Broan 52WH254DP, 52WH304PF, 52WH254DPF, 52WH304DP, 52WH304DPF Installation Instructions Manual

...Page 1

MODEL: 52WH254DP, 52WH254DPF,

52WH304P, 52WH304PF,

52WH304DP, 52WH304DPF

RECESSED MOUNTED,

STEEL MEDICINE CABINETS

INSTALLATION INSTRUCTIONS

MODEL WALL OPENING OVERALL SIZE

NO. W H D W H D

52WH254DP 191/424 4 20 25 5

52WH254DPF 191/424 4 20 25 5

52WH304P 231/429 4 24 30 5

52WH304PF 231/429 4 24 30 5

52WH304DP 231/429 4 24 30 5

52WH304DPF 231/429 4 24 30 5

1. Carefully remove all packing material. Place

hardware packages, shelves and door aside until

needed. Hardware and shelves are located in the

fillers identified by “Hardware enclosed” tape.

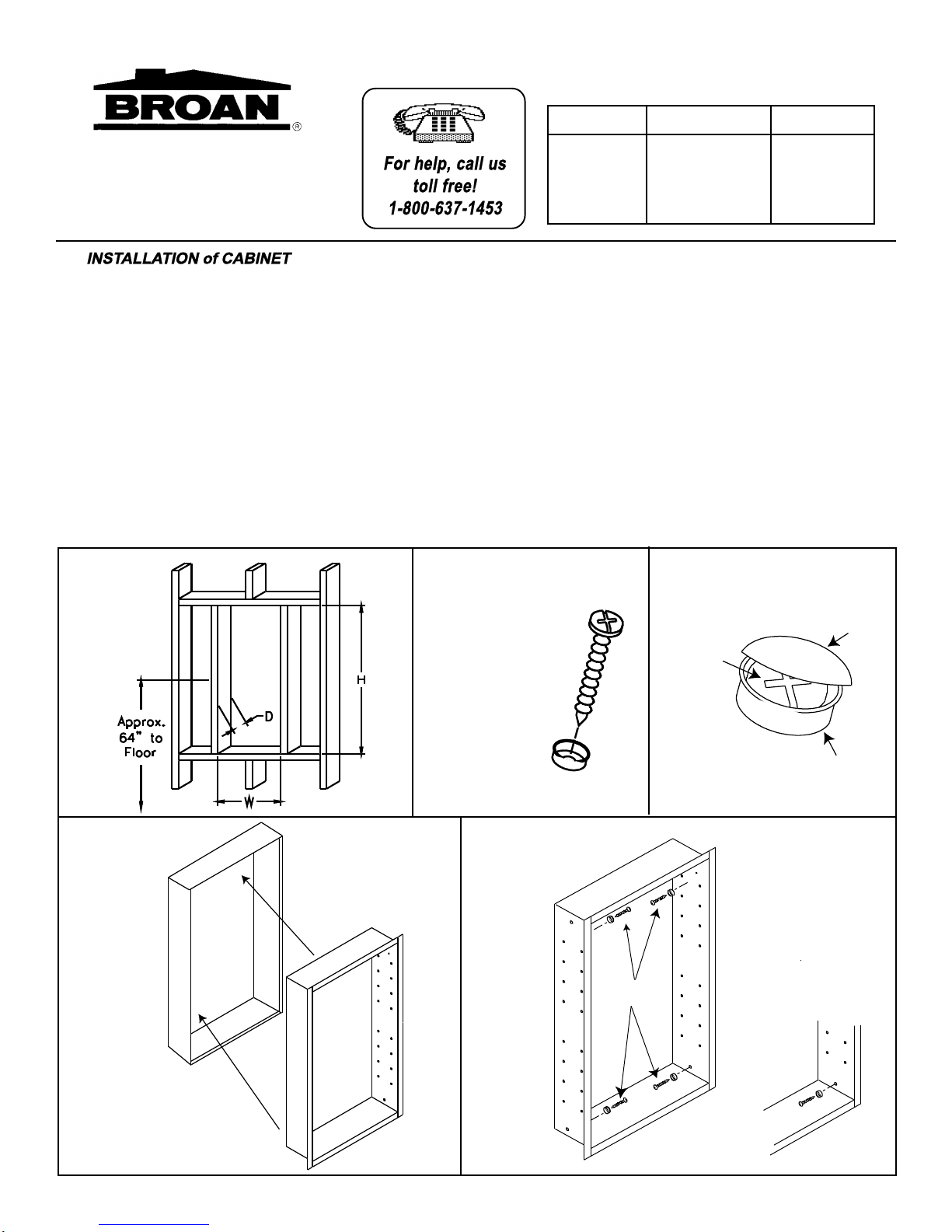

2. Determine desired location of cabinet on wall.

Mark wall to show wall opening size (see

dimension chart). Generally, the recommended

height to the center of the cabinet is 64” from the

floor. (Fig. 1)

3. CAUTION: Wall studs, plumbing or electrical lines

that interfere must be removed or relocated. Cut

wall opening, being careful not to damage the

surrounding wall surface. Insert framing to

support all plaster board edges.

Fig. 1

Insert screw

through clear

plastic base

4. Prepare the mounting screws by placing the

screws into the clear plastic bases. (Fig. 2)

5. Note: For ease of installation, an additional person is

recommended. Insert cabinet into wall opening.

(Fig.3) Ensure the cabinet is plumb and level. If

necessary use a carpenter’s level and shim corners of

cabinet. Secure to wall studs through the four (4)

mounting holes inside cabinet, using the screws that

have been placed into the plastic bases. (Fig. 4) Do

not over tighten the mounting screws as the body

side wall may bend and prevent proper shelf

installation. Only tighten screws until they are

flush with the body.

