of the tube.

Insert the tube into the fitting with

the alignment marks a quarter

turn apart, and then quickly push

and turn the fitting to align the

marks and spread the cement.

Allow 1 minute for the joint to dry.

CEMENTING FLEXIBLE TUBING

Ensure the ends of the flexible tubing are even. When joining

flexible tubing to plastic tubing or to an inlet mounting plate,

apply cement to both the inside of the flexible tubing and the

outside of the plastic tubing or mounting plate tubing ring. Twist

both pieces while joining them to evenly spread the glue. Allow

5 minutes for the cement to set in flexible tubing.

SECURE WIRE TO

TUBING

The low-voltage power wiring is

run along with the tubing. Use

electrical tape to secure the

wire to the tubing. Tape the wire

approximately every 12" to 18".

AO0010

AO0011

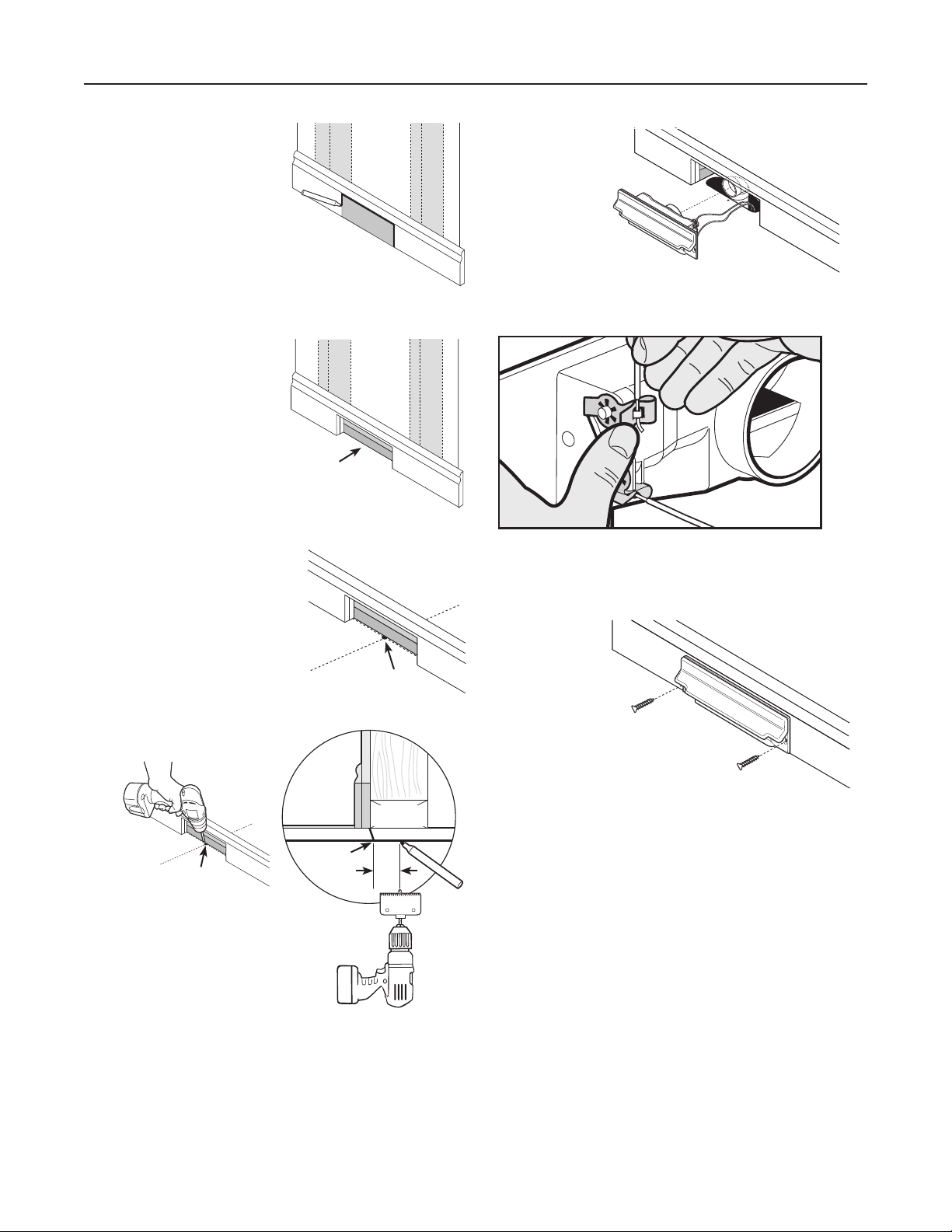

MAKING THE WALL INLET CUTOUT

The wall inlet should be located 18” on-center from the floor

and directly in line with the attic or basement inlet tubing hole

previously drilled in the wall plate or header. The wall inlet

cutout must be exactly 3

7

∕8” high by 27∕8” wide.

ATTACHING THE INLET MOUNTING PLATE

(V144)

Reach through the inlet hole and locate the inlet tubing. Pull

the flexible tubing through the inlet hole and remove the

low-voltage wiring from inside the tube.

Remove the nail flange

from the inlet mounting

plate (see illustration at

right). Apply cement to

both the inside of the

flexible tubing and to the

outside of the mounting

plate’s tube ring. Insert

the mounting plate’s

tube ring in the flexible

tubing and twisting the

pieces as you join them to spread the cement, and align the

mounting plate in a vertical position.

Now, strip the ends of the two low-voltage wires, and then

connect the wires to the screw terminals on the back of the

inlet cover. When the wiring is complete, assemble the inlet

cover to the tube guard and mounting plate.

AR0040

COMPLETING

THE INLET

ASSEMBLY

Once you have attached

the mounting plate to the

flexible tubing, pull the

low-voltage wire through

the top wiring hole in the

mounting plate.

INLET

AE0024A

MOUNTING

PLATE

INSTALLING THE

INLET (V111)

Place the inlet into the

wall cutout (the inlet

cover remains on the

outside). Hold the inlet

in place and gradually

tighten down each screw

a little bit at a time.

AO0045

4

Page 5

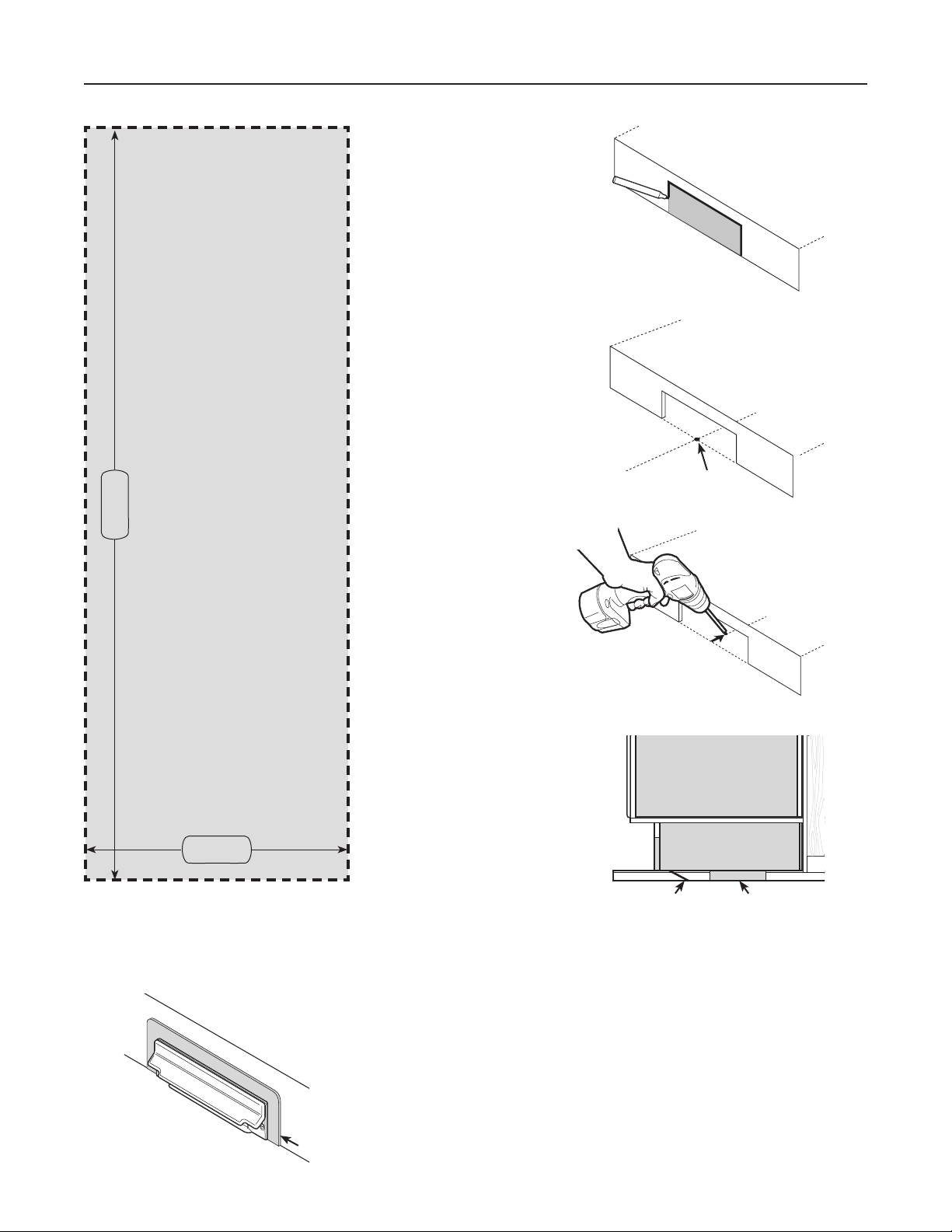

V800W CANSWEEP® UNDER CABINET INSTALLATION

Align the template

®

(cut from this

instruction sheet)

onto the kick plate to

the desired location,

and trace the outline

of the area.

Template

Cut out the desired

opening and

discretely mark the

center of the

opening on the floor.

