Page 1

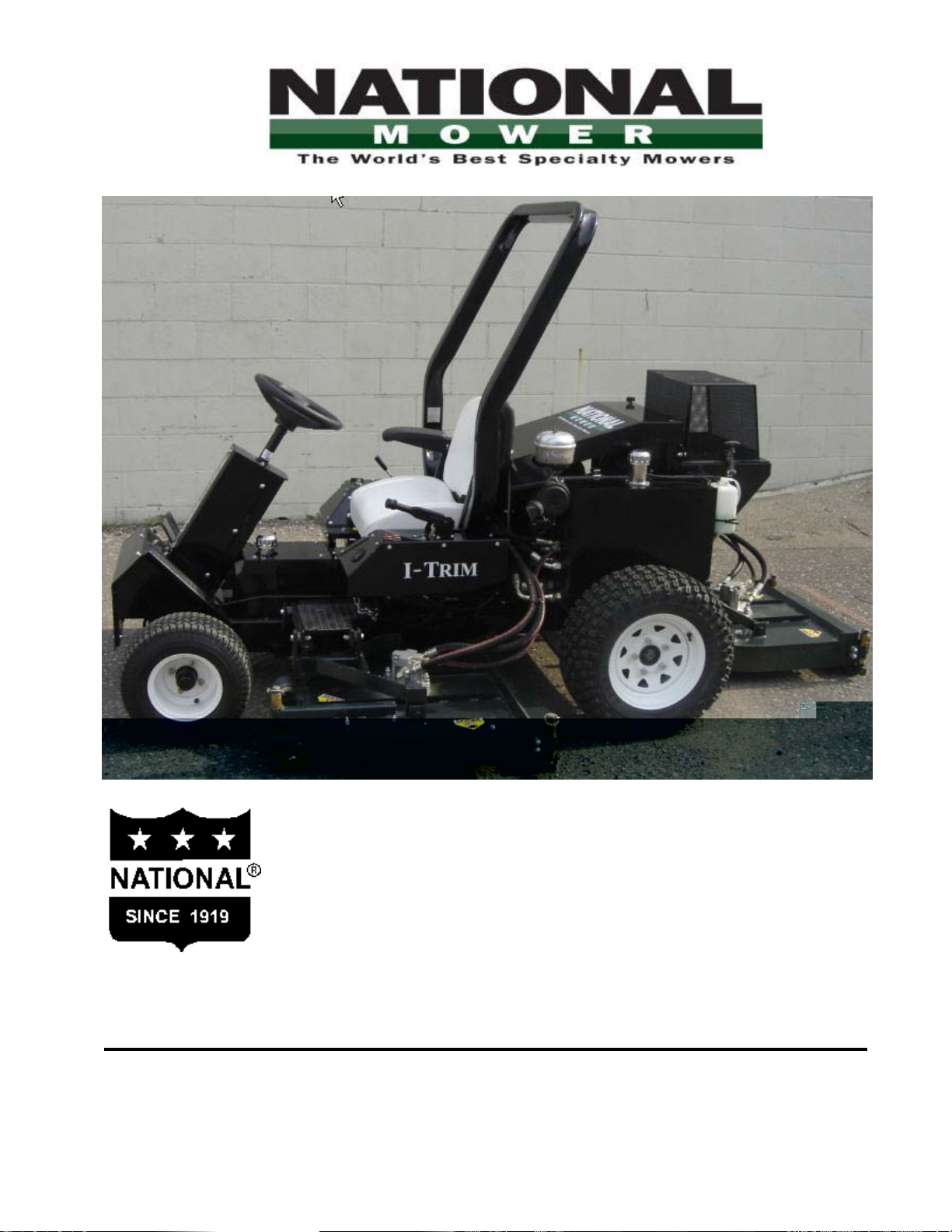

I-TRIM

OWNER'S MANUAL

Includes Specifications, Assembly, Operation,

Maintenance & Parts Lists

NA TIONAL MOWER CO.

MARCH 2006

700 Raymond Ave., P.O. Box 14299, St. Paul, Minnesota 55114-0299, U.S.A.

Phone (651) 646-4079 – Fax (651) 646-2887

www.nationalmower.com

Page 2

2

Page 3

TABLE OF CONTENTS

Table of contents...................................................... 3

Introduction............................................................... 4

Safe Operating Practices ...................................... 4-6

Decal (Transfer) Identification............................... 7-9

Introduction and Receipt of Shipment ................... 10

1— Specifications ................................................... 11

2— Assembly Instructions...................................... 12

3—General Information .......................................... 15

4—Controls............................................................. 16

5—Operation .......................................................... 18

6—Adjustments ...................................................... 20

I-TRIM

®

7—Maintenance ....................................................... 22

8—Storage................................................................ 28

9—Troubleshooting .................................................. 29

Wiring Diagram.........................................................33

Maintenance Record.................................................34

10—Parts Ordering Information ............................... 35

Screen box, guards, ROPS................... 36-37

Deck Lift Arms and Pull Arms............... 38-39

Seat, Wheels, Engine, Radiator, tank 340-41

Wheel Motors, Filters, Hyd Comp. ....... 42-43

Pedal Assy, Hyd Pumps ....................... 44-45

Front Axle, Fuel Tank, Frame ............... 46-47

Engine and Radiator Assembly ................. 48

Rear Mower Deck Assembly...................... 49

Right Mower Deck Assembly..................... 50

Left Mower Deck Assembly ....................... 51

Hydraulics- Deck Motors/Oil Cooler ..... 52-53

Hydraulics - Wheel Motors/Steering..... 54-55

Electrical System Components...................56

Steering Cylinder........................................57

Hydraulic Schematic - Steering/Drive.......................58

Hydraulic Schematic - Mower Drives/Deck Lift.........59

Warrenty...................................................................61

Appendix 1- Briggs & Stratton Operating Instructions

3

Page 4

INTRODUCTION

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. The operator is responsible for operating this

product properly and safely.

This manual identifies potential hazards and has special

safety messages that help you and avoid personal injury and

even death. Danger, Warning, and Caution are signal words

used to identify the level of hazard. Howerver, regardless of

the hazard, be extremely careful.

Danger signals an extreme hazard that will cause series

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important call attention to special mechanical information

and Note: emphasizes general information worthy of special

attention.

• Keep in mind that the operator or user is responsible for

accidents or hazards occurring to other people or their

property.

• All drivers and mechanics should seek and obtain

professional and practical instruction. The owner is

responsible for training the users. Such instruction

should emphasize:

- the need for care and concentration when working with

ride-on machines;

- the owner/user can prevent and is responsible for

accidents or injuries occurring to himself or herself, other

people, or property;

- control of a ride-on machine sliding on a slope will not

be regained by the application of the brake or putting

transmission into neutral. Some reasons for loss of

control are: insufficient wheel grip, driving too fast,

inadequate braking, using a machine that is unsuitable

for a task, lack of awareness of the effect of ground

conditions (especially slopes), and incorrect load

distribution.

SAFETY

This machine meets or exceeds ANSI B71.4-1999 specifications in effect at the time of production.

Improper use or maintenance by the operator or owner can

result in injury. To reduce the potential for injury, comply with

these safety instructions and always pay attention to the

safety alert symbols: CAUTION, WARNING, and DANGER.

Failure to comply with the instruction may result in personal

injury or death.

Safe Operating Practices

The following instructions are from CEN standard EN

836:1997, ISO standard 5395: 1990, and ANSI B71.4-1999.

Training

• Read the Operator’s Manual and other training material

carefully. Be familiar with the controls, safety signs, and

the proper use of the equipment.

• Never allow children or people unfamiliar with these

instructions to use or service the mower. Local

regulations may restrict the age of the operator.

• Never mow while people, especially children, or pets are

nearby.

• Do not carry passengers.

Preparation

• Evaluate the terrain to determine what accessories and

attachments are needed to properly and safely perform

the job. Only use accessories and attachments approved

by the manufacturer.

• While mowing, always wear substantial footwear, long

trousers, hard hat, safety glasses, and ear protection.

Long hair, loose clothing, or jewelry may get tangled in

moving parts. Do not operate the equipment when

barefoot or wearing open sandals.

• Thoroughly inspect the area where the equipment is to

be used and remove all objects which may be thrown by

the machine.

• Check that operator’s presence controls, safety

switches, and shields are attached and functioning

properly. Do not operate unless they are functioning

properly.

• Warning - Fuel is highly flammable. Take the following

precautions:

- Store fuel in containers specifically designed for this

purpose.

- Refuel outdoors only and do not smoke while refuelling.

- Add fuel before starting the engine. Never remove the

cap of the fuel tank or add fuel while the engine is

running or when the engine is hot.

- If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

4

Page 5

Operation

• Do not operate the engine in a confined space where

dangerous carbon monoxide fumes can collect.

• Operate only in daylight or in good artificial light. Stay

alert for holes in the terrain and other hidden hazards.

• Before attempting to start the engine, disengage all

blade attachment clutches, shift into neutral, and engage

the parking brake. Only start the engine from the

operator’s position. Use seat belts if provided.

• Never operate with the discharge deflector raised,

removed, or altered, unless using a grass catcher.

I-TRIM

®

• Stop the engine and disengage drive to attachment

- before refuelling;

- before removing the grass catchers;

- before making height adjustment unless adjustment

can be made from the operator’s position.

- before clearing blockages;

- before checking, cleaning or working on the mower;

- after striking a foreign opject or if an abnormal vibration

occurs. Inspect the mower for damage and make repairs

before restarting and operating the equipment.

• Reduce the throttle setting before stopping engine and, if

the engine is provided with a shut-off valve, turn the fuel

off at the conclusion of mowing.

• Remember there is no such thing as a safe slope.

Travel on grass slopes requires particular care. To guard

against overturning:

- do not stop or start suddenly when going up or downhill.

- machine speeds should be kept low on slopes and

during tight turns.

- stay alert for humps and hollows and other hidden

hazards.

- never mow across the face of the slope, unless the

mower is designed for this purpose.

• Watch out for traffic when crossing or near roadways.

Slow down and use caution when making turns and

crossing roads and sidewalks. Stop the blade rotation

before crossing surfaces other than grass. Stop reels or

deck blades if not mowing.

• When using any attachments, never direct discharge of

material toward bystanders or allow anyone near the

machine while in operation.

• Never operate the machine with damaged guards,

shields, or without safety protective devices in place. Be

sure all interlocks are attached, adjusted properly, and

functioning properly.

• Keep hands and feet away from cutting units.

• Look behind and down before backing up to be sure of a

clear path.

• Do not operate the mower under the influence of alcohol

or drugs.

• Use care when loading or unloading the machine into a

trailer or truck.

• Use care when approaching blind corners, shrubs, trees,

or other objects that may obscure vision.

Maintenance and Storage

• Keep all nuts, bolts and screws tight to be sure the

equipment is in safe working condition. Replace all worn

or damaged decals.

• Never store the equipment with fuel in the tank inside a

building where fumes may reach an open flame or spark.

• Do not change the engine governor settings or

overspeed the engine. Operating the engine at

excessive speed may increase the hazard of personal

injury.

• Disengage drive to attachements when transporting or

not in use.

• Before leaving the operator’s position:

- stop on level ground;

- disengage the power take-off and blade rotation

and lower the attachments;

- Change into neutral and set the parking brake;

- stop the engine and remove the key.

• Keep hands and feet away from the cutting units.

• Allow the engine to cool before storing in any enclosure.

