Lockout Tagout

Lockout tagout:

A critical safety regulation

Lockout tagout is an important safety component that is

critical to safeguarding workers around the machinery

and equipment they operate, service and maintain. This

important safety practice involves de-energizing electrical

circuits, closing valves, neutralizing extreme temperatures

and securing moving parts so hazardous energy isn’t

re-introduced while equipment is being serviced.

An effective lockout tagout program is most successful

when it includes the complete safety picture – locks, tags

and devices — as well as proper lockout procedures,

program documentation, employee training, periodic

inspections or other procedural elements.

Benets of a lockout tagout program

• Saving lives: Preventing an estimated 250,000

incidents, 50,000 injuries and 120 fatalities annually

• Cutting costs: Significantly decreasing lost employee

time and insurance costs

Lockout Tagout

• Improving productivity: Reducing equipment downtime

Regulatory requirements

OSHA 29CFR 1910.147 – Control of Hazardous Energy

General industry workers performing servicing and/or

maintenance on machines or equipment and who are

exposed to the unexpected energization, startup or

release of hazardous energy.

OSHA 29CFR 1910.333 – Electrical Safety

Safety-related work practices shall be employed to prevent

electric shock or other injuries resulting from either direct or

indirect electrical contacts, when work is performed near or

on equipment or circuits which are or may be energized.

ANSI Z244.1 (2016) – Lockout Tagout and Alternative Methods

A voluntary national consensus standard that represents

several industry hazardous energy control best practices and

also promotes greater flexibility through the use of alternative

methods based on risk assessments and application of the

hazard control hierarchy.

Lockout tagout is the fth most cited

OSHA violation, with 2,944 violations

during scal year 2018

Top violations involve:

1910.147(c)(4)(i)

1910.147(c)(1) Program Requirements

1910.147(c)(6)(i) Inspecting Procedures

1910.147(c)(7)(i) Training Requirements

1910.147(d) Notifying affected employees

Requirements for

General Procedures

180

Lockout Tagout

Six Essential Elements of Lockout Tagout

1. Program and policy

A written lockout document establishes and explains the

elements of your program. It’s important to take into account

not only OSHA’s guidelines, but also custom requirements for

your employees that ensure they can understand and apply the

program to their workday.

2. Machine- or task-specic procedures

Lockout procedures should be formally documented and should

easily identify the equipment covered. They should also detail the

specific steps necessary for shutting down, isolating, blocking and

securing equipment to control hazardous energy, and include steps

for the placement, removal and transfer of lockout tagout devices.

3. Identifying and marking energy isolation points

Locate and identify all energy control points, including valves,

switches, breakers and plugs, with permanently placed and

standardized labels or tags.

4. Training and periodic inspections and audits

Train authorized, affected and other employees, communicate

processes and conduct periodic inspections. Training should

include OSHA requirements and specific program elements,

such as your machine-specific procedures.

5. Provide proper lockout devices

Provide employees with the necessary devices to keep them

safe. There are many products on the market, and selecting the

most appropriate solution for your application is the key to lockout

effectiveness. It’s important to document and use devices that best

fit each lockout point.

6. Sustainability

Annually review, revise and update your program and

procedures to create a safety culture that proactively addresses

lockout tagout. This allows your company to focus on maintaining

a world-class program, instead of starting from scratch each

year and reacting only when something goes wrong.

Lockout Tagout

181

181

Lockout Tagout Procedures

Lockout Tagout Procedures

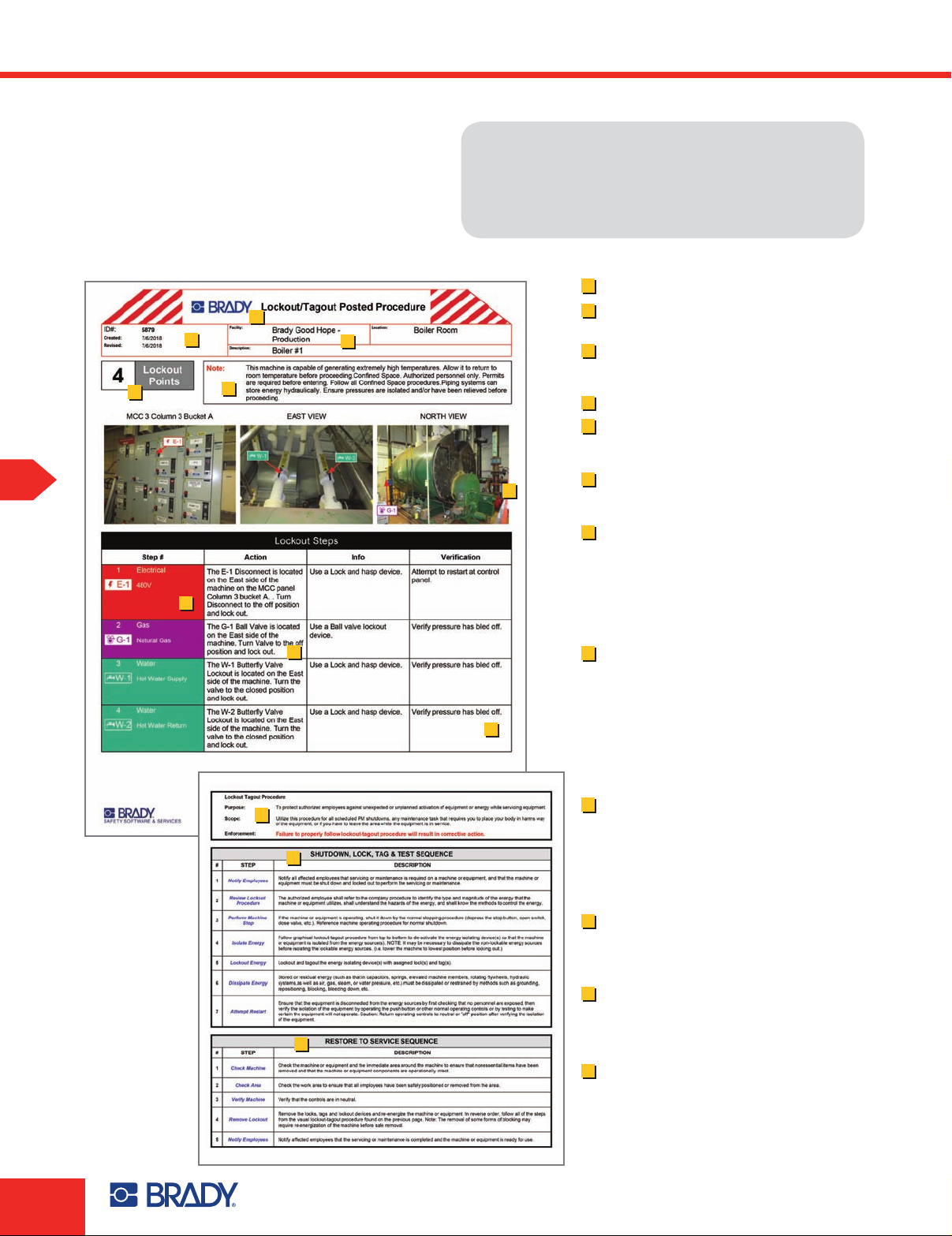

There are a variety of components in a visual

lockout tagout procedure that will help ensure your

employees will get home safe. Use this helpful

guide to determine what elements are required for

compliance, and best practices to complete an

even safer lockout procedure.

Lockout Tagout

OSHA Regulation

29 CFR 1910.147 (c)(4)

Machine-specific lockout tagout procedures are required for

equipment having more than one energy source, as well as

for much equipment having a single energy source.

1

1

Best practice: Company logo

Best practice: Machine-specific

2

1

1

2

2

5

4

4

5

7

7

8

8

10

10

11

11

3

3

6

6

9

9

2

equipment ID number

Required: Facility name, location,

3

3

equipment name

4

4

Best practice: Number of lockout points

5

5

Best practice: The caution statement is

where additional hazards and noteworthy

information can be communicated

6

Best practice: Pictures of equipment

6

displaying location of each energy source.

Required: While having corresponding

7

7

energy source tags mounted on

equipment and indicated on the lockout

procedure is considered "best practice,"

lockout procedures are required to

identify energy sources and magnitude.

(OSHA1910.147(d)(1))

Required: Action steps to isolate

8

8

energy and location of isolation points.

These must include procedural steps

for shutting down, isolating, blocking

and securing equipment to control

hazardous energy. They also must

include steps for the use of lockout

devices and their responsibility.

1910.147(c)(4)(ii)(B-C)

9

Required: Verification is required on

9

every step of your lockout procedure.

This is how your employees will know

whether or not the energy source is truly

isolated and at a zero energy state.

1910.147(c)(4)(ii)(D)

182

12

12

10

10

Required: Purpose, scope and

enforcement of lockout tagout procedure

must be included on

Physical procedure. 1910.147(c)(4)(ii)

11

11

Required: A sequential procedure

for shutdown, locking/tagging and

testing must be included on the lockout

procedure. 1910.147 App A

12

12

Required: A sequential procedure to

restore equipment to service must be

included on the lockout procedure.

1910.147 App A

Lockout Tagout Procedures

Lockout Tagout Services through Brady Safety Services

With a continually changing workforce, and frequent enhancements to processes

and technology, there is a need in the industry to efficiently develop and train new

workers to keep operations running smoothly. Having a sustainable lockout tagout

program in place allows you to bridge the knowledge gap and improve safety

throughout your facility.

Lockout Services include:

• Lockout tagout machine inventory

• Visual lockout procedure writing

• Lockout tagout procedure audit

• Lockout tagout training, including

general / affected, authorized and

train-the-trainer programs

• Alternative method

procedures/minor servicing

• Job safety analysis

• Lockout tagout program development

• Lockout tagout gap analysis

• Time- and material-based services

Create Your Own Procedures

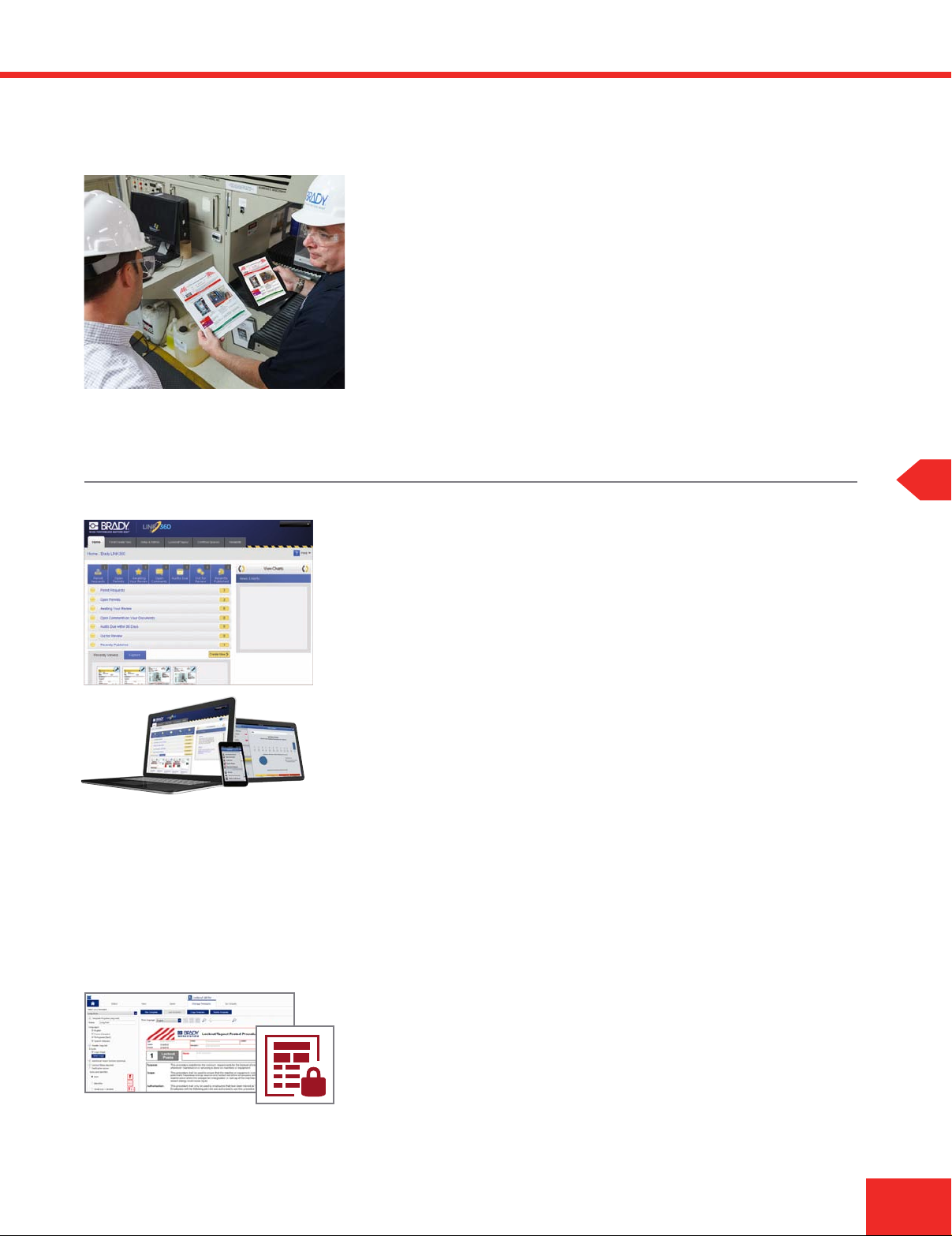

LINK360® Software

Brady’s LINK360® cloud based software offers procedure creation, procedure

maintenance, audit reminders and more in order to manage, store and sustain

machine safety and procedural information. It includes three centers that address

common areas of focus when operating your equipment safely: Lockout Tagout,

Confined Space and Reliability / Maintenance.

With Link360 software, you can:

• Create and update procedures and permits

• Facilitate reviews, comments and approvals

• Setup regularly scheduled audit processes and reminders

• Time-stamping and record keeping

• Print lockout tags containing equipment-specific information

The LINK360 advantage:

• Cloud-based software allows for

program scalability and access from

mobile and tablet devices

• User-defined permission for viewing,

editing and approving helps ensure the

correct people are doing the correct

activities

• Pre-defined templates and standardized

procedures for multi-site standardization

• Workflow and responsibility assignments

for sites, areas and equipment improves

employee accountability around

machine safety and productivity

• Audit alerts, notification and detailed

reporting help companies keep

information up to date

Lockout Tagout

Brady Workstation Lockout Writer App

Desktop app for simple lockout procedures

Save time and keep employees safe with the Brady Workstation Lockout Writer

app. This intuitive tool allows you to create, store and print simple lockout

procedures, associated tags and energy source labels quickly and easily.

