Product Manual:

Sales Order

Customer

Create Date 11-23-2009 By MGD

Last Rev Date 12-27-2013 By LAW

Manual Include Instruction Sets Description

DCM01241-XX Special Information

|------------> DCM00003 General Information

|------------> DCM00056 MWX100

|------------> DCM00002 TouchScreen Controller

Special Actuator Controller

BRANSON Ultrasonics Corporation

41 Eagle Road

Danbury, Connecticut 06813-1961 U.S.A.

(203) 796-0400

http://www.bransonultrasonics.com

Instruction Set for Special Information Page 1 of 8

BRANSON Metal Welding

Product Manual- Special Information

Table of contents

Product Manual:……………………………………………………………………………….1

Table of Contents:…………………………………………………………..…………………2

Introduction:…………………………………………………………………………………...3

Using This Manual:……………………………………………………………………………4

Classification of Hazards:…..…………………………………………………… ……………4

System Specification Sheet:…..……………………………………………………………….5

Parameter Preset Information:…..……………………………………………………………..6

File Attachments:………………………………………………………………………………7

Special Instructions:……………………………………………………………………………8

Instruction Set for Special Information Page 2 of 8

BRANSON Metal Welding

Product Manual- Special Information

Introduction:

This is the product manual for your BRANSON Metal Welding ultrasonic welding system.

Several combined Instruction Sets form the contents of this manual. This section contains

information which relates most uniquely to you as the customer, your particular system and

application. It also documents other Instruction Sets used in the manual. The figure below

illustrates how the manual is organized.

BRANSON Metal Welding Product Manual

Special Information Instruction Set

General Information Instruction Set

Actuator Instruction Set

Controller Instruction Set

(Other) Instruction Set (s)

Instruction Set for Special Information Page 3 of 8

BRANSON Metal Welding

Product Manual- Special Information

Using this manual:

It is highly recommended that you read and understand the contents of this manual prior to

operating your BRANSON Metal Welding system. Each Instruction Set has a table of contents

and is intended to logically group information in a manner which the user will find convenient.

Classification of Hazards:

The safety indications in this manual are divided into different classes. The figure below shows

the assignment of symbols (pictograms) and signal words to the specific hazards and its potential

consequence.

PICTOGRAM SIGNAL

WORD

ATTENTION !

DANGER !

NOTE

A potentially dangerous situation

that could cause injury to persons

and serious damage to equipment.

A situation that may cause damage

to the equipment

Useful information, an application

hint or other important or useful

information.

DEFINITION

Instruction Set for Special Information Page 4 of 8

BRANSON Metal Welding

Actuator

Shuttle

Controller

Power Supply

PLC

Product Manual- Special Information

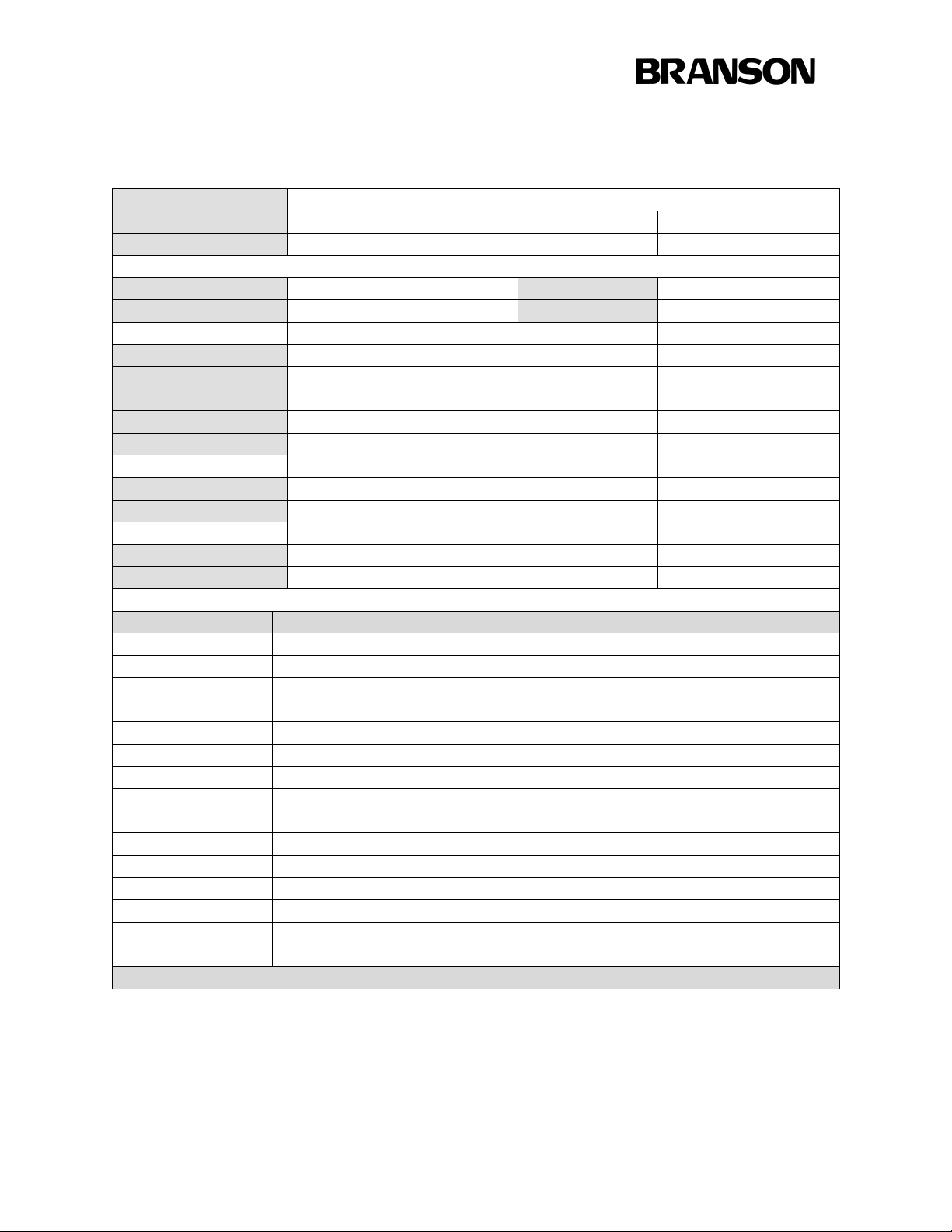

System Specification Sheet:

Sales Order

Customer

Create Date

Type

Serial Number Program No N/A

Type TouchScreen

Serial No

Firmware Type Welder

Firmware Version

Firmware Lang Multi Lingual

Type N/A

Serial Number N/A

Type N/A

Program Number N/A

Part Number Description

101-135-067R Converter

Horn

Tip

Tip Nut

Anvil

See Table 1 Booster, High Gain

To serve you better, please be aware of the following:

All tools have a 5 to 6 week lead time.

Prices are subject to change without notice.

An additional fee may be charged for expedited service.

