Brady IP Printer series, BP-IP300, BP-IP600, BP-IP300-C, BP-IP600-C Service Manual

...

Service Manual

Edition 12/07

2 Service Manual Edition 12/07

Brady IP Series Printer

Service manual for the following products

Copyright by Brady Worldwide, Inc.

All specifications about delivery, design, performance and weight are given to

the best of our current knowledge and are subject to change without prior

notice.

All rights reserved, including those of the translations.

No part of this manual nor any translation may be reproduced or transmitted

in any form or by any means, for any purpose other than the purchaser’s

personal use, without the express written permission of Brady.

PRODUCT

NUMBER

CATALOG

NUMBER

PRODUCT DESCRIPTION

103957 BP-IP300 BRADY IP PRINTER - 300DPI STANDARD

103958 BP-IP600 BRADY IP PRINTER - 600DPI STANDARD

103959 BP-IP300-C BRADY IP PRINTER - 300DPI W/CUTTER

103960 BP-IP600-C BRADY IP PRINTER - 600DPI W/CUTTER

103961 BP-IP300-P BRADY IP PRINTER - 300DPI PEEL/PRESENT

103962 BP-IP600-P BRADY IP PRINTER - 600DPI PEEL/PRESENT

103963 BPA-IP-C-FI BRADY IP PRINTER CUTTER FIELD INSTALL

103964 BPA-IP-P-FI BRADY IP PRINTER PEEL/PRESENT FIELD INSTALL

Edition 12/07 Service Manual 3

Brady IP Series Printer

Table of Contents

Table of Contents

1 Important Information .......................................................................................................4

1.1 General safety instructions..................................................................................................4

1.2 Protective devices ...............................................................................................................4

1.3 Handling electricity...............................................................................................................5

1.4 Procedure in case of accidents............................................................................................5

2 Replacing assembly units................................................................................................6

2.1 Device overview...................................................................................................................6

2.2 Tools....................................................................................................................................7

2.3 Replacing the control panel.................................................................................................8

2.4 Replacing the cover.............................................................................................................9

2.5 Replacing the outer casing................................................................................................10

2.6 Replacing the print mechanism .........................................................................................12

2.7 Replacing the printhead.....................................................................................................13

2.8 Replacing the print roller....................................................................................................14

2.9 Replacing the brake of the ribbon supply hub ...................................................................15

2.10 Replacing the drive of the cutting unit................................................................................16

2.11 Replacing the blades of the cutting unit.............................................................................17

2.12 Replacing the CPU PCB....................................................................................................18

2.13 Replacing the BDC PCB....................................................................................................19

2.14 Replacing the power unit...................................................................................................20

3 Settings and Adjustments ..............................................................................................21

3.1 Measuring the rewind torques ...........................................................................................21

3.2 Adjusting the rewind torques .............................................................................................23

3.3 Adjusting the print mechanism...........................................................................................24

3.4 Adjusting label sensor........................................................................................................27

4 Block diagram..................................................................................................................28

5 Index .................................................................................................................................30

4 Service Manual Edition 12/07

Important Information

Brady IP Series Printer

1 Important Information

1.1 General safety instructions

This service manual is intended for use by qualified service and maintenance personnel. For more operation and configuration information, refer to the user or configuration manual.

Follow the general safety rules below:

• Keep the area around the device clean at all times!

• Work with safety in mind.

• Parts of device that are removed during the maintenance work must be put in a safe place.

• Avoid risks of tripping over.

1.2 Protective devices

Wear protective goggles for:

• Knocking pins or similar parts in or out with a hammer.

• Using spring hooks.

• Inserting or removing springs, retaining rings or grip rings.

• Using solvents, cleansers or other chemicals.

DANGER!

Danger to life and limb from increased current flow through metal parts in contact with the

device.

⇒ Do not wear clothing with metal parts.

⇒ Do not wear jewelry.

⇒ Do not wear spectacles with metal frames.

CAUTION!

Items of clothing drawn into the device by moving parts can lead to injuries.

⇒ Do not wear any items of clothing which could get caught by moving parts.

WARNING!

There is a risk of injury if protective devices are missing or defective.