183

183

Lockout Tagout Procedures

Lockout Tagout Procedure Accessories

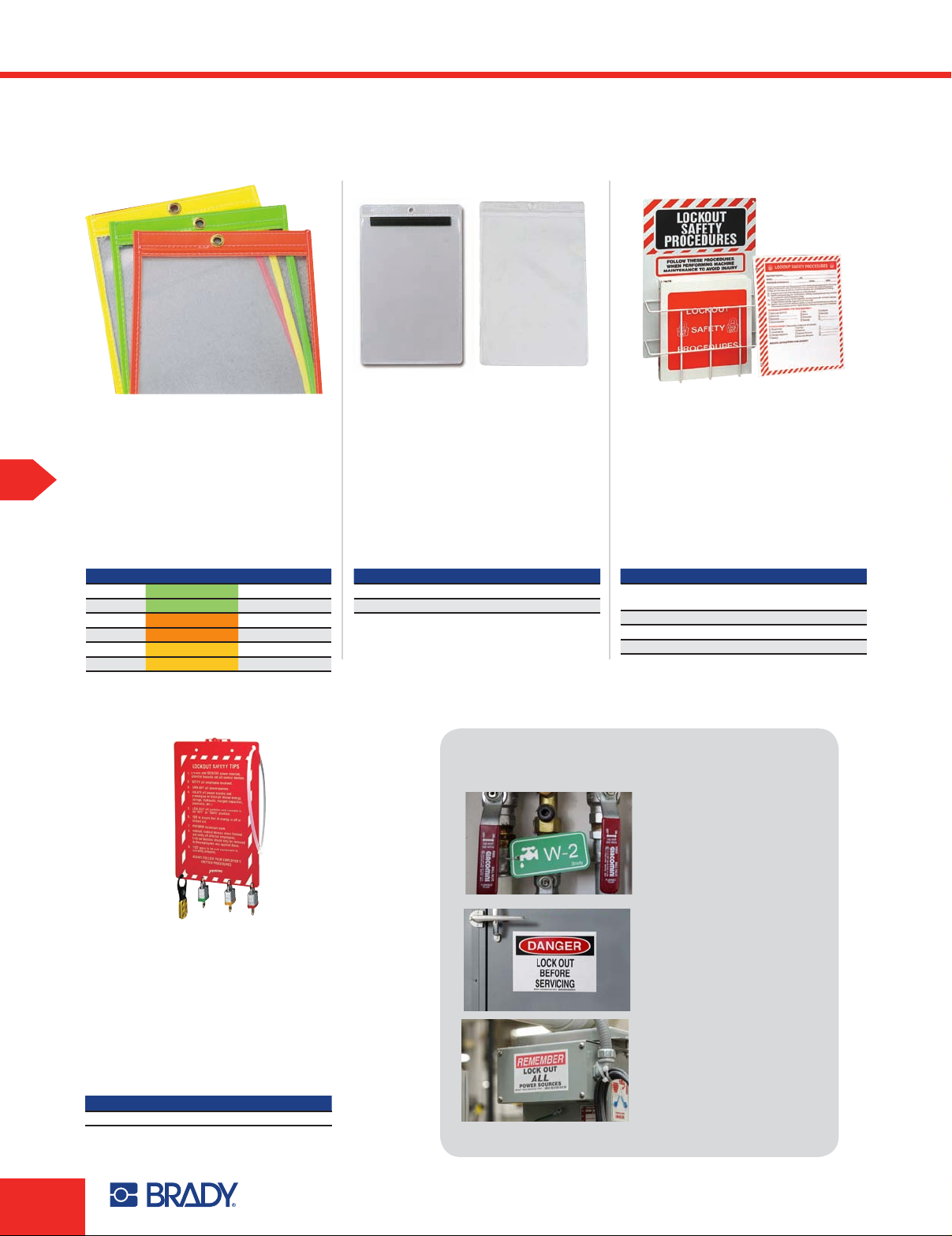

Fluorescent Protective

Envelopes

• Clear envelopes with fluorescent

edging, great for color-coding lockout

procedures and other shop information

Lockout Tagout

• Durable 8 gauge vinyl construction

withstands harsh environments

• Ideal for indoor or outdoor use

Catalog # Color Size Qty.

56941 Fluorescent Green 9 in. x 9 in. 25

56945 Fluorescent Green 9 in. x 12 in. 25

56942 Fluorescent Orange 9 in. x 9 in. 25

56946 Fluorescent Orange 9 in. x 12 in. 25

56944 Fluorescent Yellow 9 in. x 9 in. 25

56948 Fluorescent Yellow 9 in. x 12 in. 25

Magnetic Backed

Open-End

Adhesive Backed

Open-End

Adhesive and Magnetic

Backed Envelopes

• Made of non-glare clear vinyl material

• Protects tags and cards on machinery,

valves, switches, controls, and more

• Size: 8.5 in. x 11 in.

Catalog # Color Qty.

50961 Adhesive Backed Envelopes 10

50962 Magnetic Backed Envelopes 10

May we also suggest:

Lockout Procedure Station

• Silk-screened backboard made from

durable polystyrene

• Includes pre-drilled holes and

hardware for wall mounting

• 1.5 in. 3-ring binder

• Size: 20 in. x 14 in. x 4.5 in.

Catalog # Description

LOSP22

99289 Lockout Procedure Station With Binder Only

LOSB1 Lockout Procedure Binder Only

LOSF5 Lockout Procedure Forms (25/pk)

Lockout Procedure Station With Binder and

25 Forms

Energy Source Tags

View page 206

184

Lockout Clip Board

• Heavy-duty, clipboard conveniently

carries procedures and hardware

directly to the lockout location

• Clipboard can also be hung in place

using attached strap

• Lockout safety tips on the back

• Procedures, locks and hasps sold

separately

Catalog # Color Qty.

LOCB Lockout Clip Board 1

Lockout Tagout Signs

View page 504

Lockout Safety Labels

View page 392

Lockout Training and Awareness Aids

Lockout Tagout Safety Training Video:

Global Best Practice Training

• Comprehensive training video features targeted regulatory and compliance content

• 5 languages included: English, Spanish, French, Portuguese and Simplified Chinese

• Includes instructor’s guide, employee quiz and 25 min video that:

• Clearly defines and explains lockout tagout

• Overviews compliance standards and regulations from countries around the world

• Outlines an effective four-step lockout tagout program for employers

• Covers important subtopics in-depth such as handling group lockout and shift changeovers

• Bonus feature: 19 short installation videos on how to use some of the most common lockout devices

Catalog # Description

132427 LOTO Global Training Video USB

833918

LOTO Global Training Video USB - European

Supplies information in English, French, Dutch, German,

Portuguese, Italian, Spanish, Turkish, Polish and Russian

Lockout Tagout Handbook

• 16-page training booklet with quiz

instructs workers how to protect

themselves from hazardous energy

Catalog # Description Qty.

66219 Lockout Tagout Handbook 10

OSHA Training Requirements:

Authorized Employees

Those who perform servicing or

maintenance must be trained to:

• Recognize hazardous energy

sources and understand the

energy type and magnitude

• Identify and properly operate

the applicable energy-isolating

devices

• Safely apply and remove

lockout tagout devices

• Authorized employees must

undergo an annual review to

ensure they fully understand

their responsibilities under the

program

Affected Employees

Those who operate the

machinery or work in the area

where LOTO is performed

must be trained to:

• Recognize when lockout

• Understand the purpose

Lockout Safety

Training Booklet

• 16-page training booklet covers the

basics of lockout tagout safety

Catalog # Description Qty.

2112-TEN Lockout Safety 10

2112 Lockout Safety 25

2112SP-TEN Lockout Safety - Spanish 10

2112SP Lockout Safety - Spanish 25

Addtional Requirments

• Employers must document when training took

place, who attended, and the topics covered

• Employees must be retrained under the

following situations:

tagout activities are in

progress

of the energy control

program and the importance

of not tampering with

lockout tagout devices

when encountered in the

workplace

• Additional training is required when using tagout

instead of lockout. See Section (C)(7)(ii) in the

1910.147 standard.

Wallet Safety Cards

• Wallet size card contains important

reminders for lockout safety

Catalog # Description Qty.

LOSC13 English Wallet Card 10

LOSC13 BI English/Spanish Wallet Card 10

Lockout Tagout

• Employee assigned to new job

• Change made to energy control

policies or procedures

• Machinery installed or modified,

presenting a new hazard

• Whenever the employer has reason to believe

that there are problems with the employee’s

understanding or use of the procedures

185

185

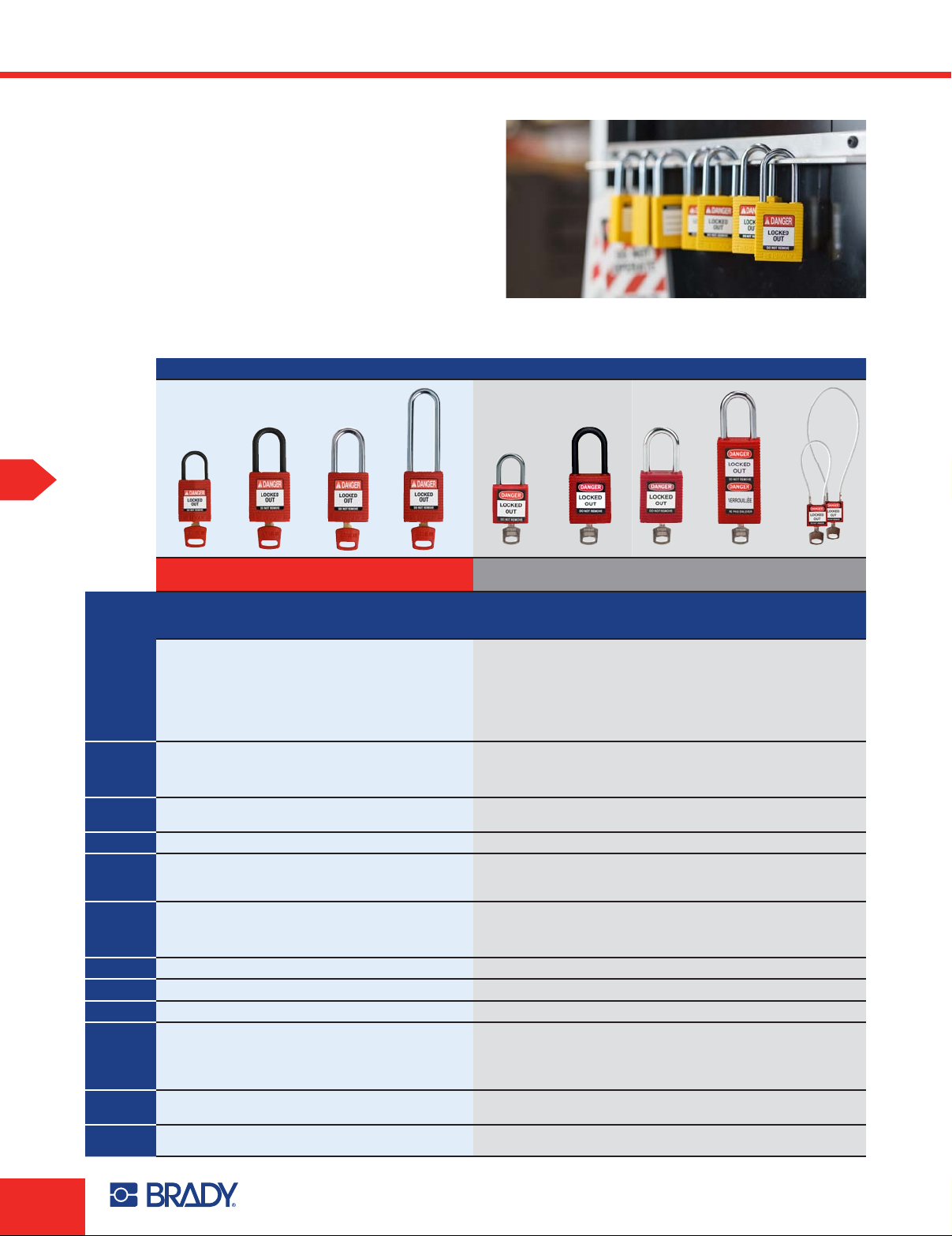

Lockout Padlocks

Lockout Padlocks

Although padlocks may seem like a commonplace device,

the durability and reliability of your padlocks is critical to

the safety of your employee. Brady provides a full line of

padlocks that withstand harsh environmental conditions,

rough handling and provide maximum safety.

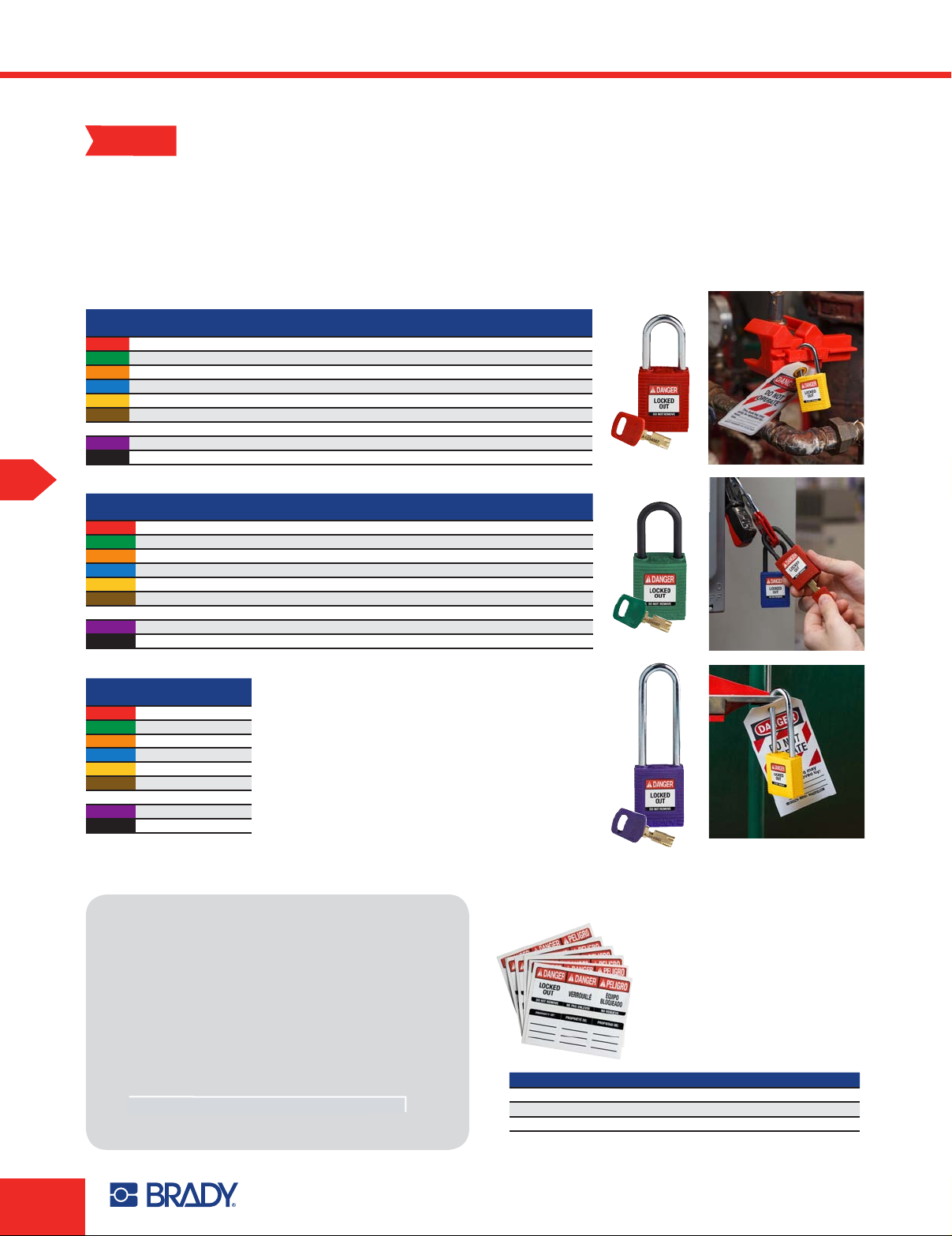

Nylon Lockout Padlocks

Lockout Tagout

Features

Main

application

Nonconductive

Non-sparking

Body

(H x W)

Shackle

Colors

Key Retaining

Key Codes

Keying

Engraving

Available

Includes

NEW SafeKey Nylon Lockout Padlocks Traditional Nylon Lockout Padlocks

SafeKey

Compact

Padlocks

Advanced

security locking

mechanism, color

matched keys,

compact size

Electrical

applications and

small spaces

Yes Yes Yes Yes Yes Yes Yes Yes Yes

Yes Yes No No No Yes No No No

Nylon body

1.7 in. x 1.25 in.