Mark Center

6¾"

TEMPLATE

V800W CANSWEEP

2⅜"

If by any chance the opening was cut too big,

a trim plate (part number V801W) is available

to provide a perfect cover.

Drill a small

reference hole

along the

center line

behind the

kick plate

through the

subfloor.

Locate the

reference hole from

beneath the

subfloor. Cut a

4” x 4” access hole

on your chosen

position along the

center line under

the kick space.

Kick Plate

Opening

Reference

Cabinet Space

Hole

Kick Space

4" x 4" Access

Hole

Trim plate

5

Page 6

V800W CANSWEEP® UNDER CABINET INSTALLATION (CONT'D)

Fig. A

Fig. B

Solvent weld a coupling

to a piece of 2” central

vacuum pipe, long enough

to reach the 4” x 4” access

hole from the opening on

the kick plate (Fig. A).

Friction fit the other end

of the coupling to the

CanSweep® until secure.

Do not glue, friction fit only

(Fig. B).

Insert the

CanSweep®/pipe

into the opening on

the kick plate.

Use a 90° sweep

elbow fitting to

determine a cut

mark on the other

end of the pipe.

Then cut the pipe

at the mark.

Slide the

low voltage wires

into the

CanSweep® clips

as shown to

complete the wiring

connections.

Slide the

CanSweep®/pipe

and low voltage

wires into the

opening on

the kick plate. Glue

both ends of the

elbow to the piping

system, and then

secure the

CanSweep® to the kick plate with the 2 supplied screws.

Screws

Glue elbow

to pipe

6

Page 7

V800W CANSWEEP® BASEBOARD WALL INSTALLATION

Do not glue

Choose a desired

position on the baseboard

between two studs.

Place the template (cut

from this instruction sheet)

on the position, and trace

the outline of the area.

Template

Make piping

connections as

required and

ready the short

90° elbow in position

behind the CanSweep®.

Make sure that the opening of the elbow will securely

attach onto the spigot on the back of the CanSweep®

when it is time for connection.

CanSweep® to

the elbow.

Attach wires

Trim the opening on

the baseboard and

through the drywall

until reaching the

2" x 4" bottom wall

plate.

2" x 4" Bottom Plate

Against the edge of the

2" x 4" bottom plate, mark the

center of the opening.

Mark Center

Reference

Reference Hole

Drill a small reference hole

at the mark through the subfloor to below.

Locate the reference hole from below

and measure back 1

to remove the 2"x4" bottom plate

section behind the opening.

7

/8”. Use a 2” hole saw

Hole

2" x 4"

Bottom Plate

1⅞"

Slide the low volt wires into the CanSweep® clips

as shown to complete the wiring connections.

Slide the

CanSweep® and

low voltage wires

into the opening

on the

baseboard.

Friction fit the

CanSweep®

spigot into the elbow. Secure the CanSweep® to the

baseboard with the 2 supplied screws.

7

Page 8

POWER UNIT INSTALLATION

!

WARNING

Do not install outdoors. Before hanging the unit,

rest it on a leveled surface to prevent it from falling

down. When performing installation, servicing or

cleaning the unit, it is recommended to wear safety

glasses and gloves.

LOCATING THE POWER UNIT

• Locate the power unit away from the general living area in

an accessible location for cleaning and maintenance.

• Locate the power unit within 6 feet of a grounded electrical

outlet. The power unit requires a 120 VAC power source,

dedicated 15-amp branch circuit.

• Do not locate the power unit close to a source of extreme

heat (i.e.: water heater) or in an area with a high ambient

temperature (i.e.: attic, furnace room).

• If the power unit is located in a closet or a small utility

room, make sure the area is well-ventilated (e.g.: with door

louvers).

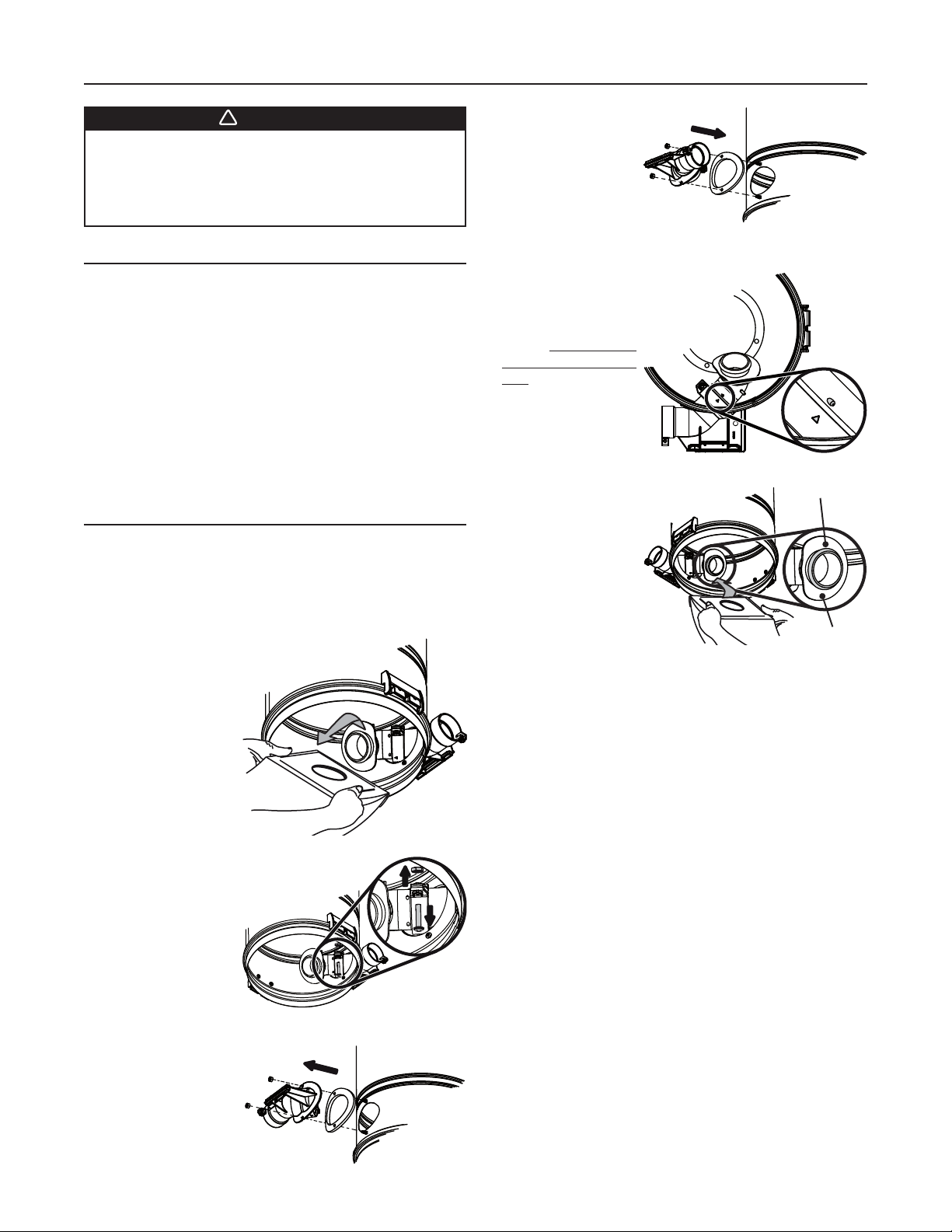

CHANGING INTAKE LINE

DIRECTION

The intake line connects to the right side of the unit. However,

it is possible to change this configuration; to connect the intake

line to the left side of the unit, follow these steps:

Remove debris pail from power unit by releasing both latches

on sides of the unit, pulling them out and then pushing up.

Detach the pail from unit.

BQ550 AND BQ500KIT

BQ550 and

BQ500KIT: Grasp

the edges of the bag

collar and pull down;

the bag will slide off

easily. Do not pull on

the bag. Set the bag

aside.

AO0078

All units: Flip the

intake elbow 180°,

then reassemble it to

the unit, taking care to

keep its gasket at its

original position.

NOTE: Ensure the

gasket is not folded in

order to prevent lack of suction and noise.

AD0077

BQ550 AND

BQ550 and BQ500KIT:

Reassemble the bag

adapter to the intake

elbow. Align triangle

with small inclined

stud, then tighten

the junction using

the screw and nut

previously removed

in

.

BQ550 and BQ500KIT:

Put the bag back in

place by grasping the

edges of its collar

and insert over bag

adapter. Be careful

not to tear the bag.

Ensure the collar is

positioned between

the taper ring and the

bag stopper on the bag adapter.

BQ500KIT

AD0078

BQ550 AND

BQ500KIT

AO0080

All units: Put the pail back in its place.

TAPER RING

BAG STOPPER

BQ550 and

BQ550 AND BQ500KIT

BQ500KIT: Using a

Phillips screwdriver

no. 2, remove the

screw tightening the

bag adapter and

intake elbow junction.

Disassemble the

bag adapter from the

intake elbow and set aside with its screw and nut.

AD0075

All units: Disassemble

the intake elbow from

the back of the unit

using a 3/8” socket to

remove both retaining

nuts and screws.

