Technical Information

Thermal Processing

Thermal Staking Design

Guidelines

In manufacturing products

with thermoplastic components,

it is often necessary to join a

thermoplastic to a part of

dissimilar material, whether

it be metal, a dissimilar plastic,

or other material. This technical

information sheet provides

design guidelines, configurations, and techniques for successful thermal (heat) staking.

GENERAL DESCRIPTION:

Thermal staking is an assembly

method that uses the controlled

melting and reforming of a

plastic stud or boss to capture

or lock another plastic or metal

component of an assembly

in place.

The plastic stud protrudes

through a hole in the component

to be locked in place. The heated

thermal tip contacts the top of

the stud, which melts and fills

the volume of the tip cavity to

produce a head, locking the component in place. The progressive

melting of plastic under continuous pressure forms the head.

When staking, the right combination of heat and pressure for the

application is critical.

ADVANTAGES:

• Simplification of machinery

• Reduced cost of machinery

• Multiple fastening points

• Allows higher density of welds

compared to hot air cold form

or ultrasonic welding

• Many different size or shaped

heads can be formed

Following are descriptions and

specifications for the various

staking profiles.

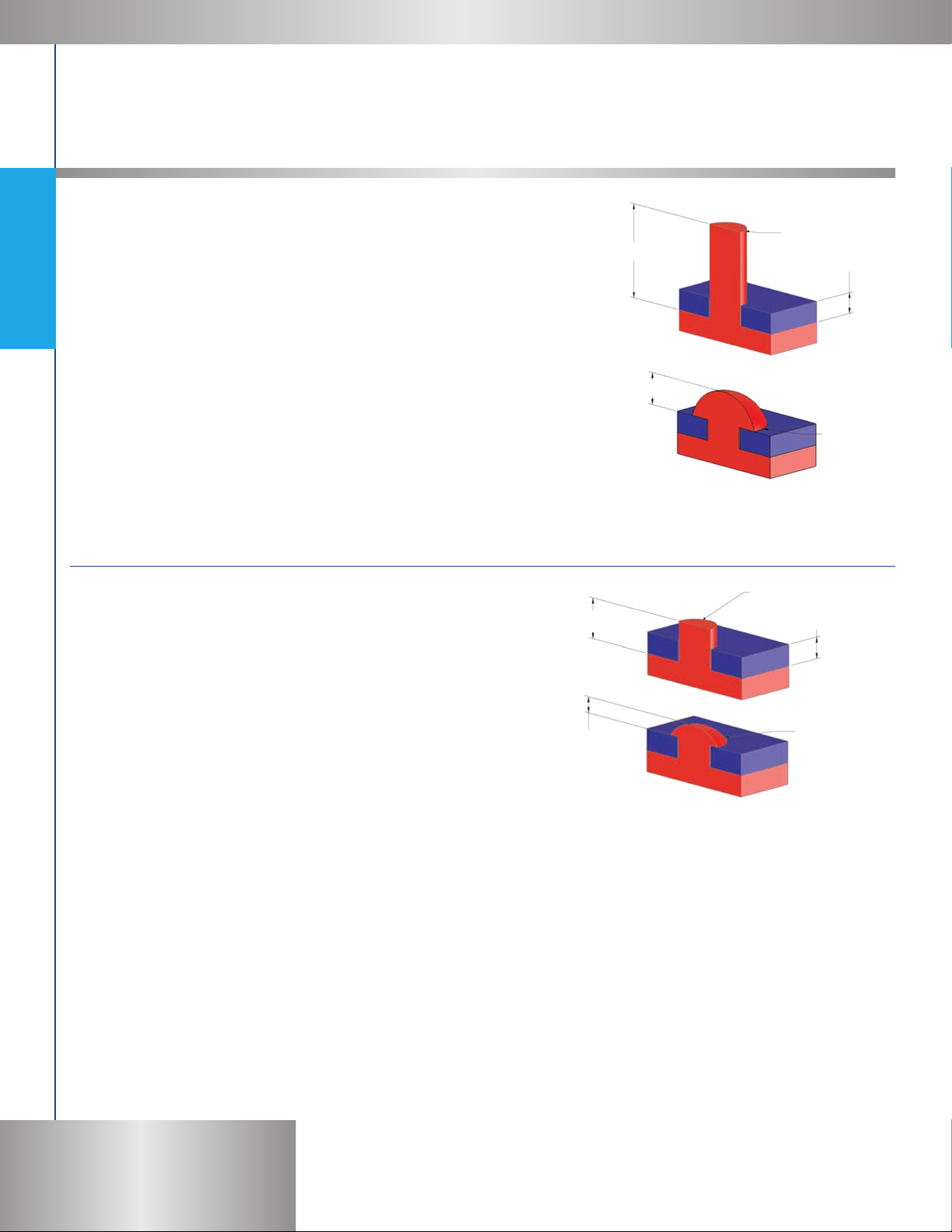

DOME STAKE - HIGH PROFILE:

• To obtain optimal results use with a boss of 0.250”

or less O.D.

• Smaller head means faster weld times

• Under normal conditions this method will create a perfectly

symmetrical weld

• Recommended for crystalline plastics with highly defined

melting points such as 33% G.F.

• Works well with plastics with abrasive fillers and for materials

that easily degrade

• Dome stakes come in two basic silhouettes: high and low

Total Boss Height =

CMT + 1.75 X

Finished Height

= 0.750 X

Boss Dia = X

CMT = Captured

Material Thickness

Finished

Diameter

= 2 X

• Counter bored holes can improve the appearance of these welds

• Stronger weld but slower weld time than a low profile

DOME STAKE - LOW PROFILE:

• To obtain optimal results use with a boss of 0.250” or less O.D.

• Smaller head means faster weld times

• Under normal conditions this method will create a perfectly

symmetrical weld

• Recommended for crystalline plastics with highly defined melting

points such as 33% G.F.

• Works well with plastics with abrasive fillers and for materials

that easily degrade

• Dome stakes come in two basic silhouettes: high and low

• Counter bored holes can improve the appearance of these welds

Total Boss Height

= CMT + 0.45 X

Finished Height

= 0.375 X

Figure 1. Dome stake, high profile.

Boss Dia = X

CMT = Captured

Material Thickness

Figure 2. Dome stake, low profile.

Finished

Diameter

= 1.5 X

Loading...

Loading...