Plastic polymer

shackle

Height: 1.0 in.

Diameter: 0.17 in.

9 colors 9 colors 9 colors 9 colors 9 colors 9 colors 9 colors 9 colors 9 colors

No Ye s Yes Yes Yes Yes Ye s Yes Yes

100,000+ 100,000+ 100,000+ 100,000+ Up to 15,000 Up to 15,000 Up to 15,000 Up to 15,000 Up to 15,000 Key Codes 100,000+ Up to 15,000 Up to 15,000 Up to 15,000 Up to 15,000

Keyed Different

Keyed Alike

Master Keyed*

Grand Master

Keyed*

Body (4 sides)

and key

1 key and labels

(EN, FR, SP)

SafeKey

Padlock with

Nylon Shackle

Advanced

security locking

mechanism, color

matched keys,

non-conductive

nylon body and

shackle

General safety

and electrical

applications

Nylon body

1.8 in. x 1.5 in.

Plastic polymer

shackle

Height: 1.5 in.

Diameter: 0.25 in.

Keyed Different

Keyed Alike

Master Keyed*

Grand Master

Keyed*

Body (4 sides)

and key

1 key and labels

(EN, FR, SP)

SafeKey

Padlock with

Steel Shackle

Advanced

security locking

mechanism, color

matched keys,

standard size

General safety

applications

Nylon body

1.8 in. x 1.5 in.

Steel shackle

Height: 1.5 in.

Diameter: 0.25 in.

Keyed Different

Keyed Alike

Master Keyed*

Grand Master

Keyed*

Body (4 sides)

and key

1 key and labels

(EN, FR, SP)

SafeKey

Padlock with

3 in. Shackle

Advanced

security locking

mechanism, color

matched keys,

3 inch shackle

General safety

applications

requiring a large

shackle clearance

Nylon body

1.8 in. x 1.5 in.

Steel shackle

Height: 3.0 in.

Diameter: 0.25 in.

Keyed Different

Keyed Alike

Master Keyed*

Grand Master

Keyed*

Body (4 sides)

and key

1 key and labels

(EN, FR, SP)

Compact

Nylon

Padlocks

Traditional pin

tumbler locking

mechanism,

chrome / nickel

plated keys,

compact size

Electrical

applications and

small spaces

Nylon body

1.4 in. x 1.2 in.

Aluminum shackle

Height: 1.0 in.

Diameter: 0.19 in.

Keyed Different

Keyed Alike

Master Keyed*

Grand Master

Keyed*

Body (4 sides)

and key

1 key and labels

(EN, FR, SP)

Nylon Padlock

with Nylon

Shackle

Traditional pin

tumbler locking

mechanism,

chrome / nickel

plated keys,

non-conductive

nylon body and

shackle

General safety

and electrical

applications

Nylon body

1.75 in. x 1.5 in.

Nylon shackle

Height: 3.0 in.

Diameter: 0.25 in.

Keyed Different

Keyed Alike

Master Keyed*

Grand Master

Keyed*

Body (4 sides)

and key

1 key and labels

(EN, FR, SP)

Nylon Padlock

with Steel

Shackle

Traditional pin

tumbler locking

mechanism,

chrome / nickel

plated keys,

standard size

General safety

applications

Nylon body

1.75 in. x 1.5 in.

Steel shackle

Height: 1.5 in.

Diameter:

0.25 in.

Keyed Different

Keyed Alike

Master Keyed*

Grand Master

Keyed*

Body (4 sides)

and key

1 key and labels

(EN, FR, SP)

Long-Body

Nylon

Padlock

Traditional pin

tumbler locking

mechanism,

chrome / nickel

plated keys,

3 in. body to

display additional

identification

General safety

applications

Nylon body

3 in. x 1.5 in.

Steel shackle

Height: 1.5 in.

Diameter: 0.25 in.

Keyed Different

Keyed Alike

Master Keyed*

Grand Master

Keyed*

Body (4 sides)

and key

1 key and labels

(EN, FR, SP)

Compact

Cable Nylon

Padlocks

Traditional pin

tumbler locking

mechanism,

chrome / nickel

plated keys,

compact body

and flexible cable

shackle

Small spaces

and multi-locking

points in electrical

applications

Nylon body

1.4 in. x 1.2 in.

Flexible cable

7.87 in. or

15.75 in. length

Keyed Different

Keyed Alike

Master Keyed*

Grand Master

Keyed*

Body (4 sides)

and key

1 key and labels

(EN, FR, SP)

*Available as custom.

186

Lockout Padlocks

Regulations

1910.147(c)(5) OSHA Lockout Device Requirements state that lockout devices must:

• Be provided by the employer and be standardized by size, shape or color

• Be distinguishable from locks used for other purposes. Lockout locks should only be used for lockout

• Identify the individual who applied the lock (both tags and lock labels are acceptable for this purpose)

• Be capable of withstanding the usage environment and be strong enough to prevent removal except by using

excessive force with special tools, such as bolt cutters

• Most importantly, whenever lockout devices are applied, they must remain under the exclusive control of the

individual who attached them. No employee should be able to open a lock attached by someone else

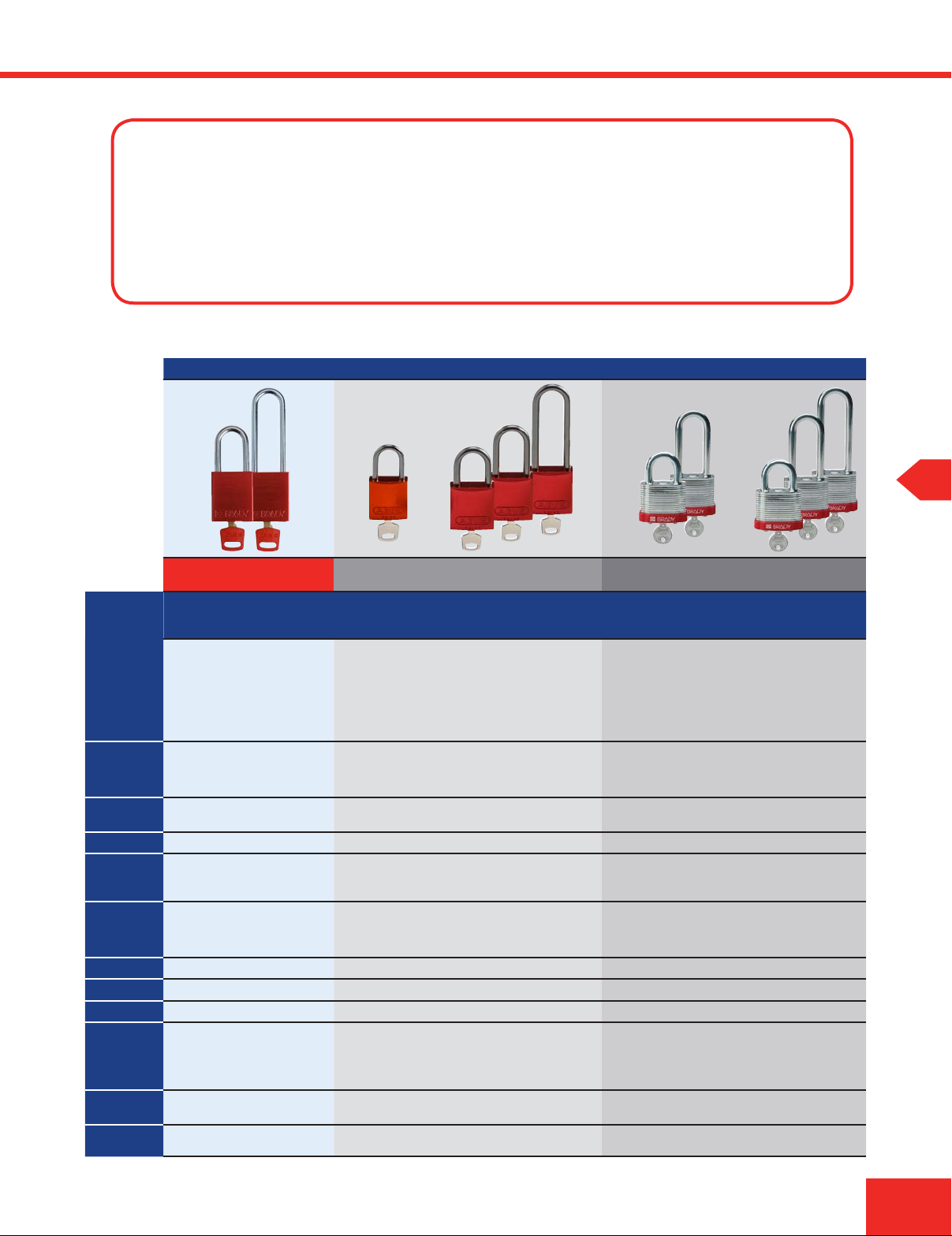

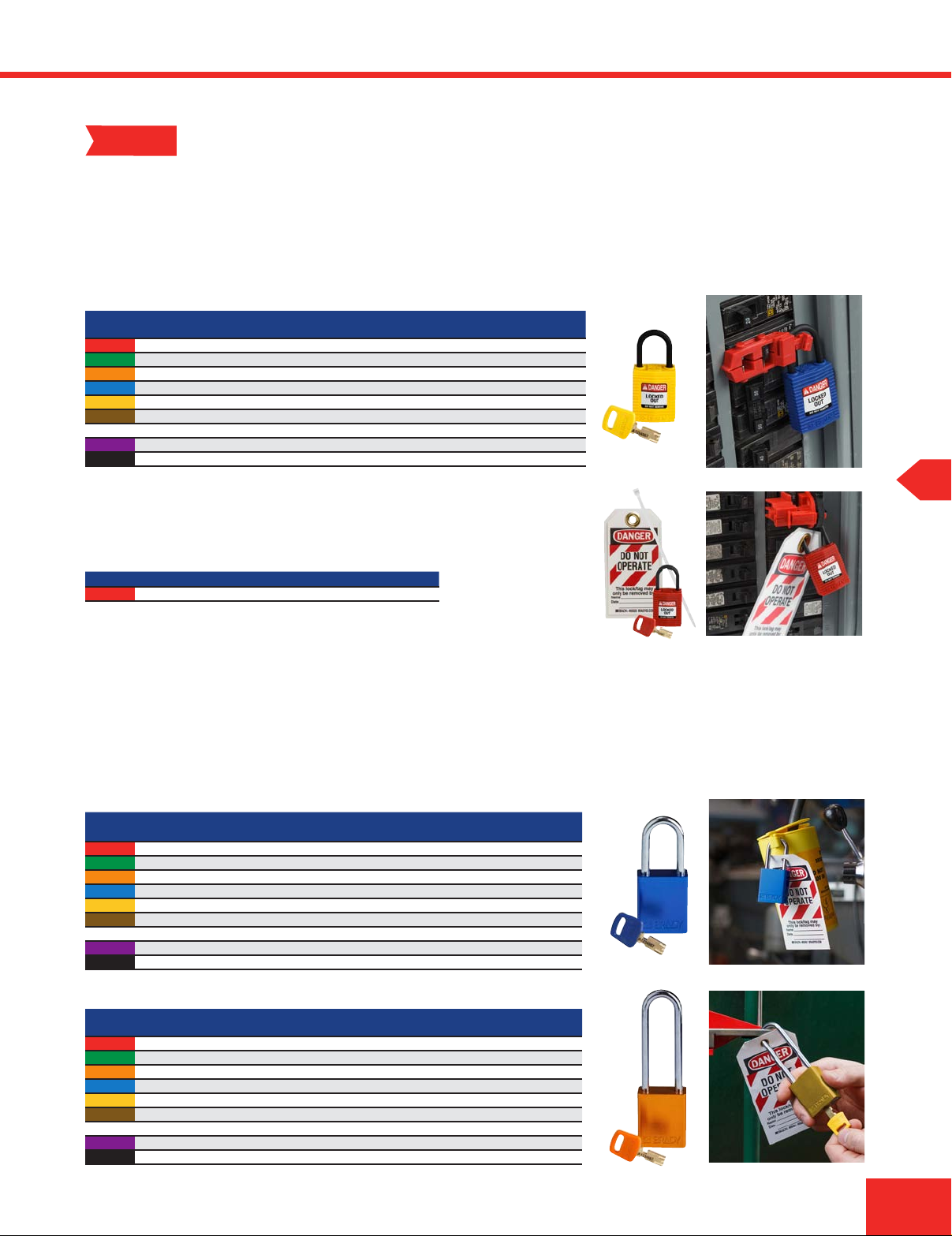

Aluminum and Steel Lockout Padlocks

Features

Main

application

Non-conductive

Non-sparking

Body

(H x W)

Shackle

Colors

Key Retaining

NEW SafeKey Aluminum

Lockout Padlocks

SafeKey Aluminum Padlocks

Advanced security locking mechanism,

color matched keys, superior corrosion

resistance

Ideal for indoor and outdoor use and

heavy-duty applications

No No No No No

No No No No No

Aluminum body

1.8 in. x 1.5 in.

Steel shackle

Height: 1.5 in. or 3.0 in.

Diameter: 0.25 in.

9 colors 9 colors 9 colors 9 colors 9 colors

No No No No Yes

Traditional Aluminum Lockout Padlocks Traditional Steel Lockout Padlocks

Compact Aluminum

Padlocks

Traditional pin tumbler locking

mechanism, chrome / nickel

plated keys, compact, superior

corrosion resistance

Small space applications Outdoor, industrial safety, food

Aluminum body

1.25 in.

Steel shackle

Height: 1.0 in.

Diameter: 0.25 in.

Aluminum Padlocks Laminated Steel Padlocks

Traditional pin tumbler locking

mechanism, chrome / nickel

plated keys, superior corrosion

resistance

and beverage applications (FDA

approved lubricant in cylinder)

Aluminum body

1.6 in.

Steel shackle

Height: 1 in., 1.5 in. or 3 in.

Diameter: 0.25 in.

Traditional pin tumbler locking

mechanism, chrome / nickel

plated keys, superior physical

and corrosion resistance

Industrial safety and severe

physical environments

Steel body

1.33 in.

Steel shackle

Height: 0.75 in. or 2 in.

Diameter: 0.27 in.

Key-Retaining

Laminated Steel Padlocks

Traditional key-retaining pin

tumbler locking mechanism,

chrome / nickel plated

keys, superior physical and

corrosion resistance

Industrial safety and severe

physical environments

Steel body

1.2 in.

Steel shackle

Height: 0.75 in., 2 in. or 3 in.

Diameter: 0.27 in.

