Page 1

This document is a supplement

to the Operating & Maintenance

Instructions for the engine that

powers this on-board generator.

This POWERLINK system includes the engine, an inverter,

and a Ground Fault Circuit Interrupter (GFCI). The GFCI is a

receptacle which protects against electrical shocks. A GFCI

detects ground faults.

If a ground fault is detected, the GFCI will interrupt the circuit

when it detects a difference in electric current. One type of

ground fault occurs when electricity flows through a person to

an earth ground instead of following the normal safe path.

Please be aware that the GFCI is not fail proof. Most brands are

susceptible to failures from power surges such as nearby

lightening strikes. For this reason and for your protection,

Briggs & Stratton makes the recommendation that the GFCI

gets tested before every use of the POWERLINK system. If

found to be defective, it must be replaced by an Authorized

Service Dealer before further use.

Also, please note that the GFCI does not protect from serious

electrical shocks resulting from contact between the system

neutral (white wire) and the “hot lead” (black wire). See listed

warnings within this document for further clarification on

hazards and how to avoid them.

The POWERLINKE Operating Instructions

contain safety information to:

• Make you aware of hazards associated with the

POWERLINK On-Board Generator System.

• Inform you of the risk of injury associated with those

hazards, and

• Tell you how to avoid or reduce the risk of injury.

Need assistance?

www.briggsandstratton.com

Go to

for information.

Or call,

1-800-233-3723, (U.S.A. and Canada)

to hear a menu of pre-recorded messages

offering engine maintenance information.

Read and follow all Safety Information and Instructions

before first use of this product. Keep these instructions for

future reference.

Failure to follow instructions could result in serious injury

or death. The safety alert symbol is used to identify safety

information about hazards which can result in death,

serious injury, and/or property damage.

DANGER indicates a hazard which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazard which, if not avoided, could

result in death or serious injury.

CAUTION indicates a hazard which, if not avoided, might

result in minor or moderate injury.

CAUTION, when used without the alert symbol, indicates

a situation that could result in damage to the engine.

SHOCK indicates a hazard which, if not avoided, could

result in death, serious injury, and/or property damage.

FIRE indicates a hazard which, if not avoided, could

result in death, serious injury, and/or property damage.

HOT SURFACE indicates a hazard which, if not avoided,

could result in death, serious injury, and/or property

damage.

TOXIC FUMES indicates a hazard which, if not avoided,

could result in death, serious injury, and/or property

damage.

SEVERING OF HANDS, OR FINGERS indicates a

hazard which, if not avoided, could result in death, or

serious injury.

SEVERING OF FINGERS indicates a hazard which, if not

avoided, could result in death, or serious injury.

PRINTED IN U.S.A. Copyright 2004 by Briggs & Stratton Corporation FORM NO. 275214-1/04