MWX100

Type N/A

Instruction Set for Special Information Page 5 of 8

BRANSON Metal Welding

Product Manual- Special Information

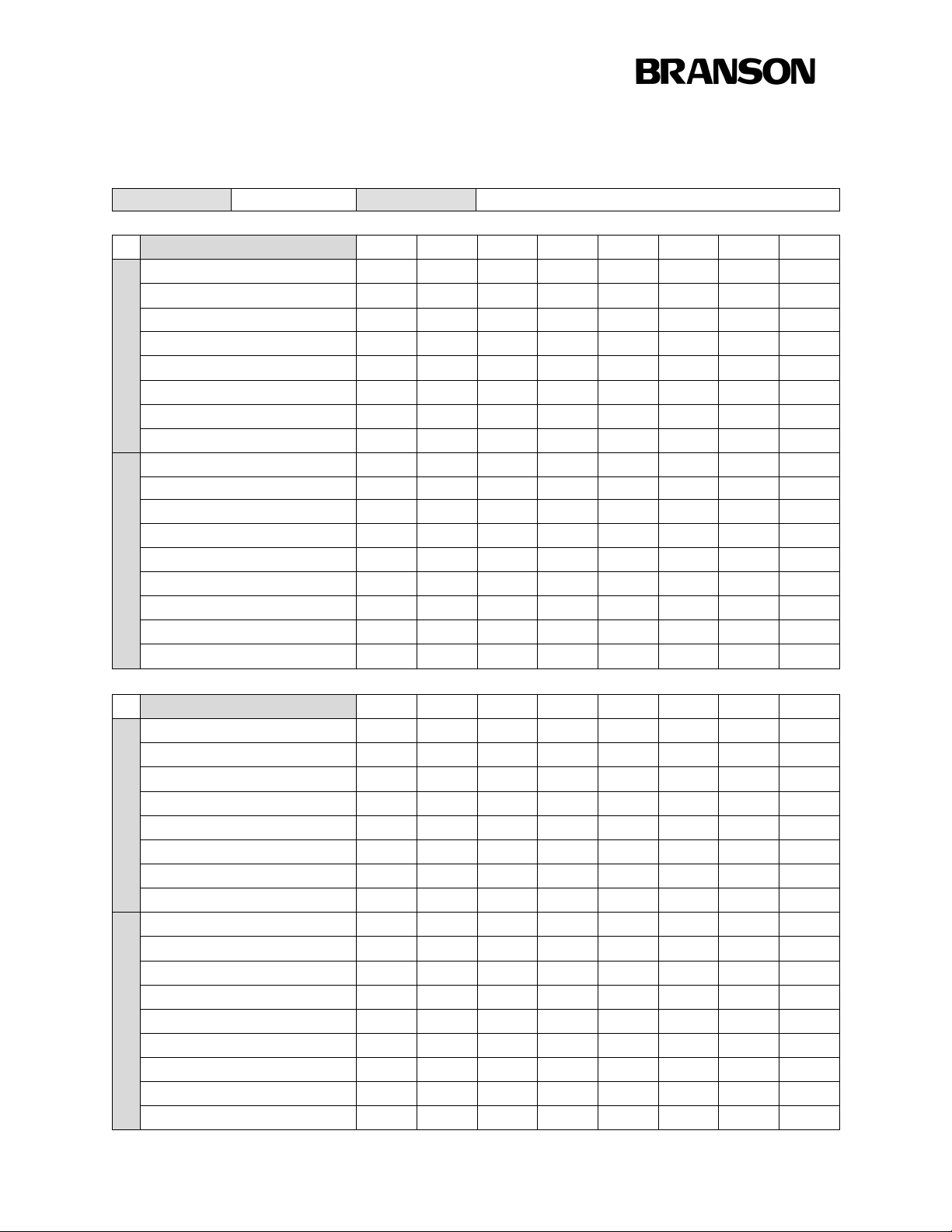

Parameter Preset Information

Sales Order «SalesOrder»

Customer

«Customer»

Name or preset Number

Energy (joules)

Force (psi/bar)

Pressure (psi/bar)

Amplitude (microns)

Squeeze Time (ms)

Pre-Burst (ms)

Hold Time (ms)

Welding Parameters

After Burst Delay (ms)

After Burst Duration (ms)

Weld Time Min. (ms)

Weld Time Max. (ms)

Weld Power Min. (watts)

Weld Power Max. (watts)

Pre-Height Min. (mm)

Pre-Height Max.(mm)

Post Height Min.(mm)

Quality Monitoring

Post Height Max. (mm)

Name or preset Number

Energy (joules)

Force (psi/bar)

Pressure (psi/bar)

Amplitude (microns)

Squeeze Time (ms)

Pre-Burst (ms)

Hold Time (ms)

Welding Parameters

After Burst Delay (ms)

After Burst Duration (ms)

Weld Time Min. (ms)

Weld Time Max. (ms)

Weld Power Min. (watts)

Weld Power Max. (watts)

Pre-Height Min. (mm)

Pre-Height Max.(mm)

Post Height Min.(mm)

Quality Monitoring

Post Height Max. (mm)

Instruction Set for Special Information Page 6 of 8

BRANSON Metal Welding

Product Manual- Special Information

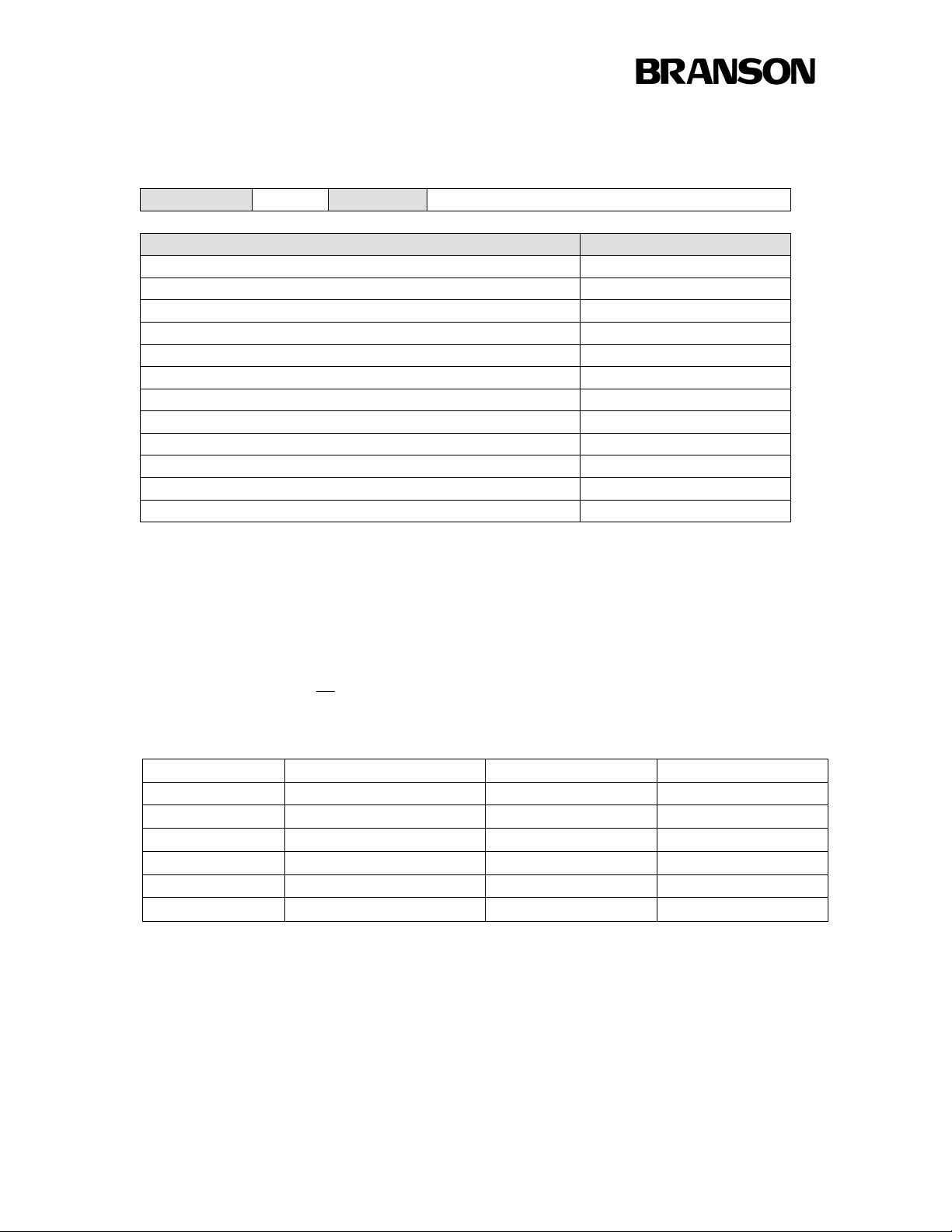

File Attachments:

Sales Order Customer

Description File

Assembly Drawing 159-132-341

File Attachments are included at the end of this instruction set.

Tooling Table:

The (computer) file name of this manual contains a two digit suffix number.

Example: DCM01241- ##. PDF

Use the suffix number from Table 1 to determine the Booster used on your welder.

DCM01241- Booster Type, Color Part Number Gain (ref only)

-01

-02

-03

-04

-05

-06

Super High Gain, Silver

High Gain, Gold

Medium High Gain, Blue

One-to-One, Red

Medium Low Gain, Blue

Low Gain, Black

Table 1

17100-00-416 2:1

17100-00-216 1.67:1

17100-00-316 1.17:1

17100-00-016 1:1

17100-00-516 0.75:1

17100-00-116 0.5:1

Instruction Set for Special Information Page 7 of 8

BRANSON Metal Welding

Product Manual- Special Information

Special Instructions:

Instruction Set for Special Information Page 8 of 8

BRANSON Metal Welding

Product Manual- General Information

General Information and Instructions

Document Number DCM00003

Last revised 03/27/2012 LAW

Use of this document is intended for use with all Branson Metal Welding products.

Branson Ultrasonics Corporation

41 Eagle Road

Danbury, Connecticut 06813-1961 U.S.A.

(203) 796-0400

(203) 796-0810 FAX

http://www.bransonultrasonics.com

This document is intended for use in conjunction with others to form a complete manual

for your Branson system.