Lockout Tagout

Keying

Engraving

Available

Includes

Keyed Different

Keyed Alike

Master Keyed*

Grand Master Keyed*

Body (4 sides)

and key

1 key

(labels sold separately)

*Available as custom.

Keyed Different

Keyed Alike

Master Keyed*

Grand Master Keyed*

Body (4 sides)

and key

2 keys

(labels sold separately)

Keyed Different

Keyed Alike

Master Keyed*

Grand Master Keyed*

Body (4 sides)

and key

2 keys

(labels sold separately)

Keyed Different

Keyed Alike

Master Keyed*

Grand Master Keyed*

Body (4 sides)

and key

2 keys

(labels sold separately)

Keyed Different

Keyed Alike

Master Keyed*

Grand Master Keyed*

Body (4 sides)

and key

1 key

(labels sold separately)

187

187

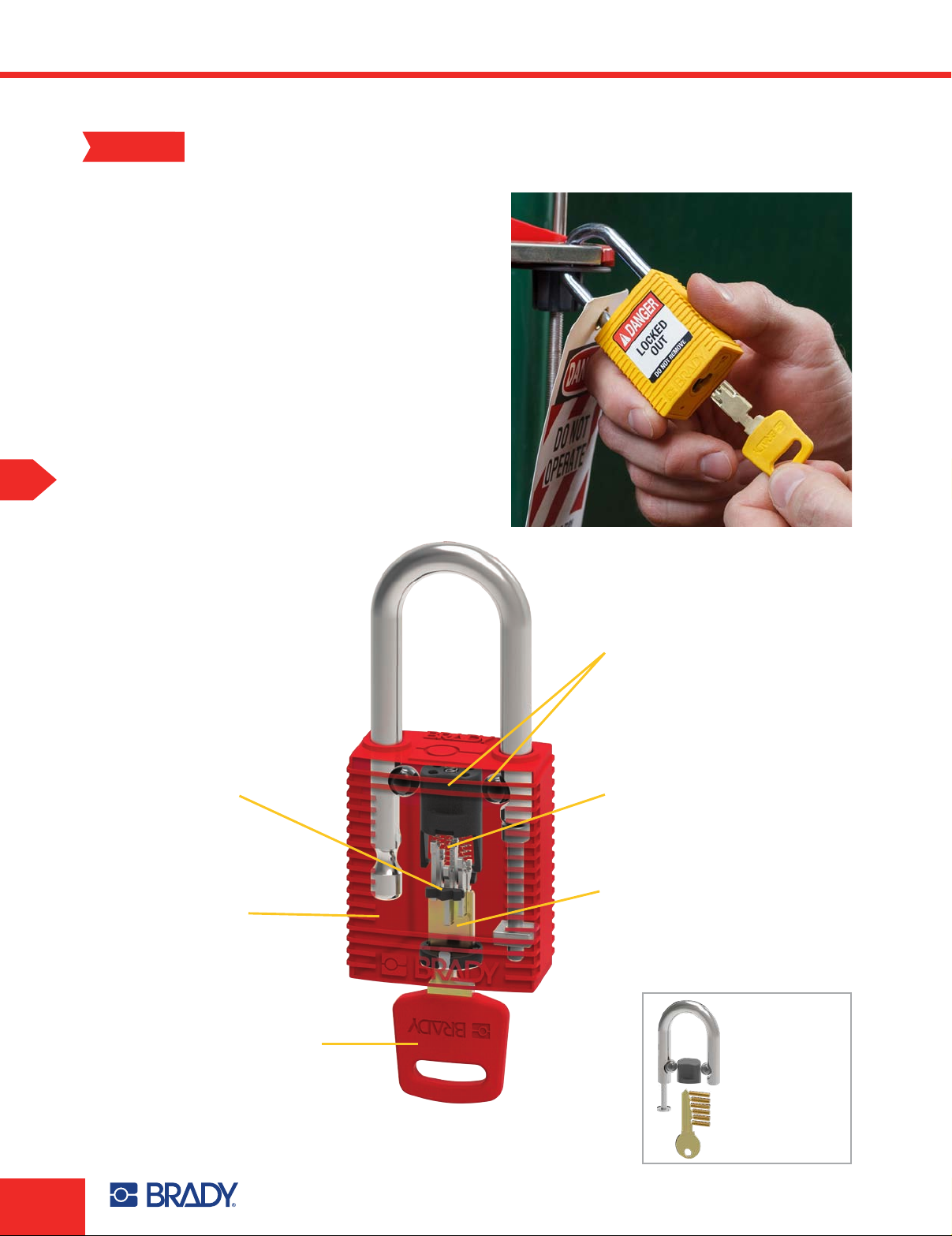

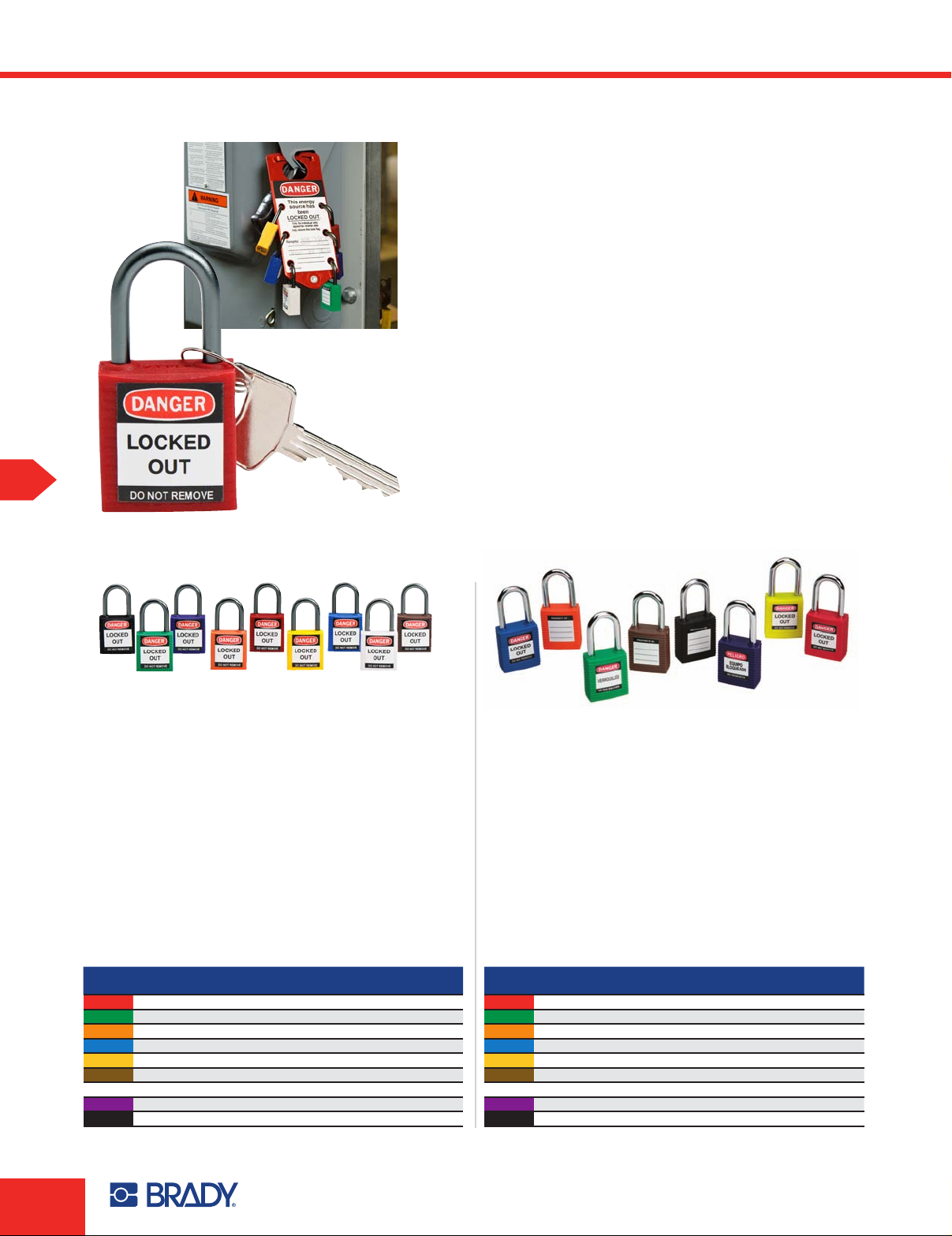

Lockout Padlocks

new

With this innovatively designed padlock, you get up to 700%

more unique key possibilities than a standard safety padlock,

without sacrificing a secure lockout. It’s all in the forwardthinking design of the locking mechanism and unique key

blade that gives you more precision and control in your lockout

program. With that level of precision, you’re covered from your

simple to highly complex lockout needs. You also get:

• Fast identification with the color-matched key

• Easy operation with extra smooth key insertion

and removal — even when wearing gloves!

• Years of use with the low-friction locking

mechanism that helps maintain key integrity

• Excellent durability in industrial environments

Lockout Tagout

Brady SafeKey Lockout Padlocks

Enhanced

security with two

side-locking bars

Extra durability

in industrial

environments

with one-piece

body design

Fast identication

with color-matched

lock and key

Added safety with

non-conductive ball

bearings and driver

More than 100,000 key codes

made possible with linear,

low-friction lock mechanism

Easy operation with smooth

key design and precision

steel tumbler blades

Traditional

safety padlocks

• Pin tumbler

lock mechanism

• Jagged key design

• Up to 15,000

key codes

188

Lockout Padlocks

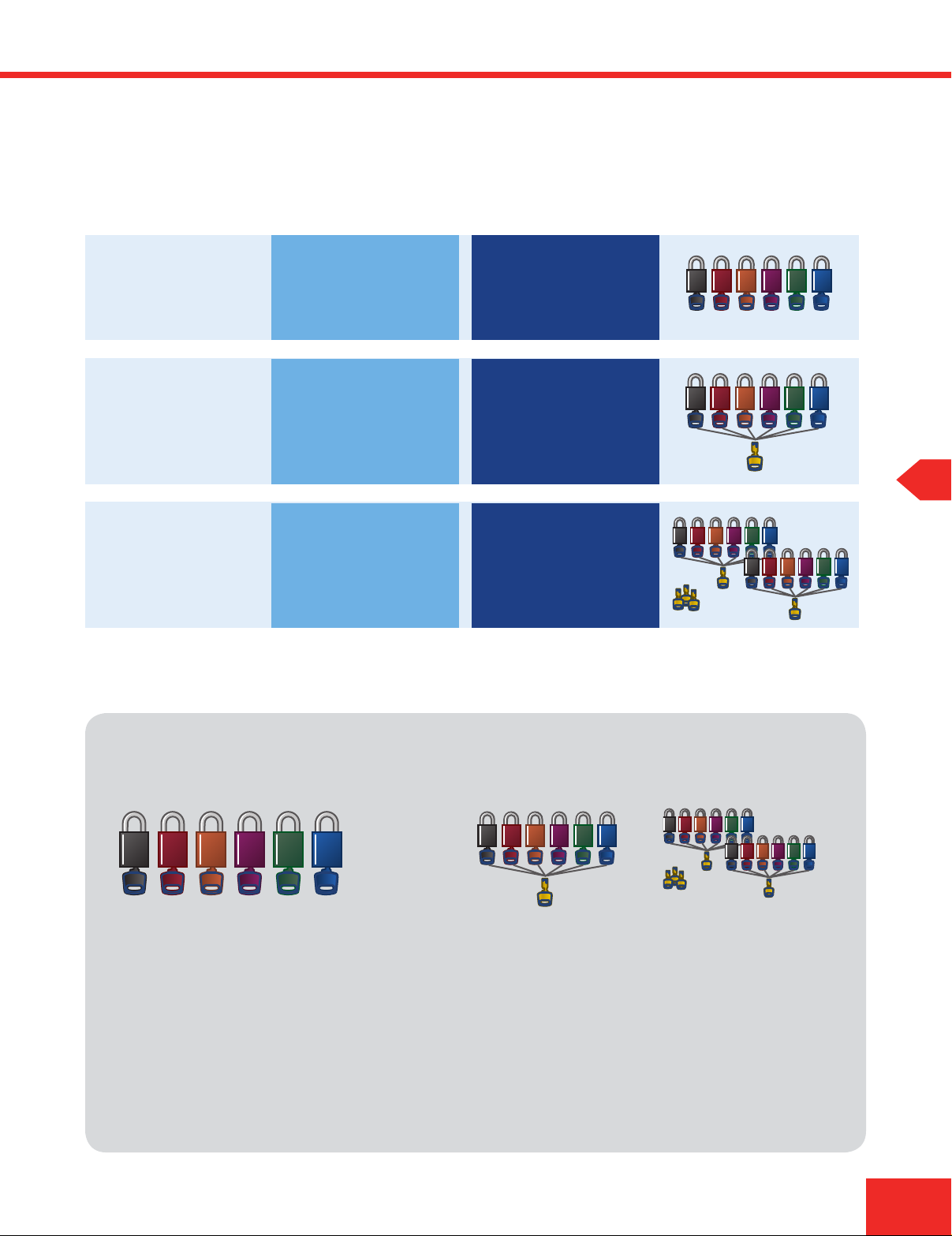

Keyed DifferentKeyed Alike

Keyed DifferentKeyed Alike

Master Keyed Grand Master Keyed

Master Keyed

Keyed DifferentKeyed Alike

Keyed DifferentKeyed Alike

Master Keyed Grand Master Keyed

Master Keyed

More really means more with SafeKey

In your lockout scenario, here's what you get with up to 700% more unique key codes:

Other Nylon Padlocks SafeKey Lockout Padlocks

Keyed

Different

1 Master

Key

25 Master

Keys

15,000

Key Codes

3,250

Key Codes

150

Key Codes

100,000

Key Codes

15,000

Key Codes

600

Key Codes

+

+

+

...

Keying options for SafeKey and traditional lockout padlocks

Standard options Custom options

Keyed Different (KD)

Each lock is opened

by its own unique key.

Perfect for simple

lockout applications

and a manageable

number of energy

isolation points.

Key Charting

Brady will keep a record of and "chart" all key numbers to ensure there's no unwanted key duplication

on current or future orders, depending on your unique requirements.

Keyed Alike (KA)

Each lock in the group

can be opened with the

same key, reducing the

number of keys needed.

Ideal for employees who

work on multiple machines

or isolation points.

Master Keyed (MK)

Each grouping of locks

(whether keyed alike or

different) can be opened

with a master key. Useful

for larger, complex systems

when supervisory access

may be required.

...

Grand Master Keyed (GMK)

The grand master key can

open all locks grouped into two

or more master keyed systems.

Useful when supervisory or

managerial access to all locks

is needed.

Lockout Tagout

189

189

Lockout Padlocks

new

SafeKey Nylon Lockout Padlocks

• Key retaining feature within a lightweight nylon body is ideal for electrical and general lockout applications

• Two shackle options available; durable, steel shackle or polymer plastic shackle that is non-conductive and non-sparking

• Each padlock includes one key and lock labels in English, Spanish and French; additional keys can be ordered if needed

• Body: 1.8 in. H x 1.5 in. W x 0.75 in. D; shackle diameter: 0.25 in.