Page 2

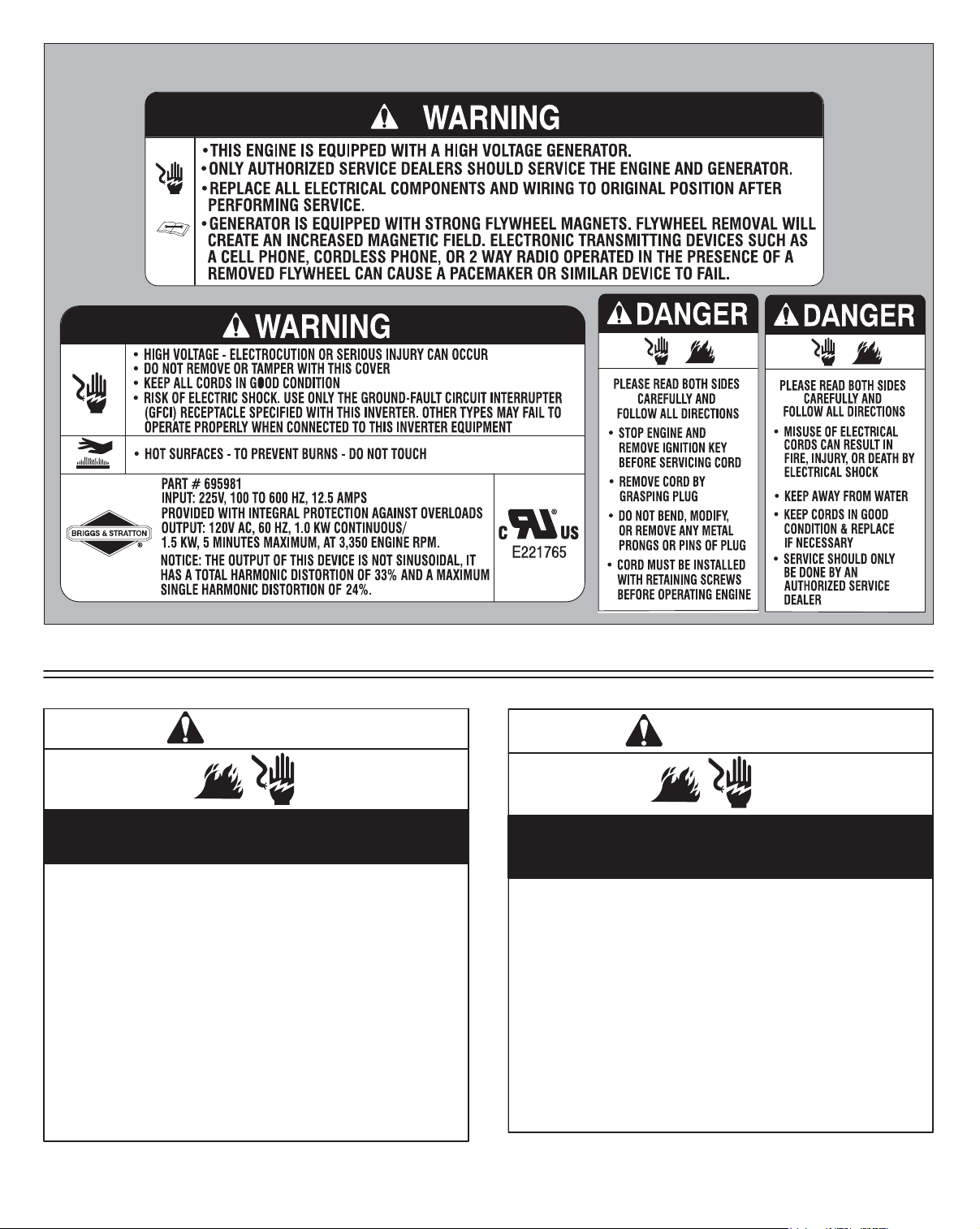

These labels warn of potential hazards that can result in death or serious injury.

Read and understand them before operating the equipment.

WARNING

Improper maintenance or repair could result in death,

serious injury and/or property damage.

An Authorized Service Dealer should perform all service.

Do not perform any maintenance on the POWERLINK

On-Board Generator System with the engine running. Stop

the engine and remove the spark plug wires from the spark

plugs.

Do not perform any modifications to the POWERLINK

On-Board Generator System, the inverter, or the GFCI

receptacle.

Do not remove cover on the GFCI receptacle.

The GFCI receptacle must be serviced with original factory

approved GFCI receptacle, and which conforms to N.E.C.

requirements. See listing under Service and Maintenance.

Never tamper with engine governed speed.

WARNING

Improper operation could result in death, serious injury and/or

property damage.

Never use unit as a backup alternative for a main power source.

Never connect the POWERLINK On-Board Generator

System to the electrical system of a building. Doing so could

cause a power back feed that may electrocute utility workers or

others who come in contact with the line.

Never operate without the factory installed GFCI receptacle.

GFCI receptacle will not protect you against:

• Line-to-line shocks (like the kind you get by touching

metal in both straight slots of a receptacle)

• Current overloads

• Line-to-line short circuits

Page 3

WARNING

WARNING

The POWERLINK On-Board Generator System produces

electricity that could result in death, serious injury and/or

property damage if proper precautions are not followed.

Never handle any kind of electrical cord or device while

standing in water, or while barefoot, or while hands and/or feet

are wet.

Do not operate unit:

• in rain.

• if electrical cord or device, which is plugged into the GFCI

receptacle over heats.

• if electrical output is lost.

• if flame, spark or smoke is observed while unit is running.

Maintain and use proper sized electrical cord sets and extension cords per electrical device specification. Use cords rated

for no less than 15 amps.

Use cords which are in good condition. Never use worn, bare,

frayed or otherwise damaged cord sets.

Avoid contact with bare wires, terminals, and damaged cords.

Keep extension cord lengths at minimum possible length. Long

extension cords draw additional power.

Running the POWERLINK On-Board Generator System

produces heat.

Severe thermal burns can occur on contact.

Avoid contact with hot surfaces, such as the inverter.

DANGER

The engine used in the POWERLINK On-Board

Generator System gives off carbon monoxide, an odorless,

colorless, and poisonous gas.

Breathing carbon monoxide can cause nausea, fainting, or

death.

Never run POWERLINK On-Board Generator System in an

enclosed area, even if doors or windows are open.

THE POWER IN POWERLINK

The POWERLINK On-Board Generator System will operate

continuously at 1000 watts output, and up to 1500 watts for brief

periods. Operating at loads above 1000 watts continuously may

trigger the POWERLINK system to reset and halt the electrical

output needed to power the load. The system produces 120 volts, 60

cycle AC electrical power. Prior to connecting any electrical device,

ensure compatibility of operating voltage and frequency

requirement.

The POWERLINK system output remains 120 volts throughout the

entire engine speed range. Output wattage increases with engine

speed. Select the engine speed that will power the electrical device

satisfactorily without triggering the POWERLINK reset.

