100-412-203 - REV. 04

DCX Web Page

Interface

Instruction Manual

Branson Ultrasonics Corporation

41 Eagle Road

Danbury, CT 06813-1961 USA

(203) 796-0400

http://www.bransonultrasonics.com

Manual Change Information

At Branson, we strive to maintain our position as the leader in ultrasonics plastics joining,

metal welding, cleaning and related technologies by continually improving our circuits and

components in our equipment. These improvements are incorporated as soon as they are

developed and thoroughly tested.

Information concerning any improvements will be added to the appropriate technical

documentation at its next revision and printing. Therefore, when requesting service

assistance for specific units, note the Revision information found on the cover of this

document, and refer to the printing date which appears at the bottom of this page.

Copyright and Trademark Notice

Copyright © 2015 Branson Ultrasonics Corporation. All rights reserved. Contents of this publication may not be

reproduced in any form without the written permission of Branson Ultrasonics Corporation.

Mylar is a registered trademark of DuPont Teijin Films.

Loctite is a registered trademark of Loctite Corporation.

WD-40 is a registered trademark of WD-40 Company.

Windows 7, Windows Vista, and Windows XP are registered trademarks of Microsoft Corporation

Other trademarks and service marks mentioned herein are held by their respective

owners.

ii 100-412-203 REV. 04

Foreword

Congratulations on your choice of a Branson Ultrasonics Corporation system!

The Branson DCX Web Page system is process equipment for the joining of plastic parts

using ultrasonic energy. It is the newest generation of product using this sophisticated

technology for a variety of customer applications. This Instruction Manual is part of the

documentation set for this system, and should be kept with the equipment.

Thank you for choosing Branson!

Introduction

This manual is arranged into several structured chapters which will help you find the

information you may need to know to safely handle, install, set up, program, operate,

and/or maintain this product. Please refer to the Table Of Contents and/or the Index of

this manual to find the information you may be looking for. In the event you require

additional assistance or information, please contact our Product Support department (see

1.3 How to Contact Branson for information on how to contact them) or y our local Branson

representative.

100-412-203 REV. 04 iii

iv 100-412-203 REV. 04

Table Of Contents

Chapter 1:Safety and Support

1.1 Safety Requirements and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 How to Contact Branson. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2:The Web Page Interface

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Models Covered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3:Connecting to the Web Page Interface

3.1 Locating the Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.2 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

3.3 Point to Point Connection (Windows Vista and Windows 7) . . . . . . . . . . . . . . . . . . .18

3.4 Point to Point Connection (Windows XP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Chapter 4:The Web Page Interface

4.1 Web Page Interface Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4.2 Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

4.3 Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.4 View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4.5 Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

4.6 Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Appendix A:Ultrasonic Welding

A.1 Resonance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

A.2 The Principle and the Components of Ultrasonic Welding . . . . . . . . . . . . . . . . . . . .67

A.3 Resonance Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

A.4 Graphics of a Weld . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

100-412-203 REV. 04 v

vi 100-412-203 REV. 04

List Of Figures

Chapter 1:Safety and Support

Chapter 2:The Web Page Interface

Chapter 3:Connecting to the Web Page Interface

Figure 3.1 Ethernet Port Location (Vertical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 3.2 Ethernet Port Location (Horizontal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 3.3 Ethernet Port Location (Back) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Figure 3.4 Ethernet Port Location (Vertical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Figure 3.5 Ethernet Port Location (Horizontal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Figure 3.6 Ethernet Port Location (Back) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Figure 3.7 Ethernet Port Location (Vertical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 3.8 Ethernet Port Location (Horizontal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 3.9 Ethernet Port Location (Back) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Chapter 4:The Web Page Interface

Figure 4.1 Web Page Interface Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Figure 4.2 Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 4.3 Weld . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Figure 4.4 Amplitude. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Figure 4.5 Save/Recall Presets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Figure 4.6 Limit/Cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Figure 4.7 Seek/Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Figure 4.8 System Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Figure 4.9 Alarm Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Figure 4.10 Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Figure 4.11 History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Figure 4.12 Weld Graphs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Figure 4.13 Seek . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Figure 4.14 Horn Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Figure 4.15 User I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Figure 4.16 Fieldbus (EtherNet/IP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Figure 4.17 Fieldbus Test (EtherNet/IP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Figure 4.18 Fieldbus Test (PROFIBUS DP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Figure 4.19 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Figure 4.20 User I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Figure 4.21 Communication (EtherNet/IP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Figure 4.22 Passcodes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Figure 4.23 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Figure 4.24 RF Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Appendix A:Ultrasonic Welding

Figure A.1 The components of an ultrasonic welding system . . . . . . . . . . . . . . . . . . . . . . . . .67

Figure A.2 Amplitude Transformation Via the Booster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Figure A.3 Commonly used horn shapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Figure A.4 Getting Scan Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Figure A.5 Graphics of a scan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Figure A.6 Horn Scan, Possible Defective Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Figure A.7 Horn Scan, Open RF Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

100-412-203 REV. 04 vii

Figure A.8 Getting Weld Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Figure A.9 Graphical Display of the Weld Curves.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure A.10 Weld Graph, Defective Horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Figure A.11 Weld Graph, Defective Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Figure A.12 Weld Graph, Open RF Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

viii 100-412-203 REV. 04

List Of Tables

Chapter 1:Safety and Support

Chapter 2:The Web Page Interface

Chapter 3:Connecting to the Web Page Interface

Chapter 4:The Web Page Interface

Table 4.1 Web Page Interface Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Table 4.2 Weld Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Table 4.3 Amplitude Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Table 4.4 Save/Recall Preset Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Table 4.5 Limit/Cutoff Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Table 4.6 Seek/Power Up Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Table 4.7 System Info Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Table 4.8 Alarm Log Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Table 4.9 Event Log Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Table 4.10 History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Table 4.11 History Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Table 4.12 Weld Graphs Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Table 4.13 Seek Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Table 4.14 Horn Signature Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table 4.15 User I/O Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Table 4.16 Fieldbus Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Table 4.17 System Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Table 4.18 Copy System and Restore System Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Table 4.19 Communication Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Table 4.20 Passcodes Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Table 4.21 Alarm Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Table 4.22 RF Switch Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Appendix A:Ultrasonic Welding

Table A.1 The components of an Ultrasonic Welding System. . . . . . . . . . . . . . . . . . . . . . . . .67

Table A.2 Commonly used horn shapes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

100-412-203 REV. 04 ix

x 100-412-203 REV. 04

Chapter 1: Safety and Support

1.1 Safety Requirements and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 How to Contact Branson. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

100-412-203 REV. 04 1

1.1 Safety Requirements and Warnings

This chapter contains an explanation of the different safety notice symbols and icons

found in this manual and provides additional safety information for ultrasonic welding.

This chapter also describes how to contact Branson for assistance.

1.1.1 Symbols Found in this Manual

Three symbols used throughout this manual warrant special attention:

WARNING General Warning

WARNING indicates a hazardous situation or practice which, if not

avoided, can result in serious injury or death.

CAUTION General Warning

CAUTION indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury. It can also alert the user to unsafe

practices or conditions that can damage equipment if not corrected.

NOTICE

NOTICE contains important information. It does not alert the user to potential injury,

but only to a situation that might eventually require additional work or modification if

you ignore it initially.

2 100-412-203 REV. 04

1.2 General Precautions

Take the following precautions before servicing the power supply:

• Be sure the power switch is in the Off position before making any electrical connections.

• To prevent the possibility of an electrical shock, always plug the power supply into a grounded

power source.

• Power supplies produce high voltage. Before working on the power supply assembly, do the

following:

• Turn off the power supply;

• Unplug main power; and

• Allow at least 2 minutes for capacitors to discharge.

• High voltage is present in the power supply. Do not operate with the cover removed.

• High line voltages exist in the ultrasonic power supply assembly. Common points are tied to

circuit reference, not chassis ground. Therefore, use only non-grounded, battery-powered

multimeters when testing the power supply assembly. Using other types of test equipment can

present a shock hazard.

• Keep hands from under the horn. Down force (pressure) and ultrasonic vibrations can cause

injury.

• Do not cycle the welding system if either the RF cable or converter is disconnected.

• When using larger horns, avoid situations where fingers could be pinched between the horn and

the fixture.

CAUTION Loud Noise Hazard

Sound level and frequency of the noise emitted during the ultrasonic

assembly process may depend upon a. type of application, b. size,

shape and composition of the material being assembled, c. shape and

material of the holding fixture, d. welder setup parameters and e.

tool design.

Some parts vibrate at an audible frequency during the process. Some

or all of these factors may result in an uncomfortable noise being

emitted during the process.

• In such cases operators may need to be provided with personal protective

equipment. See 29 CFR (Code of Federal Regulations) 1910.95

Occupational Noise Exposure.

1.2.1 Intended Use of the System

The DCX Power Supply and components are designed to be used as part of an ultrasonic

welding system. These are designed for a wide variety of welding or processing

applications.

The system can be used to perform ultrasonic welding, inserting, staking, spot welding,

swaging, degating, and continuous ultrasonic operations. It is designed for automated,

semi-automated and/or manual production operations.

1.2.2 Emissions

When being processed, certain plastic materials can emit toxic fumes, gases or other

emissions that can be hazardous to the operator’s health. Where such materials are

100-412-203 REV. 04 3

processed, proper ventilation of the workstation is required. Check your materials

suppliers for recommended protection when processing their materials.

WARNING Corrosive Material Hazard

Processing of many materials, such as PVC, can be hazardous to an

operator’s health and could cause corrosion/damage to the

equipment. Use proper ventilation and take protective measures.

4 100-412-203 REV. 04

1.3 How to Contact Branson

For additional assistance, please refer to the DCX AF Series Power Supply Instruction

Manual.

100-412-203 REV. 04 5

6 100-412-203 REV. 04

Chapter 2: The Web Page Interface

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Models Covered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

100-412-203 REV. 04 7

2.1 Introduction

The DCX Web Page Interface provides access, via Ethernet connection, to web pages

containing power supply information, diagnostics tools, and configuration options.

Communication can be established point-to-point or through a local area network. On the

web page interface you can access:

• 4.3 Setup Menu

4.3.1 Weld

4.3.2 Amplitude

4.3.3 Save/Recall Preset

4.3.4 Limit/Cutoff

4.3.5 Seek/Power Up

4.4 View Menu

•

4.4.1 System Info

4.4.2 Alarm Log

4.4.3 Event Log

4.4.4 History

4.4.5 Weld Graphs

4.5 Diagnostics Menu

•

4.5.1 Seek

4.5.2 Horn Signature

4.5.3 User I/O

4.5.4 Fieldbus

4.5.5 Fieldbus Test Menu

4.6 Configuration Menu

•

4.6.1 System

4.6.2 User I/O

4.6.3 Communication

4.6.4 Passcodes

4.6.5 Alarms

4.6.6 RF Switch

8 100-412-203 REV. 04

2.2 Models Covered

This manual applies to the web page interface of DCX AF Series power supplies.

2.2.1 DCX AF Series Manual Set

The following documentation is available in electronic format for the Branson DCX AF

Series power supplies.

