Page 1

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

MiniCAFS 2.1A

Operating Instructions

Model: MC50 with FoamLogix System

HALE PRODUCTS EUROPE

A Unit of IDEX Corporation

Charles St

Warwick

CV34 5LR

England

+44 (0)1926 623600

+44 (0)1926 623666

¬

www.haleeurope.com

admin_haleuk@idexcorp.com

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

1

Page 2

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

INDEX

SECTION PAGE

SAFETY-RELEVANT DATA 4

ENVIRONMENTAL PROTECTION 5

RECOMMENDED FUEL, LUBRICANTS and ANTI-FREEZE 5

GENERAL DATA 6

INSTRUMENTS and CONTROLS 7-8

INTRODUCTION 9-10

INSTALLATION 11-13

COMMISSIONING/START-UP PROCEDURE 14

OPERATING MiniCAFS FROM A VEHICLE WATER SOURCE 16

DISCHARGING FOAM AGENT ONLY 17

DISCHARGING CAFS 17

WET OR DRY FOAM 18

SHUTTING DOWN 18

OVERHEAT SHUT DOWN 18

TO OPERATE FROM A REMOTE FOAM SUPPLY 19

BATTERY CHARGING 19

MAINTAINANCE 20

FAULT FINDING 21

RECOMMENDED FOAM AGENTS 22

RECOMMENDED SPARES 22

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

2

Page 3

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

IMPORTANT NOTES

Please read this manual before operating this equipment.

Every care has been taken during the manufacture of this equipment to ensure that it leaves the factory

capable of giving a long period of trouble-free running.

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

3

Page 4

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

SAFETY - RELEVANT DATA

Thank you for purchasing a MiniCAFS unit.

MiniCAFS is designed to give safe and reliable service – however, BEFORE operation it is essential that

the Operating Instructions are carefully read and understood.

A risk-assessment of this equipment has been conducted with the following results:

MAINTENANCE

It is the responsibility of the user to ensure that the equipment is maintained in a safe operational condition, as

per regulation 5 in the Provision and Use of Work Equipment Regulations 1998.

TRAINING

It is ESSENTIAL the MiniCAFS is operated ONLY by TRAINED PERSONNEL. Manufacturer’s training can be

obtained on application to Hale Products Europe Ltd., Charles Street, Warwick CV34 5LR, England.

Tel: +44 (0)1926 623600.

To avoid injury, the operators should take all necessary precautions to safeguard themselves and others and

follow the operating procedures laid down in this book.

SAFETY POINTS

- DO NOT OPERATE the unit close to flammable materials or structures.

- DO NOT SMOKE while operating the unit

- Keep ALL UNTRAINED people AWAY from the unit during operation.

- PETROL IS EXTREMELY FLAMMABLE and MUST be HANDLED WITH CARE.

- DO NOT REFUEL until the engine is cold.

- DO NOT refuel whist smoking or allow sparks or flames into the refuelling area.

- DO NOT OVERFILL the fuel tank. After refuelling, ENSURE that the fuel cap is refitted.

- Be careful NOT TO SPILL fuel.

- DO NOT run the engine in an enclosed area as poisonous gases are given off which can cause injury.

- DO NOT expose volatile fluids or battery gases to a naked flame.

- Avoid prolonged skin contact with fluids, especially if corrosive or carcinogenic.

- Protect the eyes as necessary.

- The exhaust system becomes VERY HOT during operation and REMAINS HOT for a time AFTER

the engine has been stopped. DO NOT TOUCH the exhaust whilst the engine is HOT.

!

- The starting system is powered by battery. ALWAYS connect the battery positive (+ve) cable BEFORE

the negative (-ve) and disconnect the negative BEFORE the positive.

- Disconnect the battery when working on the unit to avoid accidental starting.

- Batteries produce EXPLOSIVE GASES so do not expose to sources of heat and naked flames.

- DO NOT lift heavy weights without suitable assistance.

- DO NOT inhale fumes or gases.

- DO NOT remove protective guards or shields.

NOISE

When the unit is running, suitable EAR PROTECTION should be worn at all times by personnel.