⇒ Replace all protective devices (covers, safety notices, grounding cables etc) after mainte-

nance work has been completed.

⇒ Replace parts that have become defective or unusable.

Brady IP Series Printer

Important Information

Edition 12/07 Service Manual 5

1.3 Handling electricity

The following work may only be done by trained and qualified electricians:

• Work on electrical components.

• Work on an open device still connected to the mains supply.

General precautions before starting maintenance work:

• Find out where the emergency and power switches are so that they can be quickly thrown in an

emergency.

• Disconnect the current supply before carrying out the following work:

− Installing or removing power units.

− Working in the immediate vicinity of open power supply components.

− Mechanical check of power supply components.

− Modifying circuits in the device.

• Test the zero potential of the device parts.

• Check the working area for possible sources of danger, such as wet floors, defective extension

cables, defective protective conductor connections.

Additional precautions in the case of exposed voltages:

• Ask a second person to remain near the working site. This person must know where the emergency

and power switches are, and how to switch the current off if danger arises.

• Only use one hand to work on electric circuits of devices tha t are switched on. Keep th e other hand

behind your back or in your pocket.

This prevents electricity from flowing through your own body.

1.4 Procedure in case of accidents

• Act calmly and with great care.

• Avoid danger to yourself.

• Switch off power.

• Request medical assistance.

• Give first aid, if necessary.