AD0076

8

Page 9

POWER UNIT INSTALLATION (CONT'D)

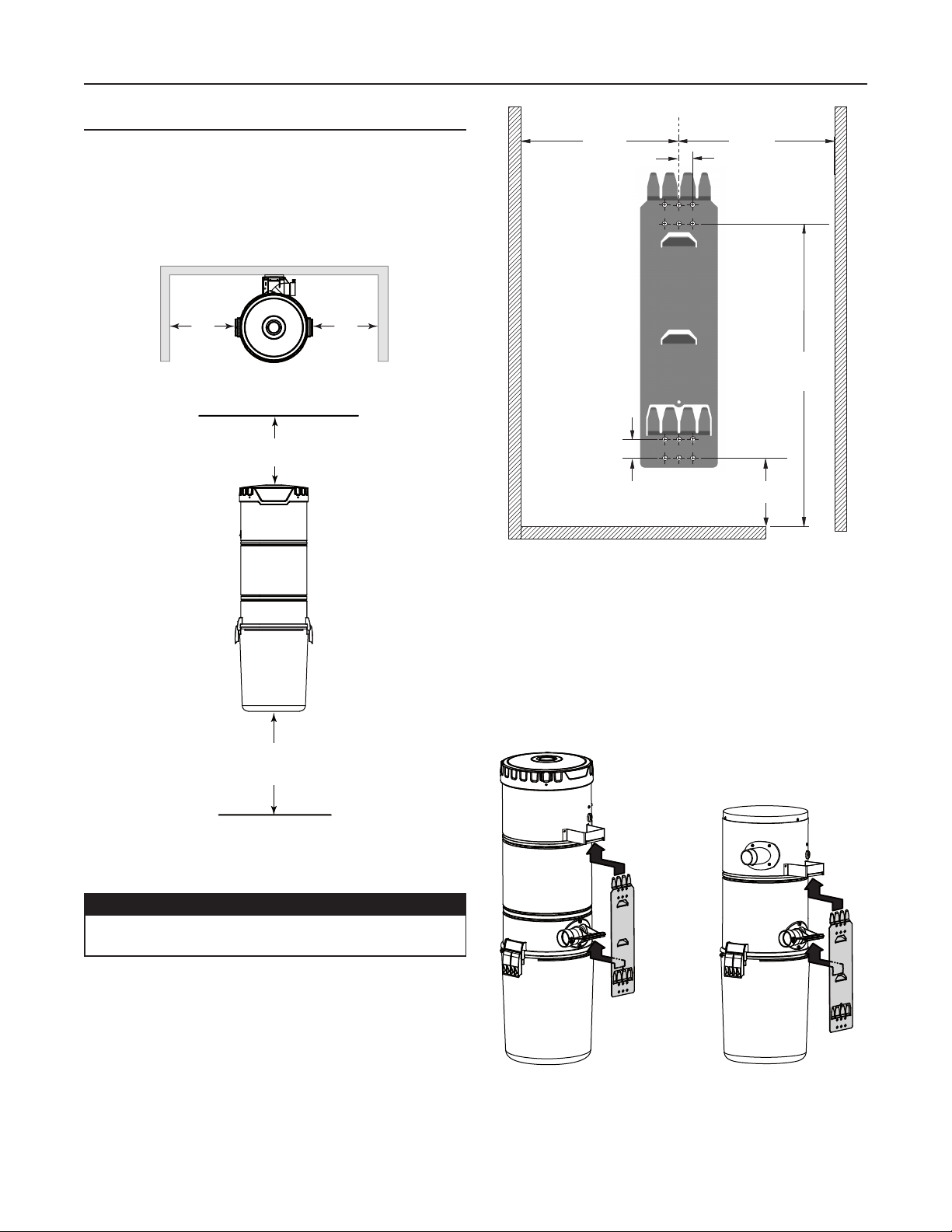

MOUNTING THE POWER UNIT

Carefully remove debris pail from power unit. Make sure

the bag is properly installed in power unit (BQ550 and

BQ500KIT units). Remove the installation kit and securely

reinstall debris pail.

Refer to illustration below to maintain minimum walls and

floor clearance dimensions.

MINIMUM CLEARANCE DIMENSIONS

TOP VIEW

12”

minimum

12” minimum

from ceiling

12”

minimum

FRONT VIEW

C

AD0079A

UPPER

MOUNTING

HOLES

LOWER

MOUNTING

HOLES

L

1” TYP.

18 ¹/

3/4” TYP.

32

8”18 ¹/ 8”

7

45¼”

MIN.

HEIGHT

/8”

Use the provided mounting screws to secure the mounting

bracket on the wall through upper and lower mounting

holes.

Hang power unit onto wall mounting bracket. Ensure

the back brackets of the power unit are engaged with

corresponding wall bracket fingers (or top fingers and lower

tab for BQ550 and BQ500KIT models; see figure below).

Pull the power unit down to secure.

18” minimum

above floor

AD0039A

Position and install the wall mounting bracket with the

provided screws. Refer to illustration in the right column for

proper mounting dimensions.

CAUTION

Make sure to screw the wall mounting bracket

directly to a wall stud for a solid installation.

BQ650 AND BQ700

BQ550 AND BQ500KIT

AD0074

9

Page 10

POWER UNIT INSTALLATION

!

(

CONT'D)

GROUNDING

INSTRUCTIONS

FITTING MAIN LINE TO POWER UNIT

Run house vacuum line up to the elbow behind the power

unit. Insert the end of the line in the elbow opening and

secure house vacuum line by hand tightening the screw

and nut provided (see illustration below) DO NOT GLUE.

INTAKE LINE TYPICAL CONNECTION

TO POWER UNIT

SCREW AND

NUT FROM

PAR TS BAG

INTAKE LINE

AJ0001

Assemble exhaust tubing to exhaust outlet on top or top

side of the unit, according to the power unit model. DO NOT

GLUE.

NOTE FOR BQ700 UNIT ONLY

If desired, the

coupling or elbow

used to connect

the exhaust line to

the top of the unit

may be secured

using two 5/8”

included screws.

See illustration at

right.

AJ0003

Make sure all

tubing connections are air tight.

The exhaust should not be vented into a wall, ceiling or

concealed space in the house. It is recommended to vent

the vacuum exhaust air to the outdoors. Exterior vented

exhaust line should end using Model V145 wall cap.

NOTE: For optimal indoor air quality, exhausting the power

unit to the outdoors is recommended but is not

required.

WARNING

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock.

Check with a qualified electrician or service person

if you are in doubt as to whether the outlet is

properly grounded. Do not modify the plug provided

with the appliance – if it will not fit the outlet, have

a proper outlet installed by a qualified electrician.

Grounding Instructions – This appliance must be grounded.

If it should malfunction or break down, grounding provides a

path of least resistance for electric current, to reduce the risk

of electric shock. This appliance is equipped with a cord having

an equipment-grounding conductor and grounding plug. The

plug must be plugged into an appropriate outlet that is properly

installed and grounded in accordance with all local codes and

ordinances.

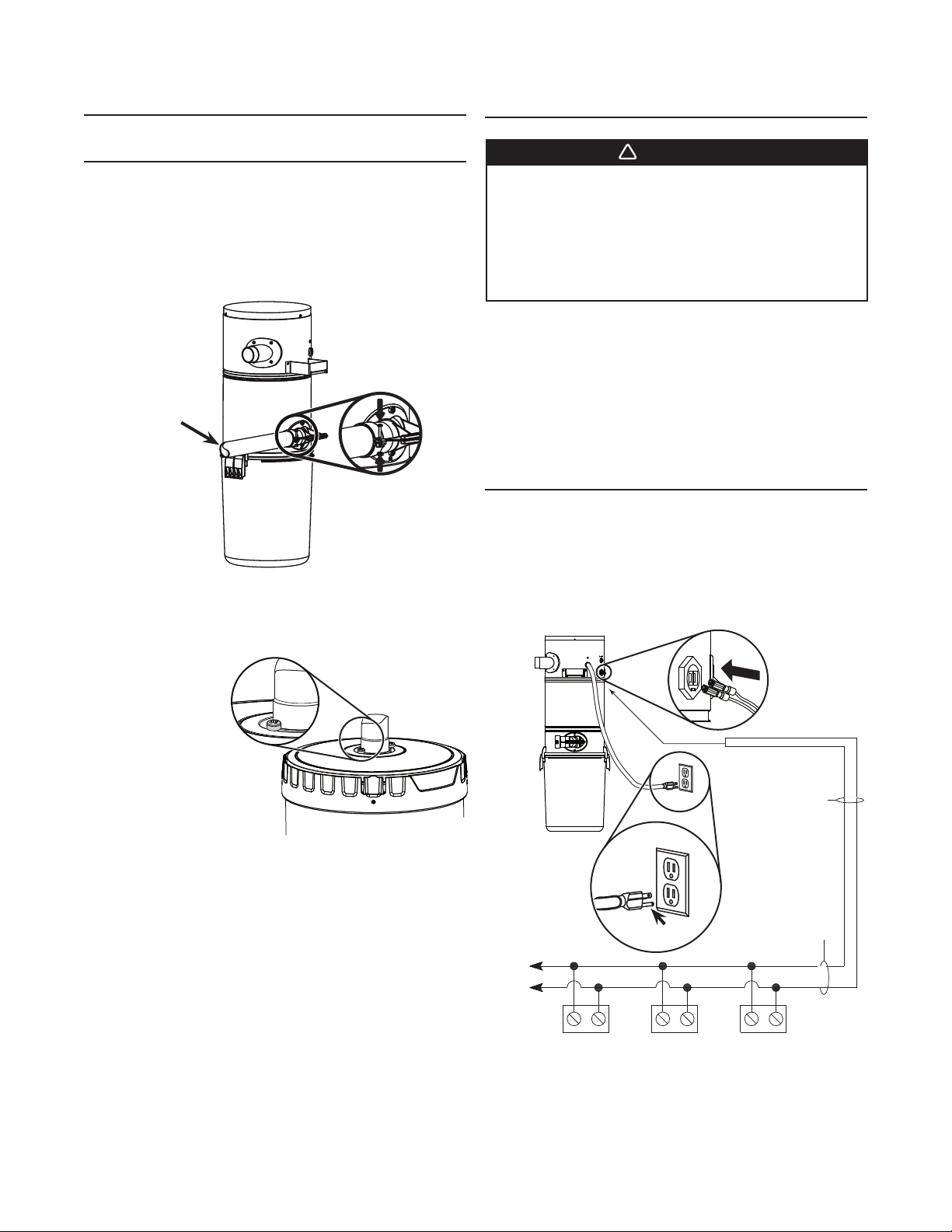

WIRING

This appliance is for use on a standard 120 VAC, dedicated

15-amp branch circuit with a NEMA 5-15R receptacle. Make

sure that the power unit is connected to an outlet and has a

grounding attachment plug that looks like the plug shown in

illustration below. No adapter should be used with this power

unit.

