BRIGGS & STRATTON Micro Engine Repair Manual

Micro Engine

Repair Manual

TABLE OF CONTENTS

GENERAL INFORMATION Section 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISASSEMBLY AND REPAIR Section 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

SECTION CONTENTS

1

Section 1

General Information

In The Interest Of Safety

Briggs & Stratton Numerical Identification System

Engine Identification

Fuel and Oil Recommendations

Gasoline

Lubrication

Maintenance

Check Oil

Change Oil

Air Cleaner

Breather Check Valve

Replace Spark Plug

Cooling System

Troubleshooting

Systematic Check

Check Ignition

Check Carburetion

Check Compression

Equipment Affecting Engine Operation

Hard Starting, Kickback or Will Not Start

Vibration

Power Loss

2

Section 2

Disassembly and Repair

General Information

Rewind Assembly

Inspect Starter Rope

Remove Blower Housing – Direct Drive Engine

Replace Starter Rope

Install Blower Housing – Direct Drive Engine

Remove Blower Housing – Clutch Drive Engine

Install Blower Housing – Clutch Drive Engine

Ignition Coil

Remove Coil

Install Coil

Adjust Air Gap

Flywheel

Remove Flywheel – Direct Drive Engine

Install Flywheel – Direct Drive Engine

Remove Flywheel – Clutch Drive Engine

Install Flywheel – Clutch Drive Engine

Fuel Tank

Remove Fuel Tank

Install Fuel Tank

Cylinder Head

Remove Cylinder Head

Install Cylinder Head

Muffler

Replace Muffler

Carburetor

Remove Carburetor

Install Carburetor

Idle Speed Adjustment

II

Section 1

General Information

Section Contents

Page

IN THE INTEREST OF SAFETY

BRIGGS & STRATTON NUMERICAL IDENTIFICATION SYSTEM

ENGINE IDENTIFICATION

FUEL AND OIL RECOMMENDATIONS (G

asoline, Lubrication) 5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE

Check Oil 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change Oil 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Cleaner 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replace Spark Plug 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling System 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Systematic Check 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Ignition (With Engine Starter) 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Ignition (Engine Running) 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Carburetion 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Compression 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Affecting Engine Operation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hard Starting, Kickback or Will Not Start 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vibration 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Loss 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. . . . . . . . . . . . . . . . . . . . . . . . .

5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Briggs & Stratton engine is made of the finest material in a state-of-the-art manufacturing facility . Please understand that Briggs & Stratton sells engines to original equipment manufacturers. It also sells to others in the

distribution chain who may sell to the ultimate consumer, an equipment manufacturer, another distributor or a

dealer . As a result, Briggs & Stratton does not necessarily know the application on which the engine will be placed.

For that reason, carefully read and understand the operating instructions of the equipment before you repair or

operate.

You should also understand that there are equipment applications for which Briggs & Stratton does not approve

the use of its engines. Briggs & Stratton engines are not to be used on vehicles with less than 4 wheels. This

includes motor bikes, aircraft products and All Terrain Vehicles. Moreover, Briggs & Stratton does not approve

of its engines being used in competitive events. FOR THAT REASON, BRIGGS & STRATTON ENGINES ARE

NOT AUTHORIZED FOR ANY OF THESE APPLICATIONS. Failure to follow this warning could result in death,

serious injury (including paralysis) or property damage.