Introduction:

This Instruction Set includes common information which relates to Branson products. It will help

you in setting up your system and to understand the fundamentals of the ultrasonic metal welding

process.

Portions of this section may be superseded by more specific and detailed information

provided in other Instruction Sets.

Instruction Set for General Information Page 1 of 30

BRANSON Metal Welding

Product Manual- General Information

Table of Contents

Introduction: ...............................................................................................................................1

Table of Contents ........................................................................................................................2

Thank You: .................................................................................................................................3

Warranty: ....................................................................................................................................4

Intended Use: ..............................................................................................................................5

Safety, Personal: .........................................................................................................................5

Safety Devices .........................................................................................................................5

Emergency Stops: ....................................................................................................................5

Safety Guidelines: ....................................................................................................................5

Maintenance Safety:.................................................................................................................6

Safety, System: ...........................................................................................................................6

System Protection Monitoring (SPM) ......................................................................................6

Thermal Switch........................................................................................................................6

Daily Functional Safety Checks: ..............................................................................................6

Unpacking, Handling & Installation: ...........................................................................................7

If damage has occurred: ...........................................................................................................7

System Location: .....................................................................................................................7

System Assembly: ...................................................................................................................7

Operating the System: .................................................................................................................8

Troubleshooting: .........................................................................................................................9

Weld Overload .........................................................................................................................9

Low Air Pressure .....................................................................................................................9

Ready Check ............................................................................................................................9

Troubleshooting Guide .......................................................................................................... 10

Periodic Maintenance ................................................................................................................ 13

Contacting Branson: .................................................................................................................. 14

Spare Parts & Replacement Tooling: ...................................................................................... 14

Questions or Problems: .......................................................................................................... 14

Returning Equipment: ............................................................................................................ 15

Return Authorization Form ................................................................................................. 16

New Applications: ................................................................................................................. 17

Evaluation Request Form .................................................................................................... 18

Terminology: ............................................................................................................................ 19

Ultrasonic Theory: .................................................................................................................... 24

What Is An Ultrasonic Weld?................................................................................................. 24

How Does It Work? ............................................................................................................... 24

Instruction Set for General Information Page 2 of 30

BRANSON Metal Welding

Product Manual- General Information

Thank You:

Thank you, and congratulations on selecting Branson MWX100/ ULTRASPLICE Systems for

your welding production. This system has been developed to produce the highest quality welds at

the lowest cost per weld.

If you should experience difficulty or have any recommendations for improvement, please do not

hesitate to contact us.

Please be advised that the MWX100/ ULTRASPLICE machine is protected under the United

States and International patents listed below. This operator’s manual is also protected by

copyright and may not be copied without prior written permission by Branson.

Trademarks

MWX100 and

ULTRASPLICE

Copyright

MWX100 Computer Software

and the MWX100 Manual

are registered trademarks of

Branson Ultrasonics Corporation

are copyrighted 1994,1995,1996,1997 by

Branson Ultrasonics Corporation

Instruction Set for General Information Page 3 of 30

BRANSON Metal Welding

Product Manual- General Information

Warranty:

Branson Ultrasonics warrants this equipment to be free from defects in material and

workmanship for one (1) year from date of original delivery by Branson or by an authorized

representative when used in accordance with written instructions. Any unit which proves

defective during this period will be repaired or replaced free of charge at the sole discretion of

Branson Ultrasonics, F.O.B. Danbury, Connecticut or an authorized repair station as advised by

Branson. This is the buyer’s sole and exclusive remedy. The defective unit must be returned

properly packed with all transportation charges prepaid.

Expendable tooling produced by Branson such as the horn, tip and anvil will wear at varying

rates depending upon the application and duty cycle. For this reason, Branson warrants that all

tooling complies with specifications on design and materials but cannot guarantee its useful life

for a fixed period of time.

The warranty provisions contained herein are expressly in lieu of all other warranties, express or

implied. THERE ARE NO IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE MADE IN CONNECTION WITH THE

EQUIPMENT TO BE DELIVERED THEREUNDER.

This warranty is limited to the original purchaser and is not transferable.

BRANSON Ultrasonics will not be liable for any consequential damages claimed in relation to

the purchase or warranty of the equipment to be delivered thereunder. Branson will not be liable

for any injury to persons or property caused directly or indirectly by the use of the equipment

delivered thereunder.

Horns fabricated by Branson for use in Branson equipment are manufactured to exacting

parameters and tuned to vibrate at the equipment’s ultrasonic operating frequency. An

improperly tuned horn can cause undue stress or damage to the converter and power supply.

Contact your Branson representative or Branson’s world headquarters in Danbury, Connecticut,

should you have any questions concerning horn qualifications.

Authorization to return equipment for repair is required. A Return Authorization Number must

be obtained from Branson’s Service Department. Equipment being returned for repair must be

packaged in the original carton(s) to protect it from damage and returned freight prepaid. Any

damage that is sustained as a result of improper packaging may void the warranty and is the

sole responsibility of the customer.

For questions relating to warranty or repair please contact our Repair Department.

Instruction Set for General Information Page 4 of 30

BRANSON Metal Welding

Product Manual- General Information

.

Intended Use:

This equipment is for the joining of metal parts using ultrasonic energy. A complete system

includes an actuator, controller and tooling (which delivers mechanical energy to the work

pieces). Some systems also include special fixturing and machine automation. Branson systems

may only be utilized to weld soft, ductile, metal parts together with Branson-supplied weld

tooling (such as horns, tips, anvils, and converters) unless an explicit, written, contrary

agreement between the ordering party and Branson has been consummated.

Safety, Personal:

Safety Devices

The removal, bridging or disabling of safety devices is not condoned for production operation.

Individual safety devices mentioned below may only be disabled if super-ordinate safety devices

are employed in their place.

Emergency Stops:

In case of danger, hit the red, emergency stop which is found on the red, top portion of the foot

pedal. The actuator, power supply and related fixturing are returned to the “Home” position. If

dual anti-tie start buttons are used, there must be a red emergency stop associated in line. Free

access to the emergency stop button must be maintained.

Controller Cover

The power supply is equipped with a top cover which should only be removed for maintenance

and installation purposes.

Safety Guidelines:

For operating safety, please observe the following precautions:

• Plug the power supply into a grounded electrical supply to avoid electrical shock.

• Ensure that no one is in contact with system moving parts when operating.

• Keep hands away from the horn tip as high force and ultrasonic vibration can cause injury to

hands and fingers.

• Do not test ultrasonics when the converter is removed from the actuator. Without the

converter there is the danger of damage or shock.

• Before adjusting or repairing the ultrasonic stack or power supply, disconnect the line power.

• Any unauthorized modification of the units control circuitry or wiring may cause a

malfunction, which could result in injury to operating personnel.

• Do not operate the equipment until repairs and adjustments have been made and the

equipment is in good working order.

Instruction Set for General Information Page 5 of 30

BRANSON Metal Welding

Product Manual- General Information

Maintenance Safety:

Safety devices, especially covers, guards and ground cables should only be removed when it is

absolutely essential for the completion of maintenance work. If safety devices were removed

prior to starting maintenance work, be sure to re-install those devices after finishing the

maintenance work. The following installation and maintenance operations must be performed

prior to any disassembly of equipment:

• All system components must be disconnected from the main electrical supply

• Remove the plug from the main electrical supply and secure it from being re-inserted

accidentally.

• All system components must be disconnected from the main air supply

• Disconnect the air hose from the main air supply and release system air pressure via the

pressure regulator.

Safety, System:

System Protection Monitoring (SPM)

The SPM (System Protection Monitoring) stops ultrasonics when the power supply has been

overloaded or when inappropriate or defective horns are used.

Thermal Switch

A thermal switch is contained within the power supply to automatically disconnect power to the

machine if the unit gets too hot. This will occur if the exhaust fans from the generator are

inadvertently blocked or clogged.

Daily Functional Safety Checks:

• Check the machine tip and anvil for any signs of grinding, cracking, or galling that could be

the result of misalignment or tooling contact. Replace tooling that has excessive wear.

• Check for any loose material or debris in the welding cavity, cleaning it out.

• Check all parameter settings on the controller to ensure they are properly set for the weld to

be made.

• Drain water and contaminants from the airline filters as necessary

Instruction Set for General Information Page 6 of 30

BRANSON Metal Welding

Product Manual- General Information

Unpacking, Handling & Installation:

Unpack the Actuator and Touchscreen Controller. Remove the top cover of the power supply

and check if any components became loose during shipment.

If damage has occurred:

Notify the shipping company immediately. Retain packaging materials for inspection and

possible re-use.

System Location:

Locate the Touchscreen Controller in an area away from radiators or heating vents. Allow

sufficient clearance in back of the controller to access the connectors. Observe the following:

• Do not block the exhaust or air intake areas. Proper air circulation is necessary to maintain a

safe operating temperature.