• DCX A Series Power Supply Instruction Manual

• DCX F EIP Series Power Supply Instruction Manual

• DCX F DP Series Power Supply Instruction Manual

• DCX AF Series Web Page Instruction Manual

100-412-203 REV. 04 9

10 100-412-203 REV. 04

Chapter 3: Connecting to the Web Page Interface

3.1 Locating the Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Point to Point Connection (Windows Vista and Windows 7) . . . . . . . 18

3.4 Point to Point Connection (Windows XP). . . . . . . . . . . . . . . . . . . . . . 21

100-412-203 REV. 04 11

3.1 Locating the Ethernet Port

3.1.1 DCX A Ethernet Port Location

Figure 3.1 Ethernet Port Location (Vertical)

Figure 3.2 Ethernet Port Location (Horizontal)

12 100-412-203 REV. 04

Figure 3.3 Ethernet Port Location (Back)

3.1.2 DCX F EIP Ethernet Port Location

Figure 3.4 Ethernet Port Location (Vertical)

100-412-203 REV. 04 13

Figure 3.5 Ethernet Port Location (Horizontal)

Figure 3.6 Ethernet Port Location (Back)

14 100-412-203 REV. 04

3.1.3 DCX F DP Ethernet Port Location

Figure 3.7 Ethernet Port Location (Vertical)

Figure 3.8 Ethernet Port Location (Horizontal)

100-412-203 REV. 04 15

Figure 3.9 Ethernet Port Location (Back)

16 100-412-203 REV. 04

3.2 System Requirements

To connect to the DCX Web Page Interface you will need a PC running a Windows®

operating system with an Internet Explorer®* web browser software (versions 8 and up).

*Windows, and Internet Explorer are registered trademarks of Microsoft Corporation.

NOTICE

The DCX Power Supply is not compatible with network scanning software. If your local

network uses these types of programs, the DCX Power Supply IP address must be

placed in an exclusion list.

NOTICE

A shielded Ethernet cable should be used to connect to the DCX Power Supply W eb Page

Interface to prevent possible EMI (Electromagnetic Interference) issues.

100-412-203 REV. 04 17

3.3 Point to Point Connection (Windows Vista and Windows 7)

To connect directly to the DCX Power Supply Web Page Interface using a PC with

Windows Vista®* or Windows 7®* operating system, complete the following steps:

*Windows Vista and Windows 7 are registered trademarks of Microsoft Corporation.

1. Connect the power supply to a computer via the Ethernet port.

2. Turn on the power supply.

3. On your PC, click on the Windows logo on the task bar and select Control Panel.

4. Select View Large Icons on the top right corner.

5. Select Network and Sharing Center.

6. Select Change adapter settings.

7. Right click on Local Area Connection and select Properties to bring up the Networking tab.

18 100-412-203 REV. 04

8. Highlight Internet Protocol Version 4 (TCP/IPv4) from the list and click on Properties.

9. Use the following IP address:

IP address: 192.168.10.101

Subnet mask: 255.255.255.0

10.Click OK. Close the rest of the dialog boxes.

11.Open the Internet Explorer web browser (version 8 and up).

12.In the address bar type the following address:

13.This will bring up the DCX Web Page Interface.

http://192.168.10.100. Press Enter.

100-412-203 REV. 04 19

14.Enter a User ID that is alphanumeric an up to 12 characters long. The passcode is numeric only

and is 9 digits long

20 100-412-203 REV. 04

3.4 Point to Point Connection (Windows XP)

To connect directly to the DCX Power Supply Web Page Interface using a PC with

Windows XP®* operating system, complete the following steps:

*Windows XP is a registered trademark of Microsoft Corporation.

1. Connect the power supply to a computer via the Ethernet port.

2. Turn on the power supply.

3. On your PC, select Start > Control Panel.

4. Select Switch to Classic View on the top left corner.

5. Select Network Connections.

6. Right click on Local Area Connection and select Properties to bring up the General tab.

100-412-203 REV. 04 21

7. Highlight Internet Protocol (TCP/IP) from the list and click on Properties.

8. Use the following IP address:

IP address: 192.168.10.101

Subnet mask: 255.255.255.0

9. Click OK. Close the rest of the dialog boxes.

10.Open the Internet Explorer web browser (version 8 and up).

11.In the address bar type the following address:

12.This will bring up the DCX Web Page Interface.

http://192.168.10.100. Press Enter.

22 100-412-203 REV. 04

13.Enter a User ID that is alphanumeric an up to 12 characters long. The passcode is numeric only

and is 9 digits long.

100-412-203 REV. 04 23

24 100-412-203 REV. 04

Chapter 4: The Web Page Interface

4.1 Web Page Interface Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2 Login. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.3 Setup Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4 View Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.5 Diagnostics Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.6 Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

100-412-203 REV. 04 25

4.1 Web Page Interface Overview

The DCX Power Supply Web Page Interface allows you to set a weld preset, diagnose and

configure the power supply I/O, perform horn scans and seeks, view system information,

and to view and download the system alarms, history and events logs.

Figure 4.1 Web Page Interface Overview

B

A

C

26 100-412-203 REV. 04

Table 4.1 Web Page Interface Overview

Item Name Description

The menu navigation tabs are always displayed on the upper

section of the web pages. Each menu navigation tab includes a

sub-menu that will be displayed when the cursor is positioned

over a tab. They provide access to the following menu options:

4.3 Setup Menu

4.3.1 Weld

4.3.2 Amplitude

4.3.3 Save/Recall Preset

4.3.4 Limit/Cutoff

4.3.5 Seek/Power Up

4.4 View Menu

4.4.1 System Info

4.4.2 Alarm Log

4.4.3 Event Log

Menu

A

Navigation

Tabs

4.4.4 History

4.4.5 Weld Graphs

4.5 Diagnostics Menu

4.5.1 Seek

4.5.2 Horn Signature

4.5.3 User I/O

4.5.4 Fieldbus

4.5.5 Fieldbus Test Menu

4.6 Configuration Menu

4.6.1 System

4.6.2 User I/O

4.6.3 Communication

4.6.4 Passcodes

4.6.5 Alarms

4.6.6 RF Switch

B

Menu

Display

Displays the contents of the currently selected menu option.

Different command buttons allow to save settings, cancel

changes, restore default settings, and to perform other

C

Command

Buttons

functions specific to each menu.

Save, Cancel, and Restore Defaults is page specific. They only

operate on the page displayed.

100-412-203 REV. 04 27

4.2 Login

When connection is established with the DCX Web Page Interface, the Login page will

display. Enter a unique User ID and a numeric password. The User ID is alphanumeric an

up to 12 characters long. The passcode is numeric only and is 9 digits long. This User ID/

Passcode combination allows for restricting access as specified on the Configuration >

Passcode menu. See

Figure 4.2 Login

4.6.4 Passcodes for more information.

NOTICE

Initial Login

• User ID: Admin

User Passcode #: 999999

28 100-412-203 REV. 04

4.3 Setup Menu

Use this menu to set weld parameters, amplitude, save/recall presets, limits and cutoffs,

seek options, and power-up actions. Use the command buttons on the bottom to save

settings, cancel changes, or to restore to factory default settings.

4.3.1 Weld

Use this menu to set weld parameters.

Figure 4.3 Weld

Table 4.2 Weld Options

Name Description

MODE

Continuous Weld mode changes to Continuous after pressing save button.

Time Weld mode changes to Time after pressing save button.

Weld mode changes to Energy after pressing save button.

Energy

Peak Power Weld mode changes to Peak Power after pressing save button.

100-412-203 REV. 04 29

NOTICE

Values above 1000.0 J will be rounded up.

Table 4.2 Weld Options

Name Description

Ground Detect Weld mode changes to Ground Detect after pressing save button.

AFTERBURST

Delay Sets the delay time in seconds if afterburst is turned on.

Time Sets the afterburst time if afterburst is turned on.

FREQUENCY

Digital Tune Starting frequency set from horn signature or manually entered.

Internal Offset

Sets the frequency offset from the Web P age as either a positiv e or

negative value offset from digital tune.

External Offset Frequency is set from 26-pin user I/O connector or fieldbus.

End of Weld

Store

Clear Memory

with Reset

Clear Memory

before Seek

Set with Horn

Scan

Select to save the frequency at the end of the weld as the starting

frequency for the following weld.

Select to clear memory with reset. Memory offset will be set to 0

when a Reset is applied. Reset can come from external I/O, front

panel or web page interface (seek or horn scan).

Select to clear memory before seek. Memory offset will be set to 0

before Seek is applied.

Select to set Digital Tune frequency with a successfully completed

horn scan.

OTHER

Energy Brake

Enables energy brake. When enables, the power supply has some

time to reduce the amplitude before the sonics are shut off.

Hold Time Enter hold time value if operating in cycle mode.

30 100-412-203 REV. 04

4.3.2 Amplitude

Use this menu to set amplitude parameters.

Figure 4.4 Amplitude

Table 4.3 Amplitude Options

Name Description

WELD AMPLITUDE

Fixed @ Amplitude 1 Select for constant amplitude.

External Analog In

Step @ Time (s) Set the step time interval in seconds.

Step @ Energy (J)

Step @ Power (%) Set the step power interval in percentage.

Step @ External

Amplitude 1 (%) Set the amplitude in percentage.

Amplitude 2 (%) Set the amplitude in percentage.

AMPLITUDE RAMP

When selected, Weld Amplitude text box inputs will be disabled.

Set the amplitude externally using the user I/O connector.

Set the step energy in joules.

NOTICE

Values above 1000.0 J will be rounded up.

When selected, it allows a digital input to choose between

Amplitude 1 and Amplitude 2.

Ramp Time Sets time for amplitude ramp from 0 to 100% amplitude.

100-412-203 REV. 04 31

Table 4.3 Amplitude Options

Name Description

TEST AMPLITUDE

Same as Amplitude 1

or External Analog in

Test Amplitude (%) Manually set the value for the test amplitude.

OTHER AMPLITUDE

Scrub Amplitude (%)

Afterburst Amplitude

(%)

When selected, test amplitude value will match the value set in

amplitude 1 or External Analog In, depending on which one is

selected in Weld Amplitude container.

Sets the scrub amplitude in percentage when ground detect

mode is selected.

Sets the afterburst amplitude in percentage when afterburst

mode is selected.

4.3.3 Save/Recall Preset

Use this menu to save and recall stored presets.

Figure 4.5 Save/Recall Presets

Table 4.4 Save/Recall Preset Options

Name Description

WELD PRESETS

Save

Recall Click to recall the highlighted preset.

Select Horn Preset

Clear Memory

Counter

32 100-412-203 REV. 04

Click to save current settings. You can save the preset with an

alphanumeric description up to 24 characters.

Click to select one of the 16 available horn presets, including a

default option.

Click to clear the memory frequency for selected horn in Selected

Horn Preset menu.

Table 4.4 Save/Recall Preset Options

Name Description

Restore Defaults Click to restore highlighted preset to default parameters.

Reset Cycle Run

Counter

4.3.4 Limit/Cutoff

Use this menu to set limits and cutoffs.

Figure 4.6 Limit/Cutoff

Click to reset the cycle run counter for highlighted preset.

Table 4.5 Limit/Cutoff Options

Name Description

LIMITS

Off Select to disable limits.

100-412-203 REV. 04 33

Table 4.5 Limit/Cutoff Options

Name Description

If selected, you can set minus and plus limits for time, energy and peak

power in seconds, joules, and percentage respectively.

On

NOTICE

For Energy (J), values above 1000.0 J will be rounded up.

CUTOFFS

Off Select to disable cutoffs.

If selected, you can set the cutoff for time, energy and peak power in

seconds, joules, and percentage respectively. You can set cutoffs for Custom

On

Input1 and Custom Input2 in voltage, which are custom analog inputs or

fieldbus. User can also set cut off for Frequency High and Frequency Low in

Hertz as an offset to the midband.

Restore

Defaults

Click to restore default limits and cutoff settings.

4.3.5 Seek/Power Up

Use this menu to set seek options and power up actions.

Figure 4.7 Seek/Power Up

Table 4.6 Seek/Power Up Options

Name Description

SEEK

Seek Time (s) Sets the seek time in seconds.

Seek Ramp (s) Sets the seek ramp time in seconds.

Frequency Offset (Hz) Sets the frequency offset in Hertz.

POWER UP

Off Select to disable seek and scan during power up.