SafeKey Nylon Lockout Padlocks with 1.5 in. (38 mm) steel shackle

Color

Red NYL-RED-38ST-KD NYL-RED-38ST-KD6PK NYL-RED-38ST-KA3PK NYL-RED-38ST-KA6PK

Green NYL-GRN-38ST-KD NYL-GRN-38ST-KD6PK NYL-GRN-38ST-KA3PK NYL-GRN-38ST-KA6PK

Orange NYL-ORG-38ST-KD NYL-ORG-38ST-KD6PK NYL-ORG-38ST-KA3PK NYL-ORG-38ST-KA6PK

Blue NYL-BLU-38ST-KD NYL-BLU-38ST-KD6PK NYL-BLU-38ST-KA3PK NYL-BLU-38ST-KA6PK

Yellow NYL-YLW-38ST-KD NYL-YLW-38ST-KD6PK NYL-YLW-38ST-KA3PK NYL-YLW-38ST-KA6PK

Brown NYL-BRN-38ST-KD NYL-BRN-38ST-KD6PK NYL-BRN-38ST-KA3PK NYL-BRN-38ST-KA6PK

White NYL-WHT-38ST-KD NYL-WHT-38ST-KD6PK NYL-WHT-38ST-KA3PK NYL-WHT-38ST-KA6PK

Purple NYL-PRP-38ST-KD NYL-PRP-38ST-KD6PK NYL-PRP-38ST-KA3PK NYL-PRP-38ST-KA6PK

Black NYL-BLK-38ST-KD NYL-BLK-38ST-KD6PK NYL-BLK-38ST-KA3PK NYL-BLK-38ST-KA6PK

SafeKey Nylon Lockout Padlocks with 1.5 in. (38 mm) plastic shackle

Lockout Tagout

Color

Red NYL-RED-38PL-KD NYL-RED-38PL-KD6PK NYL-RED-38PL-KA3PK NYL-RED-38PL-KA6PK

Green NYL-GRN-38PL-KD NYL-GRN-38PL-KD6PK NYL-GRN-38PL-KA3PK NYL-GRN-38PL-KA6PK

Orange NYL-ORG-38PL-KD NYL-ORG-38PL-KD6PK NYL-ORG-38PL-KA3PK NYL-ORG-38PL-KA6PK

Blue NYL-BLU-38PL-KD NYL-BLU-38PL-KD6PK NYL-BLU-38PL-KA3PK NYL-BLU-38PL-KA6PK

Yellow NYL-YLW-38PL-KD NYL-YLW-38PL-KD6PK NYL-YLW-38PL-KA3PK NYL-YLW-38PL-KA6PK

Brown NYL-BRN-38PL-KD NYL-BRN-38PL-KD6PK NYL-BRN-38PL-KA3PK NYL-BRN-38PL-KA6PK

White NYL-WHT-38PL-KD NYL-WHT-38PL-KD6PK NYL-WHT-38PL-KA3PK NYL-WHT-38PL-KA6PK

Purple NYL-PRP-38PL-KD NYL-PRP-38PL-KD6PK NYL-PRP-38PL-KA3PK NYL-PRP-38PL-KA6PK

Black NYL-BLK-38PL-KD NYL-BLK-38PL-KD6PK NYL-BLK-38PL-KA3PK NYL-BLK-38PL-KA6PK

Keyed Different

1/Pack

Keyed Different

1/Pack

Brady SafeKey Lockout Padlocks

Keyed Different

6/Pack

Keyed Different

6/Pack

Keyed Alike

3/Pack

Keyed Alike

3/Pack

Keyed Alike

6/Pack

Keyed Alike

6/Pack

SafeKey Nylon Lockout Padlocks with 3.0 in. (76 mm) steel shackle

Color

Red NYL-RED-76ST-KD

Green NYL-GRN-76ST-KD

Orange NYL-ORG-76ST-KD

Blue NYL-BLU-76ST-KD

Yellow NYL-YLW-76ST-KD

Brown NYL-BRN-76ST-KD

White NYL-WHT-76ST-KD

Purple NYL-PRP-76ST-KD

Black NYL-BLK-76ST-KD

Keyed Different

1/Pack

Engraving

SafeKey padlocks can be laser-engraved on one to four

surfaces to identify individuals, departments, work areas,

serial numbers and company logos. Additionally, SafeKey

keys can be engraved with up to 10 characters.

Design-Your-Own Padlock Online

Create a custom SafeKey padlock with exactly the options

you need, including engraving, in one easy-to-use online

tool.

SafeKey Padlock Labels

• Labels help send a clear message

when machine is down for service

or maintenance

• Keep track of your Brady SafeKey

Lockout Padlocks by writing who

owns that padlock on the label

Catalog # Description Size Qty.

150556 English, French, Spanish Compact 0.89 in x 1 in 6 cards

150555 English, French, Spanish Standard 1.12 in x 1 in 6 cards

65508 Lock Label Overlaminate 1 in. x 6 in. 40

190

Lockout Padlocks

new

Brady SafeKey Lockout Padlocks

SafeKey Compact Nylon Lockout Padlocks

• Ideal for use in small spaces in electrical and maintenance applications

• Extremely compact and lightweight design with non-conductive and non-sparking nylon body and polymer shackle

• Each padlock includes one key and lock labels in English, Spanish and French; additional keys can be ordered if needed

• Body: 1.7 in. H x 1.25 in. W x 0.75 in. D; shackle diameter: 0.17 in.

SafeKey Compact Nylon Padlocks with 1.0 in. (25 mm) plastic shackle

Color

Red CPT-RED-25PL-KD CPT-RED-25PL-KD6PK CPT-RED-25PL-KA3PK CPT-RED-25PL-KA6PK

Green CPT-GRN-25PL-KD CPT-GRN-25PL-KD6PK CPT-GRN-25PL-KA3PK CPT-GRN-25PL-KA6PK

Orange CPT-ORG-25PL-KD CPT-ORG-25PL-KD6PK CPT-ORG-25PL-KA3PK CPT-ORG-25PL-KA6PK

Blue CPT-BLU-25PL-KD CPT-BLU-25PL-KD6PK CPT-BLU-25PL-KA3PK CPT-BLU-25PL-KA6PK

Yellow CPT-YLW-25PL-KD CPT-YLW-25PL-KD6PK CPT-YLW-25PL-KA3PK CPT-YLW-25PL-KA6PK

Brown CPT-BRN-25PL-KD CPT-BRN-25PL-KD6PK CPT-BRN-25PL-KA3PK CPT-BRN-25PL-KA6PK

White CPT-WHT-25PL-KD CPT-WHT-25PL-KD6PK CPT-WHT-25PL-KA3PK CPT-WHT-25PL-KA6PK

Purple CPT-PRP-25PL-KD CPT-PRP-25PL-KD6PK CPT-PRP-25PL-KA3PK CPT-PRP-25PL-KA6PK

Black CPT-BLK-25PL-KD CPT-BLK-25PL-KD6PK CPT-BLK-25PL-KA3PK CPT-BLK-25PL-KA6PK

Keyed Different

1/Pack

SafeKey Compact Nylon Padlock Kits

Ideal for those needing just one lock and one tag. Kit includes:

• 1 - SafeKey Compact Nylon Padlock

• 1 - Heavy-duty Polyester Tag

• 1 - Nylon Cable Tie

Color Catalog # Description

Red 150938 SafeKey Compact Nylon Padlock Kit

Keyed Different

6/Pack

Keyed Alike

3/Pack

Keyed Alike

6/Pack

SafeKey Aluminum Lockout Padlocks

• Ideal for indoor and outdoor use and heavy-duty applications

• Aluminum padlock with steel shackle provides corrosion resistance

• Each padlock includes one key and lock labels in English, Spanish and French; additional keys can be ordered if needed

• Body: 1.8 in. H x 1.5 in. W x 0.75 in. D; shackle diameter: 0.25 in.

SafeKey Aluminum Lockout Padlocks with 1.5 in. (38 mm) steel shackle

Color

Red ALU-RED-38ST-KD ALU-RED-38ST-KD6PK ALU-RED-38ST-KA3PK ALU-RED-38ST-KA6PK

Green ALU-GRN-38ST-KD ALU-GRN-38ST-KD6PK ALU-GRN-38ST-KA3PK ALU-GRN-38ST-KA6PK

Orange ALU-ORG-38ST-KD ALU-ORG-38ST-KD6PK ALU-ORG-38ST-KA3PK ALU-ORG-38ST-KA6PK

Blue ALU-BLU-38ST-KD ALU-BLU-38ST-KD6PK ALU-BLU-38ST-KA3PK ALU-BLU-38ST-KA6PK

Yellow ALU-YLW-38ST-KD ALU-YLW-38ST-KD6PK ALU-YLW-38ST-KA3PK ALU-YLW-38ST-KA6PK

Brown ALU-BRN-38ST-KD ALU-BRN-38ST-KD6PK ALU-BRN-38ST-KA3PK ALU-BRN-38ST-KA6PK

Silver ALU-SLV-38ST-KD ALU-SLV-38ST-KD6PK ALU-SLV-38ST-KA3PK ALU-SLV-38ST-KA6PK

Purple ALU-PRP-38ST-KD ALU-PRP-38ST-KD6PK ALU-PRP-38ST-KA3PK ALU-PRP-38ST-KA6PK

Black ALU-BLK-38ST-KD ALU-BLK-38ST-KD6PK ALU-BLK-38ST-KA3PK ALU-BLK-38ST-KA6PK

Keyed Different

1/Pack

SafeKey Aluminum Lockout Padlocks with 3.0 in. (76 mm) steel shackle

Color

Red ALU-RED-76ST-KD ALU-RED-76ST-KD6PK ALU-RED-76ST-KA3PK ALU-RED-76ST-KA6PK

Green ALU-GRN-76ST-KD ALU-GRN-76ST-KD6PK ALU-GRN-76ST-KA3PK ALU-GRN-76ST-KA6PK

Orange ALU-ORG-76ST-KD ALU-ORG-76ST-KD6PK ALU-ORG-76ST-KA3PK ALU-ORG-76ST-KA6PK

Blue ALU-BLU-76ST-KD ALU-BLU-76ST-KD6PK ALU-BLU-76ST-KA3PK ALU-BLU-76ST-KA6PK

Yellow ALU-YLW-76ST-KD ALU-YLW-76ST-KD6PK ALU-YLW-76ST-KA3PK ALU-YLW-76ST-KA6PK

Brown ALU-BRN-76ST-KD ALU-BRN-76ST-KD6PK ALU-BRN-76ST-KA3PK ALU-BRN-76ST-KA6PK

Silver ALU-SLV-76ST-KD ALU-SLV-76ST-KD6PK ALU-SLV-76ST-KA3PK ALU-SLV-76ST-KA6PK

Purple ALU-PRP-76ST-KD ALU-PRP-76ST-KD6PK ALU-PRP-76ST-KA3PK ALU-PRP-76ST-KA6PK

Black ALU-BLK-76ST-KD ALU-BLK-76ST-KD6PK ALU-BLK-76ST-KA3PK ALU-BLK-76ST-KA6PK

Keyed Different

1/Pack

Keyed Different

6/Pack

Keyed Different

6/Pack

Keyed Alike

3/Pack

Keyed Alike

3/Pack

Keyed Alike

6/Pack

Keyed Alike

6/Pack

Lockout Tagout

191

191

Lockout Padlocks

Lockout Tagout

Actual size of

Brady’s

Compact Nylon

Lockout Padlock

Nylon Lockout Padlocks

• Complies with all OSHA

requirements and are a safer

alternative to metal locks

• Non-conductive body with unique

key cylinder prevents electricity

from traveling from the shackle to

the key, protecting workers when

key is inserted

• Superior temperature, chemical

and corrosion resistance

• Labels provided in English,

Spanish, French

• Key-retaining feature prevents

key from being removed until

shackle is securely closed

• Reserved paracentric keyway

provides optimal security

(prevents a copy from being

made at a local key shop)

• Locks come keyed differently or

keyed alike. Custom keying and

charting available

• Lock bodies can be custom laser

engraved upon request

• One key is supplied with

each padlock for safer key

management

Compact Nylon Lockout Padlocks

• Extremely compact and lightweight

• Easily fits in small spaces making it ideal for electrical

contractors, maintenance and electricians

• 5-pin cylinder can support same keying system as our

current Nylon Lockout Padlock

• Fiberglass reinforced nylon body for extra impact resistance

• Service temperature: 0° to 250° F (-20° to 120° C)

• Lock body dimensions: 1.4 in. x 1.2 in. x 0.625 in.

Shackle clearance: 1 in.; shackle diameter 0.2 in.

Nylon Lockout Padlocks

• Lightweight, non-conductive and non-sparking body

• Special 6-pin cylinder resists tampering

• Fiberglass reinforced nylon body and triple-coated

hardened steel shackle

• Service temperature: 0° to 250° F (-20° to 120° C)

• Lock body dimensions: 1.75 in. x 1.25 in. x 0.8 in.

• Shackle clearance: 1.25 in.; shackle diameter: 0.25 in.

• Each padlock includes 1 key and

1 each English, Spanish and French labels

• Each padlock includes 1 key and

1 each English, Spanish and French labels

Compact Nylon Lockout Padlocks with 1 in. steel shackle

Color

Red 143150 118926 118953 118954

Green 143152 118927 118955 118956

Orange 143154 118928 118957 118958

Blue 143156 118929 118959 118960

Yellow 143158 118930 118961 118962

Brown 143160 118931 118963 118964

White 143162 118932 118965 118966

Purple 143164 118933 118967 118968

Black 143166 118934 118969 118970

When keyed alike, all locks in a set can be opened with the same key. This option is beneficial when multiple locks are assigned to a single employee.

Keyed Different

1/Pack

Keyed Different

6/Pack

Keyed Alike

3/Pack

Keyed Alike

6/Pack

Nylon Lockout Padlocks with 1.25 in. steel shackle

Color

Red 99552 51339 105886 105890

Green 99564 51345 105889 105893

Orange 99576 51347 123268 123270

Blue 99556 51344 105887 105891

Yellow 99570 51346 105888 105892

Brown 103033 101956 118947 118948

White 143123 118925 118949 118950

Purple 104919 104916 118951 118952

Black 99580 51353 123269 123271

Keyed Different

1/Pack

Keyed Different

6/Pack

Keyed Alike

3/Pack

Keyed Alike

6/Pack

192

Lockout Padlocks

Compact Nylon Padlock Kits

Ideal for any worker needing

just one lock and one tag.

• 1 - Compact Padlock

• 1 - Heavy-duty Polyester Tag

• 1 - Nylon Cable Tie

Compact Cable Padlocks

• Compact 1.31 in. x 1.25 in.

nylon body with an elongated,

flexible cable as the shackle

• Flexible cable means you

can angle and twist padlock

or lockout multiple energy

isolation points with one lock

Color Description Catalog #

Red Compact Nylon Padlock Kit 123143

Compact Cable Padlocks

Color Cable Length

Red 7.87 in. cable 146120 146128

Red 15.75 in. cable 146124 146132

Yellow 7.87 in. cable 146121 146129

Yellow 15.75 in. cable 146125 146133

Blue 7.87 in. cable 146122 146130

Blue 15.75 in. cable 146126 146134

Green 7.87 in. cable 146123 146131

Green 15.75 in. cable 146127 146135

Keyed Different

1/Pack

Keyed Alike

6/Pack

Nylon Lockout Padlocks with

Non-Conductive Nylon Shackle

• Lightweight, non-conductive and non-sparking body

• Special 6-pin cylinder resists tampering

• Fiberglass reinforced nylon body with non-conductive

nylon shackle

• Lock body dimensions: 1.75 in. x 1.25 in. x 0.8 in.