• To reduct the fire hazard, keep the engine, silencer,

battery compartment and fuel storage area free of grass,

leaves, or excessive grease.

• Park machine on level ground. Never allow untrained

personnel to service machine.

• Check the grass catcher frequently for wear or

deterioration.

• Keep all parts in good working condition and all

hardware and hydraulic fittings tightened.

• If the fuel tank has to be drained, do this outdoors.

• Shut off fuel while storing or transporting. Do not store

fuel near flames.

5

Page 6

• Be careful during adjustment of the machine to prevent

entrapment of the fingers between moving blades and

fixed parts of the machine Use care when checking

blades. Wrap the blade(s) or wear gloves, and use

caution when servicing them. Only replace blades.

Never straighten or weld them.

• On multi-reel or blade machines, take care as rotating

one blade can cause other blades to rotate.

• Disengage drives, lower the cutting units, set parking

brake and stop engine. Wait for all movement to stop

before adjusting, cleaning or repairing.

• Clean grass and debris from cutting units, drives,

mufflers, and engine to help prevent fires. Clean up oil or

fuel spillage.

• Check the safety interlock switches daily for proper

operation. If a switch should fail, replace the switch

before operating the machine.

• Using the machine demands attention. To prevent loss

of control:

- Do not drive close to sand traps, ditches, creeks, or

other hazards.

- Reduce speed when making sharp turns. Avoid sudden

stops and starts.

- When near or crossing roads, always yield the right-ofway.

- Reduce foward pedal movement when going downhill to

keep forward speed slow and to maintain control of the

machine.

• Use jack stands to support components when required.

• Carefully release pressure from components with stored

energy.

• Disconnect battery before making any repairs.

Disconnect the negative terminal first and the positive

last. Reconnect positive first and negative last.

• Keep hands and feet away from moving parts. If

possible, do not make adjustments with the engine

running.

• Charge batteries in an open well ventilated area, away

from spark and flames. Unplug charger before

connecting or disconnecting from battery. Wear

protective clothing and use insulated tools.

Other Riding Mower Safety Instructions

• Always follow all safety instructions to avoid serious

injury or death. This product is capable of amputating

hands and feet and throwing objects.

• Do not touch the engine, muffler, hydraulic components,

or exhaust pipe while the engine is running or soon after

it has stopped because these areas could be hot enough

to cause burns.

• Make sure all hydraulic line connectors are tight and all

hydraulic hoses and lines are in good condition before

applying pressure to the system.

• Keep your body and hands away from pin hole leaks or

nozzles that eject hydraulic fluid under high pressure.

Use paper or cardboard, not your hands, to search for

leaks. Hydraulic fluid escaping under pressure can have

sufficient force to penetrate the skin and cause serious

injury.

• Before disconnecting or performing any work on the

hydraulic sytem, all pressure in the system must be

relieved by stopping the engine and lowering the cutting

units and attachments to the ground.

• Know how to stop the engine quickly.

• Wearing safety shoes and long pants is advisable and

required by some local ordinances and insurance

regulations.

• The operator must be skilled and trained in how to drive

on hillsides. Failure to use caution on slopes or hills may

cause loss of control and cause the vehicle to tip or roll,

possible resulting in personal injury or death.

CALIFORNIA Proposition 65 Warning - Diesel engine

exhaust and some of its constituents are known to the State

of California to cause cancer, birth defects, and other

reproductive harm.

WARNING– California, USA residents are required by law (CA PRC 4442 & CA H & SC 13005) to equip their

engines with spark arresters when operating in flammable vegitation. Arresters must be obtained from your

engine dealer and are not available from National Mower Company.

6

IMPORTANT

Page 7

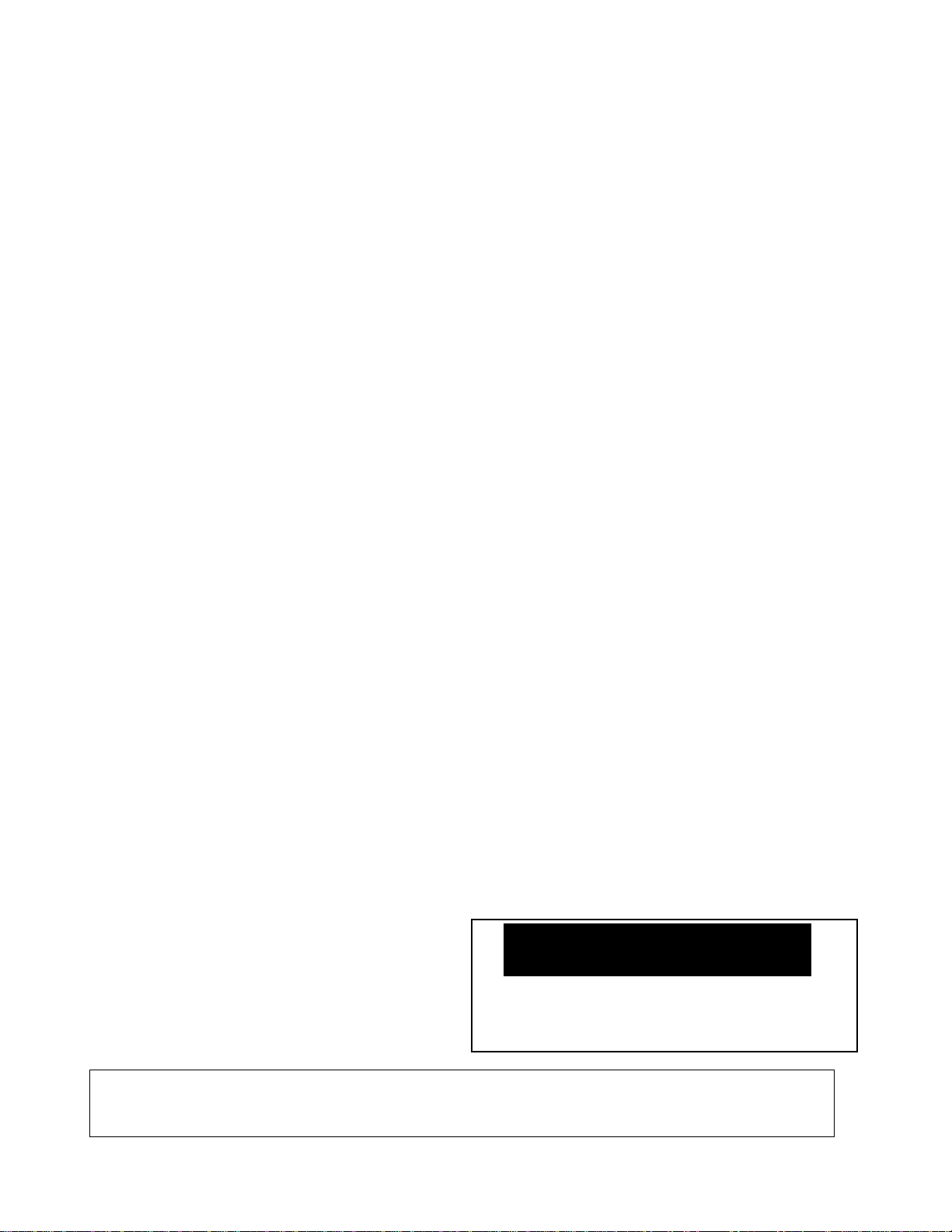

DECAL IDENTIFICATION

National has provided decals in many locations throughout

the machine to aid the operator in identifying, controlling

and operating the I-Trim safely and correctly. It is important

that all decals are clean and visable at all times. Replace

decals that are damaged, missing or accidently painted

over.

A

I-TRIM

®

B

D

E

C

7

Page 8

G

F

I

H

J

8

Page 9

K

I-TRIM

®

L

NAMES AND LOCATIONS

Item Part No. Description / Location

A 07792 I-Trim Model / Left and Right sides of operator panels

B 07794 Natinal Logo / Top of rear hood

C 07793 National Name / Front of steering column

D 07797 Diesel Fuel / Top of Fuel Tank

E 07796 Hydraulic Fluid / Top of hydraulic tank

F 07778 Warning light identification / Left side panel

G 07779 Key Switch and deck rotation switch / Right side panel

H 07777 Engine Speed / Left side panel

I 07411 Danger / Top of rear and wing mower decks

J 07780 Deck lift / Top of right operator panel

K 07795 Warning Decal / Top of steering column

L I-Trim Serial Number / Right side of steering column

M 08092 Instruction Decal- ANSI / steering column

M

9

Page 10

INTRODUCTION

This manual has been prepared by National Mower

Company as an aid to users for set up, operation and

servicing and ordering replacement parts. Additional

information will gladly be furnished by calling or writing

the company.

Please furnish us with the Model number, serial number

and date of purchase when contacting us about your

machine.

RECEIPT OF SHIPMENT

Carefully inspect your machine and crates for damage

that could have occured during shipment. If damages or

shortages are noted, have the transportation company’s

representative note this on the bill of lading.

10

Designations of right, left, front and rear are used in the

position of the operator sitting in the seat.

Metric equivalents are provided wherever possible for

users outside of the United States.

IMPORTANT

Claims for shipping damages must be noted by the

consignee at the point of designation and filed with

the transportation company.

Page 11

1—SPECIFICATIONS

1.1—ENGINE SPECIFICATIONS

TYPE: 3 cylinder turbocharged Diesel

ENGINE MODEL: Briggs & Stratton

954 DT

HORSEPOWER: 34 hp

I-TRIM

BATTERY TYPE: Exide Model 60 Premium

Type 78-60

12 V side post

7 3/16 (18 cm) height

6 ¾ (17 cm) width

10 1/4 (26 cm) length

®

1.5—CUTTING UNIT SPECIFICATIONS

COOLING: Water cooled

1.2—TRANSMISSION

TRACTION DRIVE:Oilgear variable

Displacement

Hydrostatic pump

WHEEL DRIVE Char Lynn hydraulic motors

MOTORS: with disc-parking brakes

1.3—STEERING

Eaton Power

Steering Control Unit

1.4—MOWER SPECIFICATIONS

FUEL TANK: 10 Gallons (38 liters)

CUTTING UNIT: (3) - 26” (.66m) wide decks

BLADES: (2) Right hand 26” (.66 m) wide blades

(1) Left hand 26” (.66m) wide blade

DECK MOTORS: (2) CW Hydraulic motors (Right/Rear)

(1) CCW Hydraulic motor (Left)

Rotation direction as viewed from top of deck

WIDTH OF CUT: 70” (1.778m)

HEIGHT OF CUT: 1.5” to 4” adjustment (38.1mm to

101.62mm)

1.6—LUBRICANTS

ENGINE OIL: Refer to enclosed Engine Manual

HYDRAULIC OIL: ISO 68 hydraulic grade oil.

1.7—OTHER

OIL TANK: 12 Gallons (45 liters) Approx.

TIRES: Front: 16 x 6.50 - 8 (28 psi max)

Rear: 23 x 10.50 x 12 (20 psi max)

FRAME: Welded steel construction

MOWING SPEED: 0 - 7 MPH (0 - 11.3 km)

CONTROLS: Foot operated traction pedal for forward

and reverse, hand operated throttle

conttrol, electric valve for cutting units,

and hand operated parking brake.