34 100-412-203 REV. 04

Table 4.6 Seek/Power Up Options

Name Description

Seek Select to enable seek during power up.

Scan Select to enable scan during power up.

Restore Defaults Click to restore default seek and power up settings.

100-412-203 REV. 04 35

4.4 View Menu

Use this menu to view information and log files about your DCX Power Supply. Have the

information on this screen available when calling Branson for troubleshooting help.

4.4.1 System Info

Use this menu to view information about your DCX Power Supply. Have the information on

this screen available when calling Branson for troubleshooting help.

Figure 4.8 System Info

Table 4.7 System Info Options

Name Description

SYSTEM INFORMATION

System WC

Display

DCP

Web Page This field lists the current version of the web page.

Boot Loader DCP

Boot Loader WC

Controller This field lists the version number for the FPGA software.

Display the power supply type (A or F) and the serial number of the

unit.

This will list either “OK” if a display is found or “Not Detected” if no

display is found.

This field lists the power level and frequency as reported by the DCP

board. If the DCP board is not detected at power up then “Not

Detected” is shown.

This field lists the version number and CRC for the boot loader

software that resides on the DCP board.

This field lists version number and CRC for the boot loader software

that resides on the WC board.

36 100-412-203 REV. 04

Table 4.7 System Info Options

Name Description

Actuator Detect

Fieldbus

4.4.2 Alarm Log

Use this screen to view the DCX Power Supply alarm history. The alarms can be sorted by

alarm number or alarm type. Alarms can be exported to an Excel file.

NOTICE

Only the last 100 alarms are stored in memory.

Figure 4.9 Alarm Log

This field lists “Yes” if the actuator connected pin is 24 V at power

up. Otherwise, it will list “No”.

If the unit is programmed as a Fieldbus unit, this field will show the

type of Fieldbus found or “Not Detected” if a Fieldbus was not

found. Otherwise, this field will not be shown.

Table 4.8 Alarm Log Options

Name Description

Alarm #

100-412-203 REV. 04 37

A unique alarm identification number. This number will

reset to zero if the alarm log is cleared.

Table 4.8 Alarm Log Options

Name Description

The DCX AF units feature an integrated real time clock.

Date & Time

Alarm date and time reflect the real date and time as set

on the 4.6.1 System page.

Cycle Num Displays the cycle number.

Alarm Displays the alarm description.

Alarm Code Displays the alarm code.

ALARM DESCRIPTIONS

Frequency - High Seek

Limit

Frequency - Low Seek

Limit

Frequency - High Weld

Limit

Frequency - Low Weld

Limit

Frequency reached high end limit: 20 kHz: 20.450 kHz,

30 kHz: 30.750 kHz, 40 kHz: 40.900 kHz.

Frequency reached low end limit: 20 kHz: 19.450 kHz,

30 kHz: 29.250 kHz, 40 kHz: 38.900 kHz.

Frequency reached high end limit: 20 kHz: 20.450 kHz,

30 kHz: 30.750 kHz, 40 kHz: 40.900 kHz.

Frequency reached low end limit: 20 kHz: 19.450 kHz,

30 kHz: 29.250 kHz, 40 kHz: 38.900 kHz.

Overload - Current RF current peak limit reached.

Frequency reached high or low end limit. Frequency

Overload - Frequency

numbers are the same as above depending on the system

(20 kHz, 30 kHz, 40 kHz).

Overload - Power Limit Power supply reached 115% rated power.

Overload - Temperature IGBT heat sink temperature limit is reached.

Overload - Voltage RF voltage peak limit reached.

Phase Limit Time Error

When power supply out of tune phase limit error is reached

after 500ms (default).

ALARM LOG

Clear Log Click to clear the alarm log.

Export to Excel Click to export the data to an Excel sheet.

38 100-412-203 REV. 04

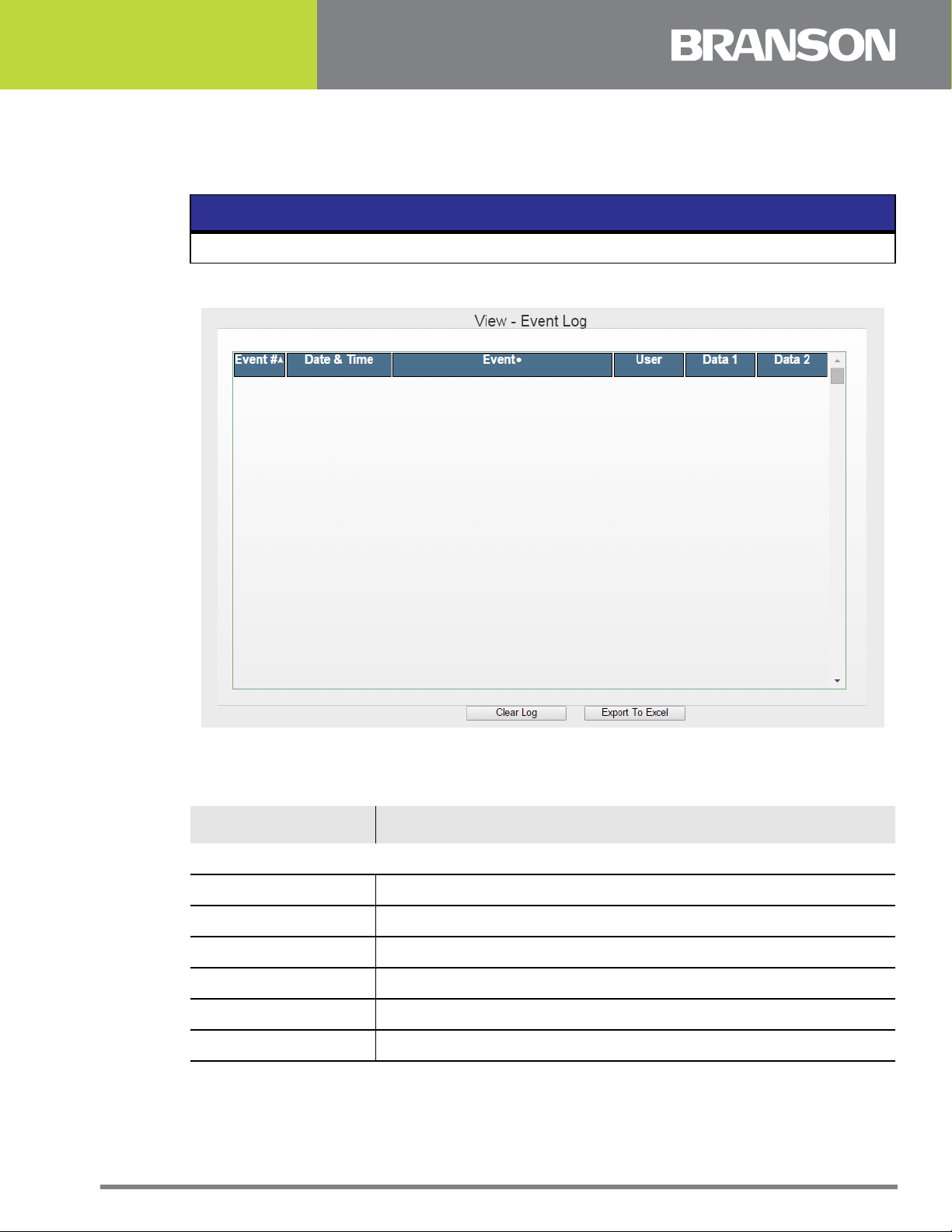

4.4.3 Event Log

Use this screen to view the DCX Power Supply event history. The events can be sorted by

event number, date/time or event type. Events can be exported to an Excel file.

NOTICE

Only the last 500 events are stored in memory.

Figure 4.10Event Log

Table 4.9 Event Log Options

Name Description

EVENT LOG

Event # Event number.

Date & Time Date and time when event has logged.

Event Event description.

User User ID at the time of event.

Clear Log Click to clear the event log.

Export to Excel Click to export the data to an Excel sheet.

100-412-203 REV. 04 39

4.4.4 History

Use this screen to view the DCX Power Supply weld history. The weld history can be sorted

by cycle number or date/time. Weld history can be exported to an Excel file.

NOTICE

Only the last 50 weld history entries are stored in memory.

Figure 4.11History

Table 4.10 History

DATA

Cycle # Date & Time

Weld Mode Weld Time

Weld Energy Peak Power

Amplitude 1 Amplitude 2

Preset # Start Frequency

Stop Frequency Frequency Change

Alarm Code CustomIn1

CustomIn2 Cycle Time

40 100-412-203 REV. 04

Table 4.11 History Options

Name Description

HISTORY

Clear History Click to clear the weld history.

Export to Excel Click to export the data to an Excel sheet.

100-412-203 REV. 04 41

4.4.5 Weld Graphs

Use this menu to view and export the weld graph. The weld graph is provided with 6

available parameters: Phase, Current, Amplitude, Power, PWM Amplitude, and Frequency.

Each parameter has a checkbox to the left of its name. Only checked parameters will be

displayed. While in this menu, if the W eld is being run from external I/O or the front panel

interface, the graph can be also displayed on the screen by using the “Update Graph”

button.

Figure 4.12Weld Graphs

Table 4.12 Weld Graphs Options

Name Description

WELD GRAPHS

Click to get the value of all the parameter and draw the graph

Update Graph

Export Graph Data Click to export the data to an Excel sheet.

Redraw Graph

Set Default

42 100-412-203 REV. 04

for Phase, Current, Amplitude, Power, and Frequency

parameters vs Time on the Y axis.

Click to redraw the same graph with those parameters which

are checked with the Time parameter on Y axis.

Click to restore the settings on the “Draw from”, “Graph

Selection”, “X Value” and “Y Value” fields.

Table 4.12 Weld Graphs Options

Name Description

Click to get the value for any parameter for any time by setting

Update Value

the parameter in the drop down list for a graph selection field

and by setting value in the X value and Y value field.

100-412-203 REV. 04 43

4.5 Diagnostics Menu

Use this menu to test your DCX AF Power Supply.