• Only operate the controller within an ambient temperature range of 41°F to 122°F (5°C to

50°C).

• Verify that neither dust nor dirt are allowed to restrict the flow of air exhaust or air intake.

Clean the air ports as necessary.

If the temperature of the power supply exceeds the recommended operating range, a thermal

switch will stop ultrasonics and the power supply will display an Overload alarm. Ultrasonics

will remain off until the power supply cools to a safe operating temperature and the RESET

button is pressed.

If the environment is excessively dirty or oily, contact Branson for assistance. Special

Touchscreen Controller enclosures, filters (i.e. filter/separator/regulator), and other equipment

are available.

System Assembly:

Connect the actuator system per the Hookup diagram contained in the Special Information

Instruction Set. Verify that connections are complete and correct before proceeding. Plug the

Controller into a proper power source. See the Touchscreen Controller Instruction Set for power

specifications, plugs and receptacles used.

To prevent the possibility of an electrical shock, always plug the power supply into a

grounded power source. Be sure the power switch is in the Off position before making any

electrical connections.

Connect the system to a clean (5 micron air filter with 0.5 micron mist separator), dry, 80 psig

(5.5 bar) minimum air supply. See the Actuator Instruction Set for information on the set up of

application tooling and the use of this equipment for ultrasonic welding.

Instruction Set for General Information Page 7 of 30

BRANSON Metal Welding

Product Manual- General Information

Crash Gap Adjustment:

In most applications, adjustment of the gap between the ultrasonic Horn Tip and the Anvil is

factory set to prevent these surfaces from contacting each other when no parts to be welded are

present and the foot pedal is depressed. A poorly adjusted crash gap can cause serious damage to

the tooling. See the Actuator Instruction Set for proper setup instructions.

Operating the System:

With all proper connections made and with tooling properly set up, welding may be performed.

In most instances it is likely that Branson has developed weld settings for your application and

stored them as presets in the controller prior to shipping. See the Touchscreen Controller

Instruction Set for information on retrieving presets. For other weld parameter information

pertaining to your system, see the parameter preset page included in the Special Information

Instruction Set.

Instruction Set for General Information Page 8 of 30

BRANSON Metal Welding

Product Manual- General Information

Troubleshooting:

This section shows how to fix some of the possible errors and problems which may occur in

normal use of the MWX100/ Ultrasplice system.

Weld Overload

Weld overloads are premature shut downs of the power supply. Overloads signify excessive

loads and must be corrected if continued reliability of the equipment is to be maintained.

Hardware internal to the supply are controlling this function and it can not be defeated.

The control system analyzes the end of weld characteristics to check for overloads. If the system

determines an overload an alarm occurs. The control halts action until the system is reset.

Some of the possible causes for overloads are:

• The tool clearances are too small, horn and anvil touch during welding

• Excessive air pressure with low amplitude

• Defective Stack assembly

• Defective Power Transistors in power supply

Low Air Pressure

The control system and its components were designed to run with a clean air supply of from 90

to 120 psi. The control system monitors the air pressure from the low air pressure switch

(optional). The low pressure threshold is set from the controller. An alarm occurs when

incoming line pressure the drops below the set pressure.

Ready Check

The system undergoes a Ready Check operation at every startup, the end of every weld, and at

the exit of Setup mode. This procedure checks the height encoder position. If an incorrect height

value is returned, an alarm occurs.

Some of the possible causes of a Ready Check alarm are:

• The horn is stuck in the closed position

• Maintenance has moved the height encoder to an out of limit condition

• Defective encoder or electronics

• Encoder not plugged in to its connector

Instruction Set for General Information Page 9 of 30

BRANSON Metal Welding

Product Manual- General Information

Troubleshooting Guide

PROBLEM SOLUTION

System will not turn on. Power cable plugged in.

Power turned on at the outlet.

Check internal fuses on the Controller Line

Board.

Plant fuse fails or circuit breaker trips

when plugging the unit into an electrical

outlet.

Plant fuse fails or circuit breaker trips

during weld cycle

Line fuse fails. Check fuse current rating, replace if

Horn will not move down or up. System not connected to air supply.

Get Emergency Stop when system is

turned on.

No Sonics when test button is pressed. RF Cable connected.

No sonics during weld cycle Check all cable connections.

Overloads when welding Stack not tuned properly.

When touching the system you get a

slight electrical shock.

Inspect power cord, replace if shorted.

Check line filter, replace if failed.

Check current rating of the plant fuse or the

circuit breaker, replace if failed.

incompatible.

Check fan motor, replace if failed.

Air not turned on.

Check Emergency Stop Switch.

All cables properly connected.

Press red switch on foot pedal. (if system is

equipped with one)

Check RF cable for broken wire.

Ribbon cable in power supply between SPM and

programmer unplugged.

Check start cable for broken wires.

Check inside power supply for loose start cable

from rear of unit to programmer board.

Check thermo switch in power supply.

Tooling not set up properly.

Crash gap not set properly.

Tip nut cracked, replace if needed.

Check weld parameters.

Check stack interfaces for fretting.

Check for loose or failed horn or booster, tighten

or replace as necessary.

Inspect power cord, replace if needed.

Inspect system ground, repair if needed.

Instruction Set for General Information Page 10 of 30

BRANSON Metal Welding

Product Manual- General Information

Tooling heats up after machine runs a

while.

Low weld strength. Check weld parameters.

Excessive welding. Reset parameters.

Time limit error or peak power error

displayed after weld cycle.

Squealing sound during welding or when

test key is depressed

Weld heights are inconsistent Re-calibrate encoders with 1mm gauge.

Horn is stuck in down position Check air pressure.

Air leaking from machine. Ensure all air line connections are tight.

Unusual sound during weld cycle. Check tooling gap.

Cooling air is not turned on or is not on long

enough.

Cooling air is not directed at tooling.

Check tooling gaps.

Check knurl on tooling. If worn replace

tooling.

Increase Energy.

Check the Down stop adjustment.

Check for part contamination.

Ensure all hardware is tight.

Reset amplitude.

Reset pressure.

Measure and re-calibrate amplitude display.

Reset limits.

Check tip, rotate or replace if worn.

Check anvil for wear, rotate or replace if worn.

Check air pressure setting.

Check up stop for proper adjustment.

Process settings have to be opened up due to

part variance or limits should be adjusted

according to the part/wire being run.

Check anvil clamp for proper torque.

Check plate screws and tighten or replace.

Check cover plate screws and tighten.

Reset gaps.

Re-square horn/tip and reset gaps.

Reset horn tip and gap.

Ensure the connector for the encoder is tightly

plugged into the actuator card.

Ensure air lines are installed properly.

Check for kinks in air lines.

Check for cracked or broken air lines.

Check converter.

Check stack assembly.

Instruction Set for General Information Page 11 of 30

BRANSON Metal Welding

Product Manual- General Information

Squealing sound from power supply when

unit is turned on.

Maintenance counter alarm. Reset maintenance counter.

Actuator arm moves sluggish Check air lines for contamination.

System has READY CHECK message The horn is stuck in the closed position.

Time, height and energy inconsistent. Switch to energy mode & open height window.

Check cooling fans in rear of unit

NOTE: Air must be filtered to 5 microns and be

oil and water free.

Check solenoid valve, replace if needed.

Check air regulator.

Maintenance has moved the height encoder to

an out of limit condition.

Defective encoder or electronics.

Encoder not plugged into the actuator card.

Make some sample welds. Check the time and

the height of the welds for consistency. If the

time or weld thickness varies greatly, check the

air regulator.

Instruction Set for General Information Page 12 of 30

BRANSON Metal Welding

Product Manual- General Information

Periodic Maintenance

In order to maintain optimum operating conditions, it is important to perform various

maintenance and equipment inspections at periodic intervals. Please observe the following

recommendations.

Daily:

• Drain water and contaminants from the airline filters, if required.

Every Tool Rotation:

• Inspect the clamping surfaces of the Tip, the Tip Nut

and the Horn for fretting.

• Vacuum and clean out any copper residue or dirt in the actuator.

After one million cycles:

• Vacuum and clean inside of power supply

• Calibrate pressure regulator.

• Clean and torque the stack interface.

• Calibrate amplitude.

FSR Assembly

Air Filter/Separator/Regulator (Optional Branson Part #207-020) should be serviced after 1 year

or when a pressure drop of 15 psi is reached.

• Disconnect the air supply.

• Remove and clean out filter bowl with a clean rag.

• Replace the white filter element and re-assemble.

• Remove and clean out separator bowl with a clean rag.