ROPS: Roll over protective structure

meets SAE J 1194 standards

11

Page 12

2—ASSEMBLY INSTRUCTIONS

2.1—TRACTOR ASSEMBLY

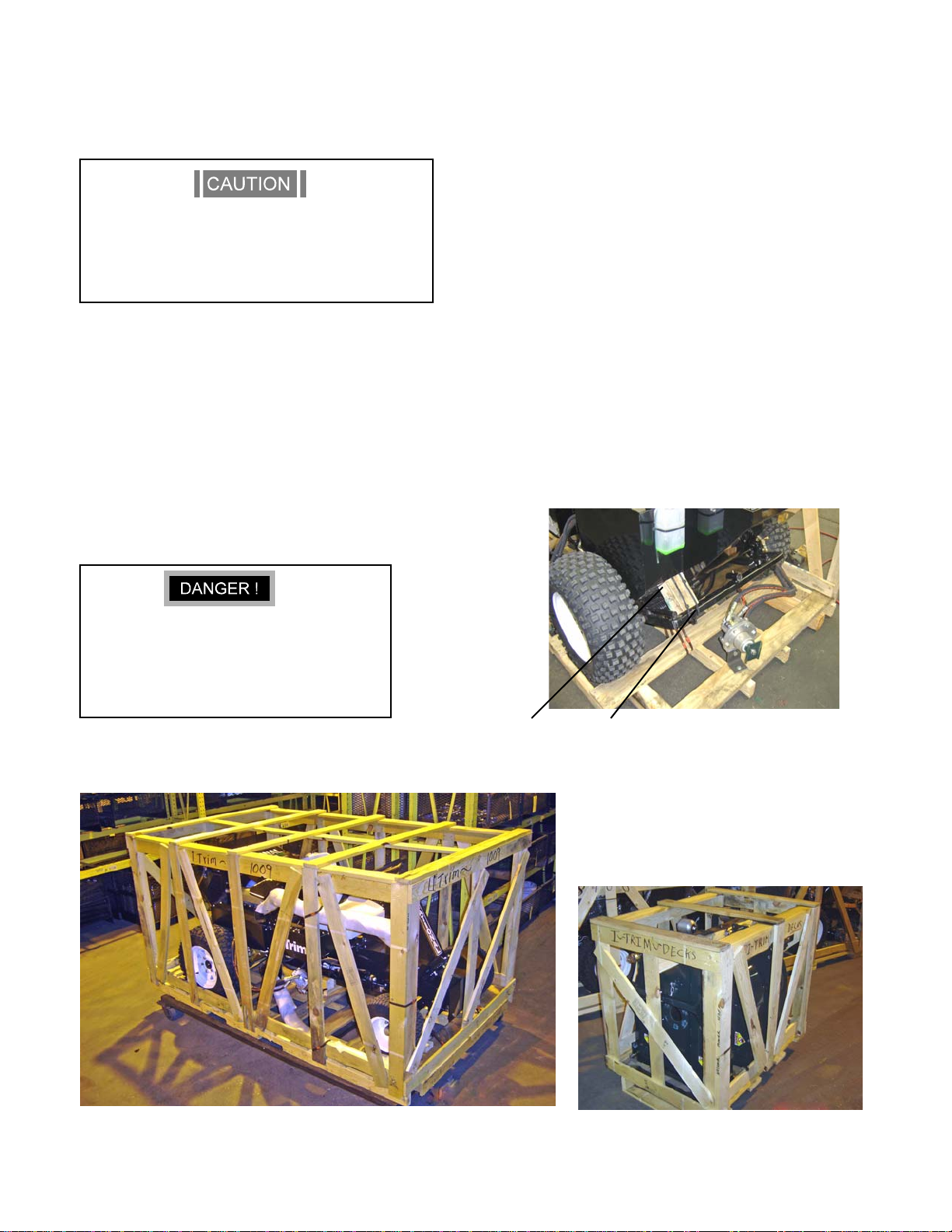

Handle banding material with caution. Use heavy

leather gloves. Banding is sharp!

The side and rear lift arms are spring-loaded up.

Take care when handeling.

1. Remove crating top, front and sides from the tractor crate.

Cut banding from Roll-Over Protective Structure (ROPS)

Fig A.

2. Cut banding from around tractor frame to crate base.

3. Unbolt rear deck motor from crate base and temporarily

strap to rear lift arm. Leave wood spacer in place on rear

lift arm to prevent damage.

3. Release parking brake and push or drive tractor off the

crate. See operating instructions. Do not engage deck

motors until tractor is fully assembled with decks. Reengage parking brake.

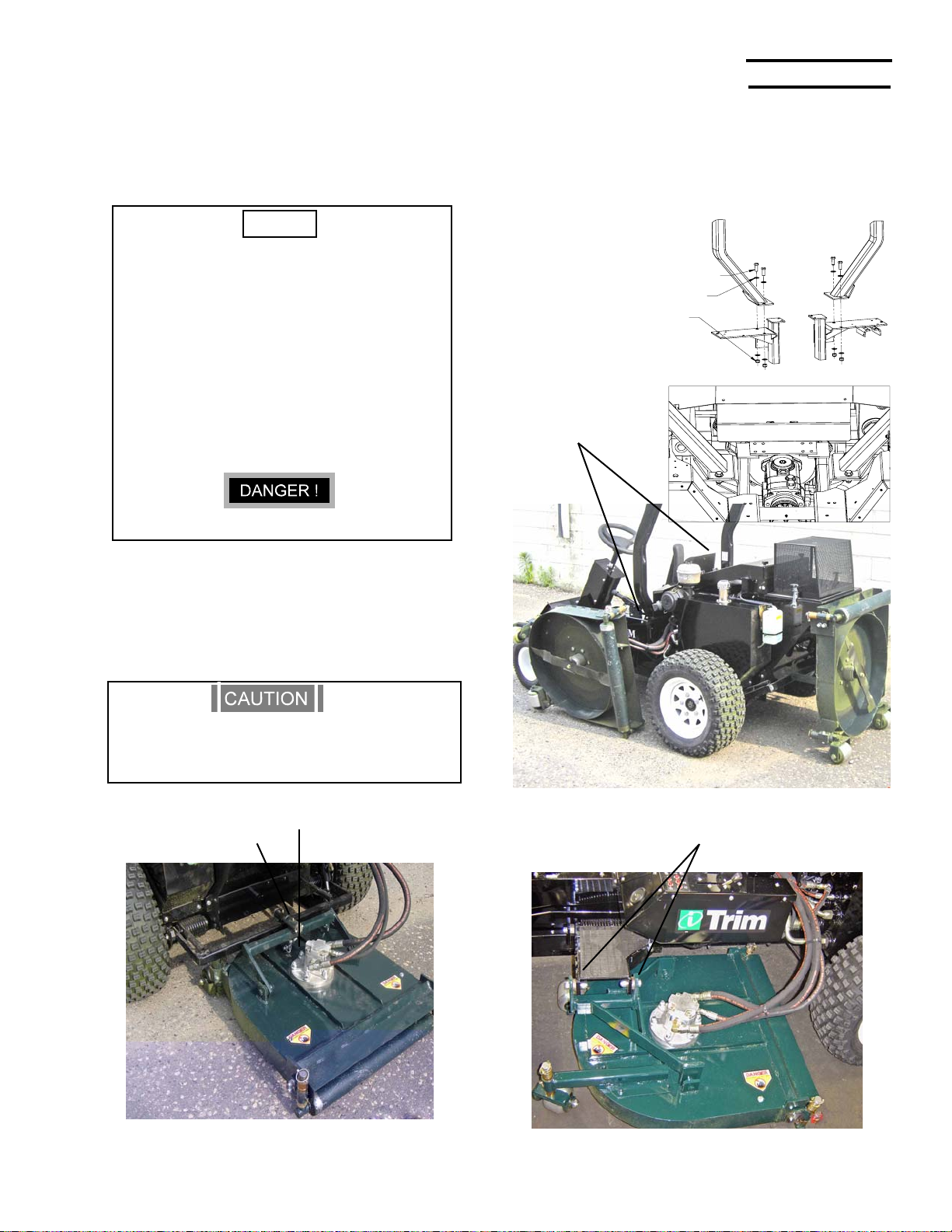

2.2—REAR DECK ASSEMBLY

1. Remove crating top, front and sides from deck crate.

Unscrew blades from crate.

2. Remove rear deck from crate and position behind

tractor as shown in Figure C. Remove roll pin and washer

from attachment shaft.

3. Insert a 1/2” rod into lift arm (Fig B) to lower and line-up the

lift arm with the deck bushing. Insert shaft and secure with

washer and roll pin. Remove wood spacer.

2.3—LEFT/RIGHT DECK ASSEMBLY

1. Remove left and right decks from crate and position near

tractor as shown in Figure D. Remove attachment bolts.

2. Hold down and line-up lift arms with decks. Attach with

supplied bolts and washers. Install lift chains.

Use jack stands under tractor whenever

elevated off the tires.

Do not engage deck motors untill tractor is

fully assembled with decks.

Wood Spacer

Insert rod

FIGURE B

12

FIGURE A

Page 13

I-TRIM

HEX BOLT ½-20 X 1½ GR 5

(4)

WASHER ½ SAE

(8)

NUT, NYLOCK ½-20

(4)

®

2.4—DECK MOTORS AND BLADES

The I-Trim is available with standard or mulching blades. The Rear/Right decks require a RH

blade and the left deck uses a LH blade.

NOTE

MULCHING BLADES

Rear/Right -P/N 306245 (stamped 306245)

Left -P/N 306311 (stamped 306311)

STRAIGHT BLADES

Rear/Right - P/N 306368 (stamped 4607)

Left - P/N 306367 (stamped 6406)

Motor rotation direction is stamped on the flange

of each deck motor. Rot ation is clockwise (from

above) on right and rear decks and counterclockwise on left deck.

NEVER START TRACTOR WITH DECKS ROTA TED

1. Rotate decks vertical as shown in Fig E. Install deck

motors with hoses rotated as shown in Fig C and D using

supplied botts and nyloc nuts. Note: install ring spacer

between motor and deck.

2.5—ROPS

1. Install roll-over protective structure with supplied bolts and

nuts as shown on Fig E. ROPS can be installed with seat in

forward position. Lower ROPS over seat and insert LH side

into position. Slide ROPS to RH side and spread it slightly

to clear brackets. Install with supplied fasteners.

.

ROPS attachment points

2. Install lift chains on rear deck with supplied bolts. Note:

The rear deck has a anti-flip chain with quick-release

connector link to allow easy removal for HOC adjustments.

Make sure anti-flip chain is installed on rear deck

to prevent deck from rotating during operation.

Anti-flip chain

Attachment shaft and roll pin

FIGURE E

Side deck attachement bolts

FIGURE C

FIGURE D

13

Page 14

2.6—ENGINE CRANKCASE

Crankcase oil has been installed at the factory. However it

is recommended that the engine be checked for proper oil

level before starting. Refer to separate engine manual

included with each I-Trim Mower.