CRIMP

CONNECTORS TO

BE CONNECTED

IN LOW VO LTAG E

TABS

GROUNDED OUTLETS

INLET LEADS

GROUNDING PIN

TO

OTHER

INLETS

MODEL V133 (22/2)

LOW VO LTAG E WIRE

AE0044

INLET

NOTE: Inlet leads to be connected to power unit low voltage

tabs using crimp connectors (included in parts bag)

and low voltage harness.

10

INLET INLET

Page 11

OPERATION AND MAINTENANCE

Open the wall inlet cover and insert the end of the hose into the

inlet to turn on the vacuum.

For non-switched hoses, inserting the hose automatically turns

on the power unit; removing the hose shuts off the power unit.

Some hoses have switches which can be used to activate

power unit. The ON/OFF switch located on the power unit

needs to be kept in the OFF position.

As you vacuum, dirt and dust are carried to the power unit

where they remain in a bag or in the debris pail (according to

the power unit model).

Use the cleaning tools as you would for any other vacuum

cleaner. Avoid picking up very large debris or lengthy as these

kinds of objects may become lodged in the hose or tubing.

WHEN TO CHANGE BAG* OR EMPTY

DEBRIS PAIL

With a 6 U.S. gallons (22.7 liters) capacity, under normal

conditions the bag/debris pail requires changing/emptying

approximately twice a year. If the bag/debris pail is full, you will

notice a reduced suction from the system. Unless this loss of

suction is caused by a blockage in the system, changing the

bag or emptying the debris pail will solve the problem.

NOTE: Even if not filled to capacity, if the bag seems tightly

stretched when removing the debris pail, changing

the bag will prevent it from tearing.

* Only BQ550 and BQ500KIT units are equipped with a

disposable bag (391C).

HOW TO EMPTY DEBRIS PAIL

(BQ650 AND BQ700 POWER UNITS

ONLY)

To empty the debris pail, release both latches on sides of the

unit by pulling out and then pushing up. Holding the pail by the

latches, lower it from unit. Carry pail to trash receptacle and

dispose of debris. Put the pail back in its place.

BQ550 AND BQ500KIT POWER

UNITS DETAILED VIEW

EXHAUST OUTLET

MOTOR FOAM FILTER

VACUUM CHAMBER

DISPOSABLE BAG

AL0009

INLET

BAG ADAPTER

LATCH

D

EBRIS PAIL

DISPOSABLE BAG REPLACEMENT

(BQ550 AND BQ500KIT POWER

UNITS ONLY)

To remove the disposable bag, release both latches on

sides of the unit by pulling out and then pushing up. Remove

the pail from unit. Grasp the edges of the bag collar and pull

down. The bag will slide off easily. Do not pull on the bag.

Unfold the new bag.

Grasp collar where indicated on the new bag and insert over

bag adapter. Be careful not to tear the bag. Ensure the collar

is positioned between the taper ring and the bag stopper on

the bag adapter (see illustration below). Put the pail back in

its place.

TAPER RING

AO0081

11

BAG STOPPER

Page 12

OPERATION AND MAINTENANCE (CONT'D)

PERMANENT FILTER (BQ650 AND

BQ700 POWER UNITS ONLY)

This filter protects the motor and stops small particles from

escaping to the outside of the power unit wihout the need to

replace it. The filter cleans itself by moving up when the power

unit starts, and dropping down when the unit is turned off.

Under normal use, there is no need to maintenance this filter.

It is possible to remove it to inspect the motor foam filter, or

to replace it if ever it has been damaged (by sharp debris, for

example).

REMOVAL AND INSTALLATION OF

PERMANENT FILTER (BQ650 AND

BQ700 POWER UNITS ONLY)

Remove the pail from unit. To remove the permanent filter,

use pull tab (A) located on edge of filter to pull and loosen

filter from inlet chamber wall. Squeeze from both sides of

the filter to the center of

the housing.Then, carefully

remove it from the unit.

Squeeze the filter in order

to move it past the inlet

opening (B) Let the filter

bear against the unit wall

by releasing the pressure.

Make sure to place the rigid ring in its groove to ensure

proper sealing.

NOTE: Make sure the filter

is installed so that

the pull tab (A)

is accessible for

future filter removal.

AD0084

AD0085

A

B

MOTOR FOAM FILTER (ALL UNITS)

A motor foam safety filter, located at the top of the vacuum

chamber provides protection against dirt being pulled into

the motor if the disposable bag or permanent filter should

accidentally be torn. This filter should be checked and cleaned

if necessary when replacement bag is installed (BQ550 and

BQ500KIT units only), or when permanent filter is removed

(BQ650 and BQ700 units only). Simply brush filter clean. If

the filter is excessively soiled, hand wash in a water and mild

detergent solution and let it dry completely on a flat surface

before reinstalling.

CAUTION

Operating the power unit without the motor foam

filter will void the warranty.

REMOVING

MOTOR FOAM

FILTER

Remove the debris pail

and disposable bag or

permanent filter. Lift the

center of the wire retaining

the motor foam filter and

slide the filter out of its

location.

REINSTALLING

MOTOR FOAM

FILTER

To reinstall the motor foam

filter, reverse the steps

described above.

AD0086

A

AA0005

CAUTION

Be sure to reinstall filter properly. Appropriate

location is critical to insure proper protection of

the motor.

12

Page 13

ACCESSORIES (BQ500KIT ONLY)

ACCESSORIES INCLUDED

B Standard floor brush

C Standard hose, 30 ft. long

D Hose hanger

E Telescopic wand for static tools

F Round dusting brush

G Upholstery tool

H Long crevice tool

I Storage bag

C

D

E

INSTALLING HOSE HANGER

Secure the hose hanger to the

wall using 2 provided screws.

According to the place chosen,

the use of wall anchors (not

included) may be necessary.

AA0023

Wind hose around its hanger

when not in use.

AA0024

SCREWS

AA0056

I

G

B

F

H

13

Page 14

TROUBLESHOOTING GUIDE

PROBLEMS POSSIBLE CAUSES POSSIBLE REMEDY

1. Loss or decrease of

suction occurs.

2. Power unit does

not start, or stops

suddenly.

• Debris pail or disposable bag is completely full.

• Debris pail gasket damaged or missing.

• Obstruction in the hose. A blockage in the hose

can be determined by inserting the hose into

any wall inlet and, while power unit is running,

check each additional inlet for normal suction

by holding the palm of your hand over the

open inlet. If normal suction is felt at all other

inlets, insert the hose into a second inlet. If the

blockage still exists it is located in the hose.

However, if the blockage does not occur when

the hose is changed, the blockage is probably

located in the tubing system leading to the

original inlet.

• Obstruction in the tubing system inside the

walls.

• Permanent filter or disposable bag torn.

• Wall inlet cover not properly sealed.

• Exhaust tubing or vent clogged.

• Defective inlet. Check other wall inlets.

• Power unit internal circuit breaker has been

activated (the reset button is popped up).

• Change the disposable bag or empty debris pail

as described on page 10.

• Replace the debris pail gasket.

• Disconnect the hose from the wall inlet and

insert a blunt instrument into the hose —

slightly smaller in diameter — such as a flexible

garden hose. Push the garden hose through the

cleaning system hose until the obstruction has

been cleared.

• Insert hose end into any inlet to make power

unit run, then place the palm of your hand over

the opposite end of the hose. When you can feel

the suction increase, hold your hand over the

hose end for a few seconds and then quickly

remove your hand. This procedure repeated

several times should clear the obstruction. If the

blockage is not cleared, contact your nearest

Service Center.

• Clean the interior or the unit and install a new

permanent filter (or disposable bag).

• Check all wall inlet covers to be sure they are

closed and sealed tightly.

• Inspect and remove any blockages.

• Replace defective wall inlet.

• Push on the circuit

breaker reset

button located on

the left side of

the power unit. If

this button pops

up again, contact

your authorized

Service Center.

RESET

BUTTON

POWER SWITCH

3. Power unit runs

continuously when

the hose is removed.

• Blown fuse or tripped circuit breaker on house

electrical panel.

• Defective hose.

• Power unit overcurrent protector has been

activated.

• The unit power switch is in ON position.

• An electrical short has occurred somewhere in

the system.

14

AC0003

• Replace fuse or reset circuit breaker on house

electrical panel. Ensure the circuit is DEDICATED

to the central vacuum unit, meaning that there

is no other electrical device connected to the

central vacuum unit circuit.

• Some brands of house panel breakers may be

more sensitive to startup current than others (for

example, Square D brand). Correct the situation

by changing the breaker with an “HM” type of

the same AMP rating.

• Replace hose as required.

• Unplug the power unit, wait at least 15 minutes

and plug the power unit back in.

• Set the unit power switch to OFF position.

• Perform a complete check of all wall inlets and

power unit low voltage control lead connections.

Contact your authorized Service Center.

Page 15

AL0018

SERVICE PARTS

BQ700 UNIT

1

2

BQ550, BQ650 AND BQ500KIT UNITS

1

11

12

10

9

REPLACEMENT PARTS AND REPAIRS

3

4

5

8

7

In order to ensure your unit remains in good working condition,

you must use Broan-NuTone genuine replacement parts

only. Broan-NuTone genuine replacement parts are specially

designed for each unit and are manufactured to comply

with all the applicable certification standards and maintain

a high standard of safety. Any third party replacement part

used may cause serious damage and drastically reduce the

performance level of your unit, which will result in premature

failing. Broan-NuTone also recommends to contact a

Broan-NuTone certified service depot for all replacement

parts and repairs.