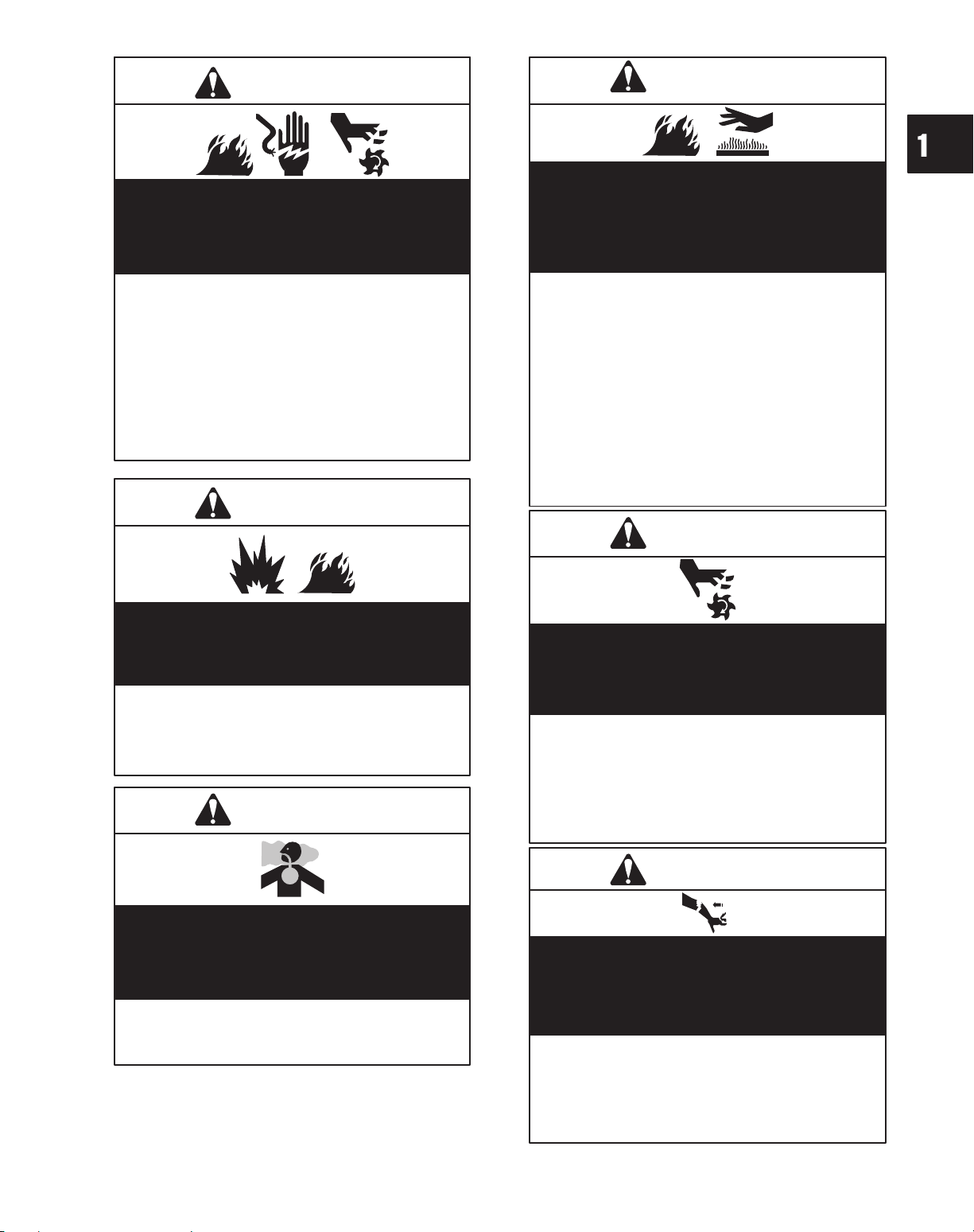

IN THE INTEREST OF SAFETY

A signal word (DANGER, WARNING or CAUTION) is

The safety alert symbol ( ) is used to identify

safety information about hazards that can result in

personal injury.

used with the al ert symbol to i ndicate the l ikelihood a nd

the potential severity of injury. In addition, a hazard

symbol may be used to represent the type of hazard.

1

DANGER indicates a hazard which, if not

avoided, will result in death or serious

injury.

WARNING indicates a hazard which, if

not avoided, could result in death or

serious injury.

CAUTION indicates a hazard which, if not

avoided, might result in minor or

moderate injury.

CAUTION, when used without the alert

symbol, indicates a situation that could

result in damage to the engine.