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

4

Page 5

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

MANUAL HANDLING

If the unit is to be removed from the appliance the design incorporates suitable lifting points.

The secondary starting method (hand-start) provided MUST BE USED WITH CARE.

Follow the operating instructions provided.

It is illegal to pour engine oil and other contaminants onto the ground, down sewers or drains, or into water

courses.

Dispose of these through authorised waste disposal contractors to licensed waste disposal sites, or to the

waste reclamation trade.

If in doubt, contact the Local Authority for advice on disposal facilities.

ENVIRONMENTAL PROTECTION

F.W. Mason

Managing Director

RECOMMENDED LUBRICANTS AND FUEL

ENGINE FUEL & LUBRICATING OIL

-30ºC -20ºC -15ºC -10ºC 0ºC +30ºC +40ºC

To API

specification

SF/CD

-22ºF -4ºF +5ºF +14ºF +32ºF +86ºF +104ºF

SAE 5W/30

SAE 10W/30

SAE 10W/40 or 10W/50

SAE 15W/40 or 15W/50

SAE 20W/40 or 20W/50

PETROL

Lead free, minimum 85 octane. (Leaded may be used if

lead free is unavailable)

COMPRESSOR LUBRICATING OIL

Preferred:

Tamrotor F2105 Screw Compressor Oil or Screw compressor oil meeting

ISO Viscosity grade 32 to 46.

Alternatively:

SAE 10W/40 automotive multigrade oil.

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

5

Page 6

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

GENERAL DATA

ENGINE

Manufacture Briggs & Stratton

Model 18HP Vanguard

Bore & Stroke 72.5mm x 70mm

Capacity 570 cc

Number of cylinders 2 cyl vee

Number of main bearings 2

Lubrication Pressurised Full Flow System

Service Oil Fill Capacity 1.7 litres

Oil filter 'Spin On' disposable canister

Fuel feed Vacuum Pulse Pump

Fuel tank capacity 8.5 litres

Battery 12v/14A

COMPRESSOR

Model HSC50

Maximum Operating Speed 7250 rpm

Nominal speed of operation 6250 rpm

Nominal power draw 12.0kW

Direction of rotation Anti-clockwise

(when looking on pulley)