6

KEY NO.PART NO.DESCRIPTION BQ500KIT BQ550 BQ650 BQ700

S10941409 BQ700 TOP CAP ASSEMBLY (INCLUDING ITEM 4) (UPPER PA R T)1

1

S10941417 BQ550, BQ650 AND BQ500KIT TOP CAP ASSEMBLY 111

2 S10941398 BQ700 TOP CAP ASSEMBLY (INCLUDING ITEM 4) (LOWER PA RT )1

3 66369 M

4 S10941400 GASKET 1 113

5 S10941401 PERMANENT FILTER 11

6 S99670648 DEBRIS PAIL (INCLUDING KEY NO. 7) 1 111

7 S10941199 LATCH AND SCREWS 2 222

8 S10941404 LATCH KEEPER WITH SCREWS 2 222

9 S10941405 BAG ADAPTER WITH NUT AND SCREW 11

10 S10941406 INTAKE ELBOW WITH GASKET, SCREWS, AND NUTS 1 111

11 S99670650 EXHAUST PORT WITH GASKET AND SCREWS 111

12 S30390555 U

* 391C DISPOSABLE BAG (SET OF 3) 1 1

* ITEM NOT SHOWN

NOTE: Order service parts by “Part No.” — not by “Key No.”

OTOR FOAM FILTER WITH FASTENER 1 111

NIT SUPPORT BRACKET 1 111

15

Page 16

WARRANTY

BROAN MODELS BQ550, BQ650, BQ700 AND BQ500KIT

VENMAR VENTILATION ULC

CENTRAL VACUUM POWER UNIT

LIMITED WARRANTY

Venmar Ventilation ULC warrants to the original consumer purchaser that its central vacuum power unit will be free from defects in materials

and workmanship for five (5) years for BQ550 and BQ500KIT units, eight (8) years for BQ650 units and ten (10) years for BQ700 units. This

warranty covers the parts and labor in an authorized service center for the first year of the warranty for BQ500KIT units, the first three (3)

years of the warranty for BQ550 units, the first five (5) years of the warranty for BQ650 units, the first six (6) years of the warranty for BQ700

units. After these time periods, the parts only will be covered under this warranty.THERE ARE NO OTHER WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

During these time periods, Venmar Ventilation ULC will, at its option, repair or replace the power unit or part without charge, which is found

to be defective under normal use and service. THIS WARRANTY DOES NOT APPLY TO THE INSTALLATION OR THE PARTS USED IN THE

INSTALLED TUBING SYSTEM. All central vacuum hoses, electric or air-driven brushes, filters, attachments and accessories are warranted

for one (1) year from the original purchase date with the exception to consumables such as light bulbs and belts. We invite you to register your

product on line at www.broan.ca. Venmar Ventilation ULC reserves the right to limit this warranty if the product is not registered.

This warranty does not cover (a) normal maintenance and service or (b) any products or parts which have been subject to misuse, negligence,

accident, improper maintenance or repair (other than by Venmar Ventilation ULC or an authorized representative), faulty installation or

installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the period as specified for the express warranty.

VENMAR VENTILATION ULC’S OBLIGATION TO REPAIR OR REPLACE, AT VENMAR VENTILATION ULC’S OPTION, SHALL BE THE

PURCHASER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. VENMAR VENTILATION ULC SHALL NOT BE LIABLE

FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR

PERFORMANCE. Please do not return your unit to place of purchase. Please visit www.broan.ca for your closest service center. You may also

call 1-877-896-1119 for the name of an authorized representative in your area. This warranty supersedes all prior warranties.

Warranty service is to be completed by an authorized Service Center designated by Venmar Ventilation ULC. Where applicable, in home

service will be made available only in areas where a contracted service provider offers service during the first year of the warranty for

BQ500KIT units, during the first three (3) years of the warranty for the BQ550 units, during the first five (5) years of the warranty for the BQ650

units and during the first six (6) years of the warranty for the BQ700 units. If in home service is not available, the product will be repaired or

replaced, at Venmar Ventilation ULC’s discretion, by the nearest authorized service provider. The unit removal and reinstallation works are

under the customer responsibility, and Venmar Ventilation ULC cannot be charged for them.

To qualify for warranty service, you must notify Venmar Ventilation ULC at the address or telephone number stated below. We will then forward

you the authorized service depot in your area. You will be required to present evidence of the original purchase date.

Date of Installation Builder or Installer

Model Number and Product Description

IF YOU NEED ASSISTANCE OR SERVICE

For the location of your nearest Venmar Ventilation ULC dealer, dial toll free: 1-877-896-1119

Please be prepared to provide: Product model number • Date and proof of purchase • The nature of the difficulty

Venmar Ventilation ULC

Product specifications subject to change without notice. Printed in Canada.

16

Page 17

GUIDE D’INSTALLATION ET D’UTILISATION

UNITÉS MOTRICES

D’ASPIRATEUR CENTRAL

!

POUR USAGE RÉSIDENTIEL SEULEMENT

!

BQ550 / BQ650 / BQ700 / BQ500KIT

AB0039

MODÈLES SFDB-DH, SFDB-DI, SFDB-DJ ET SFDB-DT

VENMAR VENTILATION ULC WWW.BROAN.CA 1 877-896-1119

ENREGISTREZ VOTRE PRODUIT EN LIGNE À : WWW.BROAN.CA

24007 rév. A

Page 18

IMPORTANTES DIRECTIVES DE SÉCURITÉ

CONSERVEZ CES DIRECTIVES

LIRE TOUTES LES DIRECTIVES AVANT D'UTILISER CET APPAREIL

Lors de l’utilisation d’un appareil électrique, toujours suivre les mesures de sécurité de base, y compris les suivantes :

AVERTISSEMENT

Afin de réduire le risque d’incendie, d’électrocution

ou de blessures corporelles :

1. N’utilisez pas cet appareil à l'extérieur ou sur des

surfaces mouillées.

2. N’utilisez pas cet appareil pour aspirer des liquides

ou des poussières fines telles que de la poussière

de gypse.

3. N’utilisez pas cet appareil pour aspirer des liquides

inflammables ou combustibles, comme de l'essence,

ni dans des endroits où ces liquides pourraient être

présents.

4. N’utilisez pas cet appareil pour aspirer des objets

brûlants ou fumants comme des cigarettes, des

allumettes ou des cendres chaudes.

5. Ne laissez pas les enfants s'amuser avec cet

appareil. Portez une attention particulière lorsqu'il

est utilisé par ceux-ci ou près d’eux.

6. Utilisez l'aspirateur uniquement de la façon décrite

dans ce guide. N’utilisez que les accessoires

recommandés par le fabricant.

7. Éloignez vos cheveux, vêtements amples, doigts ou

toute autre partie de votre corps des pièces mobiles

ou des ouvertures de l’appareil.

8. Mettez toutes les commandes en position d'arrêt

(Off) avant de débrancher l'appareil.

9. Soyez prudent lorsque vous passez l’aspirateur

dans les escaliers.

10. Ne manipulez pas la fiche ni l'appareil si vos mains

sont mouillées.

11. N’utilisez pas cet appareil si le cordon d'alimentation

ou la fiche sont endommagés. Si l'appareil ne

fonctionne pas adéquatement, s'il a été échappé,

laissé à l'extérieur ou s’il est tombé à l'eau, retournezle au Centre de services.

12. Gardez la zone de travail bien éclairée.

13. Branchez-le à une prise correctement mise à la

terre. Consultez les instructions de mise à la terre

à la page 9.

14. Il est recommandé de porter des lunettes et des

gants de sécurité lors de l’installation, de l’entretien

et de la réparation de cet appareil.

15. Lorsqu’une réglementation est en vigueur localement

et qu’elle comporte des exigences d’installation et/ou

de certification plus restrictives, lesdites exigences

prévalent sur celles de ce document et l’installateur

entend s’y conformer à ses frais.

!

ATTENTION

1. N’insérez pas d’objets dans les ouvertures

d’aération. N’utilisez pas l'appareil si une ou des

ouvertures sont bloquées. Retirez la poussière, les

cheveux ou autre objet pouvant réduire le débit de l'air.

2. Assurez-vous que l’air circule librement et que le

conduit d'évacuation du dessus ou du côté n'est pas

obstrué.

3. N’utilisez pas cet appareil sans son filtre (ou ses

filtres, selon le modèle).

4. N’utilisez pas cet appareil pour souffler des feuilles

ou des débris.

5. Ne déposez pas d’objet sur le dessus de l’appareil.

6. N’installez pas l’appareil à l’horizontale.

7. N’utilisez pas le récipient à débris comme seau de

nettoyage.

8. N’utilisez pas le récipient à débris comme escabeau.

9. Évitez d’aspirer des objets pointus.

10. Brancher cet appareil à une prise de courant de

120 V c.a. avec circuit de dérivation distinct de

15 A. Certaines marques de disjoncteurs pour

panneau électrique domestique (par exemple, la

marque Square D) pourraient être plus sensibles

au courant de démarrage. Dans l’éventualité où

un déclenchement intempestif du disjoncteur du

panneau électrique domestique survenait*, nous

recommandons de remplacer le disjoncteur par un

de type « HM », ayant exactement la même intensité

nominale.

* après s’être assuré que le circuit de l’aspirateur

central est bien un circuit de dérivation DISTINCT,

ce qui signifie qu’aucun autre appareil électrique

n’est connecté au circuit de l’aspirateur central.

11. Ne débranchez pas l'appareil en tirant sur le cordon.

Pour le débrancher, saisissez la fiche, puis retirez-la

de la prise.

12. Entreposer l’appareil à l’intérieur dans un endroit

propre, sec et éloigné des températures extrêmes.

13. Tout entretien autre que celui recommandé dans ce

guide doit être effectué par le personnel d'un Centre

de services autorisé.

14. Nous vous recommandons de faire inspecter

l’appareil annuellement par un technicien spécialisé.