CAUTION: Damage may result if the equipment

operates outside of a +/–10% voltage variation from the

rated voltage of 120V.

POWERLINK OPERATING

INSTRUCTIONS

[1] Start the engine and set the desired engine speed.

[2] No load should be applied to the engine, (Power-Take-Off

should be disengaged) and the parking brake must be

LOCKED. If these are not done, the POWERLINK system

will not operate.

[3] Actuate the POWERLINK reset switch. Move the reset

switch to the OFF position and then return it to the ON position.

[4] Plug the electrical device into the GFCI receptacle and start

device. See also, Applying Device Load.

[5] Any time the engine stops, for any reason, the POWERLINK

reset switch must be actuated. Follow the steps outlined

above. See also, Electrical Operating Power Loss.

Page 4

Applying Device Load

The electrical device requiring power should not exceed the capacity

of the POWERLINK system (See The Power in POWERLINK). It

is recommended that all electrical devices and extension cords

plugged into the GFCI receptacle have a three prong terminal. If

using more than one electrical device, plug-in and start the higher

rated load first.

WARNING

• Always ensure the device being plugged into the system is

OFF before connecting it to the GFCI receptacle.

• Check device being connected for bare wires, or frayed

electrical cords.

Types of products (requiring 1500 watts or less*) that could be

powered by the POWERLINK system:

Hedge trimmer Circular saw Lighting

Refrigerator Furnace Blower Freezer

Hand tools Chain saw String trimmer

Television Sump pump Edger

Radio Computer

*Always confirm the product’s power rating before plugging into the

POWERLINK system.

Unintentional start-up can result in

entanglement, traumatic

amputation, or laceration.

Resetting the POWERLINKE System

[1] Turn off any device or appliance that was in use prior to the loss

of electrical operating power.

[2] Verify if the RESET button on GFCI receptacle has not been

tripped.

Note: The RESET button will pop out if tripped. To

restore, press the RESET button.

[3] The engine must be running and the parking brake must be set.

[4] Actuate the POWERLINK reset switch. Move the reset

switch to the OFF position and then return it to the ON position.

For the operators safety, there is a two second delay in power

to the GFCI receptacle after reset.

TESTING THE GFCI

To ensure proper operation, and avoid injury the GFCI receptacle

should be tested before every use.

[1] Have the POWERLINK system running and the power reset.

[2] Plug in a lamp or radio for verification that electrical power is

present.

[3] Press the GFCI TEST button in order to trip the system and

stop the flow of electricity.

[4] If the device is still being powered, the GFCI is not working

properly. Seek an Authorized Service Dealer.

[5] If the power goes off, the GFCI is working properly. To restore

power, press the RESET button.

CAUTION: Do not connect a battery charger, or charge

batteries from POWERLINK. This could cause

damage to the battery charger or the POWERLINK

system.

Electrical Operating Power Loss

The POWERLINK system has safety features to protect the

system and the operator. The electrical output of the POWERLINK

system will shut down at any electrical overload caused by

temperature or a system overload.

On an overload, the reset opens and disconnects electrical power to

the GFCI receptacle, tripping the system. A manual reset switch,

located on the tractor, has been installed to reset the electrical output

of the POWERLINK system. Once reset, operating power is

returned and the work load can be reconnected.

If the system continually trips, causing the operator to reset,

increase engine speed. If engine is running at top speed and the

system is still tripping, the system is being overloaded. Decrease the

load.

If power does not resume after reset, it may be a thermal overload.

Wait 15 minutes before actuating the reset.

The electrical operating output will also cease if there is a ground

fault. The GFCI receptacle will trip to protect the operator. See also,

Resetting the POWERLINK System.

Do not perform any modifications to

WARNING

the POWERLINK On-Board

Generator System, the inverter, or

the GFCI receptacle.

Never tamper with engine governed

speed.

SERVICE AND MAINTENANCE OF

POWERLINK SYSTEM

Repairs to the POWERLINK

WARNING

The GFCI must be replaced with the appropriate parts listed in UL

Standard 943, Class A and conforming to N.E.C. requirements.

Units built before an engine date code of 040201 must be

replaced with Eagle GFCI p/n GF15BK (B&S p/n 699146).

Units built after an engine date code of 040131 must be replaced

with Hubbell/Bryant GFCI p/n GF53BKA (B&S p/n 790239).

WARNING

result. A lift must be used to remove and install the flywheel.

Always consult an Authorized Briggs & Stratton Service Dealer on

the service of this engine.

system and wiring must be done by

an Authorized Service Dealer. All

electrical components and wiring

must be in the original position when

the repair is complete.

Care must be exercised when

removing and installing the engine

flywheel. The force of the flywheel

magnets is extremely high and they

will rapidly draw the flywheel to the

engine. Hand and/or finger injury can

Loading...

Loading...