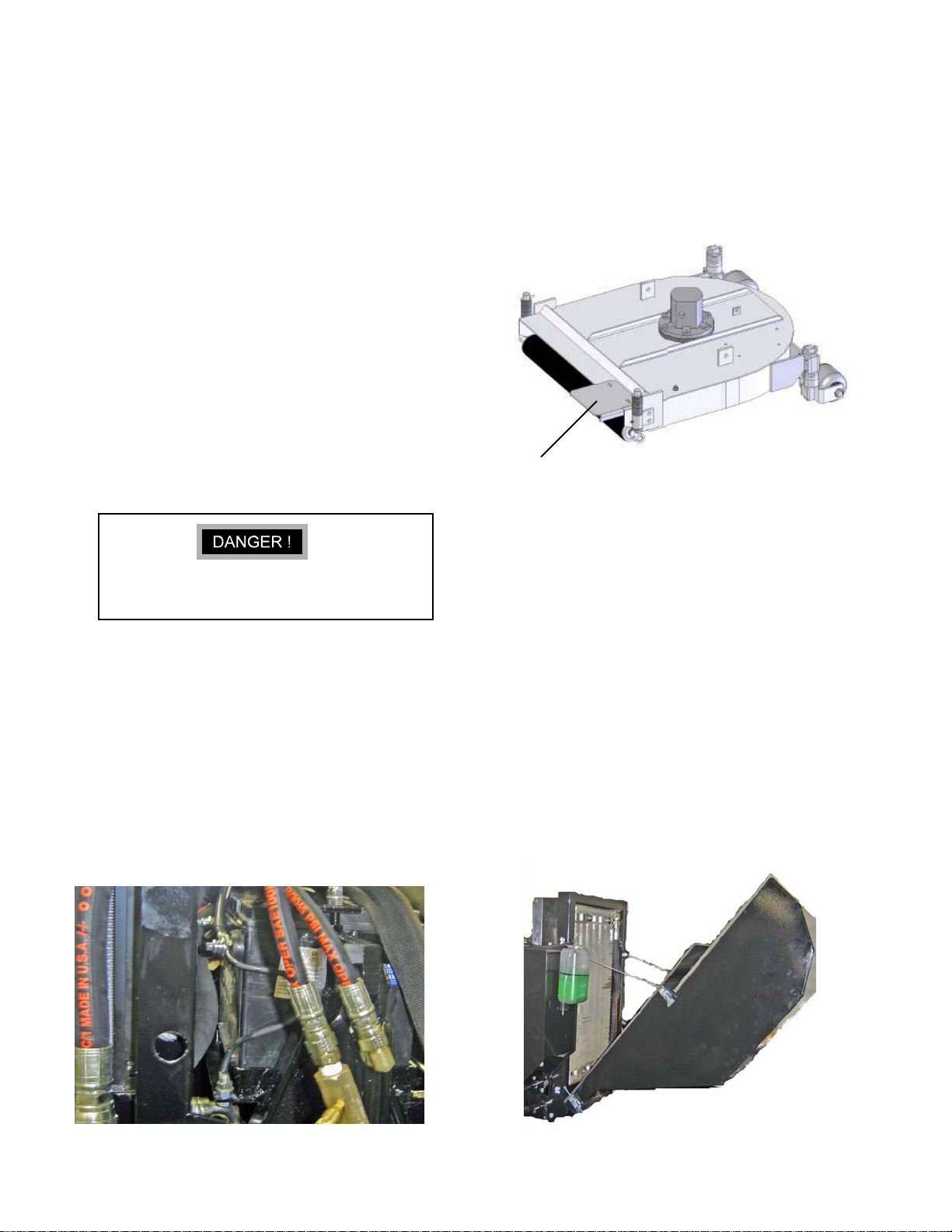

2.7—HYDRAULIC OIL

1. The hydraulic oil has been installed in the oil tank

(1, Fig. G) at the factory, however it is recommended that

the oil level be check before operation.

2. Check oil level by removing pipe cap. The oil level should

be at the bottom edge of the screen. If required, add a

small amount of oil to the tank. and replace cap.

Recommended oil is ISO 68 Hydraulic grade oil.

2.9—GUARD FOR DECK DISCHARGE

Each I-Trim Deck is supplied with a safety guard for the

rear discharge area. These guards are supplied to

prevent accidental insertion of a person’s foot and need to

be installed as shown in Fig. G.

2.8—BATTERY

Follow the battery manufacture’s instructions on

safety, maintenance and inst allation procedures.

The I-Trim is shipped with a Exide Model 60 Premium,

Type 78-60. Only replace with an equivalent battery.

1. Remove rear RH wheel to replace battery. Install

battery with side mount terminals facing toward

engine. See Fig F.

2. Place battery hold down strap over bolts and secure

with flat washers and hex nuts. Do not over-tighten.

3. Connect the red ignition wire to the positive (+)

terminal of the battery. Attach the engine ground wire

and frame ground wire to the negative (–) terminal of

the battery.

Guard

FIGURE G

2.10—SCREENBOX FOR RADIATOR

The I-Trim may be supplied with a pivoting rear screenbox

as shown in Fig. H. The screenbox needs to be installed

onto lower pivot brackets and secured with supplied

cables and snap-latches.

14

FIGURE F

FIGURE H

Page 15

3—GENERAL INFORMATION

NOTE

If adjustments are necessary see section 5.0 of

the is manual for instructions.

3.1—ENGINE

Your machine is powered by a 3-cylinder Briggs and Stratton

turbocharged diesel engine which uses diesel fuel. Engine

speed is controlled by means of a throttle lever mounted on

the dash panel.

A separate Engine Manual, prepared by the engine manufacturer is supplied. Study the manual carefully until you are

familiar the maintenance, operation, adjustment and repair of

your equipment. Proper attention to the engine manufacturers

directions will assure maximum service life of the engine and

highest operating efficiency.

I-TRIM

®

3.2—TRACTION DRIVE TRAIN

Power from the engine is transmitted by direct drive to the

variable displacement pump. The pump supplies hydraulic

fluid to the hydraulic motors.

3.3—MOWER DECK DRIVE

Hydraulic power to the deck motors is actuated by electric

switch mounted on the RH control panel. This switch actuates

a solenoid valve in the deck manifold.

3.4—INTERLOCK SWITCHES

There are three safety switches on your I-Trim. They are a

safety precaution, which will allow you to start your mower only

when the traction pedal is in neutral, the deck motor control

switch is in the disengaged position and the operator is seated

on the tractor. If you are able to start your mower with the

pedal or switch in any other position, adjustment of the

switches may be required. After engine is started, it will

continue to run if you leave the seat (as long as the deck

switch is off and the pedal is in neutral).

Never operate the machine if the interlocks are

not operating properly. Accidental startup could

cause severe injury . Refer to T roubleshooting section (Sec 9).

15

Page 16

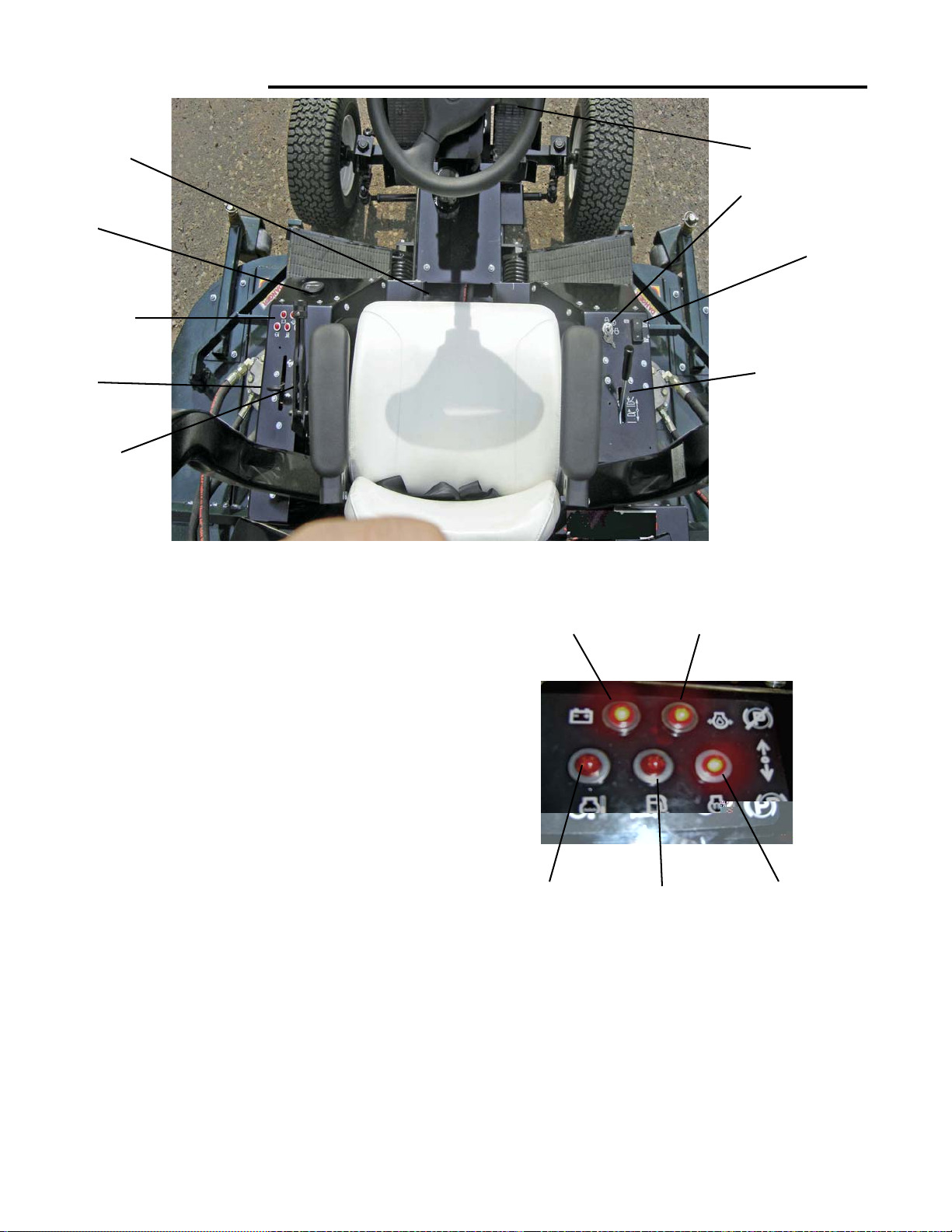

4—CONTROLS

10

2

3

4

8

FIGURE J

4.1—IGNITION SWITCH

Insert key in switch (1, Fig.J) and turn clockwise to on

position and wait until the glow plug light turns off. After light

turns off, turn key clockwise as far as it will go to start engine,

then release. The deck rotation control switch must be in the

off position, the traction control pedal in the neutral position

and a operator must be sitting on the seat before starting

engine.

5 6

1

9

7

Battery Charging Oil Pressure LOW

Do not hold key in “ON” position more than 15 second at a

time.

Key should be removed when tractor is not in use to prevent

unauthorized operation.

Refer to section “5.2” for complete starting information.