Oil volume (approximate) 3.5 litres

FOAM PROPORTIONING SYSTEM

Manufacturer Hale Products Inc

Model Foamlogix 2.1A

Type

Electronic Foam Proportioning system

Operating voltage 12 volts

Current draw 20 amp

Max. Foam Agent Flowrate 8.0 L/Min

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

6

Page 7

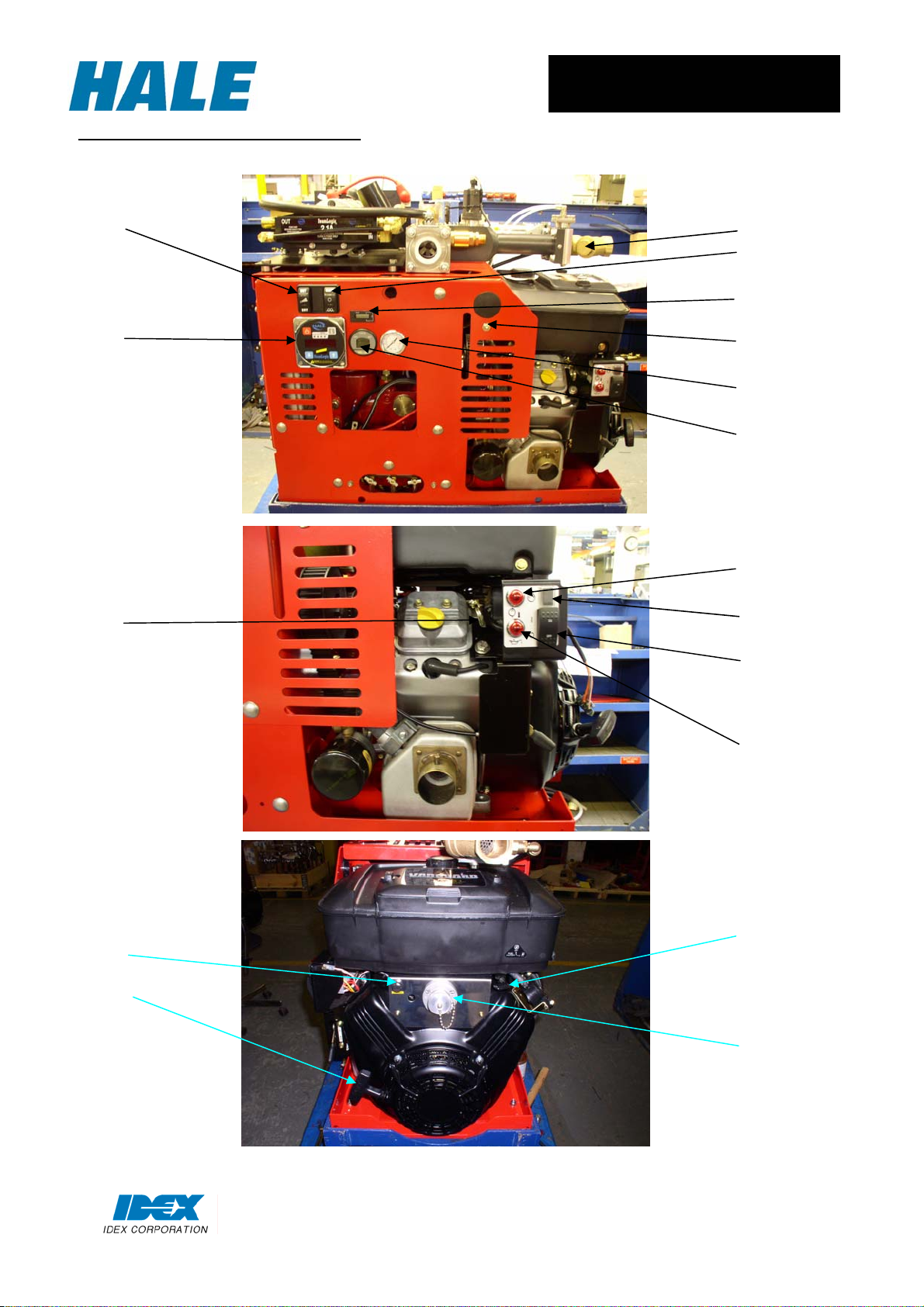

INSTRUMENTS and CONTROLS

1

2

9

14

15

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

Foam/CAFS

controls

17

3

4

5

6

7

Engine

8

10

11

12

13

16

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

7

Page 8

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

INSTRUMENTS COMMENTS

1. WET or DRY foam selector Press top to make foam wetter

Press bottom to make foam dryer

2. FoamLogix display and control See page 16 for details

3. CAFS or Foam selector Press top for CAFS, press bottom for foam

only

4. Hours run counter Records total number of hours engine has

been running

5. Air dump valve Rapid relief of compressor

pressure to aid cold starting

6. Air pressure gauge Indicates air injection pressure

7. Wet or Dry foam indicator Indicates wet or dry composition of foam

ENGINE CONTROLS

8. High compressor oil temperature Red light

9. Engine choke control Pull out fully when starting engine from cold

Gradually return the choke when engine is

running smoothly

10. Starter switch Press in to start engine

11. Ignition switch Press top to switch on ignition,

press bottom to switch off

12. Low engine oil pressure Red light

13. Fuel shut-off Turn Anti-clockwise to open

14. Fuse 10 amp fuse

15. Back-up Starting Recoil starter device

16. Charging socket For battery charging only. A fuse (item 14) is

included to prevent its use for jump starting

17. Water supply filter Remove filter for cleaning

8

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

Page 9

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

INTRODUCTION

The MiniCAFS is a Compressed Air Foam System comprising of three major components –

air compressor (driven by air-cooled engine), FoamLogix (foam proportioning unit) and

manifold (foam mixing and control system). All the components are in one integrated module

designed to fit in the standard envelope of a DIN 8kVA generator.

Water is supplied from the main pump at a pressures between of 4-10 bar, depending on

requirements or operator preference, and fed, via non-return valves, into a manifold

assembly where flowrate is measured and a metered amount of foam is injected. This

foam/water solution is then fed through an air control valve (ARC) at which wet or dry foam is

selected (air ratio control section of manifold). Compressed air is then injected and the

resulting foam/water/air solution is thoroughly mixed (X-mixers) before being fed to a

discharge connection.