6 Service Manual Edition 12/07

Replacing assembly units

Brady IP Series Printer

2 Replacing assembly units

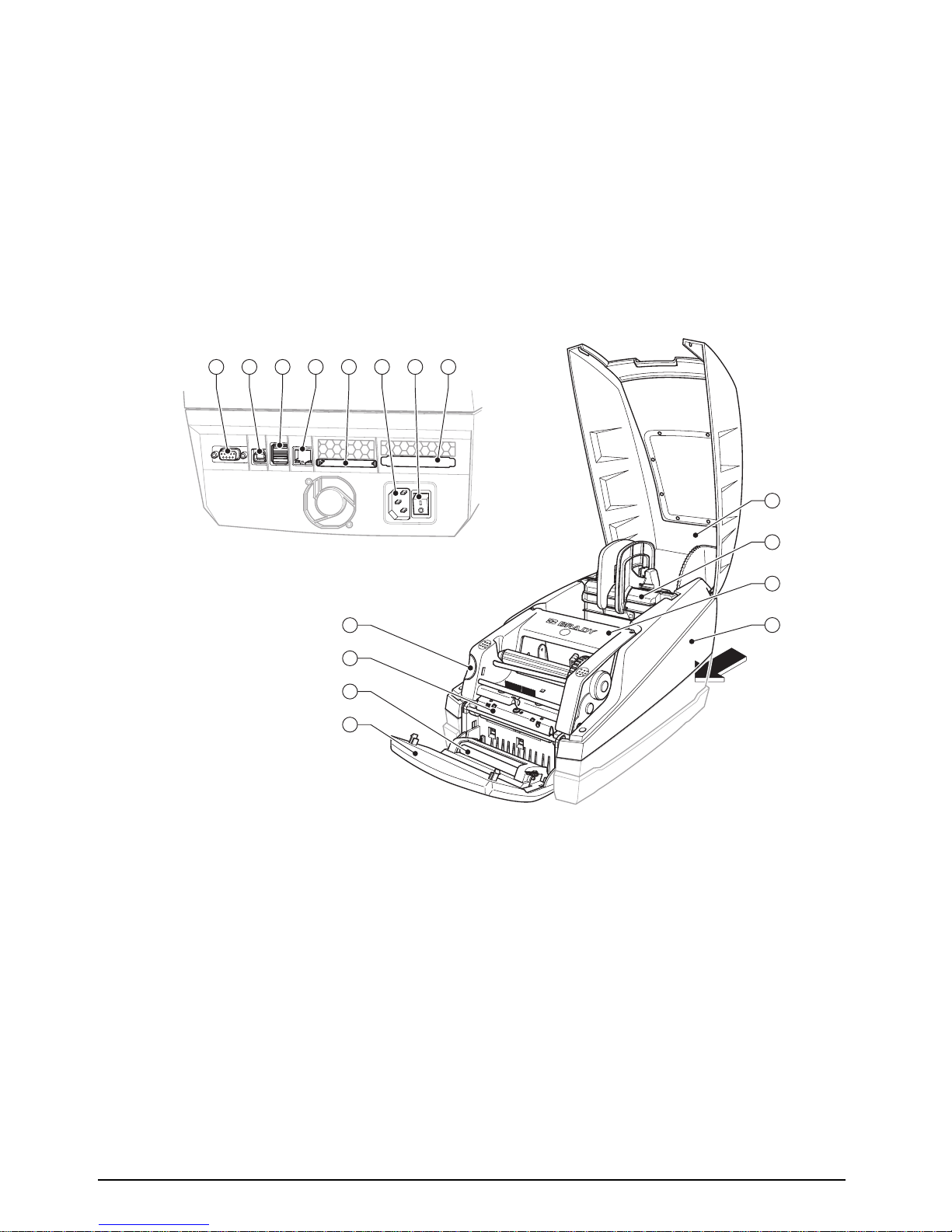

2.1 Device overview

Fig. 1: Overview

1

RS-232 serial interface

2 USB 2.0 High Speed Slave interface

3 Two USB master interfaces for

keyboard and scanner

4 Ethernet 10/100 Base T interface

5 CompactFlash card slot

6 Power supply socket

7 Power switch

8 PC card slot, type II

9 Cover

10 Media holder

11 Printhead assembly

12 Outer casing

13 Unlocking device

14 Printhead holder with printhead

15 Transport locking roller

16 Control panel

A

1 2 3 4 5 6 7 8

16

15

14

13

9

10

11

12

View A

Brady IP Series Printer

Replacing assembly units

Edition 12/07 Service Manual 7

2.2 Tools

• Do not use any worn of damaged tools.

• Only use tools and testing devices that are suitable for the task at hand.

cab special tools:

• Clutch mounting tool (part no. 5541180)

• Service key (part no. 5540301)

Standard tools:

• Screw driver Torx, size TX 10/200

• Hex screwdriver, straight, size 2.5

• Screwdriver with flat blade, size 4

• Flat-nose pliers

• Cylindrical dynamometer (spring scale), 0 - 20 N

8 Service Manual Edition 12/07

Replacing assembly units

Brady IP Series Printer

2.3 Replacing the control panel

Fig. 2: Replacing the control panel

1. Hinge down the control panel (1).

2. Hold the device with one hand, grip the control panel with the other hand, and remove one axle (5)

from of its bearings (3) by pulling strongly.

3. Grip the control panel over the second axle, and pull it until the axle comes out of its bearings.

4. Draw the lugs (2) alongside the bearings (3) out of the device.

5. Pull the plug (4) out of the printer, and put the control panel down in a safe place.

6. Pull the plug (4) of the new control panel into the printer.

7. Slide the lugs (2) past the sides of the bearings (3).

8. Tilt the control panel upwards a little.

9. Hook the axles (5) into their bearings.

10. Press firmly on the control panel until the axles audibly slot into their bearings.

3 4 2 5 31 2

1 Control panel

2 Lug

3 Bearing

4 Plug connector

5 Axle

NOTE!

To convert the printer from the standard or peel/present version to the cutter version by replacing the

control panel the peel-off edge must be removed. To convert the printer in the opposite direction the

peel-off edge must be inserted (see section 2.8, item 5).

NOTE!

Ensure that the plug connector is not damaged.