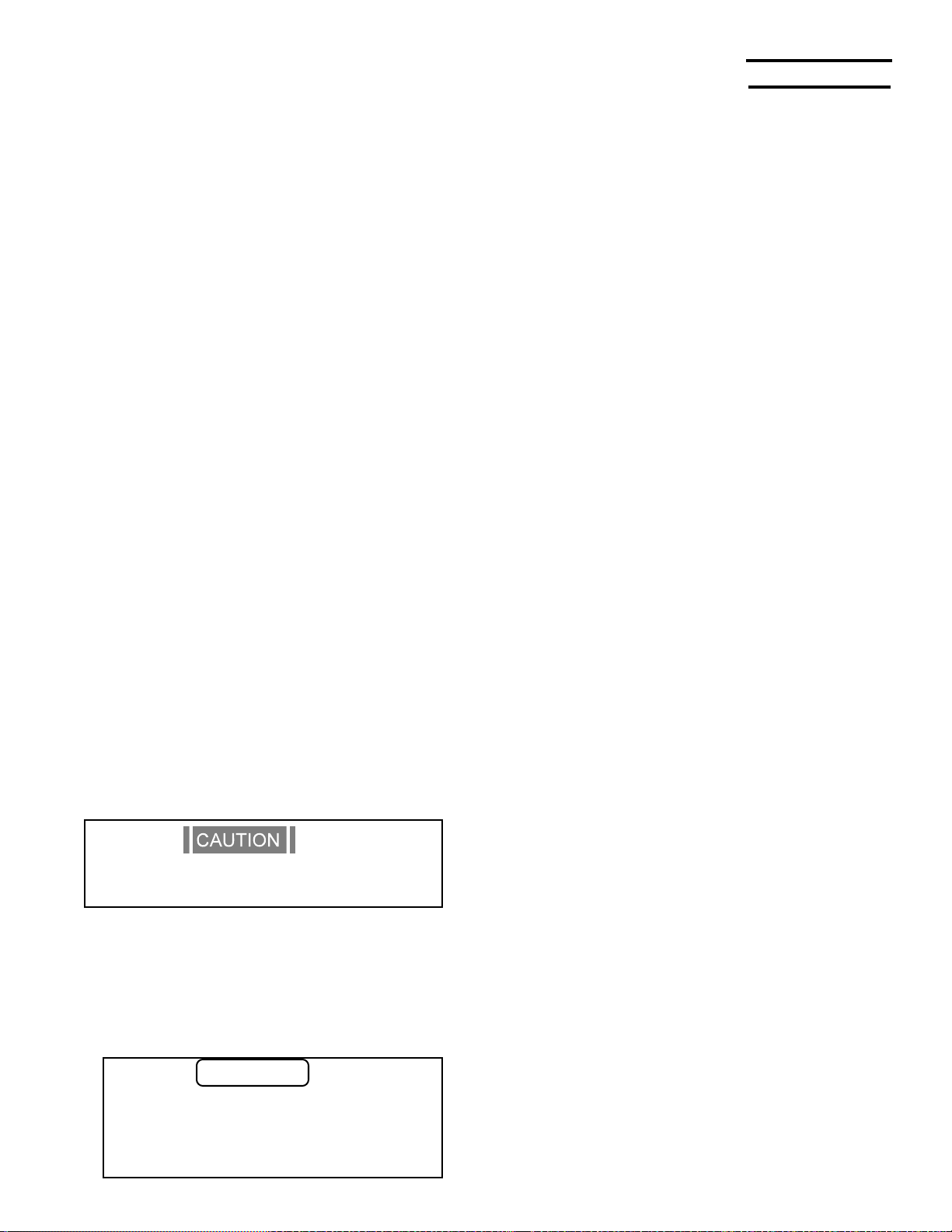

4.2—INDICATOR LAMPS

After engine is started, illumination of any indicator lamp will

indicate a problem (3, Fig J). Stop engine and correct

problem.

When Key is turned to “ON” the Battery Charging, Glow Plug

ON, and the Oil Pressure indicator lamps should illuminate.

After 5 seconds, the Glow Plug ON light should turn off (Fig

K).

16

Water Temperature Water in Fuel Glow Plug ON

FIGURE K

4.3—HOUR METER

The hour meter (2,Fig. J) indicates the number of hours the

tractor has been operated. It can be used to keep track of

maintenance intervals and the amount of time required to

perform various tasks. The hour meter operates whenever the

ignition key is in the “on” position.

Your I-Trim Mower maybe equipped with a digital hour meter.

This meter will display a signal after 5 hours and every 25

hours thereafter, recommending that you perform maintanncel

and lubricate the mower. (see sec.7). The display will

automaticly reset after 2 additional hours of run time.

Page 17

4.4—THROTTLE LEVER

I-TRIM

®

Push throttle lever (4, Fig. J) forward to increase engine

speed, pull back to decrease the engine speed.

Position throttle at full throttle or slightly less for optimum

power and deck speed during mowing.

4.5—TRACTION PEDAL

The traction pedal (5, Fig. J) operates the forward and the

reverse direction and speed of the tractor.

Moving forward: push the forward or toe of the pedal down

with the ball of your foot, to increase the forward speed.

Moving backward: push the heel of the pedal down with the

heel of your foot, to increase the reverse speed.

When the traction pedal is released the machine will slow

down and stop. The traction pedal must be in neutral position

before mower will start.

4.6—SPEED CONTROL

The speed control (6, Fig. J) is meant to ease operator

fatigue by holding the forward speed to a constant that

is best suited for the present mowing conditions. The

stop also prevents overloading of the pintle shaft.

Adjust the hex head bolt up or down and lock it with the

lock nut to limit the pedal travel. Make sure the pintle

shaft on the pump is not bottomed-out by watching the

linkage deflection when pedel is all the way down.

4.9—DECK DRIVE CONTROL

By toggling the deck drive control switch ON (9, Fig.

J), an electric solenoid valve is activated which

engages power to the deck motors.

Pushing the switch to the OFF position disengages the

valve. This contrtol must be in the OFF position before

mower will start.

4.10—SEAT POSITION LEVER

The position of the seat is adjusted forward or

backward by actuating the seat lever (10, Fig. J).

Releasing the lever will lock the seat at its present

position.

4.7—DECK LIFT

The Deck Lift valve (7, Fig. J), will lift both wing decks

and rear deck by pulling lever to rear. Pushing lever to

front will lower all deck to the ground. Always lower

decks for mowing and storage.

Do not stand on mowers when in lifted position.

4.8—PARKING BRAKE

A convenient parking brake (8, Fig. J) is located just to

the left side of the operators seat.

Pulling back and over center will engage the parking

brake and moving it forward, as shown, will release it.

See section 6.1 for adjustments.

IMPORTANT

Always make sure brake is released before moving forward and ensure that the brake is engaged

when leaving the mower. Never try to stop the

forward motion of the unit with the parking brake.

17

Page 18

5—OPERATION

5.1—CHECK LIST

1. Fill the fuel tank with good quality, clean, diesel with a

minimum of 40 octane. Fresh fuel prevents gum from

forming in the fuel system. Fill tank to 1 inch (25 mm)

below filler neck. Do not overfill.

2. Check oil in the engine crankcase. It should be filled to

the full mark on the dipstick. Refer to Section 1.6 in this

manual for recommend oil viscosity.

3. Check all lubrication points outlined in the “Section 7.14

Lubrication” section of this manual. Check linkage for

traction pedal to the pump for wear or damage.

4. Check tires for proper inflation. Refer to section 1.4 of

this manual.

5. Check oil level in hydraulic reservoir. Oil level should be

level with the bottom of the screen when looking into the

fill neck and when unit is sitting on a level surface.

6. Check decks for desired cutting height. To provide a

satisfactory cut, it is essential for all decks be accurately

adjusted to exactly the same height. See 6.9 in the

Adjustments Section.

OPERATING SUGGESTIONS

Under no circumstances should the engine be

started with the operator or bystander standing

next to tractor or cutting units.

1. When starting the engine, the operator must be seated

on the seat, deck control switch must be OFF and

traction pedal must be in neutral (the center position).

6. Operate at speeds which allow you to have complete

control of the tractor and allow you to stop the tractor or

maneuver safely in case of an emergency. It is

recommended that you adjust the Speed Control (6, Fig.

J), to maintain a constant pedal postion/speed and

reduce the operator fatigue.

7. To obtain maximum mower life, the operator must use

discretion when mowing near gravel areas (roadway,

parking areas, cart paths etc.) By operating too close to

overlapping gravel areas, stones maybe picked up by

the mower and ejected under the deck causing wear to

the blades and damage from flying objects.

5.2— STARTING THE ENGINE

1. Sit in operators seat.

2. Place deck control switch in the “OFF” position (9, Fig

J).

3. Place the traction pedal in “Neutral” position (5, Fig J).

4. Engage parking brake (8, Fig J).

5. Insert ignition key, turn clockwise to “run” position and

wait until the glow plug ON light turns off. Turn key

clockwise to “start” and release key when engine starts.

Do not hold key in “start” position for more than 15

seconds or damage to the starter may result. If engine

does not start within this time, release the key and wait

for a few minutes before trying again.

5.3—DRIVING THE TRACTOR

1. Position throttle at full throttle or slightly less for optimum

power and deck speed.

2. The operator should practice mowing in an open clear

area, to become thoroughly familiar with the operation of

the tractor.

3. Never operate the mowers when they are in the up

position because of the dangers of flying objects and

exposed blades.

4. Plan your cutting pattern to avoid any unnecessary stops

or sharp, frequent turns. Study the area to determine the

best mowing procedure. Consider the height of the grass

and the type of terrain (level, hilly, or rough). Each

condition will require certain adjustments or precautions.

5. Before leaving the mower, always lower deck mowers

so that when exiting the mower and stepping on the nonskid pads of the wing mowers, it will not put excessive

strain on the lift mechanism.

18

2. Release parking brake (8, Fig. J).

3. Moving forward: Push the toe of the traction pedal forward

with the ball of your foot, to increase the forward speed .

4. Moving backward: Push the heel of the traction pedal in

with the heel of your foot, to increase the reverse speed.

5. To return traction pedal to neutral, rock pedal with foot until

pedal stops. The pedal will stay in neutral when you

remove your foot.

T o avoid possible loss of control and/or serious bodily injury, avoid abrupt chages in

the tration pedal position. Reduce speed on

slopes, rough terrain, and in sharp turns to

prevent tipping or loss of control.

Page 19

I-TRIM

®

5.4—MOWING OPERATION

1. Check the turf area for debris that would cause

damage to the decks. Never operate the decks when they

are in the UP position because of the danagers of flying

objects and exposed blades.

2. When cutting large areas, the most satisfactory method is

to first cut the outer area and then mow clockwise toward

the center. The next time you cut, it is advised that you

mow in the opposite direction to prevent grass matting.

3. Cutting speeds are governed by conditions of turf, type of

terrain and opstacles to be encountered. Operate tractor at

slow speeds when turning.

5.5—MOWING

1. Stop tractor, by releasing the traction pedal, then slowly

lower the mower units (5, Fig.J) and (7, Fig. J).

Dropping mower decks abruptly could damage

them. Always check for bystanders before lowering.

1. When operating on hillsides or slopes, maintain full

engine speed, but let up on the traction pedal as power

requirements increase. This will maintain the

performance necessary.

2. It is best to mow along the side of the hill, starting at the

bottom and working upwards. This allows the machine to

negotiate the slope without mowing in a downhill

direction.

3. It is essential for the correct tire pressure to be

established for maximum traction and hillside holding.

5.7—PUSHING OR TOWING

INSTRUCTIONS

The I-Trim should not be pushed or towed with the engine not

running. If needed, the I-Trim can be pushed or towed at slow

speeds for very short distances without starting the engine.

Do not exceed 2 mph while pushing or towing.

A screw-adjustable valve is located on the underside of the

pump for towing. Note: Do not exceed 2 mph while pushing or

towing. Loosen the lock nut and turn the screw CCW to

release pressure. After towing, tighten the screw by turning

CW and lock into place with the locknut.

2. Engage deck control switch (9, Fig. J) to the ON position.

3. Depress traction pedal to the desired speed (sections

4.6 and 4.7). Deck speed is constant and ground speed is

variable with the traction pedal. Do not try to regulate

ground speed with engine throttle (section 4.5).

5.6—HILLSIDE OPERATION

The I-Trim has been designed for good traction and stability

under normal mowing conditions. However, caution must still be

used during slope operation, especially when the grass is wet.