• Replace brass-colored filter element and reassemble.

• Reconnect air supply.

Do not use solvent to clean filter bowls

Clean the air filter bowl with a mild household soap only. The bowl is made from a

polycarbonate material, which can rupture if exposed to synthetic lubricating oils solvents or

harsh chemicals. The bowl is rated for a maximum line pressure of 140 psig (1043 kPa) and a

maximum temperature of 120°F (49°C).

Instruction Set for General Information Page 13 of 30

BRANSON Metal Welding

Product Manual- General Information

Contacting Branson:

Spare Parts & Replacement Tooling:

Spare parts or replacement tooling for the ultrasonic welding system may be ordered directly

from Branson. A spare tooling specification sheet is included in the Special Information

Instruction Set. Additional part listings are contained in the Actuator and Touchscreen

Controller Instruction Set sections of this manual.

Branson will work with you and recommend components you need and should carry in inventory

based upon your manufacturing philosophy and or production needs. We will quote price,

delivery and can coordinate special arrangements such as expedited service or blanket orders.

When Ordering Spare or Replacement Parts have the purchasing agent Fax the order to us with

the following information provided:

• Purchase Order Number,

• Branson Part Number, Quantity, and Date Required,

• Ship To Information, (including “Ship to the Attention of”)

• Bill To Information

• Shipping Instructions, (such as air freight, truck, etc.)

• Special Instructions, (such as “Hold at Pick-Up Counter and Call” -- Be sure to provide a

name and a phone number)

Questions or Problems:

If you have any questions or are experiencing a problem, call the local Branson field sales and/or

service representative. He or she will be familiar with your equipment and application and, in

most cases, will be able to help you. He or she may have the replacement part you need, in

stock, that will return your system to operation in the shortest possible time.

If necessary, the representative will contact Branson for additional service and, in some cases,

will put you into contact with the appropriate personnel. If the local representative is unavailable,

please call us directly.

Before you call, take the following steps:

• Have this manual with you.

• Know how your system has been set up and equipped, including your MBOS version.

• Be able to describe the situation or problem.

• Have a list of steps that you have already taken.

• Have a list of spare parts in your inventory

• Have the name and phone number of the Local Branson Representative

Instruction Set for General Information Page 14 of 30

BRANSON Metal Welding

Product Manual- General Information

Returning Equipment:

In order to properly and efficiently handle an equipment return to Branson, the following

procedure must be followed. Contact your Local Sales Manager or Branson Customer Service

for assistance. Proper handling and identification of your equipment will expedite servicing

and/or return.

Using the Return Authorization Form, (next page), complete the following:

• Customer Information Section

• Description of Problem

• Equipment Information

Call Branson and Receive a Return Authorization Number (RA#) from Branson Customer

Service.

• Properly package the equipment to prevent damage

• Clearly mark the RA# on the outside of the package

• Include a copy of the completed Return Authorization Form inside the package

• Return general repairs by any convenient method. Send priority repairs via Air Freight

• Prepay the transportation charges, (FOB Danbury, CT)

Instruction Set for General Information Page 15 of 30

BRANSON Metal Welding

Product Manual- General Information

Return Authorization Form

Customer Information Authorization Information

Customer name: Return Authorization No:

Address:

Contact:

Phone:

Fax:

Description of Problem:

Equipment Information:

Machine Type:

Machine Serial Number:

Date of Original Purchase:

Part Number of Component:

PO Number for Repair:

Do not ship to Branson without an RA

number. Mark the RA number on the shipping

label. Please fax a copy of this completed

form to Branson Customer Service prior to

Shipping.

Assigned By:

Special Instructions:

For Branson Use Only

Under Warranty

Billable Repair

Charge Repair to Sales

Sold Replacement Part

Instruction Set for General Information Page 16 of 30

BRANSON Metal Welding

Product Manual- General Information

New Applications:

Branson is always eager to work with you on a new ultrasonic application. Whether it be a

manual workstation, a semi or fully automated system, Branson has the personnel and technical

competence to support your requirements. Branson’s application laboratory, product and

automation engineering, customer service and manufacturing capabilities are second to none.

Branson is the world leader in ultrasonic metal welding and our business philosophy is practiced

to assure customer success.

Application assistance is always available. For initial application review, contact your Local

Sales Manager who can indicate initial feasibility and assist you in completing the Ultrasonic

Weld Evaluation Request Form, (next page). Please complete one (1) request form for each

application.

Please copy the attached Ultrasonic Evaluation Request Form (next page), complete the

customer and application information section and forward it to Branson along with enough

component material to produce 24 assemblies, (if this is not practical please advise). A

feasibility evaluation will be performed and samples returned, for review, along with a system

quotation/ proposal. Be sure to include drawings of the completed assembly and include the

electrical, mechanical, and production requirements. Complete the form as completely as

possible. The Branson Sales Representative can assist you.

Instruction Set for General Information Page 17 of 30

BRANSON Metal Welding

Product Manual- General Information

Evaluation Request Form

Lab Application No: Date:

Please fill out this form with at least 24 samples parts for an ultrasonic weld analysis

Name:

Company:

Address:

City:

Telephone:

Component Description:

Part 1 Part 2

Material:

Hardness:

Plating:

Insulation:

Application Requirements:

Production Rate: (parts/hr)

Location tolerance: (in)

Is weld appearance important:

Pull Strength (lbs)

Drawing Notes:

This information to be completed by Branson

Representative:

Telephone:

Return samples to: Representative Customer

Sales Engineer:

Applications Engineer:

Instruction Set for General Information Page 18 of 30

BRANSON Metal Welding

Product Manual- General Information

Terminology:

Actuator: A mechanical device which houses the converter/booster/horn (stack) assembly in a

rigid mounting and is utilized to move the stack up or down. This allows for precise control of

welding pressure for efficient while delivering mechanical vibrations from the ultrasonic stack to

the work piece(s).

After Burst: A short duration (burst) of ultrasonic energy that begins after completion of the

AFTER BURST DELAY. (Also See: AFTER BURST DELAY & AFTER BURST

DURATION)

After Burst Delay: The amount of time, in seconds, between the completion of the ultrasonic

welding cycle and the start of the AFTER BURST. (Also See: AFTER BURST & AFTER

BURST DURATION)

After Burst Duration: The amount of time, in seconds, that AFTER BURST energy is

delivered. (Also See: AFTER BURST & AFTER BURST DELAY)

Amplitude: Amplitude is the peak-to-peak displacement of mechanical motion as measured at

the face of the horn tip. Amplitude is measured in thousandths of an inch or in microns. (i.e. A

standard 40 kHz converter produces approximately .0004” or 10 microns of amplitude), Inches x

25,400 = microns. -- With ‘Advanced Power Supply’ this is adjustable depending on system

frequency and application tooling.

Anti-Node: The anti-node is the area of the horn and booster that exhibits maximum

longitudinal displacement and where the internal dynamic forces are equal to zero. This area is

at the face and back surface on half-wave technology.

Anvil: A device specially designed to grip the lower component and hold it stationary against

the energy of vibration(s) which allows a weld to be created.

Baud Rate: A communications measure describing the speed at which signals are transmitted

serially (the number of signal events per second).

BBRAM: Nonvolatile random access memory (battery back-up random access memory).

Equipped with long life built in batteries, this memory area preserves weld parameters and menu

settings when the system is powered off. (also known as BBR)

Booster: The central component of an ultrasonic stack assembly. A device which transfers

mechanical energy from the converter to the ultrasonic horn. The booster will, depending on

design, increase, decrease, or maintain the specific energy (amplitude) as received from the

converter.

Calibration: The process of adjusting a device to a known position for purposes of inspection

and/or monitoring position, direction, speed, and/or velocity.

Instruction Set for General Information Page 19 of 30

BRANSON Metal Welding

Product Manual- General Information

Clock: An electronic circuit that generates timing pulses to synchronize the operations of

various other circuits in a device(s).

Communications: Transmission of information between points of origin and reception without

alteration of the sequence and or structure of that information content.

Consumable Spare Tooling: The tooling portion of the ultrasonic system that wears and

requires replacement due to production use. This includes but is not limited to ultrasonic horns,

replaceable tips, anvil, and positioning mask. A Spare Tooling Specification Sheet is included

within the Operation Manual to document the spare tooling for a specific metal welding

application.

Continuous Sonics Mode: A system setting in which the power supply will deliver ultrasonic

electrical energy until the start signal is terminated.

Controller: The portion of the welding system that provides specific settings & instruction(s) to

the overall welding system.

Converter: A device which utilizes a lead-zirconate-titanate electrorestrictive element to

change high frequency electrical energy into high frequency mechanical energy.