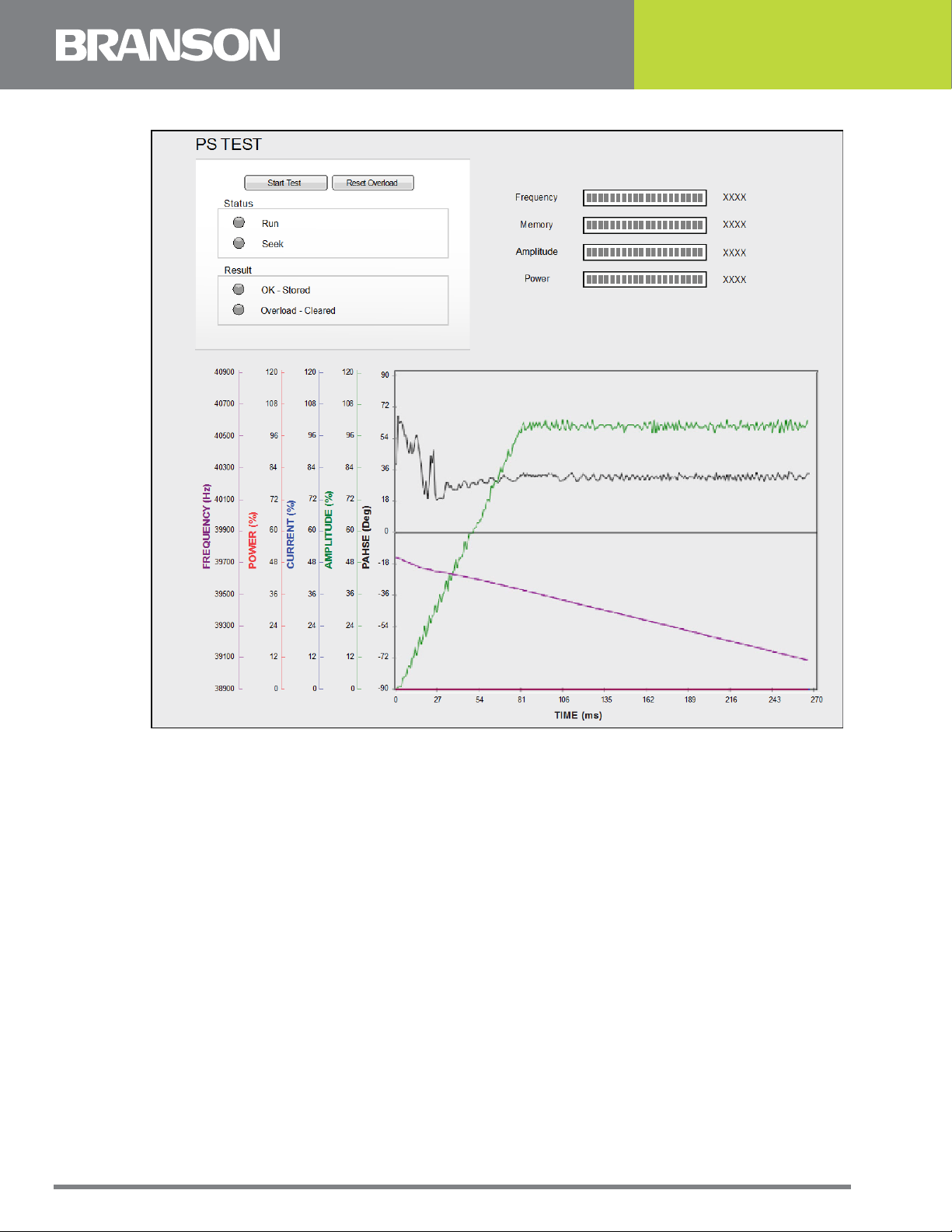

4.5.1 Seek

This feature allows you to capture seek data which you can both view and export. The

Weld Data Graph is provided with 6 available parameters: Phase, Current, Amplitude,

Power, PWM Amplitude, and Frequency. Each parameter has a check box to the left of its

name. Only checked parameters will be displayed. While in this menu, if the Weld is being

run from external I/O or the front panel interface, the graph can be also displayed on the

screen by using the “Update Graph” button.

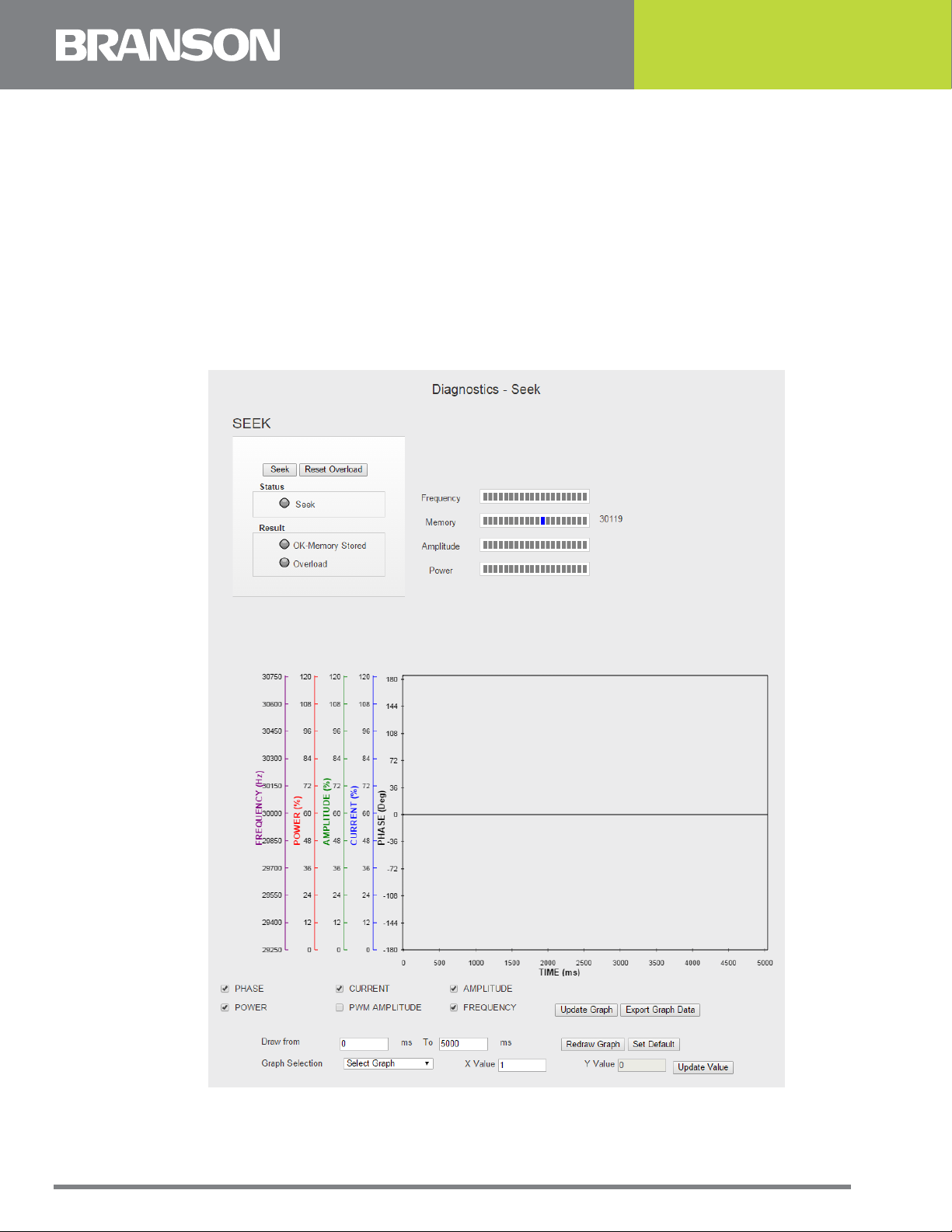

Figure 4.13Seek

44 100-412-203 REV. 04

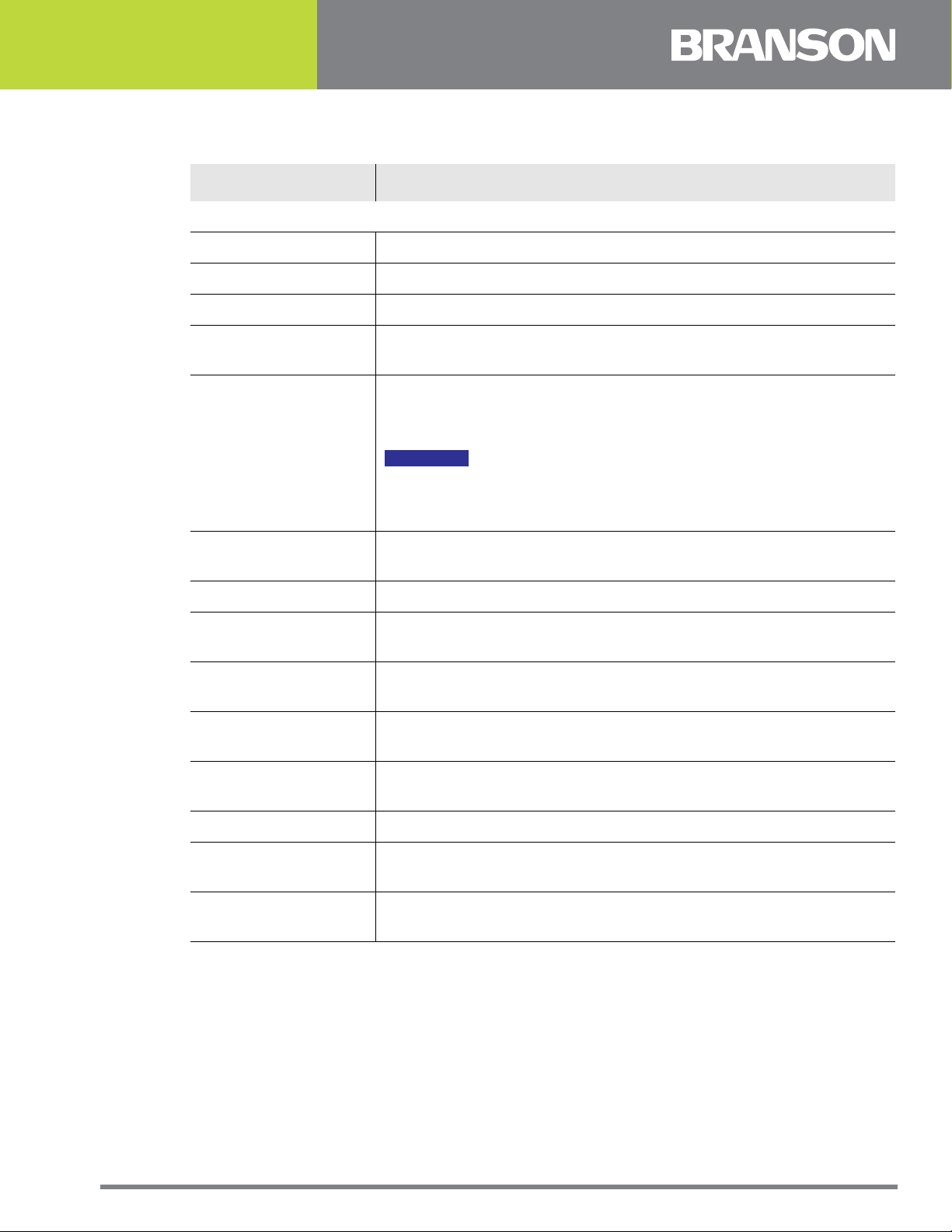

Table 4.13 Seek Options

Name Description

SEEK

Seek Click to perform a seek cycle.

Reset Overload Click to reset an overload condition.

Seek

OK - Memory

Stored

Overload

Indicates that the power supply is running at 10% amplitude for the

purpose of finding the ultrasonic stack resonant frequency.

Indicates that the horn operating frequency was stored in the DCX

Power Supply memory.

Indicates that test resulted in an overload and the memory has

been cleared.

Frequency Monitors the seek operating frequency.

Memory Displays the frequency stored in the DCX Power Supply memory.

Amplitude Displays the percentage of stack amplitude.

Power Displays the percentage of power output.

Update Graph Click to draw the graph of the last seek data.

Export Graph

Data

Redraw Graph

Draw from...

to...

Click to export the Weld Graph data to CSV file.

Click to redraw the same graph with those parameters which are

checked with the Time parameter on Y axis.

Select the “from” and “to” time values to zoom into the desired

graph region.

Graph Selection

Select a parameter and enter a particular X time value to obtain the

corresponding Y value at that particular time.

Update Value Click to update the Y value for the given graph selection.

Set Default

Click to return start time, end time and graph selection to default

settings.

Enter comments to be added at the top of exported data in CSV file.

User Comment

Box

NOTICE

This option is only available after selecting export.

100-412-203 REV. 04 45

4.5.2 Horn Signature

Use this menu to diagnose your ultrasonic horn. When performing a horn scan, ideally,

there will be only one parallel resonant frequency. The Horn Signature Graph is provided

with 3 available parameters: Phase, Current, and Amplitude. The Horn Signature Graph

can be both viewed and exported.

Each parameter has a checkbox to the left of its name. Only checked parameters will be

displayed.

Figure 4.14Horn Signature

46 100-412-203 REV. 04

Table 4.14 Horn Signature Options

Name Description

HORN SIGNATURE

Start Horn Scan Click to initiate the horn scan.