Wet grass limits traction and steering control.

In order to minimize the possibility of tipping, the least dangerous method of operating on hills and terraces is to travel

horizontally to the hill. It is also advisable to avoid any unnecessary turns while operating on hills. Use extreme caution and

travel at reduce speeds.

19

Page 20

5.8—AFTER OPERATION

6—ADJUSTMENTS

1. Clean the entire mower after use. Remove loose grass

clippings and caked grass to prevent clogging the vented

areas, lubrication points, and corroding parts.

2. The engine is water cooled. Do not permit dirt or grass

clippings to accumulate on the air intake screen, engine

or radiator/oil cooler to prevent serious heat damage to

the engine,or hydraulic pump.

3. If fan blades become damaged, replace the fan.

5.9—CLEANING RADIATOR AND OIL

COOLER

1. If grass clippings become trapped in radiator and oil

cooler, use compressed air from fan side to blow them out.

The screenbox can tilted back for cleaning by loosening

quick-latches (Sec. 2.10 or Fig. H below ).

2. If grass clippings become trapped between radiator and

oil cooler, the oil cooler can be tilted back for cleaning

(Fig M). Be careful not to damage the fins on the

radiator and oil cooler during cleaning.

Read each instruction completely and, make sure you understand it before making any adjustments. Follow all the safety

precautions.

To avoid possible serious injury, before making

any adjustments or performing maintenance, engage parking brake, place all tractor controls in

neutral, lower decks to the ground, turn ignition

switch “off” and remove key.

6.1--TRACTION PEDAL ADJUSTMENTS

The traction pedal (1, Fig.M) is equipped with a safety switch

(2, Fig. M) and a neutral centering device. The switch prevents

the engine from starting when the pedal is positioned in

reverse or forward. The centering device locates neutral

positioning of the pump.

1. Prior to adjusting for creep, elevate the wheels off the

ground and support the vehicle with jack stands. Any

adjustments should be done while the hydraulic oil is

warm.

FIGURE L

2. To adjust the creep of the drive wheels, loosen the

fastener attaching the clevis to the control arm. Rotate the

clevis and re-atach to achieve neutral.

3. Once the traction pedal has been adjusted, the safety

switch (2, Fig. M) should not have to be re-adjusted.

Check neutral switch operation before use. If needed,

adjust the switch so that the engine cannot be started

unless the pedal is in the neutral position.

6.2—PARKING BRAKE ADJUSTMENT

The parking brake should be set so that it holds the tractor

securely. The parking brake must be released before the

traction pedal is engaged.

1. Adjust the brake by loosening set screw in the brake knob

and turning knob clockwise to tighten, or counterclockwise

to loosen, then retighten set screw.

2. After making any adjustment check brake on flat ground, so

that the tractor will not move with brake engaged.

3. Further testing by putting tractor on a hill, leaving the engine

on and engaging park brake. and then test with the engine

off.

20

FIGURE M

Page 21

I-TRIM

®

6.3—GROUND SPEED CONTROL

The I-Trim does not have an adjustable ground speed control.

See Section 4.7 for pedal adjustment.

6.4—REAR MOWER LIFT

The rear mower lift height has been preset at the factory and

normally will not need to be adjusted.

The I-Trim may be

fitted with a needle valve on the rear lift cylinder.

Turning the needle valve CW will slow the lift and

lowering speed of the rear deck. Always lock the

adjusment knob down when done adjusting.

6.5—HEIGHT OF CUT ADJUSTMENT

1. To set the height of cut, lift the deck to a vertical position (Fig.

O). Remove linch pins and assemble spacers (1 Fig. 0) to set

height of cut desired. Loosen side attachmement bolts of rear

roller if needed to slide rear roller out (2 Fig. O). Min HOC is 1.5”

with no spacers under the roller attachment shaft. Max HOC is

4”

REAR, RIGHT DECKS -SHARP EDGE UP

LEFT DECK- SHARP EDGE UP

2

1

FIGURE O

6.6—BLADE REPLACEMENT PROCEDURE

IMPORTANT

Rollers must be adjusted to the same height so

that there will be uniform cutting the entire width

of the mower.

To avoid possible serious bodily injury, before

performing and adjustments, maintenance, or lubrication, place all controls in “neutral”, lower

the mowers to the ground, engage parking brake,

turn ignition switch off and remove key.

Use heavy gloves and be careful. Blades are

very sharp.

Replace blades with factory blades only. Standard discharge

blades and mulching blades are available. Note: The Rear

and Right decks use the same blade (RH). The Left deck uses

a LH blade.

Be extremely careful not to let tools, your fingers

or clothing get caught in the blades. Use approved safety glasses to protect eyes from flying

particles and abrasives.

NEVER START ENGINE WITH DECKS ROTATED

UP AND NOT IN A HORIZONTAL POSITION.

1. Loosen 1/2-13 Grade 8 bolts and remove blades. Install

new blades as shown in Fig. O. Make sure cutting edge is

closest to ground and correct blade is on each deck.

2. Install bolts and torque to 98 ft-lbs. If needed, replace

2. Make sure adjustment nuts are tight before mowing.

21

Page 22

7—MAINTENANCE

To avoid possible serious bodily injury, before

performing and adjustments, maintenance, or lubrication, place all controls in “neutral”, lower the

mowers to the ground engage parking brake, turn

ignition switch off and remove key.

7.1—GENERAL MAINTENANCE

The long trouble free life of your machine depends on the

maintenance it receives. Set-up a maintenance program for

your I-Trim to cover the following points:

Keep tractor and decks clean

.

Keep all moving parts properly lubricated (sec. 7.14).

Keep all parts properly adjusted.

Inspect for loose, worn or damaged parts.

Keep shields in place at all times.

Keep tires properly inflated.

7.3—BATTERY

1. Make certain the ignition switch is in the “off” position and

the keys have been removed.

2. Refer to section 1.4 in this manual for battery

specifications.

Always wear protective glasses or goggles and

protective clothing when working with batteries.

Always connect the “ground” (black) cable last

and remove it first whenever performing any

maintenance.

Batteries contain sulfuric acid and generate explosive mixtures of hydrogen and oxygen gases.

Keep any device, which may cause sparks or

flames away from the battery to prevent explosions.

Read and follow the battery manufacture’s instructions on safety, maintenance and installation procedures.

If your inspection reveals worn or damaged parts replace

these parts before operating machine or before actual

breakdown occurs.

To avoid injury from hot, high-pressure oil, never

disconnect hydraulic hoses with attachments in

up position. Never rub hands across tubes, hoses

or fittings to check for leaks. Hydraulic fluid escaping under pressure can have sufficient force

to penetrate the skin.

7.2—ASSEMBLY AND DISASSEMBL Y

Use the illustrations in the parts catalog as reference for

disassembly and assembly of components. Always maintain

relative position of parts when disassembling. Clean and

lubricate individual parts and components as required.

3. When the battery is being installed or removed make

sure that the positive and negative terminals do not

come in contact with metal tractor parts at the same time

or severe damage may result.

4. Battery connections must be kept clean and tight at all

times. Loose cables will cause eventual battery failure.

Keep terminal covers in place.

5. Use soap and water to clean the battery as required.

Care must be taken to prevent soap and water from

getting inside battery.

6. Clean the terminal contact surfaces with a battery

terminal brush or steel wool.

7. Tighten cables securely to battery terminals.

8. Apply a light coat of petroleum jelly or chassis lubricant

to terminals and cable ends after assembly to prevent

corrosion.

22

Page 23

I-TRIM

®

7.4—CHARGING A BA TTER Y

To avoid possible injury, stand away from

battery when charger is turned on. A damaged

battery or a battery with an internal short could

explode

Charge battery ONLY in a well verted location, away from

sparks or open flame.

1. Remove the battery from the tractor before charging.

2. Be sure charger is “off “.

3. Connect charger leads to battery. Connect the positive

(+) connector from the charger to the positive battery

terminal. Connect the negative. (–) connector of the

charger to the negative battery terminal.

4. Charge the battery using one of the methods shown below.

Follow the manufacturer’s instructions on the charger.

5. If when charging the battery, if violent gassing or spewing

of electrolyte occurs, or the battery case feel hot

(125*F - 52C), reduce or temporarily halt charging to avoid

damaging battery.

6. Always turn charger to “off” before removing a charger

lead from the battery.

7.5—BELTS

There are no belts on the I-Trim.

7.6—ENGINE FUEL FILTER

Before servicing the fuel filter, thoroughly clean outside of filter

housing and fuel hoses, dirt must not be allowed to enter into

fuel or fuel system. Refer to manufacturer’s Engine Manual for

instructions.

7.7—ENGINE

Refer to manufacturer’s Engine Manual for maintenance

schedule recommendations. Change oil and oil filter after the

first 50 hours of operation.

7.8—ELECTRICAL SYSTEM

Make certain all terminals and connections are kept clean and

properly secured.

1. Check switches regularly to be sure they are kept clean

and operating correctly

2. Keep wire harness and all individual wires away from

moving parts, hot parts, or sharp edges. this will prevent

abrasive wear or potential short circuits.

3. Exercise extreme care when working with electrical

system.

7.9—HYDRAULIC HOSES

To avoid serious bodily injury , always lower mowers to the ground, place all controls in neutral

and shut off engine before inspecting hydraulic

lines or hoses. Never run hands across tubes,

hoses or fittings to check for leaks.

Hydraulic hose and tube lines should be inspected every week

to check for cuts, loose connections, kinks and wear.

Be sure tubes and hoses do not come in contact withother

frame parts which could cause abrasive wear. Always replace

worn hoses or tubes before operating machine.

1. Assemble nut, sleeves and tube to fitting body with

minimum torque (finger tight) until flare contacts

seat on fitting body.

2. For tightening reference, mark a line lengthwise on both

the nut and adapter fitting with a marker.

3. Using a wrench, rotate the nut to tighten. Turn the nut the

amount shown in the chart below. The line will show which

fitting have been tightened and how much.

4. On hoses with “o-ring” fittings, make sure o-rings are

clean and hose fittings are properly seated by hand before

wrench tightening.

5. Hold the fixed portion of the hose coupling with one

wrench; use a second wrench to tighten or loosen the hose

nut. This will prevent damage to the fitting seal. When

tightening a hose, do not allow it to twist; hold it in a

normal, straight position.

Tube O.D. or hose, Rotate Number. of flats

3/8” 2

1/2” 2

5/8” 1-1/2 to 2

1” 3/4 to 1

23

Page 24

7.10—HYDRAULIC OIL

7.12—JUMPER CABLES

1. The oil level should be checked if any oil leaks are

dicovered. Oil level should be brought to decal mark on

the side of the oil tank.

2. Park the tractor on a level surface.

3. Oil should be at 60° F to 90° F (16 – 32 °C), when

checking level. Do not check level when oil is hot.

4. Drain and replace the hydraulic oil every 200 hours.

Use ISO 68 Hydraulic grade oil. Replace both hydraulic

filters every 200 hours.

The oil should be changed after a major component failure,

or if you notice any of the following.

• Present of water - (noted by a cloudy or milky

appearance)

• Present of air - (noted by foaming)

• Excessive heat - (noted by rancid odor)

5. To drain hydraulic oil tank, remove the drain plug in the

back of the hydraulic tank.

6. Reinstall drain plug and fill hydraulic tank until the oil is

evel with the bottom of the screen in the fill tube. Use only

filtered hydraulic oil. The total hydraulic system oil capacity

is approx. 10-12 gallons.