2

Page 19

TABLE DES MATIÈRES

INFORMATION GÉNÉRALE .......................................................................................................4

LISTE DES OUTILS NÉCESSAIRES .....................................................................................................................4

TRAVAIL DES TUYAUX EN PLASTIQUE ...............................................................................................................4

D

ÉCOUPE DU TUYAU .................................................................................................................................................4

CONCEPTION D'UN JOINT ...........................................................................................................................................4

COLLAGE DU TUYAU FLEXIBLE .....................................................................................................................................4

FIXATION DU FIL D’ALIMENTATION À LA TUYAUTERIE ..........................................................................................................4

INSTALLATION D'UNE PRISE MURALE ..................................................................................4

DÉCOUPE DE LA PRISE MURALE ..................................................................................................................................4

FIXATION DE LA PLAQUE DE MONTAGE (V144) ...............................................................................................................4

ASSEMBLAGE FINAL DE L'ENSEMBLE DE PRISE MURALE ....................................................................................................4

INSTALLATION DE LA PRISE MURALE (V111) ...................................................................................................................4

INSTALLATION SOUS UNE ARMOIRE V800W CANSWEEPMD ............................................ 5-6

INSTALLATION SUR UNE PLINTHE V800W CANSWEEPMD ....................................................7

INSTALLATION DE L'UNITÉ MOTRICE .....................................................................................8

EMPLACEMENT DE L'UNITÉ MOTRICE ..............................................................................................................8

CHANGEMENT DE L'ORIENTATION DE LA LIGNE D'ASPIRATION ....................................................................8

MONTAGE DE L'UNITÉ MOTRICE ........................................................................................................................9

RACCORD DE LA LIGNE PRINCIPALE À L'UNITÉ MOTRICE ........................................................................... 10

INSTRUCTIONS DE MISE À LA TERRE .................................................................................10

CÂBLAGE ............................................................................................................................................................. 10

FONCTIONNEMENT ET ENTRETIEN ...................................................................................... 11

QUAND REMPLACER LE SAC* OU VIDER LE RÉCIPIENT À DÉBRIS ............................................................. 11

COMMENT VIDER LE RÉCIPIENT À DÉBRIS (UNITÉS MOTRICES BQ650 ET BQ700 SEULEMENT) .......... 11

VUE DÉTAILLÉE DES UNITÉS MOTRICES BQ550 ET BQ500KIT .................................................................... 11

REMPLACEMENT DU SAC JETABLE (UNITÉS MOTRICES BQ550 ET BQ500KIT) ......................................... 11

FILTRE PERMANENT (UNITÉS MOTRICES BQ650 ET BQ700 SEULEMENT) ................................................12

RETRAIT ET INSTALLATION DU FILTRE PERMANENT (UNITÉS MOTRICES BQ650 ET BQ700 SEULE-

MENT) ..................................................................................................................................................................12

FILTRE EN MOUSSE POUR MOTEUR (TOUS LES APPAREILS)......................................................................12

RETRAIT DU FILTRE EN MOUSSE POUR MOTEUR ............................................................................................................ 12

R

EMISE EN PLACE DU FILTRE EN MOUSSE POUR MOTEUR ............................................................................................... 12

ACCESSOIRES (BQ500KIT SEULEMENT) .............................................................................13

ACCESSOIRES INCLUS ..................................................................................................................................... 13

INSTALLATION DU SUPPORT DE BOYAU ......................................................................................................... 13

GUIDE DE DÉPANNAGE ..........................................................................................................14

PIÈCES DE REMPLACEMENT ................................................................................................15

GARANTIE ................................................................................................................................16

3

Page 20

INFORMATION GÉNÉRALE

INSTALLATION D'UNE

LISTE DES OUTILS NÉCESSAIRES

Selon l'installation, les outils suivants peuvent être nécessaires.

Pince à dénuder, forets de 1/4 po et de 1/2 po, couteau tout

usage, couteau à mastic, scie-cloche de 2½ po, scie à guichet,

marteau, ciseau à froid, niveau, lampe de poche, perceuse,

ruban isolant, tournevis Phillips n° 2, clé, scie à métaux, ruban

à mesurer, lunettes de sécurité.

Les outils électriques permettent d'effectuer l'installation plus

rapidement. Porter un masque et des gants de sécurité lors de

la coupe de conduits et de l’utilisation de la colle.

TRAVAIL DES TUYAUX EN PLASTIQUE

DÉCOUPE DU TUYAU

Mesurer la longueur requise. Laisser 5/8 po de tuyau pour

l'insertion dans les raccords et 1½ po pour l'insertion dans le tuyau

flexible. Couper le tuyau en plastique avec une scie à métaux, en

s'assurant que la découpe soit droite. Utiliser un coupe-fil ou une

cisaille de ferblantier pour couper le tuyau flexible. Les tuyaux

flexibles de 8 po de long ne doivent pas être coupés.

Utiliser un petit couteau ou de la laine d’acier pour ébarber

l'intérieur du tube.

Utiliser une lime pour tailler légèrement en biseau la partie

extérieure du tuyau afin qu'il glisse facilement dans le raccord.

À l'aide d’une laine d'acier ou d'un papier abrasif fin, poncer la

surface du tuyau qui sera enduite de colle.

CONCEPTION D'UN JOINT

Insérer le tuyau dans le raccord, en alignant les 2 pièces

d'après l'installation requise.

Marquer le tuyau et le raccord afin

de pouvoir aligner de nouveau le

joint.

Appliquer la colle sur une

zone de 1 po de largeur à

l'extérieur du tuyau. Insérer

le tuyau dans le raccord avec

les marques d'alignement

à une distance d'un quart

de tour l'une de l'autre. Enfoncer

rapidement le tuyau et tourner le

raccord pour aligner les marques

et répandre la colle. Laisser la

colle sécher pendant une minute.

COLLAGE DU TUYAU FLEXIBLE

S'assurer que les extrémités du tuyau flexible sont égales.

Au moment de joindre le tuyau flexible au tuyau en plastique

ou à la plaque de montage d'une prise, appliquer la colle à

l'intérieur du tuyau flexible et à l'extérieur du tuyau en plastique

ou de la bague de tuyau de la plaque de montage. Tourner les

2 pièces pour étaler la colle. Attendre 5 minutes pour laisser la

colle sécher dans le tuyau flexible.

FIXATION DU FIL

D’ALIMENTATION À LA

TUYAUTERIE

Le fil d'alimentation basse tension

court le long de la tuyauterie.

Utiliser du ruban isolant pour le

fixer à la tuyauterie, à intervalles

de 12 po à 18 po.

AO0010

AO0011

PRISE MURALE

DÉCOUPE DE LA PRISE MURALE

La prise murale doit être située à 18 po du centre à partir du

plancher et en ligne directe avec l'orifice de la tuyauterie de

prise d’aspiration du grenier ou du sous-sol qui a déjà été

percé dans la lisse ou le chevêtre. La découpe de la prise doit

être exactement de 37∕8 po de hauteur par 27∕8 po de largeur.

FIXATION DE LA PLAQUE DE MONTAGE

(V144)

Repérer la tuyauterie d'aspiration à travers l'orifice de la prise

d'aspiration. Sortir ensuite le tuyau d'aspiration à travers le point

d'accès, puis retirer

le fil basse tension de

l'intérieur du tuyau.

Retirer la bride de

clouage de la plaque de

montage de la prise

murale (voir ci-contre).

Enduire de colle

l'intérieur du tuyau

flexible et l'extérieur de

la bague de la plaque de

montage. Insérer la bague de la plaque de montage dans le

tuyau flexible en tournant afin de bien répartir la colle, puis

aligner la plaque de montage pour qu'elle soit en position

verticale.

Dénuder maintenant l'extrémité des deux fils basse tension,

puis les connecter aux bornes à vis situées au dos de la plaque

de montage. Lorsque tous les fils sont connectés, assembler

le couvercle de la prise d'aspiration sur le protège-tube et la

plaque de montage.

ASSEMBLAGE

FINAL DE

L'ENSEMBLE DE

PRISE MURALE

Après avoir fixé la plaque

de montage au tuyau

flexible, passer le fil

basse tension à travers

le trou de câblage qui

se trouve dans la partie

supérieure de la plaque

de montage.

INSTALLATION

DE LA PRISE

MURALE (V111)

Installer la prise murale

dans la découpe du mur

(le couverce de la prise

demeure à l’extérieur).

Maintenir la prise murale

en place et serrer

chacune des vis de quelques tours à la fois.

4

AR0040

PRISE

AE0024F

AO0045

PLAQUE

DE MONTAGE

Page 21

INSTALLATION SOUS UNE ARMOIRE V800W CANSWEEP

Aligner le gabarit

MD

(découpé sur la

présente feuille

d’instruction) sur le

coup de pied à la

position désirée, et

tracer le contour de

la surface.

Gabarit

Tailler l’ouverture

désirée et marquer

discrètement le

centre de l’ouverture

sur le plancher.

Marquer le centre

MD

6¾ po

GABARIT

V800W CANSWEEP

2⅜ po

Si jamais l’ouverture a été taillée trop grande,

une moulure est offerte (pièce n V801W)

pour créer une couverture parfaite.

Percer un

petit trou de

référence le

long de la

ligne centrale

derrière le

coup-de-pied

à travers le

sous-plancher.

Repérer le trou

de référence à

partir du dessous

du sous-plancher.

Tailler un trou

d’accès de

4 po x 4 po à la

position choisie,

le long de la ligne

centrale sous le coup-de-pied.

Ouverture du

coup-de-pied

Trou de

référence

Espace de l'armoire

Retrait

Trou d'accès

de 4 po x 4 po

Moulure

5

Page 22

INSTALLATION SOUS UNE ARMOIRE V800W CANSWEEPMD (SUITE)

Fig. A

Fig. B

Souder ensuite au solvant

un raccord sur un bout de

tuyau d’aspirateur central

de 2 po, assez long pour

atteindre le trou d’accès

de 4 po x 4 po à partir de

l’ouverture sur le

coup-de-pied (Fig. A).

Ajuster par friction l’autre

bout du raccord au

CanSweep

qu’il soit bien fixé. N’utiliser

pas de colle, ajuster par

friction seulement (Fig. B).