Abort Horn Scan Click to abort the horn scan.

Status Indicates the horn scan progress.

Result

Indicates if the horn scan passed, failed, or if the operation was

aborted.

Displays the parallel resonant frequencies of the ultrasonic

horn. The parallel resonant frequency is the operating frequency

of the ultrasonic stack.

Parallel Resonant

Points

NOTICE

If multiple parallel frequencies are found, they will all be listed.

The frequency at which the ultrasonic stack is running will be

displayed in blue.

Series Resonant

Points

Displays the series resonant frequencies of the ultrasonic horn.

Update Graph Click to draw the graph of the last horn scan.

Export Graph Data

Redraw Graph

Draw from... to...

Graph Selection

Click to export the scan graph data with scan settings to CSV

file.

Click to redraw the same graph with those parameters which

are checked with the Time parameter on Y axis.

Select the “from” and “to” time values to zoom into the desired

graph region.

Select a parameter and enter a particular X time value to obtain

the corresponding Y value at that particular time.

Update Value Click to update the Y value.

Set Default

User Comment Box

Click to return the sample rate, start time, end time and graph

selection to default settings.

Enter comments to be added at the top of exported data in CSV

file.

100-412-203 REV. 04 47

4.5.3 User I/O

Use this menu to monitor and control the DCX Power Supply digital and analog I/O. For

user I/O configuration instructions see 4.5.3 User I/O.

NOTICE

The assigned power supply functions will not be performed by the power supply, only

the signals levels can be controlled and monitored while in this menu.

Figure 4.15User I/O

Table 4.15 User I/O Options

Name Description

USER I/O

Digital Inputs A LED icon will light when that corresponding input is active.

Analog Inputs

Digital Outputs

48 100-412-203 REV. 04

The analog inputs have text boxes that display the actual

voltage being read from the corresponding pins.

Check the digital outputs before selecting Refresh Outputs to

designate which digital outputs they wish to see active.

Table 4.15 User I/O Options

Name Description

Analog Outputs

The analog outputs allows to input a voltage value wanted to

see on the output pin.

These boxes display the information to the user that was

Activity Definition

defined on the I/O Configuration page about how each pin is

defined as far as active high versus active low.

Pressing the Refresh Outputs buttons will read all the check

Refresh Outputs

boxes for digital outputs and all the input text boxes for

analog outputs and output the appropriate values to the

connector.

The stop button will be grayed out until Refresh Outputs is

Stop

pressed. Pressing stop will cause the outputs to revert to the

actual state of the outputs and Refresh Outputs shall become

enabled.

Fan On/Off Click to turn on/off the fan.

100-412-203 REV. 04 49

4.5.4 Fieldbus

Use this menu to check Fieldbus information. See DCX AF Series Power Supply Instruction

Manual for setup and operation.

Figure 4.16Fieldbus (EtherNet/IP)

Table 4.16 Fieldbus Options

Name Description

FIELDBUS INFO

The Fieldbus info box will display all relative information

Fieldbus Info

Slave Status - Offline

Slave Status - Stop

Slave Status - Idle Shows whether the Fieldbus device is in the idle state.

Slave Status - Operate Shows whether the Fieldbus card is in data exchange.

COMMUNICATION STATE

50 100-412-203 REV. 04

regarding high level diagnostic data. Things such as slave

address, on/off and whether an error is present or not are

viewed here.

The Fieldbus card is offline when it does not have a valid

configuration.

The Fieldbus device was stopped by the application program

or it changed to the Stop state because of a bus error.

Table 4.16 Fieldbus Options

Name Description

Ready

This bit is set by the Slave automatically, when the

parameters sent by the master are containing wrong or

insufficient data.

Running

Bus On

Configuration Locked

This shows whether the Fieldbus card has been configured

correctly.

This shows whether the Fieldbus card and WC board are

communicating.

Shows whether the Fieldbus configuration is locked, to avoid

the configuration data are typed over.

This bit is set by the Slave automatically, when the

Parameter Fault

parameters sent by the master are containing wrong or

insufficient data.

Configuration Fault

At startup, if configuration of the master does not match that

of the slave, this bit is set.

CONTROL AND STATUS LEDS

Control Word Status

Word

Control and status LEDs show the binary signals exchange

between master and slave. Green = 1, Gray = 0.

100-412-203 REV. 04 51

4.5.5 Fieldbus Test Menu

Use this menu to perform a Fieldbus test.

4.5.5.1EtherNet/IP

Figure 4.17Fieldbus Test (EtherNet/IP)

Press the Update button to get the Control and Status (STW and ZSW) binary signals

currently being exchanged with the EtherNet/IP master.

Pressing the Update button will also display the last explicit message received from the

master and the reply of the same sent by the WC. CIP Status tells the success or failure of

the processed Explicit message.

52 100-412-203 REV. 04

4.5.5.2PROFIBUS DP

Figure 4.18Fieldbus Test (PROFIBUS DP)

Press the Update button to display the last parameter number accessed by the PROFIBUS

master through the PKW channel and the answer replied by the WC.

100-412-203 REV. 04 53

4.6 Configuration Menu

4.6.1 System

Use this menu to set the date/time of your DCX Power Supply and backup/restore the

system.

Figure 4.19System

Table 4.17 System Options

Name Description

CONFIGURE SYSTEM

System Date & Time

Select Date Format

Select Time Format

Get Time From PC

Backup System

This label updates its value every second from the power

supply with system date and time.

Select the date format. Available formats are MM-DD-YYYY

and DD-MM-YYYY.

Select the time format. Available formats are 12 Hours and 24

Hours.

The time and date will be loaded from the PC. It will be

displayed in the format selected above.

NOTICE

You must click save to confirm the change.

This button will bring up a Windows pop up box to select a

location to save a binary file that contains the contents of

system memory.

54 100-412-203 REV. 04

Table 4.17 System Options

Name Description

Browse

Copy System

Selecting Browse will bring up a Windows pop up for selecting

the location of a backup system file (.cfg) to import. Once the

file has been browsed to, either Copy System or Restore

System can be selected.

Click to copy the system settings of another DCX unit using a

backup system file (.cfg). See 4.6.1.1 Copy System and

Restore System Data for more information.

NOTICE

The backup system file (.cgi) must be from another DCX

system using the same software version. See 4.4.1 System

Info to see the software version.

Click to restore the system with a previously saved backup

system file (.cfg).

Restore System

NOTICE

The backup system file (.cgi) must be from another DCX

system using the same software version. See 4.4.1 System

Info to see the software version.

Load Preset On Start check box will allow the user to turn on

Load Preset On Start

or off automatic loading of preset regardless of the preset

signal on the I/O.

This option configures the “STD-Status” digital output to show

the status of the power supply. The digital output can be

connected to an external device, for example, an external

beeper. When this option is enabled, the user must check

either “Trigger – 1” and/or “Alarm – 3”.

External Status

Enabled

If Trigger - 1 is checked, there will be 1 digital output pulse on

the STD-Status output pin and 0.5 second beep will occur

when trigger is received.

If Alarm - 3 is checked, then when an alarm occurs (e.g.

overload alarm), 3 pulses will be output on the Status pin to

indicate an alarm occurred. Beeps 0.5 seconds on, 0.5

seconds off long are in between each beep.

Restore Defaults Click to restore system configuration default settings.

100-412-203 REV. 04 55

4.6.1.1Copy System and Restore System Data

The following data will be overwritten.

Table 4.18 Copy System and Restore System Data

System Setting

Presets Yes Yes

Horn Presets Yes Yes

Alarm Configuration Yes Yes

Passcode Configuration Yes Yes

User I/O Configuration Yes Yes

Even Log Yes No

Alarm Log Yes No

Weld History Yes No

System Configuration

IP Address

PROFIBUS and EtherNet/IP Address

MAC Address No No

Power Supply Frequency and Power Level No No

Total Alarm Counter Yes Yes

Overwritten

by Restore

Yes No

Overwritten

by Copy

Total Cycle Counter Yes Yes

Hours of Sonics Yes Yes

Power on Hours Yes Yes

Manufacturing Cycle of Parameters and Results Yes Yes

Advanced R&D Parameters Yes Yes

Memory Frequencies

NOTICE

A soft reset of the system is performed after a restore

or copy. Memory frequencies will be adjusted to

midband if they don’t fall within the minimum/

maximum range of the power supply frequency.

Alarm Group Counters Yes Yes

Serial Number Yes No

Control Level Yes No

Yes Yes

56 100-412-203 REV. 04

4.6.2 User I/O

Use this menu to configure the DCX Power Supply I/O according to your specific

interfacing needs. Use the command buttons on the bottom to save settings, cancel

changes, or to restore to factory default settings.

NOTICE

See DCX equipment manual for a list of I/O.

Figure 4.20User I/O

100-412-203 REV. 04 57

4.6.3 Communication

Use this menu to setup the DCX Power Supply’s network settings. The DCX P ower Supply’ s

default IP setting is Static IP with the address shown in the figure below.

Figure 4.21Communication (EtherNet/IP)

Table 4.19 Communication Options

Name Description

IP SETUP

Select this option to manually assign an IP address to the DCX

Static IP

IP Address The IP address assigned to the DCX Power Supply.

Subnet Mask

Gateway

MAC Address Displays the MAC address assigned to the DCX Power Supply.

DHCP Server

Enabled

Power Supply. The DCX Power Supply will alert if an invalid IP

address setting is entered.

The mask used to determine to what subnet the DCX Power Supply’s

address belongs to.

The gateway address assigned to the network for communication

with other computers or networks.

Select this option to have DCX Power Supply assign IP addresses to

any devices connected to it. This facilitates connecting a computer

or laptop point to point (P2P) with the DCX Power Supply.

NOTICE

Connecting a DCX Power Supply with DHCP server enabled to a

network which already has a device working as a DHCP server will

cause connectivity problems.

Select this option to have the DCX Power Supply automatically

DHCP

FIELDBUS

58 100-412-203 REV. 04

request an IP address from a DCHP Server. The IP address will be

grayed out.

Table 4.19 Communication Options

Name Description

The Fieldbus section will only be displayed if the power supply

Fieldbus

version is a DCX F. If Profibus is enabled, then only the Profibus

Address will be displayed. Likewise if it is EtherNet/IP enabled, then

everything but the Profibus Address will be displayed.

NOTICE

All changes on this menu take effect on the next power-up.

At any time you may determine the DCX Power Supply’s IP address by going through the

associated registers using the front panel LCD. A Cold Start can also be performed to take

your power supply back to it’s factory default IP address. For details on navigating the

DCX registers or performing a Cold Start, consult your power supply manual.

NOTICE

Beware that other settings will also be reset to their defaults when a Cold Start is

executed.

100-412-203 REV. 04 59

4.6.4 Passcodes

Use this menu to manage users, passcodes and privileges of each user.

Figure 4.22Passcodes

Table 4.20 Passcodes Options

Name Description

PASSCODES

The user ID is an alphanumeric character string of up to 12

User ID

Passcode

Privilege Click to change user privileges.

60 100-412-203 REV. 04

characters. This is the text that will appear in the logs under the

User column.

The passcode is numeric only and up to 9 characters long. The

passcode is what the user enters along with their User ID when he

logs into the web page. An admin can see everyone's passcode.

Table 4.20 Passcodes Options

Name Description

Only an admin can check or uncheck this box. If passcodes are

required, at least a user must be logged in through the web page

before any changes can be made through the web page. Changes

can always be made through the Fieldbus, if connected. If

unchecked, the User IDs will still display in the logs, but if no User

Passcodes

Required

ID is associated with a passcode, then the passcode is used for the

log.

To access as an admin, use the following information at login:

User ID: Admin

User Passcode #: 999999

100-412-203 REV. 04 61

4.6.5 Alarms

Use this menu to configure the alarms.