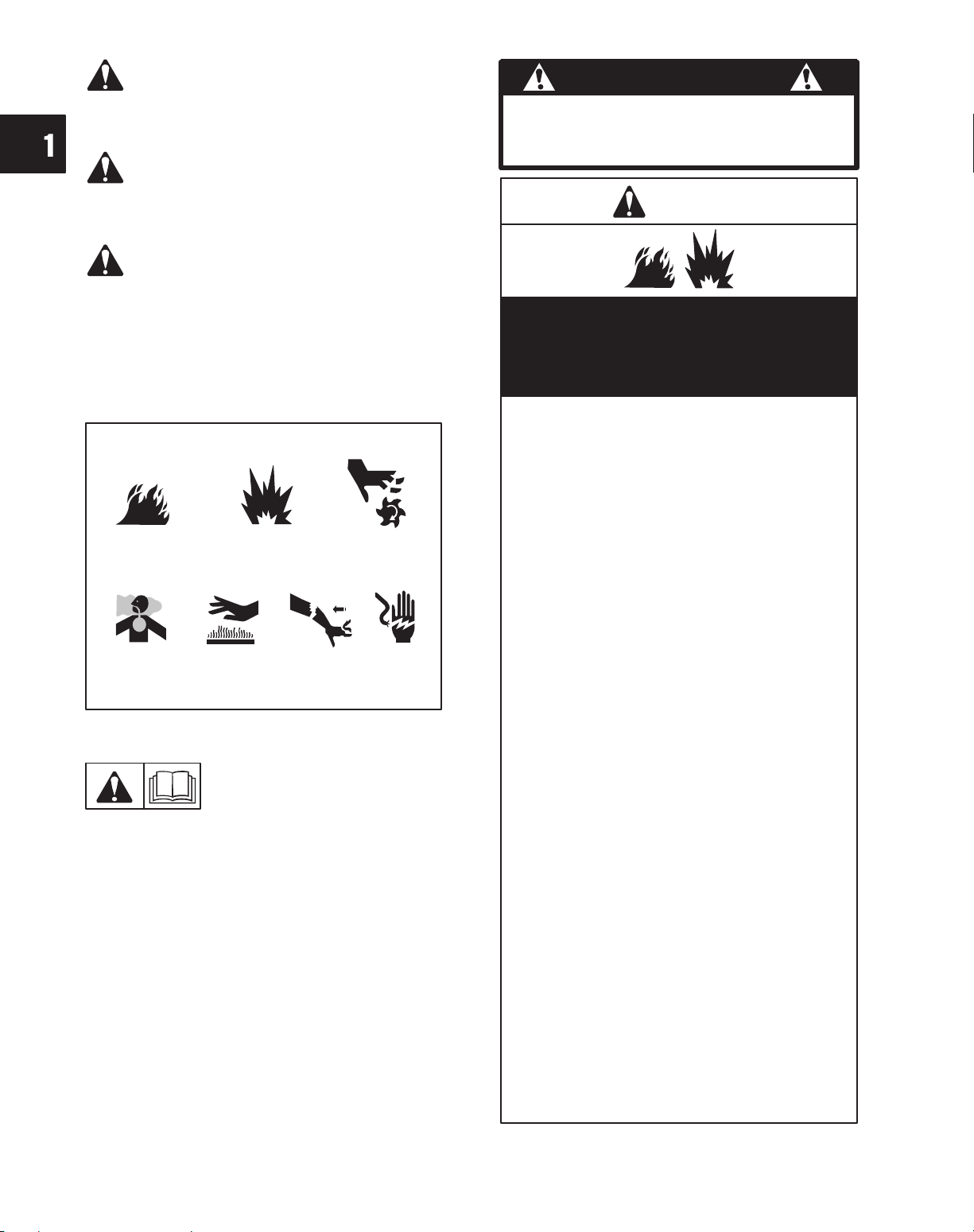

HAZARD SYMBOLS AND MEANINGS

Fire

Toxic Fumes ShockHot

4Prior to work, read and understand the section(s)

of this manual that pertain to the job. Follow all safety

warnings.

4WEAR suitable eye protection (safety glasses,

goggles or face shield when performing repair procedures).

4PREVENT ACCIDENTAL STARTING by removing spark plug wire from spark plug when servicing

engine or equipment.

4PERIODICALLY clean engine. Keep carburetor

parts free of dirt, grass and other debris which can

affect engine speed.

4USE fresh gasoline. Stale fuel can gum carburetor

and cause leakage.

4CHECK fuel lines and fittings frequently for cracks

or leaks. Replace if necessary.

Explosion

Kickback

Surface

Moving

Parts

WARNING:

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects, or other reproductive harm.

WARNING

Gasoline and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe burns or

death.

WHEN ADDING FUEL

• Turn engine OFF and let engine cool at least

2 minutes before removing gas cap.

• Fill fuel tank outdoors or in well-ventilated

area.

• Do not overfill fuel tank. Fill tank to

approximately 1-1/2 inches below top of

neck to allow for fuel expansion.

• Keep gasoline away from sparks, open

flames, pilot lights, heat, and other ignition

sources.