• Shackle clearance: 1.25 in.; shackle diameter: 0.25 in.

• Each padlock includes 1 key and 1 each English,

Spanish and French labels

Long Body Nylon Lockout Padlocks

• 3 in. long body has ample space for your most important

identification information

• Lightweight, non-conductive and non-sparking body

• Special 6-pin cylinder resists tampering

• Fiberglass reinforced nylon body and triple-coated

hardened steel shackle

• Service temperature: 0° to 250° F (-20° to 120° C)

• Lock body dimensions: 3 in. x 1.25 in. x 0.8 in.

• Shackle clearance: 1.25 in.; shackle diameter: 0.25 in.

• Each padlock includes 1 key and 1 each

English/Spanish and English/French labels

Nylon Lockout Padlocks with 1.25 in. nylon shackle

Color

Red 123324 123351 123333 123342

Green 123326 123353 123335 123344

Orange 123328 123355 123337 123346

Blue 123325 123352 123334 123343

Yellow 123327 123354 123336 123345

Brown 123330 123357 123339 123348

White 123332 123359 123341 123350

Purple 123331 123358 123340 123349

Black 123329 123356 123338 123347

When keyed alike, all locks in a set can be opened with the same key. This option is beneficial when multiple locks are assigned to a single employee.

Keyed Different

1/Pack

Keyed Different

6/Pack

Keyed Alike

3/Pack

Keyed Alike

6/Pack

Long Body Nylon Lockout Padlocks with 1.25 in. steel shackle

Color

Red 123405 123396 123414 123423

Green 123407 123398 123416 123425

Orange 123409 123400 123418 123427

Blue 123406 123397 123415 123424

Yellow 123408 123399 123417 123426

Brown 123411 123402 123420 123429

White 123413 123404 123422 123431

Purple 123412 123403 123421 123430

Black 123410 123401 123419 123428

Keyed Different

1/Pack

Keyed Different

6/Pack

Keyed Alike

3/Pack

Keyed Alike

6/Pack

Lockout Tagout

193

193

Lockout Padlocks

Key-Retaining Laminated Steel Lockout Padlocks

• Key-retaining safety feature prevents key

from being removed until shackle is closed

• Reinforced laminated steel withstands severe

physical abuse while hardened steel shackle

resists tampering, cutting, prying and rusting

• Body plates individually coated for superior

rust protection

• 5-pin cylinder offers more unique key cuts,

better tamper resistance than conventional

4-pin locks

• Colored bumpers supplied for identification

(custom stamping available)

• Made from recycled material

• Each padlock includes 1 key. Custom keying

and charting also available. Lock labels sold

separately.

• Shackle clearance: 0.75 in., 2 in. or 3 in.

Shackle diameter: 0.27 in.

Lock body: 1.2 in. x 1.313 in. x 1 in.

Key-Retaining Steel Lockout

Padlocks with 0.75 in. shackle

Color

Red 143126 118935

Lockout Tagout

Green 143128 118936

Blue 143130 118937

Yellow 143132 118938

White 143134 118939

Black 143136 118940

Brown 123272 123280

Purple 123273 123281

Keyed

Different

1/Pack

Keyed

Different

6/Pack

Key-Retaining Steel Lockout Padlocks

with 2 in. shackle

Color

Red 143144 118944 118977 118978

Green 143142 118943 118975 118976

Blue 143140 118942 118973 118974

Yellow 143148 118946 118981 118982

White 143146 118945 118979 118980

Black 143138 118941 118971 118972

Brown 123274 123282 123276 123278

Purple 123275 123283 123277 123279

When keyed alike, all locks in a set can be opened with the same key. This option is beneficial when

multiple locks are assigned to a single employee.

Keyed

Different

1/Pack

Keyed

Different

6/Pack

Keyed

Alike

3/Pack

Keyed

Alike

6/Pack

Key-Retaining Steel Lockout Padlocks

with 3 in. shackle

Color

Red 123244 123236 123252 123260

Green 123245 123237 123253 123261

Blue 123246 123238 123254 123262

Yellow 123247 123239 123255 123263

White 123248 123240 123256 123264

Black 123249 123241 123257 123265

Brown 123250 123242 123258 123266

Purple 123251 123243 123259 123267

Keyed

Different

1/Pack

Keyed

Different

6/Pack

Keyed

Alike

3/Pack

Laminated Steel Lockout Padlocks

• Reinforced laminated steel withstands

severe physical abuse while hardened

steel shackle resists tampering

• Body plates individually coated for

superior rust protection

• 5-pin cylinder offers more unique key cuts,

better tamper resistance than conventional

4-pin locks

• Colored bumpers supplied for identification

• Each padlock includes 1 key. Custom

keying and charting also available. Lock

labels sold separately

• Shackle clearance: 0.75 in. or 2 in.

Shackle diameter: 0.27 in.

Lock body: 1.33 in. x 1.188 in. x 0.875 in.

Keyed

Alike

6/Pack

194

Steel Lockout Padlocks with 0.75 in. shackle

Color

Red 99500 51279

Blue 99504 51280

Green 99508 51281

Yellow 99512 51282

Orange 99516 51283

Black 99520 51284

Brown 101957 102696

Purple 104920 104917

Keyed Different

1/Pack

Keyed Different

6/Pack

Steel Lockout Padlocks with 2 in. shackle

Color

Red 99524 51290 105894 105898

Blue 99528 51291 105895 105899

Green 99533 51292 105897 105901

Yellow 99539 51297 105896 105900

Orange 99543 51298 - -

Black 99548 51299 - -

Brown 101958 102698 - -

Purple 104921 104918 - -

When keyed alike, all locks in a set can be opened with the same key. This

option is beneficial when multiple locks are assigned to a single employee.

Keyed Different

1/Pack

Keyed Different

6/Pack

Keyed Alike

3/Pack

Keyed Alike

6/Pack

Aluminum Lockout Padlocks

• Lightest-weight aluminum lock in the

market and made from recycled material

• Aluminum shackle has superior spark

and corrosion resistance

• Reserved paracentric keyway provides

optimal security (prevents someone from

getting a copy made at a local key shop)

• Anodized aluminum finish gives better

fade resistance when used outdoors

• FDA approved lubricant in cylinder

Lockout Padlocks

• Shackle clearance: 1 in., 1.25 in. or 3 in.

Shackle diameter: 0.25 in.

• Compact body: 1.25 in. x 1.25 in.

Regular body: 1.6 in. x 1.25 in. x 0.75 in.

• Compact body has a 5-pin cylinder.

Regular body has 6-pin cylinder for

more unique key changes and tamper

resistance

• Each padlock includes 2 keys.

Custom keying and charting also

available. Lock labels sold separately

May we also

suggest:

Custom Keying

Solutions

At Brady, we can help

you with your custom

keying program. Just call

Brady customer service

to get started!

Combination Lock

Compact lock with a

steel shackle and a

4-digit re-settable code

Catalog # Description

101963 Combination Lock

Compact Aluminum with 1 in. shackle

Color

Red 133270 133261 133279 133288

Blue 133271 133262 133280 133289

Green 133272 133263 133281 133290

Yellow 133273 133264 133282 133291

Orange 133274 133265 133283 133292

Black 133275 133266 133284 133293

Brown 133276 133267 133285 133294

Purple 133277 133268 133286 133295

Silver 133278 133269 133287 133296

When keyed alike, all locks in a set can be opened

with the same key. This option is beneficial when

multiple locks are assigned to a single employee.

Keyed

Different

1/Pack

Keyed

Different

6/Pack

Keyed

Alike

3/Pack

Keyed

Alike

6/Pack

Aluminum Padlocks with 1.25 in. shackle

Color

Red 99615 51370 105902 105882

Blue 99616 51371 105903 105883

Green 99617 51376 105881 105885

Yellow 99618 51377 105904 105884

Orange 99619 51378 123432 123437

Black 99620 50274 123433 123438

Brown 104578 104579 123434 123439

Purple 104576 104577 123435 123440

Silver 123321 123323 123436 123441

When keyed alike, all locks in a set can be opened with the same key. This option is beneficial when

multiple locks are assigned to a single employee.

Keyed

Different

1/Pack

Keyed

Different

6/Pack

Keyed

Alike

3/Pack

Keyed

Alike

6/Pack

Aluminum Padlocks with 1 in. shackle

Color

Red 99608 51360

Blue 99609 51361

Green 99610 51362

Yellow 99611 51363

Orange 99612 51368

Black 99613 51369

Brown 104574 104575

Purple 104572 104573

Silver 123320 123322

Keyed

Different

1/Pack

Keyed

Different

6/Pack

Aluminum Padlocks with 3 in. shackle

Keyed

Color

Different

1/Pack

Red 123293 123284 123302 123311

Blue 123294 123285 123303 123312

Green 123295 123286 123304 123313

Yellow 123296 123287 123305 123314

Orange 123297 123288 123306 123315

Black 123298 123289 123307 123316

Brown 123299 123290 123308 123317

Purple 123300 123291 123309 123318

Silver 123301 123292 123310 123319

Keyed

Different

6/Pack

Keyed

Alike

3/Pack

Lockout Tagout

Keyed

Alike

6/Pack

195

195

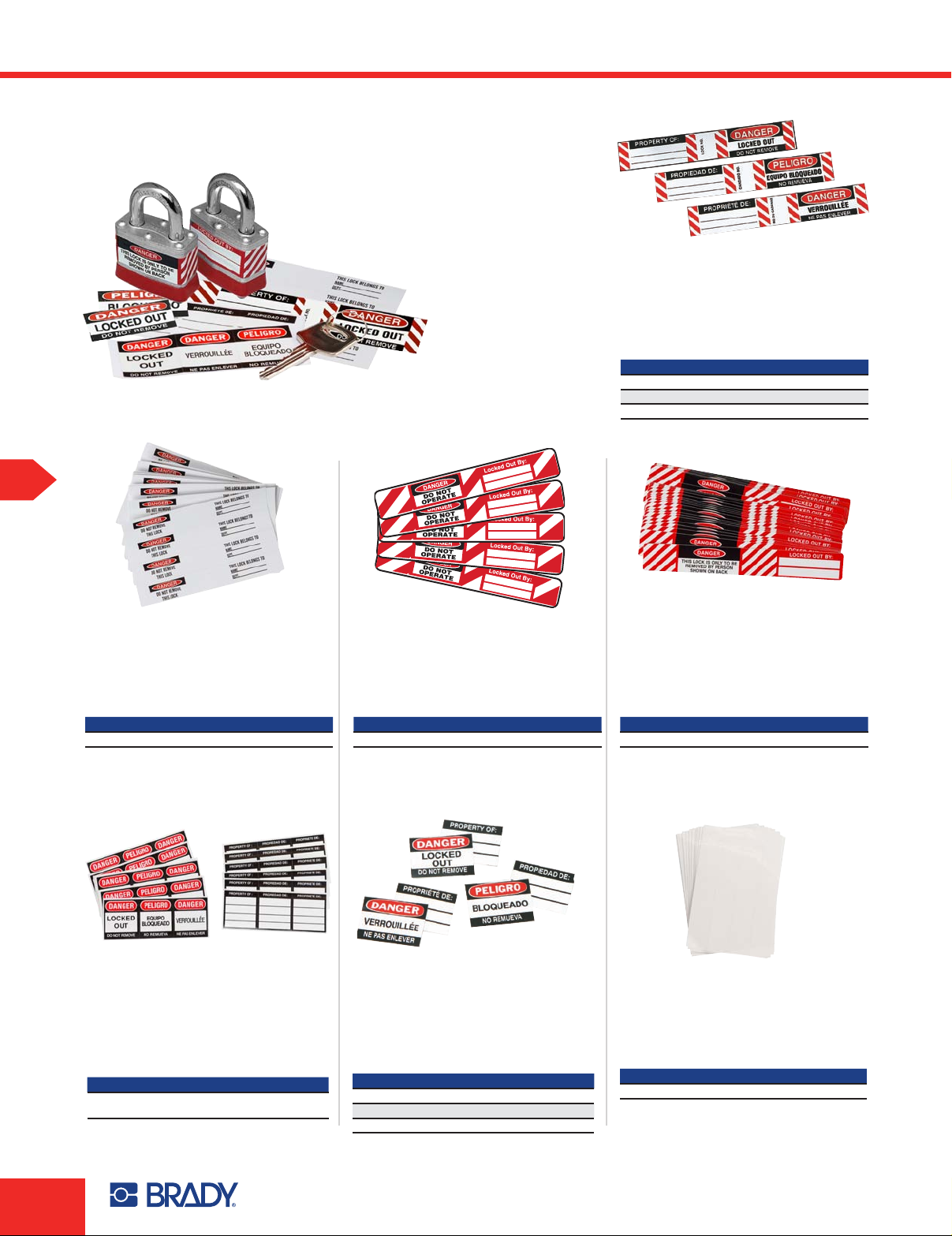

Padlock Labels

Padlock Labels

Padlock labels are a great way to quickly

identify padlocks. They help send a clear

message to workers when a machine is

down for service or maintenance.

Labels for Steel Padlocks

• Durable vinyl labels include

overlaminate strips

• Labels accept pencil, pen or marker

• Designed to fit Steel Padlocks

Catalog # Description Size Qty.

50280 English 0.75 in. x 4.5 in. 6

50281 Spanish 0.75 in. x 4.5 in. 6

50283 French 0.75 in. x 4.5 in. 6

Lockout Tagout

Labels for Steel Padlocks

• Durable vinyl labels accept

pencil, pen or marker

• Designed to fit Steel Padlocks

Catalog # Size Qty.

121448 0.75 in. x 5 in. 40

Self-Laminating Labels for

Steel Padlocks

• Durable vinyl labels accept

pencil, pen or marker

• Designed to fit Steel Padlocks

Catalog # Size Qty.

121449 0.625 in. x 4 in. 5

Wrap-Around Lockout

Labels for Steel Padlocks

• Labels accept pencil, pen or marker

• Designed to fit Steel Padlocks

Catalog # Size Qty.

LID-3 0.75 in. x 4.5 in. 25

196

Labels for Nylon Padlocks

• Durable vinyl labels accept

pencil, pen or marker

• Designed to fit Nylon Lockout Padlocks

• Labels supplied with multiple languages

Catalog # Description Qty.

51379 English/Spanish/French

6 of each

language

Labels for Aluminum Locks

• Durable vinyl labels accept

pencil, pen or marker

• Designed to fit Aluminum Lockout

Padlocks

Catalog # Description Size Qty.

50289 English 0.8 in. x 1.1 in. 6

50292 Spanish 0.8 in. x 1.1 in. 6

50293 French 0.8 in. x 1.1 in. 6

Lock Label Overlaminate

• Clear overlaminate protects existing

lock label from dirt and grease

• Lock label sold separately

Catalog # Description Qty.