MD

jusqu’à ce

Insérer le

CanSweepMD/tuyau

dans l’ouverture sur

le coup-de-pied.

Utiliser un raccord

coude de 90° pour

déterminer une

marque de coupe

à l’autre bout du

tuyau. Puis, couper

le tuyau au niveau de la marque.

Glisser les fils de

basse tension dans

les agrafes du

CanSweep

conformément à

l’illustration pour

finaliser la

connexion

des fils.

MD

Glisser le

CanSweepMD/tuyau

et les fils à basse

tension dans

l’ouverture sur le

coup-de-pied.

Coller les deux

bouts du coude

sur le système de

tuyaux puis fixer le

CanSweepMD au coup-de-pied à l’aide des 2 vis fournies.

Vis

Coller le coude

au tuyau

6

Page 23

INSTALLATION SUR UNE PLINTHE V800W CANSWEEP

Ne pas coller le

Choisir la position désirée

sur la plinthe entre deux

montants. Placer le

gabarit (découpé sur la

présente feuille

d’instructions) à la position

voulue et tracer le contour

de la surface.

Gabarit

Effectuer les raccords

de tuyaux

nécessaires et

installer le raccord

coude de 90° en position

derrière le CanSweepMD.

S’assurer que l’ouverture du coude se fixe fermement

sur le bout uni au dos du CanSweepMD au moment du

raccordement.

CanSweepMD au

coude.

Fixer les fils

Taillez l’ouverture

sur la plinthe et

dans la cloison

sèche jusqu’à ce

que la lambourde

de 2 po x 4 po

soit atteinte.

Lambourde de 2 po x 4 po

MD

Contre le bord de la

lambourde de 2 po x 4 po,

marquer le centre de

l’ouverture.

Marquer le centre

Lambourde de

2 po x 4 po

Trou de

Trou de référence

Percez un petit trou de référence

au niveau de la marque, à travers le

sous-plancher jusqu’en dessous.

Repérer le trou de référence en partant

du dessous et mesurer un retrait

de 1 7/8” po. Utiliser une scie-cloche

de 2 po pour retirer la section de

lambourde de 2 po x 4 po derrière l’ouverture.

référence

1⅞

po

Glissez les fils de basse tension dans les agrafes du

CanSweepMD conformément à l’illustration pour finaliser

la connexion des fils.

Glisser le

CanSweepMD et

les fils de basse

tension dans

l’ouverture de la

plinthe.

Ajuster par

friction le bout

uni du CanSweepMD sur le coude. Fixer le CanSweepMD

sur la plinthe à l’aide des deux vis fournies.

7

Page 24

INSTALLATION DE L'UNITÉ MOTRICE

!

AVERTISSEMENT

Ne pas installer à l’extérieur. Avant de l'accrocher,

déposer l'appareil sur une surface plane pour éviter

qu'il ne bascule. Lors de l'installation, de l'entretien

ou du nettoyage de l'appareil, il est recommandé de

porter des lunettes et des gants de sécurité.

EMPLACEMENT DE L'UNITÉ

MOTRICE

• Installer l'unité motrice le plus à l'écart possible de la zone

habitée de la maison, dans un endroit facilement accessible

pour effectuer le nettoyage et l’entretien.

• Installer l'unité motrice à moins de 6 pi d'une prise de courant

avec mise à la terre. L’unité motrice requiert une prise de

120 V c.a. reliée à un circuit de dérivation distinct de 15 A.

• Ne pas installer l'unité motrice près d'une source de chaleur

élevée (par exemple un chauffe-eau) ou dans un endroit où la

température ambiante est élevée (grenier, salle de chaudière).

• Si l'unité motrice est installée dans un placard ou une

petite buanderie, s'assurer que la pièce soit bien aérée (par

exemple au moyen d'une persienne).

CHANGEMENT DE L'ORIENTATION

DE LA LIGNE D'ASPIRATION

La ligne d'aspiration se raccorde à droite de l'appareil. Toutefois,

il est possible de changer cette configuration; pour raccorder la

ligne d'aspiration à gauche de l'appareil, veuillez suivre ces étapes :

Libérer les 2 loquets situés sur les côtés de l'unité motrice

en les tirant vers l’extérieur, puis en les poussant vers le

haut. Retirer le récipient à débris.

BQ550

BQ550 et BQ500KIT

: Saisir les rebords du

col du sac et tirer vers

le bas. Ne pas tirer

sur le sac. Mettre le

sac de côté.

ET BQ500KIT

Tous les appareils :

Désassembler le

coude d'admission de

l'arrière de l'appareil à

l'aide d'une douille de

3/8 po pour retirer ses

2 écrous et ses 2 vis

de retenue.

AD0076

Tous les appareils :

Retourner le coude

d'admission à 180°

puis le réassembler à

l'appareil, en prenant

soin de placer son

joint d'étanchéité à sa

position originale.

NOTE : S'assurer que le joint d'étanchéité n'est pas plié

pour éviter de générer une baisse d'aspiration et du bruit.

BQ550 et BQ500KIT :

Réassembler

l'adaptateur du sac au

coude d'admission.

Aligner le triangle

avec la petite tige

inclinée, puis serrer la

jonction à l'aide la vis

et de l'écrou retirés

précédemment en

BQ550 et BQ500KIT :

Remettre le sac en

place en saisissant

les rebords de son col

du sac et l’insérer sur

l’adaptateur. Attention

de ne pas déchirer le

sac. S’assurer que le

col du sac est placé

entre la bague et la

butée de l’adaptateur.

AD0077

BQ550 ET

BQ500KIT

.

AD0078

BQ550 ET

BQ500KIT

AO0080

BAGUE

BUTÉE

Tous les appareils : Remettre en place le récipient à débris.

AO0078

BQ550 et BQ500KIT

: À l'aide d'un

tournevis Phillips n° 2,

enlever la vis serrant

la jonction entre

l'adaptateur du sac et

le coude d'admission.

Dégager l'adaptateur

du coude et le mettre

de côté avec la vis et

l'écrou.

BQ550

ET BQ500KIT

AD0075

8

Page 25

INSTALLATION DE L'UNITÉ MOTRICE (SUITE)

É

MONTAGE DE L'UNITÉ MOTRICE

Retirer délicatement le récipient à débris. S’assurer que le

sac jetable est correctement installé (appareils BQ550 et

BQ500KIT). Retirer la trousse d’installation et remettre en

place le récipient à débris.

Consulter l'illustration ci-dessous pour s'assurer de

respecter les dégagements minimaux aux murs et plancher.

DIMENSIONS MINIMALES DE D

VUE DU

DESSUS

12 po

minimum

12 po minimum

du plafond

GAGEMENT

12 po

minimum

AD0079F

TROUS DE

FIXATION

SUPÉRIEURS

TROUS DE

FIXATION

INFÉRIEURS

1 po TYP.

C

L

18 ¹/ 8 po18 ¹/ 8 po

3/4 po TYP.

32 7/8 po

HAUTEUR

MINIMALE

DE 45¼ po

VUE AVANT

18 po minimum

du plancher

AD0039F

Positionner et fixer le support mural à l’aide des vis fournies.

Voir l'illustration de la colonne de droite pour les dimensions

relatives au montage.

ATTENTION

Pour une installation solide, s'assurer de visser le

support mural directement sur un montant.

À l'aide des vis de montage fournies, fixer le support au

mur en utilisant un trou de fixation supérieur et un trou de

fixation inférieur.

Accrocher l'unité motrice au support mural. S'assurer que

les supports arrière de l'unité motrice sont imbriqués avec

les doigts du support mural correspondants (ou doigts et

patte, modèles BQ550 et BQ500KIT; voir l'illustration cidessous). Abaisser l'unité motrice afin de la fixer solidement

au support.

BQ650 ET BQ700

BQ550 ET BQ500KIT

AD0074

9

Page 26

INSTALLATION DE L'UNITÉ

!

INSTRUCTIONS DE MISE À

MOTRICE (

SUITE)

RACCORD DE LA LIGNE

PRINCIPALE À L'UNITÉ MOTRICE

Raccorder la tuyauterie d'aspiration au coude situé à

l'arrière de l'unité motrice. Insérer l'extrémité du tuyau dans

l'ouverture du coude et serrer l'assemblage en vissant à la

main la vis et l'écrou fourni (voir ci-dessous).

NE PAS COLLER.

RACCORD TYPE DE LA LIGNE

D'ASPIRATION À L'UNITÉ MOTRICE

VIS ET ÉCROU

DU SAC

DE PIÈCES

LIGNE D'ASPIRATION

LA TERRE

AVERTISSEMENT

Le branchement non approprié du conducteur de

mise à la terre de l'appareil entraîne des risques

d'électrocution. En cas de doute, demander à un

électricien qualifié ou à un technicien d'entretien

de vérifier la prise pour s'assurer qu'elle soit bien

mise à la terre. Ne pas modifier la fiche du cordon

d'alimentation de l'appareil. Si elle ne peut se

brancher dans la prise de courant actuelle, faire

installer une nouvelle prise par un électricien qualifié.

Instructions de mise à la terre : Cet appareil doit être mis à

la terre. En cas de bris ou de défaillance, la mise à la terre

constitue un trajet de moindre résistance pour l'évacuation du

courant électrique, réduisant ainsi le risque d’électrocution.

Cet appareil est muni d'un cordon d'alimentation comportant

un fil de mise à la terre et une fiche avec une troisième broche

pour mise à la terre. Cette fiche doit être branchée dans une

prise de courant avec mise à la terre et installée conformément

aux codes et aux règlements locaux en vigueur.

CÂBLAGE

AJ0001

Raccorder la tuyauterie d'évacuation à la prise d'évacuation

située sur le dessus ou le côté de l'appareil, selon le modèle.

NE PAS COLLER.

NOTE POUR L'APPAREIL BQ700 SEULEMENT

Si désiré, le raccord ou le coude utilisé pour relier la ligne

d'évacuation

au dessus de

l'appareil peut

être fixé à l'aide

de deux vis de

5/8 po incluses.