• Check fuel lines, tank, cap, and fittings

frequently for cracks or leaks. Replace if

necessary.

WHEN STARTING ENGINE

• Make sure spark plug, muffler, fuel cap and

air cleaner are in place.

• Do not crank engine with spark plug

removed.

• If fuel spills, wait until it evaporates before

starting engine.

• If engine floods, set choke to OPEN/RUN

position, place throttle in FAST and crank

until engine starts.

WHEN OPERATING EQUIPMENT

• Do not tip engine or equipment at angle

which causes gasoline to spill.

• Do not choke carburetor to stop engine.

WHEN ST ORING GASOLINE OR EQUIPMENT WITH FUEL IN TANK

• Store away from furnaces, stoves, water

heaters or other appliances that have pilot

light or other ignition source because they

can ignite gasoline vapors.

2

WARNING

Unintentional sparking can result in fire or

electric shock.

Unintentional start-up can result in entanglement, traumatic amputation, or laceration.

WARNING

Running engines produce heat. Engine parts,

especially muffler, become extremely hot.

Severe thermal burns can occur on contact.

Combustible debris, such as leaves, grass,

brush, etc. can catch fire.

BEFORE PERFORMING ADJUSTMENTS

OR REPAIRS

• Disconnect spark plug wire and keep it away

from spark plug.

WHEN TESTING FOR SPARK

• Use approved spark plug tester.

• Do not check for spark with spark plug

removed.

WARNING

Starting engine creates sparking.

Sparking can ignite nearby flammable gases.

Explosion and fire could result.

• If there is natural or LP gas leakage in area,

do not start engine.

• Do not use pressurized starting fluids

because vapors are flammable.

WARNING

• Allow muf fler, engine cylinder and fins to cool

before touching.

• Remove accumulated combustibles from

muffler area and cylinder area.

• Install and maintain in working order a spark

arrester before using equipment on

forest-covered, grass-covered, brush-covered

unimproved land. The state of California

requires this (Section 4442 of the California

Public Resources Code). Other states may

have similar laws. Federal laws apply on

federal land.

WARNING

Rotating parts can contact or entangle hands,

feet, hair, clothing, or accessories.

Traumatic amputation or severe laceration can

result.

• Operate equipment with guards in place.

• Keep hands and feet away from rotating parts.

• Tie up long hair and remove jewelry.

• Do not wear loose-fitting clothing, dangling

drawstrings or items that could become

caught.

Engines give off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide can cause

nausea, fainting or death.

• Start and run engine outdoors.

• Do not start or run engine in enclosed area,

even if doors or windows are open.

WARNING

Rapid retraction of star ter cord (kickback ) will

pull hand and arm toward engine faster than

you can let go.

Broken bones, fractures, bruises or sprains

could result.

• When starting engine, pull cord slowly until

resistance is felt, then pull rapidly.

• Direct coupled equipment components such

as, but not limited to, blades, impellors,

pulleys, sprockets, etc., must be securely

attached.

3

YOUR KEY TO THE WORLD’S FINEST ENGINES

This chart explains the unique Briggs & Stratton numerical model designation system. It is possible to determine most

of the important mechanical features of the engine by merely knowing the model number. Here is how it works:

A. The first one or two digits indicate the approximate CUBIC INCH DISPLACEMENT.

B. The first digit after the displacement indicates the BASIC DESIGN SERIES, relating to

cylinder construction, ignition, general configuration, etc.

C. The second digit after the displacement indicates ORIENTATION OF CRANKSHAFT.

D. The third digit after the displacement indicates TYPE OF BEARINGS, and whether or not

the engine is equipped with REDUCTION GEAR or AUXILIARY DRIVE.

E. The last digit indicates the TYPE OF STARTER.

BRIGGS & STRATTON MODEL NUMBERING SYSTEM

FIRST DIGIT

AFTER DISPLACEMENT

A B C D E

CUBIC INCH

DISPLACEMENT

ă6

ă8

ă9

10

11

12

13

16

18

19

20

21

22

23

24

25

28

29

30

31

32

35

38

40

42

43

44

46

47

52

54

58

EXAMPLE - To identify Model 303447:

30 3 4 4 7

30 Cubic Inch Design Series 3 Horizontal Shaft Ball Bearing

BASIC

DESIGN SERIES

0

1

2

3

4

5

6

7

8

9

A to Z

A to G - Horizontal Shaft

H to Z - Vertical Shaft

TYPE 1234Ć01, The type number identifies the engines mechanical parts, color of paint, decals, governed speed, and

Original Equipment Manufacturer.