The unit is provided with several safety interlocks to ensure that: -

1. Foam cannot be injected unless water is flowing through the unit.

2. Air cannot be injected unless foam and water are flowing through the unit. This

prevents “slugging” in the discharge line caused by air and water, which cannot mix

3. A low level switch in the foam tank will stop air injection when the tank is empty to

prevent slugging.

Compressor

The rotary twin-screw compressor provides 50 scfm of compressed air at 7 bar and is driven

by an 18hp air-cooled petrol engine, running generally at a constant speed. The engine has

its own built in 8.5 litre fuel tank, which is sufficient for in excess of one hours running. The

oil in the rotary air compressor is cooled by water taken from the vehicle main pump via the

water supply line. To ensure adequate cooling water must be supplied to the unit prior to

starting the engine. A return line delivers the cooling water back to the vehicle tank.

Alternatively, the water can be run to drain, but this is not recommended.

If the unit is run from a closed tank the water will gradually heat up and at an increasing rate

as the volume of water reduces.

NOTE: The compressor should never be run without the pump providing a water supply for

cooling.

The compressor will reject approx. 8.0 kW of heat energy to cooling, and the installer must

consider this additional thermal load

A blowdown valve is fitted to the compressor to remove any constrained pressure in the

system when the compressor is stopped.

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

9

Page 10

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

FoamLogix

The FoamLogix 2.1 foam proportioning system consists of three main components:

1) Foam Pump / Motor Assembly, mounted on top of the unit.

2) Control Panel, mounted on the side of the unit.

3) Flow measurement and injection manifold, mounted on top of the unit.

All three parts work together to provide accurate and reliable foam proportioning. From the

control panel, the operator can turn the system on, adjust the foam injection percentage,

read real time water flowrate and record total water and foam usage.

The FoamLogix system is powered up when the engine is started. Foam agent is only

injected when the red ON control button is depressed

Hale FoamLogix foam proportioning systems are completely engineered; factory matched

foam-proportioning systems that provide reliable, consistent foam concentrate injection for

Class A foam operations. Hale FoamLogix systems accurately deliver from 0.1% to 9.9%

foam concentrate directly into the water discharge stream. It is then fed as foam to the mixing

chamber and discharge piping.

Manifold

The manifold incorporates an air ratio control valve at which varying wet or dry foam mixtures

can be selected. Compressed air is then injected and the resulting foam/water/air mixture is

mixed by passing through the X-mixer section before being fed to a discharge connection.

CAFS units are best suited for use with Fresh Water. For compatibility of foams in salt water

conditions advice should be sought from the foam agent manufacturers.

The unit is provided with several drain taps located at the bottom of the frame that can be

opened to drain water from the manifold and compressor cooling system. This should be

done whenever the unit is not intended to be used for a prolonged period (1 week+).

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

10

Page 11

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

INSTALLATION

Caution: MiniCAFS is shipped without oil in the Compressor or Engine.

Oil MUST be added before the unit is started.

All connections are labelled and must be secured before starting the unit.

A

B

E

F

C

D

G

H

J

K

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

11

Page 12

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

1. If the unit is installed in the side locker of a fire fighting vehicle, provision must be made

for access to the engine oil dipstick (A), compressor oil-fill (B) and sight glass (D), all

located on the rear side of the MiniCAFS. The drive motor is air-cooled, and cooling air

must be allowed to flow unhindered into and out of the unit. Avoid any enclosing cladding

at a distance of approx. 300mm around the engine cooling air intake. Compressor oil filter

is item (C).

2. The cooling line (L) from the heat exchanger should return to the top of the vehicle water

tank using φ 13 min. diameter flexible hose. There must be no kinks or obstructions in this

line.

3. The preferred method of supplying foam agent is from an on board foam tank. This MUST

be mounted to give a head of foam agent to the FoamLogix pump. The Low-level switch

(Supplied) must be installed so that the circuit becomes closed when the foam tank is

empty. Connect the low-level switch connection on the foam tank to the Interlock wiring

harness (M) on the MiniCAFS, using the extension harness provided.