Counter: A programmable device used to monitor system cycles and alert personnel when

specific conditions are met.

Data: Any representation(s) of instructions, characters, information, or analog quantities to

which meaning may be assigned

Default: A chosen system setting or parameter in which the system does not require external

data input. In some cases the default value will be changed based upon equipment use.

Dynamic Spring: An, adjustable, energy storage mechanism (shock absorber) which allows for

stack follow through upon engagement of application tooling with the work pieces to be welded.

Energy: Energy is the area beneath the ultrasonic power curve and is calculated in joules,

(Watts X Seconds = Joules). When the ultrasonic welding system is setup in the “Weld In

Energy” mode the system will deliver the amount of energy as programmed. NOTE: The

maximum (default) time allowed for delivering ultrasonic energy is five (5) seconds.

Energy Mode: A welding method in which the ultrasonic power supply is active until the

required amount of energy is delivered (See ENERGY)

Fixture: A device for positioning and or holding a component for assembly.

Force: The amount of mechanical pressure that is used to deliver, (bring down) the mechanical

actuator. This programmed force is also called TRIGGER FORCE and is used to engage the

knurl pattern into the component part(s) prior to the initiation of ultrasonic energy.

Instruction Set for General Information Page 20 of 30

BRANSON Metal Welding

Product Manual- General Information

Frequency: The number of complete oscillations per second expressed in Hertz (Hz) or

kilohertz (1 kilohertz = 1000 Hz). Typically 20 kHz or 40 kHz.

Gain: The ratio of the amplitude of motion produced by the converter and delivered by the horn

is called the gain. It is determined by the difference in mass on either side of the nodal point.

Hand Shaking: The procedure (signal exchange) when a connection is established between two

electronic devices. A common example is the signal exchange between a terminal and a

MODEM. These signals (hardware and software) are used to control the flow of data (start/stop)

between devices.

Height: A display value, in millimeters (mm), as registered by a linear encoder upon completion

of an ultrasonic welding cycle. -- Programmable, in millimeters, with Upper Control Limit &

Lower Control Limit

Height Encoder: A device utilized to monitor position, direction, speed, and/or velocity.

Horn: An acoustically designed metal tool that delivers mechanical energy from the converter/

booster into the work piece. Most applications utilize half wave technology, (40 kHz = 2.2” ±,

20 kHz = 5.5” ±).

Hold Time: The amount of time after delivery of ultrasonic energy until the stack tooling begins

to retract from the component material(s).

Joint: The welded surfaces

Linear Height Encoder: (See: Height Encoder)

Loading Meter: A meter which indicates the power drawn from the ultrasonic power supply.

Maintenance Counter: A programmable device used to alert production personnel of the need

to review/ inspect application tooling and/or the ultrasonic system for preventive maintenance

purposes. The device increments one (1) count for each system cycle. (See: Counters)

Mode: The method of operating the system (also see WELDING MODE)

Node: The node is the area of the horn, (and booster), that exhibits no longitudinal displacement

and where the internal dynamic forces are at the maximum. This area is in the center location on

half-wave technology.

Parameter(s): Programmable units used to control and or monitor the ultrasonic process. -Include but not limited to ENERGY, FORCE, PRESSURE, AMPLITUDE

Parts Counter: A programmable device used to monitor system cycles and alert personnel

when specific conditions are met. (See: Counters)

Instruction Set for General Information Page 21 of 30

BRANSON Metal Welding

Product Manual- General Information

Peak Power: Peak power is the maximum amount of power in watts that was required to keep

the ultrasonic stack in motion during the weld cycle.

Power: Power, measured in watts, is a function of pressure and amplitude. The amount of

power, (watts) required to keep the ultrasonic stack in motion is monitored and used to develop a

power curve. This power curve is used to calculate the amount of energy delivered/ dissipated,

(Watts = Joules / Time). The power as displayed on the control box is peak power.

Power Supply (Ultrasonic): An electronic device that converts 50/60 cycle electrical current

into 40 kHz, (40,000) or 20 kHz, (20,000) cycles per second high frequency electrical energy.

Power Supply Overload (Ultrasonic): The point or limit at which the amount of power in

watts, required to keep the ultrasonic stack in motion, exceeds the available power from the

power supply. The system will go into an overload condition in order to prevent system damage.

Preheight: A pre-sonic inspection display, in millimeters (mm), as registered by a linear

encoder prior to initiation of the ultrasonic welding cycle. -- Programmable, in millimeters, with

Upper Control Limit & Lower Control Limit

Presets: System memory available for storage and retrieval of welding parameters.

Pressure: The amount of mechanical pressure supplied to the ultrasonic stack assembly while

delivering ultrasonic energy to the components.

Quality Widows & Limits: Programmable values used by the system to compare actual

process data. Actual process data must be within limits or an alarm condition will exist.

Setup Mode: The condition the control box must be in prior to adjusting parameters, quality

windows, and/or any others settings except those contained within the Command Mode.

Squeeze Time : The amount of time after the ultrasonic tooling engages the component(s) and

before delivery of ultrasonic energy. -- Adjustable from 0 - 0.5 seconds

Stress: Stress is the amount of dynamic force per cross sectional area.

Time : Time is the duration of the ultrasonic, mechanical, activity. Time is a component used to

calculate the amount of ultrasonic energy delivered during a weld cycle, (Time = Joules / Watts).

Tip: Device specially designed to grip the upper component, to be welded, and to direct the

ultrasonic energy into the work piece, (Also: Horn Tip & Replaceable Horn Tip).

Tip Nut: Device specially designed to securely clamp a replaceable tip onto the horn.

Trigger Force: (See: Force)

Instruction Set for General Information Page 22 of 30

BRANSON Metal Welding

Product Manual- General Information

Tuning: Adjusting to optimize power supply performance according to resonance frequency,

especially with regard to the horn and converter.

Velocity: The rate of motion at a specific time [velocity = distance / time] (also referred to as

speed)

Weld Mode:

• Weld In Energy: System delivers ultrasonic energy until a predetermined amount of energy,

in joules is dissipated. The system determines energy by calculating the area beneath the

power curve -- Watts x Time = Joules (1 watt per second = 1 joule).

• Weld In Height: System delivers ultrasonic energy until the ultrasonic tooling reaches a

predetermined position.

• Weld In Time: System delivers ultrasonic energy for a predetermined amount of time.

• Welding Parameters: (See: Parameters)

Instruction Set for General Information Page 23 of 30

BRANSON Metal Welding

Product Manual- General Information

Ultrasonic Theory:

What Is An Ultrasonic Weld?

Ultrasonic welding joins metal parts by applying the energy of high frequency vibrations onto the

interface area between the parts to be welded.

How Does It Work?

Electrical Energy is transformed into high frequency mechanical vibration. This mechanical

vibration is transferred to a welding tip through an acoustically tuned horn (Figure 1). The parts

are “scrubbed” together under pressure at 20,000 or 40,000 cycles per second. This high

frequency vibration, applied under force, disperses surface films and oxides, creating a clean,

controlled, diffusion weld (Figure 2). As the atoms are combined between the parts to be

welded, a true, metallurgical bond is produced.

Figure 1 Figure 2

Benefits of Ultrasonic Welding

Ultrasonic metal welding exhibits unique welding properties that include:

• Excellent electrical, mechanical, and thermal connections between similar and dissimilar

metals.

• Low heat build up during the ultrasonic process (no annealing of materials).

• Compensation for normal surface variations of the material.

• Ability to clean surface oxides and contaminants prior to welding.

• Ability to weld large areas using minimal energy.

• Ability to weld thin materials to thick materials.

• Low cost per weld.

Instruction Set for General Information Page 24 of 30

BRANSON Metal Welding

Product Manual- General Information

How Is An Ultrasonic Weld Made?

Although the theoretical process of producing an ultrasonic weld is uncomplicated, the

interactions of the various weld parameters are important and should be understood. When

producing an ultrasonic weld, there are three primary variables that interact; they are:

Time: The duration of applied ultrasonic vibration

Amplitude: The longitudinal displacement of the vibration

Force: The compressive force applied perpendicular (normal) to the direction of vibration

Power required to initiate and maintain vibration (motion) during the weld cycle can be defined

as:

P = F x A

Where:

• P = Power (watts)

• F = Force * (psi)

• A = Amplitude (microns)

*Note:

Force is determined by multiplying:

Force = (Surface Area of the Cylinder) X ( Air Pressure) X ( Mechanical Advantage)

Energy is calculated as:

E = P x T

Where:

• E = Energy (joules)

• P = Power (watts)

• T = Time (seconds)

Thus the complete ‘Weld To Energy’ process would be defined as:

E = ( F x A ) x T

A well designed ultrasonic metal welding system will compensate for normal variations in the

surface conditions of the metals by delivering the specified energy value. This is achieved by

allowing Time (T) to adjust to suit the condition of the materials and deliver the desired energy.