6. Snap the screw covers over the screw bases.

(Fig.5)

Fig. 2

Fig. 5

Snap on Cover

Screw

Cover

Fig. 3

Wall

Opening

Cabinet

Body

Base

Fig. 4

Mounting

Screws

Mounting

screw into

mounting

hole

Page 2

1. Remove hinges and screws from hardware

bag. Mount hinge unit on door as shown in

Fig. 6 and Fig. 7 securing with screws

provided.

2. Install the door by inserting door side of the

hinge into the bracket on the body as shown;

A) 125 degree hinge

Insert door side of clip hinge as shown

in Fig. 8

B) 170 degree hinge

Insert door side of clip hinge as shown

in Fig. 9

3. Check door for proper alignment. If the door

needs to be adjusted please refer to the

adjustment procedures in Fig. 10 and

Fig. 11. Door edges should be aligned with

the edges of the body and should fit evenly

to the face of the body.

4. 125 degree hinge only: Snap on hinge

cover plate. (Fig. 12)

Fig. 6

Fig. 7

125 Degree Hinge

Mounted to Door

170 Degree Hinge

Mounted to Door

Fig. 8

125 Degree Hinge

mounted to Cabinet

Press down

on hinge until

it clips in place

Fig. 10

125 Degree Hinge

This screw

for depth

adjustment

This screw

for left and right

adjustment

Hook bottom of

hinge into place

on the bracket

This screw for

up and down

adjustment

Fig. 11

170 Degree Hinge

This screw

for depth

adjustments

This screw

for left and right

adjustments

Fig. 9

This screw for

up and down

adjustments

170 Degree Hinge

Mounted to Cabinet

Press down

on hinge until it

clips in place

Hook bottom of

hinge into place

on the bracket

Fig. 12

Hinge Cover

2

Page 3

1. Select where you want the shelves to

be placed.

2. Insert two (2) shelf brackets at each

endof the shelf location. (Fig. 13)

3. Set shelves in place on the shelf

brackets, pressing down on shelf to lock

in place. (Fig. 13)

4. Remove hole plugs from hardware bag

andplace in remaining holes. ( Fig. 14)

5. Remove bumpers from hardware bag

andposition to body. (Refer to Service

Parts Drawing - Key No. 9 for bumper

locations).

•Use only clean warm water and a

clean, soft, lint-free cloth.

•DO NOT USE cleaners that contain

solutions of ammonia, vinegar, or chlorine.

•DO NOT USE powdered cleansers or

steel wool.

•Never spray cleaning agent directly on

mirror, especially on exposed edges and

mirror backing. Apply cleaner to soft

cloth and wipe mirror. Dry mirror

thoroughly.

•Keep mirror dry. A well ventilated bath

room is important.

Fig. 14Fig. 13

BROAN-NUTONE ONE YEAR LIMITED WARRANTY

Broan-NuTone warrants to the original consumer purchaser of its product that such products will be free from defects in

materials or workmanship for a period of one year from the date of original purchase. THERE ARE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

During this one-year period, Broan-NuTone will, at its option, repair or replace, without charge, any product or part which is

found to be defective under normal use and service.

THIS WARRANTY DOES NOT EXTEND TO FLUORESCENT LAMP STARTERSAND TUBES. This warranty does not cover (a)

normal maintenance and service or (b) any product or parts which have been subject to misuse, negligence, accident,

improper maintenance or repair (other than by Broan-NuTone), faulty installation or installation contrary to recommended

installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states

do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

BROAN-NUTONE’S OBLIGATION TO REPAIR OR REPLACE, AT BROAN-NUTONE’S OPTION, SHALL BE THE PURCHASER’S

SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY. BROAN-NUTONE SHALL NOT BE LIABLE FOR INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH PRODUCT USE OR PERFORMANCE.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

This warranty gives you specific legal rights, and you may also have other rights, which vary from state to state. This

warranty supersedes all prior warranties.

To qualify for warranty service, you must (a) notify Broan-NuTone at the address or telephone number stated below, (b)

give the model number and part identification and (c) describe the nature of any defect in the product or part. At all time of

requesting warranty service, you must present evidence of the original purchase date.

Broan-NuTone LLC, 926 West State Street, Hartford, WI 53027

(1-800-637-1453)

3

Page 4

#"

” * * * * * *

%

&

'

(

$

'

%

$

#

+

)

*

KEY PART NUMBER

NO. DESCRIPTION 52WH254DP 52WH254DPF 52WH304P 52WH304PF 52WH304DP 52WH304DPF

1 Door Assembly A97016500 A97016501 A97016455 A97016456 A97016457 A97016458

2 Hinge Assm w/screws A97016214 A97016214 A97016213 A97016213 A97016214 A97016214

3 Screw, hinge (4 req.) A99160423 A99160423 A99160423 A99160423 A99160423 A99160423

4 Hole Plug A99111239 A99111239 A99111239 A99111239 A99111239 A99111239

5 Screw cover & base A99111240 A99111240 A99111240 A99111240 A99111240 A99111240

6 Mounting Screw

7 Shelf supports A99111223 A99111223 A99111223 A99111223 A99111223 A99111223

8 Shelf, glass A99050307 A99050307 A99050303 A99050303 A99050303 A99050303

9 Bumpers 7189 7189 7189 7189 7189 7189

10 Hinge cover --- --- A99111249 A99111249 --- ---

* Standard hardware - may be purchased locally.

Order replacement parts by “PARTNUMBER” - NOTby KEY NO.”

#8 x 11/

2

4

Loading...

Loading...