CODE 01061201, The code is the manufacturing date and is read as follows:

YEAR MONTH DAY ASSEMBLY LINE AND MANUFACTURING PLANT

01 06 12 01

Revised 5/03

SECOND DIGIT

AFTER DISPLACEMENT

CRANKSHAFT

ORIENTATION

0 to 4 - Horizontal Shaft

5 to 9 - Vertical Shaft

THIRD DIGIT

AFTER DISPLACEMENT

PTO BEARING,

REDUCTION GEAR,

AUXILIARY DRIVE,

LUBRICATIONă TYPE OF STARTER

0 - Plain Bearing/DU

NonĆFlange Mount

1 - Plain Bearing

Flange Mounting

2 - Sleeve Bearing

Flange Mounting

Splash Lube

3 - Ball Bearing

Flange Mounting

Splash Lube

4 - Ball Bearing

Flange Mounting

Pressure Lubrication

5 - Plain Bearing

Gear Reduction

(6 to 1) CCW Rotation

Flange Mounting

6 - Plain Bearing

Gear Reduction

(2 to 1) CCW Rotation

7 - Plain Bearing

Pressure Lubrication

8 - Plain Bearing

Auxiliary Drive (PTO)

Perpendicular to

Crankshaft

9 - Plain Bearing

Auxiliary Drive

Parallel to Crankshaft

A - Plain Bearing

Pressure Lubrication

Without Oil Filter

Flange Mounting

Pressure Lubrication

FOURTH DIGIT

AFTER DISPLACEMENT

0 - Without Starter

1 - Rope Starter

2 - Rewind Starter

3 - Electric Starter Only

110 or 230 Volt Gear

Drive

4 - Electric Starter/110 or

230 Volt Gear Drive

with Alternator

5 - Electric Starter Only

12 or 24 Volt Gear

Drive

6 - Alternator Only

7 - Electric Starter

12 or 24 Volt Gear

Drive with Alternator

8 - Vertical Pull Starter or

Side Pull Starter

9 - Mechanical Starter

A - Electric Starter

12 or 24 Volt Gear

Drive with Alternator

and Inverter

Electric Starter

12 or 24 Volt Gear Drive

with Alternator

4

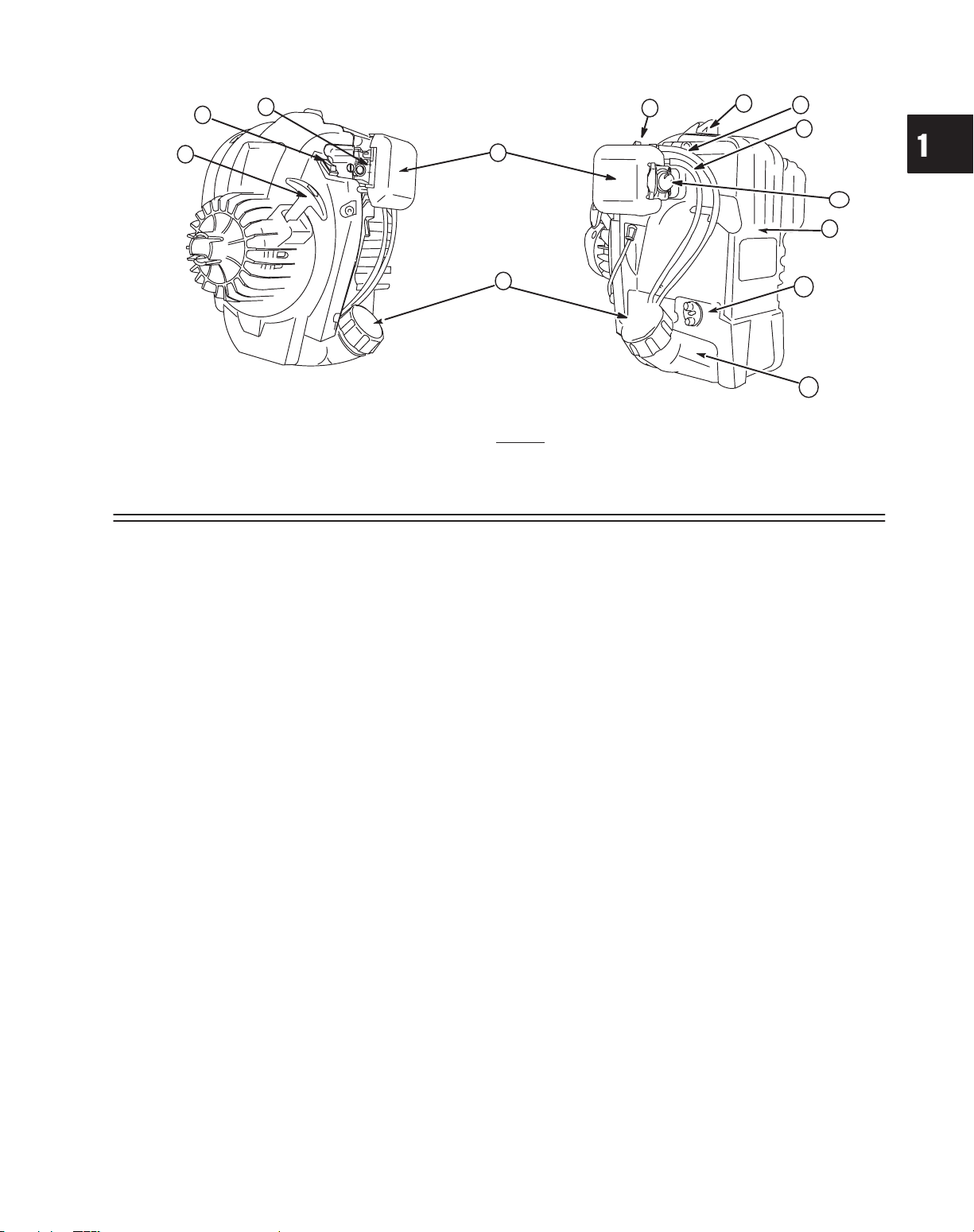

ENGINE IDENTIFICATION

2

3

1. Carburetor

2. Stop switch

3. Rope handle

4. Fuel fill

5. Air cleaner

6. Choke lever

7. Spark plug

1

5

4

6

7

8. Fuel return hose

9. Fuel intake hose

8

9

10

11

12

13

10. Primer bulb

11. Engine

Model Type Code

xxxxxx xxxx xxxxxxxx

12. Oil fill / dipstick

13. Fuel tank

FUEL AND OIL RECOMMENDATIONS

Gasoline