Voir l'illustration

ci-contre.

S'assurer que

tous les joints de

tuyauterie sont

étanches.

AJ0003

L'évacuation NE doit PAS se faire dans un mur, un plafond ou

un espace clos de la maison. Il est recommandé d'évacuer

l'air aspiré à l'extérieur. La ligne pour l'évacuation à

l'extérieur doit être dotée d’un capuchon mural, modèle V145.

NOTE : Pour une qualité de l'air intérieur optimale,

l'évacuation extérieure de l'air provenant de

l'unité motrice est recommandée, mais n’est pas

obligatoire.

Cet appareil est conçu pour se brancher à une prise de

courant de 120 V c.a. avec circuit de dérivation distinct de 15 A

et prise NEMA 5-15R. S'assurer que l'appareil est branché

dans une prise et muni d’une fiche tripolaire qui ressemble à

celle illustrée ci-dessous. Aucun adaptateur ne doit être utilisé

avec cet appareil.

RACCORDS

À SERTIR

CONNECTÉS

AUX BORNES

BASSE TENSION

PRISES AVEC

MISE À LA TERRE

FIL DES PRISES

VERS

LES

AUTRES

PRISES

AE0044

PRISE

BROCHE DE MISE

À

LA TERRE

P

RISE PRISE

MODÈLE V133 FIL

BASSE TENSION (22/2)

NOTE : Les fils des prises doivent être connectés aux bornes

basse tension de l'unité motrice à l'aide des raccords

à sertir (inclus dans le sac de pièces) et du faisceau

de fils basse tension.

10

Page 27

FONCTIONNEMENT ET ENTRETIEN

Au moment de passer l'aspirateur, ouvrir le couvercle de la

prise d'aspiration murale et insérer l'extrémité du boyau dans

la prise.

Pour les boyaux non munis d'un interrupteur, l'insertion du

boyau dans une prise met automatiquement en marche l'unité

motrice, laquelle s’arrête dès le retrait du boyau. Certains boyaux

sont munis d'un interrupteur qui peut être utilisé pour mettre

en marche l'unité motrice. L'interrupteur MARCHE/ARRÊT

situé sur l'unité motrice doit demeurer en position ARRÊT.

La saleté et la poussière sont ainsi acheminées vers l'unité

motrice où elles demeurent dans le sac jetable ou dans le

récipient à débris (selon le modèle d'unité motrice).

Utiliser les accessoires de nettoyage de la même manière que

pour tout autre modèle d'aspirateur. Éviter d'aspirer de gros ou

de longs débris car ils peuvent se coincer dans le boyau ou

la tuyauterie.

QUAND REMPLACER LE SAC* OU

VIDER LE RÉCIPIENT À DÉBRIS

En conditions normales, le sac/récipient d'une capacité de

6 gallons américains (22,7 litres) nécessite d’être remplacé/

vidé environ deux fois par année. Si le sac/récipient est rempli,

vous remarquerez l’absence d’aspiration dans le système. À

moins que cette absence d’aspiration ne soit causée par une

obstruction dans le système, remplacer le sac jetable ou vider

le récipient à débris corrigera le problème.

NOTE : Même s’il n’est pas rempli à pleine capacité, si le sac

semble tendu lors du retrait du récipient à débris,

remplacer le sac jetable préviendra que celui-ci ne

se déchire.

* Seuls les appareils BQ550 et BQ500KIT sont munis d'un sac

jetable (391C).

COMMENT VIDER LE RÉCIPIENT À

DÉBRIS (UNITÉS MOTRICES BQ650

ET BQ700 SEULEMENT)

VUE DÉTAILLÉE DES UNITÉS

MOTRICES BQ550 ET BQ500KIT

PRISE

FILTRE EN MOUSSE

POUR MOTEUR

COMPARTIMENT

PRESSURISÉ

SAC JETABLE

AL0009

D'ÉVACUATION

PRISE

D'ADMISSION

ADAPTATEUR DU SAC

LOQUET

R

ÉCIPIENT

À DÉBRIS

REMPLACEMENT DU SAC JETABLE

(UNITÉS MOTRICES BQ550 ET

BQ500KIT)

Pour retirer le sac jetable, libérer les deux loquets situés sur

les côtés de l'unité motrice en les tirant vers l’extérieur, puis

en les poussant vers le haut. Retirer le récipient. Saisir les

rebords du col du sac et tirer vers le bas. Ne pas tirer sur le

sac.

Déplier le nouveau sac.

Saisir le col du sac à l’endroit indiqué sur le sac et l’insérer

sur l’adaptateur. Attention de ne pas déchirer le sac.

S’assurer que le col du sac est placé entre la bague et la

butée de l’adaptateur (voir l’illustration ci-dessous). Remettre

le récipient en place.

Pour vider le récipient à débris, libérer les 2 loquets situés sur les

côtés de l'unité motrice en les tirant vers l’extérieur, puis en les

poussant vers le haut. Abaisser le récipient de l'unité motrice

en le tenant par les loquets. Vider le contenu du récipient dans

un contenant à déchets. Remettre le récipient en place.

BAGUE

AO0081

11

BUTÉE

Page 28

FONCTIONNEMENT ET ENTRETIEN (SUITE)

FILTRE PERMANENT (UNITÉS

MOTRICES BQ650 ET BQ700

SEULEMENT)

Ce filtre protège le moteur et empêche les petites particules

de s'échapper à l'extérieur de l’unité motrice et puisqu’il est

permanent, nul besoin de le remplacer. Le filtre se nettoie de

lui-même en se soulevant lors du démarrage de l'unité motrice,

puis en s'abaissant lors de l’arrêt. En conditions normales

d'utilisation, ce filtre ne requiert aucun entretien. Il est possible

de le retirer pour inspecter le filtre en mousse pour moteur ou

pour le remplacer si jamais il était endommagé (par des débris

coupants, par exemple).

RETRAIT ET INSTALLATION DU

FILTRE PERMANENT (UNITÉS

MOTRICES BQ650 ET BQ700

SEULEMENT)

Retirer le récipient à débris

de l'unité motrice. Pour

retirer le filtre permanent,

tirer sur la languette (A)

située sur le rebord du

filtre, dégager le filtre du

compartiment d’admission

en le pressant sur lui-même,

puis le sortir délicatement

de l’unité.

AD0084

A

FILTRE EN MOUSSE POUR MOTEUR

(TOUS LES APPAREILS)

Un filtre de sécurité en mousse pour moteur, situé en haut du

compartiment pressurisé, offre une protection au moteur si le

sac jetable ou le filtre permanent se déchirait accidentellement.

Ce filtre doit être vérifié et nettoyé au besoin lorsque le sac

est remplacé (appareils BQ550 et BQ500KIT seulement), ou

lorsque le filtre permanent a été retiré (appareils BQ650 et

BQ700 seulement). Un simple brossage du filtre suffit. Si le

filtre est très sale, le laver à la main dans une solution d'eau et

de détergent doux, le rincer et le laisser sécher complètement

sur une surface plane avant de le remettre en place.

ATTENTION

Faire fonctionner l’unité motrice sans le filtre en

mousse pour moteur annulera la garantie.

RETRAIT DU

FILTRE EN

MOUSSE POUR

MOTEUR

Retirer le récipient à débris

ainsi que le sac jetable ou

le filtre permanent. Soulever

par le centre la broche de

retenue du filtre en mousse

pour moteur pour le glisser

hors de son emplacement.

Presser le filtre afin de le

faire passer par-dessus

l'ouverture d'admission (B).

Relâcher la pression sur le

filtre pour que celui-ci se

déploie contre les parois de

l'unité motrice. S'assurer de

placer le cerceau rigide dans

sa rainure afin d'assurer

une bonne étanchéité.

NOTE : S’assurer que le filtre

est installé de façon à

ce que la languette (A)

soit accessible pour un

éventuel retrait du filtre.

AD0085

A

B

AA0005

REMISE EN PLACE

DU FILTRE EN

MOUSSE POUR

MOTEUR

Inverser les étapes décrites

ci-dessus afin de replacer le

filtre en mousse pour moteur.

ATTENTION

S’assurer de réinstaller correctement le filtre pour

protéger adéquatement le moteur.

AD0086

12

Page 29

ACCESSOIRES (BQ500KIT SEULEMENT)

ACCESSOIRES INCLUS

B Brosse standard pour plancher

C Boyau standard de 30 pi de longueur

D Support de boyau

E Manchon télescopique pour les accessoires statiques

F Brosse à épousseter ronde

G Brosse à capitonnage

H Embout plat biseauté

I Sac de rangement

E

C

D

INSTALLATION DU SUPPORT DE

BOYAU

Fixer le support au mur à

l'aide des deux vis incluses.

Selon l'endroit choisi, il peut

être nécessaire d'utiliser des

douilles à expansion (non

incluses).

AA0023

Enrouler le boyau sur son

support pour le ranger.

AA0024

VIS

AA0056

I

G

B

F

H

13

Page 30

GUIDE DE DÉPANNAGE

PROBLÈMES CAUSES POSSIBLES MESURES CORRECTIVES

1. Perte ou diminution de

la puissance d’aspiration.

2. L’unité motrice ne

démarre pas ou

s’arrête de façon

soudaine.

• Le récipient à débris ou le sac jetable est rempli

à pleine capacité.

• Le joint d'étanchéité du récipient à débris est

endommagé ou manquant.

• Le boyau est obstrué. Insérer le boyau dans

une prise d'aspiration murale, puis pendant

que l'unité motrice fonctionne, vérifier chacune

des prises d’aspiration pour voir si la puissance

d'aspiration est normale en maintenant la

paume de la main sur l'entrée d'aspiration

ouverte. Si la puissance d'aspiration de toutes

les prises d’aspiration est normale, insérer le

boyau dans une deuxième prise murale. Si le

blocage est toujours présent, cela signifie que

le boyau est bouché. Toutefois, si le blocage ne

se produit plus après avoir changé le boyau,