7. Jack up rear tires so they spin freely.

8. Start engine; operate the traction pedal and turn steering

from right to left to free the system of air. Recheck oil level.

The battery on the I-Trim is located at the rear of the tractor,

See.

1. Stop the engine on the vehicle with the good battery.

2. Connect one jumper cable to the positive terminal on the

good battery. Connect the other end of the jumper cable to

either the positive terminal on the dead battery or the

battery side of the solenoid located on the right front of the

engine.

3. Connect one jumper cable to negative terminal on dead

battery. Connect the other end to ground (frame) of vehicle

with the good battery.

7.13—DECK BLADE REPLACEMENT

When the deck blades become damaged or too worn to keep

sharp, they must be replaced. Follow the procedure below.

1. See Section 6.13 for instructions to replace deck blades.

7.11—HYDRAULIC OIL FILTERS

To prevent damage to the hydraulic system, the hydraulic oil

filters (located under right fender and under steering column

shroud) should be changed after the first 25 hours of operation

and every 200 hours thereater.

1. Remove the old filter

2. Install new filter, filling filter with oil before re-installing.

Apply oil to the O-ring of the filter prior to installation. Hand

tighten only.

3. Run engine at idle speed with hydrostatic pump in neutral

for five minutes.

4. Check hydraulic oil level and add oil if necessary.

Frequent checks of oil level in the hydraulic tank.

Should the pump run short of oil, immediate and perma

nent damage will result

24

Page 25

THIS PAGE IS BLANK

I-TRIM

®

25

Page 26

7.14—LUBRICATION

Figure U shows the top view of the I-Trim

with guards removed. Lubricate your

tractor at the recommended locations and

intervals using proper lubricants so that

maximum service and long life of the

machine may be obtained.

Your I-Trim Mower maybe equiped with a

digital hour meter. This meter will display a

signal after 5 hours and every 25 hours

thereafter, recommending that you change

engine oil and lubricate the mower.

Before doing any work on

your machine, stop the

engine, remove the ignition

key and set parking brake.

SYMBOLS

GREASE - Lithium base

or equivalent

OIL - Light machine oil

FIGURE U

Fre- No.

Item quency Location Type of of

(Hrs.) Lubrication Places

1 Daily Dipstick / left side of Engine Check level 1

2 Daily Radiator Reservoir Bottle Check level 1

3 Daily Hydraulic Tank Check level 1

4 Daily Fuel Tank Check level 1

5 Daily* Pre-Air Filter Inspect/Clean 1

6 Daily* Screenbox, Radiator Fins/ Rear Inspect/Clean 1

7 Weekly Height Adjustment Shaft Housings Grease, Lithium 12

8 Weekly Tires Check Pressure 4

9 Weekly Hardened Bushines/Deck Lift Arms Light Machine Oil 10

9100/600** Air Filter Element / Left side of Engine Inspect, Replace as Nec. 1

10 100 Fan Belt / Rear of Engine Inspect, Adjust 1

11 150** Drain Plug / Underneath Engine Change Oil 1

12 Monthly Front Axel - Rod Ends, King Pin.pivot Grease, Lithium 6

13 Monthly Radiator / Rear of Engine Check coolant level cold 1

14 Monthly Rear Lift Pivot / Above Rear Deck Grease, Lithium 2

15 Monthly Lift Shaft Bushings / Under Seat Grease, Lithium 1

16 200 Battery / Right Side of Engine Check Electrolyte 1

17 300** Canistor / Left Side of Engine Change Oil Filter 1

18 600 Rocker Arms / Top of Engine Check Valve Clearance 1

19 800 Fuel Filter / Left side of Engine Replace 1

20 Yearly Pedal Shaft Bushings / Behind Bumper Grease, Lithium 2

21 200*** Hydraulic filters (2)/RH shroud,steering Replace 2

22 200* Hydraulic Tank / To Left side of Engine Drain, Flush, Refill 1

23 Yearly Radiator, Engine Block Change Coolant 1

* More often as necessary

** Perform first maintenance operation after 50 hours. All subsequent maintenance

performed at this interval. Service more often when operating under heavy load or in high

termperature.

*** Perform first change of hydraulic filters at 25 hours. All subsequent replacements at

200 hours

26

Page 27

I-TRIM

®

27

Page 28

8—STORAGE

8.5—TIRES

8.1—GENERAL INSTRUCTIONS

When you do not plan to use your vehicle for some time, it

should be stored in a dry and protected place. Unnecessary

exposure to the elements may deteriorate its appearance and

shorten the usual service life.

8.2—ENGINE

1. Drain the fuel from the fuel tank.

2. While the engine is still warm, change oil. Refer to

Engine Manual for manufacture’s instructions.

3 Remove glow plugs and pour about 3cc of engine oil

into each cylinder. Replace glow plugs and crank slowly

to distributre oil.

4. Clean exterior of engine. Paint the exposed metal or

coat it with a light coating of rust preventative oil.

8.3—BATTERY

1. Before storing the vehicle, clean the tires thoroughly.

2. Jack up the vehicle so that the load is off the tires. If it is

not jacked up, check the tires at regular intervals and reinflate as necessary to keep them at the recommended

maximum pressure. (Indicated on tires side wall)

3. Store the vehicle so that the tires are protected from

sunlight.

8.6—STARTING THE ENGINE AFTER

STORAGE

If mower is cold, move the mower to a heated location and

allow it to come to room temperature( 70° F - 22 °C) before

starting. This will prevent premature wear of hydraulic system

components.

Follow the towing procedure (in Sec. 5.8).

1. Check and recharge the battery according to recommen-

dations given in Section 7.4 page 22.

2. Reinstall the battery

1. Remove battery and clean it. Refer to manufacturer’s

manual for specific instructions.

2. Maintenance free batteries should be stored in an

upright position in a cool dry place. Storage above 80° F

greatly increases self-discharge. If wet batteries are

discharged, the electrolyte will freeze when stored below

20° f (-7 °C)

IMPORTANT

The battery should be checked every 60 to 90

days while in storage, and should be recharged

if necessary.

8.4—TRACTOR

Wash, clean and completely lubricate the tractor. Paint any

exposed metal.

3. Check oil level in crankcase and hydraulic oil tank.

4. Fill the fuel tank with fresh diesel fuel. Prime fuel filter by

pushing down and releasing until firm.

5. Before driving the vehicle, check to make certain that the

tires are properly inflated to the proper pressure.

6. Either move the vehicle outdoors or keep doors and or

windows wide open to provide sufficient ventilation before

starting engine this will prevent danger from carbon

monoxide gas in the exhaust.

7. Start the engine but do not operate at high speed

immediately after starting. Allow time for it to become

properly warmed and lubricated.

28

Page 29

9—TROUBLE SHOOTING

T o avoid possible serious injury , before making any adjustments or performing maintenance, place all controls in neutral, fully lower

cutting units to the ground, turn ignition

switch to “OFF”, remove key and set parking

brake.

ENGINE WILL NOT START

I-TRIM

1. MAKE WORK AREA SAFE:

Make sure personnel in the area are out of

harms way if the engine starts or the decks

run unexpectedly. Engage the vehicle

parking brake.

2. READ MANUAL:

Become familiar with wiring diagram and

the locations of the various electrical

components.

®

The operator must be seated.

Check position of controll switch (on dash).

Switch must be in the OFF position.

Check to see that the traction pedal is in neutral.

(neutral is in the center position).

Check all safety switches for conductivity. See

Electrical System diagram, Fig. 11, Page 48.

Replace switches if necessary.

Check fuel in tank

Check battery. Check charge level, charge or replace as

needed. Clean battery terminals if necessary.

Check electrical wiring and safety switch operation.

TRACTOR WILL NOT MOVE

Check that parking brake is not engaged.

Check the linkage from the traction pedal to the pump control

mechanism to ensure complete attachment of all linkages.

3. DISCONNECT HOUR METER BEFORE

REMOVING SIDE COVER:

It may be necessary to remove both side

covers, rear cover and hood to give access

to battery, ignition switch, circuit breaker,

blade run switch, circuit board and other

electrical components. It may also be

necessary to remove the front bumper

cover to gain access to the neutral pedal

switches.

4. CHECK BATTERY:

Make sure battery is in good condition and

fully charged.

5. CHECK BATTERY CABLES:

Check battery cables for tightness at both

battery and engine.

6. CHECK GROUND STRAP:

Check ground strap for tightness and

condition.

DECKS WILL NOT TURN

Check for debris jammed between the blade and

deck platform.

9.1—ADVANCED TROUBLE SHOOTING PROCEDURES

VEHICLE PREPARATION FOR DIAGNOSIS AND

COMPONENT IDENTIFICATION

7. DECK RUN SWITCH OFF:

Put deck run switch in the off position.

8. RESET CIRCUIT BREAKER:

The circuit breaker has a reset button.

Reset circ uit breaker after checking for a

short or grounded wire downstream of the

circuit breaker.

29

Page 30

9. SAFETY INTERLOCK BOARD (SIB):

The ITrim is equipped with an integrated

circuit board designated as the Safety

Interlock Board (SIB). The SIB controls the

vehicle starter cranking, engine run and

deck run circuits and the indicator lights.

The starter motor won’t crank unless the

following conditions are met:

a. Operator must be sitting in the

seat.

b. Foot Pedal must be in neutral

position.

c. Deck Switch must be off.

If the operator gets up off the seat the

engine will continue to run if the following

conditions are met:

a. The foot pedal is in neutral

position.

The deck switch is off.

If engine doesn’t crank:

1. With a test light, check for power at plastic

connector on the starter solenoid while an

assistant turns the key.

If test light doesn’t come on:

The problem is in the wiring or

terminals between the start relay

and the starter solenoid.

If test light comes on:

The problem is in the starter

solenoid or starter.

If engine cranks:

1. Remove jumper and reinstall terminals on start

relay.

2. Turn the ignition switch to the on position.

3. Check the indicator lights on the SIB with an

assistant sitting on the seat of the vehicle.

a. All four indicator lights should be on.

PROBLEM: STARTER WON’T CRANK - with

pedal in neutral position, operator in seat and

deck run switch in off position.

1. Using a test light, check for power to the start

relay, terminal 87 when the ignition switch is

turned to the start position.

If test light doesn’t come on at start relay, terminal

87:

1. With a test light, work back from the start

relay, checking for power at the ignition

switch, circuit breaker and positive battery

post on the starter solenoid.

2. Replace defective components or repair

wiring.

If test light comes on at start relay, terminal 87:

1. Remove contact terminals, terminals 87 and

30, from start relay.

2. Connect the contact terminals together with

a temporary jumper made with spade

terminals and 10 GA wire.

3. Turn the ignition switch to the start

position.

If no lights come on:

1. Check for a blown fuse on the SIB and

replace if faulty.

2. Check for power to the SIB by checking

fuse receptacle with a test light. The left

slot of the fuse receptacle should have

power.

If there is no power to the left slot of the fuse

receptacle:

1. Check for power at terminal J2-2 on the SIB

with a test light. (Insert test light probe into

backside of connector.)

If there is power at terminal J2-2 on the SIB but

not at the left slot of the fuse receptacle, the

SIB is faulty and should be replaced.

If there isn’t power at terminal J2-2 on the SIB,

the problem is in the wiring or the terminals

between the ignition switch and the SIB.

30

Page 31

If no lights come on and fuse is good

and there is power to the board:

1. Make sure SIB is grounded by checking the

resistance between the capacitor ground on the

SIB and the vehicle frame. Resistance should

be 0.