Instruction Set for General Information Page 25 of 30

BRANSON Metal Welding

Product Manual- General Information

Welding To Energy - Why?

Most metal welding applications are produced by ‘Welding To Energy’ in order to compensate

for the various surface oxides and contaminants associated with the metals being joined. In a

few applications ‘Welding To Time’ or ‘Welding To Height’ will yield better results. Since the

majority of all metal welds are produced using energy as the controlling factor we will confine

our discussion to that condition.

Welding to energy is necessary because of the non-metallic oxides that form on the metal’s

surface as well as other contaminates such as grease and dirt. To producing quality welds

reliably it is necessary that the surfaces to be joined are clean. The high frequency scrubbing

action, combined with pressure, cleans the weld interface at the beginning of the weld process.

The following graph (Figure 3) illustrates a weld produced. The weld ‘power graph’ is

sometimes referred to a weld ‘footprint’. It can be used to visualize the weld cycle and assists in

parameter optimization. Graphs from consecutive welds will vary slightly as the system

dynamically adjusts time to accommodate varying surface conditions. The weld power data is

gathered by sampling the power used in 5 millisecond intervals.

Instruction Set for General Information Page 26 of 30

BRANSON Metal Welding

Product Manual- General Information

Power

The converter/ booster/ horn, (stack assembly), requires minimal electrical power to initiate and

maintain motion (vibration) at a ‘no-load’ condition. As the mechanical load increases, the

power required to maintain the mechanical vibration also increases. The maximum power

required during a weld cycle is ‘Peak Power’.

Figure 3

By increasing Pressure and maintaining all other parameters, the mechanical load or force on the

weld joint increases, therefore, the amount of Power required to maintain the vibration of the

stack increases. Subsequently, because of the increased Power Level, less time is required deliver

the same amount of Energy. This relationship is illustrated in the following diagram (Figure 4):

Figure 4

The difference in the appearance of each of the above weld graphs is the result of increased

Power loading. Based upon an increase in Pressure, additional Power is required to maintain the

motion of vibration. Thus, the same amount of energy is delivered in less time. This approach is

typically used to raise the loading of the power supply during a weld cycle to the desired level as

determined by the application.

Instruction Set for General Information Page 27 of 30

BRANSON Metal Welding

Product Manual- General Information

Time:

The time required to deliver the necessary energy is defined as the Weld Time. For most welds,

the time required will be less than one second. If more energy is required and all other weld

parameters are maintained, the weld time will increase (Figure 5).

Figure 5

Amplitude:

An ultrasonic tool is a resonant acoustical device. The term Amplitude is used to describe the

amount of longitudinal expansion and contraction that the tooling endures as it vibrates (Figure

6). The amplitude correlates to the scrubbing action at the weld interface. This scrubbing action

combined with pressure is what advances the weld by a diffusing or mixing of the base materials.

Figure 6

Instruction Set for General Information Page 28 of 30

BRANSON Metal Welding

Product Manual- General Information

As previously mentioned, the converter/ booster/ horn, (stack assembly), requires minimal

electrical power to initiate and maintain vibration in a ‘no-load’ condition. As the amplitude

increases, the power required to maintain the increased velocity of vibration also increases.

Subsequently, because of the increased Power less time is required deliver the same amount of

Energy. This relationship is illustrated in the power diagram (Figure 7):

Figure 7

Resonant Frequency:

The ultrasonic tooling acts as a spring having node points and anti-node points. The mechanical

energy used to vibrate the tool is created by the converter. As the vibrations are propagated

through the acoustical tool, a harmonic resonance is established consisting of nodes and antinodes. This action results in a resonant wave being transferred through the tooling (Figure 8).

The efficiency of the resonant wave transfer depends on the natural resonant frequency of the

horn and is determined by two factors:

• The speed of sound through the material

• The geometric shape of the object

Figure 8

Instruction Set for General Information Page 29 of 30

BRANSON Metal Welding

Product Manual- General Information

Avoiding An Overload Condition: It is possible to increase the Amplitude and or the Pressure

to a point where the power available is not adequate to initiate or maintain vibration under the

given mechanical load. At this point, the power supply will stall resulting in an Overload

condition. Electronic circuits in the system will protect the power supply if this condition exists.

Welding To Time: In specific applications, ‘Welding To Time’ may be desired. As previously

mentioned, there are three primary variables that interact; they are:

• TIME: The duration of applied ultrasonic vibration.

• AMPLITUDE: The longitudinal displacement of the vibration.

• FORCE: The compressive force applied perpendicular (normal) to the direction of vibration.

Generally, welding for a specific time will produce acceptable results when:

• The equipment is installed on an automated production line and each station must complete

its process within a certain time limit.

• Very small low energy welds on clean components are being made.

Welding Temperature: Ultrasonic welding produces a localized temperature rise from the

combined effects of elastic hysteresis, interfacial slip and plastic deformation. The weld

interfaces reach approximately 1/3 the temperatures needed to melt the metals. Since the

temperature does not reach the melting point of the material, the physical properties of the

welded material are preserved. As the ultrasonic welding process is an exothermic reaction, as

welding time increases so does weld temperature.

Instruction Set for General Information Page 30 of 30

Branson Product Manual - Actuator Information

MWX100

Actuator Information and Instructions

Document Number: DCM00056

Last revised: 03/27/2012 LAW

Branson Ultrasonics Corporation

41 Eagle Rd

Danbury, Connecticut 06810 U.S.A.

(203) 796-0400

(800) 888-6089

(203) 796-0380 FAX

http://www.bransonultrasonics.com

This document is intended for use in conjunction with others to form a complete manual

for your BRANSON Metal Welding system.

Introduction:

This Instruction Set includes information for the BRANSON MWX100 actuator. This actuator is

intended for use with a BRANSON controller.

Portions of this section may be superseded by more specific and detailed information

provided in other Instruction Sets.

Instruction Set for Actuator Information Page 1 of 23

Branson Product Manual - Actuator Information

MWX100

Table of Contents

Introduction: ...............................................................................................................................1

Table of Contents ........................................................................................................................2

Mechanical Actuator System .......................................................................................................4

Ultrasonic Stack Assembly ......................................................................................................5

Converter ..............................................................................................................................5

Booster .................................................................................................................................5

Horn .....................................................................................................................................6

Welding Tip (Replaceable Tip Tooling) ................................................................................6

Tip Nut (Replaceable Tip Tooling) .......................................................................................6

Polar Shell & Ultrasonic Stack. .............................................................................................7

Anvil .......................................................................................................................................7

Actuator ...................................................................................................................................7

Application Tooling ....................................................................................................................8

Controls and Adjustments ...........................................................................................................9

Speed Up .................................................................................................................................9

Speed Down ............................................................................................................................9

Cooling Air ..............................................................................................................................9

Adjustment of the Down Stop ................................................................................................ 10

Adjustment of the Up Stop ..................................................................................................... 10

Tool Gap Requirements............................................................................................................. 12

Knurl Pattern Imprint Evaluation............................................................................................... 13

Torque Check............................................................................................................................ 14

Check Welder Performance ....................................................................................................... 14

Establishing Weld Parameters ................................................................................................... 14

Ultrasonic Stack Disassembly ................................................................................................... 15

Ultrasonic Stack Assembly ........................................................................................................ 16

Encoder Board Calibration ........................................................................................................ 19

Calibrate Height ..................................................................................................................... 19

Height Span Adjustment ........................................................................................................ 20

Slide Maintenance ..................................................................................................................... 21

File Attachments ....................................................................................................................... 23

Recommended Spare Components List ..................................................................................... 23

Instruction Set for Actuator Information Page 2 of 23

Branson Product Manual - Actuator Information

MWX100

List of Figures

Figure 1: Equipment Specifications .............................................................................................4

Figure 2: Ultrasonic Stack Assembly ...........................................................................................5

Figure 3: Actuator Slide Mechanism ...........................................................................................8

Figure 4: Speed Controls and Cooling Knob Location .................................................................9

Figure 5: Up/Down Stop Locations ........................................................................................... 11

Figure 6: Tool Gap .................................................................................................................... 12

Figure 7: Knurl Pattern Imprint Evaluations .............................................................................. 13

Figure 8: Cleaning object mating surface direction .................................................................... 16

Figure 9: Exploded Ultrasonic Stack Assembly ......................................................................... 17

Figure 10: Tool Cleaning .......................................................................................................... 18

Instruction Set for Actuator Information Page 3 of 23

Branson Product Manual - Actuator Information

MWX100

Mechanical Actuator System

The MWX100 system is comprised of a power supply and control box, ultrasonic stack

assembly, application tooling, and mechanical actuator. The mechanical actuator is the system

that rigidly holds and moves the converter, booster, and horn assembly known as the ultrasonic

stack. A pneumatic cylinder drives the actuator to apply a precise pressure to the parts to be

welded during the weld cycle.