Brady IP Series Printer

Replacing assembly units

Edition 12/07 Service Manual 9

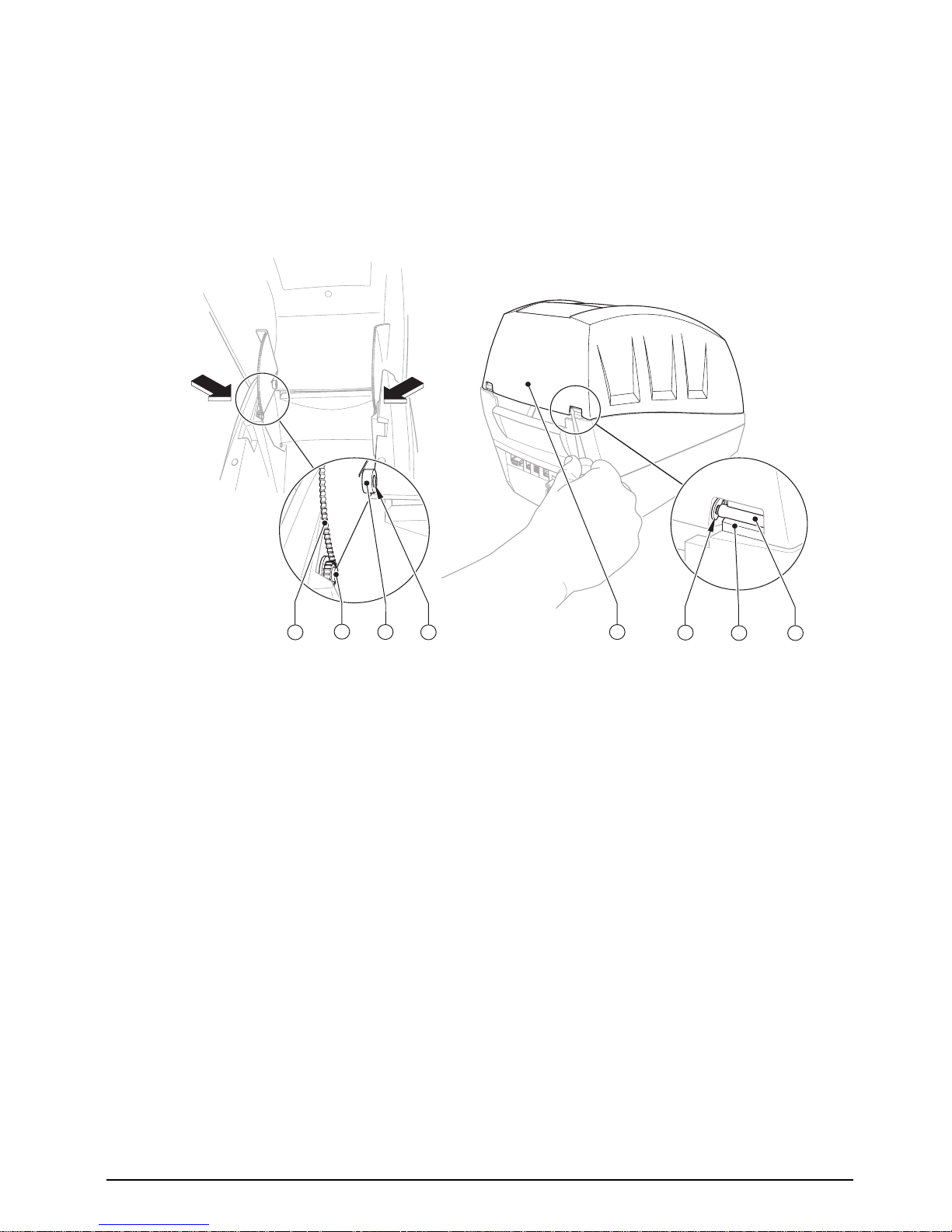

2.4 Replacing the cover

Fig. 3: Replacing the cover

1. Open the cover (5), remove the media hub and label stock.

2. Disconnect the damping mechanism by pressing both toothed lugs (1) towards the center of the

device.

3. Press the cover further back until the axles (4) come out of the guide (7).

4. To fit the new cover, first remove the locking ri ng s (6) an d the axle s (4 ).

5. Place a new cover (5) on the casing, ensure that the damping wheels (2) mesh with the toothed

lugs (1).

6. Push both sides of the axles (4) into the hinged aperture (3) from the inside.

7. Close the cover.

8. Attach the locking rings (6).

1

Toothed lug

2 Damping wheel

3 Hinged aperture cover

4 Axle

5 Cover

6 Locking ring

7 Guide for outer casing

7

5

4

6

3

2

1

4

Loading...

Loading...