Note: the low foam level switch must be installed in the tank in the correct orientation.

The switch device has a raised marker on the casing where the wires enter the device.

This marker must be installed at the 12 o clock (top) position for correct functioning.

The foam tank requires a 23mm hole for secure fitting of the switch device and the

maximum allowable thickness of tank wall material is 4mm.

The switch device should be installed at a location in the tank wall that allows for

activation when there are approximately 3 litres of foam left before running out.

This marker must be

at 12 o clock (top)

when the switch

device is installed

Connection (M)

for low foam level

switch

(L) Compressor

cooling return

line, inside

panel

4. Connect the foam agent supply to the inlet connection on the FoamLogix pump (F),

situated on top of the unit. Note the location of the By-pass valve and connection point

(G) and the foam filter (E).

Note. Connections must be secure and pressure tight if the FoamLogix pump is

to operate correctly.

CAFS or foam

discharges here

Water supply of

between 4-10 bar

connected to here.

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

12

Page 13

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

5. Connect a water supply of 4-10 bar pressure from the main pump to the inlet connection

on the MiniCAFS manifold. This should be of φ50, flexible, non-kinking hose. An isolating

valve must be provided between the vehicle pump and the MiniCAFS unit to prevent the

unit being pressurised when not being used.

6. Fill the engine with engine oil & fuel as per the Briggs & Stratton manual.

7. Fill the compressor with the correct grade of oil until the sight glass is 3/4 full.

8. Remove the battery, fill with electrolyte, fully charge to 12 volts and reconnect.

Note the battery connection leads, positive (+) is the red lead (H), the negative (-) the

black lead (I),

9. The exhaust silencer of the MiniCAFS unit is provided with a DIN socket for an exhaust

extension hose. With the aid of such a hose, the exhaust gases can be conducted out of

the body of the vehicle and led away from the unit.

Caution: Pressurised water must be supplied to the unit any time the engine

is run and must be circulating before the engine is switched on.

Caution: The exhaust extension and the exhaust gases are very hot.

10. Following the Briggs & Stratton operator’s manual (attached at back of manual), start the

engine and run for 30 seconds to circulate the oil.

Note: The engine has an electric start button located above the rocker ignition

switch and a recoil rope back-up starter for manual operation.

11. If the engine should stall after starting (especially from cold) it may be necessary to

relieve the pressure in the compressor by pressing the air dump valve (5, Page 7).

12. Shut the unit down and allow the oil to settle for 5 minutes.

13. Add additional oil as necessary to the engine to keep the oil level between the Max. and

Min. marks on the dipstick.

14. Add additional oil as necessary to the compressor to keep the oil at least 3/4 full in the

sight glass.

15. Note the location of the drain taps (K) for draining the system of water after use and

before storage, this is particularly necessary if freezing weather is expected.

The unit is now ready for commissioning of the foam proportioning and CAFS system.

13

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

Page 14

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

COMMISSIONING/ START-UP PROCEDURE

Caution: The heat exchanger return flow is over 40 l/min. This flow must not

be restricted.

Caution: The unit should be run in open air with any compartment doors open

and the containment drawer ideally pulled out to improve ambient airflow.

1. Follow the installation procedure in the previous section.

2. Supply the MiniCAFS with water at a pressure of 4-10 BAR.

3. Make sure that an adequate foam supply is available (i.e. foam tank is full).

4. Connect a suitable delivery hose and branch to the MiniCAFS discharge.

φ38 to φ45mm diameter layflat hose is suitable for delivering CAFS. If a single

discharge is being used, a φ25 to φ38mm smooth bore nozzle would be suitable. If two

delivery hoses are to be deployed, then two φ19 nozzles would be appropriate.

Note: The engine should be run at full speed. The compressor pressure and load is

changed but the engine throttle will remain in the fast position.

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

14

Page 15

FoamLogix control panel functions -

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

Check that all the necessary connections have been made as described in the previous

sections

1. Run the compressor for 30 seconds to allow oil to circulate. Press the CAFS switch

(3, P8) on the instrument section.