Specifications

Length

Height

Width

Stroke

Weight

Figure 1: Equipment Specifications

Instruction Set for Actuator Information Page 4 of 23

18.4in (467mm)

14.7in (373mm)

8.5in (216mm)

0.98in (25mm)

49 lbs (22kg)

Branson Product Manual - Actuator Information

Diaphragm

MWX100

Ultrasonic Stack Assembly

Converter

Figure 2: Ultrasonic Stack Assembly

Converter

The 40 kHz electrical energy from the power supply is applied to the transducer element

or converter, which transforms the high frequency electric current into high frequency

mechanical vibrations at the same frequency. The heart of the converter is a leadzirconate-titanate electrostrictive element that, when subjected to an alternating voltage

expands and contracts. The converter’s efficiency of changing electrical energy to

mechanical vibrations exceeds ninety-five percent.

Booster

A booster couples the converter to the horn and helps determine the amplitude of

vibration produced at the face of the horn. The booster is a resonant half-wave metal

device made of titanium or aluminum and is designed to resonate at the same frequency

as the converter with which it is to be used.

A booster has two functions:

1. A rigid mounting for the converter/booster/horn stack

2. An amplitude-of-vibration increaser or decreaser as ultrasonic energy is

transmitted from the converter through the booster to the horn. The ratio of

input to output amplitude is called the gain.

Booster Horn Tip

Springs

Instruction Set for Actuator Information Page 5 of 23

Branson Product Manual - Actuator Information

MWX100

Horn

The horn is a half-wave length resonant metal device that transfers the ultrasonic

vibrations from the booster to the weld tip. The horn is made of steel (titanium for

replaceable tip tooling) and is designed to resonate at 40 kHz. The acoustical efficiency

of the steel and titanium helps to maintain constant amplitude throughout the operating

temperature of the welder. Since the horn is a vital part of the ultrasonic assembly

system, it should not be altered without proper training and advice from BRANSON

Metal Welding. Depending upon the particular application at hand, the horn may be

either a solid horn as shown in Figure 2a, or a Horn with a replaceable tip that can be

rotated or replaced as shown in Figure 2b.

Figure 2a Figure 2b

Welding Tip (Replaceable Tip Tooling)

The welding tip is designed to grip the upper component of the part to be welded, and to

couple the ultrasonic vibrations through that element into the bonding area. Welding tips

are fabricated from high-speed tool steel and heat-treated to precise specifications to

provide maximum life. The tip is coated to further enhance tool life and to provide

corrosion resistance. The patented tip design offers multiple weld surfaces by indexing

the tip on the horn to a new weld area.

Tip Nut (Replaceable Tip Tooling)

The tip nut is made of titanium and is designed to securely clamp the tip onto the horn.

The horn-welding tip-tip nut assembly is an efficient system for transmitting ultrasonic

vibration to the parts to be welded and offers an interchangeable tool at a low cost.

Instruction Set for Actuator Information Page 6 of 23

Branson Product Manual - Actuator Information

MWX100

Polar Shell & Ultrasonic Stack.

The converter-booster-horn assembly, or ultrasonic stack, is supported in a steel Polar

Shell by means of two diaphragm springs. The diaphragm springs are mounted at either

end of the booster and are securely bolted to the Polar Shell. The diaphragm shaped

springs are made from titanium and are acoustically tuned at the 40 kHz operating

frequency. This system permits efficient transmission of ultrasonic vibration along the

axis of the ultrasonic stack while providing rigid mounting.

Anvil

The anvil is made of high-grade tool steel and coated for maximum wear and corrosion

resistance. The patented tool design allows it to be rotated to present multiple weld

surfaces.

Actuator

The ultrasonic stack is mounted into a steel polar block and securely clamped in place.

The polar block is mounted to a crossed roller recirculating bearing which provides

precise vertical travel of the stack assembly, while providing excellent rigidity to resist

any loss of ultrasonic energy in the horizontal direction of sonic vibrations. See Figure 3.

Instruction Set for Actuator Information Page 7 of 23

Branson Product Manual - Actuator Information

Tip

Anvil

Anvil Clamp

Anvil Holder

MWX100

Application Tooling

Application tooling is designed and manufactured to position and weld component

materials to meet customer specifications. Application tooling typically consists of a

horn / tip / tip nut, anvil, anvil clamp, anvil holder, and tool support. See Figure 3.

Tip Nut

Tool Support

Horn

Figure 3: Actuator Slide Mechanism

Instruction Set for Actuator Information Page 8 of 23

Branson Product Manual - Actuator Information

MWX100

Controls and Adjustments

Speed Up

The Speed Up knob, located on the rear of the actuator, controls the upward speed of the

ultrasonic stack. This is useful for raising the stack quickly for other mechanism actions

and for quick part removal.

To DECREASE the upward speed, turn the indicated knob clockwise.

To INCREASE the upward speed, turn the indicated knob counter-clockwise.

Speed Down

The Speed Down knob, located on the side of the actuator, controls the downward speed

of the ultrasonic stack. This is useful to prevent damaging the parts to be welded,

increasing/decreasing cycle times to get better weld results.

To DECREASE the downward speed, turn the indicated knob clockwise.

To INCREASE the downward speed, turn the indicated knob counter-clockwise.

Cooling Air

Do not turn cooling air off completely using the cooling air adjustment knob.

Doing so may damage the converter.

Cooling air is designed to keep the weld area and the converter cooled to a reasonable

temperature during welding.

To INCREASE cooling airflow rate, turn the cooling air control knob counter-clockwise.

To DECREASE cooling airflow rate, turn the cooling air control knob clockwise.

Speed Down

Cooling

Speed Up

Figure 4: Speed Controls and Cooling Knob Location

Instruction Set for Actuator Information Page 9 of 23

Branson Product Manual - Actuator Information

MWX100

Adjustment of the Down Stop

See Figure 5 for location.

The down stop is used as a safety to prevent contact between the Horn and Anvil if the

welder is cycled without the part(s) to be welded. Unless otherwise specified, a 0.004”

(0.10 mm) gap between the Horn and Anvil is recommended.

To adjust the down stop:

1. Loosen the M10 Hex Nut on top of the weld cylinder.

2. Turn the Down Stop Knob counter-clockwise to increase the maximum

downward travel end position.

3. Turn the Down Stop Knob clockwise to decrease the maximum downward travel

end position.

4. Tighten theM10 Hex Nut when the desired down travel location is achieved.

Adjustment of the Up Stop

See Figure 5 for location.

The up stop is used to limit the upward travel of the Horn. Two examples for the use of

the up stop are limiting the upward travel to quicken cycle times and for easier loading

and unloading of components

To adjust the down stop:

1. Loosen the M6 set screw (accessed through the front plate) so that the up stop

screw moves smoothly.

2. Using a long wrench or T-handle, turn the M10 Set Screw counter-clockwise to

increase the maximum upward travel end position.

3. Using a long wrench or T-handle, turn the M10 Set Screw clockwise to decrease

the maximum upward travel end position.

4. Tighten the M6 set screw when the desired upward travel location is achieved.

Instruction Set for Actuator Information Page 10 of 23

Branson Product Manual - Actuator Information

Down Stop

Down Stop

U

p Stop

Up Stop

Up Stop

MWX100

Wrench

Access Hole

M10 Hex Nut

Adjustment

Knob

M10 Set Screw

M6 Set Screw

Figure 5: Up/Down Stop Locations

Instruction Set for Actuator Information Page 11 of 23

Branson Product Manual - Actuator Information

MWX100

Tool Gap Requirements

Tooling includes the Horn (or Horn Tip), Anvil and all surfaces that contact the weld

nugget during processing. The tooling should be inspected to confirm a gap as per the

application tooling set up sheet. If the tooling is in contact during the application of

ultrasonic energy, severe damage may result to the tooling and power supply

This test should be checked whenever the tooling is changed. Also perform this test

whenever you suspect tool contact.

Most tooling that contacts the weld nugget is designed with several weld surfaces. When

one surface is worn and no longer useful, an alternate surface may be used resulting in

extended tool life.

To set the Tool Gap set the air regulator at the same pressure as the weld pressure.

Ensure that there are no work pieces between the Horn and Anvil. Press the SETUP

button on the power supply, then press the HORN button, which will cause the Horn to