These engines are certified to operate on unleaded

gasoline. Use clean, fresh, regular unleaded

gasoline with a minimum of 85 octane. Do not mix o i l

with gasoline. Fresh fuel prevents gum from forming

in fuel system or on essential carburetor parts.

Purchase fuel in quantity that can be used within 30

days to assure fuel freshness. We recommend the

use of Briggs & Stratton Gasoline Additive. (See

your Authorized Briggs & Stratton Service Dealer

for Part No. 5041 or the single-use pouch.)

In countries other than U.S.A., leaded gasoline may

be used if it is commercially available and unleaded

is unavailable.

NOTE: Some fuels, called oxygenated or reformu-

lated gasolines, are gasoline blended with

alcohols or ethers. Excessive amounts of

these blends can damage the fuel system or

cause performance problems. Do not use

gasoline containing Methanol. If any undesirable operating symptoms occur, use gasoline

with a lower percentage of alcohol or ether.

Lubrication

Oil has four purposes. It cools, cleans, seals and

lubricates. During normal operation, small particles

of metal from the cylinder walls, pistons, bearings

and combustion deposits will gradually contaminate

the oil. Dust particles from the air also contaminate

the oil forming an abrasive mixture which can cause

wear to all of the internal moving parts of the engine,

if the oil is not changed regularly. Fresh oil also

assists in cooling. Old oil gradually becomes thick

and loses its cooling ability as well as its lubricating

qualities.

Oil Recommendations

Use a high quality detergent oil classified “For Service SF, SG, SH, SJ” or higher. Briggs & Stratton

strongly recommends the use of synthetic oil such

as Briggs & Stratton (#100030C) or equivalent. If

synthetic oil is not available, Briggs & Stratton nonsynthetic 30 weight oil is an acceptable substitute.

No special additives should be used with recommended oils.

Do not mix oil with gasoline.

5

Loading...

Loading...