If SIB is not grounded:

1. Check the resistance between terminal J1-7 on

the SIB and the vehicle frame. Resistance

should be 0.

If number 1 above is not 0 and number 2 above is 0:

The SIB is faulty and should be replaced.

If number 1 above is 0 and number 2 above is not 0:

The problem is in the wiring or terminals between

J1-7 and the frame ground which is located on

the ROPs support behind the SIB bracket.

If SIB is grounded and lights still don’t come on:

1. Temporarily put jumper between terminals

J3-1 and J3-2 on SIB. (The jumper can be

a thin piece of U-shaped wire inserted into

the backside of the connector.)

a. The seat relay indicator light, (the first light

on the left side of the SIB,) should come

on.

If the seat relay indicator light doesn’t come on:

The board is faulty and should be replaced.

If the seat relay indicator light comes on:

(With the jumper but not with a person in the

seat) The problem is in the seat or the

wiring between the SIB and seat.

If the seat relay indicator light comes on but

none of the others do with the SIB

grounded:

The SIB is faulty and should be replaced.

If the seat relay indicator light on the SIB and

the run relay indicator light on the SIB are on

but the pedal relay indicator light and/or the

blade relay indicator light are not on,

troubleshoot the pedal and blade relay circuits

individually as follows:

I-TRIM

®

If the pedal relay indicator light is off with seat

and run relay indicator lights on:

Temporarily put jumper between terminals J3-3

and J3-4 on the SIB. (The jumper can be a

thin piece of U-shaped wire inserted into the

backside of the connector.)

The pedal relay indicator light, (the second light

from the left side of the SIB,) should come on.

If the pedal relay indicator light doesn’t come

on with the jumper:

The board is faulty and should be replaced.

If the pedal relay indicator light comes on with

the jumper:

The problem is in the pedal switches at the

front of the vehicle or in the wiring from the SIB

to the pedal switches. (The arms that the

pedal switches are mounted on, must fully

contact the foot plate of the vehicle to actuate

the switches. Both switches must be actuated

to complete the circuit to the SIB.)

If the blade relay indicator light is off with seat

and run relay indicator lights on.

Temporarily put jumper between terminals J2-2

and J2-3 on SIB. (The jumper can be a thin

piece of U-shaped wire inserted into the

backside of the connector.)

The blade relay indicator light, (the third light

from the left side of the SIB,) should come on.

If the blade relay indicator light doesn’t come

on with the jumper:

The board is faulty and should be replaced.

If the blade relay indicator light comes on with

the jumper:

The problem is in the deck run switch the

wiring or terminals to the deck run switch

terminal 5 or the wiring or terminals from the

blade switch to the SIB.

The starter should crank with all the above

operating correctly.

31

Page 32

Problem: STARTER CRANKS BUT ENGINE

WON’T START

Check the electrical system after checking for fuel

in the tank and after priming the fuel system.

Using a test light with the ignition switch in the on

position, check for power at the fuel pump

connector on the engine.

If light comes on:

Test the resistance of the deck run

hydraulic valve coil (at coil connector).

The resistance should be approximately

4c ohms. Current flow through the coil

therefore should be approximately 3

amps. at 14 volts.

If test light comes on:

Make sure fuel pump is properly

grounded by using the fuel pump for the

test light ground.

If the fuel pump is properly grounded

the problem is in the fuel pump.

If test light doesn’t come on:

Using a test light check for power at

terminal J4-2 on the SIB.

If test light comes on at terminal J4-2

on the SIB:

The problem is in the wiring or

terminals between the SIB and the

fuel solenoid.

If test light doesn’t come on at terminal

J4-2 on the SIB:

The board is faulty and should be replaced.

Problem: DECK MOTORS WON’T RUN WITH

ENGINE RUNNING

1. Temporarily disconnect connector at blade

run hydraulic valve.

2. Start engine, put deck run switch to on

position.

3. Check terminals of wiring connector with

test light.

If the coil resistance is correct the

problem is not in the electrical system.

If light doesn’t come on:

1. Check for power at

terminal J2-6 on the SIB.

2. Check for power at

terminal 2 on the Deck

Run Switch.

3. Check for power at

terminal 1 on the Deck

Run Switch.

If the light doesn’t come on for number 1

above:

The board is faulty and should be

replaced.

If the light comes on for number 1 above

but not 2:

The problem is in the wiring or

terminals between the SIB and the

deck run switch.

If the light comes on for numbers 1 and 2

above but not 3:

The deck run switch is faulty and

should be replaced.

If the light comes on for numbers 1,2 and 3

above:

The problem is in the wiring or

terminals between the deck run switch and the

blade run valve.

32

Page 33

I-TRIM

®

FRAME

GROUND

BLK

-

BATTERY

+

D

R

E

ENGINE

GROUND

BLK

RUN

BLADE

RED

5

RED

4

STARTER

3

RED

ALTERNATOR

L

IG

47

48

RED

WHT

BLK

RED

VALVE

FUEL

PUMP

4

2

OIL

44

YEL

PRESSURE

ENGINE

TEMPERATURE

46

BLU

WHT

PLUGS

GLOW

FUEL

FILTER

51

7

BLK

RED

BLU

WIRING DIAGRAM

LTBLU

23

LTBLU

25

ITRIM

5

7

5

2

5

6

5

FRAME

GROUND

LTBLU

RED

24

RED

4

LTBLU

START

RELAY

30

86

85

87

0

3

6

26

B

A

5

2

1

4

SWITCH

DECK RUN

WHT

2

RED

RED

WHT53

3

LTBLU

22

JUMPER

D

R

E

IGNITION

RED

5

6

RESET

BUTTON

CIRCUIT

RED

BREAKER

OIL

PRESS

1

L

S

B

SWITCH

BATT

RED

BLK

SEAT

PANEL

LIGHT (5)

INDICATOR

INSTRUMENT

PLUG

GLOW

1

6

-

+

-

FILT

FUEL

+

-

14

+

-

TEMP

+

WATER

O

HOUR

METER

PEDAL

SWITCHES

0

1

7

WHT

19

18

K

L

B

5

0

BLK

5

0

D

R

E

K

L

B

5

1

C

K

L

B

B

A

1

2

15

-

K

L

B

O

+

O

BLU

10

WHT

K

L

B

K

L

B

W

H

T

K

L

B

BLK

RED

K

L

B

D

R

E

123

17

BLK

4

J3

3

2

1

J3

9 10

9

8 10

5 7

6

3

4

J1

1

2

JI

1 2 3 4 5 6 7 8

11

BOARD

SAFETY INTERLOCK

LTBLU

LTBLU

LTBLU

LTBLU

LTBLU

4

5

6

321

J2

3

1

4

4

2

J2

RELAY

LIGHT (4)

INDICATOR

YEL

RED

WHT

BLU

WHT

6

5

478

123

J4

5

6

5

3

1

7

6

4

2

8

WHT

WHT

D

B

A

C

J4

55

R

E

Z

Z

B

U

L

A

Y

E

R

N

U

R

L

A

Y

E

R

B

L

A

D

E

R

L

A

Y

E

D

A

E

L

P

L

A

Y

E

R

S

A

T

E

R

L

A

Y

E

GROUND

CAPACITOR

TIMER

GLOW PLUG

WHT JUMPER

RED

RED

6

RELAY

GLOW PLUG

30

WHT JUMPER

86

85

87

7

50

RED

FIGURE 11

33

Page 34

34

Page 35

I-TRIM

®

35

Page 36

FIGURE 1

36

Page 37

I-TRIM

®

FIGURE 1—SCREEN BOX, GUARDS, ROPS, MISC

1 1 306435 WELDMENT - SIDE COVER, LH

2 1 07063 HOUR METER

3 5 07697 LED

4 1 306341 PANEL - INSTRUMENT, LH

5 1 203086 THROTTLE CONTROL

6 1 306162 WELDMENT - BUMPER PLATE

7 1 306298 COVER - STEERING TOWER

8 1 305984 STEERING COLUMN

9 1 07071 STEERING WHEEL

10 1 07731 ROPS, FULL VISION

11 1 07065 KEY SWITCH

12 1 07496 SWITCH - DECK MOTOR

13 4 07399 KNOB, DAVIES MOULDING CO #3035

14 1 306227 HOOD

15 1 07695 STARTER SOLENOID RELAY, WAYTEK #75002

ITEM NO. QTY. PART NO. DESCRIPTION

306526

16 1 07700 CIRCUIT BREAKER, WAYTEK #46374

17 4 07840 LATCH

18 1 306438 WELDMENT - SIDE COVER, RH

19 1 306351 ASSY - INSTRUMENT PANEL, RH

20 1 306350 WELDMENT - REAR COVER

21 1 306489 WELDMENT - SCREENBOX

22 1 306488 ASSY - SCREEN

23 2 306498 ASSY - SCREENBOX CABLE

24 1 306427 WEATHERSTRIP ASSY

37

Page 38

38

FIGURE 2

Page 39

I-TRIM

®

FIGURE 2—DECK LIFT ARMS AND PULL ARMS

1 2 07719 BUSHING - 1X1.5X2, BOSTON #B1624-16

2 5 02511 THRUST WASHER

3 1 02263 HEX NUT 3/8-24 NYLOCK

4 3 02403 FLAT WASHER - 3/8 SAE

5 1 07709 LIFT CYL - WING DECK

6 10 204447 BUSHING - PULL ARM

7 1 02036 HEX BOLT, 0.375 -24 UNF x 2¼ ZINC PL

8 1 306062 WELDMENT - LOWER PULL ARM, L

9 2 306188 WELDMENT - WING LIFT ARM

10 1 306191 WELDMENT - WING LIFT X-SHAFT

11 1 306061 WELDMENT - UPPER PULL ARM L

12 1 306242 NON SKID - WING PULL ARM

13 5 306177 BUSHING - PULL ARM INNER

14 1 04079 EXTERNAL RETAINING RING, 1.00 ID, H/D, McM #98585A121

15 1 306359 NON SKID - WING PULL ARM

ITEM NO. QTY. PART NO. DESCRIPTION

16 1 306232 WELDMENT - UPPER PULL ARM R

17 1 306234 WELDMENT - LOWER PULL ARM R

18 4 04048 ROLL PIN, .25 X 1.5

19 2 07714 LIFT SPRING - REAR PULL ARM

20 2 306320 END CAP - SPRING MOUNT, OUTER

21 1 07710 LIFT CYL - REAR DECK

22 1 306128 WELDMENT - LIFT ARM, RR PULL FRAME

23 2 02061 HEX BOLT, ½ -13 UNC x 1¼

24 1 306129 BUSHING - LONG, RR PULL FRAME

25 2 02333 EXTERNAL TOOTH LOCK WASHER, 1/2 ADAMS #348800

26 1 02751 HEX JAM NUT, NYLOCK, 3/4-16

27 1 306123 WELDMENT - PIVOT FRAME, RR PULL ARM

28 1 306241 PIVOT PIN - REAR DECK

29 1 306120 WELDMENT - LIFT FRAME, RR PULL ARM

30 2 306167 MOUNT - SPRING, RR DECK

31 2 306185 END CAP - SPRING MOUNT

32 2 02166 HEX BOLT, ½ -13 UNC x 5½

39

Page 40

40

FIGURE 3

Page 41

I-TRIM

®

FIGURE 3— SEAT, WHEELS, ENGINE, RADIATOR, HYD TANK