65508 1 in. x 6 in. overlaminate 40

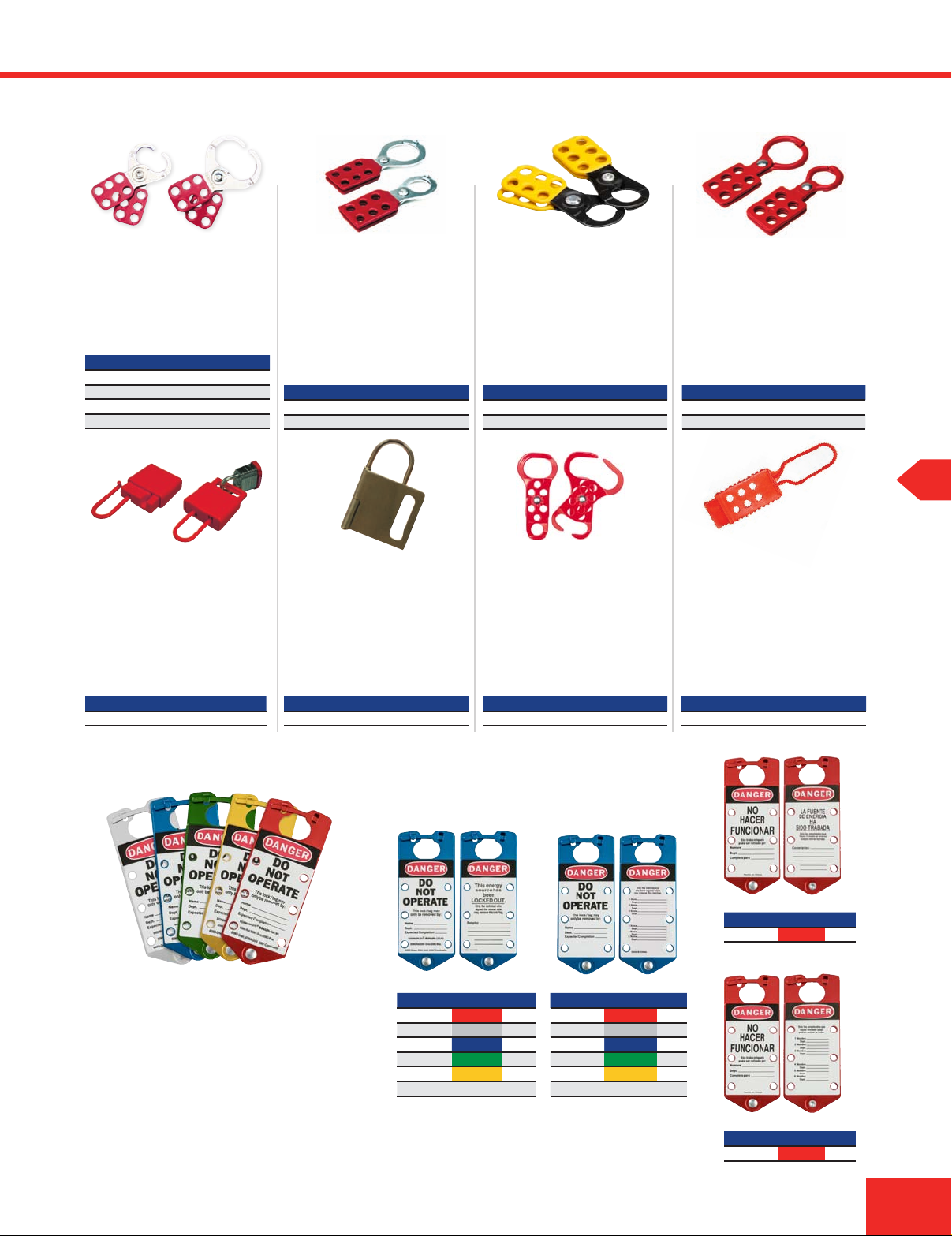

Hasps

Steel Group

Lockout Hasps

• Constructed of vinyl-coated

high tensile steel w/ rust

resistant plating

• Lock holes: 0.375 in. dia.

Catalog # Description Qty.

133161 1 in. diameter jaws 1

65375 1 in. diameter jaws 12

133162 1.5 in. diameter jaws 1

65376 1.5 in. diameter jaws 12

Non-Conductive

Group Lockout

Hasps

• Strong, rigid plastic resin

• Excellent electrical

insulating

• Performs at low temps,

excellent heat resistance

Catalog # Description Qty.

LH220A-RD Lockout hasp 1

Steel Group Lockout

Hasps with Tabs

• Tamperproof interlocking

tabs prevent unauthorized

opening

• Case-hardened steel with

rust proof plating

• Lock holes: 0.375 in. dia.

Catalog # Description Qty.

105718 1 in. diameter jaws 1

105719 1.5 in. diameter jaws 1

Heavy-Duty

Lockout Hasp

• Hasp allows multiple

workers to lockout at each

isolation point

• Stainless steel construction

• Accommodates 0.33 in. dia.

padlock shackles

Catalog # Description Qty.

871239 Heavy-Duty Hasp 24

Corrosion-Resistant

Group Lockout

Hasps

• 12 gauge epoxy coated

steel provides superior

rust resistance and added

dielectric strength

• Lock holes: 0.313 in. dia.

Catalog # Description Qty.

T218 1 in. diameter jaws 1

T220 1.25 in. diameter 1

Dual Jaw Hasp

• Dual construction allows

for increased versatility in a

single product

• Larger jaw measures

1.25 in. x 1.75 in.

• Smaller jaw measures

0.75 in. dia.

Catalog # Description Qty.

236919 Dual Jaw Hasp 1

Aluminum

Economy Group

Lockout Hasps

• Non-sparking, aluminum

small hasps are a great

addition to your tool box

• Lightweight: Only 1.25 oz

• Lock holes: 0.375 in.

diameter

Catalog # Description Qty.

105720 1 in. diameter jaws 1

105721 1.5 in. diameter jaws 1

Non-Conductive

Nylon Group

Lockout Hasp

• Accommodate up to 6 locks

• Withstands up to 1,000 lbs

despite weighing only 1 oz.

• Dimensions: 7 in. x 1.75 in.

Lock holes: 0.375 in. dia.

Catalog # Description Qty.

99668 Nylon Lockout Hasp 1

Labeled Group Lockout Hasps

• Tough 5052 anodized aluminum alloy

hasps include tamperproof locking tabs

• Write-on label accepts pencil, pen or

marker. Pen and pencil markings are

easily erased for repeated use

• Size: 7 in. x 3 in. x 0.187 in.

Lock holes: 0.313 in. dia.

Legend option 1

Catalog # Color Qty.

65960 Red 5

65961 Silver 5

65962 Blue 5

65963 Green 5

65964 Gold 5

65967 Combo* 5

*Combo includes 1 each of the five colors listed above.

Legend option 2

Catalog # Color Qty.

65970 Red 5

65971 Silver 5

65972 Blue 5

65973 Green 5

65974 Gold 5

65975 Combo* 5

Legend option 3

Catalog # Color Qty.

39480 Red 5

Legend option 4

Catalog # Color Qty.

39481 Red 5

Lockout Tagout

197

197

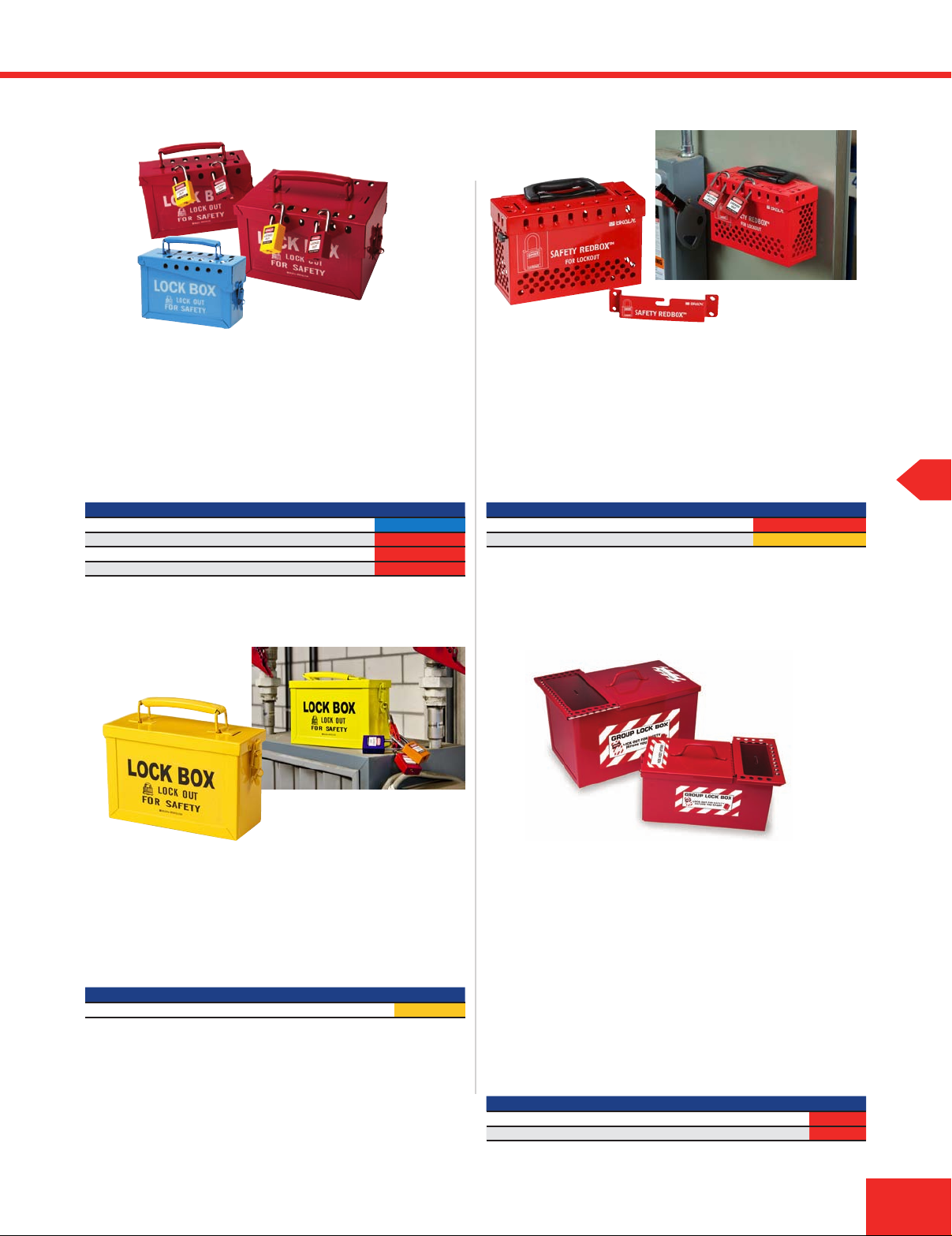

Group Lock Boxes

Group Lock Boxes

For group lockout situations involving a large number of workers and

equipment, lock boxes can offer a number of advantages including fewer

padlocks and hasps needed.

How group lockout boxes work:

• Supervisor uses a single job lock on each energy control point to lock out

equipment. Keys for that lock are placed in the lock box

• Each worker applies his own lock to the lock box. As long as any one

worker’s lock remains on the lockout box, the keys to the job locks cannot

be accessed, and the energy isolating devices cannot be operated. Each

employee retains exclusive control, as required by OSHA.

Lockout Tagout

new

SlimView™ Group Lock Box

• Innovative narrow design and recessed door allow

padlocks to hang straight, reducing the overall footprint

by 60% compared to traditional lock boxes

• Steel body and clear polycarbonate door to see contents

• Built-in padlock and key hangers

• Storage for up to 12 padlocks

• Wall mountable

• Size: 10.125 in. x 4.0 in.

Catalog # Description

150505 SlimView Lock Box

Padlocks sold separately.

Ultra-Compact Lock Box

• Compact size for portability in your lockout kit or toolbox

• Simple storage with wall-mount bracket when not in use

• Hinged transparent cover for easy viewing of contents

• Can accommodate up to 12 locks

• Size: 5.25 in. x 3.25 in. x 2.25 in.

Catalog # Description

149173 Box without locks

149172 Box with 6 Yellow Keyed-Alike Locks

149176 Box with 6 Yellow Keyed-Different Locks

149174 Box with 6 Red Keyed-Alike Locks

149175 Box with 6 Red Keyed-Different Locks

198

Group Lock Boxes

Portable Metal Group Lockout Boxes

• Made of heavy-duty steel, powder-coated

for extra rust resistance

• Features lockable clasp and 12 holes along lid

• Standard: 6 in. x 9 in. x 3.25 in.

Compartment holds up to 40 padlocks

• Extra large: 6 in. x 7.375 in. x 9.25 in.

Compartment holds up to 75 padlocks

Catalog #

45190 Standard-English 6 in. x 9 in. x 3.25 in. Blue

65699 Standard-English 6 in. x 9 in. x 3.25 in. Red

65040 Standard-Spanish 6 in. x 9 in. x 3.25 in. Red

51171 XLarge-English 6 in. x 7.375 in. x 9.25 in. Red

Padlocks sold separately.

Description Size Color

SAFETY REDBOX™ Group Lockout Box

• Use as a portable or a wall-mounted lockbox

• Quick release internal slide button allows lockbox to be

carried to the point of need

• Can accommodate up to 12 padlocks

• Size: 6 in. x 9 in. x 3.25 in.

Catalog # Description Color

145579 Mountable Lockbox Red

145580 Mountable Lockbox Yellow

Padlocks sold separately.

Lockout Tagout

Portable Metal Group Lockout Boxes

• Made of heavy-duty steel, powder-coated

for extra rust resistance

• Standard: 6 in. x 9 in. x 3.25 in.

• Compartment holds up to 40 padlocks

Lockable clasp only

Catalog #

65672 Standard-English 6 in. x 9 in. x 3.25 in. Yellow

Padlocks sold separately.

Description Size Color

Lock Storage / Group Lockout Box

• Heavy-duty steel, powder-coated for extra rust resistance

• Features a lockable storage compartment and a group

lockout compartment

• Lockout compartment has clear window with keyhole slot

• Standard Box:12.25 in. x 7.25 in. x 6 in.

Compartment: 8.25 in. x 6 in. x 6 in.

Compartment holds approx. 50 locks.

17 lock holes along box lid

• Large box: 15 in. x 10.25 in. x 9 in.

Compartment: 10.25 in. x 9 in. x 9 in.

Compartment holds approx. 125 locks

34 lock holes along box lid

Catalog # Description Size Color

105716 Standard 12.25 in. x 7.25 in. x 6 in. Red

105717 Large 15 in. x 10.25 in. x 9 in. Red

Padlocks sold separately.

199

199

Group Lockout Boxes

Metal Wall-Mounted Group

Lockout Boxes

• Made of durable, powder-coated steel

with key slot on top

• Clear window slides out when locks

are removed

• Comes with key pegs and ID labels

• Wall-mounting holes and hardware

• Small lock box: 7 in. x 8 in. x 2.25 in.

7 key pegs that hold 5 keys each,

7 lock holes along bottom

• Large lock box: 7 in. x 16 in. x 2.25 in.

Lockout Tagout

15 key pegs that hold 5 keys each,

12 lock holes along bottom

Catalog # Description

105714 Small Metal Lock Box

105715 Large Metal Lock Box

Padlocks sold separately.

Acrylic Wall-Mounted

Group Lockout Boxes

• Made of acrylic plastic with

transparent front cover

• Includes pre-drilled holes for easy

wall mounting

• Pre-attached plastic hooks for

hanging keys, tag stubs, etc.

• Small: 3 key hooks, max 6 locks

• Medium: 8 key hooks, max 10 locks

• Large: 18 key hooks, max 14 locks

Catalog # Description Size

LG003E Small 6 in. x 6 in. x 2.5 in.

LG008E Medium 7.5 in. x 12 in. x 2.5 in.