Figure 4.23Alarms

Table 4.21 Alarm Options

Name Description

ALARMS

Reset Required

Log Alarm

General Alarm

Custom Alarm

Output

Cycle Counter

This option determines if the alarm is latched or not. Latched

alarms require a reset before another cycle can start.

This option determines whether or not the alarm is entered into a

log. Communication and Hardware alarms will be logged into the

event log.

If selected, this alarm group will activate the general alarm

output, if defined.

If selected, this alarm group will activate the Custom Alarm

output, if defined.

If selected, the cycle will count toward both the preset counter. If

deselected, the preset counter will not count.

62 100-412-203 REV. 04

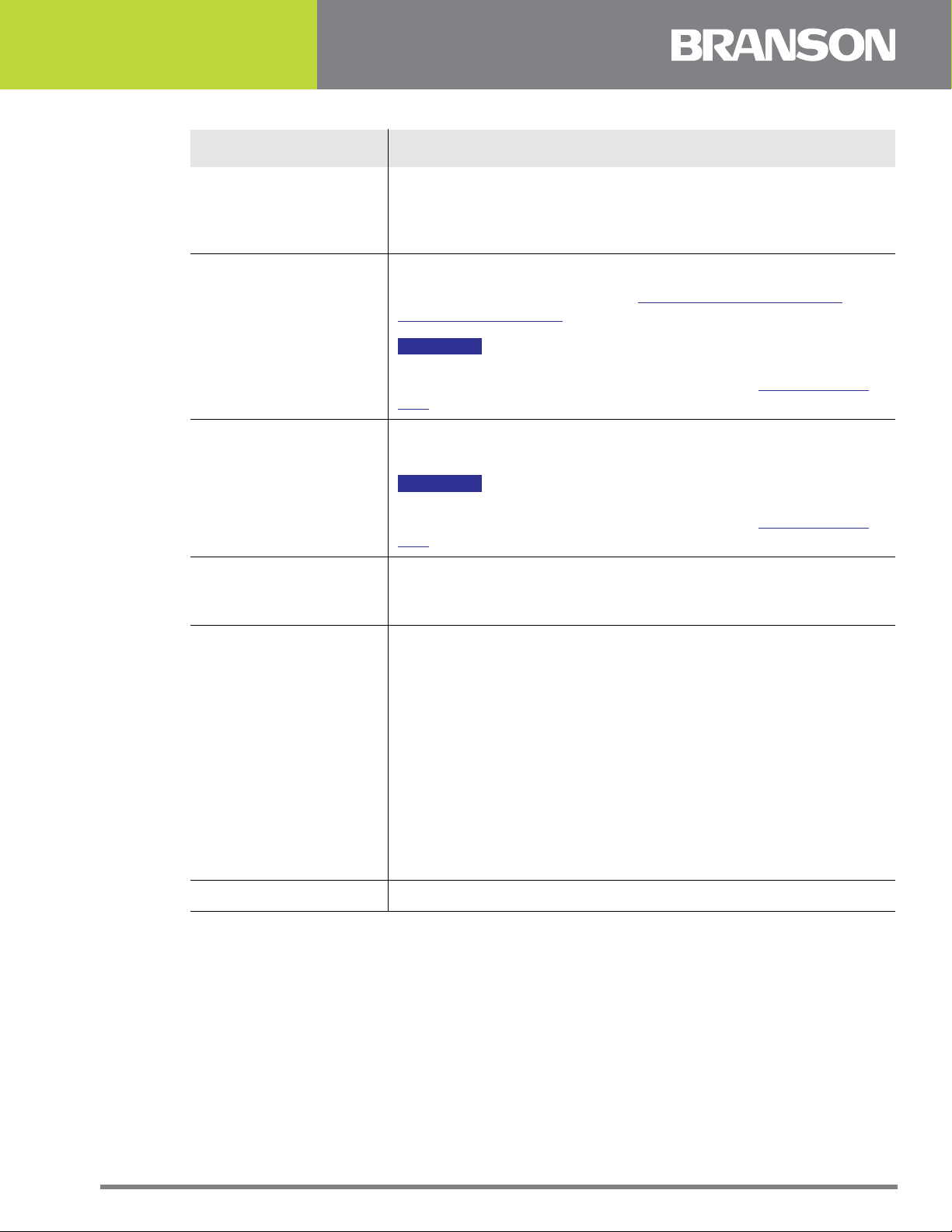

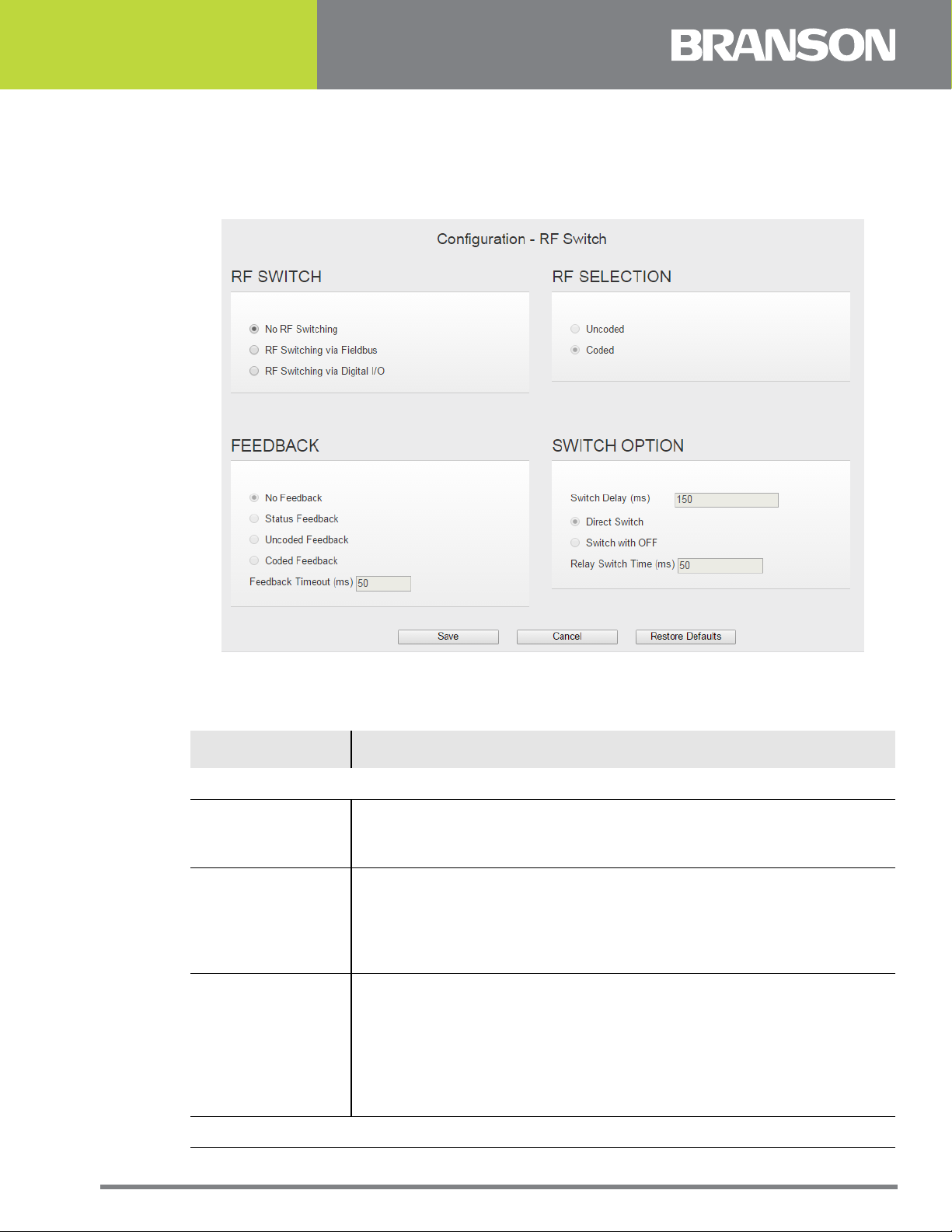

4.6.6 RF Switch

Use this menu to configure the RF Switch options. RF switches are external to the DCX

and control RF output to a stack.

Figure 4.24RF Switch

Table 4.22 RF Switch Options

Name Description

RF SWITCH

If selected, there will be no RF switching using either the Fieldbus

No RF Switching

RF Switching Via

Fieldbus

RF Switching Via

Digital I/O

RF SELECTION

or digital I/O. If this option is selected the rest of the web page is

grayed out and unavailable.

When a preset is recalled through the Fieldbus, after the

appropriate delay a response will be sent back to the PLC with the

stack number. It's up to the PLC to then send the proper command

to the RF switch to select the correct output. This option will not be

available unless the system is defined as an Fieldbus unit.

When a preset is recalled via the user-defined I/O, after the

appropriate delay the user defined outputs will be set to the correct

value to select the correct stack as defined by the recalled preset.

There is a limit of seven stacks that can be supported with digital I/

O. If a stack number greater than 7 is requested an E707 alarm will

be created. Feedback, if enabled, can only occur as a coded value

(4 inputs) or a single input to indicate the selection was made.

100-412-203 REV. 04 63

Table 4.22 RF Switch Options

Name Description

RF Selection will decide the input format for RF selection bits. It will

RF Selection

only be applicable in case of RF switching through IO. User can

decide the coded or uncoded format for RF selection input.

FEEDBACK

This option assumes the correct stack has been selected. No error

No Feedback

checking will be done. The Relay Switch Time must elapse before

sonics can be turned on.

Status Feedback

This option requires a single input pin. The pin must go active

within the Relay Switch Time or an alarm (E705) will be created.

Uncoded

Feedback

This option requires four input pins. The stack number uncoded on

these pins must go active within the Relay Switch Time or an

alarm(E705) will be created.

This option requires four input pins. The stack number encoded in

Coded Feedback

binary must be on these pins at the end of the Relay Switch Time

or an alarm (E705) will be created.

Feedback Timeout

(ms)

If feedback is selected, then this will be the maximum time that

the system will wait before creating an RF Switch Feedback Failure

(E705) alarm.

SWITCH OPTION

Switch Delay

(ms)

Direct Switch

The system will wait this many milliseconds after sonics turns off

before the system will return to the Ready state. RF relays can only

be switched when the system is Ready.

Direct switch changes the relays from one setting to the new

setting.

Switch With Off This setting allows an “OFF” state in between each stack setting.

Relay Switch Time

(ms)

Switch time is the duration of the “OFF” status.

64 100-412-203 REV. 04

Appendix A: Ultrasonic Welding

A.1 Resonance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

A.2 The Principle and the Components of Ultrasonic Welding . . . . . . . . . 67

A.3 Resonance Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

A.4 Graphics of a Weld . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

100-412-203 REV. 04 65

A.1 Resonance

Every solid body has its natural resonance. This is determined by the material it is made

of and its total mass.

If, for example, a spanner falls on the ground, the typical metallic sound is generated. If

we would measure the tone pitch, we would have determined the natural resonance of the

spanner. Another classic example is the tuning fork. It is designed in a manner that it

exactly vibrates at 440 Hz (philharmonic pitch A).

These are examples for resonance in the audible range (approx. 40 Hz to 16 kHz).

Starting from a frequency of 20 kHz this is referred to as ultrasonics. Also, any

combination of converter, booster, and has its natural resonance.

The aim is to utilize this resonance in order to achieve a maximum effect at lowest

possible energy consumption. This is the case if - to ease the explanation - the vibrating

frequency fed in corresponds to the resonant frequency of the acoustic stack. In this

respect, it is important that an acoustic stack has two resonance points: a serial and a

parallel one. The parallel resonance point is the decisive one.