2. Stop the unit and check compressor oil level – top up if necessary.

3. Turn the bypass valve on the FoamLogix pump to bypass (arrow points to left) and

provide a suitable receptacle to collect the foam, agent (G, P11).

4. Ensure that there is sufficient foam agent in the tank.

5. Select simulated flow on the FoamLogix by pressing both up ↑ & down ↓ at the same

time.

6. Press the red on button, and the pump will prime itself. The pump will run for 30

seconds or until prime is achieved. If no prime is made, the display will show “no pri”.

Repeat this step once more to attempt to prime the pump.

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

15

Page 16

”no Pr” = No prime display

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

7. When prime is achieved, deselect simulated flow by pressing both up ↑ & down ↓ at the

same time.

8. Return the bypass valve to the inject position (arrow points to right).

The unit is now ready to run.

OPERATING MiniCAFS FROM A VEHICLE WATER SOURCE

1. Connect a suitable delivery hose and branch to the CAFS discharge. φ38 to φ45mm

diameter layflat hose is suitable for delivering compressed air foam. If a single discharge

is being used, a φ25 to φ38mm smooth bore nozzle would be suitable. If two delivery

hoses were to be deployed, then two φ19 nozzles would be appropriate.

Note: The best foam quality is produced using a smooth bore nozzle with the foam going

through the minimum number of valves and sharp bends. However, the scrubbing action

of the foam on the hose wall tends to improve the foam quality.

Note: A standard fog nozzle can be used with CAFS if used on the ‘Flush’ setting. Using

the ‘Fog’ settings will severely degrade the foam quality.

Note: the following controls on the FoamLogix Control Panel -

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

16

Page 17

FoamLogix Control Panel

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

1. Discharging foam agent only

1.1. Set water feed from supply pump at required pressure

1.2. Ensure that the foam only option is selected by pressing the bottom of the

Foam/CAFS selector switch, marked with the symbol -

(No.3, Page 7)

1.3. Press the red on button, and choose desired foam % setting. (Default is 0.5%)

Foam %

Press ↑ to increase foam %

Press ↓ to decrease foam %

1.4. Open CAFS discharge valve to deliver foam agent.

Note: the WET/DRY control (ARC valve) is only operable when CAFS is selected. The

control will default to the wet condition when CAFS is turned off.

2. Discharging CAFS

2.1. Select CAFS by pressing the top of the CAFS selector switch – marked “CAFS”

(No.3 Page 7)

2.2. Ensure that engine throttle on MiniCAFS is fully open

2.3. Open CAFS discharge valve to deliver foam agent.

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

17

Page 18

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

Wet Foam or Dry Foam

2.4. A continuously variable foam type from WET to DRY is available, selectable by the

pump operator.

2.5. The WET or DRY foam composition is selected by using the WET/DRY control on the

panel (No.1 Page 7). An indication of foam type is given by the WET or DRY foam

indicator (No.7 Page 7), but the pump operator may choose to optimise the liquid flow

as displayed in the FoamLogix display.

2.6. To increase the WET or DRY property of the foam, press the WET/DRY control

(No.1) at the top for WET or the bottom for DRY.

2.7. Note: when discharging dry foam at low pump pressure, the possibility of hose

kinking is increased and should be considered when deploying hoses on the fire

ground.

Note: the WET/DRY value will always default to wet when the compressor is stopped.

Shutting Down

2.8. Set WET/DRY selector switch to the WET foam setting (Press in bottom of switch)

2.9. Turn off the FoamLogix, press RED button.

2.10. Run water through the CAFS discharge system to flush out the foam agent.

2.11. Close the CAFS discharge valves

2.12. Switch off the engine.

2.13. If cold weather is expected, open the drain taps (K, Page 12) to drain the CAFS

manifold.

Overheat Shut down

If the compressor is running hot, a warning indicator light will illuminate on the control panel

when oil temperature reaches 105

o

C.

If the compressor oil temperature exceeds 110º C, the unit will shut down automatically. The

compressor can sustain 105ºC temperatures for short periods without damage. The unit can

be re-started when the compressor has cooled.

The most likely cause of compressor overheat problems is insufficient cooling water flow.