GLOBOX Large 7.5 in. x 15.75 in. x 2.5 in.

Padlocks sold separately.

Wall-Mounted Group

Lockout Box

• Injection molded for extra durability

• Excellent chemical and heat resistance

• Slot in front allows keys to be inserted

when locked

• Includes pre-drilled holes for easy

wall mounting

• 6 interior hooks for hanging keys/locks

• Lock rails hold up to 8 padlocks

• Dimensions: 6.2 in. x 4 in. x 5.25 in.

Catalog # Description

50938 Miniature Wall Lock Box

50939

Padlocks sold separately.

Extra Key Hooks (12/Pkg)

200

Portable / Wall-Mounted

Plastic Group Lockout Box

• Durable plastic lockbox with

transparent windows

• Excellent chemical and heat resistance

• Slot in front allows for keys to be

inserted when box is locked

• Pre-drilled holes for wall mounting

• 12 interior hooks for keys or locks

• Lock rails hold up to 16 padlocks

• Size: 7.25 in. x 8.25 in. x 4.25 in.

Catalog # Description

50937 Portable Plastic Lock Box

50939 Extra Key Hooks (12/pkg)

Padlocks sold separately.

Portable / Wall-Mounted

Group Lockout Box

• Powder-coated steel lock box includes

a removable handle for portability as

well as holes for wall mounting

• Accommodates 8-10 locks

• Dimensions: 6 in. x 15 in. x 3 in.

Catalog # Description

LG252M Metal Wall Lock Box

Padlocks sold separately.

SHOCK-STOP™

Group Lockout Box

• Combines lock box with storage board

for hasps

• Lock box accommodates up to 6 locks

and provides rail for storing locks

• Includes two SHOCK-STOP™ hasps,

mounting hardware and instructions

• Size: 16.25 in. x 10.25 in. x 2.25 in.

Catalog # Description

87692 Group Lock Box (w/2 hasps)

87693 Hasp (5/pkg)

Padlocks sold separately.

Padlock Storage

Padlock and Tag Carrier

• Convenient transportation and storage

of 12 locks, keys, tags and hasps all in one place

• Reduces the amount of lost or misplaced padlocks and hasps

• Offset design for flush wall mounting, equipment mounting

or hanging on a belt clip

• Available with or without padlocks

• Carrier Components

• 1 - Lock and Tag Carrier

• 2 - Small Carabineers

• 1 - Large Carabineer

• 1 - Coiled Key Strap

Catalog # Color Includes

148866 Padlock and Tag Carrier Red Carrier 148865 Padlock and Tag Carrier Yellow Carrier 148862 Padlock and Tag Carrier Blue Carrier 148861 Padlock and Tag Carrier Green Carrier -

148864 Padlock and Tag Carrier Kit Red Carrier

148869 Padlock and Tag Carrier Kit Red Carrier

148867 Padlock and Tag Carrier Kit Red Carrier

148863 10 Write-On Lockout Procedure Tags

• 3 - Labels in English / French / Spanish

• 3 - Write-on Lockout Procedure Tags

• Optional: nylon padlocks and hasps

6 Red Keyed Alike

6 Yellow Keyed Alike

2 Hasps

3 Red Keyed Alike

3 Yellow Keyed Alike

3 Blue Keyed Alike

3 Green Keyed Alike

2 Hasps

12 Red Keyed Different

2 Hasps

Padlock Stations

• Constructed of 14 gauge steel with

red plastic coating

• Small: 2.25 in. x 3 in. x 1.25 in.,

holds up to 4 padlocks

• Large: 3 in. x 16 in. x 1.25 in.,

holds up to 24 padlocks

Catalog # Description

LR060E Small Padlock Station

LR360E Large Padlock Station

Padlocks sold separately.

Enclosed Padlock Storage

Modules

• Constructed of sintra with lockable,

transparent acrylic doors

• Provides safe storage and controls

access to padlocks

• Small: 15 in. x 15 in. x 3.5 in.,

holds 16 locks

• Large: 30 in. x 15 in. x 3.5 in.,

holds 40 locks

Catalog # Description

65240 Small Padlock Storage Module

65241 Large Padlock Storage Module

Padlocks sold separately.

Steel Lockout Padlock

Control Centers

• Constructed of red powder-coated

22 gauge steel

• Each metal hook can hold 2 locks

• Two keys supplied for cabinet lock

• Small: 10 in. x 12 in. x 2 in.

holds 16 locks

• Large: 15.5 in. x 18 in. x 2 in.

holds 32 locks

Catalog # Description

LR008E Small Padlock Control Center

LR018E Large Padlock Control Center

Padlocks sold separately.

Lockout Tagout

201

201

Lockout Tags

Standard Lockout Tags

Lockout Tagout

Communicate safety and lockout information at the point

of need with the wide selection of OSHA-compliant lockout

tagout tags from Brady. Tags come in a variety of materials

and legends to suit your application needs.

OSHA Lockout Tagout Regulations

The following requirements apply only to tags used as tagout devices (i.e., tags used alone without locks).

Tags used in combination with locks are not required to meet the same restrictions as tagout devices.

Tagout devices must:

• Be provided by the employer

• Be standardized by size, shape or color

• Be distinguishable from tags used for other purposes

• Be understandable to all employees

• Identify the individual who applied the tag

• Withstand the usage environment to which they are

exposed for the maximum period of time that exposure

is intended. Tag should not deteriorate or the message

become illegible when exposed to weather, wet or

damp conditions, chemical or corrosive environments

• Employ a means of attachment that is substantial

enough to prevent accidental removal. The means of

attachment must be of a non-reusable type, attachable

by hand, self-locking and non-releasable with a

minimum unlocking strength of no less than 50 pounds

• Warn against hazardous conditions if the machine or

equipment is energized

• Tag shall also include a legend such as the following:

Do Not Operate, Do Not Start, Do Not Open, Do Not

Close, etc.

How to order tags

1. Select from the materials below based on your application

2. Choose the tag legend for your tag

3. Order by part number for desired reverse side legend

Materials Options:

Heavy-Duty Polyester (B-837)

• Durable polyester laminate completely

encapsulates and protects graphics

• Designed to withstand moisture, grease,

chemicals and extreme temperatures

• Accepts pencil, pen and marker. Pen and

marker can be completely erased using

isopropyl alcohol

• Exceeds OSHA pull requirement

withstanding up to 80 lbs. of pull force

• Tag size 5.75 in. x 3 in.

• 0.375 in. dia. heavy-duty brass grommet

• Includes OSHA-compliant nylon fasteners

• 2-year outdoor fade resistance

Economy Polyester (B-851)

• Rigid polyester surface is easy to

write on and stays legible longer than

cardstock

• Exceeds OSHA 50 lb. pull requirement

for tagout devices

• Tag size 5.75 in. x 3 in.

• 0.375 in. dia. rolled brass eyelet

accepts most padlock shackles

• Includes OSHA-compliant nylon

fasteners

• Provides good outdoor UV resistance

• 3- to 5-year outdoor fade resistance

Cardstock (B-853)

• Cost-effective tags designed for

one-time use

• Does NOT meet OSHA 50 lb. pull test

for tagout devices, but can be used in

conjunction with locks (see OSHA tag

requirements above)

• Tag size 5.75 in. x 3 in.

• 0.375 in. dia. rolled brass eyelet

accepts most padlock shackles

• Includes attachment strings

202

Lockout Tags

Catalog #

Heavy-Duty Polyester

65502 Side B 25

65535 Side F 25

65670 Side G 25

Economy Polyester

66050 Side B 25

66051 Side F 25

66052 Side G 25

Cardstock

65407 Side B 25

65408 Side F 25

65440 Side G 25

Catalog #

Heavy-Duty Polyester

65503 Side B 25

65521 Side F 25

133545 Side G 25

Economy Polyester

66053 Side B 25

66054 Side F 25

133546 Side G 25

Cardstock

65441 Side B 25

65442 Side F 25

133547 Side G 25

Reverse

Legend

Reverse

Legend

Catalog #

Qty.

Heavy-Duty Polyester

65520 Side B 25

65525 Side F 25

65671 Side G 25

Economy Polyester

66063 Side B 25

66064 Side F 25

66065 Side G 25

Cardstock

65451 Side B 25

65452 Side F 25

65453 Side G 25

Catalog #

Qty.

Heavy-Duty Polyester

65504 Side B 25

65522 Side F 25

133548 Side G 25

Economy Polyester

66055 Side B 25

66056 Side F 25

133549 Side G 25

Cardstock

65443 Side B 25

65444 Side F 25

133550 Side G 25

Reverse

Legend

Reverse

Legend

Catalog #

Qty.

Heavy-Duty Polyester

65515 Side B 25

65524 Side F 25

133489 Side G 25

Economy Polyester

66061 Side B 25

66062 Side F 25

133490 Side G 25

Cardstock

133491 Side B 25

65450 Side F 25

133492 Side G 25

Catalog #

Qty.

Heavy-Duty Polyester

133551 Side B 25

133552 Side F 25

133553 Side G 25

Economy Polyester

50198 Side B 25

50199 Side F 25

133554 Side G 25

Cardstock

133555 Side B 25

50250 Side F 25

133556 Side G 25

Reverse

Legend

Reverse

Legend

Catalog #

Qty.

Heavy-Duty Polyester

65526 Side B 25

65527 Side F 25

133493 Side G 25

Economy Polyester

66066 Side B 25

66067 Side F 25

133494 Side G 25

Cardstock

65454 Side B 25

65455 Side F 25

133495 Side G 25

Catalog #

Qty.

Heavy-Duty Polyester

65506 Side B 25

65534 Side F 25

133557 Side G 25

Economy Polyester

133558 Side B 25

66060 Side F 25

133559 Side G 25

Cardstock

65447 Side B 25

65448 Side F 25

133560 Side G 25

Reverse

Legend

Reverse

Legend

Qty.

Catalog #

Heavy-Duty Polyester

65505 Side B 25

65523 Side F 25

133496 Side G 25

Economy Polyester

133497 Side B 25

133498 Side F 25

133499 Side G 25

Cardstock

65445 Side B 25

65446 Side F 25

133544 Side G 25

Catalog #

Qty.

Heavy-Duty Polyester

133561 Side B 25

50258 Side F 25

133562 Side G 25

Economy Polyester

133563 Side B 25

133564 Side F 25

133565 Side G 25

Cardstock

50261 Side B 25

133566 Side F 25

133567 Side G 25

Reverse

Legend

Reverse

Legend

Qty.

Qty.

Lockout Tagout

Can’t nd what you’re

looking for?

Call your Brady

Representative to nd

out more about custom

solutions.

Reverse Legend Options

Reverse Side B Reverse Side F Reverse Side G

203

203

Lockout Tags

new

Lockout Tagout

RipTag™ Safety Tag Rolls

• Complete and convenient take-it-with-you system for tagging

• Includes a bulk roll of tags that easily tear off and cable ties for quick attachment

• B-851 polyester tags comply with OSHA’s 50 lb. pull force regulation for lockout tagout

Easy access

cable tie

compartment

150502

150501

5.75 in x 3 in 250/roll

5.75 in x 3 in 100/roll

150504

150503

5.75 in x 3 in 250/roll

5.75 in x 3 in 100/roll

ToughWash® Metal-Detectable Tags

• ToughWash B-869 polypropylene tags feature in-molded, protected graphics for use in

harsh washdown environments

• With metal and X-ray detectable properties, these tags won’t compromise your food safety

• Durable plastic-encapsulated material withstands harsh washdown environments with

temperatures up to 175° F (80° C) and pressure up to 1500 PSI

• Includes 10 metal-detectable cable ties

145766

5 in. x 3 in. 10 pk

98219

5.75 in. x 3 in. B-837 25/pk

Extra Metal Detectable Ties

145767

5 in. x 3 in. 10 pk

145768

5 in. x 3 in. 10 pk

145769

5 in. x 3 in. 10 pk

145588

145589

7" ToughWash Ties 10 pk

7" ToughWash Ties 100 pk

Spanish Lockout Tags

• B-837 Heavy-Duty Laminated Polyester Tags meet OSHA’s 50 Ib. pull force requirement and have

superior chemical resistance and 2 year outdoor fade resistance. Nylon ties included.

• B-851 Economy Polyester Tags meet OSHA’s 50 lb. pull force requirement, have moderate

chemical resistance and 3-5 year outdoor fade resistance. Nylon ties included.

• B-853 Cardstock Tags are a economical, yet durable material option. Attachment strings included.

121514

5.75 in. x 3 in. B-851 25/pk

Includes self-laminate flap to

protect face of tag and photo.

121515 5.75 in. x 3 in. B-837 25/pk

121516 5.75 in. x 3 in. B-851 25/pk

121517 5.75 in. x 3 in. B-853 25/pk

121518 5.75 in. x 3 in. B-837 25/pk

121519 5.75 in. x 3 in. B-851 25/pk

121520 5.75 in. x 3 in. B-853 25/pk

204

Lockout Tags

Mini Safety Lockout Tags

• Heavy-duty plastic tag includes metal grommet

for added durability

• Small size makes them ideal for use within

electrical panels

• Fasteners sold separately

Catalog # Description Size Qty.

148824 Mini Tag 2.5 in. x 2 in. 25

81762 Nylon Fasteners 7 in. 100

Detachable Key Stub Tags

• Perforated heavy cardstock tag with detachable key stub

• Matching identification numbers printed on each part

• Includes tie strings and rings for attaching stubs to keys

Front

Back

Self-Laminating Photo Tags

• Include employee photos for easy

identification and greater impact

• Constructed of durable B-851 polyester

• Available with or without 1 mil polyester overlay on front

• Includes nylon fasteners

Catalog # Description Size Qty.

65500 Unlaminated Photo Tag 5.75 in. x 3 in. 25

65501 Photo Tag w/ Laminate 5.75 in. x 3 in. 10

96222 Photo Tag w/ Laminate 7 in. x 4 in. 10

Padlock Tags

• 0.375 in. metal grommet that fits over most lock shackles

• Dimensions: 3 in. x 2 in. (grommet adds 1 in. to height)

Lockout Tagout

Catalog # Legend Size Qty.

WKT2 Equipment Locked Out 5.75 in. x 3 in. 25

WKT3 Do Not Operate 5.75 in. x 3 in. 25

Two-Part Perforated Tags

• Remove stub when tag is installed. Only the employee in possession

of the stub has the authority to remove. After job is completed, return

stub to management for verification and monitoring of tagout activity

• Matching identification numbers printed on each part of tag

Catalog # Legend B-# Size Qty.

PLLT2

CLT2

PLLT4

CLT4

Locked Out B-851 polyester 7.5 in. x 4 in. 25

Locked Out B-853 cardstock 7.5 in. x 4 in. 25

Do Not Operate B-851 polyester 7.5 in. x 4 in. 25

Do Not Operate B-853 cardstock 7.5 in. x 4 in. 25

Catalog # Legend Size Qty.

105722 Equipment Locked Out 3 in. x 2 in. plus grommet 1

105723 Do Not Operate 3 in. x 2 in. plus grommet 1

105724 Do Not Operate English/Spanish 3 in. x 2 in. plus grommet 1

Front

Back

Front

Back

205

205

Energy Source Tags

Energy Source Tags

Energy source tags can be used to mark your facility’s points of control for energy

sources. These tags help make the lockout process quicker, safer and easier.

These energy source tags are made of plastic and available with color coded