66 100-412-203 REV. 04

A.2 The Principle and the Components of Ultrasonic

Welding

A.2.1 The Principle

The tool vibrating at ultrasonic frequency is pressed onto the plastic parts to be welded.

The plastic material has the propensity to absorb the vibrations fed in, which results in

heating up of the joints to the melting point. The mechanical pressure exerted generates a

flow of the plasticized material between the two parts.

After cooling down, a virtually homogeneous joint is the result.

A.2.2 The Components

Figure A.1 The components of an ultrasonic welding system

Table A.1 The components of an Ultrasonic Welding System

Item Description

1 Ultrasonic Power Supply

2 Converter

3 Booster

4 Horn

5 Acoustic Stack

The power supply (1) transforms the energy supplied at 50/60 Hz from the mains to an

ultrasonic frequency of 20 kHz, 30 kHz or 40 kHz.

The high-frequency electrical oscillations of the power supply are transformed by the

converter (2) via a piezoelectric oscillator into mechanical vibrations of the same

frequency, i. e. into mechanical vibrations at 20 kHz, 30 kHz or 40 kHz.

100-412-203 REV. 04 67

The mechanical vibrations must be transferred to the plastic part to be welded via an

acoustic tool combination of booster (3) and horn (4). The booster amplifies the amplitude

of the mechanical vibration (amplification factor K1).

The Booster

The booster is a one half wavelength long resonant section made of aluminum or titanium.

It is mounted between the converter and the horn, and modifies the amplitude of vibration

applied to the horn. The amplitude is amplified according to the energy conservation law.

To amplify the amplitude of the vibration the cross-sectional area of the booster is varied.

As the vibratory energy must remain constant over the whole length of the booster

(energy conservation law) the amplitude is amplified proportional to the area ratio. This

process can be illustrated by an undamped spring-mass system. When the spring-mass

system is excited it will emerge that the short thick spring has a shorter elongation

compared to the thin long spring although both spring oscillate at the same frequency. For

the ratio the following formula applies:

Where:

• A

= Input Amplitude

e

= Output Amplitude

A

e Ve Me

F = = =

A

a Va Ma

• A

a

= Input Oscillating Velocity

• V

e

= Output Oscillating Velocity

• V

a

= Input Mass

• M

e

• M

= Output Mass

a

Figure A.2 Amplitude Transformation Via the Booster

Nodal Point

The Horn

The horn (also: welding tool) transmits the mechanical vibrations transformed by the

converter and amplified by the booster to the plastic part.

Not only the booster but also the horn can amplify the amplitude (amplification factor K2).

For calculation of the amplitude ratios almost the same approach applies as for boosters.

68 100-412-203 REV. 04

Figure A.3 Commonly used horn shapes

Table A.2 Commonly used horn shapes

Item Description

1 Rectangular horn

2 Catanoidal horn

3 Exponential horn

4 Step horn

The combination of converter, booster and horn is referred to as acoustic stack.

The prerequisite for a transfer of ultrasonic vibrations to the workpiece without losses is a

transfer of acoustic energy between the individual components of acoustic stack with the

lowest possible amount of reflection. The quality of the transfer essentially depends on the

assembly of the individual components.

100-412-203 REV. 04 69

A.3 Resonance Analysis

The acoustic stack is an acoustic precision tool that, like any other tool, is subject to wear.

Depending on load, maintenance, and conditioning of this tool, defects may occur: the

threaded joints between the components may become loose, deposit may build up at the

mating surfaces, or cracks may be generated in the horn. The result: the resonant

properties of the acoustic stack are impaired. The quality of the weld is reduced, and the

power supply frequently switches to overload state.

For this reason, the DCX W eb P age Interface provides the possibilit y to “scan” the acoustic

stack. This means that ultrasonics is applied, with the ultrasonics frequency going through

a preset frequency range, e. g. 19500 Hz to 20500 Hz. In the course of this, taking preset

values, e. g. for amplitude and step width, into account, important characteristics like

output current and phase are recorded and shown graphically on the display.

The curves of phase, amplitude, and current over the frequency indicate the points of

serial resonance and parallel resonance of the acoustic stack. The parallel resonance

relevant for operation lies at the point at which the algebraic sign of the phase changes

the second time.

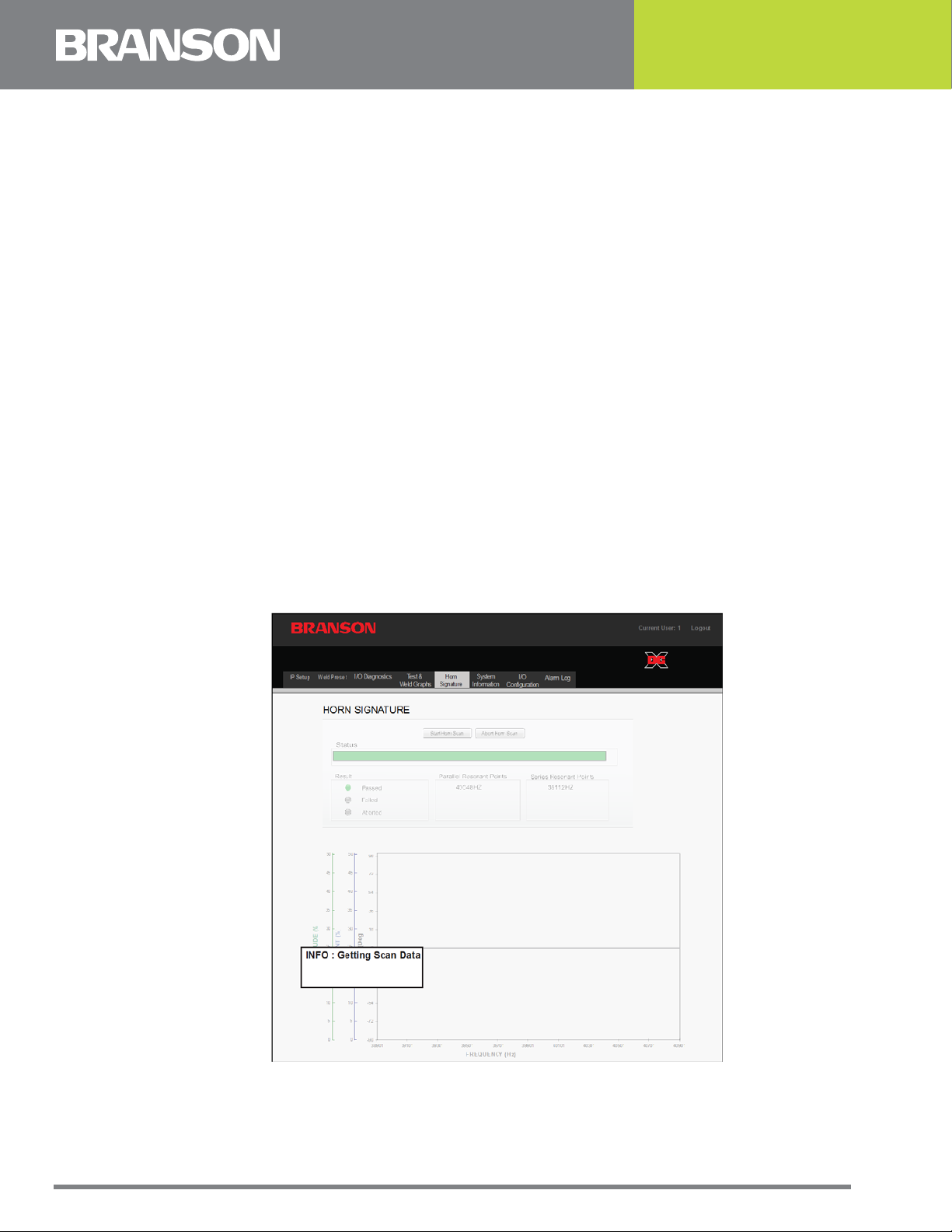

A.3.1 Getting a Horn Scan Data

Click the Start Horn Scan button to initiate the horn scan, the progress of the Scan is

displayed on progress bar. When the Scan is completed, the Scan data is imported. During

import a message appears as shown below. Message is automatically cleared when all

data is received for graph.

Figure A.4 Getting Scan Data

70 100-412-203 REV. 04

A scan is an automatic frequency seek. The values determined are stored and graphically

displayed. The values inform about the resonance properties of the system. When you

compare the curve with other curves you can draw conclusions with respect to the

functioning and the acoustic properties of the acoustic stack.

In the course of the scan, ultrasonics are applied to the acoustic stack (converter/booster/

horn) without load. The stack freely vibrates in the air, starting with a start frequency that

is continually increased up to the adjusted end frequency.

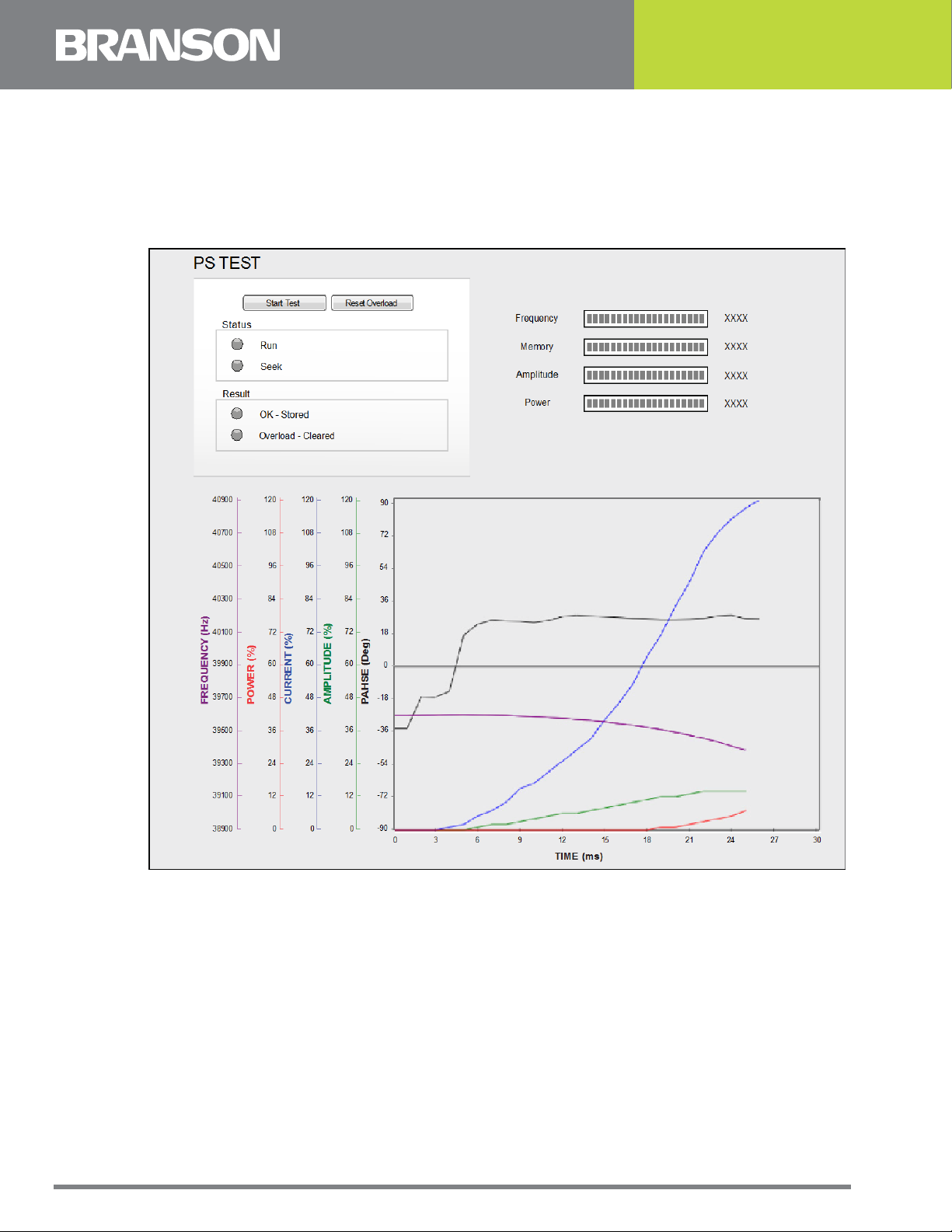

Figure A.5 Graphics of a scan

At the point of resonance, the current falls, the amplitude is at the maximum value, and

the phase changes its sign.