Verify that the cooling water return line is not kinked or restricted before running again.

Cooling water flow is approximately 40l/min minimum.

Note: The system is designed to allow the air pressure to decay slowly which

reduces the tendency of the oil to froth when releasing the entrained air.

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

18

Page 19

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

TO OPERATE FROM A REMOTE FOAM SUPPLY

Foam agent can be inducted out of conventional commercial canisters. The base of the

canisters must be above the FoamLogix Pump and the MiniCAFS. A suitable dip tube should

be manufactured for the suction line. The bypass pipe should be fed back into the foam

canister.

Note The FoamLogix must be re-primed each time the foam canister is changed.

Note The system will not have the protection of a low foam level switch, and if the foam

supply is exhausted, air may be drawn into the FoamLogix Pump, and “Slugflow” may

result.

BATTERY CHARGING

A battery charging plug is included on the unit and a fuse (14, 16, page 7) rated at 10 Amps

is installed between this connector and the battery to prevent jump-starting a dead battery

through this connection.

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

19

Page 20

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

MAINTENANCE

Weekly:

Check the oil levels and top up if necessary.

Check the belt tension/condition and adjust if necessary.

Check the hose connections.

Check battery charge.

Every 50 hours or every 3 months

Check and clean the water supply filter (M, Page 12) for debris

Every 100 hours or every 6 months (whichever comes first):

Change the engine oil and filter. B&S oil filter P/N 4929325

Change compressor oil and filter. Filter P/N 59271/01

Clean the Foam filter.

Annually or every 400 hours:

Change the air cleaners (engine & compressor).

Engine Air Filter – part number 57799

Compressor Air Filter – part number 59271

Every Two Years

Change drive belt - part number 59062

Note: Both the drive belt and the air cleaners may have to be changed more often in

dusty/dirty/heavy duty applications.

20

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

Page 21

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

FAULT FINDING

EFFECT CAUSE ACTION

Compressor overheats No water supply or restricted flow Turn on water supply.

Check oil cooler pipe work

for obstructions

Unable to produce foam

solution

FoamLogix not operating Switch on engine ignition

Switch on FoamLogix

No Foam in tank Refill with foam agent

No air injection CAFS switch not on Turn CAFS switch on Low foam switch activated

Refill foam Tank

(If fitted)

Air and liquid not mixing

(Slugflow)

Surging of hose and

pressure gauge.

Depleted foam supply (Low level

switch not fitted)

Foam % set too low

Insufficient air pressure in hose

Refill foam tank

Increase foam % setting

Increase compressor speed

if not at maximum.

Reduce nozzle diameter.

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

21

Page 22

MiniCAFS 2.1A Operating Manual

GP/211/05 Issue 2. April 2005

RECOMMENDED FOAM AGENTS

Class A Foam Manufacturer Brand name

US Forestry Service

Approved

ANSUL Silvex Class A Foam

Concentrate

Angus Forexpan S (0.1% - 1.0%)

Chubb National Foam 1st Defense Class A

Coldwater Foam

Chubb National Foam Knock-Down

Monsanto Phoscheck WD881

Chemonics Fire-Trol Fire Foam 103

Chemonics Fire-Trol Fire Foam 104

3M Light Water FT-1150

Non U.S. Forestry Service

Approved

ChemGuard Class A Plus

Unifoam Co Ltd. UniA 1%

3M Light Water SFFF

RECOMMENDED SPARES

FOR 2 YEARS OPERATION

ITEM

PART No QTY DESCRIPTION COMMENTS

ENGINE GROUP

1 (B&S) 4929235 4 OIL FILTER

2 57799 2 AIR FILTER

3 2 SPARK PLUGS CHAMPION RC12YC

4 THM10998 1 O-RING UNDER OIL COOLER BODY

5 57807 2 O-RING OIL FILTER ADAPTER

COMPRESSOR GROUP

1 59271/01 4 OIL FILTER

2 59271 2 AIR FILTER

3 59062 1 DRIVE BELT

4 UFP2303/8 2 DOWTY WASHER DRAIN PLUGS AND OIL LINES

©Hale Products Europe. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

22

Loading...

Loading...