NOTICE

If multiple parallel frequencies are found, they will all be listed under Parallel Resonant

Points. The frequency at which the acoustic stack is running will be shown in blue.

100-412-203 REV. 04 71

A.3.2 Scan Horn Error Analysis

On the following pages, typical sources of error are shown.

Compare your system's curves with these examples to identify some of the possible

problems you may encounter.

Figure A.6 Horn Scan, Possible Defective Converter

72 100-412-203 REV. 04

Figure A.7 Horn Scan, Open RF Cable

100-412-203 REV. 04 73

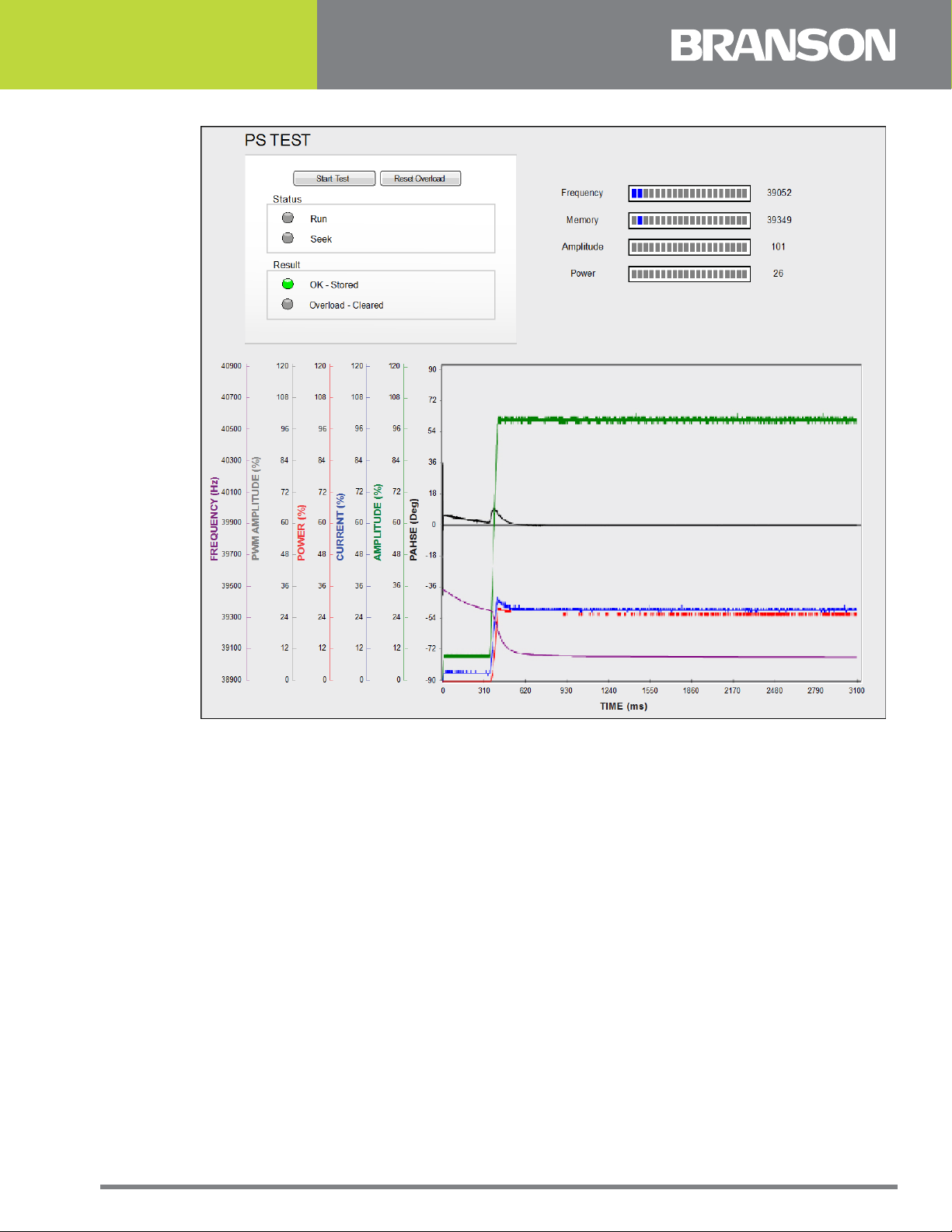

A.4 Graphics of a Weld

Weld Values can also be displayed as curves.

When you click on the Update Graph button, the Weld data is imported. While data is

being transferred a message is appears, as shown below. Message is automatically cleared

when all data is received for graph.

Figure A.8 Getting Weld Data

74 100-412-203 REV. 04

Figure A.9 Graphical Display of the Weld Curves.

At the beginning of the process, the frequency is increased until resonance is reached. At

the point of parallel resonance the weld starts. The following happens:

• The amplitude is controlled to the maximum value, and it remains virtually constant

• The phase changes the polarity

• The current increases to the maximum value and then decreases down to a relatively low

constant value

• The power output increases and then quickly decreases down to a constant value

• The PWM (Pulse Width Modulation) increases and remains constant.

100-412-203 REV. 04 75

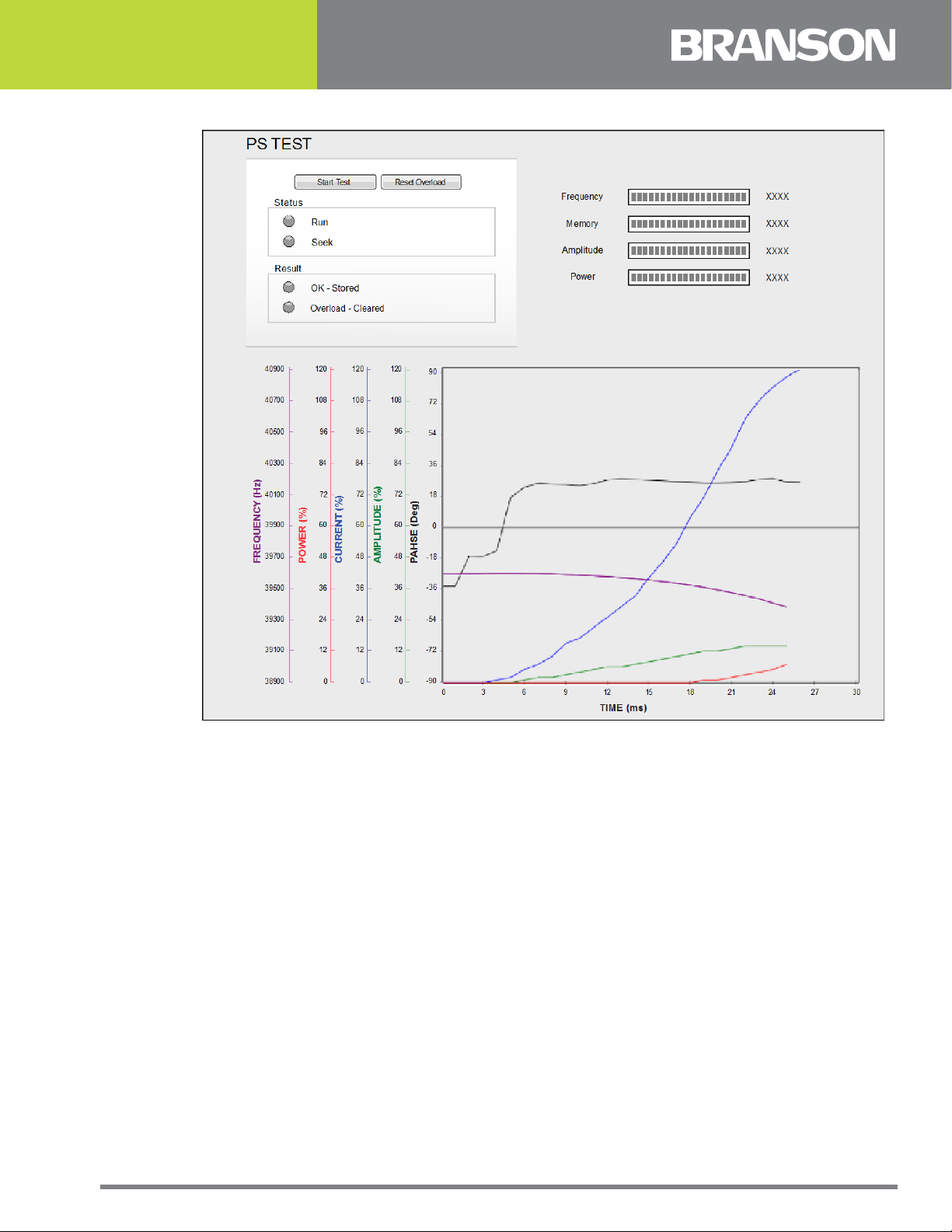

A.4.1 Weld Graph Error Analysis

On the following pages, typical sources of error are shown.

NOTICE

Compare your system's curves with these examples to identify some of the possible

problems you may encounter.

Figure A.10Weld Graph, Defective Horn.

This figure resulted in a Overload-Current Alarm.

76 100-412-203 REV. 04

Figure A.11Weld Graph, Defective Converter

This figure resulted in a Overload-Current Alarm.

100-412-203 REV. 04 77

Figure A.12Weld Graph, Open RF Cable.

This figure resulted in a Overload-Frequency Alarm.

78 100-412-203 REV. 04

Index

A

alarm log 37

alarms 62

amplitude 31

B

booster 68

C

coded feedback 64

communication 58

components 67

configuration menu 54

connecting 11

contact Branson 5

D

DCX A ethernet port location 12

DCX F DP ethernet port location 15

DCX F EIP ethernet port location 13

diagnostics menu 44

direct switch 64

E

emissions 3

ethernet port 12

EtherNet/IP 52

event log 39

F

feedback timeout (ms) 64

fieldbus 50

fieldbus test menu 52

G

general precautions 3

graphics of a weld 74

H

history 40

horn 68

horn scan data 70

horn signature 46

I

intended use of the system 3

100-412-203 REV. 04 79

introduction 8

L

limit/cutoff 33

login 28

N

no feedback 64

no RF switching 63

O

overview 26

P

passcode 28

passcodes 60

point to point connection 18, 21

principle 67

profibus DP 53

R

relay switch time (ms) 64

resonance 66

resonance analysis 70

RF selection 64

RF switch 63

RF switching via digital I/O 63

RF switching via fieldbus 63

S

safety and support 1

safety requirements 2

save/recall preset 32

scan horn error analysis 72

seek 44

seek/power up 34

status feedback 64

switch delay (ms) 64

switch with off 64

symbols 2

system 54

system info 36

system requirements 17

U

ultrasonic welding 65

uncoded feedback 64

User I/O 57

user I/O 48

user ID 28

V

view menu 36

80 100-412-203 REV. 04

W

warnings 2

web page interface 7, 25

weld graph error analysis 76

weld graphs 42

Windows 7 18

Windows Vista 18

Windows XP 21

100-412-203 REV. 04 81

82 100-412-203 REV. 04

Loading...

Loading...